RESEARCH CENTERS AND INSTITUTES

The Samuel Ginn College of Engineering is growing exponentially, ranking among the nation’s top institutions in research expenditures. We welcome the opportunity to collaborate with government agencies, businesses and foundations to identify research needs, expand technological boundaries and support workforce development by sharing industry-relevant training and best practices.

Auburn University Subject Matter Experts (AUSME) have been honored at the international, national, and regional levels for their impactful academic and professional contributions. Our faculty, students and staff believe in our land-grant mission, and they are, therefore, committed to building strategic partnerships that help improve lives and enable the pursuit of happiness.

Our researchers are advancing the frontiers of advanced manufacturing and materials through interdisciplinary research that integrates additive manufacturing, composites, smart materials and process modeling. Collaborative efforts span partnerships with federal agencies such as the U.S. Army and NASA, leading industry partners, and regional innovation hubs focused on workforce development and technology transfer. These partnerships have accelerated innovations in aerospace, automotive and defense applications, resulting in high-performance materials, reduced production lead times and scalable manufacturing solutions. The impact of this work is seen not only in technical breakthroughs but also in strengthened economic development across Alabama and beyond.

We are leading impactful efforts in infrastructure and transportation through applied research in areas such as pavement design and materials, intelligent transportation systems, structural health monitoring and sustainable infrastructure. Leveraging strong partnerships with the Alabama Department of Transportation (ALDOT), the Federal Highway Administration (FHWA), local municipalities and industry leaders, faculty collaborate to address regional and national challenges related to transportation safety, asset management and durability. This work has contributed to the development of advanced asphalt and concrete technologies, real-time traffic monitoring systems and resilient bridge and roadway designs. The impact of these initiatives is seen in improved public safety, cost-effective infrastructure

maintenance, and the integration of data-driven decisionmaking tools for transportation planning and policy.

Our engineers conduct cutting-edge research in cybersecurity and intelligent systems, addressing critical needs in national defense, critical infrastructure protection, autonomous systems and data security. Faculty research spans areas such as secure embedded systems, machine learning for threat detection, resilient control systems and AI-driven decision-making. These efforts are supported by partnerships with government agencies and industry leaders in aerospace, automotive and communications sectors. Our projects have led to the development of robust cybersecurity frameworks, intelligent sensor networks and autonomous platforms with enhanced situational awareness. The impact is evident in improved national security posture, smarter and more secure infrastructure, and workforce development in high-demand areas of AI and cybersecurity.

Researchers in the college are advancing solutions in energy and environment through interdisciplinary work in renewable energy systems, environmental remediation, sustainable water and wastewater treatment, and energy-efficient technologies. Key partnerships with the U.S. Department of Energy, Environmental Protection Agency, corporate partners and local utilities support applied research addressing both regional and global challenges. Efforts include innovations in bioenergy, battery storage, grid resilience, pollutant mitigation and resource recovery. The impact of this work includes enhanced environmental quality, reduced carbon emissions and the development of resilient, sustainable infrastructure – strengthening both ecological health and economic growth across Alabama and the Southeast.

Our engineers are making significant strides in biomedical and health systems research, focusing on areas such as drug delivery, biomaterials, medical imaging, tissue engineering, assistive technologies and healthcare systems modeling. Collaborations with other academic institutions, government agencies and regional healthcare providers have enabled interdisciplinary approaches that bridge engineering with clinical practice. Faculty are developing advanced therapies, wearable sensors, and diagnostic tools aimed at improving patient outcomes and accessibility to care. The impact of this research is reflected in innovations that enhance disease detection, enable personalized treatment, and support aging populations – contributing to a more effective and equitable healthcare ecosystem in Alabama and beyond.

For more than 150 years, Auburn University’s Samuel Ginn College of Engineering has been a pillar of research that has driven the economic engine of our state and region. As the state’s land-grant institution, we embrace those values to transform lives and enhance society through impactful research and education.

Our dynamic faculty and community of undergraduate and graduate students are leaders in research that improves quality of life and fosters economic growth. Auburn engineers are innovating medical breakthroughs, making roads safer, protecting critical infrastructure, advancing domestic manufacturing, making the world more sustainable and so much more.

To address some of the most pressing problems at home and abroad, the Samuel Ginn College of Engineering deploys nearly 20 research institutes and centers to collaborate with other academia, industry and government agencies to identify needs, expand established technologies, develop new technologies and transfer that knowledge back to our partners.

These institutes and centers are mainly centered on our five key research focus areas:

• Advanced manufacturing and materials

• Infrastructure and transportation

• Cybersecurity and intelligent systems

• Energy and environment

• Biomedical and health systems

Our researchers are experts in these fields and have been honored at the international, national, regional and state levels for their academic and professional contributions. With safety at the forefront, our faculty, staff, students and external partners are committed to the discovery of new engineering technologies, concepts and processes and the hardware necessary to realize them.

As a result, the college’s new research awards, contracts and grants have grown exponentially over the past decade, rising from $29 million to $120 million in just six years.

But as we say around here, this is “Just the beGINNing!”

We invite you to visit with us, partner with us and let us show you just what Auburn’s Samuel Ginn College of Engineering is all about.

War Eagle!

Mario R. Eden Dean of Engineering

Extending Auburn’s expertise and resources to Huntsville’s Defense, Aerospace, and Biotech leaders

The Auburn University Applied Research Center (ARC) within the Auburn University Applied Research Institute (AUARI) is Auburn Engineering’s new home for cuttingedge applied research and development supporting our partners in the City of Huntsville’s rapidly expanding defense, aerospace and biotech sectors.

Housed at the Auburn University Research and Innovation Campus near Redstone Arsenal and the NASA Marshall Space Flight Center, ARC has quickly become the primary pipeline for connecting Auburn Engineering faculty and students with Huntsville-based defense agencies.

Focused research areas include advanced manufacturing, additive manufacturing, biotechnology, quantum metrology, digital engineering, cyber and critical infrastructure security and assured position, navigation and timed missile systems, and radiation hardening testing.

With government partners that include NASA, Missile Defense Agency, Space Development Agency, Space and Missile Defense Command, Redstone Test Center, and the U.S. Army, our vision is to maintain Auburn University’s position as a national leader in transformative engineering research.

• Recently secured a three-year, $50-million contract designated for boosting the modernization efforts of the U.S. Army Combat Capabilities Development Command Aviation & Missile Center.

• Facilitates one-of-a-kind additive manufacturing education and training program connecting Huntsville City Schools with Auburn University’s additive manufacturing resources and expertise.

• Secured a $10 million U.S. Army Ranger Regiment Award on the Army Research Laboratory Pathfinder Program.

• Specialized laboratories include design for additive manufacturing, military robotics, space manufacturing, applied cybernetics, and digital engineering.

• Partnered with the Missile Defense Agency on an $11.5-million project providing radiation hardening testing on space hardware, the only project of its kind in the country.

• Organized and executed more than 150 internal and external events. Hosted community partners in government, industry, and Auburn University internal stakeholders, including the annual Graduate Engineering Research Showcase, VIP visitors, workforce development functions, and recruiting events.

5,000+

VISITORS HOSTED SINCE OPENING IN 2022

20+ FULL-TIME RESEARCH ENGINEERS AND SCIENTISTS

40K

Driving research and economic development through the production of microfibrous materials

Founded in 1996, the Samuel Ginn College of Engineering’s Center for Microfibrous Materials Manufacturing facilitates research development, education, technology transfer, and economic development by the establishment of a small-scale manufacturing facility to produce microfibrous materials, the center’s core proprietary technology.

Research is conducted on campus inside the Wilmore Engineering Laboratory and within Chemical Engineering’s Ross Hall.

Researchers are offered a plethora of next-generation equipment, including process-integrated wet-lay machines, sintering, cutting and forming operations, reactor/electrode loading stations, and analytical quality assurance/quality control devices.

