Baltic Transport Journal

REPORT

Baltic transport 2023 highlights

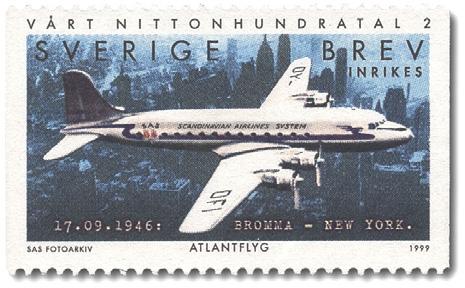

SUSTAINABILITY Collecting solar power – offshore

TECHNOLOGY

Can a single maritime AI research project cut 1% of total global emissions?

MARITIME

How a Baltic cruise ferry rescued a Finnish sailor in the middle of the Indian Ocean

OFFICIAL MEDIA PARTNER OF: ISSN 1733-6732

bimonthly-daily companion

LEGAL Advances in technology aiding

№ 1/2024 (117), JANUARY/FEBRUARY

seaport and terminal security

The Port of Opportunities

The Port of HaminaKotka is a versatile Finnish seaport serving trade and industry. The biggest universal port in Finland is an important hub in Europe and in the Baltic Sea region.

Welcome to the Port of HaminaKotka!

haminakotka.com

Dear Readers,

Isincerely hope you had a fantastic end of 2023, a much-needed & deserved break in between the years, and a smooth start to the rolling 12 months.

The first issue of 2024 may seem a bit husky, but that’s because the latest round-up of Baltic transport highlights is probably the biggest we have produced thus far: 25 pages! That is a looong read if I ever saw one! The summary brings, first & foremost, a heavy chunk of all things green as the Baltic Sea region continues to pep its sustainability game.

The digest goes hand-in-hand with the Baltic Green Map we’re working on, a snapshot of the various green developments already in place, ‘under construction,’ or in the pipeline throughout our beautiful & pioneering corner of the world. We have prepared a video that details what you can expect from our newest map. It also introduces the accompanying Baltic Green Map Catalogue , a publication that further specifies what can be found on the map under the various icons. And there’s the other side of the Baltic Green Map: the Baltic Offshore Wind Energy Map that’s peppered with the existing & planned wind power harvesting farms in the region.

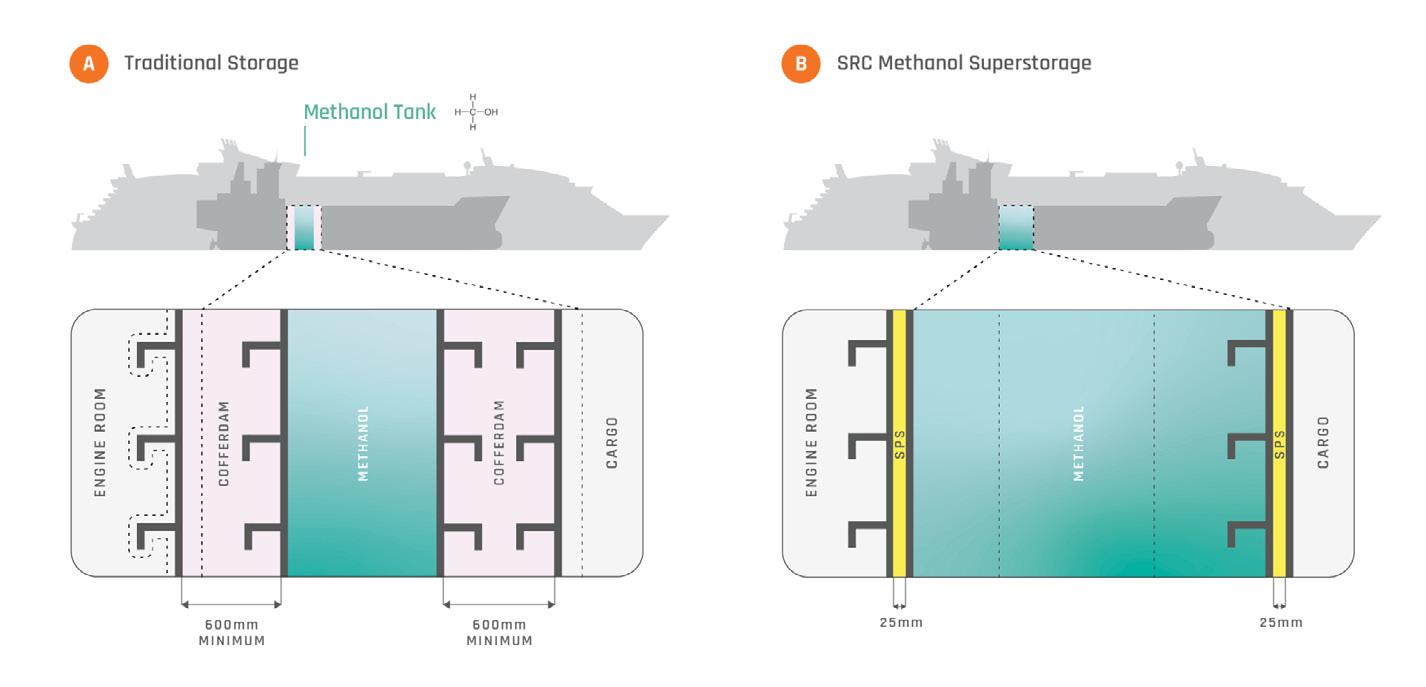

Other than that, the 1/24 edition is, as always, packed with topical reads. ‘Talking green,’ the Sustainability column brings forth a project tasked with making the Port of Hirtshals not only a carbon capture & storage hub – but the biggest one in Europe! There are also pieces on collecting solar energy – but out there in the open sea! As well as articles on storing methanol on board vessels, the challenging particulars of decarbonising dry bulk carriers, and the Sustainable First Movers Initiative and its toolbox, which, I believe, can come in handy in the Baltic, too.

The Legal section goes in depth & breadth about port security, likewise analyses stern tube damages and unpacks the concerns with shipping lithium-rich minerals for the increasingly battery-hungrier global market. The Maritime column is very, very Baltic in its nature, though not without a twist here & there. While the article on the most recent developments in HaminaKotka keeps us within the region, Finnlines’ other Superstar ferry will take you to the Indian Ocean, while Elomatic’s piece to Canada.

And, naturally, I just couldn’t end without mentioning what we cooked up for you in the Technology section. Starting with how artificial intelligence (AI) in shipping can decrease global emissions by 1% (yup, you read that right); through how AI, green shipping corridors, and digitalisation are redefining maritime operations; what are the dual benefits of digitalising the shipping business; ways of tackling the data scrapping menace; to how port operations can change thanks to digital identity verification.

With this, I wish you nothing but the most splendid reads and all the best in 2024 (these two go together, as I’m sure you already know perfectly)!

Oh, and don’t forget that the BTJ Trip season is open – we’ll be more than happy to visit your port to share what fascinating things are happening at your place with the other readers!

Przemysław Myszka

Baltic Transport Journal

Publisher

BALTIC PRESS SP. Z O.O.

Address: ul. Pułaskiego 8

81-368 Gdynia, Poland office@baltictransportjournal.com

www.baltictransportjournal.com

www.europeantransportmaps.com

Board Member BEATA MIŁOWSKA

Managing Director

PRZEMYSŁAW OPŁOCKI

Editor-in-Chief

PRZEMYSŁAW MYSZKA przemek@baltictransportjournal.com

Roving Editor MAREK BŁUŚ marek@baltictransportjournal.com

Proofreading Editor EWA KOCHAŃSKA

Contributing Writers

JOHN BALAOURAS, NIRAJ BHATT, NEIL DALUS, KOSTAS GKONIS, KADRI HAUFE, RAMI HIRSIMÄKI, GRANT INGRAM, ALEXA IVY, CASPER JENSEN, SVEND LEO LARSEN, JAANA NIEMI, ANISA RIZVANOLLI, MONIKA ROGO, FITZWILLIAM SCOTT, JOHN SOUTHAM, LEE STENHOUSE, EMMANUEL VERGETIS

Art Director/DTP DANUTA SAWICKA

Head of Marketing & Sales

PRZEMYSŁAW OPŁOCKI po@baltictransportjournal.com

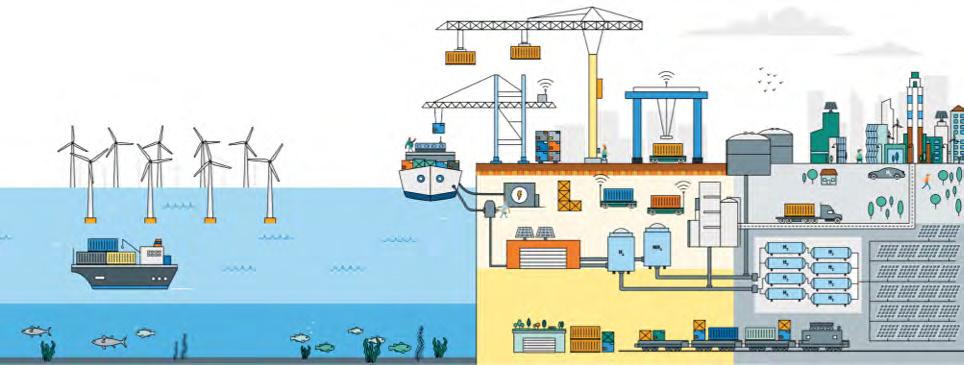

If you wish to share your feedback or have information for us, do not hesitate to contact us at: editorial@baltictransportjournal.com

Contact us:

PRZEMYSŁAW OPŁOCKI tel.: +48 603 520 020

EDITORIAL 1/2024 | Baltic Transport Journal | 3

Children of the Sea by Jozef Israëls, photo: Artvee

Cover Port of Riga Subscriptions Go to www.baltictransportjournal.com and click: SUBSCRIPTION or contact us at subscription@baltictransportjournal.com ISSN 1733-6732 REPORT Baltic transport 2023 highlights Baltic Transport Journal bimonthly-daily companion SUSTAINABILITY Collecting solar power – offshore LEGAL Advances in technology aiding seaport and terminal security № 1/2024 (117), JANUARY/FEBRUARY TECHNOLOGY Can a single maritime AI research project cut 1% of total global emissions? MARITIME How a Baltic cruise ferry rescued a Finnish sailor in the middle of the Indian Ocean

3 REGULAR COLU MNS

3 Editorial

8 BTJ calendar of events

9 Safety news by TT Club

10 Market SMS

12 What’s new?

14 Map news

16 Venture forth

18 Chart of the issue: Global Maritime Trends 2050. What does the future of the maritime industry look like?

22 What’s in the Cabinet

90 Transport miscellany

92 Who is who

24 As safe as ports?

– Advances in technology aiding seaport and terminal security by Neil Dalus

26 A concerning new trend?

– Increase in stern tube damages by John Balaouras and Svend Leo Larsen

28 Rock-solid shipping

– A surge in lithium demand raises stability concerns over transporting its minerals by John Southam and Lee Stenhouse

30 MARITIME

30 Keeping an upright position while on a bumpy road

– An eventful year for the Port of HaminaKotka by Jaana Niemi

32 Assistance at sea

– How a Baltic cruise ferry rescued a Finnish sailor in the middle of the Indian Ocean

