www.commercialbaking.com THE MAKING OF A BUN LEGACY

ISSUE Q3 | BBU’S RAMON RIVERA | ALTERNATIVE GRAINS | MERGERS AND ACQUISITIONS AUG 2023 DIGITAL EDITION

Alpha Baking Co.

Find out more at www.jkingredients.com or call us at 973-340-8700 We make clean labels a piece of cake! Our Clean Label line of SOR-Mate™ products will keep your cakes, muffins, and other baked goods mold-free without the need for artificial preservatives all while maintaining the quality! Effective alternative to chemical preservatives! Introducing SOR-Mate™ CL NG Clean Label Non GMO Kosher Pareve KP Certified Gluten-Free version now available! Delivering Trusted Food Solutions

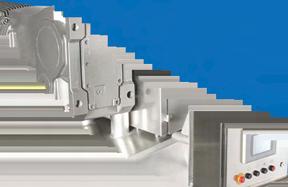

Many players, one team. www.syntegon.com Many players working hard to ensure the productivity, safety, and sustainability of our machines are always at their best. One team dedicated to providing exemplary service — every time. Visit us in Las Vegas! PACK EXPO C-2800

Customized solutions from the beginning. Committed partnership that never ends.

Our experience helps you select the perfect equipment to meet your specific needs.

Our skill createsa creates a custom stom solution,builttodelive olution, built to deliver unbeatable bea performanceand erformance and longevity. gevit

Our service delivers accessible, responsive support ble, respons anytime you need it. ytime youneed

Peerless: World-class food equipment and service. Driving innovation, sanitation, quality and longevity.

Our customized solutions drive your innovative food creations.

Peerless Food Equipment

500 S. Vandemark Road, Sidney, OH 45365-0769 USA

(937) 492-4158, (877) 795-7377 | peerlessfood.com

AIM TECHNOLOGY FOR PIZZA

Automation for pizza handling that no one else can deliver.

Active Integrated Motion™ (AIM™) technology transforms frozen pizza handling by enabling automation in washdown environments.

Intralox® AIM solutions include sorting, switching, and merging equipment that deliver maximized, reliable throughput and gentle product handling to your pizza packaging lines.

© 2022 Intralox, L.L.C. 5011057_EN

Scan QR code to learn more.

AVANT FOOD MEDIA

Paul Lattan President - Principal Steve Berne Vice President - Principal

Joanie Spencer Director of Content - Partner

COMMERCIAL BAKING

Paul Lattan Publisher 816.585.5030 | paul@avantfoodmedia.com

Steve Berne Director of Media 816.605.5037 | steve@avantfoodmedia.com

Joanie Spencer Editor-in-Chief 913.777.8874 | joanie@avantfoodmedia.com

Mari Rydings Editorial Director mari@avantfoodmedia.com

Jordan Winter Creative Director jordan@avantfoodmedia.com

Olivia Siddall Multimedia Specialist olivia@avantfoodmedia.com

Annie Hollon Managing Editor annie@avantfoodmedia.com

Evan Bail Associate Editor evan@avantfoodmedia.com

Maggie Glisan | Bella Foote Contributors info@commercialbaking.com

OUR

Commercial Baking is published by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. Commercial Baking considers its sources reliable and verifies as much data as possible, although reporting inaccuracies can occur. Consequently, readers using this information do so at their own risk. Commercial Baking is distributed with the understanding that the publisher is not liable for errors and omissions. Although persons and companies mentioned herein are believed to be reputable, neither Avant Food Media nor any of its employees accept any responsibility whatsoever for their activities. Commercial Baking magazine is printed in the USA and all rights are reserved.

No part of this magazine may be reproduced or transmitted in any form or by any means without written permission of the publisher. All contributed content and advertiser supplied information will be treated as unconditionally assigned for publication, copyright purposes and use in any publication or digital product and are subject to Commercial Baking ’s right to edit.

Commercial Baking , ISSN 2767-5319 / USPS Publication Number: 25350, is published quarterly in February, April, August, and October, with special issues in June and December, in print and digital formats by Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108. POSTMASTER: Send address changes to Commercial Baking, c/o Avant Food Media, 1703 Wyandotte St., Suite 300, Kansas City, MO 64108.

Circulation is tightly controlled, with print issues sent only to hand-verified industry decision makers and influencers. To apply for a free subscription, please visit www.commercialbaking.com/subscription

6

COMMUNITY

FIND US ON AUGUST 2023 Q3

MEDIA Magazines Website Newsletters Podcasts Webinars Videos | digital edition

American Society of Baking

OUR

Beekeepers BEES NEED

Beekeepers work hard to make sure honey bees have a diverse diet, a hive free from parasites and plenty of honey to eat.

A healthy hive produces more honey than it needs. Any extra honey is extracted and made available for sale.

Purchasing honey helps support the beekeepers that protect our bees.

Honey helps.

Contact keith@honey.com to learn how your company can support honey bees and beekeepers.

Where medieval recipes meet modern technologies. Heinen USA Corporation 1225 Old Alpharetta Rd, Suite 260 Alpharetta, GA-30005 www.heinen.biz meetLet’s at iba HallMunich,Germany A1 – Booth 171 October 22–26 2023

Ramon Rivera: Student and Teacher

24 Alpha Baking Co.: A Bun for All Seasons

Alpha Baking puts handheld fare on tables and in stadiums nationwide … and keeps a Chicago icon on the map.

43 Emerging Brand: Steiner’s Coffee Cake

49 Milwaukee Pretzel: The Pretzel Next Door

COMMERCIAL BAKING 9 IN THIS ISSUE

PLUS: Look for QR codes that contain exclusive digital content throughout the issue.

Alpha

has mastered the art of the iconic Chicago-style hot dog bun ... and then some. Read more on page 24.

Features

Cover:

Baking

Product photo courtesy of Alpha Baking Co.

Cover graphic by Olivia Siddall | Avant Food Media

36

DYMOMIX Mastering dough production

In seconds to a homogeneous dough. Suitable for various hydration levels

•Ensures highest product quality

•Versatile for a wide range of applications, i.e. ferment, pre-fermentation

•Operates 24/7

•Temperature-controllable

• Suitable for any baked goods

Zeppelin Systems USA, Inc.

13330 Byrd Dr, Odessa, FL 33556, USA

Tel. +1 813-920-7434, info@zeppelin-usa.com

zeppelin-systems.com

COMMERCIAL BAKING 11 85 108 TRENDS Critical Issues: 57 Mergers and Acquisitions Product Development: 64 Alternative Grains Category Outlook: 73 Salty Snacks Category Outlook: 79 Cake INNOVATIONS Category Insight: 85 Salty Snacks Category Insight: 93 Cake Commercial Baking Channel 104 Supplier Solutions 108 Ad Index 112 QUICK READS Editor’s Note 12 Seen and Heard 15 Business Intel 101 The Last Word 114 64 Departments IN THIS ISSUE

Treading on Iconic Trails

My job is so cool! I get to spend time with not only emerging leaders but also some of the biggest names in the industry, all of whom are paving the way for innovation.

Relatively speaking, I’m still a newbie in this industry, and when I look at the veterans, I see them as somewhat ubiquitous. I imagine that’s the case for lots of people new to baking. But I’ve had some amazing opportunities to have deep conversations and learn how many of these icons have gotten to where they are today. (Spoiler alert: It’s never easy.)

These conversations are a privilege, but sharing their stories is a huge responsibility. It’s not only about honoring the hard work these people have put in over the course of their careers, but it’s also about providing inspiration for what can be accomplished for the future.

Great leaders stand on the shoulders of those who came before them, and future leaders learn from the ones they look up and see.

JOANIE SPENCER Editor-in-Chief | joanie@avantfoodmedia.com

To those who have granted me the honor of telling your stories: Thank you. I cherish every conversation and hope my words give justice to all you have given the industry. And to those who read them: I hope you are inspired by the tales of these epic journeys. After all, trails are blazed to be tread upon … and footsteps are meant to follow.

AUGUST 2023 Q3 12

A NOTE FROM THE EDITOR

Maximize the Life of Your Pans with Synova & Pan Glo®

Using Synova’s release agents and applicators along with a Pan Glo® pan cleaning schedule, your bakery can take control of oil usage and ensure pans are always achieving their best and longest release life.

SPECIALTY FORMULAS

Synova’s release agents are formulated specifically for baking and come in a variety of special formulas.

IMPROVED APPLICATION & RELEASE

Synova’s release agent applicators use precise metering and placement to reduce oil usage while improving pan coverage and release.