Our vision is to provide a platform for businesses in scale-up and development stages by enhancing training, experience, and overall value of the student while at the same time offering a timely, attractive and cost-effective service to industry.

• Specializations include metal fiber, microfibrous media, process intensified reactors, thermal management, and desulfurization systems.

• Certified compliant with Defense Contract Audit Agency standards.

• More than 150 graduate, undergraduate and co-op students earned degrees at Auburn University with Center for Microfibrous Materials Manufacturing Director Bruce Tatarchuk as their adviser.

• One of five global producers of micron diameter metal fibers.

• Products created, or impacted, by the center include conductive additives to eliminate static charging on airplanes, nickel-fiber electrode-powered weather satellites, and state-of-the-art gas masks worn by NATO and U.S. soldiers.

BRUCE TATARCHUK

Building a collaborative community in polymers and advanced composites

A dynamic hub for interdisciplinary and collaborative research within the Samuel Ginn College of Engineering, the Center for Polymers and Advanced Composites (CPAC) is a leader in materials processing and manufacturing research.

Pushing the envelope in materials design, synthesis, processing, manufacturing, and characterization research, the CPAC facilitates an inclusive and synergistic research ecosystem to generate and exchange fundamental and applied knowledge of high relevance to the polymer and composites industries.

Housed within the Gavin Engineering Research Laboratory, CPAC offers educational opportunities, technical expertise, and specialized polymer and composite synthesis, processing, and characterization capabilities. CPAC’s state-of-the-art facilities include an A2LA-accredited ISO/IE 17025 laboratory for a range of mechanical and thermal ASTM standard tests.

In addition to close industry and academic ties through our advisory board, CPAC continues to seek long-term university and industry partnerships to advance our research and educational missions.

• Polymer and material characterization equipment includes mechanical and chemical analyses, polymer 3D printers, advanced 3D imaging, injection molding, rheometer, FTIR spectroscopy, porometer, melt pressing, and extrusion.

• Specialized testing capabilities available in chemical, mechanical, and thermal characterization with A2LA accreditation (ISO/IEC 17025) for many common ASTM standards including mechanical testing such as tensile (D638, D3039/D3039M, and D412), flexural (D790), compression (D575) as well as thermal testing by DSC (D3418), TGA (D3850, E1131), and spectroscopic tests (E1252).

• Advanced 3D imaging of materials by X-ray Microcomputed tomography (CT).

• The Research Amplification Program (RAMP) allows new faculty complimentary access to facilities and aid for start-up research to obtain preliminary data, or to conduct proof of concept studies.

• ReMake program, in conjunction with the Auburn University Waste Reduction and Recycling Department, recycles 3D filament waste across campus.

FACULTY/RESEARCHERS

Bridging the digital divide for small and medium manufacturers through training and education

With a vision to better prepare tomorrow’s manufacturing workforce, the Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) at Auburn University continuously seeks partnerships with small- and mediumsized manufacturing operations and training programs to pursue cutting-edge research.

With a 20,000-square foot, hands-on learning environment, ICAMS offers equipment and expertise to train students and industry personnel in advanced manufacturing technologies, including Industry 4.0 capabilities, while focusing on reducing barriers that inhibit the introduction of advanced manufacturing systems. ICAMS serves as a training ground and works with industries to analyze problems and develop solutions to raise their capabilities and competitiveness.

With a vision to produce world-class research that includes, but is not limited to, metrology, cyber security, agile and adaptive manufacturing systems, tribology, and mechatronics, ICAMS will remain at the nation’s forefront of manufacturing research and education.

• Offers upskill training in machining, programming, coordinate measuring machines, and other areas of advanced manufacturing concepts for incumbent and future employees.

• Recent programs included Okuma OSP-300 Interface Training, DMG Mori Celos Software Orientation, and GD&T, Manual Metrology, and CMM Orientation and Assessment.

• Longitudinal study of technology adoption by small- and medium-sized manufacturers referenced in U.S. Senate and House Committee meetings as a national policy for advanced manufacturing.

• Awarded a $1.7 million grant from the Department of Defense to expand the Bird, Inc., program, which exposes middle school students to jobs.

• Offers graduate and undergraduate engineering students the opportunity to apply knowledge in a handson manufacturing setting, preparing them for future careers.

FUNDED RESEARCH DOLLARS SINCE 2018

COMPANIES INTERACTED WITH SINCE 2018

DEMONSTRATIONS OF DIGITAL MANUFACTURING SINCE 2018

Advancing interdisciplinary materials research, education and industry collaboration

