MARTIAL ARTS CENTRE

PROJECT 1

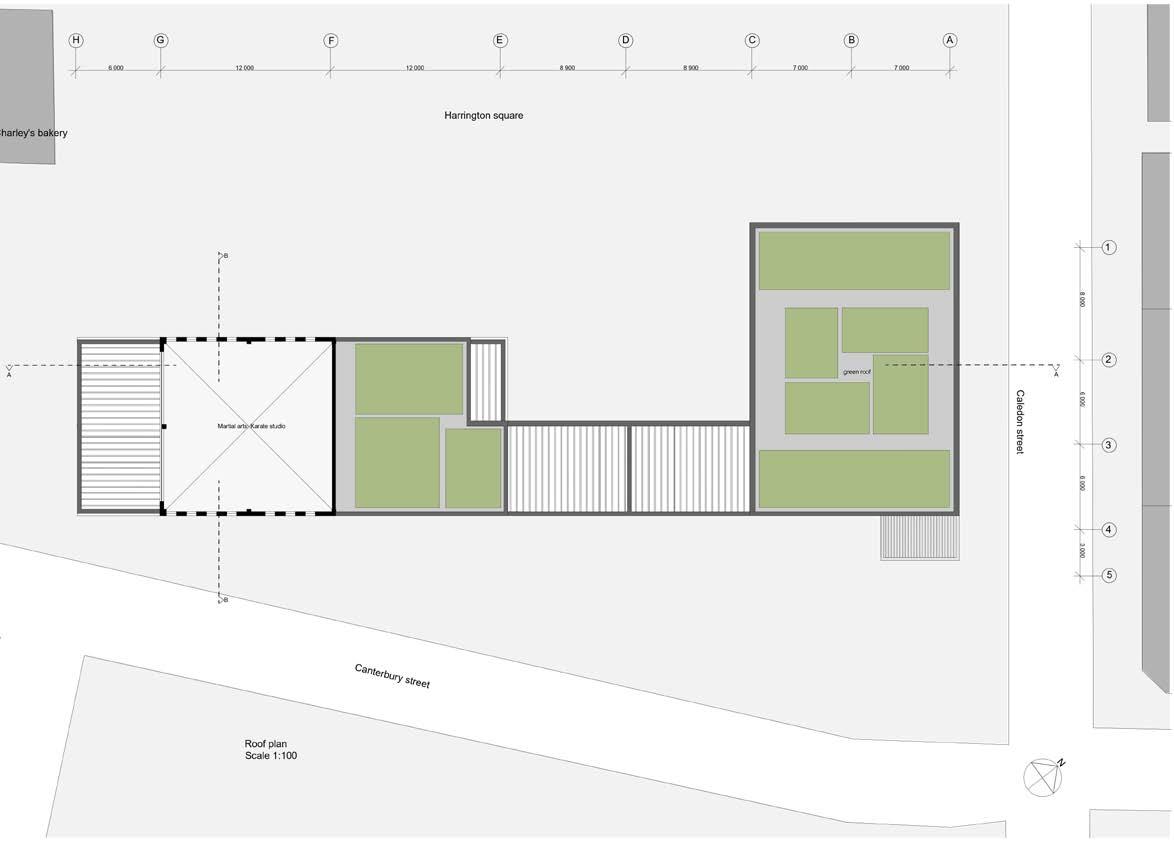

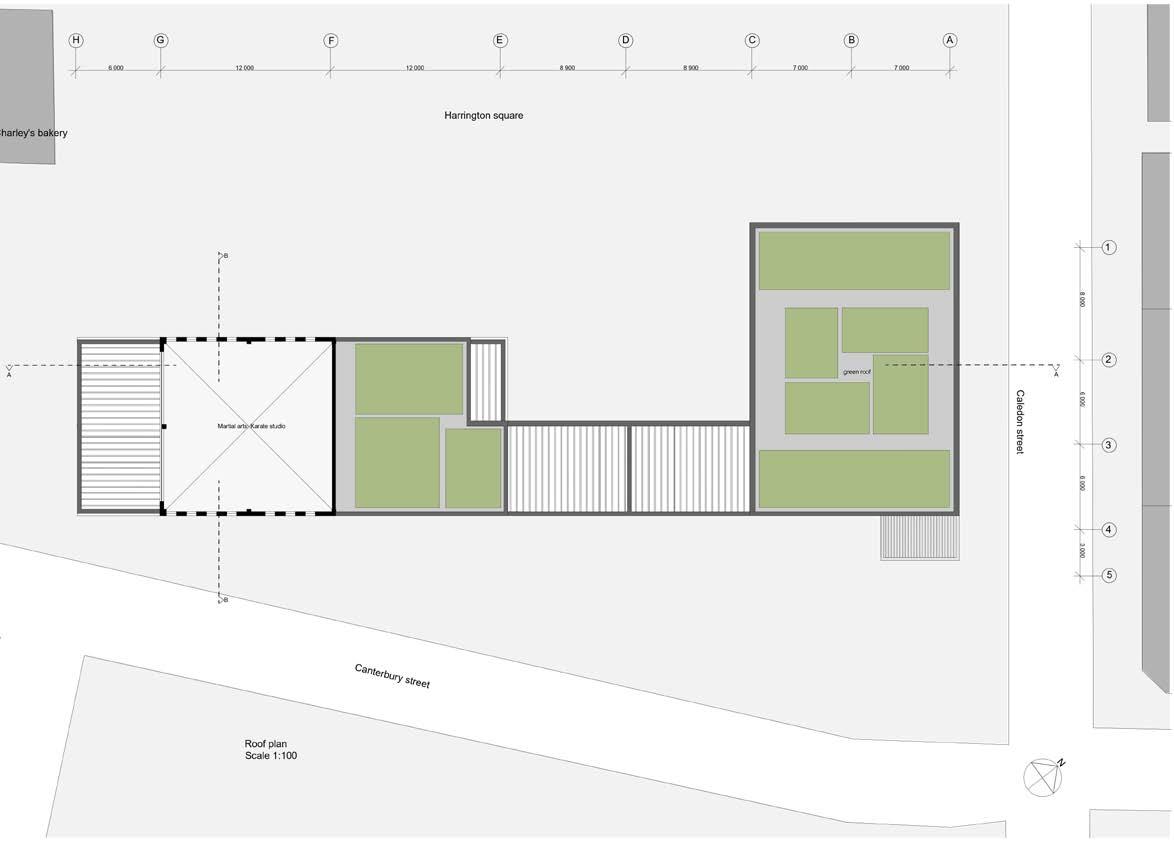

Proposed site location: Harrington square, Cape Town CBD

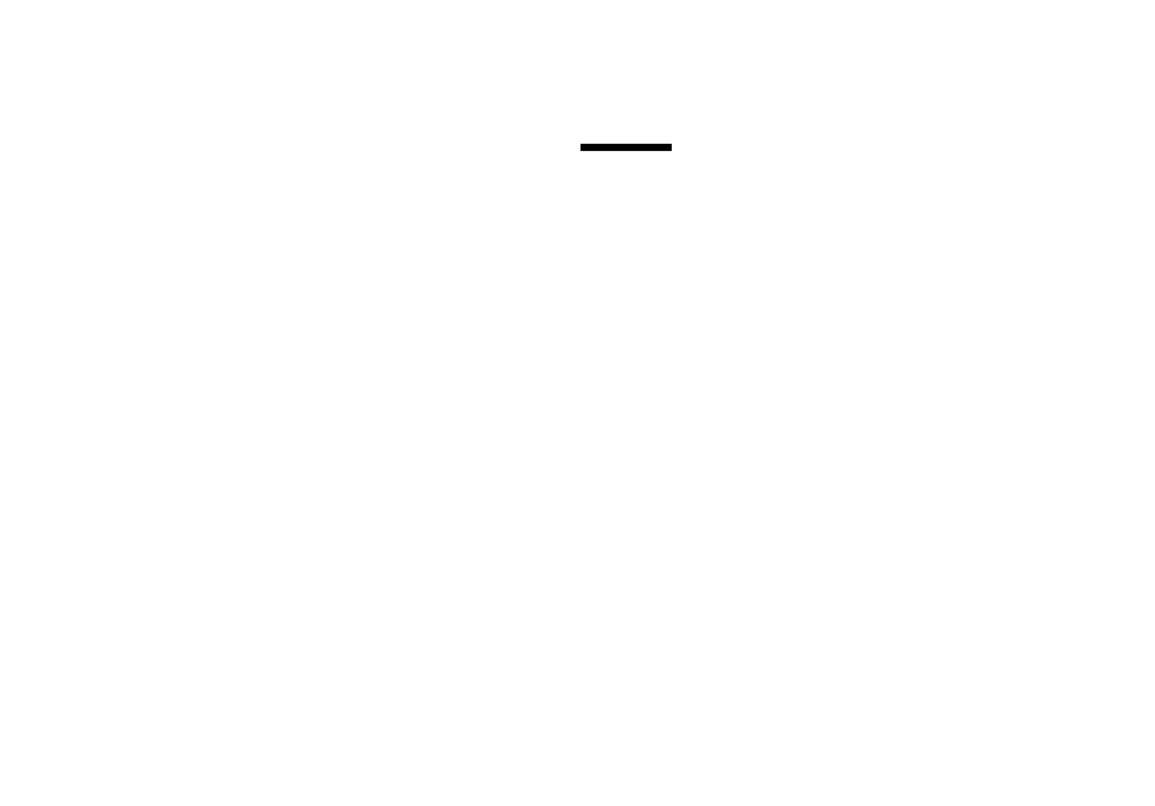

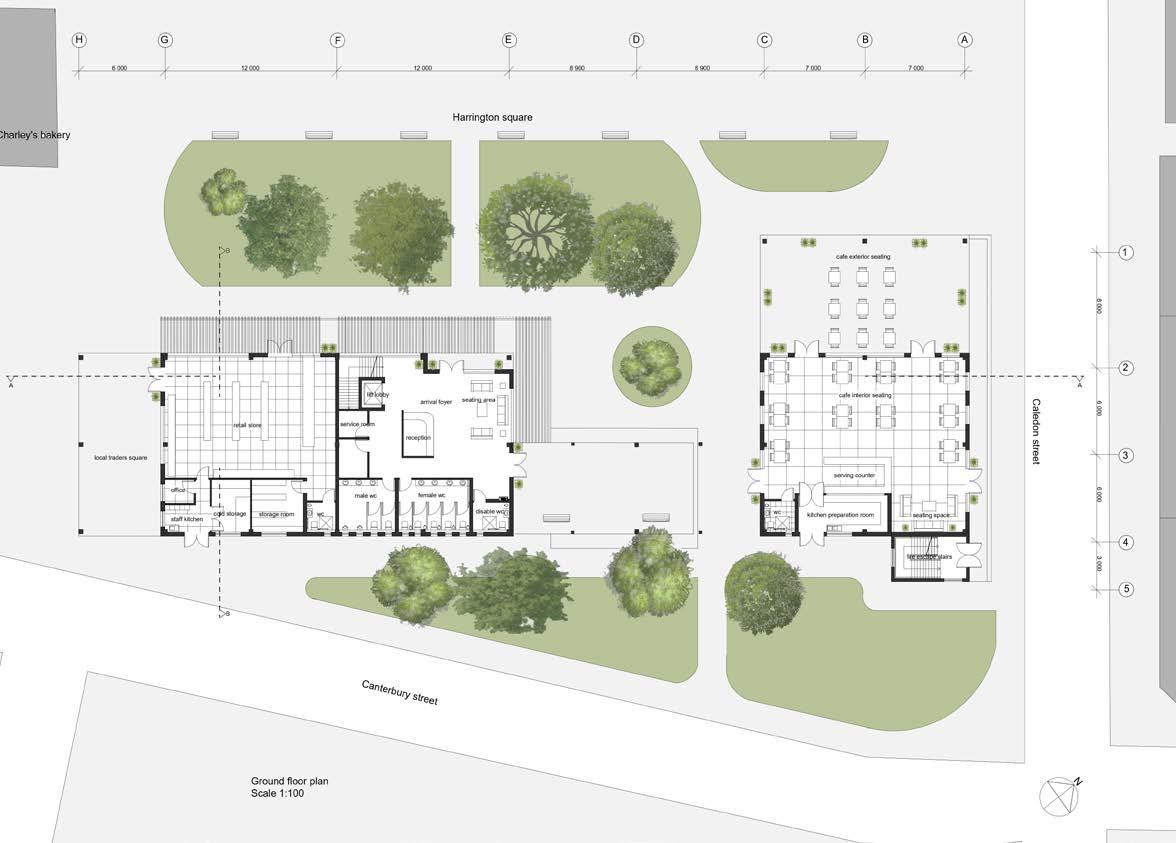