34 Designed in the Baltic

– Working on Canada’s largest & most powerful Polar icebreaker by Rami Hirsimäki

36 SUSTAINABILITY

36 Leap forward for an ambitious carbon capture & storage project

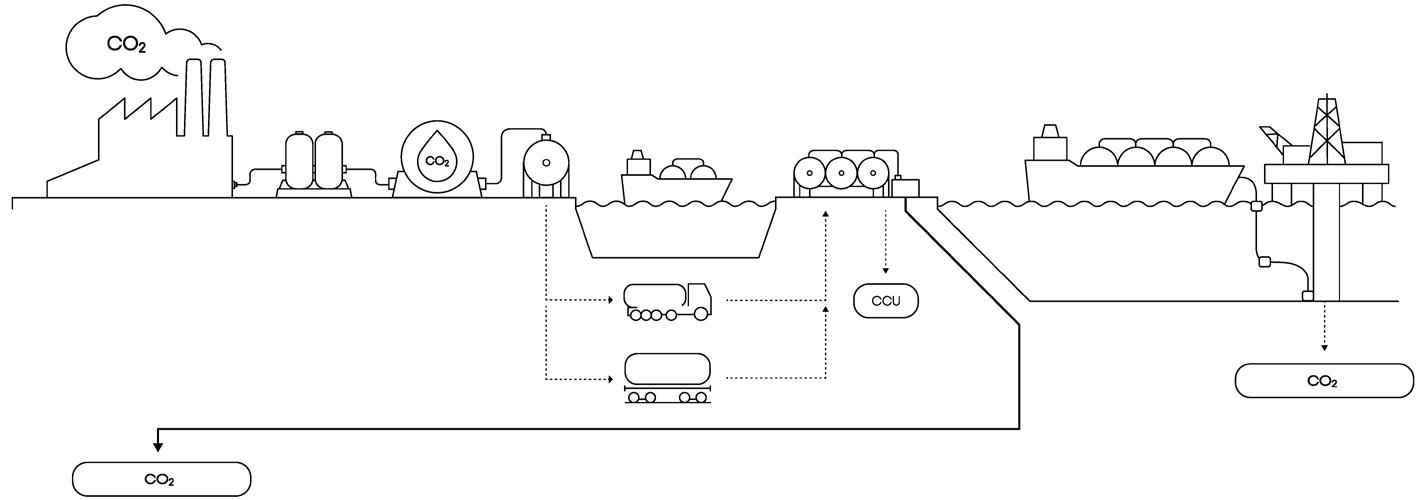

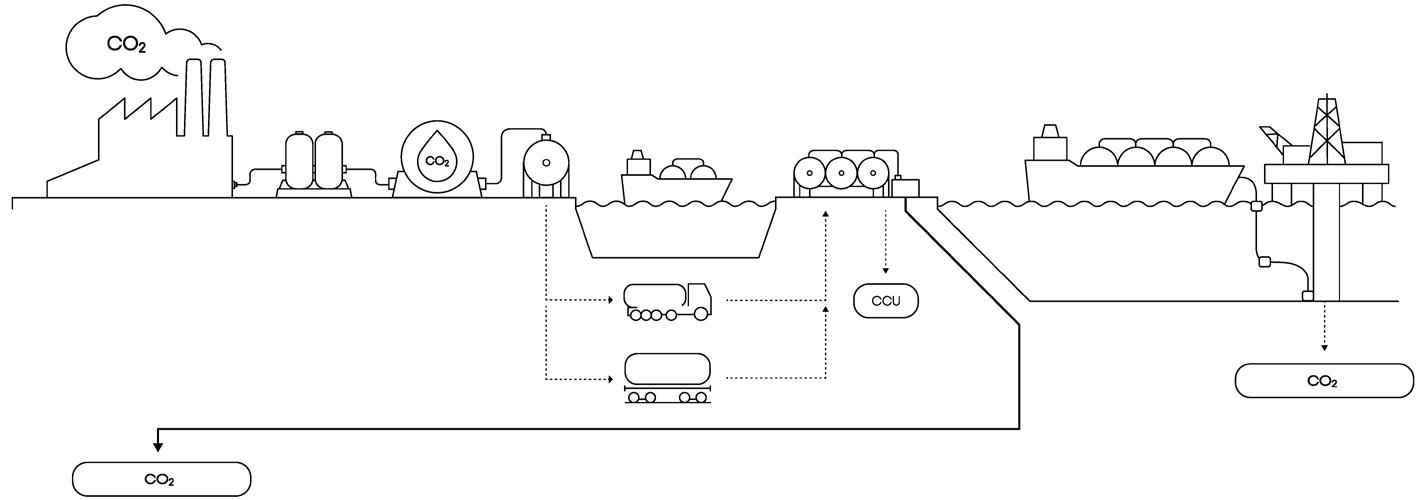

– The Port of Hirtshals to become Northern Europe’s largest CO2 hub by Fitzwilliam Scott

38 ‘Adversity is the mother of progress’

– The Sustainable First Movers Initiative by Ewa Kochańska

44 Know the differences to make a difference

– The challenges with decarbonising bulk carriers by Kostas Gkonis and Emmanuel Vergetis

46 The energy transition’s new duck in the pond

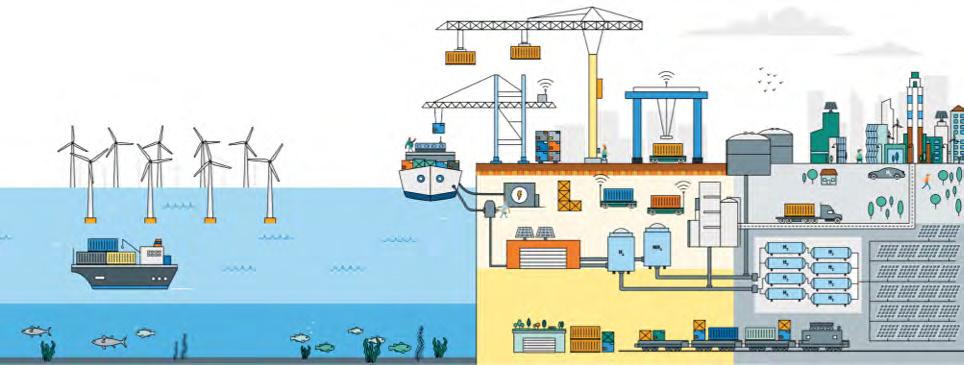

– Collecting solar power – offshore by Alexa Ivy

48 Turn up the volume!

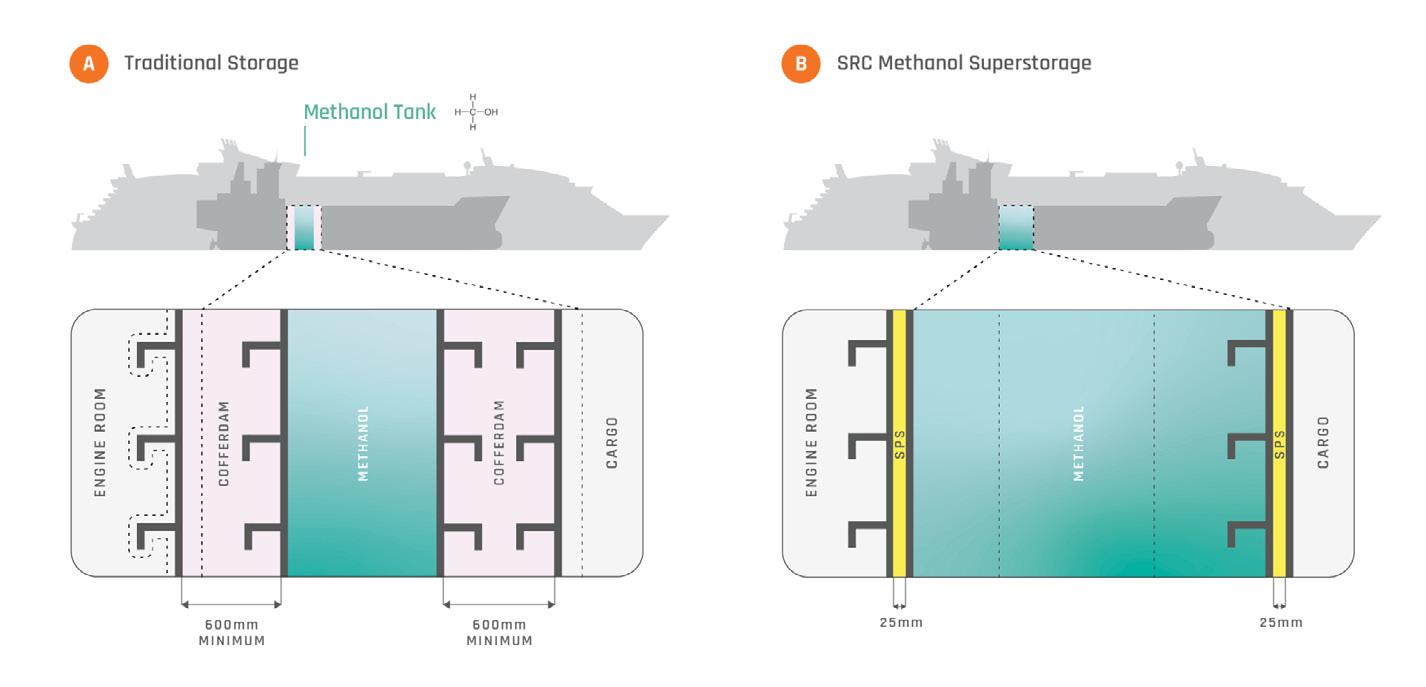

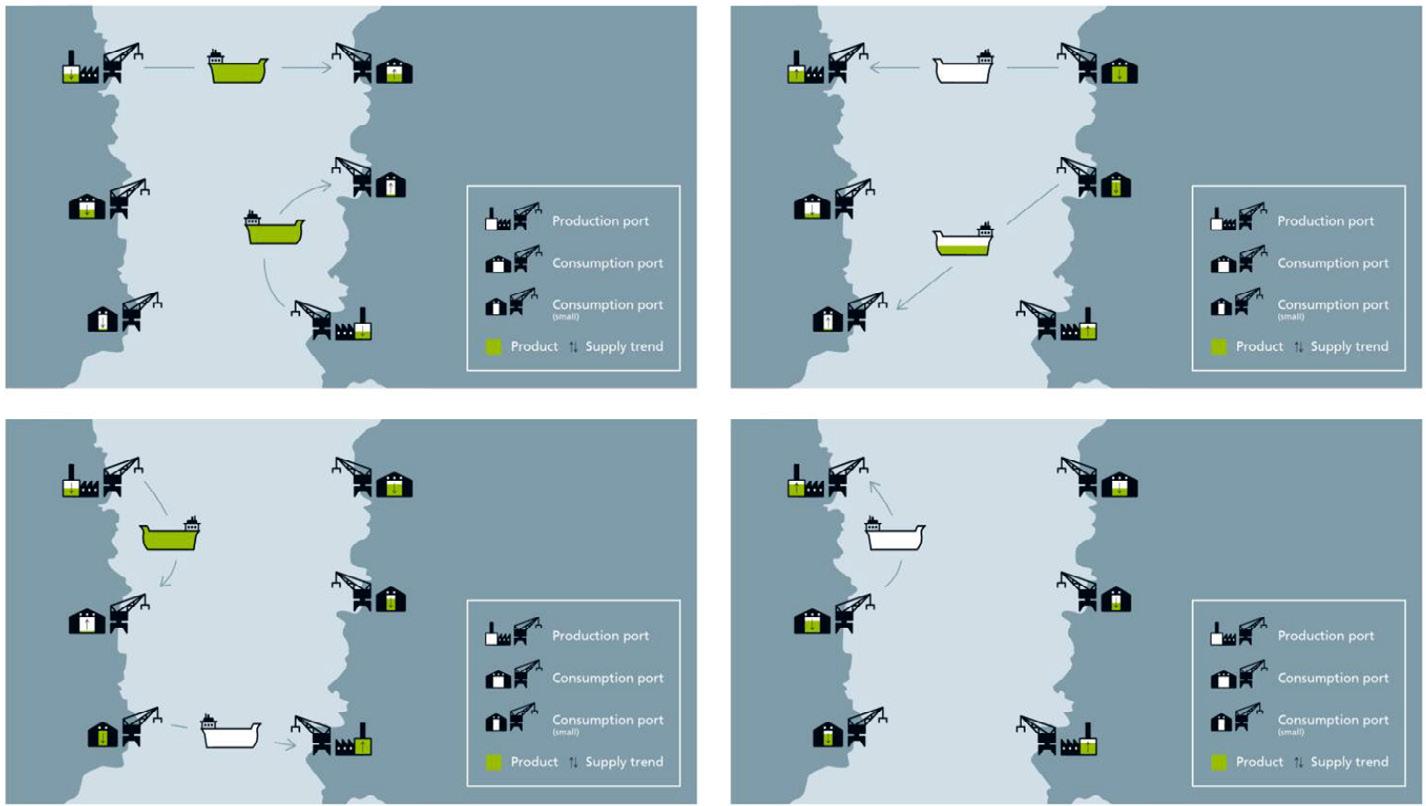

– Addressing the storage challenge of methanol as a marine fuel by Fitzwilliam Scott

CONTENTS 1/2024 | Baltic Transport Journal | 5

24 LEGAL

Moves a lot. Changes everything.

