The Port of Opportunities

The Port of HaminaKotka is a multipurpose seaport serving trade and industry. This major Finnish port is an important hub in Europe and in the Baltic Sea region.

Welcome to the Port of HaminaKotka!

Dear Readers,

Like a seed-turned-plant, the idea of creating what we eventually named the Baltic Green Map was growing in me for a long time. I have been rounding up the Baltic transport highlights for some time now for the year-opening issues of the Baltic Transport Journal . Since a few editions of these summaries, the number of all-thingsgreen transport & logistics developments has steadily accumulated into a critical mass. In 2023, I thought the time was ripe to embody the concept.

But there was just too much information to put it all on the map without running the risk of it turning into some utterly incomprehensible collection of motley icons overloaded with super-small text. As such, it became crystal clear from the very beginning that the Baltic Green Map would have to be accompanied by an inventory of sorts that substantiates the snapshot seen on the map.

The Baltic Green Map Catalogue was thus born. The intention is to make it a yearround in-the-making project, with its digital version updated and shared regularly as the Baltic Sea region forges ahead with its green agenda, on- and offshore.

Both parts of the map and its catalogue, the land and sea ones, go beyond what we otherwise would call core transport & logistics. Recently, it became evident that ports, terminals, shipping lines, trucking companies, etc., are reaching outside their usual ‘comfort zone’ to pep their green game, likewise to support the overall green transition. That is precisely why we put on the map and in the inventory such investments as bioLNG and e-methanol production plants, while the other side of the map presents the existing and planned (at various stages) offshore wind energy farms throughout the Baltic Sea region. Not to mention the addition of green tech suppliers, hard- and software alike.

I sincerely hope you’ll like what we have prepared. As always, we are more than open to making our products better, so please don’t shy away from dropping us a note at bgm@baltic-press.com

Thanks – and may you flourish like a green bay tree!

Przemysław Myszka , Editor-in-Chief

Publisher: Baltic Press sp. z o.o.

Aleja Zwycięstwa 96/98 81-451 Gdynia, Poland

The Baltic Green Map 2025 Catalogue

bgm@baltic-press.com

www.baltictransportjournal.com www.europeantransportmaps.com

Editor-in-Chief

Przemysław Myszka

Art director/DTP Danuta Sawicka

Marketing & sales Przemysław Opłocki

Cover photo Ørsted

Photo: Maersk

The Baltic Green Map 2025 Catalogue

Baltic Green Map 2025 – key

T

X

onshore power supply (offering as a port or using as a shipping line)

alternatives to fossil fuel (e.g., hydrotreated vegetable oil, HVO)

Y photovoltaics (port/terminal installations or on board vessels)

Z

wind energy (wind turbines or auxiliary wind propulsion for ships)

O automooring (offering as a port or using as a shipping line)

PS

future fuel

(production or usage of hydrogen, ammonia, methanol, next-gen biofuels, etc.)

carbon capture and storage (port infrastructure or onboard ship equipment)

\ liquefied natural gas (LNG; handling in a port, offering as bunker, or using as a shipping line)

\ bioLNG (handling in a port, offering as bunker, or using as a shipping line)

Q research and development of green solutions

R green tech development centre

V electricity (e.g., battery packs on board vessels, e-trucks, or electric cargo handling equipment)

W other (e.g., Green Corridor projects, geothermal energy, new type of fuel-saving propeller blades, etc.)

bioLNG production plant

e-methanol production plant

[P] Present products, infrastructure, services, etc., already in use

[F] Future products, infrastructure, services, etc., under construction, planned, researched, etc.

Photo: Vestas

XTCOPENHAGEN MALMÖ PORT – COPENHAGEN

PRESENT

The 40-foot container-unit (10kV system, certified with IEC/ISO/IEEE 80005, 3.0MVA/approx. 2.7MW) by Actemium is located at DFDS’ terminal on Dampfærgevej.

According to the project’s technical advisor, COWI, cold ironing DFDS ferries results in an annual emission reduction of approximately 912t of CO2, 18t of NOX, and 400kg of particulates.

Phasing in HVO: the port’s container terminal’s newer terminal tractors, rear loaders, and industrial trucks will be the first to run on HVO100.

Switching to HVO100, which replaced some 286 thousand litres of fossil diesel consumed by CMP in Copenhagen annually, will result in reducing CO2e emissions by 640 tonnes/year.

The new battery-hybrid straddle carriers CMP ordered in April 2023 will also tank HVO100 (the terminal’s ship-to-shore gantries and other work vehicles run on green electricity).

CMP’s box-handling facility in the Danish capital has fully switched to hydrotreated vegetable oil (HVO100) as well as green electricity to run its quay and yard machinery in mid-September 2024 – more than half a year ahead of the original schedule.

TCold ironing the Crown Seaways and Pearl Seaways ferries in the Port of Copenhagen.

Fleet of 125 e-trucks: Volvo FM Electric lorries (total load of 44t, range of up to 300-380 km when fully charged).

Already, 95 e-trucks are running across Belgium, Denmark, Lithuania, the Netherlands, and Sweden, with the remaining 35 due for delivery in 2024.

WVThe company intends to have 25% of its trucks battery electric by 2030, a step towards achieving carbon neutrality by mid-century.

The company shared that the e-truck investment (October & December 2021) reduced its greenhouse gas emissions by 1,516t (well-to-wheel) by the end of 2023.

A drone support system as part of the equipment on commercial ships (first implementation on the Selandia Seaways ro-ro).

FUTURE

PThe hydrogen 23MW fuel cell ferry of working name Europa Seaways According to DFDS, running on green hydrogen will avoid emitting 64kt CO2 /year.

VAn additional order of 100 e-trucks.

Volvo will deliver the FH Electric and FM Electric models, upping the Danish shipping & logistics company’s heavy-duty electric truck fleet to 225. The newest batch will be deployed in Ireland, Norway, and the UK.

PRESENT

YVOperating Volvo electric trucks in Denmark and Sweden, having also established charging stations in its distribution centres in Horsens and Landskrona (with electricity coming from photovoltaics).

VFUTURE

The Danish transport & logistics firm has purchased 300 electric trucks from Volvo, including the FH Aero Electric model with improved aerodynamics (the agreement also includes 500 Volvo trucks with fuel-efficient diesel and gas drive lines). All trucks are expected to be delivered between 2024 and 2026.

DSV plans to run a fleet of 2,000 e-trucks by 2030.

DSV has set a near-term goal to reduce scope 1 & 2 emissions by 50% and scope 3 ones by 30% in 2030 vs 2019-baseline. The company intends to become net-zero by mid-century.

ELECTROCHAEA/BIOCAT ROSLEV

PRESENT FUTURE

PE-methane letter of intent with the Swedish shipping line Erik Thun – off-take negotiations to replace LNG with e-methane as a marine fuel.

Working on establishing a power-to-gas facility in the municipality of Skive. There, renewable wind power will be used to produce green hydrogen that will be mixed with the CO2 from biogas production at Rybjerg Biogas in a bioreactor to produce e-methane using Electrochaea’s patented bio-methanation technology.

ESVAGT

PRESENT FUTURE

The Danish Esvagt saw the launching of its latest service operations vessel (SOV) at the Turkish Cemre Shipyard in mid-2024, said to be the world’s first methanol-powered SOV for offshore wind farms. The 2022-ordered SOV will be handed over at the end of 2024.

PThe dual-fuel ship, also equipped with batteries, will serve Ørsted’s 1.32-gigawatt (165 8.0-megawatt turbines) Hornsea 2 offshore wind energy farm 89 kilometres off the Yorkshire coast.

If fuelled and running on e-methanol, produced with renewables and biogenic carbon, the newbuild will have its annual footprint reduced by some 4,500 tonnes of CO2 vs when bunkered with fossil fuel.

EUROPEAN ENERGY

PRESENT

The company has inaugurated its first hydrogenproducing facility in Måde, near Esbjerg, with the output delivered to the Port of Esbjerg and an industrial gases company.

PThe Danish Stiesdal supplied the first electrolyser to the plant (which was completed in June this year). “Plans are already in place to expand the facility with two additional electrolysers, of which the next is expected to be installed in 2025. When all three electrolysers are operating, the plant will have a total capacity of 12MW and an expected annual production of 1,500 metric tonnes of hydrogen,” European Energy added in a press brief.

Excess heat generated from the hydrogen production process will be utilised by DIN Forsyning, a local heating utility.

Centrica will serve as the facility’s balancing and optimisation partner, ensuring that energy usage and hydrogen production are managed to maximise output and minimise costs.

PRESENT

PFUTURE

FUTURE

Co-op with Copenhagen Malmö Port to scrutinise the set-up of a biofuel plant in Malmö.

The parties have kicked off the works with a pilot study, which will include securing relevant permits. If everything goes according to the plan, the facility should be up & running by 2030.

PRESENT

PFUTURE

The Danish shipowner has entrusted the Chinese New Jiangzhou Shipbuilding with delivering eight dual-fuel (methanol) chemical tankers.

The shipbuilder, which also provided the tanker design, will supply the 6,800-tonne deadweight vessels in 2026.

GREEN2X

M.H. SIMONSEN

PZPRESENT

Norsepower Rotor Sail on Maersk Tankers’ Maersk Pelican (now Timberwolf ).

PLaura Mærsk : the 172 m long container ship of 2,136 TEUs capacity running on methanol.

PPECO Delivery: using certified green fuel (such as second generation biofuels made of waste feedstocks) instead of fossil bunker to run the company’s container ships.