PAN SERVICE PLAN*

A Pan Service Plan provides bakeries with a rotating supply of clean and recoated pans from Pan Glo to better manage oil usage and keep product quality consistent from the first bake to the last.

*Using DuraShield® coating? We have a plan for that too!

+1.937.652.2151 | info@bundybakingsolutions.com bundybakingsolutions.com Synova | Pan Glo

VISIT US September 25-28 Hall B1 - Stand 110

Seen Heard AND

“There’s

COMMERCIAL BAKING 15

“What I would hope we can all do — and should do — as the overall food community is maintain that love and not get so lost in our own micro-communities that we forget we’re part of one of the biggest communities on Earth.”

Alton Brown | cook, author, filmmaker and TV personality During IDDBA 2023 keynote

something around an entrepreneurial mindset combined with a sense of practicality. These people are not shy to roll up their sleeves and go … They are comfortable with the uncomfortable and aren’t afraid to lean into hard conversations.”

Barbara Schandl | insights lead, SnackFutures | Mondelez International On food innovation strategies during The Food Institute Podcast with Chris Campbell

“We need immigration reform; we need to have the ability to get more workers in the workforce that are willing to do the jobs that need to be done in both of our industries.”

Greg Ferrara | president and CEO | National Grocers Association On the future of the workforce during the American Bakers Association’s Bake to the Future podcast

SEEN AND HEARD

“As a good leader, especially in our business, it’s important to understand every part of the business ... When you are buying equipment, how does it make people’s lives better? All these things are about people first.”

Elana Schulman | director of special projects | Eli’s Cheesecake Co. From a live recording of the Troubleshooting Innovation podcast during BakingTECH 2023

We’re baking up something new!

We’re baking up something new!

RoboStack: The next generation of robotic pan stacking

RoboStack: The next generation of robotic pan stacking

We’re putting the finishing touches on Capway’s latest innovation in bakery automation.

We’re putting the finishing touches on Capway’s latest innovation in bakery automation.

RoboStack ensures the smooth transition of pans as they leave the production line.

RoboStack ensures the smooth transition of pans as they leave the production line.

RoboStack is designed and built to:

RoboStack is designed and built to:

• offer precision handling of multiple pan sizes

• offer precision handling of multiple pan sizes

• your desired pan stack height

• your desired pan stack height

• work with most existing pan carts

• work with most existing pan carts

• maximize uptime for your production line

• maximize uptime for your production line

Custom engineered conveyor systems allow for the seamless integration of our RoboStack system into your bakery’s existing footprint or new expansion. It all stacks up to the world’s most efficient operation in daily pan logistics.

Custom engineered conveyor systems allow for the seamless integration of our RoboStack system into your bakery’s existing footprint or new expansion. It all stacks up to the world’s most efficient operation in daily pan logistics.

Call today to be the first in line to have our new RoboStack system installed in your bakery. 877.222.7929

Call today to be the first in line to have our new RoboStack system installed in your bakery. 877.222.7929

A Fresh Approach To Custom Automation®…

capwayautomation.com

A Fresh Approach To Custom Automation® capwayautomation.com

“If you advertise as an industry that this is a family-minded place, you’re going to make friends, you’re going to have a community here, you’re going to be able to build a lifelong career here. The more you can push that out, the more you’re going to find people who find that attractive and who will want to work here.”

Jeff Havens | founder | The Jeff Havens Co. During the keynote address at BEMA Convention 2023

18

“Vertical integration really supported stocks within our stores, and it continued to grow our respective volume.”

Brad Clarkin | VP of production operations | Kwik Trip

During a panel on vertical integration at BEMA Convention 2023

“I was always around food. The kitchen was where all the secrets were exchanged and the decisions were made. The kitchen had the power of the house. And to me, I always equated food with femininity.”

SEEN AND HEARD AUGUST 2023 Q3

Padma Lakshmi | food expert, author and TV personality During fireside chat at IDDBA 2023

“Everybody is focused on sustainability. If you are in food, you are in sustainability. Because if you don’t do better, we don’t have food.”

Roxi Beck | president | Look East During the session How Are We Rethinking Supply Chains in the Face of Increased Global Tensions? at IFT FIRST 2023

Made for your blending process for process

ROSS Ribbon Blenders meet the toughest requirements for quality materials and heavy-duty construction. Standard features include thick stainless steel troughs, low-maintenance gearmotors, BISSC-certified design and much more.

Need a Ribbon Blender customized for your process? ROSS offers MANY options. Complete control systems, spray nozzles for coating, pressure feed vessels and vacuum operation, to name a few.

Used in a wide range of food applications, from trail mix snacks and sugar confections to cake batters and icings, we can customize a ROSS Ribbon Blender for your application.

Sizes from ½ cu. ft. to 1000 cu. ft. A variety of standard models are in stock for faster delivery. Available worldwide.

mixers.com/ribbon-blenders mixers.com 1-800-243-ROSS

During the Ask-A-Baker panel at BEMA Convention 2023

20

“The reluctant embrace technology to keep up. The visionary embrace it to leap forward.”

Jeff Winter | advisory board member | CESMII On Industry 4.0 and smart manufacturing via LinkedIn

“Food powers humanity, and soil powers food.”

SEEN AND HEARD AUGUST 2023 Q3

Herrish Patel | general manager | Unilever Nutrition North America During the session Building the Business Case for Regenerative Agriculture at IFT FIRST 2023

“ESG is not just sustainability. It also has to have a social piece to it. At Flowers, we have a steering committee of subject matter experts who can bring it all together because ESG is about partnerships between those different areas.”

Margaret Ann Marsh | senior VP of safety, sustainability and environmental | Flowers Foods

Pfening’s in-house production capabilities allow full control over our equipment design and quality. www.pfening.com | sales@pfening.com WITH PFENING IT’S ALWAYS Customer First Delivering Superior Value Since 1919 • Water and liquid dosing systems • Dough conditioning systems • Comprehensive engineered systems • Automated ingredient handling systems • Turnkey projects from design to startup • Integrated control systems

THE FUTURE POWERED BY EXPERIENCE

AT IBA OCT. 22-26

MUNICH, GERMANY Stand B1.150 & B1.170

In addition to meeting and exceeding current production needs, we look to the future of processing.

Our experienced and knowledgeable engineers and food technologists work with you to optimize end to end solutions.

UNLEASHING THE POWER OF NEXT-GEN BAKING

Breads | Buns | Cookies | Crackers | Cakes | Muffins | Pastries | Pies | Pizzas

LESS WASTE MORE IMPACT.

REDUCE GREENHOUSE GAS EMISSIONS

MINIMIZE WASTE

OUR BAKERY BRANDS

MINIMIZE ENERGY CONSUMPTION

OPTIMIZE WATER CONSUMPTION

HUNGRY FOR MORE?

FACILITY AUTOMATION & EQUIPMENT SANITATION BRANDS

BREAKTHROUGH TECHNOLOGY FOR BETTER BAKING

Auto-Bake F3 Oven - Daily Show Demos

Fossil Fuel Free Electric Direct Forced Convection Oven

Auto-Bake Inline Vacuum Cooling System

› Depan Quicker and Cleaner

› Up to 50% less floor space

› +15% more yield

› Up to 40% less energy cost

Baker Thermal Solutions RapidBake Oven (electric or gas)

Sustainability Benefits using Air Impingement & Radio Frequency

› Faster bake times + increased yields 20% - 40% time reduction based on product

› Smaller footprint – Reduced time means a shorter oven with the same output and less raw materials

Burford Smart Seeder +

› Target topping application

› Active topping reclaim system

› 20% - 50% seed savings

› Integrated pan control

Escher AGV / Robotics Mixing Systems

› Efficient use of space

› Consistent preparation

› Reduced labor

Spooner Vicars FGR Roller Hydraulics

› Uniform dough thickness

› Accurate weights

› Reduced giveaway

Stewart Systems Viper Chain

Lubeless chain offering exponential oil and labor saving

Stewart Systems Rack N Stack

Integrates our industry leading pan stacking / unstacking expertise with our Laser Guided Vehicles (LGV) for a custom designed pan handling solution for every bakery application

Stewart Systems MAP-PAK 20

Modified Atmosphere Packaging - sealing and gas technology in our Pillo-Pak. Achieve extended shelf life in a bulk format package for individual (QSR) buns.

Sveba Dahlen Artista Deli

New stone-belt tunnel oven for industrial production of pizza, pizza bottoms & much more

Middleby Bakery Group Remote Service Solution

Live video feed & conferencing for real-time assistance

A BUN FOR ALL SEASONS

Alpha Baking puts handheld fare on tables and in stadiums across the country … and keeps a Chicago icon on the map.

