Subsea tooling catalogue

Specialist subsea tooling and equipment within our mechanical solutions service line ashtead-technology.com

For details on our full equipment fleet, visit ashtead-technology.com

What we do

Through our three service lines – survey & robotics, mechanical solutions and asset integrity – we support the installation, IMR and decommissioning of offshore energy infrastructure.

offshore Technology, Overview

leading

What we do

Through our three service lines – survey & robotics, mechanical solutions and asset integrity – we support the installation, IMR and decommissioning of offshore energy infrastructure.

Overview

What we do

Through our three service lines – survey & robotics, mechanical solutions and asset integrity – we support the installation, IMR and decommissioning of offshore energy infrastructure.

Support services

We provide offshore deployment services carried out by our highly-skilled and experienced personnel. We also provide an asset management service for equipment repair, maintenance and storage to ensure the operational readiness of our customers’ assets.

Extensive tooling fleet

Ashtead Technology offers the broadest and most advanced range of subsea rental equipment from leading manufacturers. Leveraging our in-house engineering capability, we also specialise in a wide range of in-house designed equipment.

Overview

ashtead-technology.com Key Contacts

01 Valve manipulation tools & accessories 02 Dredging & jetting 03 Cutters & grinders 04 Subsea pumping & injection 05 Topside pumps 06 Cleaning tools 07 Manipulators 08 Hydraulic power units & reelers 09 Sampling tools 10 Intervention skids 11 Grabs 12 Bags, mattresses & baskets 13 Miscellaneous ROV tools 14 Camera boom arms inspection camera’s 15 ACE Winches Lifting, pulling and deployment contents Looking for a bespoke solution or something not featured in this catalogue? Visit our website: www.ashtead-technology.com

Our international team of experts are ready to support you

Section 1

Valve manipulation tools & accessories 02 Dredging & jetting 03 Cutters & grinders

Subsea pumping & injection 05 Topside pumps 01

01

04

Valve manipulation tools & accessories

Applications

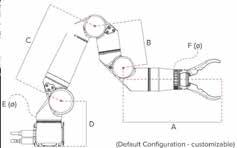

7-function (or custom fit)

Highly modular & configurable

450m depth rating

10kg full reach lift

In-build kinematics

Master arm controlled

Features

Ready-built and designed for industry leading inspection class vehicles

All-electric, zero oil

End effectors: grabbers, probe handlers, cutters (or BYO)

Advanced software interface with 3D visualisation

One-click deploy/stow position

Adjustable grab force

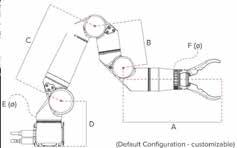

Reach Robotics Bravo 7 Arm

A tough, 7-function manipulator for inspection class vehicles

The Bravo 7 is a 7-function manipulator that opens up new compact inspection and intervention opportunities for service providers, researchers, and other operators. Designed to conduct tasks usually reserved for human drivers, the arm's dexterity and responsiveness pave the way for advanced applications. The form factor was specifically designed for industry leading inspection-class ROVs making it ready-to-go option for existing fleets.

Reach Robotics Bravo 7 Arm

Specifi cations

Joint

End-effector accuracy

Grabber close force

Optional sensor interface

Control modes

Power interface

Bulkhead

Pigtail

Comms interface

Bulkhead

Pigtail

<10mm

80kg (800N)

PWR + 485 + Ethernet

Position, velocity, cartesian (XYZ)

MCBH4M - MC 4C male

MCIL4F - MC inline, 4C female, 60cm

MCBH8ME - MC Ethernet, 8C male

MC Ethernet inline, 8C female 100cm

20-48V Voltage Nominal power Peak power Electrical 200W 300W COMS RS232/RS485/Ethernet

Depth Temp Material 450MSW 0°C to 40°C AL7075 T6

Lift capacity Max lift Weight (air) Weight (water) 10kg 20kg 9.5kg 4.5kg Reach Full reach lift

Environmental

Mechanical

speed

force 900mm 10kg 45°/s 10kN

Linear

Applications

Class 1-4 valve operations

Flying lead operations

Features

ISO 13628-8 fig 18 (API 17D)

Class 1-4

Modified client specific interfaces available

Max torque 2,711Nm / 2,000 lbf-ft

Provides torque feedback, output turns count & visual indication of motor turns

In the box

Class 1-4 torque tool

Fish tail handle

Hose set

Operations and maintenance

manuals

All hoses supplied

Zetechtics Class 1-4 Torque Tool

500-2,711Nm

class 1-4 torque tool

The Jupiter Subsea Intelligent Torque Tool Class 1-4 Rotary Docking interfaces with subsea production systems and is capable of producing torque up to 2,711Nm (2,000 lbf-ft). The tool can provide torque feedback, turns count, torque range sensing and visual indication of motor turns.

The tool conforms to the ISO 13628-8 fig 18 class 1-4 bucket interface used extensively in the subsea industry for valve overrides operated by ROV.

Zetechtics Class 1-4 Torque

Tool Specifications

Interface

Maximum working torque

Weight in air

Weight in water

Maximum working depth

Maximum motor supply

Maximum latch supply

Recommended hydraulic fluids

Electrical interface

Hydraulic connections

Class 1-4 Rotary docking interfaces to BS EN ISO 13628-8 2006

Low Torque Gear : 500Nm (369 lbf-ft)

High Torque Gear : 2,711Nm (2,000 lb-ft)

47.7kg

37.1kg

3,000m

160bar (2320psi)

210bar (3045psi)

Shell Tellus 22 or 32 Castrol Hyspin AWS 22 or 32

Burton 55 series 1508

CW & CCW: 8 JIC

Latch & unlatch: 4 JIC

High torque: 4 JIC

Motor Case: 4 JIC

Comp: 4 JIC

Applications

Class 1-4 valve operations

Flying lead operations

Features

ISO 13628-8 fig 18 (API 17D) class 1-4

Max torque 2700 Nm / 2000ft lbs

Dual range

Dual sensor electronic turns counter

Internal strain gauge Latching wings

Can be configured for diver use

In the box

Class 1-4 torque tool

Class 1 & 2 socket (11/16” sq)

Class 3 socket (1-1/8” sq)

Class 4 socket (1-1/2” sq)

Fish tail handle

Cage with USD mount (optional)

Hose Set

Low range converter

Operations and maintenance manual

All hoses supplied

Class 1-4 Torque Tool (API 17D)

100-2700Nm class 1-4 torque tool

This torque tool has been specifically developed to provide the highest level of performance. It has integral torque and turns counting sensors for closed loop control. When matched with a PSS supplied torque tool control manifold, it can provide precise feedback on torque response of any subsea operation. These can alternatively be utilised by connecting a PSSL universal subsea display, which would give a visual read-out of live torque feedback and turns counter.

The tool conforms to the ISO 13628-8 fig 18 class 1-4 bucket interface used extensively in the subsea industry for valve overrides operated by ROV. The tool has latching wings allowing the tool to hold on to the interface. The latching wings are hydraulically driven forward and spring retracted. Thus in the case of a loss of hydraulic power the wings will release. The tool uses a high specification drive motor for consistent torque output characteristics, even if used with direct hydraulic pressure control without the feedback sensor. The motor shares casing oil with the gearbox therefore avoiding the need for a separate compensator.

Note that for applying torques less than 108Nm (80ft lbs) the class 1&2 tool is recomended.

Class 1-4 Torque Tool (API 17D)

Specifications

Torque interface

Torque range

Motor size

Latching strength

Weight in air

Weight in water

Electrical connector

Recommended hydraulic fluids

CW

CCW

Latch

Case Drain

ISO 13628-8 fig 18 class 1-4

540-2700Nm / 400-2000ft lbs (gearbox fitted)

108-540Nm / 80-400ft lbs (direct drive)

236cc

1t at 160bar

34kg / 75lbs

28kg / 62lbs

8 pin mini burton

Shell Tellus 22 or 32 Castrol Hyspin AWS 22 or 32

4 JIC

4 JIC

¼ Swage

4 JIC

Applications

Class 5 valve operations

Features

ISO 13628-8 fig 18 (API 17D) class 5 Max torque 6750Nm / 5000ft lbs

Dual sensor electronic turns counter

In the box

Class 5 Torque Tool

Fish tail handle

All hoses supplied

Operations and maintenance manual

Class 5 Torque Tool (API 17D)

Class 5 valves up to 6,750Nm

This torque tool has been specifically developed to provide the highest level of performance using a high specification motor and robust gearbox in an efficient, low weight assembly. The socket is specially profiled for easy alignment. A range of control accessories is available including a precision surface torque verification unit for pre-dive testing.

The tool conforms to the ISO 13628-8 fig 18 class 5 interface used extensively in the subsea industry for pipeline valve operations by ROV. The tool uses a high specification drive motor for consistent torque output characteristics.

Class 5 Torque Tool (API 17D)

Specifications

Torque interface ISO 13628-8 fig 18 class 5

Maximum torque 6,750Nm / 5,000ft lbs

Torque range 1350-6750Nm / 1000-5000ft lbs

Socket size 2” square

Motor size 315cc

Weight in air 54kg / 119lbs

Weight in water 41kg / 90lbs

Electrical connector 8 pin mini burton

Recommended hydraulic fluids Shell Tellus 22 or 32 Castrol Hyspin AWS 22 or 32

JIC

CCW 4

CW 4

JIC

Applications

Class 6 valve operations

Class 7 valve operations

Features

ISO 13628-8 fig 18 (API 17D) class 6/7

Max torque 17,000Nm / 12,600ft lbs

Dual sensor electronic turns counter

In the box

17kNm Torque Tool Class 6/7

Class 6 socket

Class 7 socket

Fish tail handle

Bladder style compensator Operations and maintenance manual

All hoses supplied

17kNm Torque Tool Class 6/7 (API 17D)

Class 6/7 short nose torque tool

This torque tool has been specifically developed to address the increasing requirement for a 17kNm tool. The interface is based on the ISO 13628-8 fig 18 class 7, with the exception of the length of the nose of the tool, this is based on the industry standard. The tool is supplied with a class 6 socket.

The tool can be supplied with a hot stab receptacle, electronic turns counter and integrated compensator unit, to allow the tool to be deployed to the subssea work site in a basket, separate from the ROV and then connections made with a hot stab.

