InkGo has been reformulated to remove its odor… and to improve its performance.

InkGo is still the environmentally friendly,* safe way to remove ink stains from all types of fabric. It’s still great at removing autoclave tape and adhesives. And since it’s odor free, InkGo is more pleasant to work with. Does odor really matter? As more drycleaners position themselves as good environmental stewards, keeping chemical odors in the plant to a minimum can help them differentiate from their competition. And odor-free is a real plus if you’re working on ink for an extended period of time.

Now that’s worth noticing!

*InkGo is Biodegradable and is California Prop 65 and California VOC Compliant.

Become a STAIN WIZARD at ALWilson.com

To learn more, visit ALWilson.com or call 800-526-1188 A. L. WILSON CHEMICAL CO.

“The support from CBS was great. Even before we signed up, they were responsive and flexible in their approach. They have helped our team become more efficient.”

Since 2003, CBS has given me consistent updates and easy to understand tech support, all at a price that our industry can afford. I would recommend CBS, and I have, to anyone who is still wasting their time and money on those over priced POS systems.

Making the decision to buy a new piece of drycleaning equipment can be difficult. There’s a whole mess of factors to consider.

I think our Management Strategies columnist, Diana Vollmer, has done an excellent job of summarizing the obvious effects of upgrading to new equipment, as well as shining the light on some more subtle effects that it might take the prospective buyer some time to detect.

Althought some advantages are more difficult to equate in monetary terms, she says in her story starting on page 20, most benefits can be assigned a fairly predictable financial value and thus contribute to a more rational buying decision.

Publisher

Charles Thompson 312-361-1680 cthompson@ATMags.com

Editorial Director

Bruce Beggs 312-361-1683 bbeggs@ATMags.com

Production Manager

Roger Napiwocki

National Sales Director

Donald Feinstein 312-361-1682 dfeinstein@ATMags.com

Digital Media Director

Nathan Frerichs 312-361-1681 nfrerichs@ATMags.com

Main: 312-361-1700 Fax: 312-361-1685

Meanwhile, I think every business-minded dry cleaner would like to develop a loyal customer base. It seems that small-business owners in general are shifting investment from customer acquisition to engagement, based on a recent survey. Check out our story on page 28 for that and for some tips on developing a customer loyalty program.

Elsewhere in this month’s issue, business writer Phillip Perry examines retail lease renewals and suggests strategies for protecting your storefront and your bottom line.

Columnist Howard Scott takes a longtime dry cleaner to task for allowing its flagship plant to degrade to what Scott calls “a squalid movie set.” Read his no-holdsbarred assessment beginning on page 16.

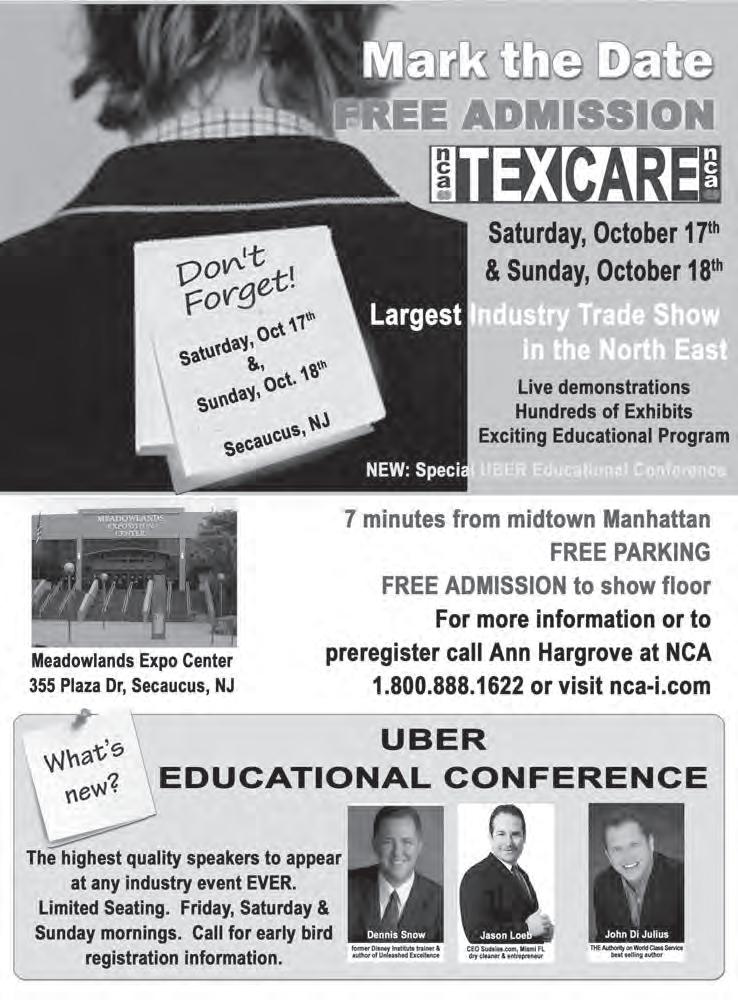

Plus, there’s Martin Young’s Spotting Tips column on handling expensive gowns, a preview of next month’s NCA TexCare show in New Jersey, and much more.

Well, what are you waiting for? Dig in! ADC

American Drycleaner (ISSN 0002-8258) is published monthly except Nov/Dec combined. Subscription prices, payment in advance: U.S., 1 year $39.00; 2 years $73.00. Foreign, 1 year $89.00; 2 years $166.00. Single copies $7.00 for U.S., $14.00 for all other countries. Published by American Trade Magazines LLC, 566 West Lake Street, Suite 420, Chicago, IL 60661. Periodicals postage paid at Chicago, IL and at additional mailing offices.

POSTMASTER, Send changes of address and form 3579 to American Drycleaner, Subscription Dept., 440 Quadrangle Drive, Suite E, Bolingbrook, IL 60440. Volume 82, number 6. Editorial, executive and advertising offices are at 566 West Lake Street, Suite 420, Chicago, IL 60661. Charles Thompson, President and Publisher. American Drycleaner is distributed selectively to: qualified dry cleaning plants and distributors in the United States. The publisher reserves the right to reject any advertising for any reason. © Copyright AMERICAN TRADE MAGAZINES LLC, 2015. Printed in U.S.A. No part of this publication may be transmitted or reproduced in any form, electronic or mechanical, without written permission from the publisher or his representative. American Drycleaner does not endorse, recommend or guarantee any article, product, service or information found within. Opinions expressed are those of the writers and do not necessarily reflect the views of American Drycleaner or its staff. While precautions have been taken to ensure the accuracy of the magazine’s contents at time of publication, neither the editors, publishers nor its agents can accept responsibility for damages or injury which may arise therefrom.

American Drycleaner, September 2015

It seems the push for a higher federal minimum wage may not have much effect on the majority of dry cleaners who took August’s American Drycleaner Your Views survey. Why? Because more than two-thirds of them already pay their employees more than the minimum.

Dry cleaners who responded to the unscientific survey employ, on average, 32.9 people (including both part-time and full-time) across all of their store/plant locations. The lowest total reported was three, and the highest was 175.

Among the respondents, 68.8% do not pay any of their employees the minimum wage. Roughly 19% of respondents pay less than 10% of their workforce minimum wage. Equal shares of 6.3% pay minimum wage to “more than 10% but less than 50%” and to “more than 50%” of their workforce.

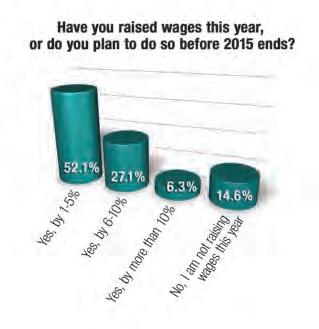

Roughly 85% of respondents have raised wages this year, or plan to do so before the year ends.

Among them, 52.1% say it’s by 1-5%, 27.1% say it’s by 6-10%, and 6.3% say it’s by more than 10%.