With a maximum lifting capacity of 1,600 tons, our travelling cargo crane TCC 78000 will drive your heavy-duty projects to success. www.liebherr.com

Maritime cranes

51 REPORT

51 Baltic transport 2023 highlights by Przemysław Myszka

76 NEWSLETTER BPO

76

7

78 TECHNOLOGY

78 Well, duh!

– Can a single maritime artificial intelligence (AI) research project cut 1% of total global emissions? by Alexa Ivy

80 SPEARheading the right approach

– Five steps to tackle the data scraping menace by Niraj Bhatt

82 From news buzz to buzzing with activity – How AI, green shipping corridors, and digitalisation are redefining maritime operations by Grant Ingram

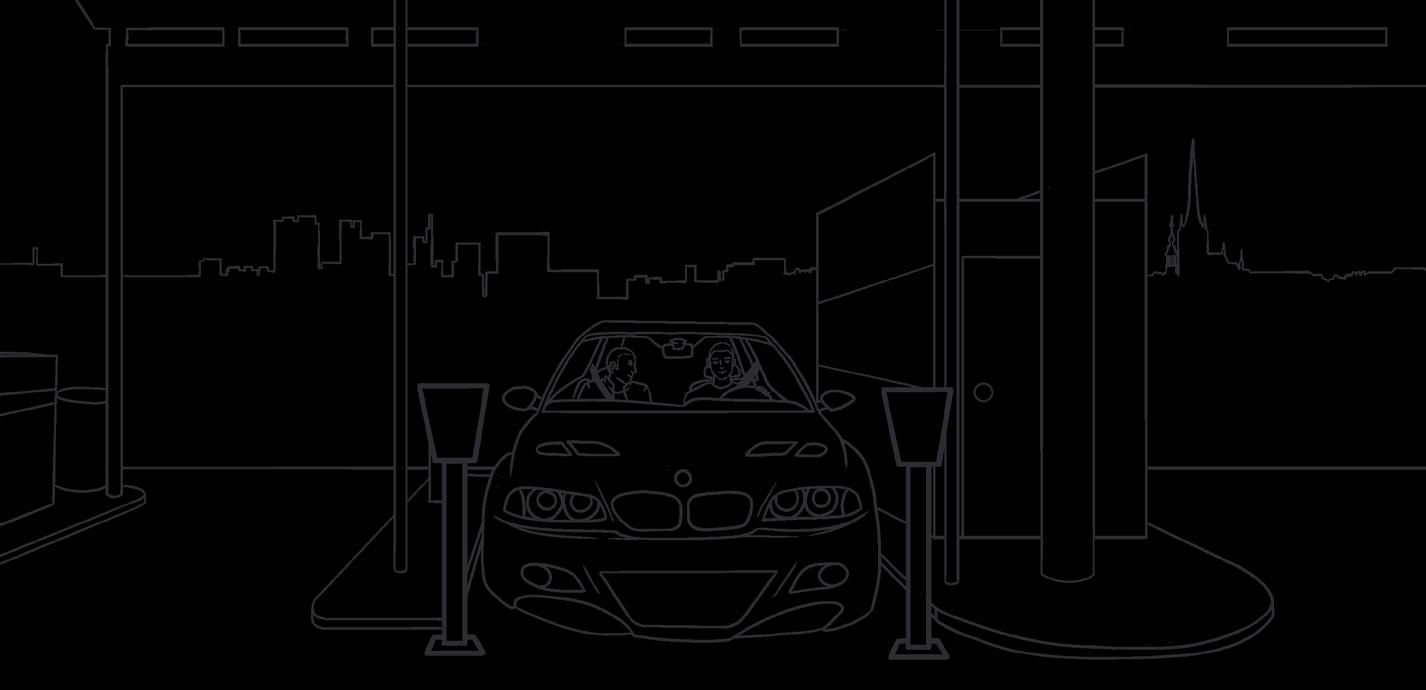

84 Identify as smart

– Digital identity verification in port operations by Kadri Haufe

86 The power of partnership

– Dual benefits of digitalisation steer shipping towards environmental and economic sustainability by Casper Jensen

98 The first step before a quantum leap

– Investigating the benefits of quantum computing in maritime logistics by Anisa Rizvanolli

CONTENTS 1/2024 | Baltic Transport Journal | 7

the

on the horizon

Wind turbines at sea –

BPO Offshore Wind Conference

7 Destination: climate issues by Monika Rogo

Transport Week 2024 , 12-13/03/24, PL/Gdynia, transportweek.eu

The next edition of the Transport Week conference will be held on 12-13 March 2024 in Gdynia, Poland. Expert speakers and a fantastic audience will once again tackle topics that shape the current face of the transport sector, from geopolitics, through market analysis to infrastructure development.

WindEurope Annual Event 2024 , 20-22/03/24, ES/Bilbao, windeurope.org/annual2024

The organisation’s annual on- and offshore wind energy event will be heading to Bilbao for a three-day conference and exhibition. You can expect 12,000+ attendees to join us for a look at the shape of European wind energy today. There will be dozens of conference sessions, hundreds of speakers, and 400+ exhibitors from the whole value chain looking to showcase their innovations and seal new deals.

ESPO 2024 , 25-26/04/24, FR/Paris, espo-conference.com/en

This year’s anniversary 20 th edition of the European Sea Ports Organisation’s annual conference will go under the ‘net-zero, resilient and competitive ports: acting now to deliver tomorrow’ theme. In 2024, the new normal will most likely be defined by disruption, geo-economic and geopolitical tensions leading to more frequent disruptions to supply chains, greater volatility on the energy markets and a fiercer international competition. Adding to this, the need to act and progress on the ambitions and concrete policies that Europe has put in place over the last five years, it is clear there is a lot to discuss.

Scandinavian Maritime Fair, 14-15/05/24, DK/Copenhagen, www.scandinavianmaritimefair.com

Scandinavian Maritime Fair recognizes the need of bringing together the Scandinavian maritime community. The aim is to unify and leave a lasting imprint on the world. Whether designers, manufacturers, suppliers, operators, shipowners, or service providers – both onshore and offshore – this is where industry leaders, young innovative companies and decision makers meet.

TOC Europe 2024 , 11-13/06/24, NL / Rotterdam, tocevents-europe.com

With an unrivalled 40+ year heritage, TOC Europe is the place to learn from and network underneath one roof with the world’s leading port decision-makers, policy experts, solution-providers, and more, enabling you to both supercharge your strategies and make your port operation visions a reality. Whether your focus is on adapting to the unpredictable economic climate or simply embracing the exciting new technologies revolutionising the sector, join us on the road back towards growth at the essential container supply chain event.

World Ports Conference 2024 , 8-10/10/24, DE/Hamburg, worldportsconference.com

2024 will be a pivotal year for ports and their communities. Geopolitical instability is on the rise. Physical and digital security is under threat, at sea and on shore. Shipowners, supply chain providers, and cargo owners must adapt rapidly. The energy transition towards low- and zero-carbon fuels must be balanced against national energy security concerns. #IAPH2024 will offer attendees insights on these topics, revealing how ports – from developing and developed nations – are building secure and sustainable solutions to these shared challenges, in a deeply interconnected world.

BTJ CALENDAR OF EVENTS i

! i

! preview

t ’ s o u t

t ’ s o u t

A YEAR IN FOCUS – A FOCUS ON SAFETY CULTURE FOR THE YEARS TO COME

TT Club released its latest review of current and ongoing risk trends. The publication includes a variety of studies and reports, including, among others, an analysis of the insurer’s own claims data, as well as detailed research into and advice on mitigating invasive pests in containers, increased cybersecurity risk as ports automate, increasing customs documentation errors; clandestine immigration threats; dangers of plastic micro pellet spillages; and what safety & security aid can drone technology provide. “TT has recently witnessed a renewed focus and commitment towards loss prevention activities, with additional emphasis placed on the Club’s mission statement to make the industry safer, more secure and more sustainable,” comments Mike Yarwood , TT Club’s Loss

Prevention Managing Director. He furthered, “Greater safety goes hand-in-hand with enhanced security and consequently sustainability. TT’s mutual ethos demands that we guide those we insure – and indeed the wider industry – in all aspects of risk through the container transport and global logistics supply chain. Via our latest Year in Focus , we aim to add to the large cannon of knowledge and guidance.” Josh Finch , TT Club’s Logistics Risk Manager, also underscores, “The importance of culture within an organisation, particularly where safety is concerned, cannot be underestimated. Safety is everybody’s responsibility, and everyone has a voice in safety matters. A strong safety culture will positively impact safety performance.”

THE EUROPEAN PORTS ALLIANCE PUBLIC PRIVATE PARTNERSHIP

The cooperative has been launched to fight organised crime and drug trafficking by leveraging the collective resources and expertise of multiple stakeholders to enhance security measures and enforce stringent controls within port facilities. Praising the initiative, the Federation of European Private Port Companies and Terminals (FEPORT) warned that “[…] we are reaching a situation where criminal networks are using extreme violence, corruption and intimidation that require exceptional mobilisation from public and private stakeholders in ports, national authorities, and law enforcement agencies. Seizures of cocaine in the EU have reached record levels, with more than 300 tonnes seized on an annual basis in recent years.” The Federation also notes that many effective solutions

are already in place, such as screening, intelligent cameras, virtual fences, port worker identity checks, and others. Still, closer international cooperation will be needed as we “[...] should also be aware that the creativity on the side of drug traffickers is huge and that it is going to be a race, a long marathon.” Ylva Johansson , European Commissioner for Home Affairs, stresses, “The vast majority of illicit drugs into the EU are trafficked along maritime routes. 70% of drug seizures are in EU ports. That is why cooperation between national & EU authorities and EU ports is vital. Organised crime is adept at moving from one port to another as opportunities rise and fall. To challenge this network, we must build a network. The violent consequences of drug trafficking are as big as the threat of terrorism.”

MARITIME SECURITY – A PRACTICAL GUIDE FOR MARINERS

The Nautical Institute has published its new compendium of essential maritime security advice, guidance and insights. The publication includes a broad range of topics, among many, a detailed examination of the ISPS Code and its implications. Author and global security expert Steven Jones AFNI FRSA, adds to the list, “The book tackles many of the issues that we have previously focused on within Maritime Security, such as coping with piracy, stowaways at sea and migrants. It also covers other challenges faced by officers, such as

cybersecurity and criminality at sea, in ports and across the entire supply chain. This has made it a real focal point, a book that can be relied upon to illuminate some of those darker issues within the industry.” Master Mariner and Maritime Consultant Dariusz Godźik MNI shares, “ I have learned a great deal from reading this updated and extended edition of Maritime Security. The book is written in an engaging and accessible way that makes it an essential reading for mariners everywhere.”

TRAINING SEAFARERS FOR A DECARBONISED FUTURE

The Maritime Just Transition Task Force has launched a collaborative project tasked with creating a framework to equip seafarers with skills as shipping transitions to zero-emission operations. Research commissioned by the organisation identified that 800 thousand of seafarers may require additional training by the mid-2030s in order to operate vessels running on zero- or near-zero emission fuels. The project will be run by the International Maritime Organization (IMO) and the Maritime Just Transition Task Force Secretariat. Lloyd’s Register (whose Foundation will fund the framework alongside IMO) will develop the training framework for seafarers and officers, as well as an instructor handbook for maritime training institutions. The World Maritime University will provide academic expertise, while a large number of organisations will be involved through a global industry peer learning group to provide knowledge-sharing. “Moving towards a low-emission future will require new green jobs and re-skilling, and the global maritime industry is no different.