The carrier says these alternatives offer 65-80% (low) or 80-95% (very low) lower life cycle emissions compared to fossil fuels. The GHG emission savings are confirmed to customers with a certificate. Additionally, ECO Delivery for ocean transports will be exempted by Maersk from the EU Emissions Trading System charges.

PFUTURE

25 methanol-run container carriers to be deployed by 2027.

E-methanol production capacity in Spain (some 2.0mt/year).

The global container carrier from Copenhagen has signed a long-term offtake agreement with the Chinese LONGi Green Energy Technology for the supply of bio-methanol for the former’s growing fleet of dual-fuel vessels.

The first batch of the fuel, produced at LONGi’s facility in Xu Chang in Central China from residues such as straw and fruit tree cuttings, will be supplied in 2026, with full production expected by enddecade. “It will meet Maersk’s methanol sustainability requirements including at least 65% reductions in GHG emissions on a lifecycle basis compared to fossil fuels of 94g CO2e /MJ,” the Danish shipping company said in a press release.

Maersk’s combined offtake agreements now [beginning of November 2024] meet over 50% of the dual-fuel methanol fleet’s bunker demand in 2027 (seven vessels are already operational, sailing also in the Baltic).

PRESENT

ZFUTURE

The Copenhagen-based shipping company has selected the wind-assisted propulsion system developed by bound4blue, a tech company from Barcelona, to be installed on five of its tankers.

Maersk Tacoma, Maersk Tampa, Maersk Tangier, Maersk Teesport, and Maersk Tokyo will see the installation of altogether 20 eSAIL® 26-metre-tall suction sails during their dry docking in 2025-26. The eSAIL® system is automated, adjusting the sails to the wind conditions for optimal performance.

Njord, appointed by Maersk Tankers as their green transition partner for the project, has managed the design and technology selection process end-to-end and will lead the integration and installation of the systems, while also validating the savings.

Maersk Tankers expect double-digit percentage reductions in fuel consumption and CO2 emissions per vessel.

MAERSK TANKERS

MOLSLINJEN

PRESENT FUTURE

Alslinjen (a subsidiary of Molslinjen) will receive two all-electric ferries from the Turkish Cemre Shipyard.

VNerthus – to be delivered in August 2024 – will be a 116.8-m long ferry offering room for 600 passengers and 188 vehicles across the Fynshav-Bøjden crossing.

Nerthus will feature technology for automatic docking and charging its 3.1MWh battery system (supplied by Echandia).

Tyrfing, the sister ship for the Ballen-Kalundborg link, will have a bigger battery pack (3.8MWh) as the service is longer.

ZOption to sail on biofuel (made from waste cooking oil).

ODENSE PORT

PRESENT FUTURE

Leading global manufacturers, such as Vestas and produce nacelles, monopiles, and substations at the Odense Port.

RZOdense is not only a production port, but at the same time a ‘knowledge port,’ with several test centres and a unique robotics centre that is in development.

RThe Odense Port is one of Europe’s leading production ports within offshore wind and has prepared to also become an installation port in the coming years to offer the whole package for wind customers.

A new Danish robotics center, Large Structure Production Center, will in 2025 move into the Odense Port, with the University of Southern Denmark at the helm.

The aim of the robotics centre, which will be the only one of its kind in the world, is to develop robots that can build large structures, such as wind turbines, ships and buildings, creating huge synergies for the shipyard Fayard as well as the wind industry and sub-suppliers located at the Odense Port.

VThe Lindø Offshore Renewables Centre (LORC), located at the Odense Port, has recently expanded its business with a new focus on energy storage by installing a giant battery.

The battery, a Rolls Royce model, fills an entire 40-foot container and weighs 36 tonnes. The battery has a capacity of 2.0MW (equivalent to charging 30 Tesla cars) and will be used for tests for the wind turbine industry to store surplus electricity.

Thus, with the energy group Ewii’s first giant battery at the Odense Port, an extra dimension is added to the port’s already unique test facilities for the development of new technology.

VThe idea with LORC is to establish a battery park, with several huge batteries, that can be used by the wind and energy industry as well as universities and researchers to develop technology for storing electricity.

PORT OF AALBORG

PRESENT FUTURE

VTQFuture green fuel acceleration test facility in East Port (3,000 m2 plant, with space for potentially adding four more test facilities).

ZSPE-methanol production plant: 75kt/year (plus green aviation fuel).

4.0mt/y receiving facility.

Siemens Gamesa will receive DKK162.2 million (around €27.4m) from the Danish Green Investment Fund to expand its blade factory in the Port of Aalborg’s East Harbour.

The Aalborg City Council has completed the local development plan according to which the manufacturer’s premises in the Danish seaport will grow by 400 thousand square metres for storing blades for the wind energy industry.

ZPORT OF AARHUS

The Aalborg City Council has completed the local development plan according to which the manufacturer’s premises in the Danish seaport will grow by 400 thousand square metres for storing blades for the wind energy industry.

PRESENT

Denmark’s first to offer OPS to cruise ships: 16MW on Pier 129 (75% of provided electricity was green in 2023, aiming at up to 90% by 2025).

Hybrid (Li-ion) Blue Bots (straddle carriers) operating across APM Terminals Aarhus.

TEU.OPS.Network – a joint project of the ports of Aarhus, Bremerhaven, Gothenburg, and Stockholm – will receive €18.8 million from the Connecting Europe Facility (CEF) for the set-up of cold ironing infrastructure for container ships.

The EU.OPS.Network project, to last from 2024 to 2027, has a total budget of €37.61m.

FUTURE

PORT OF FREDERICIA

PRESENT FUTURE

TThe 24-DK-TG-GreenFRED-SSE project received support (€2.05 million) from the Connecting Europe Facility’s (CEF) Alternative Fuels Infrastructure Facility (AFIF) for setting up an onshore power supply facility, which will serve container ships.

PORT OF FREDERIKSHAVN

PRESENT FUTURE

VPORT OF GRENAA

Installation port for the Anholt 400MW offshore wind energy farm.

Helping Stena Line in developing the all-electric ro-pax Stena Elektra

PRESENT FUTURE Z

One operation and maintenance (O&M) facility. Z

Two more O&M facilities.

PORT OF HIRTSHALS

PRESENT FUTURE

ZTFour wind energy turbines (4.2MW)

VZ500 m3 bunkering station of Fjord Line (built by Liquiline Group) set up for their gas-run Bergensfjord and Stavangerfjord ferries.

SPThe port has initiated a dialogue-based tender to erect up to nine additional wind energy turbines at its premises: the new ones will be from 150 to 180 or 200-metre-tall (nine, six, and four pieces, respectively), producing 169/174/135MWh/year from 2027.

The Danish seaport will house a 5.0-megawatt electrolyser facility of Norwegian Hydrogen, set to produce 500t/y. The decision follows the granting of €9.0m by Horizon Europe for the five-year CONVEY project, which aims to establish an integrated hydrogen ecosystem at the Port of Hirtshals.

Led by Norwegian Hydrogen, a consortium of expert partners from various sectors is tasked with making Hirtshals a model for green ports by focusing on its decarbonisation and sustainable transformation.

Partner of the Greenport Scandinavia’s CCUS project: the facility can be up and running in 2025/2026, with an initial capacity for handling 0.5mt/year of CO2 for permanent storage in empty oil and gas fields in the Greensand area of the Danish part of the North Sea. If provided with a pipeline for transporting CO2 to the Port of Hirtshals, the carbon capture, utilisation and storage project of Greenport Scandinavia would be able to take care of 3.0mt/y of CO2 in 2029, up to beyond 15mt/y in the early 2030s should the Danish and European infrastructure be integrated.

E.ON Drive Infrastructure’s e-truck charging station in Hirtshals Transport Center (three 400kW fast chargers into which six trucks can plug; possibility to upgrade the loading bays to 1.0MW).

PORT OF KALUNDBORG

TPRESENT

The onshore power supply facility, delivered by PowerCon, is located in the Port of Kalundborg’s East Harbour.

The station has enough capacity to provide electricity to three ships simultaneously.

The Danish seaport said that up to 40% of ships visiting it annually can connect to the new facility, meaning that 28 vessels can turn off their auxiliary engines when visiting Kalundborg.

The Port of Kalundborg also underlined the role of the low electricity tax of 0.4 øre/kWh to incentivise shipping lines to draw power from the shore (a scheme that will run till 17 June 2027).

SXUsing HVO as fuel for the machinery fleet of APM Terminals Kalundborg (said to reduce CO2 emissions by up to 90% vs running on fossil fuel).

The Danish seaport has, together with 14 industrial partners, founded CCS Zealand, an association tasked with creating a carbon capture and storage value chain on the largest island in Denmark proper.

VFUTURE

Electrifying all cranes in its deep-water container terminal, operated by APM Terminals (three Konecranes Gottwald mobile harbour cranes: two capable of lifting 100 tonnes and the third – 150t).

PORT OF RØNNE

PRESENT FUTURE Z

Base port for installations, operations, and maintenance of offshore wind energy farms. P

Possible green maritime fuel bunkering station.

PORT OF VORDINGBORG

PRESENT FUTURE P Bio- and e-methanol 300kt/year factory.

SCANDLINES

PRESENT FUTURE

ZNorsepower Rotor Sails on the Berlin and Copenhagen ferries (each has one 30 m-tall and 5.0 m in diameter cylindrical sail said to reduce CO2 emissions by 4-5%).

WVWinner of the National Energy Globe Award: for optimising the ferries operating the Rostock-Gedser (cutting 6% their total energy consumption and as much as 11% of the propulsion energy).