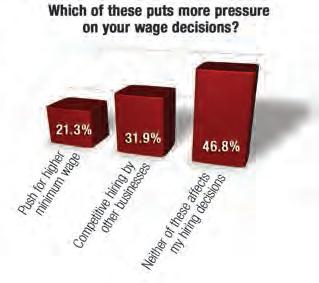

Which of these puts more pressure on your wage decisions: the push for a higher minimum wage, or competitive hiring by other dry cleaners or businesses in your area?

For the majority of respondents (46.8%), neither of these affects their wage decisions. Roughly 31.9% are pressured more by competitive hiring by other businesses. The remaining 21.3% of respondents say they feel the most pressure from the push for a higher minimum wage.

“The effective minimum wage in our area is about $8.50,” writes one respondent. “We start at $9 in stores, $10 in plants, and are struggling to staff. Big distribution warehouses are starting at $14 for unskilled labor.”

Have you lost any workers to competing dry cleaners or other businesses because the wages paid there were higher? Among our respondents, 81.3% say they have not. Roughly 13% say they have, and 6.3% are unsure.

When asked point blank if the federal minimum wage of $7.25 should be raised, one-third (33.3%) of respondents said yes and the remainder (66.7%) said no.

The Your Views survey presents a snapshot of readers’ viewpoints at a particular moment and should not be considered scientific. Percentages may not add up to

100% due to rounding.

Subscribers to American Drycleaner e-mails are invited each month to take a brief industry survey they can complete anonymously. The entire trade audience is encouraged to participate, as a greater number of responses will help to better define owner/operator opinions and industry trends.

Textile Rental Services Association. Annual Conference, to be held Sept. 9-11 in Isle of Palms, S.C. Call 877-770-9274.

International Drycleaners Congress. 2015 Convention, to be held Sept. 14-15 in Osaka, Japan. Call 403-685-4755.

Independent Textile Rental Association. 2015 Annual Convention, to be held Sept. 27-29 in San Diego. Call 706-637-6552.

National Cleaners Association. TexCare 2015, to be held Oct. 16-18 in Secaucus, N.J. Call 800-888-1622.

JET Expo. To be held Nov. 8-10 in Paris, France. Visit www.jet-expo.com.

Texcare Asia: International Trade Fair for Modern Textile Care. To be held Nov. 25-27 in Shanghai, China. Visit www.texcare-asia.com.

Drycleaning & Laundry Institute/National Cleaners Association Five Star Brainstorming. To be held Jan. 14-17, 2016, in Cancun, Mexico. Call 800-638-2627 (DLI) or 212-967-3002 (NCA).

Southwest Drycleaners Association. Cleaners Showcase 2016, to be held April 2224, 2016, in Fort Worth, Texas. Call 512-8738195.

Texcare International: World Market for Modern Textile Care. To be held June 1115, 2016, in Frankfurt am Main, Germany. Visit www.texcare.com.

South Eastern Fabricare Association. Southern Drycleaners and Launderers Show, to be held June 24-26, 2016, in Jacksonville, Fla. Call 877-707-7332.

California Cleaners Association. Fabricare 2016, to be held July 15-17, 2016, in Long Beach, Calif. Call 916-239-4070. ADC

Total Training for CSRs. NCA webinar, to be held Sept. 9. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Stain Removal Course. Three-day DLI course, to be held Sept. 16-18 in Laurel, Md. Call 800-638-2627 or visit www.dlionline.org.

Total Training for CSRs. NCA webinar, to be held Sept. 23. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Total Training for CSRs. NCA webinar, to be held Oct. 7. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Human Resources. Michigan Institute of Laundering and Dry Cleaning seminar, to be held Oct. 10 in Okemos, Mich. Call 877-390-6453.

Introduction to Drycleaning. Five-day DLI course, to be held Oct. 12-16 in Laurel, Md. Call 800-638-2627 or visit www.dlionline.org.

Advanced Drycleaning. Ten-day DLI course, to be held Oct. 19-30 in Laurel, Md. Call 800638-2627 or visit www.dlionline.org.

Wet Cleaning (UGGs). NCA course, to be held Oct. 23 in Bronx, N.Y. Call 212-967-3002 or e-mail ncaiclean@aol.com.

Wedding Gowns. Midwest Drycleaning & Laundry Association seminar, to be held Oct. 28 in Notre Dame, Ind. Call 765-939-6630.

NY State DEC Certification. Two-day NCA course, to be held Nov. 8 and Nov. 15 in Nanuet, N.Y. Call 212-967-3002 or e-mail ncaiclean@ aol.com. ADC

Check out www.americandrycleaner.com/ drycleaning-events for updates between issues!

American Drycleaner, September 2015 www.americandrycleaner.com

It’s time for your lease renewal. Are you ready to negotiate? If you’re like many service businesses, your answer is “No.” But a lack of preparation can be costly.

Rent is typically a business’ second largest operating expense after labor. And the common industry practice of adjusting staff levels to reflect a changing business environment simply won’t work with lease payments: You’re pretty much stuck with them once you’ve signed on the bottom line.

It’s more important than ever to negotiate a better deal in today’s real estate environment, characterized as it is by rising prices. The higher the rent, after all, the greater the damage to profits.

“The market for retail space has changed significantly in recent years,” says William D. Himmelstein, CEO of Chicago-based Tenant Advisory Group, a real estate tenant brokerage firm. “Across the country, there is less space available. Landlords are keenly aware of that, so rental rates are on the increase.”

What’s behind the tightening of available space? The post-2008 economic rebound has a lot to do with it. But so does the growing availability of business loans.

“When lending loosens up, more people are able to start businesses,” says Himmelstein. “When that happens, they need space. And we are starting to see a more business-friendly environment with more borrowing opportunities.”

Things are coming together to put pressure on the best locations.

When should you start planning your own strategy for landing a better deal? Early, according to the experts.

“Time is your friend in real estate,” says Himmelstein. “The earlier you can start thinking about renewal, the more advantage you will have over the landlord. … if you delay until three or four months before lease expiration, the landlord will have the upper hand.”

Start too early, on the other hand, and you may find yourself locked into your current spot when a better location becomes available. So, what’s a good compromise?

“The short answer is one year in advance of the lease expiration,” says Dale Willerton, a Los Angeles-based tenant lease consultant and author of Negotiating Commercial Leases and Renewals for Dummies. “But there is a caveat: If you have a renewal option clause, you want to be sure to start at least six months before that.”

The option might not be your best choice (as we will see later) but you still want it as a backup. “The renewal option clause is your fail safe, your insurance.”

Before you do anything else, double-check your lease’s expiration date. Get that wrong and your chances of a successful negotiation plunge.

“The day you opened your store is not necessarily the day your lease expires,” cautions Willerton.

If your lease is like most others, it calls for a five-year term and one or more five-year renewal options. But the renewal option, while designed to offer

Our new generation of Point Of Sale system is designed for both small and larger cleaner stores. DryClean PRO Enterprise (DCPe) is even simpler to use than before. With user friendly screens and menus, DCPe will make your life easy. We offer, promise, and guarantee the best after sales support to our end users. Save time and money and add to your profits by contacting existing clients and reaching out to new clients through DryClean PRO Enterprise’s built in MARKETING and EMAILING functionality. You’ll be able to send Thank You emails to new or Top 100 customers, Customers with overdue inventory, Customers that have not visited you for awhile, Route customers & e-mail coupons to all your customers.

Call us about our new version of Uniform Tracker.

Ask us about our DCPe RENTAL

some protection to the lessee, is not necessarily your best choice.

“One of the biggest myths is that the only way to renew your lease is to exercise your renewal option clause,” says Willerton. That’s not the case. In fact, if you do so, you suffer a significant downside: Everything but the rent amount will be off the negotiating table.

No wonder that in 98% of the lease renewals negotiated by Willerton, the renewal option is not exercised.

“Bear in mind that, most of the time, the landlord wants you to stay,” he says. “That gives you some negotiating leverage. You lose that, though, if you exercise your renewal option.”

Once you have determined your lease renewal date, put yourself in a better negotiating position by locating alternative store locations you can move to if your landlord’s terms are not to your liking.

“The most common mistake is to only negotiate with the existing landlord on the current location,” says Willerton. “Doing so fails to give the landlord a reason to give you a good deal.”