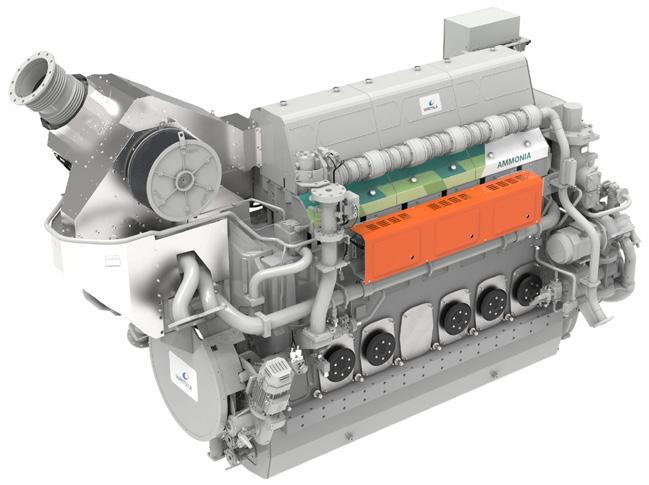

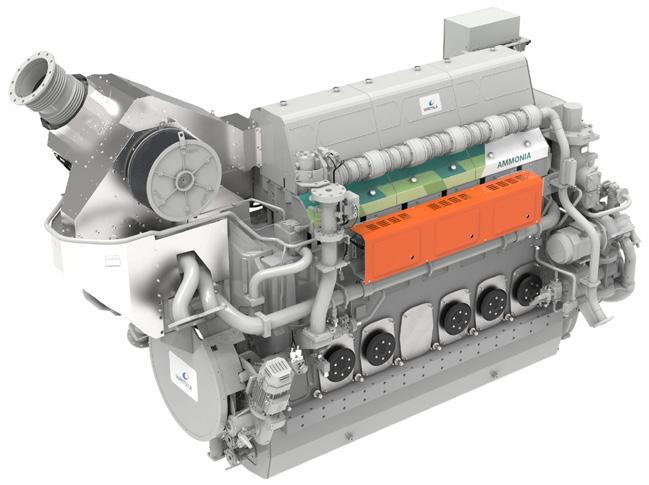

Future alternative fuel technologies, such as hydrogen, ammonia and methanol, means there is a vital need to up-skill all seafarers,” highlights Ruth Boumphrey, CEO of Lloyd’s Register Foundation. Sturla Henriksen, Special Advisor Ocean of the United Nations Global Compact , adds, “Decarbonising shipping is essential to combat the climate crisis. The global nature of this transition means that no one is alone in tackling this issue, and the Maritime Just Transition Task Force is committed to providing resources to support stakeholders making this journey.” Stephen Cotton , General Secretary of the International Transport Workers’ Federation , shares, “We have heard the message loud and clear from seafarers around the world: they are ready to lead, they are ready to shape the training frameworks for the zero carbon fuels of the future.” In light of these future demands, IMO is reviewing and revising the International Convention on Standards of Training, Certification and Watchkeeping for Seafarers , with input from the industry and seafarer unions.

1/2024 | Baltic Transport Journal | 9 SAFETY NEWS BY WORKING TOWARDS SAFER PRACTICES TT Club is the leading provider of mutual insurance and related risk managment services to the international transport and logistics industry. Its core mission is to make the industry safer and more secure. To find out more visit ttclub.com

The Port of HaminaKotka:

617,181 TEUs handled in 2023 (-1.9% yoy)

The Finnish seaports took care of 14.12 million tonnes in international traffic last year (-13.2% year-on-year), plus 196.4kt in cabotage (-73.2% yoy). At the same time, the Port of HaminaKotka welcomed 13 cruise calls with 20k guests, twice as many as in 2022.

The Port of Helsinki:

8.92 million ferry passengers served in 2023 (+12.2% yoy)

There were also 1.48m private vehicles that went through Helsinki’s ferry berths last year (+5% year-on-year). With 162,813 travellers, Helsinki’s 2023 cruise season was on par with that of 2022. On the cargo front, the Port of Helsinki took care of 13.94 million tonnes (-8.2% yoy), including 13.39mt made in international (-11.3% yoy) and 553kt in cabotage traffic (+508% yoy). With 11.51mt (-8.7% yoy), unitised freight traffic continues to be the Finnish seaport’s prime trade. Wheeled (ro-ro & ferry cargo) accounted for 8.1mt (-7.9% yoy), while containerised for 3.42mt (-10.2% yoy). Helsinki also took care of 1.52mt of dry bulk (-2.1% yoy) and 765.3kt of break-bulk (-13% yoy). A total of 643,629 ro-ro cargo units went through Helsinki’s harbours (-8.3% yoy). At the same time, container traffic totted up to 451,760 TEUs (-8.1% yoy).

The Port of Riga:

465,391 TEUs handled in 2023 (+1% yoy)

The Latvian seaport took care of 7.73 million tonnes of general cargo, an advance of 2.4% on the 2022 result, including 5.11mt of containerised freight (+9.8% year-on-year). Although the handling of grains rose by 23.1% yoy, becoming Riga’s leading dry bulk trade, the entire category lost 29.5% yoy down to 10.22mt (chiefly because of the 73.2% yoy drop in coal & coke turnover). Liquid cargo contracted as well – by 42.4% yoy to 846.2kt. The Port of Riga overall handled 18.79mt (-20.1% yoy). A total of 81,681 cruise travellers went through Riga’s quays, a year-on-year increase of 7.9%.

The Port of Gdańsk:

81 million tonnes handled in 2023 (+19% yoy)

The handling of liquid bulk propelled the seaport’s growth the most, up 47.5% year-on-year to 37.6mt. With 22.9mt, general cargo came in second, including 20.5mt of containerised freight (+2.5% yoy). Coal turnover totted up to 13.3mt (+1.1% yoy), of which 12.5mt were imported. Other dry bulk goods contracted by 0.9% yoy to 3.5mt. Then again, grains advanced by 60% to 3.1mt.

Hupac: 975 thousand road consignments carried by rail in 2023 (-11.7% yoy)

“This negative development is mainly due to the declining demand for transport in Europe,” the Swiss combined rail transport company said in a press release. The brief further read, “The recessionary trend started in the autumn of 2022 in connection with the [war in] Ukraine and the energy crisis and affected large parts of the world economy in the course of 2023. To make matters worse, a number of factors are putting increasing pressure on the rail system. First and foremost is the poor quality of the rail network, especially in Germany, due to neglected maintenance and inadequate national and international construction planning. Capacity bottlenecks, delays and cancellations are the order of the day on many corridors. The massive double-digit cost increases in the rail system are also counterproductive.”

The Port of Gothenburg:

914 thousand TEUs handled in 2023 (+3.3% yoy)

As such, the Swedish seaport noted a new all-time high for containers going over its quays (16k more boxes than the port’s previous record result from 2012). At the same time, Gothenburg’s rail container traffic contracted 8.7% year-on-year to 473k TEUs (though it was still the second-best year in this area for the seaport). Fewer ro-ro cargo units were taken care of, too, down 3.7% yoy to 540k trucks & trailers. On the other hand, more new vehicles were handled, up 12.2% yoy to 267k. Whereas less liquid bulk was handled (-17.5% yoy to 18.4 million tonnes), the Port of Gothenburg saw more dry and break-bulk (+17.1% yoy to 439kt). The Swedish seaport welcomed 1.4 million ferry passengers (+7% yoy) and 118k cruise travellers (+45% yoy).

The Port of Tallinn:

7.92 million passengers served in 2023 (+12.7% yoy)

The Tallinn-Helsinki crossing welcomed 7.0m travellers last year (+13.7% year-on-year), followed by 537k between Tallinn and Stockholm (+18.3% yoy), and 170k on the Muuga-Vuosaari service (+7.8% yoy). On the other hand, fewer cruise guests came to visit the Estonian capital (-4.3% yoy to 165k). Passengers categorised as ‘others’ totalled 45k (-47.8% yoy). In addition, the port’s domestic passenger company, TS Laevad, carried 2.41m passengers (+4.9% yoy) and 1.13m private vehicles (+3.3% yoy). On the cargo front, the Port of Tallinn handled 12.59mt (-29.1% yoy), including 6.41mt of wheeled (ro-ro & ferry) cargo (-7% yoy), 2.16mt of dry bulk (-26.7% yoy), 1.88mt of containerised freight (-11.4% yoy), 1.7mt of liquid bulk (-67.1% yoy), 418kt of break-bulk (-31.6% yoy), and 24kt of non-marine cargo (-23.5% yoy). Tallinn’s container traffic amounted to 221,405 TEUs (-17.3% yoy).

Viking Line:

125,269 ro-ro cargo units carried in 2023 (+6.4% yoy)

The ferry company from the Åland Islands also served 4,897,494 passengers (-1% year-on-year) and transported 563,081 private vehicles (-10.7% yoy). The Turku-Åland-Stockholm, the prime crossing in the company’s network, saw 2,123,647 passengers last year (+8.6% yoy). Helsinki-Tallinn added 1,655,548 (+18% yoy), Stockholm-Mariehamn – 534,149 (+3.2% yoy), and Helsinki-Åland-Stockholm – 496,844 (-3.6% yoy). A total of 71,116 guests were hosted during Viking Line’s special cruises. Additionally, Rosella managed to serve 16,190 in January 2023 before being sold.

For more Market Statistics Made Simple please visit: www.baltictransportjournal.com 10 | Baltic Transport Journal | 1/2024

Photo: Harri Tarvainen/VisitHaminaKotka

Wasaline:

279,590 passengers served in 2023 (+4.4% yoy)

The company’s Aurora Botnia ferry also carried 63,647 private vehicles between the ports of Umeå and Vaasa, up 14.3% on the 2022 result. On the other hand, the Finnish-Swedish ferry line transported fewer ro-ro cargo units, down 5.9% year-on-year to 20,886.

The Port of Rauma:

4.72 million tonnes handled in 2023 (+4.7% yoy)

The Finnish seaport took care of nearly 4.51mt in international traffic (+3.2% year-on-year), of which exports totalled 3.05mt (+0.7% yoy) and imports – 1.46mt (+8.8% yoy). The remaining 214.5kt was made in cabotage traffic (+51.5% yoy). Rauma’s container traffic advanced 2.1% on the 2022 result, totting up to 213,644 TEUs. Of these, 209,875 (+0.5% yoy) were handled in international and 3,769 (+828%) in domestic traffic.

The Port of Szczecin-Świnoujście: 35.32 million tonnes handled in 2023 (-4% yoy)

General cargo, the Polish seaports’ leading trade, totalled 15.88mt (-10.4% year-on-year), of which freight brought on board ferries amounted to 12.94mt (-10.5% yoy). Liquid bulk, on the other hand, advanced by 14.4% yoy to 8.56mt, including 4.76mt of liquefied natural gas (+7.1% yoy). Goods classified as other dry bulk amounted to 3.99mt (+20.6% yoy), followed by coal – 2.94mt (-31.9% yoy), grains – 2.63mt (+59.5% yoy), iron ore – 1.14mt (-46.1% yoy), and timber – 182.2kt (-20.4% yoy). The Port of Szczecin-Świnoujście also handled 67.6k TEUs (-10.3% yoy).

BTJ’s on issuu.

MARKET SMS 1/2024 | Baltic Transport Journal | 11

C L I C K H E R E T O S T A R T F L I P P I N G T H E P A G E S Advertisement

Photo: Wasaline Photo: Port of Rauma

Oulu upgrades its TEN-T status

The Finnish seaport, until recently designated as a Comprehensive Port of the Trans-European Transport Network (TEN-T) of the European Union, is now a Core Port. The seaport shares that the new status will, among many, expand its EU funding possibilities as well as impose obligations regarding infrastructure development (with a focus on environmentally friendly transport solutions). Oulu’s status upgrade follows the revision of the TEN-T, according to which the Core Network will be completed by 2030, the Expanded Core Network ten years later, and the Comprehensive Network by mid-century. “This decision is particularly significant now, as the importance of the northern region in Finland’s security of supply and connections to the west is emphasized,” the port underlined in

Schwenk’s new Swedish terminal

The German family-owned cement specialist began operating its new facility in the Port of Gävle. After two years of planning and construction, the 90 thousand tonnes of yearly handling capacity terminal was commissioned in December 2023. The facility includes a 45-metre-tall silo that can store up to 8.0k m 3

Stena Oil moves into Frederikshavn

The company’s subsidiary, Stena Terminals, has signed a takeover agreement with the Danish seaport and will now run the 75 thousand m 3 facility. Stena will also deploy a bunker vessel in Q1 2024 to operate from the 14-metre-deep terminal, which will be able to handle various fuel types, including bio and methanol. Stena Line will be one of the customers served from Frederikshavn (the company runs a ferry service with Gothenburg from the Danish seaport).