BY JOANIE SPENCER

BY JOANIE SPENCER

24 AUGUST 2023 Q3

Opening photo courtesy of Alpha Baking Co. |

All

other photos by Olivia Siddall Avant Food Media

FEATURED BAKERY: ALPHA BAKING CO.

There are plenty of ways a bakery can predict if business is ready to boom. It can look at sales projections, market conditions, data analysis and a host of other things. But sometimes, it’s just in the air.

“You can drive through the city with your windows down, and when you smell the grills going, you’re like, ‘Alright, it’s started,’” said Tim Lotesto, senior director of national retail key accounts for Chicago-based Alpha Baking Co. “That’s when you know it’s bun season.”

For Alpha Baking, a producer of specialty bread, buns and rolls for foodservice and retail, the bakery’s products are in demand throughout the year. But from roughly April through September — affectionately known in bakery circles as “bun season” — it’s a whole new ballgame.

It was more than four decades ago that two cousins, Mike Marcucci, chairman of the board, and Larry Marcucci, CEO, launched Alpha Baking through a series of acquisitions involving operations in Detroit, and South Bend, IN, before rescuing MaryAnn Baking Co. from bankruptcy in their hometown of Chicago.

Between the MaryAnn acq uisition and Alpha’s 1982 merger with S. Rosen’s, the bakery took on bun production that has become synonymous with any sandwich requiring a bun, but most notably the iconic Chicago-style hot dog.

“That’s really what got us rolling,” Larry said. “It was then that we had the volume to really get things moving.”

That momentum led Alpha to a 172,000-sq.-ft. facility on Polk Street in Chicago’s South Side, where today it cranks out about 2 million lbs. of bread a week ranging from S. Rosen’s branded

and private-label specialty loaves for retail, to French rolls for foodservice. But it’s also from where nearly every kind of premium hamburger and hot dog bun hits bars, ballparks, food carts and more — in areas ranging from Chicago streetcorners to grills across the US and North America.

“If you look back at our history, MaryAnn Baking Co. was a strong purveyor of hot dog buns — they were the best buns — in the marketplace,” said Mark Marcucci, Larry’s brother and Alpha Baking’s president. “We’ve been building on that tradition, and through the years, it’s grown to where we’re serving about 95% of hot dog stands in Chicago.”

So, what is a Chicago-style hot dog, and how exactly did two brothers and their cousin build a bun empire along with it?

Also known as a Chicago Dog, this specific fare includes a particular ingredient list, including an all-beef frankfurter, yellow mustard, relish, chopped white onions, tomato wedges, a pickle spear, sport peppers, celery salt and, of course, a poppyseed bun. It’s a hefty load for the bun to bear, and that’s where Alpha honed its quality focus: Build a bun that can hold the Chicago Dog fixins.

Warmed in a steam table, a Chicago-style hot dog bun has to be pliable enough to handle such heavy fillings, and the key to that is in the hinge. Product quality is undoubtedly the foundation, and it was paramount to getting the dogs cleanly into consumers’ hands.

“It was the combination of the quality of our product and the service of our sales team that has been the key difference maker for us,” Mark said. “In those early years, our bond with the

COMMERCIAL BAKING

“Without our commitment to superior service and efficient distribution, our customers wouldn’t be able to compete, and we took that very seriously.”

25

Mark Marcucci | president |

Alpha Baking Co.

—Left

The bun is an integral part of what makes the iconic Chicago Dog so famous.

restaurants was essential. Without our commitment to superior service and efficient distribution, our customers wouldn’t be able to compete, and we took that very seriously. So, our logistics and service teams have focused on getting buns to the customers on time with consistent quality. We take great pride in the quality of our products and the service that we provide, and our customers realize that it’s an advantage for them.”

WATCH NOW:

For just about every handheld delicacy, the carrier is its unsung hero. Whether it’s a fully loaded Chicago Dog, a craft burger or an unforgettable gourmet sandwich, the bread is foundational to the experience. That’s especially true during the summer months when people hit the local pubs for a burger and beer or head to a stadium to enjoy a signature hot dog while cheering on America’s pastime.

Every menu — and every handheld — is different. Even Chicago Dogs, with their signature ingredients, have their own idiosyncrasies, right down to the size of the pickle slice. And those toppings can greatly impact bun specifications, which vary for each customer. To that end, Alpha has upwards of about 2,000 SKUs to manage.

“It can be hard to grasp the size and magnitude of what the bread business is,” Mark said. “It’s something that you just have to experience because there are just so many tentacles.”

Managing that many SKUs for so many clients requires a heavy emphasis on logistics, something Alpha has greatly invested in ... and what enables the bakery to not only remain unique for its customers, but also do it at scale.

That’s something Alpha Baking has developed a reputation for. In fact, visitors to the Polk Street bakery won’t get 10 steps without seeing a vendor award from one of its myriad customers. Perhaps the most notable in the building is a life preserver ring bearing the Alpha Baking name, a token from a customer who called the bakery a real “life saver.”

It’s a testament to Alpha’s dedication to customer service, especially during the summertime when it’s entirely conceivable that a foodservice operator could run out of buns on any given day.

“We’ll be delivering products to morrow that we might not have an order for yet,” said Bob McGuire, VP and director of logistics.

ALPHA BAKING CO. 26 AUGUST 2023 Q3

—Above Alpha Baking’s sesame products are only made on dedicated lines and in specific facilities.

Mark and Larry Marcucci describe the team effort involved in creating a quality bun.

Investing in logistics enables Alpha Baking to manage thousands of SKUs.

937.652.4480 | info@shaffermixers.com | shaffermixers.com FOLLOW US Easy maintenance and sanitation Slide out drop conveyor Ability to handle stiff doughs Aggressive cutter design Level floornot required Self-leveling casters No trip hazards from floor tracks Mixer mounted traversing guide Manage mix start times and auto selection of multiple chunkers Load cells 24/7 PARTS & SERVICE +1 888.508.1298 service@shaffermixers.com YOUR BAKERY. YOUR MIXER. Quality mixers, processing equipment and service.

In this 24/7 operation, incorporating frozen business became a game changer because of its unique ability to be all things to all customers. It enhanced not only the volume of product that went out from all six facilities but also the customer formats that Alpha could serve. While frozen business is usually heavier during the week, fresh deliveries to certain restaurants almost always peak on the weekends, allowing more synchronicity in the operation.

“When we started doing frozen, we discovered that we could interweave production between frozen and fresh, and that helped balance things out,” Larry said. “So, when we’re running frozen production early in the week, once it’s into the freezer and we start running fresh at the end of the week, we can throttle back on the frozen. It’s allowed us to even out and become more concise and consistent in scheduling.”

What’s more, by building up frozen inventory — and its subsequent scheduling strategy — Alpha freed up capacity

needed to accommodate bun season on the fresh side. In fact, adding frozen production sparked incredible growth for Alpha’s distribution when traditional models like direct-store delivery began to wane. Today, the frozen-fresh ratio is about an even split.

“At first, we wondered, ‘Who is ever going to buy frozen bread?’” recalled Tim Gill, Alpha’s VP of frozen foodservice division. “But as quality of frozen bread has evolved, and with the continued industry retraction within the freshdirect geographical service footprint, it’s impacting every market and influencing the national frozen side of the business. In those rural areas, where do they get their bread? They’re leaning on broadline, specialty distribution, and that’s what’s causing the frozen side to escalate.”

LISTEN NOW: Tim Gill explains how the evolution of distribution has impacted frozen bakery production.

In a world of technology advances that can streamline everything from scheduling to packaging, the Alpha team holds one tool in highest regard: communication.

Since long before the pandemic, team leads from all six facilities join an 8 a.m. call to check on progress and get ahead of any troubleshooting that might be needed in the day ahead. With Polk serving as a distribution hub for several Alpha Baking facilities, communication is vital. The group has dialed in efficiency to the point it can hit everything in 30 minutes or less. During those high production times when things get a bit chaotic, they kick up the frequency to twice a day.

It’s summertime, and if the sun’s out, the buns are out. But these buns aren’t going to make themselves. Operations in five of the six plants are cranking out bread and buns at breakneck speed (with the nearby Fullerton facility focused solely on batter-based products such as muffins).

ALPHA BAKING CO.

