® APRIL 2024 © Copyright 2024 American Trade Magazines All rights reserved. ■ KEEPING THE TENSION ON ■ WORKING ON OR IN YOUR BUSINESS? The Makings of a Great CSR

6

The Makings of a Great CSR

To many of your clients, your customer service representative is the face of your business. So, mistakes made in hiring the right person for this role and training them to succeed can impact your company on every level. What is innate and what can be taught when hiring — and keeping — great CSRs?

15

Keeping the Tension On

Today’s tensioning machines can take someone who has never worked in a drycleaning plant and, with a little training, allow them to finish garments to a like-new state. What should cleaners look for when shopping for this piece of equipment, and what might the future hold for in this section of the finishing process?

HUNG UP ON THE HIDDEN HANGER?

If you need a little help finding this month’s hanger hidden on our cover, here’s a clue. Good luck!

2 American Drycleaner, April 2024

AMERICAN AMERICAN April 2024 Vol. 91, No. 1

drycleaner

FEATURES

2024 © Copyright The

APRIL

®

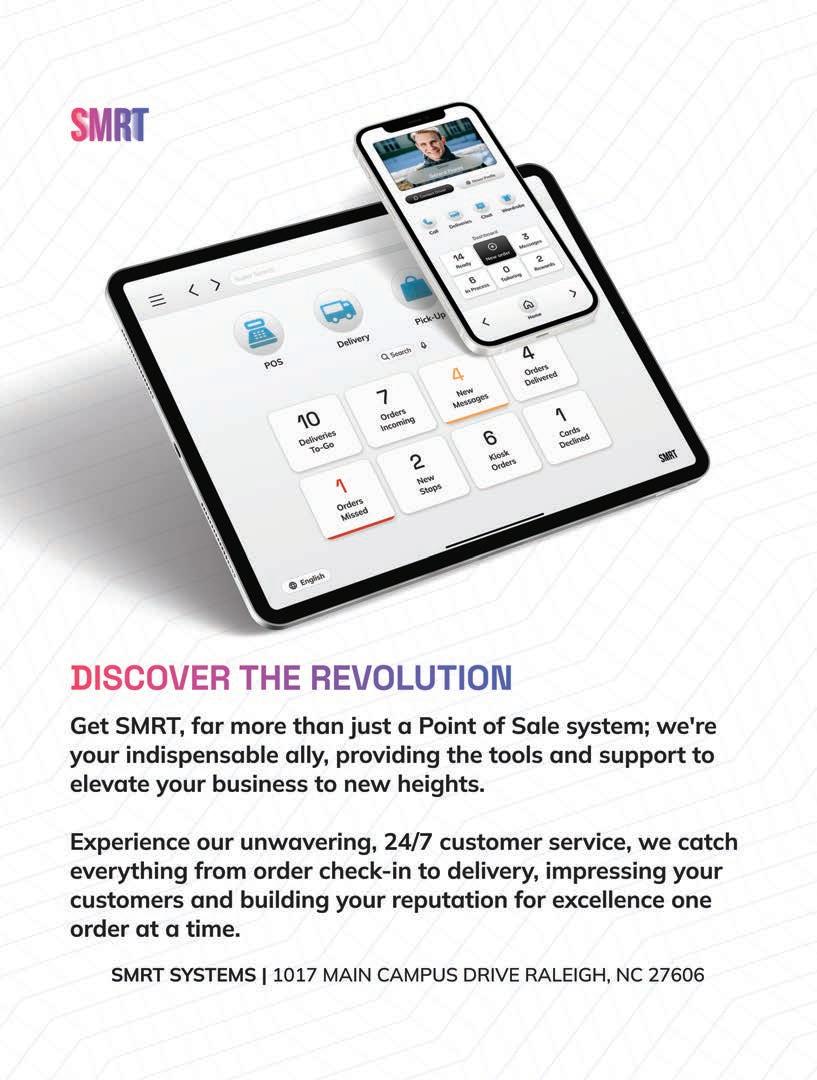

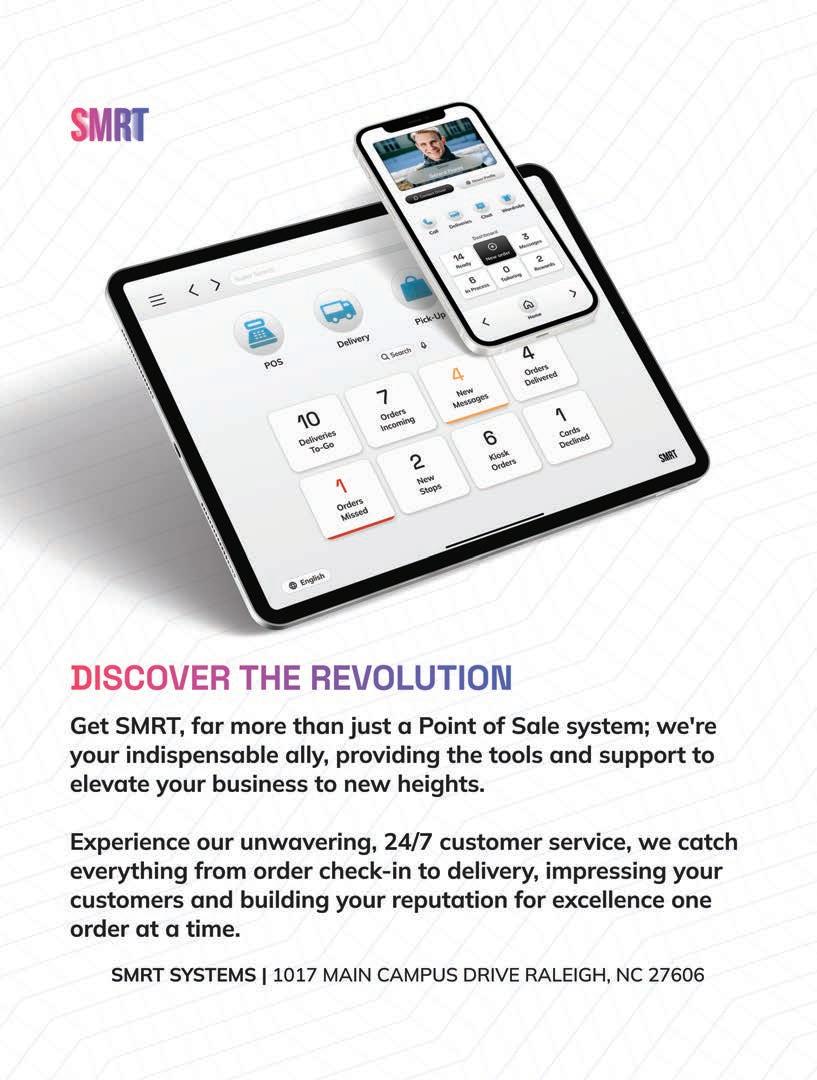

414 Gateway Boulevard, Burnsville, MN 55337 800.406.9649 www.cleanerbusiness.com • sales@cleanerbusiness.com Is your POS Software leaving you exhausted? Cleaner Business Systems keeps you running smoothly with: • The most reliable customer service from real people with real solutions • Subscriptions starting at $50 per month • Equipment Loaner Program • Text Messaging/Integrated Credit Cards/Coupons and Promotions. Freezing Software? No Support? No Customization? No Loaner Equipment?

Finish Strong

No matter how much work goes into the start of a project, it’s the effort at the end that the customer will often notice and remember the most. If the final product doesn’t meet their standards, the labor in the beginning ultimately doesn’t matter.

Dave Davis

Dave Davis

In this month’s issue of American Drycleaner, we’re looking at what it takes to both start off well and finish strong to delight the customer and keep them coming back.

Our cover feature, “The Makings of a Great CSR,” examines the value of the front counter personnel, who are often the first, last and only points of contact the average customer will have with your business. While the current labor market might make it tempting to take the first available warm body who can fill the role, cleaners who settle for “first come, first hired” might be setting both that employee and their business up for unfortunate results.

Our other feature, “Keeping the Tension On,” takes a look at the use of tensioning machines and their role in the modern drycleaning plant. While this piece of equipment can help cleaners not only avoid pressing, the ease of use can allow new operators to deliver excellent finishing results. In fact, for some types of cleaning, this machine is essential for that like-new look that customers are hoping to see in their finished garments.

This month, we also have the results of our quarterly Your Views survey. This time, we’ve asked our respondents about their role in their company, and if they are pulled off-task when it comes to leadership because of the day-to-day demands of the work coming through the doors. While many cleaners can perform most, if not all, the functions in the plant when it comes to cleaning clothes, there is higher-level work in the company that only the owner can accomplish.

Starting off a project well is key to success, but to use some football terminology, a 99-yard run fumbled at the 1-foot-line will rob a team of a touchdown. There’s no substitute for finishing strong.

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $50.00; 2 years $100.00. Single copies $10.00 for U.S. Published by American Trade Magazines LLC, 650 West Lake Street, Suite 320, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 125 Schelter Rd., #350, Lincolnshire, IL 60069-3666. Volume 91, number 1. Editorial, executive and advertising offices are at 650 West Lake Street, Suite 320, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason.