A socket inset is used to allow class 6 size socket or class 7 size socket valves to be operated.

17kNm Torque Tool Class 6/7 (API 17D)

Specifications

Torque interface

Maximum torque

Socket sizes

Weight in air

Weight in water

Electrical connector

Sensors

Recommended hydraulic fluids

CW

CCW

ISO 13628-8 fig 18 (reduced length)

17,000Nm / 12,600ft lbs

3-1/2” square & 2-5/8” square

74kg / 160lbs

55kg / 120lbs

8 pin mini burton

Dual sensor inductive turns count sensor

Shell Tellus 22 or 32 Castrol Hyspin AWS 22 or 32

4 JIC

4 JIC

Applications

Class 6 / 7 valve operations

Features

ISO 13628-8 class 7

Up to 35,000Nm / 25,814 ft lbs

Class 4 torque tool input

Built in compensator

Two different nose lengths supplied

In the box

Norbar torque wrench

Standard length tool

Class 6 nose cone

Class 6 socket

Short nose conversion

Operation and maintenance manual

Class 4 to Class 6/7 Gearbox Adaptor

Class 6 and 7 valves up to 35,000Nm

Class 7 requires 35,000Nm to achieve this with a stand alone tool requires a very large tool which even with an ROV is not easy to manoeuver. To overcome this issue the convertor tool is used. The tool contains a class 7 output interface and a receptacle for a class 4 torque tool, in between the two is a multiplication gearbox. The tool provides the required torque but maintains all the control (torque and turns) of a class 4 torque tool.

Class 4 to Class 6/7 Gearbox Adaptor

Specifications

Input

API 17D class 4 rotary torque receptacle

2,700Nm / 2000ft lbs maximum with 1 ½” male square drive

Output 35,000Nm / 25,814ft lbs maximum with female square drive adaptors

Ratio

Depth rating

3 ½” (class 7) and 2 5/8” (class 6)

12.2:1 mechanical advantage / 14.1:1 velocity ratio

3,000m / 2842ft with integral pressure compensation

Weight - class 7 standard in air 76kg / 167.5lbs

Weight - class 7 standard in water54kg / 119lbs

Weight - class 7 short in air 60kg / 132.2lbs

Weight - class 7 short in water 54kg / 119lbs

Materials

High strength lightweight materials for manipulation via an ROV

Applications

Subsea torque tool calibration

Features

ISO 13628-8 fig 18 (API 17D)

Class 1-4

Max Torque 2,711Nm / 2,000 lbf-ft

Prove torque tool accuracy pre/ post application of valve/actuator operation

Battery lift 5 days (average display on continuously) & 5 months

standby

Rechargeable NiMH cell with low battery warning

In the box

Class 1-4 subsea torque verification system

Class 1 & 2 adaptor

Class 3 adaptor

Class 4 adaptor

Rechargeable NiMH cell

Operations and maintenance manuals

Zetechtics Subsea Torque Verification Class 1-4

Subsea class 1-4 torque tool calibration

The Class 1-4 subsea torque tool verification system allows the ROV operators to prove the accuracy of a torque tool immediately before & after operating a client’s valve or subsea actuator. The system interfaces to API 17D Class 1-4 torque tool interfaces with three different stem sizes.

The system has an ‘inbuilt’ light sensor technology that enables the display only when illuminated by ROV lights., allowing the verification system (when deployed subsea) to remain dormant for months before operation.

Information can be recorded via ROV camera or captured into the Jupiter control system ‘data logging software’ (where applicable) or both.

Zetechtics Subsea Torque

Verification Class 1-4

Specifications

Interface Class 1-4 BS EN ISO 13628-8 2006

in air

in water 11.5kg

Maximum torque 2,711 Nm (2,000 lbf-ft) Weight

16.8kg Weight

Applications

Surface torque tool calibration

Features

ISO 13628-8 fig 18 (API 17D) class 1-4

Max torque 2711Nm / 2000ft lbs

Hand held digital read out

USB output to torque tool control system

Includes easily interchangeable shafts to suit full range

Configured for 17H and Petrobras

In the box

ISO 13628-8 Class 1-4 (API 17D)

Torque tool bucket inc sensor

Class 1 & 2 adaptor (11/16” Sq)

Class 3 adaptor (1-1/8” Sq)

Class 4 adaptor (1-1/2” Sq)

Handheld display

Transducer to display cable

Display to computer cable

Operations and maintenance manual

ISO 13628-8 Class 1-4 (API 17D)

Surface

Verification Unit

Surface class 1-4 torque tool calibration

This unit is used to give pre-dive surface confirmation of the torque tool calibration. It consists of a standard ISO class 1-4 torque reaction bucket with sturdy base and built in torque sensor. The unit comes complete with USB cable to connect to torque tool control system for auto calibration.

ISO 13628-8 Class 1-4 (API 17D)

Surface Verification Unit

Specifications

Torque interface ISO 13628-8 fig 18 class 1-4

Maximum torque 2711Nm / 2000ft lbs

Handheld unit Battery powered

Materials Steel shaft, aluminium housing

Applications

Subsea torque tool calibration

Features

ISO 13628-8 fig 18 (API 17D) class 1-4

Max torque 2711Nm / 2000ft lbs

4000m / 13,123ft rated

Interchangeable shafts

Self contained unit

Rechargeable battery or ROV power

In the box

ISO 13628-8 Class 1-4 (API 17D)

Dual Line USD

Battery pack

Subsea verification unit

Battery charger

Connection cables

PC calibration software

Class 1-2 shaft

Class 3 shaft

Class 4 shaft

Operations and maintenance manual

ISO 13628-8 Class 1-4 (API 17D)

Subsea Verification Unit

Subsea class 1-4 torque tool calibration

This unit has been developed to give subsea confirmation of torque tool calibration. It consists of a standard class 1-4 torque reaction bucket with a compact torque sensor. To change shafts only one bolt has to be undone.

Torque is displayed on separate universal subsea display unit. The display contains a power on indicator (green LED) and battery low indicator (red LED). The unit can operate continuously for 30 hours, but if no activity is detected after 10 minutes the unit will go into ‘sleep’ mode and the display will power down, sleep mode can be maintained for up to eight days. The display will ‘wake up’ as soon as there is a change in signal.

ISO 13628-8 Class 1-4 (API 17D)

Subsea Verification Unit

Specifications

Torque Interface ISO 13628-8 fig 18 class 1-4

Maximum torque 2711Nm / 2000ft lbs

Battery life 30 hours permanently on 200 hours in sleep mode (sleep mode auto on)

Materials Steel shaft, aluminium housing

Weight in air 22kg / 48.5lbs

Weigh in water 18kg / 39.6lbs

Applications

Surface torque tool calibration

Features

ISO 13628-8 fig 18 (API 17D) class

5 Max torque

6750Nm / 5000ft lbs

Hand held digital read out

Output to torque tool control system

In the box

ISO 13628-8 Class 5 (API 17D)

Torque tool bucket inc sensor

Handheld display

Transducer to display cable

Display to computer cable

Operations and maintenance manual

ISO 13628-8 Class 5 (API 17D)

Surface

Surface class 5 torque tool calibration

This unit is used to give pre-dive surface confirmation of the torque tool calibration.

It consists of a standard ISO class 5 torque reaction bucket with sturdy base and built in torque sensor. The unit comes complete with USB cable to connect to the torque tool control system for auto calibration.

ISO 13628-8 Class 5 (API 17D)

Surface Specifications

Torque interface

ISO 13628-8 fig 18 class 5

Maximum torque 6750Nm / 5000ft lbs

Handheld unit Battery powered

Materials Steel shaft, aluminium housing

Applications

Surface torque tool calibration

Features

ISO 13628-8 fig 18 (API 17D) class

7 Max torque

34,000Nm / 25,000ft lbs

Hand held digital read out

Output to torque tool control system

In the box

ISO 13628-8 Class 7 (API 17D)

Torque tool bucket inc sensor

Handheld display

Transducer to display cable

Display to computer cable

Operations and maintenance manual

ISO 13628-8 Class 7 (API 17D) Surface

Surface class 7 torque tool calibration

This unit is used to give pre-dive surface confirmation of the torque tool calibration. It consists of a standard ISO class 7 torque reaction bucket with sturdy base and built in torque sensor. The unit comes complete with cable to connect to the torque tool control system for auto calibration.

ISO 13628-8 Class 7 (API 17D)

Surface Specifications

Torque interface

ISO 13628-8 fig 18 class 7

Maximum torque 34,000Nm / 25,000ft lbs

Input square Class 7 (3.5” square)

Applications

17H valve operations

Features

ISO 13628-8 fig 14 high torque

Max torque 2000Nm / 1500ft lbs

Dual sensor electronic turns

counter

Internal strain gauge

In the box

Torque Tool

Fish tail handle

Bladder style compensator

All hoses supplied

Operations and maintenance

manual

High Torque Tool (API 17H) 100-2,000Nm 17H torque tool

This torque tool has been specifically developed to provide the highest level of performance. It has integral torque and turns count sensors. When matched with a PSSL supplied control manifold, it can provide precise feedback on torque response of any subsea operation.

The tool conforms to the ISO 13628-8 fig 14 high torque interface used extensively in the subsea industry for valve overrides operated by ROV.

The tool uses a high specification drive motor for consistent torque output characteristics under hydraulic pressure control.