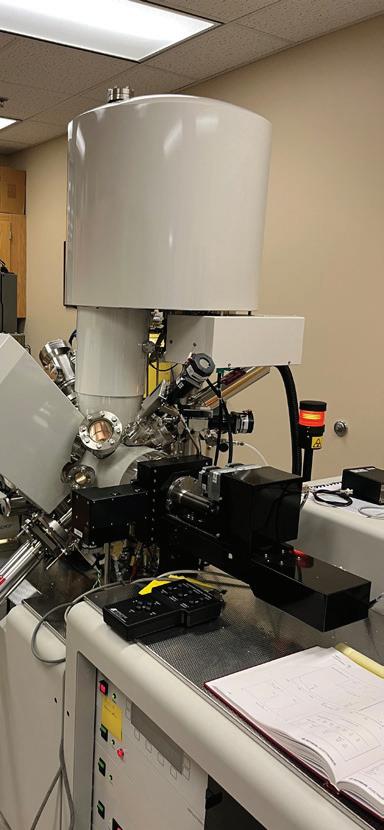

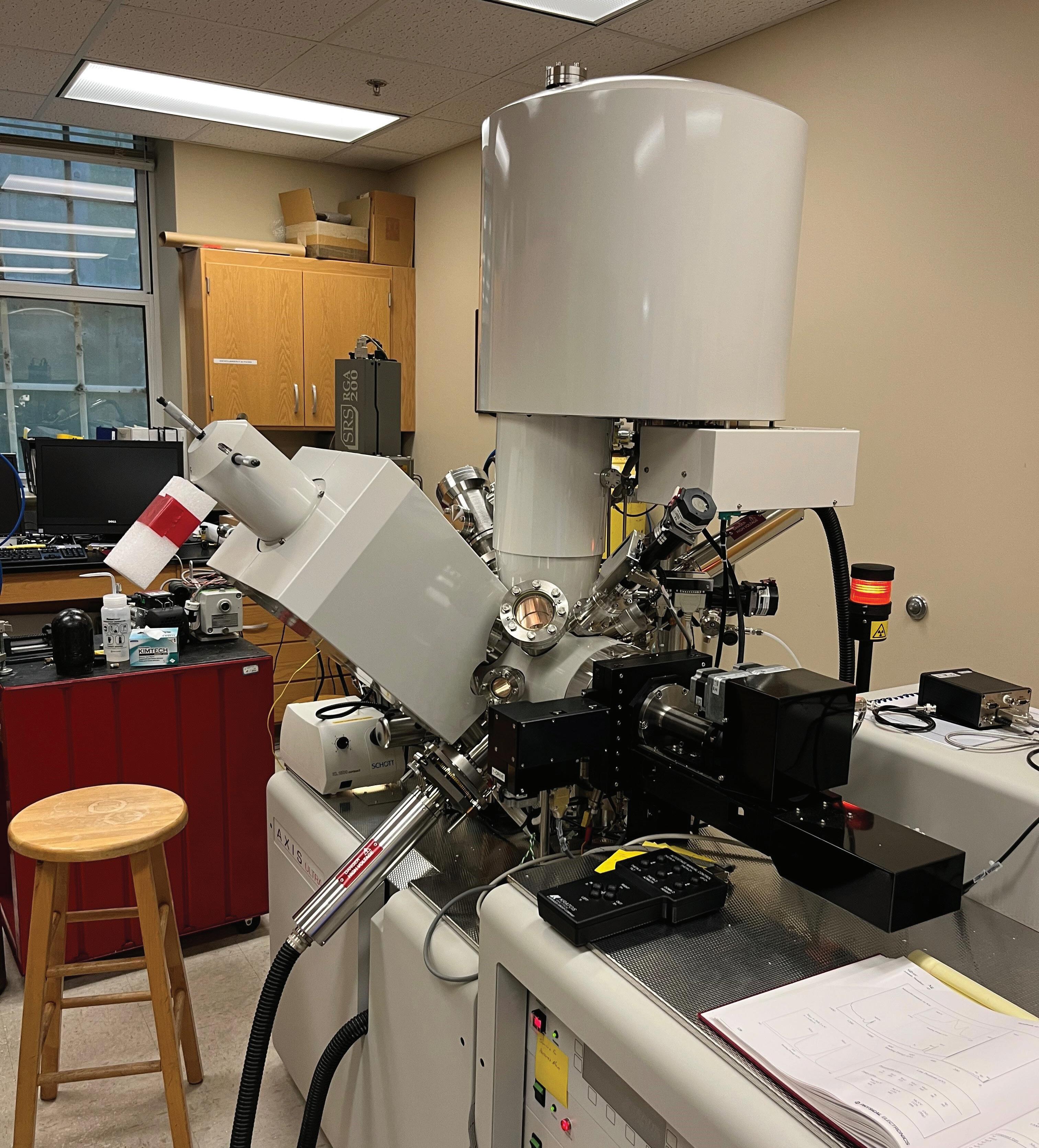

The Materials Research and Education Center (MREC) at Auburn University advances materials science research, education and industrial collaboration. Founded on the principle that materials innovation underpins technological advancement, the center brings together faculty experts, students and industry partners to address critical challenges in structural materials, electronic and magnetic materials, biomaterials and sustainable manufacturing.

Housed within Wilmore Laboratories, MREC boasts a comprehensive suite of analytical and processing capabilities, including electron microscopy (SEM, TEM), X-ray diffraction, X-ray Computed Tomography, mechanical testing, surface and thermal analysis and materials fabrication. These capabilities enable highresolution characterization, failure analysis and material property evaluation across metals, ceramics, polymers and composites. As a fully integrated research environment, the center also supports AI-driven materials discovery, design and modeling through computational resources.

Beyond research, MREC offers experiential learning opportunities that prepare undergraduate and graduate students in materials engineering and related disciplines. For careers in academia, national laboratories and industry. By fostering innovation and developing technical talent, MREC contributes to national priorities in advanced manufacturing, aerospace, energy and defense.

30+ YEARS OF INTERDISCIPLINARY MATERIALS RESEARCH, BOTH NATIONALLY AND INTERNATIONALLY

• Research focus includes functional/smart materials, high-temperature materials, nanomaterials and nanocomposites and materials processing and fabrication.

• MREC laboratories feature a Class 100 cleanroom and facilities for high-temperature material processing.

• Advanced instrumentation includes electron microscopes, optical microscopes, mechanical testing units and chemical analysis tools.

• MREC's infrastructure and expertise supports Auburn University's mission of driving discovery and economic development through advanced interdisciplinary materials research, education and workforce training.

1,200 SQUARE FEET OF LABORATORY SPACE

Aiming to improve society by advancing knowledge on infrastructure resilience and renewal

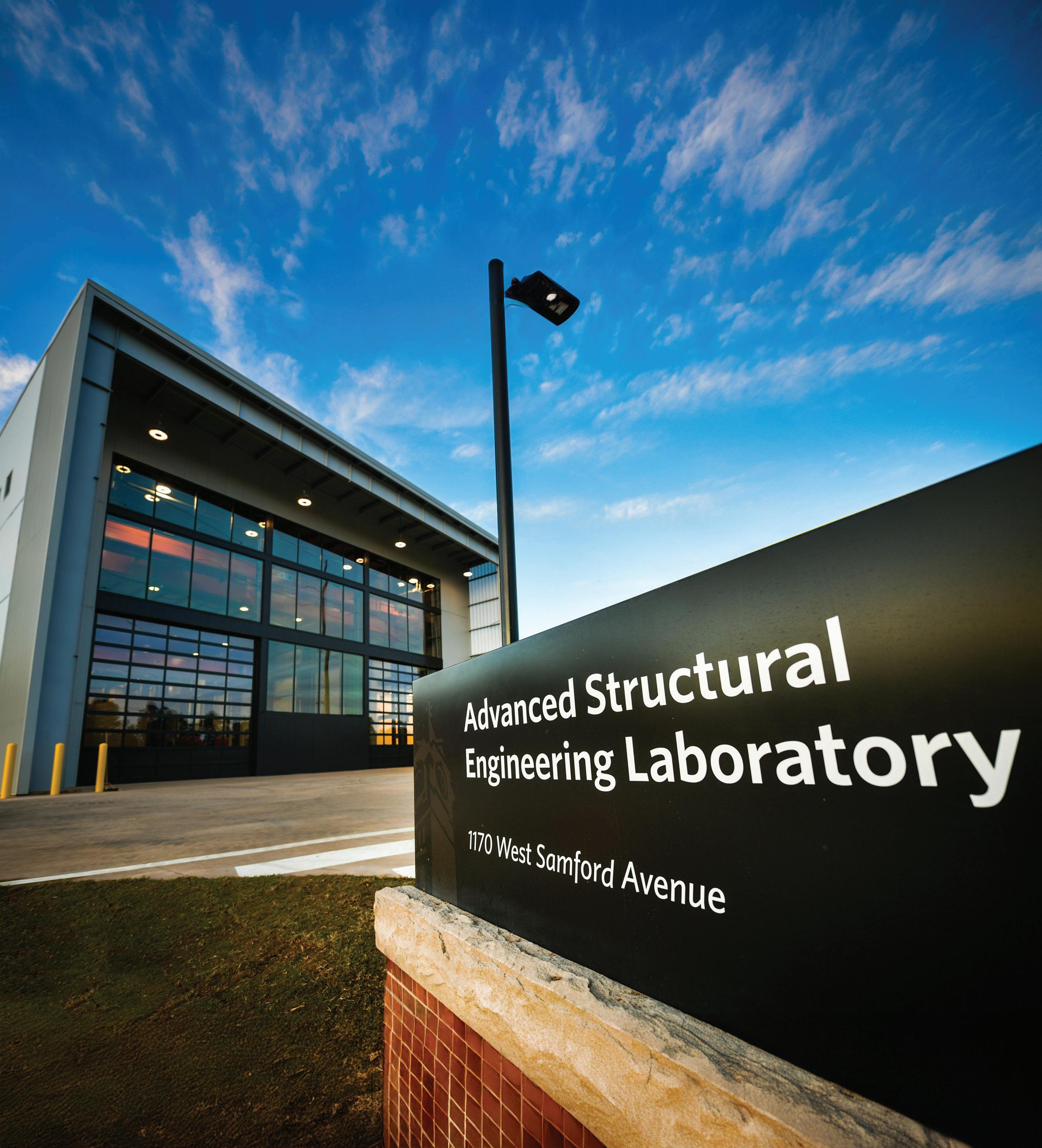

The $22 million Advanced Structural Engineering Laboratory (ASEL) at Auburn University is a state-of-theart facility that provides experimental characterization and performance testing of engineering materials, structural components and systems, geotechnical materials and integrated soil-structure systems. Primarily focused on transportation projects, ASEL is equipped to evaluate up to 140 feet long concrete and steel members.

ASEL highlights include a high bay laboratory with a strong wall and strong floor, featuring a geotechnical chamber engineered to handle extreme structural testing loads; a concrete materials research and testing laboratory; and wind-testing capabilities that can replicate hurricane-force level loads and administrative space.

Partnering with world-class multi-disciplinary faculty within Auburn University’s peer research centers, laboratories, and institutes, ASEL is positioned to accelerate research aimed at reducing the impacts during extreme events and increase the lifespan and safety of structures under all loading conditions. Moving forward, ASEL’s vision is to develop research that improves society by advancing infrastructure resilience and renewal knowledge.