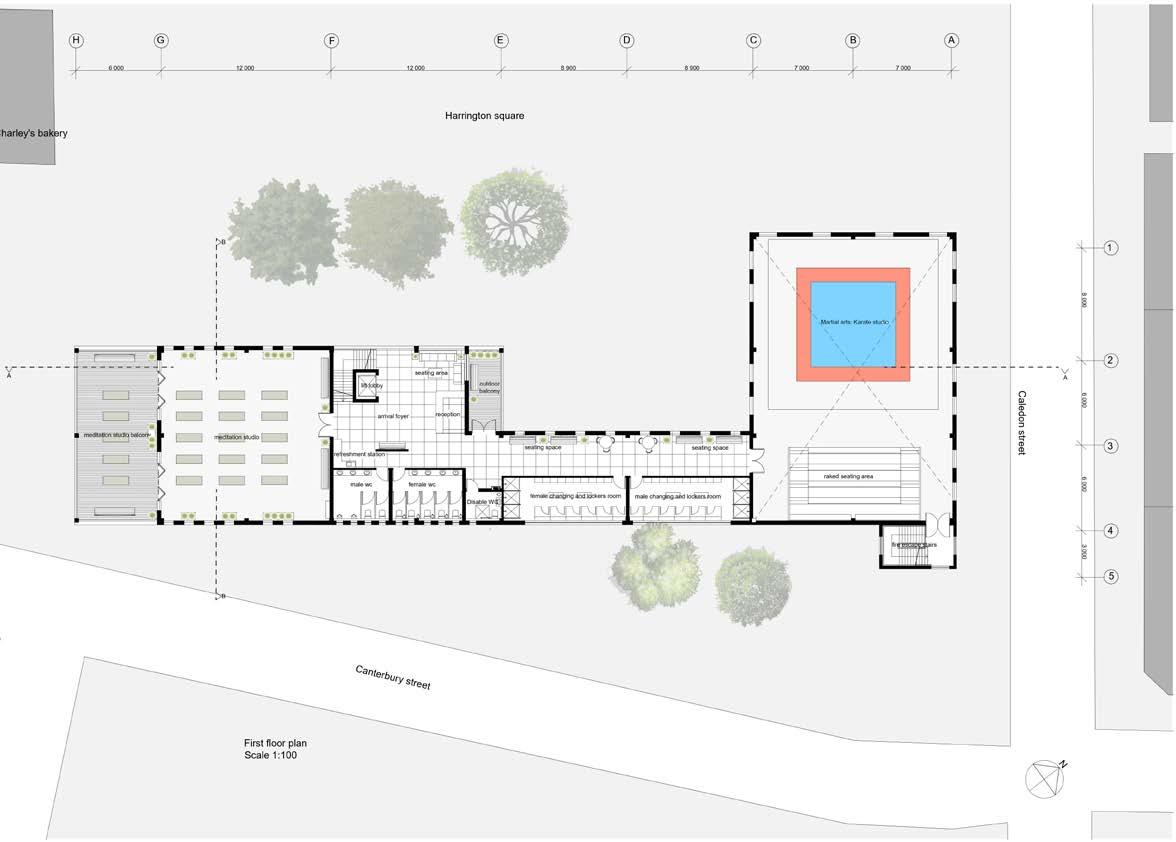

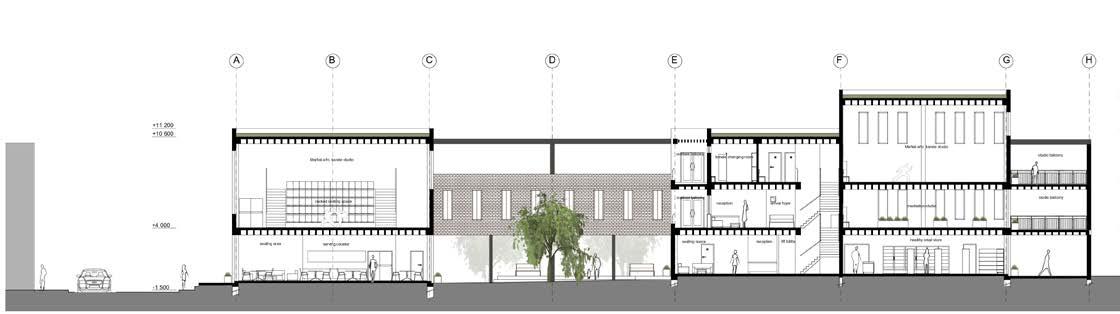

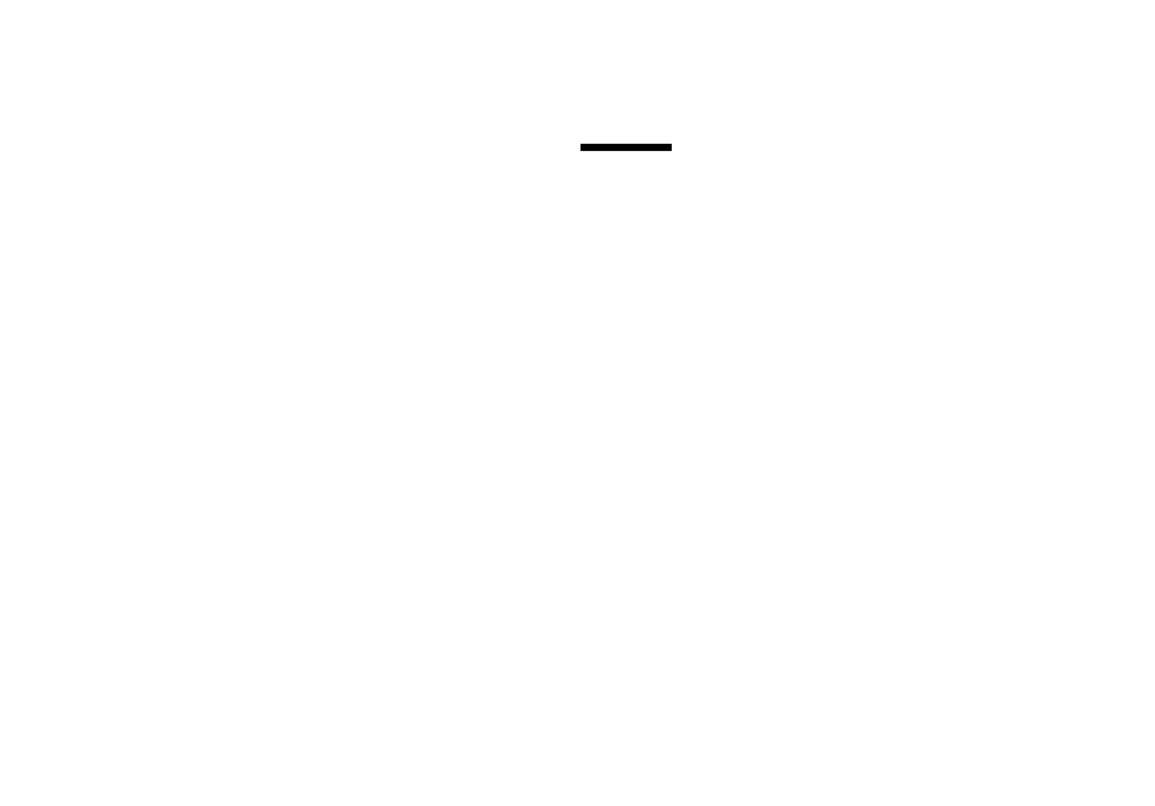

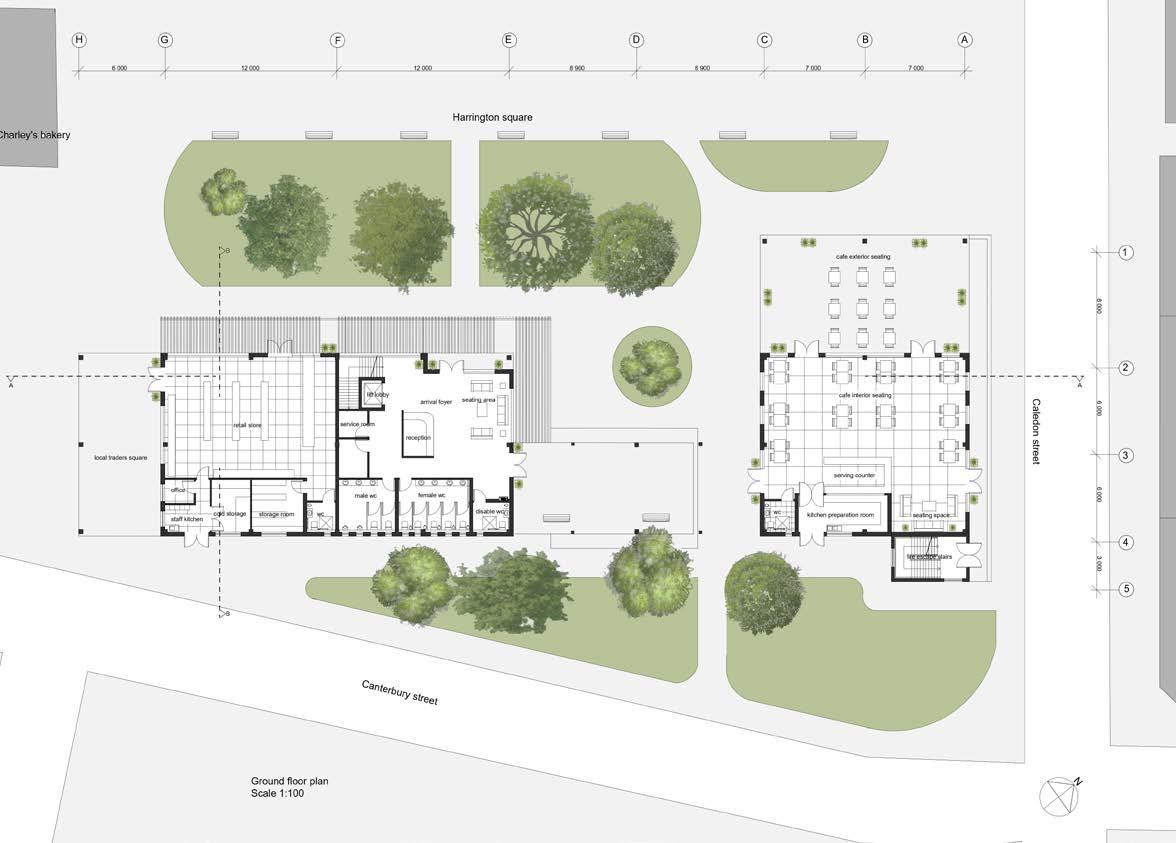

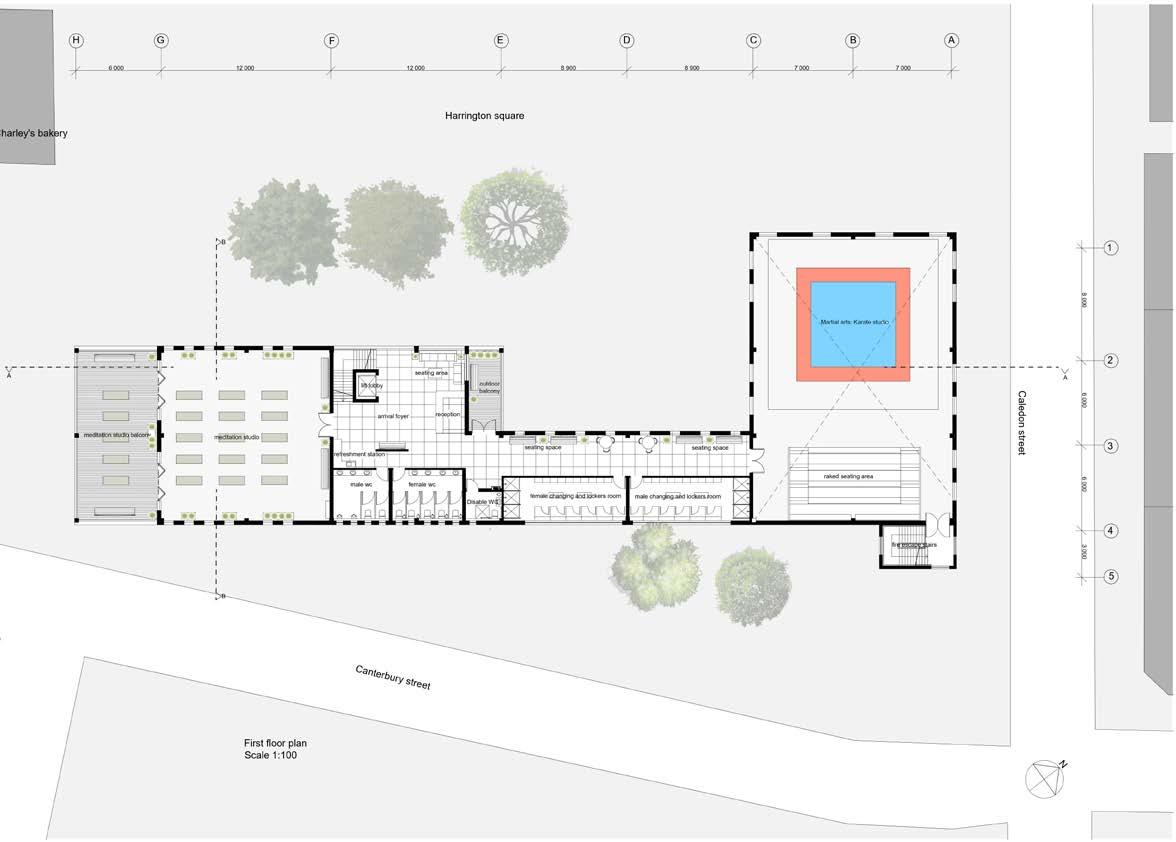