AUGUST 2023 Q3 28

(From left) Tim Lotesto, Bob McGuire, Todd Thornberg, Larry Marcucci, Mark Marcucci, Tim Gill and William Houston ensure Alpha Baking gets through bun season seamlessly.

www.rademaker.com High quality laminated dough products INNOVATIVE PRODUCTION LINES FOR BREAD PASTRY LAMINATED DOUGH FLATBREAD CROISSANT PIE PIZZA T: +1 330 650 2345 E: info@rademakerusa.com Flexible line lay-out Fast and Easy cleaning High production efficiency VISIT US AT BOOTH C2.350 E: info@rademakerusa com

“They’re moving at 90 mph these days,” Larry said.

While automation is a vital necessity in mixing, proofing, baking and cooling, Alpha is still strategizing for how robotics can be used with the flexibility that’s required when packaging seemingly infinite configurations for thousands of SKUs in a land-locked operation.

“We’re challenged by the fact that all our bakeries are space-constrained while our varieties are voluminous,” Larry said. “It’s that big question: How do you incorporate automation or robotics into the flexibility that we need for our customer base? That’s always been the challenge for us.”

However, as some foodservice customers expand across the US and require consistent product in multiple locations, the need for longer runs that lend themselves more to end-of-line robotics will increase.

The company has invested in improvements as needed for automated bagging systems and other equipment throughout the facilities, including a new LeSaffre cream yeast system and PremierTech palletizing robot in 2020, a Motivair chiller in 2021, and two new Shaffer high-capacity mixers last year, all in the Lyndale facility. The most recent equipment upgrades at Polk Street include two new UBE bagger systems set for installation later this year, which follow a 140-ft. Babbco tunnel oven that was installed in 2019.

Polk Street’s space constraints require creative configurations, including a custom-built Rademaker makeup line that runs serpentine for space saving. And where products converge to ride conveyors upstairs to the second-floor

packaging area, the scene resembles the South Loop at rush hour, only with products running faster on the conveyors than the commuters on Interstate 90.

Innovation doesn’t just live inside the bakery, though.

“When we think about investments in the future, people immediately consider equipment,” McGuire said. “But investing in the future could be looking into technologies that are totally different.”

Since the early 2000s, the company has made significant investments in alternative fuels and electric vehicles, setting the pace for sustainability in the industry. It started with an experiment around how to run trucks on vegetable oil waste, with findings presented at the American Society of Baking’s BakingTECH conference. Although the concept didn’t take off, it sparked brainstorming on what’s possible, leading to dialogue between baking and trucking industry leaders.

“We invested a lot of time, money and effort,” McGuire recalled. “And it wasn’t about the ROI; it was about finding a solution that could take hold. We learned to ask the smart questions and think about other alternative energies.”

In 2013, Alpha was the first baking company to deploy an all-propane classified fleet, followed by an all-electric step van, and they’re still running today.

Through his work with the Alpha fleets and his leadership with the American Bakers Association’s logistics committee, McGuire has positioned the bakery at the forefront of sustainability and alternative energy strategies.

“It’s been a good ride, if you will,” he said. “We’ve done well for investing in the future in that way.”

This year, however, the biggest challenge by far has been the US Food and Drug Administration’s ruling on sesame

ALPHA BAKING CO.

For a bakery that runs thousands of SKUs, packaging configurations require the most strategic solutions.

AUGUST 2023 Q3 30

Ask us about our CleanBake Multi-Fuel Hybrid Heating Technology. Clean Energy Solutions with same Superior performance. Ask us about our CleanBake Multi-Fuel Clean Energy Solutions with same performance. • Direct-fired • Indirect-fired • Air Impingement • Infrared • Radiant-tube • Thermal-oil • Electric • Hybrid • Sanitary Washdown Our CustomDesigned Ovens include: The Finest Custom Tunnel Ovens Anywhere In The World A MEMBER OF: 508-977-0600 SALES@BABBCO.COM WWW.BABBCO.COM

as the ninth allergen. For a company producing that many bread, bun and roll SKUs, it’s a potentially crippling change. But Alpha’s fierce commitment to food safety has driven the team to do whatever it takes to segregate lines that run sesame-topped products.

Todd Thornberg, VP of manufacturing, has been focused on the sesame issue for more than a year. Because sesame is a bit like glitter — it winds up everywhere — Thornberg reconfigured production to have sesame products run on dedicated lines in two facilities. This helps control changeovers and enables product tracking for allergen purposes. And ultimately, it could lead to those longer runs needed to support robotic automation.

That said, even with these efforts, non-sesame products that are made in the same facility with a sesame line include on-package warning to that effect. But if the company knows there’s risk of a severe allergic reaction, it will turn down business, especially for a school foodservice account.

“We do a lot of school business, and you can’t take that risk,” Thornberg said. “So, all our products for schools are made in facilities that don’t handle sesame at all.”

Then there are supply chain-related changes that all bakeries are learning to deal with while still reeling from the COVID reality that no one can predict the future. But those lessons have sharpened the bakery’s focus on the future and heightened the need for internal collaboration and longevity.

“Our people not only care, but they also have an intimate familiarity with every facet of their job,” said William Houston, VP of IT and administration services. “We collaborate constantly, always bouncing ideas off each other. This is our life, not just a job. And above all, it’s a team effort.”

There have been certain points on the industry’s timeline where bread has fallen, perhaps alarmingly, out of favor. But the past five years have proven that bread is, in fact, back.

“It’s back in a big way,” Gill said.

Undoubtedly, premium buns play a role in that, whether it’s a high-end brioche bun or that iconic steamed hot dog bun adorned with poppyseeds that make an unforgettable dining experience. And Alpha Baking is here for it.

“That’s our lot in life,” Larry said. “That’s what we do.” CB

INNOVATIONS FROM THE BAKERY FLOORS

In five of its six facilities, Alpha Baking Co. cranks out tons of buns every week, with the sixth specializing in batter-based products, primarily muffins. With a focus on speed and efficiency, the Alpha teams at each plant work together to create around 2,000 SKUs for fresh and frozen products for foodservice and retail customers. While it’s busiest during bun season, the bakeries serve customers year-round, rarely ever saying no, often earning the bakery “Supplier of the Year” distinctions. Below is a list of supplier innovations that can be found throughout all six facilities.

AMF Bakery Systems dough makeup

Babbco tunnel ovens

Bettendorf Stanford bagger

Burford Corp. tyer and topper system

Flynn oven burners

Formost Fuji horizontal packaging

Gemini divider

Hitachi videojet packaging printers

Kwik Lok bag closures

Mecatherm ovens

Peerless horizontal mixers

Rademaker sheeting and makeup

Shaffer horizontal mixers

Syntegon muffin wrappers

UBE baggers

ALPHA BAKING CO.

32 AUGUST 2023 Q3

YOUR RECIPE AUTOMATED TO PERFECTION

Whether it’s storing, sifting, metering, weighing, transferring or flour recovery, Shick Esteve is your complete ingredient automation system provider.

FOLLOW US

shickesteve.com VISIT US IN DALLAS AT NEXUS 2023 SCAN ME

Student and Teacher

BY

If you ask Ramon Rivera about the last book he read, you might not get a straight answer. He reads for habit, not hobby, with as many as six books open at any given time. It’s a mark of an insatiable curiosity — about business, innovation and how the world works — that has led him on a journey spanning four decades in an industry he didn’t expect to join.

The timeline of his career is a classic tale of the baking industry’s history makers. In bakery manufacturing, leaders are rarely born; they start on the pro duction line and work their way up. That’s exactly how Rivera became senior VP of operations for Horsham, PA-based Bimbo Bakeries USA (BBU), the North American business unit of Mexico City-based Grupo Bimbo, the world’s largest commercial baking company.

“It’s been a long journey,” said Rivera, who has been with Grupo Bimbo for 42 years, 13 of which he’s spent in the US with BBU.

That longevity stems from a few key principles that include setting purpose, constantly learning and loving the craft.

When Rivera steps into a new situation, he believes it’s incumbent upon him to be the learner. That has been formative for

36

AUGUST 2023 Q3

With an unending quest for knowledge, BBU’s Ramon Rivera leads on the principle of purpose.

JOANIE SPENCER

All photos courtesy of Bimbo Bakeries USA

not only his professional development but also his achievements in his company and the industry.

Formally trained in chemical engineering, Rivera spent the first few months of his career learning how to become a baker. In 1981, Grupo Bimbo was not yet the global powerhouse it is today. Although the company was already growing at a rapid rate, its operations were focused in Mexico, and there were not many ch emical engineers on staff.

Baking was a totally new world to Rivera, and as Grupo Bimbo was opening one to two plants a year at the time, the learning curve was short. But for Rivera, it was a worthy challenge.

“I came as a trainee in manufacturing as part of a plan to grow people for potential plant openings,” he said. “I quickly learned everything a baker should know on a production line. I had to cover all positions, and that started by learning the basics.”

