SOLUTIONS FOR 7-STAR HOMES

AWS, is your partner for success.

Aluminium window and door systems, designed and made for Australian regulations and conditions.

Want to know more? www.awsaustralia.com.au

Introducing the DR2210, our latest Australian designed and engineered piece of innovative sliding door hardware.

Suits a wide range of residential and commercial sliding door systems, including some that have not been invented yet.

Talk to us or your Doric Rep for more information.

Outer and internal assembly manufactured to withstand corrosive environments Recommended

Fully adjustable carriage gives 10mm height adjustment

Purpose built end caps to suit specific extrusions

AUSTRALIA’S BEST & BIGGEST RANGE OF WINDOW AND DOOR HARDWARE

For sales & information: sales@doric.com.au

1300 132 389 www.doric.com.au

Self-adjusting load distribution bogey for smooth and durable rolling

Being INNOVATIVE has brought us success for over fifty years, so of course we’re going to continue rolling with what works for us.

EDITORS

Melissa Baker, Ingrid Pagura

SUB EDITOR

Helen Dawes DESIGN

Webqem Pty Ltd

Ahmad Awick, AGWA

EDITORIAL & ADVERTISING ENQUIRIES

Helen Dawes

+61 2 9498 2768 marketing@agwa.com.au

PUBLISHED BY

AWA-AGGA LIMITED

ABN 57 629 335 208 Suite 1, Level 1, Building 1, 20 Bridge Street, Pymble NSW 2073 +61 2 9498 2768 admin@agwa.com.au www.agwa.com.au

COVER IMAGE & CONTENTS PAGE IMAGE

City Beach House, City Beach, WA

Project by Westec Doors & Windows

Architect: Steeg Banham, Banham Architects

Builder: Tony Tomizzi Builders

Photograph: Andrew Pritchard Photography

CONTRIBUTORS

Clinton Skeoch, Derek Tidey, Tom Devitt, Atul Singh, Eloise Turnbull, Sam Nelson, Ingrid Pagura, Helen Dawes, Melissa Baker, Samantha Anderson, Angela Farrell, Tony Song, Vivienne Munter, Ahmad Awick, Mike Ward, Russell Harris, Brenton Beahan, Elizabeth Dimabuyu, Mari Lehtinen, Roger Bishop, Joshua Ianni, Melissa Varga-McGaw, Jack Baker, Chris van Dijk, Frank Castellano and Daniel Johns.

PRINTED BY

SOUTHERN IMPACT

southernimpact.com.au

Our printer conforms to the ISO14001 environmental management standard and the ISO-9001 quality management standard.

DISTRIBUTED BY

D & D MAILING SERVICES www.ddmail.com.au

BuiltView Magazine is proudly packaged in Biowrap, 100% degradable plastic wrapping.

DISCLAIMER

Copyright © 2023. All rights reserved. Reproduction in whole or part without written permission from AWAAGGA Limited is strictly prohibited. It is impossible for the publisher to ensure that the advertisements and other material herein comply with the Australian Consumer Law Competition and Consumer Act 2010. Readers should make their own inquiries in making decisions and where necessary seek professional advice.

Clinton Skeoch CEO and Executive Director, Australian Glass & Window Association

As we reach the halfway mark of 2023, it's time to reflect on the progress we've made and the challenges we face in the months ahead. At AGWA, we've had a busy start to the year, with over 33 dispute and non-compliance investigations already underway. We're committed to ensuring that our industry maintains the highest standards of safety, quality, and professionalism, and we will not hesitate to take action when necessary.

Looking ahead, I would like to remind you all of our upcoming AusFenEx23 Conference, which will take place from the 29-31 August 2023 at the Royal Pines Resort on the Gold Coast. This event promises to be a highlight of the year, providing our members with a fantastic opportunity to connect with industry leaders, exchange ideas, and learn about the latest developments in our field.

For those who may have missed it, the NCC General Provisions have come into effect on the 1 May in most states, with alternate adoption dates for livable housing and condensation provisions being staggered. Most notable, the 7-Star energy efficiency provisions will come into effect in most markets for developments post-October this year. We encourage our members to look out for further information in the other sections of this magazine, as well as on our website and social media channels.

For those who may be unsure of the impact of these changes on their markets, we remind you that our hardcopy NCC 7-Star Report has been sent to all members. This Report provides invaluable insights on the likely impacts of the changes, helping you navigate these once-in-a-decade changes. If you have any questions or concerns relating to any of the NCC amendments or adoption timelines, please reach out to our Tech team for support.

In closing, I would like to thank all of our members for their continued dedication and commitment to our industry. Together, we can build a brighter future for the glass and window sector in Australia.

Derek Tidey Chairperson of the Board NationalSecurity Screen Association

The NSSA is always seeking to connect with, engage and support our members. We are pleased to announce the launch of the new NSSA website and APP. A member-friendly website and APP that is loaded with learning resources, marketing guides and technical updates, all at your fingertips and accessible via your phone or iPad. Download 'Member Jungle' from your APP Store now and search for ‘NSSA’ sign up and you're in.

The review of the Australian Standards has been out for public review and the NSSA Technical Committee has provided members with an overview of the changes now represented as AS 5039.1 and AS 5039.3 and have put forward the NSSA position on the proposed changes. I encourage members to be involved in this process and provide feedback via the Australian Standards platform or through the NSSA Sub Committee. A review of AS 5040 is now underway and will go through the same process of public review. The NSSA will keep you updated on the progress.

Lobbying of the QBCC for the inclusion of a new License Class for Blinds, Awnings, Security and Grilles continues, with Letters of Support from NSSA Industry Partners and other associations, businesses, and government bodies being collated. We will present these letters to the Department of Energy & Public Works. The proposed qualification for this License Class will be the Cert III Blinds Awnings, Security and Grilles (MSF30919).

The NSSA Forums and Training sessions are due to kick off with Melbourne Training 17 May and Forum 18 May; Sydney Training 14 June and Forum 15 June and; Brisbane Training 19 July and Forum 20 July. These events are for our members to unite, share and learn. I ask that you invest the time for you and your staff to attend and participate in these events.

BuiltView Magazine is a quarterly publication of the Australian Glass & Window Association and the National Security Screen Association.

Atul is a Director at Adams & Partners in charge of the Litigation Department, covering both civil and criminal litigation.

He has over 17 years of experience in the legal industry in the public and the private sectors, successfully achieving great and practical results for businesses and individuals in New South Wales. His experience expands from extensive court work in litigation and appeals in criminal and civil matters, including contracts, building and construction, contracts, defects, property and development, extraditions and defence proceedings.

Atul was also a recipient of the Minister’s Award during his time with the public sector.

Ingrid Pagura Industry Development Coordinator, AGWA

Ingrid began her role with AGWA in May 2021 looking after the training needs of members. Her role soon progressed to include working on BuiltView, the AGWA Design Awards, the website and other marketingrelated activities.

Prior to AGWA, Ingrid worked for a legal publishing company as an editor, a publishing manager and then an editorial trainer. Her time at Butterworths saw her work on their building and local government and environment suite of products and with the CSIRO and ABCB on other BCA projects. She also previously worked for many years as a part time teacher at TAFE teaching law, business, communications and work health and safety across multiple faculties.

Samantha Anderson National Marketing Manager, AWSSamantha Anderson is an award-winning marketing and business strategist with over 20 years’ experience in commerce and 10 years in the building materials industry. Samantha is the National Marketing Manager of Architectural Windows Systems and has a proven track record leading successful brands with customer-centric strategies. Utilising curiosity and a challenger mindset, Samantha tailors and takes control of the marketing funnel to deliver increased long-term brand equity. Samantha is passionate about building better homes for comfort, energy efficiency and long-term sustainability.

Russell Harris Technical Manager, AGWAWith over 20 years’ industry experience Russell has a thorough understanding of fenestration, including compliance, product design, development, and testing. Russell’s background in R&D means he is familiar with many of the emerging technologies, innovations and market influences that are likely to impact the industry in the future. Since joining the Association in 2016, Russell has been a noteworthy leader in the technical space, and an active contributor to the ongoing development of the Regulatory framework affecting the window industry.