The problem worsens if you tip your hand by letting the landlord know you are not shopping around.

“Suppose your landlord asks, ‘Are you looking at other properties?’” poses Willerton. “You might respond, ‘Oh, we don’t want to move—we are not talking with any other landlords.’ Right there, your landlord has you.”

It’s far better to line up some alternative locations where you can relocate if your landlord becomes unreasonable.

“You need to create some competition for the landlord,” says Willerton. “Ask yourself: Where would I go if I have to move? Do I have relocation options if this landlord will play hardball and double my rent?”

Having alternative locations in your pocket will give you the freedom to reject onerous terms.

“Tenants only get the best deal when they are walking away from the negotiating table—not when they are at it,” says Willerton. “Remember that landlords always hold something back that they will give up only if it’s clear the [tenant] might move.”

Indeed, having the landlord chase you as you are walking away from a deal is the best position to be in.

“The tenant is the landlord’s customer, and the customer deserves to be pursued,” says Willerton. “That is the mindset too many tenants do not understand.”

What’s the going rate for retail space in your town? Maybe it has changed since you last went shopping. You want to find out early in the negotiating process.

“Do your due diligence,” advises Sharon Kahan, first vice president at the Chicago office of CBRE, a Los Angeles-based commercial real estate company. “Investigate your local market and find out what other retailers are paying in your area.”

That means talking not only with real estate agents but also other businesses—especially those with property from the same landlord. They can tell you a lot more than just what they are paying.

“Some of your fellow tenants will have recently gone through the renewal process,” says Willerton. “They can give you some valuable insights into how your landlord negotiates.”

Avoid relying on oral promis es when negotiating your lease renewal. They can evaporate like clouds on a summer day. Consider this scenario: “Eight months before your lease expires, you have a con versation with your property manager,” says Dale Willerton, a Los Angeles-based tenant lease consultant and author of Negotiating Commercial Leases and Renewals for Dummies. “The manager says something like this: ‘We will have to raise your rent by about 5%. But don’t worry about it—we will get to it in a few months.’ Later, two months before your lease expires, you get hit with a 50% increase. What does the prop erty manager say? ‘Yeah, I was surprised, too.’”

Here’s a similar scenario

from Willerton: “Suppose that eight months before your lease is up, the property manager sends you a renewal proposal with some attractive terms. You say, ‘That’s not so bad; I’ll sign it.’ A few months later, you get the actual lease from the landlord, with far more onerous terms. What does the property manager say? ‘I didn’t know they were going to do that to you.’”

Both scenarios can hap pen even if you have a great relationship with the property manager, warns Willerton: “Landlords often give leasing people and property manag ers ‘plausible deniability’ by not telling them of future plans. Remember that nothing counts until it is in writing, and signed by the landlord.”

Also, your neighboring retailers can alert you to reloca tion plans of their own. That can be a major factor when it comes to the desirability of your current location.

“If you assume everyone else will be there after you renew, you might be wrong,” says Willerton. “You can lose four neighbors and get four new ones in a five-year cycle. Knowing someone is moving can make a difference in terms of your decision to stay or move.”

You may also find out some surprising things. Maybe the landlord is planning to reconfigure the space surround ing your store, or maybe an adjacent tenant with more bucks wants to expand—in your direction.

Successful businesses take the initiative when it comes to lease renewal negotiations.

“Most tenants think the landlord is going to come to them and remind them in a timely manner that their lease is expiring,” says Willerton. “But most landlords will not do that. That’s because they want the clock to tick right down to where they have you over a barrel.”

Suppose only four weeks remain before expiration, posits Willerton. What can you do if the renewal terms are onerous? There’s no time to move or negotiate. “Be proactive. Don’t lose your time advantage.”

Speaking up early is great, but don’t tip your hand.

“Too many times, tenants say the wrong thing,” says Willerton. “Suppose you see the property manager in the parking lot, and you casually say, ‘By the way, our lease will be expiring and we want to do some major renovations and look forward to five more years.’ You have just given the property manager a ‘buy signal.’ You have said you intend to stay. So why would the landlord do anything but try to raise your rent?”

And on that topic of renovations: Avoid doing them too close to renewal time.

“If you do a $100,000 renovation a year before your lease is up, you have just given a ‘buy signal’ that puts you in a bad negotiating position,” says Willerton. “Time your renovations to be concurrent with, or just after, renewal time.”

While five years is the norm for retail renewals, consider negotiating a longer term—say, 10 years—if that’s more to your liking. One benefit is that banks will only lend money for the length of your lease, and you may prefer a longer-term loan. You may be able to swing more years if you have been a good tenant, because longterm leases benefit landlords, too.

“Long-term leases are particularly valuable for landlords, because they help improve the value of a com-

mercial property,” says Kahan. Conversely, you can negotiate a shorter-term lease if that’s better for your business plan.

And how about the rent increase percentage?

“Most leases call for an increase of 3% per annum,” says Willerton. It’s important to negotiate for lower increases if you possibly can. “The big problem is that 3% compounded over 10 years is more like a 50% increase—not 30%.” And that can be onerous. “There is a limit to how much retailers can raise prices—and it is generally not 3% per year. So, the landlord is asking for something that the tenant cannot keep up with.”

You may be able to get a lower increase, says Willerton. “Some landlords are more open to lesser increases, saying that they just want to match inflation, which is seldom over 3%.”

You should also try to negotiate terms that go beyond pricing. Remember: Any inducement that can be negotiated on a new lease can be negotiated on a renewal. Maybe you can get some site improvements such as better lighting, a new paint job, or more attractive signage.

Renewal time is the right time to put these and similar items in play.

Negotiating a favorable lease renewal is far more complicated than just signing off on a renewal option, and it will often pay to have some outside assistance.

Consider using a tenant broker. Bear in mind that they cost nothing to use because their payment comes in the form of commission splits with landlord brokers. At the very least, they can get you a fair price.

“A qualified commercial broker can reference comps and help you figure out what you should be paying,” says Kahan.

You might also want to consider the services of an attorney, who can be beneficial in other ways.

“Brokers are there to minimize costs,” says Himmelstein. “Attorneys are there to minimize risk.”

The broker will make sure your lease terms are competitive with those of other leases in your vicinity; the attorney will rewrite clauses that might put you at risk. Together, with your own investigations of the local marketplace, these professional services can help you turn lease renewal time from a costly exigency into an opportunity to bolster your bottom line. ADC

Award-winning journalist Phillip M. Perry, who resides in New York City, is published widely in the fields of business management, workplace psychology and employment law, and his work is syndicated in scores of magazines nation wide.

Iwalked into a long-established dry cleaner—50 years in existence, second-generation ownership—to a pitiful sight. The flagship plant store looked like a squalid movie set. Barren, dilapidated, dirty and uninspired are some of the adjectives that would best describe the premises. The space was small. Paint was peeling off the walls. The front counter looked like it had been there from day one.

There was no seating for customers. There were no signs stating proudly the cleaner’s identity. There were no pictures on the wall, no touch of attractiveness, no sign of humanity. The front window contained a half-dozen taped-on notices about town events.

What gives? The company had four drop stores, plus the plant, so surely there is enough revenue to make changes. Moreover, surviving 50 years in the industry gives management something to brag about; two generations of owners and family have walked through that front door.

Has no one noticed that the place looks grungy? Does management not understand that customers don’t feel encouraged to bring in their clothes to be cleaned, that the workspace isn’t uplifting for employees? Is no one in authority ever inspired to give the place a face lift? Has everyone lost hope?

It angers me to think that I am in an industry where such neglect still exists. Of course, no one can force the owners to do anything about the disastrous front. I suppose I could be considered as someone with influence. And I could expose them in this article. I could name them, offer photographs as proof, and possibly embarrass them into making a change. But I will not do that. It would be one thing if the company was struggling to pay its bills, but 50 years in business and it’s come to this. Come on.

What could be done in such a small space? Well, first, it doesn’t have to be such a small space. Management owns the property, which gives it the right to double or triple the storefront space. But, even within the existing space, much can be done. For starters, they could make

the front entrance attractive.

