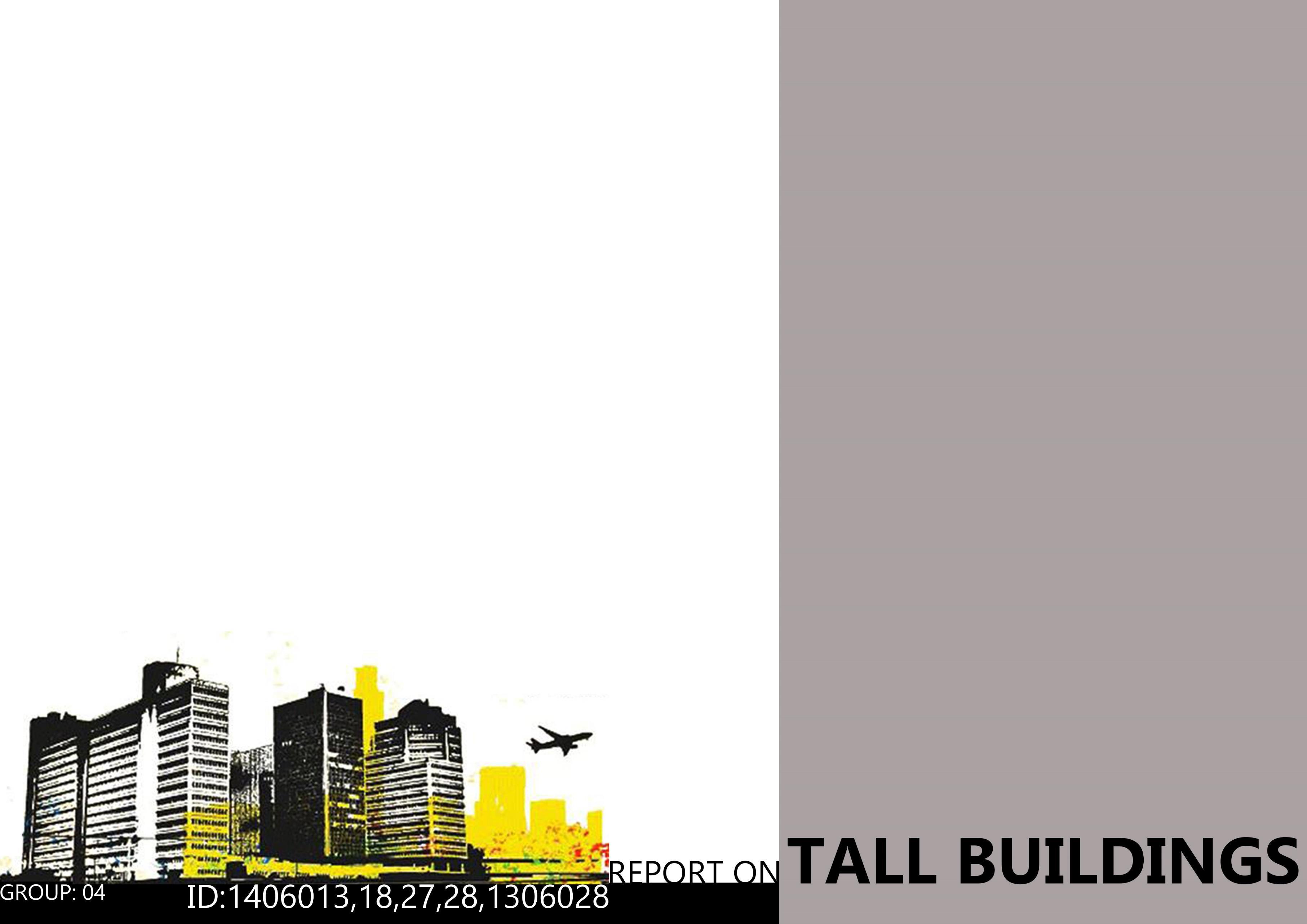

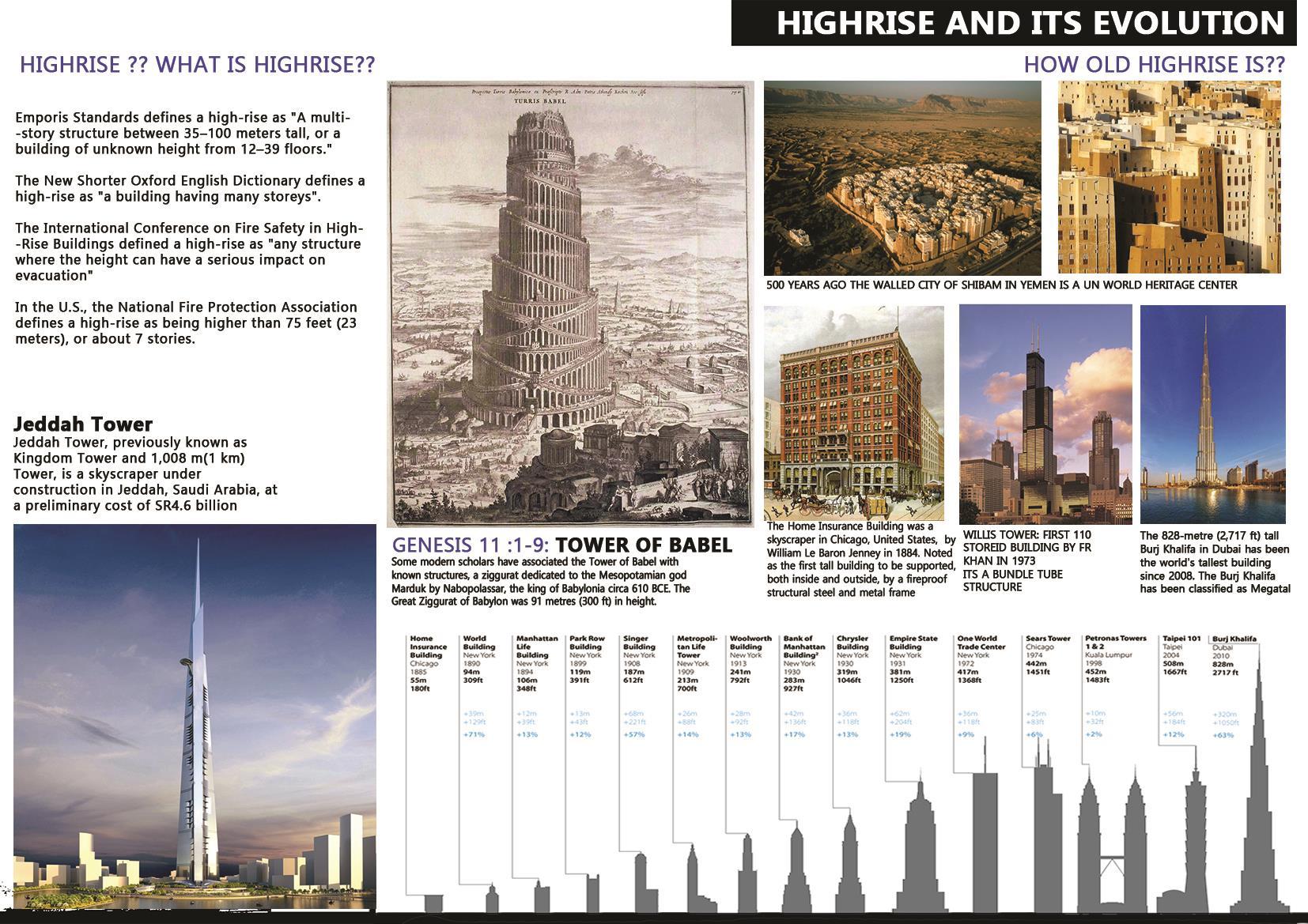

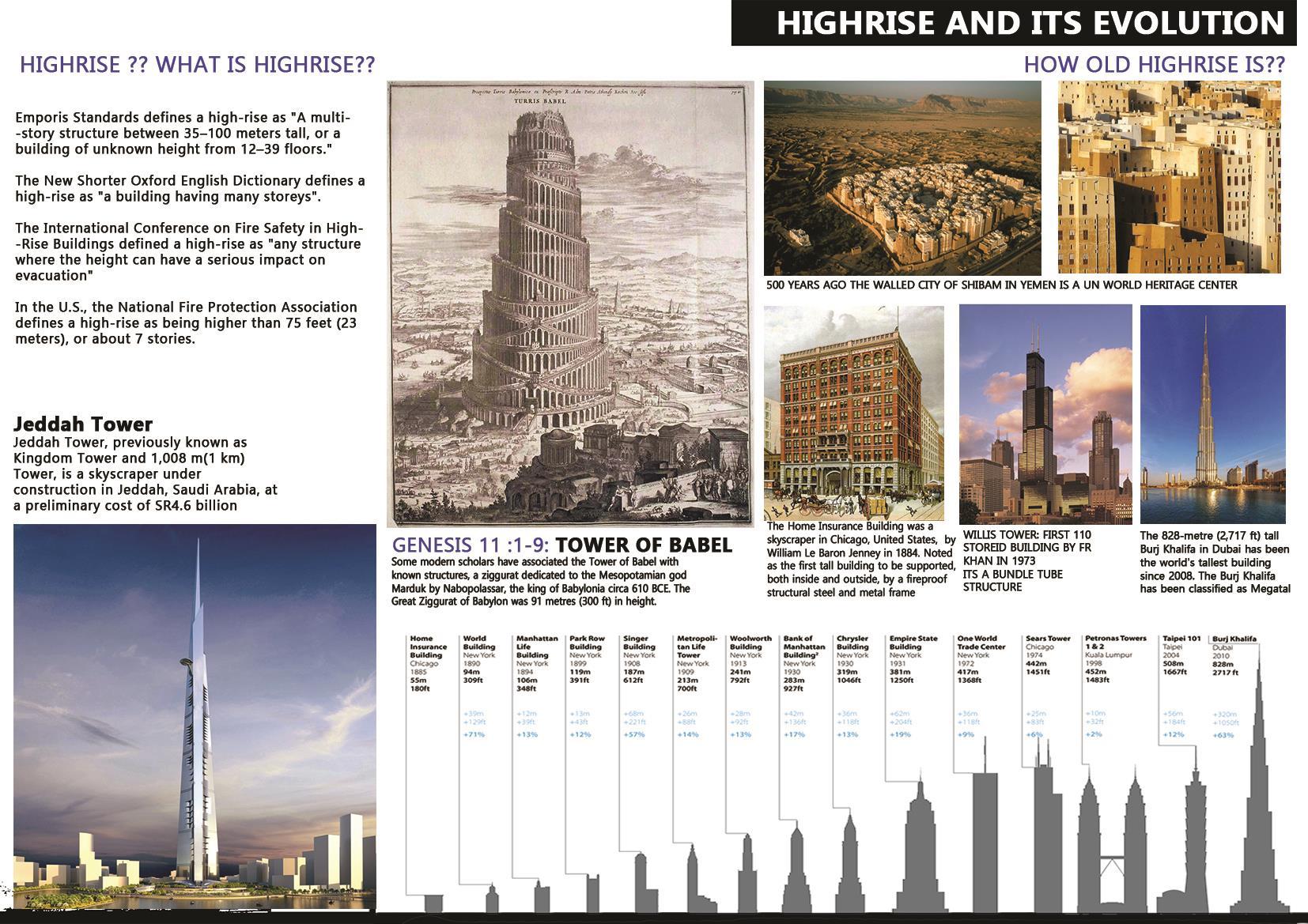

• EVOLUTION

• CORE

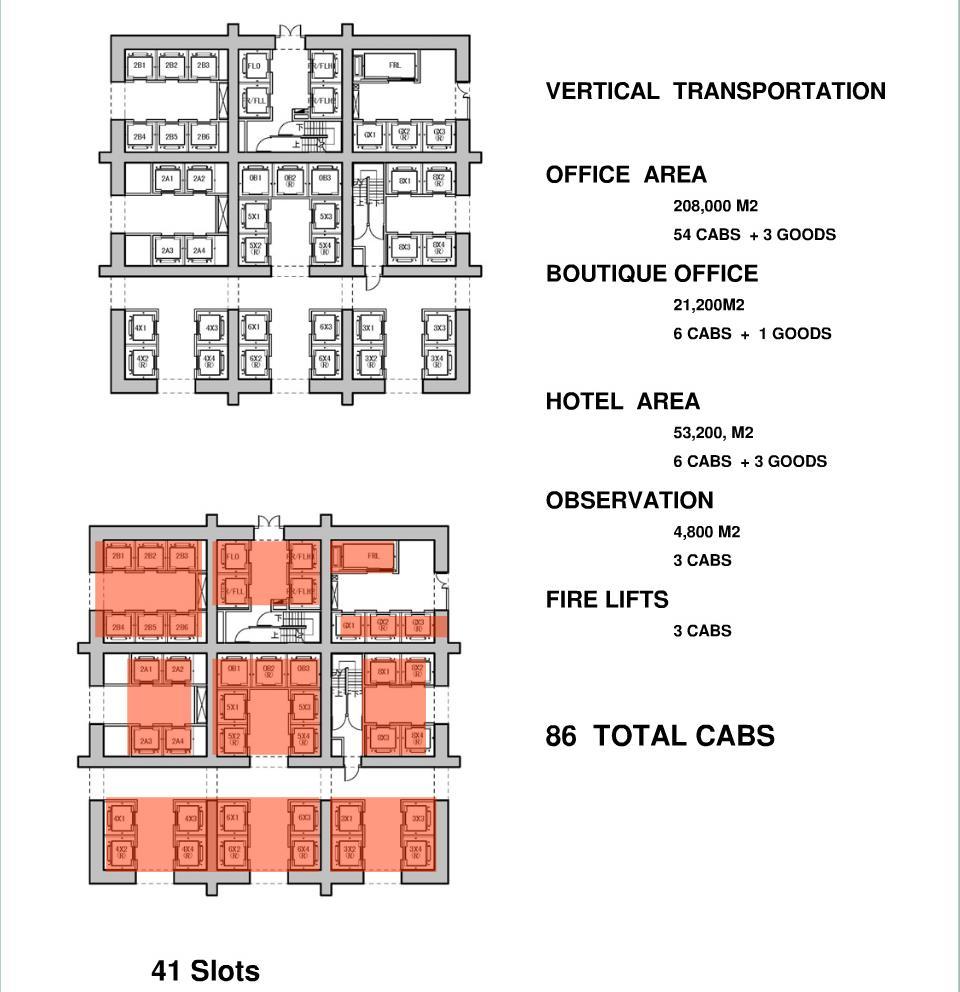

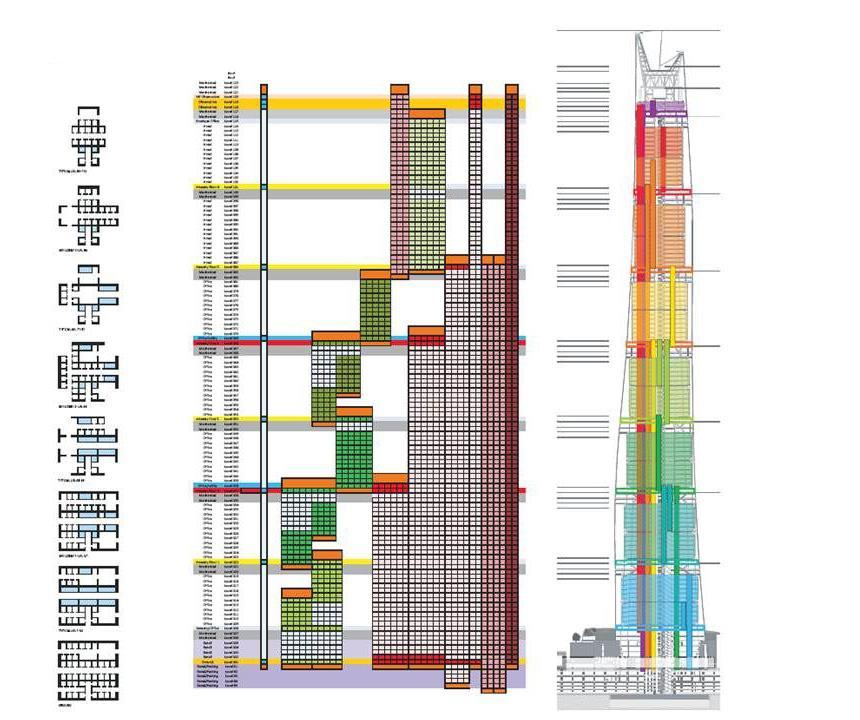

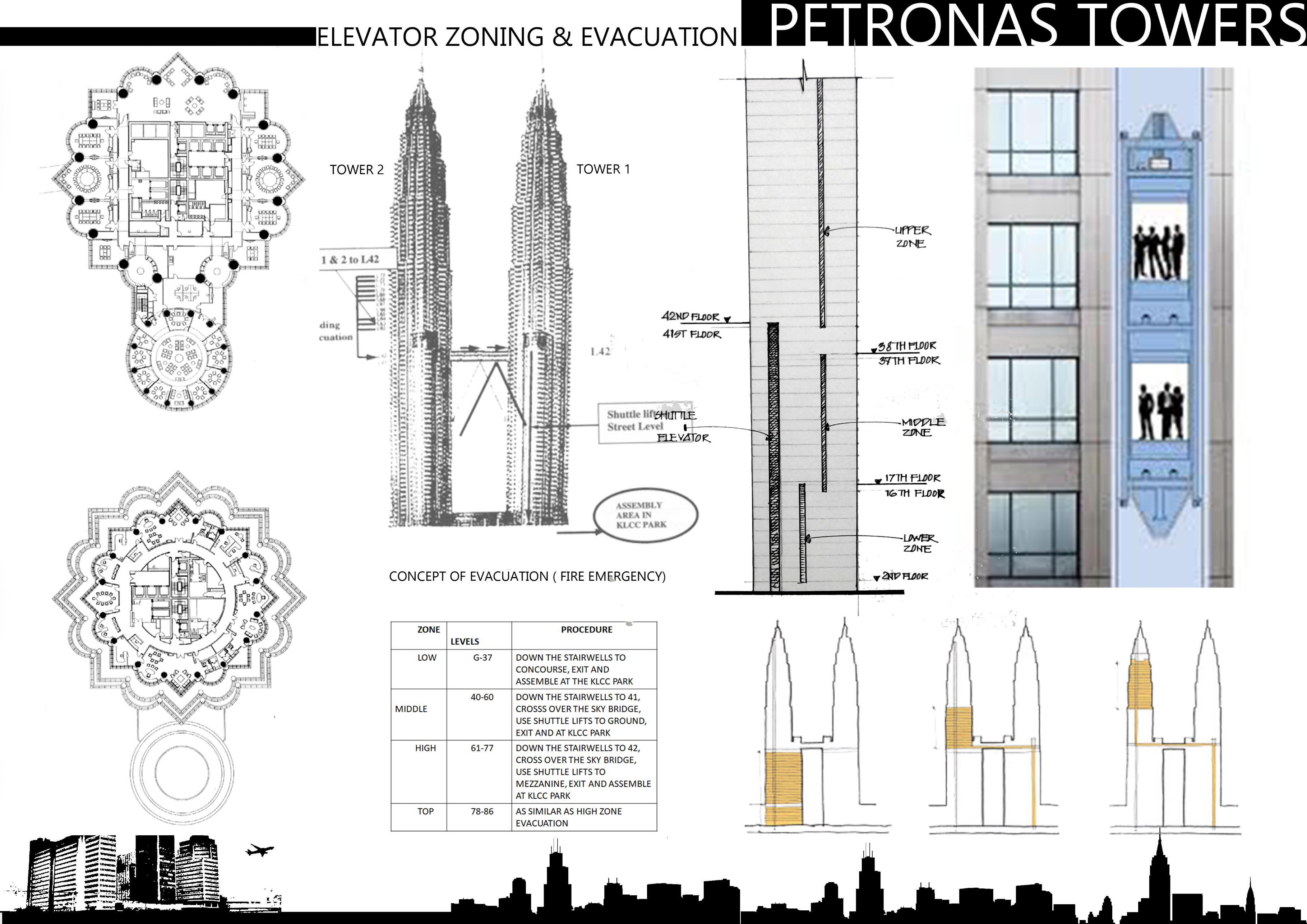

• ELEVATOR

• ESCALATOR

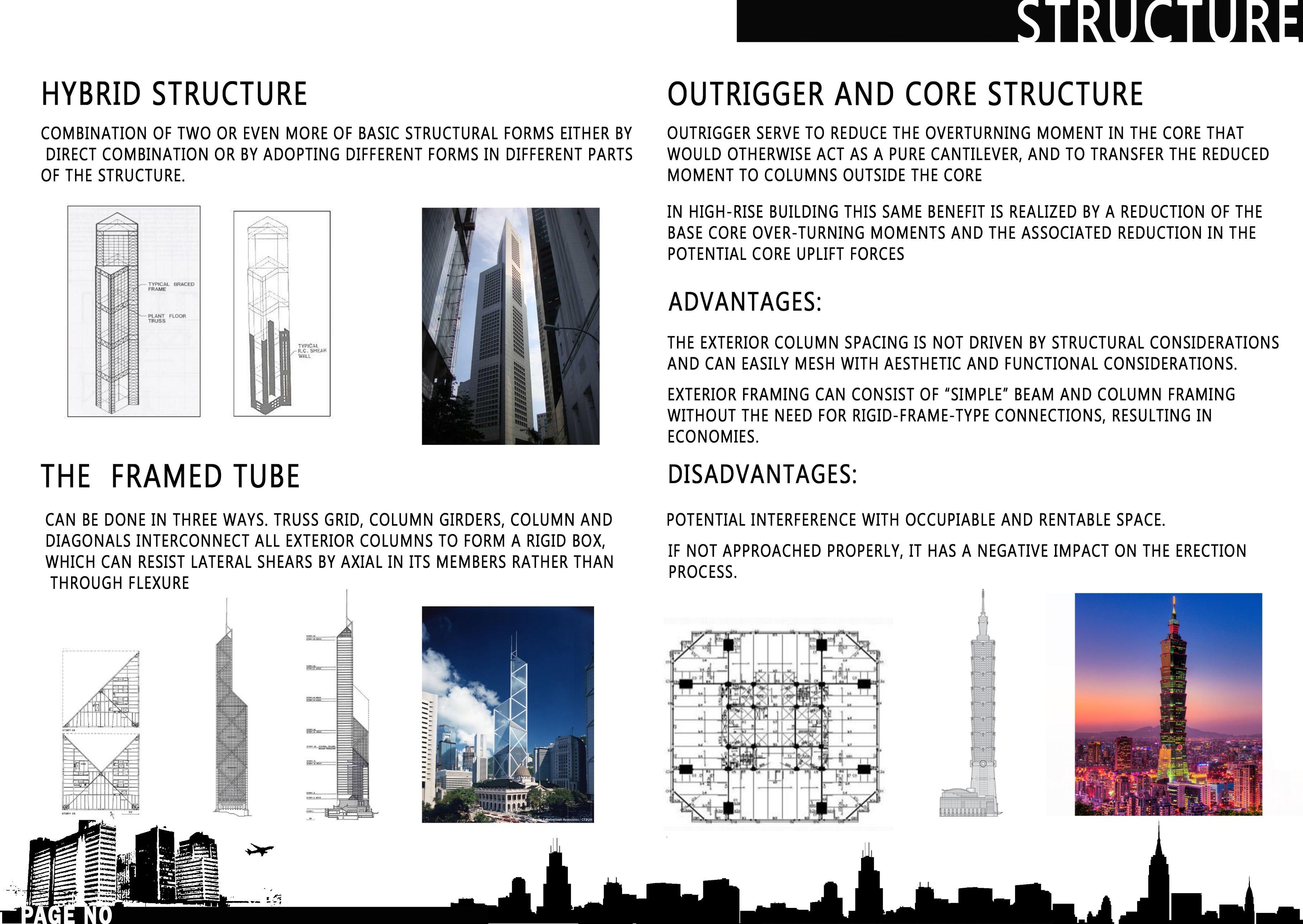

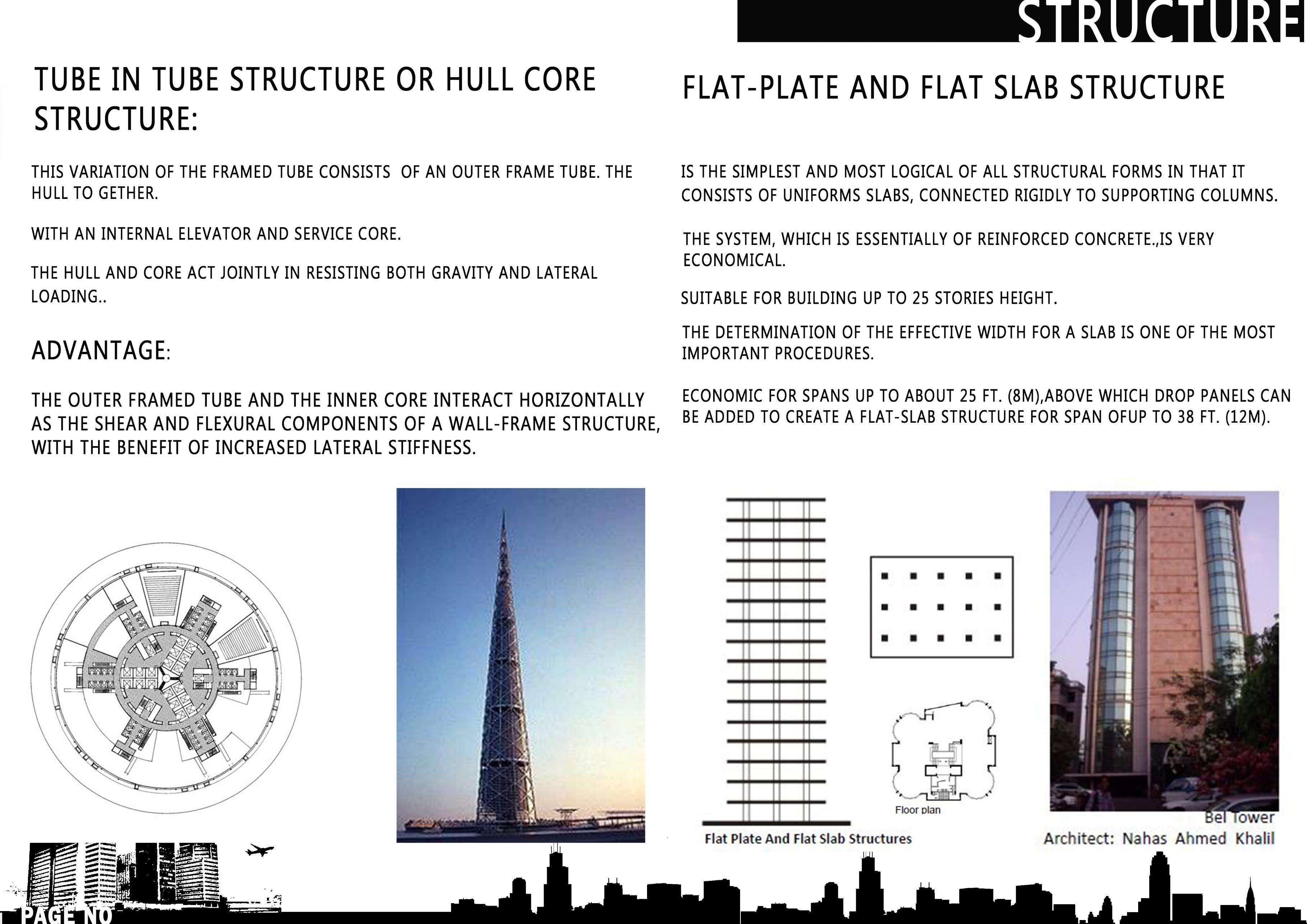

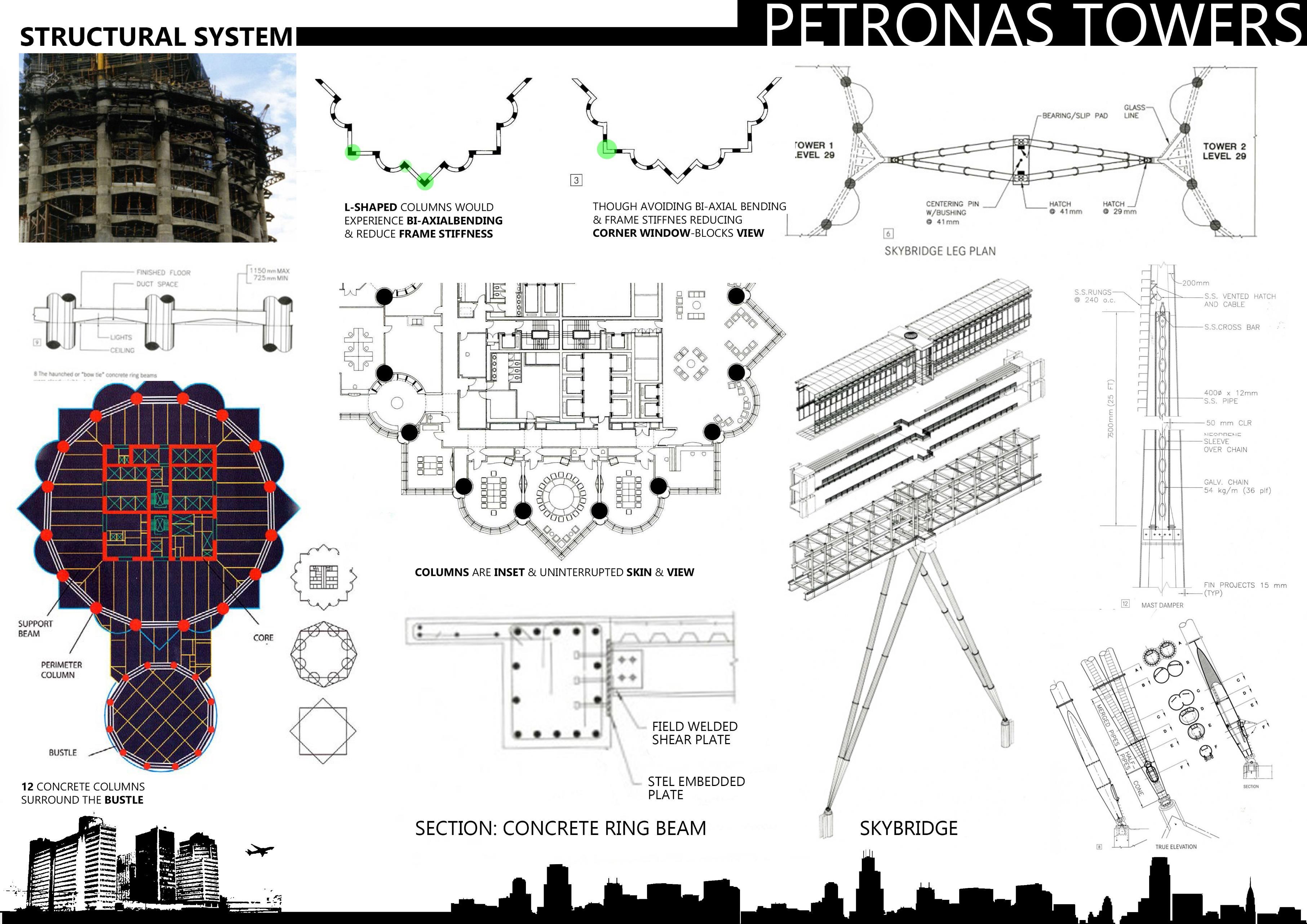

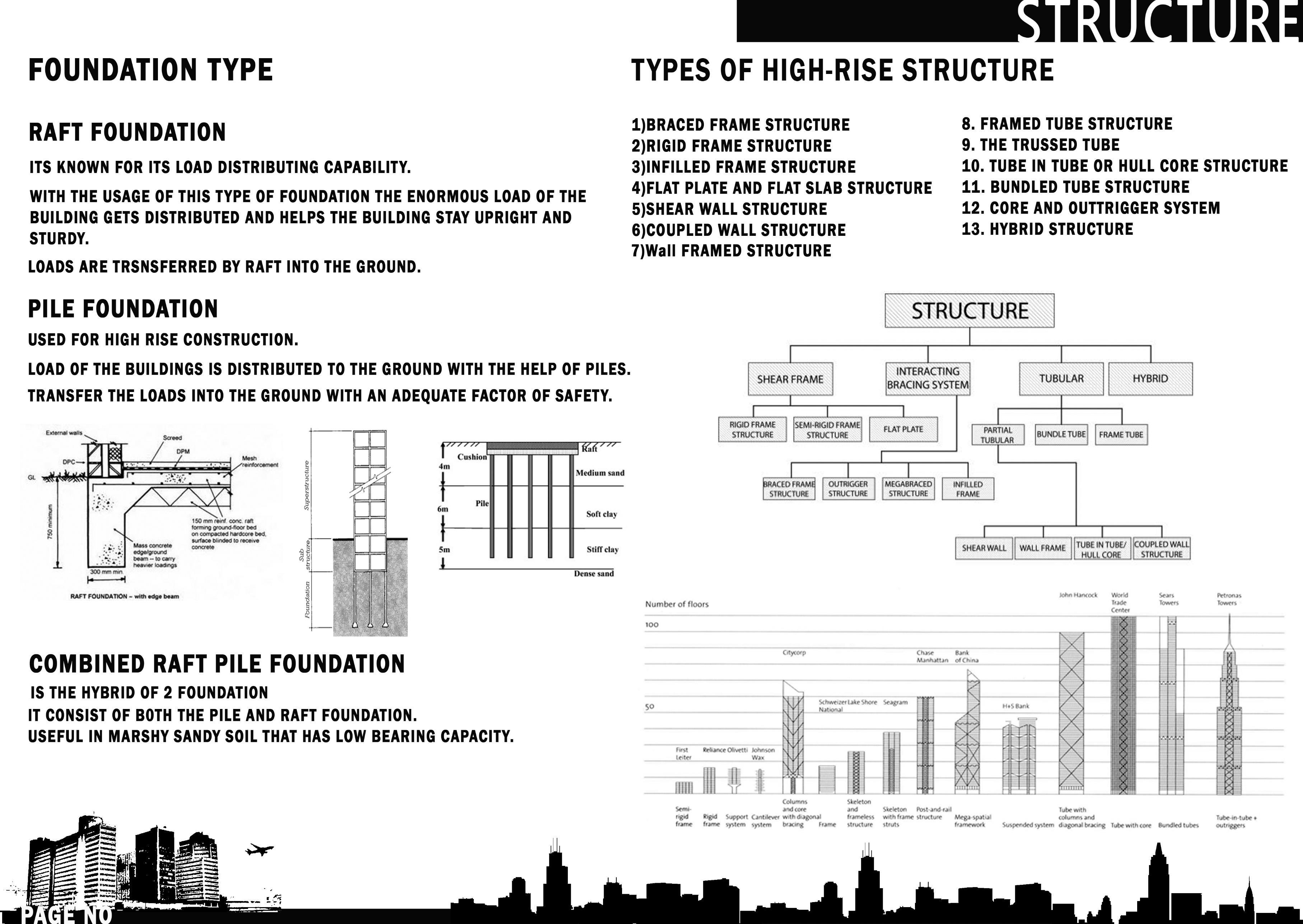

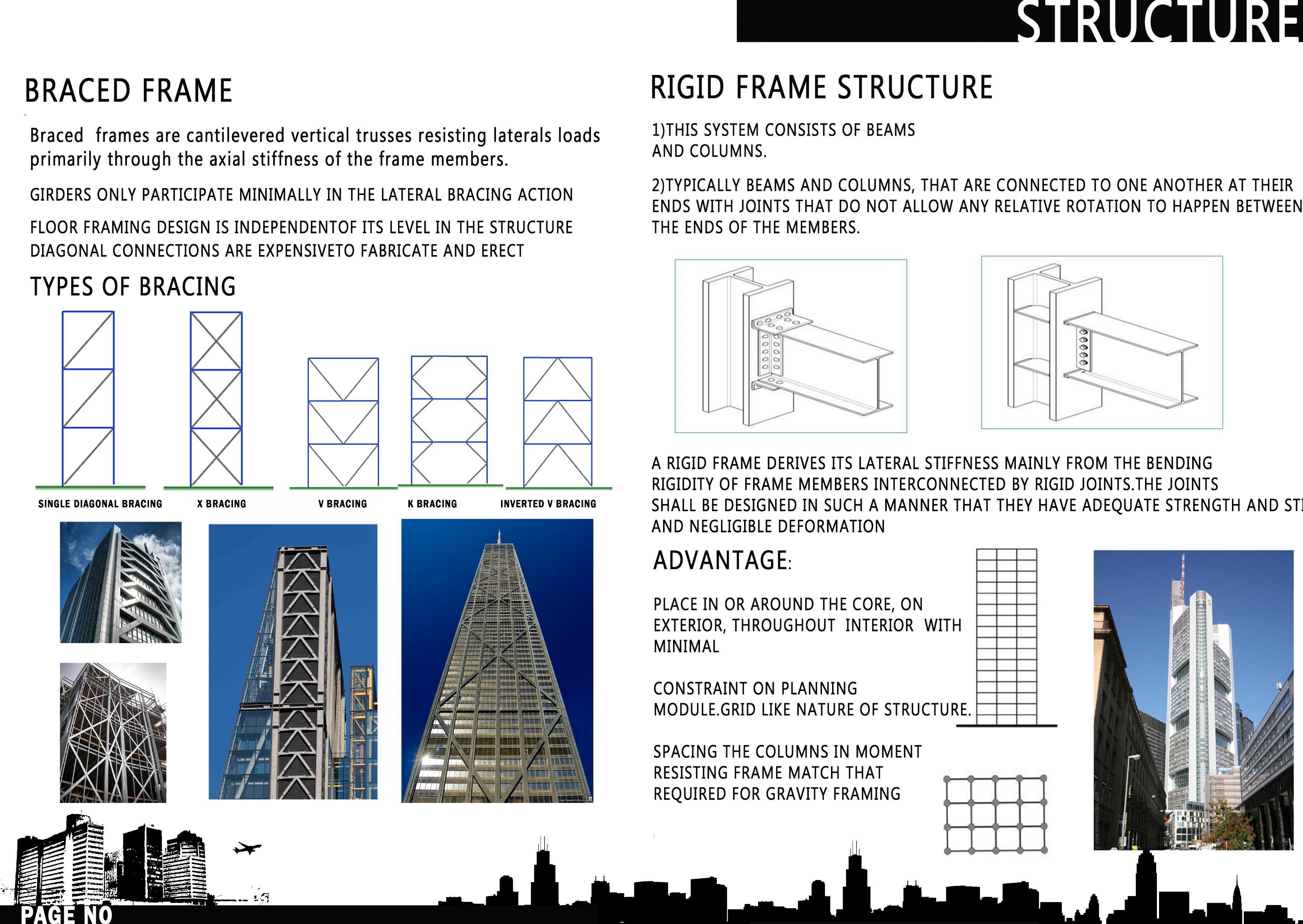

• STRUCTURE

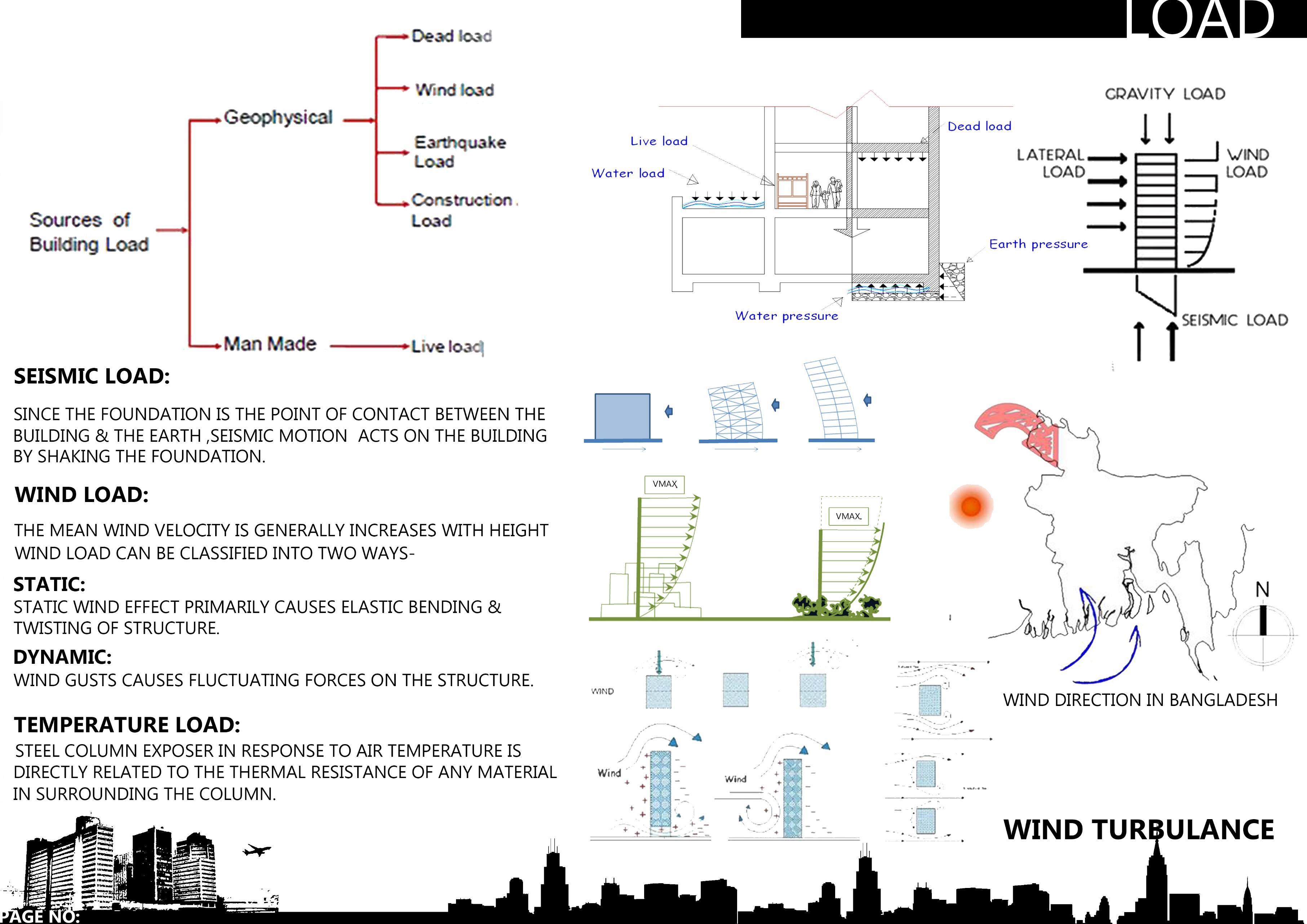