• Employs approximately 30 graduate students along with several post-doctoral researchers each year, providing them with hands-on research for their future careers.

• The Vulcan High Bay Laboratory has a 200-foot by 73foot footprint, with a 120-foot by 45-foot strong floors, and 30-foot-tall L-shaped strong wall.

• ASEL’s 4,700-cubic foot geotechnical testing chamber is 24 feet long, 10 feet wide, and built 20 feet deep with the lab’s strong floor.

• Alabama Department of Transportation and Federal Highway Administration funding current research projects to fortify the long-term functionality of bridges and culverts.

• Active research projects aimed at improving the steel building industry, national defense program via blast-resistant structures, and future nuclear reactor foundations funded by the American Institute of Steel Construction, Air Force Civil Engineer Center, and Nuclear Regulatory Commission.

Improving state, regional and federal highways, and roads and bridges through collaboration and research

The Highway Research Center (HRC) was established in 1985 with a mission to support Alabama’s highway industry through coordinated research programs.

Part of the Samuel Ginn College of Engineering, the HRC is leading the charge to ensure industry professionals have the latest technologies and guidelines for designing, constructing, and maintaining highways and bridges. An advisory committee, which includes six Alabama Department of Transportation professionals and eight industry leaders and faculty, helps focus the Center’s efforts on current industry needs.

Research conducted through the HRC includes improving the safety, user friendliness, sustainability, longevity and return on investment of highway infrastructure.

While focused on the needs of the Alabama Department of Transportation, regional and national research programs (National Cooperative Highway Research Program, Federal Highway Administration, other universities) are also significant partners, including county and municipal agencies, and material suppliers and contractors.

• In FY 23, the HRC led or partnered on projects that brought in more than $4.9 million in external research awards.

• Areas of expertise include construction; environmental; geotechnical; hydraulics and hydrology; pavement and materials; structures; and transportation.

• Leverages the world-class Advanced Structural Engineering Laboratory, which is a 45,000 square-foot state-of-the-art research and testing facility.

• Full-scale testing at the Stormwater Research Facility to develop sustainable construction practices.

• Offers a graduate student scholarship in honor of Buddy Cox, a U.S. Air Force veteran, Auburn alumnus and 25year ALDOT engineer.

• Organizes the Alabama Transportation Conference, which has been around for 67 years and hosts about 1,000 transportation professionals annually.

4.9M

FUNDED-RESEARCH DOLLARS IN FY23

Delivering innovative research, technology, and education for safe and sustainable asphalt pavements

The National Center for Asphalt Technology (NCAT) was established in 1986 as a partnership between Auburn University and the National Asphalt Pavement Association (NAPA) Research and Education Foundation to provide practical research and development to meet the needs of maintaining America’s highway infrastructure.

NCAT researchers are dedicated to ensuring this industry’s ability to provide pavements that are durable, sustainable, quiet, safe, and economical. Through collaboration with state highway agencies, the Federal Highway Administration, and the highway construction industry, new products, design technologies, and construction methods are developed and evaluated, leading to rapid pavement improvements.

NCAT also houses the Test Track, a national research proving ground for asphalt pavements. Highway agencies and industry sponsors fund research on the 1.7-mile oval in 200-foot test sections. This real-world laboratory allows for cutting-edge experimentation while avoiding the risk of failure on actual roadways.

• One of the world’s leading institutions for asphalt pavement research and testing. NCAT develops and evaluates new products, design technologies, and construction methods that lead to asphalt pavement improvements.

• Provides resources to industry professionals,to contribute to the advancement of asphalt technology worldwide, through training, programs, workshops, and technical publications.

• The 22,000 square foot laboratory is equipped with state-of-the-art technology and testing equipment, enabling cutting-edge research and development

• 65% of NCAT funding comes from the Alabama Department of Transportation.

• Organizes the Test Track conference, occurring every three years, to present research from the latest cycle of accelerated pavement testing at the Test Track to more than 300 industry professionals .

• More than 120 former graduate students are now employed in diverse roles across the asphalt sector.

11M+

TOTAL MILES DRIVEN ON TEST TRACK $13M+

IN TOTAL EXPENDITURES IN RESEARCH, TRAINING AND TESTING SERVICES IN FY22 & FY23

OPERATING AS A RESEARCH CENTER AT AUBURN UNIVERSITY

Innovating stormwater management through research, education and product evaluation

The Auburn University – Stormwater Research Facility (AU-SRF) is an internationally recognized 12-acre outdoor laboratory dedicated to conducting full-scale evaluations to improve practices used to manage stormwater runoff. This facility engages professionals in the stormwater industry by conducting research, product testing and development and hands-on educational events.

The AU-SRF, established in 2006 through a collaboration between Auburn University's Highway Research Center and the Alabama Department of Transportation, operates within the Auburn University Highway Research Center at the National Center for Asphalt Technology Pavement Test Track in Opelika, Alabama.

The AU-SRF leads the development of practical, engineering-driven stormwater solutions that are recognized as best practices in the field. Through hands-on training opportunities, workshops and field days, the facility helps bridge the gap between theory and real-world application. These efforts empower stormwater professionals, policymakers and local communities to adopt effective, science-backed practices that improve water quality and protect natural resources.

• One of the largest outdoor stormwater research laboratories in the world.

• The AU-SRF works with local, state, and federal partners including: the National Cooperative Highway Research Program, U.S. Federal Highway Administration, U.S. Department of Agriculture, U.S. Geological Survey, U.S. Environmental Protection Agency, Alabama DOT, Iowa DOT, Nebraska DOT, Ohio DO, and the Alabama Department of Environmental Management.

• Research findings have led to new standards and best practices being adopted by state agencies across the country.

• The AU-SRF conducts a variety of ASTM-based testing for the stormwater industry.

• The annual Erosion and Sediment Control Installer Training and Field Day events bring in more than 200 stormwater professionals for training and education.

• In addition to the 12-acre outdoor facility, the AU-SRF operates a 2,500 square-foot training center and a 2,000 square-foot wet laboratory in the Harbert Engineering Center.

Improving infrastructure, safety and mobility through research, education, and technology transfer

Established in 2021, the Auburn University Transportation Research Institute (AUTRI) provides a unified presence and strategic direction for promoting renowned transportation-related research conducted within academic departments and research centers in the Samuel Ginn College of Engineering.

Established in 2021, the Auburn University Transportation Research Institute (AUTRI) provides a unified presence and strategic direction for promoting renowned transportation-related research conducted within academic departments and research centers in the Samuel Ginn College of Engineering.

AUTRI is comprised of several units, each dedicated to advancing transportation-related research. They include the National Center for Asphalt Technology (NCAT) and its affiliated asphalt test track, the Highway Research Center (HRC), the Alabama Transportation Assistance Program (ATAP), and the GPS and Vehicle Dynamics Laboratory (GAVLAB).

AUTRI is comprised of several units, each dedicated to advancing transportation-related research. They include the National Center for Asphalt Technology (NCAT) and its affiliated asphalt test track, the Highway Research Center (HRC), the Alabama Transportation Assistance Program (ATAP), and the GPS and Vehicle Dynamics Laboratory (GAVLAB).

From testing pavement resiliency, developing autonomous vehicles technology, improving highway infrastructure, and providing technical assistance to local municipalities with the tools needed to improve their transportation needs, our mission is transforming how people, information, and goods are moved across Alabama and the country.

From testing pavement resiliency, developing autonomous vehicles technology, improving highway infrastructure, and providing technical assistance to local municipalities with the tools needed to improve their transportation needs, our mission is transforming how people, information, and goods are moved across Alabama and the country.

• NCAT is home to the world’s only high-speed, full-scale 1.7-mile accelerated asphalt paving test track, which allows faculty, staff, and students to conduct cuttingedge research.