Put in freshly painted wooden flower boxes in front of the large windows. Tear down the town notices. Install an interesting display, such as a life-sized mannequin, attractively dressed, with a rakish hat angled forward, with a sign that reads, “We make you look swell here.”

How about a scrim of wood with several lovely outfits hung or spread out to show their classic lines? The sign nearby: “Beautiful garments aren’t born, they are drycleaned regularly.” Or place an old-fashioned tub washer with attached rollers alongside a high-tech machine, with a sign that reads, “We combine the best of old-fashioned and high-tech.”

Replace the worn wooden counter with a glitzy chrome and glass unit, including a mirrored surface and metal racks to take in clothes. Or, have a counter custom-built to perfectly align with your space. In other words, create gracefulness in your front.

Clean up the walls. Paint the surfaces. A wainscoting effect might give the space a classy, colonial touch.

Hang pictures enclosed in lime-green frames. Include a

picture of your entire staff, your mission statement (handmade in artful calligraphy), a collage of several well-dressed customers, and a photo of the Little League baseball team you sponsor.

Rotate these shots with a photograph of the owners and an aerial view of the store with accompanying shots of each drop store. Contrast photos of the business in its early days alongside a photo of today’s plant, and several black-and-white shots of key employees. The possibilities are endless.

Improve the lighting, because nothing creates a sense of freshness like strong lighting. A bank of fluorescent lights covering every square inch of floor

“Does management not understand that customers don’t feel encouraged to bring in their clothes to be cleaned...?”

While other solvents have come and gone, our innovative cleaning process has been scientifically proven to deliver better cleaning results, year after year. 1,700 dry cleaners in over 40 countries have already experienced the GreenEarth difference, which translates to millions of customers who see, smell and feel the GreenEarth difference.

Better Cleaning: GreenEarth Cleaning uses sustainable silicone (liquid sand) to keep clothes looking newer, longer, with no harsh chemicals, no odor and no hazardous waste.*

Expert operational guidance produces truly sustainable results through the lowest utility costs in fabric care.

Seamless Transition: Reinvigorate Your Brand:

Our marketing tools are designed and proven to leverage the GreenEarth difference and separate your business from the competition. Science proves it, customers love it!

Learn more at greenearthcleaning.com

*Waste stream classification may be impacted based on garment soil characteristics.

space would do the trick. Use track lighting to highlight displays or the workstation; the bright glow would make processed garments look really clean, and that’s what you want.

Add a few funky touches. The place is small, but there is still room for creativity. Set up a table stand that carries a book which explains, in simple terms, what dry cleaning does, every step of the way. Place a bowl of mints—not those cheap red-and-white candies that everyone puts out, but something special—on the countertop.

Hang a photo montage of different clothing styles— turn-of-the-last-century formal, flapper age, Depression chic, practical ’40s, golfing ’50s, hippie ’60s, casuallook contemporary, etc.

Examine your hobbies. If you are a sailor, hang photos of your boating adventures. If you are a car enthusiast, place large models of your favorite dream cars on wallmounted shelves. If you like to fish, create a life-sized photograph of you, and mount it onto the wall using wallpaper paste. Your image holds a fishing rod extended from your fingers. Dangling from a string is an enlarged drycleaning invoice with the words, “You’re our greatest catch.”

If you are creatively challenged, hire someone to do the imaginative thinking. It doesn’t have to be a profes-

sional designer. It could be a local art student. Perhaps he or she would do it for the experience, or you might have to pay a few hundred dollars. Young artists have such fertile imaginations these days that you’ll come out with something really exciting and unique.

If the owners of that shop I described read this article, I’m curious what they’ll do. Would they argue that they’d be throwing away good money, that the customer doesn’t care a whit about their store’s appearance and are only concerned that they turn out quality garments?

Or, would they grasp that a clean, wholesome storefront goes a long way toward the customer thinking he/ she received good value from money spent. And that giving customers this perception is just as important as the reality.

Two things could happen: 1. More patronage would come in. 2. Management would raise prices perceptibly, and make more profits.

But, hey, who cares about what I think, right? ADC

Howard Scott is a longtime industry writer and dryclean ing consultant. He welcomes questions and comments, and can be reached by writing Howard Scott, Dancing Hill, Pembroke, MA 02359, by calling 781-293-9027, or via e-mail at dancinghill@gmail.com.

By Diana Vollmer

By Diana Vollmer

Seeing new drycleaning equipment almost always generates a temptation to own it or another preferred alternative. It looks so fresh and appealing that the draw to buy is sometimes hard to resist.

Should you surrender to that appeal or should you fight the impulse? The only logical answer is to weigh the impact of a purchase as thoroughly as possible.

Some effects of buying new equipment are obvious, some are more subtle and may not be apparent initially.

Results that are more easily valued are:

• Higher productivity and pieces per operator hour (PPOH)

• Lower cost of labor

• Elimination of bottlenecks

• Financial return on investment (ROI)

• Availability of funds (cash, loan or lease)

• Improved quality (cleanliness and finishing)

• Consistency of quality

• Better tracking and control

• Increased effectiveness of management

• More efficient use of space to allow for growth

Higher PPOH on one machine may not result in higher PPOH in the entire plant unless it eliminates a bottleneck or frees labor for other productive processes. For example, if the only thing a team member can do is press household goods, it does no good to have them finish that job only to have the work wait for the rest of the items in an order to be ready for delivery. The ROI is dependent on the increased productivity of the entire operation.

The most common objection to upgrading equipment is the cost or the lack of funds available for the purchase. With the flexibility available from suppliers and lenders now, the funds are usually available. The key is to determine if the purchase is worth the investment and at what point will it pay for itself in operational savings or increased sales growth. If that period is less than two years, the purchase should be self-funding and a reasonable investment.

Improved quality of both cleanliness and finishing will reduce the items that must be re-cleaned or touched up, thus reducing labor and improving consistency.

No assembly required. The complete Drapery Strut hanger from M&B Hangers is produced totally in-house from 10.5 gauge wire and a strong high-quality tube. Ideal for drapes, table cloths, and comforters, the M&B Drapery Strut hanger comes complete in a 200-pack box 100% assembled and ready to strut its stuff.

To try our Drapery Strut, go to www.mbhangers.com to find your local distributor, or call 888-699-5644 to speak with one of our customer service representatives.

The equipment with built-in productivity feedback helps the operators pace themselves at the goal rate and alerts the manager to slowdowns due to a possible desire to stretch out hours.

Since a key advantage of new equipment is higher productivity and efficiency, the same size plant can produce more work, allowing for more sales growth without the investment required for plant expansion or a move to a larger facility. Improved dependability also provides the ability to run longer or more shifts due to less maintenance downtime.

Potential impacts that may be less obvious include:

• Better customer service at the stores

• Fewer “lost” garments due to fewer holdbacks

• Better capturing of special care fees

• Less support staff required

• Higher customer acceptance

• Staff morale, recruitment and retention

• Lower maintenance cost

• Minimized disruption

• Availability of support

• Energy savings due to higher efficiency

• Self-funding potential

Brett McLeod, owner of Garment Management Systems, says auto assembly systems such as those his company makes offers many advantages over the “old-school, manual way of assembly.” Further, “purchasing an auto assembly system will reduce the amount of labor used in the assembly process, and will never call in sick. Not only does auto assembly reduce labor costs, it reduces other headaches as well.”

About features or capabilities that sets today’s equipment

What would Jack Burnett, president of drycleaning equipment maker Union Drycleaning Products USA, say if a prospective customer were to ask what today’s advanced equipment can do that his tried-and-true machines can’t?

• “Advancements in technology have allowed for direct monitoring of machine operations from remote locations (computer-controlled machines).”

• “Increased solvent mileage on alternative solvents.”

• “Saves on utilities.”

• “Features to enhance cleaning of alternative

apart from previous generations, McLeod says, “We are constantly looking for ways to improve our system and listening to what our customers want.”