Angela Farrell Copywriter, Trade Advertising Agency. Australian Olympian.

Angela Farrell Copywriter, Trade Advertising Agency. Australian Olympian.

Angela is an advertising copywriter and business content writer with over 15 years, advertising agency experience. She loves the challenge of working across industries and genres; writing radio ads for snack brands, websites for SaaS, articles for AGWA, and everything in between!

Having represented Australia in the sport of sailing, Angela is passionate about the teamwork and hard work that goes into success — be it in sport or business.

Tom Devitt Senior Economist, HIATom joined HIA as an Economist in 2018. As Senior Economist, he assists in the research and analysis of housing market trends and manages the assumptions and statistical modelling behind HIA’s residential building forecasts. He has also authored many of HIA’s wide range of economics publications. This provides him with the insight and expertise to advocate to all levels of government and media on behalf of the housing industry, for the purpose of informing policy debate. He has provided advice to both the private and public sectors across a range of areas.

Sam Nelson Head Solicitor, Litigation team Greenhalgh PickardSam is the Head Solicitor in the litigation team at Greenhalgh Pickard. He has a Bachelor in Law from the University of the Sunshine Coast and is admitted to the Supreme Court of Queensland and the High Court of Australia. Sam has been involved in and has experience in a wide range of both commercial and civil litigation disputes. He also volunteers at the Suncoast Community Legal Service.

Prior to commencing his legal career, Sam worked in the financial planning and selfmanaged superannuation fund industry for over 10 years.

Eloise is a solicitor in Greenhalgh Pickard’s litigation team. She holds a Bachelor of Laws (Honours Class I) from the University of the Sunshine Coast. In 2021, Eloise completed her Graduate Diploma of Legal Practice at the College of Law and was admitted to the Supreme Court of Queensland.

Eloise Turnbull Solicitor, Greenhalgh Pickard

Eloise Turnbull Solicitor, Greenhalgh Pickard

It is with a profound sense of loss that we acknowledge and honour the life of the AGWA Chair Elizabeth North. She was a truly remarkable woman who has touched the lives of so many in our industry and her local community.

Liz served on the Board of the Australian Glass & Window Association as both Chair and Treasurer, as well as on the board of the AWA prior to the merger. The Liz I have grown to know well over the last five years, was not only a successful businesswoman and director of AVS Windows and Doors, but she was a passionate and selfless individual who dedicated her life to serving her community. Her service to me, and AGWA more broadly, was incredibly appreciated.

With her long history in the window and glass industry, many of those years as a key part of one of our industry’s leading companies, Liz not only understood the needs of bigger business, but also the needs of the small. Over the past almost 19 years, Liz, in a dynamic business partnership with Darren Andrew, built AVS Windows and Doors into a strong window and door company known for its quality and customer orientation.

In every engagement I had with Liz it was clear she always made decisions with integrity and a solid sense of what was right and fair. In our discussions, many an industry problem was discussed, with Liz asking me to work through the problem using the Rotary four-way test.

• Is it the TRUTH?

• Is it FAIR to all concerned?

• Will it build GOODWILL and BETTER FRIENDSHIPS?

• Will it be BENEFICIAL to all concerned?

To those who met Liz, it was clear she was hard to forget, not only for her vibrant orange outfits, but also for straight talking. Her proactive and pragmatic approach to industry challenges, was always to see them as opportunities for growth, renewal and optimism. While much of what I have outlined talks to her business skills, she was so much more than just a strong female leader in our industry. In fact, it was Liz's caring heart and passion for serving her community that truly set her apart. She was a committed volunteer with the Rotary Club of Wyong and Tuggerah and Bendigo Bank Wyong, where she mentored and created opportunities for the next generation of Australian leaders through RYLA (Rotary Youth Leadership Awards) and the Wyong Bendigo Bank Youth Director Program. Her tireless efforts helping many young people realise their potential and making a difference in the world require equal recognition. While her contributions to the industry and community were immeasurable, there are not enough words to describe the love and sense of pride she had for her family. Often Liz would talk fondly about the experiences she had with daughter Kiera and the ‘little people’ around her small farm. She would deliver advice to me in the midst of nurturing her beloved grandkids or her cows … an action that sometimes led to some confusing words of wisdom when she tried to multi-task while corralling cows in the paddocks.

Liz was an amazing woman, a true leader, and a dear friend to me and indeed many. Her counsel and leadership will be sorely missed, but her legacy will live on through the countless lives she touched and the impact she made on our industry, her community and most importantly her family. I will always remember her considered counsel, unwavering integrity, and her passion for making a difference.

In recognition of Liz and her contribution as AGWA Chair, the AGWA Board has decided to dedicate the Gala Dinner at the AusFenEx23 Conference in her honour. Rest in peace, Liz.

Clinton Skeoch Executive Director and CEO

Clinton Skeoch Executive Director and CEO

LENDING IS A RISKY BUSINESS

Thomas Devitt, HIA Senior EconomistRBA adds insult to injury

The steepest cycle of RBA rate increases in a generation is compounding several structural problems that have been decades in the making, undermining homeownership in Australia.

In the years since the Global Financial Crisis (GFC), Australia’s financial market and banking regulators have sought to create an ‘unquestionably strong’ financial system. This decade of reforms has reduced risk in the system but has come at a cost. This cost is borne by first-time home buyers and less affluent Australians who are being forced out of the market, which is contributing to the decline in homeownership.

The collapse of several major financial institutions in the USA and Europe during the GFC, led banking regulators in Australia and around the world, to work to reduce the risk of residential mortgage business within the banks, for fear that they may be faced with a similar financial contagion in the future.

It is worth noting that while the GFC led to an increase in impaired loans, the share of lending that this affected was still very small. At its worst in mid-2010, impaired loans by authorised deposit-taking institutions (ADIs) accounted for only 1.6% of lending. This was small compared with the experience of banks in other jurisdictions during the GFC.

Despite the resilience of the Australian financial system during the GFC, the Government and regulators have adopted a ‘belt and braces’ approach designed to ensure that the banking sector is ‘unquestionably strong’. This means they have enough capital reserves to withstand any conceivable financial or economic shock and that there are rules in place to prevent excessive risk taking.

The riskiness of a bank’s loan portfolio dictates the amount of capital the bank must hold — a riskier portfolio of assets requires a bank to hold more capital in reserve.

Recent changes imposed by the Australian Prudential Regulatory Authority mean that lending in segments of the market that are perceived to be risky, required banks to hold more capital in reserve than they had in the past, thereby increasing the cost of lending.

Since 2008, ADIs have increased their capital as a share of total risk-weighted assets from around 10.5% to as high as 18.5%.

Residential mortgages were also deemed to be riskier than they had been considered prior to the GFC. This meant that mortgage lending became more capital intensive and lenders priced-in the additional costs through higher

borrowing costs. This was more significant for riskier types of loans, such as interest-only loans, loans to investors, loans with high loan to value ratios and loans in riskier geographic areas.

Just in case this wasn’t enough, banks must also now apply much greater scrutiny on the income and living expenses of applicants; there are tighter criteria for assessing loan serviceability buffers; lenders are required to discount non-salary income (such as rental income, bonuses, overtime etc) when establishing an applicant’s income; there are more restrictive criteria for assessing applications for interest-only loans; and guidelines were added for mortgage lending to self-managed super funds.

The combined impact of a decade of tightening lending restrictions means that it is considerably more difficult for many home buyers to obtain housing finance.

Banks continue to assert that they are open for business and the RBA echoes this sentiment, noting that there is strong competition for borrowers of high quality. This is great news for ‘high quality’ borrowers — those with high verifiable incomes and a large asset base against which loans can be secured. But many aspiring homeowners don’t satisfy the new narrow criteria of a ‘high quality’ borrower.