PHybrid 10MWh zero-emission ferry Scandlines Futura

The Copenhagen-headquartered ferry company has partnered with Caterpillar Motoren to scrutinise the conversion of the MaK diesel engines of the GedserRostock hybrid ferries to run on green methanol.

Caterpillar Motoren will provide a test engine in its workshop by 2025. If Scandlines concludes that it meets the expectations and fulfils the conditions, then the first ferry diesel engine could be converted in 2027.

Scandlines has committed itself to zero direct emission ferry operations by 2040.

TCold ironing in the Port of Gävle (as the first shipping company to do so with a tanker in the Baltic).

Z P V

Three 15k dwt methanol-ready, hybrid and wind-assisted tankers due for delivery in 2025.

The wind-assist technology is expected to reduce emissions by up to 19%, in addition to the 40% reduction achieved on Terntank’s six previous vessels (the new vessels are to have an Energy Efficiency Design Index close to 40% below the 2025 Phase 3 requirements).

China Merchants Jinling Shipyard (Yangzhou) has been entrusted with constructing a 15,000 deadweight tanker, with an option for another.

Two gas-run dual-fuel 15,000 dwt big chemical and oil products tankers (16,500 m3 of cargo capacity across 14 epoxy-coated tanks).

TZ PV

The vessel will feature a dual-fuel engine able to sail on marine gas oil as well as bio-fuel, including green and e-methanol.

The 14-segregation tanker will also be equipped with auxiliary wind propulsion, a battery system, and a cold ironing connector.

Delivery is scheduled for Q1 2027.

FUTURE

Secured charters for four 1,250-TEU-capacity methanol-run feeders (three from Elbdeich Reederei, one from MPC Container Ships).

The container carriers are scheduled for delivery in 2026. Unifeeder will use the container vessels in its decarbonisation plans, reducing its carbon footprint by 25% by 2030 on the company’s way towards net zero in 2050.

TERNTANK

ESTONIA

Photo: HHLA/Mihkel Notta

BALTIC WORKBOATS

PRESENT

Designing and constructing a new multi-purpose hybrid biomethane ship for the Estonian State Fleet.

PThe €22 million contract, supported by NextGenerationEU, will see Baltic Workboats delivering the 40 by 10 metres, max speed of 12 knots vessel in 2026 (exact parameters of the workboat will be determined during the detail design process).

FUTURE

Development

of

OWE in the Baltic Sea

(Poland, Lithuania, Latvia, Estonia, Finland, Sweden, Denmark, Germany)

August 2025

PORT OF TALLINN

PRESENT FUTURE

TCold ironing at five piers: nos. 3, 5, 7, 12, and 13 in the Old City Harbour (11kV-400V solution provided by ABB).

YTHHLA TK Estonia: 240kWp (generating an average of 720kWh/day).

YThe ports of Helsinki and Tallinn have yet again secured financial backing from the EU, this time some €15.4 million for, among others, reducing emissions from shipping in their cargo harbours.

The total budget of the TWIN-PORT VI project amounts to €30.8m, of which Tallinn will contribute €20.3m and Helsinki €10.5m. The EU-supported investments will include onshore power supply facilities in Tallinn’s Muuga and Helsinki’s Vuosaari

HHLA TK Estonia: 640MWh.

The company has started preparations to install two additional power parks on the roofs of other warehouses: the 100kWp power park will supply the main office building and container maintenance and repair workshop; another 400kWp plant will support the Container Yard Electrification project with green energy. \ \ Bunkering (ship-to-ship, provided by Gasum).

ZDedicated infrastructure in Paldiski South: 310 m quay wall and 10-ha yard.

X-Press Feeders and six North European ports – Antwerp-Bruges, HaminaKotka, Helsinki, Klaipėda, Riga, and Tallinn – have joined forces to establish two North Sea-Baltic green (methanol) corridors.

Following the agreement, X-Press Feeders will, as of Q3 2024, run two sea container routes powered by green methanol.

The Green Baltic X-PRESS (GBX) loop will connect the ports of Rotterdam, Antwerp-Bruges, Klaipėda, and Riga.

The Green Finland X-PRESS (GFX) service will link Rotterdam, Antwerp-Bruges, Helsinki, Tallinn, and HaminaKotka.

PVX-Press Feeders’ green methanol, made from green hydrogen and the decomposition of organic matter (waste and residues), will be sourced from the fuel supplier OCI Global. The company’s green methanol is certified by the International Sustainability and Carbon Certification (ISCC) Association.

X-Press Feeders says that green methanol as an alternative marine fuel produces at least 60% less greenhouse gas (GHG) emissions vs conventional bunker. Additionally, the parties will work together to further develop infrastructure for the provision and bunkering of alternative fuels; encourage the development of supply chains for fuels that are zero or near-zero in terms of GHG emissions; provide further training programmes for port workers and seafarers with regards to the handling of alternative fuels; leverage digital platforms to enhance port call optimization; and hold regular meetings to update and discuss progress on actions to continue developing green shipping corridors.

HHLA TK Estonia: hybrid Mantsinen 120 DER.

PORT OF TALLINN

PRESENT FUTURE

WPurchasing renewable energy from Eesti Energia, thus consuming only green electricity that’s produced in the country.

PWMember of the FIN-EST Green Corridor initiative (aimed at making the Tallinn-Helsinki and Vuosaari-Muuga crossings climate-neutral for passenger and cargo traffic, on- and offshore).

In late September 2024, the Port of Tallinn signed a memorandum of understanding with the US-based Protio for the production of e-fuels (e-methanol, sustainable aviation fuel, and potentially e-NG) at the Muuga Harbour.

In mid-November 2024, JetGas signed an agreement with the Estonian seaport for setting up a liquefied methane facility in the Muuga Harbour.

PUpon final completion by 2030, the terminal – covering some 7,000 square metres in the eastern part of Muuga – will feature up to five storage tanks and a quay-connecting pipe. The first tank is expected to be erected by end-2027.

The Port of Tallinn and JetGas signed the terminal deal for 30 years.

SAARTE LIINID

PRESENT FUTURE

SRC GROUP

PRESENT FUTURE

Developing the Methanol Superstorage, a fuel tank solution said to increase volume of carried bunker by as much as 85%.

Approval in Principle granted by Lloyd’s Register in October 2023.

TALLINK & SILJA LINE

PRESENT

The company’s ferries are cold ironing in: Megastar – Helsinki, MyStar – Tallinn, Baltic Queen – Tallinn and Stockholm, Silja Serenade and Silja Symphony – in Helsinki and Stockholm.

WTAccording to Tallink Grupp, drawing power from ashore decreases Megastar and MyStar’s monthly CO2 emissions by 112t each (1,344t/year), Baltic Queen’s by 95t/1,140, and Silja Serenade and Silja Symphony ’s by 154t/1,872t.

The gas-run dual-fuel cruise ferries MyStar (212.4 by 30.6 m, 2,800 pax, 3,190 lane metres) and Megastar (212 m long, 2,800 pax, 3,650 lane metres).

Testing a new propeller blade manufactured by Kongsberg Maritime Sweden on Baltic Queen

According to initial results, the new equipment saves no less than 14% fuel.

At the same time, the acoustic pressure radiated into the water at low frequencies is now at least three times, and at all frequencies combined, at least twice as low vs the old propeller blades.

WFUTURE

Member of the FIN-EST Green Corridor initiative (aimed at making the Tallinn-Helsinki and VuosaariMuuga crossings climate-neutral for passenger and cargo traffic, on- and offshore).

FINLAND

Norsepower

32 Port of Oulu

32 Port of HaminaKotka

34 Port of Hanko

34 Port of Helsinki

35 Port of Kaskinen

35 Port of Kemi

35 Port of Långnäs

36 Port of Naantali

36 Port of Pietarsaari

37 Port of Pori

37 Port of Rauma

38 Port of Tornio/Outokumpu

38 Port of Turku 39 Seaber.io

Viking Line

Photo: Norsepower

AHOLA TRANSPORT

VPRESENT

The Finnish Ahola Transport has deployed a 64-tonne vehicle combination, with the use of an electric 40R truck from Scania, for transporting Elgiganten’s consumer electronics to Finland and SSAB’s steel products to Sweden, which is the the first FinlandSweden regular e-truck combination service.

BORE

PRESENT

Two fixed Norsepower’s Rotor Sails on the Estraden ro-ro: 18 m tall and 3.0 m in diameter (6.1% fuel consumption lowering – data verified by NAPA).

Three gas-run dual-fuel con-ros: Bore Way, Bore Wave, and Bore Wind (120 by 21 m, Ice Class 1A, 435 lane metres for wheeled freight and space for 264 TEUs).

DELTAMARIN

FUTURE

FUTURE

PRESENT

FUTURE Z

Design work for installing wind propulsion (incl. retractable) on ships (newbuilds and retrofits). Q

Designing future-fit vessels (incl. gas- and methanol-run).

PRESENT

ELOMATIC

RFUTURE

The two currently under-construction vessels of CLdN will be fitted with Elomatic’s tunnel thruster technology, marking the first time the Turku-based company’s Elogrid is installed on a ro-ro.

The Elogrid tunnel thruster grid is an energy-saving device, designed to maximise side thrust for better manoeuvrability, simultaneously minimising noise and vibrations throughout the vessel.

The solution reduces fuel consumption by 1-2% per thruster tunnel (depending on the speed) by reducing flow entry into the bow thruster tunnels at cruising speeds, as well as providing further reductions in associated vibrations.

\

The gas-run Haaga and Viikki dry bulkers (bunkered with 100% renewable biogas).