High Torque Tool (API 17H)

Specifications

Torque interface

Torque range

Socket size

Motor size

Weight in air

Weight in water

Electrical connector

Recommended hydraulic fluids

CW

CCW

ISO 13628-8 fig 14

100-2000Nm / 73-1500ft lbs

35mm square

200cc

36kg / 79lbs

28kg / 62lbs

8 pin mini burton

Shell Tellus 22 or 32 Castro Hyspin AWS 22 or 32

4 JIC

4 JIC

Applications

Torque tool control operations

High-flow manifold control

FLOT operations

Features

4 off bi-directional solenoid valves (15lpm) adjustable pressure & flow on each valve

RS232 or RS485 options available

Surface software runs on PC or laptop

Compact & lightweight 4000m water depth rated

In the box

Jupiter 2 Torque Tool Control

System

Laptop

Operational hoses

Operations and maintenance manual

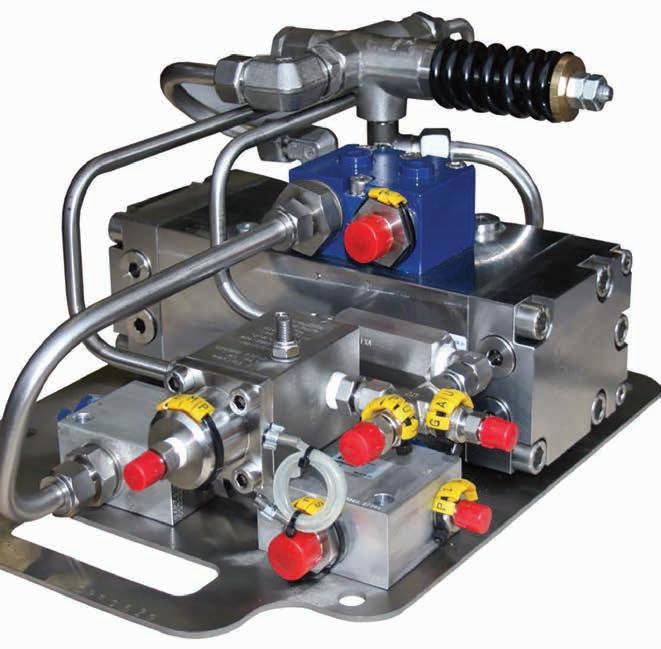

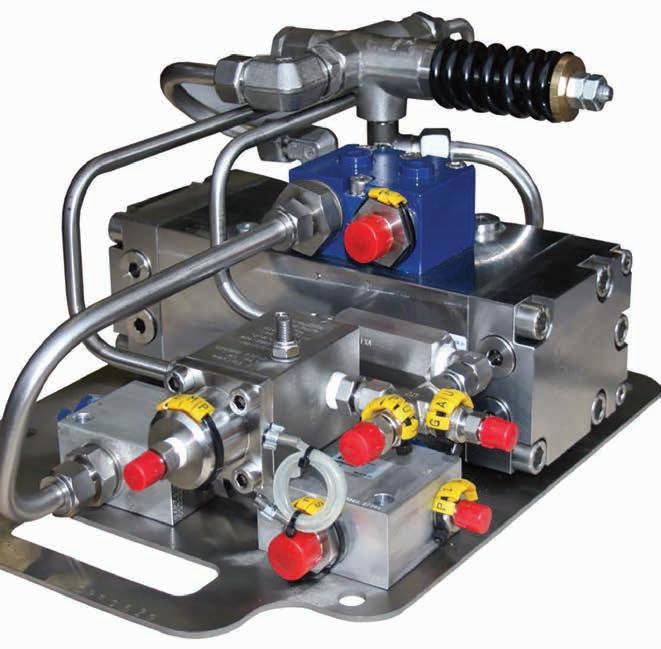

Zetechtics Jupiter 2 Torque Tool Control System

Jupiter 2 valve pack

The Jupiter 2 Torque Tool Control System offers an accurate & repeatable solution to client requirements for the control or torque tools in high integrity applications, the unit provides real time torque feedback and tool turns.

The system consists of a single valve pack with a fully integrated proportional control system. The unit is suitable for use with hydraulic torque tools operated from any Work Class ROV.

The system includes options for data-logger and features automatic calibration of the torque tools and sensors, users customisable set-up and comprehensive diagnostics.

Zetechtics Jupiter 2 Torque Tool

Control System

Specifications

Outputs

Hydraulic input

Hydraulic output

Electrical supply

Weight in air

Weight in water

Depth rating

Hydraulic connections

1 off NG6 pressure & flow control

4 off NG3 bi-directional solenoid valves

40lpm (max) @ 250bar

15lpm @ 250bar

115v AC 50/60 Hz or 24v Raw DC

28kg

16.4kg

4000m

Pressure: 6 JIC

Return: 8 JIC

Comp: 4 JIC

Applications

Torque tool control operations

High-flow manifold control

FLOT operations

Features

1 off bi-directional pressure & flow control output

3 off bi-directional output

Strain gauge and turns count input

4000m / 13,123ft depth rated

RS232 or RS485 options available

External pressure sensor

In the box

TTCS Hydraulic Manifold

Panasonic Toughbook control PC

Interconnect cables

In-line filter

Operational hoses

Operations and maintenance manual

Torque Tool Control System

Multi-purpose

intelligent valve pack

The torque tool control system allows the user, from the surface, to adjust the torque and speed. This system is particularly suitable for deepwater operations where torque required for a particular operation may be uncertain, or has multiple values for different operations on the same dive. The actual torque and speed is user controlled and measured at all times and recorded as a signature of the subsea operation for future reference.

The controller can be used with any torque tool supplied by Ashtead Technology. The system can also be used as a pressure / flow controller for tools not equipped with feedback sensors.

Torque Tool Control System

Specifications

Outputs

Pressure sensor

Electrical inputs

Protection

Hydraulic input

Hydraulic output

Electrical supply

Connects with laptop controller

1 X 8 pin female feedback cable

1 X 8 pin mini burton female tail

3 off NG3 mini

1 off proportional pressure & flow

One on proportional pressure line

Strain gauge

Turns counter

Internal ground fault detection

External pressure relief valve

20lpm / 5.2gpm at 207bar / 3000psi

8lpm / 2.1gpm at 200bar / 2900psi (per station)

110VAC, 2A maximum

in air 18kg

Weight in water 14kg

6

Return Comp 6

6 JIC

Weight

/ 39.6lbs

/ 30.8lbs Pressure

JIC

JIC

Applications

Suction pile operations

High flow tooling operations

Features

NG6 bi-directional proportional pressure and flow valve

NG10 proportional pressure and flow valve

Differential pressure sensor

Flow meter input

In the box

High Flow Manifold

Connection cable to TTCS

Operational hoses

Operations and maintenance manual

High Flow Manifold High flow system for TTCS

The high flow manifold is an auxilary manifold that connects to the standard torque tool control system. The manifold contains an NG6 bi-directional proportional pressure and flow control and an NG10 proportional pressure and flow control valve. Also in the manifold is a differential pressure sensor used for suction pile operations. The manifold has an input for a optional flow meter. The standard torque tool control sytem software controls and displays readings from the manifold. Additionally input from an external gyro can be displayed on the software for suction pile operations.

High Flow Manifold Specifications

Working pressure

207bar / 3000psi

Maximum flow 80lpm / 21.1gpm

Weight in air 31kg / 68lbs

Dimensions 345 x 220 x 358mm / 13.5 x 8.6 x 14in

Applications

Class 1-4 valve operations

Paddle value operations

Features

Tool supplied with a calibrated torque wrench to allow accurate torque setting adjustment and predive verification

Lightweight construction

Smart socket

Fitted with torque resistant compliant mount

In the box

Fish tail handle

Calibrated torque wrench

Paddle valve interface

Operations and maintenance manual

Manipulator Held Clutch Tool

API 17D, ISO 13628-8 class 1-4

The Manipulator Held Clutch Tool is designed to allow the ROV manipulator operation of API 17D, ISO 13628-8 Class 1-4 rotary torque interfaces. The tool limits the torque that can be transmitted from the ROV manipulator to the valve stem during an ROV intervention operation, mitigating against the possibility of excessive torque being applied, ensuring damage to the valve does not occur. The tool is fitted with an integral, adjustable torque limiting clutch which can be pre-set for torque ranges of 20200 Nm. The front of the tool features a “smart” multi-socket interface which eliminates tool reconfiguration time on deck.

Manipulator Held Clutch Tool

Specifications

Depth rating Can be used at any water depth

Adjustable maximum torque settingFrom 20 to 200 Nm

Approx weight in air 14kg

Approx weight in water 12kg

Applications

Class 1-4 valve operations

Features

ISO 13628-8 fig 18 (API 17D) class 1-4

Max torque 2700Nm / 2000ft lbs

Manually operated torque tool built in 5:1 gearbox

Integrated carrying loop

Can be configured for 17H interface In the box

Class 1-4 Hand Operated Torque Tool

Gearbox assembly

Class 1-2, 3 and 4 sockets ¾” drive torque wrench

Operations and maintenance manual

Class 1-4 Hand Operated Torque Tool

Ideal for manual valve operations

The hand operated torque tool confirms to the ISO 13628-8 fig 18 interface requirements, it is supplied with a class 4 socket. Extra sockets can be supplied on request. The tool is intended for subsea operation to verify the interfaces on subsea equipment and to operate valves without the need for an ROV and a hydraulic supply.

The tool has a built in 5:1 gearbox to supply torques up to 2700Nm by hand. The tool is supplied with a torque wrench so torques can be accurately applied.

Class 1-4 Hand Operated Torque Tool

Specifications

Torque interface

Torque range

Socket size

Gearbox ratio

Materials

ISO 13628-8 fig 18 class 1-4

30-2700Nm / 22-2000ft lbs

Class 1-2, 3 and 4

5:1

Steel motor and gearbox, duplex socket, aluminium housing and acetal hose

Applications

17H valve operations

Features

ISO 13628-8 class 4 female bucket

API 17H male interface 35mm AF square Max torque 2700Nm / 2000ft lbs

In the box

17D-17H Adapter 900Nm / 663ft lbs sheer pin 2700Nm / 2000ft lbs shear pin

Operations and maintenance manual

Ashtead Technology

17D to 17H Adapter

Convert class 1-4 to 17H high torque interface

The adaptor is used to convert from ISO 13628-8 class 4 (API 17D) to API 17H high torque interface. Shear pins are supplied with the tool to protect the high torque interface from over torque.

Ashtead Technology 17D to 17H Adapter

Specifications

Female interface ISO 13628-8 fig 18 class 4

Male interface ISO 13628-8 fig 14 high torque

Maximum torque 2700Nm / 2000ft lbs

Weight in air 14kg / 30.8lbs

Weight in water 10kg / 22lbs

Applications

Manual valve operations

Features

ISO 13628-8 fig 18 (API 17D) class 1-2

Direct manipulator operation

Stainless steel construction

Class 1-2, Class 3, Class 4 High torque

In the box

Manipulator Operated Torque Tool

Operations and maintenance manual

Manipulator Operated Torque Tool Ideal for manual valve operations

The tool is used to operate ISO Class 1-2, 3 or 4 interfaces without the use of a torque tool. The tool utilises the rotate function on the manipulator to generate the required torque.

