Tips on how to do sandblasting when required. The most distasteful part of the Restoration process I can think of is sandblasting. You get sand in places that you didn't even know existed, you have a hot hood over your head for the duration, it's hard to breathe with or without a respirator, and it's slow to go what equipment you need to do the job. If I hadn't so profoundly believed in it, I wouldn't doubt it for a minute. Sandblasting is the easiest and only accurate way to eliminate dust and corrosion that better trains the metal for a long-lasting paint job. Rust neutralizers, paint-over-rust goods, wire cleaning, nothing works like sandblasting to get into the metal and deep clean.

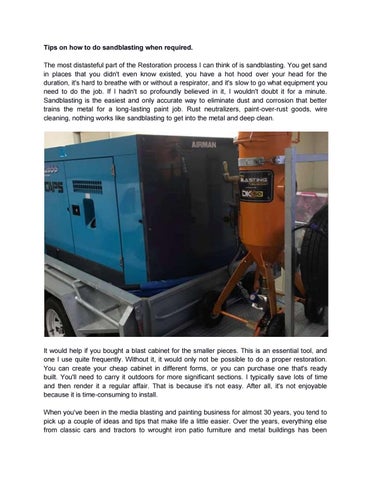

It would help if you bought a blast cabinet for the smaller pieces. This is an essential tool, and one I use quite frequently. Without it, it would only not be possible to do a proper restoration. You can create your cheap cabinet in different forms, or you can purchase one that's ready built. You'll need to carry it outdoors for more significant sections. I typically save lots of time and then render it a regular affair. That is because it's not easy. After all, it's not enjoyable because it is time-consuming to install. When you've been in the media blasting and painting business for almost 30 years, you tend to pick up a couple of ideas and tips that make life a little easier. Over the years, everything else from classic cars and tractors to wrought iron patio furniture and metal buildings has been