VTOrder book of 12 hybrid coasters via its AtoB@C Shipping subsidiary: two already delivered – Electramar and Stellamar (90 by 16 m, 5,350 dwt, Ice Class 1A, 7,650 m3 of carrying capacity; all coasters will be able to draw power from the shore).

EcoVadis’ silver medal (upgraded to gold at the 2023/2024 turn).

VTThe last of AtoB@C Shipping’s hybrid coasters is scheduled for completion by Q2 2026.

WMember of the Climate Partners network.

Part of the Science Based Targets initiative (SBTi).

The Finnish dry bulk carrier has committed itself to reducing its footprint in line with the global warming limit of 1.5°C.

In 2021, the company shared that it intends to reduce its emission intensity per tonne-mile by 50% by 2023 as a step towards net-zero operations by mid-century. By joining SBTi, ESL Shipping wants to reach climate neutrality already in 2040.

FINFERRIES

PRESENT

Three hybrid domestic traffic ferries: Elektra (98 by 15 m, 90 vehicles/cars, 1.6MWh battery pack by the Canadian PBES), Altera (140 by 16.5 m, 375 pax and 92 vehicles, 2x0.6Mwh), and L-317 (70.2 by 13.9 m, 200 pax and 52 vehicles).

FINNLINES

WVOYTPRESENT

Cold ironing the Superstar ferries Finnsirius and Finncanopus in the ports of Naantali and Kapellskär.

On board the three Eco class ro-ros: 600 m2/freighter (Finneco I, Finneco II, Finneco III – each 238 by 34 m, 5,800 lane metres, Ice Class 1A Super).

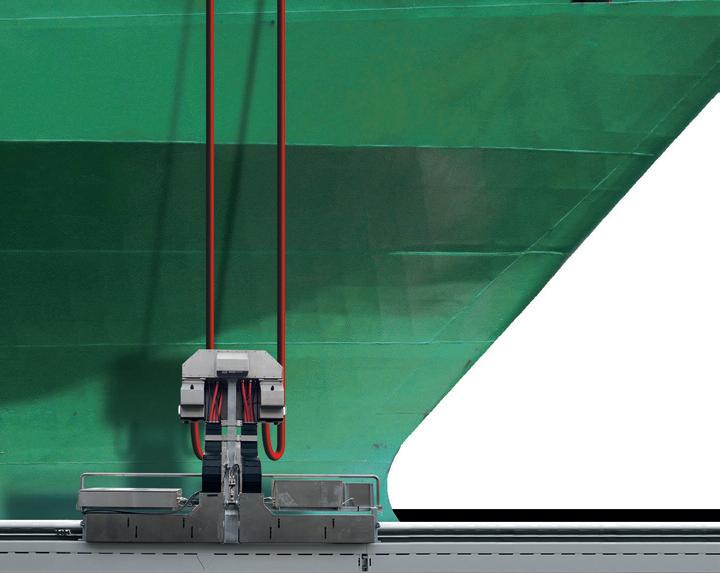

Automooring the Superstar ferries Finnsirius and Finncanopus in the ports of Naantali and Kapellskär.

5.0MW of energy storage system (Corvus Orca) on board the Eco class ro-ros and the two Superstars.

Waste heat recovery system and air lubrication on the Eco class ro-ros and Finnsirius and Finncanopus

WFUTURE

NAPA’s e-logbooks: electronic reporting, fleet monitoring and stability management systems on the two Superstars.

PRESENT

Bunkering (incl. with the company’s 5,800 m3 bunker vessel Coralius).

GASUM

BioLNG production plants in Oulu (35GWh/year), Kuopio (35GWh), Honkajoki (35GWh), Huittinen (35GWh), Vehmaa (30GWh), Turku (61GWh), Lohja (40GWh), and Kouvola (13GWh).

PFUTURE

E-methane deal with Nordic Ren-Gas, according to which Gasum will buy the entire output of Nordic Ren-Gas’ Tampere Power-to-Gas plant (set for launch in 2026). The facility – developed, built, and operated by Nordic Ren-Gas – will produce 160GWh/year of e-methane (35 thousand tonnes) out of 18kt hydrogen by using renewable electricity from Finnish wind energy farms and biogenic CO2 captured from existing power plants (110kt).

GREEN NORTH ENERGY

PRESENT FUTURE

PPGreen North Energy’s €580m investment in its first green hydrogen and ammonia plant (primarily focusing on further refining hydrogen into green ammonia). Production at the 280MW-strong plant is planned to start in 2026.

Co-op with Meriaura and Wärtsilä to build a project cargo vessel that runs on ammonia produced using renewable electricity.

KVARKEN PORTS – VAASA

PRESENT

STCold ironing Wasaline’s Aurora Botnia

ZLANGH TECH

PRESENT

Offering a scalable onboard carbon capture system (capture rate of 90%), which also delivers an end product, sodium carbonate, that can be sold for industrial purposes (e.g., in glass and detergent manufacturing).

The solutions was successfully tested & optimised on board Langh Ship’s Laura. It will be installed on the company’s three newbuildings, plus on another freighter.

LIQUID WIND

PRESENT

FUTURE

OX2, the developer of offshore wind energy (OWE), and the Finnish Port of Vaasa signed a letter of intent concerning the construction, operations, and maintenance of the Tyrsky OWE farm.

The partnership follows a similar one between the two around the Laine OWE farm.

FUTURE

FUTURE

Liquid Wind and Turun Seudun Energiantuotanto (TSE) have signed a memorandum of understanding as a step towards establishing a 100 thousand tonnes per year e-methanol production plant to be located in the former Neste harbour area.

The facility – for which the final investment decision is expected in 2026, ahead of operations commencing in 2029 – will sit next to TSE’s Naantali 4 power plant, which will feed the e-fuel production with 160 thousand of biogenic CO2 and which will, in return, receive process and waste heat for district heating.

MERIAURA

PRESENT

PSailing on the VG Marine EcoFuel biofuel (produced by Meriaura’s daughter company VG-EcoFuel).

PFUTURE

Co-op with Green North Energy and Wärtsilä to build a project cargo vessel that runs on ammonia produced using renewable electricity.

The Finnish shipping line has entrusted the Dutch Royal Bodewes shipyard with the construction of two 6,750 deadweight Ecotraders.

PThe 105-metre-long, Ice Class 1A vessels will be built in Hoogezand, with delivery planned for January and December 2026.

The pair will sail on biofuel; specifically, on one made from recycled raw material produced by Meriaura’s subsidiary VG-Ecofuel.

The company intends to become carbon-neutral in the 2030s.

NESTE

PRESENT

Offering the Neste Marine 0.1 Co-processed lower emission fuel, ISO 8217-compliant and ISCC PLUS-certified; available in Denmark, Finland, and Sweden (Södertälje).

PAccording to the Finnish manufacturer, the renewable part of the co-processed bunker enables up to 80% lower greenhouse gas emissions over the fuel’s life cycle than fossil fuel.

FUTURE

Two fixed Rotor Sails on Bore’s ro-ro Estraden: 18 m tall and 3.0 in diameter (6.1% fuel consumption lowering –data verified by NAPA).

Two fixed Rotor Sails on the Timberwolf (ex Maersk Pelican) tanker: 30 m tall and 5.0 in diameter (7-10% average fuel consumption reduction on typical global shipping routes).

Two fixed Rotor Sails on one of MOL’s tankers: 35 m tall and 5.0 m in diameter (to be mounted in H1 2024 and expected to lower the vessel’s fuel consumption by 6-10% – combined with voyage optimisation technology).

Study with BHP and Pan Pacific Copper to retrofit one tiltable Rotor Sail on the combination carrier Koryu

ZOne fixed Rotor Sail on Scandlines’ ferry Copenhagen: 30 m tall and 5.0 m in diameter (CO2 reduction of 4-5%).

Z18 in total 35-m-tall Rotor Sail fitted on Louis Dreyfus Armateurs’ (LDA) three con-ros (built for charter for Airbus).

LDA’s Rotor Sails will feature the brand-new patented Norsepower Sentient Control™, a real-time force measurement, control, and savings reporting system. It will allow controlling the rotors individually. Additionally, routing software will optimise the vessels’ journey across the Atlantic, maximising wind propulsion and avoiding drag caused by adverse ocean conditions.

Estimations say that the new con-ros will halve the carbon footprint of LDA-Airbus’ Transatlantic voyages by 2030 vs 2023 levels (from 68kt to 33kt/year).

ZZOne fixed Rotor Sail on Scandlines’ ferry Berlin: 30 m tall and 5.0 m in diameter (CO2 reduction of 4-5%).

One tiltable Rotor Sail on SEA-CARGO’s side-door ro-ro SC Connector : 35 m tall (according to the parties, up to 25% in fuel savings can be expected from the investment; moreover, in favourable wind conditions SC Connector is able to maintain regular service speed by sail alone).

ZZZOne fixed Rotor Sail installed on the Viking Grace cruise ferry: 24 m tall and 4.0 m in diameter (according to Viking Line and Norsepower, emitting as much as 900t of CO2 /year can be avoided in result of using the Rotor Sail).

Five tiltable Rotor Sails on Vale’s ore carrier Sea Zhoushan: 24 m tall and 4.0 m in diameter (manufacturer’s analysis – efficiency gain of up to 8% and a consequent reduction of up to 3.4kt/year of CO2).

Two fixed Rotor Sails on Socatra’s tanker Alcyone : 35 m tall and 5.0 m in diameter (an estimated 8% lowering of fuel consumption on her crossing from South Korea to French Polynesia).

