WOOD ADHESIVES

PAPER AND PACKAGING ADHESIVES

HOTMELT ADHESIVES

STRUCTURAL ADHESIVES

WOOD ADHESIVES

PAPER AND PACKAGING ADHESIVES

HOTMELT ADHESIVES

STRUCTURAL ADHESIVES

Smart material technologies are a combination of distribution, our own products, smart process technology solutions, services, and own application laboratories/technical centers. We strive to be known as an innovative material technology company with knowledge and heritage dating back to 1927.

Adhesive Solutions is a part of Bang & Bonsomer Group.

WOOD ADHESIVES

PAPER AND PACKAGING ADHESIVES

HOTMELT ADHESIVES

STRUCTURAL ADHESIVES

is a series of 1-component EN 204 -D4, -D3, -D2 classified PVAc adhesives and 2-component EPI adhesives for nonstructural wood applications.

• Window and door componets

• Glued panels and boards

• Vaneering and lamination

• Parquet and wood flooring

• Wood, plastic, and board laminates

• Excellent and efficient bonding of wide range of wood-based applications

• Properties adjusted to industry standards

• Fast and strong bonding

• Sustainability target in a development

• M1 certificated (low odor emissions)

• High and stable quality

• Reliable on time and volume delivery

• Professional products that adhere to industrial standards

Bang & Bonsomer provides a wide range of research and development services to its customers through its application laboratory and piloting facilities in Espoo, Finland.

Our team has a strong background in product development, adhesive analysis, pilot testing, industrial scale up and production of water-based adhesives.

• Recipe customisation for demanding processes

• Pre-testing in our testing facility

• Analysis of wet adhesive and resulting jointing

• On-site technical support

is a series of 1-component adhesives for a wide range of paper and board surfaces, construction materials, as well as challenging plastics such as PVC, PP, PE.

• Packaging

• Lamination

• Construction boards

• Tubewinding

• Tissue

• Sustainability and economical products

• Sustainability target in a development

• Food contact approval (Regulation (EC) 1935/2004, art. 3 BfR XIV Polymer dispersions, part A)

• Tailored solutions for a wide range of paper/carton application (also see our LARUMELT ® products)

• Excellent and efficient bonding results in demanding process

• Solutions for demanding plastic lamination processes (PVC, PP, and PE)

• High and stable quality

• Reliable on time and volume delivery

• Professional products that adhere to industrial standards

• Tailored solutions for demanding process

Bang & Bonsomer provides a wide range of research and development services to its customers through its application laboratory and piloting facilities in Espoo, Finland.

Our team has a strong background in product development, adhesive analysis, pilot testing, industrial scale up and production of water-based adhesives.