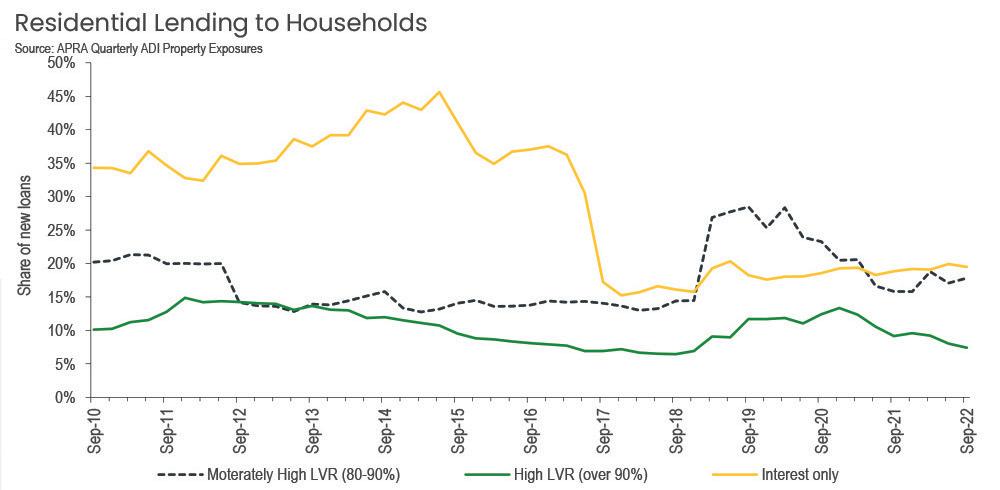

Lending to home buyers with a loan to valuation ratio (LVR) of over 90% (ie, a deposit of less than 10% of the property value) exceeded 20% of new lending in 2009, but now accounts for just 7% of new loans. The ability to access finance with a high LVR was a factor that assisted many first home buyers enter the market, but this is no longer an option for most. In addition, lending to buyers with a deposit between 10% and 20% dropped from 20% of new lending to 15% of new lending.

These reforms over the past decade in residential mortgage lending have been successful in creating an ‘unquestionably

strong’ financial system. Lenders have increased their capitalisation, they have cut back lending on terms that are perceived to be high risk and they managed to implement temporary measures to lean against a property boom.

The problem is that in the pursuit of this ‘unquestionably strong’ financial system, the regulatory squeeze has forced the banking sector to eliminate much of the flexibility that made home ownership accessible for households of variable credit quality.

This compounds the long-term structural undersupply of housing across Australia. For decades, governments at all levels have failed to deliver enough new land supply, or sufficient infrastructure and housing density in existing suburbs, to produce affordable living for Australians.

Add to this the effect on interest rates from the steepest RBA tightening cycle in a generation, and the less affluent end of the financial spectrum is at a serious disadvantage heading out of the pandemic.

Having an ‘unquestionably strong’ financial system is essential to the future of the building industry, but home ownership must remain an attainable goal for all Australian households — and there are plenty of regulatory and planning levers that could be pulled in service of this goal.

• Lifting Capacity Up To 500kg

• Overload Sensor & Alarm

• Dual Pump Vacuum System

• Dual Front Wheel Drive With Off Road Tread

• Combats Uneven Ground Surfaces

• Narrow 800mm Footprint

• Fits Within Site Elevators

• Highly Manoeuvrable

• Through-Door 90° Side Pivot Action

• 360° Unimpeded Rotation

• Variable Hydraulic Speed Control

• Precision Adjustment For Glazing

• 5 X Function Remote Control To Lift; Extend; Tilt; Side-Shift; & 360° Rotation

• And More Features & Options….

HOW TO INDUCT A NEW EMPLOYEE

How you introduce a new employee into your business has a long-lasting effect of their performance and longevity. Taking the time to introduce the employee to your policies, particularly those around safety and to your workplace culture is a great return on your investment. Better still having an Induction Procedure and Checklist means that it will be easier to complete as you won’t need to think about what you may have forgotten to tell them.

Read this article to get some tips on how to run an effective induction of a new employee.

Adapted for AGWA from My Business Workplace — a product of Australian Business Solutions Group’ from an article published/ posted in March 2023.

Induction, or orientation, is the process of introducing a new worker to the workplace and your business. Its aim is to assist the worker to settle into the job and become fully productive and committed to the business as soon as possible.

A well-structured induction program reassures the worker they have made a good decision in joining the business. There are also legal reasons why induction is essential. These include:

• employment documentation, such as confirming contracts and processing tax declarations;

• an obligation to inform workers about their terms and conditions of employment;

• work health and safety issues — the employer has a duty of care to ensure the health and safety of workers and other parties such as customers and visitors to the workplace, which means workers must be aware of their obligations and trained to perform their work safely and with diligence;

• information regarding evacuation procedures, including risk management.

What does an induction program entail?

Induction goes beyond simply training the worker on how to do the job. It also includes:

• introducing the worker to the business and the type of work;

• outlining their roles and responsibilities;

• confirming terms and conditions of employment and completing the initial paperwork;

• introducing them to work colleagues;

• introducing them to the actual job and specific on-the-job training;

• making it as easy and as pleasant as possible for them to settle in quickly;

• fostering a positive attitude towards the business, so they not only become productive quickly but also develop loyalty and commitment to your business’ values and behaviours, and code of conduct.

Induction should not just be a brief set of tasks on the first morning. Successful inductions are a process of building productivity, loyalty and commitment.

While there are routine initial steps to complete, other aspects involve an ongoing process over several days, weeks and possibly even months. Therefore, everyone involved in the process needs to be prepared and know their role.

An induction checklist is also helpful to ensure all steps in the process are covered and followed through.

What do new employees want during an induction?

Surveys of employees suggest their immediate priorities are to:

• know they are safe and their work environment is as well;

• meet their boss;

• meet their co-workers;

• acquaint themselves with their job;

• receive their first work assignment;

• learn the business rules and procedures, both official and unofficial (ie, unwritten)

Here are some tips for successful inductions:

• Have the worker perform productive work as soon as possible — this will help their confidence and sense of achievement.

• Don’t commit information overload on the first day. Provide only essential information at first, further information can be gradual.

• Pay great attention to creating a favourable first impression. Disorganisation, or managers who don’t have enough time, will create a negative first impression, which can be difficult to turn around.

• Continually reassure the worker, provide feedback and answers to questions, monitor and follow up as required.

Induction Checklist PRE-ARRIVAL

• Alert other workers of the new arrival;

• Appoint a work buddy to greet new employees and introduce them to team colleagues;

• Arrange an up-to-date copy of the job description;

• Ensure workstation is ready, with adequate resources to do the job.

INITIAL PAPERWORK

• Go through and explain the employment contract, and arrange signatures;

• Explain Award, contract or agreement coverage, if applicable;

• Explain the operation of employment and probation period, if applicable;

• Complete tax forms and other payroll requirements;

• Outline how the induction program will work and provide information form (see below)

INITIAL 'SURVIVAL' INFORMATION

• Conduct a physical tour of the workplace;

• Show location of amenities — toilets, meal room, lockers, car park, notice boards, printers, HRs office, public transport stops, nearby shops and banks;

• Highlight safety issues — first aid, first aid officer, emergency exit, and security issues;

• Identify the location of other work sections.

INTRODUCTION TO WORK SUPERVISOR

• Provide a personal introduction;

• Provide a brief initial introduction to co-workers and their job roles;

• Issue a copy of the job description and discuss;

• Outline briefly how the worker's job contributes to the business;

• Explain procedures and requirements for hours of work, time-keeping, annual leave, personal and carer’s leave and meal breaks;

• Explain safety procedures and rules that apply to the job and their workplace;

• Issue any property required to perform the job ie, security pass, uniform, tools, mobile phone;

• Explain basic policies and procedures, such as how to answer the phone, leaving work station, dress requirements, use of email, and confidentiality;

• Explain any workplace customs, such as ordering lunches, paying for tea and coffee and paying for the personal use of company property;

• Provide details of major customers and suppliers.

STARTING WORK

• Assign a 'buddy' as a contact person for information and problems, and to accompany the employee to lunch and breaks;

• Explain how to work equipment, eg, computers and machines, operate and check the employee is able to use them properly;

• Assign a simple first work task;

• Make sure someone is available to assist if required and check the work.