Over the next few decades, as he grew in his role at Grupo Bimbo — and the company expanded globally — Rivera took on challenges such as developing and benchmarking best practices for operations in Mexico, based on Am erican and European principles. The work taught him a great deal about immersion into new cultures and how to apply different practices into a standardized process.

Developing expertise in navigating cultural differences has been foundational for Rivera, most notably when he entered the realm of BBU in 2010, when the business unit was on the brink of quadrupling through acquisitions including George Weston Ltd. and Sara Lee.

“There were big differences, and I had to learn a lot,” Rivera said. “Not only

culturally but also in the way the business of baking is conducted; it’s very different in the US and in Mexico. I had to learn about categories, competitors, customers, consumers and about the cultural differences among regions in the US. There was a lot to learn, but I enjoy that.”

Through collaboration and mentorship from peers such as Gary Prince, Fred Penny and Tony Gavin — then George Weston president, BBU president and BBU executive VP, respectively — Rivera led the integration of people, assets, systems and cultures into a cohesive BBU system, all while keeping product moving.

“With these types of integrations, the one thing we cannot do is disrupt the market,” Rivera said. “We have to keep serving customers without disruption.”

The two key factors in seamlessly executing large-scale integration without disruption, according to Rivera, are keeping the team focused on serving customers and consumers and keeping the people safe.

“If you can successfully combine those two things simultaneously,” he said, “the execution will be close to perfect.”

By focusing on culture, operations and business, Rivera has also naturally enhanced his affinity for innovation and sharpened his eye for talent. These are also important factors in maintaining operational efficiency while managing continued expansion.

Known as an early adopter, Rivera’s own propensity for discovering technology — and applying it in areas like operations and product development — is a centrifugal force that drives his leadership and, consequently, his teams.

37 COMMERCIAL BAKING EXECUTIVE PROFILE: RAMON RIVERA

“If you have a culture that enables people to fail fast, you can correct, realign the priorities and get to the next big thing.”

Ramon Rivera | senior VP of operations | Bimbo Bakeries USA

“You can’t compete if you don’t have the right skills and the right people on your team,” Rivera said. “The moment you stop learning new things, you’ll lose that competitive edge. And I have been lucky to learn from the best. I had the fortune to have great mentors like Don Lorenzo and Don Roberto Servitje and learn philosophy and management principles from them.”

He’s learned lessons not only from Don Lorenzo and Don Roberto but also worked several years with Daniel Servitje, Grupo Bimbo CEO, and a reliable group of peers and colleagues. Over the years, that mentorship has complemented continuing education, including advanced management courses from IPADE Business School in Mexico, supply chain management courses at IMD

Business School in Switzerland, an MBA from Arizona State University and ITAM in Mexico, and bakery-specific training through the American Society of Baking (ASB) and the American Institute of Baking.

“I have a hunger to learn and try new things,” he said, noting that education must not be solely focused internally but should, in fact, begin with understanding consumer needs, whether it’s nutrition, consumption, inflation or something else.

Innovation is rooted in serving the consumer. It can’t be forced, nor should it be stifled.

That said, with innovation comes some level of risk that’s often most evident in

terms of product development. Companies can invest a great deal in creating the next big product, but without consumer buy-in, there’s seemingly no reward. But, in Rivera’s view, the reward is not always tangible.

“You can put any number of products out in the market and have only a few of them become successful,” he said. “But it’s a matter of how you develop the innovation, how you run the process. There will be failures, but if you have a culture that enables people to fail fast, you can correct, realign the priorities and get to the next big thing. When that happens, when consumers adopt it, you have to make it available for everyone. That’s when a company becomes healthy and competitive.”

38

EXECUTIVE PROFILE

AUGUST 2023 Q3

Ramon Rivera (center) believes the greatest innovation happens in an environment where ideas are free to flourish and product development begins with consumer-driven purpose.

Automated Pan Handling and Post-Packaging Solutions

© 2023 AMF Bakery Systems USA | Netherlands | UK | China | Singapore | Canada | Mexico AMFBAKERY.COM | SALES@AMFBAKERY.COM Through continuous innovation, AMF Workhorse is maximizing profitability by seamlessly integrating pan handling and distribution solutions to improve line efficiencies and operator safety while eliminating downtime. The AMF Workhorse portfolio ensures efficient delivery of your bakery's most valuable assets, and features pan and peel board handling as well as a variety of product loading solutions, basket handling, palletizing, and automated storage and retrieval systems for pans and baskets.

booth #SL-6380 Scan to learn more Delivering ingenuity in automation

Rivera believes that innovation must be rooted in purpose. Product development for the sake of having a new item on the shelf is a meaningless endeavor. But a product with purpose can take on a life of its own. When that happens, innovation will follow.

WATCH NOW:

Ramon Rivera explains the importance of prioritizing innovation.

The most productive creativity requires a culture where ideas are free to flourish. Granted, there has to be a gatekeeper, as Rivera attested to the Grupo Bimbo organization that allows for innovation to happen in a structured environment. But he also believes that when ideas are allowed to thrive, a natural life cycle will occur.

“It tends to be very natural when someone realizes that a good idea is simply not possible or that we need to ‘put it in the freezer’ for some time,” he said. “But when an idea flourishes, if we have the consumer in mind, and we understand how to adapt to a complex learning curve by adopting new technologies, formulations and processes, in the end, we will be successful.”

Rivera feels blessed to have started his career with a company not only set on growth and innovation but also invested in training and education for its workforce. He was provided endless opportunities to learn — and lead — the craft. As the first non-American to chair the ASB board of directors, Rivera’s leadership has focused on achieving results through positive influence.

Throughout his career, he has welcomed challenges and also challenged his teams to be the best they can be. And while that is always driven by purpose, it also starts by understanding the definition of what being the best means.

“It’s amazing what your team can do when you’re clear on expectations,” he said. “It’s about having a purpose and an end in mind … and understanding that what is the end today may not be the end tomorrow because situations change.”

As Rivera has grown with this company, he could not imagine his accomplishments without the people in his life, the least of which being his family. In essence, the people in his life have allowed him to grow with his teams and innovate together.

“I have been blessed by the support of my family, and I am lucky to have worked with many excellent people in my different teams over the years,” Rivera said. “They have all helped me to address challenges and constantly improve, to be the best and always achieve excellence.”

Rivera could have followed any path, perhaps in any industry. His ability to learn — and pass his knowledge to others — has not only helped grow one of the most influential companies in the world, but it has also bettered the business of baking.

“I chose to become a baker, to learn food,” Rivera said. “I made that decision because this is a great company and also because I enjoy my work. The baking industry is like a family. Even when we compete, we compete as a family in some respect. It’s a lot of work and requires a lot of energy. But this is a great place to be.” CB

AUGUST 2023 Q3 40

EXECUTIVE PROFILE

“It’s amazing what your team can do when you’re clear on expectations. It’s about having a purpose and an end in mind … and understanding that what is the end today may not be the end tomorrow.”

Ramon Rivera | senior VP of operations | Bimbo Bakeries USA

www.formostfuji.com 425-483-9090 sales@formostfuji.com “Quality is: First and Formost” Innovative Packaging Solutions for Bakeries Baggers, Wrappers, and Automated Systems Induction heat technology that provides top quality seals while conserving energy is another advantage of doing business with Scan to Learn how to improve the eco-efficiency of your packaging line Join us at Pack Expo in Las Vegas! Register for free using our comp code: 61B64

www.reiser.com Reiser • Canton, MA • (781) 821-1290 Reiser Canada • Burlington, ON • (905) 631-6611 Reiser UK • Milton Keynes, Bucks • (01908) 585300 2021 At Reiser, we have the experts, the process knowledge, the experience and the equipment to help you improve your entire bread line. Our Bakery Specialists will show you how to improve scaling without sacrificing quality. Come run your product with us at the Reiser Customer Center. Unmatched scaling and quality.

BRAND:

Imperceivable Innovation

What began as a grandfather’s hobby is becoming the Steiner family’s gluten-free legacy.

BY ANNIE HOLLON

The dawn of a new product, especially in the baking industry, often stems from necessity. Take Glen Cove, NY-based Steiner’s Coffee Cake of New York. After just seven years, the brand is emerging to the masses while simultaneously crafting a family legacy that’s been generations in the making.

While the baking company began operating in 2016, the story of Steiner’s starts in the ’60s with Malcolm Steiner, fatherin-law of Nanci Steiner and grandfather to Jennifer Pool, the bakery’s creatorin-chief and president, respectively. Malcolm baked as a hobby and passed his knowledge and recipes on to Nanci. When Nanci was diagnosed with celiac disease more than 30 years ago, she took it upon herself to create a proprietary gluten-free flour blend.

