Evolve® Process Chromatography Columns (350-600 mm)

Validation Support – Process-Wetted Materials

Evolve® Process Chromatography Columns (350-600 mm)

Validation Support – Process-Wetted Materials

All materials in contact with the process stream have been selected for their suitability for use in equipment utilised in biopharmaceutical applications , and either conform to relevant sections of FDA code of Federal Regulations Vol. 21, 170 - 199 and/or have passed the USP Class VI test for in vivo toxicity.

This document provides generic certification statements for the process-wetted materials used in the construction of the Evolve® Process Chromatography Columns, specifically columns within the diameter range 350-600 mm.

In addition, a statement is provided in Appendix J, which further clarifies details of ADI (Animal Derived Ingredient) status.

Column Tube

Fixed flow cell

Column Bottom flange (350 & 450)

Column Bottom Flange Shield ring (600 only)

Adjuster flow cell

Adjuster cell inlet Liner

Fixed cell Inlet

Bed support retaining ring (adjuster)

Adjuster flow tube

Flow tube seal (fixed and adjuster)

Sanitary clamp seals

Adjuster Seal (350 only)

Adjuster Seal, Fixed flange seal, bed support seals and tube seals

Flow tube flange gasket seal

Bed Supports (Sinter)

Sanitary clamp adapters

Bed support retaining bolt (adjuster and fixed)