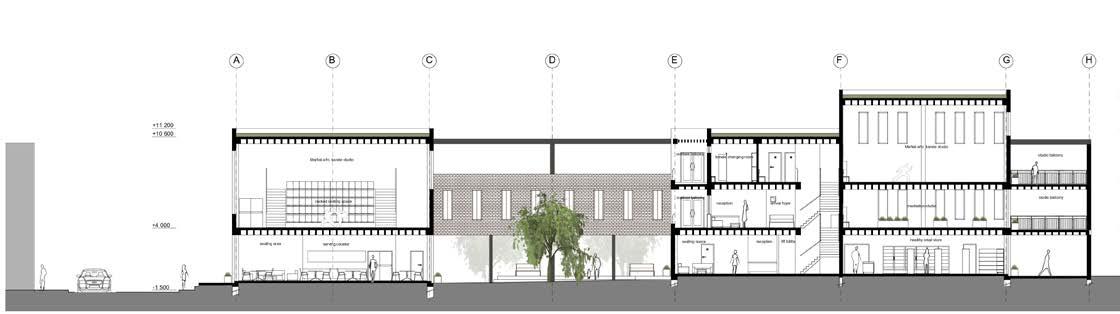

The Martial arts center is a mixed-use commercial building. The concep for the proposed building is 'Architecture of balance'. The ground floor area is designed for public access. The programme for the building provides for two martial arts studios and a meditation studio. On ground floor area a through route is located below the bridge connecting the two mass spaces. The design intention was to incorporate the mind and body of space with the interior spaces.

