22 minute read

Brake system service

from Auto Service Professional - February 2020

by EndeavorBusinessMedia-VehicleRepairGroup

Tips to avoid comebacks By Mike Mavrigian

TThe two most critical component systems lease/cooling based on the heat generated by brakon any vehicles include the tires and the ing friction. As a result, as the disc plates wear and brakes. The tires provide the contact of the vehi- become thinner, and as the fins contract, the rotor cle to the ground and the brakes provide stopping surfaces may become uneven, with small peaks power. The vehicle can have gobs of reliable engine and valleys apparent at ambient temperatures. power, the suspension can provide exquisite han- When brakes are still cold — for instance, when dling and the interior can boast an array of com- a driver has just started up the engine, before the fort features, but without ground contact of the brakes have generated enough friction to warm tires or stopping capability, the vehicle is merely an up — the uneven surface of the rotors comes into expensive paperweight. contact with the brake pads, which can cause the

Shortcuts in terms of components or labor in- front end, steering, and/or brake pedal to vibrate volving brake service are simply unacceptable. Here, we’ll briefly discuss brake system service and tips that help to provide optimum braking and to avoid customer comeback complaints.

Rotor design Depending on the specific vehicle, front brake rotors generally feature ventilation fins in between inner and outer plate layers, while rear rotors (in cases of four-wheel disc systems) may feature either solid or vented rotors. The disc elements on the inner and outer pad contact surfaces get worn down little by little while braking, and the vent fins provide a heat release, or heat sync to aid in heat re40

Measuring rotor thickness is easy but sometimes neglected. Measure thickness at a minimum of four evenly spaced locations.

Before attempting to remove an old ABS wheel speed sensor, first remove debris/dirt from the immediate mating area. If after removing the mounting bolt, the sensor does not move easily, soak with a penetrating fluid. Try to rotate the sensor before attempting to pull it out to avoid breaking the sensor. If stuck, with the bolt removed, tap the mounting ear back and forth until the sensor can be rotated in its bore.

and sometimes generate noise. This can also account for brake noise that is primarily noticeable when first driving.

Once rotor designs were changed to be thinner in order to reduce unsprung weight, friction formulations needed to be changed as well, as the highly abrasive formulations of the past would cause even more vibration with thinner rotors that wear out more quickly. New friction materials were developed that are softer and work in conjunction

Always inspect the dust boots on a slider style caliper assembly. If the boot is torn, cracked or improperly installed, moisture and road grit will enter and cause the slider pins to seize, preventing the caliper from properly sliding and applying even pressure to both inboard and outboard pads. This is especially prone to happen if the vehicle is parked for long periods without allowing the calipers to slide. The pins in this Ford F-350 front caliper bracket were frozen in place and required replacement of the caliper bracket. Note the rust buildup on the slide where the boot has become dislodged.

with rotor design to minimize vibration and noise. Noise, vibration and harshness (NVH) control is at the forefront of modern automotive brake design, as brake manufacturers strive to provide customers with the quiet, comfortable ride performance they expect.

This means that when changing brake pads, rotors should either be replaced as well, or, if the rotors are still within specifications, should be thoroughly cleaned and potentially resurfaced. The caliper and caliper hardware, piston, seals and other components should be checked to ensure that

It’s been said many times and always bears repeating: Especially considering the thinner rotor hats on many of today’s vehicles and those equipped with alloy wheels, wheel fastener tightening should always be done with a calibrated torque wrench, never with an impact wrench, Tighten to spec and use a tightening pattern that alternates fastener tightening in order to evenly apply the clamping load. This avoids rotor warp and a potential brake pedal vibration/jump complaint. Ventilated brake rotors allow heat dissipation. If they become clogged with dirt, debris or excessive rust buildup, the venting feature is diminished. Use a stiff wire rifle brush to clean out the vent holes. If the buildup is extreme, the rotor should be replaced.

Removing an old ABS wheel speed sensor can sometimes pose a challenge if seized in its bore. This failed sensor was severely contaminated with rust and debris buildup and took quite a bit of coaxing to remove.

Before installing a new wheel speed sensor, clean the bore with a rifle brush and apply a light coat of brake lube to the metal case. When installed, rotate it a bit to work the lube onto the bore surface.

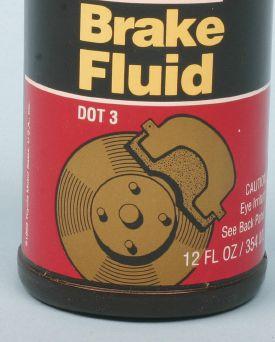

Electric/hybrid vehicles may require DOT 5.1 brake fluid that provides a lower electrical conductivity and higher boiling point.