END OF DAY ONE

• Have a debriefing session — answer the employee’s questions, and continue to encourage and reassure them;

• Explain the next steps in the induction program;

• Ask the employee for comments and feedback on their first day and beyond as the induction rolls out.

Repeat the last three steps at regular intervals, for example after one week, one month, and at the end of the probation period. Remember, induction has to be an ongoing process, not a one-day drop-andrun activity.

Printed or online support material for inductions

Even in a small business, it is a good idea to provide back-up information in a printed or online form for future reference. Much of the following should appear in a written contract if not, it should be integrated with the induction package.

Suggested support material includes:

• terms of employment — job title, work section, award or agreement coverage, name of supervisor, a probation period, type of work (full-time, part-time, casual, etc);

• pay rate, pay method, pay days;

• hours of work — start and finish times, meal breaks, overtime or shift provisions;

• time-keeping requirements — method, location, lateness, absenteeism;

• leave provisions — annual, personal and carers, how to apply, medical certificates required;

• health and safety — guidelines, procedures, first-aid facilities, incident recording, workers compensation;

• handover documents — outlining key roles and responsibilities for the new employee;

• facilities — parking, public transport, eating and recreation areas, bathrooms, lockers;

• other information — may include dress requirements, uniforms, petty cash, expenses, personal use of various types of employer property, mail, confidentiality, etc;

• performance review — including discipline, the grievance process;

• termination of employment — procedure, notice period, dismissal.

A good approach is to have a standard format that allows generic information to remain constant, and gaps where specific information for each worker's details can be added.

If you have employees who do not speak English well, consider having this information translated or use an interpreter.

My Business Workplace has an induction guide as well as employment contracts and other resources to get set you up for success.

If you would like a copy of a Workplace Induction Checklist to use in your business please contact training@agwa.com.au.

COMMERCIAL WINDOW & DOOR SYSTEMS

Offering high performance, versatility and design flexibility, the CityView TM range of commercial windows and doors, seamlessly integrate into the aesthetic of any commercial project.

Suitable for a range of architectural and commercial applications, the CityView range has been designed & engineered in Australia and tested to AS2047.

To find out more about CityView scan the QR code

A system by

KEY FEATURES & BENEFITS

Easy to fabricate & install

Meets & exceeds AS2047

BAL40 Bushfire rated*

Designed and engineered in Australia

WERS rated for energy efficiency

*Refer to www.darleycityview.com.au for more information.

BAL 40

BAL

Fire Rating

SYDNEY HEAD OFFICE . T: (02) 8887 2888 . E: sales@darleyaluminium.com.au

MELBOURNE . T: (03) 9238 3888 . E: salesvic@darleyaluminium.com.au

BRISBANE . T: (07) 3287 1888 . E: salesqld@darleyaluminium.com.au

PERTH T: (08) 9437 2999 E: saleswa@darleyaluminium.com.au

PAY CLOSE ATTENTION TO THE GLASS/WINDOWS YOU ARE INSTALLING

Atul Singh, Director/Lawyer, Adams & Partners, LawyersIn New South Wales, and throughout Australia, there are Regulations that govern the installation and maintenance of glass and windows in buildings, such as AS 1288 and AS 2047. A contractor may enter into an agreement to either supply and install or install only to their clients.

CASE STUDY 1

An owner decided that it would be cost effective for them to supply the windows and glass to be installed by their glass contractor. That consumer purchased and shipped glass/windows from China. These were promptly installed. On inspection by a building consultant/ certifier it came to light that these products were not compliant with the required Standards here in New South Wales, nor were there any Compliance Certificates. The owner made a claim (of over $200,000) against the glass/window installer, as they had relied on the expertise of their glass/window installer to ensure that there would be no issues with the products. Of course, by the time the case was ready to be heard in court, the prices of labour and materials had increased, which meant that the glass/window installer was looking at a much higher lawsuit. To save on upcoming legal and experts costs all parties entered into a settlement.

CASE STUDY 2

A developer entered into a contract with a builder to carry out the construction of townhouses. That developer contracted directly with a glass manufacturer to manufacture, supply and install glass and windows. The builder’s sub-contractor on-site helped unload the glass and assisted in installing.

A year later, after torrential rain, the windows failed, and the townhouses were flooded. The new owners sued the builder. The builder, during the process, showed evidence to the new owners that he was not contracted for the glass/windows however, as the manufacturer had liquidated, the new owners kept their claim against the builder. This was mostly because it was suggested that the builder (or builder’s glass/window installer who assisted) had ‘a hand’ in relation to work around the windows, the framework, and the lintels. They had other relatively small items to claim in addition, but the window’s claim was the largest by far.

Experts investigated and it was confirmed by both the owners’ and builder’s experts that the window manufacturing was at fault. Further, any certification provided by the manufacturer was invalid as it did not comply with the requirements of the Australian Standards.

The owners then argued that they relied on the builder’s expertise and those faults should have been identified and advised at the time of construction.

(As a side note: section 18D of the Home Building Act 1989 (NSW) provides that the entitlement to the benefit of statutory warranty passes on to the purchaser (if it has not been enforced). There is similar legislation in other states, for example in Victoria (Domestic Building Contracts Act 1995) and in Queensland (Building and Construction Commission Act 1991). Please check the relevant legislation in your own state or territory.

Eventually, after the hearing (and after thorough cross-examination of the owners’ expert), the owners conceded their windows/glass claim.

If you require any legal advice or assistance for personal and/ or commercial matters, get in touch with Adams & Partners, Lawyers at multiple locations on (02) 4721 6200 or visit www.adamslawyers.com.au

CVD COMMERCIAL GLASS AND ALUMINIUM WINDOWS

CVD: A business story that’s worth sharing, liking, and following

‘Three years ago, my wife was using social media to showcase the work of her beauty salon “Lash Esthetica” and their positive results convinced me I should at least try social media for CVD’, explains Chris, who started the company in 2011 in a tiny factory alongside his glazier father and supportive mother.

CVD has steadily built a strong online presence via website SEO, which has seen them climb to the top five organic search results under multiple relevant search options. This presence on Google is a vital step to helping people find out more about CVD’s aluminium windows and commercial glass service before making a purchasing decision. ‘The use of online tools and social media is extremely important, in my opinion’ says Chris. ‘Clients can see our work to get inspired and build trust in us, plus we can contact potential clients through this media.’ CVD uses a photographer to help shoot content, then a digital agency to create their posts and schedule them to platforms such as Facebook, Instagram, Tick Tok and LinkedIn, and soon they plan to create YouTube shorts. ‘My favourite platform would have to be Instagram because you can see photos and videos of projects and other companies' works’, says Chris. Working his way up from the bottom as an estimator and installer, Chris has in-depth knowledge of every system in the business, giving him the ability to pick up issues with architect drawings, assist specification teams at Alspec and ensure designs are fully compliant. ‘Besides our passion for what we do, our main business advantage is that we value compliance. The door and window industry is not government regulated, so there are many companies providing services that don’t fully comply with Standards or requirements’, Chris explains. ‘Our team members are all very proud to be working for CVD and take great pride in quality workmanship. We don’t cut corners and we will not manufacture or install a system or product which is non-compliant.’

This passion and workmanship shines through CVD’s social media accounts on a daily basis. ‘The visibility social media gives us is extremely beneficial, because it’s a platform where we can showcase our projects and market our company and services in a cost-effective way. We’ve reached out to many new customers and gained new business through social media. It also attracts highly skilled tradespeople and staff who, after seeing our social media, want to come across and work for our company — an added benefit I hadn’t anticipated!’ adds Chris.

‘I would have to say the strongest pieces of content we’ve produced are the ones that keep the viewers entertained: how to’s, tips and tricks, and most importantly showing the process of how we do the work’, explains Chris. ‘Client reviews are also extremely valuable for potential clients to gain an understanding on how the business has performed.’

