Room for expansion at container group

TheUK’s largest container firm is diversifying into the hire and modular markets with the launch of a new group.

Latest range from Magog Industries

Magog Industries offer their latest range in coatings and materials, designed to further enhance longer life and greater resistance in demanding processing where increased proportions of glass reinforced and recycled material is used.

Applied Maintenance Technology

Barrier Networks

See them on page 6

Dalton Safety

See them on pages 8&9

Contents:

See them on page 6 Water, Energy & Environment ..................... 2

Cleveland Containers, which is based in Stocktonon-Tees, Teesside, has recently announced the launch of the Cleveland Group, which encompasses the container arm along with two new divisions: Cleveland Hire and Cleveland Modular.

Johnathan Bulmer, chief executive officer of Cleveland Containers, said, “By responding to the needs of our 15,000 strong customer base and answering their increased calls for eco-friendly site accommodation and modular buildings, we have seized the opportunity to expand into these markets.”

The group will now offer a full turnkey service, providing all essential site set-up units and accessories including offices, canteens, toilets, furniture, temporary power supplies, fencing and lighting.

To aid the expansion, Cleveland Containers has also strengthened its team with the appointment of a number of new roles.

Jon Hurford has joined as chief financial officer, Richard Tredwin, has been appointed as non-executive chair. Meanwhile former Mobile Mini managing director Andrew Thompson joins as chief operating officer.

For more information on Cleveland Containers and its range of products, visit: www.clevelandcontainers.co.uk

“We constantly strive to offer solutions from optimal design to reduce wear to offering a wide range of surface technologies, explained John Allsop, Director and General Manager. “We design everything in-house but also work closely with specialist partners to meet our customers’ specific processing and production requirements.”

Enhanced coatings specification include: Thin Dense Chrome (TDC) to enhance wear with low friction and is FDA Approved for food process environments. Ceramic Seal coatings reduce porosity and increase plating/coating life 4 to 10 times longer in corrosive environments.

In addition, HVOF (High Velocity Oxygen Fuel) that is thermally sprayed applied provides a crack-free 98% density with hardness of 62 to 72 HRC. This scratchresistant tungsten carbide coating has gained much interest among plastics moulders. Magog also offer screws and barrels for processing more aggressive material from through hardened D2 toolsteel to high-performance alloys such as Hastelloy (nickel-molybdenum) and Incoloy (nickel-iron-chromium). All standard screws

and barrels are manufactured in highgrade tool-steel. For example, EN41B steel provides hardwearing performance but also allows of hard welded bi-metallic alloy flights at a later date. Further enhanced specifications for barrels include Hot Isostatic Pressing (HIP) to reduce porosity & increase the density of the barrel surface & can be used as an alternative to Hastelloy or Incoloy when processing, for example using PTFE or Fluoropolymer material. For more information, contact Magog Industries: enquiries@magog.co.uk or call 01920 465201 or visit: www.magog.co.uk

10

Dyneo+ New synchronous motors manufactured by Nidec, combining reluctance and permanent magnets

The new range offers high reliability, unrivalled performance and interactive commissioning. Sizes from11kW to 500 kW with speeds up to 6,000 rpm. Specially designed for variable speed, DYNEO+ is available in aluminium or cast iron versions from 11 to 500kW, 132 to 355mm frame size, with IP55 or IP23 protection. Whether compact or interchangeable IEC type, these motors are easy to integrate into new machines as they are to retrofit existing installations.

GES Group’s 5 Pillars of Expertise

Established as Grants Electrical Services over 40 years ago, the group has grown into GES Group, a leading Electrical and Mechanical Engineering business, now serving customers throughout Ireland, the UK and Europe. Currently employing over 80 staff, including many professionally trained and accredited Engineers, we respond quickly to Industry's ever-changing demands and needs, while offering geographic coverage to many of our customers.

Traditionally AC/DC motor rewind and re-manufacture specialists, we have developed our portfolio as a market leader to now provide an extensive range of technically advanced products and services.

Nidec (Leroy Somer) Electric Motors stocked in Mallusk and Newbridge (IRL)

GES Automation (IRL), based in Newbridge, is the authorised distributor for Nidec (Leroy-Somer) Ireland. This is a very exciting time for both GES Group and Nidec as we have worked together in partnership in Northern Ireland for several years and by expanding the distributorship to Southern Ireland our partnership will create a more comprehensive infrastructure with enhanced experience and expertise and will provide our customers with a first class customer service experience.

Telephone: 02825 656406

Email: info@ges-group.com

www.ges-group.com

Water, Energy & Environment

Supporting a sustainable future

Reduce emissions. Net zero 2030. Reduce energy dependency. Now or Never. 1.5 Degrees. Heading for a climate disaster. Governments must act now. New energy strategies. The cost of climate inaction.

These are just some of the soundbites from the news in recent weeks as the acceleration to net zero 2030 goals speeds up. With rising energy costs across the globe putting pressure on household and commercial expenses, and the actions of Russia in Ukraine emphasising the need to reduce energy dependencies from overseas, harnessing energy from the Earth’s elements is in full focus.

In this corrosive environment a wind turbine can see corrosion start in many different areas – monopiles, ladders, walkways, boat landings, guard rails and rotor heads – each of which can compromise the overall integrity of the structure. Protective coatings that can be applied to prevent corrosion from developing, or halt its progression, are essential to providing long term asset protection.

And as we have seen in many other industries, a major consideration to the ideal protective coating is surface preparation. The need for aggressive blasting to apply protective coatings is a burden in these confined & hostile environments, let alone the contamination to surroundings. Preventative coatings that can mitigate this issue are a major step forward, combine that with ease of application & minimal manpower and offering benefits to time, long-term protection, costs and production.

One brand paving the way to simpler futures is Easy-Qote; a brand on a mission to change the way corrosion prevention is viewed, and conducted, with it being applied simply as a patch. With traditional approaches we would see a variety of materials and equipment brought to site: surface preparation tools, coatings and application tools, rope access equipment and PPE.

Earlier this year the UK published its strategy for increasing energy independence. Nuclear, wind, solar and hydrogen all play a part in that with strong targets to achieve by 2030; hydrogen capacity to double and solar to increase by up to 5 times the current outputs. The Offshore Wind target is to generate 50GW of energy by 2030, currently sitting at 11GW. These are ambitious targets and that sort of commitment is going to take some serious infrastructure installation projects.

The UK are not alone in the push to renewable energy, especially offshore wind. The USA conducted an offshore wind lease sale off the coast of New York, fetching over $4 billion, a major step in the US push to renewable energy. In March we saw a new study reveal that the Asia-Pacific region’s wind energy sector could soon account for nearly a quarter of their power this decade, with China set to be the largest market by 2030. And in the same time the Government of India announced funding for a offshore wind energy test facility by India’s National Institute of Wind Energy (NIWE). Since the conditions in Indian waters are different to those experienced in Europe, there is a need to perform testing to ensure wind turbines are designed for their best performance.

The future of offshore wind is looking bright, and busy. But to make this energy truly sustainable, preventative asset protection is vital to ensuring longevity.

The push to offshore wind is to take advantage of the power of the wind produced at sea, moving at a much higher and more consistent speed thanks to the open space and absence of structures. What is a benefit to production, however, poses a logistical disadvantage to construction and maintenance along with an aggressive corrosive environment. These increased offshore developments will see stronger winds and bigger waves, beneficial to production, but adding pressure to not just the installation phase, but ongoing operation and maintenance.

In the case of Easy-Qote, one individual or small team is armed with a wire brush and a roll of patches. Simply brush loose corrosion away, apply the patch and return to base. No blasting is required avoiding the all-important issue of environmental contaminants. Overhead costs will be greatly reduced with transportation and manpower costs down. Instead, protection is immediate and with a service lifetime of 25-30 years, the asset can now reach its full potential with long term protection.

These ambitious targets for 2030 will take swift and dedicated action, and it should be done with longevity at the core. A sustainable future is not just working with greener energies and renewable sources, but it involves extending the lifetime of assets and existing infrastructure, so that they can carry out their duties long beyond what the environment might normally allow.

