ATHESISREPORT

Submitted by SIVASHAKTHIR

Reg.no:723818251057

in partial fulfillment for the award of the degree of BACHELOROFARCHITECTURE IN ARCHITECTURE

SASICREATIVESCHOOLOFARCHITECTURE COIMBATORE–641032

(AffiliatedtoAnnaUniversity,Chennai)

ANNAUNIVERSITY:CHENNAI600025

BONAFIDECERTIFICATE

Certificate that this project report “TEXTILE HUB @ KARUR” is the is the bonafideworkof“SIVASHAKTHIR”whocarriedouttheprojectworkunder thesupervision.

Prof.ManinderSingh Ar.N.Dhinesh DIRECTOR SUPERVISOR AssistantProfessorINTERNALEXAMINAR

EXTERNALEXAMINAR

ACKNOWLEDGEMENT

It’s my pleasure to present the thesis report undertaken during B.Arch. X semester. I would like to express my sincere gratitude and appreciation to the individualswhohaveplayedasignificantroleinthesuccessfulcompletionofmy thesis.

IwouldliketoexpressmywholeheartedgratitudetomyguideAr.Dinesh.N whoshowedmethewaywithhisvaluableinputsandsuggestions.Hisexperience andguidancehelpedme,motivatedandinspiredthroughoutthisjourney.Iwould like mention my special thanks and extend gratitude to my thesis coordinator Ar.PrasathandAr.Gajalakshmifortheirvaluableinputs.andsuggestions. Also expressmythankstotheinternalreviewcommitteefortheirvaluableadviceand guidancethroughoutthisjourney.

Iwouldalsoliketospecialthanksto myDadand myfamily asa wholefor their continuous support and understanding when undertaking my project Your prayerformewaswhatsustainedmethisfar.

Finally,IwouldIlketothankGod,forlettingmethroughallthedifficulties. I have experienced yourguidancedaybyday.Youaretheonewholet me finish mydegree.Iwillkeepontrustingyouformyfuture.

ABSTRACT

The proposedTextile Industrial Hub in Karur will act as a focal point for a varietyoftextile-relatedactivities,suchasproduction,R&D,design,andtraining. The hub will establish an environment that is favourable to innovation, skill development, and business growth by bringing together producers, suppliers, designers,researchers,andentrepreneursunderoneroof.

The objective of the project is to bring the awareness among the textile industriesofKarur.Thisprojecthelpsonbetterunderstandingontheconceptand workflowofthetextileindustryamongthedistrictsofTamilNaduandalsohelps toreducetheproductioncostofthefabricperunitmeter.

This project also addresses theunemployment andworkersmigration.The maingoalistounderstandthespacesoftextileindustryandbuildingtheindustry climateresponsive.

Overall,creatingatextileindustrialhubinKarurhasenormouspotentialto promotethesector'sexpansion,innovation,andsustainability.

LISTOFFIGURES

FIGURE1DESIGNMETHODOLOGY(SOURCE:AUTHOR).........................................2

FIGURE2WORKFLOW(SOURCE:AUTHOR)............................................................2

FIGURE3PRODUCTSMANUFACTUREDATKARUR(SOURCE:PARADIGM INTERNATIONAL)..............................................................................................3