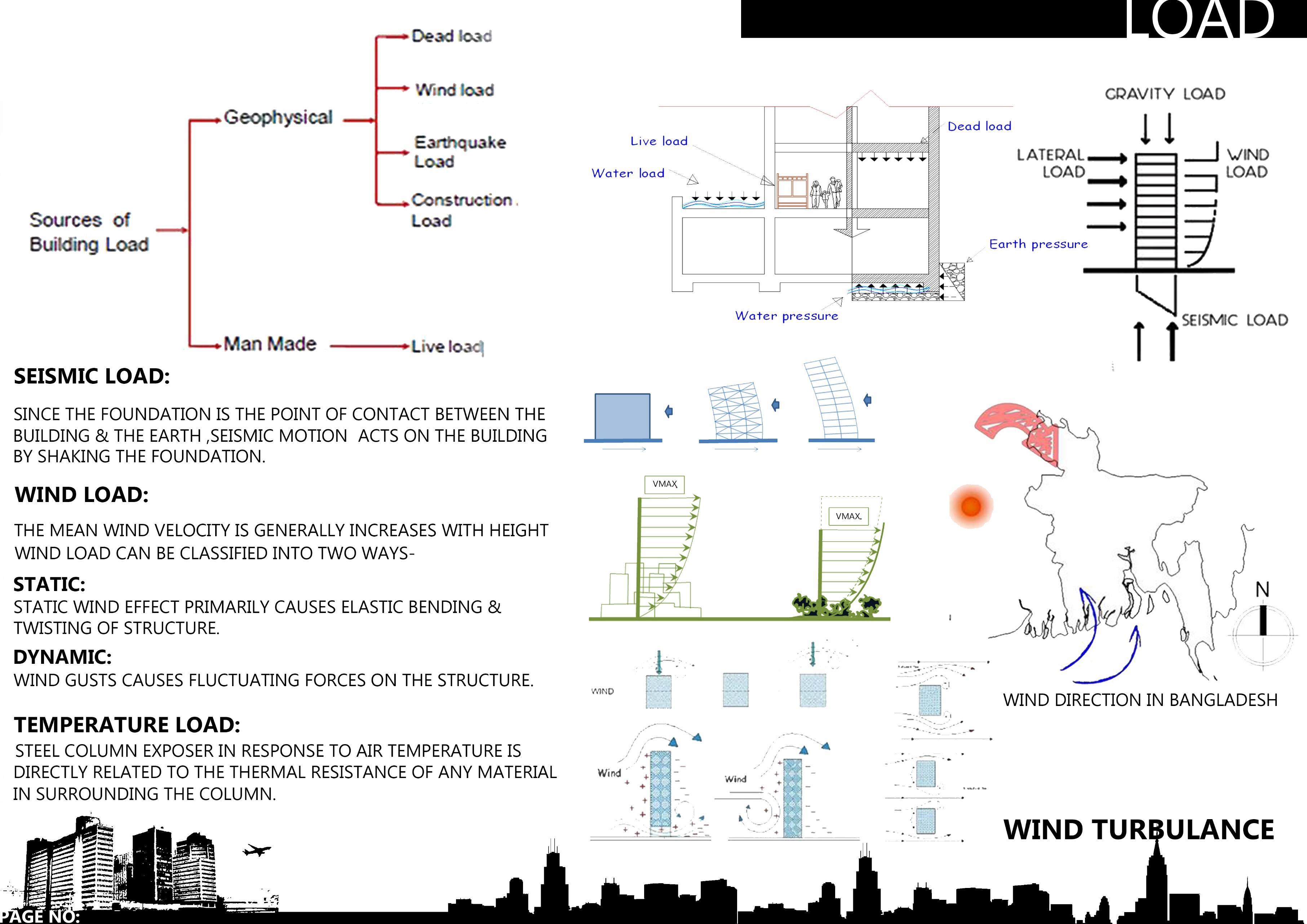

• LOAD

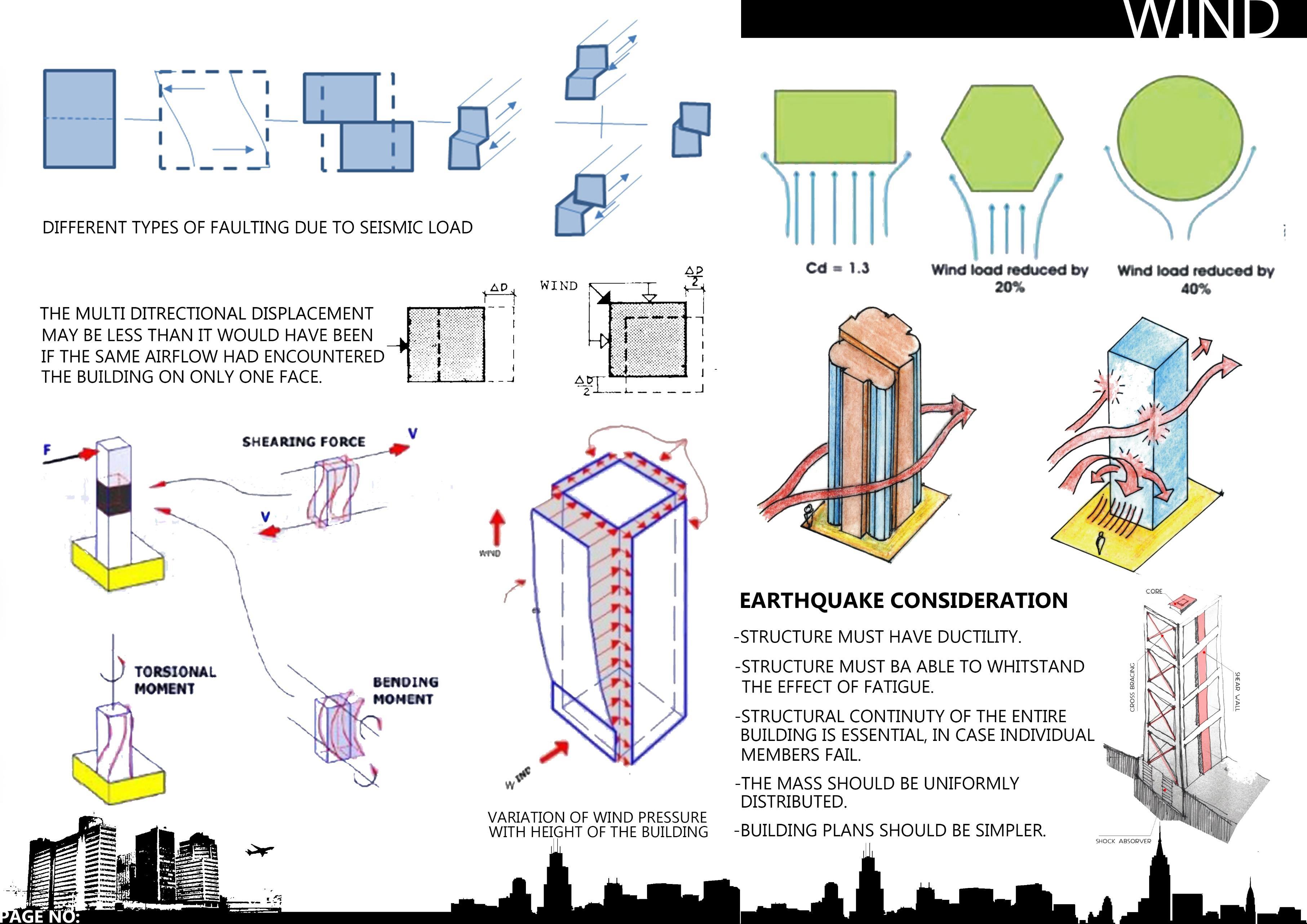

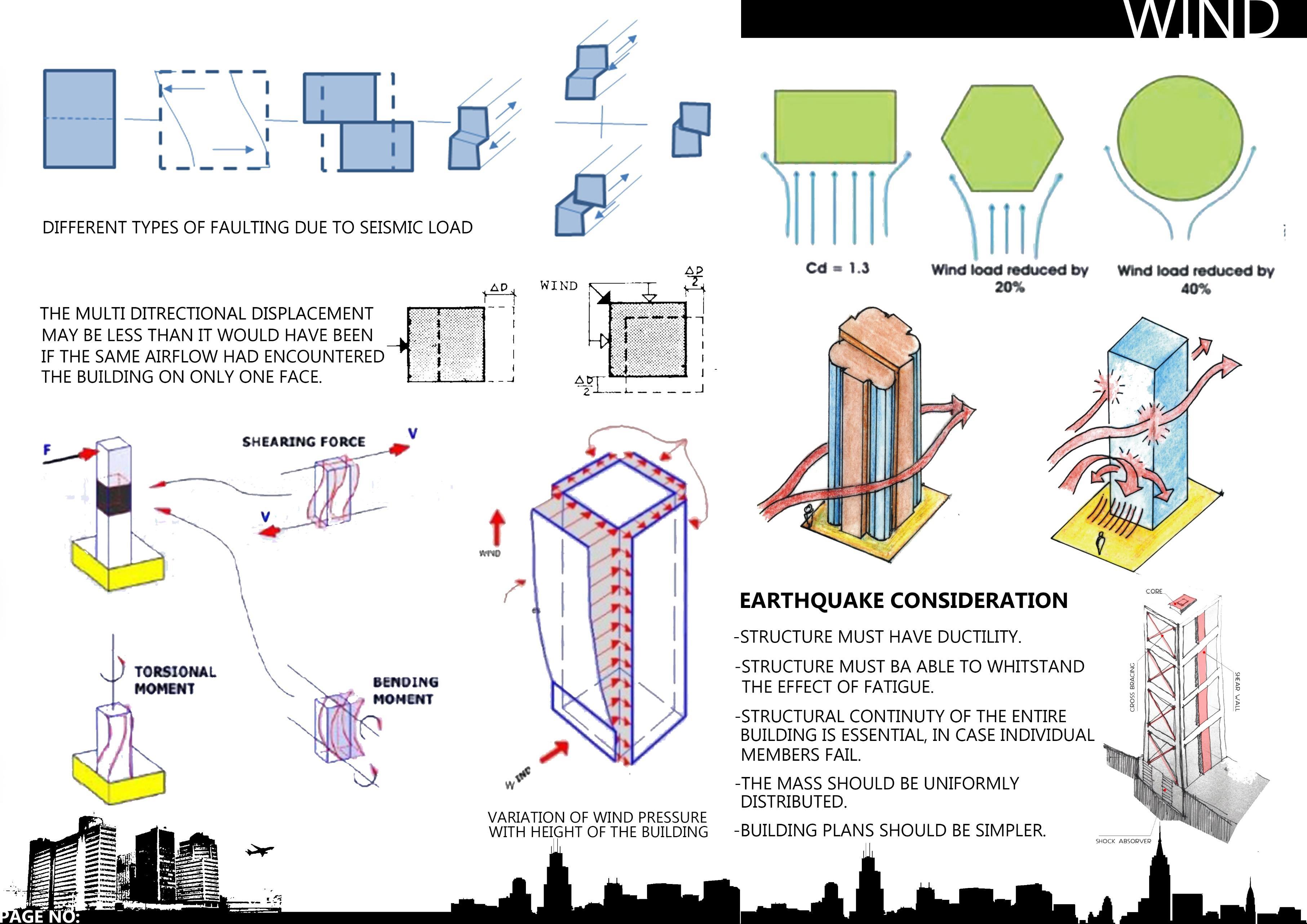

• WIND

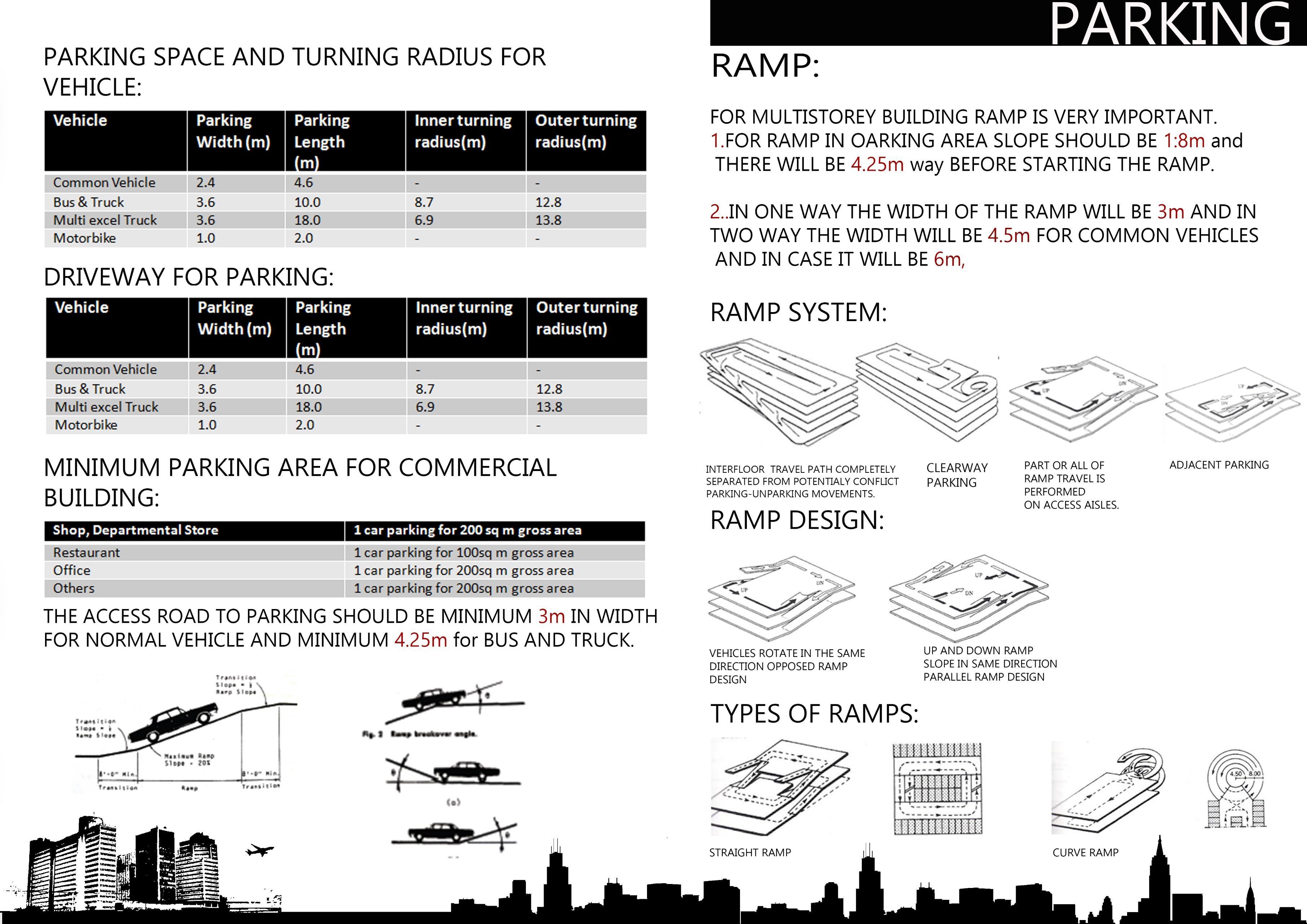

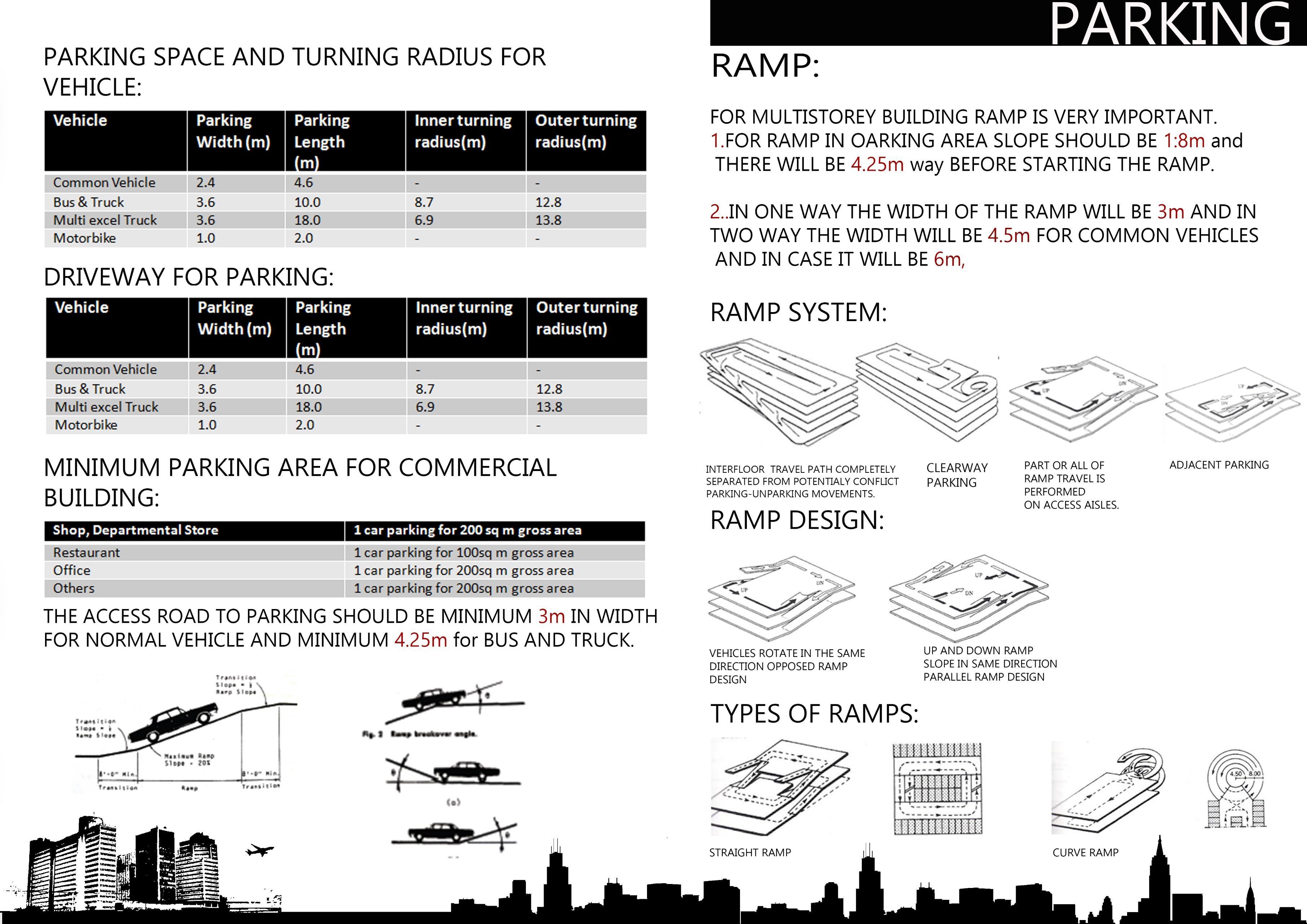

• PARKING

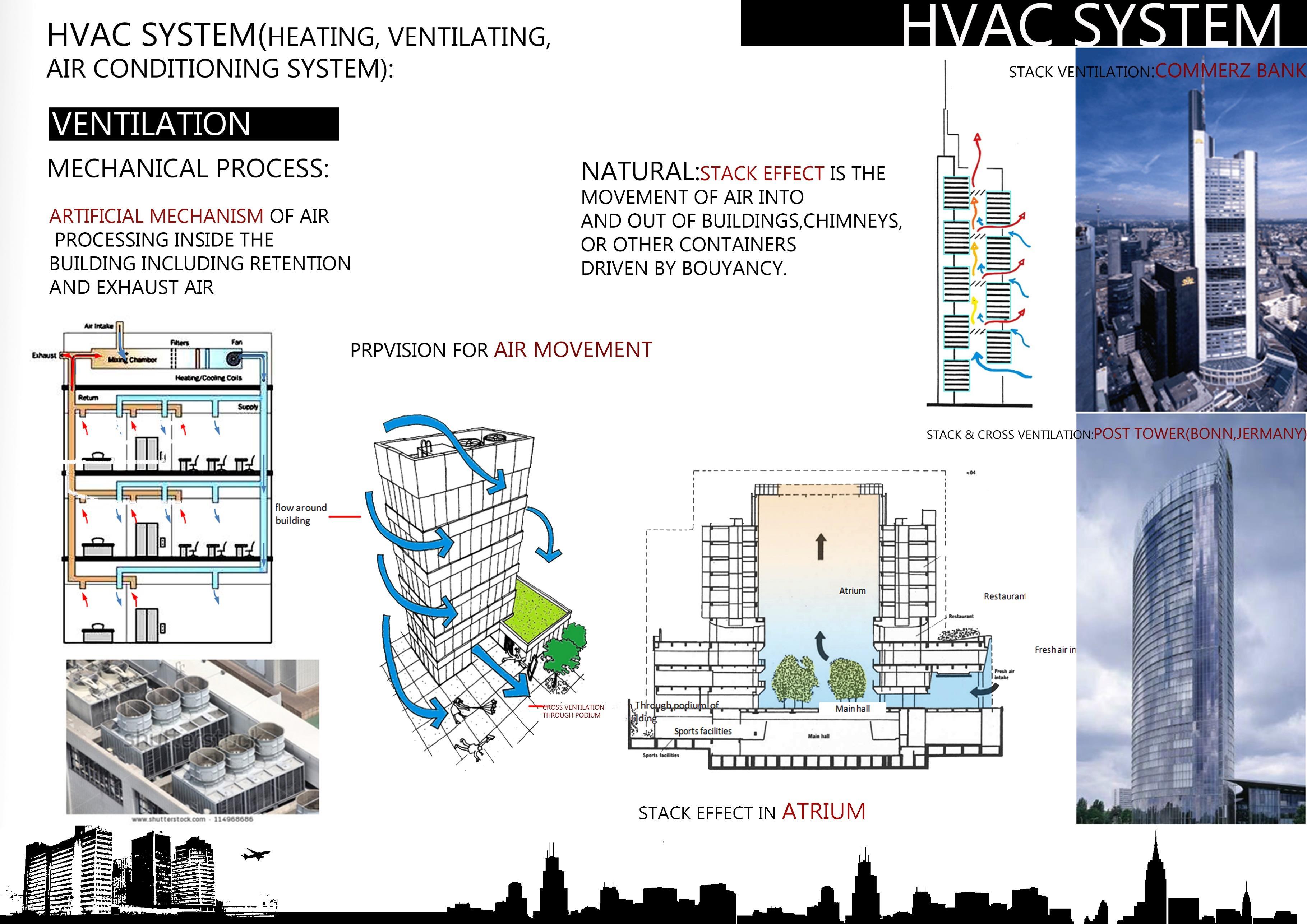

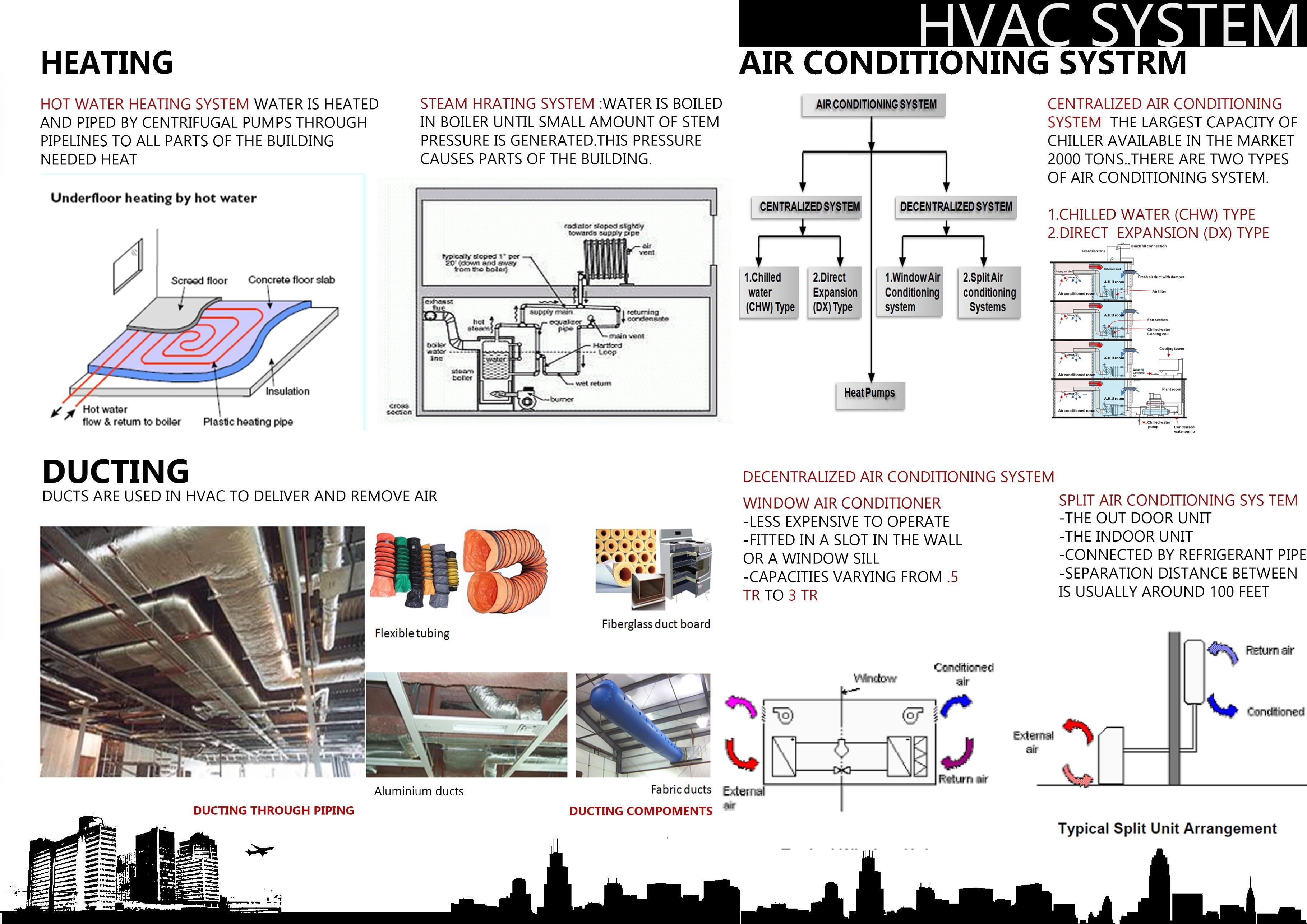

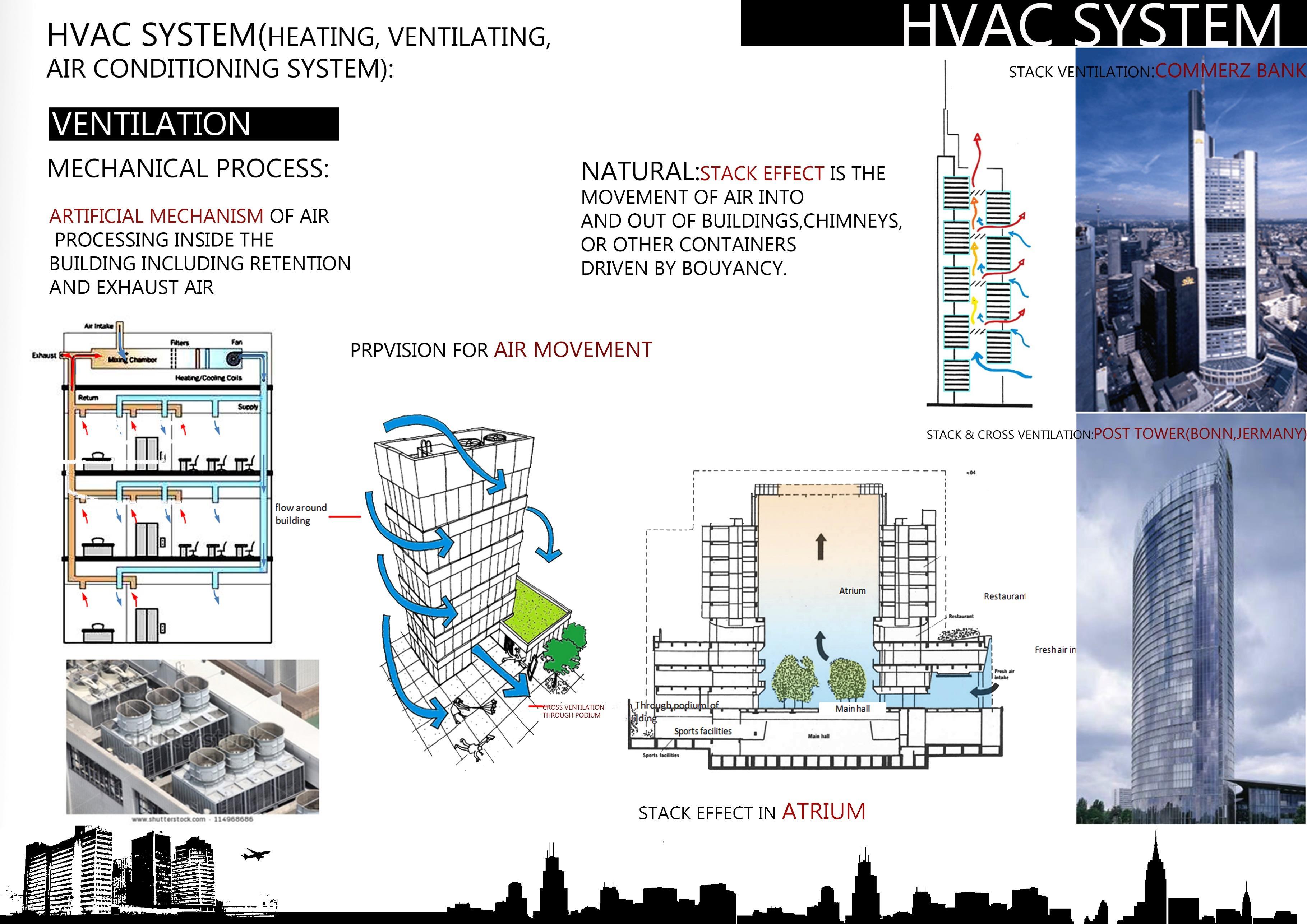

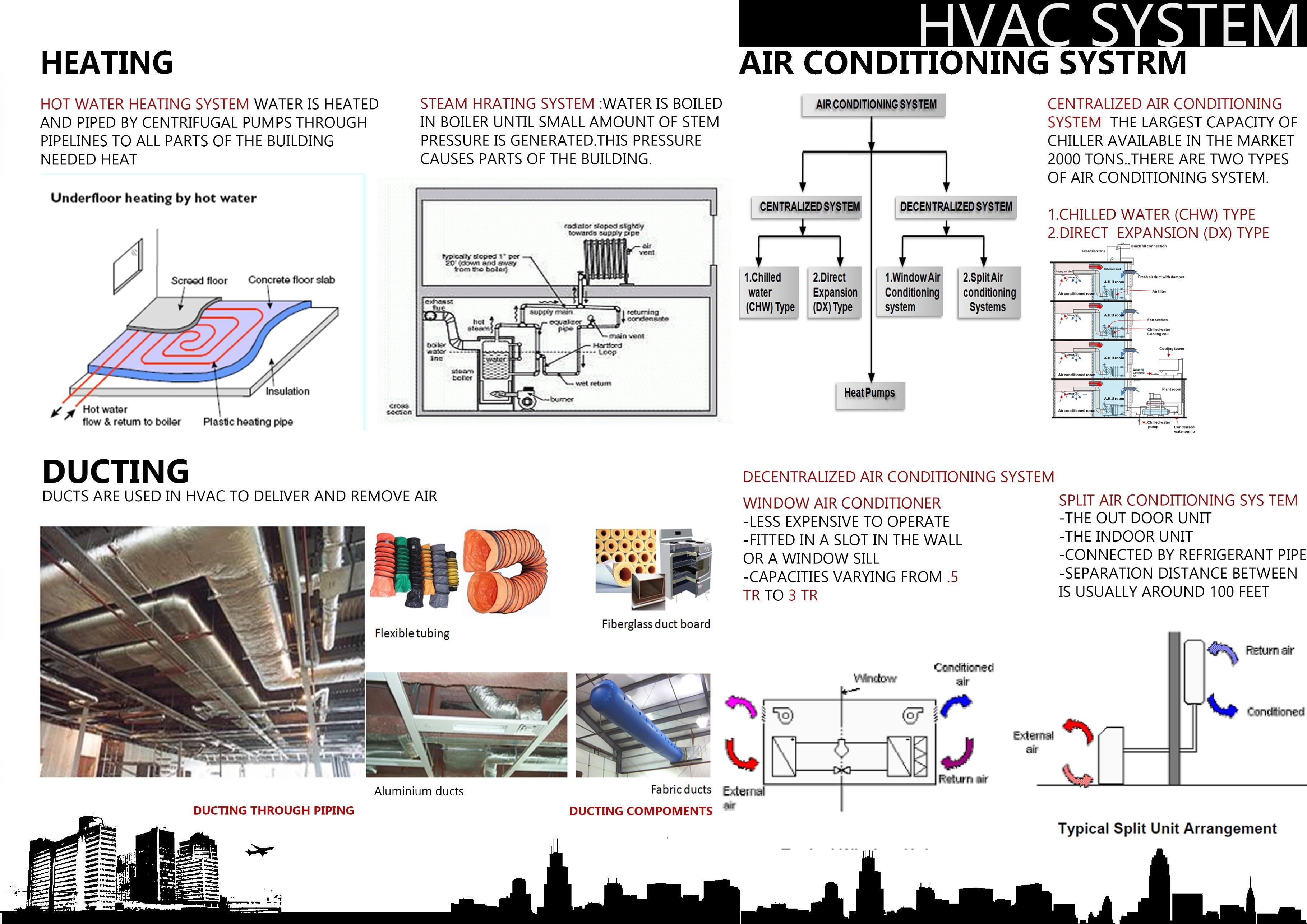

• HVAC SYSTEM

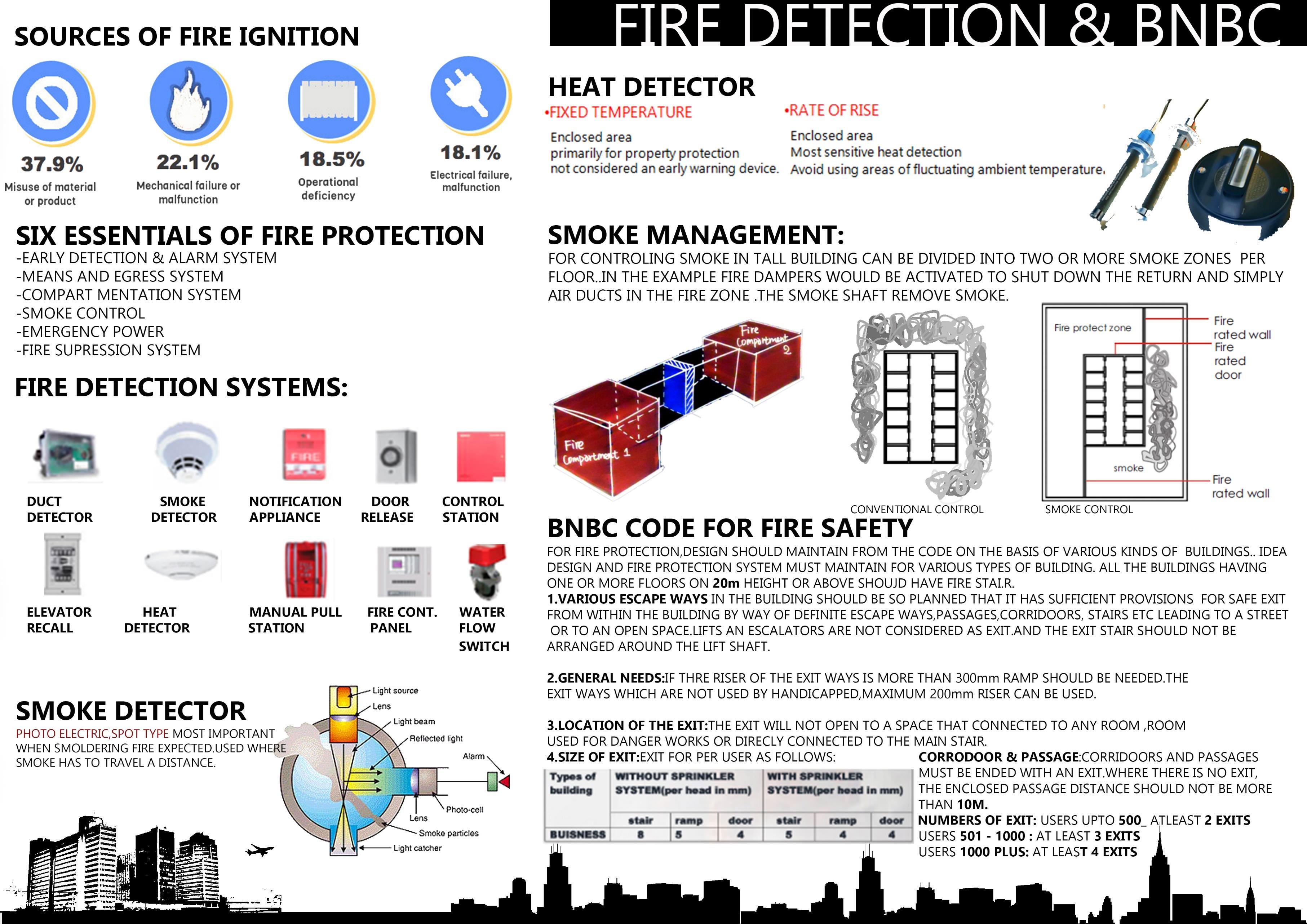

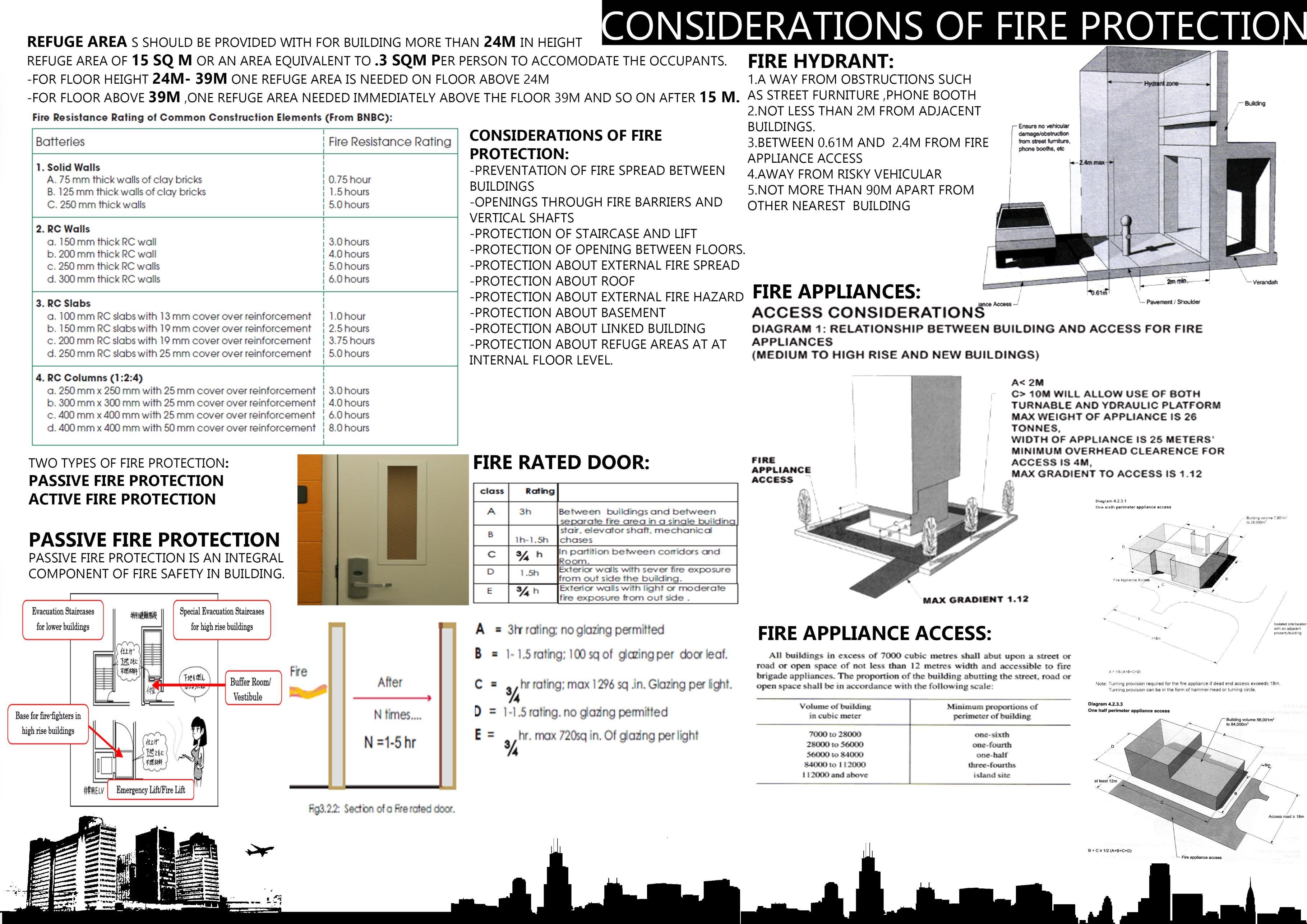

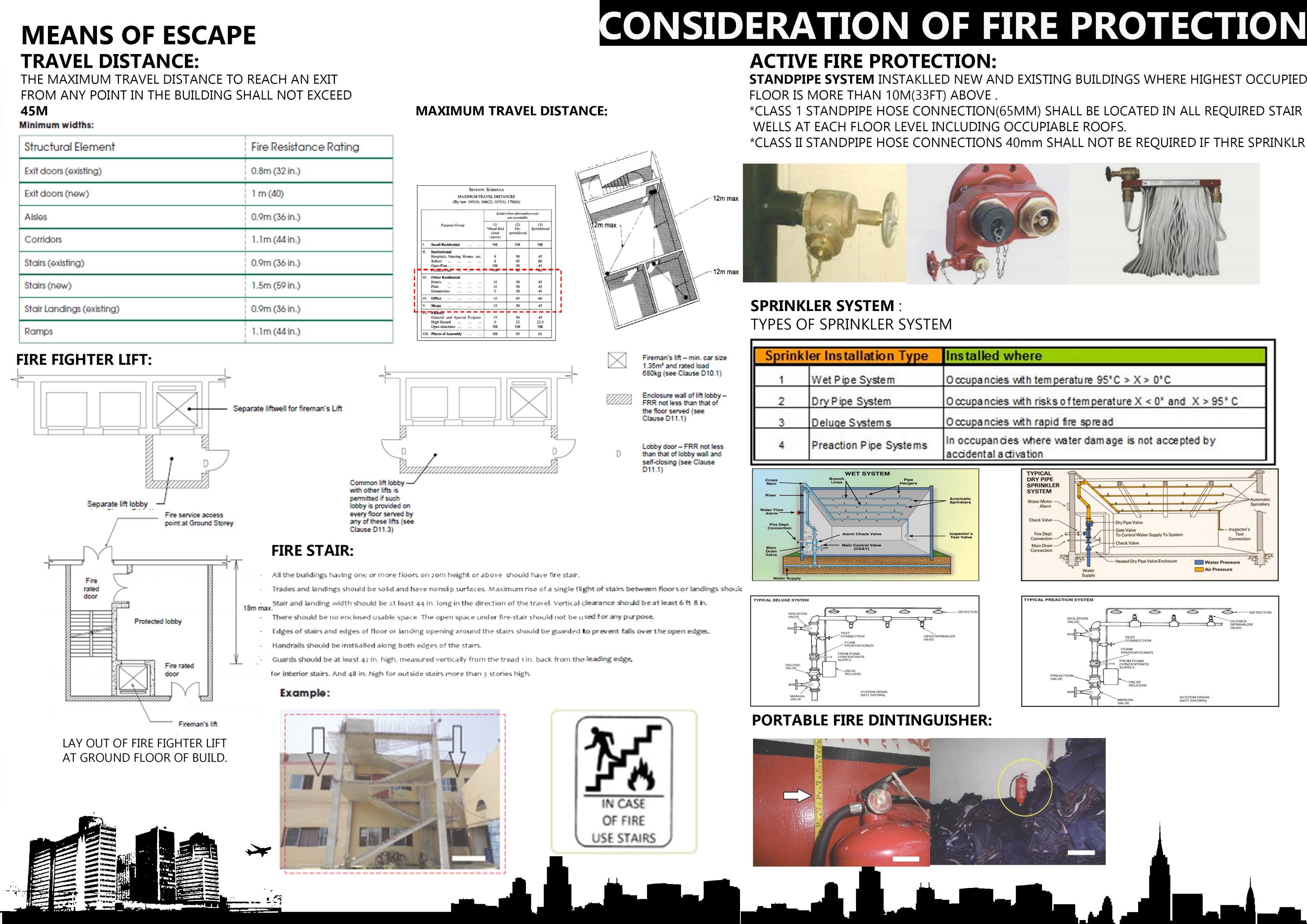

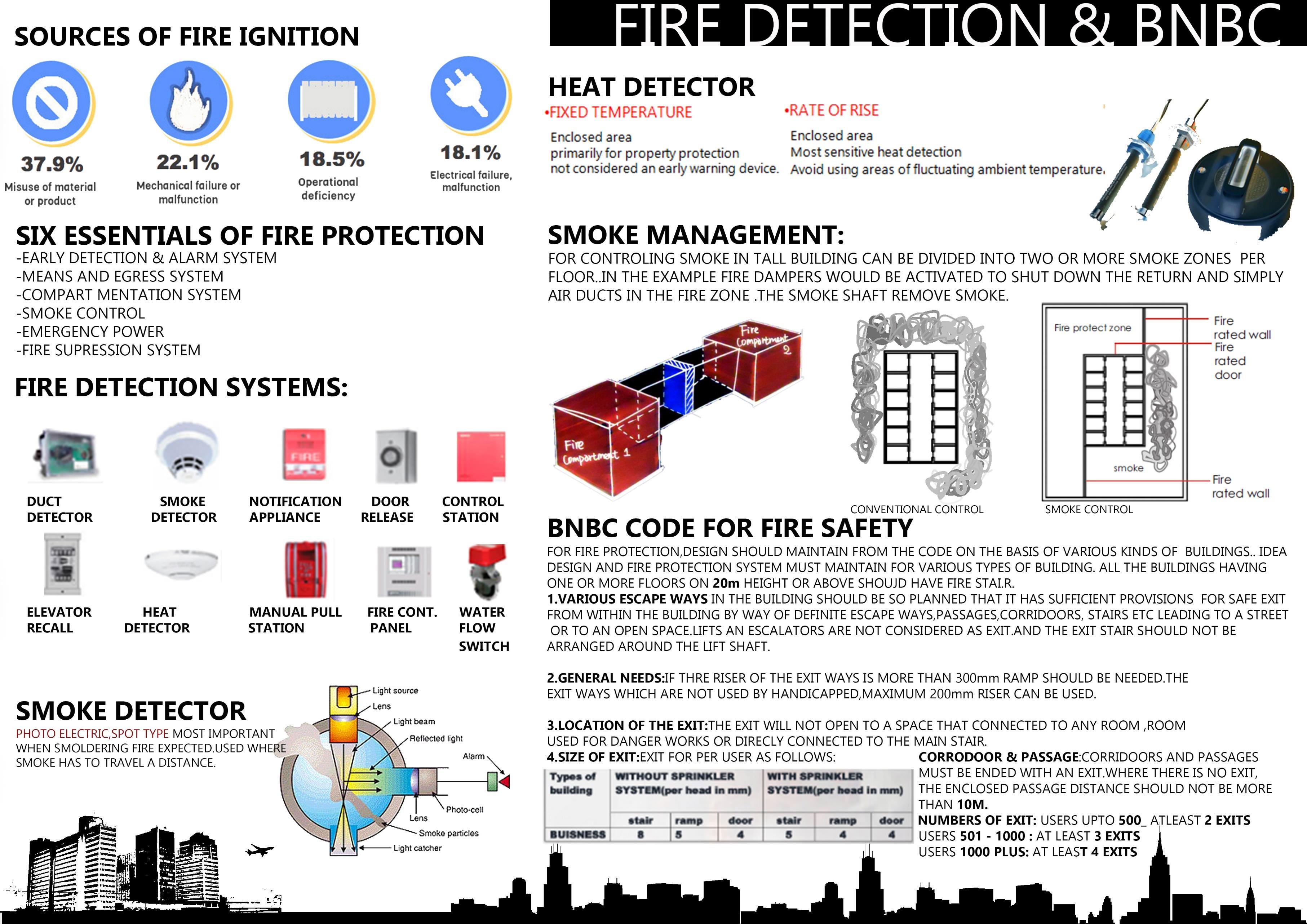