Put simply, with Easy-Qote, we are committed to helping the wind energy industry reduce failure from corrosion issues, improve productivity, longevity, and as a result, make renewable energy truly sustainable.

Laura Hall, Senior Marketing & Communications Manager, Seal For Life Industries

Somaieh Salehpour, Vice President Technology and Strategic Marketing, Seal For Life Industries info@sealforlife.com www.sealforlife.com

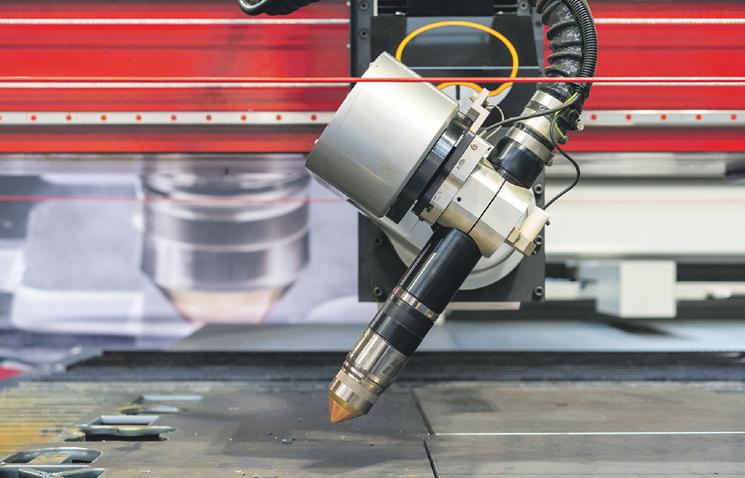

Cutting & bending excellence for 150 years and beyond

From humble beginnings in 1872 manufacturing plate working machinery, Morgan Rushworth has become a leading supplier of high quality, high performance, specialist sheet metal and fabrication machinery, built to exacting specifications and standards. Top class machinery, combined with outstanding customer service and a warranty-backed product support package, has made Morgan Rushworth the machine partner of choice for metal fabrication, engineering and manufacturing businesses across the UK.

From the very beginning, the company founders believed that it was important to stay true to one’s roots. Morgan Rushworth wanted to create innovative plate working machinery, which was a new thing at the time, and bring it to the British market over 150 years ago. Today it takes pride in the fact that it is still bringing innovation and meeting the needs of a market always in evolution.

Morgan Rushworth is a full-range machinery supplier that specialises in thin and thick profiling, folding, shearing, drilling and punching. It continues to drive

the manufacturing industry to modernisation by supplying innovative and tailored solutions, and the company is always ahead of the latest changes in the industry, and continually strives to supply its customers with the most advanced and innovative technology available.

The Morgan Rushworth name has always stood for excellence, and 150 years on from the establishment of Rushworth and Co, Morgan Rushworth continues to set new standards in the metal fabrication industry. From the belt driven section rolling machines of the 1870s to its state-of-the-art fully programmable XS fibre laser cutters of today, the company continues to build on its heritage and values, ensuring that customers’ operations run productively, free of concerns over downtime or service issues, day in and day out.

The company’s main goal is to provide its clients with the solutions and services they need to succeed. It does this by providing innovative plate working CNC machinery, as well as training in how to use it. Morgan

Rushworth has over ten showrooms in addition to offices all over the United Kingdom and Ireland, and although it has national coverage, the local approach to the service and customer care helps to distinguish it from other companies. In addition to this national reach, the company likens itself to a local company with a national presence, as this allows it to stay true to its roots.

Morgan Rushworth is a leading reference point for the metalworking Industry in the United Kingdom & Ireland. Oil & Gas, Structural Steel and General Fabricators, OEM Plants and Workshops are in daily contact to discuss solutions that vary from supporting a legacy machine to new investment solutions such as automated machinery and consulting.

In a busy industry, Morgan Rushworth works hard to stay at the forefront of the industry, and its value proposition is being attentive to all customers and genuinely approaching every customer’s need, thinking of itself as partners in the customer’s business growth. Morgan Rushworth believes that the best way

to succeed in an industry where there are so many players is by focusing on what makes it unique, and it has a special approach to customer service, and this is something that clients do not always get from larger companies.

Morgan Rushworth’s portfolio of products is wide and varied, including Press Brakes; Bending & Forming Presses, Folding Machines and many others, but its vision for the future is crystal clear: The company intends to help solve the biggest challenges of productivity in the metalworking industry – its goal is to become a leading partner in accelerating automation, increasing safety, and shifting manufacturing to Industry 4.0. Having recently celebrated its 150th anniversary, Morgan Rushworth will be adding new content on its machines as the year progresses.

T 01785 247575 sales@morganrushworth.com

www.morganrushworth.com

Crimping Machinery Company of the Month

Precision in crimping: Hydraulic Hose Crimpers

In this issue of Industrial Process News, we are pleased to announce that we have selected Hydraulic Hose Crimpers as our Crimping Machinery Company of the Month.

Kevin Leonard, Director, set up the company in 2019 after a solid 10 years successfully selling crimping machinery in the industry and proudly states, “We are now the main stockist in the UK, with excellent stocks of Crimpers and all the associated equipment. Hydraulic Hose crimpers are based in Stafford and Scotland are the main outlet and stockist for a large range of machinery based on the manufacture of Hydraulic Hose assemblies and all the associated Equipment.

“Our Hose Crimpers are also used in other industries such as tube reduction, rope crimping both steel and hemp and especially in the Pneumatics industry. As the machines come with a range of dies, it’s possible to obtain a perfect clean smooth Swage on any form of Ferrule or Sleeve in any material.

“Our machines are predominantly sold into established Hydraulic Hose companies, Agricultural Dealers Mining and quarrying, and heavy plant operators throughout England, Scotland, Wales and Ireland. We stock the full range of hand operated mobile units that will crimp up to 1.1/2 bore hose. Depot Machines in 240 V and 3 phz up to 350 Ton which will do 2-inch Multi Spiral hose. One of our main Swagers are in

“The Accessories for the hose and fittings industry is based around Hose Cutters which we have a large selection in any voltage. We have Hose storage racks in 6 and 7 tier, Hose coilers and Hose measuring devices, Ferrule Marking Machines, Hose Skivers both Manual and Electric and a good range of Pellet Cleaning systems for the hose assemblies.

“Please feel free to call myself, Kevin Leonard, any time on my mobile 07484 760684. I am available to visit your place of work, whatever the industry and supply you the Hose Crimper best suited for your needs and offer the best advice and that is backed by training on whatever machine you purchase. I have been in the Hose and fittings and Hose assembly Machinery industry for 40 years so I can promise you a professional service at all times.”

the

V DC mobile Van Market, again we stock three sizes of machine which covers most hoses completed from a mobile hose service van. Whatever your requirements we have the machines in stock. Our own staff deliver our machinery so that we quickly work out if it’s the right machine for the job and I am always available on my mobile if required, any day of the week.

Contact Hydraulic Hose Crimpers today for all your comprehensive crimping machinery needs.

M 07484 760684

kevin@hydraulichosecrimpers.co.uk

www.hydraulichosecrimpers.co.uk

Industrial Process Technologies

Improve plant performance

Global software developer eschbach, the provider of Shiftconnector® digital manufacturing software for process manufacturing, announces that Artificial Intelligence (AI) is now an integral component of its enterprise platform. Now with AI search engine capabilities, Shiftconnector will bring a new level of intelligence to the plant floor. eschbach made its announcement at AVEVA World in San Francisco and at the SOCMA Annual Summit in New Orleans, events that are focused on process manufacturing innovations and digitalisation.

For nearly 20 years, Shiftconnector’s software platform has been enabling process industry manufacturers to enhance communications among shift teams for effective shift handovers, transparent team communications, and increased asset performance.