Continued efforts to hone system design pushes the equipment to move at optimal speeds while minimizing downtime thanks to its simplicity. “The assembly system is a production piece of equipment, and speed and reliability are critical,” he says. ADC

—Sidebars by Bruce Beggs, Editorial Director

solvents (such as solvent heating).”

Features or capabilities that sets Union’s equipment apart from previous generations, according to Burnett, include:

• Solvent heating

• Inverter-driven motors that help lower power consumption

• Remote monitoring of machine functions, and data logging

• High-pressure solvent concentration for heavily soiled garments

• Better visualization of solvent level in tank, as well as basket conditions ADC

In addition to reducing production labor directly, well-trained operators using efficient, high-functioning equipment will most likely reduce the search for “lost garments” that aren’t really lost but rather needed more work and added excessive touch-up and re-do labor. It also reduces labor costs caused by holding up the inspection, bagging, assembly, route drivers and shuttle delays.

Possibly the most important result of equipment upgrades is the potential impact on meeting customers’ expectation to have the work back on time and in professionally finished condition.

Their ecological expectations are part of this consideration as well, so even if you are not required to switch from perc, there are marketing reasons to do so in specific areas.

Fulfilling customer wants and needs will increase their bond and loyalty to a service brand, increase their volume, and convert them to an unpaid sales force who will tell their friends and colleagues.

Don’t minimize the impact that equipment upgrades can have on employee morale. Often, a new unit to operate is viewed as a validation of their worth to the company and a reward for their service.

The productivity feedback from the equipment can lead to more realistic pricing and more accurate capturing of special care fees as it tracks the time required to process specialty work.

All equipment needs regular preventative maintenance and care. However, when searching for the funds to allocate to equipment improvement purchases, look at current maintenance costs and estimate how much will be saved in wasted production labor hours, maintenance wage, and expense (continued)

“The advanced technology used in today’s drycleaning machines far exceeds that used in previous-generation models,” says Scott Mondi, general manager for Renzacci USA “Whether you choose to use perc or an alternative solvent, today’s machines are loaded with money-saving and moneymaking features.

“The increasingly popular soft-mount technology used in alternative-solvent machines reduces cycle time and increases throughput capability. Today’s machines are more efficient, so it is common to see higher solvent mileage and lower utility costs.

“Drycleaning machines also have more efficient stills today, and are better at removing unwanted water from the system. This can result in longer solvent life and less waste.

“Today’s new ‘smart’ touchscreen computer interfaces make customizing programs a breeze, and cross-training employees easy.

making a selection.

Another contributor to covering the purchase would be energy savings from the better energy-efficiency ratings of the new machines.

When all of the savings listed are added together and combined with the higher sales potential of a consistently good customer experience, a new equipment purchase can be self-funding in a short period of time.

Other factors to be taken into consideration when making a purchasing decision:

• Number of employees

• Efficiency of current staff

• Availability of dependable workforce

suggests that if a dry cleaner has aging equipment and is considering an upgrade, switching to a wetcleaning system will take an operation into the next few decades when environmental laws are bound to be even more stringent.

“Recently, more and more landlords have been making it difficult for dry cleaners to operate on premise by stipulating that they can no longer use perchloroethylene, or perc, because of the inherent environmental risks,” he says. “In many states, grant incentives are being offered to dry clean-

“New washer-extractors and tumbler dryers are also built with utility savings in mind. Investing in new equipment can improve employee morale, produce better-quality garments and result in significant utility savings.”

• Number of pieces processed

• Required turnaround time

• Facility configuration

• Propensity for technology

• Pride of ownership

• Advantageous pricing

ADC

ers to switch to the innovative wetcleaning system.”

Miele offers equipment designed to prevent fabrics from pilling and allow garments to last longer than those processed in traditional machines. Washers control water levels, temperatures, drum rotation rhythm/settings and detergent dosing levels while dryers measure garments’ residual moisture and optimize cycle times, according to the company.

“You can help protect the environment, provide truly clean garments and differentiate yourself in the market to expand your customer base,” Rocha says. ADC

if the equipment works well and requires less emergency maintenance.

Disruption of any kind is expensive, as it puts the entire plant and distribution system out of sync with maximum efficiency. The reliability of the desired unit and the availability of good support are additional factors to consider in

The total number of employees needed to produce the work, and their efficiency, should be factored into deliberations. Saving “onethird” of an employee may just result in that employee reducing his/her PPOH on the new unit in order to maintain full-time status. In this case, the savings of the purchase will not be realized unless the “freed” time is managed through reduced hours or diversion of those saved hours to a different productive purpose. It is easier to realize the savings of fully eliminating a full-time or part-time employee.

With the more challenging recruitment and retention being experienced by the industry, lower reliance on people to produce the work is a huge benefit of more efficient equipment and automation.

For example, in conjunction with a touch-up board and an experienced finisher, a goodquality steam tunnel may be used as a complete finishing station for a high percentage of items. Depending upon the product mix, these stations have regularly achieved 75 PPOH. The steam tunnel can also provide fast, highvolume pre-conditioning for items that would normally be put on a suzy one at a time.

Other examples of higher production while maintaining quality goals are:

• A high-performance double-legger can increase the PPOH to the 50 range. Since pants are typically 30-40% of the pieces processed, this increase in performance can cut total labor significantly.

In today’s workplace environment, it is critical that pressing and finishing equipment be easy to use, says Wesley Nelson, vice president of sales for Sankosha USA

“In many areas, labor is at a premium and having equipment that anyone can use efficiently with minimal training in a short period of time relieves an owner from the stresses of labor procurement.

“Today’s machines are also more technically advanced, providing the operators with production statistics, self-diagnostics and operating options to deal with the wide variety of fashions that are popular today.

“Tensioning is another feature in most finishing equipment that you see in the marketplace today. This allows for finishing more efficiently, and also makes it possible to finish garments of various constructs. This makes the machines do more of the work and allows operators freedom from having to manipulate the garments unnecessarily.

• Adjustable tensioning equipment that requires fewer steps and is easier to train new operators.

The number of total pieces processed and the required turnaround time can influence the decision as well. If 1,000 sheets must be produced for a hotel account overnight, the equipment, labor and shift needs are much more demanding than retail work done for consumers on a regular retail schedule.

Facility configuration will dictate the amount of adaptation required to change or add equipment.

Stuart Ilkowitz, president

Trevil America, says that current models of his company’s equipment “have become faster and more productive. The quality of the finished garments have improved and become more consistent without the need of a highly skilled and experienced operator. Also, the machines have been improved to be more energy-efficient as well as to reduce and simplify maintenance, resulting in less downtime.”

For dry cleaners who are having trouble finding skilled workers—a common theme when his representatives meet with cleaners—improving their shop’s machinery will reduce their need to rely on a particular “skilled” employee, Ilkowitz says.

“Today’s machines are designed with today and tomorrow in mind in an everchanging marketplace. … Many of the features on our current equipment directly reflect changes in fashion and how garments are being manufactured.”

Another important factor to consider is your own propensity, and that of your staff, for technology.

ADC

For example, Trevil offers an automated machine able to finish the entire pair of pants. “You can take somebody and train them for about 30 minutes, and because the skill is in the machine, they can quickly begin to produce quality finished garments at a productive pace.

“By updating the equipment in the plant, the owner can … always get their daily production done, making the plant more capital-intensive and less labor-intensive.”

In thinking about customers, Ilkowitz says he finds that the more successful cleaners are the first to embrace new technologies and make the necessary investments to make their businesses more efficient, while those who wait tend to be the ones who struggle to make ends meet. ADC

A computerized addition to equipment has no value if it is not utilized for refinements, improvements and ease of management. Many plants we visit have installed capabilities far beyond those that are being utilized, so the excess expense appears to have been wasted. Conversely, productivity systems that are integrated with POS and financial systems produce real-time, actionable reports; reduce the office time spent by managers; and have resulted in higher efficiency and productivity.

If you determine that a purchase is not appropriate at the moment, you can still upgrade existing units by tuning, cleaning and freshening their finish.

When a new-equipment purchase decision is made, do not neglect the maintenance of existing equipment prior to installation of the new units.