OUR TECHNICAL SUPPORT INCLUDES: PROPERTIES BENEFITS

• Recipe customisation for demanding processes

• Pre-testing in our testing facility

• Analysis of wet adhesive and resulting jointing

• On-site technical support

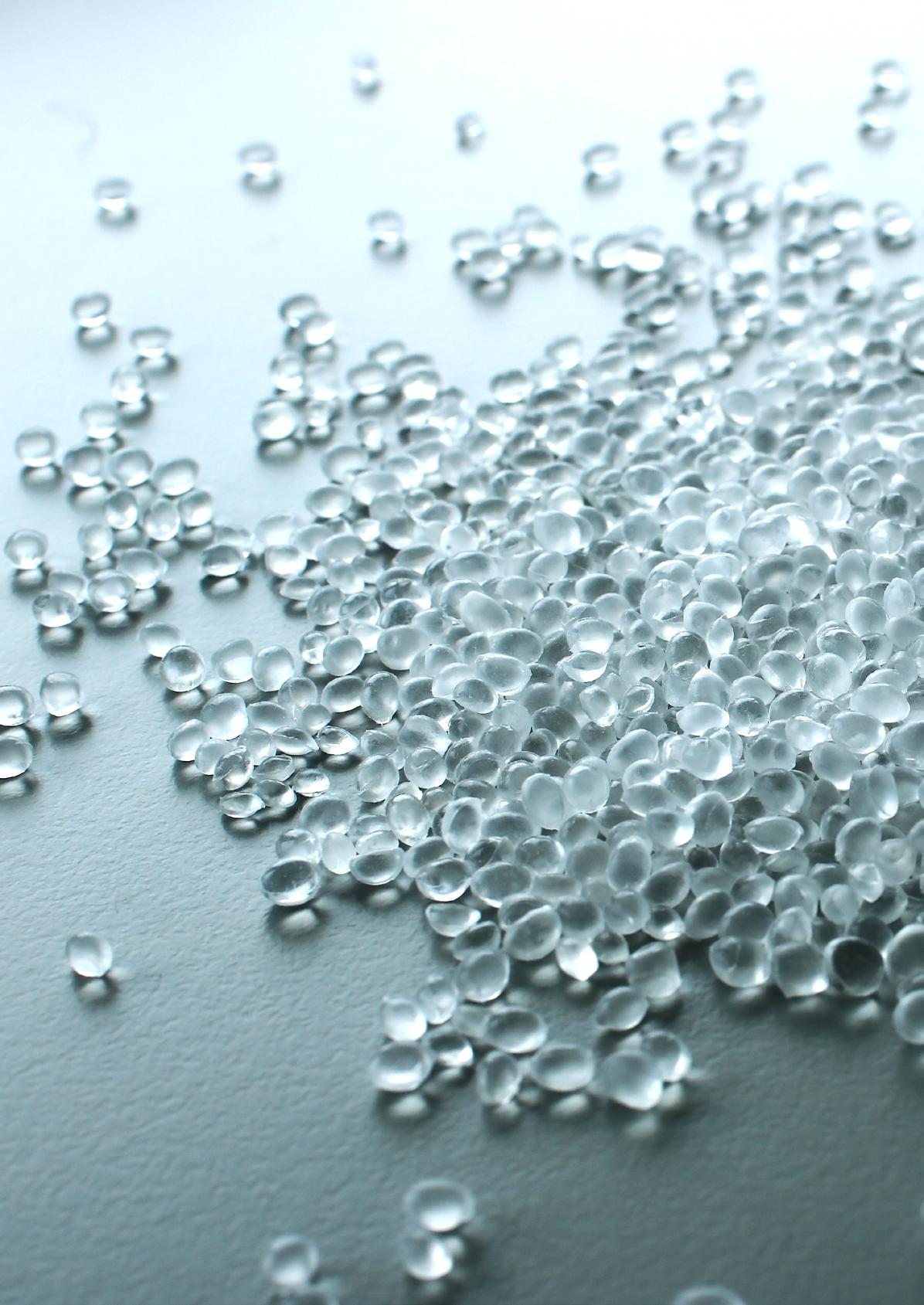

is a series of pressure sensitive and (regular/hard) hotmelt adhesives for wide range of paper and board to challenging plastic.

• Packaging, primary and secondary

• Lamination

• Construction boards

• EVA and Polyolefin based adhesives.

• Sustainability and economical products

• Excellent and efficient bonding results in demanding process

• High and stable quality

• Reliable on time and volume delivery

• Professional products that adhere to industrial standards

Bang & Bonsomer provides a wide range of research and development services to its customers through its application laboratory and piloting facilities in Espoo, Finland.

Our team has a strong background in product development, adhesive analysis, industrial use of hotmelt adhesive.

OUR TECHNICAL SUPPORT INCLUDES: PROPERTIES BENEFITS

• Analysis of adhesive and resulting jointing

• On-site technical support

is a series of 2-component adhesives for wide range of materials wood, plastic, metal, and glass surfaces.

• Sandwich panels

• Air filters

• Sustainability target in development

• Excellent and efficient bonding results in demanding process

• High and stable quality

• Reliable on time and volume delivery

• Professional products that adhere to industrial standards

Bang & Bonsomer provides a wide range of research and development services to its customers through its application laboratory and piloting facilities in Espoo, Finland.

Our team has a strong background in product development, adhesive analysis, material working, pilot testing, industrial scale up and production of 2C polyurethane adhesives.

OUR TECHNICAL SUPPORT INCLUDES:

• Recipe customisation for demanding processes

• Pre-testing in our testing facility

• Analysis of wet adhesive and resulting jointing

• On-site technical support