ZZA 24-m-tall and 4-m-diameter Rotor Sail be installed on Baltrader’s cement carrier CEMCOMMANDER, reducing the bulker’s fuel consumption by up to 14%.

Each of Berge Rederi’s two general cargo vessels, to be constructed by Jiangsu SOHO Marine Heavy Industry, will house a pair of 24-metre-tall and 4.0-metre-in-diameter Rotor Sails.

ZZPRESENT

Oldendorff Carriers’ Post-Panamax dry bulk carrier Chinook Oldendorff (ex- Dietrich Oldendorff ) was fitted with three 24-m-tall and 4.0 m in diameter Rotor Sails in November 2024.

These are expected to reduce the vessel’s fuel consumption by about 10-15% on transpacific routes (Chinook Oldendorff carries Elk Valley Resources’ steelmaking coal from the Port of Vancouver to customers across the Pacific Ocean).

One fixed Rotor Sail retrofit on IINO LINES and J-Power’s coal carrier Yodohime: – 24 m tall and 4.0 m in diameter.

The sail, installed on the forecastle deck, utilises artificial intelligence to automatically control the rotation, direction, and speed of the rotor, using realtime meteorological information from sensors, such as wind direction and speed.

In combination with a voyage optimisation system, Yodohime ’s Rotor Sail is expected to reduce fuel consumption and CO2 emissions by approximately 6-10%.

WZTwo fixed Rotor Sail on IINO LINES’ very large gas carrier Oceanus Aurora: 20 m tall and 4.0 m in diameter (estimated fuel consumption reduction of 4% –verified by ClassNK).

PORT OF OULU

PRESENT

The Finnish seaport, which first replaced oil in October 2022 with district heating to keep its port house warm (which alone reduced Oulu’s carbon footprint by 32%), is now heating its premises with renewable energy & waste heat.

The change forms part of Oulu’s general target of making its operations carbon-neutral.

PFUTURE

FUTURE

The French Verso Energy has reserved a plot in the Oritkari Harbour of the Finnish Port of Oulu for the potential set-up of a plant for producing hydrogen and synthetic fuel.

Verso Energy already produces synthetic fuels in France with the use of its own green hydrogen and carbon dioxide captured from paper and pulp mills.

AFRY Finland, involved in evaluating the investment, has estimated the probability of the project coming to fruition to be high.

PORT OF HAMINAKOTKA

26,300kWh atop the Merituuli office building in Mussalo.

PORT OF HAMINAKOTKA

PRESENT FUTURE

PFintoil’s tall oil distillation plant (100m litres of bio-diesel/year) in Hamina.

PUPM’s biorefinery in Kotka (500kt/year of renewable fuels).

X-Press Feeders and six North European ports –Antwerp-Bruges, HaminaKotka, Helsinki, Klaipėda, Riga, and Tallinn – have joined forces to establish two North Sea-Baltic green (methanol) corridors.

Following the agreement, X-Press Feeders will, as of Q3 2024, run two sea container routes powered by green methanol.

The Green Baltic X-PRESS (GBX) loop will connect the ports of Rotterdam, Antwerp-Bruges, Klaipėda, and Riga.

The Green Finland X-PRESS (GFX) service will link Rotterdam, Antwerp-Bruges, Helsinki, Tallinn, and HaminaKotka.

\30k m3 storage capacity LNG terminal in Hamina.

PX-Press Feeders’ green methanol, made from green hydrogen and the decomposition of organic matter (waste and residues), will be sourced from the fuel supplier OCI Global. The company’s green methanol is certified by the International Sustainability and Carbon Certification (ISCC) Association.

X-Press Feeders says that green methanol as an alternative marine fuel produces at least 60% less greenhouse gas (GHG) emissions vs conventional bunker. Additionally, the parties will work together to further develop infrastructure for the provision and bunkering of alternative fuels; encourage the development of supply chains for fuels that are zero or near-zero in terms of GHG emissions; provide further training programmes for port workers and seafarers with regards to the handling of alternative fuels; leverage digital platforms to enhance port call optimization; and hold regular meetings to update and discuss progress on actions to continue developing green shipping corridors.

Rohe Solutions, the Finnish subsidiary of the Estonian Alexela, has added the liquefaction-from-the-grid process in the terminal in the Port of Hamina, using it to produce (in collaboration with Hamina LNG) liquefied biomethane (bioLNG).

Recovering construction material for subsequent use.

Wastewater is taken to a local treatment facility, after which the solid waste created in the process is converted into biogas and soil improvement material.

TPRESENT

PORT OF HANKO

FUTURE

ZPORT OF HELSINKI

The Port of Hanko and the Euroports Group have signed a letter of intent to establish a hub for the offshore wind energy supply chain at the former’s Koverhar Harbour.

PRESENT FUTURE

Cold ironing available at Olympia Terminal in the South Harbour and at West Terminal 2 (both sides of the terminal).

According to the port, shore power reduces the emissions of berthed vessels by 50-80%.

YTThe first solar panels were installed next to Vuosaari Harbour’s noise barrier in 2016. After that, panels were also installed atop the passenger bridge at West Terminal 2. Next, a total of 307 new solar panels were put on the roof of the V6 and V7 buildings in Vuosaari as well as 200 panels on West Terminal 2’s roof (these 507 units produce approx. 145MWh/year).

PThe ports of Helsinki and Tallinn have yet again secured financial backing from the EU, this time some €15.4 million for, among others, reducing emissions from shipping in their cargo harbours.

The total budget of the TWIN-PORT VI project amounts to €30.8m, of which Tallinn will contribute €20.3m and Helsinki €10.5m. The EU-supported investments will include onshore power supply facilities in Tallinn’s Muuga and Helsinki’s Vuosaari harbours.

X-Press Feeders and six North European ports –Antwerp-Bruges, HaminaKotka, Helsinki, Klaipėda, Riga, and Tallinn – have joined forces to establish two North Sea-Baltic green (methanol) corridors.

Following the agreement, X-Press Feeders will, as of Q3 2024, run two sea container routes powered by green methanol.

The Green Baltic X-PRESS (GBX) loop will connect the ports of Rotterdam, Antwerp-Bruges, Klaipėda, and Riga. The Green Finland X-PRESS (GFX) service will link Rotterdam, Antwerp-Bruges, Helsinki, Tallinn, and HaminaKotka.

X-Press Feeders’ green methanol, made from green hydrogen and the decomposition of organic matter (waste and residues), will be sourced from the fuel supplier OCI Global. The company’s green methanol is certified by the International Sustainability and Carbon Certification (ISCC) Association.

X-Press Feeders says that green methanol as an alternative marine fuel produces at least 60% less greenhouse gas (GHG) emissions vs conventional bunker.

Additionally, the parties will work together to further develop infrastructure for the provision and bunkering of alternative fuels; encourage the development of supply chains for fuels that are zero or near-zero in terms of GHG emissions; provide further training programmes for port workers and seafarers with regards to the handling of alternative fuels; leverage digital platforms to enhance port call optimization; and hold regular meetings to update and discuss progress on actions to continue developing green shipping corridors.

PORT OF HELSINKI

PRESENT FUTURE

Six Cavotec Finland’s MoorMasters at West Terminal 2. W

\ Bunkering.

WSmart check-in gate system for smoother wheeled traffic (developed by Visy Oy).

PORT OF KASKINEN

Member of the FIN-EST Green Corridor initiative (aimed at making the Tallinn-Helsinki and Vuosaari-Muuga crossings climate-neutral for passenger and cargo traffic, on- and offshore).

PRESENT FUTURE

Handling wind turbine components. Z

Dedicated quay and 4.5 ha storage area for handling wind turbine components. W

Tech for ship call management (developed by Grieg Connect).

PORT OF KEMI

PRESENT FUTURE

TPORT OF LÅNGNÄS

The Finnish seaport will receive money from the EU’s Connecting Europe Facility within the 23-FI-TG-Arctic SSE project to set up an onshore power supply facility on the new autumn 2023-opened quay.

Once the investment is up and running, two ships will be able to draw power from the shore concurrently.

PRESENT FUTURE

Partaking in the the Långnäs Mega Green Port study, a 12-month-long feasibility study (carried out by OX2 and Ålandsbanken Fondbolag) on setting up a green hydrogen production facility on the Åland Islands.

PORT OF NAANTALI

PRESENT FUTURE

OTHitachi’s installation (for Finnlines’ Superstars, Finnsirius and Finncanopus).

PCavotec’s multi-unit MoorMaster NxG (the biggest the company has thus far delivered; also for serving Finnlines’ Superstars, Finnsirius and Finncanopus).

Heating and cooling the renovated passenger terminal and port office building with geothermal energy.

PGreen North Energy’s €580m investment in its first green hydrogen and ammonia plant (primarily focusing on further refining hydrogen into green ammonia). Production at the 280MW-strong plant is planned to start in 2026.

A feasibility study is underway for a bio-ethanol production site in Naantali.

PORT OF PIETARSAARI

PRESENT FUTURE T X Z

Handling wind turbine components. Y \ Bunkering.

PORT OF PORI

PRESENT

\Gasum’s 28.5k m3 of storage capacity terminal.

ZFUTURE

The City of Pori – together with the Port of Pori, the city-owned company Suisto Kiinteistöt, as well as Suomen Hyötytuuli, Enersense, and the Dutch logistics service provider Olmar – is working on setting up an international hub for expertise and operations based on offshore wind power. The competence hub will be located on a 50-hectare plot in the Port of Pori’s Mäntyluoto Harbour. In the initial phase, the area will be used for pre-installation services, assembly, and storage of offshore wind turbines.

