MOVING UP: CREATIVE DESIGN INTERIORS

EXPANDS CAPACITY WITH ROBOTIC TECH

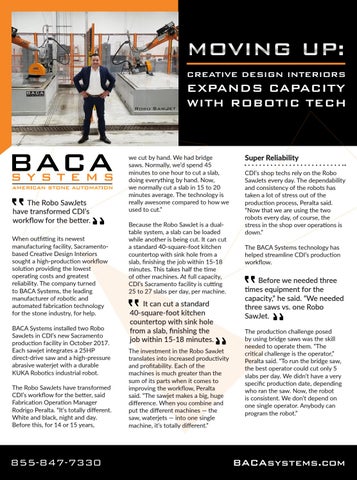

The Robo SawJets have transformed CDI’s workflow for the better. When outfitting its newest manufacturing facility, Sacramentobased Creative Design Interiors sought a high-production workflow solution providing the lowest operating costs and greatest reliability. The company turned to BACA Systems, the leading manufacturer of robotic and automated fabrication technology for the stone industry, for help. BACA Systems installed two Robo SawJets in CDI’s new Sacramento production facility in October 2017. Each sawjet integrates a 25HP direct-drive saw and a high-pressure abrasive waterjet with a durable KUKA Robotics industrial robot. The Robo SawJets have transformed CDI’s workflow for the better, said Fabrication Operation Manager Rodrigo Peralta. “It’s totally different. White and black, night and day. Before this, for 14 or 15 years,

we cut by hand. We had bridge saws. Normally, we’d spend 45 minutes to one hour to cut a slab, doing everything by hand. Now, we normally cut a slab in 15 to 20 minutes average. The technology is really awesome compared to how we used to cut.” Because the Robo SawJet is a dualtable system, a slab can be loaded while another is being cut. It can cut a standard 40-square-foot kitchen countertop with sink hole from a slab, finishing the job within 15-18 minutes. This takes half the time of other machines. At full capacity, CDI’s Sacramento facility is cutting 25 to 27 slabs per day, per machine.

It can cut a standard 40-square-foot kitchen countertop with sink hole from a slab, finishing the job within 15-18 minutes. The investment in the Robo SawJet translates into increased productivity and profitability. Each of the machines is much greater than the sum of its parts when it comes to improving the workflow, Peralta said. “The sawjet makes a big, huge difference. When you combine and put the different machines — the saw, waterjets — into one single machine, it’s totally different.”

Super Reliability CDI’s shop techs rely on the Robo SawJets every day. The dependability and consistency of the robots has taken a lot of stress out of the production process, Peralta said. “Now that we are using the two robots every day, of course, the stress in the shop over operations is down.” The BACA Systems technology has helped streamline CDI’s production workflow.

Before we needed three times equipment for the capacity,” he said. “We needed three saws vs. one Robo SawJet. The production challenge posed by using bridge saws was the skill needed to operate them. “The critical challenge is the operator,” Peralta said. “To run the bridge saw, the best operator could cut only 5 slabs per day. We didn’t have a very specific production date, depending who ran the saw. Now, the robot is consistent. We don’t depend on one single operator. Anybody can program the robot.”