Manipulator Operated Torque Tool

Specifications

Interface ISO 13628-8 fig 18 class 1-2, 3 or 4 socket

Maximum torque Dependant on manipulator

Materials Stainless steel

Weight in air 3kg / 6.6lbs

Weight in water 2kg / 4.4lbs

Applications

Linear valve operations

Features

Range of interfaces

Up to 100t force

Range of strokes up to 10.75"

Hydraulic set, mechanical locked Manipulator or diver deployed

Can be configured for different stroke sizes

Actuator operated with either hand pump or 10K panel

In the box

LAOT actuator

LAOT locking head

ROV handle

Operational hoses

Operations and maintenance manual

Linear Actuator Override Tool (LAOT)

5.8" strokes and 10.75" strokes

Linear actuator override tools are available in a range of loads up to 100 tonnes. The tool supplied usually comprises two parts, the locking head, and the actuator. The actuator contains a hydraulically operated piston powered by an intensifier. Actuators can be supplied with hot stabs and check valves. The locking head is a purely mechanical device and is left behind on a subsea interface when the valve is required to be let over-ridden.

Interfaces available are ISO 13628-8 Type A, ISO 13628-8 Type B and customer specific two lug interface. A range of strokes are available to suit specific applications.

Linear Actuator Override Tool (LAOT) Specifications

Interface

Maximum load

Maximum pressure

Operating flow range

ISO 13628 Type A,B

Up to 100t

690bar / 10,000psi

2-14lpm / 0.5-3.7gpm

ISO 13628 Type A,B

Up to 100t

690bar / 10,000psi

2-14lpm / 0.5-3.7gpm

5.8" Strokes

10.75" Strokes

5.8" Strokes

10.75" Strokes

5.8" Strokes

10.75" Strokes

5.8" Strokes

10.75" Strokes

Applications

Flying lead operations

Class 1-4 torque tool operations

Features

+/- 15 deg roll angle

+60, - 90 degrees pitch

Counter-balance valve on both

actuators

250kg / 551.1lbs payload

In the box

Flying lead orientation tool

Adaptor to fit torque tool

Operational hoses

Operations and maintenance

manual

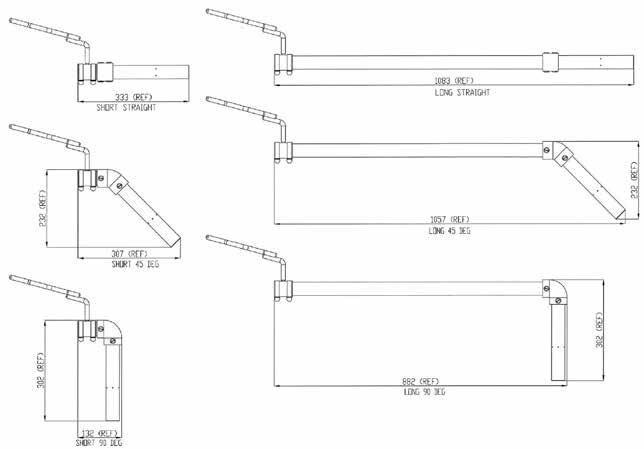

Upright FLOT Flying lead installation and removal

The FLOT tool is designed to operate in conjunction with a torque tool and is used to orientate and guide flying leads into the stab plate connections. The FLOT tool is designed to take the PSS class 1-4 torque tool, but can easily accommodate similar tools from other manufacturers. A rotary actuator allows a pitch alignment of plus 60 or minus 90 degrees with a load of up to 250kg attached. The tool is also equipped with a roll alignment function giving a rotation of plus or minus 15 degrees.

The FLOT tool is compact and the tool mounting base is supplied with a selection of mounting holes for mounting within the forward structure of the ROV. The pitch and roll actuators can be controlled from the TTCS or ROV’s spare directional control valves.

Upright FLOT Specifications

Pitch Rotation

Payload capacity

Hydraulic control from ROV

Operating fluid

Operating pressure

Hydraulic fittings

Weight in air

Weight in water

CCW

CW

Up

Down

+60, - 90 degrees

+/- 15 degrees

250kg / 551lbs mounted on torque tool, through full range of travel Two off bi-directional solenoid control valves plus drain

Hydraulic oil

207bar / 3000psi

JIC or swagelok

77kg / 169lbs

57kg / 125lbs

4 JIC

4 JIC

4 JIC

4 JIC

Applications

Torque tool feedback Pressure transducer feedback Flow counter

Features

Power input range 3.5v-35v

User-friendly configuration

software

Rugged construction

3000m / 9842ft depth rated

External battery

Multiple functions

Up to 240hrs standby

Up to 48hrs of continious

operations

In the box

Universal Subsea Display (USD)

Battery pack

Battery charger

Programming cable

Programming software

Battery pack to USB cable USD to torque tool cable

USD to ROV flying lead (power)

Function labels

Operations and maintenance manual

Universal Subsea Display (USD) Display electrical signals subsea

The Universal Subsea Display (USD), displays information from a wide range of sensor types. It is viewed using ROV cameras or directly by divers. The USD is housed in a robust anodised aluminium alloy housing with an integrated compensator. The unit is available with a two line display (6 digits per row) or a single line (4 digits and a minus sign). The two line display can display information from two separate inputs.

The USD readily interfaces to equipment through two subsea connectors. The first connects to a battery pack or a vehicle / tooling package with both power and communication. The second connects to the equipment to be monitored providing the interfaces for sensing and the supplies for powering the equipment sensors.

The USD uses ultra-efficient LED types, a very low power processor and sophisticated power switching regulators which, together, mean it can operate from a wide DC voltage input range, requiring very low current and equally able to operate from ROV supply or from battery. In addition, it has a software configurable sleep mode with option to wake up on sensor activity or from the light sensor on the front face. The unit can be configured for a multitude of applications.

Universal Subsea Display (USD)

Specifications

Depth rating

Available sensor inputs

Sensor supplies

Sensor supply protection

Serial out

Input voltage

3000m / 9842ft

Strain gauge bridge (full Wheatstone)

0-5V & 0-10V analogue voltage

4-20mA analogue current

PNP or NPN type contact / proximity

Contact closure - reed switch / digital

1 off 5V to 250mA

1 off 12V to 500mA

Current limited & short circuit protected

RS232 or RS485 (software selectable)

3.5 - 35V DC (reverse polarity protected)

Applications

Rotary valve operations

Stab plate operations

Features

ISO standard interface

Full suite of supporting tools

Twin point docking

Buoyancy block

In the box

Tool Deploment Unit (TDU)

High torque tool

Class 1-2 torque tool

Operations and maintenance manual

10 x 8 cabin

Tool Deployment Unit (TDU) ROV workskid and tool deployment unit

The Tool Deployment Unit (TDU) is used where subsea equipment has been designed around this ISO interface. It has the advantage of giving a high degree of precision when deploying tools.

The unit conforms to the ISO interface requirements with the full range of supporting tools: including torque tool, gripper, stab plate and linear override tools.

The system is fitted to a host ROV, usually at rear, and is controlled over its own data link from a laptop computer. The operating software includes the Forum torque tool control suite with full turns and torque feedback as standard.

Tool Deployment Unit (TDU)

Specifications

Host ROV requirements

RS485 / RS232 data link

Hydraulic Supply 20lpm / 200bar

Standard working pressure 207bar / 3000psi

Depth rating Buoyancy block to client requirement, max 4000m

Weight in air/water 562kg / 0kg (with 1500m buoyancy rating)

Cameras

Lights

Hydraulic functions

4 off with zoom and focus control

2 off with dimmer control

8 off NG3 switching DCV

1 off NG6 proportional DCV

Applications

Site Integration Testing (SIT)

Valve access simulation

Operational access simulation

Features

7 function manipulator

5 function manipulator

Smart valve packs

In the box

Mock-up ROV Control van

Workshop

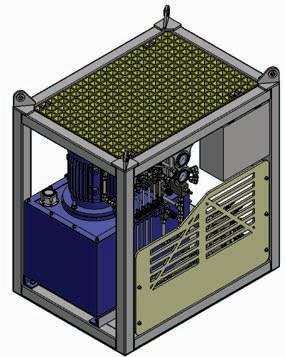

Mock-up ROV (MROV)

Site integration testing

The mock-up ROV system is used to carry out onshore site integration testing (SIT) to ensure that ROV-operable functions can be tested for accessibility and functionality prior to subsea deployment.

Our unit is based on a standard ROV frame format including imitated buoyancy, a 5 function manipulator and intelligent valve pack. Optional configurations include a 7 function manipulator and other tooling requirements such as a FLOT tool or multipurpose skid.

Operations are managed from the control van, with operational points for controlling ROV tooling and manipulators. An IP camera system allows for remote access, negating the need to be physically present on-site for the duration of testing.