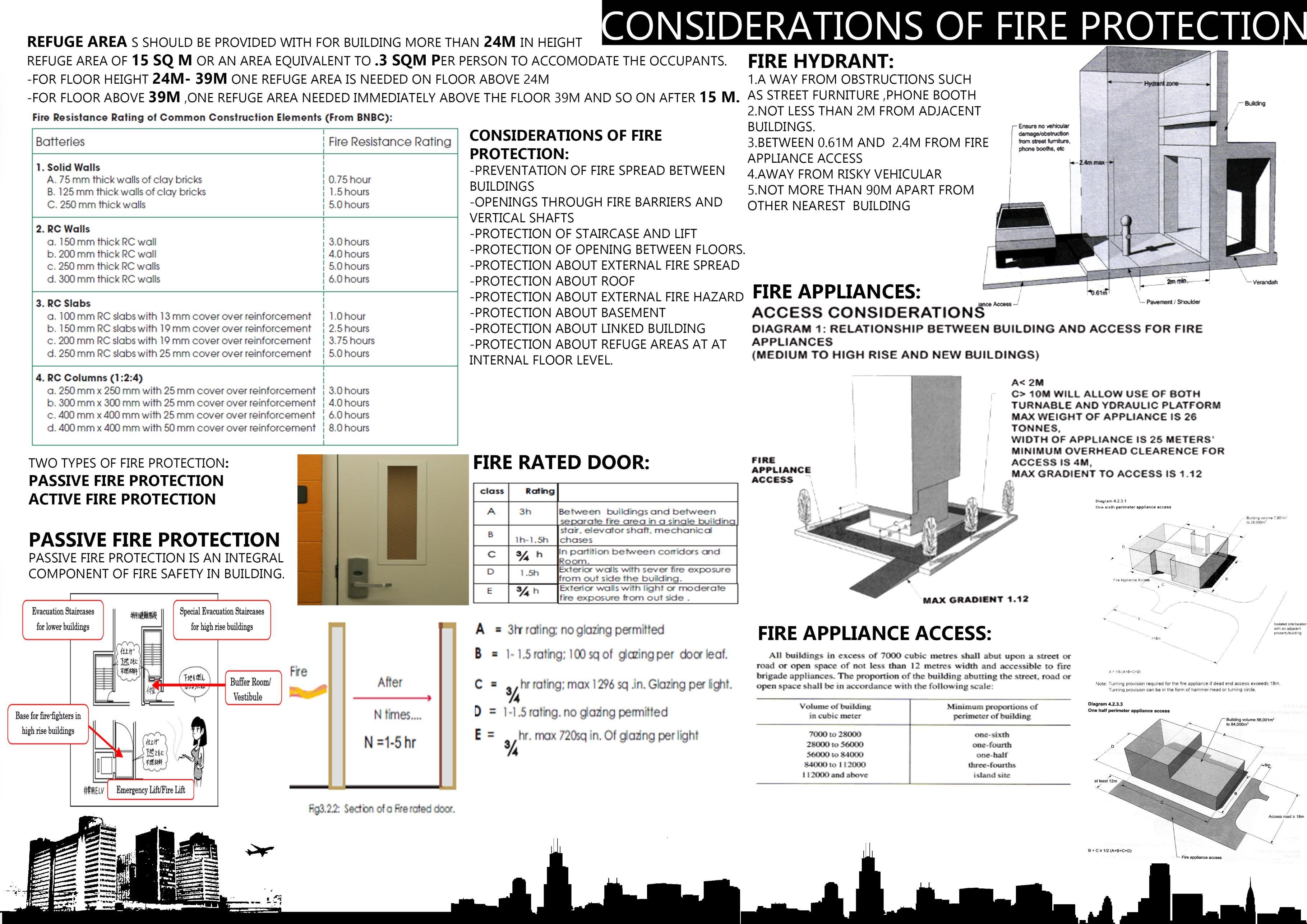

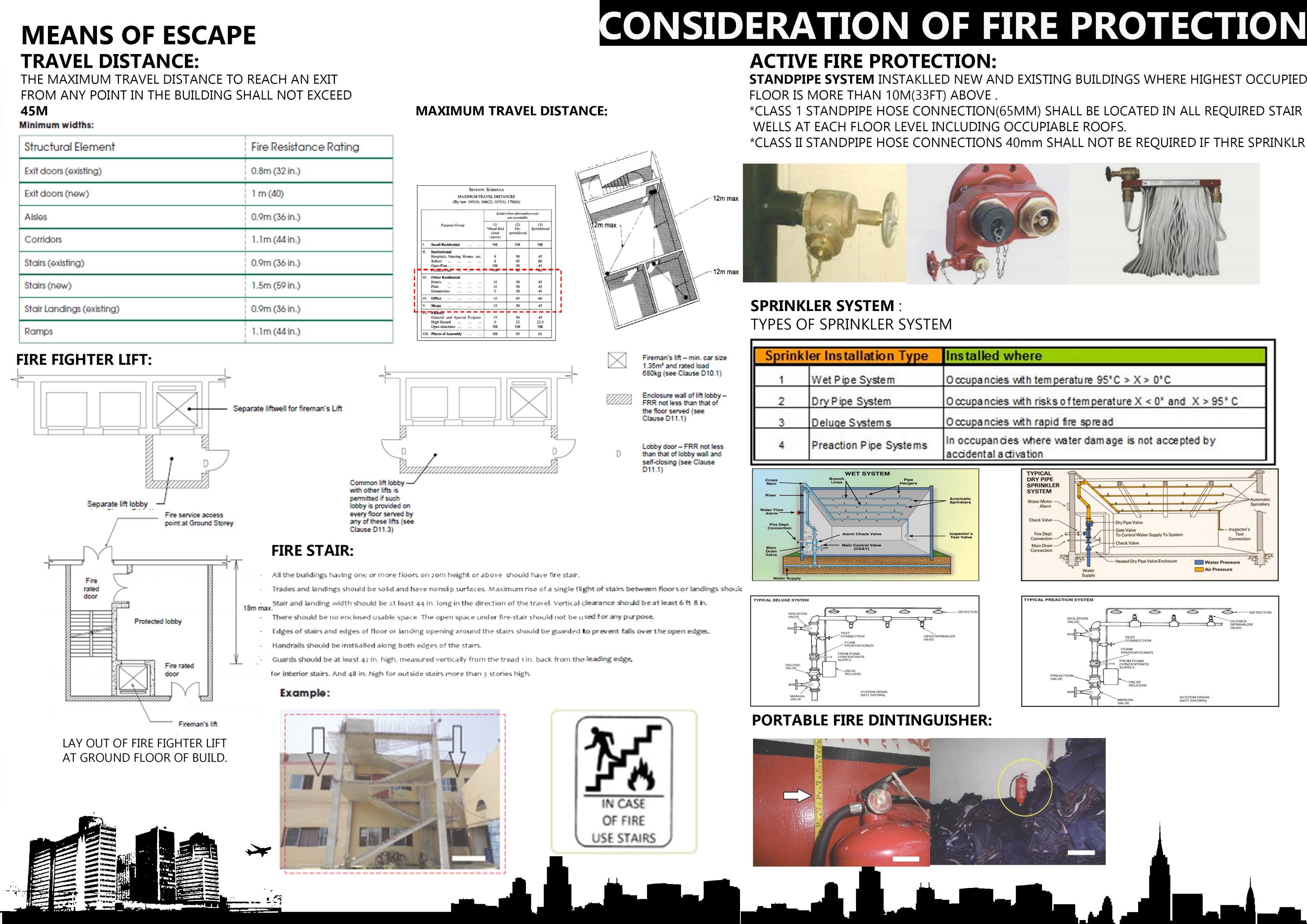

• FIRE DETECTION AND BNBC

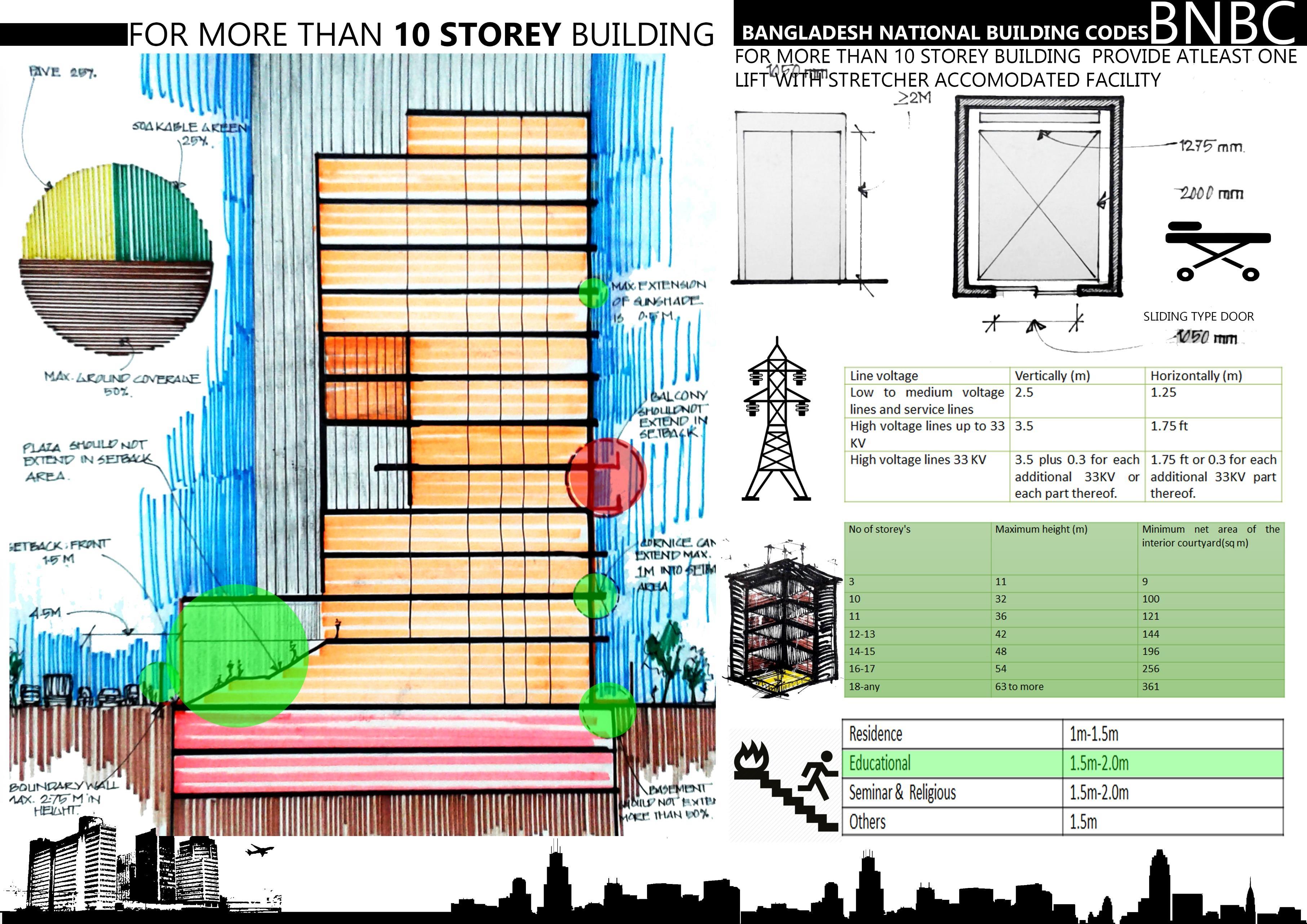

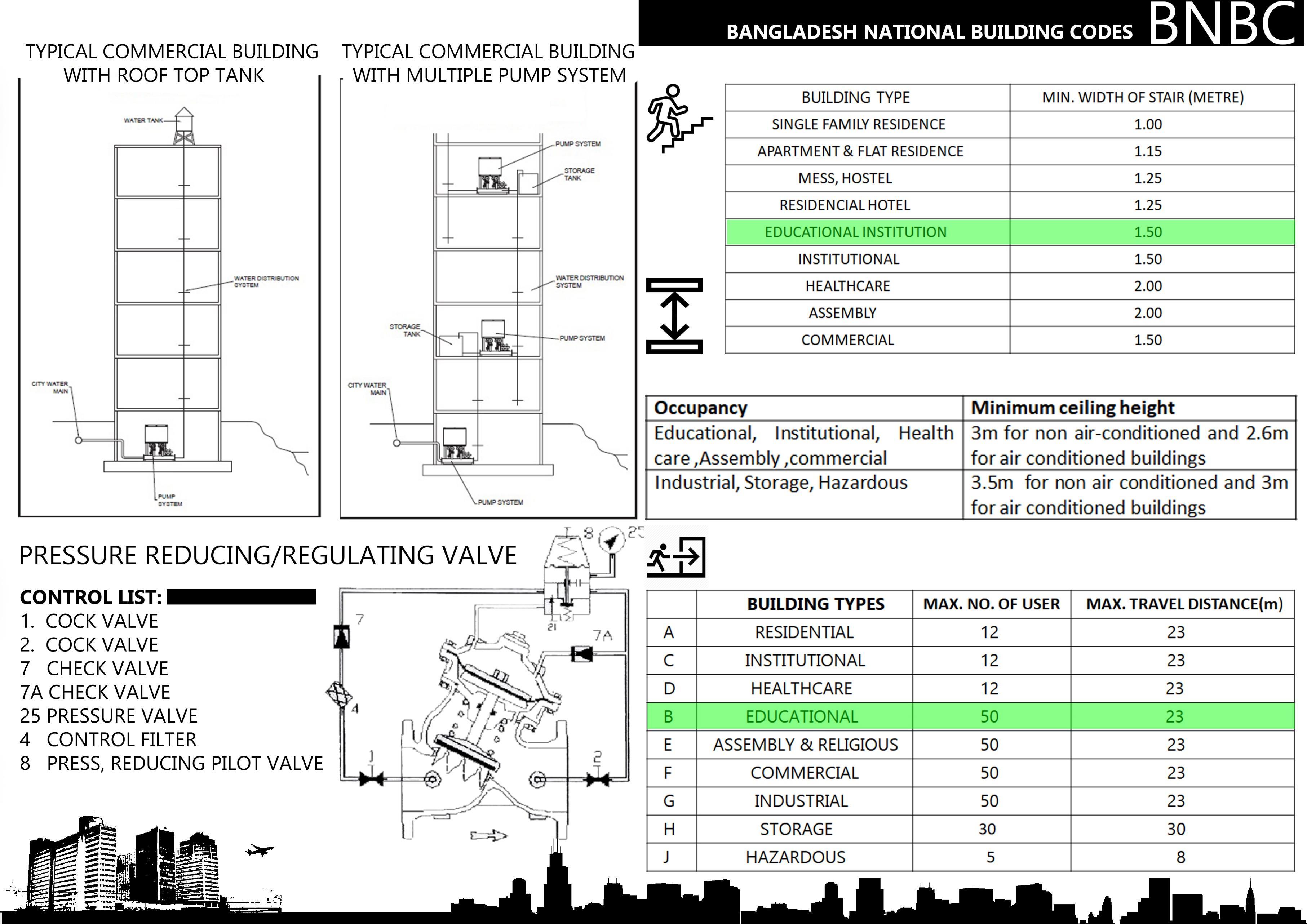

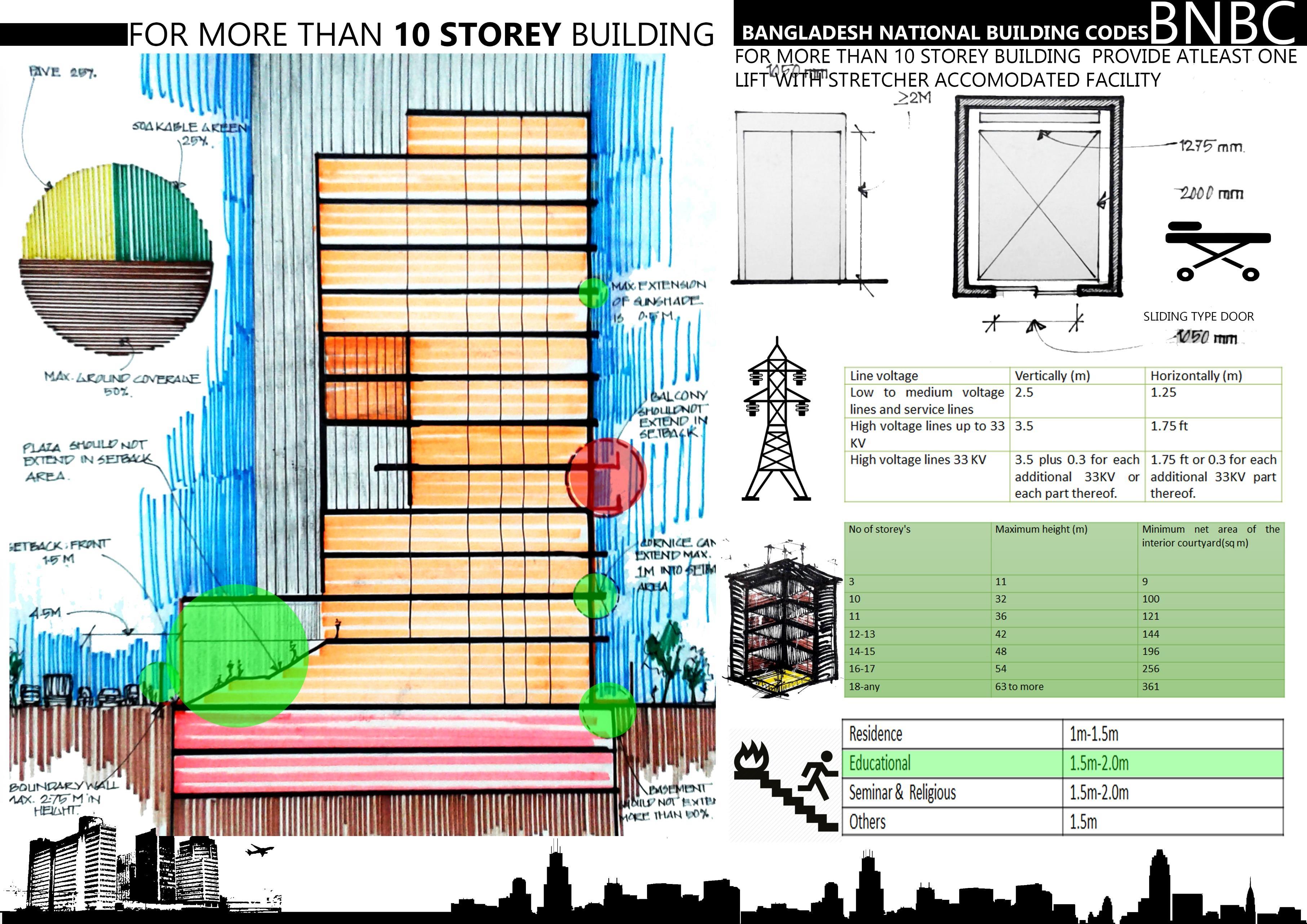

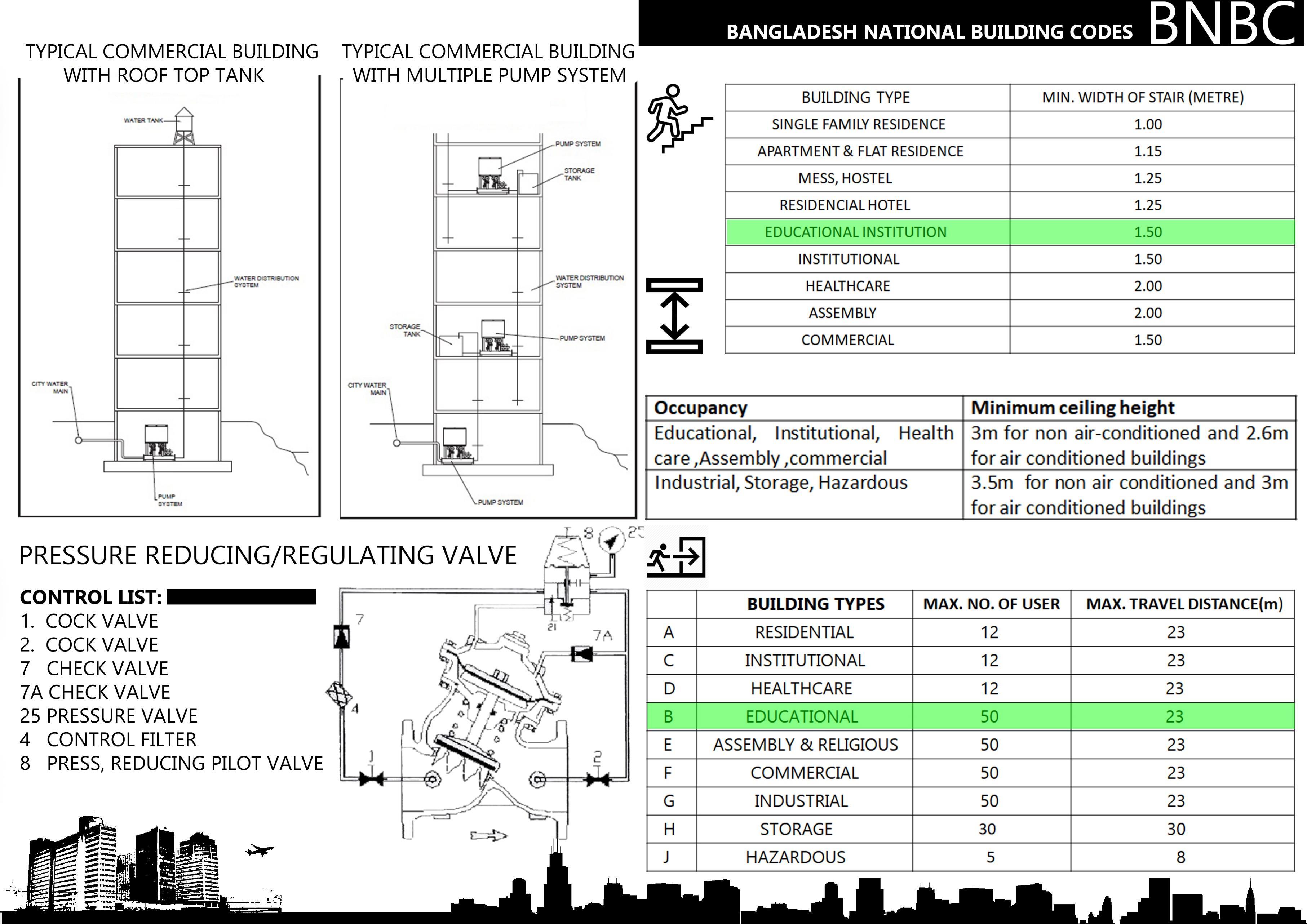

• BNBC

• CASE STUDY

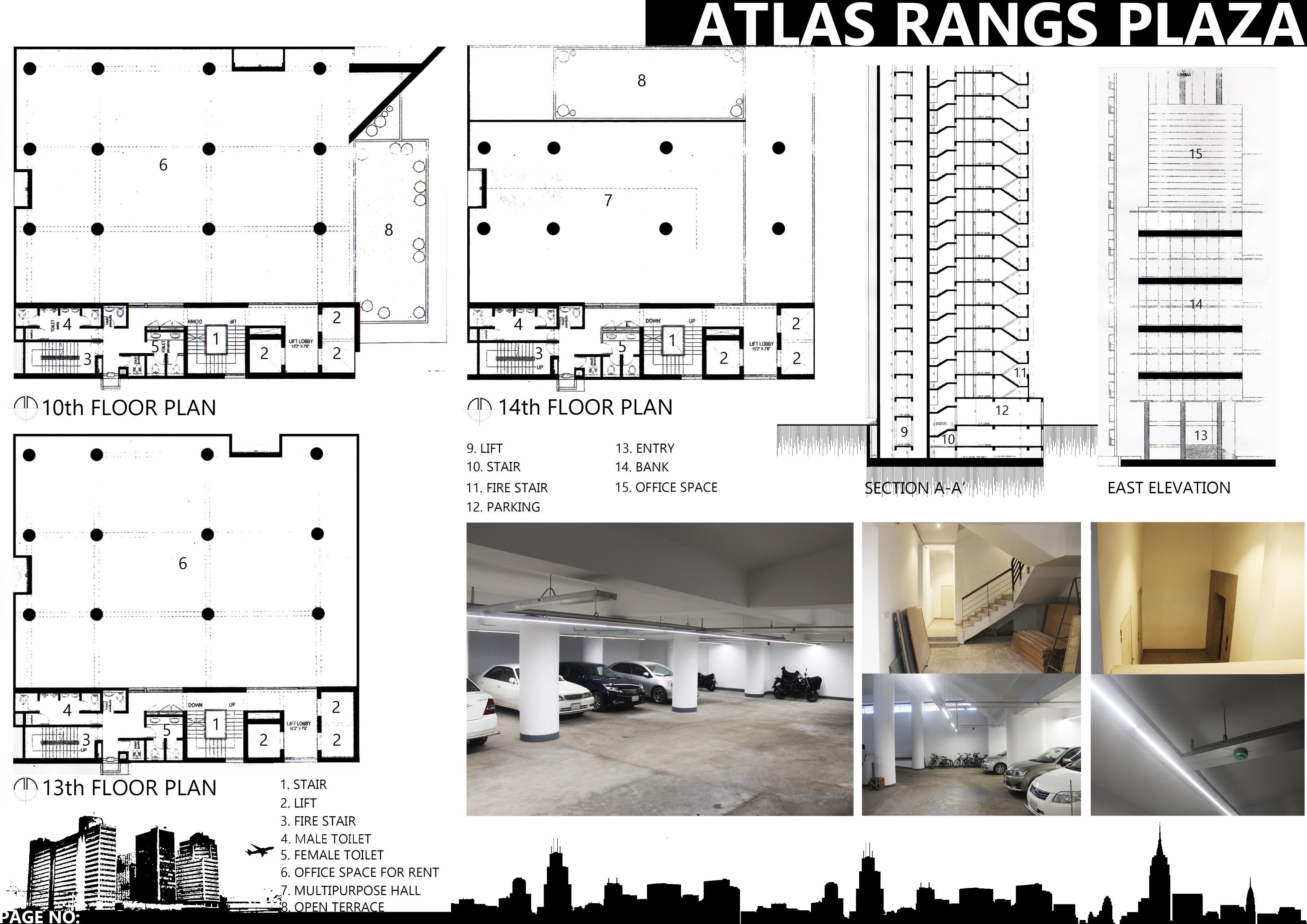

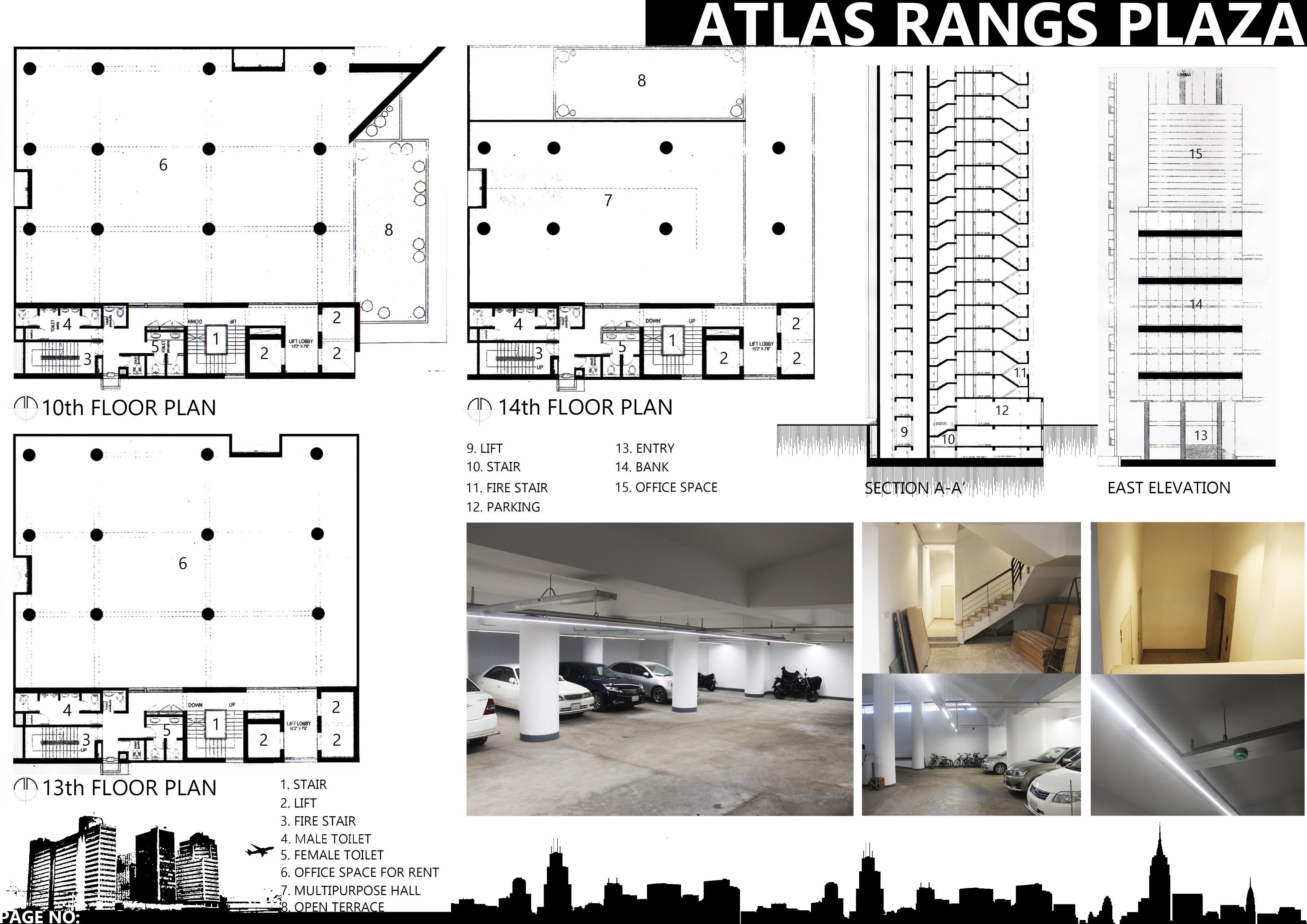

I. ATLAS RANKS PLAZA

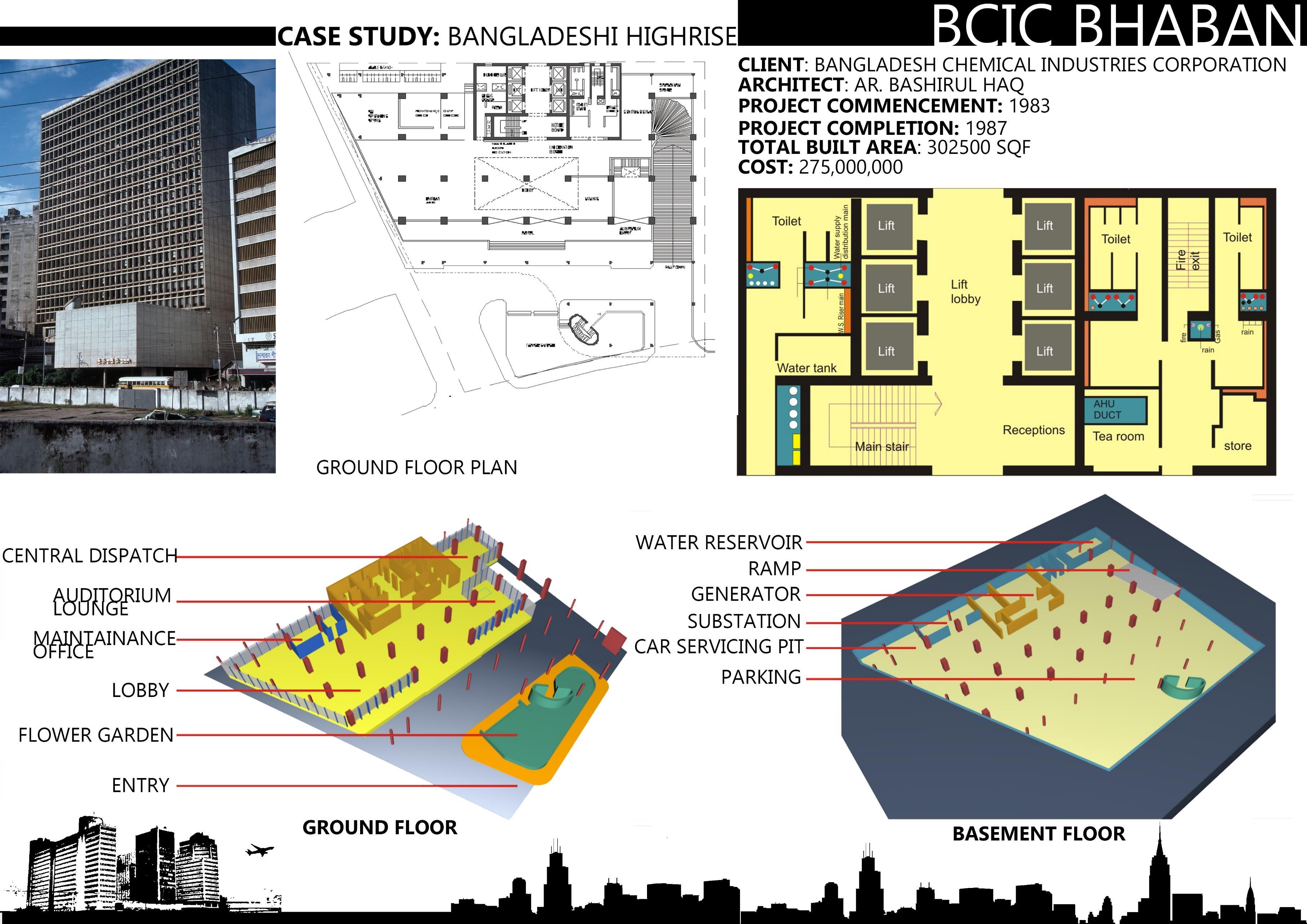

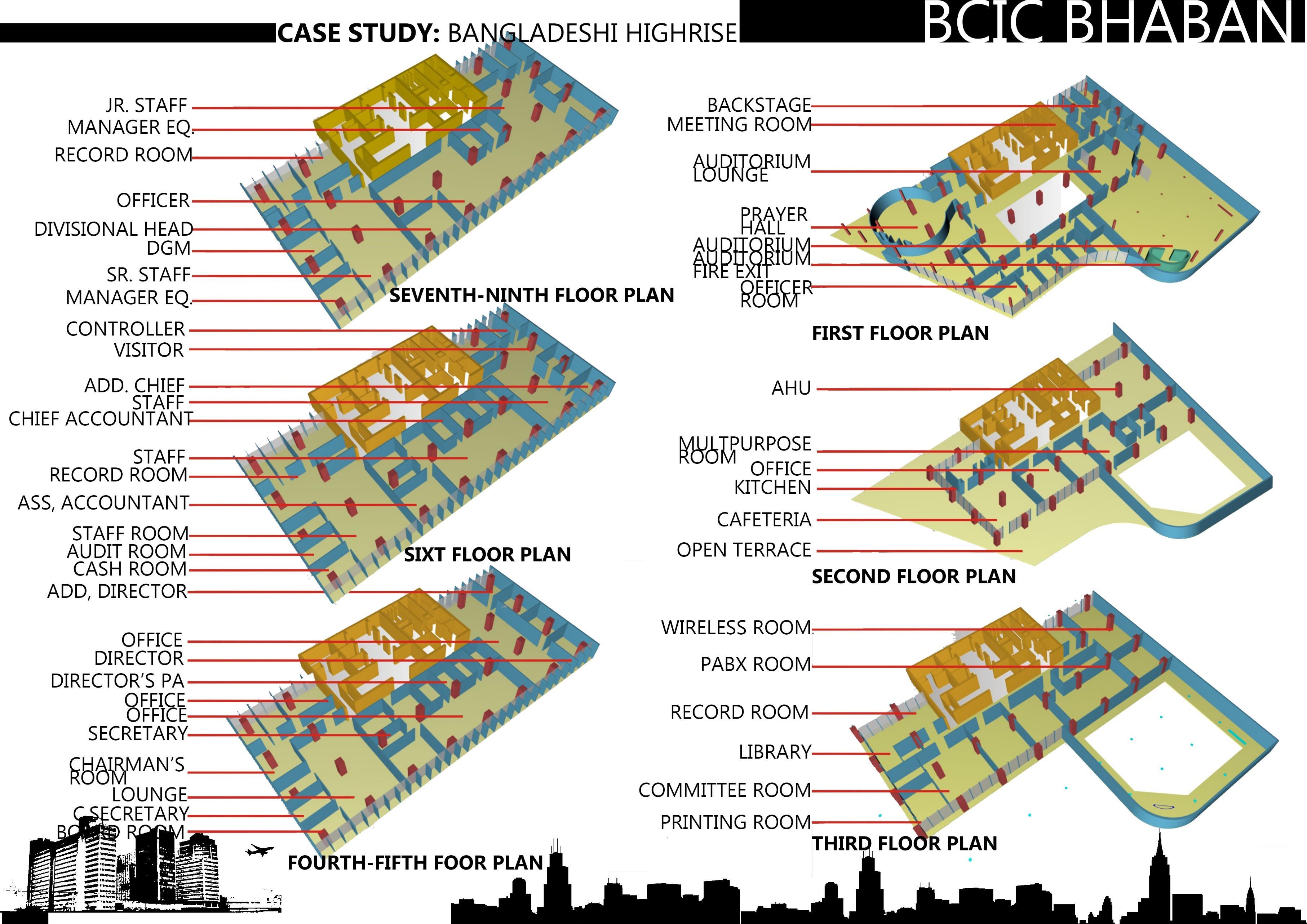

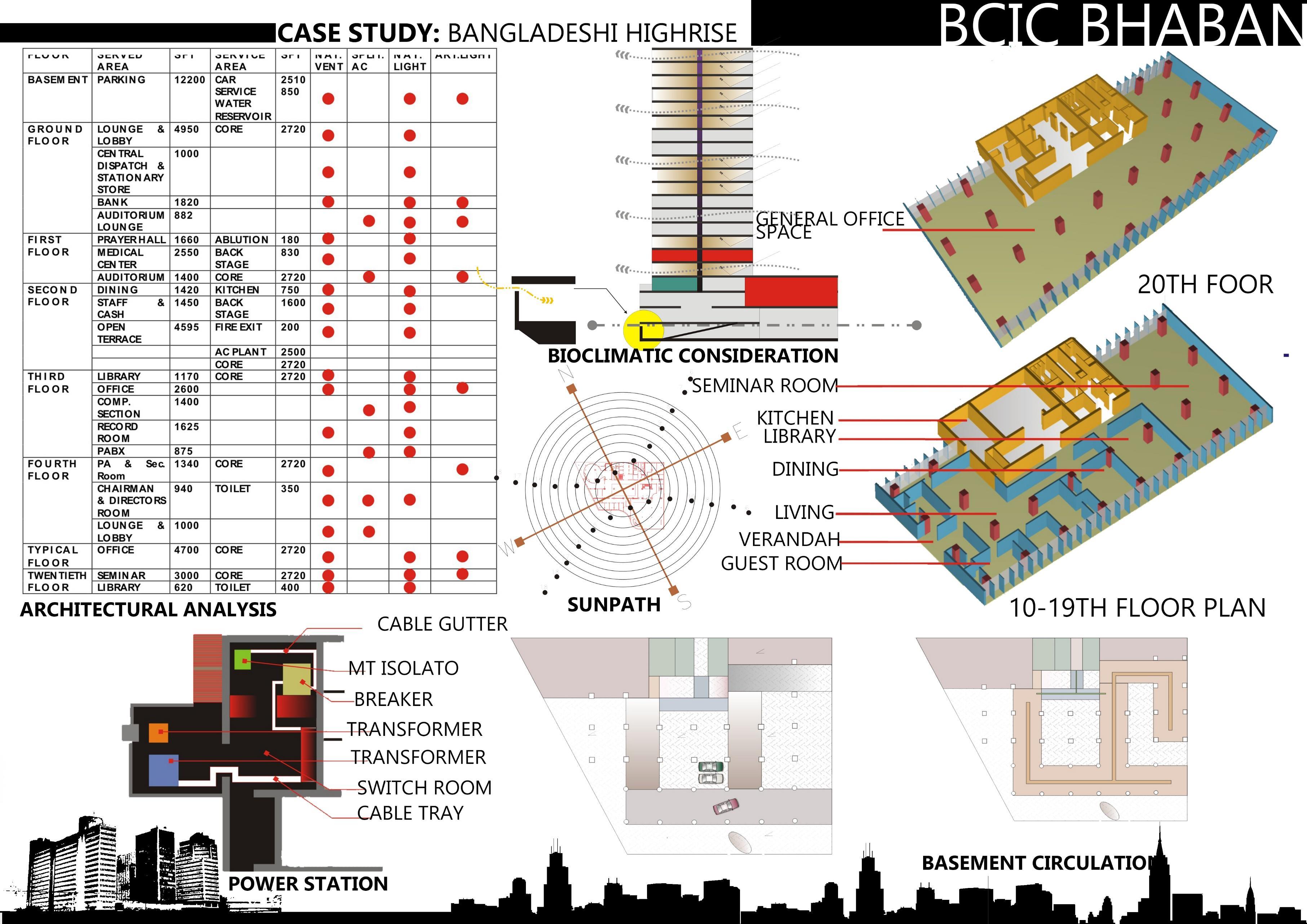