© Copyright AMERICAN TRADE MAGAZINES LLC, 2024. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

4 American Drycleaner, April 2024 www.americandrycleaner.com

PRE-INSPECTION

Publisher Charles Thompson Editorial Director Bruce Beggs 312-361-1683 bbeggs@ATMags.com Editor Dave Davis 312-361-1685 ddavis@ATMags.com Digital Media Director Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com Production Manager Mathew Pawlak Advisory Board Jan Barlow Mike Bleier John-Claude Hallak

Manter Wesley Nelson Kyle Nesbit Fred Schwarzmann Vic Williams Wayne Wudyka Office Information Main: 312-361-1700 www.american drycleaner.com Subscriptions 847-504-8175 ADC@Omeda.com

Monika

Working On or In Your Business?

When the owners of drycleaning businesses can’t find enough help to fill roles due to a tight labor market, they are sometimes forced to roll up their sleeves and pitch in on the production side, rather than perform the actions only leaders can accomplish.

For this American Drycleaner Your Views survey, we asked owners about the roles they are currently playing in their businesses and why.

When asked to describe the current employment levels at their companies, the majority felt they were in a comfortable position, with 45.2% reporting they had “the right number of employees,” and 35.7% saying they could “use a few more.” On the other end of the scale, 7.1% felt they did not have enough employees “to keep up with demand,” and 4.8% said that “labor limits what services we provide.” The remaining 7.1% reported that they had “too many employees.”

“I do more with fewer employees,” a respondent says. “This is the reality of what I term ‘COVID Economics.’ This year, 2024, I hope to finally surpass 2019 in revenue.”

When they describe their role at their company, there are extremes at both ends, with 39.5% saying that “production demands pull me away from leadership too often,” while 27.9% report that “I am solely focused on leadership and growth.” Tying with 16.3% each were owners who say they “occasionally pitch in to help production” and “almost all my time is spent in production.”

“I have done it all, from bookkeeping to production and delivering, and now machine repair tech,” one respondent says. “It’s very hard to manage when you are working in your business and not on your business.”

“During the pandemic,” another says, “I was forced back into routes and day-to-day customer service management as our staff and clients shrunk. Post-pandemic, I still oversee customer service, but I’m back in the office trying to grow the company through profitable sales growth only.”

“Growth, culture and training employees to become leaders,” was the answer of one respondent when asked what they saw as their most important role as a leader. “I try to fire myself from many things and delegate these things to capable staff members. This sounds good, but it’s rather difficult.”

No matter what their role in their business, half (50%)

Describe your current employment levels

Describe your current employment levels

We have too many employees.

We have too many employees.

We have the right number of employees.

We have the right number of employees.

We could use a few more employees.

We could use a few more employees.

Labor limits what services we provide.

Labor limits what services we provide.

We don’t have enough people to keep up with demand.

We don’t have enough people to keep up with demand.

How would you describe your role at your company?

How would you describe your role at your company?

I am solely focused on leadership and growth.

I am solely focused on leadership and growth.

I occasionally pitch in to help production.

I occasionally pitch in to help production.

Production pulls me away from leadership too often.

Production pulls me away from leadership too often.

Almost all my time is spent in production.

Almost all my time is spent in production.

of owners reported working more hours now than they were before the pandemic. Of the remaining half, 23.8% reported working about the same, while 26.2% said they were working less.