With the addition of AI’s smart search capabilities to the Shiftconnector platform, teams will now be able to improve plant performance by quickly finding solutions based on the history of documented tribal knowledge from plant operations teams. By retrieving the most relevant information, it will accelerate operations and bring capabilities to help teams recover from disruptions by immediately identifying appropriate fixes. Also, captured knowledge can be managed to support workforce changes.

Large amounts of data flow through a plant operation and it can be costly to the overall operations when similar processes occur regularly, and downtimes occur to find solutions. As different teams need to develop unified responses, act on unexpected events, and maintain a cohesive workflow throughout multiple shifts, natural language processing is essential.

Contact: Felix Michler +49 7761 55959 272 felix.michler@eschbach.com www.eschbach.com

New contactless proximity switch range

Terahertz enables wireless 6G communication

Sixth-generation mobile communications (6G) will enable completely new application scenarios in industry, medical technology and everyday life. This will be accompanied by new requirements in terms of latency or the transmittable data rate, which cannot be met by current communication systems.

A promising technological solution to enable the highest data rates is the development of new frequencies up to the terahertz (THz) range. For the development of 6G, it is therefore important to develop THz transmission sources that have high signal quality and cover as wide a frequency range as possible. This goal can be achieved in the future by integrating optical technologies & electronics. If successfully developed, such THz components can also be used beyond the communications sector, as they can be applied in sensor technology or imaging in addition to data transmission.

In the 6G-ADLANTIK project, components for the THz frequency range are being developed based on photonic-

electronic integration. Signal sources and detectors are to be created that cover almost the entire targeted frequency range of 6G mobile radio. For this purpose, it is planned to develop stabilised laser systems and optical frequency combs and to build THz signal sources from these components. In a further step, innovative waveguide structures will be designed and manufactured for the targeted frequency range. These waveguides will then be integrated with the photonic components to form transmitter and receiver units. Finally, the individual components will be brought together for the demonstration of a high-performance radio transmission system.

T +49 89 858370 info@toptica.com www.toptica.com

Our new CTL-SW range of touchless, infrared proximity switches are now available. Designed to be easily activated without the need for physical contact, the CTL-SW switches make for a good replacement for typical push buttons in situations where touching the button isn’t required or desirable.

Running on 12VDC and drawing a minimal 15mA when in standby mode where the device will display a red LED and 25mA when in active mode where it will display a green LED to provide the user with the visual feedback that their motion has been registered.

In this range we have four models:

n CTL-SW-MC (Normally Closed) Momentary Touchless

Infrared Proximity Switch

n CTL-SW-MO (Normally Open) Momentary Touchless

Infrared Proximity Switch

n CTL-SW-LC (Normally Closed) Latching Touchless

Infrared Proximity Switch

n CTL-SW-LO (Normally Open) Latching Touchless Infrared

Proximity Switch

Check out the range and view the datasheet on our website: T 01794 884567 sales@lascar.co.uk www.lascarelectronics.co.uk

Industrial Process Technologies

TOPTICA Projects: Management board expanded

Next to the company founders, Dr Wilhelm Kaenders (also Managing Director, TOPTICA Photonics AG) and Dr Frank Lison (Managing Director, TOPTICA Projects), Armin Zach will become responsible for research and technology. TOPTICA Projects was spun-off from TOPTICA Photonics AG as a separate entity in 2016.

Armin Zach was one of the start-up members of TOPTICA Photonics AG in 1998. He has spent his entire career in the laser industry, with deep experience in research and product development. He graduated in 1998 with a degree in biomedical engineering and precision engineering from the University of Applied Sciences in Ulm.

During his diploma thesis at the chair of Professor Hänsch at the Ludwig-Maximilians-Universität Munich, he became

enthusiastic about laser physics. Thus he joined TOPTICA Photonics, which was founded as a start-up company at that time. In the following years he worked in research and development of semiconductor lasers and ultrafast fibre lasers, where many products of TOPTICA Photonics AG originated.

Subsequently, he headed the R&D department of TOPTICA in the field of fibre lasers and frequency comb technology. As a co-founder of TOPTICA Projects GmbH, he has overseen the company’s R&D since its spin-off in October 2016.

Contact T +49 89 858370 info@toptica.com www.toptica.com

Green & yellow laser modules with new wavelengths

Besides the already well-known green laser modules from Lasence with the wavelengths 532nm & 545nm, new laser modules are now available with wavelengths 520nm, 555nm and 577nm. These laser modules from the GLM series are offered with output powers up to 1W, have a fast rise time and are very reliable.

The typical output beam has a diameter of 0.5mm with divergence ≤40mrad. With dimensions of just 18mm x 55mm (Diameter x Length) they are very compact for this high output power.

There are plenty of applications in which these laser modules can be used:

n Biomedical Applications – Cytogenetics, Optogenetics and Intravital Imaging

n Clinical Applications – Photoluminescence Microscopy, Robotic Surgery and Endoscopy

n Industrial Applications – Agriculture, Food and Semiconductor Inspection.

sales@frlaserco.com

www.frlaserco.com

Britbots and Sapphire launch the British Robotics start-up fund

Britbots and Sapphire

Capital Partners are pleased to announce the launch of the British Robotics Start-Up Fund (the ‘Fund’), to take advantage of the new, more beneficial environment for investing under the Seed Enterprise Investment Scheme (‘SEIS’).

Over the past six years, the British Robotics funds have invested in 34 companies, backing entrepreneurs creating productivity-boosting technologies, particularly in the areas of robotics, artificial intelligence and automation. The Fund will continue this technology focus and seek to capitalise on major global trends such as shortages of skilled labour, the transition away from fossil fuels, supply chain inefficiencies and the depletion of natural resources.

The majority of the British Robotics funds investments have been made under the tax-advantageous Seed Enterprise Investment Scheme, which substantially mitigates the risks to investors of backing young, high potential businesses.

It was recently announced that the limits available to companies and investors utilising SEIS will be extended from 6th April 2023. Despite other parts of the mini-Budget having been reversed, HMRC has confirmed that the extension to SEIS will stand. This will make SEIS-eligible opportunities an even more attractive investment option for private investors. Individuals will be able to invest up to £200,000 in SEIS-qualifying companies each year, and companies will be able to accept up to £250,000 within their first three years under SEIS. It is worth noting that such a beneficial tax scheme may not survive a further change of government, therefore appropriate investors should take advantage of the scheme while they can.

The Fund allows investors to subscribe between £10,000 and £300,000 into the fund each year with at least 60% of the investment going to SEIS-qualifying companies & the remainder in opportunities that qualify for the Enterprise Investment Scheme (EIS). This means that each investor will be able to immediately offset at least 42% of the amount they invest in the Fund against their tax bill, as well as potentially also benefiting from subsequent tax benefits.

Dominic Keen, Britbots: dominic@britbots.com

Alex Pejacsevich, Britbots: alex@britbots.com www.britbots.com

Boyd Carson, Sapphire Capital Partners: boyd@sapphirecapitalpartners.co.uk

Ben McMeekin, Sapphire Capital Partners: ben@sapphirecapitalpartners.co.uk www.sapphirecapitalpartners.co.uk

Manufacturing + Engineering Week Review – Top Exhibitors

The future of manufacturing + engineering

Celebrating the best in UK manufacturing and engineering excellence and innovation, Manufacturing + Engineering Week, held at Birmingham’s NEC from 6-10 June 2022, brought the entire community together for a festival of innovation featuring a dynamic, interactive series of digital and live events to inspire, inform and entertain.

Covering the full product life cycle from design, engineering, manufacturing and maintenance, it truly celebrated the sector, flying the flag for manufacturing and engineering in the UK.

With the Government’s plan to help UK manufacturers sell products around the world, the release of the first roadmap to net zero for the sector and ongoing skills shortages, Manufacturing and Engineering Week came at a crucial time to bring the community together to debate and discuss the current challenges.

With high profile speakers, practical workshops, market-leading suppliers, and co-located exhibitions, Manufacturing & Engineering Week is always of great value to UK businesses.

Terryberry: Support your employees

Thecost-of-living crisis is having a catastrophic effect on the financial and personal wellbeing for people across the country. The cost of living is spiralling out of control, to such an extent that people are having to choose between heating or eating, which is a devastating thought.