FIGURE4CARCEMAL TEXTILEFACTORY(SOURCE:ARCHDAILY).........................3

FIGURE5CARCEMAL-GROUNDFLOOR(SOURCE:ARCHDAILY)...........................4

FIGURE6CARCEMAL-FIRSTFLOOR(SOURCE:ARCHDAILY)................................5

FIGURE7CARCEMAL-SECTIONS(SOURCE:ARCHDAILY)......................................6

FIGURE8CACEMAL–INTERIOR(SOURCE:ARCHDAILY)........................................6

FIGURE9GIANTTEXTILE(SOURCE:CONTEXTBD)...............................................7

FIGURE10GIANTTEXTILE-GROUNDFLOOR(SOURCE:CONTEXTBD).................8

FIGURE11GIANTTEXTILE-EASTELEVATION(SOURCE:CONTEXTBD)................8

FIGURE12GIANTTEXTILE–WATERTREATMENTPLANT(SOURCE:CONTEXTBD)8

FIGURE13PARADIGMINTERNATIONAL(SOURCE:AUTHOR)..................................9

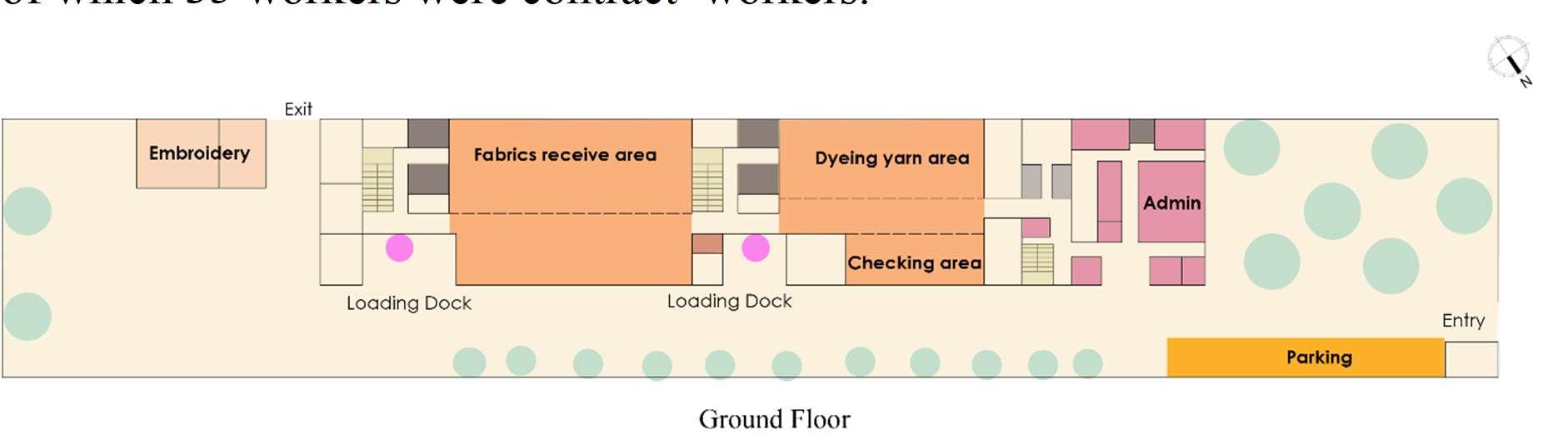

FIGURE14PARADIGM-GROUNDFLOOR(SOURCE:AUTHOR)...............................9

FIGURE15PARADIGM-FIRSTFLOOR(SOURCE:AUTHOR)..................................10

FIGURE16PARADIGM-SECONDFLOOR(SOURCE:AUTHOR)..............................10

FIGURE17PARADIGM-CHECKINGUNIT(SOURCE:AUTHOR).............................11

FIGURE18PARADIGM-STICHINGUNIT(SOURCE:AUTHOR)...............................11

FIGURE19TAMILNADUMAP(SOURCE:TNDATABASE).....................................13

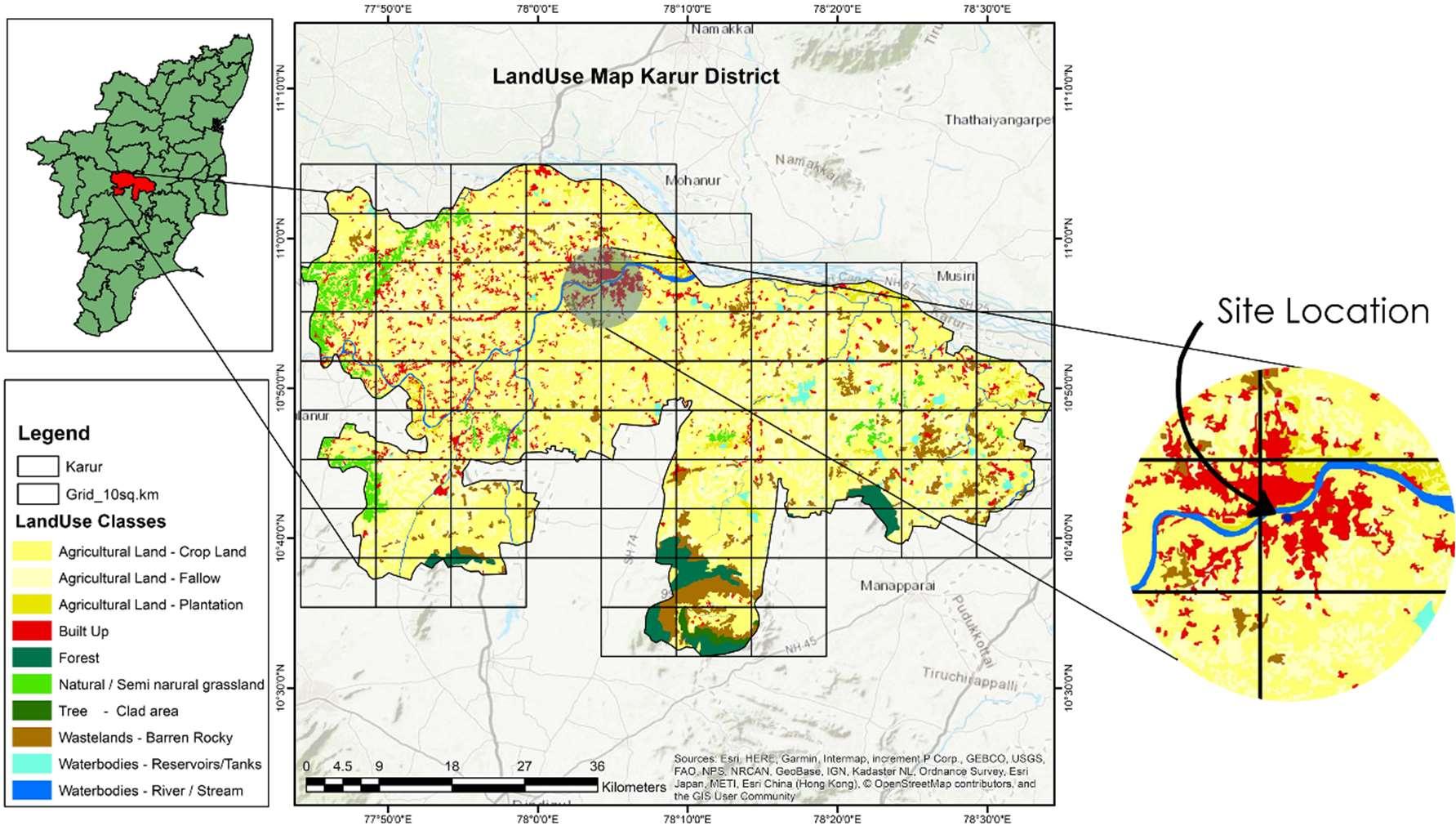

FIGURE20LANDUSEMAPOFKARUR(SOURCE:KARURDATABASE)...................14

FIGURE21SITE(SOURCE:AUTHOR)....................................................................15

FIGURE22CLIMATEDATA(SOURCE:METEOBLUE).............................................16

FIGURE23WINDROSE(SOURCE:METEOBLUE)..................................................16

FIGURE24SITEIMAGE-VIEW1(SOURCE:AUTHOR)..........................................17

FIGURE25SITEIMAGE-VIEW2(SOURCE:AUTHOR)..........................................17

FIGURE26SITEIMAGE-VIEW3(SOURCE:AUTHOR)..........................................17

FIGURE27USERACTIVITY(SOURCE:AUTHOR)..................................................26