Remontowa contracted by Torghatten Nord

The shipbuilder from Poland will construct a double-ended passenger-car hybrid vessel for the Norwegian ferry company. The 63.65 by 15.5-metre vessel, designed by the Norwegian Ship Design Company, will serve the Stornes-Bjørnerå crossing once delivered in Q1 2026. She will offer room for 149 passengers and space for 50 vehicles. The newbuild will be equipped with two azimuth thrusters powered by batteries (or a backup diesel generator), which will be loaded during port calls. It will be the ninth ferry delivered by Remontowa Shipbuilding to Torghatten Nord, including six electric ferries in 2018-2021. The Torghatten Nord order ups Remontowa’s order book to six turnkey vessels (the company also works on five units for the Polish Navy).

For more news items please visit: www.baltictransportjournal.com 12 | Baltic Transport Journal | 1/2024

Photo: The Norwegian Ship Design Company

a press release. Photo: Port of Oulu

Anker Christensen Eftf. grows its foothold in Aalborg

The Danish heavy-duty road haulage company from Hjørring has decided to expand its area of activity in the also Danish seaport by 14.4 thousand m2 to 25k m2 . The agreement follows the increased demand for disposal, sorting, and recycling of construction waste. The establishment of the new site is expected to be completed this summer. “We are pleased with the agreement, which helps us futureproof our business. The area will help meet the high demand for handling construction waste such as soil, sand and concrete that can all be recycled elsewhere,” commented Per Nielsen, Owner of Anker Christensen Eftf.

Helsingborg’s e-reachstacker – delivered

After around one year of delay, the Swedish seaport finally got hold of the Kalmar 587kWh battery-capacity machine. The cargo handling gear, rolling on Continental tyres, can stack containers up to five high. The loading capacity is 45, 32, and 16 tonnes for the first, second, and third row, respectively. The e-reachstacker joins the Port of Helsingborg’s four all-electric terminal tractors from Terberg. The deal with Kalmar also includes supporting the port’s mechanics with training. Bart Steijaert, the Port of Helsingborg’s CEO, highlighted, “An important part of our sustainability work is the development of climate-neutral, electrified port operations. We aim to have 75% of our work machines running on electricity by 2026, which is a demanding target within our ambition of being the most modern port in the Nordics.”

Thun Resource – delivered

The first in a series of eight coastal product tankers of Thun Tankers’ Resource Efficient Class was handed over by shipbuilders from the Dutch Ferus Smit. The vessel – Ice Class 1A, 114.95 by 15.87 metres, 7,999 deadweight – offers 9,540 m3 of carrying capacity (currently under long-term employment for Nynas). “Adaptive propulsion to minimize energy usage, readyfor-shore electricity connection, UPS battery pack, the latest hull design and the newest and most resource-efficient machinery are some examples of the vessel’s new features,” Thun Tankers underlined in a press brief.

Kalmar’s e-machinery goes to the US

Wallenius Wilhelmsen has ordered four heavy forklift trucks and two reachstackers, all of them electric, as well as three heavy terminal tractors for the company’s US operations. The deal also includes the Kalmar Insight fleet performance management tool. The order is part of Wallenius Wilhelmsen’s onshore emission reduction activities, in which the company switches to zero-emission equipment wherever practicable.

WHAT’S NEW? 1/2024 | Baltic Transport Journal | 13

Photo: Port of Aalborg

Photo: Kalmar

Finnlines’ second Superstar enters traffic

The cruise ferry Finncanopus arrived in the Port of Naantali, from which she, alongside her sister ship Finnsirius, sails to & from Kapellskär via the Åland Islands as of 16 February 2024. Both newbuilds offer room for 1,100 passengers and 5,200 lane metres for cargo. The 235.6 by 33.3 m Ice Class 1A Superstar ferries feature several emission-reduction technologies, such as air lubrication, batteries, scrubbers, and waste heat recovery. They also have ballast water treatment plants. Finnsirius and Finncanopus also take advantage of auto-mooring and draw power from the shore while berthed in Naantali and Kapellskär. You can read more about Finnsirius ’ launch in BTJ Trip 2023 \ Naantali. Compact but capacious & versatile

Two new Germany -Sweden rail links

Kombiverkehr, in co-op with DB Cargo Scandinavia, has put in motion two services between Lübeck Dänischburg Cargo-Terminal Lehmann and Arlanda North (near Stockholm). The first full-rail crossing (via Denmark) is up and running from 3 January 2024, including a stop in Hallsberg. The other one, using Finnlines’ ferry service from Lübeck to Malmö with a stopover in Norköpping, started running on 15 January 2024. Both services offer three weekly round trips and can take various cargo units, including P400 semitrailers (but excluding type 1 and 7 dangerous goods).

Unity Line takes hold of Epsilon

The Polish ferry line has deployed the 2011-built ro-pax on its Świnoujście-Trelleborg service. The 187 by 26 m ferry offers room for 299 passengers and 2,860 lane metres for wheeled cargo and other vehicles.

For Europe-wide maps news on ro-ro & ferry container intermodal please visit: www.europeantransportmaps.com 14 | Baltic Transport Journal | 1/2024

Photo: Finnlines

Photo: S. Wołosz/Unity Line

TX Logistik links Lübeck and Verona

The company has launched a twice-a-week rail service for trailers (incl. non-craneable) and containers (incl. tank) between Cargo-Terminal Lehmann in Germany and Interporto Quadrante Europa in Italy. The train set comprises up to 32 cargo transport units (CTU). Meanwhile, TX Logistik has increased the number of round trips from four to six per week on its Lübeck-Segrate intermodal 32-CTU service (trailer & container, also including non-craneable and tank). The terminal of call in Germany is BRG, while it’s the Italia Milano Segrate facility in Italy. TX Logistik takes care of the entire traction for both routes.

Smyril Line orders new ro-ros

The Faroese shipping company has contracted the Chinese CIMC Raffles to construct two 190-metrelong, 3,300 lane metres for wheeled cargo, e-methanol-ready freighters. The newbuilds, designed by KNUD E. HANSEN, will also feature battery systems and onshore power supply connectors. The duo is planned to start sailing in 2026, serving Smyril Line’s Europe-Faroe Islands-Iceland trade.

Visborg again in the Med

Gotland Company’s ferry has once more been chartered by the Spanish Baleària, putting her on the ValenciaPalma-Ibiza service. The 2003-built 196 by 25 m ro-pax offers room for 1,650 passengers and 1,500 lane metres for wheeled freight. Visborg’s recent employment was a short charter for DFDS on the KarlshamnKlaipėda route, before which she plied for Baleària between the Spanish Almería and

Isabelle – sold

New rail service crisscrossing Sweden

Träfraktkontoret and its subsidiary TFK Logistics have kicked off a twice-a-week container (incl. tank) service that links Gothenburg and Piteå. In the north of Sweden, the train set is handled by ShoreLink in the Port of Piteå and at the rail-connected terminal of Stenvalls Trä at Lövholmen. In Gothenburg, the rolling stock goes directly into the sea container facility operated by APM Terminals. As of March 2024, the service will also carry trailers (which will be handled by Gothenburg RoRo Terminal’s Arken Intermodal Terminal).

Gotland Alandia Cruises’ maiden voyage

The Gotland Company-Viking Line JV will see its Birka Gotland departing from Stockholm’s Stadsgårdskajen to the Port of Mariehamn on 20 March 2024. Subsequently, the cruiser (offering room for 1,800 passengers) will ply each evening between the two destinations, also visiting Visby from time to time (the first trip to the island of Gotland is scheduled for 30 March 2024). Gotland Alandia Cruises also shares that Birka Gotland will call the Baltic ports of Härnösand, Riga, Rønne, and Ystad throughout the year.

Lakeway Link takes hold of a vessel

The JV between Greencarrier and Wallenius has acquired the 1999-built ro-ro Miramar Express, to be re-named Lakeway Express ahead of her launch on the Gdynia-Södertälje service this April. The 1,624 lane metres of capacity freighter will initially offer three weekly departures. Lakeway Link intends to incorporate the Swedish Port of Västerås into the service by 2026 following the reconstruction of the Södertälje locks.

Bridgemans Floatel Limited Partnership’s subsidiary from Cyprus Notamare Shipping Company has taken over Tallink’s ferry. The purchase is an exercise of the option included in the multi-year charter from April 2023 between Tallink Grupp’s subsidiaries Tallink Latvia & Hansalink and Bridgemans. The ferry, operating the Riga-Stockholm crossing before COVID-19 and offering room for 2,200 passengers (plus 970 lane metres for wheeled cargo), left Tallinn for Canada in December 2023. Isabelle joined Bridgemans’ fleet of ‘floatels’ (floating hotels) the following month. “We are pleased that after nearly 11 years as part of the Tallink Grupp fleet and at the respectable age of 35, Isabelle will now continue to offer a valuable and much-needed service, like the one she was able to offer here in Tallinn to the Ukrainian war refugees – safe accommodation – albeit this time to workers of major global industrial and resource projects,” Paavo Nõgene, Tallink Grupp’s CEO, commented. He added, “Tallink Grupp has a long-standing history and cooperation with Bridgemans, dating back over a decade, so we are pleased Isabelle is in trustworthy hands and know that she will be looked after well by the new vessel owners.”

MAP NEWS 1/2024 | Baltic Transport Journal | 15

the Moroccan Nador.

Photo: TX Logistik

Photo: KNUD E. HANSEN

HIRTSHALS EYES MORE WIND ENERGY…

• The Danish seaport has initiated a dialogue-based tender to erect up to nine additional turbines at its premises. These could come online in 2027, joining the existing four turbines (4.2MW; Denmark’s first set up on commercial terms – in 2019). The new turbines will be from 150 to 180 or 200 metres tall (nine, six, and four pieces, respectively),

producing 169/174/135MWh/year. The energy from the existing and future wind turbines will be used for power-to-x purposes. “[…] Hirtshals is perhaps the first port in the world to require that the electricity generated by its wind turbines be used to produce the green fuels of the future,” the Danish seaport underlined in a press brief. •

… AND BECOMING A CCUS HUB

• The EU Just Transition Fund has supported the establishment of a CO2 storage and shipment hub in the Port of Hirtshals with 109 million Danish crowns (€14.6m). The facility can be up and running in 2025/2026, with an initial capacity for handling 0.5 million tonnes per year for permanent storage in empty oil & gas fields in the Greensand area of the Danish

part of the North Sea. If provided with a pipeline for transporting CO2 to the Port of Hirtshals, the carbon capture, utilisation and storage (CCUS) project of Greenport Scandinavia would be able to take care of 3.0mt/year of CO2 in 2029, up to beyond 15mt/year in the early 2030s should the Danish and European infrastructures be integrated. •

NORSEPOWER SCORES TWICE

• First, the Lübeck-headquartered Oldendorff Carriers chose Norsepower to retrofit the company’s post-Panamax bulk carrier Dietrich Oldendorff with three 24 m tall and 4.0 m in diameter Rotor Sails. The installation will be carried out in Q2 2024 and finished by mid-year. Next, Louis Dreyfus Armateurs (LDA), a French shipowner who works on a fleet to be chartered by Airbus, will see these con-ros equipped with Rotor Sails. Each of the three dual-fuel (e-methanol) freighters will be outfitted with six 35-metre-tall sails. LDA’s Rotor Sails

will feature the brand-new patented Norsepower Sentient Control™, a real-time force measurement, control, and savings reporting system that will allow controlling the rotors individually. In addition, routing software will optimise the vessels’ journey across the Atlantic, maximising wind propulsion and avoiding drag caused by adverse ocean conditions. Estimations say that the new con-ros, expected to set sail in 2026, will halve the carbon footprint of LDA-Airbus’ Transatlantic voyages by 2030 vs 2023 levels (from 68kt to 33kt/year). •

LAND RECLAMATION FOR TALLINN’S

• Van Oord’s trailing suction hopper dredger Vox Amalia has arrived at the Paldiski South Harbour, where the Port of Tallinn will erect a dock to serve the offshore wind energy (OWE) industry. Vox Amalia will supply approximately

OWE QUAY – STARTED

830 thousand m3 of sand to create ten hectares of land for the quay (expected to become operational in 2025), with the sand dredged from a borrow area on the northern coast of Hiiumaa (about 125 km from the port).

