AWAIS AHMED

Y3

01 WUDU BOCHORD

‘THE WOODEN LIBRARY’

LOCATED:

Worchester Car Park, Oxford, UK

FUNCTION:

Multi-Functional Library to facilitate students, staff and local.

PROJECT BRIEF:

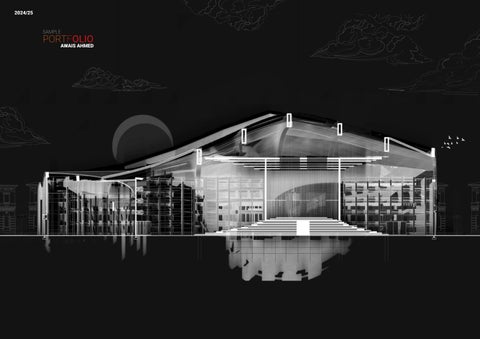

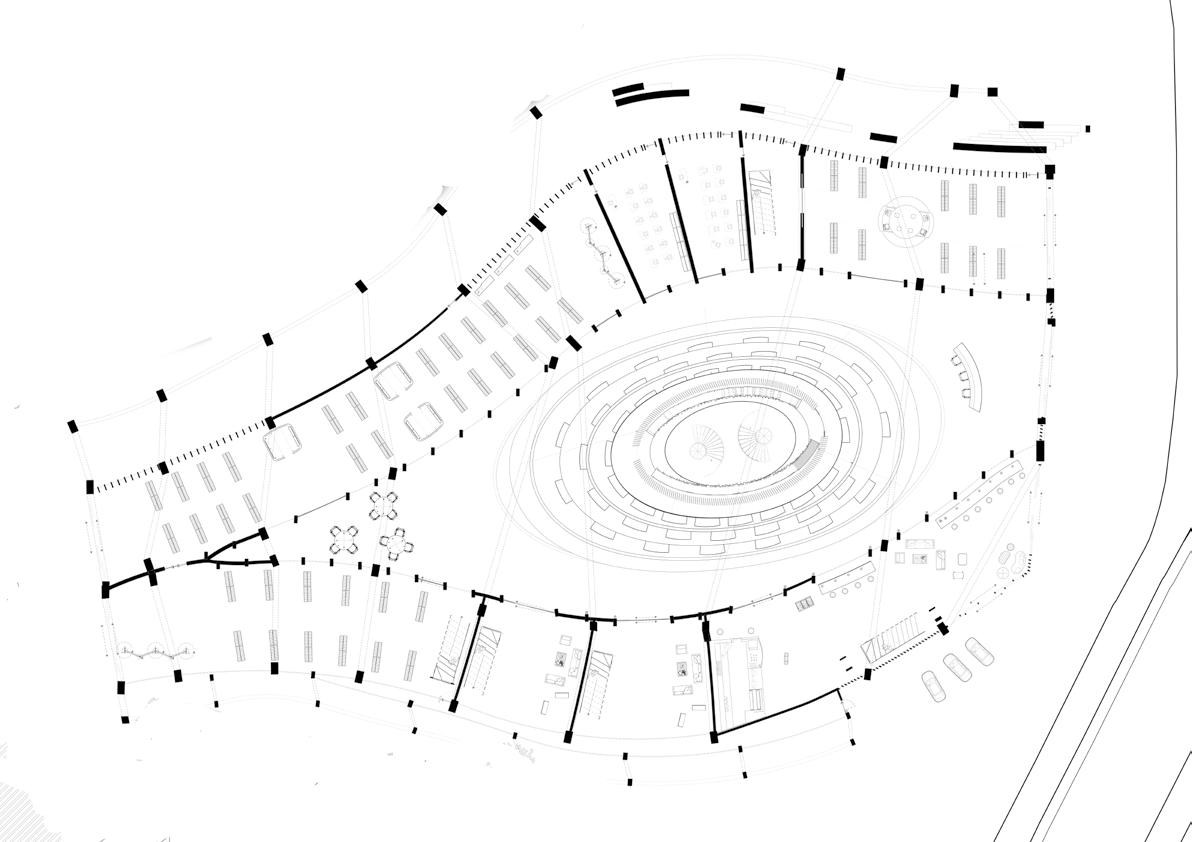

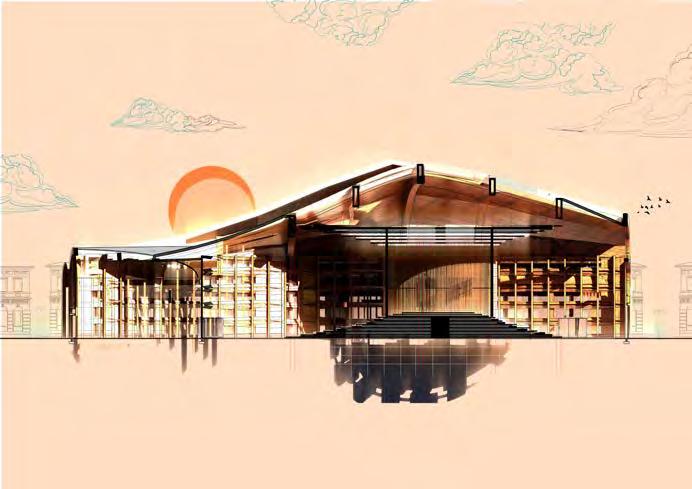

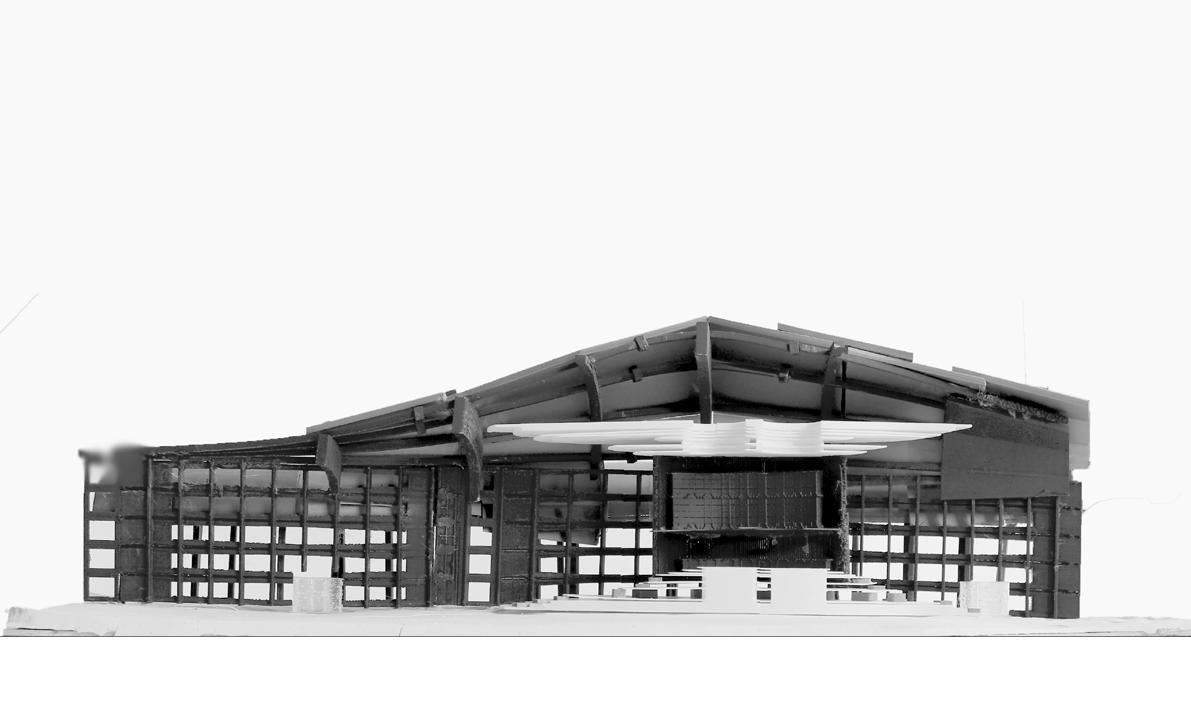

Wudu Bochord, also known as ‘The Wooden Library’ Located in Oxford, this project replaces the existing Worcester Street car park with a dynamic multipurpose library that bridges public and private realms. Designed to serve both the local community and university students, the library offers open public spaces alongside quieter, more secluded study areas. Drawing inspiration from the Taijin Library’s spatial organisation and the British Library’s rich interior language, the design fosters a sense of openness.The roof structure takes cues from EMBT’s organic train station designs, introducing a sculptural, light filled canopy.

Wudu Bochord is a solution to remove an overly saturated car park with a space which serves both the purpose for the Locals and Students attending there respective university with Educational andversatile facilities.