Meanwhile, Enersense is already constructing technically demanding foundations for offshore wind turbines in Mäntyluoto.

Additionally, Suomen Hyötytuuli and the Port of Pori have agreed to build a gravel loading dock at the Tahkoluoto Harbour to serve the construction of wind turbine foundations.

The City of Pori, the Port of Pori, and Tahkoluoto Offshore have signed a memorandum of understanding aimed at developing the Pori Offshore Wind Hub.

WZPRESENT

Tech using real-time info for ship call management (developed within the EU-supported STM EfficientFlow project).

SThe collaboration will define the role of the Hub as the primary logistics and pre-installation base for the Tahkoluoto Offshore Wind Farm Extension project. The 42-megawatt Tahkoluoto, the world’s first offshore wind energy farm erected in freezing waters and operational since 2017, will see the addition of 40 turbines of 15-20MW capacity in 2027-29.

To that end, the memorandum provides a two-year time frame for implementing the necessary infrastructural investments in the port area.

The City of Pori and the Port of Pori have commissioned Wega to conduct a preliminary study on the construction of an import/export terminal for handling liquid carbon dioxide.

FUTURE

PORT OF RAUMA

PORT OF TORNIO/OUTOKUMPU

PRESENT FUTURE

W

Outokumpu will invest around €40 million in a plant for producing biocarbon, some 15 thousand tonnes per year, in the German Baltic Mukran Port. The factory, slated for commissioning in H1 2026, will use secondary wood raw materials as feedstock. The end product, a fine granulate that looks like black sand, will be shipped to the Port of Tornio for further processing into biocoke pellets (with the pelletising plant ready in mid-2025). These, in turn, will be used by Outokumpu to replace coal and other fossil energy sources in various stages of stainless steel production (with biocoke specifically used as a reductant in ferrochrome smelting).

The waste heat generated by the ‘black sand’ plant will be fed into the district heating network on the island of Rügen.

The Finnish company says that approximately 50% of its direct emissions could be reduced by replacing fossil coke with biocoke.

PORT OF TURKU

PRESENT FUTURE

OCavotec’s multi-unit MoorMaster system at the Viking Line’s berth.

WYTThe ports Turku and Stockholm, alongside Viking Line, have signed an agreement to make the crossing between them fossil-free by 2035 at the latest.

The partnership will act as an innovative platform to develop scalable solutions for phasing out fossil fuels.

The initiative will also leverage the advances and solutions from the Decatrip project , a collaboration between Rauma Marine Constructions, Viking Line, Åbo Akademi University, and Kempower.

The Stockholm-Turku Green Corridor – ‘green’ as per the Clydebank Declaration, of which Finland and Sweden are signatories – is open to onboarding other stakeholders from the shipping and port industries, as well as cargo owners, freight forwarders, etc.

TWPRESENT

Improved ship & freight planning tech tool: for Neste (to eco-optimise its logistics); for Wilson (a Norwegian shipping line disposing of a 130-big-fleet to digitalise its vessel scheduling to drive efficiency, likewise, reduce costs and emissions); and for Alba Tankers (to optimise the chartering process).

VIKING LINE

PRESENT

Cold ironing in the ports of Helsinki, Mariehamn, Stockholm, and Tallinn (sparing the environment some 780t/year of greenhouse gas emissions).

ZNorsepower’s Rotor Sail installed on the Viking Grace cruise ferry: 24 m tall and 4.0 m in diameter. According to Viking Line and the manufacturer, emitting as much as 900t of CO2/year can be avoided in result of using the Rotor Sail.

WFUTURE

Heat and cold recovery, plus dynamic ventilation and lighting on board Viking Glory

Partaking in the Decatrip project.

WFUTURE

Member of the FIN-EST Green Corridor initiative (aimed at making the Tallinn-Helsinki and Vuosaari-Muuga crossings climate-neutral for passenger and cargo traffic, on- and offshore).

The ports Stockholm and Turku, alongside Viking Line, have signed an agreement to make the crossing between them fossil-free by 2035 at the latest.

The partnership will act as an innovative platform to develop scalable solutions for phasing out fossil fuels. The initiative will also leverage the advances and solutions from the Decatrip project , a collaboration between Rauma Marine Constructions, Viking Line, Åbo Akademi University, and Kempower.

The Stockholm-Turku Green Corridor – ‘green’ as per the Clydebank Declaration, of which Finland and Sweden are signatories – is open to onboarding other stakeholders from the shipping and port industries, as well as cargo owners, freight forwarders, etc.

Automooring Viking Glory in the Port of Turku.

\ The gas-run Viking Grace and Viking Glory cruise ferries.

TPRESENT

Cold ironing in the ports of Umeå and Vaasa with the Aurora Botnia ferry (150 by 26 m, 800 pax + 1,500 lane metres, Ice Class 1A Super).

YFUTURE

Installing photovoltaics on board Aurora Botnia \ \

Aurora Botnia is equipped with dual-fuel engine able to run on gas.

\PThe so-called Green Fridays: gas-running Aurora Botnia on bioLNG each Friday from 13 October 2023 until Christmas 2023, with the ferry line covering the price spread between bioLNG and standard LNG.

With certified climate-neutral bioLNG from Gasum, Wasaline intends to reduce its carbon footprint: the company shared in a press release from October 2023 that its 2023 emissions were already 22% lower than last year.

WWVAurora Botnia features a 2.2MWh battery pack.

Part of the SAILS Initiative (Sustainable Actions for Innovative and Low-Impact Shipping Initiative for Good Practices in Maritime Transport for the Protection of the Marine and Coastal Environment).

The Finnish-Swedish ferry line has made it possible also for private travellers to pay a nominal voluntary fee when crossing between Umeå and Vaasa on board the company’s Aurora Botnia ro-pax.

The climate compensation scheme, earlier introduced for cargo customers, is used to buy bioLNG to propel the vessel.

PAssessing the options (such as biogas, methane) price- and availability-wise.

Liquid Wind-Umeå Energi-Wasaline e-methanol letter of intent.

The parties will explore the opportunities to fuel Wasaline’s ferry Aurora Botnia with e-methanol to be produced by Liquid Wind’s FlagshipTHREE facility in Umeå (the plant can be up & running in 2027, supplying some 100kt/y).

WWorking on making the Umeå-Vaasa crossing a Green Corridor.

PPRESENT FUTURE

The marine sector’s first commercially available 4-stroke engine-based solution for ammonia fuel (the full suite includes the AmmoniaPac fuel gas supply system, the Wärtsilä Ammonia Release Mitigation System, and the Wärtsilä NOX Reducer). According to the manufacturer, Wärtsilä 25 ammonia can reduce greenhouse gas emissions by more than 70% compared to a similar sized diesel solution.

SOpen loop 35MW scrubber systems, prepared for upgrading to capture and store CO2 (testing a system with 70% capture rate).

PBunker testing ammonia, including partaking in the ShipFC project, the aim of which is to install a 2.0MW ammonia fuel cell on board one of Eidesvik’s offshore vessels (Wärtsilä will develop the fuel cell).

PCo-op with Hycamite to develop a solution for producing hydrogen from liquefied natural gas on board vessels (with high-grade allotropes of carbon as a by-product). \ \ Manufacturing gas-run engines

PCo-op with Green North Energy and Meriaura to build a project cargo vessel that runs on ammonia produced using renewable electricity. QR Sustainable Technology Hub in Vaasa.

WTrialling with the Grimaldi Group an open loop exhaust gas treatment system that traps microplastic particles before the wash water returns to the sea. The filtration system, designed and patented by Grimaldi, efficiently captures particles smaller than 10µm, and the captured concentration by volume equals around 76 particles/m3 A 10MW engine will see scrubbers processing approximately 450 m3 of water per hour.

44 LHG (Lübecker Hafen-Gesellschaft)

44 Mukran Port

44 Port of Kiel

45 Port of Lübeck

45 Port of Rostock

45 Port of Wismar

46 TT-Line

46 X-Press Feeders (Agency)

Photo: Port of Kiel

LHG (LÜBECKER HAFEN-GESELLSCHAFT)

PRESENT

WMUKRAN PORT

PRESENT

ZOperations and maintenance base for the 257MW Arcadis Ost 1 offshore wind energy farm.

Transition pieces base port for the 476MW Baltic Eagle’s offshore wind energy farm.

WTWEnergos Infrastructure’s 174k m3 of capacity floating storage & regasification unit (FSRU) Energos Power berthed at Deutsche ReGas’ terminal in the Mukran Port.

Another FSRU, earlier docked in Lubmin Neptune, joined Energos Power in the spring of 2024.

PORT OF KIEL

PRESENT

Cold ironing at the Ostseekai cruise terminal (100kWp, 90,000kWh/year), as well as in Ostuferhafen (210,000kWh/y) and at Norwegenkai (4.5MW, 10kV, 50Hz).

With Stena Line, Stena Rederi, Stena Recycling, Batteryloop, the Port of Gothenburg, and DNV – working on ‘port power banks.’

FUTURE

Lübeck-Trelleborg Green Shipping Corridor.

The ports of Lübeck and Trelleborg, the port operator LHG, and the ferry company TT-Line have partnered to make the crossing fossil fuel-free by 2040 at the latest.

FUTURE

The Finnish Outokumpu will invest around €40 million in a plant for producing biocarbon, some 15 thousand tonnes per year, in the Mukran Port.

The factory, slated for commissioning in H1 2026, will use secondary wood raw materials as feedstock. The end product, a fine granulate that looks like black sand, will be shipped to the Port of Tornio for further processing into biocoke pellets (with the pelletising plant ready in mid-2025).