•

THE STOCKHOLM-TURKU GREEN CORRIDOR

• The ports of Stockholm and Turku, alongside Viking Line, have signed an agreement to make the crossing between them fossil-free by 2035 at the latest. The partnership will act as an innovative platform to develop scalable solutions for phasing out fossil fuels. The initiative will also leverage the advances and solutions from the Decatrip project, a collaboration

between Rauma Marine Constructions, Viking Line, Åbo Akademi University, and Kempower. The Stockholm-Turku Green Corridor – ‘green’ as per the Clydebank Declaration, of which Finland and Sweden are signatories – is open to onboarding other stakeholders from the shipping and port industries, as well as cargo owners, freight forwarders, and others.

•

FINLAND’S FIRST OWE FARM TO GET STRONGER

• Suomen Hyötytuuli has obtained the building and water permits for adding new turbines to the 42MW Tahkoluoto offshore wind energy (OWE) farm off the coast of Pori. The so-called demonstration project, supported by NextGenerationEU funding, will see the addition of two at least 15MW-strong turbines (the current ones, 11, have a capacity of

2.3-4.2MW). The project aims to demonstrate the construction of new-scale offshore wind turbines, likewise testing foundations capable of withstanding harsh sea conditions (Tahkoluoto is the world’s first OWE farm erected in freezing waters). The entire expansion project assumes placing 40 new turbines, thus increasing the farm’s capacity by 600-800MW by 2027-2029. •

VENTURE FORTH 16 | Baltic Transport Journal | 1/2024

Photos: Norsepower

VENTURE FORTH

TAILWIND FOR SZCZECIN-ŚWINOUJCIE

• First, Vestas announced it plans to invest in a new plant producing blades for the V236.15.0MW wind energy turbine model. The facility, which could come online in 2026, will be located on a site acquired by the company in February 2023 and situated near an island where Vestas will have its nacelle assembly factory (expected to start operating in 2025). Second, the Spanish Windar Renovables and the Port of Szczecin-Świnoujście ratified the October 2023-signed preliminary land concession agreement. The company will now establish an offshore wind energy tower production centre in the Port of Szczecin. The factory and its storage area will occupy 17 ha. The towers produced by Windar Renovables in Szczecin will be designed to support the new generation turbines with 20MW of installed capacity. Third, the Port of Szczecin-Świnoujście joined the

Offshore Wind Port Alliance. The Polish duo has become the seventh member of an organisation that aims to cooperate to provide sufficient handling & storage capacity for Europe’s offshore wind energy industry. “Specifically, the collaboration between the seven ports consists of ongoing coordination and knowledge sharing, which enables them to optimise capacity utilisation between the ports to build wind farms more efficiently. Wind turbines require a lot of space at the ports, so lack of space is a specific challenge the ports are working to solve together. If one port only has space for half a project, another port may have space for the other half. In this way, the offshore wind farm can be built as scheduled, and the client will not have to wait for space at one specific port,” the Offshore Wind Port Alliance underscored in a press release. •

BWB TO BUILD A HYBRID BIOMETHANE VESSEL

• The Estonian State Fleet has entrusted the also coming from Estonia Baltic Workboats (BWB) with designing and constructing a new multi-purpose ship. The €22 million contract, supported by NextGenerationEU, will see BWB delivering the 40 by 10 metres, max speed of 12 knots vessel in 2026 (exact parameters of the workboat will be determined during the detail design process). “The new workboat will enhance the capacity for regular buoy tender works, maintenance of waterways, scientific research, pollution

monitoring and response and search and rescue missions in Estonian waters,” BWB detailed in a press announcement. The company also underlined, “The multi-purpose vessel will be Estonia’s first 100% alternatively fuelled workboat that will use sustainable biomethane as the main fuel, thanks to which it will be possible to minimize the ship’s CO2 emissions. In addition, the ship will be equipped with a battery bank that allows the operation of the vessel also in 100% electric mode with zero emissions.” •

ESL SHIPPING JOINS SBTI

• The Finnish dry bulk carrier became part of the Science Based Targets initiative (SBTi), having committed itself to reducing its footprint in line with the global warming limit of 1.5°C. In 2021, the company shared that it intends to reduce its emission intensity per tonne-mile by 50% by 2023 as a step towards net-zero operations by mid-century. By joining SBTi, ESL Shipping wants to reach climate neutrality already in 2040. The shipping line’s efforts include, among others, sailing their gas-run

vessels on bioLNG and ordering hybrid coastal ships (via the AtoB@C Shipping subsidiary). ESL Shipping has also recently upgraded its EcoVadis sustainability assessment from silver to gold. “For years, we have worked hard to find solutions to reduce our carbon footprint, and by committing to the Science Based Targets initiative, our clients and stakeholders can be convinced that we have a robust plan to achieve net zero by 2040,” underlined Mikki Koskinen, ESL Shipping’s Managing Director. •

GASUM-NORDIC REN-GAS E-METHANE DEAL

• The two have signed an offtake agreement, according to which Gasum will buy the entire output of Nordic Ren-Gas’ Tampere Power-to-Gas plant, set for launch in 2026. The facility (developed, built, and operated by Nordic Ren-Gas) will produce 160GWh/year of e-methane (35 thousand tonnes) by using renewable electricity from Finnish wind energy farms and biogenic CO2 captured from existing power plants (110kt). The Tampere plant will be located next to the existing Tammervoima waste incineration plant, from which CO2 will be captured from the flue gas.

In addition, excess process heat from production will be provided to the Tampere district heating network (600GWh/y). “In the power-to-gas process, hydrogen is first produced [18kt/y in case of the Tampere facility] using renewable electricity and water. The hydrogen is then further processed into e-methane by combining the hydrogen with biogenic carbon dioxide. E-methane produced in this way is fully renewable and will replace fossil fuel usage in transportation, maritime and industrial sectors,” Gasum detailed in a press release. •

WISMAR INVESTS IN HYBRID MACHINERY

• The German Baltic seaport took hold of a rubber-tyred Mantsinen 120 Hybrilift crane, said to be 35% more energy efficient than

a corresponding fossil fuel-only gear. According to the owners, it’s the first such Mantsinen deployed in a German seaport. •

HALLAND-HIGHFIVE AI CO-OP

• The Swedish port authority (managing Halmstad and Varberg) has teamed up with the tech company which wants to use artificial intelligence (AI) to foster sustainable and innovative growth. Over Q1 2024, the two will work on identifying the areas in which AI can be implemented to boost productivity and create new customer offerings. “We focus on the interplay between AI and humans,

where the former helps us make better decisions. With our team of researchers in design and AI, we strive to match technological expertise with practical applications to create solutions that are both innovative and user-friendly. We want to inspire locally and regionally as well as pitch in so that Sweden doesn’t lag on digitalisation,” underlined Sandra Johannesson, CEO of Highfive. •

1/2024 | Baltic Transport Journal | 17

Global Maritime Trends 2050

What does the future of the maritime industry look like?

Commissioned by

The maritime industry will transform over the coming decades, driven by technology adoption, the climate agenda, and intensifying geopolitical and macroeconomic shifts.

More than ever, maritime leaders and policymakers need robust insights to support critical decisions shaping the future of the industry.

80%

3%

Defining impacts

Global Maritime Trends 2050 analyses the leading drivers of transformation over the next 30 years, and how they impact five key components of the maritime industry.

“The renewed focus on energy security, particularly in light of heightened tensions and conflicts, is accelerating the global energy transition. ”

2050

CHART OF THE ISSUE

Maritime trade Commercial shipping, energy transport, fishing Vessels Design, fuels, technologies Energy Green energy supply, o shore energy Ports Port infrastructure and logistics People Skills, training programmes Maritime economy

Global Maritime Trends

of global emissions are produced by shipping

of the world’s trade

The research led us to four insightful futures that depict Revealing

is delivered by ships

Revealing futures

The research led us to four insightful futures that depict what the maritime industry of 2050 could look like.

Most notably, the outlooks consider various scenarios around speed of technology uptake and the nature of global co-operation on climate change.

Co-operation

Gradual

Just, gradual transition

High global co-operation combined with a gradual uptake of novel and/or advanced technology

Global co-operation on climate change

Delayed transition

High global fragmentation combined with a slow uptake of novel and/or advanced technology

Rapid tech-driven transition

High global co-operation combined with a rapid uptake of novel and/or advanced technology

Speed of technology uptake

Fragmentation

Regionalised and fragmented transition

High global fragmentation combined with a rapid uptake of novel and/or advanced technology

Rapid

Towards 2050

different scenarios will impact the maritime

1/2024 | Baltic Transport Journal | 19 energy transport, fishing economy

Explore our four futures to discover how

Towards 2050

Explore our four futures to discover how different scenarios will impact the maritime industry. Although fictional, each is grounded in science, historical fact and current speculation.

01

Just, gradual transition

What if nations embrace widespread adoption of green hydrogen?

The maritime industry could become a decarbonisation enabler, linking key future producers of green energy such as China, Saudi Arabia, South Africa and the US.

With further development, ammonia is likely to become the safest and most efficient way to transport hydrogen, creating many new jobs and upskilling opportunities.

How we get here

• Global co-operation on climate change with clear targets

• Political support through investments and incentives

• Rapid uptake of new fuel technologies by ships

• Ports redesigned for supply and storage of new fuels

• Demand for tech-savvy ship managers enables more women seafarers

2026

Target date for Europe's first green ammonia facility

90%

Most electricity expansion over the next five years will be renewable

02

Rapid tech-driven transition

What if automated technology solutions became widely adopted?

Remote control, automation and IoT technologies will greatly enhance the efficiency of ships and ports, creating opportunities to increase maritime trade.

Human supervision by skilled employees will be critical, with AI-powered assistants and immersive technologies such as the metaverse to simplify and enhance tasks.