“It is wonderful to work on your business and get out of the day-to-day weeds as much as possible,” says an owner. “This leads to better decisions, more profitability and a better company for owners and our team.”

“You must balance time on the floor with time at the desk,” another owner offers. “The view from the penthouse is as important as the view from the shoreline. Both are necessary for leadership.”

The “Your Views” survey offers a current snapshot of the trade audience’s views. The publication invites qualified subscribers to American Drycleaner emails to participate anonymously in the unscientific poll each quarter.

6 American Drycleaner, April 2024 www.americandrycleaner.com

TALK OF THE TRADE

7.1% 31.5% 31.5% 31.5% 31.5% 45.2% 35.7% 4.8% 7.1%

0424 ADC Charts.indd 1 3/11/24 4:2 PM

7.1% 31.5% 31.5% 31.5% 31.5% 45.2% 35.7% 4.8% 7.1%

0424 ADC Charts.indd 1 3/11/24 4:2 PM

The Makings of a Great CSR

By Dave Davis, Editor

By Dave Davis, Editor

CSkills can be taught, but the best bring innate tools with them

ustomer service representatives (CSRs) are often the first, last and sometimes only point of contact your customers have with your drycleaning business. A tight labor market might tempt owners to hire the first live body through the door when filling positions, but hastily made decisions in finding CSRs can have ramifications for the entire business.

So, what should dry cleaners look for when they need to fill this vital role?

NATURE VS. NURTURE

Certain skills can be trained and encouraged, but great CSRs possess some innate talents when they first walk through the door.

www.americandrycleaner.com American Drycleaner, April 2024 7

(Photo: © NewAfrica/Depositphotos)

“First and foremost, it’s their attitude,” says Jennifer Whitmarsh, owner of Snappy Dry Cleaning in Williamsville, New York. “It’s not tactical skill. It’s how they are as a person, how they approach problems, and how they behave when no one’s looking. Anything else can be taught, but we can’t teach a positive attitude.”

While this seems like a simple idea, Whitmarsh says it’s a critical distinction in the hiring process.

“I know that might sound cliche, but in my years of experience, that’s been the common denominator between a rock-star CSR and a just-OK one,” she says. “Obviously, if they’ve got a bad attitude, then they’re not even going to be an OK CSR. There are other things to look for, such as being able to multitask and solve problems, but, really, everything comes down to their attitude and their approach to life.”

“Behaviors of a great CSR include their communication skills, their listening skills, their attentiveness and their empathy,” says Jennifer Davis, training and development people manager for the ZIPS Cleaners network of drycleaning stores. “These attributes lead to an overall positive experience for our customers. A great CSR has to read the customer in the situation. For example, if they’re in a

hurry, or on their way to work, they need to read that in the customer and use that to lead their interaction.”

Davis echoes Whitmarsh’s views on what can be taught — and what can’t be.

“When we’re hiring, we’re looking for someone who is friendly, has a positive attitude, clear communication skills, is patient, and they’re willing to go above and beyond,” she says. “When they have those attitudes, that’s great for us because they can be taught the ZIPS way. So, attitude and personality are key traits, and we know we can teach them about the garment’s journey so they can be knowledgeable about everything we offer and best serve our customers.”

THE HIRING AND ONBOARDING PROCESS

Owners can tell a lot about a prospective CSR from the very beginning.

“How do they behave when you’re interviewing them?” Whitmarsh asks. “How are they answering the phone? Can they have a conversation with a stranger? Because, essentially, all the customers who come in are going to be strangers at first. Do they have a smile on their face? Are they making good eye contact? Do they have good listen-

(Photo: © NewAfrica/Depositphotos)

ing skills? Those would be things to look for when you’re talking with a potential individual for this role.”

“We tell our franchisees, owners, managers, or whoever is doing the hiring that they should consider experience, attitude and willingness to learn, and then consider their overall interaction with the person who comes as the candidate,” Davis says. “And keep in mind that, while they may not have experience, they need to be trainable. If someone is trainable, they’re a great hire. They are willing to learn and show us that by asking questions and being excited about the interview.”

The old saying “Act in haste, repent in leisure” is true for making any hiring decisions, Whitmarsh says, but especially for customer-facing roles.

“We have to resist the temptation to just hire somebody because you want them to work out and make them fit,” she says. “The No. 1 way to demotivate the team around them is just to hire a warm body. It increases the frustrations for everybody involved.”

The path to success for a CSR begins by being honest in the interview stage, Whitmarsh adds.

“You need to have a good onboarding process,” she says, “which includes great interview questions and even telling the individual the not-so-awesome parts of the job. If you paint it like it’s rainbows and butterflies all the time, you’re setting expectations up in a way where the CSR is going to be surprised and upset as soon as it’s not.”

This honesty not only screens out people who wouldn’t be a good fit, it gives those who might be right for the role an accurate picture of their day-to-day activities.

“Let them know that, yes, sometimes we get an upset customer,” Whitmarsh says. “We get garments that are less exciting to inspect. Give them a more realistic representation of what they can expect. If you do, you’re going to set up their foundation for success, as opposed to setting it up to develop cracks and then crumble.”

TRAINING FOR SUCCESS

Once the owner or manager has hired the right CSR candidate, it’s time to teach those drycleaning skills they’ll need to serve the customer and make a great impression.

“If they’re coming in with those characteristics and behaviors that we’re looking for, we’re really just training them in the ZIPS way,” Davis says. “That includes teaching them our way to greet and interact with our customers, the way to handle the garments, and being knowledgeable about everything we do offer so that we

can best serve them.”

She says that ZIPS training for new hires includes online courses offered in English and Spanish, as well as hands-on training and a final validation.

“We want to empower them with the knowledge to be able to answer any questions that may come up, whether it’s specific about the services we offer, a garment that we take or don’t take, or just specific to that location,” Davis says. “It could be a complaint or an issue. So throughout that training, we are empowering them on how to speak, how to act, how to listen and how to respond so that we come up with the best solution.”

Whitmarsh believes in taking time during initial training to give the candidate all the tools they’ll need.

“Ours could be anywhere from 100 to 150 hours of oneon-one training,” she says. “It’s important to have one-onone training because their training never ends, even when they’re on their own. They shouldn’t stop learning, and you shouldn’t stop touching base with them. If you don’t give them enough training, you are setting your CSR up to be behind as opposed to launching them into success.”