CVD specialises in the difficult projects that others are unable to do due to complexities. Chris puts this down to his licensing and accreditation. ‘I have undertaken the AFRC simulator training as well as multiple AGWA courses and I am a qualified Glazier and have a Master security licence’, he remarks. One of CVD’s most memorable jobs was for St Luke’s Grammar School in Sydney, where CVD was engaged to design and install a curtain wall system spanning 15 m high and 18 m wide curving around the building. ‘This project was highly engaging for our Instagram audience.’ CVD assisted Alspec in the design phase as well as the V6 software to produce the fabrication sheets and was the first ever to manufacture this in Australia, and install this system in Sydney. And it’s not just online that’s keeping Chris and his marketing team busy, there’s lots happening offline for CVD over the next 12 months too: In June they will move into a larger 950 m2 factory to better service their growing number of happy and engaged clients; they will open a new showroom to display high end residential ‘Carinya 92 mm Select’ range of window systems; and CVD is sponsoring the Penrith Panthers, a deal that includes behind goal post signage (which is ironic since their first-ever job was installing water polo goal posts!) and signage on two buses in the Katoomba and Penrith areas. Combining passion, compliance, and a determination to grow their brand online and offline, we look forward to following, liking, and sharing the CVD story for many years to come.

You’d be forgiven for assuming that sharing photos and videos of aluminium and glazing work on social media wouldn't be worth the trouble; but Chris van Dijk of CVD Commercial Glass and Aluminium Windows jumped on to digital marketing a few years ago, and the business hasn’t looked back since.

Brenton joined the AGWA Master Glazier program in 2022 and is employed with WA Custom Glass in Jandakot, WA. The project Brenton has chosen to highlight is the refurbishment of a home in Dudley Park, WA. He explains the project as follows:

The project we undertook in Dudley Park was a multiangled, commercially framed job on a house, using a diverse selection of configurations. I was heavily involved in this project from start to finish. The project required me to attend multiple consultations, deal with design variations and a lot of laser level measuring.

The project needed three separate types of ventilation, which made use of sliding windows, louvres, and a hinged door. We used 6.38 mm laminated glass in all the framing except for the louvre blades, which were 6 mm toughened safety glass, in accordance with AS 1288. The reason we used this was for safety and to help dampen sound.

We had to bring in various contractors to remove the original steel balustrading, the carpet and to install the scaffold we needed to complete the project. Our team of glaziers then set to work installing the high-quality windows and doors supplied and manufactured by Jason Windows. This was done over two days and required

set planning and a high attention to detail. Some of the challenges included dismantling and reassembling the large frame inside the home due to access, mitring and joining sill trays on varied floor heights and cutting the cornices to allow the frames to seamlessly connect to the ceiling.

Our team and I couldn’t be happier with the outcome, which exceeded our customers’ expectations of transforming their unused space upstairs to a muchneeded retreat where they are able to shut off, reflect and look out over the Mandurah estuary. I am really proud of the work we did.

If you would like to find out more about aspects of this project, please contact Brenton Beahan at WA Custom Glass.

MASTER GLAZIERS PROGRAM

AGWA welcomes the following new Master and Certified Glaziers:

They say Melbourne can experience four seasons in one day, which makes for a difficult design brief for anyone creating outdoor living spaces that can be enjoyed all year round.

Owners of a colonial home in the leafy bayside suburb of Brighton, Victoria, had an outdoor patio that was tastefully furnished but fully exposed to the elements. This made it mostly unusable during the winter months. Browsing the internet and home design magazines, they realised glass would be a smart choice for enclosing the outdoor space, without closing off their view of the beautiful garden and pool beyond it. However, the circular shape of the patio left them wondering how a glass company could ever make the space work without compromising the classic and clean style of the building.

A clear edge in seamless indoor-outdoor living

They engaged Melbourne-based Clear Edge Glass, a relatively new player in the glass manufacturing industry specialising in frameless retractable glass systems that can enclose outdoor entertainment areas.

Clear Edge Glass owners Archie and Tacita Shaw proposed a custom solution for the Melbourne home; segmenting the ‘Clear Edge Glass System’. The frameless system is a game-changer, as it allows for uninterrupted views of the garden and does not block any natural light from entering the home.

The system has 160 components, each of which is meticulously engineered and manufactured to deliver exceptional performance and meet Australian building Standards. The design is practical, easy to use and maintain, making it an ideal choice for homeowners and commercial properties alike.

The Brighton homeowners were delighted with result, which is essentially a curved glass wall enclosing their outdoor patio space fully, giving the owners a comfortable and stylish space to entertain guests, fully protected from the elements. ‘The beauty of our Clear Edge Glass systems is that they are designed to be thrown wide open on beautiful days, allowing the family to enjoy the space as a true outdoor area when they want to’ explains Tacita.

This innovative product offers a seamless transition between indoor and outdoor living spaces, while providing complete protection from the elements.

Business founders and innovators Archie and Tacita Shaw share a passion for frameless glass products that began in Germany and the UK, where they honed their skills. In 2012, they moved to Melbourne and started designing, engineering, and manufacturing the Australian frameless retractable system. Today, they are supported by a growing team of agents who help the company provide exceptional service to clients nationwide.

Clear Edge Glass offers an innovative and practical solution for those seeking a seamless indoor-outdoor living experience. With its commitment to excellence, exceptional service, and top-of-theline manufacturing, Clear Edge Glass is undoubtedly a manufacturer with a vision for seamlessly integrating the Australian indoor-outdoor life.

Photography: Katherine and Camera

Double Glazing for 7 Star - and Beyond

Australian Glass Group has your 7 Star glass solutions covered. With a full range for compliance to NCC 2022 and beyond, while also satisfying your specific design needs and environment.

The October mandatory date is fast approaching for the Energy Efficient section of the NCC 2022, requiring newly built residential homes to have more energy efficient solutions within the building envelope.

Improvements in Glazing will play a significant role; in colder climates there is a need for improved Insulation (lower U-Value); while in warmer climates a greater need for Solar Control (lower SHGC); mixed climates will need a balance in both areas… while still meeting design and construction factors, and ultimately, the home owners requirements - without compromise on glazing size, style and the amount of natural light ingress.

Australian Glass Group’s range of Insulglass® Double Glazing is your solution; starting from regular Double Glazing to High-end Performance Softcoat LowE Double Glazing. Australian Glass Group has your 7 star solution for higher demands, now and into the future.

Insulglass ® Double Glazed Units - available in a full range of options to suit your needs;

A full range of non-coated DGU options, surpassing any single glazed option in terms of insulation.

An ideal LowE for Warmer climates to minimise Glare and a balance of Solar Control and great Insulation.

An ideal LowE for Colder climates with maximum Visible Light, Passive Heat Gain and excellent Insulation.

Excellent performance to advance both Solar Control and Insulation without compromising Visible Light.

Superior performance to maximise both Solar Control and Insulation without compromising Visible Light.

Proudly manufactured, stocked and supported in Australia by Australian Glass Group

Australian Glass Group offers a full customised range with all Insulglass ® offerings

• Warm Edge spacer for further Thermal performance

• Tempershield ® toughened options for strength and Grade A safety

• O bscure Pattern and Acid Etch for privacy

• L aminated for security and Grade A safety – available in:

– S tandard laminate

– W hite translucent laminate for privacy

– Audioshield ® acoustic laminate for superior sound performance

All management, staff and workers must receive regular WHS training. They must be provided with information, training, instruction or supervision so they can carry out their work safely. There are also certain safety training requirements, including training first aid, emergency evacuation procedures, risk assessments, manual handling and the handling of hazardous materials.

Worker WHS training should include whatever knowledge and skills are needed for them to work safely. They should receive training:

- During induction (ie, when they are new or starting a new job)

- Prior to commencing hazardous tasks they have not previously done

- Regularly as updates.

What is a toolbox talk?

A toolbox talk is a short presentation or discussion, usually 15 minutes or less, with a group of workers about a specific health and safety topic. Generally, they focus on one point and are a great way to complement and cement knowledge gained from more formal training. They are a great way to promote a safety culture within a workplace.

Keeping it short is very important as you don’t want people’s attention to wander. They can be done at the beginning of the day before everyone starts work, at lunchtime or added onto a regular staff meeting. Remember though, they aren’t a substitute for formal training or onsite training that is required, but a way to reinforce it.

Why are they important?