• NCAT is home to the world’s only high-speed, full-scale 1.7-mile accelerated asphalt paving test track, which allows faculty, staff, and students to conduct cuttingedge research.

• GAVLAB is a worldwide leader in connected and autonomous vehicle research, focusing on robust control of vehicles using GPS, and Inertial Navigation System.

• GAVLAB is a worldwide leader in connected and autonomous vehicle research, focusing on robust control of vehicles using GPS, and Inertial Navigation System.

• AUTRI’s extramural transportation-related research on infrastructure, transportation systems, mobility, connected and autonomous vehicles, and electric vehicles is larger than any other portfolio on Auburn’s campus.

• AUTRI’s extramural transportation-related research on infrastructure, transportation systems, mobility, connected and autonomous vehicles, and electric vehicles is larger than any other portfolio on Auburn’s campus.

• AUTRI faculty, staff, and students have access to worldclass research facilities including Advanced Structural Engineering Laboratory (ASEL), the NCAT Test Track, and the Autonomous Vehicle Laboratory.

• AUTRI faculty, staff, and students have access to worldclass research facilities including Advanced Structural Engineering Laboratory (ASEL), the NCAT Test Track, and the Autonomous Vehicle Laboratory.

• Research contracts for AUTRI span numerous diverse private, state, and federal funding agencies, including the Alabama Department of Transportation, the U.S. Department of Transportation, and the U.S. Department of Defense.

• Research contracts for AUTRI span numerous diverse private, state, and federal funding agencies, including the Alabama Department of Transportation, the U.S. Department of Transportation, and the U.S. Department of Defense.

Creating innovative solutions for modern challenges through micro/nano technology research and development

Unleashing the blended power of AI and cybersecurity to revolutionize digital defense

Housed within the Department of Computer Science and Software Engineering, the Auburn University Center for Artificial Intelligence and Cybersecurity Engineering (AU-CAICE) is dedicated to spearhead pioneering advancements at the intersection of artificial intelligence and cybersecurity.

AU-CAICE builds upon the legacy of the Auburn Cyber Research Center, continuing its dedication to cybersecurity excellence while expanding its reach and impact. The center focuses on three hybrid areas (in addition to AI & Cybersecurity): SecureAI, CyberAI, and SecureCyberAI, which integrate AI and cybersecurity to create robust, real-time, self-healing systems. By advancing research in these areas, AU-CAICE aims to maintain Auburn’s position at the forefront of AI and cybersecurity research and education, ensuring that the university remains a leader in these critical fields.

The center is committed to cultivating long-term, extramurally funded research and educational relationships, serving as a hub for collaboration with academia, industry, national laboratories, and government entities. Together, we can build a more secure digital world.

• Lead unit for Auburn University’s designation by the National Security Agency and the Department of Homeland Security as a National Center of Academic Excellence in Cyber Defense, Cyber Research, and Cyber Operations – one of only 10 universities in the nation to hold all three designations.

• Lead unit for Auburn University’s CyberCorps Scholarship for Service program.

• Associated academic programs include the Master of Science in Cybersecurity Engineering, Master of Science in Artificial Intelligence Engineering, graduate certificates in cybersecurity engineering and artificial intelligence engineering, and undergraduate certificates in cyber defense and Artificial Intelligence Engineering.

• Hosts regional cyber competitions, including CyberFire Puzzles by the Los Alamos National Laboratory and Tracer FIRE by Sandia National Laboratory.

• Associated with the Auburn University AI@AU initiative.

• Research partners include the Auburn University Applied Research Institute and the McCrary Institute for Cyber and Critical Infrastructure.

1,305

AFFILIATED RESEARCHERS

Solving technology gaps in the development of next-generation electronics

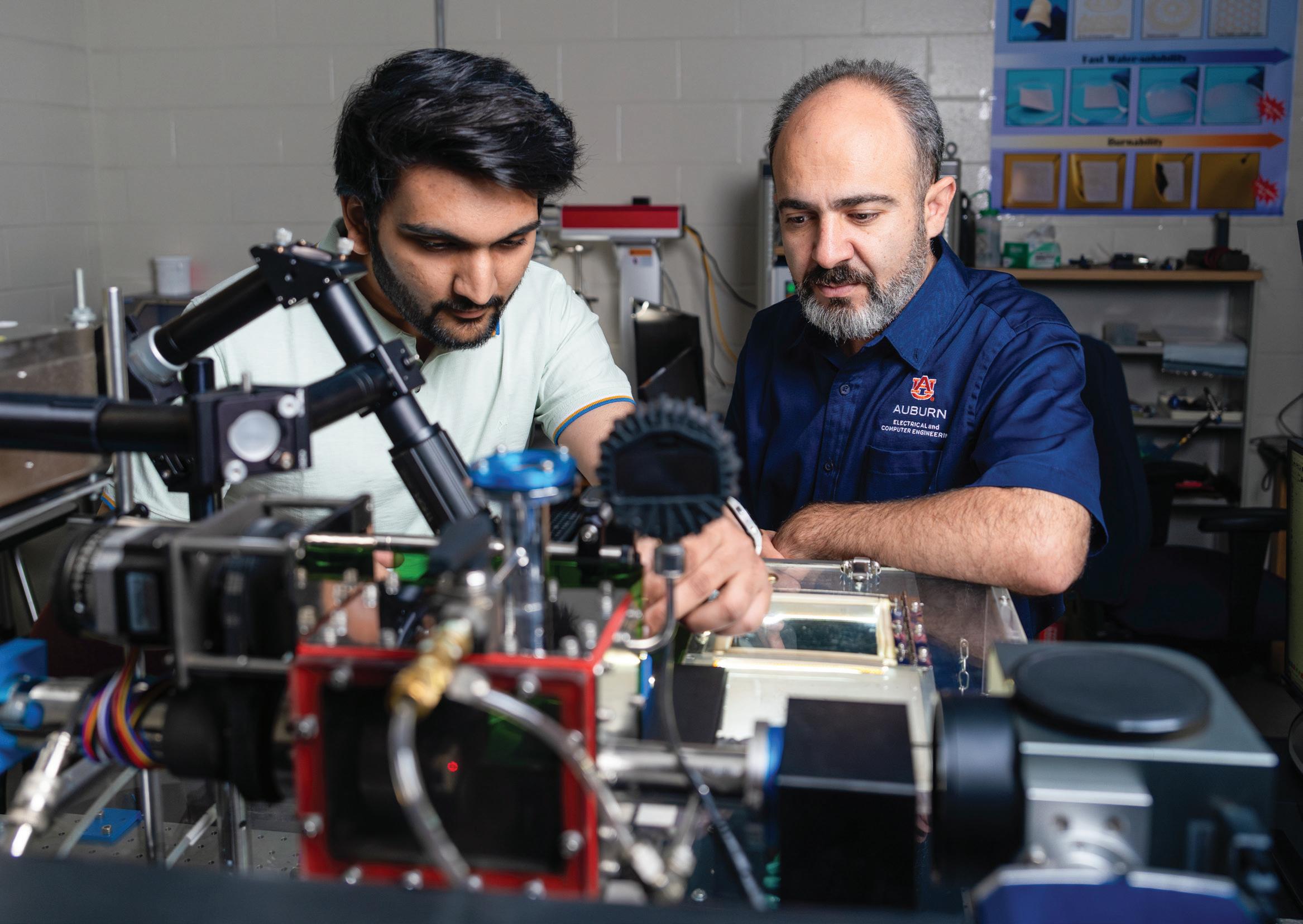

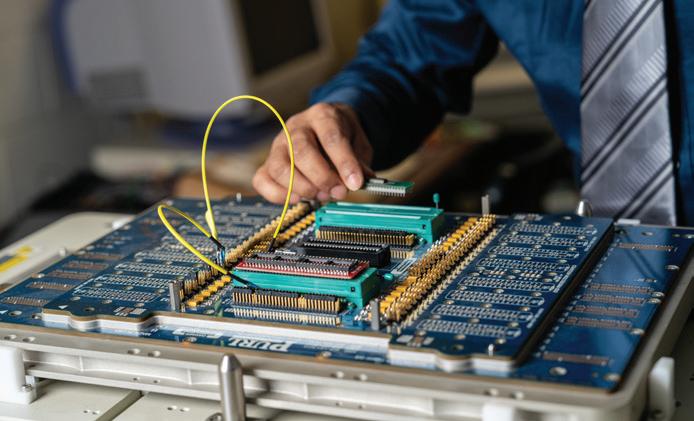

Established in 1999, the Auburn University Electronics Packaging Institute (AUEPRI) develops and implements new technologies for the packaging and manufacturing of electronics.