FIGURE28PROXIMITY(SOURCE:AUTHOR).........................................................26

FIGURE29BUBBLEDIAGRAM(SOURCE:AUTHOR)..............................................27

FIGURE30SITEZONING(SOURCE:AUTHOR).......................................................28

FIGURE31CONCEPT(SOURCE:AUTHOR)............................................................29

FIGURE32LOUVRES(SOURCE:GOOGLE)............................................................29

FIGURE33SCIOGRAPHY-6:00AM(SOURCE:AUTHOR).......................................29

FIGURE34SCIOGRAPHY-12:00PM(SOURCE:AUTHOR).....................................30

FIGURE35SCIOGRAPHY-6:00PM(SOURCE:AUTHOR).......................................30

FIGURE36CONCEPTUALSECTION(SOURCE:AUTHOR).......................................30

FIGURE37SITEPLAN(SOURCE:AUTHOR)...........................................................31

FIGURE38MASTERPLAN(SOURCE:AUTHOR)....................................................32

FIGURE39ADMINGROUNDFLOOR&FIRSTFLOOR(SOURCE:AUTHOR).............33

FIGURE40DYEINGBLOCKGROUNDFLOOR(SOURCE:AUTHOR).........................33

FIGURE41WEAVINGGROUNDFLOOR(SOURCE:AUTHOR)..................................33

FIGURE42PACKING&STACKGROUNDFLOOR(SOURCE:AUTHOR)...................34

FIGURE43TOILET&DINNINGGROUNDFLOOR(SOURCE:AUTHOR)...................34

FIGURE44SECTIONAA(SOURCE:AUTHOR).......................................................34

FIGURE45SECTIONBB'(SOURCE:AUTHOR)......................................................35

FIGURE46NORTHELEVATION(SOURCE:AUTHOR).............................................35

FIGURE47SOUTHELEVATION(SOURCE:AUTHOR)..............................................35

FIGURE48EASTELEVATION(SOURCE:AUTHOR)................................................35

FIGURE49VIEWS(SOURCE:AUTHOR).................................................................36

1.Introduction