Manufacturing + Engineering Week returns next year to Birmingham’s NEC from 7-8 June 2023. This is our pick of the best exhibitors from this year’s event, listed here in alphabetical order: Applied Maintenance Technology Ltd, Barrier Networks, British Encoder Products, Good to Go Safety, Gruetzner GmbH, Invent Design Build, Onesys, Terryberry & UE Systems. Further details can be found on this page and the next.

www.mandeweek.co.uk

The escalation of industrial cybercrime

If the last year has taught us anything, it’s that no industry is immune to cyberattacks.

Every sector has been hit – some attacks spurred business dissolution, others caused financial losses, but when it came to the most destructive incidents, these were attacks against industrial organisations.

Unlike financially-motived cybercrime, industrial cyberattacks are carried out to hurt societies and citizens often come directly in the firing line.

With Operational Technology (OT), that was traditionally air gapped, now being routinely connected to IT equipment, attackers have hijacked on this opportunity to hit critical processes within OT environments and cut off essential supplies.

In the last year, these incidents have grown in frequency and notoriety, and the bad news is things are going to continue to escalate in the year ahead.

As a result, industrial organisations must be working

Applied Maintenance Technology Ltd provides reliability improvement services and products utilising Operator Empowered Reliability® (OER) to make significant advances to process and equipment reliability. Developed over 30 years our OER frameworks conform to the requirements of Asset Condition Management, driving business-oriented reliability through operators.

OER integrates operators into the maintenance process, involving them in key decision-making regarding plant criticality and priority, and allowing them to undertake simple maintenance tasks. They are integral in collecting data relating to equipment performance efficiency.

Complemented by our range of FETCH® operator-based condition monitoring, we present simple, yet clear information about the condition and performance of critical equipment and assets. This allows the operator to make an assessment of acceptable or unacceptable performance and trigger an appropriate investigation and corrective actions. FETCH then provides experienced engineers and analysts with a full suite of diagnostic tools via the onboard CBM database.

Designed on a machine-by-machine basis, FETCH is a bespoke monitoring solution for a wide range of equipment and machinery. Vibration intensity evaluation provides electrical and mechanical integrity, grease and oil lubrication measurement derives lubrication certainty, and monitoring of process efficiency data provides process assurance for all monitored equipment.

T +44 (0)1925 940566

sales@applied-maintenance-technology.co.uk www.applied-maintenance-technology.co.uk

to harden their environments now.

Barrier Networks has been at the forefront of industrial cybersecurity for over a decade. From incident response, patch management, OT and IT segmentation, to helping organisations implement robust cybersecurity programs, Barrier has been leading the way in helping secure these highly critical environments.

As we move into the new year, it is essential industrial organisations take steps to get ahead of this increased threat.

Working with cybersecurity partners and experts, like Barrier Networks, is one of the best ways to achieve this much-needed industrial cyber-resilience.

T 0141 356 0101

www.barriernetworks.com

This is also having a severe impact on employers, who are already facing huge challenges in retaining and engaging people. A full, highly engaged workforce is critical to business success, yet with around 1.3 million job vacancies, many companies are understaffed, and morale is low. The impact of financial insecurity is creating pressure on employers to match pay rises with inflation, which isn’t sustainable, leaving companies in the perilous position of risking losing their people or stressing out their workforce.

Terryberry is providing an answer by offering a scheme whereby employers can help support their employees during these times. Its cost-effective benefits solution means you can give employees access to an easy-to-use discount platform, with average savings of £3,000. These deals are designed to reduce costs at checkout, help provide entertainment, and ensure access to necessary services for families, as well as supporting physical, mental and financial health.

Find out more at: www.terryberry.com/gb/employee-benefits/

Invent Design Build pilot critical design review service

Invent Design Build are piloting a critical design review service and application that offers businesses the opportunity to capture the knowledge from disparate cross-functional teams and truly learn lessons from project to project speeding up the development process and avoiding costly design and development iterations late in the product life cycle.

The critical design review application provides a secure central repository capturing the project documentation at a specific project phase. Team members and experts are then invited to review and raise concerns identifying and prioritising risks that may if not contained or mitigated cause costly project delays or customer dis-satisfaction. The project team are then able to review and take corrective actions in a timely manner reducing the risks of exceeding project budget, time to market or product technical failure.

Baseline checklists are provided to facilitate a thorough review, and these are continuously improved provided for future teams in either in a secure manner for company use or via a published interface allowing the engineering and development community to benefit.

Key benefits from the CDR process and tool are:

n Early identification and mitigation of product development risks.

n Knowledge sharing and learning across distributed

teams and projects

n Increased awareness and collaboration across disciplinary functions.

n A central repository with the ability for ML/AI to predict risks in future projects.

We are inviting research and development managers and engineers to participate in the pilot system from Q1, 2023. Participants will receive free training and support in the implementation and trials of the CDR process and tool in their organisation.

Contact

M +44 (0)7378 557533

Liddledel@inventdesignbuild.com

contact@inventdesignbuild.com

Invent Design Build enables businesses to get new products to market. Our engineers create smart, manufacturable, and sustainable products that are easy to use. Our experienced team takes the risk out of product development.

Invent:

♦ Patents – searching new technologies & creating patent applications

♦ Writing winning funding proposals

♦ Requirements capture and refinement

♦ Identifying applicable standards and specific requirements

♦ Creating proof of concept systems

♦ Project planning & estimating

Design:

♦ Supplier Selection – manufacturing partner selection

♦ Electronics – Altium schematic capture and PCB layout

♦ Software – ARM A series and M series SoC and SOMs

♦ Mechanical – Industrial and detailed component design

♦ Design Validation – Creating and executing hardware and firmware testing

♦ Security – IOTSF Secure by Design implementation

Build:

♦ Pilot Build – Assembly drawings, BOMS and manufacturing instructions

♦ PCBA Testing – Automated functional test processes and scripts.

♦ Product Approvals – Technical file creation and liaison with accredited laboratories

♦ Pilot Validation – Environmental, Transport, Performance and Reliability Testing

For further information: contact@inventdesignbuild.com www.inventdesignbuild.com

Manufacturing + Engineering Week Review – Top Exhibitors

TakeAIM at equipment inspection

The TakeAIM app received great acclaim when showcased at Maintec 2022, with visitors blown away by the quality and functionality of the equipment inspection software, coupled by its low cost affordability and ease to set up.

The TakeAIM app allows companies to register any number of assets and users which can then be inspected on smart phones/tablets. The app contains a large number of pre-installed equipment checklists to use but additional checklists can be created quickly and easily at no additional charge. Assets can also be linked to QR codes which, when scanned will automatically open the relevant checklist to complete.

Photos and notes can be added during the digital inspection and each step is time stamped to ensure accurate checks are being completed. Upon completion the checklist is stored in the company ‘dashboard’ where management can view trends and analyse findings in real-time – allowing instant decisions to be made on actions to take if faults are found.

Using ultrasound to enhance energy efficiency

One of today’s greatest challenges for industry is to improve energy efficiency. A major contributor to energy waste is leaks: both in compressed air systems and steam traps. Ultrasound instruments can detect these leaks, leading to potential energy savings.

Detecting compressed air leaks

The app helps schedule routine checks of all workplace equipment at a time convenient to the user.

By carrying out regular inspections TakeAIM helps to improve safety, reduce maintenance costs and equipment downtime, and provides if evidence of regulatory obligations under PUWER/LOLER etc to ensure work equipment is in good working order. With so much more to discover, visit: https://takeaim.goodtogosafety.co.uk/ and sign up for a free trial.

Automatic lubrication systems

Gruetzner GmbH has established itself as a specialist for automatic lubrication systems since 1993.

Automatic lubrication systems dispense small, precise amounts of lubricant at short, regular intervals. The amount of time and personnel required for large plants and machines located in hazardous areas mean that manual lubrication is often dangerous, impractical and expensive. Automatic lubrication systems as part of maintenance can resolve this issue.