Acrylic MCS25, MCS45, MCS47 A

Polypropylene (black) MCS38 MCS50 B

Polypropylene (black) MCS38 MCS50 B

Polypropylene (black) MCS38 MCS50 B

Polypropylene MCS36 C

Polypropylene (black) MCS38 MCS50 B

Polypropylene (black) MCS38 MCS50 B

Polypropylene MCS13 D

Santoprene MCS28 E

Santoprene MCS28 E

Santoprene MCS29 F

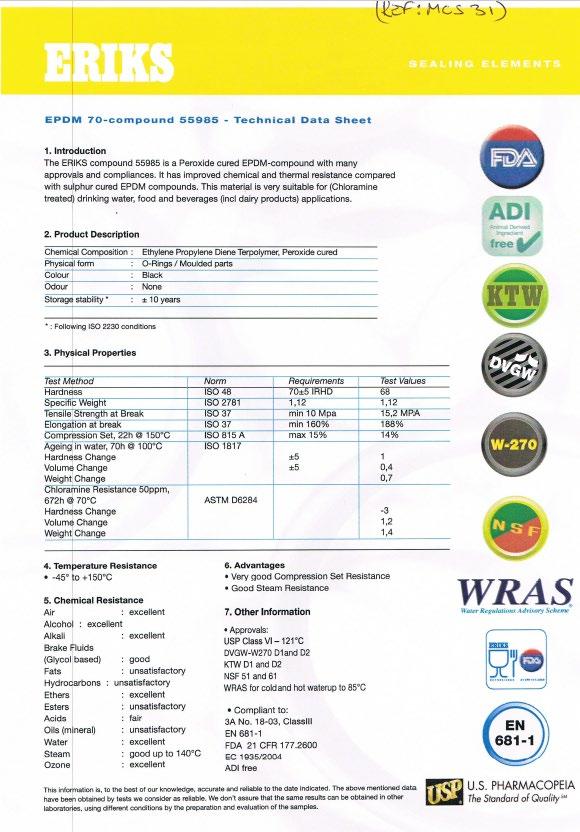

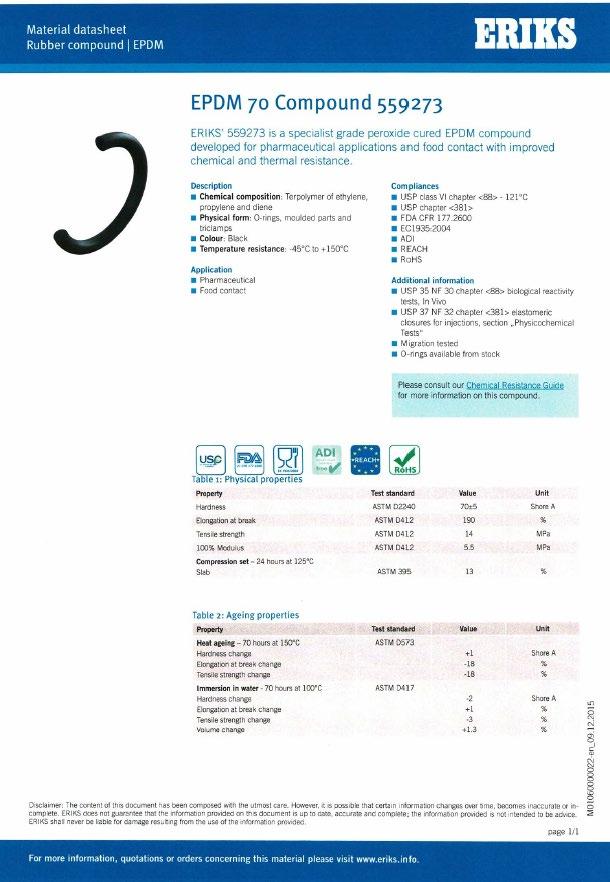

EPDM MCS31 MCS43 MCS48 MCS51 G

EPDM MCS31 MCS43 MCS48 G

Polyethylene MCS27 H

Polypropylene MCS36 C

20% Glass-filled polypropylene MCS21 I

Polypropylene Extruded Tube 20% Glass-filled polypropylene end connections MCS13 MCS21 D I

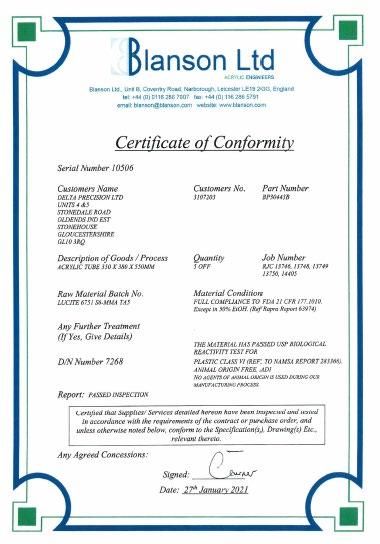

A – Acrylic Tube (Page 1 of 5)

A – Acrylic Tube (Page 2 of 5)

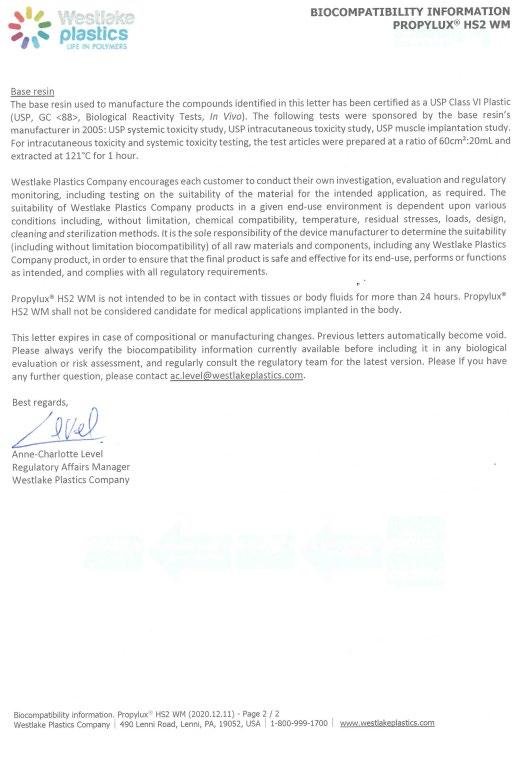

A – Acrylic Tube (Page 3 of 5)

A – Acrylic Tube (Page 4 of 5)

A – Acrylic Tube (Page 5 of 5)