They are important as they keep health and safety at the forefront of every worker’s mind. I know what many of you are thinking right about now, ‘what a pain we have to do this too’, but there are many benefits to having these.

First, they reduce workplace accidents and injuries. Second, this has a flow on effect to improving morale and increasing productivity, because workers feel more valued and satisfied in doing their job, as they are being kept up to speed and have an opportunity for communication.

Third, toolbox talks save you money. If you could avoid having to change rosters and reorganise jobs because someone is off work that would save you both time and money. Let’s think about other costs you could save. No costs from cleaning up where an incident has taken place or repairing it. No lost income from knocking back jobs because you don’t have the staff available. No increased costs from increased insurance premiums, and of course, no costs from having to pay fines for non-compliance. Then also think about all that paperwork you’ll have to complete in reporting the incident and then the return-to-work program. So, a 15-minute talk is suddenly looking really easy!

Finally, toolbox talks are an easy way to show your commitment to health and safety.

How do I get started?

1. Pick a topic (more about that later in this article)

2. Ask someone to run it. Usually this is a senior or experienced member of staff. Ideally, someone who has a good understanding of the topic.

3. Give them guidance. Keep the talk to 15 minutes and be specific about what should be included in the topic. Keep it to one part of the topic if it is a big one.

4. Sort out your presentation. Will you need handouts? Do you have a video to show? Do you need equipment?

5. Pick a time to run the toolbox talk. Ideally, these should be done weekly or fortnightly, so keeping it to the same time is helpful.

6. Invite others. Keep the group of workers small, about 10 is ideal. That allows for more communications from both sides. Make sure the topic is relevant to the people who are attending ie, office staff may not need to know about how to properly put on gauntlets.

7. Keep a record. Record the topic, who attended and if there are any action points coming out of it.

What sort of topics can I include?

The short answer is anything!

Think of all the areas of hazards there are that you’d like to prevent injuries from. Here are just a few to get you started: slips, trips and falls, cuts and lacerations, working at heights, ladder safety, electrical safety, hazardous substances, fire safety, manual handling, mental health, environmental and of course, PPE. You could also think of topics relating to more administrative type things such as reporting accidents in the workplace, evacuation procedures and housekeeping.

After I have finished the talk is there anything else I need to do?

It is a good idea to record the fact that you did the toolbox talk. This just means that you pass around an attendance sheet at the talk and include some details about what you covered, for example the date, the topic, main points covered and any action items.

AGWA can help

If you still aren’t sure how to get started, AGWA can help you. On our Member website we have a whole section of templates to help you with this and other safety requirements. Go to AGWA/Members/ Technical Resources/Safety Documents. There you will find two templates. The first is a Template for Toolbox Talks (Template 2c). It gives you the outline and guides you as to what to include. The other template is Record of Toolbox Talks (Template 2d) which gives you the document you can use as a sign off sheet. Both are downloadable and you can fill it in for your business. Take some time and have a look at the Safety Documents Section, as there is a lot more available for you to use for your business.

If you still feel unsure about how to get started, AGWA has prepared a sample Toolbox talk on PPE. If you would like a copy, please contact training@agwa.com.au.

A toolbox talk is a short presentation or discussion, usually 15 minutes or less, with a group of workers about a specific health and safety topic. Generally, they focus on one point and are a great way to complement and cement knowledge gained from more formal training. They are a great way to promote a safety culture within a workplace.

VARGA FAMILY:

THE LAST MIRROR MAKERS

KEEPING THE ART OF HANDMADE MIRRORS ALIVE

In Melbourne, the Varga family of mirror makers is determined to honour the bespoke hand-silvering process passed down to them over five generations, well aware that they might in fact be the last mirror makers.

Melissa and Matthew Varga are the fifth generation of owners at Varga Bros specialising in hand bevelling and hand silvering. Melissa explains ‘Our family business originated in an area that was once a part of Hungary. The art was passed down to each generation from mother to son, father to son, and so on, until my father Les and his brother Steve arrived in Australia in 1956, following the Hungarian Revolution. After working for many other glass companies, they started the Varga Bros business in 1979’.

Matthew and Melissa are both continuing the tradition, while adding a bit of their own magic to mirror-making. ‘Hand silvering is a bespoke process that takes a good deal of expertise and accumulated knowledge to create artistic pieces, each unique and each beautiful in their own way’, explains Melissa.

While there are some aspects of mirror making that are strictly part of the process, there are other parts that each maker can adapt to suit their style. ‘Our family’s first silvering room in Australia was a converted bedroom, and instead of a heating table, my grandfather would take the mirror outdoors and use the sun’, explains Melissa.

There is no formal training for mirror-making. Children learn from their parents as they work and pass it down to each generation, just as Melissa and Matthew did in their father’s workshop. While there are differences in how each generation approaches mirrormaking, the passion for the art of it has never waned with the Varga Bros business. They continue to use the tools and machines their grandfather used and specialise in the beauty of hand silvering and bevelling, which is something mass manufacturing simply cannot replicate.

‘Our business focus now is on making mirrors that are no longer made by anyone else; mirrors that are hand bevelled, unique, beautiful, and customised’, says Matthew Varga. Handmade mirrors may not be perfect, but it's the imperfections that make them an art, and so are more special than factory-made mirrors.

While Matthew and Melissa may be the last mirror makers of their generation to keep this art alive, they have made it their passion to see that handmade mirror-making continues to thrive.

As the last mirror makers in Australia, Varga Bros sells its antique and retro mirrors all over Australia and worldwide. The company specialises in the re-silvering of vintage mirrors, antique mirrors, silvering of splashbacks, all aspects of bevelling, and a wide variety of old-world techniques for modern applications.

Whether it’s reversing a car, taking a photo, trying on new pair of jeans or getting ready in the morning, we use mirrors every day, often taking their magic for granted. Though modern mirrors have an extraordinary history dating back to the 1830s in Europe, the art of hand mirror making (silvering) is under threat of extinction, thanks to faster mechanical production.

Windows play a significant role in determining thermal comfort and energy efficiency in buildings. They not only influence the amount of natural daylight and ventilation but also affect the temperature and overall performance of a building envelope. The selection of the appropriate window and glass type is vital in achieving an optimal balance of thermal performance, energy efficiency and visual appeal. This article examines the benefits of window and glass selection on thermal comfort and energy efficiency in buildings.

Windows are an integral part of any building design, providing natural light, ventilation, and connection with the outdoors. However, they also play a key role in regulating energy efficiency and occupant thermal comfort.

In recent years, as energy consumption and environmental concerns have become more pressing, energy-efficient windows have gained popularity. The implementation of 7-Star Energy Efficiency rating for homes, under NCC 2022, is likely to drive further increases in energy-efficient windows featuring double-glazing, incorporated specialised low-e coatings, and highperformance window framing technologies.

AGWA has undertaken a comprehensive study to understand the impacts of 7-Star, identify key variables which influence performance and raise awareness of the likely market responses in terms of window selection across a range of climates.

The National Construction Code 2022 introduces improved energy-efficiency requirements, adopting a 7-Star NatHERS Rating as the minimum. This delivers energy reductions to the value of between $613 million and $1.5 billion in present value terms of benefits to the economy and reduces greenhouse gas emissions by up to 16 Mt by 2060.*

*GHG and economic benefits are discussed in the Decision Regulation Impact Statement prepared by ACIL Allen for the Australian Building Codes Board.

PRINCIPLES OF ENERGY EFFICIENT DESIGN

Effective design is governed by the principles of passive solar, insulation and ventilation. Designing for energy efficiency in homes involves considering a range of factors, including climate, house size, orientation, window selection, overshadowing, ventilation and window-to-floor area ratio. By taking these factors into account, homes can be designed to be more energy efficient, reducing the need for heating and cooling and saving energy and money.

AGWA’s 7-Star Impact Analysis explores number of variables influencing the overall energy efficiency of a home and so driving appropriate window and glass selection.

Climate

Designing for climate involves maximising solar access in colder climates and minimising solar heat gain in warmer climates. Taking advantage of natural light and ventilation, as well as using thermal mass to store and release heat helps achieve this.