In summary, a decision to buy new equipment, while seeming simple on the surface, is actually a complex set of considerations. It may help you discover an abundance of benefits that will contribute to your ability to capitalize on advantages of ownership and pay for the acquisition you want to make.

Although some advantages are more difficult to equate in monetary terms, most benefits can be assigned predictable financial value, so the decision becomes more rational. ADC

Diana Vollmer is managing director of Methods for Management (MfM), a consulting firm that has served the drycleaning industry with affordable management expertise and improved profitability since 1953. She can be reached at dvollmer@mfmi.com, 415-577-6544.

It seems that small-business owners are shifting investment from customer acquisition to engagement, placing greater emphasis on generating customer loyalty.

In 2012, research and advisory firm BIA/Kelsey reported that small-business owners (SBOs) prioritized customer acquisition over customer retention at a 7-to-1 ratio. Two years later, 61% of SBOs surveyed reported more than half of their annual revenue came from repeat customers rather than new customers. As such, they were spending less time and money on customer acquisition.

Even with this shift in behavior, the study found that only 34% of SBOs have a loyalty program, and that the majority of SBO loyalty programs are offline rather than online.

When starting to build a loyalty program, BIA/Kelsey and Manta, an online resource dedicated to small businesses, suggest the following:

Start with the End in Mind — Start with the desired outcome in mind. Define your goals and what you want to achieve from a customer loyalty program. Make sure the goal is specific and can be measured, as it will dictate

the strategy and tactics that you put in place. The goal of wanting more business is too broad, so instead determine if you want to decrease customer “churn,” increase average order size, improve customer acquisition, etc.

Determine Your Audience — You may want to target customers by spending thresholds, frequency of purchases or even specific service types. Targeting a specific group helps you reward ideal buying behavior, subsequently driving more of it.

If it’s your first time launching a customer loyalty program, starting with one group could keep you focused and make it easier for you to track results and metrics.

Structure Your Program to Be ROI-Positive — Once your primary goal and audience are in place, you can then determine your program structure. Will it be points-based or have a tiered reward structure? Make a list of multiple options that could help you meet your goal, assess how much they cost and how much they will net you in return to identify the best structure for your business.

Meanwhile, writing for the U.S. Small Business Administration, marketing consultant Caron Beesley says the key is to create a loyalty program that

is accessible and easy to use. She shared these tips:

Punch Cards — “If you’re new to loyalty programs and want a low-tech option, the simple punch card formula is a good place to start,” she writes. “Just design and print out a card and offer a free gift after a certain number of purchases have been made.”

Obvious drawbacks to this method include lack of abil ity to track consumer demographics, and the program’s complete reliance on customers remembering they have a punch card and where it’s located.

Start an Opt-In Program — Set up a simple “sign up for offers/rewards” program. “Ask customers to share their e-mail addresses and add them to an opt-in e-mail list—you can do this online or at the point of sale,” Beesley writes.

This form of sign-up eases the application process and spares customers the hassle of having to download an app or share heaps of personal information. In exchange, you promise to send them regular communications and special offers only available to loyalty members.

Consider a Premium Loyalty Program — If you want to reward customers who spend the most, develop a program that limits who may be eligible to qualify, advises Beesley.

“Use your customer relationship management software

to track higher value purchases over time and invite customers who meet certain thresholds to join,” she writes. “Alternatively, simply invite high-spending consumers to sign up for your program at the point of sale.”

Offer Branded Loyalty Membership Cards — There are commercially available loyalty card services that allow businesses to design branded cards, and track and manage customer behavior such as number of store visits, average spend, etc.

Add a Digital Component — “While not all your customers will be digitally savvy, chances are many are, and it’s increasingly important that you cater to the growing mobile loyalty trend,” Beesley writes.

Many point-of-sale systems can easily integrate customer loyalty programs. “Explore your options and look for services that offer social media integration.”

Choose Incentives Carefully — “Freebies don’t always appeal to all, and they can even de-value your services,” warns Beesley. Think of ways you can make incentives and rewards as unique as your business.

Communicate Regularly — “Treat your loyalty members royally,” Beesley writes. “Segment them out in your e-mail and direct marketing efforts, and communicate with them often. Share news of upcoming loyalty incentives or events, and don’t forget birthdays.” ADC

There always comes a point when you choose to clean a “special” gown or to pass that gown on to a competitor. That choice depends on the tools that you have at your disposal.

Confidence, experience and knowledge are all tools. See, tools are not necessarily mechanical. Knowledge leads to experience, experience leads to confidence, and confidence leads to added revenue. There is no reason you should allow a high-profit-margin item like a formal gown, beaded cocktail dress or even a wedding dress to go to your competitor.

The biggest drawback to processing expensive gowns is a noticeable lack of training. The key to restoring these high-end gowns is strictly adhering to basics of fiber construction and dyeing, and going beyond the basics when it comes to pre-spotting.

A cocktail dress is usually characterized by a knee-length, flowing skirt. In most cases, it will contain a modest to excessive level of trim, the characteristic that first catches one’s eye. This trim must be dealt with (protected) during the cleaning process.

Protecting trim starts with a commitment to pre-spotting. Many times, a garment can be meticulously pre-spotted, allowing the cleaner/spotter to reduce the runtime for the garment to the absolute minimum. In cases of light to moderate amounts of trim, the garment can be further protected by turning it inside-out and running it in a loose bag.

With a heavily trimmed bodice area, a pillowcase can be pulled over the upper portion of the garment and secured around the waist with a length of cotton cord from your local home improvement store. When the entire dress is heavily trimmed, the addition of a second pillowcase, pulled up from the bottom and secured with cord around the waist, will greatly reduce any risk of damage from the mechanical action in the chosen cleaning process.

A formal dress is usually characterized by a skirt that is floor-length or longer. These dresses can be expected

to have a “custom” tailored fit, even if the trim is minimal or nonexistent. Many times, there are plastic strips (boning) sewn into the inside of the bodice to add stability to the area above the waist. These strips may well be sensitive to overexposure to your cleaning solution, so runtimes should be reduced to minimize the risk of making the strips brittle by removing some or all of the plasticizer. The ornamental trim can be treated in the same way as with the cocktail dress.

You can expect to pay close attention to the bottom hemline of the dress. If worn outdoors, you will be faced with grass stains, gravel and mud. If worn inside, you can expect to find fine dirt clinging to floor preparations or wax. These stains are best pretreated on the dry side with a general pre-spotter. After the first cleaning, you will have a better understanding of the individual stains that were under the hemline and can post-spot where necessary.

The mere mention of wedding dresses will cause some operators to duck for cover. The combination of high monetary value and sentimental value is just too much for them to accept the risk. However, somebody has to do it, so why not you? It’s a white garment that has been tried on multiple times but truly worn only once. It is not all that risky; it just takes time and effort. Walk, don’t run, and you will be fine.

Inspect the dress with the customer at the counter. Ask about the reception: food and drink served, condition of the floor, flowers that were in the bouquet, etc. Make notes for the spotter.

Re-inspect the dress in an open area by hanging the bodice, stretching the dress to its full length and placing a No. 3 safety pin in the train at the end of the center seam. Slowly inspect for stains, grass, twigs, even blood.

“ The key to restoring these high-end gowns is strictly adhering to basics of fiber construction and dyeing...”

If necessary, pre-spot the hemline on the wet side and allow to dry. Pre-spot food and beverage stains and allow them to dry.

If dry cleaning, treat areas previously spotted wetside with a leveling agent. If the beads and sequins are minimal, turn the dress inside-out and bag it in a large mesh bag (about 2 feet wide and about 5 feet long). If the beads and sequins are excessive, they can be covered with a pillowcase and secured at the waist with a length of cord, then turned inside-out. This will reduce the risk of the trim or settings causing a snag during the mechanical action of cleaning.

This is another chance for me to suggest that you consider wet cleaning as a supplement to your solvent operation. If the trim is glued on, true wet cleaning offers a greater margin of safety for the trim (crushed ice). A 100% polyester garment is a wetcleaning candidate if the staining substance or volume of the stain makes water an advantage.