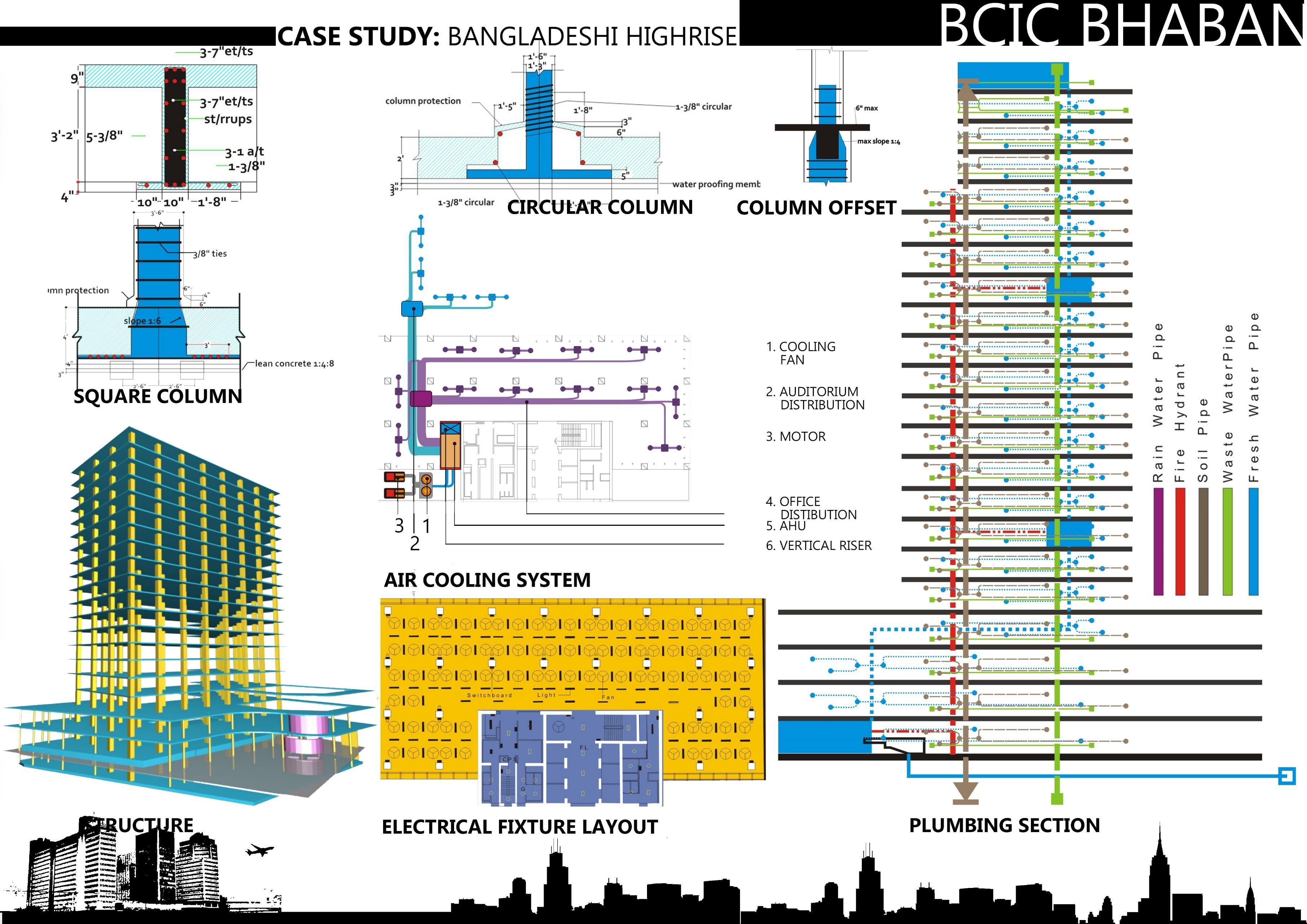

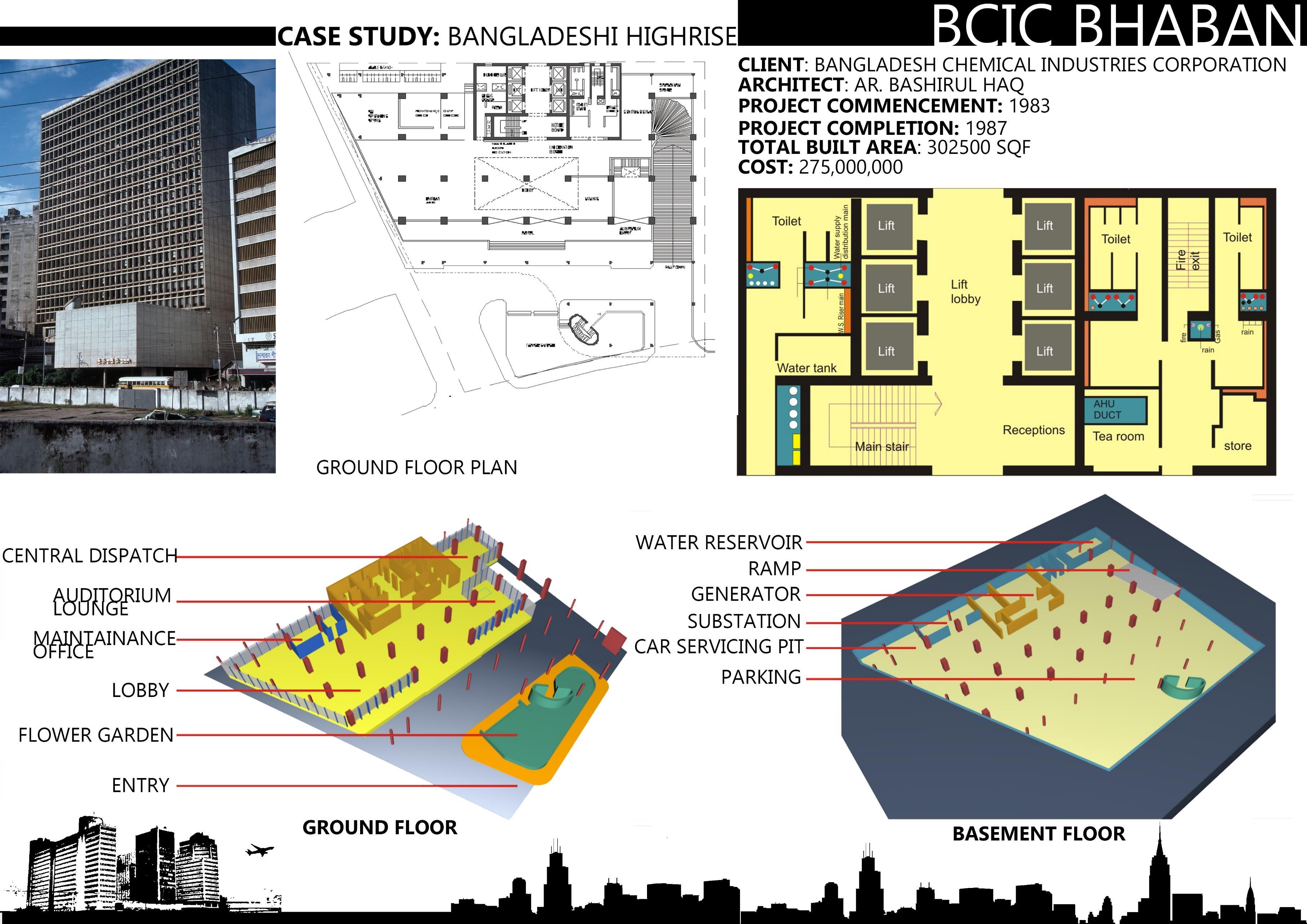

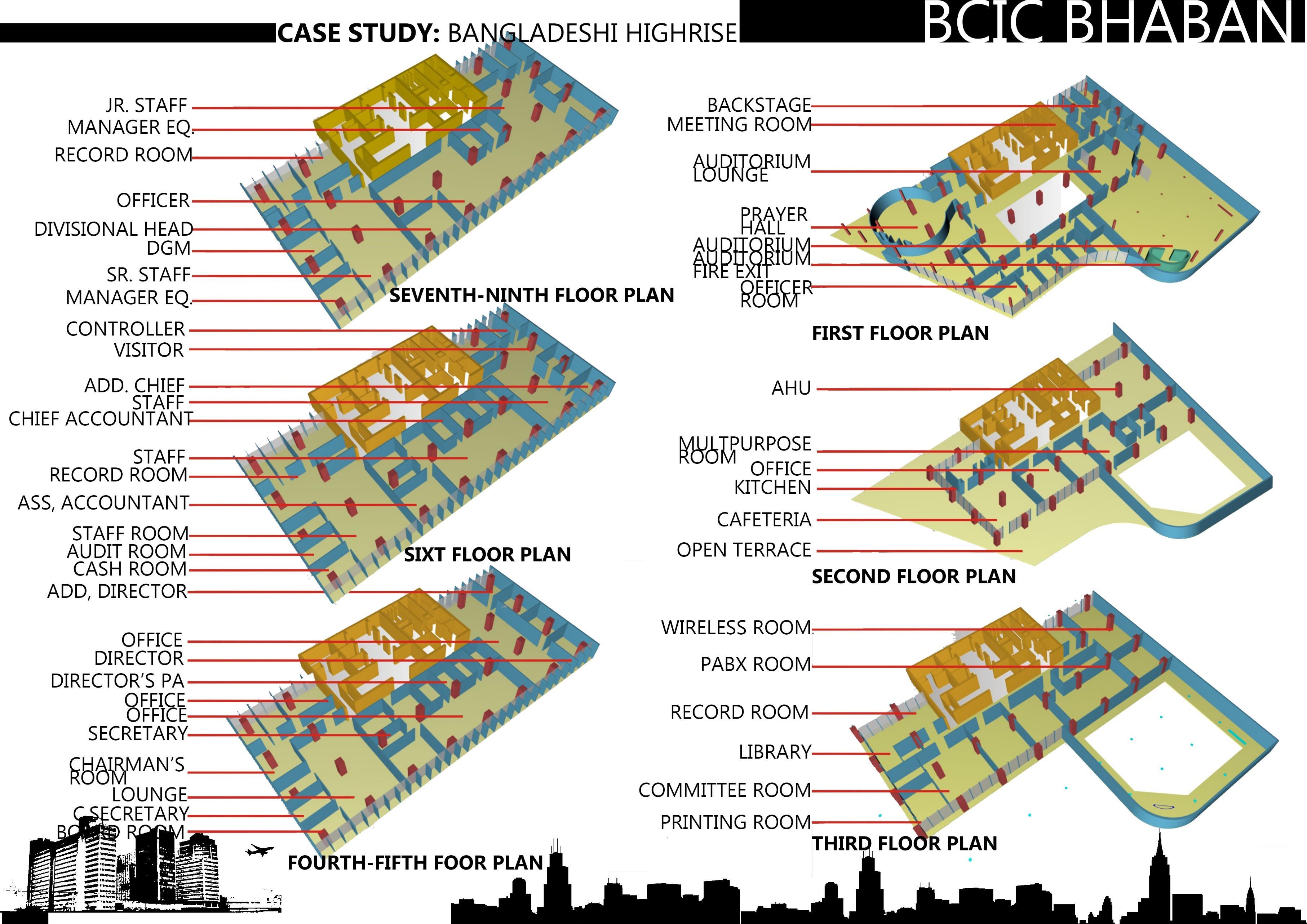

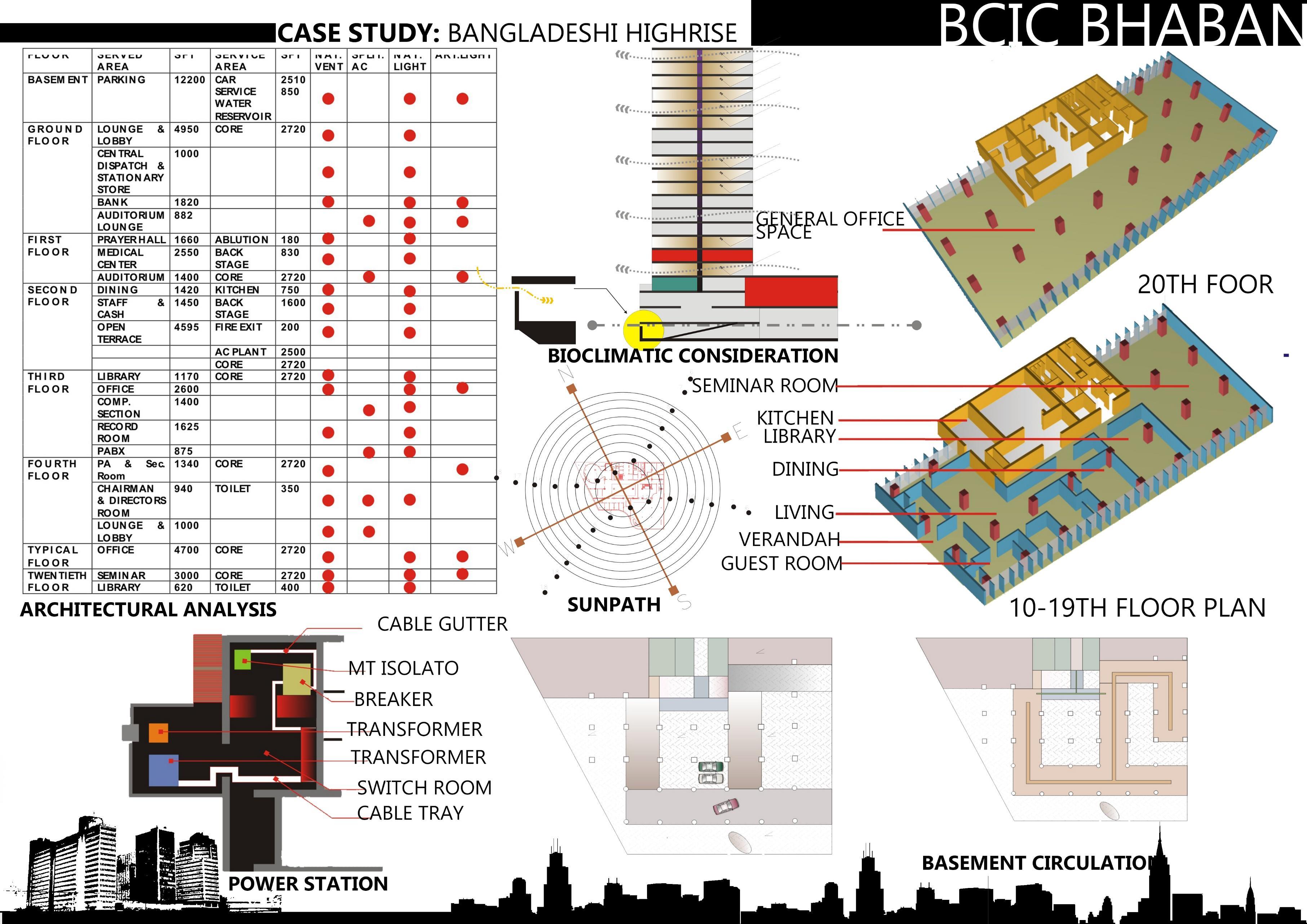

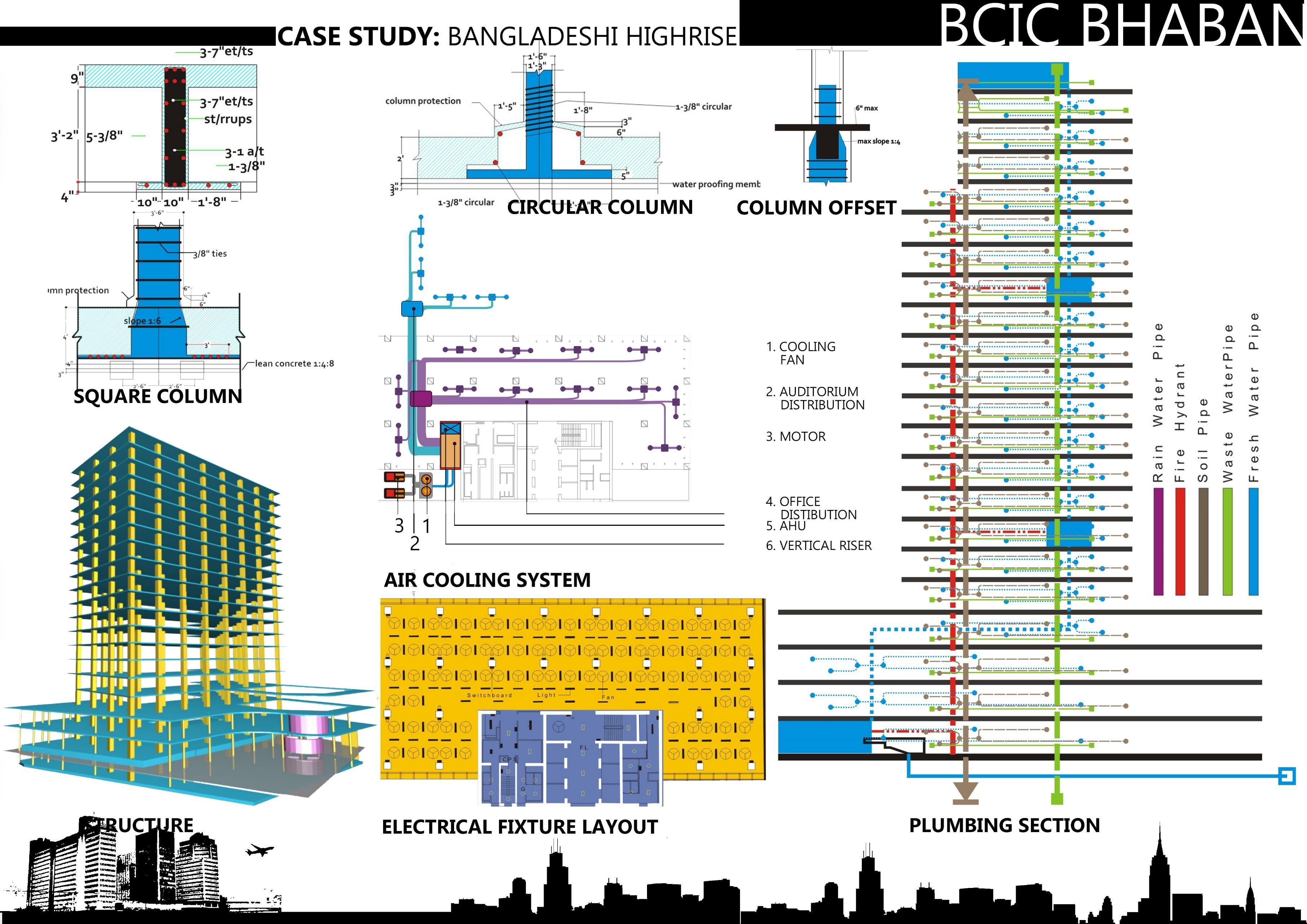

II. BCIC BHABAN

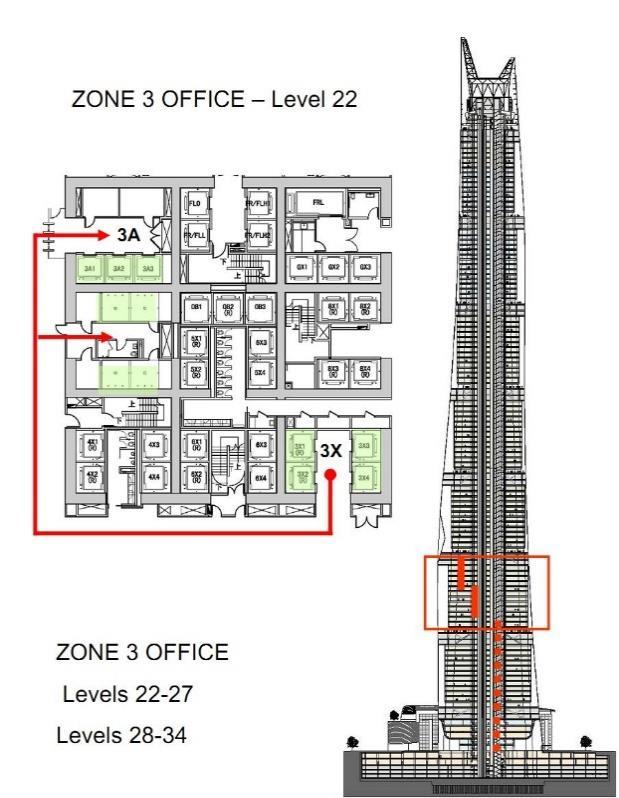

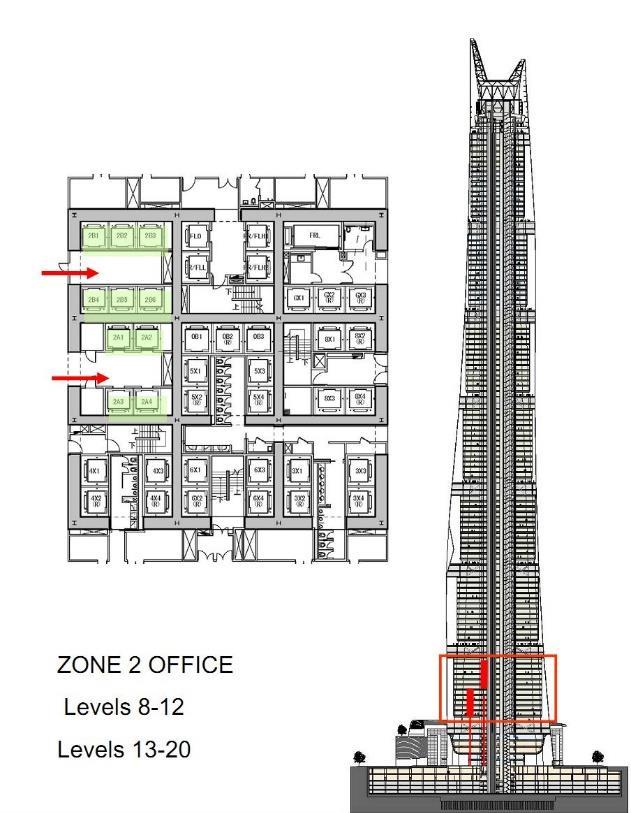

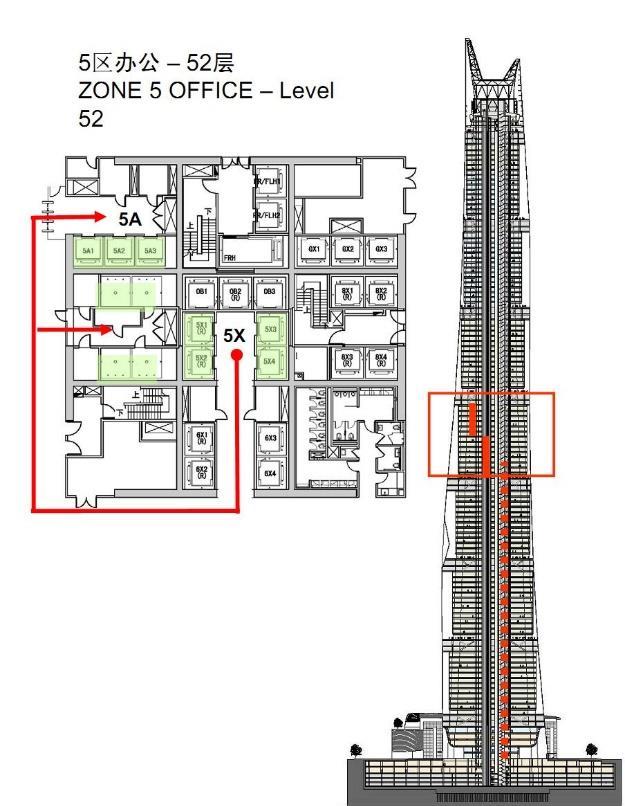

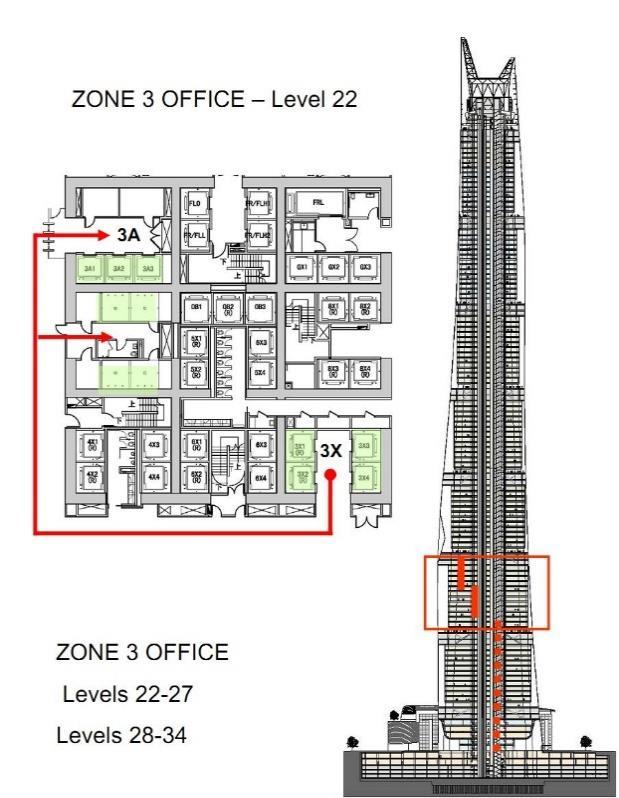

III. SHAGHAI TOWER

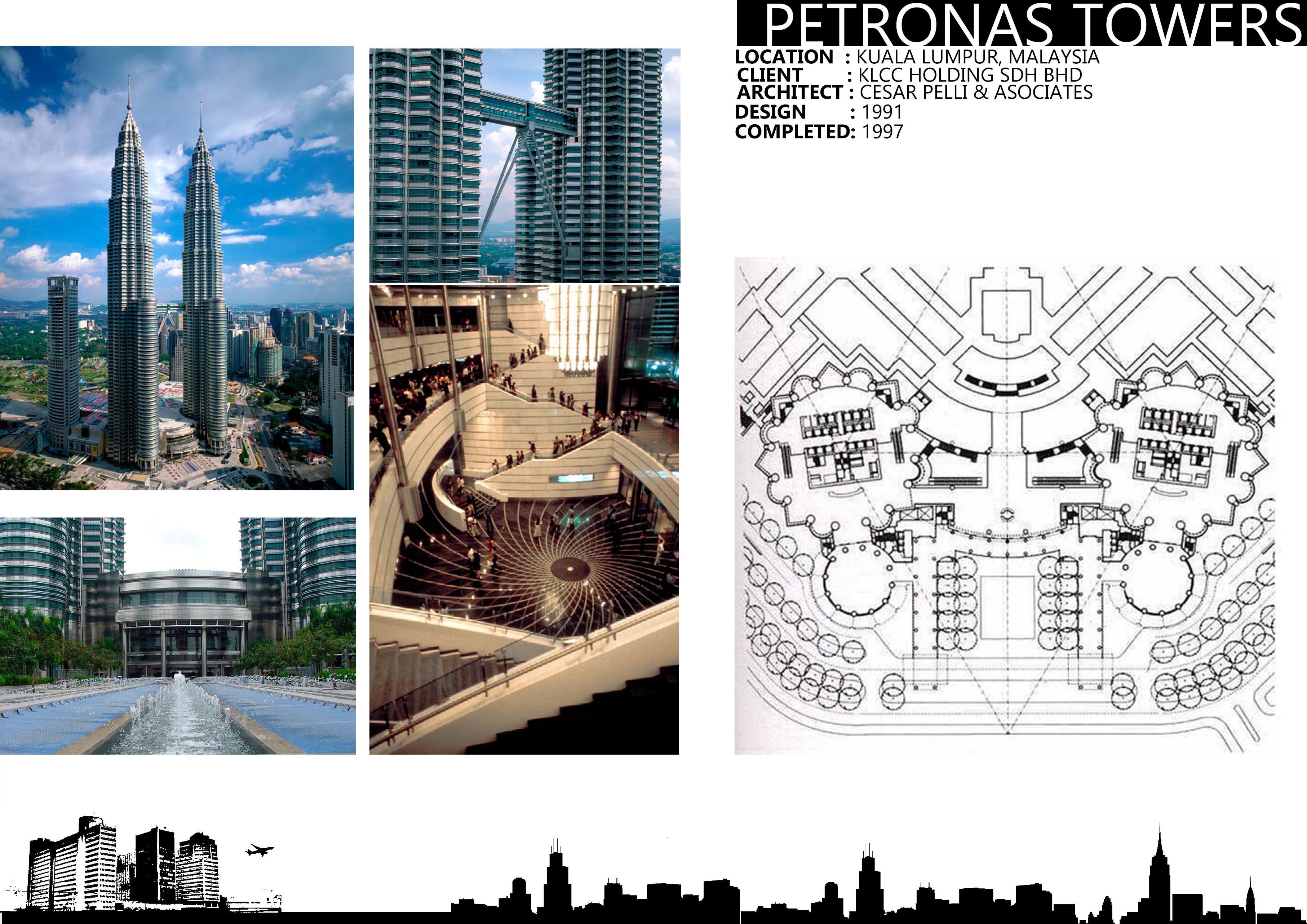

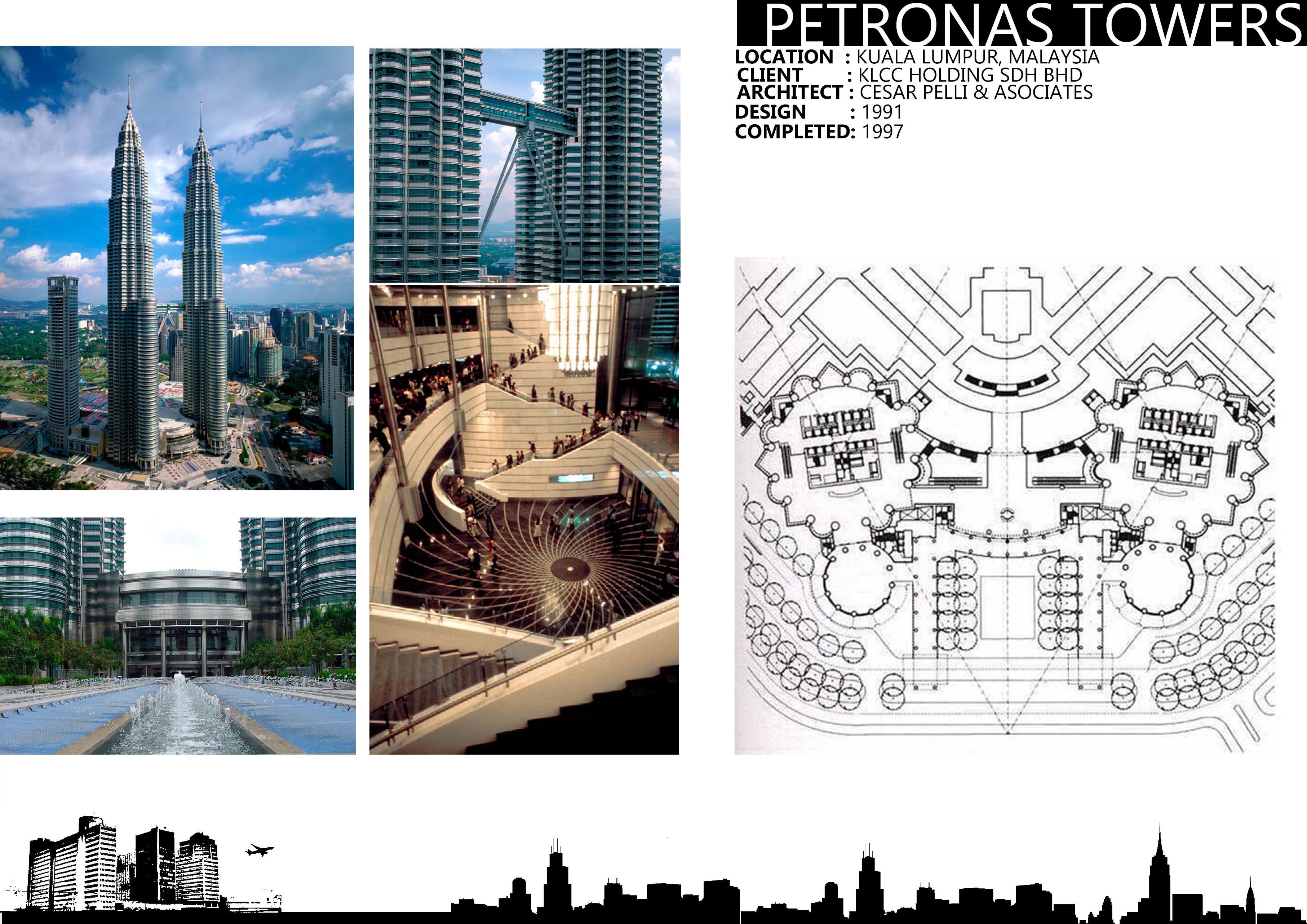

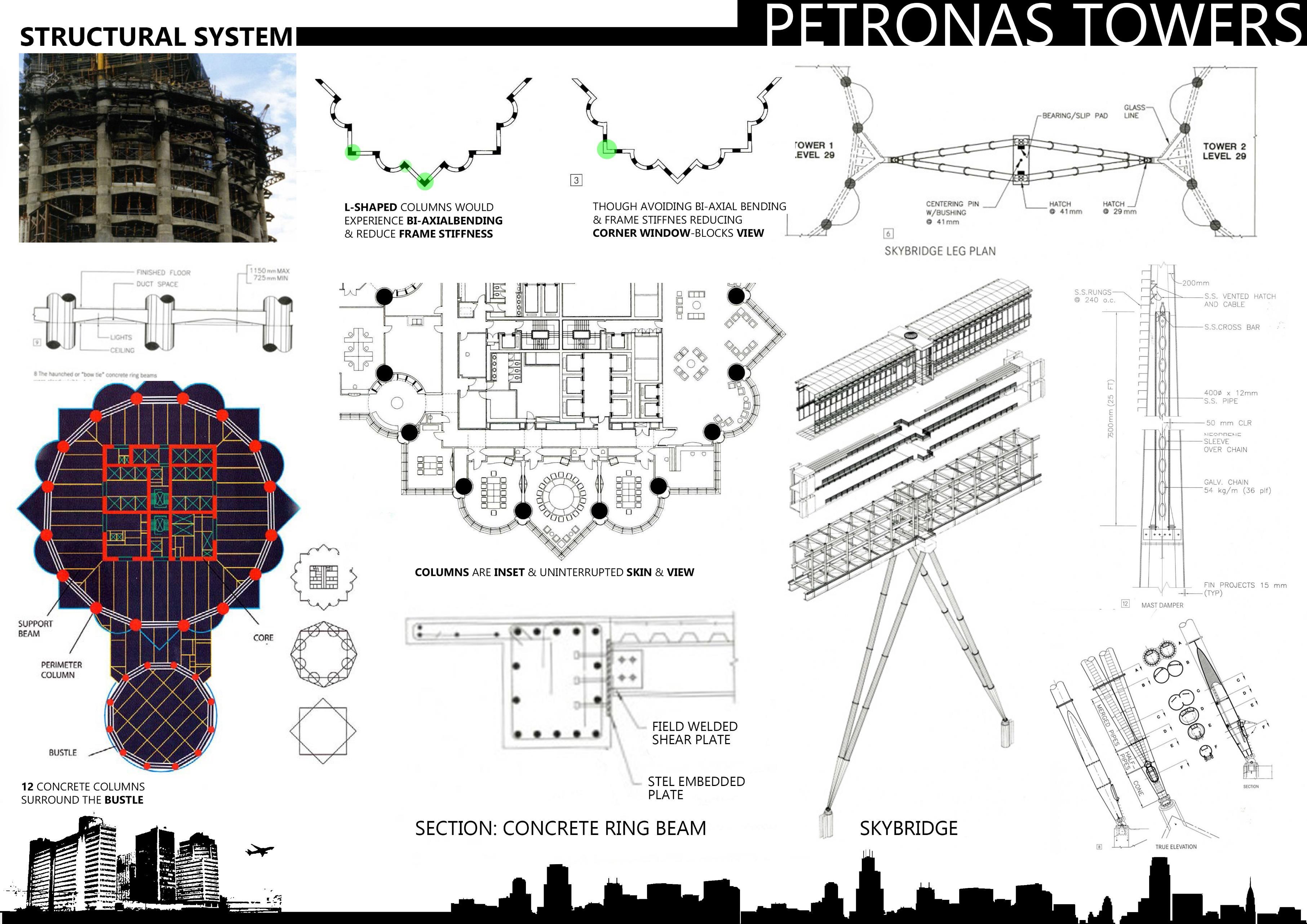

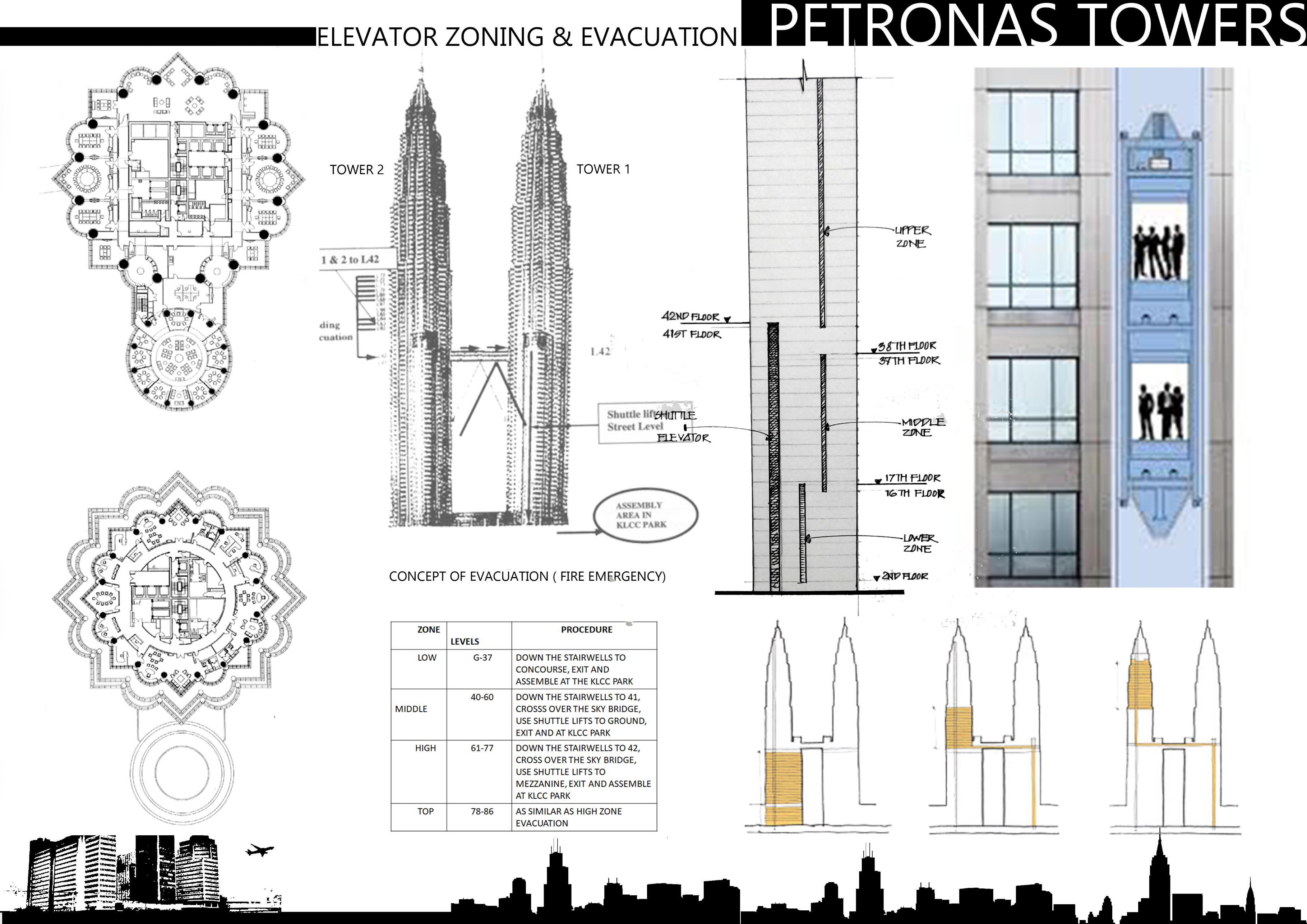