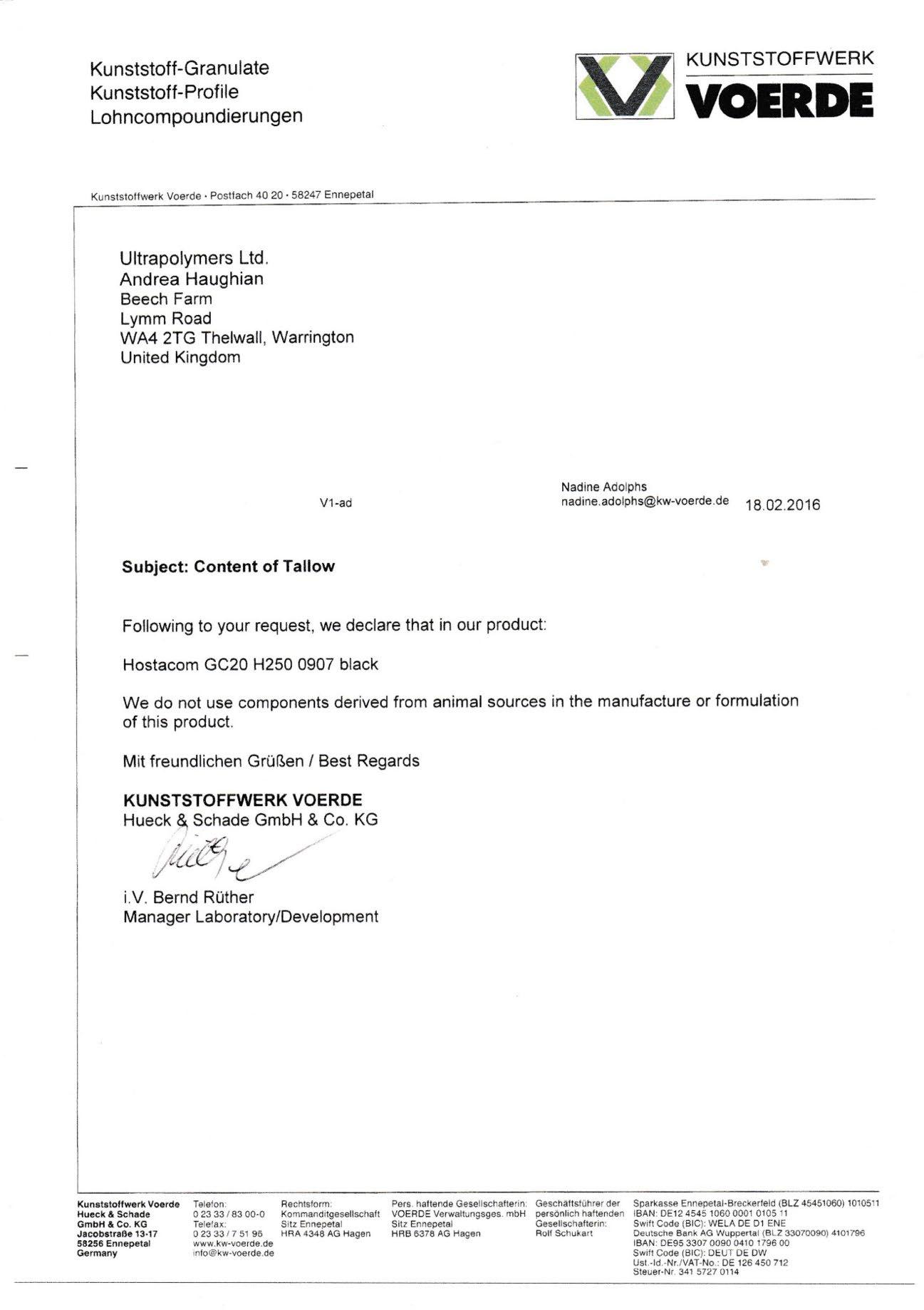

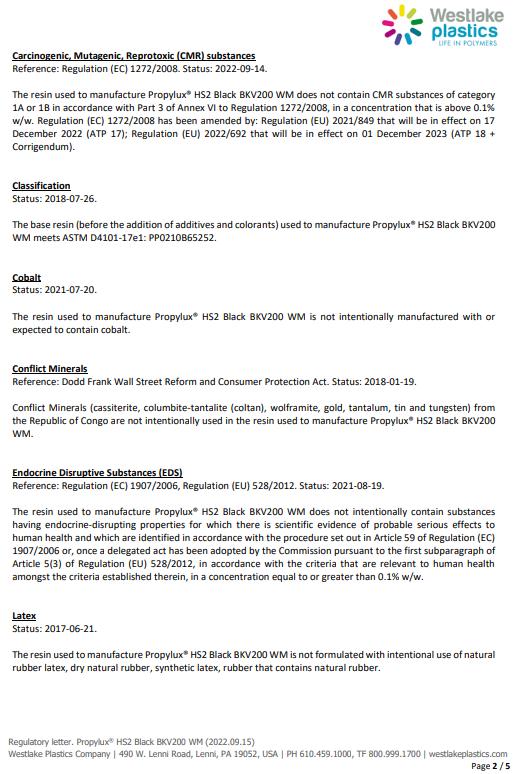

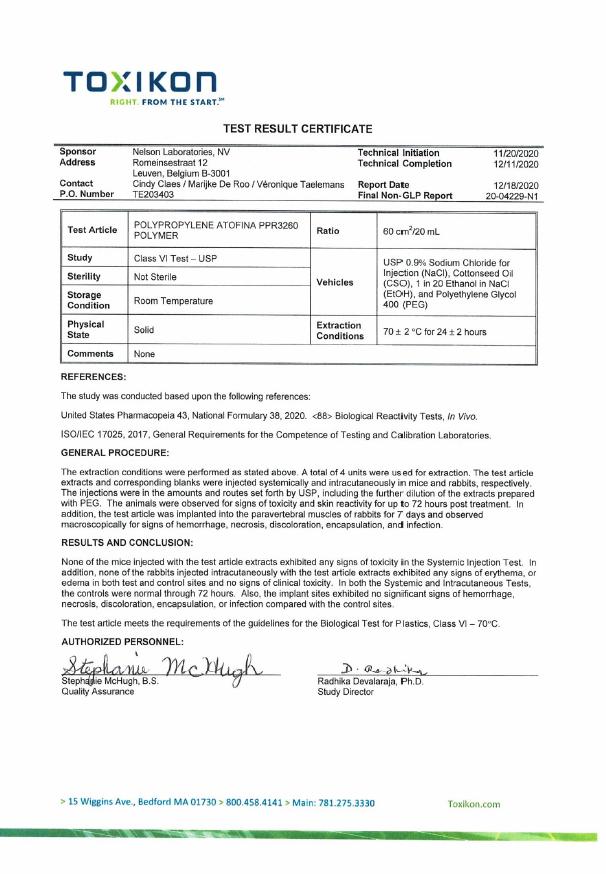

B – Polypropylene Sheet Material (Page 1 of 8)

Appendix B – Polypropylene Sheet Material MCS50 (Black) (Page 2 of 8)

Appendix B – Polypropylene Sheet Material MCS50 (Black) (Page 3 of 8)

Appendix B – Polypropylene Sheet Material MCS50 (Black) (Page 4 of 8)