A lack of training for both the CSR and the person hiring them is a critical error that owners sometimes make, Whitmarsh says.

“They don’t have a process for it,” she says, “so they just wing it. Sometimes owners have elevated a manager who has taken over the hiring, but they haven’t had adequate training themselves in this, so they’re hiring warm bodies and repeating the process when that person doesn’t work out.”

Proper feedback is also a crucial element in training.

“Another mistake some make is consistently pointing out everything the new hire is doing wrong without balancing it out with things they’re doing well,” Whitmarsh says. “That’s a huge demotivator, especially when starting out.”

READING THE ROOM

Being outgoing and talkative might seem like good attributes for a CSR to have, but the genuine talent that great representatives possess is knowing how the customer wishes their front-counter encounter to go.

“Dry cleaning is different from most industries, as the interactions are very quick,” Davis says. “They’re trying to get in and out, whether it’s a pickup or a drop-off. So, we want our front-counter associates to interact, get to know the customers by showing they care, and be attentive, but also be mindful of the customer’s needs or

www.americandrycleaner.com American Drycleaner, April 2024 9

desire to get on with their day.”

Because every customer is different, Davis says, great CSRs tailor the interactions they have with them, meeting their needs as best as possible.

“It’s important to know that some people don’t want to talk, but it’s good to get to know the customers’ habits,” she says. “You might have that customer who stops in every Monday and drops off all the clothes from the week before as they go to their office. And then, on Friday, they’re doing all their pickups for the following week. I do believe there’s a fine line between being friendly and understanding if the customer just wants to get in and out. They need to read the room.”

And, during interactions, there are lines between “friendly” and “too familiar.”

“You don’t want to be that person who overshares,” Whitmarsh says. “When a customer comes in and asks you how your day is going, don’t tell them about all the problems you have going on in the nooks and crannies of your personal life — that’s not why they came in.”

Conversations can stay on the proper side of that line, she believes, but don’t have to be solely about the weather.

“When customers ask, ‘How are you?’ give them the surface answer, but then turn it around and start asking the customer how they’re doing. Don’t get too personal, but ask if they have any fun plans for the weekend, or if there are sporting events or other things going on around town to talk about. Be genuine — you don’t want to be disingenuous with your conversation, but you also want to have your personality shine through.”

WHEN PROBLEMS ARISE

While CSRs shouldn’t be able to make every decision when dealing with angry customers, Whitmarsh says, they should be able to take care of some situations to both streamline the process and preserve the customer’s loyalty to the store.

“They should certainly have some ownership of it, and some autonomy,” she says. “It shouldn’t always be, ‘My manager will have to call you,’ because that can be a big waste of time. Overall, they need to understand what their limits are, and every company is going to be different. You want to share with the team the guidelines you have, and let them know what they can do and what they can’t do. But I certainly think they should have some say, because every little thing does not need to go up the food chain.”

“Our CSRs are the first and, most of the time, the last

interaction that we’re having with the customer,” Davis agrees, “so we empower them through the training and give them the tools they need to be able to listen to, respond and then act to make the situation correct.”

“For some bigger things, of course, you’ll need to get the owner or manager involved,” Whitmarsh says, “but if there are dollar amounts they’re able to credit to the customer’s account, then set those guidelines up, and communicate it to them. Train with it, teach it, and then, when it happens, they’ll be able to handle the situation and manage it to where the customer walks away and feels they’ve been treated fairly.”

KEEPING THE BEST FOR YOURSELF

One of the lessons the recent labor market has taught business owners is that it can be difficult to keep talented staff members because their skills are in higher demand. The training you’ve provided might walk out the door if the CSR doesn’t feel valued at your company and is offered a better paycheck.

“This is a big one in this industry,” Davis says. “We understand employee retention isn’t easy. However, we put a key focus on training, and if the employee has the opportunity to learn, grow and develop within a company, I feel like it’s a win-win for both the company and the employee. The employee then needs feedback, encouragement and rewards so they continue to grow within our company.”

Building and maintaining a relationship is crucial for retention, Whitmarsh believes.

“You want to make sure you’re constantly communicating with them,” she says. “Ask if they are still happy. Are things going well? What are some obstacles? What are some things you don’t like?”

And the communication doesn’t always have to be work-related.

“Make it an environment where it’s fun to come to work, and where work isn’t a ‘four-letter word,’” Whitmarsh says. “That doesn’t mean you have parties every other day, or you let them slack off. That just means you’re talking to them, seeing how things are going, and meeting them in the middle.”

If the owner or manager treats their staff as individuals, Whitmarsh says, they might avoid unpleasant surprises.

“You should know if a team member wants to leave before they leave,” she says. “If you have a good pulse on your team, you will know that beforehand and work to avoid it.”

10 American Drycleaner, April 2024 www.americandrycleaner.com

Keeping the Tension On

Finishing strong to give customers high-quality results

By Dave Davis

For dry cleaners looking to save both time and labor costs while increasing the quality of their finished products, tensioning machines are a type of equipment that can check all the boxes. And, as consumer fabric choices and labor conditions have evolved, these machines have advanced as well, keeping pace in the pursuit of meeting customer needs.

Tensioning machines get their name from the tension they use to stretch garments over a form or frame, and then use steam and heat to remove wrinkles and creases. They then cool down and, in some cases, use a vacuum system to remove excess moisture from the garment. The result is a finished garment that is dry, wrinkle- and crease-free, and ready for the consumer.

“These machines allow an operator to finish a piece quickly, eliminating the need to hand-press the entire

www.americandrycleaner.com American Drycleaner, April 2024 15

(Image licensed by Ingram Image)

garment,” says Mike Tungesvick, national sales manager for equipment manufacturer Sankosha USA. “It speeds up production and allows fewer hands to be needed. The quicker you can get done, the quicker you can shut your boiler off and keep your labor costs in check.”

Their ease of use and how quickly employees are able to get up to speed on operating them has only added to their value, says Yuriko Tanabe, vice president of Eu-

ropean Finishing Equipment Corp./Hi-Steam, based in Secaucus, New Jersey.

“Tensioning machines achieve a high-quality result with less time, less labor and lower energy consumption,” she says, “whether you are a high-end or an economy-priced cleaner. It’s great for everybody.”