IV. PETRONUS TOWER

CONTENT

Contains:

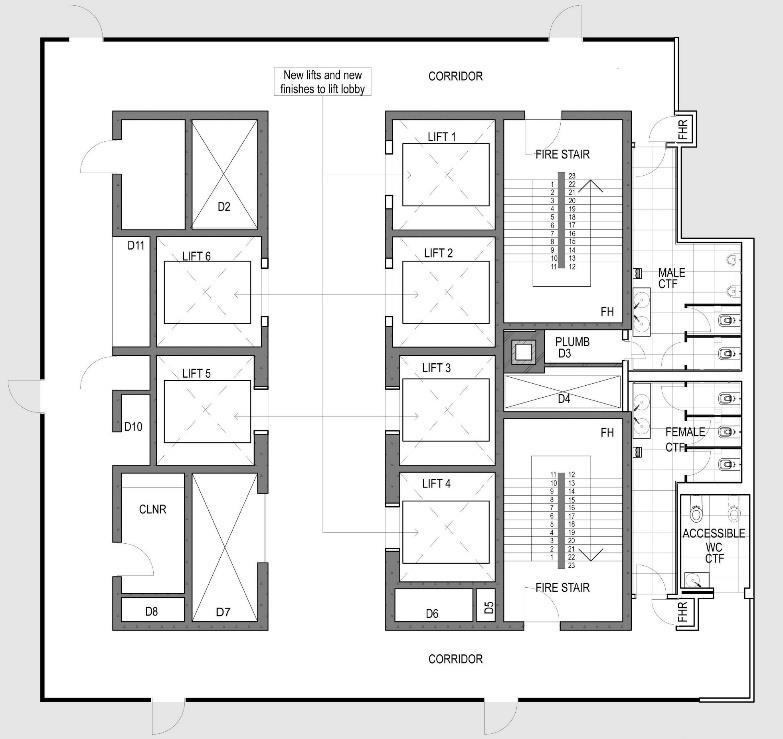

• ELEVATOR SHAFTS

• ELEVATOR Lobbies

• STAIRCASES

• FIRE PROTECTED LOBBIES

• TOILETS

• ANCILLARY ROOMS eg. PANTRY,SPACE FOR CLEANING MATERIAL

• RISER DUCTS

• M&E SERVICES PLANT

• WALLS

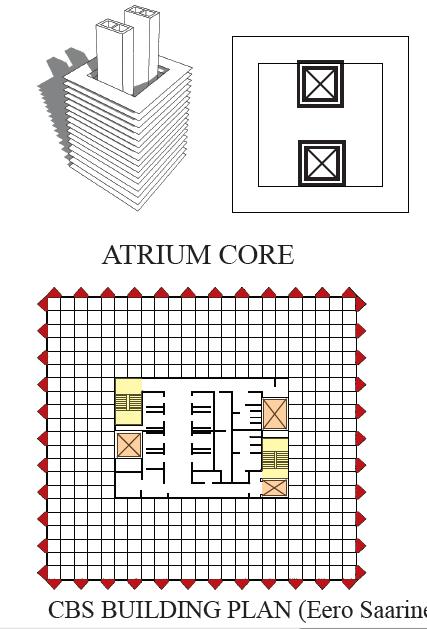

A CORE IS A VERTICAL SPACE USED FOR CIRCULATION AND SERVICES. IT MAY ALSO BE REFERRED TO AS A CIRCULATION CORE OR SERVICE CORE. A CORE ALLOWS PEOPLE TO MOVE BETWEEN THE FLOORS OF A BUILDING, AND DISTRIBUTES SERVICES EFFICIENTLY TO THE FLOORS.