Appendix B – Polypropylene Sheet Material MCS50 (Black) (Page 5 of 8)

Appendix B – Polypropylene Sheet Material MCS50 (Black) (Page 6 of 8)

Appendix B – Polypropylene Sheet Material MCS50 (Black) (Page 7 of 8)

Appendix B – Polypropylene Sheet Material MCS50 (Black) (Page 8 of 8)

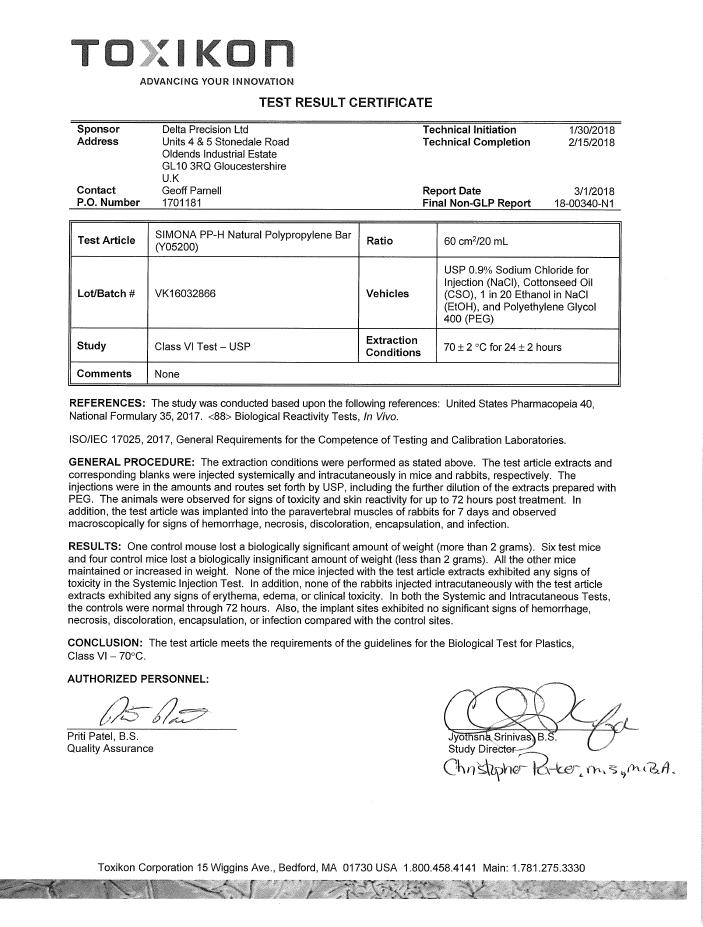

C – Polypropylene Bar (page 1 of 4)

C – Polypropylene Bar (page 2 of 4)