“On the labor side, less-experienced operators and finishers are driving the engineering changes,” says Jim Groshans, sales manager for Unipress Corp., headquartered in Tampa, Florida. With the help of tensioning equipment, operators can provide superior outcomes, “and may even be able to complete the job a bit faster.”

TODAY’S MACHINES

Programmable digital controls that allow real-time data for performance and process, better adjustable forms, improved materials, and increased safety features all work to make sure today’s tensioning machines provide the desired results, Tanabe says. And, since the machines are easier to use, it gives owners and managers more options when it comes to who will run them.

“The machines are easy to learn how to use,” she says, “so cleaners can hire unskilled labor to run them, which is nice, especially in these days of labor shortages. You don’t need someone who has 20 years of experience. You can take someone off the street and teach them how to use them.”

“What’s really evolved is trying to make the equipment easier for the operator,” Groshans says. “Things like rotating carriages for upper garments are key because it makes loading a lot easier. It makes using the equipment more userfriendly and still puts out a very good quality of product and fabric choice for the consumer. No-crease pants, for example, are perfect for a tensioning topper where, after the cycle, you can just place the pair of pants on a hanger and skip the press all together.”

Today’s machines are also friendlier to the environment — and to their operators.

16 American Drycleaner, April 2024 www.americandrycleaner.com

Modern tensioning machines can help drycleaning plants cut the pressing process out when dealing with many types of garments, providing a dry, wrinkle- and crease-free product for customers. (Photo: Sankosha USA)

“Programming is allowing the machines to cut steam consumption by 25%,” Tanabe says. “It uses less heat, which makes for a more comfortable atmosphere for the workers and is more energy-efficient. People should pay attention to the environment.”

TIMES FOR TENSION

For most garments, Tanabe says, tensioning equipment should be the go-to machine for cleaners.

“You can do almost everything on a tensioning machine — all types of fabrics with today’s casual clothing,” she says. “The finish you get from tensioning machines is ideal. They can restore the garment to its original shape and allows it to move with the body.”

“Medium-finished garments are perfect for tension equipment,” Groshans says. “This type of garment includes some of your blends — cotton, wool or polyester — and they do really well with tensioning steam and drying.”

He goes on to say, however, that tensioning isn’t the best tool to use for everything that comes across the front counter.

“For shirts or tablecloths that need pressing — what

we call ‘hard-finish’ items — you need high temperature, high pressure and extended pressing times,” he says.

“Soft-finish items — things that are very delicate — need just steam or heat, and maybe limited vacuum or limited air. Those do not work well on tension equipment. You also need to avoid any fabric blends that stretch, such as spandex and all the related cousins, like Lycra and elastane. Once those expand, they never come back.”

WET OR DRY?

With those caveats, however, Groshans believes that tensioning equipment should have a firm place in the plant.

“Tensioning is desirable, and a ‘want’ to have for dry cleaning,” he says. “Taking a jacket and putting it on a piece of tensioning equipment gives you very highquality results, especially in the shoulder area, where the seams are. It pulls the stitching down and makes it look brand-new again, and you have a very limited amount of actual pressing when it comes to dry cleaning.”

When it comes to wet cleaning, however, Groshans believes the focus shifts.

www.americandrycleaner.com American Drycleaner, April 2024 17

GROW YOUR BUSINESS. PARTNER WITH NAB TODAY! 866.481.4604 © 2023 North American Bancard, LLC (NAB). All rights reserved. NAB is a registered ISO of BMO Harris Bank N.A., Chicago, IL, Citizens Bank N.A., Providence, RI, The Bancorp Bank, Philadelphia, PA, and First Fresno Bank, Fresno CA. American Express may require separate approval. *Durbin regulated Check Card percentage rate. A per transaction fee will also apply. **Some restrictions apply. This advertisement is sponsored by an ISO of North American Bancard. Apple Pay is a trademark of Apple. WWW.NYNAB.COM REDUCE YOUR CREDIT CARD PROCESSING FEES FREE Credit Card Terminal Placement Wireless/Landline/High-Speed/Dial-Up Easy setup (with no setup fees and quick approvals) Seamless integration with your current POS $295** towards your early termination fee (if you have one) with your current processor Access to Payments Hub - our secure, online merchant portal Free paper** OPTIONAL PROGRAMS: EDGE: The Best CASH DISCOUNT PROGRAM from North American Bancard Are you ready to get rid of the impact of payment processing costs on your business? With the Edge Cash Discount program you will enjoy the same profit margins from cash payments as you do from non-cash payments. • Point of Sale Systems Recommendations, Solutions & Integrations SWITCH NOW AND GET YOUR FREE SMART TERMINAL Send Digital Receipts: Email or SMS a Receipt Send Invoices Accept EMV/NFC (Apple Pay, etc.) with 4G / Wifi FREE STANDARD TERMINALS AVAILABLE AS WELL Accept EMV/NFC (Apple Pay, etc.) EBT, Snap, Checks and more Next Day Funding with weekend settlement SAVE MONEY TODAY! Rates As Low As 0.05%* ADC_Hhalf.indd 1 10/2/23 3:20 PM

“On wet cleaning, the difference is that it’s not a ‘nice’ to have — it’s a ‘need’ to have,” he says. “Tensioning equipment was designed because of wet cleaning. Without tensioning equipment, when you’re trying to wet-clean, you will never be able to restore the size or the shape of the garment back to the original condition. You have to have tensioning equipment to do that.”

“For wet cleaning, you do need a tensioning form finisher,” Tungesvick agrees. “A lot of times on a suit jacket, for instance, the shell will shrink up a bit and the lining will show, hanging out of the bottom. A tensioning form finisher will bring that back into alignment.”

“I’ve spoken to a cleaner who didn’t have a tensioning machine,” Tanabe says, “and I asked them, ‘How do you finish the garment?’ They said they hung it up on a clothesline, left it overnight and then went back in the morning to finish it with hand irons. I couldn’t believe it!”

THE LEARNING CURVE

One of the advantages of today’s tensioning equipment, with its improved controls and streamlined designs, is that it’s easier for operators to learn how to use, with a much lower learning curve — a true advantage in a time where cleaners are having trouble filling roles in their businesses.

However, as with any piece of equipment, Tungesvick says, it’s important to train operators in a plant on how to use the machines and get the best results.