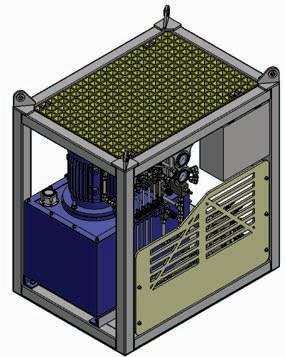

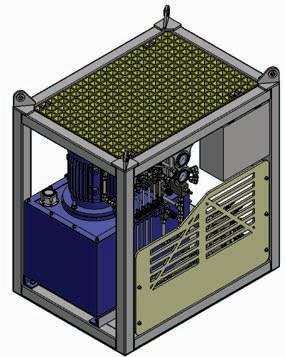

Mock-up ROV (MROV) Specifications

Hydraulic system

Control system

Supply requirements

Mock-up ROV weight

Control van weight

Mock-up ROV dimensions

Aircooled built-in HPU

210bar / 3000psi

20-55lpm / 4.5-14.5gpm

Forum SVP with proportional control

1 master IP camera

2 slave IP cameras

1 roving IP camera

Remote access for camera system via web browser

440v 63 Amps three phases

1,160kg / 2557lbs (including 7 & 5 Function manipulator)

6,000kg / 13,228lbs

Length: 2,540mm / 8ft 4in

Width: 1,420mm / 4ft 8in

Height: 1,850mm / 6ft 1in

Length: 6,058mm / 20ft

Width: 2,438mm / 8ft

Height: 2,896mm / 9ft 6in

2

01 Valve manipulation tools & accessories 02 Dredging & jetting 03 Cutters & grinders 04 Subsea pumping & injection 05 Topside pumps 02

& jetting

Section

Dredging

Applications

ROV dredging work

Excavation

Removal of gravel, rocks & sediment

Features

Compact dredge designed for easy mobilisation

Lightweight with low power requirements

Compensated, no depth limitations or risk of water ingress

In the box

WeSubsea Hydraulic ROV Dredge

3 x certified hydraulic hose

@3m long with 08 JIC female swivel

4m suction hose with camlock for mounting on dredge Suction head with fishtail 0.5m long, 45 degrees

Suction head 0.7m long, 45 degrees

Discharge extension hose 0.9m

2 x hose lock clamps

2 x gaskets

Optional hot stab

Additional spare parts and custom parts on request

WeSubsea Hydraulic ROV Dredge

Lightweight

titanium high-performance dredge

Ashtead Technology’s WeSubsea Hydraulic ROV Dredge’s are designed with a focus on performance. The dredge’s are supplied as a complete out of the box dredging package with no external pump units or further hardware to assemble. These highly efficient dredge’s are supplied ready to be mounted on to the ROV for quick and easy operation.

6 JIC female

6 JIC female

6 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

8 JIC female

Removal

8 JIC female

8 JIC female

8 JIC female

54kg

120kg

24kg 18kg 952 x 639 x 365mm

38kg 30kg 1200 x 800 x 800mm

120kg

41kg 32kg 1296 x 699 x 579mm

200kg

75kg 63kg 1200 x 800 x 800mm

300kg

95kg 75kg 2400 x 800 x 800mm

300kg

95kg 75kg 2400 x 800 x 800mm

300kg

Specifications:

(2300lpm) 65mm 18 (28t/hr) 15-22lpm @140-200 bar

26 (41t/hr) 18-23lpm @ 140-200 bar

38 (61t/hr) 30-50lpm @170-200 bar

205 (3,400lpm) 90mm

118 (1970lpm) to 140

162 (2,700lpm) to

292 (4867lpm) 90mm

498 (8300lpm) 140mm 45 (70t/hr) 50-60lpm @ 200 bar

70 (110t/hr) 70lpm @ 200 bar

84 (130t/hr) 150lpm @ 200 bar

95kg 75kg 2400 x 800 x 800mm

300kg

3"

4"

4 High capacity" 6"

185mm

708 (11800lpm)

1002 (16700lpm) 185mm

90 (140t/hr) 70lpm @ 200 bar

230mm

8"

8" High capacity

785 (13500lpm)

300kg

2400 x 800 x 800mm2400 x 800 x

800mm

75kg 95kg

108 (168t/hr) 150lpm @ 200 bar

1223 (20383lpm) 230mm

82kg 103kg

108 (168t/hr) 150lpm @200 bar

1482 (24700lpm) 270mm

10" 12"

10" High capacity"

WeSubsea Hydraulic ROV

Specifi cations

Dredge

flow rate (m³/h) Max rock size (theoretical) Hydraulic requirement Weight in air Weight in water Dimensions (LxWxH) Weight Pressure Return Case drain Shipping: Hydraulic

Max

connections:

capacity (m³/h (t/hr))

Applications

Excavation

Removal of gravel, rocks and sediment

Features

Designed to move different types of sediment on the seabed

Powered by Top Side HPU for water depth to 300m

Powered by ROV hydraulics through HotStab for deeper water depths

Lightweight and compact design

Suction hose 20m +, soil dependent

Operated by diver or ROV

Can be fitted with flexible discharge hose

Suction hose and discharge hose can be mounted subsea using a slip over flange

In the box

WeSubsea Diver Dredge Certified hydraulic hoses with Aero-Quip couplings

Suction hose with slip-on flange

Back flush

Suction head with D-handle Hose lock clamps

Optional hot stab

Optional discharge hose

Additional spare parts and custom parts on request

WeSubsea Hydraulic Diver Dredge

Stand-alone titanium diver dredge system

Ashtead Technology’s WeSubsea Hydraulic Diver Dredge's are stand-alone system designed for excavation and removal of gravel and sediment. Built with safe operations as a priority, the system comes with hydraulic back flush and can be operated with diver or ROV.

The WeSubsea Hydraulic Diver Dredge suits a range of subsea applications including deep-water dredging, debris removal, rock dump and drill cut removal, pipeline deburial, excavation and environmental work. Ashtead Technology’s WeSubsea range includes the lightest and most efficient dredges on the market today.

460kg

Hydraulic

Max rock size (theoretical)

2000x800x1500mm

460kg

460kg

2000x800x1500mm

2000x800x1500mm

500kg

1200x800x800mm

2000x800x1500mm 500kg

500kg

500kg

2500x800x1500mm

2500x800x1500mm

500kg

Max flow rate (m³/h)

205 (3400Lpm) 90mm 26 (41t/hr) 23Lpm @ 200 bar

292 (4867Lpm) 90mm 38 (61t/hr) 150Lpm @ 200 bar

292 (4867Lpm) 90mm 38 (61t/hr) 50-60Lpm @ 200 bar

708 (11800Lpm) 185mm 70 (110t/hr) 70Lpm @ 200 bar

1002 (16,700Lpm) 185mm 84 (130t/hr) 150Lpm @ 200 bar

785 (13,500Lpm) 230mm 90 (140t/hr) 70Lpm @ 200 bar

1223 (13,500Lpm) 230mm 108 (168t/hr) 150Lpm @ 200 bar

2500x800x1500mm

1686 (28,100Lpm) 270mm 108 (168t/hr) 150Lpm @ 200 bar

4"

4" High capacity 6" 8"

8" High capacity

10" 12"

10" High capacity"

Specifications

WeSubsea Hydraulic Diver Dredge

requirement Removal capacity Dimensions Weight

Applications

Work-class ROV construction

Work-class ROV drill support

Relocation of mud, silt and rocks

Relocation of drill cutting

Marine archaeology

Salvage operations

Features

Excavates seabed sand, gravel, clay and rocks

Power efficient electric motor

No hydraulics required

Small deck area required

ROV friendly hose connection

Proven reliability

Compact design

Superior performance

Compliant to IEE wiring regulation (BS7671)

Compliant to IMCA DO45 (safe use of electricity underwater)

Bespoke options

UCS have specialist in-house design and fabrication capabilities and are able to modify any tool to suit client / project requirements.

UCS Dredge System (12', 8'' and 6') Electrical dredge system

This electrically-driven 12” dredge system allows the excavation of seabed sand, gravel, clay and rocks up to 254mm (10”) in diameter.

Regardless of the dredge size chosen, the UCS electrical dredge system utilises a reduced deck footprint by removing the need for large hydraulic umbilical reels and power units as required by hydraulic dredging systems. Replacing hydraulic hoses with an electrical umbilical eliminates the considerable power losses associated with transferring hydraulic oil through long hose lengths. The use of electric power also negates the risk of environmental damage due to oil leakage or loss. As a result, UCS systems offer superior suction and efficiency compared to hydraulic dredges.

Our standard offering comprises of an umbilical winch, skid unit, 10m suction hoses and spares package, with bespoke revisions also available.

Umbilical winch dimensions

1685mm / 66.4in

1964mm / 77.3in x 2067mm / 81.4in x

Dredge skid dimensions

Dredge umbilical winch

Dredge skid mass in air

Standard exhaust hose length

Standard suction hose length

1898mm / 74.7in

4000kg / 8818lbs 2576mm / 101.4in x 1990mm / 78.4in x

na 2450kg / 5401lbs

Max rock size

Suction rate

Electrical requirements

Dredging capacity

ID 305mm / 12in @ 10m/5m/4m

254mm / 10in

10400lpm / 2746gpm @ 60Hz

3 phase 440v, 50-60Hz, 125amp

waste content

640 cubes p/h (100% water) rate varies with

59in

2000mm / 78.8in x 1700mm / 67in x 1500mm /

47.3in

680kg / 1499lbs 2250kg / 4960lbs 1690mm / 66.5in x 800mm / 31.5in x 1201mm /

ID 250mm / 9.8in @ 1m

ID 200mm / 8in @ 10m / 32.9ft

140mm / 5.5in

5300lpm / 10630gpm @ 60Hz

3 phase 440v, 63amp

waste content

320 cubes p/h (100% water) rate varies with

Specifications

1500mm / 51.2in

1800mm / 70.9in x 1700mm / 59in x

1033mm /40.7in

470kg / 1035lbs 1500kg / 3307lbs 1608mm / 63.3in x 700mm / 27.6in x

ID 200mm / 8in @ 1m

ID 150mm / 6in @ 10m / 32.9ft

102mm / 4in

2600lpm / 687gpm @ 60Hz

3 phase 440v, 32amp

waste content

180 cubes p/h (100% water) rate varies with

UCS 12' ' Dredge System

UCS 8 '' Dredge System

UCS Dredge System (12'', 8'' and 6'')

UCS 6 '' Dredge System

Applications

ROV dredging work

Excavation

Removal of gravel, rocks & sediment

Features

Quick and easy to mobilise

No depth limitations

Designed for rapid deployment

In the box

Vortex Dredge

Operations and maintenance manual

Operational hoses

Vortex Dredge

The most powerful 4in, 6in & 8in dredge on the market

The Vortex Dredge's are designed for subsea excavation and disposal of seabed materials. The Vortex Dredge's can be mounted onto any work class ROV without requiring deck space or sea fastening. With no moving parts, this powerful dredge is quick and straightforward to mobilise.

