Optimizing endotoxin removal with EtoxiClear® adsorbent

Endotoxin from bacterial expression cells lines, such as E.coli, pose a critical challenge in biopharmaceutical purification, requiring strict control in final products. EtoxiClear® captures endotoxin in flow-through mode under flexible pH and salt conditions, minimizing protein loss. This application note describes a simple, cost-effective method using SPE columns and a vacuum manifold to optimize endotoxin removal.

Endotoxin, composed of lipopolysaccharides (LPS) derived from the cell wall of Gram-negative bacteria such as E. coli, represents a major challenge in the purification of biopharmaceuticals produced in bacterial systems. Contamination can also arise from external sources, meaning even non-bacterial expression systems are vulnerable. Endotoxins can trigger strong immune responses in patients, and therefore biotherapeutics are subject to stringent regulatory testing, with intravenous products required to remain below 5 EU/kg of patient body weight[1]. EtoxiClear® is a mixed-mode adsorbent specifically developed for its ability to bind endotoxin. Operated in flow-through mode, EtoxiClear® binds endotoxin molecules in the sample, while allowing the desired therapeutic protein to pass through.

Unlike traditional ion-exchange adsorbents, EtoxiClear® has multiple bonding interactions, enabling endotoxin binding even at higher NaCl concentrations. This flexibility allows process conditions (pH and NaCl) to be tuned so that endotoxin removal is maximized, while target protein binding is minimized.

Identifying the best pH & salt conditions for a given protein system can be complicated by the risk of contamination during testing. For example, FPLC systems ideally require the flow path to be fully depyrogenated between runs to prevent cross contamination. While automated liquid handling systems offer the benefit of speed and high throughput testing, the aerosols generated in the enclosed equipment space can contaminate open buffer reservoirs with endotoxin. These practical hurdles can slow development and add unnecessary cost.

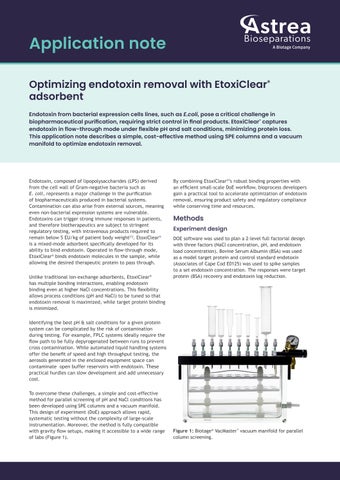

To overcome these challenges, a simple and cost-effective method for parallel screening of pH and NaCl conditions has been developed using SPE columns and a vacuum manifold. This design of experiment (DoE) approach allows rapid, systematic testing without the complexity of large-scale instrumentation. Moreover, the method is fully compatible with gravity flow setups, making it accessible to a wide range of labs (Figure 1).

By combining EtoxiClear®’s robust binding properties with an efficient small-scale DoE workflow, bioprocess developers gain a practical tool to accelerate optimization of endotoxin removal, ensuring product safety and regulatory compliance while conserving time and resources.

Methods

Experiment design

DOE software was used to plan a 2-level full factorial design with three factors (NaCl concentration, pH, and endotoxin load concentration). Bovine Serum Albumin (BSA) was used as a model target protein and control standard endotoxin (Associates of Cape Cod E0125) was used to spike samples to a set endotoxin concentration. The responses were target protein (BSA) recovery and endotoxin log reduction.

Equipment and reagents

Equipment/reagent

6 mL empty SPE style columns

10 µm PE frits

Vacuum manifold or gravity flow rack

General lab equipment

Endotoxin reader

Spectrophotometer or plate reader at 280 nm

Endotoxin free consumables

Buffer preparation materials

Control standard endotoxin

Target protein

EtoxiClear® adsorbent

ISOLUTE® Reservoir, 6 mL,120-1003-C

ISOLUTE® Frits, 6 mL (13 mm) 10 µm PE, 120-1063-C

Biotage® VacMaster™ or Biotage® gravity rack

Vortex mixer, pH meter, conductivity meter

Charles River Endosafe® nexgen-MCS™ and cartridges

Thermo Scientific™ NanoDrop™ One

Endotoxin-free pipette tips, collection tubes, bottles for buffers

Endotoxin-free water, ideally pharmaceutical grade buffers

Associates of Cape Cod E0125

In this case: BSA

Astrea Bioseparations 3250

Table 1: Equipment and reagents used for small-scale DoE endotoxin removal screening, equivalents acceptable.