“When we are in the field to install and train on these machines, we make sure the operators know everything there is to know about them,” he says. “Then, we’ll look at what’s coming down their line — suit jackets, dresses, knit tops, polos and so on. There’s a function on these machines that will allow you to do all those different types of garments. You want to be able to utilize them, because that’s the whole purpose of putting in a tensioning form finisher — to make production faster.”

Still, as the machines get easier to use and new technology becomes more available, getting staff familiarized with operations isn’t quite the challenge as it was before.

“It’s easier to get people up to speed now, especially with everyone having cellphones,” Groshans says. “You can video things quickly. We’ve done that in the field where, once we set up a piece of equipment, we have an employee going through the proper steps. An owner or manager might go ahead and video that person. That way, they can refer to it later. But the equipment’s gotten

easier to use, as well.”

Because the learning curve isn’t a steep one, Tanabe says that cross-training also becomes much easier.

“All team members should be trained so they can step in to do the job when needed,” she says. “It’s very simple to learn.”

MISTAKES MADE

However, even though today’s machines are easier to use, Groshans urges owners not to skimp on the education part of the process.

“Skills training is key,” he says. “We find that when people buy a piece of equipment, it’s important to constantly follow up and make sure that employees know how to use the equipment properly.”

To get the best results, it’s more than just knowing how to press a garment, Groshans says. It’s that they understand why they’re doing certain things.

“It’s knowing why you’re putting things on a piece of tensioning equipment or not putting it on the tensioning equipment, rather than just going through the motions and saying, ‘OK, I’ve gotta press every piece that comes through.’”

Tanabe has also seen owners make this mistake after purchasing a tensioning machine.

“They don’t give their team instructions, so they don’t know what they are doing,” she says. “All owners and managers should get involved in training so they know how to use it. It’s easy to learn how to use, but some say, ‘Here’s a new machine — good luck to you,’ and walk away. That’s no good.”

“Just because you bought a piece of equipment doesn’t mean it’s going to be used properly,” Groshans says. “It’s like any tool in the toolbox. My dad used to say: ‘A tool is only as good as the person who’s been trained to use it.’”

CARE AND MAINTENANCE

To get the best out of any machine — tensioning equipment included — it’s important to take care of it by providing regular preventative maintenance and replacing worn parts.

“My first thought when it comes to preventive maintenance is that it’s always going to be the steam,” Groshans says. “The boiler is the heart of the operation, and it’s typically neglected. It’s tucked away in the boiler room, out of sight and out of mind. All that steam goes through nearly every piece of equipment in the plant, and yet, people don’t pay attention to it. So, I always want to look at the quality of the steam and the water that’s in the

18 American Drycleaner, April 2024 www.americandrycleaner.com

boiler, because that will affect the quality of steam in all the presses and, ultimately, the quality of the garment.”

The other element Groshans always urges cleaners to examine are the lungs of the plant: the air compressor.

“All too often, the air compressor is put in the boiler room because they are really loud, but that’s the worst place to put it,” he says. “It actually takes more energy to compress hot air — the air compressor itself or the air intake should really be outside. We find that air compressors can be very inconsistent, and they have moisture in them. Anytime you have inconsistent air or moist air going through your system, anything that’s air-operated will be affected.”

Tanabe says that the operator should be a key player in the preventative maintenance schedule.

“They should maintain the covers on the machine and ensure that there is maximum air flow,” she says. “Also, avoid using spray starch on the machine because it can clog up the air flow. Check the lint filter weekly so it doesn’t get clogged up. That’s it. It’s not difficult. You just have to keep an eye on it.”

TENSION IN THE FUTURE?

So, as tensioning machines continue to meet the needs of cleaners who are working to meet their own customers’ demands, what is the future for this type of equipment?

“I look at the evolving technologies and engineering, and it’s always going to focus on labor, fashion, and reducing touches within an operation,” Groshans says. “The ultimate goal with a lot of your new owners, especially when they come from outside the industry, is to have zero employees. We’re in the service business, however, so we’re in the people business, and you’re going to need bodies. But how many more bodies do we need? Because we’re looking at equipment where, if you had three people back there pressing shirts, can you get down to two? If you have two, can you get down to one?”

“The improvements that will be made in the future will be in the operation of the equipment,” Tungesvick concurs, “to make them more efficient and increase their ease of use. That’s our goal with any of our equipment — make it easy for anybody to use, because the reality of this industry is that we’re running out of skilled operators.”

www.americandrycleaner.com American Drycleaner, April 2024 19

Contactless Automation at the Front Counter, Plant & Routes • Heat Seal Presses • Permanent Barcode Clothing Labels • EzLabelO • EzLabelDispenser A Proven Industry Leader & Recommended by the Consultants You Trust Toll Free 877.906.1818 www.ezpi.us The Ultimate Heat Seal Machine Call Toll Free 877.906.1818 •Presses and Solutions for all Budgets •Best and Free Technical Support Forever •OSHA, UL, CE and TÜV SÜD Safety Certified Presses •Very reliable, easy to fix and upgradeable •Pre-printed Sequentially Numbered Heat Seal Barcode Labels •Safely remove a permanent barcode label with EzLabelO •Lift a label o in numerical order with EzLabelDispenser ADC_Hhalf.indd 1 2/ /24 2:1 PM

Hargrove-Avery Named NCA Executive Director

Former director of digital marketing and media had served as interim director

NEW YORK — The National Cleaners Association (NCA) recently announced the appointment of Dawn Hargrove-Avery as the organization’s new executive director. Hargrove-Avery had served as director of digital marketing and media and was named interim executive director after the passing of former director Nora Nealis.

Hargrove-Avery brings “a rich blend of industry knowledge, digital/content marketing expertise, and a forward-thinking approach to leadership,” the NCA says in the statement announcing her appointment.

Since officially joining the NCA in May 2010, Hargrove-Avery has been instrumental in revolutionizing the association’s digital marketing strategies, enhancing member engagement, and driving significant growth, the organization states. Her strategies have not only increased the NCA’s visibility but have also fostered a sense of community and collaboration among members.

In her new role, Hargrove-Avery says she aims to leverage the latest advancements in AI and digital tools to further innovate the association’s services and offerings. “Her approach to leadership is characterized by a blend of professionalism, approachability, and a laid-back style that encourages open communication and teamwork,” the NCA says.