The Textile Industry in India is the most followed traditional occupation after agriculture and this is the only industry which generates employment for boththeskilledandtheunskilledlabours.

Textileindustryisthesecondlargestindustryemploymentgenerationsector inIndiawhichprovidesemploymenttoover35millionpeople.

"Nocountryiseversuccessfulinthelongterm.withoutareallystrongand Vibrantmanufacturingbase"

- AlanMulally1.1Aim

To design a hub for Textile Industry which consists of all the units of thetextileproduction

1.2Objectives

TodesignahubforTextileIndustrywhichresolvestheproblemsfaced bytheproductionlineandtheworkers.

To address thedemand for textile workers across Tamil Naduthrough aninnovativearchitecturalsolution.

1.3ScopeandStudy

Tamil Nadu ranks 2nd in the Textile Industry in terms of percentage contribution by state in the total industrial output of respective industriesinIndia.

20%contributiontoIndia’stotalExportofReadymadeGarments

Constitutes 28% of total employment in India’s textile and Apparel sector.

1.4 NeedforHub

Anyhow KARURhas its own manpower and textile units, it depends on the other districts like Thirupur, Erode, Nammakal, Coimbatore, etc.,fortheprocessofspinning,dyeing,weaving,printing,embroidery, etc.,

Ahugeamountofenergyandtimeisspentonthetransportationofthe goodsfromonedistricttoother.

The energy spent on the transportation can be used on the production processofthegarmentswhichleadtoenergysavings.

1.5Methodology

Stage1

Scopeand

Feasibilitystudy

Problem identification

FramingAimsand

Objectives

Backgroundstudy

Datacollection

Stage2

Casestudiesand literaturestudies

Inference

Sitestudy

Analysisand comparison

Stage3

Revisingand Reviewingthe objectives

Detailedproject areaand assessment

Conceptand preliminarydesign development

Stage4

Developingdesign andfinalizingthe floorplans

Presentation drawings

Model

3Ddrawing

Designassessment

1.6WorkFlowinTextileIndustry

Stage1involvesthebuyingofthe threadfromtheseveraldistrictslike Coimbatore,Dindukaletc.,thenit wasprocessedintofabric.