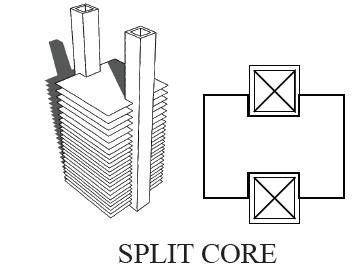

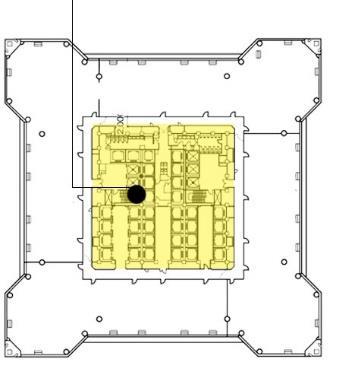

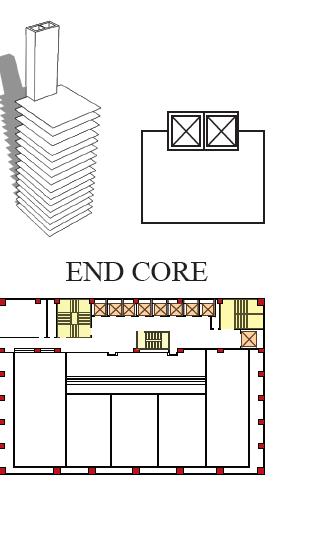

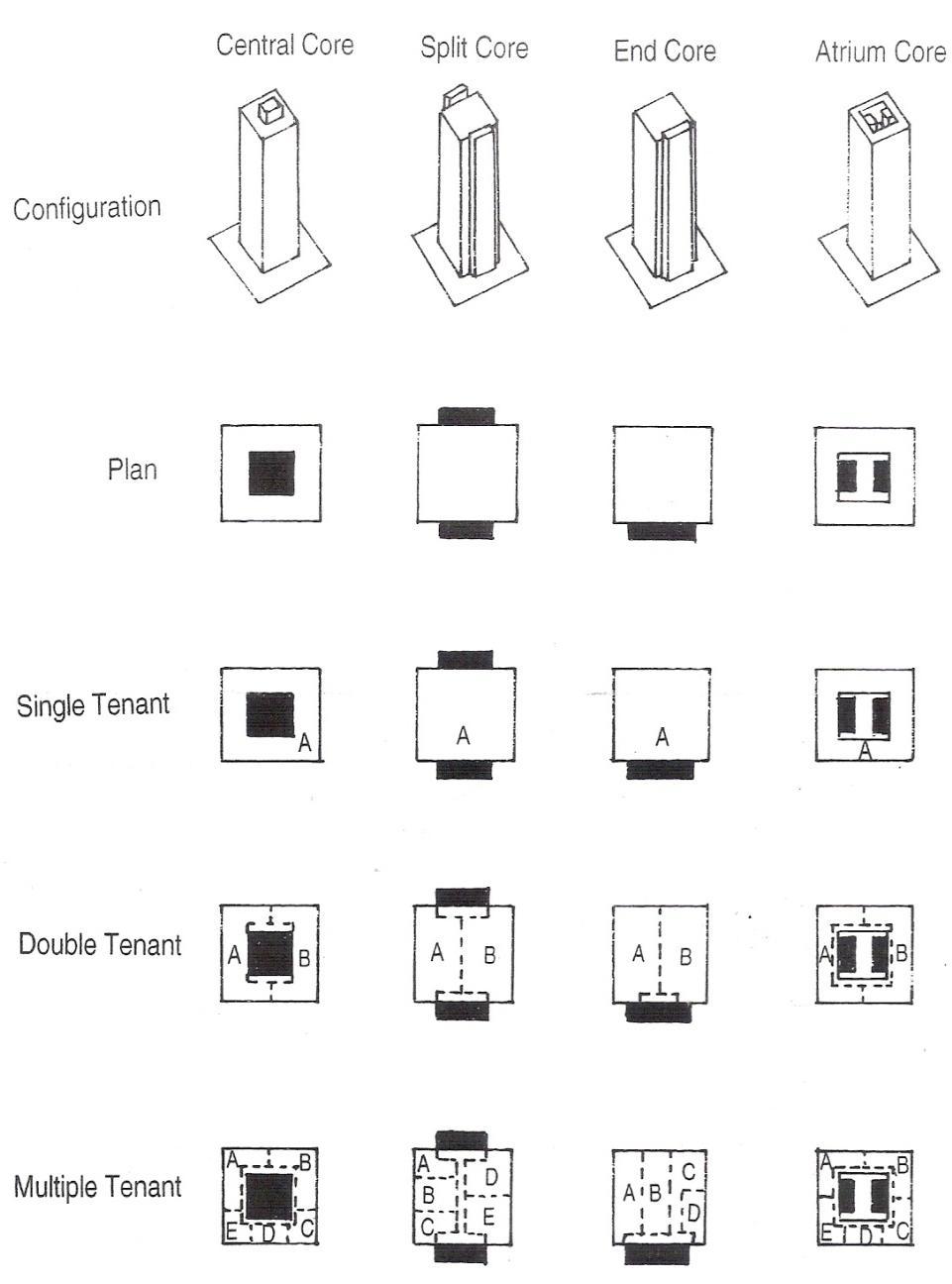

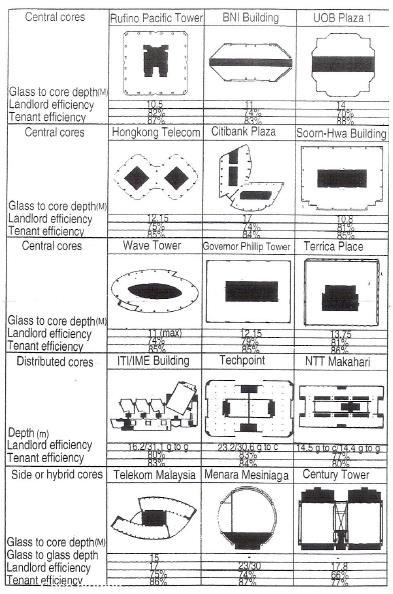

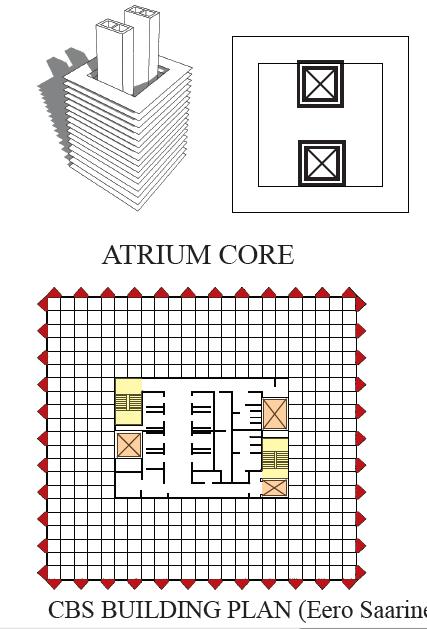

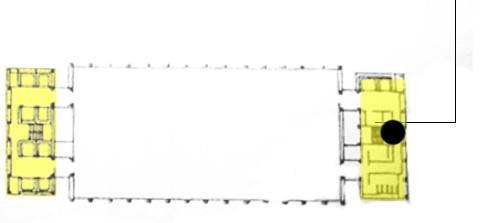

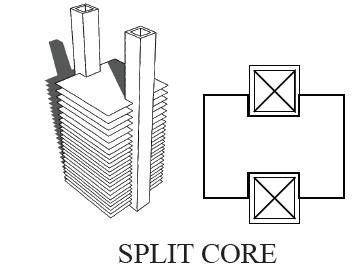

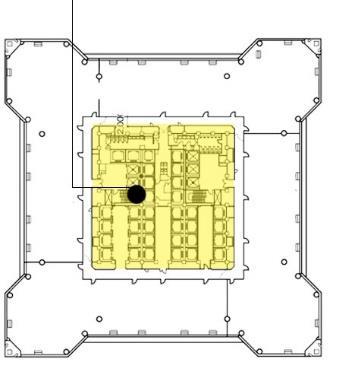

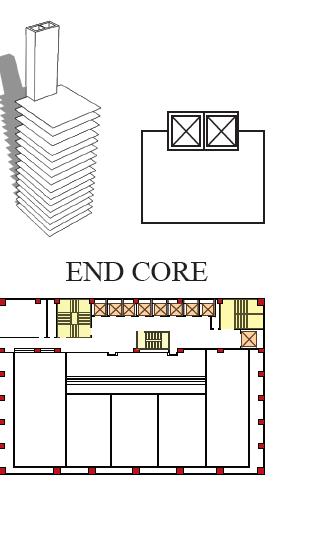

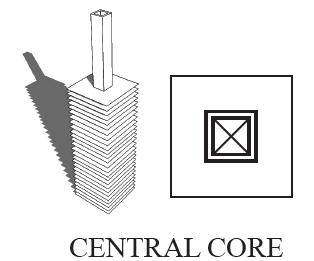

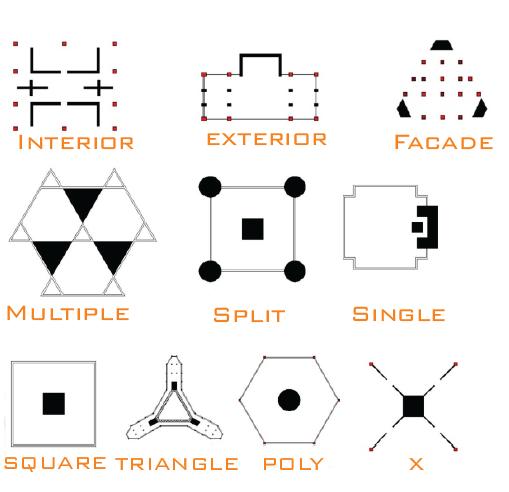

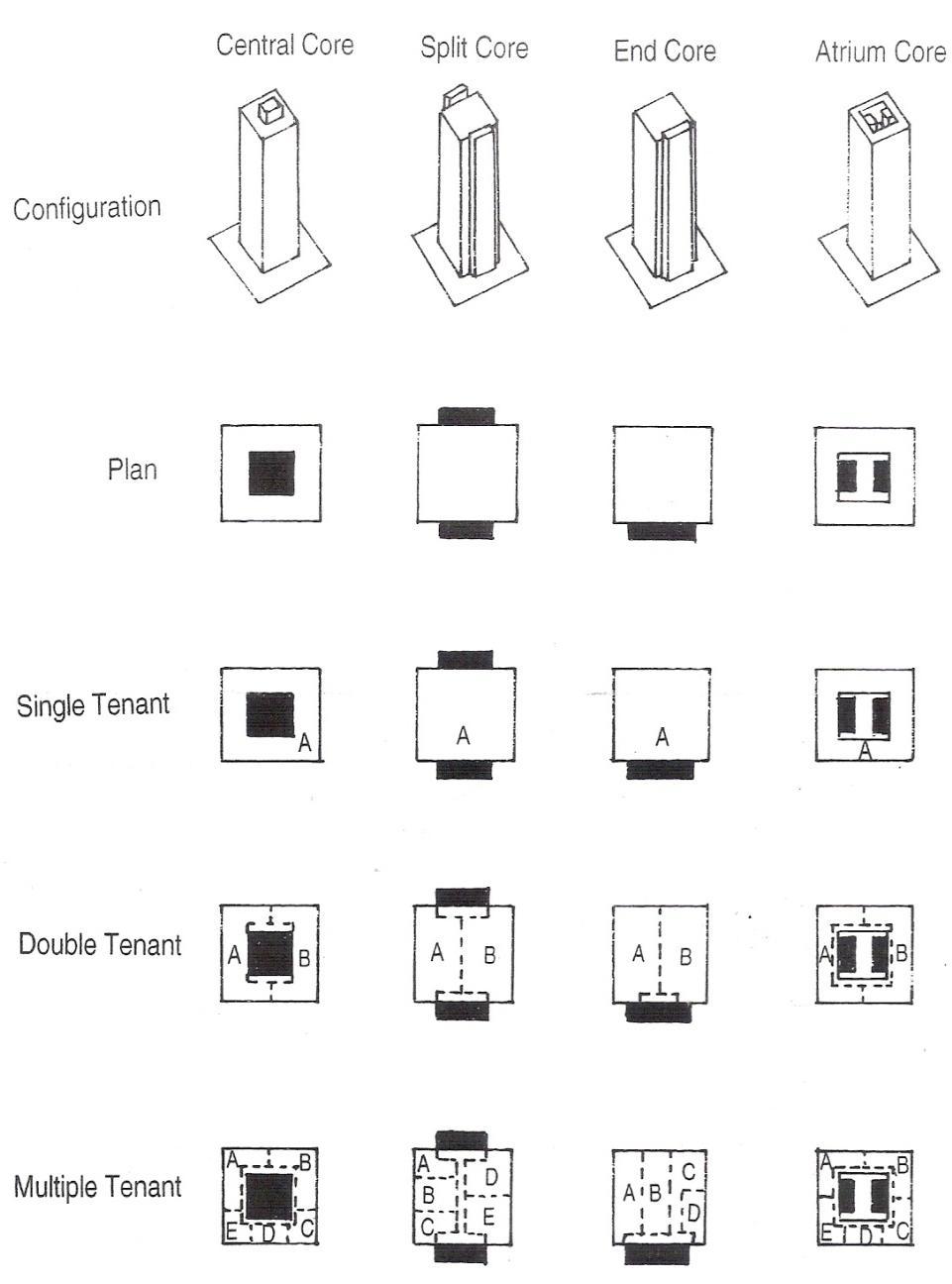

THE PLACEMENT OF THE SERVICES CORE STEMS FROM FOUR GENERIC TYPES

IBM Headquarters,Tokyo

Landmark Tower, Yokohama

Mitsui Marine Insurance, Nagoya

CORE

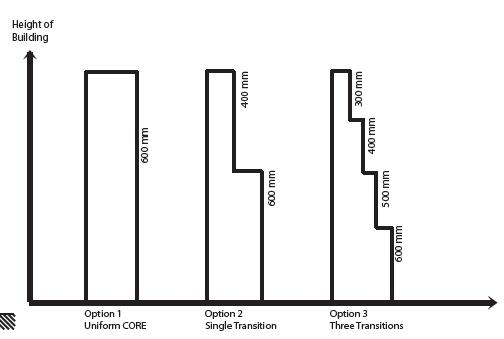

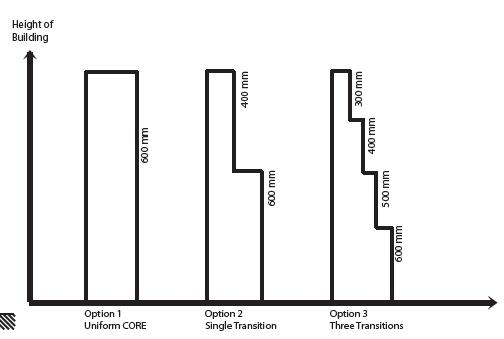

TENANT DISTRIBUTION CORE TRANSITION

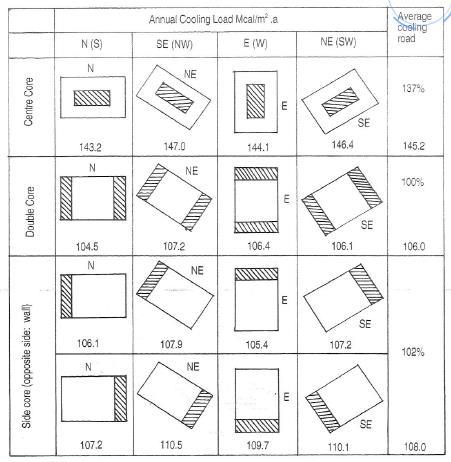

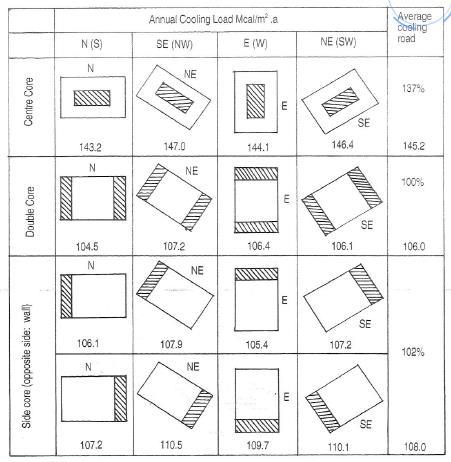

HIGHEST COOLING LOAD

Slender ratio for tower maximum is 1:10 or 1:12

LOWEST COOLING LOAD

DESIGN SYSTEM SHOULD AVOID THE HIGHEST COOLING LOAD

CORE

CORE

M & E SERVICES

THE SERVICE CORE PROVIDES MEANS OF ACCOMODATING VERTICAL M&E SERVICES RUNS, SUCH AS

• DUCT RISERS

• MECHANICAL PIPE RISES

• HYDRAULIC STACKS

• ELECTRICAL AND COMMUNICATIONS CABLING

• AIR HANDLING UNIT (A.H.U)

TOILETS

IN THE EVENT OF SINGLE OCCUPANCY OF THE FLOOR

PLATE ENTRY TO THE TOILETS

MIGHT BE ORGANISED SO THAT USERS ARE ABLE TO ACCESS THEM WITHOUT GOING

THROUGH THE ELEVATOR LOBBY

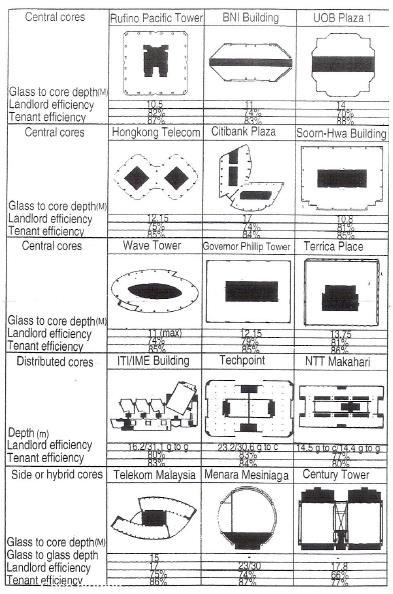

CORE TO GLASS DEPTH AND ITS EFFICIENCY

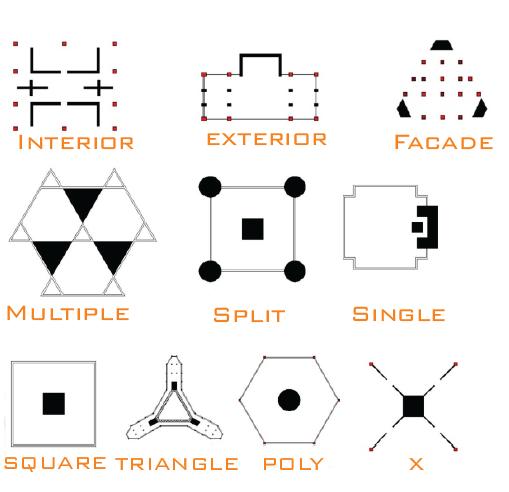

TYPOLOGY

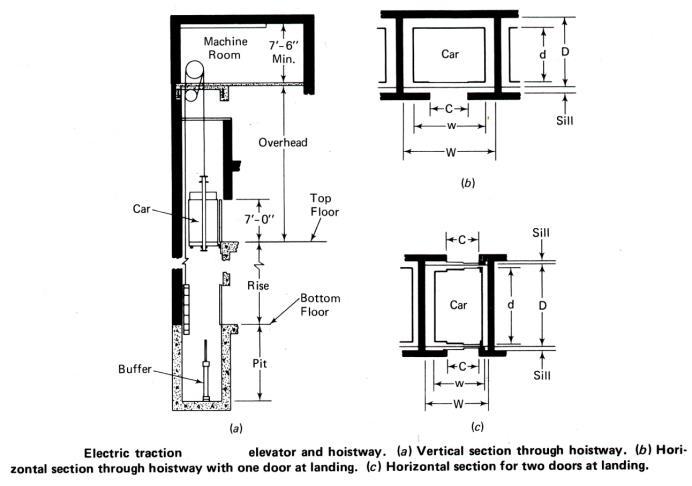

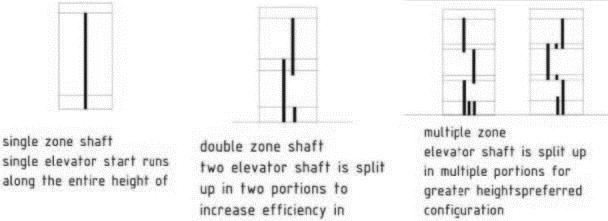

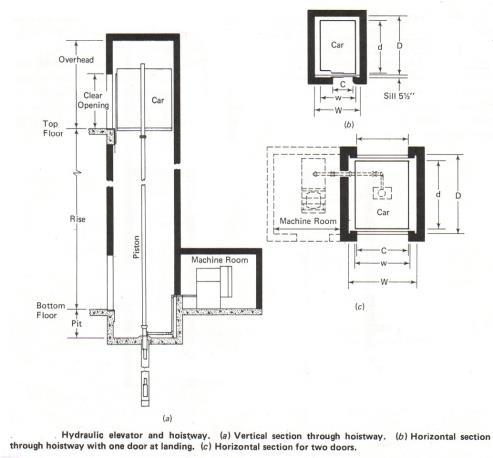

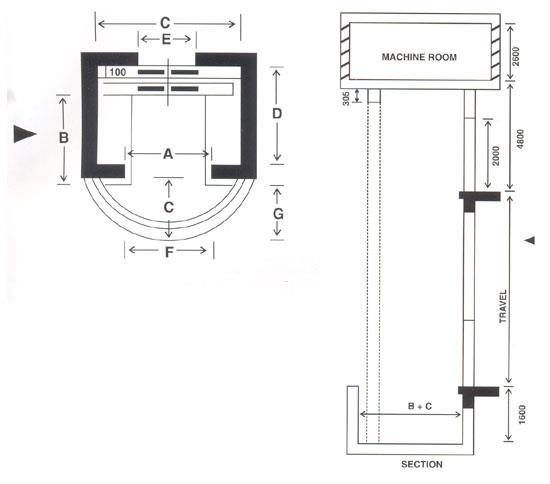

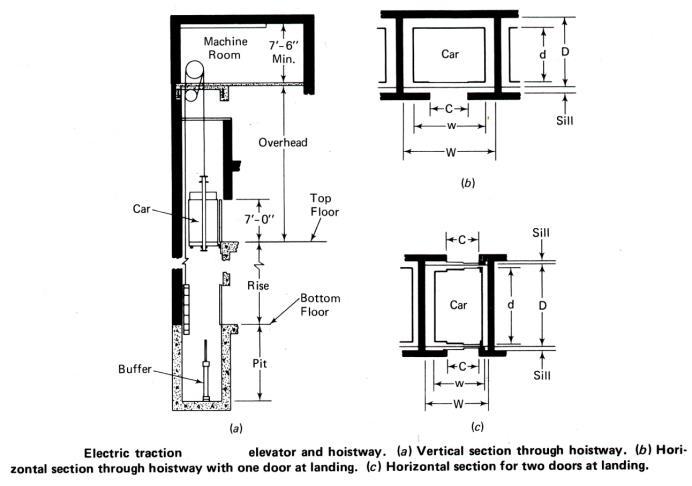

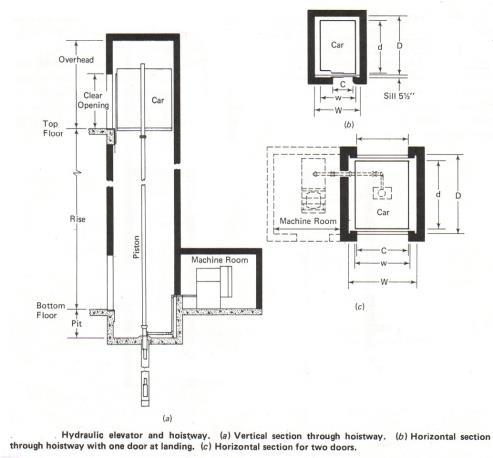

Major Types of elevator Definition advantage disadvantage

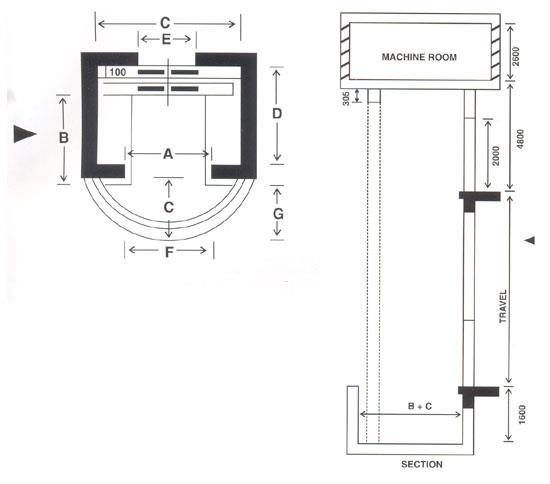

a.Hydraulicelevator: 1.powered elevator

2.energy is applied by a liquid under pressure in a cylinder equipped with a plunger or piston.

1. efficient, safer, and friendlier to the environment.

2. Does not require brakes,

3. Can use very small motor to pump fluid .

4. Very powerful

1. if there is a catastrophic oil line failure (it has happened) the elevator will drop uncontrolled 2. limited to about 6 or 7 floors max.

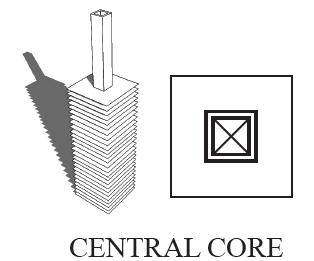

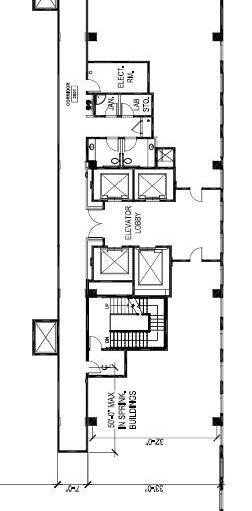

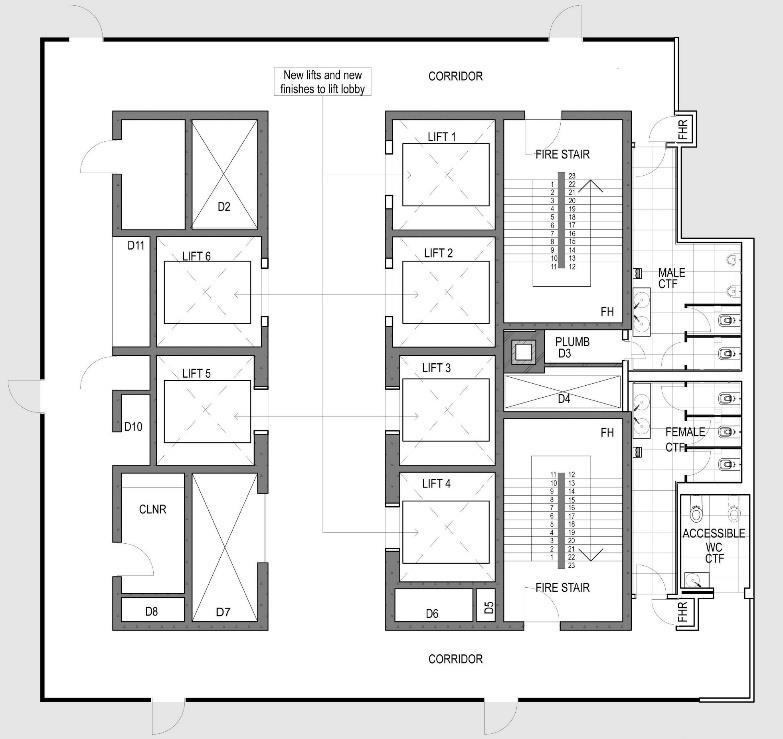

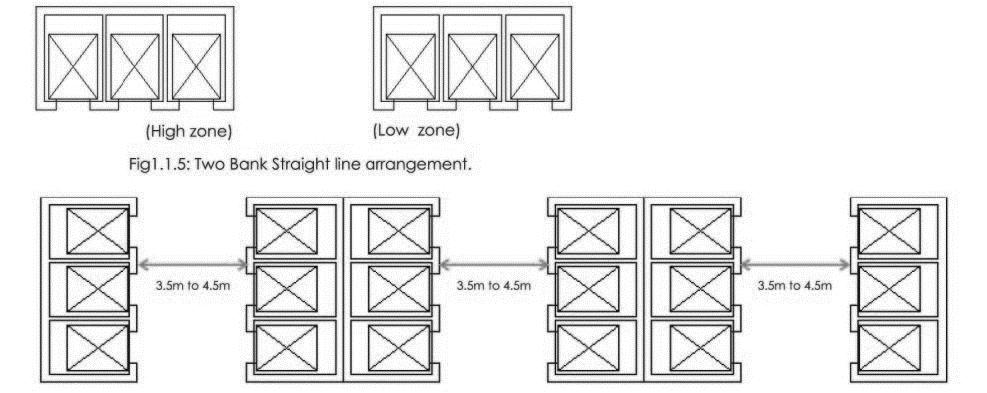

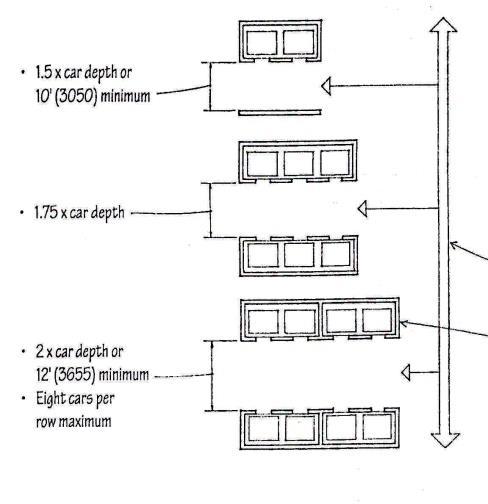

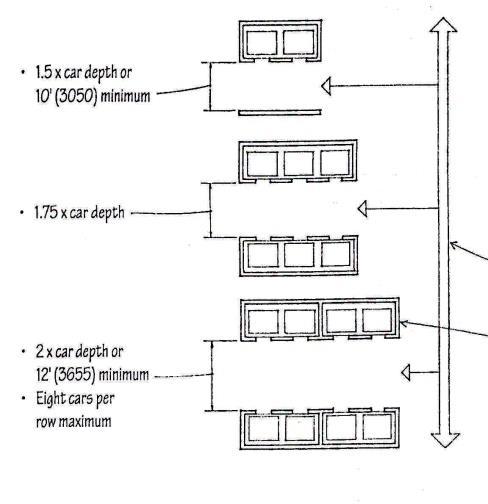

CAR ARRANGEM ENT:

CORE ELEVATOR

b.Electricelevator: 1.energy is applied by electric driving machine .

2.used in tall buildings

1.Electric elevators consume less energy than hydraulic elevators.

2.no. of floors are not limited

Failure of electricity creates panic

•Capsulelift: similar to electric elevator. Machine room is not essential largest version of electric elevator.

Hydraulic elevator Electric elevator Capsule lift

Lobby depth

Are used for fire safety

help firefighters to get to the fire and to permit people evacuation

elevator landing must be min. 5m² wide for a gurney to be brought out of the elevator.

required to display a written notice in the car that the passengers are prohibited.

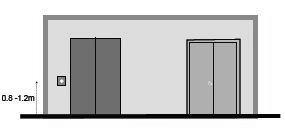

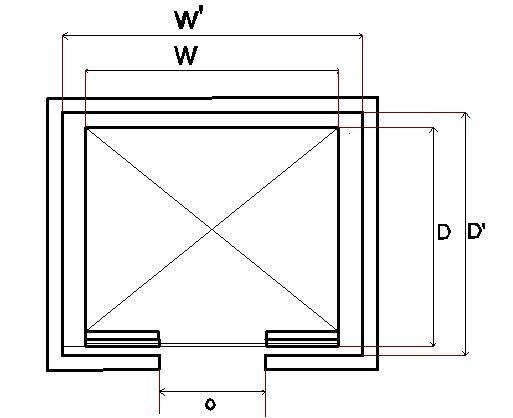

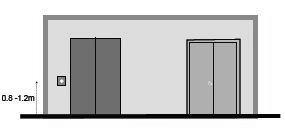

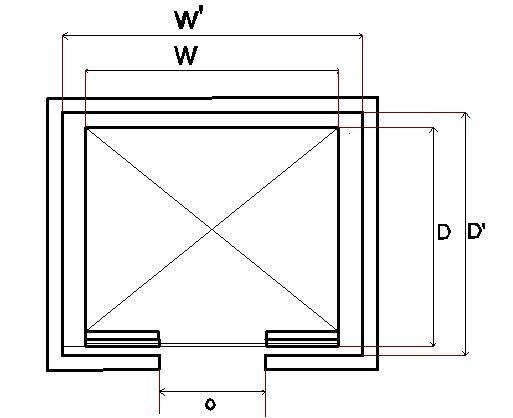

Capacity (lb) Passe ngers Width, w Depth , D Clear width .w’ Clear depth , D’ Doors clear openings ,o Over head Max. rise 1500 10 5’-0” 4’-6” 6’-8” 4’-11” 2’-8” 10’-9” 29’ 2000 13 6’-4” 4’-5” 7’-8” 4’-10” 3’-0” 11’-0” 41’ 2500 16 7’-0” 5’-0” 8’-4” 5’-5” 3’-6” 11’-3” 42’ 3000 20 7’-0” 5’-6” 8’-4” 5’-11” 3’-6” 11’-3” 42’ 3500 23 7’-0” 6’-2” 8’-4” 6’-7” 3’-6” 11’-3” 42’ 4000 26 8’-0” 6’-2” 9’-4” 6’-7” 4’-0” 11’-3” 42’ Height of call button= .8-1.2m According to BNBC= 3.12’- 3.9’ 3.125’3.9’ZZZ

elevators

ELEVATOR STANDARDS Firefighter

•1.10m wide

deep

the

at least

wide •minimum

capacity

630kg.

by 1.40m

with

door entry

800mm

loading

is regulated at

elevator

Freight

Is designed to carry goods. capable of carrying heavier loads than a passenger elevator, generally from 2,300 to 4,500 kg. The number of LIFT PxtxHC 300x100xq N=

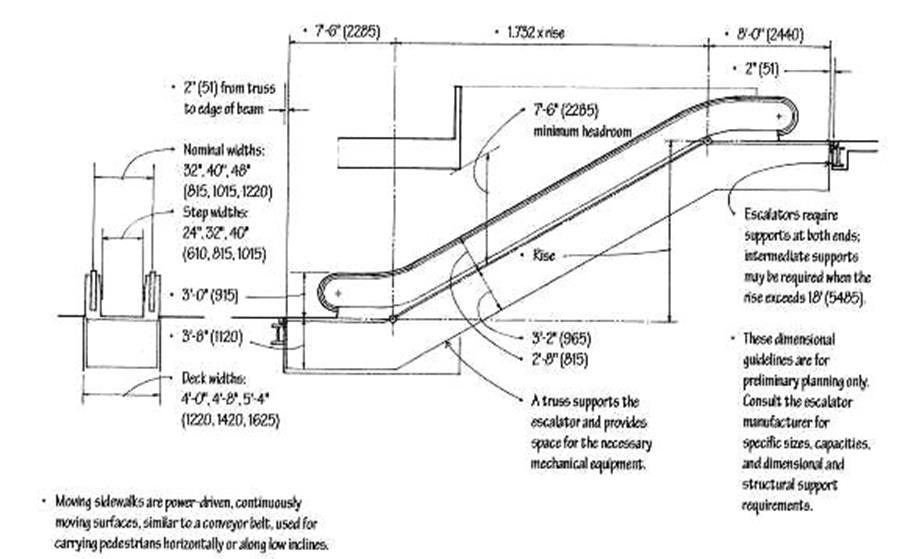

COMPONENTS OF ESCALATOR

• Top and Bottom Landing Platforms

• The Tracks

• The Steps

• The Handrail

• Anti-slide devices

• Complete impact switches

• Deflector brush

• Emergency Stop button

• Extended balustrades

• Flat steps

• Handrail inlet switches

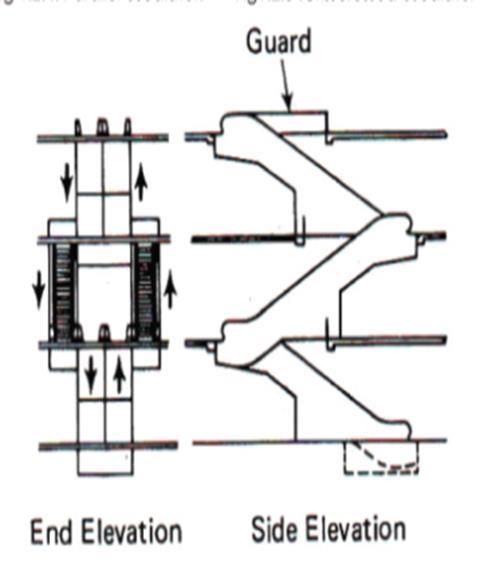

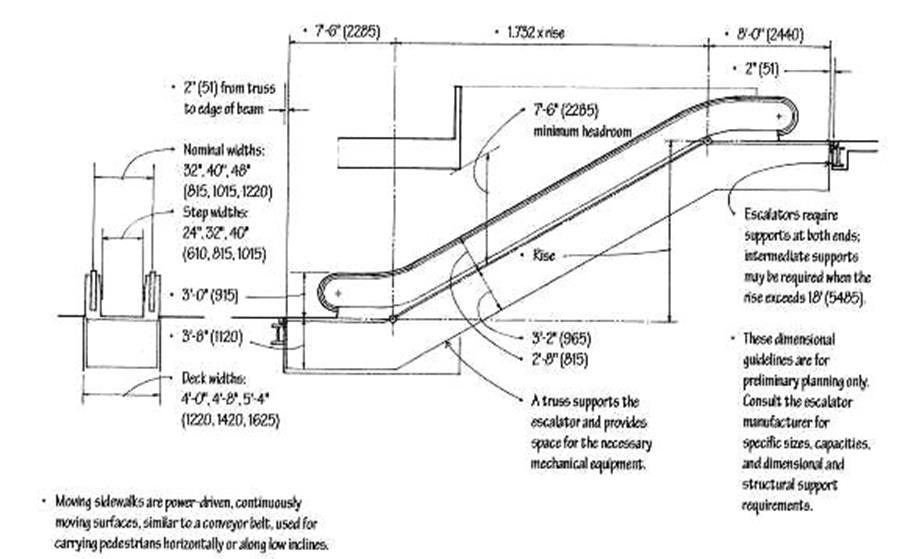

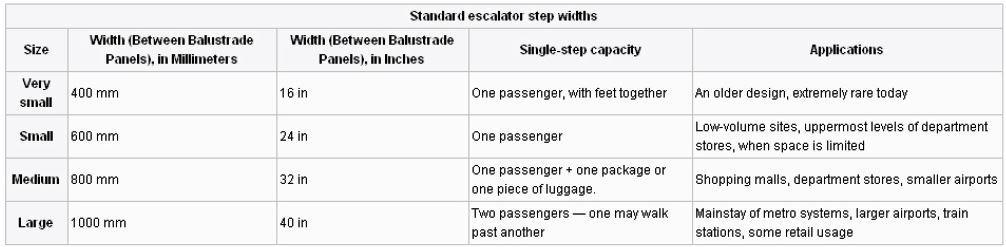

STANDARDS FOR ESCALATOR

• Speed is usually 90 or 120 fpm

• Standard widths are 32 to 48 in. between handrails.

• A 32-in. escalator operating at 90 fpm can transport between 5000 and 8000 persons per hour.

• A 48-in. escalator operating at 120 fpm can transport as many as 10000 persons per hour.

• The maximum angle of inclination of an escalator to the horizontal floor level is 30 degrees with a standard rise up to about 60 feet (18 m).