Nanci’s first attempt fell flat. It wasn’t until she was on the brink of her 70th birthday that she landed on the perfect blend … unintentionally fueling the flames for a baking company.

“One day in 2016, she served my brother and me my grandfather’s German sour cream coffee cake, and I said, ‘Mom. You have something here. This is amazing,’” Pool said. “I quit my job the next day.”

COMMERCIAL BAKING 43

Photo courtesy of Steiner’s Coffee Cake

Steiner’s Coffee Cake of New York’s flagship fresh-frozen product is shaking up the gluten-free market.

EMERGING

STEINER’S COFFEE CAKE

While Pool now oversees the production of Steiner’s baked goods — coffee cakes, ginger snaps and brownies — she knew nothing about baking, much less bakery manufacturing, when she left a marketing career to start the company. However, she did know that her mom’s flour blend and Malcolm’s recipe had the potential to be something big.

“At this point, I didn’t know how to bake a thing; I don’t even make my family dinner,” Pool recalled. “[My mom] said, ‘If we’re going to do this, you’re going to have to learn to bake.’ And I said, ‘Okay.’”

Nanci taught Pool everything she knows about baking, which proved critical as an operator since Pool spent the first four years baking everything herself. Though she may have left the advertising profession, Pool’s penchant for sales and love for consumer behavior was baked in. The learning curve came in operations.

“The flour was the first hurdle,” Pool said. “Could we make the flour over and over again with the same quality outcome: a premium product that nobody knew was gluten-free?”

The answer was yes. Within three months, Pool had found a flour mixer to create her mother’s certified gluten-free, kosher and Non-GMO Project-verified blend. Over six years later, Steiner’s uses the same Denverbased SQF2-certified provider that specializes in custom blends to produce between 5,000 lbs. and 20,000 lbs. of flour at a time. Steiner’s also sells the flour on Amazon, its website and in retail locations.

Growing the business came down to ensuring Steiner’s could do three things: scale the recipe, replicate it consistently and make the product defensible.

Set with the right flour blend and the ability to produce Malcolm’s original recipe at scale, Steiner’s took off, selling its first coffee cake on Amazon in January 2017 and obtaining its first retail client, Grassroots, that April.

The coffee cake’s quality and Pool’s raw determination caught the attention of Chicago-based Mondelez International.

SnackFutures is Mondelez’ innovation and venture hub, which provides earlystage brands with materials such as a virtual curriculum, one-on-one mentorship and expertise from the company’s network ranging from innovation to brand building. Through a 12-week CoLab startup engagement program, early brands have access to resources that can help them build a venture pipeline.

“The program provides a lot of resources that the founders are able to leverage in the way that best serves them and their business,” said Jackie Haney, innovation and CoLab program manager at Mondelez International.

44 EMERGING BRAND

Jennifer Pool (center, in orange) is one of the entrepreneurs in SnackFutures’ CoLab class of 2023.

Photo courtesy of Mondelez International

“Whether it’s on the supply side or the consumer side, relationships matter. You have to be authentic and genuine.”

AUGUST 2023 Q3

Jennifer Pool | president | Steiner’s Coffee Cake of New York

Cavanna: scalable Flowpack, Cartoning & Casepacking CAVANNA PACKAGING USA INC. 3400 Corporate Way | Suite F | Duluth GA 30096 Phone: (770) 688-1501 Fax: (770) 810-3528 sales@cavannagroup.com www.cavanna-usa com Cavanna Packaging specializes in: • Turn-key Flow Wrapping, Cartoning and Casepacking solutions • Sanitary Design Systems for the Food Industry • Easy to clean toolless Poke Yoke solutions • Fully Caustic Washdown Flow Wrapping lines • Unique space and labor saving Flow Wrapping solutions Turn-key Flowpack & Cartoning

Drawn in by Mondelez’ pillars — growth, execution, culture and sustainability — and its perspective on the future of snacking, Pool submitted the online application.

“It was just a click, and I never in a million years thought they would choose us,” Pool said. “It’s been phenomenal from day one.”

Steiner’s fit into this year’s CoLab theme of Disruptively Delicious. Pool lets the coffee cake speak for itself before pulling back the curtain to reveal the product’s gluten-free status. This ability to blend in made the emerging brand stand out to Mondelez.

“What was really unique and caught our eye about Steiner’s — aside from

Jennifer, who is such a passionate, intelligent, hard-working entrepreneur — is that the product is imperceivably gluten-free,” Haney said. “We know that eating is a shared experience, and so we love when there are products out there that meet the needs of niche consumers but can be shared with mainstream consumers without there being any trade-off in taste.”

For Pool, the program has not only lent Steiner’s credibility and national awareness, but it’s also introduced her to business connections that could help grow the company.

“I can have conversations with different folks in the supply chain that I was never able to have before, and people call me back,” Pool said. “And the

research that I have at my disposal now enables me to become a better supplier and make more pointed, better-informed sales calls. That’s a huge win for us. I’m not flying blind.”

This experience has also enhanced how Pool connects with buyers and category

EMERGING BRAND

Photo courtesy of Steiner’s Coffee Cake

managers to find ways Steiner’s can meet consumer demand.

“My job is to help [retailers] understand how Steiner’s fits into their offering,” Pool said. “They shouldn’t have to do that work. I can do that really well now, and they’re willing to have a conversation with me because Mondelez thinks we are someone to listen to.”

Harkening back to her advertising and marketing experience, Pool is intent on building those key relationships in all aspects of the Steiner’s business.

“Whether it’s on the supply side or the consumer side, relationships matter,” she said. “You have to be authentic and genuine. They won’t always work out, and that’s okay. You can still be gracious

and appreciate the value of the person sitting across the table from you. In the end, everyone brings something that makes you better at what you do.”

Beyond the brand’s signature coffee cakes and flour blend, Steiner’s plans to expand with a gluten-free cheesecake, not to mention new ideas rolling in daily from Nanci. Although there are certain milestones Steiner’s must meet before expanding further, the future she envisions for her family’s company is crystal clear.

“I want us to be a household name,” Pool said. “I want people to think of Steiner’s and say, ‘They’re invited to my table. Steiner’s can be in my kitchen.’ That’s my vision, that’s my hope, that’s my dream.” CB

Beyond the brand’s signature coffee cakes and flour blend, Steiner’s plans to expand.

Minimize labor issues!

THE PRETZEL NEXT DOOR

BY JOANIE SPENCER

If Matt and Katie Wessel knew then what they know now, Milwaukee Pretzel Co. might never have been on the map.

When the concept of this Mi lwaukeebased pretzel brand was conceived, the Wessels — Matt, president and COO, and Katie, CEO — hoped they could start a business that would involve around 500 pretzels a day.

But they didn’t anticipate how the predominantly Germanic Milwaukee market would receive the pretzels … or how it would lead them down a path of automated innovation. Sometimes, a big dream and a little blind faith can take entrepreneurs a long way.

“If someone would have shown us 10 years ago what we have today and said, ‘This is what you’re working toward,’ we probably would have been too scared to jump in,” Matt said. “What we have today — and the path we’re headed down — far exceeds what we thought we’d be doing.”

The Wessels never actually planned to manufacture pretzels. They originally sought a co-manufacturer to produce the Bavarian-style delicacy they fell in love with while living in Munich.

COMMERCIAL BAKING 49

Food Media

All photos by Avant

FEATURED BAKERY:

PRETZEL

Consistency in size, weight and shape is critical to Milwaukee Pretzel’s process. Automation helps achieve that goal.

MILWAUKEE

How Milwaukee Pretzel Co. turned a Bavarian tradition into a hometown staple.

However, the complicated process involving a caustic bath — what gives the product its signature color and flavor — was not appealing to a typical bakery operator. So, the Wessels forged ahead, making them by hand.

Within two years, Milwaukee Pretzel had not only gained notoriety in its hometown, but it had also caught the attention of broadline distributors with clients in Chicago and Minnesota’s Twin Cities. Soon, the business was in a growth cycle between expanding clientele and a hiring boom to keep up with demand.

“When you’re building a business, you see yourself going in one direction, but sometimes you go a little off the path, and you discover that’s the direction you were

meant to go,” Katie said. “You obviously need to have expertise and knowledge to steer things in the right direction, but at the end of the day, a lot of our growth was fueled by demand.”