In hot climates, the aim is to limit heat gain through the roof, walls and windows. Large roof overhangs and shading devices can block the sun during the hottest parts of the day and prevent overheating as does insulating the walls, roof, and windows. Good ventilation is important to promote air circulation and cool down the house.

In cold climates, the principles of passive solar design are used to maximise heat gain. Large north-facing windows and thermal mass materials are used to absorb and store heat from the sun during the day and release it at night. Good insulation helps retain the heat inside the house.

Houses in colder climates benefit from windows with higher Solar Heat Gain Coefficient (SHGC), while warmer climates require lower SHGC solar control and, optimally, external shading. Houses in milder, more temperate climates demonstrate lower sensitivity to solar heat gain due to winter gains offsetting summer losses.

House size

The size of a house can have a significant impact on its energy efficiency. Larger houses require more energy to heat and cool and have more surface area for heat to escape. On the other hand, smaller houses have less surface area, meaning less heat is lost in the winter and less heat enters in the summer.

However, it is important to note that the relationship between house size and energy efficiency is not always straightforward. For example, a smaller, poorly oriented house may be less energy efficient than a larger house with a more optimal orientation. Additionally, the design and construction of the house, including the location of living areas and bedrooms, can have a greater impact on energy efficiency than the house's size alone. In two-storey homes, a stairwell (or lightwell) connecting upstairs and downstairs living spaces provides significant benefit in colder climates. Our study showed that single-storey homes typically outperformed double-storey equivalents by around 0.7 stars on average, when using similar product specifications. The effects were more noticeable in warmer climates with Brisbane having a 0.9 average star difference in favour of single-storey homes. In Sydney, the difference was less apparent with singlestorey homes outperforming their twostorey counterparts by around 0.5 stars. In Melbourne, there was only a moderate 0.3-star improvement in single-storey over double-storey homes

Overall house size, layout and specific design attributes such as shading/eave projection or the location of windows in living spaces etc contribute to the home’s performance. Larger homes require more significant thermal fabric specifications. Typically, we found that single-storey homes outperform equivalently specified two-storey home by around 0.9 stars in hot climates, 0.5 stars in mixed climates and 0.3 stars in cold climates.

Orientation

Orientation is another important factor to consider. The orientation of the house, and the placement of windows and doors, can have a significant impact on the amount of sunlight entering the house. A house, oriented to take advantage of the sun's energy, can reduce the need for heating in winter, while reducing unwanted heat gain in summer.

For example, in cold climates a house with a lot of windows facing north will take advantage of the warmth from the sun in the winter. This can be used to reduce the need for artificial heating.

Orientation of windows, particularly with daytime living areas, is a significant influencing factor on overall house performance. Optimally sited houses typically perform around 0.6 stars better than worst performing orientations across all climates.

Window Size

The relationship between window area and energy efficiency can be complex. On one hand, windows can provide natural light, which can reduce the need for artificial lighting and save energy. Windows can also provide solar gain, helping to heat the building in the winter. However, windows can also let in heat in summer and allow heat to escape in winter, which can decrease energy efficiency.

The size and the location of windows can be a significant contributor to the overall energy efficiency of a building. Larger windows can provide more natural light and solar gain, but they can also let in more heat and allow more heat to escape.

The AGWA study compared the results of both a high (27%) and low (20%) windowto-floor area ratios. It found that while the smaller window size, on average, yielded a slight improvement in the whole-of-house rating of around 0.15 stars, the specific benefit fluctuated greatly, depending on the climate and house size.

For example, a single-storey house in Brisbane actually benefits from bigger windows with the net difference being a dramatic 0.6-star gain for the larger window size.

While window size can influence the energy efficiency of the home, the influence of house size and orientation are far more significant. Optimising window size for climate, house size and specific orientation will yield the greatest benefits.

WINDOW SELECTION AND DESIGN

The selection of appropriate window and glass type is vital for optimal thermal comfort and energy efficiency in buildings in all climates.

The choice of window and glass type can significantly affect indoor thermal conditions, from the amount of heat gained or lost to the reduction of draughts and cold spots. Windows that provide ample daylight and fresh air, while minimising heat loss or gain, can significantly improve thermal comfort. Installing energy-efficient windows can improve indoor thermal conditions while reducing energy bills and carbon footprint.

• Glass Type

Selecting the appropriate glass type is essential in determining thermal comfort and energy efficiency. Double or tripleglazed windows help to keep the heat inside the house in the winter and outside the house in the summer. Low-e (low-emissivity) coatings reduce the amount of heat that enters or leaves the house, while allowing visible light to pass through.

• Frame Material

Selecting the appropriate frame material also significantly affects energy efficiency. The frame material affects the window's insulation properties and condensation resistance. The most common window frame materials are aluminium, timber and uPVC. Each material has its unique thermal properties (conductivity) which affect energy efficiency and thermal comfort.

• Operating Types and Openability (Ventilation)

Improving window openability has benefits in all climates and the choice of operating type can have a substantial impact overall thermal comfort and energy efficiency. Windows featuring a continuous compression type seal around their perimeter greatly reduce unwanted air infiltration (leakage). This contributes to significant energy savings. Large, highly-openable windows introduce fresh air into a building, removing stale, contaminated air.

Proper ventilation can benefit a building in several ways, including:

- Improved indoor air quality: Adequate ventilation can help to remove pollutants, such as volatile organic compounds, dust and carbon dioxide from the indoor air. This improves the overall air quality and reduces the risk of indoor air pollution.

- Increased thermal comfort: Proper ventilation can help to regulate the temperature and humidity levels in a building, increasing thermal comfort and reduce the need for heating and cooling.

- Reduced moisture and condensation: Adequate ventilation can help to remove excess moisture from the indoor air, preventing mould and mildew growth and reducing the risk of indoor air pollution.

- Reduced energy consumption: Proper ventilation can help to reduce the need for heating and cooling, decreasing energy consumption and saving money.

- Improved overall health: Proper ventilation can help to reduce the risk of indoor air pollution and improve the overall air quality, improving the health and wellbeing of the building's occupants.

• Colour

Colour selection can impact thermal performance substantially. Light-coloured materials reflect more sunlight than darkcoloured materials, whereas darker colours absorb and retain more heat. This means that dark-coloured window frames are beneficial in cold climates but have adverse impacts in hot climates. The opposite is true for light-coloured window frames.

The selection of windows and glass plays a crucial role in house design for both hot and cold climates. In hot climates, tinted or solar control low-e glass types can prevent sun rays from entering the house and reduce the need for air conditioning. In cold climates, double and triple-glazed windows will substantially improve not only the energy efficiency but also the thermal comfort for the home’s occupants. Selecting windows with low airinfiltration is essential to prevent cold drafts from entering the house.

Good ventilation is paramount to efficient design, particularly in warmer climates with larger openings providing significant benefits to offset solar heat gains in both bedrooms and living spaces.

Window selection is the most critical consideration with respect to the thermal envelope. AGWA’s analysis shows a relatively uniform improvement of around 0.4 stars on average for each U-value reduction in the window specification. This was true across all climates and star bands.

with Viridian Glass

You’ve heard of 7 Star, but how does this impact your glass choices? Join your local Viridian team at one of our upcoming exclusive events where we’ll discuss glass solutions that work towards better insulation and 7 Star compliance.

NCC2022 is effective 1st October 2023 so get 7 Star ready and register below. By attending you will go in the draw to win an array of prizes on offer!

To register, scan the QR code and enter your details or visit viridianglass.com/customer-engagement-events

SKILLS AND TRAINING

— ARE YOU READY FOR YOUR AUDIT?

AGWA’s auditors have now started their audit rounds nationwide. Over the coming months Members will be contacted to arrange an on site audit. The better prepared you

quicker and more efficient the audit will

ensuring that you can get on with your day.

To satisfy Pillar 2 (Skills and Training) at least ONE staff member on site must demonstrate, by way of a valid certificate/s, that they have undertaken training in Australian Standards AS 2047 and/or AS 1288 within the last 3 years.