Automatic lubrication systems prevent under and over-lubrication, thus enhancing the service life of your machines. It reduces your costs, protects the environment, improves work safety and enables monitoring and provides an overview.

Our flexible and user-friendly lubrication solutions are used in almost all areas of maintenance in every industry across the globe.

As an international established, family-owned enterprise flexibility and outstanding service are our core competencies. An individual, custombuilt lubrication concept which is adjusted to your machines and constructions will gladly be developed by our experts.

We additionally take on responsibility for the environment with our modern lubrication solutions. By reducing lubricant and energy consumption as well as extending the service life of wear parts we achieve a significant reduction in CO2 emissions in factories and plants around the world.

Get in touch with us. We look forward to your enquiries. Contact: Volker Gruetzner, CEO

T +49 911 277399-0

Volker.Gruetzner@G-LUBE.com www.G-LUBE.com

Contrary to what some might think, compressed air is not free. It is estimated that more than 50% of all compressed air systems have energy efficiency problems. Around 30% of all industrial compressed air is usually lost to leaks, resulting in huge losses. A leak that is just 1cm can cost a plant upwards of £15.000 per year if it goes undetected.

Ultrasound instruments detect the turbulent flow produced as the compressed air moves from the high-pressure side to the low-pressure side of a leak. Using the characteristics of Ultrasound, locating leaks is fast and easy.

Inspecting steam traps with ultrasound

Steam leaks are also among the most wasteful, and therefore, expensive issues found in a plant. In fact, leaking steam traps can increase operating expenses by as much as 33%. For this reason, energy conservation programmes should start with a steam

trap survey. Even the smallest steam trap leak can cost up to £7,000 per year.

Reporting steam trap inspections

Findings from a steam trap survey can also be documented with UE Systems Ultratrend DMS software, or the SteamTrap Survey app for mobile devices. The report will outline the potential economic losses due to the faulty steam traps.

Contact: Christopher Hallum, Regional Manager UK & Ireland

M +44 (0)7930 352188

chrish@uesystems.com www.uesystems.co.uk

British Encoder Products

British Encoder Products (BEPC) is the European branch of the Encoder Products Group, a worldwide manufacturer of motion sensing and control devices. As a customer driven company, BEPC is highly responsive in the areas of customer service and technical support, with an acute focus on high performance, excellent delivery and competitive pricing.

In addition to its wide selection of incremental and programmable encoders, BEPC has released its new range of absolute encoders now also with the PROFINET protocol, which provides a unique code for each increment of shaft rotation. This means that the encoder indicates both that the shaft position has changed, and the absolute position of the shaft. Now available with up to 16 bits for single turn resolution and 43 bits for multi-turn resolution, our encoders can measure with greater resolutions and have a longer run-time before reset.

This range is ideal for systems which need exact

position information in order to prevent damage to machinery and its operators. This is also particularly valuable during power loss when the absolute encoder will maintain its value without being powered, so any movement during the loss of power is tracked and retained for immediate transmission once power is restored.

Contact

T 01978 262100 sales@encoder.co.uk www.encoder.co.uk www.encoder.com

Manufacturing solutions

Withyears of manufacturing industry experience, we are very aware that no two manufacturing businesses operate the same. Which is why Onesys works with manufacturing solutions to match your requirements and budget. Whether you are a Batch, Jobbing or Mixed Mode manufacturer, we can help guide you through which manufacturing system will work best for your business and explain the difference between the solutions we offer.

We offer solutions to ensure you have full control over your processes, providing greater visibility across your business:

n Barcoded Stock Movements

n Shop Floor Data Capture

n Batch & Serial Number Traceability

n Multiple Suppliers per Product

n Supplier Quantity Pricing

n Configurable Quotation System

n Full Manufacturing with MPS/MRP

n Audit Trails and Costing Histories

Whether you are looking for enhanced stock functionality, going beyond the capabilities of your standard Sage system, or looking for a complete manufacturing solution, we will have a system for you. Onesys will work with you at every stage of the process, ensuring the solution is configured for your individual business requirements. We also provide a full support package with friendly and professional advice from our UK-based team. Onesys has offices throughout the UK and has over 1,000 Sage system customers.

Email:

IMHX 2022 The Logistics Solutions Show Review – Top Exhibitors

The logistics event with the ‘wow’ factor

After a three year hiatus, IMHX – the UK’s premier logistics solutions and intralogistics technology event – returned to Birmingham’s NEC over three action-packed days from 6-8 September 2022 to showcase the developments that are shaping the global logistics industry.

With many of the world’s most innovative and influential manufacturers and suppliers presenting intralogistics solutions ranging from the humblest hand pallet truck to the latest ‘all singing and dancing’ fully automated warehouse system, a visit to IMHX

is an absolute must for logistics professionals who want to remain ahead of the curve in the rapidly changing supply chain world.

A brand new feature of IMHX 2022 was the Sustainability Zone. Combining physical displays, augmented reality, and virtual reality demonstrations, this dedicated area of the show ground gave visitors a ‘deep dive’ into the many steps that companies operating in the supply chain space could take to make sure that they perform as sustainably as possible.

IMHX returns in three years’ time

UK’s leading storage manufacturer achieves Gold Rating in EcoVadis sustainability assessment

to Birmingham’s NEC from 9-11 September 2025. This is our pick of the best exhibitors from this year’s event, listed here in alphabetical order: Dalton Safety, Davis Derby, GEBHARDT ECS, SmartFreight, Supply Chain Network & Whittan. Further details can be found on this page and the next.

www.imhx.net

Sorter wows IMHX crowds with automatic unit handling

GEBHARDT ECS specialises in intralogistics solutions for manufacturers and distributors. We can help you meet your supply chain goals by automating your processes and optimising your warehouse systems.

Our product range consists of conveyor systems, goods lifts, sorters, automatic storage and retrieval machines, automated guided vehicles, and software. With 30 years of expertise, we can design and install new systems, based on your individual requirements.

IMHX 2022 was our first physical event after several years of social distancing. We were pleased to see so many professionals in attendance, keen to learn more about the latest technology advancements.

This year we exhibited the GEBHARDT SpeedSorter® line, a conveyor system that can automatically sort units as it transports them throughout your warehouse. The sorter’s built-in sensors can detect barcodes on passing trays, totes, boxes, and bags. Once the order has been identified, the machinery will eject the unit onto diverging chutes to deliver it to its destination.

Automated equipment can improve warehouse throughput, order accuracy and order traceability. Our advanced solutions can support goods receipt

SmartFreight

Founded in 1997, SmartFreight specialises in multi-carrier LTL and parcel shipping solutions. Customers include blue-chip organisations such as 3M, Yamaha, Mazda, Hyundai, Seiko, Epson and Pandora Jewellery, as well as hundreds of transport and logistics providers such as DHL, Australia Post, Aramex, StarTrack, FedEx, and many more.

The firm provides its clients with an agnostic optimisation selection from their chosen transport providers, shipping by price/service/delivery time or CO2 footprint coupled with client branded end-end tracking visibility and final transport provider invoice reconciliation. Headquartered in Sydney with distribution networks in New Zealand, South Africa, Ireland and the UK.

Multi award-winning SmartFreight is now part of the WiseTech Global Group, a leading developer and provider of software solutions to the logistics industry worldwide. Its customers include more than 8,000 of the world’s logistics companies across 130 countries. SmartFreight is a pioneer of SaaS (Software as a Service) shipping software and designs solutions, aimed at helping to drive businesses forward through a suite of feature-rich carrier management solutions.

T 0333 996 2216 https://smartfreight.com/

processing, picking, packing and dispatch. We work with a range of industries and supply to small and large businesses alike.

T +44 (0)115 987 4363 www.gebhardt-group.com

Whittan is best known for our wide range of pallet racking, shelving and locker solutions which we supply to almost every industry across the UK and Europe. We are pleased to announce our most recent achievement, having been awarded the EcoVadis Gold Rating, putting us in the top 5% of all businesses assessed across all industries.