Here, special emphasis is paid to the harsh environment and reliability requirements of electronics in automotive and defense applications, including electronics required to operate at sustained high or low temperatures, high or low temperature extremes, high acceleration, and in the presence of contaminants.

Driven by AUEPRI board members representing material, component, equipment, and electronic assembly industries, the institute’s research focus includes semiconductor packaging, additive manufacturing, electronics, chip and package manufacturing, electronics assembly and electronics, and reliability and prognostic health management.

With more than 30 member companies represented on the institute’s advisory board, AUEPRI continues to identify challenges and opportunities for new materials, processes and approaches toward electronics manufacturingsetting the standard among peer institutions.

• AUEPRI regularly leads project calls and technology innovations in additive manufacturing electronics for the NextFlex National Manufacturing Institute for Flexible Hybrid Electronics.

• Auburn University is a Tier-1 founding member of NextFlex.

• Formerly known as the National Science Foundation Center for Advanced Vehicle and Extreme Environment Electronics (CAVE3).

• Laboratory space inside Wiggins Hall includes a variety of research/testing equipment ideal for chip fabrication and characterization, additive printed flexible hybrid electronics, modeling and simulating, material characterization, surface mount assembly, non-destructive analysis, and packaging prototype lines, accelerated testing and high-G survivability.

Dedicated to protecting America’s Cyberspace and Critical Infrastructure

Auburn University’s McCrary Institute for Cyber and Critical Infrastructure Security seeks practical solutions to real-world problems, underpinned by research and scholarship. Founded in 2015 through a generous donation from the Alabama Power Foundation, in honor of its retiring CEO and Auburn alumnus Charles D. McCrary, the Institute fuses theory with practice, and policy with technology, to protect and advance U.S. interests in the areas of cyber and critical infrastructure security.

A non-partisan think tank and research facility, the McCrary Institute utilizes a leading group of public/ private sector cyber experts to provide unique end-toend cyber capabilities from research and development, cybersecurity education/training, policy-relevant analysis to future technology research.

Our vision is to serve the nation by acting as a catalyst for enhancing cyber/critical infrastructure security and striving to be the most respected, sought out, singleexpert source on cyber/critical infrastructure security issues for government agencies, private companies, educators, and the media.

• Strategic expertise includes:

1) radio frequency and electronic warfare

2) AI and machine learning

3) operational technology and cyber-physical security

4) vulnerability assessments and penetration testing

5) threat intelligence, open-source intelligence and data analytics.

• We identify the most concerning cyber and critical infrastructure security issues and challenges, inform decisionmakers, and collaborate with them in order to help shape strategy and outcomes that support and advance U.S. national and economic security.

• We partnered with the U.S. Secret Service’s National Computer Forensics Institute to detect digital counterfeit components, develop network incident response framework, and create a malware reverse engineering curriculum.

• We partnered with Oak Ridge National Laboratory and industry to create the nation’s first regional cyber security operations center focused on protecting the electric grid (Southeast Cybersecurity Collaboration Center). This center will help test, evaluate, and validate the latest cybersecurity technologies and protocols to better safeguard America’s electrical grid and operational technologies.

DOE GRANT IN PARTNERSHIP WITH OAK RIDGE NATIONAL LABORATORY

Addressing challenges associated with the growing demand for evolving wireless systems

The Wireless Engineering Research and Education Center (WEREC) at Auburn University is a dynamic organization dedicated to addressing challenges associated with the growing demand for evolving wireless systems, communications networks, and their applications.

Drawing upon the expertise of more than 20 faculty members positioned within the Samuel Ginn College of Engineering’s Department of Electrical and Computer Engineering, Computer Science and Software Engineering, and the College of Sciences and Mathematics, the WEREC produces a robust research portfolio ranging from radio frequency integrated circuits and low-power integrated circuit design to wireless systems, wireless multimedia, and robotic applications.

Already a focal point for cross-disciplinary studies and academic activities, the WEREC continues to make connections within industry where dramatic and positive impacts upon society can be applied and realized.

• Initiated in 2001 by a $25 million gift to the College of Engineering by Auburn alumnus and telecommunications pioneer Samuel L. Ginn, the Wireless Engineering Research and Education Center was the first program of its kind in the nation.

• Research focus includes device integrated circuit design and testing, communications and networks, cybersecurity and privacy, wireless applications and statistics, and wireless machine learning.

• Impactful research projects include, but are not limited to, exploring means to optimize AR/VR device speeds, using RFID tags to create a low-cost, unobtrusive posture capture system for healthcare, and devising innovative approaches that enable wireless practitioners to acquire data more efficiently and cost-effectively.

• Three faculty members involved in the center — Shiwen Mao, Xiaowen Gong and Yin Sun — are National Science Foundation CAREER Award recipients.

• Leadership positions within professional societies, including the Institute of Electrical and Electronics Engineers and the Association for Computing Machinery, provide WEREC faculty to leverage their research and collaborate with peer scholars internationally.

9

AFFILIATED RESEARCH LABS WITHIN

Fostering industry growth through partnership with the Alabama Pulp and Paper Foundation

Established within Auburn University’s Department of Chemical Engineering in 1985, the Alabama Center for Paper and Bioresource Engineering (AC-PABE) facilitates research programs in line with the pulp and paper industry’s evolving research and development agenda and educates its next generation of impactful leaders.

Focused on industry research needs, the center offers a complete, controlled-conditioned, wet-test laboratory for chemically and physically evaluating pulp, paper and biomass — with an emphasis on advanced manufacturing technologies and value-added byproducts. Research and development activities are driven by those that 1) achieve the highest possible sustained value from our nation’s forest-based biomass, and 2) deliver superior technical service to the paper industry.

Dedicated to providing a highly skilled training and academic program for future engineers, the center also offers nationally and internationally recognized curricular and experiential education to both undergraduate and graduate students.

The AC-PABE is driven to meet the growing and changing needs of the pulp and paper industry and we are actively looking to build strong public-private partnerships through the Auburn Pulp & Paper Foundation (APPF).

• Since 2017, AC-PABE has led or partnered on 31 grants totalling more than $40 million.

• Undergraduate specializations offered for students majoring in chemical, electrical, biosystems, industrial & systems, and mechanical engineering

• 95 undergraduate students enrolled in the specialization and awarded APPF scholarships for 2024-25.

• Pulp & paper graduate certificate is available both online and in-person

• Graduate students and faculty enjoy a multidisciplinary research environment

• The center offers approximately 5,000 square feet of laboratory space equipped with state-of-the-art M/K laboratory digesters, chip screening, lab scale and pulper, lab scale bleaching, valley beaters, PFI mill, and standard handsheet-making and testing, including mechanical, optical, surface, and barrier properties.

FUNDED-RESEARCH PROJECTS SINCE 2017

Fueling low-carbon economy with bioenergy and bioproducts

Established in 2007, the Auburn University Center for Bioenergy and Bioproducts (CBB) is a hub for innovation that leverages the state’s vast reserves of renewable forestry and agricultural biomass. With a mission to identify bioenergy and bioproduct opportunities in the southeast, the CBB is positioned to address barriers to the universal development of alternative fuels and reduce the nation’s dependence on foreign energy sources and advance statewide economic development.