These, in turn, will be used by Outokumpu to replace coal and other fossil energy sources in various stages of stainless steel production (with biocoke specifically used as a reductant in ferrochrome smelting).

The waste heat generated by the ‘black sand’ plant will be fed into the district heating network on the island of Rügen.

The Finnish company says that approximately 50% of its direct emissions could be reduced by replacing fossil coke with biocoke.

FUTURE

PORT OF LÜBECK

PRESENT FUTURE

Bunkering (ship-to-ship, provided by Gasum).

WTThe 24-EU-TG-Baltic-Green-NET joint project (with the Port of Trelleborg) received support (€2.23 million) from the Connecting Europe Facility’s (CEF) Alternative Fuels Infrastructure Facility (AFIF) for setting up onshore power supply facilities in the two seaports.

Lübeck-Trelleborg Green Shipping Corridor. The ports of Lübeck and Trelleborg, the port operator LHG, and the ferry company TT-Line have partnered to make the crossing fossil fuel-free by 2040 at the latest.

WLübeck-Liepāja green co-op: the two cities and their seaports have teamed up to make the crossing between them more environmentally friendly. The parties will work on decreasing the footprint of the ports’ own operations and consumption, provide means for ship, road and rail port users to green their activities, as well as invest in infrastructure and equipment to handle larger vessels.

PORT OF ROSTOCK

PRESENT FUTURE

T20MVA in Warnemünde (Europe’s strongest OPS for cruise ships at the moment of its launch).

Bunkering (ship-to-ship, provided by Gasum).

V

EUROPORTS Germany: Liebherr’s all-electric portal slewing crane LPS 420 E.

PORT OF WISMAR

FABER Solartechnik’s system across 10k m2 (2,200kWh/year).

Electric forklifts.

A rubber-tyred Mantsinen 120 Hybrilift crane (said to be 35% more energy efficient than a corresponding fossil fuel-only gear).

Erecting own wind turbines.

PRESENT

Two gas-run dual-fuel Green Ships: the ferries Nils Holgersson and Peter Pan (230 by 31 m, 800 pax, 4,000 lane metres).

WVCharging stations, 32, for e-cars on board the Green Ships.

Energy-saving air conditioning, heat recovery, LED lighting, and an AI algorithm that advises the crew on the optimal parameters of operating the Green Ships.

WFUTURE

Lübeck-Trelleborg Green Shipping Corridor. The ports of Lübeck and Trelleborg, the port operator LHG, and the ferry company TT-Line have partnered to make the crossing fossil fuel-free by 2040 at the latest.

X-PRESS FEEDERS (AGENCY)

PRESENT

PFUTURE

X-Press Feeders and six North European ports –Antwerp-Bruges, HaminaKotka, Helsinki, Klaipėda, Riga, and Tallinn – have joined forces to establish two North Sea-Baltic green (methanol) corridors.

Following the agreement, X-Press Feeders will, as of Q3 2024, run two sea container routes powered by green methanol.

The Green Baltic X-PRESS (GBX) loop will connect the ports of Rotterdam, Antwerp-Bruges, Klaipėda, and Riga.

The Green Finland X-PRESS (GFX) service will link Rotterdam, Antwerp-Bruges, Helsinki, Tallinn, and HaminaKotka.

X-Press Feeders’ green methanol, made from green hydrogen and the decomposition of organic matter (waste and residues), will be sourced from the fuel supplier OCI Global. The company’s green methanol is certified by the International Sustainability and Carbon Certification (ISCC) Association.

X-Press Feeders says that green methanol as an alternative marine fuel produces at least 60% less greenhouse gas (GHG) emissions vs conventional bunker. Additionally, the parties will work together to further develop infrastructure for the provision and bunkering of alternative fuels; encourage the development of supply chains for fuels that are zero or near-zero in terms of GHG emissions; provide further training programmes for port workers and seafarers with regards to the handling of alternative fuels; leverage digital platforms to enhance port call optimization; and hold regular meetings to update and discuss progress on actions to continue developing green shipping corridors.

48 Port of Liepāja

Port of Riga 50 Port of Ventspils 55

Photo: Canva

PORT OF LIEPĀJA

PRESENT FUTURE

Van Oord-Liepāja Special Economic Zone (SEZ) agreement, following which the former will scrutinise the set up of an offshore wind energy (OWE) support base and cargo terminal in the Latvian seaport.

WSeaData’s tech for air and water quality monitoring.

ZA number of organisations – including the Liepāja Special Economic Zone Authority, Van Oord, Euroports, and GI Termināls – have set up the Liepāja Sustainable Industry Hub to push forward a few green projects, totalling €4.0+ billion over 2025-2035.

The investments include an offshore wind energy (OWE) support base and three terminals in the Port of Liepāja: for handling heavy OWE cargo, storing & exporting CO2, and for producing green hydrogen.

POver the next two years, Van Oord will carry out the preparatory work, including research, business plan development, and technical design elaboration.

If everything goes according to plan, construction could kick off in 2026, with the OWE support base coming online in mid-2027.

A number of Latvian, Norwegian, and Swedish companies have formed CIS Liepāja, a joint project management team to scrutinise the set-up of a power-to-X complex in the Port of Liepāja.

The Liepāja Special Economic Zone (SEZ) and CIS Liepāja have concluded a two-year reservation contract for the potential construction site.

The 1,000MW plant, capable of producing 150 thousand tonnes of hydrogen yearly, will feature a sea terminal.

The total investment is estimated to be around €1.0 billion.

Liepāja-Lübeck green co-op: the two cities and their seaports have teamed up to make the crossing between them more environmentally friendly.

PThe parties will work on decreasing the footprint of the ports’ own operations and consumption, provide means for ship, road and rail port users to green their activities, as well as invest in infrastructure and equipment to handle larger vessels.

PORT OF RIGA

PRESENT

WT Terminal, operating in the Port of Riga, has commissioned a photovoltaic (PV) installation that comprises 480 panels with a total capacity of 220.8kW.

YThe two other PVs in the Port of Riga are the 4.61MW system of Kronospan Riga and the 0.875MW of Baltic Container Terminal.

Riga Universal Terminal is also working on its 250kW installation.

YFUTURE

100MW (producing a minimum of 100,000MWh/year).

PPRiga – together with numerous Latvian energy, technology and transport companies, academia, and governmental bodies – has signed a memorandum of understanding to develop a hydrogen ecosystem in the country (incl. production, storage, and transportation capacities).

X-Press Feeders and six North European ports – Antwerp-Bruges, HaminaKotka, Helsinki, Klaipėda, Riga, and Tallinn – have joined forces to establish two North Sea-Baltic green (methanol) corridors.

Following the agreement, X-Press Feeders will, as of Q3 2024, run two sea container routes powered by green methanol.

The Green Baltic X-PRESS (GBX) loop will connect the ports of Rotterdam, Antwerp-Bruges, Klaipėda, and Riga.

The Green Finland X-PRESS (GFX) service will link Rotterdam, Antwerp-Bruges, Helsinki, Tallinn, and HaminaKotka.

X-Press Feeders’ green methanol, made from green hydrogen and the decomposition of organic matter (waste and residues), will be sourced from the fuel supplier OCI Global. The company’s green methanol is certified by the International Sustainability and Carbon Certification (ISCC) Association.

X-Press Feeders says that green methanol as an alternative marine fuel produces at least 60% less greenhouse gas (GHG) emissions vs conventional bunker.

Additionally, the parties will work together to further develop infrastructure for the provision and bunkering of alternative fuels; encourage the development of supply chains for fuels that are zero or near-zero in terms of GHG emissions; provide further training programmes for port workers and seafarers with regards to the handling of alternative fuels; leverage digital platforms to enhance port call optimization; and hold regular meetings to update and discuss progress on actions to continue developing green shipping corridors.

PORT OF RIGA

PRESENT

PFUTURE

PARS Termināl is scrutinising the construction of a production plant in the Latvian capital seaport, set to supply 93 thousand tonnes of hydrotreated vegetable oil and 87kt of sustainable aviation fuel per year.

The €120-million investment, the completion of which is estimated to take 20 months, will be located in Kundziņsala in the Port of Riga.

It will have the capacity to process 236kt/year of feedstock (mainly vegetable oils).

ZThe government of Latvia has approved a €64.5 million investment to develop 30 hectares within the Port of Riga’s Kundziņsala into a production hub for the (off- and onshore) wind energy industry.

The port authority added that €40m of private, clean tech investments are expected by 2029.

PORT OF VENTSPILS

YPRESENT

Vitol Terminal Latvia has commissioned a 400kW photovoltaic system that produces up to 20% of its yearly energy consumption.

PFUTURE

Co-op with the Riga-based PurpleGreen Energy C: research into setting up a green hydrogen factory within the Port of Ventspils.

LITHUANIA

Port of Klaipėda

Photo: Höegh LNG

FUTURE

ZPORT OF KLAIPĖDA

Rebuilding of the former international ferry terminal in Klaipėda into Lithuania’s first offshore wind assembly and loading facility.

The 21-hectare terminal should be ready in 2026.

PRESENT FUTURE

X-Press Feeders and six North European ports –Antwerp-Bruges, HaminaKotka, Helsinki, Klaipėda, Riga, and Tallinn – have joined forces to establish two North Sea-Baltic green (methanol) corridors.

Following the agreement, X-Press Feeders will, as of Q3 2024, run two sea container routes powered by green methanol.

The Green Baltic X-PRESS (GBX) loop will connect the ports of Rotterdam, Antwerp-Bruges, Klaipėda, and Riga.