How we get here

• Strong industry-wide technology investment

• Coordinated approach to decarbonisation

• Global harmonisation of technology protocols

• Industry training matches emerging innovation

30.6bn

Number of IoT units expected to be in operation by 2025

90%

Percentage of vessel data that AI-based models can process

CHART OF THE ISSUE 20 | Baltic Transport Journal

04 03

Percentage of vessel data that AI-based

03

Regionalised and fragmented transition

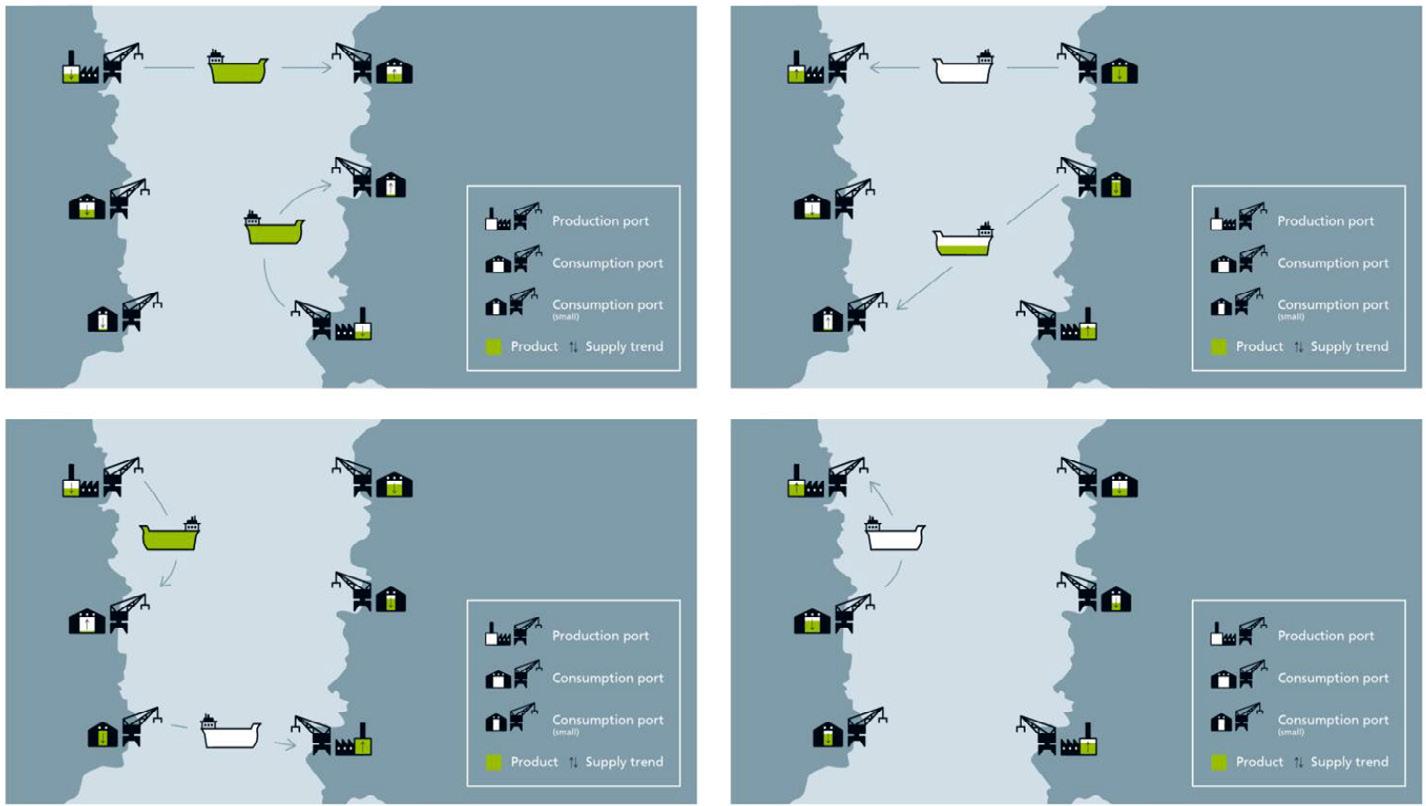

What if regionalisation and population expansion lead to fragmented maritime trade?

Localised systems of trade could lead to smaller ships making shorter journeys, with escalating costs due to varied adoption of technology in different regions.

Lack of global co-operation on governance and trade increases the risk of ‘dark fleets’ operating under the radar.

How we get here

• Shifting population dynamics drive consumer demand in Asian and African economies

• Geopolitical and supply chain challenges lead to regionalisation

• Low co-operation on innovation, data sharing and decarbonisation

• Disparate technology uptake causes port incompatibility

50%

By 2050, half of the world's top ten economies will be Asian

25% Africa will contribute a quarter of the world’s population by 2050

04

Delayed transition

See the full picture

What if average global sea levels rise by at least 40 cm?

Unchecked, climate change is set to destabilise many traditional shipping routes, prompting increased traffic in the unpredictable Arctic Ocean as ice retreats.

Extreme weather and natural disasters will increase the costs and requirements for insurance, while rising sea levels could submerge many vital economic ports.

How we get here

• Low co-operation and action on climate change

• Slow and fragmented technology uptake

• Rising water and soil salinity disrupt supply chains

• Rising sea levels increase coastal inundation

800m

Number of people already vulnerable to a 0.5 metre sea-level rise

2030

Predicted start of ice-free Septembers in the Arctic Ocean

Read more about the scenarios in our online hub and report: http://impact.economist.com/ocean/global-maritime-trends-2050/

© The Economist Group 2023

CHART OF THE ISSUE 1/2024 | Baltic Transport Journal | 21

electricity expansion over the next five years will be renewable

Most

can process

models

Temporary storage period – debated

The European Parliament is discussing the Commission’s (COM) proposal for a new EU Regulation on the Union Customs Code. The European Sea Ports Organisation (ESPO) shared a series of concerns over the file, most notably regarding reducing the time for the temporary storage to three days. “The 90 days temporary storage plays a crucial role in ensuring the fluidity of cargo flows through ports, in particular, when other parties in the logistics chain do not provide in a timely manner the data required to place goods under a customs procedure,” highlighted ESPO in a press brief. The Organisation also

noted, “In fact, the ‘temporary storage’ status must be seen as a useful ‘administrative waiting room’ either to get the necessary information/data or, in case of transhipment call to collect the cargo and/or wait for the vessel to continue the voyage to the end destination of the goods. A shortened temporary storage period would leave an unacceptable amount of goods without an adequate customs procedure, forcing terminals & shipping lines to be responsible for putting goods under a customs bonded procedure.” ESPO has also published a position paper on the Customs Reform Proposal (COM(2023) 258).

TEN-T – under review

On 18 December 2023, the European Parliament and Council reached a deal on the review of the TEN-T Regulation. Among others, the European Sea Ports Organisation (ESPO) strongly supports the legislators’ decision to include energy ports in the EU’s Trans-European Transport Network (TEN-T). In accordance with the reached agreement and the Organisation’s longstanding plea, a port’s position in the TEN-T will now be assessed not only on the basis of the amount of cargo handled but also on its contribution to the energy transition. “Even if volumes and tonnes remain an important indicator for ports as hubs in the logistic chain, it is not anymore the only indicator of performance. The decision to include ports that play an important role

in the supply of energy in the TEN-T is a huge step forward. It shows that the legislators recognise that energy is an important commodity and ports are key in ensuring both Europe’s energy security and energy transition. This energy role cannot always be counted in tonnes,” underscored Isabelle Ryckbost, ESPO’s Secretary General. At the same time, ESPO welcomed the Parliament’s adoption of the Berendsen report, an initiative on building a comprehensive European port strategy. The Organisation especially highlights the report’s understanding of the strategic challenges modern ports face and, similarly, the sheer amount of investments they need to carry out to continue supporting the EU’s society and economy in a future-fit manner.

OPS workshop package – available

The package – developed by the IMO-GreenVoyage2050 project in collaboration with the International Association of Ports and Harbours – has been released . It explains how ports can use onshore power supply (OPS) and support the use of cold ironing to reduce ship emissions in harbours, in line with the objectives of IMO resolution MEPC.366(79), which encourages voluntary

cooperation between the port and shipping sectors to contribute to the reduction of greenhouse gas emissions from vessels. The package goes through several topics, including key issues when exploring OPS, common drivers and influencing factors that affect the viability of OPS as an emission reduction strategy. and types of analyses required to assess the feasibility and potential usage.

Sustainable Ocean Principles – developed

The UN Global Compact has, in consultation with more than 300 stakeholders worldwide, developed the Principles in question. The purpose of the Practical Guidance – Ports edition is to promote the well-being of the ocean for current and future generations,

as well as to emphasize the shared responsibility of businesses to take necessary actions to secure a healthy and productive ocean. The nine principles cover three areas: ocean health and productivity, governance and engagement, and data and transparency.

Guidance on the Safety of Battery Energy Storage Systems (BESS) On-board Ships – released

“BESS installations on board ships have been increasing in number and installed power as battery technology also develops. There are more than 800 battery ships in operation across the world, 60% of which are known to be operating in Europe, using batteries onboard for propulsion either in pure electric or hybrid functions,” said the European Maritime Safety Agency in a press release

on the launch of its publication. The Guidance – developed with the support of experts who brought essential knowledge on the requirements of classification societies, industry standards, and available research – aims at supporting maritime administrations and the industry by promoting a uniform implementation of the essential safety requirements for batteries aboard vessels.

CIG4U – presented

On a visit to Kyiv, the Lithuanian Ministry of Transport and Communications, supported by Canada, Sweden and Ukraine, presented the Common Interest Group for Transport in Ukraine (CIG4U) support platform within the International Transport Forum (ITF) and as one of the priority activities of the Lithuanian ITF Presidency. CIG4U is to help Ukraine meet its immediate transport needs by contributing to the long-term reconstruction of the country’s transport links.

As such, CIG4U will act as an information exchange platform about the transport and infrastructure needs identified as urgent by the Ukrainian government, e.g., immediate repairs, replacement material, or other actions to ensure the functioning and safety of Ukraine’s transport systems. The ITF platform will also coordinate the mobilisation of international support for the reconstruction of the country’s infrastructure, ensuring transparent use of aid for Ukraine’s key priorities.

WHAT’S IN THE CABINET 22 | Baltic Transport Journal | 1/2024

As safe as ports?

by Neil Dalus, Risk Assessment Manager, TT Club

Security is key for container terminals and ports generally. The threat horizon is vast, incorporating cargo theft and illicit trades alongside operational safety and the prevention of terrorist attacks. Inevitably, land and water interfaces are needed to be taken into account. Let us then consider some fundamental aspects of modern-day port security challenges and offer some guidance.

Acentral reference in the context of security for port operators is the International Ship and Port Facility Security (ISPS) Code, a supplement to the Safety of Life at Sea Convention. It sets minimum security arrangements for ships, ports and governmental agencies.

Dating back to 2004, the ISPS Code ascribes responsibilities to a variety of stakeholders, including port personnel, related to detecting threats and taking preventive measures affecting ships or port facilities used in international trade. The Code also specifies the appointment of a port facility security officer responsible for the development and maintenance of a port facility security plan.

Barrier fundamentals

Physical security will be a primary consideration. Getting the simple things right, such as perimeter fencing, is fundamental. Measures that go beyond that will need to be proportionate to the risks assessed, inevitably influenced by volumes, throughput, the type of cargo being handled, the layout of the terminal and the technology available.

There is an array of options and combinations to consider for perimeter fences; some designs may be more secure than others. It is recommended that palisade-style fencing, for instance, be avoided as it may be more easily manipulated, allowing access. A mesh style of fencing is generally thought

to offer greater levels of security. The height of the perimeter fence (influenced by local topography) is another critical factor. A minimum of 2.4 metres is recommended to deter bad actors from scaling or being able to pass items over. Higher fences or topping with electric fencing or razor wire for added security may need to be considered.

Accessibility

Controlling access is a necessary starting point; strict controls will assist in managing the flow of people (legitimate and otherwise) to the facility, together with reducing the number of physical entry and exit points to the minimum necessary. Alongside this, consider how such areas will be monitored and managed. This includes the extent to which security personnel will be deployed, the introduction of physical barriers, and what logs will be kept and for how long.

There will typically be a large number of restricted areas, buildings and rooms within a facility, where locks are utilised to prevent unauthorised access. Regardless of who may have them, robust processes are necessary to ensure that keys are returned and controlled with timely intervention protocols.

The implementation of electromechanical key systems may significantly improve essential control and operational efficiencies; these remove the risk of lost or stolen keys and security compromises while providing valuable user data for management and control. Central programming ensures

efficient and speedy modification of access permissions. Further smart and high-security locks may be appropriate.

Line of sight

The deployment of cameras can add to security provisions and can have multiple benefits. Sophisticated systems monitoring the entry gate can serve not only to record access but also to capture the condition of the vehicle, container, chassis and cargo. All such records might prove invaluable evidence in the event of any dispute.