“I am deeply honored to lead the NCA and build upon the strong foundation we have in place,” says HargroveAvery. “The future of the drycleaning industry is bright, and I am committed to introducing innovative solutions that will benefit our members and the industry at large. Together, we will navigate the challenges ahead and seize the opportunities that lie ahead in this new era of dry cleaning.”

Hargrove-Avery journey in the drycleaning industry began in her teenage years, the NCA’s announcement says, working in her mother’s drycleaning business.

“This early experience instilled in her a profound understanding of the industry’s challenges and oppor-

tunities,” the NCA says. “Her educational background includes a bachelor of science in technical management, along with certifications in social media, content management, and AI certifications, equipping her with a broad skill set that spans both traditional business management and the digital domain.”

Drycleaning Associations to Collaborate on Shows

DLExpo East, DLExpo West to run on off-Clean Show years

CHICAGO — The sponsors of the four largest regional drycleaning and laundry trade shows in the United States recently announced they will be collaborating to strengthen the exhibitions. The South Eastern Fabricare Association (SEFA), California Cleaners Association (CCA), Southwest Drycleaners Association (SDA) and Pennsylvania Delaware Cleaners Association (PDCA) will co-brand the shows and work together on marketing agreements.

This action will reduce the number of live equipment shows from the traditional four on off-Clean Show years to two: DLExpo East & DLExpo West.

“This is a great move for the industry,” says SEFA President Randy Parham in the announcement, “and one we think will only strengthen each show. These shows are important. Without them, the typical dry cleaner doesn’t have access and the opportunity to see all the new and innovative products and services. By reducing the number of shows from four to two, we have made it easier for exhibitors to commit to exhibiting and having a much bigger presence. We will be able to showcase the best of the industry.”

The Drycleaning and Laundry Expo East will be held on June 7-9, 2024 at the Gaylord Palms Resort and Convention Center in Kissimmee, Florida. The Drycleaning and Laundry Expo West will be held Oct. 4-6, 2024, at the Horseshoe Resort and Casino in Las Vegas, Nevada.

20 American Drycleaner, April 2024 www.americandrycleaner.com

INDUSTRY

AROUND THE

HargroveAvery

Moving forward, the DL Expo East will move to the Baltimore/Washington area and the DL Expo West will be held in Texas in 2026. The associations are still exploring options for 2028 and beyond.

In addition to live equipment exhibits, the announcement states that the shows will also feature educational sessions and networking opportunities. These conventions, the announcement says, are designed for the everyday dry cleaner to get a chance to experience the best of the industry and to explore ways to run more efficiently, more productively, and drive more profit.

With a greater anticipated attendance, the associations say they believe the shows will have more resources to bring in great speakers and leaders to share their stories.

The DLExpo East Educational program currently has four featured presentations, two on Saturday morning and two on Sunday. Kicking off the program will be the duo of Terry Brock and Gina Carr of Stark Raving Entrepreneurs, who will demystify the ever-evolving world of Artificial Intelligence.

The next presentation will be from Glen Gould of Drycleaning Connection in Peachtree City, Georgia who will explore the dynamics of team building and using enthusiasm-based leadership to increase performance. He is the author of four books on leading and connecting for success including “Meet Me At Starbucks,” “Million Dollar Meetings,” “Is Your Networking Working?” and “101 Networking Nuggets.”

On Sunday morning, Chris Kuehl of Armada Corporate Intelligence will explore the current trends and forecast the economy of the upcoming months take advantage of the opportunities that lie ahead. Kuehl has spoken throughout the country and has been a featured speaker at numerous drycleaning and laundry conferences and events.

Rounding out the speaker slate is Dan Miller, CEO of Mulberry’s, who will discuss, “From Laundry to Literature” and explore his secrets to success in realizing your goals and achieving your dreams.

The education program is being finalized for DL Expo West.

“This is an exciting opportunity for the entire industry,” says CCA Convention Chair Toran Brown. “I think limiting the shows to only two, an East Coast one and a West Coast one, each of the shows will be bigger, have a greater attendance, and will be a better experience for everyone. With all the changes in the industry, we really feel four shows were just too much, and we all feel the excitement, attendance, and the exhibitors were all being diluted. These will be tremendous events and I am confident the value will resonate with our members – and the entire industry.”

For more information about each show, visit the joint website at https://dlexpo.org

www.americandrycleaner.com American Drycleaner, April 2024 21

Find what you’re looking for wherever you are. Stay on top of the latest industry news and updates on your tablet, phone or in your mailbox. www.americandrycleaner.com ® APRIL 2024 © Copyright 2024 American Trade Magazines All rights reserved. ■ KEEPING THE TENSION ON ■ WORKING ON OR IN YOUR BUSINESS? The Makings of a Great CSR 0424adc_0C1-Cover-FINAL.indd 1 0424adc_House Digital_Vhalf-Bleed.indd 1 3/14/24

2024 RATES: One- to five-time rate: $2.35 per word, boldface $2.40 per word. Minimum charge: $50.00 per ad. Call or write for our threeand 11-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted.

DEADLINE: Ads must be received by

month. For example, for a August ad, the closing date is July 1st.

FOR CLASSIFIED ADS: Must accompany order.

22 American Drycleaner, April 2024 www.americandrycleaner.com

the

of

PAYMENT

SLOW TIME SPECIAL SALE! $700.00/ALL IN ONE, REF $900.00/REGULAR, REF $1,750.00/REGULAR, NEW Includes Computer, Touch Monitor, Invoice Printer. All Name Brands & One Year Warranty! 773-878-0150, westernk@msn.com Patriot Business Advisors Specializing in Selling Drycleaners in NJ, PA, DE & MD. Sell or Buy Drycleaners. WE HAVE BUYERS!!! Call Liliane at 267-391-7642 CARTS, TRUCKS & BASKETS COMPUTER SYSTEMS PLANTS FOR SALE Your Ad Should Be Here PARTNER WANTED Looking for a partner to help run an established Dry Cleaners in Philadelphia. Call Joe for more info 609-605-7552 www. americandrycleaner .com BUSINESS FOR SALE BUSINESS FOR SALE IN CHARLOTTESVILLE, VA: OWNER RETIRING. THE LONGEST RUNNING AND MOST SUCCESSFUL OPERATION IN THE COMMUNITY WITH 60+ YEARS OF SERVICE. CONVENIENTLY LOCATED NEAR THE UNIVERSITY OF VIRGINIA DARDEN, LAW & JAG SCHOOLS. CLIENTS INCLUDE SEVERAL UVA DEPARTMENTS, LOCAL HOTELS, AND MUNICIPAL DEPARTMENTS. LONG STANDING CUSTOMER BASE. RECENT MAJOR EQUIPMENT UPGRADES. contact: David Cooke 434-981-1667 or email: davidcooke2@mindspring.com Sell your stuff at American Drycleaner online classifieds www.americandrycleaner.com www. americandrycleaner .com

1st

the preceding

2024 RATES: One- to five-time rate: $2.35 per word, boldface $2.40 per word. Minimum charge: $50.00 per ad. Call or write for our threeand 11-time rates. If box number is used, add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted.