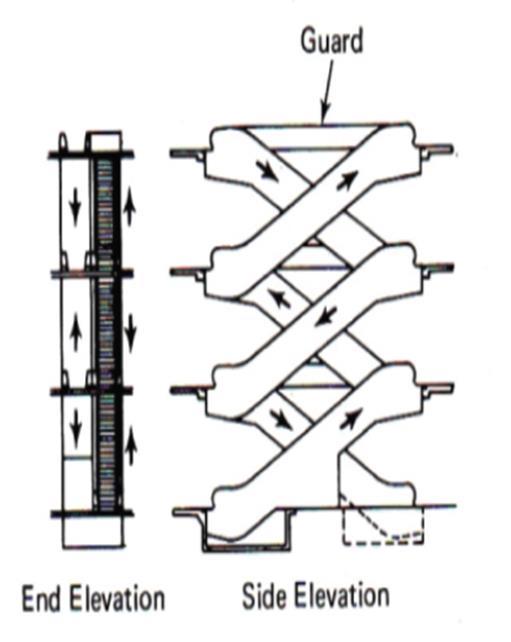

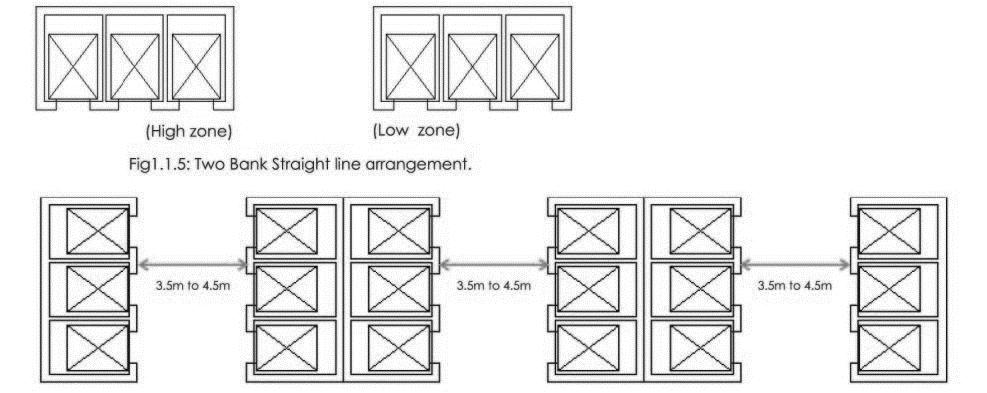

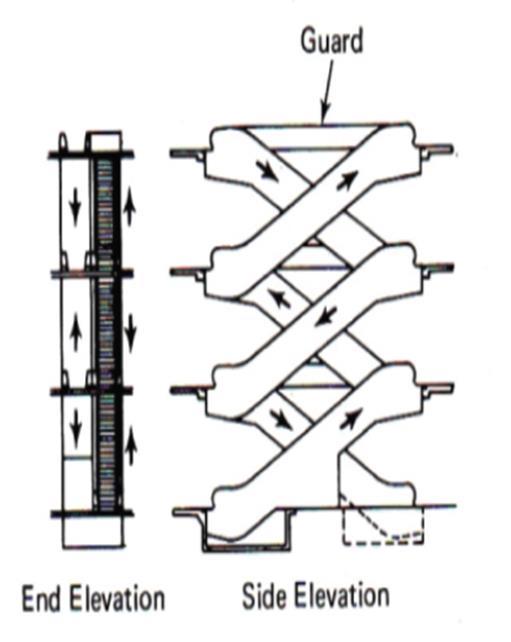

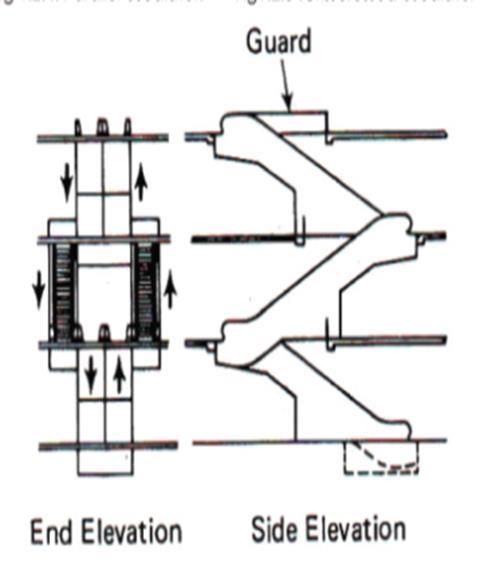

TYPES OF ARRNGEMENT:

• PARRALLAL

• CRISSCROSS

ESCALATOR

GENERATOR ROOM

WATER PUMP

PLACE FOR AC EQUIPMENT

STAIR

FIRE EQUIPMENT

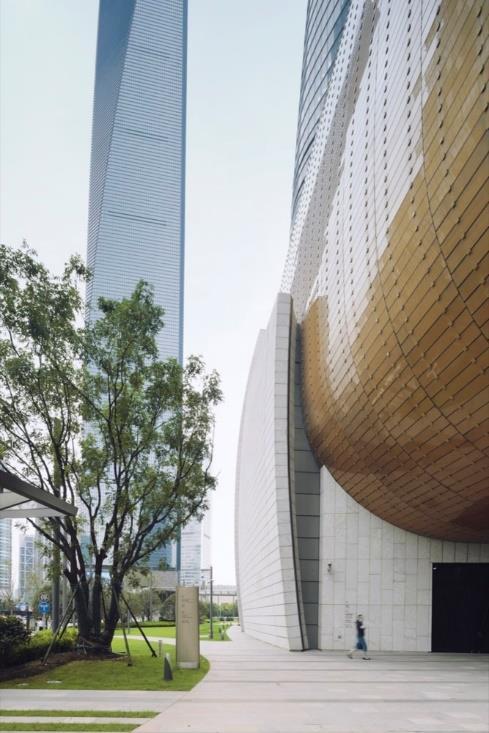

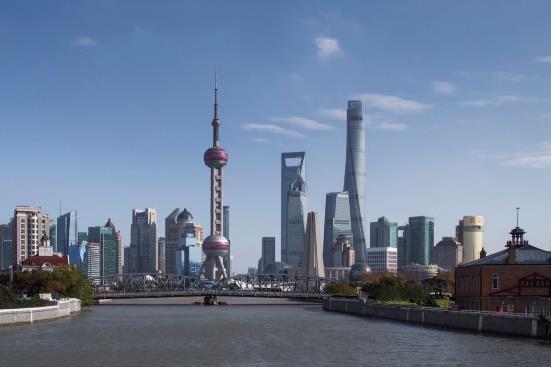

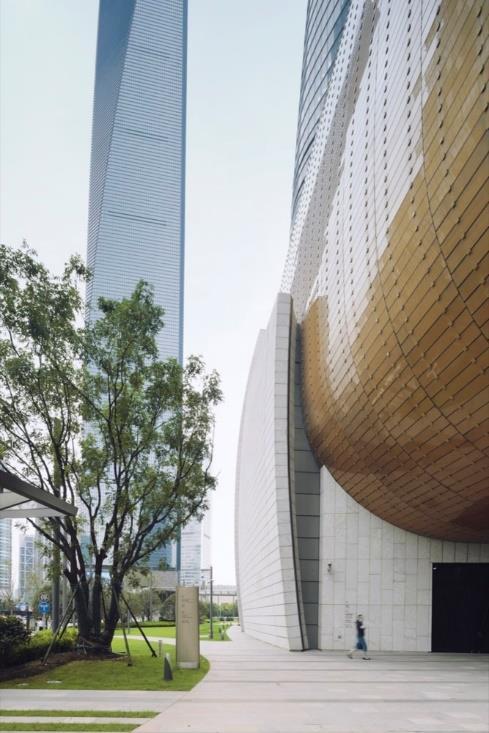

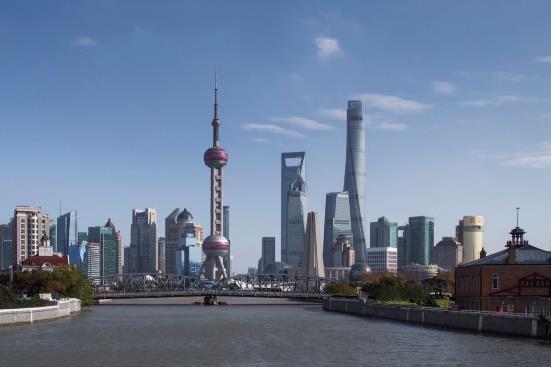

General information

Status: Topped-out

Location: Lujiazui, Pudong,Shanghai

Architectural: 632 m (2,073 ft)

FIRM: Gensler

Architect: Marshal Strabala, Jun Zia and Aurthur Gensler

Floor count: 121

Floor area: 380,000 m2 (4,090,300 sf ) above

CASE STUDY

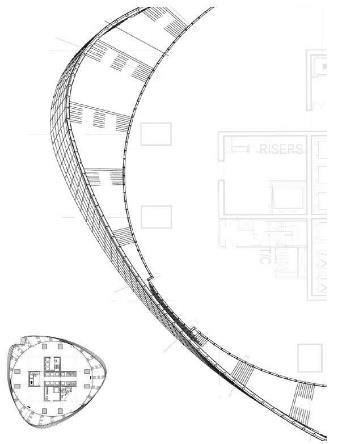

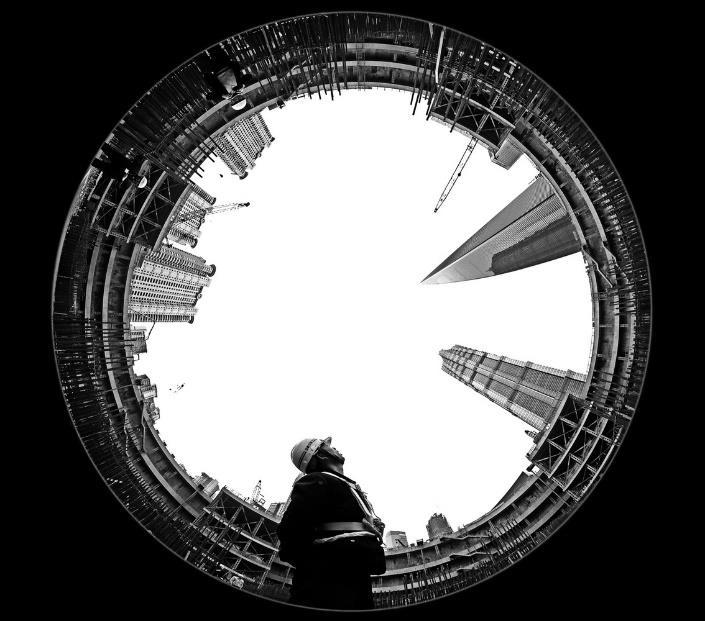

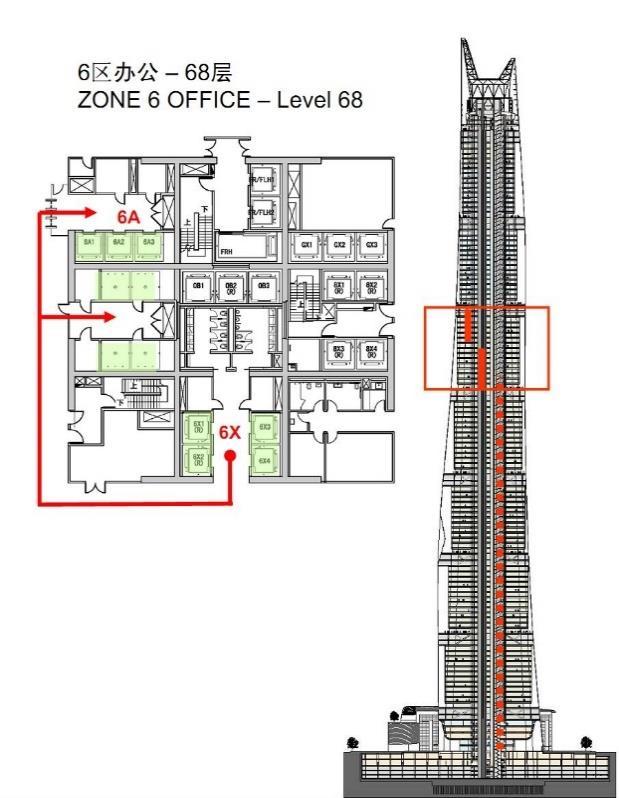

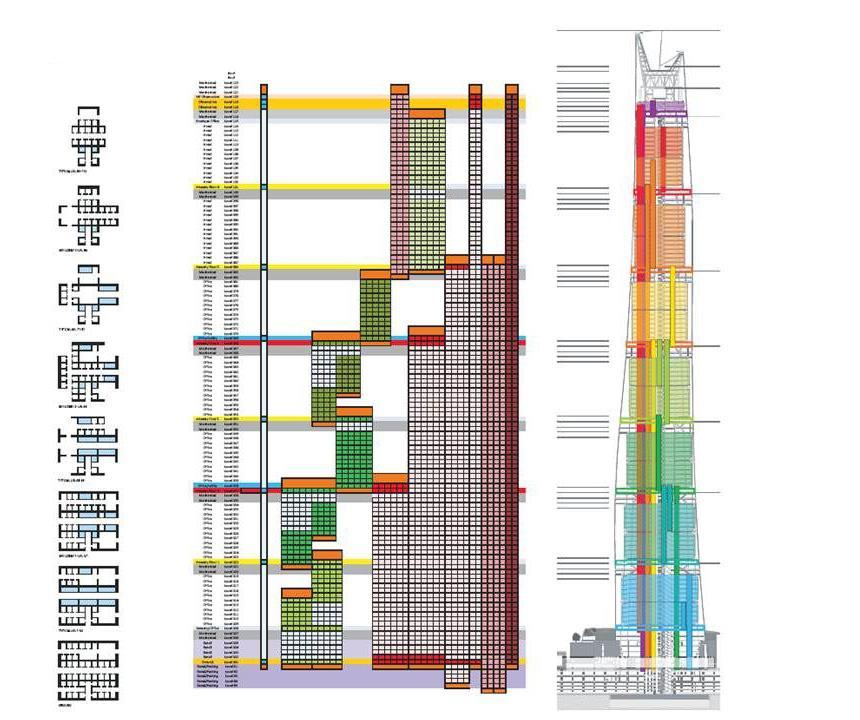

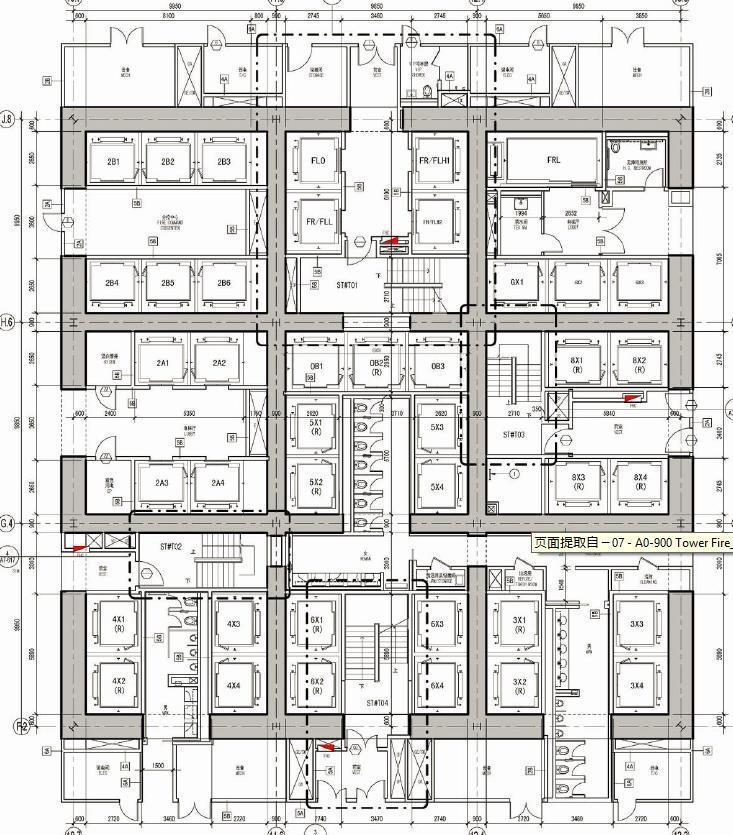

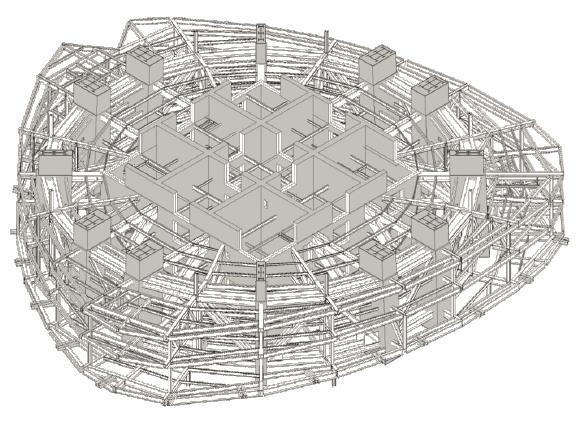

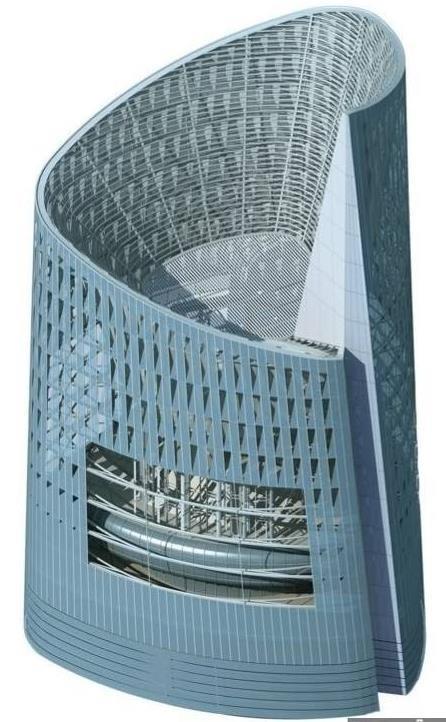

SHANGHAI TOWER CASE STUDY

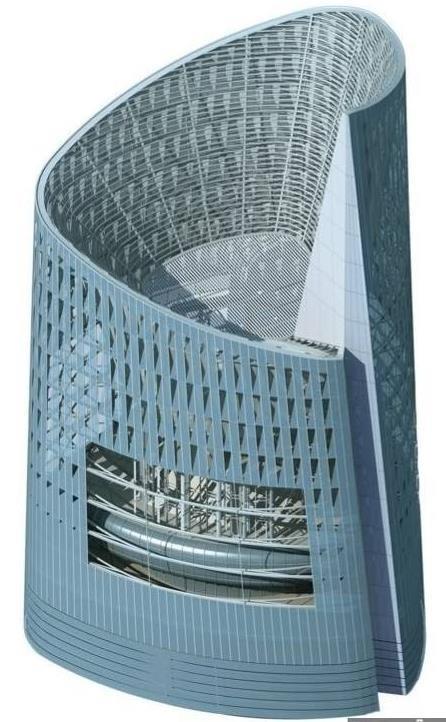

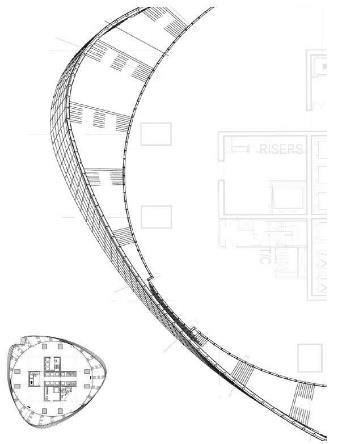

SCULPTED FOR EFFICIENCY

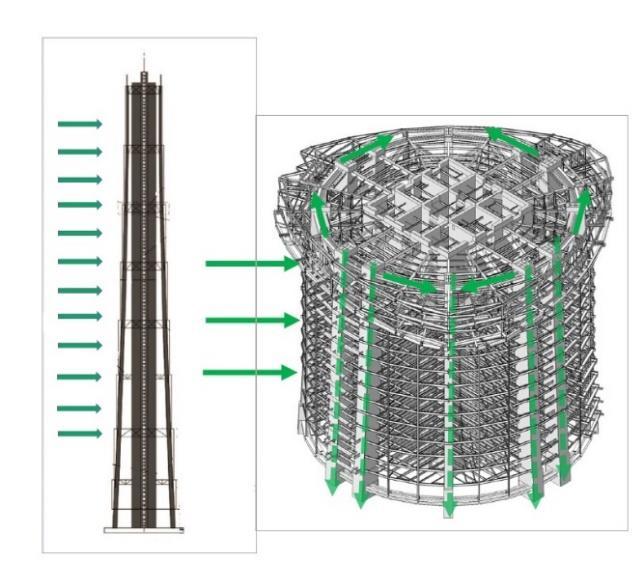

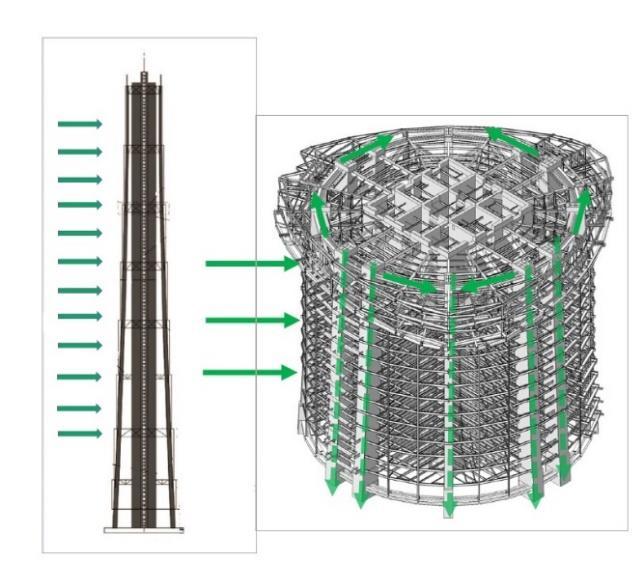

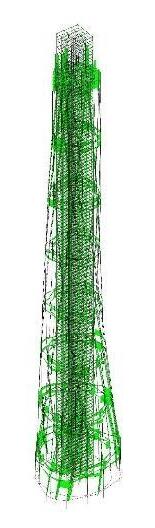

The wind tunnel test is used to find the most beneficial scaling factor of about 55% and rotation at 120°, which is account for the 24% savings of the wind load working on the structure.

TECHNICAL INNOVATION

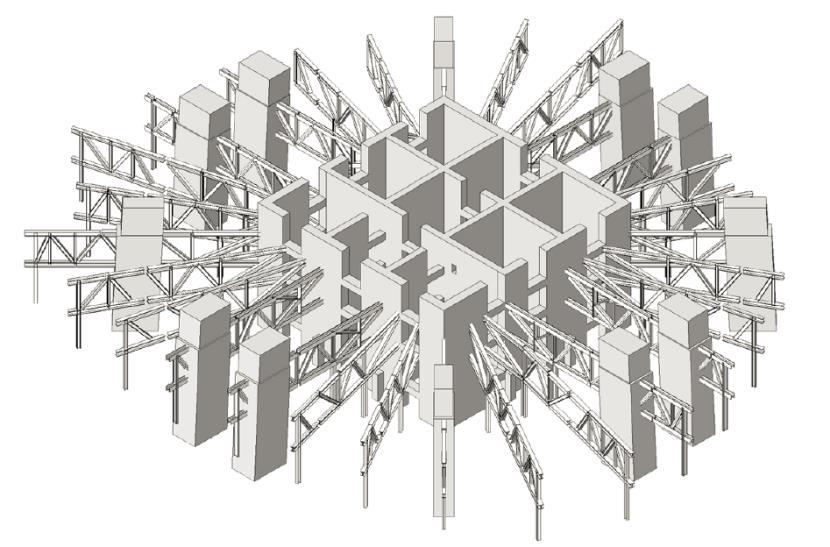

The concrete core acts with outriggers and super columns are the advances science of super-high rises.

VERTICAL COMMUNITY

Shanghai tower embodies a new concept of super-tall building by emphasizing public spaces at the atrium levels.

SUSTAINABLE ACIEVEMENTS

There are two lays of skin wrapping the entire building. The atriums created by the skins features as an insulation which keep the temperature stable.

CASE

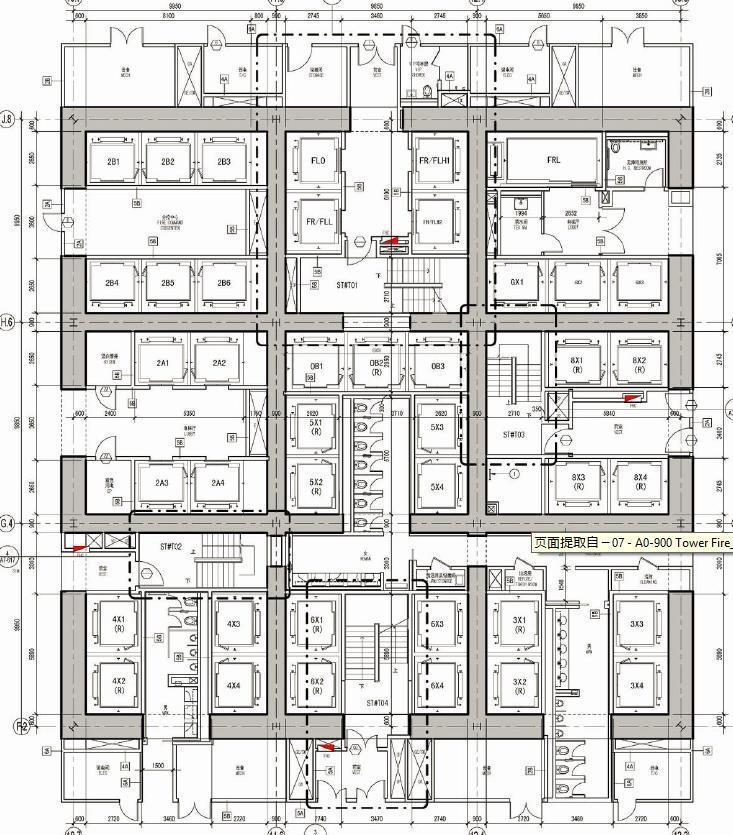

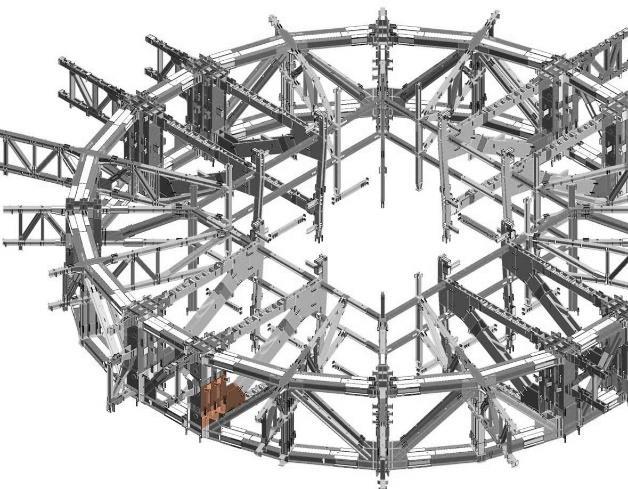

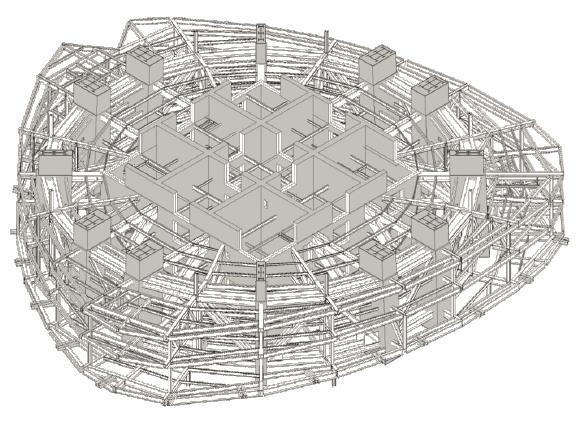

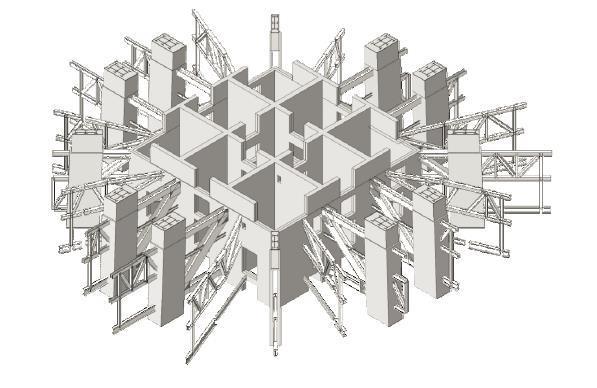

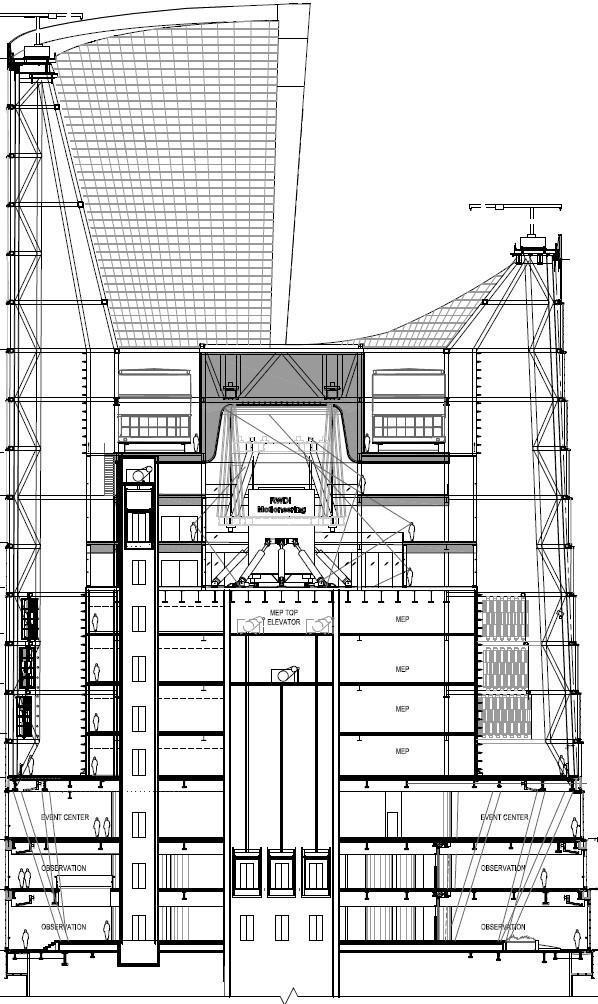

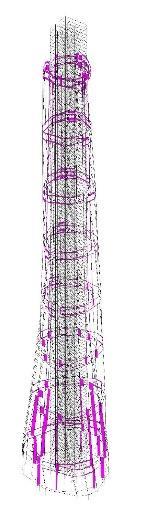

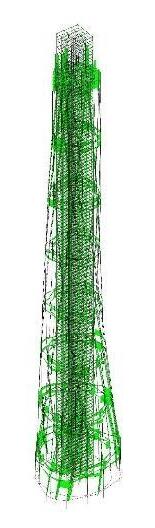

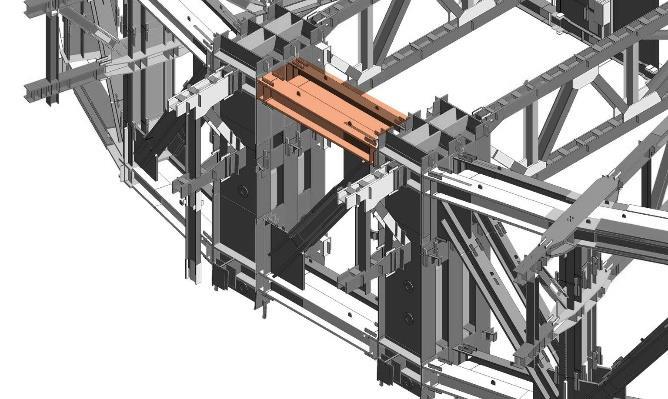

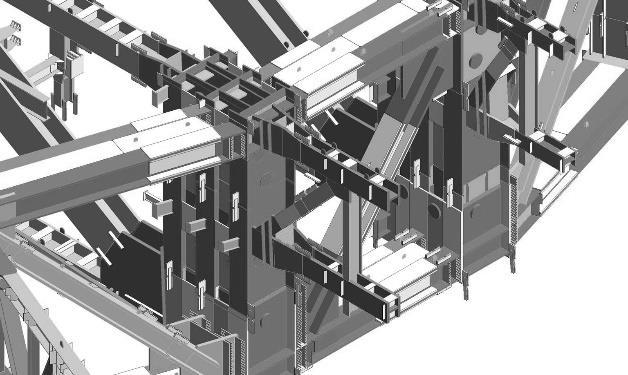

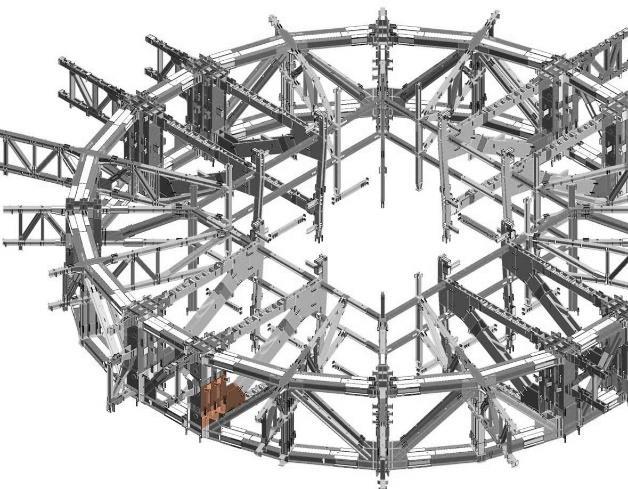

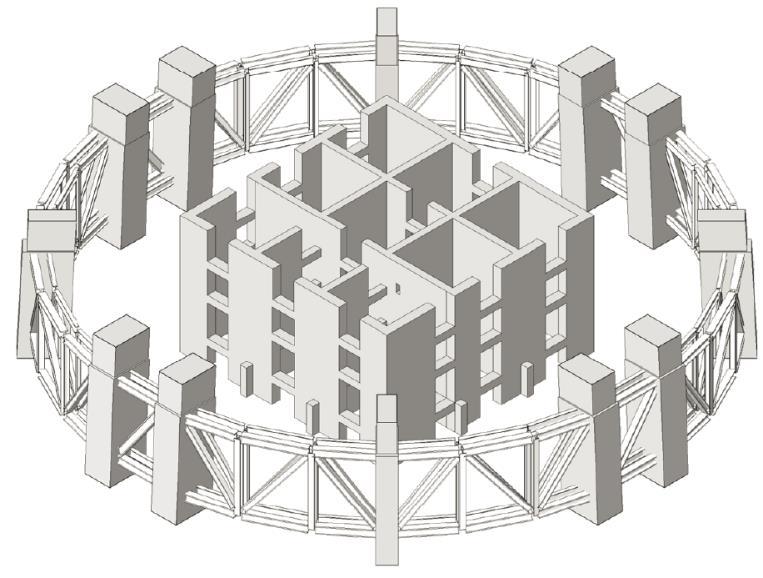

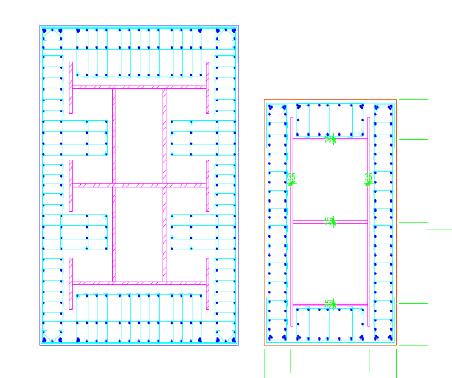

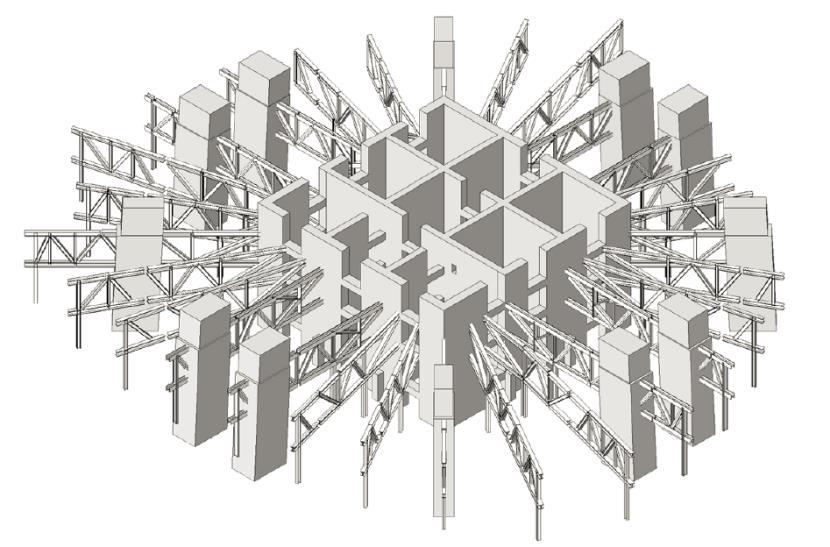

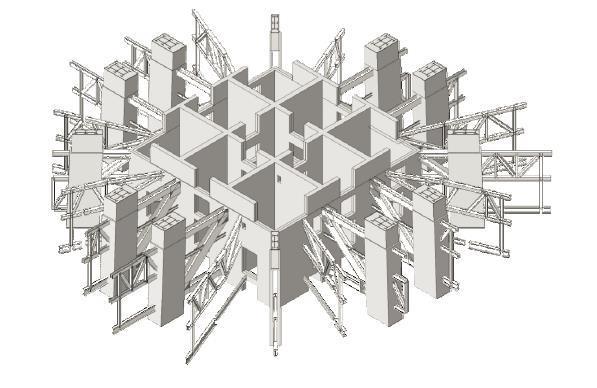

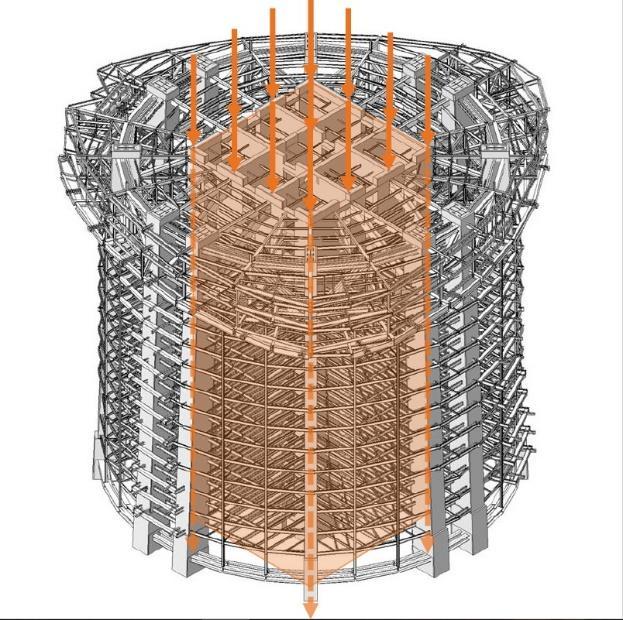

SHANGHAI TOWER PLANDETAIL TWO STOERY OUTRIGGER TRUSS ONE STORY RADIAL TRUUS CORE WALL DIAGONAL CORNER COLUMN SUPER COLUMN BELT TRUSS BUILDING