Interdisciplinary research capabilities include catalyst characterization, biomass characterization, liquid fuel characterization, pilot-scale gasification and gas conditioning, and catalytic liquid fuel synthesis, allowing industries the opportunity to utilize locally available biomass for providing fuels, chemicals, and materials in a sustainable manner.

With laboratory space inside the Center for Advanced Science, Innovation and Commerce and at the Biological Engineering Research Laboratory at the Auburn Research Park, the CBB is poised to meet these challenges for years to come.

• Collaborators include the Forest Products Development Center, Auburn University’s Departments of Chemical Engineering and Biosystems Engineering, the National Center for Asphalt Technology, and the USDA Forest Service.

• Specific focus areas include thermal and biochemical conversions, biomass production logistics, syngas cleaning, catalyst development, and sustainability.

• Awarded a $1 million grant from the USDA’s National Institute of Food and Agriculture in 2023 to test the efficacy of dual-function biochar substrate, which captures excess phosphorus in soils and releases it slowly to meet plant needs.

• Facilities include a pilot-scale gasification and gas conditioning laboratory, a catalytic liquid fuel laboratory that contains fixed bed reactors and continuously stirred tank reactors; biomass characterization laboratory with walk-in refrigerated rooms and enclosed laminar hoods; liquid fuel characterization laboratory with pH meter, Karl-Fisher titrator, thermogravimetric analyzer, and more.

Improving occupational health through innovative research, instructional excellence, and education

The Center for Occupational Safety, Ergonomics and Injury Prevention — part of the Samuel Ginn College of Engineering at Auburn University — aims to improve occupational health and safety by shaping the future of work through innovative research, instructional excellence, and continuing education.

Officially established in 2017, the center is the culmination of years of research and funding from the National Institute for Occupational Safety and Health (NIOSH) dating back to the 1980s.

Auburn University and the University of Alabama at Birmingham collaborate to form the Deep South Center for Occupational Health and Safety, serving as the region’s sole NIOSH education and research center. There are 18 such centers throughout the country.

• Focuses on two main programs: Occupational Safety and Ergonomics (OSE) and Occupational Injury Prevention (OIP).

• Masters and doctoral degrees are available through the Department of Industrial and Systems Engineering.

• The OSE Graduate Certificate Program is available online and on campus.

• World-class, national award-winning faculty.

• Recently renovated offices, labs, and student spaces since 2020.

• Provides safety training on emerging topics to the Auburn University community.

GRADUATE CERTIFICATES AWARDED IN THE PAST 15 YEARS. YEARS OF FUNDING BY NIOSH

PERCENT JOB PLACEMENT IN ENGINEERING, OCCUPATIONAL SAFETY OR ERGONOMIC FIELDS

The Auburn University Neuroimaging Center is a dynamic research hub within Auburn’s Samuel Ginn College of Engineering with a $20 million, 45,000-square-foot facility located in the Thomas Walter MRI Research Building at the Auburn Research Park.

Leveraging Auburn University’s existing expertise in engineering, sciences, and veterinary medicine, we aim to improve healthcare and contribute to medical and scientific advancements. Collaborative, interdisciplinary research projects within the center vary from exploring PTSD biomarkers in older adults to examining how AI can be used to predict brain disorders – even measuring the effect of gene therapy for Tay-Sachs disease in animals.

Our vision is clear: to become a leading center for MRI research, emphasizing brain imaging, cardiovascular imaging and orthopedic imaging. These areas align with both the needs of the MRI research community and the existing strengths of Auburn University.

• The $9 million state-of-the-art MAGNETOM wholebody Terra.X 7-Tesla scanner provides unprecedented resolution, advancing our understanding of brain health and function.

• Cutting-edge Siemens Skyra Open-Bore 3T scanner.

• State-of-the-art cognitive neuroscience research with functional MRI (fMRI) with world-class magnetic resonance spectroscopy (MRS) to study biochemistry and energy production in the brain and muscle.

• Utilizes sodium imaging of the brain to provide insight into cellular function.

• Emphasized research in these critical areas: brain, cardiovascular, muscle/brain energy production, orthopedic imaging, and brain disorders/human behavior studies.

INSTALLED, CLINICALLY APPROVED PARALLEL TRANSMIT 7T MRI SCANNER

IN FEDERAL FUNDING TO THE STATE OF ALABAMA THROUGH COLLABORATIVE RESEARCH GRANTS

PUBLISHED RESEARCH ARTICLES IN LEADING JOURNALS SINCE 2010

Empowering Auburn engineering students to launch careers through coaching, partnerships and learning

The mission of the Samuel Ginn College of Engineering Office of Career Development and Corporate Relations (CDCR) is to equip and empower engineering students to discover, develop, and launch professional experiences and purposeful careers.

We do so by delivering customized, student-centered career coaching and programs, curating and integrating career education tools and resources, promoting workbased learning experiences and cultivating industryfocused partnerships.

Employers seeking to connect with Auburn Engineering talent can leverage tailored recruitment strategies, curated events and strategic campus partnerships to boost their visibility and hiring outcomes.

Our support services for students provide guidance at every phase of their career development journey, offering guidance on major selection, career exploration, securing co-op or internship opportunities and navigating the full-time job search process. Through integrated classroom curriculum, we also help students effectively articulate their learning experiences and professional growth, ensuring they are prepared for success beyond graduation.

• Internship conversion rates increased from 26% in 2022 to 33.6% in 2024.

• Co-op conversion rates increased from 14.7% in 2020 to 21.2% in 2024.

• In the past five years, the average reported starting salary has increased 11% from $68,744 in 2020 to $76,444 in 2024.

• Over the past three years, the average number of reported job offers for engineering graduates is 1.89.

• More than 75% of students participate in one or more high impact practices during their degree program.

• 83% of students report acceptance of full-time employment, military commission or admission to graduate school within six months of graduation.

• The average salary for students across all graduate engineering programs in the class of 2024 was $94,720.

• 93% of graduate students reported successful employment or enrollment in a graduate program within six months of graduation.

Engineering progress through continuous education and professional development

We know working professionals never stop learning, and this is essential to achieving their career goals in constantly evolving industry. The Auburn Engineering Professional Development (EPD) program offers a large variety of online continuing education courses and certificate programs to allow engineers to earn CEUs for license renewals as well as develop new professional skills. Our non-academic credit classes are taught by Auburn Engineering faculty and other subject matter experts, giving EPD students the same quality experience as students on campus.

Course topics include aerospace, civil/landscape architecture, electrical, mechanical, structural, and surveying as well as more business-based courses in ethics, legal issues, and management. In 2022, EPD began partnering with the Project Management Institute to offer a Project Management Professional (PMP) certification prep course. PMP is the world’s leading project management certification, designed to elevate careers for professionals in all disciplines.

EPD also offers customized professional development to companies who may need training on a special topic at a specific time and location. EPD staff can work with companies to identify their needs and then coordinate the appropriate faculty and resources.

• Offers more than 100 online continuing education courses for working engineers in all fields and with all levels of experience

• Business Essentials for Engineering Professionals (BEEP) is one of EPD’s most popular programs, designed to help engineers develop the business knowledge needed to become a successful leader within their company.

• PMP certificate prep course aligns with the official PMP exam content and satisfies the 35 training hours required to apply for the PMP certification.

• Began offering continuing education courses in 1995, starting with mailing VHS tapes to customers and soon moving to DVDs. In 2023, EPD began offering all courses exclusively via online streaming.

• Partners with National Center for Asphalt Technology (NCAT) at Auburn University to offer courses on pavement design, construction, and maintenance.