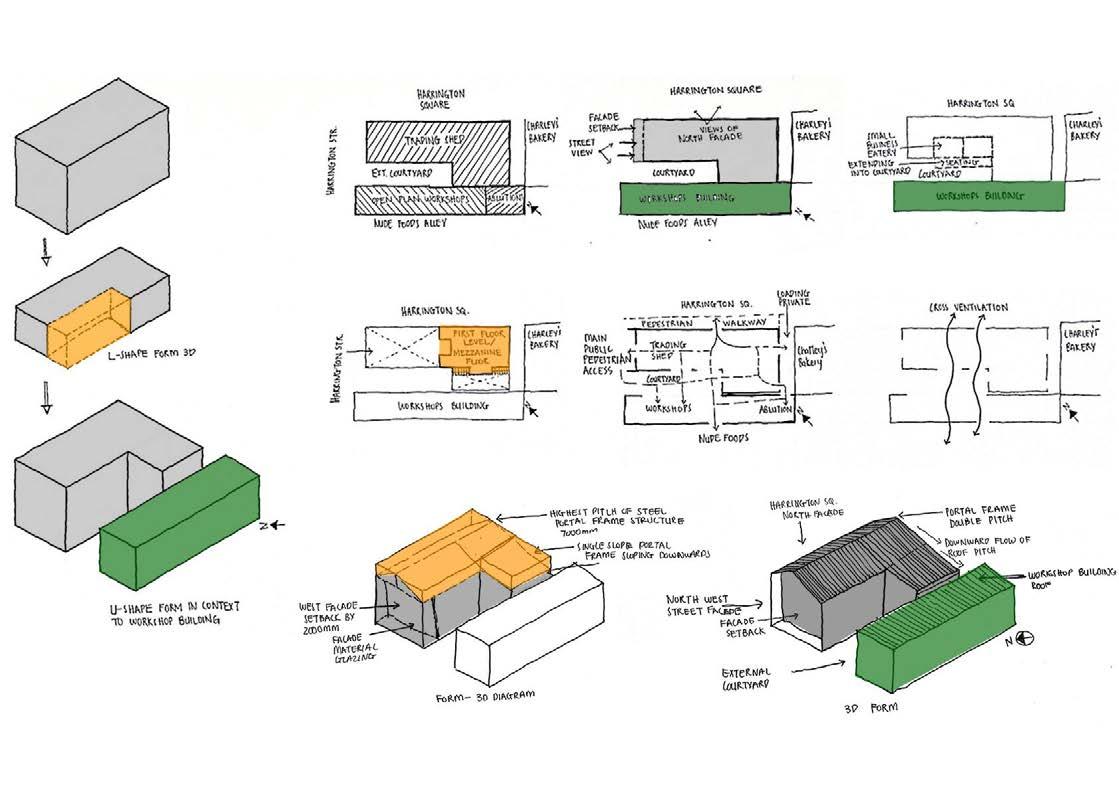

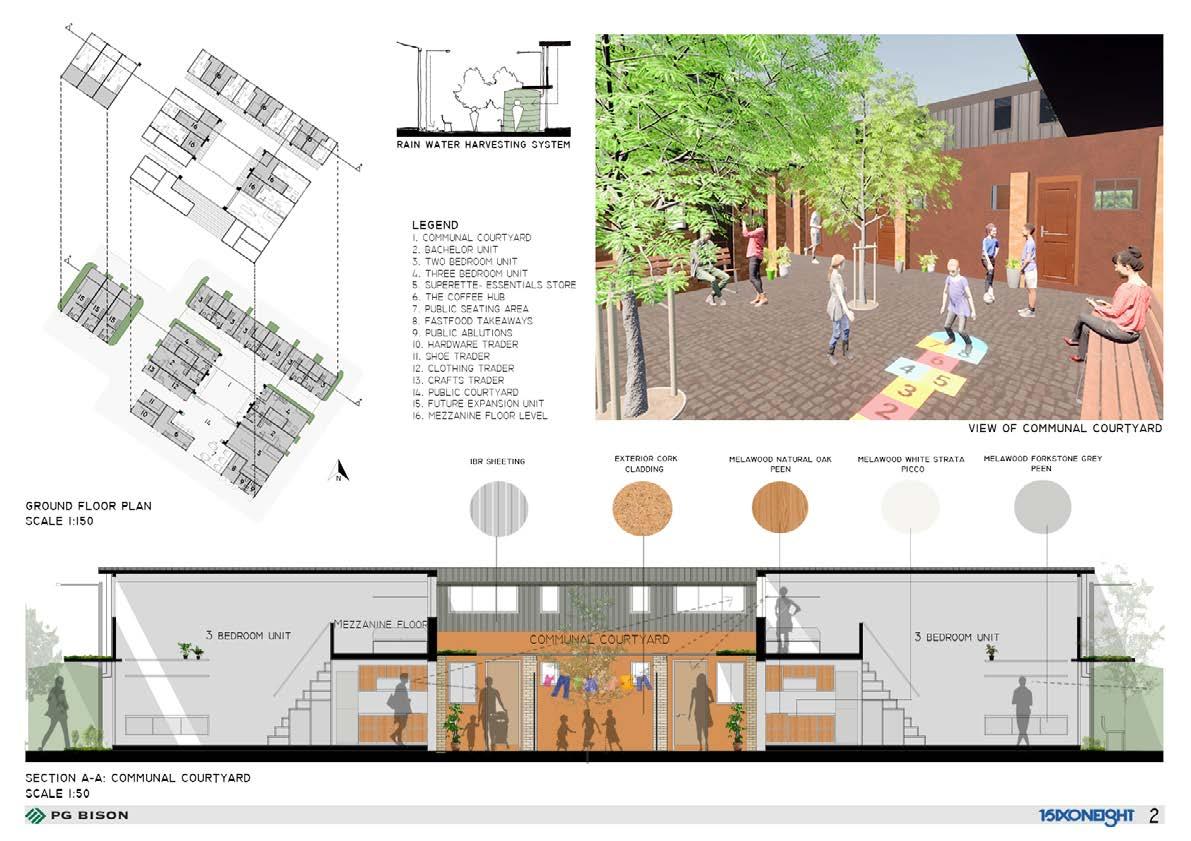

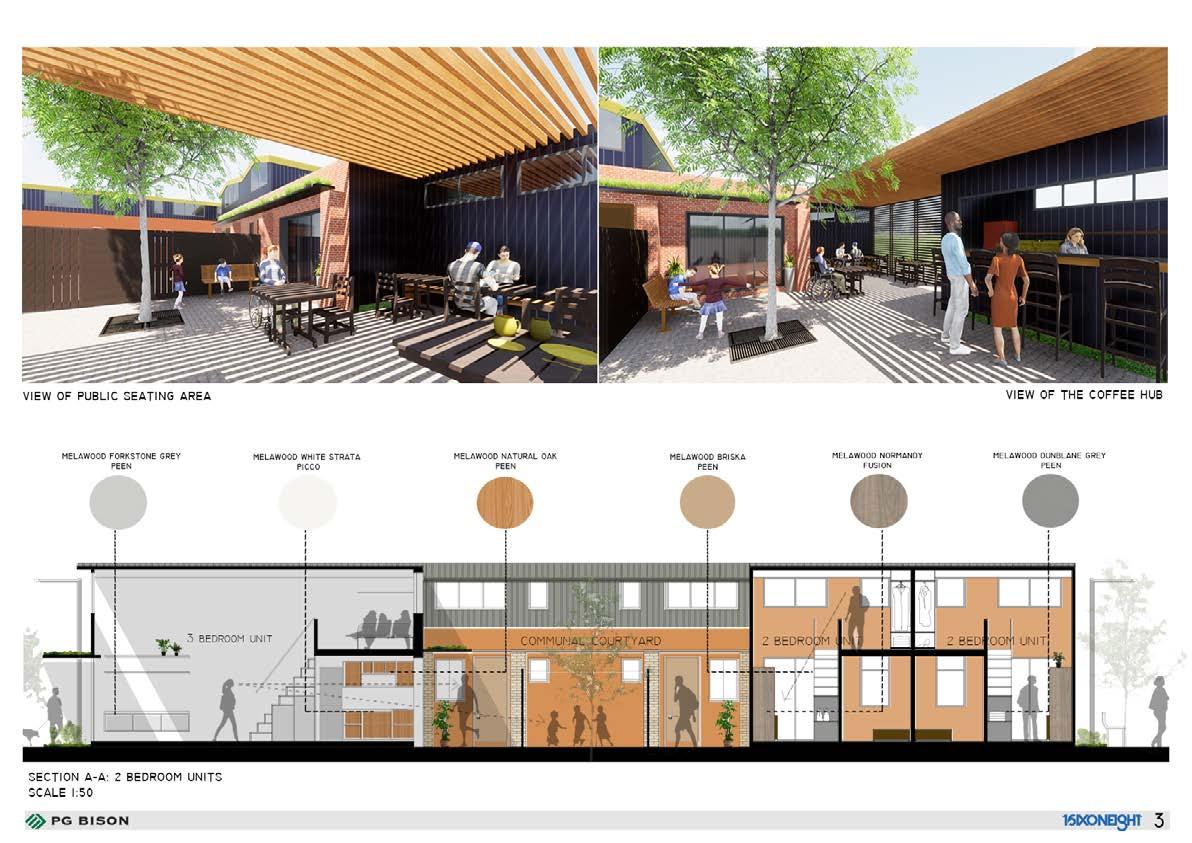

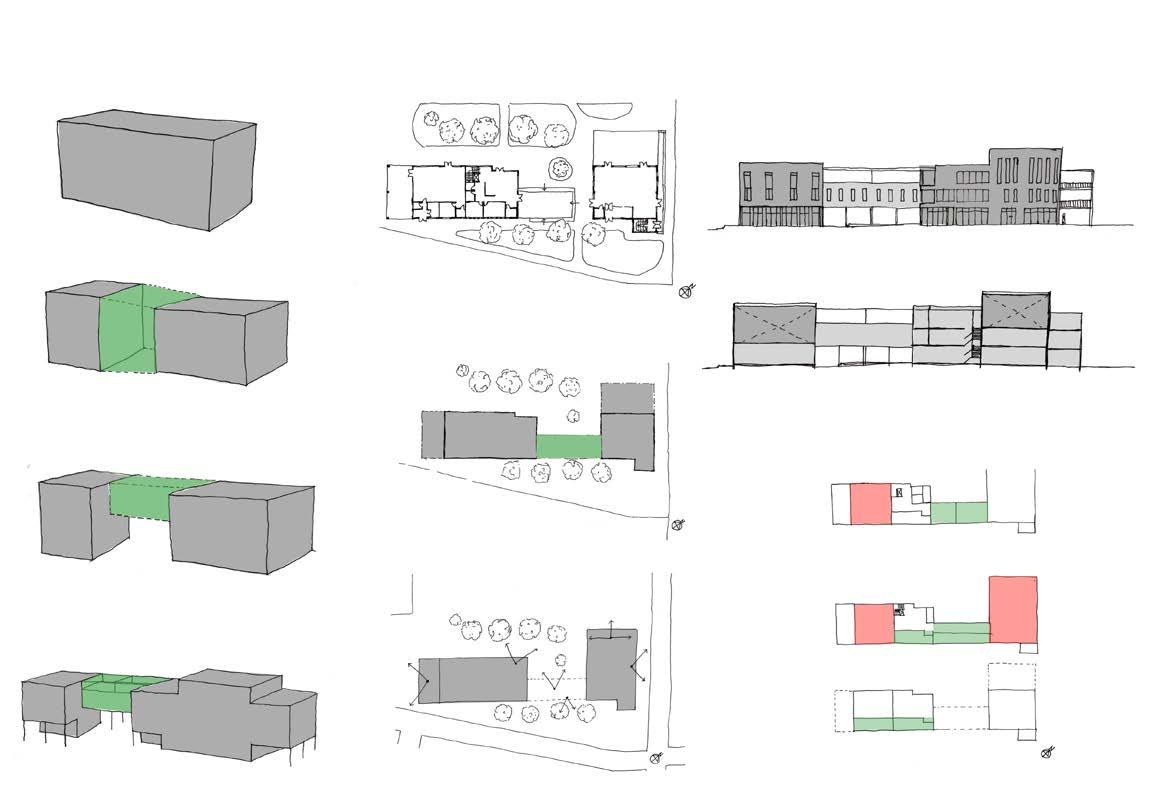

Sketch development and configuration

Sketch development and configuration

North Elevation Scale 1:100

Section A-A Scale 1:100

North Elevation Scale 1:100

Section A-A Scale 1:100

West Elevation Scale 1:100

Section B-B Scale 1:100

West Elevation Scale 1:100

Section B-B Scale 1:100

retail store storage room reception seating area male wc female wc disable wc cafe interior seating cafe exterior seating kitchen preparation room fire escape stairs lift lobby service room serving counter A B C D E G I J 1 2 3 4 5 Ground floor plan Scale 1:100 seating space 6 000 6 000 8 900 8 900 7 000 7 000 8 000 6 000 6 000 3 000 A A B B wc wc office cold storage staff kitchen arrival foyer Canterbury street Caledon street Harrington square N local traders square 6 000 6 000 6 000 H F North elevation Scale 1:100 -0 000 +3 500 TOC 1st floor level +6 800 TOC 2nd floor level +13 500 +4 000 TOC 1st floor -1 500 +10 600 TOC 3rd floor +11 200 A B C D E F I H J G 7 000 7 000 6 000 6 000 6 000 6 000 6 000 8 900 8 900 B B +12 900 TOC 3rd floor Drawing date: Drawing title: Scale: Project title: Institution: Course code: Student number: Name: Rev CAPE PENINSULA T4:CONCRETE REFERENCE 19/06/2022 General notes: Ground floor 300x300mm 110x50x110 Fire escape North elevation 00 01 02 22/05/22 30/05/22 16/06/22 19/06/22 03