Vortex Dredge

Specifications

Debris removal rates (ton / hr)

Venturi inner diameter

Rated maximum stone size

Suction hose diameter

Exhaust hose diameter

Inlet suction hose length

Exhaust throw length

Hydraulic flow required

60t per hour, 27m³/hr, 15% solids by volume

100mm / 4in

100mm / 4in

100mm / 4in

100mm / 4in

Up to 40m

Up to 4m

78lpm

Hydraulic pressure required 165bar

Optimum pressure

206bar / 3000psi

Available suction at inlet 100kpa

Optional Jetter nozzle water pressure60psi

Up to 80t per hour, 30m³/hr, 10% solids by volume

150mm / 6in

149mm / 6in

149mm / 6in 149mm / 6in

Up to 40m

Up to 4m

78lpm

206bar

206bar / 3000psi

Up to 128t per hour, 5860m³/hr, 10% solids by volume

200mm / 8in

198mm / 8in

202mm / 8in

202mm / 8in

Up to 40m

Up to 4m 52kpa 60psi

206bar

206bar / 3000psi

Hydraulic hose requirements:

return

in

50kg

in water 39kg Operation in air No 4" 6" 8"

Weight

air

Weight

99kg 76kg No

60psi 111kg 89kg No

32kpa

85lpm

2 x 12 JIC 1 x 6 JIC 2 x 4 JIC 2 x 8 JIC 1 x 6 JIC 2 x 4 JIC 2 x 8 JIC 1 x 6 JIC 2 x 4 JIC

Pressure &

Case drain Reversal valve

Applications

Relocation of mud, sand, gravel, clay and rocks up to 205mm (8in in diameter)

Features

ROV-friendly cradle

Proven reliability

Compact design

Superior performance

Manufactured from carbon steel with neoprene gaskets

Easy assembly and operation

Bespoke options

UCS have specialist in-house design and fabrication capabilities and are able to modify any tool to suit client / project requirements.

UCS 10in Air Lift Dredge

For excavation of seabed sand, gravel, clay and rocks

This Air Lift Dredge system is designed for effective excavation of seabed sand, gravel, clay and rocks up to 205mm in diameter, in water up to 50 MSW.

The system has no exposed pipe work, delivering the water and air requirements internally which limits any snagging and hose damage. High flow water is supplied to the suction head to lower the density of the material to be dredged. Adjustable jetting nozzles can be moved to deliver horizontal, vertical or 45-degree jetting depending on the project requirements. High volume compressed air is forced in to the 10in pipe work creating a high rate suction force caused by the pressure differential ensuring loosened debris is ejected safely through the exhaust.

The 10in airlift dredge is to be used with a high volume water pump, lift pump, umbilical

UCS 10in Air Lift Dredge

Specifications

System flow rate

Suction pipe ID

Suction pipe length

Exhaust pipe ID

Exhaust pipe length

Max rock size

Air requirement

Water pump requirement

Mass in air

Dimensions (L x W x H)

>15,000lpm / >3963gpm

260.3mm / 10in

23m / 75ft

260.3mm / 10in

Horizontal displacement

205mm / 8in

28.3cubic metre/minute @ 14bar / 1000cfm @ 203psi

1,000m³/hr @ 14 bar / 35314ft³/hr @ 203psi

4800kg / 10582lbs

23.7m / 78ft x 900mm / 53.4in x 900mm / 53.4in

Applications

Work-class ROV construction

Work-class ROV drill support

Pile & hollow structure dredging

Relocation of mud, silt and rocks

Marine archaeology

Features

Power efficient electric motor

No hydraulics required

Depth monitoring

Water jetting attachment

Compliant to Lifting Operations and Lifting Equipment Regulations

SI 1998 No 2307

Compliant to IEE wiring regulation (BS7671)

Compliant to IMCA DO45 (safe use of electricity underwater)

Bespoke options

UCS have specialist in-house design and fabrication capabilities and are able to modify any tool to suit client / project requirements.

UCS Pile Cleaning System

Electrical dredge system

The UCS pile cleaning system is ideal for cleaning sand, debris and clay from piles. The suction hose is supported off the vessels crane and the solid pipe for the suction end can be installed with a high pressure jet, if required for clay conditions.

The suction hose set up can be adapted to suit specific project requirements.

UCS Pile Cleaning System

Specifications

Dredging capacity (as standard) 320 cubes p/h (100% water) rate varies with waste content

Electrical requirements 3 phase 440v, 63amp

Suction rate 5300lpm / 10630gpm @ 60hz

Max rock size 140mm / 5.5in

Standard suction hose ID 200mm / 8in @ 20m / 65.8ft

Standard exhaust hose ID 250mm / 9.8in @ custom

Dredge skid mass in air 680kg / 1499lbs

Dredge chute mass in air (with hose)132kg / 291lbs

Dredge umbilical winch

Dredge skid dimensions

Umbilical winch dimensions

2250kg / 4960lbs

1740mm / 68.5in x 800mm / 31.5in x 1191mm / 46.7in

2000mm / 78.8in x 1700mm / 67in x 1500mm / 59in

Applications

Break up and excavation of sea bed

Removal of drill cuttings

Clearing of seabed manifolds

Removal of soft marine growth

Marine archaeology

Treasure hunting and salvage

Features

Robust and compact design

Will not block or jam

Easy in-field maintenance

ROV mounting system

Modular pump core

Mulitple mounting configurations

In the box

Tritech Super ZipJet

Jetting nozzle

Dredging nozzle

Operational hoses

Operations and maintenance manual

Tritech Super ZipJet

Lightweight ROV dredge pump

The Tritech Super ZipJet ROV dredge pump replaces the successful Tritech ZipJet Ultra range of suction & jetting systems.

The Super ZipJet pump incorporates many technical advances over the previous generation of ROV suction and jetting systems. These advances are a direct result of customer feedback.

Considerable emphasis has been placed on increasing the pump’s efficiency in both the suction and jetting modes. The Super ZipJet pump incorporates several design features which improve its reliability and substantially reduce its maintenance costs.

The Super ZipJet pump will not block or jam because there are no moving parts on the dredging side of the system. Power is derived from a stream of high velocity fluid creating a low-pressure region behind the suction nozzle. The pump may be rapidly switched from suction to jetting mode.

Tritech Super ZipJet

Specifications

Hydraulic motor pressure

Hydraulic motor flow

Actuator minimum pressure

Actuator maximum pressure

Jetting performance

Suction flow

Solids removal rate

Jetting

Discharge

Suction

Clean water inlet

Weight in air

Weight in water

Materials

Pressure & return

Case drain

Acuators

150-220bar / 2175-3190psi

40-60lpm / 10.5-15.8gpm

110bar / 1595psi

240bar / 3480psi

1000lpm/264gpm @ 2bar / 29psi

500-1000lpm / 132-264gpm

5-10t per hour

25mm ID / 1in

100mm ID / 4in

75mm ID / 3in

100mm ID / 4in

25kg / 55lb

11kg / 24lb

Nylacast, UHMWPE

12 JIC

6 JIC

4 x 4 JIC hoses

• 1 x 1" Medusa 5m length

• 1 x 3" Medusa 5m length

• 2 x 4" Medusa 5m length

Applications

Break up and excavation of sea bed

Removal of drill cuttings

Clearing of seabed manifolds

Removal of soft marine growth

Marine archaeology

Treasure hunting and salvage

Features

Robust proven design

Small and light

Rapid switch from suction to jetting

Modular pump core

Reverse flush for suction nozzle

Double shaft seal

Option of close fitting inlet strainer

Fitted to most work class ROVs

In the box

Merlin ROV Pump

25mm/1in jetting nozzle

100nn/4in eductor nozzle

Clean water inlet filter

High-flow pilot operated valve

Operational hoses

Operations & maintenance manual

Tritech Merlin Pump

Robust excavation pump that will not block or jam

The Tritech Merlin is a smaller, lighter and more robust pump with greater performance in both excavation and jetting functions. It features the same double seal arrangement as the Super ZipJet dredge pump and its modular design provides great ease of maintenance.

These are significant efficiency increases in both the impeller and eductor making this the tool that no work-class ROV should be without. As with all Tritech pumps, the merlin will not block or jam because there are no moving parts in the suction flow path.

The flow reversal valve can be operated to back flush the suction nozzle should there be an construction. Power is derived from a stream of high velocity fluid creating a low pressure region behind the suction nozzle.

The pump may be rapidly switched from suction to jetting, or be configured to an intermediate position allowing jetting and excavation to be carried out simultaneously.

Tritech Merlin Pump

Specifications

Hydraulic motor pressure

Hydraulic motor flow

Actuator minimum pressure

Actuator maximum pressure

Jetting performance

Suction flow

Solids removal rate

Jetting hose

Jetting nozzle diameter

Discharge hose diameter

Suction hose diameter

Weight in air

Weight in water

Materials

Pressure & return

Case drain

Actuators

170-250bar / 2465-3625psi

65-110lpm / 17 to 29gpm

120bar / 1740psi

240bar / 3480psi

Up to 600lpm / 158 5gpm @ 8bar / 116psi

2000-4000lpm / 528 - 1056gpm

10-40t per hour

25mm / 1in BSP hose barb

20mm / 0.8in

150mm / 6in

100mm ID / 4in

40kg / 90lb

17kg / 38lb

Stainless steel, Nylacast UHMWPE

12 JIC hose

6 JIC hose

4 x 4 JIC hoses

• 1 x 1" Medusa 5m length

• 1 x 3" Medusa 5m length

• 2 x 4" Medusa 5m length

Applications

ROV dredging operations

Removal of drill cuttings

Clearing of subsea manifolds

Removal of soft marine growth

Marine archaeology

Treasure hunting and salvage

Features

TP03:

Submersible and self-priming

Dredge solids up to 75mm (3in) in size

Easy bowl inspection and clean out Build in reverse flow check

Can run dry without damange CE certified

TP08:

Submersible and self priming

Dredges solids up to 100mm (4in) in size

Easy volute inspection and clean out

Can run dry without damage

In the box

TP03 or TP08 Trash Pump

ROV dredging nozzle

Operational hoses

Operations and maintenance manual

Stanley TP03 & TP08 Trash Pump

Ideal for dredging and cleaning tasks

The Stanley TP03 submersible trash pump boasts 450gpm of output flow, this is an efficient way to move large volumes of liquid with concentrations of solids up to 25% by volume. The TP03 handles solids up to 3 inches in size and is used for dredging and light cleaning tasks.