Our glaziers need to demonstrate currency in ONE of the AS 1288

courses we offer. Window manufacturers need to demonstrate currency in BOTH AS 1288 and AS 2047 (or Intermediate Fenestration). AGWA has TWO options to assist members to upskill their knowledge and achieve compliance BEFORE their planned audit.

OPTION 1 OPTION 2

For members who are confident in their knowledge of AS 2047 and AS 1288, there is an option to attempt a compliance quiz only. AGWA allows ONE attempt each at the AS 2047 and AS 1288 Compliance Quizzes in lieu of completing the full course/s. There is no cost for attempting the quizzes only.

- The AS 1288 Compliance Quiz has 20 questions. You must get 100% correct to be able to download the Certificate.

- The AS 2047 Compliance Quiz has 15 questions. You must get 100% correct to be able to download the Certificate. Depending on your level of knowledge and experience each quiz should take approximately an hour to complete.

Important: You MUST complete each compliance quiz in ONE sitting or session. DO NOT OPEN it until you are ready to start and don’t close it until you have finished. If you do, this counts as your attempt.

With either option, these Certificates are valid for 3 years and your AGWA member profile will be updated to show currency in training when the Exam/s is completed.

To enrol in either the Compliance Quizzes or the Online courses, log on to the website and register under ‘Training — on Demand Courses’ using the link below: https://agwa.com.au/Members/Training/On-Demand-Courses

If you (or another staff member) would prefer to refresh your knowledge or you are not confident in passing the stand alone quiz on a single attempt, you need to enrol in the AS 1288 Human Impact and Wind Loading online course and/or the AS 2047 online course at the member rate of $99 each.

These can be completed in your own time and at your own pace prior to your audit. Once you have completed the content you will need to complete the quiz/quizzes. You can attempt this as many times as needed to pass, getting feedback on your answers. You can then download your Certificate ready to show your auditor when he/she visits.

You will need a copy of the relevant Standard to refer to pass each quiz.

Get ready NOW

If you have any questions regarding training, please contact training@agwa.com.au.

So ‘get your ducks in a row’ and get ready for your audit! If you have any queries regarding the audit in general please email: accreditation@agwa.com.au

are, the

be,

AUSFENEX23 - A CLEAR FUTURE

PINES RESORT, BENOWA QLD

Key Speakers

Rob Carlton

Conference MC + Closing Keynote Awards Gala Dinner MC Opening Keynote

Rob Carlton is an Australian actor, best known for his Logie-winning performance as Kerry Packer in ABC’s Paper Giants.

Rob is also a writer, winning an Australian Writers Guild Award (an AWGIE), for best narrative comedy, Chandon Pictures (STAN). Rob won Tropfest with short film Carmichael and Shane.

Andrew Daddo is one of Australia’s favourite corporate MCs and Conference Hosts.

Andrew has hosted high profile television events including the Logies, People’s Choice Awards, and the Australian Music Awards. Working across all industries, his clients have included Subway, McDonald’s, CBA, Westpac, BT, National Insurance Brokers, AusRail, Baker’s Delight, Engineering group SMEC, Holden, Travellers Choice and Arbonne.

Jason Clarke is one of the most sought-after creative minds in the country, but he thinks of himself a Plumber of the Mind, the guy you go to when your head gets clogged.

As founder of Minds at Work, he’s been helping people ‘think again’ since the end of the last century, working with clients across Australia in virtually every industry and government sector on issues ranging from creativity and trouble-shooting to culture change and leadership.

Andrew Daddo

Jason Clarke

Andrew Daddo

Jason Clarke

8.30 AM

Housekeeping and Opening

Rob Carlton (Conference MC)

9.00 AM

Welcome Address

Clinton Skeoch (AGWA CEO/Excecutive Director)

9.15 AM

Keynote 1: A Clear FutureAdapting to Change

Jason Clarke

Sponsored by Capral

9.00 AM

Breakout Session 1: Sustainability and Innovation

Laureate Professor Veena Sahajwalla (UNSW)

Breakout Session 2: Product and Material Durability and Performance - The Key to Value

Prof Michael Stacey (Bartlett School of Architecture London)

Breakout Session 3: Managing Hazardous Manual Handling with an Ageing Workforce

Rick Carlei (Quattrolifts)

9.45 AM

Breakout Session 4: Innovative Performance Glass (Solar Facades, Electrochromic Glass and Glass Coating)

Anthony Breach (George Fethers)

Breakout Session 5: All Things IGU

Adam Davies (AGWA)

10.00 AM

Keynote 2: Change in the Regulation Space (2025 and beyond)

Russell Harris (AGWA) and the ABCB

11.20 AM

Keynote 3: The Changing Economic Outlook

Tom Devitt (HIA)

11.55 AM

Keynote 4: Change or Be Changed (NZ Perspective)

Brett Francis and Rob Campion (Window and Glass Association of NZ)

1.50 PM

Keynote 5: Innovation in Construction

Georgina North (Laing O’Rourke)

2.35 PM

Keynote 6: Energy and the Future of Buildings

Rob Murray-Leach (Energy Efficiency Council)

3.20 PM

Keynote 7: Energy Sustainability

Discussion Panel

Energy Sustainability Panel

Breakout Session 6: The Future of Building Certification

KPMG

11.00 AM

Breakout Session 7: Disputes and Non Compliance Investigations

Russell Harris, James Whitehouse and Adam Davies (AGWA)

Breakout Session 8: Tangible Benefits of Silicone Sealants V Organic Solutions in the Facade Sealant Market

John Cook (Shin-Etsu) Sponsored by Admil Adhesives

Breakout Session 9: Lessons Learnt in the Safety Space

Kate Wendt (Dragon Glass)

11.45 AM

Breakout Session 10: WERSlink and Supporting Efficient Window Selection

Russell Harris (AGWA)

Breakout Session 11: Standards and Consumer Law

Adams and Partners Law Firm

Breakout Session 12: Industry Training, Recruitment and Skill Development, Licensing

Melissa Baker and Clinton Skeoch (AGWA)

1.20 PM

Breakout Session 13: Transforming Mindsets for Business Growth

Leanne Luhrs (DLG)

Breakout Session 14: Laminated Glass – The Fit for Purpose product for today’s NCC requirements

Geoff Rankin (Eastman)

2.00 PM

Final Keynote: Coming Together to Thrive Through Change

Rob Carlton

Sponsored by Viridian

PROUDLY INDEPENDENT PREMIER TESTING FACILITY IN AUSTRALIA

Azuma Design, located in Wetherill Park, NSW, is one of Australia’s largest privately-owned compliance testing and engineering company. Part of the Alchin Long Group of companies, it offers a wide range of industrial design, engineering and testing services throughout the Asia-Pacific region.

Azuma is fully equipped to service the rigorous testing requirements of the window and door industry. Proudly independent, Azuma provides technical support with an engineering design capacity and a stateof-the-art product testing facility. Azuma is the expert, offering the largest capacity and range of testing services for the building industry in Australia.

In 2003, Azuma designed a wind and water pressure test chamber to provide essential testing services that meet the requirements of AS 2047 and the test procedures AS 4420, as called up as a deem to satisfy requirement of the Building Code of Australia, now known as the National Construction Code (NCC). The test chamber was commissioned in 2004 and was bought online in November of that year. This, together with the National Association of Testing Authority (NATA) accreditation in early 2005 and ISO 9001 Quality Assurance Accreditation, ensured Azuma was up and running to be able to achieve Standards’ testing to satisfy its client’s requirements.

The wind and water test pressure chamber was quickly followed by investments in additional testing services, with the addition of a security door testing centre (AS 5039, AS 5040, AS 5041), hardware testing rigs (AS 4145) and surface finishing testing capabilities.

Azuma’s early investment in servicing the window and door industry, has established Azuma Design as the premier independent testing facility in Australia. Azuma also invested heavily in its involvement with the peak bodies servicing the industry such as the Australian Glass & Window Association (AGWA), Australian Institute of Surface Finishing (AISF), Insulated Glass Manufacturing Association (IGMA) and the National Security Door Association (NSSA). Azuma’s industry involvement takes the form of serving on many of the Associations’ Technical Committees, sitting

on many Australian Standards Development Committees and ISO Standards International Committee work.