If you caught Whittan’s presentation at IMHX in September, you’ll know that sustainability is currently our key focus. With more than 70 years’ experience supporting British businesses with high quality, durable storage solutions manufactured right here in England, Whittan has been offering a more sustainable solution than its European competitors since day one. With our steel-based products being specified to ensure 100% re-use, even our IMHX stand will be re-used for many years to come!

Oliver Vaughan, Whittan’s Chief Financial Officer, comments, “We are extremely proud to have achieved the Gold Rating in the EcoVadis Sustainability Assessment.

“We are continuously exploring systematic ways of creating value and positive impact, future-proofing the business and integrating environmental and

social considerations throughout our operations. This process has begun with investment in more efficient machinery, promoting hybrid and electric car usage and installation of LED lighting.”

We are constantly strengthening our commitments to sustainability, therefore also helping our customers to do the same through offering sustainable storage solutions.

For more information, call 01952 682251, email: enquiries@whittan.com or visit: www.whittan.com

Supply Chain Network (SCN)

Completing projects with prestigious clients including Gardiner Brothers Shoes, EDF Hinkley Point C, Clarke Energy, & BBH among others – the Supply Chain Network (SCN) team are specialists in everything Logistics, from Warehouse Modelling and Design to Optimisation and Fit-Out and can help you reach your facility’s capacity & fulfilment potential in 2023 and beyond.

Experts in all aspects of Warehouse and Network Design, The SCN team understands the importance of remaining competitive in what is a very dynamic industry, and the ongoing vital data analysis and physical facility adaptations required to achieve this.

As many changes across all sectors will surely continue to develop throughout 2023, the supply chain industry is constantly adapting as best it can to both technology and labour shifts. The SCN team is aware of this and ensures that all solutions are tailored specifically not only to each client, but to each project and its particular industry.

Our philosophy is that “We are in it together” with our clients. We work to ask questions about their supply chain at all levels. Contact SCN today to learn about the work that we do and to ensure you are ready, and future-proof your business plans and logistics solutions.

T 01529 455340 admin@scnuk.com www.scnuk.com

IMHX 2022 The Logistics Solutions Show Review – Top Exhibitors

Davis Derby reflects on IMHX

As 2022 draws to a close Davis Derby took a moment to look at IMHX and felt that it was another successful event.

Dave Randle, Operations Director at Davis Derby, commented, “Although this years IMHX was certainly quieter in terms of footfall, we felt that visitors were all there for a purpose. Our stand was well positioned and busy, we have also made some good quality new contacts and followed up with a number of quality meetings.”

Davis Derby’s stand at the show focused on live demonstrations including:

n Trucklog TK5 system with a new Vision dashboard designed to easily provide live forklift fleet management information at the click of a button

n The LOPOS proximity warning system that is an UltraWideband solution that helps prevents collision between forklifts and pedestrians

Trucklog is an established and independent forklift truck fleet management solution that can be fitted to forklift trucks, new or existing. Trucklog has a fully accessible dashboard that gives managers details about the safety of their forklift truck fleet and gives live feedback to help monitor productivity and safety. It also offers full details of driver vehicle access, pre-operational checks, vehicle shock

Dalton Safety

Dalton Safety Ltd, formerly Slice Products Ltd, exhibited for the first time at IMHX to highlight its range of safety knives to the logistics industry. Dalton Safety offers three brands of knives – Slice, Klever and PHC – and can supply solutions that meet the needs of all industries. Highlights were the recently launched Slice 10563 Auto-Retractable Squeeze Trigger Knife and the 10564 Smart-Retracting Squeeze Trigger Knife, possibly the safest utility knives on the market, both of which utilise Slice’s ‘finger friendly’ blade design.

and impact reporting, driver training needs, vehicle service and maintenance schedules, and speed zoning.

Overall, the last 12 months have been an incredible journey for Davis Derby and we look forward to what the next 12 months will bring.

T 01332 227500

info@davisderby.com www.davisderby.com

Dalton Safety also showed the range of enclosed bladed cutters from Klever including the KJC-1 Klever Kutter which can be customised to include your own company name and logo. Also popular from Klever was the Klever exchange range that allows users to swap out enclosed blades when they are blunt, thus reducing costs.

For customers looking for a more traditional

utility knife, the PHC QBAR was very popular. The innovative design allows the knife to be used by both right and left handed users; its fully automatic retracting blade makes this one of the safest steel bladed knives available.

To find out more, contact Dalton Safety at: enquiries@daltonsafety.com or call 0800 9874 000 or visit: www.daltonsafety.com

Manufacturing & Supply Chain Conference & Exhibition Review – Top Exhibitors

Manufacturing excellence

The Manufacturing & Supply Chain Conference & Exhibition took place at Milton Keynes’ Arena MK on 10 March 2022. This event served as a national forum for manufacturers and operators involved throughout the associated supply chains from across the UK to gather to discuss pressing issues facing the industry. It is now firmly established as a ‘must-attend’ annual event, which successfully connects key stakeholders across the full spectrum of British manufacturing, including aerospace, automotive, chemical & pharmaceutical, construction, defence, electronics, energy, food & drink, nuclear, plastics, security, steel, space and textiles.

In addition to Brexit and the global trading environment,

other issues high on the agenda at the event included the challenges and opportunities provided by constantly changing customer demands, the rapid pace of technological advances in areas such as artificial intelligence, machine learning and robotics, along with heightening environmental concerns and intensifying competition both domestically & in international markets. There was an impressive line-up of manufacturing leaders, academics and government agencies who engaged in a stimulating blend of key note addresses and debates. The event also featured an extensive exhibition showcasing the latest technological solutions and business services.

DSL’s industrial computing solutions

DSL is known in the industry for our robust and reliable products. From bespoke electronic design services through to off-the-shelf panel PCs, DSL are able to provide industrial computing solutions to suit your requirements, timescales and budget.

We provide a fast and reliable bespoke electronic product design service for when an offthe-shelf solution simply cannot meet your needs.

Our expert electronic design engineers take you from concept to reality – whether you require a simple circuit board design to managing and delivering entire multi-layer, multi-board projects, from inception, design, prototyping to delivering high volumes of fully assembled and tested products.

Have you been struggling with finding components for your designs? Contact us about our Design Health Check!

Our UK-based team provide a wealth of knowledge and expertise, providing you with high quality technical support and a 5 year warranty.

Visit us at: www.dsl-ltd.co.uk/ electronic-design or contact us for more information about our products and services.

The disruptive changes generated by the unfolding fourth Industrial revolution (Industry 4.0) were also examined by many keynote speakers as well as both the resulting challenges and opportunities for British industry.

The Manufacturing & Supply Chain event returns to Milton Keynes’ Arena MK on 20 April 2023. This is our pick of the best exhibitors from this year’s event, listed here in alphabetical order: Applied Lean Consulting, DSL, Electron-X Ltd & European Springs & Pressings. Further details can be found on this page.

www.manufacturingevent.co.uk

X-ray services

Based in Milton Keynes, Electron-X Ltd offers a range of industrial x-ray services in the local area, the UK, and the rest of the world:

X-ray Inspection Service – Quality control and failure analysis NDT X-ray inspection of your product. Individual parts, small or large batches – chargeable by the hour. Rapid turnaround available.

Equipment Rental – For large quantity, short duration requirements, we can install an x-ray inspection machine at your premises.

Radiation Safety – For anyone using or thinking of using x-ray equipment, we offer short training courses for radiation awareness and up to RPS level (Radiation Protection Supervisor).

Radiation Equipment Testing – For businesses with x-ray equipment or facilities already on site, we can complete radiation testing and IRR2017 compliance and issue a Critical Examination Certificate.

Radiation Equipment Support – Our team of fully trained x-ray engineers can service and maintain a variety of x-ray equipment.

Bespoke Radiation Enclosures – Our in-house design engineers and installation team can provide the x-ray cabinet or room to best suit your requirements.

T 01908 566794

sales@electron-x.co.uk www.electron-x.co.uk

How many tethered cats do you have in your business?