The condition levels for the DoE can be seen in Table 1, each combination of the low and high levels (Table 2) was tested in duplicate and the mid-point (Condition 9) was tested in quadruplicate. The equilibration buffers matched the conditions shown in Table 2, without BSA or endotoxin added. All buffers were prepared with endotoxin-free water in sterile vessels to prevent endotoxin contamination.

A negative control was also run matching the mid-point with no load to confirm no cross contamination during the workflow.

Table 2: Low, high, and mid-point condition levels for the factors involved in the DOE screen using DOE software.

Table 3: Specific buffer compositions and load conditions tested across the DoE screen.

Column packing

The empty SPE columns were assembled by inserting a 10 µm PE frit into the bottom and placing onto the vacuum manifold. EtoxiClear® adsorbent, which had been stored as a 70% slurry in 20% EtOH, 0.1 M NaCl, was resuspended by inversion and then 1 mL of resin slurry transferred into each SPE column. Cutting the end of the pipette tip off can aid in transferring the resin slurry. An additional frit was inserted and gently pushed down to the top of the bed with a glass rod, resulting in 0.7 mL columns. If the slurry percentage of the solution is not known, this can be calculated by transferring 10 mL of slurry into a 10 mL measuring cylinder, covering with parafilm, and allowing the adsorbent to settle overnight to find the settled bed height. In the case of a 70% slurry, the settled bed height would be at the 7 cm mark on the measuring cylinder.

The columns were set up on a vacuum manifold, which aids in the rinsing steps with a reservoir to collect the waste. The vacuum manifold also has a tube rack to collect the column run fractions and taps to close the flow for incubation. However, it is advised to only use gravity flow during the equilibration and sample load steps to prevent the risk of drying out of the resin bed. Alternatively, the whole workflow can be performed using a Biotage® [2] gravity rack.

The columns were rinsed with 10 CV of water, followed by 10 CV 0.5 M NaOH. The columns were filled with 0.5 M NaOH, sealed and left to sit overnight to depyrogenate, a critical step to prevent endotoxin contamination. Following depyrogenation, the columns were rinsed with 50 mL endotoxin-free water, followed by 200 mM sodium phosphate pH 6 through the column until the eluent was around neutral pH. Finally, the columns were equilibrated with 20 CV of the

condition-specific equilibration buffer (Table 3). The final 10 CV of equilibration buffer was collected and tested for endotoxin concentration to confirm successful depyrogenation.

After equilibration, 10 CV of feedstock was applied, followed by 10 CV of the corresponding equilibration buffer which was collected together as the non-bound fraction. Columns were stripped with 0.5 M NaOH and can be regenerated for re-use if required by neutralizing (as before), and storing in 20% EtOH, 0.1 M NaCl.

The samples were tested for BSA concentration using UV280, and the endotoxin concentration was measured by LAL assay (Charles River, Endosafe® nexgen-MCS™ endotoxin reader). Because buffers can interfere with the assay, all samples were diluted at least 1 in 100 in endotoxin-free water.

The BSA recovery and endotoxin log reduction results were analyzed through the DOE software, with the goal of maximizing both the BSA recovery and endotoxin log reduction.

Results

Across all conditions tested, the BSA recovery was excellent (Table 4) with the recovery consistently ≥96% target protein, with no significant impact by any of the factors in the study.

The non-bound fraction from the negative control and collected equilibration fraction from each column had no endotoxin detected by the LAL assay (<1 EU), confirming that the depyrogenation of the columns was successful and no cross contamination occurred with this set up.

The endotoxin log reduction ranged from 0.22–1.89 log, showing that EtoxiClear® achieved removal under a wide range of conditions. DoE analysis indicated that pH and NaCl concentration were significant factors influencing log reduction of endotoxin, whereas the endotoxin load concentration was not. A heat map model shown in Figure 2 identified the most effective conditions for endotoxin removal as pH 8, 0 mM NaCl.