TECHNICAL DRAWINGS

Cross Section B-B Scale 1:25

Retail store Storage room Meditation studio Martial arts: karate studio 30mm

150mm

DPM

150mm

(containing little

50mm

81mm overall

80X320mm concrete coping with 40mm overhang fixed on 110x75x220mm masonary brick wall (outer skin facebrick) 600 6 100 3 300 3 500 150

polished screed casted on

reinforced concrete floor slab casted on 50x1200mm isoboard closed cell insulation boards on 250 micron

layed on 50mm sand blinding layed on

layers of compacted earth fill

to no organic and clay material)

cavity infill between 110x75x220mm facebrick wall cladding fixed to 500mm RC slab with steel shelf angle

thickness of sprung sports hall hardwood flooring fixed on 50mm screed casted on 500mm RC waffle floor slab

Interior Exterior Interior Exterior 2 3 4 +150 TOC Ground floor level +3 500 TOC 1st floor level +6 800 TOC 2nd floor level +12 900 TOC 3rd floor level +13 500 6 000 6 000 0 NGL 40mm mulch plants fixed in 150mm planting soil layer fixed on geotextile filter fabric fixed on 8mm dimple sheet fixed on geotextile filter fabric fixed on fixed on 25x1200mm isoboard closed cell insulation fixed on Perma SEAL 20P Green roof drainage layer on Perma SEAL root barrier fixed on Bituminious waterproofing membrane torched applied on 50mm screed to fall 1:60 casted on Concrete waffle floor slab 50mm cavity infill