After building an operation that consisted of little more than rolling, cutting and twisting pretzels by hand, the brand and workforce grew in tandem. And while growth changed the game for the business, it also meant a steeper learning curve.

“When you’re training people while also producing large volumes by hand, you end up with a lot of rejects,” Katie said. “It takes a lot of time and investment to teach someone how to roll a pretzel because it’s not a skill that people inherently have.”

AUGUST 2023 Q3 50 MILWAUKEE PRETZEL

“What we have today — and the path we’re headed down — far exceeds what we thought we’d be doing.”

Matt Wessel | president and COO | Milwaukee Pretzel Co.

Automating the twisting of standard-size pretzels freed up employees to focus on more artisanal tasks.

#WeDoughItAll Variety Specialty Rolls Round Rolls | Moulded Roll | Pretzel Rolls Contact a Bakery Expert Today! CREATING CUSTOM SOLUTIONS SINCE 1972 www.geminibakeryequipment.com | 215.673.3520

The early days of entrepreneurship can look more like a constant stream of small, immediate decisions. But as a business grows, those decisions can often get bigger, cost more, have a longer-lasting impact and require a more strategic view.

Those kinds of decisions are how the company has successfully executed its slow, managed growth.

The move to automation was calculated, but it also came out of need. One foundational aspect of Milwaukee Pretzel is the customer-first mentality that Katie established when she started the company. So, as the operation grew into a need to automate, she prioritized educating her team on the specificities of each customer’s product.

“I’ve worked with our production teams to help them understand the customer and the process,” Katie said. “If I tell them something has to be done a certain way, there’s a reason. I help them connect the dots by saying, ‘These pretzels have to be done this way — or in this shape — because the customer is doing something specific with them.’ That has become the basis for everything we do.”

Katie’s integrity ensured that when it was time to scale the pretzels wouldn’t change. That proved to be one of the hardest challenges when the complicated nature of the process limited their immediate resources.

“I still say that the biggest accomplishment of my professional life is, hands down, scaling a Bavarian pretzel,” Katie said. “It’s hard to do, and there aren’t a lot of people in the country who have done it.”

While automation can make things faster, easier or perhaps even cheaper, none of

those were motivating factors for Milwaukee Pretzel. Baking is a combination of art and science, but when scaling a product like this, precision is everything.

WATCH NOW:

The Wessels took great care in seeking supplier partners that could create pretzels with the same quality as the original handmade version without changing the formula.

Some decisions were easy, such as moving from baking on parchment paper to using custom-coated pans from Chicago Metallic, a Bundy Baking Solution. But the Wessels also fiercely focused on automation as a means to make the process more efficient and the workers’ lives easier.

One of the earliest investments was automating the caustic bath, a tedious and labor-intensive process that’s now achieved through a lye shower from WP Riehle.

“We were using lye buckets, so when we got this machine, it was the best thing ever,” Katie said. “Before automating, we had to use huge gloves and masks, and it was really difficult.”

A recent investment allowed a portion of Milwaukee Pretzels to be automatically divided and rounded on Gemini equipment, then formed, rolled and twisted on two Fritsch makeup lines, both of which have provided consistency in size, weight and shape that’s critical to the process.

“If shaping and folding is not done well, it’s a domino effect everywhere else,” Katie said. “I’ve learned that the key to scaling is that it has to be done exactly the same every time. If one piece isn’t done well, it affects everything down the line, and you’re constantly making adjustments.”

AUGUST 2023 Q3 52

MILWAUKEE PRETZEL

Katie Wessel shares her insights on producing Bavarian pretzels at scale.

Even as Milwaukee Pretzel gains national recognition, Matt and Katie Wessel remain committed to keeping it a customer- and workforce-centric business.

+1 (978) 667-0400 | www.wilevco.com | sales@wilevco.com | 10 Fortune Drive, Billerica, MA Take control with Wilevco. Batter MixingTemperature ControlCoating Grill Marking Oil Filtration Integrated Coating System Better coating.

“Seeing Fritsch’s passion for their equipment — and knowing they’re a premier pretzel equipment manufacturer — made us very comfortable taking the leap with them,” Katie said. “When we ran our dough on the equipment and saw the results, that was the ‘wow’ moment. They understood what a Bavarian pretzel was supposed to look and taste like. They wanted it to be as perfect as we did, and they weren’t frustrated at our expectations for perfection.”

The two lines provide relief for small, tedious tasks like cutting and twisting, freeing up workers to focus on bigger, more artisanal tasks like twisting the gigantic 16- and 24-oz. pretzels, which require fewer twists to make.

As Milwaukee Pretzel’s founders and original brand ambassadors, Matt and Katie have spent a decade developing tribal knowledge that’s already being passed on to the bakery’s growing workforce. In a classic entrepreneurial learn-as-you-go mentality, the team is tapping into automation to develop a workforce made up of more than just line workers. This company is a group of operators, marketers and product developers who, together, are creating something they believe in.

After a decade in operation, Milwaukee Pretzel remains a customer- and workforce-centric family-owned business that often still feels like a startup, especially when it comes to making work feel more like fun sometimes.

“We have a fun brand,” Matt said. “We’re not above poking fun at ourselves and being whimsical at times. At the same time, we’re really connected to our community, and I think all that rubs off on the people who work here. We still call ourselves a startup, even after 10 years, because we still feel that small and tight-knit. Everyone here works hard and helps each other, and that’s what we’re trying to hold onto.”

That’s the culture the Wessels have built, and as the brand grows to national notoriety, it’s the hometown feel that will remain. CB

INNOVATIONS FROM THE BAKERY FLOOR

In just a decade, Milwaukee Pretzel has gone from a handmade labor of love to an automated operation in a 22,000sq.-ft. facility located on 4.5 acres. The pretzels are sold in 20 states through retail and foodservice, as well as direct to consumer nationwide via e-commerce. Below is a list of suppliers that have enabled this bakery to make a consistent product at scale while never straying from the original formula.

ABS mixers

ADCO Manufacturing cartoner

Chicago Metallic, a Bundy Baking Solution custom-coated pans

Dinamica/Sottoriva divider/rounder

Fritsch sheeting, makeup, twisting lines

Gemini divider/rounder, proofer

LBC proofer

Macadams Baking Systems rack ovens

MIWE rack ovens

WP Riehle caustic bath system

AUGUST 2023 Q3 54 MILWAUKEE PRETZEL

The company chose to work with Multivac/Fritsch to automate dough makeup and twisting for its standard-size pretzels, specifically because of Fritsch’s pretzel expertise.

Investing in automated dough makeup lines helped Milwaukee Pretzel maintain control over product quality.

TORTILLA BASKETCASE LOADER

Unlock the Beauty of Simplicity

Servo-driven retractable conveyor belt that loads all type of flat breads in movable baskets/cases. Made for tortilla producers in USA and Canada.

• Versatility. It can be used for a lot of different types of flat bread of all sizes. The size of the conveyors can also be adjusted according to product matrix.

• Accelerate the shipping and post-production steps by eliminating downtime and keeping high efficiency in the loading process.

• Reduce labor by automating the loading of baskets with retractable conveyors.

Features

Energy savings: Entirely servo driven.

Maintenance: Low maintenance cost among timing belt options.

Operator Friendly: No need to adjust the recipe for different trays or baskets (in most cases).

Installation & Operation: Plug and play type feature.

Safety: A safety scanner eliminates the need for fencing or obstructive guarding and improves access to components for maintenance and sanitation.

CONTACT US TO AUTOMATE SMARTER (879) 846-4490 | rexfab.com

All Quiet on the M&A Front

Food companies are taking a more disciplined, strategic approach to how they grow their businesses.

BY MARI RYDINGS

In the three years leading up to the pandemic, the food industry was in its heyday of mergers and acquisitions (M&As), with many companies engaging in the activity as a source of cost-cutting — and just as many companies looking for a good deal. Fast-forward five years: Food companies, leery of recession fears, inflation, rising interest rates and the ongoing battle against supply chain disruptions have turned their attention away from M&A activity. Instead, they’re choosing to funnel energy and cash into their core businesses and infrastructure.

The pivot caused a significant slowdown in big-money deals across the food and beverage industry. The commercial baking sector, specifically, has followed suit.

“Commercial baking is following the current trend in the larger food and beverage space of slowing down when it comes to mergers and acquisitions,” confirmed Glenn Pappalardo, managing director of JPG Resources, a consultancy focused on innovation, strategy and execution in the CPG food beverage space. “Bigger-end strategic buyers are looking to derive value from their existing portfolios versus going out and spending half a billion dollars on perhaps a fast-growing but highly valued emerging brand.”