EXTERIOR PERSPECTIVE OF THE COLONADE:

The project is wrapped around 4 colonades, housing different functional needs..

ARIEL PERSPECTIVE OF THE WOODEN LIBRARY:

The Wooden Library

WUDU BOCHORD ‘THE WOODEN LIBRARY’

PROJECT BRIEF: CLT TIME

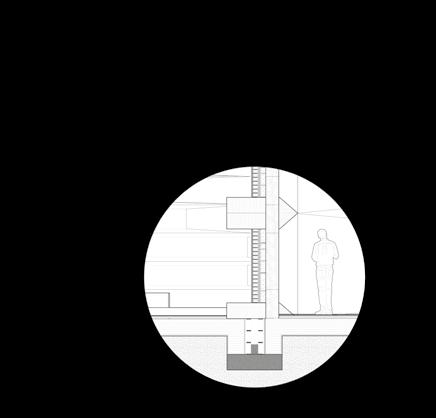

TECHNICAL

This technical report will dive into an on going project to create a Library in Oxford, replacing Worcester Car Park. As mentioned, due to the nature of the project, the focus of this technology report is to find wether the functionality of materials used in the structure and experimenting with different structural needs using Timber and CLT production, can create a mass supporting roof structure.

The project aims for this design is to be able to build Timber supported and designed roof structure throughout a massive building structure. To be able to understand the different uses of Timber and how it can be adapted to fit my project.

CNC production of timber frames ensures precision and efficiency in structural woodwork. The process begins with design and preparation, where CAD software is used to create digital models, which are then converted into CNC-compatible instructions.