110x75x220mm

movement joint 3500mm slab-to-slab aluminum storefront glazing system with 122mm mullions and transoms 1100mm CTC distance 12.38mm laminated double glazing with thermal break bolted onto 420x460mm ground floor beam 710x2200mm aluminum glazing system with 122mm mullions and transoms 12.38mm laminated double glazing with thermal break 710x4500mm aluminum glazing system with 122mm mullions and transoms 12.38mm laminated double glazing with thermal break 710x2300mm aluminum glazing system with 122mm mullions and transoms 12.38mm laminated double glazing with thermal break 710x2200mm aluminum glazing system with 122mm mullions and transoms 12.38mm laminated double glazing with thermal break 1800x700mm aluminum window with 122mm framework 12.38mm laminated double glazing with thermal break Detail 1: Flat roof level Detail 2: Middle floor level Detail 3: Ground floor level 30mm polished screed to fall (1:60) casted on 150mm reinforced concrete floor slab casted on 250 micron DPM layed on 50mm sand blinding layed on 150mm layers of compacted earth fill (containing little to no organic and clay material) full bore corner outlet drainage connected to 75mm diameter stormwater downpipe Drawing Drawing Scale: Project Institution: Course Student Name: Rev CAPE PENINSULA T4:CONCRETE 19/06/2022 FULL General 00 01 02 03

between

facebrick wall cladding fixed to RC slab with steel shelf angle

80x320mm concrete coping with 40mm overhang fixed to 110x75x220mm masonary brick wall (outer skin facebrick)

40mm mulch plants fixed in 150mm planting soil layer fixed on geotextile filter fabric fixed on 8mm dimple sheet fixed on geotextile filter fabric fixed on fixed on 25x1200mm isoboard closed cell insulation fixed on Perma SEAL 20P Green roof drainage layer on Perma SEAL root barrier fixed on Bituminious waterproofing membrane torched applied on 50mm screed to fall 1:60 casted on Concrete waffle floor slab

full bore corner outlet drainage connected to 75mm diameter stormwater downpipe

Section detail 1: Flat roof level

Scale 1:5

710x2200mm aluminum glazing system with 122mm mullions and transoms

12.38mm laminated double glazing with thermal break

Section detail 2: Middle floor level

Scale 1:5

300x300mm RC column concealed by 50mm cavity infill between 110x75x220mm facebrick wall cladding fixed to RC slab with steel shelf angle

81mm overall thickness of sprung sports hall hardwood flooring fixed on 50mm screed casted on 500mm RC waffle floor slab

Exterior Interior

3500mm slab-to-slab aluminum storefront glazing system with 122mm mullions and transoms

1100mm CTC distance

12.38mm laminated double glazing with thermal break 420x460mm bolted onto ground floor beam

Movement joint

30mm polished screed casted on 150mm reinforced concrete floor slab casted on 50x1200mm isoboard closed cell insulation boards on 250 micron DPM layed on 50mm sand blinding layed on 150mm layers of compacted earth fill (containing little to no organic and clay material)

sealant and movement joint with weep holes to allow for head flashing drainage

steel shelf angle and continuous metal shelf angle flashing integrated with wall waterproofing

Section detail 3: Ground floor level Scale 1:5

Drawing date: Drawing Drawing title: Scale: Project title: Institution: Course code: Student number: Name: Rev Date AYESHA 219038740 2022_0_FT_AHT370S CAPE PENINSULA UNIVERSITY T4:CONCRETE STRUCTURE 19/06/2022 SECTION DETAILS: AS INDICATED General notes: 00 01 22/05/22 30/05/22 02 16/06/22 03 19/06/22

TECHNICAL DRAWINGS

North Elevation Scale 1:100

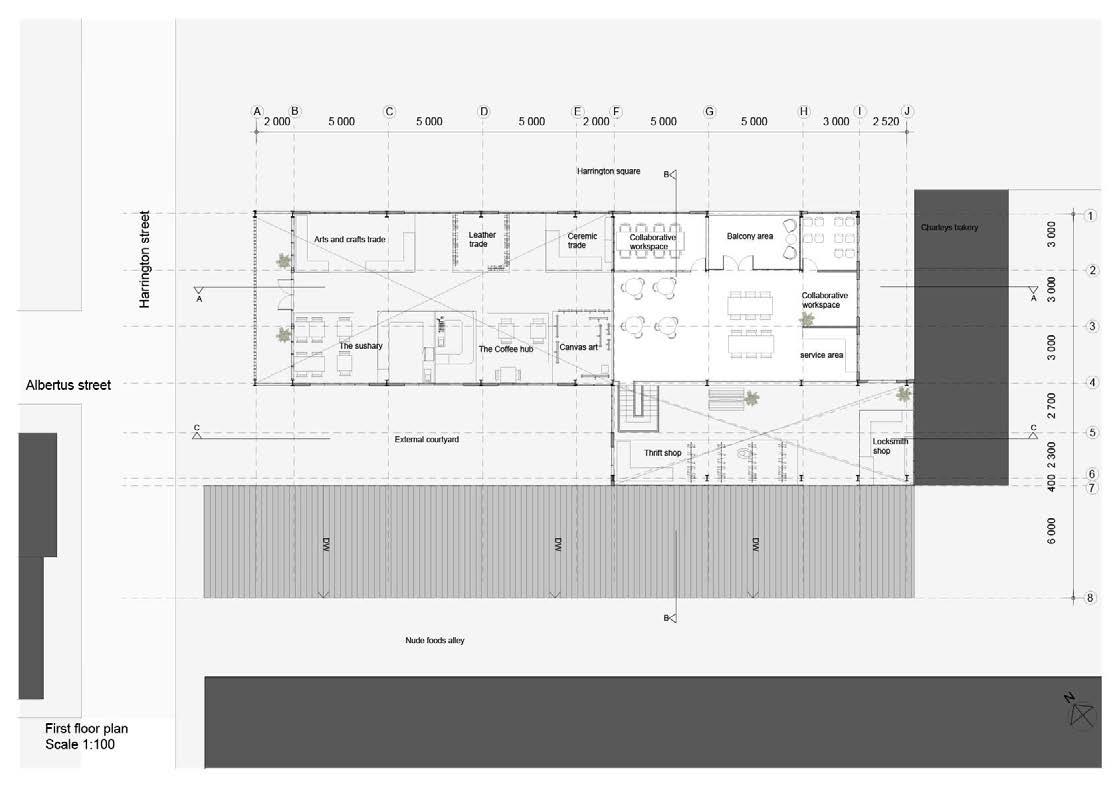

West Elevation Scale 1:100 Nude Foods alley +7 700 +6 700 +3 000 0 000 -1 300 Harrington square A A B West Elevation Scale 1:100 Nude Foods alley Rental space -1 300 +3 000 +7 700 +6 700 0 000 FFL GFL Harrington street square Balcony West entrance A B B West Elevation Scale 1:100

Section A-A (North West facade)

The sushary seating area Entrance facade setback Double volume area Mezzanine floor level Steel column level Roof pitch level Finish floor level Natural ground level (Concrete paving finish) Harrington street +7 700 +6 700 +3 000 0 000 -1 300 37x 725mm Galvinised steel with Chromadeck colour coated finish IBR metal roof sheeting bolted on Water proof vapor barrier on Rigid insulation board on 75x125mm CFLC steel purlins on 12mm plaster ceiling board 165x300mm exposed portal frame I-beam rafter 12mm plaster board interior wall vertical supported by 75x125mm CFLC sheeting rail bolted below 165x300mm steel portal frame I-beam rafter 75X125mm CFLC sheeting rail flush joint supporting interior 12mm plasterboard wall and exterior 37x725mm IBR metal cladding facade Isotherm insulation placed between 75x125mm CFLC vertical sheeting rails 30mm polished screed flooring on 150mm concrete floor slab on DPM on 50mm Sand blinding on 150mm Compacted earth fill 150mm concrete floor slab constructed between 380x380mm concrete ground beam on stub column on pad foundation (depth specified by engineer) 115x200mm Steel beam bolted between 165x300mm steel portal frame structure on 100x3600mm Patent glazing facade system Flexi sealant between 100x3600mm Aluminium patent glazing facade system and 115x200mm steel I-beam connected above 1500x2100 Aluminium frame glazed door 30x1800mm Timber louvers bolted by 55x55mm angle cleats between 165x300mm steel portal frame columns 30x115x2 400mm Timber louvers bolted by 40x60x100mm angle cleats between 165x300mm steel portal frame and 115x 200mm steel I-beam Rod bracing between 165x300mm steel portal frame columns for structural stability 2 400 200 200 2 100 200 300 690 125