Once there was a monastery where the monks befriended a stray kitten. While they played with it in the refectory and garden, it became a distraction when they went to pray. The Abbot took the decision to go into town and solve the problem by buying a tether to restrain the cat outside the chapel while the monks were praying.

Time went on and the cat grew up and became a part of the monks’ daily life. It loved the attention it received, but when the monks went to pray, the cat was tied up outside the chapel to await their return. After the Abbot died, the monks continued the practice and it became a regular sight to find the cat on its leash during prayers.

Then one day, the cat died and the monks were in crisis. How could they pray without a cat being tied up outside?

After some discussion, they went into town to buy another kitten… How many tethered cats do you have in your business? How much value do they add and how much do they cost you?

At ALC we’re cat lovers, but we also know what adds value to process and what waste looks like. Contact us for details of how we can help you.

info@appliedleanconsulting.com

www.appliedleanconsulting.com

Berry Global merges its M&H and PET Power businesses to form Berry Distribution Division

Joe Horton, Product Line Director at Berry Distribution, commented, “Both M&H and PET Power already have extremely strong reputations in the packaging industry for both quality service and innovation.

“Although the companies will now be marketed as Berry Distribution Division, their customers can and should expect that exact standard of service as there will be a smooth transition.”

Berry Global creates innovative packaging and engineered products that help make life better for people and the planet. Harnessing the strength in their diversity and industry leading talent of 47,000+ global employees across more than 300+ locations, Berry partners with customers to develop, design, and manufacture innovative products with an eye toward the circular economy.

In late September, Berry Global will be combining its M&H and PET Power businesses to form a new panEuropean operation that will be relaunching and rebranding as Berry Distribution Division.

The merger means that Berry Distribution Division will have an even greater portfolio of products to offer, as not only will it provide the existing range of products from the merged companies, but it can also offer the near 5,000 products from across the wider Berry Global network. Berry Distribution Division can also supply a range of supplementary items, such as closures and dispensers, enabling the company to offer a complete single-source solution to bring products to market in the fastest possible time.

Like its parent company, Berry Distribution Division will offer both short lead times and low minimum order quantities, including multiproduct orders to provide customers of all sizes with fast access to one of the widest ranges of high-quality packaging solutions.

The organization is unique in that it works with companies from start-up businesses buying packaging for the first time, through large bluechip companies, providing enormous scalability to accommodate customers’ needs across the industry.

The Berry Distribution portfolio will also include products from Berry’s B Circular range, which feature important circularity benefits, such as the incorporation of recycled content, mono-material packs, and designs for refill and reuse, to help brand owners meet and exceed their sustainability goals. This will provide further support to customers to satisfy consumer demands and meet legislative requirements such as the recent UK Plastic Packaging Tax.

The company will be making its debut at the London Packaging Week event at Olympia in September.

T 01502 715518

www.berryglobal.com

Water, Energy & Environment

Stuart Turner continues its expansion

Hot on the heels of several other acquisitions over the past couple of years, Stuart Turner, the well-known manufacturer of pumps and water-boosting products for residential and commercial uses, has acquired Aquatronic Group Management (AGM), a key provider of cold-water boosting installation and maintenance equipment and services in the UK.

Founded in 1906 and headquartered in Henley-on-Thames, Stuart Turner supplies water-boosting products that manage water pressure in residential and commercial/ industrial applications. These range from domestic shower pumps, where the company’s Monsoon product is the UK market leader, to bespoke systems that combine cold-water boosting, pressurisation units and circulators to manage the supply of hot and cold water in commercial buildings and for industrial purposes.

Based in Colchester, AGM designs and manufactures pressurisation and water booster units and installs and maintains fresh and waste-water pump systems. The company offers a nationwide service from its centres in Manchester, Colchester, and Southampton.

This complementary acquisition not only expands the overall product range presented by Stuart Turner, but also brings a hugely important servicing capability into the business. It supports the strategy to transform the company into the leading provider of water-boosting solutions and services in the UK.

Commenting on this lasted purchase, Richard Harden (pictured right), Stuart Turner’s Chief Executive, said, “AGM is a great fit for our product portfolio and gives us immediate access to the services market, which is seen as a

Surface, paint & coatings technology

Over 1,100 visitors passed through the doors of Coventry Building Society Arena for Surfex 2022 this 7-8 June. They came to find new ideas, answers to technical challenges and source information for immediate use in the working environment.

Despite being delayed by two years, this edition of Surfex was the most packed it has ever been. Working with OCCA, BCF and other key industry associations, the content was design to continue to attract high numbers of technical attendees and to encourage face-to-face and business discussions where the emphasis was on technology. This is particularly important post pandemic with the industry needing to meet, to restart stalled projects and start working on future projects.

Initial results from the registration desk and also reports from exhibitors indicate that Surfex attracted the correct attendee profile, with many commenting they were seeing people they hadn’t seen at Surfex for a long time, and they were impressed with the technical attendees met on their

stand over the two days.

Surfex returns in two years’ time to the Coventry Building Society Arena from 4-5 June 2024. This is our pick of the best exhibitors from this year’s event, listed here in alphabetical order: CDR Pumps, Plastribution Speciality Chemicals, Quantum Design International UK & Ireland Ltd, SIAM & Siltech. Further details can be found on this page.

Contact www.surfex.co.uk

Plastribution Speciality Chemicals

Plastribution’s chemicals division, Plascoatings, has rebranded to Plastribution Speciality Chemicals

The move is aimed at providing better opportunities for the business to evolve its brand and reinforce the breadth of products it represents. From a strategic perspective, the rebrand strengthens its position in the marketplace by making clear relations with its parent company – the Plastribution Group of Companies.

As Plascoatings, the business was formerly a €6m interest of Plastribution’s parent company, ITOCHU. The business became part of Plastribution in 2016, serving civil engineering, automotive, and domestic markets. Since then, Plascoatings has developed its brand by stocking and distributing an extensive range of curing and crosslinking agents for coatings, paints, films, inks and adhesive applications,

including polyurethane systems, reactive diluents, adhesion promoters, resins, solvents, polyaspartic system components, solvents and general additives.

Plastribution Speciality Chemicals’ Joanne Holmes said, “This is an exciting time for the business, with the rebrand marking the next phase in our journey and new opportunities to provide our customers with quality products and excellent service.”

For further information, call 01530 561957 or email: speciality.sales@plastribution.co.uk

Say goodbye to fluid contamination

Handling toxic and hazardous fluids with any kind of particulates has always been a challenge for the industry. With the two main pump types both offering advantages and disadvantages, it’s about time we levelled the playing field. Centrifugal pumps, a very popular choice of pump for many applications, are known to be robust & long-lasting but face problems when handling fluids with any kind of solid fines.

Positive displacement pumps move solid-laden fluids better but they have higher maintenance requirements and are not suitable for hazardous or toxic vapours.

Until now, handling hazardous and toxic fluids with solid particles have traditionally been moved using mechanically sealed pumps, with double mechanical seals, and an external flushing system, all of which require regular monitoring and could include costly additional ATEX instrumentation so we needed to find an alternative solution; something that is safe, reliable, and easy to maintain.

The introduction of the new solids handling mag drive pump is reinvigorating the industry; a centrifugal pump that can handle up to 30% solids with zero vapour loss. These pumps allow solid particulates to flow freely without blocking the system with an open impeller and specially designed diamond-coated SiC bearings which allow solids to pass through the pump. With this unit being magnetically driven

and zero vapour-loss, cross-contamination and expensive seal support systems are eradicated giving a cleaner, safer unit.

Manufactured by CDR Pumps, the new solids handling mag drives are available in stainless-steel or PFA-lined giving a wide range of chemical compatibilities.

T 01933 674777 sales@cdrpumps.co.uk www.cdrpumps.co.uk

significant area of growth for the company.

“The team at AGM have established a fantastic reputation for both service and technical capability and we are looking forward to welcoming them into the Stuart Turner family.”