The Green Finland X-PRESS (GFX) service will link Rotterdam, Antwerp-Bruges, Helsinki, Tallinn, and HaminaKotka.

\The 170k m3 of storage capacity FSRU Independence (owned and operated by Klaipėdos Nafta).

PX-Press Feeders’ green methanol, made from green hydrogen and the decomposition of organic matter (waste and residues), will be sourced from the fuel supplier OCI Global. The company’s green methanol is certified by the International Sustainability and Carbon Certification (ISCC) Association.

X-Press Feeders says that green methanol as an alternative marine fuel produces at least 60% less greenhouse gas (GHG) emissions vs conventional bunker. Additionally, the parties will work together to further develop infrastructure for the provision and bunkering of alternative fuels; encourage the development of supply chains for fuels that are zero or near-zero in terms of GHG emissions; provide further training programmes for port workers and seafarers with regards to the handling of alternative fuels; leverage digital platforms to enhance port call optimization; and hold regular meetings to update and discuss progress on actions to continue developing green shipping corridors.

Bunkering (by truck and tank-to-ship, provided by the Port of Klaipėda, Klaipėdos Nafta, and Gasum).

The Klaipėda LNG reloading station has C-type LNG tanks with total capacity of 5.0k m3

PIn a deal worth €1.4 million, the MT Group has contracted Nord Steel to design, manufacture, and deliver three advanced hydrogen storage tanks to the Port of Klaipėda.

The contract includes a 40-bar buffer tank and two storage tanks capable of withstanding pressures of 550 and 1,000 bars.

POLAND

60 Baltic Hub

60 Baltic Towers

60 PKN ORLEN

60 Polferries & Unity Line

61 Port of Gdańsk

61 Port of Gdynia

61 Port of Łeba

62 Port of Szczecin-Świnoujście

63 SeaData

Photo: SeaData

BALTIC HUB

PRESENT FUTURE

The Polish Development Fund (PFR), a 30% shareholder in Baltic Hub, plans to spend PLN500m (€116m) on setting up a dedicated installation & maintenance quay in the Port of Gdańsk.

ZThe 21-hectare investment catering to the offshore wind energy (OWE) industry is planned for completion in 2026, with construction works kicking off in mid2024. It will comprise two 17.5-metre deep berths: 451 m for installation and 349 m for maintenance purposes. Additionally, the terminal will include a ro-ro berth.

BALTIC TOWERS

PRESENT FUTURE

ZPKN ORLEN

TZOffshore wind tower factory in Gdańsk on the Ostrów Island to be ready in Q2 2025 and capable of producing 150 towers/y.

PRESENT FUTURE

Under construction terminal in Świnoujście: two each 250 m long, 12.5 deep berths, with handling capacity of 80 turbines/year (models of up to 15MW).

POLFERRIES & UNITY LINE

PRESENT FUTURE

Cold ironing in Ystad and Trelleborg (Unity Line).

Three hybrid gas-run dual-fuel ferries to be delivered in 2025-27 (195 m long, 400 pax, 4,100 lane metres).

The ferry lines intend to run their newbuilds entirely on bioLNG already from 2025.

The newbuildings will be equipped with connectors to draw electricity from the shore.

PORT OF GDAŃSK

PRESENT FUTURE

98.4kW for own needs.

Bunkering (truck-to-ship, provided by PGNiG). Y 440kW for own needs.

Dedicated installation quay/terminal.

PORT OF GDYNIA

PRESENT FUTURE

T3.5MW at the Public Ferry Terminal (onboard 11kV 50Hz/60Hz ships installation; 15kV 50Hz shore power grid).

OT Port Gdynia: 225kW.

Bunkering (truck-to-ship, provided by PGNiG).

Dedicated installation quay/terminal in the Outer Harbour.

PORT OF ŁEBA

PRESENT FUTURE

Equinor’s operations and maintenance base for offshore wind energy projects.

PRESENT

PORT OF SZCZECIN-ŚWINOUJŚCIE

LNG terminal in Świnoujście: two 160k m3 storage tanks.

\Bunkering (truck-to-ship, provided by PGNiG in both Szczecin and Świnoujście).

TFUTURE

Investigating mobile installation(s).

\ LNG terminal in Świnoujście: adding the third storage tank (180k m3).

ZZZUnder construction PKN ORLEN’s terminal in Świnoujście: two each 250 m long, 12.5 deep berths, with handling capacity of 80 turbines/year (models of up to 15MW).

Vestas’s two OWE factories in Szczecin: nacelle assembly (expected to start operating in 2025) and blade production (for the V236.15.0MW wind energy turbine model; possibly online in 2026).

Windar’s offshore tower production facility in Szczecin (for turbines with up to 20MW of installed capacity).

ZMember of the Offshore Wind Port Alliance, an organisation that aims to cooperate to provide sufficient handling & storage capacity for Europe’s offshore wind energy industry.

Apart from Szczecin-Świnoujście, the Alliance comprises the ports of Cuxhaven (Niedersachsen Ports), Eemshaven (Groningen Seaports), Esbjerg, Humber (Associated British Ports), Nantes Saint-Nazaire, and Oostende.

PPart of the West Pomeranian Hydrogen Valley.

SEADATA

WPRESENT

Tech for air and water quality monitoring: fixed stations and drones (used by the ports of Gdańsk and Gdynia, as well as Liepāja in Latvia).

FUTURE

SWEDEN

5 The Baltic Green Map 2025 – key 7 Denmark 19 Estonia 25 Finland

Germany

Latvia 55 Lithuania 59 Poland 65 Sweden

66 ATOB@C SHIPPING

66 Copenhagen Malmö Port – Malmö

67 Destination Gotland & Gotland Company

68 Echandia

68 Erik Thun Group

68 Gasum

68 HYDRI

69 Kvarken Ports – Umeå

69 Liquid Wind

70 Lhyfe

70 MaserFrakt

71 Mälarhamnar – Köping and Västerås

71 Port of Gothenburg

73 Port of Gävle

73 Port of Halland

73 Port of Helsingborg

74 Port of Karlshamn

74 Port of Norrköping

74 Port of Oskarshamn (Smålandshamnar)

75 Port of Oxelösund

75 Port of Södertälje

76 Port of Trelleborg

76 Port of Uddevalla

76 Port of Ystad

77 Ports of Stockholm

78 PowerCell

78 Qtagg

78 Scandinavian Biogas

79 ScanOcean

79 Stena Line

79 Vänerhamn

80 Wallenius Marine

80 Wallenius SOL

81 Wallenius Wilhelmsen

82 Öresundslinjen

Photo: Wallenius Wilhelmsen

PRESENT FUTURE

VTOrder book of 12 hybrid coasters: three already delivered (90 by 16 m, 5,350 dwt, Ice Class 1A, 7,650 m3 of carrying capacity; all coasters will be able to draw power from the shore).

The last is scheduled for completion by Q2 20

EFO, a joint venture of Swedish energy companies, has partnered the Ystad-based arm of the Finnish ESL Shipping to reduce the carbon footprint of its sea transports.

The initiative will involve substituting 10% of the annual fuel consumption of EFO’s shipments with renewable alternatives, resulting in a projected 8.5% reduction in lifecycle emissions.

In addition, the companies have agreed to implement virtual arrival (VA) as a standard operational practice to optimise the speed of the vessels when there is a known delay in port. On average, VA has reduced voyage emissions in AtoB@C Shipping’s traffic by 11% in the voyages it has been applied for.

Upon announcing the cooperation on 10 September 2024, already two voyages were carried out with 100% renewable fuel. The contract saw AtoB@C Shipping’s plug-in hybrid Electramar unloading cargo in the Port of Oxelösund.

COPENHAGEN MALMÖ PORT – MALMÖ

PRESENT FUTURE

XCargo handling equipment running on HVO (emissions reduced by approximately 840t CO2e /year vs fossil fuel).

PSThe CNetSS project, led by Växjö Energi, has chosen the main alternative for interim storage of CO2 before transport to final depot: Copenhagen Malmö Port’s Norra Hamnen.

Co-op with the Hellerup-based company Green2x to scrutinise the set-up of a biofuel plant in Malmö.

The parties have kicked off the works with a pilot study, which will include securing relevant permits. If everything goes according to the plan, the facility should be up & running by 2030.

DESTINATION GOTLAND & GOTLAND COMPANY

PRESENT FUTURE

Developing the Gotland Hydrocat catamaran ferry, featuring a multi-green fuel engine (with hydrogen as the preferred fuel).

TCold ironing in the Port of Nynäshamn.

PThe 35 knot-max speed vessel will offer room for 1,600 passengers, plus space for 450 cars.

Gotland Company intends to place an order on Gotland Hydrocat in 2025 (with the catamaran entering traffic in 2030).

Bunkering the ferries Visby and Gotland via Gasum’s gas bunkering station in Nynäshamn (incl. LNG-bioLNG blend).

WPPPWorking on the Gotland Horizon ferry, which will also feature a multi-green fuel engine (with hydrogen as the preferred fuel).

The 28-knot ro-pax will offer room for 1,900 passengers and cargo capacity for 100 trucks and trailers.

Order/entry into traffic: 2025/2030.

Developing the Horizon X catamaran ferry, offering room for 1,450 passengers.

MoU signed with the Austal shipyard in February 2023.

The newbuild could be sailing in 2027.

When originally revealed in October 2022, as Gotland Hydrocat, the catamaran was to feature a multi-green fuel engine (with hydrogen as the preferred bunker).

The 35 knot-max speed vessel was said to offer room for 1,600 passengers, plus space for 450 cars.