Stage2involvesthedyeingprocess wherethethreadsaredyedinto specificcoloursaccordingtoend product.

Stage3involvestheprocessof weavingthedyedthreadintoa fabricofnmeterlength.

Stage4theweavedclothisthen stitchedintoseveralthinglike kitchentowel,napkins,outdoor linenetc.,ofappropriatesizeand shape.

Stage5involvesthequalitycontrol check,thenthedamagedfabricsare recycled/retreatedintogoodquality fabric.

Stage6involvespackingofthe finishedgoods.

2.CaseStudy

2.1CarcemalTextileFactory,Barelos,Portugal(Literature)

Architects:Proj3ct

Area:4142m²

Manufacturers:Saint-Gobain,Arconic,CIN,Sanindusa,Sosoares

ThesiteislocatedinBarcelos,industrialtownintheNorthofPortugal.It referstoanexistingindustrialcomplexcomposedbytwoindustrialpavilionsand technicalareas,detachedfromeachotherandplacedoveran8775m2area.The existingbuildingsaretwostoryhighonthefrontsidefacingtheentrance, gatheringallmainpublicandofficeareas,whiletheremainingareasweresetto theproductionandstorageprocesses.Theexteriorareaswereessentiallysetto parkingareaswithnarrowstripsofvegetationandtwoentrancegates.The topographyiscomposedbytwoplainplatforms,linkedbyarampinbetween pavilions.Thesiteishometoatextilemanufacturingcompanyandallthe installationswerelicensedandfullyoperational.

Figure5Carcemal-GroundFloor(Source:Archdaily)

ThebuildingsisG+1onthefrontsidefacingtheentrance,gatheringallmain publicandofficeareas,whiletheremainingareasweresettotheproductionand storageprocesses.

Ithasthreemajorzonesaspublic,Production,Stack.Themajormaterials usedissteel,concreteandwood.

Thedesignofthefaçadesandexteriorspaceswereguidedbytheconcepts ofunityandformalhomogeneity,leadingtoanoverlayofanewskininwavy perforatedmetalsheetsalongtheexistingexteriorwalls.Theform,textureand permeabilityofthisskinrelatestothefabrics,primarymaterialtothecompany. Thisformalanalogyisthenusedintheinteriorspaces,mainlyintheoffice moduleslocatedintheproductionareasandstorageareas.

The goal was to renew, re-organize and expand a set of functional areas due to the limited and constricted spaces and disconnected areas. The overall design implied a complex and intense task of correct and adjust the functional layout, optimizing and updating all work areas towards a more efficient and articulated set of services. Our approach was to enforce a sense of identity, creating a uniform pattern of construction solutions and coating materials to assure spatial coherency, and to enhance the visual correspondence between the functionalareas.

2.2 GiantTextileLtd.,Gazipr,Bangladesh(Literature)

BuiltupArea-22662m2

SiteArea-40115 m2

Architect- Binyasharchitects

Manufacturers-GiantTextileLtd.,

The Major role of this textile industry is to provide the woven cloth to the next stage of the production. Giant Textile Ltd. has several factories where the stitchingandotherprocessarehappening.

Giant Textile Ltd., is a factory complex comprised of a Production Facility building, Utility building, Bonded Warehouse and ETP. The industry is for knitting, dyeing and finishing. Total site area is 5.6 acre while actual building footprintis553,012ft2 approx.

The large and simple brick building dominates the whole campus. Preengineeredbuilding systemhelpedtocompletethe ‘ProductionBuilding’within nine months. The shape of the roof aids air flow over the structure instead of obstructing. Interplay of transparency and solidity has eliminated the monotony ofthecontinuingfaçadeofthefactorybuilding.