The Stanley TP08 heavy duty trash pump is used for dewatering, dredging, cleaning and as a effective bilge pump. The gear motor is direct drive to the cast iron impeller with easy access for clean out of fabricated steel volute. The TP08 uses only 9gpm/34lpm of hydraulic flow, the unit will pump over 800gpm (3,028lpm) and a 10ft (2.54m) head. The free-flow Impeller and 4in (100mm) inlet and outlet combine to make to TP08 ne of the most efficient pumps in the business.

Stanley TP03

Stanley TP08

Stanley TP03

Stanley TP08

Stanley TP03 & TP08 Trash Pump

Specifications

Capacity

Pressure

Flow range

Porting

Connect size & type

Discharge diameter

Inlet diameter

Weight

Height (over handle)

Length

Width

TP03

1688lpm

105-140 bar (1500-2000psi)

26-34lpm (7-9 gpm)

1/2in NPTF

1/2in male pipe

75mm (3in camlock)

75mm (3in)

14kg

420mm (16.5in)

355mm (14in)

410mm (16in)

TP08

3028lpm / 800gpm

140bar / 2000psi

26-38lpm / 7-10gpm

#10 SAE (pressure) #12 SAE (return)

1/2in male pipe

100mm / 4in camlock

100mm / 4in

26.7kg

420mm / 16.5in

483mm / 16.5in

381mm (15in)

Applications

Light subsea cleaning operations

Pumping & injection operations

Features

Numerous nozzles available

Mounted on ROV friendly plate

PO check valve

Flow control valve

Integral relief valve (0.5-520bar)

In the box

0-520bar Jetting System

T bar nozzle handle

Turbo nozzle

Suction filter

Basic spares kit

Operational hoses

Operations and maintenance manual

1 x spare filter

Ashtead Technology 0-520 Bar Jetting System

High pressure water jetting system

The 0-520bar jetting system is widely recognised and used throughout world due to its reliability and impressive pumping capabilities; no other system offers the same power and reliability. The Integral relief valve is adjustable to provide any pressure range desired from 0.5-520bar.

The pump is suitable for connection to any subsea reservoir via the ¾ suction port. The system is designed to be capable of pumping water, sea water, hydraulic oil or glycol. This highly versatile system can be used as either an IHPU or Jetting system making it an invaluable and effective tool for any ROV system.

Ashtead Technology 0-520 Bar

Jetting System

Specifications

Hydraulic input pressure

Hydraulic input flow

Hydraulic output pressure

Hydraulic output flow

Maximum jetting

Dimensions

Weight in air

Fluids

180-210bar / 2610-3045psi

30-60lpm / 8-16gpm

0.5-520bar / 7.25-7500psi

15-30lpm / 4-8gpm

400bar / 5801psi (Standard nozzle)

431mm x 345mm x 233mm / 17 x 13.5 x

9.1in 27kg / 59.5lbs

Water, sea water, hydraulic oil and glycol

Pressure & return 2 x 8 JIC female swivel hose, 4m

Output 1 x AJIC swivel hose, 1m

Pilot 1 x AJIC female swivel hose, 1m

Applications

Water jetting operations

Suction pump operations

Features

435lpm / 115gpm output

Simple and reliable jetting solution

Range of jetting nozzles available

Can be controlled to suction upon request

In the box

Low Pressure Jetting System

ROV jetting handle

Operational hoses

Operations and maintenance

manual

Low Pressure Jetting Unit

Low pressure, high flow water jetting system

Designed for use when our high pressure jetting system offers too much power for the application, the low pressure system is as reliable, durable and simple to use providing a constant water jet stream at a maximum of 435lpm.

Mounted on an ROV friendly stainless steel plate this unit is shipped ready for immediate integration and operation.

Low Pressure Jetting Unit

Specifications

Hydraulic input pressure 150bar / 2175psi

Hydraulic input flow 27lpm / 7.1gpm

Maximum output pressure 6.4bar / 92.8psi

Maximum output flow 435lpm / 115gpm

Pressure & return

Pilot

Output

2 x 6 JIC female swivel hoses, 4m

1 x 4 JIC female swivel hoses, 4m

1 x 12 JIC female hoses, 4m

Applications

High-flow cleaning

Pumping & injection operations

Features

150lpm jetting capabilities

Cavitation nozzle cleans without causing damage

Numerous nozzle designs

In the box

150lpm Cavitation Jetting System

Jetting nozzle

ROV handle

Dual, tripple and quad nozzle

C-spanner

Operational hoses

Operations and maintenance manual

150Lpm Cavitation Jetting System

High-flow cavitation water jetting system

The 150lpm jetting system is widely recognised and used throughout world due to its reliability and impressive pumping capabilities; no other system offers the same cleaning power and reliability.

Utilising a specially designed nozzle to induce cavitation this unit has been proved to be a highly effective cleaning tool which does not cause damage to delicate surfaces.

The pump is suitable for connection to any subsea reservoir via the ¾ suction port and is capable of pumping water, sea water, hydraulic oil or glycol.

150Lpm Cavitation Jetting System

Specifications

Hydraulic input pressure

Hydraulic input pressure flow

Hydraulic output pressure

Hydraulic output flow

Maximum cavitation range

Maximum water jetting depth

Dimensions

Weight in air

Fluids

Pressure & return

Pilot

Output

180-210bar / 2600-3045psi

30-75lpm / 7.9-19.8gpm

0.5-100bar / 7.25-1450psi

15-150lpm / 3.9-39.6gpm

0-25m / 0-82ft

3000m / 9842ft

400 x 390 x 350mm / 15.75 x 15.35 x

13.75in 35kg / 77.1lbs

Water, sea water, hydraulic oil and glycol

2 x JIC female swivel hoses, 4m

1 x 4 JIC female swivel hoses, 4m

1 x 12 JIC female swivel hoses, 4m

Applications

Seabed jetting

Saturation of solid clay and cuttings

Features

No depth limitations

Quick mobilisation

Easy to rig

Flexible installation

High effi ciency

In the box

3000mm water jetting hose

Jetting lance with fi shtail handle

2 x hose lock clamps

Hot stab

Operational hoses

Additional spare parts and custom parts on request

WeSubsea Jetting Lance

Out of the box jetting solution

Ashtead Technology’s WeSubsea Jetting Lance is an easy to rig, out of the box solution. It’s lightweight and high efficiency makes this a unique product. Built with as few parts as possible, and using only the highest quality components, the WeSubsea Subsea Jetting Lance is a highly efficient and a very reliable unit. Designed for seabed jetting and saturation of solid clay and cuttings.