That’s not to say M&A is dead; there are still deals to be made. Food and beverage companies are taking a more strategic approach than they may have in years past, with many of them acquiring brands that will either help them expand quickly into fast-growing categories or build out the distribution of a core business.

© inimalGraphic on Adobe Stock

© inimalGraphic on Adobe Stock

COMMERCIAL BAKING 57

CRITICAL ISSUES: MERGERS AND ACQUISITIONS

US VC Deal Activity in Consumer Food & Beverage (2018-YTD*)

However, contrary to recent years when companies were willing to pay premium valuations in return for fast growth from an emerging brand, analysts have observed a change in perspective. Businesses are more cautious of the valuation and ensuring the premiums align with the growth expected from the acquisition.

“Companies are looking for ‘tuck-in’ acquisitions, things that add to growth,” said Brittany Quatrochi, an equity research analyst with Edward Jones. “Major food companies may use these smaller acquisitions to get their sales line going a little bit, which is going to be increasingly important. These will likely be deals they pay for with cash, that don’t require a large amount of integration, and that help them boost those faster-growing areas.”

Quatrochi noted Hershey, PA-based The Hershey Co.’s December 2021

purchase of Dot’s Homestyle Pretzels, which helped the company broaden its salty snacks portfolio.

“That was not a large-scale acquisition, but meaningful for them in terms of their growth outlook,” she said.

On a larger scale, Chicago-based Mondelez International acquired Clif Bar & Co. in 2022 as a way to quickly increase its presence in the fast-growing bar category. The purchase expanded the company’s global snack bar business to more than $1 billion.

Additionally, Thomasville, GA-based Flowers Foods spent $270 million on Papa Pita Bakery, a manufacturer and distributor of high-quality bagels, tortillas, breads, buns, English muffins and flatbreads. The deal included a sizeable co-manufacturing business and a state-of-the-art 270,000-sq.-ft.

baking facility. The strategic move also expanded the bakery manufacturer’s geographic reach with direct-store distribution in the Western US.

“We have identified very clearly what kind of M&A we would like to do,” said Martin Renaud, executive VP and chief marketing and sales officer of Mondelez, during the annual Consumer Analyst Group of New York (CAGNY) conference earlier this year, when asked about the global snack manufacturer’s current approach to acquisitions. “But it’s just being very clear on what we want, having clear criteria on what are they bringing to us, and then trying to find the right partners and build the right deals to make that happen.”

While the right deal looks different for every company, current M&A trends point to three common themes: maturity, scalability and sustainability.

AUGUST 2023 Q3 58 MERGERS AND ACQUISITIONS

Data, Inc. DEAL VALUE ($B) A noticeable decline in venture capital funding for early-stage food and beverage companies over the past few quarters indicates investors are being more selective. DEAL COUNT $3 $1 $2 2,500 2,000 1,500 1,000 500 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 Q3 Q4 Q1 Q2 2019 2020 2021 2022 2023* $0.6 $0.7 $0.4 $0.5 $1.1 $0.8 $0.8 $1.2 $1.0 $1.7 $1.5 $2.3 $1.3 $1.5 $0.8 $0.8 $1.0 0 587 678 396 484 1,087 774 810 1,239 1,013 1,737 1,536 2,316 1,349 1,505 761 785 1,030 $0 0 Deal Value ($B) Deal Count 2019 Q1 $0.6 587 Q2 $0.7 678 Q3 $0.4 396 Q4 $0.5 484 2020 Q1 $1.1 1,087 Q2 $0.8 774 Q3 $0.8 810 Q4 $1.2 1,239 2021 Q1 $1.0 1,013 Q2 $1.7 1,737 Q3 $1.5 1,536 Q4 $2.3 2,316 2022 Q1 $1.3 1,349 Q2 $1.5 1,505 Q3 $0.8 761 Q4 $0.8 785 2023* Q1 $1.0 1,030 Q2 $0.0 0 *as of Apr. 4, 2023

Source: PitchBook

CAPTURE THE WINDS OF CHANGE. QUICKLY, AND WITH GENTLE HANDLING. BROUGHT TO LIFE WITH SCHUBERT.

Fresh, crispy baked goods are delicious, But they tend to crumble during packaging. Our solution: gentle robotic hands and a 3D scanner to monitor quality. In a machine that adapts to a wide variety of products in no time at all, Packaging them fully automatically in sustainable materials. In line with our Mission Blue: Only if it’s good for the planet, it’s good enough for our customers. www.schubert.group/en/Confectionary-snacks/

PACK EXPO LAS VEGAS

SEPTEMBER 11-13, 2023

SOUTH UPPER HALL BOOTH 7654 WELCOME

PACK EXPO LAS VEGAS

SEPTEMBER 11-13, 2023

SOUTH UPPER HALL BOOTH 7654 WELCOME

All three were key factors in Lenexa, KS-based Hostess Brands’ $320 million acquisition of Voortman’s Cookies Ltd. in January 2020. During a presentation at the Deutsche Bank dbAccess Global Consumer Conference in June, Andy Callahan, president and CEO of Hostess Brands, commented on the strategy behind the acquisition.

“The Voortman’s business is a branded business in what we call a scalable niche in a sub-segment of a large category that we thought was growing at greater the rate, similar to Hostess,” Callahan said. “We were able to transform the portfolio in an area we thought was growing greater than food, which snacking is. When we invested in these capabilities, whether it’s data, innovation or brand growth — all that works through our warehouse distribution model — all these capabilities Voortman was scalable to … and it’s been successful.”

At the same time major players have been re-evaluating their acquisition strategy, venture capitalists and private equity investors typically interested in early-stage food and beverage companies are also rethinking their approach to funding these types of businesses.

According to data provided by PitchBook Data, Inc., in the first three months of 2023 there were 1,030 deals that raised about $1 billion, compared to 1,349 deals totaling $1.3 billion during the same period in 2022. The last quarter of 2022 recorded a significant drop, both in the number of deals closed and capital raised, with 785 transactions raising $800 million, compared to 2,316 deals that raised $2.3 billion during the same period in 2021.

“A lot of venture capital and private equity investors have pulled back because the multiples were already high before the pandemic,” Pappalardo said.

“Many people thought the onset of the pandemic might be a correction, but with all the relief funding put into the system, it actually propped up the multiples and, in some cases, made them worse. Eventually, a lot of investors weren’t seeing enough value out there at those levels of multiples to keep looking, especially when you factor in an uncertain economic outlook.”

With a six-year track record of heightened multiples, investors also began to see how some of those earlier investments have panned out and their lackluster performance is giving them pause.

AUGUST 2023 Q3 60

MERGERS AND ACQUISITIONS

“Just a few years ago, strategic buyers would be chomping at the bit for a company with top-line revenue growth of $25 million to $50 million.”

Kevin Weigand | M&A diligence lead | JPG Resources

Photo courtesy of Voortman’s Cookies

Ltd.

Hostess Brands’ acquisition of Voortman’s Cookies in 2020 fit the snack cake manufacturer’s current criteria: It was a scalable business in a niche sub-segment of a category that is experiencing growth.

GASHOR boasts over 50 years experience providing customized turnkey solutions in handling, automation and dosing of powders, granules and liquids.

Our headquarters are in Europe and we deliver complete automatic ingredients installations around the world.

- Flour Cooling System

- Indoor and Outdoor Storage Silos

- Super Bags Loading and Unloading Stations

- Bag Dump Stations

- Special Solutions For Dosing and Conveying of Micro Ingredients

- Mechanical And Pheumatic Conveying Systems

A.A. Bakery is a supplier of European Bakery Solutions and Equipment and is the Authorized Dealer of GASHOR equipment.

contact A.A. Bakery for your

sales@aabakeryservices.com | (732) 575-9740 Contact AA Bakery to Get Started. aabakeryservices.com

Please

needs.

“Just a few years ago, strategic buyers would be chomping at the bit for a company with top-line revenue in the range of $25 million to $50 million,” said Kevin Weigand, M&A diligence lead at JPG Resources. “That appetite has soured. Right now, they aren’t looking at anything below $50 million to $100 million. They’re looking at slightly more mature companies with a larger focus on things like scalability, profit margins and a clear path to profitability. It can’t just be a promise. There has to be some real groundwork laid there.”

In the past, larger companies were willing to acquire smaller brands they could nurture and grow. Today, they are seemingly hesitant to take a leap of faith and figure out how to unlock growth by increasing capacity or putting their own team in place.

“They have way less of an appetite for doing the work themselves,” Pappalardo said.

Weigand also noted that he’s had clients stop an acquisition deal when an emerging brand couldn’t meet certain requirements.