The whole complex is naturally ventilated, thus the height of the building posedahugeadvantageincreatingaveryspaciousandcomfortableenvironment fortheworkers.

Thisindustryhasawatertreatmentplantofareaplantofarea350m2which

2.3ParadigmInternational,Karur,TamilNadu(Live)

BuiltupArea-15000m2

SiteArea-21200m2

About30%ofthespaceisusedforcirculation

ParadigmInternationalisoneofthelargesttextileindustriesofKarur,which hasthecapacitytoproduce2500m/dayapprox.withthehelpof165workersout ofwhich35workerswerecontractworkers.

ListofspacesinParadigmInternational:

AdministrationArea

oMDroom

oAccountsDept.

oBPO(BusinessProcessOutsourcing)

oProductionDept.

oSamplingDept.

Apparels

oPrinting

oEmbroidery

StitchingUnit

Gudown

YarnStorage

FabricStorage

InspectionRoom

SampleDisplayArea

CheckingArea

PackingArea

StaffDinning

Parking

CommonToilet

Roplant

Pumproom

Ironingroom

AsitisoneofthetextileindustriesofKarurwhichonlythethreemajorunits oftheindustry,madeittodependonothersfordyeingandweavingprocess.

It has stairs for every 25 m and it has only one service lift at the middle of thelongitudinalbuilding.As thebuildingis longitudinalitmakesthecirculation ofthegoodsmorecomplexthanusual.

ThebuildingorientationisofNW–SEdirectionwhichreducestheamount of sunlight getting into the building, requires more artificial lighting to all the spaces.Eachandeverysectionoftheindustryneedsgoodnaturallightingtosee theexactcoloursoffabric.

2.4 ComparativeAnalysis

2.5 Inference

Makingthefullfactoryairconditioned/Naturallyventilatedwillreduce thedustparticles

Thusweaving&Stitchingzonewillproducemorenoise,itshouldbe bufferedfromothersectorsofthefactory

TheProductionratedirectlydependsonman-powerandmachinery

3.SiteAnalysis

3.1SiteLocation

SiteCoordinates:10.939413”N,78.06761”E

Location:Selandipalayam,Karur

Sitearea:40254m2

ExistingRoadWidth:14m

3.2LandUse

TheSitehavebeenspottedontheindustrialzoneofKarurdistrict,which isjust500mawayfromtheAmaravatiRiverasTextileindustryneedslarge amountofwaterforitsproduction.

AsthematerialwaterratioofTextileIndustryis1:9

3.3SiteData

SiteislocatedontheSelandipalayamroadwhichconnectstheNH-7 andtheTrichymainroad,thosearethemajorconnectingroadsofKarur District.

Siteissurroundedbythecommercialshopslikepettyshops,tea/coffee shopandsomeretailshops.EverybuildingaroundthesiteisofonlyG andG+1,doesn’texceedmorethanthat.

KarurhasaTropicalMonsoonclimatewithhighesttemperatureof38oC andhighestrainfallofabout60mmpermonthandthewindspeedvariesupto 30km/h.

3.5 SiteImages

4.By-LawsandDataCollection

4.1 TN-DCRandNBC

The road width, FSI, Setbacks etc. for cottage industries, Green industries, Orange industries and Red industries shall be regulated according to the table below.

D. Minimum

WhereStreetAlignment/newroadisprescribed,itshall be fromthatstreetalignment/newroadline.Inthecaseof others,itshallbefromthepropertyboundary.

Parking - 1 car space for every 100 m2 of office floor area or part thereof and 1 two-wheeler space and 1 cycle space for every 50sq.m of workshop floor areaorpartthereofand1lorryspaceforevery500sqmorworkshopfloorareaor partthereof

Toilets - The no. of toilets are specified in the NBC code book shall be regulatedaccordingtothetablebelow.