WeSubsea Jetting Lance

Specifications

Flow rate through lance 2000Lpm / 5bar

Hydraulic requirement 60*Lpm @ 200bar

Weight of pump unit 50kg

Weight of lance 30kg

Lance (l,w) 1430x85mm

Pump (l,w) 850x200mm

Jetting hose length 3000mm

Jetting hose inner diameter 55mm

Certified hydraulic hoses 3 x 1/2", 3m, 8 JIC female swivel

*50-60Lpm hydraulic operating range is optimal

Applications

Deploy large suction anchors

Recover large suction anchors

Features

Aluminium frame skid

Tritech AnchorZIP 10 pump

Differential pressure sensor

Flow meter

Control manifold

Laptop controlled

Docking latches

In the box

Tritech AnchorZip 10 pump

Flow meter

Control manifold

Laptop

Smart manifold

Buoyancy

Operational hoses

Operations and maintenance manual

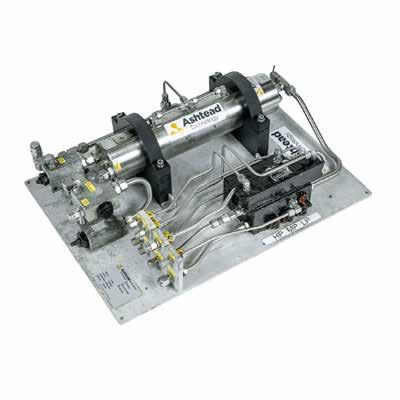

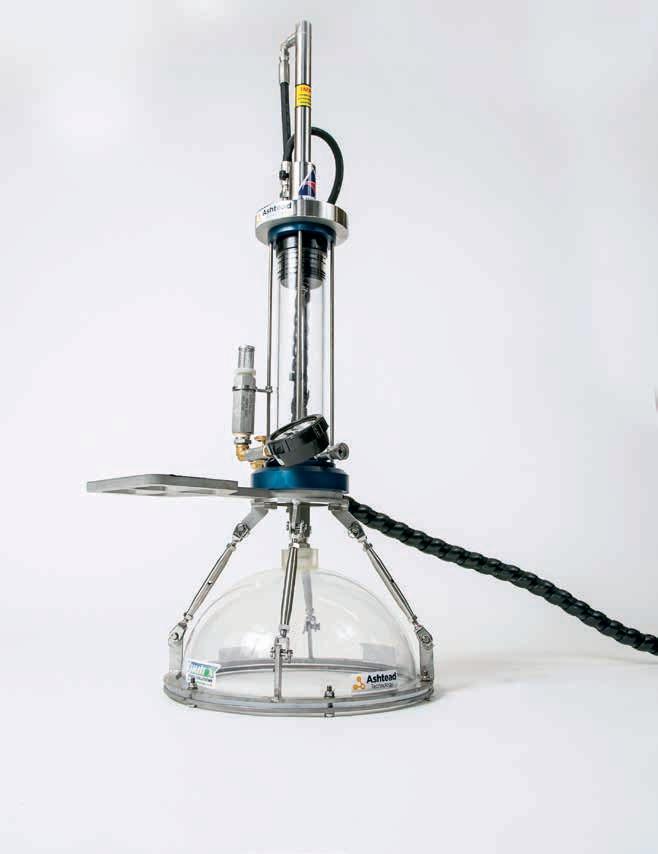

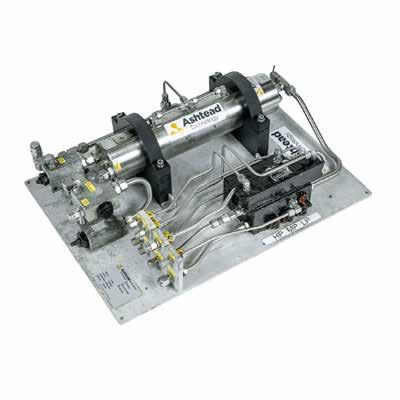

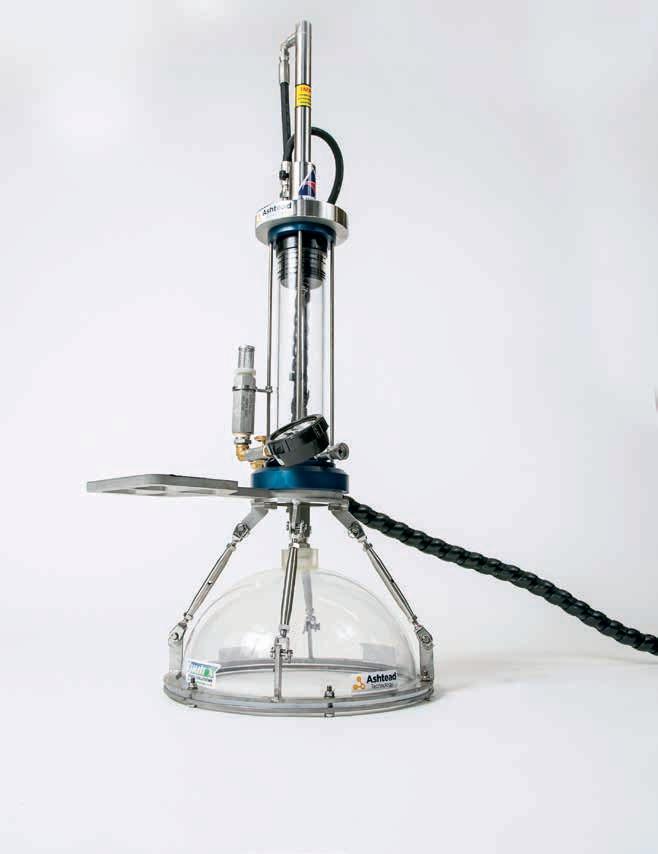

Suction Skid Suction anchor skid

The suction anchor skid is used for suction pile operations. The skid comprises of an aluminium skid frame with buoyancy, a zip pump, a high-flow manifold, control manifold and optional flow meter.

The high-flow manifold is an auxilary manifold that connects to the standard torque

Suction Skid Specifications

Working pressure

207bar / 3000psi

Hydraulic flow 80lpm / 21.1gpm

Actuator minimum pressure 70bar / 1015psi

Actuator maximum pressure 240bar / 3480psi

Maximum output differential pressureUp to 9.5bar / 137.7psi

Maximum output suction flow Up to 80 cubic metres per hour at 7.5bar / 108.7psi

Applications

Suction pile / anchor installation

Suction pile / anchor removal

Features

Efficient pump with superior flow

Erosion resistant impeller

Filtered suction into pump

Data feedback redundancy via

Perry USD and topside laptop

Integrated water flow meter

In the box

Vortex Anchor Boss Suction Pump

Topside laptop

Perry subsea display

Relief valve springs

Pump spares kit

Operational hoses

Operations and maintenance manual

Vortex Anchor Boss Suction Pump Using the latest technology to reduce vessel time

The suction anchor system is a suction pump system that is designed to be mounted on the side, rear of the ROV or skid mounted.

The tool consists of the proven high flow vortex water pump, high flow suction and pressure relief valves, task specific water flow meter and Perry USD to display real time water flow and water pressure.

The anchor boss system is primarily used for suction pile / anchor installation and removal in addition to riser flushing applications where high water flow is required. The system uses the latest pump and flow technology which enables it to remain subsea for the duration of the pile installation. Other conventional systems require change out for low flow / high pressure pump which as a result increases vessel time.

Vortex Anchor Boss Suction Pump

Specifications

Minimum hydraulic pressure 60bar / 870psi

Maximum hydraulic pressure (Hyd motor)350bar / 5076psi

Maximum hydraulic flow 180lpm / 47.5gpm

Relief valve Adjustable from 0.3-8.0bar / 4.3-116psi

Maximum water flow 215m3 / hr with 180lpm / 47.5gpm at 248bar / 3596psi

Maximum pressure differential 9.5bar / 139psi

Connections 75mm / 3in ID hose

Weight in air 125kg / 275.5lbs

Materials Aluminium, stainless steel, thermoset epoxy resin

Pressure & hoses 2 x 2 JIC hoses

Case drain 1 x 6 JIC hose

Applications

Deploy large suction anchors

Recover large suction anchors

Features

High efficiency

High performance

Easily interfaced

Flow reversal for anchor recovery

Variable suction release valve

preset

Durable moving body design

In the box

Tritech AnchorZip10

50-75mm / 2-3in hose flange

Operational hoses

Operations and maintenance manual

Tritech AnchorZip 10

Heavy duty ROV suction anchor pump

The AnchorZip 10 is a heavy duty suction anchor pump designed for work vehicles able to produce 25 HP of hydraulic power.

The AnchorZip 10 is a unique product which incorporates many technical advances developed from several years of producing and operating Tritech’s industry-standard range of ROV mounted jetting and excavation systems.

The AnchorZip 10 is specifically designed for ROV deployment and will interface with most work ROV hydraulic systems. ROV fitted with the new AnchorZip 10 pump will offer a very quick and cost effective way of installing and removing suction anchors. Output pressures may be regulated to ensure that differential pressures remain within the structural limits of all types of suction anchor. Flow reversal for anchor recovery is cleverly and simply achieved by sliding the motor and top assembly from the input to the output side of the centrifugal pump.

Tritech AnchorZip 10

Specifications

Hydraulic motor pressure 276bar / 4000psi

Hydraulic motor flow 70lpm / 18.4gpm

Actuator minimum pressure 70bar / 1015psi

Actuator maximum pressure 240bar / 3480psi

Maximum output differential pressureUp to 9.5bar / 138psi

Maximum output suction flow Up to 80 cubic metres per hour at 7.5bar / 108psi

Weight in air 30kg / 66lbs

Weight in water 14kg / 31lbs

Materials Stainless steel, Nylacast, UHMWPE

Pressure & return

Case

Suction or blow

1 x 5m

4 x 4

6 JIC hose 12 JIC hose

medusa

JIC for cylinders

Applications

Pipeline / structure maintenance

Marine archaeology

Salvage operations

Features

Designed for depths of 600FSW

Air operated simplistic system

Proven reliability

Twin pot for continuous operation

Easy maintenance

Bespoke options

Specialist in-house design and fabrication capabilities and are able to modify any tool to suit client / project requirements.

UCS Subsea Grit Cleaning System

Diver operated grit cleaning system

The UCS subsea grit cleaning system is a low pressure air / grit entrained cleaning system suitable for cleaning operations down to a water depth of 600FSW (180mtr) which provides a fast, reliable and cost effective cleaning solution for removing marine growth, corrosion and other coatings to a S.A 2.5 finish. Continuous cleaning operations due to a twin grit pot design.

The system utilises air as the delivery system for the cleaning grit which can be supplied by either the vessel or a third party air compressor.

UCS Subsea Grit Cleaning System

Specifications

Grit consumption

Grit pot capacity

150kg / 331lbs/hr per hopper

250kg / 551lbs per hopper

Grit type ‘J-Blast’ Supa expandable abrasive - 0.2 -1.5mm

System rated pressure 27.6bar / 400psi

Compressor air flow

Air compressor requirements

Operational water depth

Typical cleaning rate

Dimensions

Gross weight

510 - 1444m³/hr / 300-850cfm

24bar @ 21m³/hr / 350psi @ 750cfm (Down to 152m)

24bar @ 24m³/hr / 350psi @ 850cfm heavy duty / high volume (Below 152m)

30-183m / 98-600ft (Refer to regulator depth pressure setting chart)

5m²/hr / 97in²/hr (Application dependent)

3340mm / 131.5in x 2420mm / 95.3in x 2740mm / 107.9in

8000kg / 17637lbs

Section 3 Cutters & grinders

01 Valve manipulation tools & accessories 02 Dredging & jetting 03 Cutters & grinders 04 Subsea pumping & injection 05 Topside pumps 03

Applications

Cutting of horizontal or vertical pipe, casings and structures

Features

Fast and accurate cut

2in to 56in capacity

Patented self-regulating feed

Superior performance

Simple operation

Diver or ROV operated

Compact design

Bespoke options

UCS have specialist in-house design and fabrication capabilities and able to modify any tool to suit client / project requirements

UCS Diamond Wire Saw

Diver or ROV operated diamond wire saw

The UCS diamond wire saws have been developed to cut tubulars ranging from 2in up to 56in.

The patented auto-feed system automatically regulates cutting progress, minimising the probability of broken wires. This has the advantage of removing human interference from the operation, assisting UCS Diamond Wires Saws in achieving world-leading cutting times.

Providing a fast and accurate cut, the diamond wire saw is especially good for cutting pipe in pipe, concrete filled multi-string bundles and coated products in both horizontal and vertical orientation.

Compact design enables easy installation and operation. This system can be supplied set up in a number of configurations to suit client project requirements.

22"

42"

22"

42"

56" 305-1,422mm (12-56in)

80-90l/min / 21.1-23.8gal/min

42" 50-1,067mm (2-42in)

80-90l/min / 21.1-23.8gal/min

210bar / 3,045psi

ISO VG32 or equivalent 60mm/min (2.3in/min)

4-50mm/min (0.161.97in/min)

730kg / 1,609lbs

475kg / 1,047lbs

22" 50-558mm (2-22in)

60-70l/min / 15.9-18.5gal/min

210bar / 3,045psi

ISO VG32 or equivalent 60mm/min (2.3in/min)

4-50mm/min (0.16-1.97in/min)

570kg / 1,257lbs

373kg / 822 lbs

210bar / 3,045psi

11" 50-279.4mm (2-11in)

50-60l/min / 13.2-15.9gal/min

210bar / 3,045psi

ISO VG32 or equivalent 60mm/min (2.3in/min)

4-50mm/min (0.16-1.97in/min)

269kg / 593lbs

185kg / 408lbs

Hydraulic flow rate

Hydraulic requirements

ISO VG32 or equivalent 60mm/min (2.3in/min)

4-50mm/min (0.16-1.97in/min)

88kg / 194lbs

53kg / 117lbs

381mm / 15in

460mm

UCS

Diamond Wire Saw Specifications

cutting