C – Polypropylene Bar (page 3 of 4)

C – Polypropylene Bar (page 4 of 4)

D – Polypropylene Tube (Page 2 of 11)

D – Polypropylene Tube (Page 3 of 11)

D – Polypropylene Tube (Page 4 of 11)

D – Polypropylene Tube (Page 5 of 11)

D – Polypropylene Tube (Page 6 of 11)

D – Polypropylene Tube (Page 7 of 11)

D – Polypropylene Tube (Page 8 of 11)

D – Polypropylene Tube (Page 9 of 11)

D – Polypropylene Tube (Page 10 of 11)

D – Polypropylene Tube (Page 11 of 11)

Appendix E –Santoprene Natural 8281 Med grade (page1 of 1)

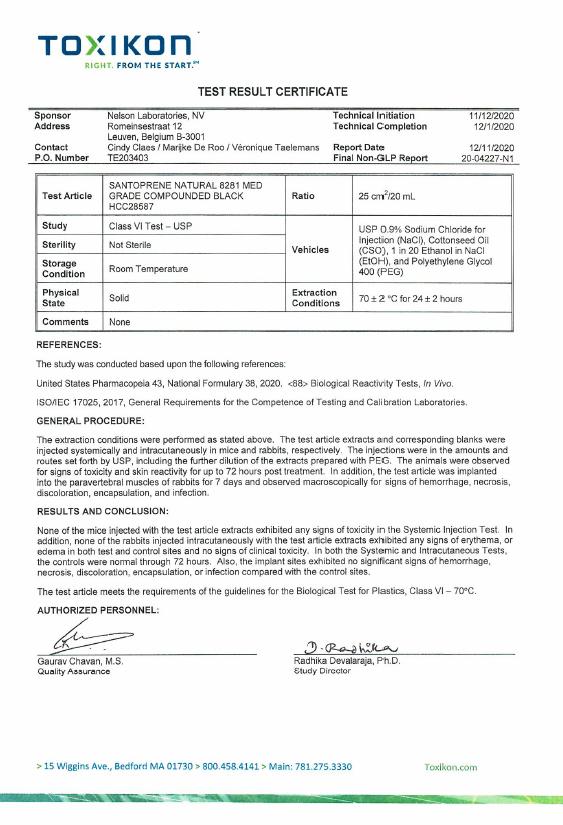

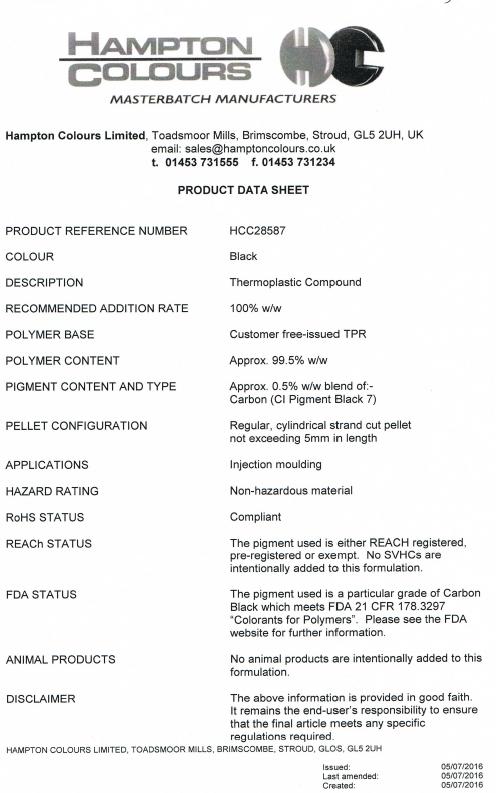

Appendix F –Santoprene 8281 MED grade compunded Black (Page 1 of 2)

Appendix F –Santoprene 8281 MED grade compunded Black (Page 2 of 2)

Appendix G – EPDM (page 1 of 5)

Appendix G – EPDM (page 2 of 5)

Appendix G – EPDM (page 3 of 5)

Appendix G – EPDM (page 4 of 5)

Appendix G – EPDM (page 5 of 5)

Appendix H – Polyethylene sinter (page 1 of 5)

H – Polyethylene sinter (page 2 of 5)

Appendix H – Polyethylene sinter (page 3 of 5)

Appendix H – Polyethylene sinter (page 4 of 5)

Appendix H – Polyethylene sinter (page 5 of 5)

I – 20% Glass Filled Polypropylene (page 1 of 2)

I – 20% Glass Filled Polypropylene (page 2 of 2)