Advancing Assured PNT and vehicle dynamics for autonomous and hypersonic vehicles

The GPS and Vehicle Dynamics Laboratory (GAVLAB) is advancing the robust navigation and control of autonomous vehicles. Established in 2001, GAVLAB’s mission revolves around integrating GPS with other vital on-board sensors to achieve highly accurate and reliable navigation solutions. Its three main research thrusts are: assured positioning, navigation and timing (APNT) and orbital estimation, robust control methods for autonomous vehicles, and vehicle dynamics and controls for a range of platforms including heavy trucks, passenger cars, off-road vehicles, and hypersonic vehicles. This includes crucial areas like sensor fusion, signal processing, online system identification, and adaptive control techniques.

GAVLAB’s Autonomous Vehicle Research Facility provides a controlled environment for real-world testing and demonstrations. GAVLAB’s expertise is also showcased through the Autonomous Tiger Racing (ATR) team, which regularly demonstrates high-speed autonomous capabilities through deep reinforcement learning for challenging environments.

Through collaborations with entities like the Department of Defense, Federal Highway Administration, and various private industry partners, GAVLAB continues to develop innovative solutions for the future of APNT as well as autonomous vehicles.

(20+ Ph.D, 100+ MS)

• Collaborated in the first combined military-commercial autonomous international bridge crossing

• Patented a precise GPS positioning technology for poor signal environments

• Conducted the first on highway testing in Canada of an automated truck platoon

• Only university research program in the nation to participate in every Army PNT Assessment Experiment (PNTAX)

• Performer on initial Army Dismounted and Mounted Assured PNT System (MAPS and DAPS) programs

EXTERNALLY FUNDED RESEARCH AND DEVELOPMENT

The premiere on-campus makerspace in the country

Since opening its doors in 2019, the Design and Innovation Center, known as the Makerspace, has served as a dynamic hub of creativity and ingenuity inside the Brown-Kopel Engineering Student Achievement Center. Featuring a woodshop, a prototype shop, an electronics shop, a metal shop, and a machine shop with some of the most advanced fabrication equipment on the market, the impressive 11,000-square-foot, student-run facility offers unparalleled opportunities for hands-on learning — and the freedom to innovate — distinguishing it as the premiere on-campus makerspace in the country.

Prioritizing safety and student success, the Makerspace offers comprehensive student-taught training programs covering a wide range of cutting-edge tools and equipment. It also provides students with invaluable experiential learning opportunities beyond traditional coursework, enabling them to explore diverse interests and develop practical skills not readily available elsewhere. This vibrant Makerspace fosters essential collaboration across various engineering disciplines, actively helping transform innovative ideas into tangible, completed projects while meticulously preparing students with critical, practical skills for their future careers as highly well-rounded engineers.

• Available Trainings: Training courses include Basic Safety; Laser Cutter; Craft World; Embroidery; Electronics Shop; Metal Shop; MIG/TIG/Stick Welding; Sand Blaster; Machine Shop; Manual Mill; Manual Lathe; Water Jet; CNC Mill; Wood Shop; Powered Hand Saw; and Router, Planer, and Jointer.

• The Makerspace works with various project-based classes, hosts engineering events, provides space for technical workshops by organizations like the Society of Women Engineers (SWE) and the American Society of Mechanical Engineers (ASME), and supports summer programs and Camp War Eagle.

• Overseen by more than 60 trained student Makerspace Assistants (MAs).

SQUARE FEET

2,100

3,390 TRAININGS PERFORMED (2024-2025 ACADEMIC YEAR) 11K

NUMBER OF ACTIVE USERS (AS OF SPRING 2025)

Connecting engineering, business, and industry through innovation and technology

The Thomas Walter Center for Technology Management is an interdisciplinary umbrella organization affiliated with the Samuel Ginn College of Engineering’s Department of Industrial and Systems Engineering and the Harbert College of Business that fosters programs to help private sector organizations and government increase their effectiveness through better use and understanding of technology.

Since its establishment in 1989, the center continues to improve business and engineering student preparation for the industrial world with new curricula, applied research, and continuing education initiatives.

The center’s mission is accomplished through various programs, most visibly the Business-EngineeringTechnology minor for both business and engineering students. This two-year minor provides students with the education and training to develop new products, business models, and plans for start-ups while working in a team environment. Moving forward, the center will expand its global footprint through the 2024 addition of an international Business-Engineering-Technology minor.

• The Business-Engineering-Technology program minor is available to both engineering and business students.

• A Master of Engineering Management degree available to those currently working in an engineering-related field.

• The Tom and Jean Walter Accelerated Bachelor’s/ Master’s Fellowship sponsors 10 engineering students each year.

• Students are given opportunities each year to study abroad in countries such as Spain and Germany.

• World-class faculty and facilities are provided within the Department of Industrial and Systems Engineering.

• Students in the program develop entrepreneurial skills used toward the creation of startup companies and management positions.

Developing leaders to implement Lean Systems and drive continuous improvement culture

Tiger Motors, affectionately known as the “Lego Lab,” is a state-of-the-art simulated assembly plant in Auburn University’s Samuel Ginn College of Engineering. It provides hands-on, high-volume production experience while teaching students the principles of Lean Manufacturing.

Lean concepts are introduced in the classroom and brought to life in the lab, where students tackle realworld challenges like system interdependence, human factors, and continuous improvement. At the center of the lab are two intricate Lego vehicle builds (234 and 277 pieces). Student teams strive to meet customer demand, producing each unit within a 70-second takt time and 60-second cycle time.

The lab offers a dynamic, hands-on environment for industry-focused Lean Manufacturing training. While many companies are already familiar with Lean principles, ongoing training ensures a consistent and deeper understanding across teams.

Each session is tailored to meet the specific needs and Lean maturity of the company. Depending on existing knowledge, organizations can choose between one- or two-day training programs.

• Serves as a training hub for industry partners like Honda, Brose, Borbet, G.E. Aerospace and Hartzell Aviation

• More than 500 Lean Six Sigma Green Belt certifications awarded

• Nine core Lean Manufacturing elements featured in the lab

• 4,000-square-foot facility located on the bottom floor of Shelby Center

• An ideal setting for student research, the Lego Lab has supported three Ph.D. dissertations based on work conducted within the lab.

• Supported by generous industry contributions from companies such as the Denso and Honda Foundations, Bendix, Uline, Omron and Uplift Desks.

The Auburn University Subject Matter Expert (AUSME) tool utilizes advanced semantic AI tools to identify researchers whose expertise matches specified keywords. By inputting these keywords, AUSME identifies researchers whose academic focus aligns closely with the designated areas of interest.

AUSME creates detailed researcher profiles by analyzing a repository of more than 100 papers per researcher sourced from Google Scholar. These profiles include comprehensive data such as paper titles, abstracts, authors, and citation metrics. Utilizing semantic analysis, the system extracts key keywords from these papers, providing a nuanced understanding of each researcher’s expertise based on their scholarly contributions.

Upon receiving a set of query keywords (e.g., 'machine learning', 'cybersecurity'), AUSME employs semantic algorithms to filter out researchers whose work is less relevant. By evaluating the semantic context of keywords within papers, it excludes those falling below a predefined relevance threshold. Subsequently, AUSME computes a weighted average score for all pertinent keywords, aggregating these scores to produce a comprehensive ranking for each researcher. This approach ensures AUSME delivers a curated list of top-ranked researchers whose expertise best aligns with the query keywords.

I believe that this is a practical world and that I can count only on what I earn. Therefore, I believe in work, hard work.

I believe in education, which gives me the knowledge to work wisely and trains my mind and my hands to work skillfully.

I believe in honesty and truthfulness, without which I cannot win the respect and confidence of my fellow men.

I believe in a sound mind, in a sound body and a spirit that is not afraid, and in clean sports that develop these qualities.

I believe in obedience to law because it protects the rights of all.

I believe in the human touch, which cultivates sympathy with my fellow men and mutual helpfulness and brings happiness for all.

I believe in my Country, because it is a land of freedom and because it is my own home, and that I can best serve that country by "doing justly, loving mercy, and walking humbly with my God."

And because Auburn men and women believe in these things, I BELIEVE IN AUBURN AND LOVE IT.

-George

Petrie (1943)