A disclaimer: Wet cleaning a garment marked “Dryclean” or “Dryclean only” is always done at the cleaner’s risk if a hold-harmless release is not signed by the customer prior to cleaning. By following strict wetcleaning protocol, you can enhance your reputation and increase your income.

Strict wetcleaning protocol is control of detergent pH (7 or less), water temperature (90 F or below), mechanical action in cleaning (one rotation in each direction per minute), and humidity-controlled drying. Your laundry cycles, alkaline detergents, and hot drying ain’t wet cleaning. ADC

Martin L. Young Jr. has been an industry consultant and trainer for 20 years, and a member of various stakeholder groups on environmental issues. He grew up in his parents’ plant in Concord, N.C., Young Cleaners, which he operates to this day. Contact him by phone at 704-786-3011, e-mail mayoung@vnet.net.

The Meadowlands Expo Center will be the site of the 2015 TexCare Dry Cleaning & Laundry Show here on Oct. 17-18. The biennial ex hibition is sponsored by the National Cleaners Association (NCA).

“TexCare has always been a very well-attended event,” says Ann Hargrove, NCA’s special projects director. “In 2013, we had over 3,000 cleaners come through our doors, and the feedback we received from the exhibitors was that the show was a great success for almost all of them.”

There is no fee for professional cleaners to attend, and more than 40 companies have registered to exhibit during the weekend show (see list).

But Hargrove warns the freeadmission policy doesn’t apply to tradespeople who are not exhibiting.

TexCare is also known for its educational seminars. This year, free programs in English and Korean will be offered, plus a limited number of cleaners will have the opportunity to attend a special “Uber Conference on World Class Customer Service.”

Free seminars will include Understanding Online Reputation Management, to be presented 8 a.m. Oct. 17 by NCA Digital Marketing

Manager Dawn Avery; Problem Garments 2015, 9 a.m. Oct. 17, by NCA Director of Technical Services Alan Spielvogel; a panel discussion with New York City agencies, to include the Fire Department, Depart ment of Consumer Affairs, Depart ment of Environmental Protection, and Department of Buildings, at 9 a.m. Oct. 18.; and a Korean-language session, Must-Have Technology for Dry Cleaners, at 10 a.m. Oct. 18.

The Uber Conference, which is separate from the free conference and starts a day earlier, will feature Disney trainer and consultant Dennis Snow (appearing 10 a.m. Oct. 16), Jason Loeb of Sudsies.com (9 a.m. Oct. 17), and customer service guru and author John DiJulius (9 a.m. Oct. 18). All will share insights into “creating the world-class culture vital to supporting a world-class customer experience,” NCA says. Seating is limited; contact Hargrove for pricing.

DiJulius has appeared for NCA at several Brainstorming events, giving him special insight into the industry’s concerns. Snow’s many years of experience with the Disney organiza tion, both as a front-line employee and a Disney University instructor, as well as his consultancy serving small and big business, also make him a centerpiece.

“We are seriously elevating the caliber of the speakers this year, because we want this kind of high-level message delivered in a location that is accessible not only to owners, but middle management and CSRs as well,”

As of Aug. 20

Air World Pads and Covers

A.L. Wilson Chemical Co.

B&G Lieberman Co.

BeCreative360

Caled Chemical

Columbia/ILSA

Comca Systems Inc.

Compassmax/Maineline

Computer Connection

Dry Cleaning Computer Systems (DCCS)

Drycleaning & Laundry Institute

Easy Plus

European Finishing Equipment (Hi-Steam)

EZ Products International

Fabricare Management Systems

Fabritec International

Fulton Boiler Works

GreenEarth Cleaning Hangers Direct

Hoffman-New Yorker

Hwasung Washing Machine Co.

HYAC Corp.

Kreussler Inc.

Leonard Automatics Inc.

Liberty Computer Equipment

Machine World Depot (A+ Plus)

Maruso

Metropolitan Laundry Machinery

Need Parts Inc.

New York Machinery

NIE Insurance

Pariser Industries

Sankosha USA

Scan Q

SNA Manufacturing

Spot Business Systems

Super Laundry

Union Drycleaning Products

Unipress Corp.

Wascomat (Laundrylux)

Wedding Gown Preservation Co.

White Conveyors

says NCA Executive Director Nora Nealis.

“TexCare is a wonderful oppor tunity for cleaners who missed the Clean Show to get up to speed, and for cleaners who attended the show to follow up on things that caught their eye there,” Hargrove says.

To register, or to learn more, contact Hargrove at 800-888-1622, ann@nca-i.com.

■ Have you invested in renovations, equipment upgrades, or an entirely new drycleaning plant? Enter your project in the 55th Annual American Drycleaner Plant Design Awards!

Every year, our magazine honors the best new plants and renovation projects, recognizing them for appearance, efficiency, convenience and comfort. Your plant could be next! You can find our online entry form at: https://americandrycleaner.com/ 55th-annual-plant-design-awardsentry-form

■ Fill out the form completely and upload a layout (blueprint or sketch) and several photos (300 dpi digital files are preferred, but color photos will also suffice) that show off the features that make your drycleaning plant an excellent place to do business.

And include any information you believe is relevant to the way your plant’s design attracts customers and fulfills your production needs. The more detailed the entry, the better!

Perhaps you’ll join the likes of previous grand prize-winners Wooven, Pompano Beach, Fla.; Corona Del Mar (CDM) Cleaners, Newport Beach, Calif.; and Rainbow Cleaners, Oxford, Miss., at the pinnacle of the drycleaning industry. But you can’t win if you don’t enter!

■ Entries are subject to verification. Contact Editorial Director Bruce Beggs, 312-3611683, bbeggs@ATMags.com, with any questions.

American Drycleaner is accepting entries until Friday, Oct. 2. Good luck!

Zengeler Cleaners recently promoted longtime employee Oscar Gonzalez to direct the cleaning company’s busi ness operations.

Gonzalez, who is an 11-year employee of the familyowned company, will supervise operations at all eight Zengeler Cleaners store locations in the Chicago area. Most recently, he had served as store manager at the company’s Dundee Road location in Northbrook, Ill., since 2008.

“Zengeler Cleaners is delighted that Oscar Gonzalez has accepted our newly created posi tion of director of business opera tions,” says Tom Zengeler, president of Zengeler Cleaners. “Oscar has done an outstanding job as manager of our Northbrook store for the past seven years. He is well liked and respected by our customers and em ployees alike—important qualities in his new role.”

Zengeler says it was the “perfect time” to create the new position with the recent opening of a brand-new Northbrook store and continued growth at all eight store locations, and that Gonzalez is the “per fect person to lead our team.”

Clifton Eugene “Gene” Hurst, founder of the Hurst Boiler & Welding Co., died July 22 in Thomasville, Ga. He was 79.

Describing him as an “entrepreneur, skilled engineer, and devoted family man,” the company says Hurst will be remembered for his “kindness, dedication, vision and inexhaustible will.” It adds that he not only grew Hurst

Boiler into a world leader among boiler companies, he helped transform the boiler industry through innovation.

Hurst started his family business in 1967 with wife Edna in a shop behind their Thomasville home. In 1970, he moved the company to its present location in Coolidge, Ga., where the company manufactures a full line of solid waste-, wood-, gas-, coal- and oil-fired steam and hot wa ter boilers and related equipment in a 314,000-square-foot manufacturing facility.

Forty-eight years later, the busi ness remains in the family, under the direction of the Hurst children: Tommy, Hayward, Teri and Jeff. It employs more than 350 people at full production capacity.

Gene Hurst attributed his success to his faith, his fam ily’s support, and the dedication of the Hurst Boiler team and customers, the company says.

In lieu of flowers, the family requests memorial dona tions be made to the Lives Without Limits organization, www.liveswithoutlimitsga.org.

The Round Table of Launderers and Dry Cleaners—an in formal group of top executives from laundry, linen, indus trial and drycleaning companies—convenes annually to learn about innovation in the industry, to address mutual concerns and to openly exchange ideas. Fifteen members, invited to join the organization based on their company’s demonstrated best practices, gathered in Maui, Hawaii, earlier this year for its 76th Annual Meeting.