Supported by private equity firm, Epiris, which invested in Stuart Turner in January of this year, the latest acquisition maintains the momentum as the company strives to become a complete solutions provider across the key market segments of Water Supply, HVAC, Drainage & Sewage and Service.

Contact: Morgan Warren-Ross, Marketing Director T +44 (0)1491 636736 morgan.warren-ross@stuart-turner.co.uk www.stuart-turner.co.uk

Surfex Review – Top Exhibitors

manage and distribute your SDSs and labels

Create,

SIAM S.L., Spain has been at the forefront of SDS Authoring & CLP/GHS Labelling Software development since 2007 using their innovative nature, automation drive and technical brilliance to offer the best possible solution and support services to its clients. The company was started as a response to the needs of the Chemical industry to comply with an ever-growing demand for global regulations, complex legislations, etc that form part of Chemical products with regards to Material Safety Data Sheet generation, Labelling, etc. SIAM is present in over 50 countries with thousands of clients covering several Chemical products, segments, and end-uses.

SIAM offers an ultra-modern, highly automated SDS Authoring Software (CHEMETER) in both installed and Cloud versions with loads of features and freebies. CHEMETER is easy-to-use, highly flexible, modular and above all a very competitive, tailor-made price for every budget backed by super-fast customer service. CHEMETER is available in over

60 world legislations. The software helps companies in reducing manual data entry, human errors whilst increasing productivity. Even users with minimum or no prior regulatory knowledge find it easy to work with the software. The pre-installed database with the software contains thousands of substances armed with H, P Statements, Pictograms, PhysicoChemical, Toxicological and Eco-Tox properties, Transport information plus loads of other information at a user’s fingertips. If your company or contacts are looking for an SDS Authoring Software coupled with an add-on solution for automatic SDS Distribution and Management, look no further!

Call or email today – Nirav Banker, Head of Business (UK, Asia & The Middle East) M +44 (0)7470 964875 n.banker@siam-it.com www.siam-it.com

An established & well-respected laboratory equipment supplier

Quantum Design International UK & Ireland Ltd is a global laboratory equipment manufacturer, and it distributes scientific and industrial instrumentation through an international network with subsidiaries in every major technological centre around the world.

QDUKI’s success in distributing scientific products is based on over 30 years’ experience in manufacturing and distributing its own industryleading materials characterisation system. It is an established and wellrespected supplier, and specialises in advanced scientific instruments for research in academic institutions, R&D departments, and company laboratories across the UK and Ireland.

QDUKI carries a range of products covering Ellipsometry, Hyperspectral Imaging cameras and Electron

Microscopy among other things, and its staff of passionate scientists work collaboratively with clients to find the best fit for their applications.

QDUKI recently exhibited at Surfex 2022 which was organised in recognition of the importance of keeping up to date with all aspects relating to innovation, development, and manufacture of coatings, paints, adhesives and an array of allied and associated industries. QDUKI are also

proud to be members of The Oil & Colour Chemists’ Association who coorganise the show.

On the stand, the key focus was on the J A Woollam alpha-SE ellipsometer which is a budget-friendly option for routine measurements of thin film thickness and refractive index in the visible spectral range. Patented technology allows accurate measurements on any substrate.

Visitors to the stand were invited to provide samples for measurement which proved to be very popular. This is an ongoing measurement service that can be provided by QDUKI and J A Woollam.

Contact: Shayz Ikram

T 44 (0)1372 378822 shayz@qd-uki.co.uk www.qd-uki.co.uk

Secondary printing (over-printing) onto linerless labels is now possible

Half the cost of adhesive labels is in the cost of the backing paper. Labels are offered ‘linerless’, ie. without backing paper, but instead there is a requirement for a release lacquer on the surface of the label.

This does not prevent a pre-printed label from being readable, but it will prevent it from being overprinted.

Silmark Ltd offers a solution.

Silmark manufactures special inks. Many of these inks change colour if they are heated, or are exposed to other sources of energy. Accordingly, secondary printing can be carried out using a direct Thermal printer to

activate a pre-coated patch of Silmark’s ‘Thermoprint’ ink. The thermoprint can change from white to black, or to one of several other colours.

Silmark also offers a similar system which uses a laser beam. This is noncontact & uses the light beam from a laser to produce a black (or other colour) image in a patch of special ‘Silmark’ ink. This system is capable of very high speeds.

Contact: Dr J Bannard (pictured)

T 0115 9229182

F 0115 8373556

jbannard@siltechlimited.com www.siltechlimited.com

Cuttingedge subsea technology

Winn & Coales International Ltd celebrates 140 years’ service to industry: 1883 - 2023

Winn & Coales International Ltd, leading manufacturer and supplier of corrosion prevention, waterproofing and sealing products, is celebrating its 140th Anniversary.

First established as an import/export house in London in 1883, the company has earned an enviable reputation for supplying highquality, effective, long-term solutions for its customers’ problems. Its well-known brands such as Denso Premier Archco Protal , Premier Shrink Sleeves , Steelcoat SeaShield and Sylglas provide effective

protection for buried, submerged, or exposed steel and concrete pipes, tanks, and structures. A vast number of industries benefit from the tailor-made solutions Winn & Coales provides, with the company demonstrating a clear commitment to continual improvement of its productoffering through innovative research and development, and product acquisitions – a notable example of which being Viscotaq visco-elastic coatings in 2021.

Today, Winn & Coales International Ltd.

comprises seven subsidiary companies – two in the UK, and one each in the USA, Canada, South Africa, Australia, and New Zealand –with multiple regional offices, and a network of global agents and distributors. The shared knowledge and experience across the group of companies ensure its extensive range of corrosion and chemical resistant coatings and linings are available almost anywhere in the world.

T 020 8670 7511 mail@denso.net

Cumbria based Digital Edge Subsea is a world leader in offshore digital video recording (DVR) and inspection systems. The company supplies the oil and gas industry with its digital video recording system that includes diving, remote operated vehicle (ROV) and topside operations.

Digital Edge Subsea’s products fit mainly into two categories, Subsea Robotics and Inspection Systems. The former includes both single and dual use modules as well as manipulators, which are high quality state of the art robotic solutions for the subsea market.

Digital Edge Subsea is also a market leader in producing subsea inspection systems, and with 10 years’ experience in the industry has nurtured strong customer relationships allowing for honest customer feedback which has been incorporated into the development of the Version 5 EdgeDVR.

The EdgeDVR has become an essential part of any ROV and Diving system offshore as it is easy to use and reliable. The new V5 software includes an online training platform and certification, as well as a powerful portable laptop version which comes in addition to the original 4U rackmounted version.

To work alongside this, Digital Edge Subsea has also recently released the Edge DVR Archive application. Edge Archive handles the transfer of data from the internal DVR drives to client storage, either on a NAS, a Raid, or a phased delivery to multiple external hard drives. Archive can act as a simple data mirror of the correct internal drive data folders or can be used to create multiple simultaneous backups of client deliverables. This can be done in continuous backup or a phased approach that is conducted after each dive.

Digital Edge Subsea now produces a range of products, and supply systems to many of the major offshore operators worldwide. The company is a trusted brand with a reputation for excellent support. With around 750 systems in use offshore, the company has a proven record of reliability.

For further information regarding Digital Edge Subsea, please contact: T +44 (0)1229 206456 info@digitaledgesubsea.com www.digitaledgesubsea.com

OFFSHORE DIGITAL VIDEO+INSPECTION SYSTEMS

INTRODUCING EDGEDVR

The EdgeDVR is currently used worldwide by most of the major ROV and Diving contractors. With our Version 5 software, we have 6 models. The EdgeDVR has become an essential part of any ROV and Diving system offshore, easy to use and reliable. The system is capable of recording simultaneous High Definition and Standard Definition video, together with auto creation of Dive, Video, Photo and Anomaly logs. Multi channel digital overlay is also available for all recorded channels, logos and realtime survey data can be displayed. With around 800 systems now offshore, we have a proven record of reliability.

Diving | Workclass & Inspection ROV Platform & Pipeline Inspections | Construction & Decomissioning

Watlow® completes acquisition of Eurotherm®