Scale 1:20

Section B-B (North East facade)

Scale 1:20

Printing services Scan Email Fax / Photocopy/ Printing

Collaborative workspace Printing shop Pedestrian walkway Roof pitch level +7 700 Steel column level +6 700 Mezzanine floor level +3 000 Detail 3 0 000 Natural ground level (Concrete paving slabs finish) -1 300 Harrington Square 37x 725mm Galvinised steel with Chromadeck colour coated finish IBR metal roof sheeting bolted on Water proof vapor barrier on Rigid insulation board on 75x125mm CFLC steel purlins on 12mm plaster ceiling board 165x300mm exposed portal frame I-beam rafter 12mm plaster board interior wall vertical supported by 75x125mm CFLC sheeting rail bolted below 165x300mm steel portal frame I-beam rafter and 75x 125 CFLC studs at 600mm c/c 75X125mm CFLC sheeting rail flush joint supporting interior 12mm plasterboard wall and exterior 37x725mm IBR metal cladding facade Isotherm insulation placed between 75x125mm CFLC vertical sheeting rails 30mm polished screed flooring on 150mm concrete floor slab on DPM on 50mm Sand blinding on 150mm Compacted earth fill 150mm concrete floor slab constructed between 380x380mm concrete ground beam on stub column on pad foundation (depth specified by engineer) Flexi sealant between 75x125mm CFLC sheeting rails and 1500x2100 Aluminium frame glazed door 1 260 1 400 200 2 100 200 120 300 700 Flexi sealant between 75x125mm CFLC sheeting rails and 50x1 400mm Aluminum frame window 30mm concrete screed floor finish on 75x120mm Trapezoidal concrete floor bolted on 115x200mm steel I-beam bolted between 165x300mm steel portal frame I-beam columns 75X125mm CFLC sheeting rail flush joint supporting interior 12mm plasterboard wall and exterior 37x725mm IBR metal cladding facade Isotherm insulation placed between 75x125mm CFLC vertical sheeting rails 120x 180mm concealed box gutter on Waterproof vapor barrier on Rigid insulation board on 75x125mm CFLC steel purlins on 165x300mm exposed portal frame I-beam column Detail 2 Detail 1

Detail 1:

Concealed roof gutter detail

Scale 1:5

30mm polished screed flooring on 150mm concrete floor slab on DPM on 50mm Sand blinding on 150mm Compacted earth fill 150mm concrete floor slab constructed between 380x380mm concrete ground beam on stub column ) on pad foundation (depth specified by engineer)

Detail 3:

Concrete floor slab detail

Scale 1:5

Galvinised steel with Chromadeck colour coated finish IBR metal roof sheeting bolted on Water proof vapor barrier on Rigid insulation board on 75x125mm CFLC steel purlins on 6mm plaster ceiling board 165x300mm exposed portal frame I-beam rafter

Detail 2: Trapezoidal floor detail

30mm concrete screed floor finish on 75x120mm Trapezoidal concrete floor bolted on 115x200mm steel I-beam bolted between 165x300mm steel portal frame I-beam columns

Scale 1:5

Exterior Interior Interior Exterior Rev Date Name: Student Number: Course Code: Institution: Project Title: Scale: Drawing Title: Drawing Date: Drawing General Notes: 11/11/2022 STRIP T2- PART B STEEL CAPE PENINSULA UNIVERSITY 2022_0_FT_AHT370S AYESHA 001 11/11/22

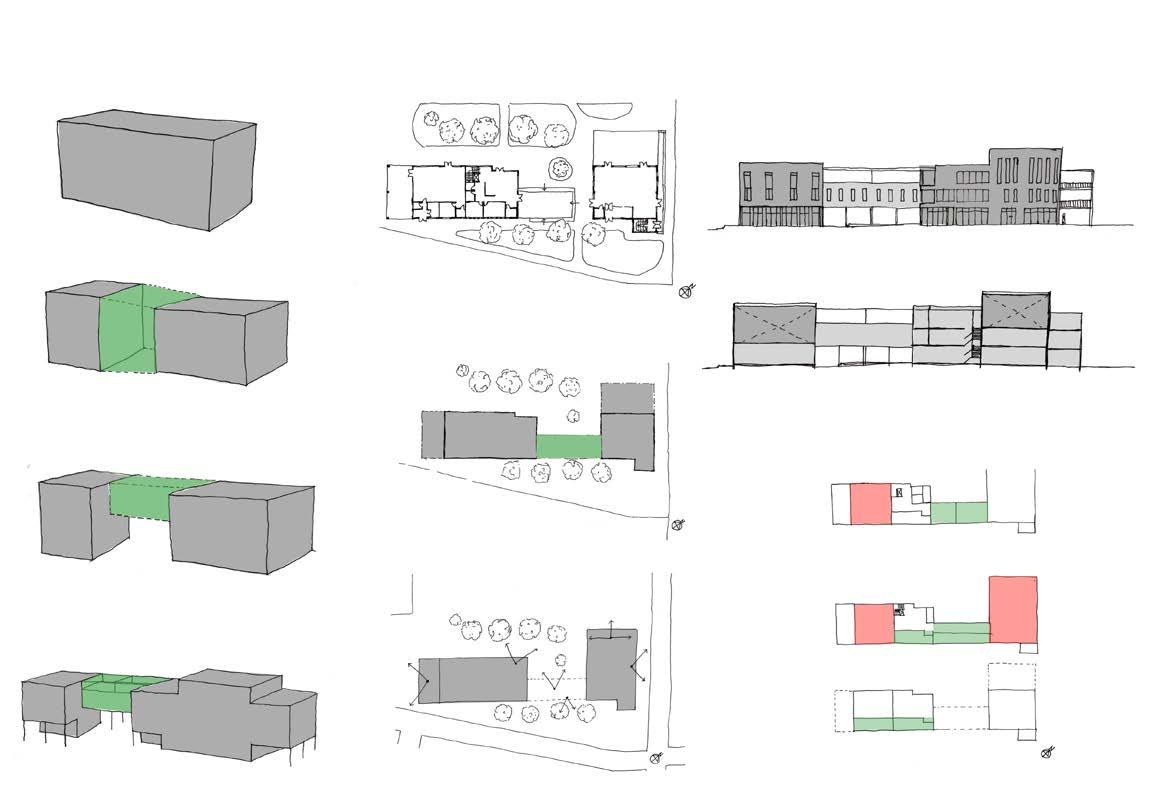

Sketch development and configuration

Sketch development and configuration

North Elevation Scale 1:100

Section A-A Scale 1:100

North Elevation Scale 1:100

Section A-A Scale 1:100

West Elevation Scale 1:100

Section B-B Scale 1:100

West Elevation Scale 1:100

Section B-B Scale 1:100