The gathering featured five days of meetings covering key topics for running a successful business in today’s economic environment. Each day featured a different subject, moderated by a different industry leader.

In keeping with the Round Table’s tradition of hear ing from invited guests and potential new members, this year’s invited guest was Jackson, Miss.-based Hallmark Cleaners. Also presenting was the new ownership of Red Hanger Cleaners, headquartered in Salt Lake City, Utah.

Tom Zengeler of Zengeler Cleaners, Northbrook, Ill., and Steven Toltz of Dependable Cleaners, Denver, presented a session on technology advances in the clean ing industry, along with a comparison of U.S. and Japan business models.

“The Round Table’s 76th Annual Meeting provided great insight regarding our industry’s strategic direction from a variety of highly successful companies,” notes Zengeler. “This exchange of different perspectives will help each of us improve our operations, better meet the ever-changing needs of today’s customer, and leverage advances in technology and equipment to assure the fu ture success of the cleaning industry.”

The Tuchman Cost Group staged its most recent meet ing in Washington, D.C., in mid-June, touring the host Bergmann’s Cleaning facilities, discussing drycleaning business practices, and enjoying some of the tourist des tinations our nation’s capital has to offer.

Group members gathered on the opening evening for cocktails and dinner, followed by reports from half of the

companies represented.

After breakfast the second day, cost group members toured Bergmann’s Cleaning. Ellen Tuchman Rothmann, president of Tuchman Training Systems, says the group “saw a state-of-the-art facility and employees fully en gaged and motivated.”

“We have been longtime Tuchman Cost Group mem bers and appreciate our national relationships to learn and grow,” says Peter Bergmann, president of Berg mann’s Cleaning.

After lunch, Bergmann’s organized a unique VIP tour of the Newseum, an interactive museum of news and journalism. The day ended with dinner and the remain der of the cost group companies’ reports.

On the final day, the cost group welcomed Nick Chap leau, co-founder and CEO of Starchup, a start-up that builds and deploys “white label” apps for dry cleaners and laundry businesses. He spoke on Starchup and Attracting Millennials, providing statistical information on millenni als and their purchasing habits and how on-demand dry cleaning services can reach a new generation.

The meeting ended with an in-depth financial analysis of each cost group member company (based on the fi nancial reports that each is required to submit monthly) and a general discussion on industry topics. ADC

The Tuchman Cost Group met recently in Washington, D.C.: (Front row, from left) Jung Haddox, Gage Wilson, Terry Quinn (MW Cleaners), Brett Allen (Medlin-Davis Cleaners), and David Makepeace (Medlin-Davis Cleaners). (Middle row, from left) Jessica Ramirez, Ann Nash (Highland Cleaners), Cyndee Billoni (Colvin Cleaners), Keri Quinn, Paul Billoni (Colvin Cleaners), Peter Bergmann (Berg mann’s Cleaning), Chris Billoni (Colvin Cleaners), Sid Tuchman (Tuchman Training Systems), Charlene

Tuchman, Donna Bergmann, and Phyllis Kirksey. (Back row, from left) Drew Singer (Flair Cleaners), Jana Janssen (Martinizing Cleaners), Ellen Tuchman Rothmann (Tuchman Training Systems), Chuck Haddox (MW Cleaners), Gary Futterman (Flair Cleaners), Keith Houston (Crest Cleaners), Jeff Bergmann (Bergman’s Cleaning), Alex Bergmann (Bergmann’s Cleaning), Dave Coyle (In The Bag Cleaners), Ron Garrett (MW Cleaners), Rick Kirksey (Munro Cleaners), and Elizabeth Garrett. (Photo: Tuchman Training)

2015 RATES: One- to five-time rate: $2.00 per word, boldface $2.10 per word. Minimum charge: $25.00 per ad. Call or write for our three- and 12-time rates. If box number is used,

add cost of 5 words. Display classified rates are available on request. All major credit cards are accepted.

DEADLINE: Ads must be received by the 1st of the preceding month.

For example, for a June ad, the closing date is May 1st.

PAYMENT FOR CLASSIFIED ADS: Must accompany order.

Model PS-65 Marvel Petro Slim 65# Petroleum machine with 5 Tube Jumbo Filter System. Both working and in very good condition. $3,500.00 MS. Call Donnie 662-417-2501

Excellent condition $5,000 Contact Art Baryames 517-484-8900 ext. 205

10 YEARS AGO. Demand for perchloroethylene (perc) in the U.S. drycleaning industry dropped 2 million pounds in 2004 to 37 million pounds, according to an annual survey from the Textile Care Allied Trades Association (TCATA). The industry has achieved a dramatic reduction in perc consumption in the last 20 years, the association says; annual consumption totaled 260 million pounds in 1985. The 2004 results represent reporting from the four primary producers and importers of perc for use in the drycleaning industry: Dow Chemical Co., INEOS Chlor Americas, PPG Industries and Vulcan Chemicals. … Maytag Corp. has accepted a buyout offer from rival Whirlpool Corp. in a deal that will create the world’s largest appliance manufacturer. The acquisition, if approved by shareholders and Federal antitrust regulators, would create a $17.9 billion company with almost 50% of U.S. market share in washers, dryers and refrigerators. … The National Cleaners Association (NCA) is offering members a new program, “My E-Mail,” which helps retain customers by sending them a personalized e-mail newsletter each week.

25 YEARS AGO. You can’t miss Elvis Presley at all if you visit Armitage Cleaners in the Lincoln Park area of Chicago. Three plastic busts of the entertainer sit in the front window. The call office is chock-full of Elvis clocks, posters and other curios such as a music-box figurine whose head pops off to allow access to the bourbon in the belly.

Owner Maximiliano Gonzales, originally a closet fan of the King in Fidel Castro’s Cuba, now flaunts his love of the singer, sells about 100 Elvis busts a year at $20 apiece and says, “For me, he lives here.”

… “We were looking for something to fill in the valleys,” Bill Fortinberry of Nu-Way Dry Cleaning in Forest, Miss., says of Nu-Way’s diversification into uniform rental. That was in January 1980, just about the time he was thinking of giving up his other career as an athletic trainer with a minor league baseball

team. He and his wife, Gaybie, had owned Nu-Way since 1971. Bill’s dual career worked out well until their two children grew older. “That’s when we decided it was time to put all our energy into the cleaning business,” he says. Their second business, Nu-Way Uniform Rental, an Apparelmaster franchise, was part of that plan, and its success was the real reason they decided to divide the two operations and build a new drycleaning plant.

50 YEARS AGO. Classified ad in a Durham, N.C., newspaper: “For Sale. Beautiful debutante or wedding dress, size 9, worn once. Eakes cleaned, perfect condition, $75.” That shows how well Matt Eakes and his plant are known for their cleaning of fancy dresses. … The complete service center is no longer the plant of the future. It’s now a very present reality. And Clean-It Laundry-Drycleaners, Overland Park, Kan., illustrates the successful blending of professional drycleaning with coin laundry and cleaning and shirt laundry service. The 3,200-square-foot plant is air-conditioned, and conveyorized. Its pre-assembly system makes possible 39-minute cleaning. Operating with only five employees, Clean-It’s combined services have an annual capacity of $125,000.

75 YEARS AGO. When Uncle Sam invented the penny postcard, few people realized that the government had placed at the disposal of its citizens an excellent advertising medium at a small cost. Few successful advertising campaigns have been conducted entirely by government postcards, but the one-cent postcard has played an important role in many sales promotions. In a cleaner’s campaign, the postcard functions as a brief, pointed reminder. It cannot be a whole campaign in itself. When used correctly, it supplements letters, newspaper advertising, route solicitation, the radio, window displays and package inserts. … There’s a return to easy simplicity in women’s clothes this fall. Gone are the skirts that billowed like parachutes a season ago, the thickly padded shoulders, the bird-cage hip pads, the tiny wasp waists. Events in Europe which have abruptly cut off this country from Paris inspiration coincide with a season where fashion is undergoing radical change. ADC

— Compiled by Bruce

Beggs

Beggs