DEADLINE: Ads must be received by the 1st of the preceding month. For example, for a June ad, the closing date is May 1st.

PAYMENT FOR CLASSIFIED ADS: Must accompany order.

www.americandrycleaner.com American Drycleaner, April 2024 23

Poly Made for: Sankosha Metalprogetti Unipress Save 30% on Poly! Heat Seal Poly Reliable & Affordable Reduce Waste - Cut out the Middle Man - Build Profit Any Size or Gauge, Clear or Branded 10 Roll SPECIAL - 32 Roll Pallet Discount - 56 Roll Best Value 800-568-7768 CLEANERSUPPLY.COM WE SHIP FAST American Dry Cleaner.indd 3 8/25/20 1:12 PM Cleaner Business Systems . . . . . . . . . .3 Cleaner’s Supply . . . . . . . . . . . . . . . .23 EzProducts International . . . . . . . . . .19 Garment Management Systems. . . IBC Iowa Techniques . . . . . . . . . . . . . . . . .5 Luetzow Industries. . . . . . . . . . . . . . .23 Newhouse Specialty Co. . . . . . . . . . .23 North American Bancard. . . . . . . . . .17 Patriot Business Advisors . . . . . . . . .22 Royal Basket Trucks . . . . . . . . . . . . .22 Sankosha USA. . . . . . . . . . . . . . . . .BC SMRT Systems . . . . . . . . . . . . . .11-14 SPOT Business Systems . . . . . . . . IFC Union Drycleaning Products . . . . . . . .1 WIRE The latest news, straight to your inbox, 2X a week THE SUPPLIES SUPPLIES SUPPLIES ARROW LEATHERCARE SERVICES Finest quality cleaning refinishing & repairs Leather, suede, fur, UGGs & handbags • FREE RETURN SHIPPING in USA • FOR MORE INFORMATION: www.arrowleathercare.com E-mail: bruce@arrowcare.com Call 800.54 ARROW (27769) Prepaid Shipping Program SUEDE & LEATHER SERVICE www.AMERICANDRYCLEANER.com For more classifieds, visit: 312-361-1700 Advertise Today 312-361-1700 Reach 400 + Dry Cleaning Plants ADC Website Reach Plants 2022 3 inch.indd 1 2/ /24 2: 9 PM

Barton Bill, Wholesaling and Rainy Day Friends

10 YEARS AGO. Rolling Up Their Sleeves — Almost half (47.3%) of cleaners said they did “most” of their plant’s basic maintenance tasks themselves, according to the American Drycleaner Your Views survey, with 14.9% saying they did “all” the work. On the other side, 25.7% reported that they did “little” of the maintenance themselves, and 12.2% said they did “none.” When it comes to maintenance, 63% of respondents said they had no formal, written schedule for their plant, with the remaining 37% saying they did have one in place. “Get your hands dirty, take notes and get to know the factory technicians,” one respondent said. “Many times, they can talk you through a problem without paying for a service call.”

25 YEARS AGO. Barton Bill, Take Three — The law firm of Baise, Miller & Freer reported that Rep. Joe Barton (R-Texas) was still strongly supportive of the Small Business Remediation Act he introduced in the past two Congresses and was waiting for a Democratic cosponsor to give the bill stronger bipartisan support before reintroducing it. He stated that he would like Rep. Ron Klink (DPa.) — a powerful Democrat on the Commerce Committee who became a late cosponsor the year before — to be an original sponsor and encouraged Klink’s constitutes to voice their support.

50 YEARS AGO. We Can Do It for You Wholesale — Some dry clean-

ers looking to expand their volume were increasingly turning to providing wholesale services to cleaners or tailors without equipment, observed the Neighborhood Cleaners Association. Other dry cleaners were rejecting the idea, however, because they believed wholesale work was not as profitable as retail work. The Association noted that dry cleaners who decided to accept wholesale work should understand their costs. Otherwise, they may be just trading dollars or, even worse, losing money on the extra work. The rule of thumb, the association said, was that 50% of the retail price is the correct wholesale price.

75 YEARS AGO. Rainy Day Friends

— Peter Petri, a cleaner in North Adams, Massachusetts, learned the

true meaning of friendship when his plant was practically destroyed by a flood. Flood insurance was unobtainable in that area, so Petri was at a loss as to what to do next. His friends answered that question by setting up a fund to re-establish his business. The local Elks Club was heading the movement, but the committee chairman said many of Petri’s friends had come up to ask how they could get him started again. As a result, a fundraising committee was formed. All this was done without Petri’s knowledge — they were afraid he’d object. His friends said that Petri would have been at the forefront of any movement to help someone else.

24 American Drycleaner, April 2024 www.americandrycleaner.com WRINKLE IN TIME

— Compiled by Dave Davis, Editor

Our Automation Systems will help you do more - with less! Are you short-handed? ReliableAffordableAvailable Simple design along with great customer service. Keep it simple! Provides the best return on investment. Made in the USA. Delivery available in as little as 2 weeks. 501-420-1682 garmentmanagement.com 247 EXPRESS Dry Clean at Your Convenience

Peace of Mind When you purchase a piece of our equipment, you become a part of the Sankosha family. And you get the highest standard of service plus Sankosha USA Inc. TOLL FREE: (888) 427-9120 • TEL: (847) 427-9120 www.sankosha-inc.com • LP-5600U - High-Speed Single Buck

Dave Davis

Dave Davis