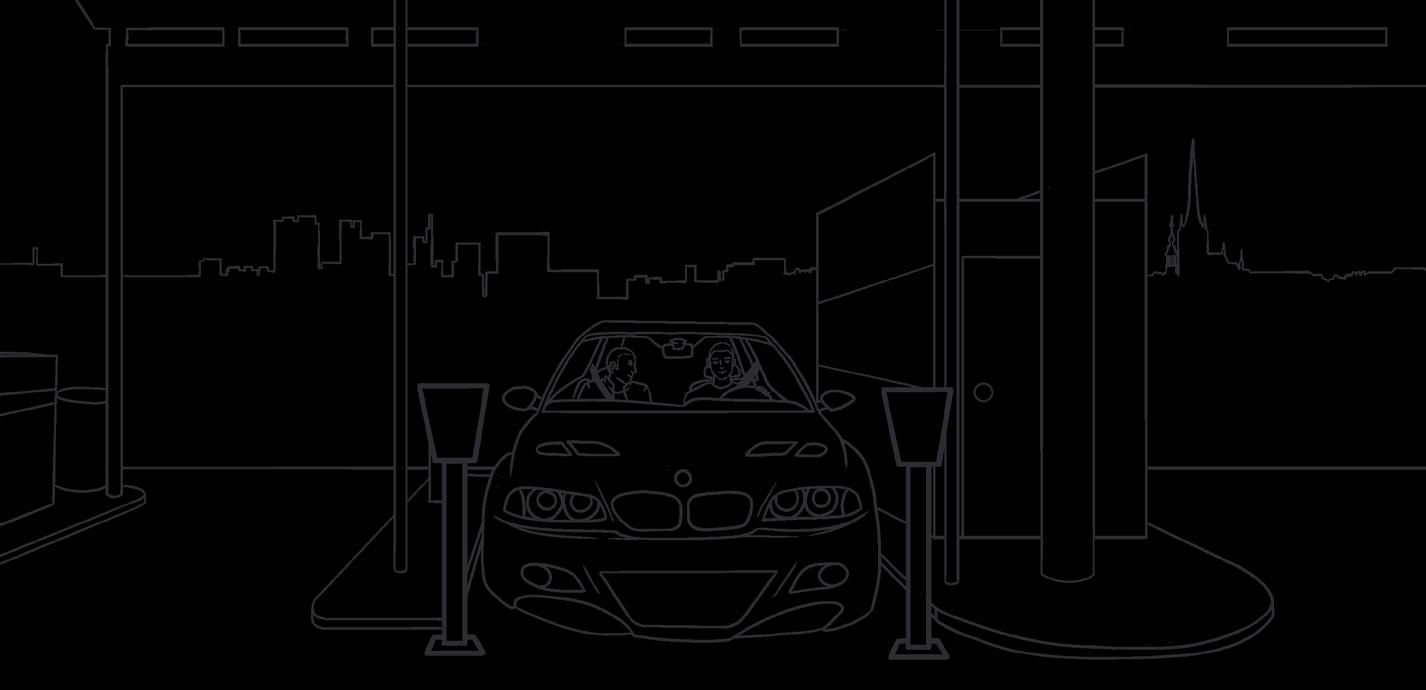

Cameras can also be linked to a terminal operating system. At the same time, using optical character recognition technology can drive the development of operational efficiencies, identifying and locating individual containers. Automatic number plate recognition cameras can identify expected site visitors, providing both security and efficiency, potentially controlling the release of vehicles and containers with a binary ‘release/don’t release’ prerogative.

Visual analytics software can provide unrivalled insight, including managing the movement of visitors and restricting & controlling the areas of the facility that they are able to access. Additionally, if linked to the relevant authority and national databases, this could serve to identify bad actors and vehicles operating on false registration plates (often used to facilitate theft of cargo).

Thermal cameras are now being used for both security and fire detection.

24 | Baltic Transport Journal | 1/2024

Advances in technology aiding seaport and terminal security

These may eliminate the need for continuous monitoring of cameras by alerting security personnel at the point of detection due to a fire or a trespasser.

CCTV cameras and software can also provide a deterrent to bad actors. However, take care to ensure that the procured system is fit for purpose, well-maintained and that operators are trained to use the equipment proficiently. And don’t forget simple housekeeping – overgrown foliage or litter can trigger unwelcome false alarms!

Eye in the sky

The supporting use of drones not only helps pinpoint an area of suspicion but also can provide and record additional data, such as thermal imagery and geo-location, which can deliver valuable insights for any ongoing incident or subsequent investigations.

Tethered drones are, in particular, a useful refinement allowing a permanent land-based power supply in the form of a fixed cable attachment. This technique removes the limitations of the flight time due to the capacity of the batteries and avoids battery changeover interruptions. Tethering allows the drone to operate for a much longer duration; it lends itself to use in more prolonged surveillance operations where a high viewpoint from the drone can be used to maximum effect while utilising the camera’s zoom and thermal imaging functions. The collateral limitation is reduced freedom of movement around a facility.

Drones can be further adapted. Thermal imaging may identify and track heat sources over a wide area and in poor lighting conditions, allowing this information to be relayed to the team on the ground, thus supplying them with intelligence that would not be otherwise available.

The object tracking function – available for use with a regular image camera as much as with thermal imaging – allows the drone operator to fix onto an object and then let the drone camera track it. This enables the drone operator to relay/record the data without losing sight of the object being tracked. In each case, it’s possible to relay the thermal image/camera data directly to the ground team so that they can see exactly what is being seen by the drone and its operator, who may be some distance from what is being observed. These capabilities can support the detection of intruders (including clandestine migrants)

as much as give early warning of developing fire risks in cargo or assets.

Interfaces and insider risk

Some facilities might fall under the jurisdiction of the port police; regardless, working closely with local law enforcement will be vitally important. While operation-specific security measures should consistently be implemented, interacting with port police or other local law enforcement agencies will be beneficial in ‘layering’ protections.

Technologies are likely to overcome the human-moral hazard. This can be further enhanced, for example, with forensic coding security solutions: gels, sprays and liquids can be an effective deterrent, remaining on clothing and skin for prolonged periods, and thus increasing the risk of apprehension (this may be during questioning in relation to unconnected crimes since those involved in criminal activity in and around ports will typically be entangled in other crime, too).

Insider risk is prevalent within TT’s claims experience; information is the lifeblood of criminal activity and can be sourced from within an operation. This may be access codes, the location of a particular container or details of on-site security provisions. Information security is, therefore, critical. Carry out a risk assessment of the information that your operation collects, stores and shares. Recognise the value of that information in the wrong hands and consider thoroughly who has access and why, balancing access restrictions with operational efficiency. Prevent workstation sharing or sharing of passwords. The terminal operating system is pivotal in the management of a container terminal. Protecting this key infrastructure is critical to maintaining operational integrity and avoiding business disruption.

Advanced technologies require skill & awareness advancement

The use of automation and innovative technologies – including artificial intelligence, big data, the Internet of Things (IoT) and blockchain – to improve port and terminal operational performance is becoming more commonplace.

Although the industry is often regarded as conservative and resistant to change, this image is fast-changing. However, together with the opportunity to improve efficiency come new risks in terms of cybersecurity,

such as an increase in the potential access points to the valuable data that is being collected through IoT devices. These issues force increased focus and resources into the development of measures to secure the data and prevent unauthorised access.

Cybercriminals often exploit the ‘people factor’ through the use of common hacking tool kits readily available in the public domain. Consequently, an ongoing mandatory awareness programme should be implemented for the workforce to explain the risk of cybersecurity events and set up preventive measures. It is vital to establish an appropriate cybersecurity incident response team along with an assigned contact point.

Further to this, it should be recognised that many elements of operations are likely to be outsourced to third-party vendors; it remains the responsibility of the company to ensure sufficient due diligence has been taken to avoid a cyberincident resulting from the action or inaction of third parties. For example, ensuring information security management standards, such as ISO 27001, are complied with by the third party can reduce the risk substantially. It is essential to develop an appropriate strategic approach and a formal cybersecurity incident response process to tackle cyberincidents effectively and consistently.

Closing the window

The sheer volume of cargo moving through ports and onto their final destinations is staggering – and only likely to grow with the predicted increase in global population. Unfortunately, this makes it a target for criminal exploitation through the trade in illicit commodities and theft of cargo, to name a few.

Therefore, the adoption of ‘smart’ technologies such as IoT and blockchain within ports can increase the ‘visibility’ of the cargo throughout the supply chain. This augmented oversight not only has the potential to improve efficiency, but it can also improve security through transparency of the entire process.

Increasing the visibility of the cargo flow by providing real-time information can reduce the opportunity time window for criminal activity. Likewise, the digital fingerprint that is left through the use of blockchain provides a smaller hiding place for criminals operating in the margins of our industry.

TT Club specialises in the insurance of intermodal operators, non-vessel owning common carriers, freight forwarders, logistics operators, marine terminals, stevedores, port authorities and ship operators. The company also deals with claims, underwriting, risk management as well as actively works on increasing safety through the transport & logistics field. Please visit www.ttclub.com for more info.

LEGAL 1/2024 | Baltic Transport Journal | 25

Increase in stern tube damages

A concerning new trend?

by John Balaouras, Senior Claims Executive, Piraeus, and Svend Leo Larsen, Senior Claims Adviser, Bergen, Gard

The number of stern tube-related damage claims has increased considerably over the last few years, and such damages are now one of the more frequent claim types handled by Gard under the hull and machinery policies. A recent analysis carried out by our organisation sheds light on the problem.

The nature and severity of damage suffered by stern tube/shafting systems vary greatly – ranging from a simple aft seals’ leakage that can be rectified over a few days whilst afloat to loss of propulsion involving costly salvage operations and extended dry-dock repairs.

In the past, surveyors often considered damage to a stern tube a relatively straightforward casualty. The cause was often obvious: contact with a floating object such as ice, fishing nets or ropes, for example.

These causes still exist, of course, but the significant increase in frequency over the past years, without any apparent explanation, raises concern.

A new ‘thorn’ for owners and insurers

Over the last decade, the number of shaft/ stern tube-related claims Gard has handled, either as claims’ lead or on follow accounts, exceeds 700 (Fig. 1).

To be clear, the number of vessels insured with Gard also increased over this period. So, did the increasing claims just reflect the higher number of vessels insured? No. Even when taking into account the total number of ships covered, we still see that the share of stern tube-related damages is on the rise (Fig. 2). So, what is happening?

The use of EALs

As shown in the first bar graph, the significant increase in claims seems to have followed the introduction of the revised Vessel General Permit (VGP) requirements in 2013 by the U.S. Environment Protection Agency. These require all vessels over 79 feet trading in U.S. waters to use Environmentally Acceptable Lubricants (EALs) in all oil-to-water interfaces.

According to a study performed in 2019 by DNV GL with the assistance of Scandinavian insurers (Gard, Skuld, the Swedish Club, and the Norwegian Hull Club), it was discovered that two key features of EALs make them different from the traditional mineral oils widely used before VGP requirements came into force. First, the pressure/viscosity coefficient – under

high load operations (i.e., hard turns at high speeds), the EALs operate with a lower safety margin of the minimum oil film between the tailshaft and the bearings. Second, the viscosity index (EALs significantly higher than mineral oils) – EALs operate with lower viscosity under lower temperatures (i.e., mooring trials and cold start-up).

Damage caused due to the above characteristics can be prevented to some extent by either using EALs with higher viscosity (one grade up) or by modifying the aft bearing design to smoothen/increase the contact surface between the bearing and tailshaft by double slope design instead of single.

In addition, another notable characteristic of the EALs is poor hydrolysis stability when interacting with seawater once bypassing the aft seals. When contaminated with seawater, lubricant decomposes, and carboxylic acid is generated, which can damage the seals, resulting in even greater seawater ingress.

The speed of hydrolysis depends on various factors, including the chemistry of the oil, temperature and additives. However, the most important factor is the quantity of seawater in the lubricant. According to the International Association of Classification Societies (IACS), the upper water limit suggested is 1% (the same for both traditional mineral oils and EALs). Experience has nevertheless shown that this limit is quite ‘relaxed’ and somehow misguiding when it comes to EALs, as apparently even minor water quantities can trigger the hydrolysis reaction of an EAL and affect its characteristics, including stability.

In sum, it has been confirmed that the performance capacity of the traditional mineral oil – the strong lubricating oil film, consistency in the presence of water in the oil and excellent seal compatibility – cannot be matched by the EALs. This is why ship owners tend to go back to the ‘traditional’ mineral oils combined with air-type seals for both newbuildings and existing vessels.

New root cause analysis

In Gard, we have conducted an internal investigation of all the stern tube damage

cases we encountered in the previous ten years (2013-2022) in an attempt to identify any patterns with respect to causation.

It was evident from the start that the vessels that suffer most from such damages are bulk and container carriers, accounting for 53% of the occurrences (these segments make up 44% of Gard’s Hull and Machinery portfolio). The root cause investigation was thus narrowed down to focus on bulkers and container ships, with the reported causes categorized as follows in Fig. 3.