There was no negative effect on the BSA recovery in any of the conditions.

However, at a moderate conductivity (~20 mS/cm, PBS, 50 mM NaCl, 0.001% pluronic F68 pH 7.4) recovery improved dramatically to 86%, while endotoxin clearance remained strong (99%, 1.9 log reduction).

As EtoxiClear® has weak ion-exchange character, users may occasionally experience binding of the target protein to EtoxiClear® if the conditions used are above the isoelectric point (pI) of the target protein. In such cases, recovery can often be improved by increasing the conductivity (i.e., by increasing the buffer concentration or addition of NaCl), but this must be balanced against the endotoxin clearance, which can be reduced at salt concentrations greater than 300 mM NaCl.

The effect is illustrated with AAV2 (Table 5-6). For an AAV2 feedstock post-affinity capture and buffer exchange, in a low conductivity 50 mM Tris buffer at pH 9 (<5 mS/cm), there was complete binding of the AAV2 to EtoxiClear® (0.27% recovery).

Table 6: Endotoxin clearance using a moderate conductivity load with EtoxiClear® from an AAV2 feedstock (PBS, 50 mM NaCl, 0.001% pluronic F68 pH 7.4, ~20 mS/cm). The run was spiked with control standard endotoxin to determine the endotoxin removal performance, demonstrating effective endotoxin clearance.

In other cases, if the running conditions have a pH below the pI of the target protein, (i.e., the target protein is positively charged), interactions between the endotoxin (negatively charged) and the target protein can occur resulting in good target protein recovery, but poor endotoxin removal. In these cases, increasing the pH above the pI of the target protein can help to disrupt these interactions and allow the endotoxin to bind to EtoxiClear®.

Taken together, these results show that a DoE is essential for identifying the best pH and conductivity conditions to balance both the target protein recovery and endotoxin removal responses. A decision diagram for when to implement each optimization option can be seen in Figure 3.

1 2 3

Conductivity may be too high

Endotoxin may be interacting with target protein

Run DOE of pH and conductivity conditions

May be improved with higher conductivity or change in pH

Run DOE of pH and conductivity conditions

Figure 3: Decision diagram for DoE-guided optimization of EtoxiClear® conditions, illustrating potential binding scenarios and recommended next steps.

Conclusion

EtoxiClear® adsorbent consistently demonstrated excellent target protein recovery (albumin) and endotoxin reduction across a wide range of pH and NaCl conditions (pH 4-8; NaCl 0–300 mM).

The optimal balance between recovery and clearance will naturally vary with the characteristics of the target protein, underscoring the need for tailored optimization. For example, endotoxin removal from an AAV2 feedstock benefitted from operating at a higher conductivity which significantly improved target recovery while still delivering excellent endotoxin reduction.

This highlights the critical importance of screening studies to identify the most effective process conditions for each application and target protein. By employing a simple, low cost DoE approach, this study demonstrates how users can rapidly

evaluate pH and conductivity ranges to establish the best balance between protein recovery and endotoxin clearance.

In doing so, EtoxiClear® proves to be a robust and versatile adsorbent capable of supporting a wide variety of bioprocesses, from traditional protein therapeutics to advanced modalities such as viral vectors. Its ability to maintain high recovery while meeting stringent regulatory requirements for endotoxin reduction positions EtoxiClear® as a powerful and accessible tool for biomanufacturers, enabling safer, more efficient production processes.

References

[1] United States Pharmacopeial Convention. Bacterial Endotoxins Test (USP <85>). Rockville, MD: USP; 2011. Available from: Bacterial Endotoxins Test (USP <85>)

[2] Biotage. Biotage – Official Website. Available from: https://www.biotage.com/

Astrea Bioseparations is a world class provider of chromatography adsorbent and resin services. With over 30 years of chromatography manufacturing expertise, we deliver a unique and trusted service in close partnership with our clients. For more information, please don’t hesitate to reach out at sales@astrea-bio.com or visit astreabioseparations.com.