S. No Fitments For Male Personnel For Female Personnel

1 Washingtaps with draining arrangements

2 Drinking water fountains

3 Baths (preferably showers)

1forevery25personsorpartthereof

1forevery100personswithminimum1on eachfloor

Asrequiredforparticulartradesor occupations

4.2 MachineData Machine

Size

Winding Machine 20'*50'permachine

Warping Machine 40'*70'permachine

Folding Machine 140"*120"permachine

Loom 80"*8'permachine

Stitching machine 20"*36"permachine

Cutting table 9m*1.2mpertable

Folding Table Customizable

Checking Table Customizable Dyeing Machine 60kgmachinesize10'*10'

All the size of machines are taken directly from the industries of different sectorslikedyeing,weaving,stitching,packingandstack.

5.AreaStatement

5.1 DailyProduction

DailyProductioninMeters

As the average of all these daily production calculations, the daily production of the Textile hub can be varied from 2500 meter per day to 3100 metreperday.

With the daily production ratio, the weight of the yarn to be processed can becalculated,asonemeterofclothweightsabout0.3kg.

Totalamountofyarnprocessed-3100*0.3=930kg

5.2 AreaCalculations

TotalBuiltup–10388m2

Circulationspace–18%of10388m2

GroundCover–40%oftotalsitearea

PermissibleFSI–1.5

FrontSetback–6m

SideSetback–4m

6.DesignProcess

6.1 UseranalysisandZoning

Activates of workers, vendors, byers and load man are taken into account fortheproximityandzoning.

Theiractivitiesaremarkedbetweentheentranceandtheexitofthesite,with referencetoallthespacesoftextileindustry.

Two different bubble diagram is done to under stand the pedestrian and vehicularcirculationinsidethesitearea.

Totalrequirementsareclassifiedintothreezones:

Zone1–AdminBlock

Zone2–Industry

Zone3–Dormitory

Thesiteiszonedinawaygivingimportancetoboththehumanandgoods circulation.Theparkingiszonedinthreedifferentplacestohaveeasyaccessto alltheblocksofindustry.Servicecoreisplaceatthebackendofthesitenearer totheserviceentry/exit.

6.2 Concept

Thedegreeofvisualandspatialcontinuity that occurs between two adjacent spaces depends on the nature of the plane that both separatesandbindsthemtogether.

The spaces are bought adjacent to each other for the betterment of circulation of the goods from one segment of the industry to anothersegment.

Even when closed, louvre windows provide for ample light and airflow. These windows provide indoor buildings with protection from excessive brightnessandglarewithoutcompromisingairflowinanyway.

Louvers are placed at an angle of 35o correspondence to the North, it is alignedinawaytogetdirectlightinginsummerseasonanddiffuselightinwinter season.

To bring the ventilation to allthesidesofthe industrialblock, the roofs are inclined in a way which creates the vortex effect in the between the two blocks improvesventilation.

Louvers are placed on the both the sides of the wall to enhance the cross ventilationandbetterlighting.

6.3 SitePlan

6.4 MasterPlan

Scale–Nottoscale

6.5 FloorPlans

Scale–Nottoscale

6.6 Sections

Scale–Nottoscale

6.7 Elevations

Scale–Nottoscale

BIBILIOGRAPHY

DataCollection

1. StateIndustrialProfile2014-15

2. BriefIndustrialProfileofKARURDistrict2012-13

3. MinistryOfMicro,Small&MediumEnterprises20

4. TamilNaduGovernmentGazette,2022

5. TamilNaduNewTextileIntegratedPolicy,2019

CaseStudy

1. ParadigmInternational(https://paradigmtex.com/)

2. Archdaily-Carcemal(https://www.archdaily.com/968589/jiangnandistrict-embroidered-garment-factory-minaxarchitects?ad_source=search&ad_medium=projects_tab)

3. ContextBD-GiantTextile(https://contextbd.com/giant-textile-ltd-anindustrial-building-by-binyash/)

Standards

1. TN–DCR2019

2. Neuferts

3. NationalBuildingCodeBook

4. IS.962.1989Codebook