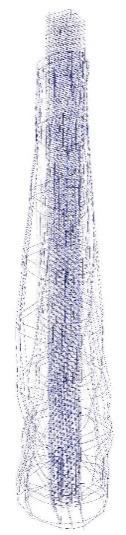

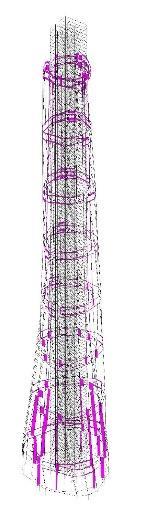

INNER CYLINDICAL TOWER • CORE • OUTRIGGERS • MEGA FRAME: SUPER COLUMN SYSTEM AND BELT TRUSS

STUDY

SYSTEM MAINSTRUCTURE

CASE STUDY

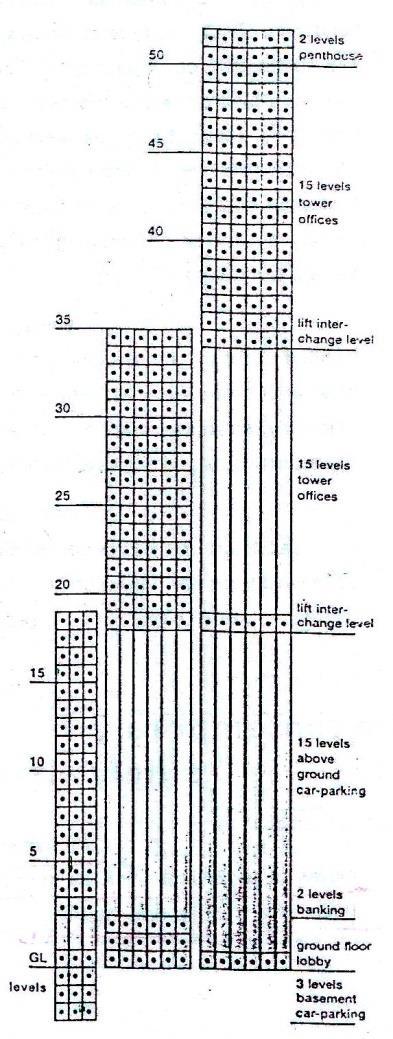

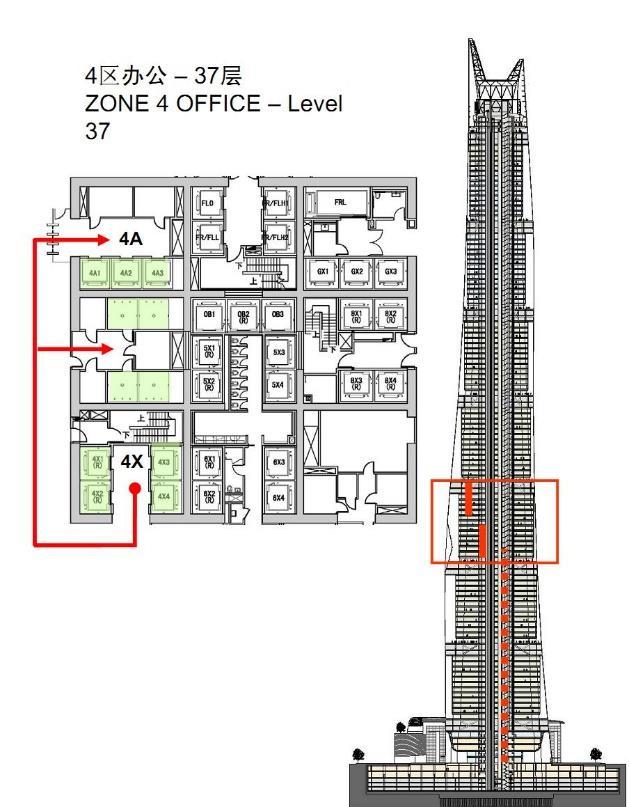

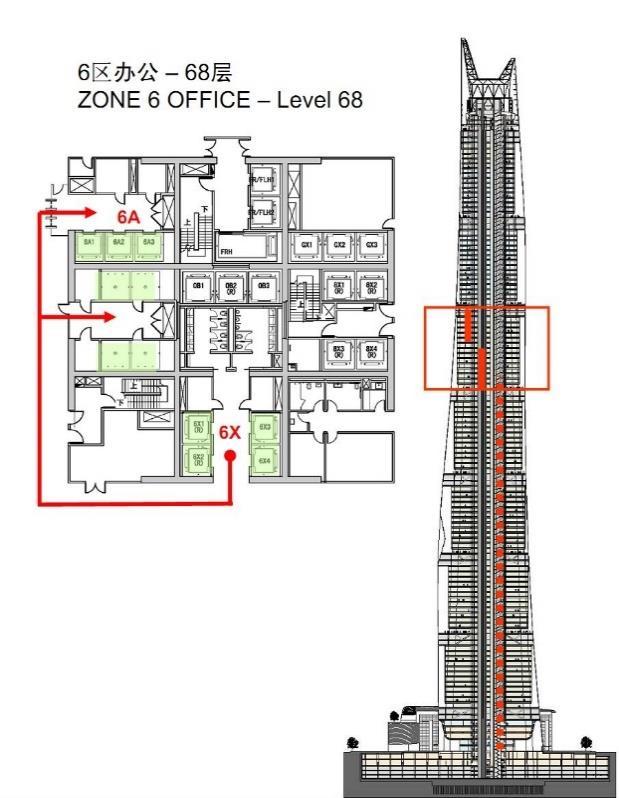

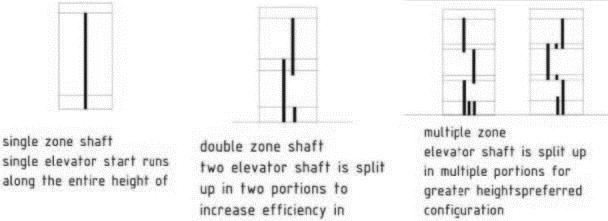

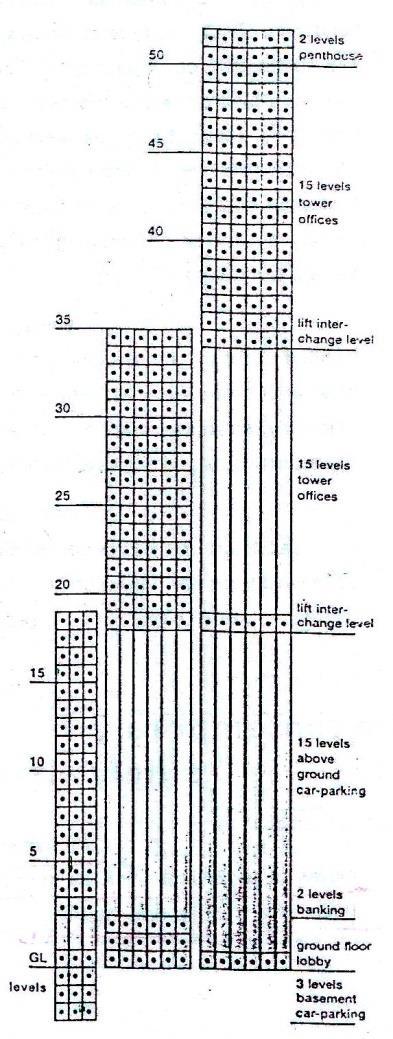

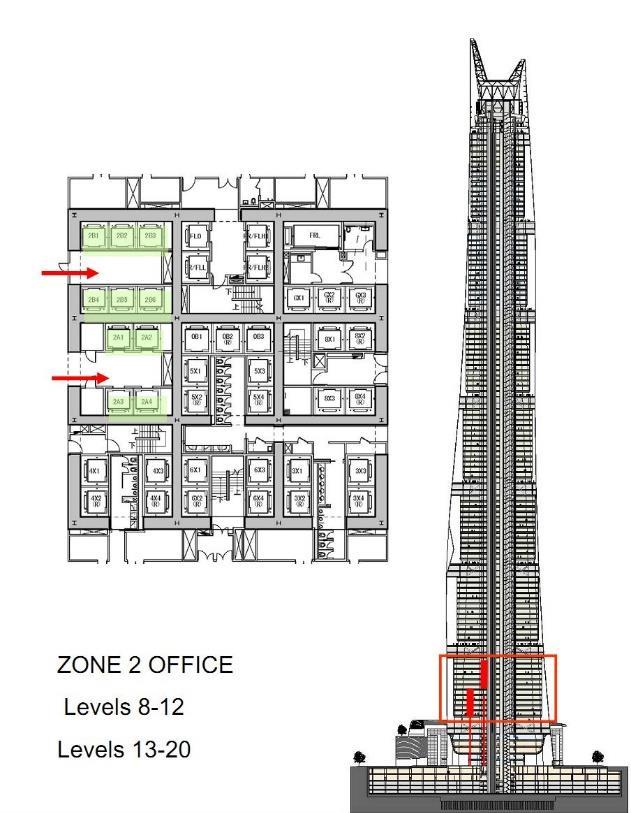

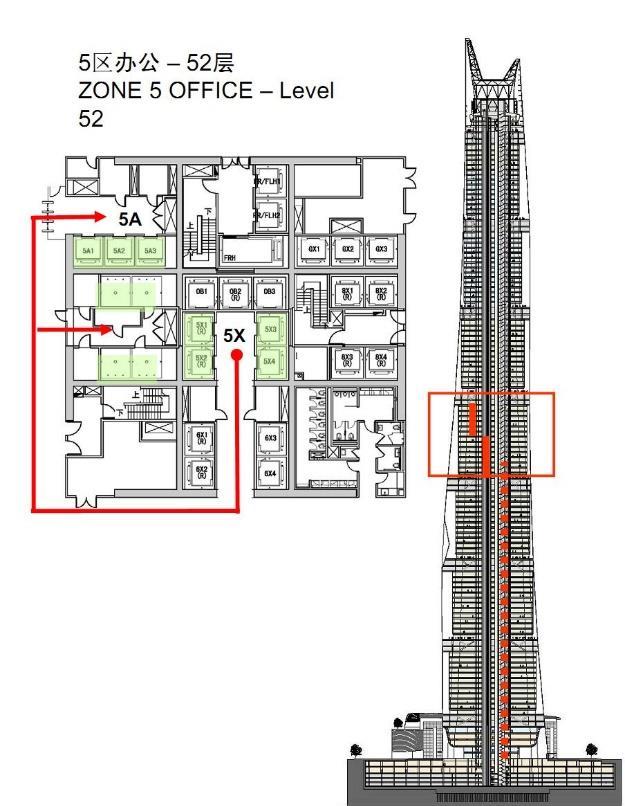

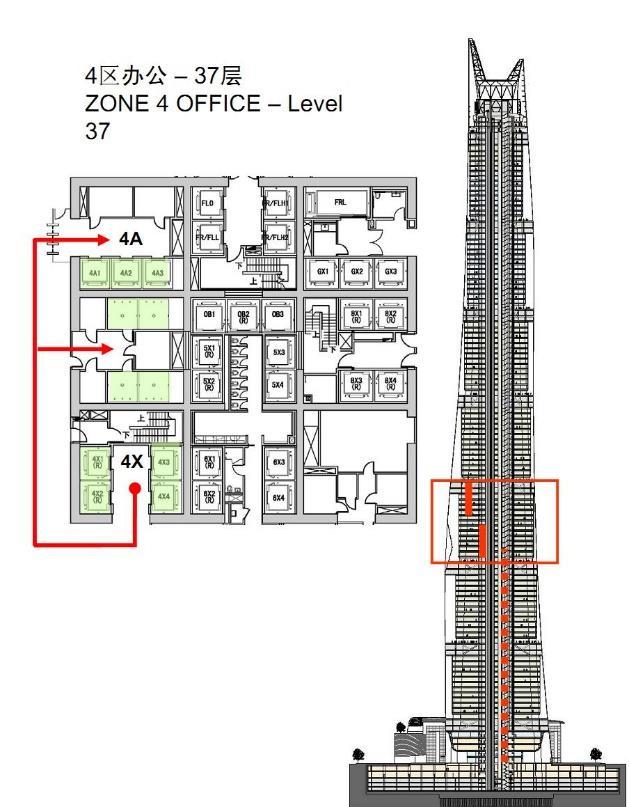

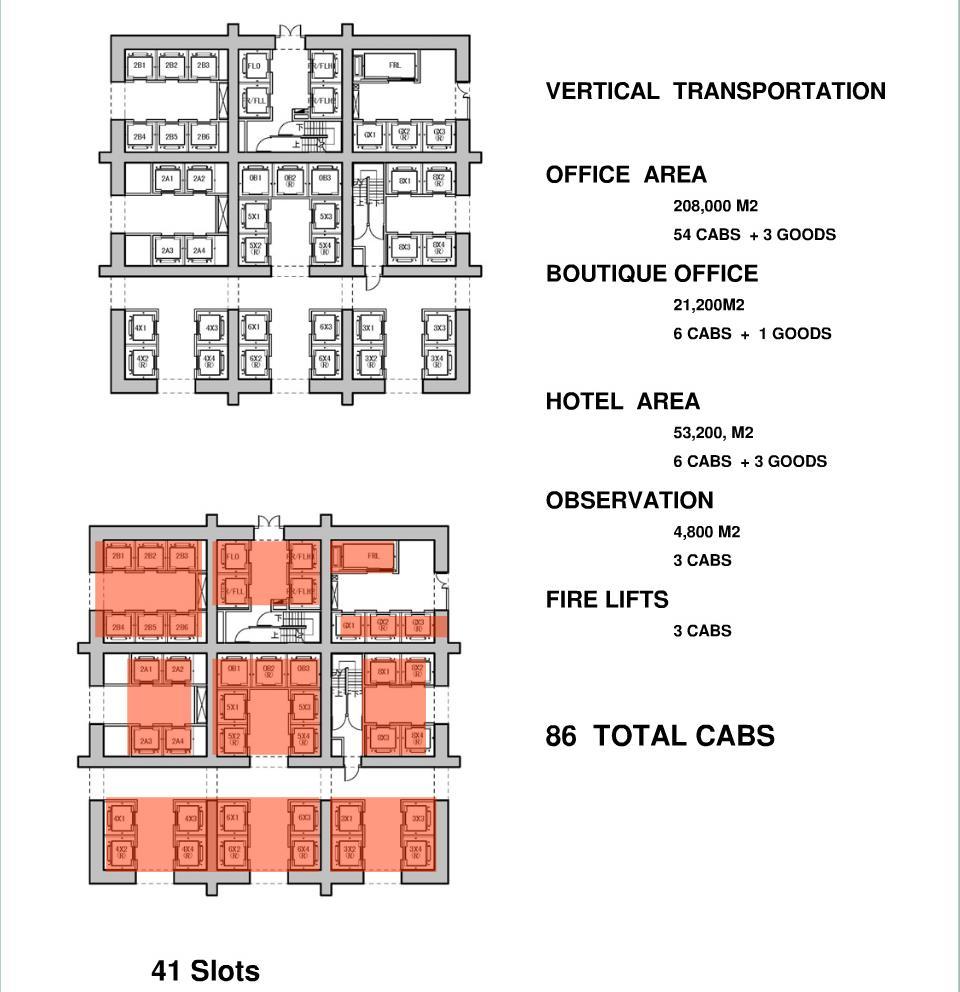

CAR ARRANGEMENT

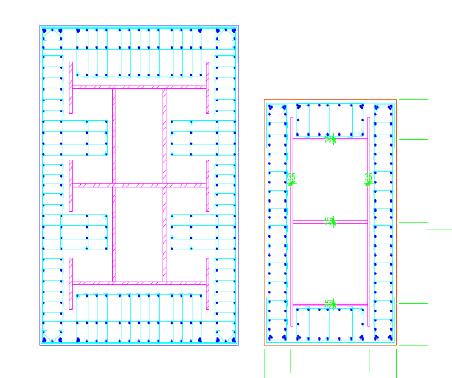

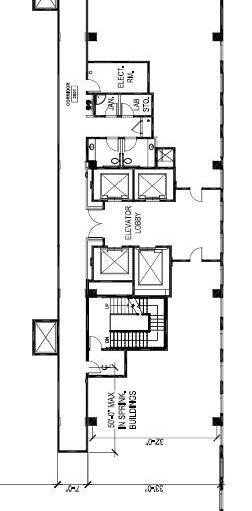

CORE ZONE 1 AND BASEMENT CORE

SHANGHAI

CASE STUDY

TOWER

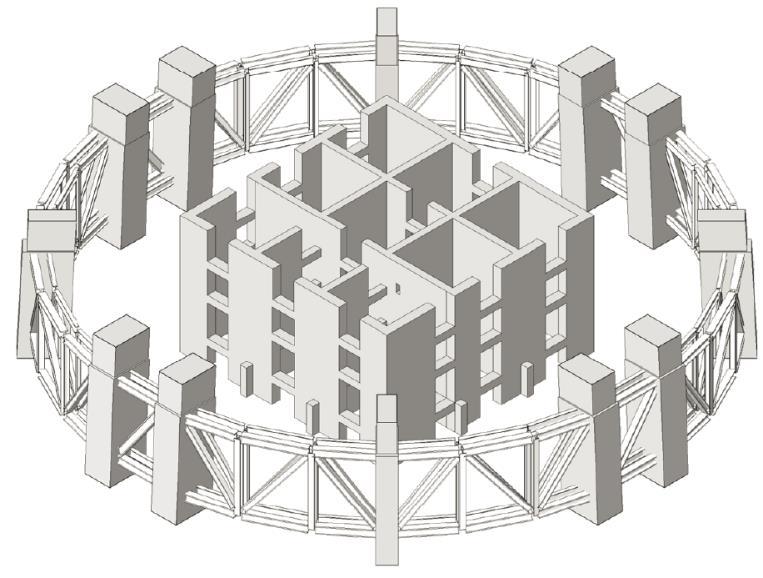

Inner Cylindrical TowerMEGA FRAME

Super column System: two at each end of each orthonormal axis four diagonal super columns along each 45-degree axis

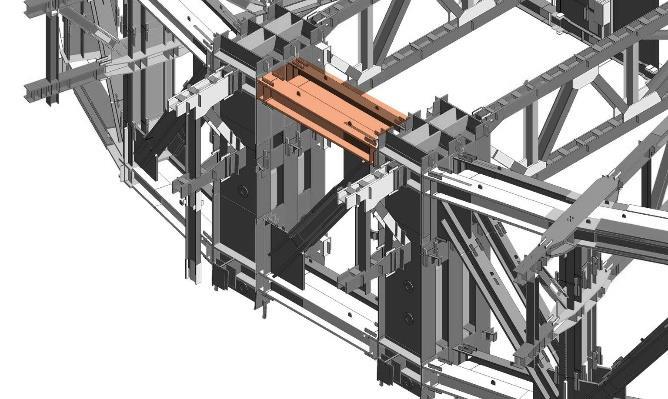

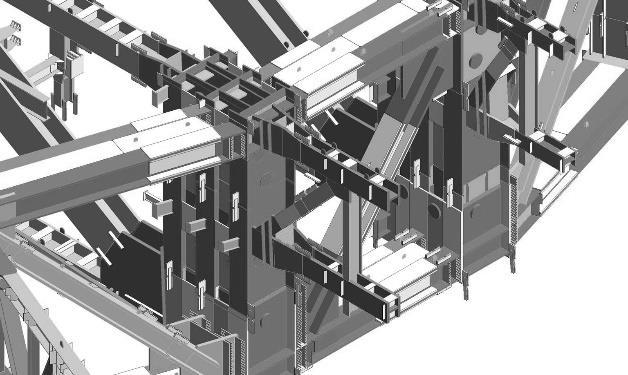

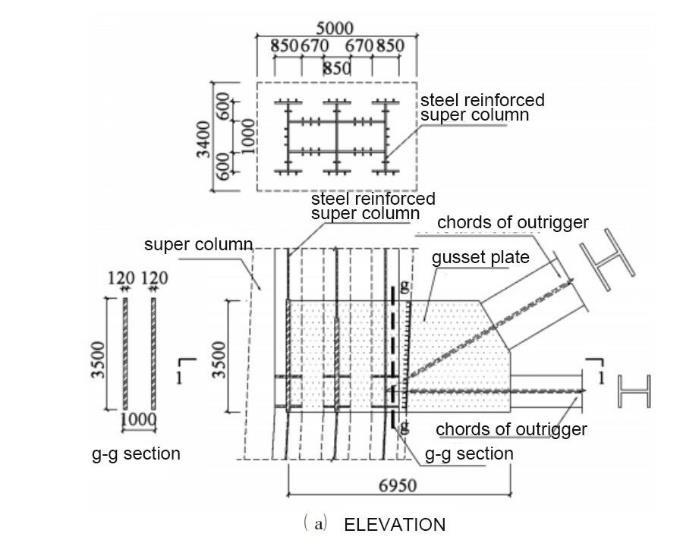

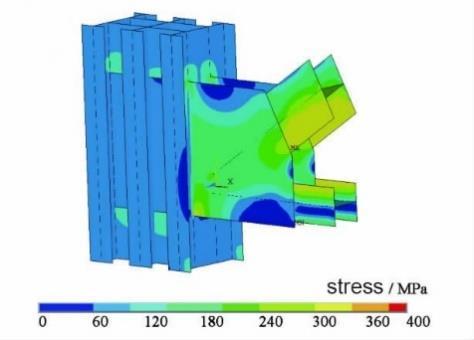

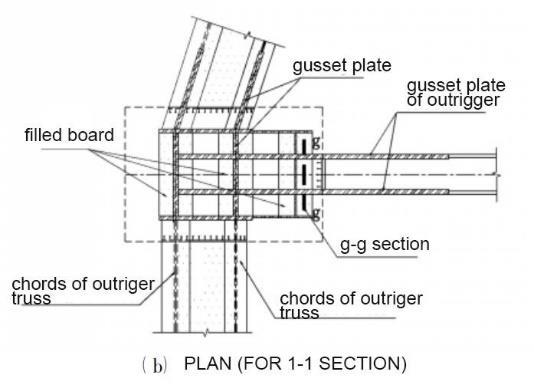

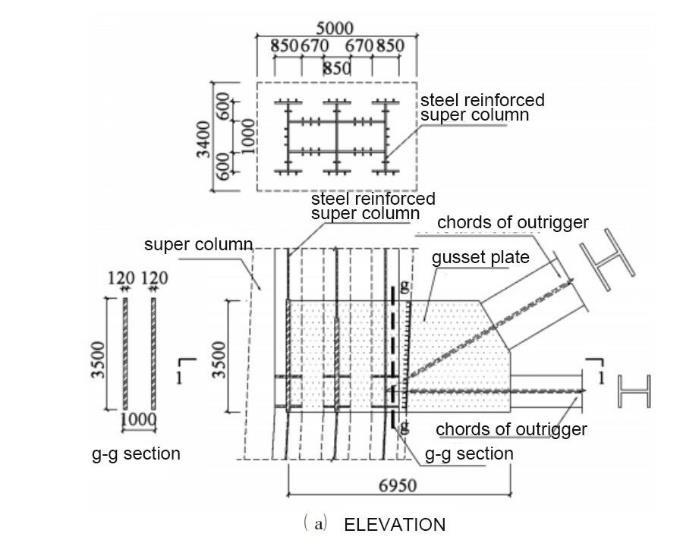

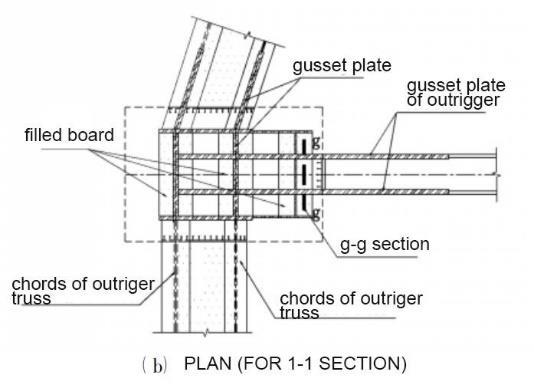

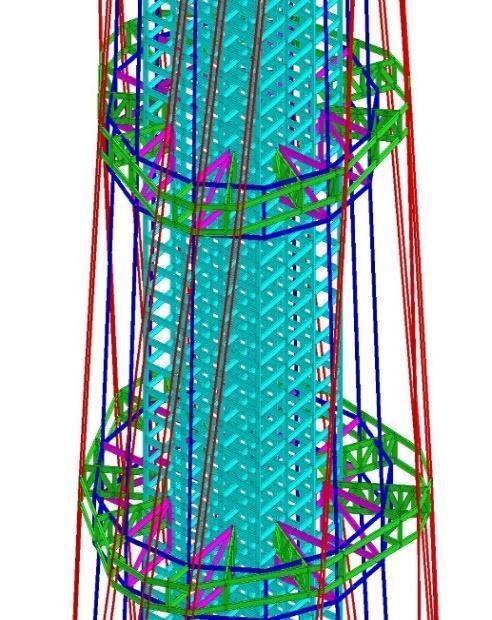

CONNECTION DESCRIPTION

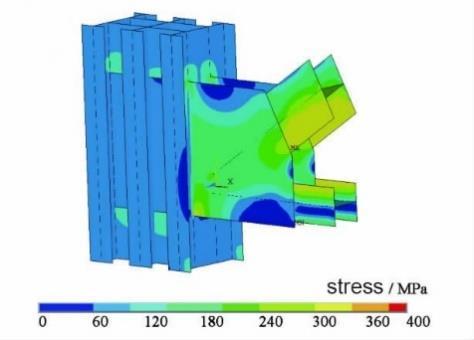

• Complexity of stress state.

• Connections should be broken after the destructiveness of members

• Different connections have different design criteria, according to the variation of structure members.

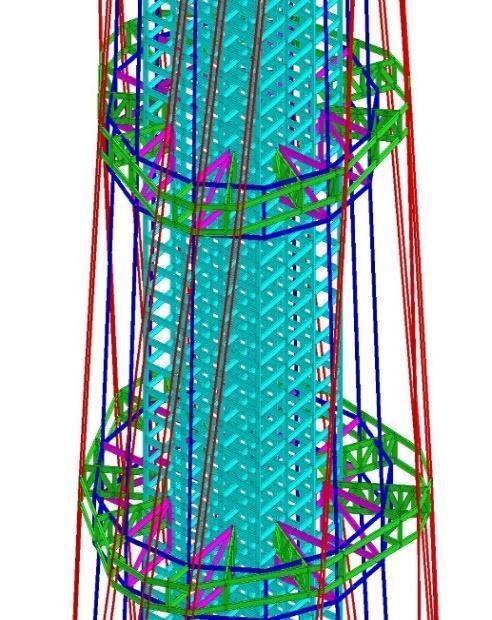

Outrigger

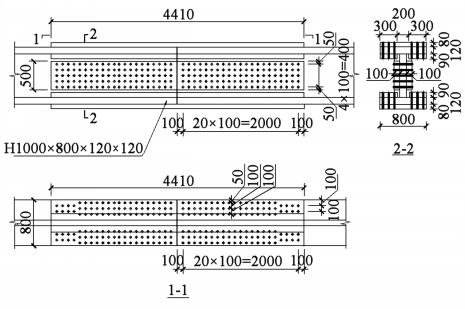

Double stories

In the steel section of the super columns, there are perpendicular cross ribs that align with belt trusses

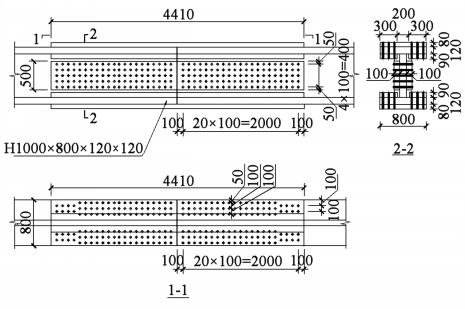

TECHNICAL FEATURES

• The chords of outrigger truss

• Gusset plates, 120mm thickness, Q390GJC steel

• The steel reinforced dual web of the super-column

• The belts trusses

Radical Outrigger

One story

Technical Feactures

• Since there exist large member force of the chords in the belt trusses, there are large quantity of the bolts, and super length of the bolts set.

SHANGHAI TOWER CASE STUDY

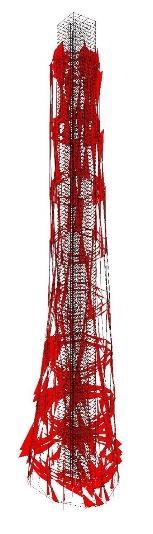

STRUCTURAL FEATURE

1-6 ZONE 7-8 ZONE

SECTION OF THE SUPER COLUMN

Type A: The Joint of Outrigger to Super-column

Type B: The Long Bolt Joint of the Belt Truss

CASE STUDY

SHEAR MOMENT TENSION DEFLECTION

LATERAL LOAD TRANSFER

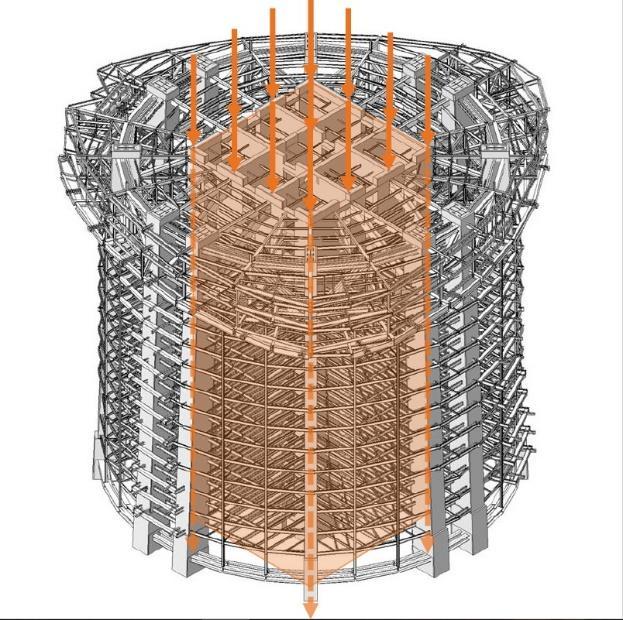

Type C: The Detail of Interior Curtain Wall Type D: The Detail of Exterior Curtain Wall LOADING ANALYSIS GRAVITY LOAD TRANSFER PATH THE MEGA FRAME 50% TUBE OF COLUMN 50% STRUCTURE COMPONENT SHEAR FORCE OVERTURNING MOMENT THE MEGA FRAME 47% 76% TUBE OF COLUMN 53% 24%

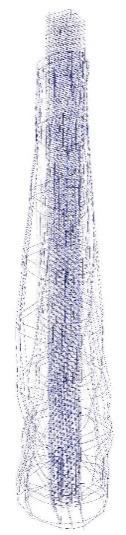

Building resist to Lateral loads through 3 layers of structure, they transfer wind and seismic load one by one, from inside to outside.

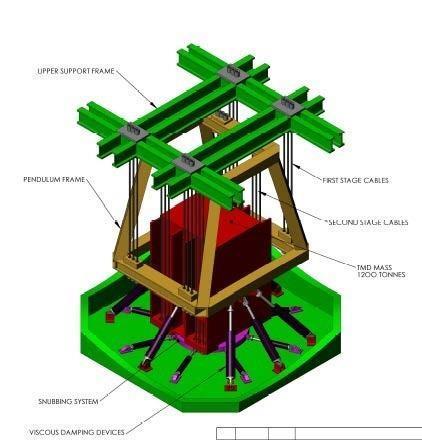

Tower Top

• Vertical fin-like truss

• Two-way truss

• Octagonal steel frame bracing system

CASE STUDY SHANGHAI TOWER

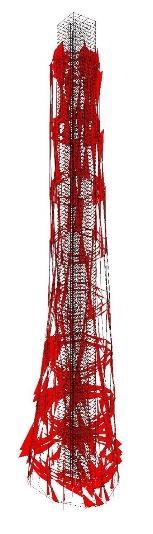

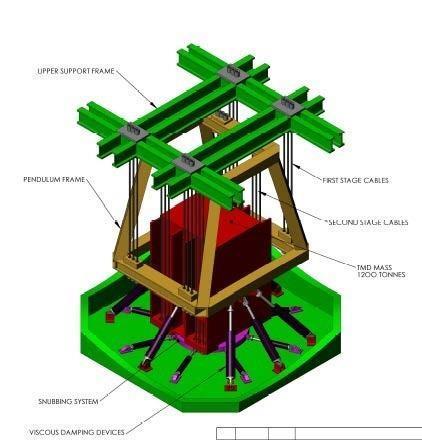

The tuned mass damper

Multi-frame Analysis

The Supper core is the first layer of Resistance. The double belt truss and super column are the second layer of Resistance. The outriggers and radial trusses are the third layer.

CASE STUDY SHANGHAI TOWER

THANK YOU

PHOTO GALLERY

THANK

YOU