Use only a high temperature brake hardwarespecific lubricant on pad retention clips.

they are all working properly and are adequately lubricated. Opting for a complete brake job when it is time to service the brakes is the best way to ensure that all components will work together for noise-free and vibration-free braking. Attempting to cut costs by not replacing or resurfacing rotors will almost certainly lead to noisy, uncomfortable and potentially poor braking, resulting in longer required braking distances.

Take the time to measure rotor thickness using a micrometer. Measure thickness at a minimum of four evenly spaced locations around the diameter of the friction surface. If under specification, the rotor(s) must be replaced. Some fail to do this when in a hurry to get the brake job done, assuming that if the disc “looks OK,” it must be OK. This check will not only allow you to verify thickness but can 42

also reveal uneven thickness issues. Also, measure rotor lateral runout. With the rotor firmly secured in place with all wheel fasteners that are torqued to spec, use a dial indicator and check for runout as you slowly rotate the rotor.

Refer to manufacturer specifications for maximum allowable runout. Generally speaking, if runout exceeds 0.0015-inch, the rotor should be replaced. But remember, this check must be done with the rotor fastened in place to simulate the fi nal wheel installation in terms of fastener torque. Excessive runout will result in pedal bounce and erratic and uneven pad-to-disc contact.

ABS sensors When you see an ABS warning light, chances are good that the issue is a bad ABS wheel speed sen-

sor. While there are multiple fault codes that indi- installing, verifying an easy slip-in fit. Do not apcate an ABS issue, as an example, code C0031 can ply any grease to the sensor tip. indicate an issue with the left front sensor/circuit, and C0040 refers to the right front sensor/circuit. Brake fluid for electric vehicles Naturally, depending on the vehicle, the rear will A special DOT 5.1 brake fluid specifically for the feature either a single sensor or rear wheel specific needs of electric high-powered vehicles is available sensor. from various brake fluid manufacturers. Due to

Once you’ve identified the problem sensor, the electrical currents found near the brake syssimply remove the offending sensor (along with its tem, a lower conductivity fluid is needed. Where integrated harness). When I say “simply,” this isn’t specified by the automaker, for ABS, ESP and always the case. After you disconnect the speed ADAS systems, there is a greater emphasis on cycle sensor harness from its retaining clips (generally time and frequency, placing increased demands clipped to the brake line and frame), disconnect on brake fluid viscosity and lubricity. Examples the connector. Now the fun part: removing the include Champion’s new Evolution X 5.1 and Valsensor from the hub. voline’s EV brake fluid. The formulations provide

Depending on the age of the sensor, sometimes for high boiling points (both wet and dry), noise they easily pull out of the sensor bore after remov- elimination, brake fade reduction and low viscosing the single hold-down bolt, and sometimes ity at low temperatures for today’s advanced antithe sensor will be stuck due to lock brake systems (ABS), eleccorrosion. Never try to man- tronic stability programs (ESP) handle the sensor by prying, and advance driver assistance tugging or hitting it, as you can systems (ADAS). easily snap the sensor, leaving According to Champion, part of it stuck in the bore. along with brake fluids, the

Once the bolt has been re- other fluids used in electric vemoved, try to wiggle/rotate hicles require electrical insulathe sensor to free it. If it’s re- tion properties. The fluid must ally stuck, spray the area with be insulating to prevent any a penetrating lube such as PB arcing since it is going to be in Blaster or WD-40 and allow to close contact with the electrisoak for at least an hour. Using cal and/or electronic compoa small pry bar, drift or screw- nents of the vehicle. Dielectric driver, attempt to slightly ro- properties must remain stable tate the sensor by applying side throughout the time in spite pressure to the sensor mount- Pay attention and use only the of harsh operating conditions: ing tab. Tap it clockwise, then DOT grade brake fluid specified particle abrasion, humidity, counterclockwise, etc. until it begins to rotate easier. This can by the automaker. Avoid using partially filled brake fluid bottles, as the fluid can absorb rising temperatures, and oxidation. Power electronics and take a while, especially consid- airborne moisture over time. the electric engine must operering difficult access on some ate within a defined temperavehicles. Once you can rotate ture range. the sensor with your fingers, wiggle/rotate and Operating at higher than the desired temperapull and it should come out. Employing patience ture range inevitably reduces the vehicles’ service will pay off, avoiding the need to remove the ro- life, efficiency and power. The components are subtor and hub, drilling out or drifting out the broken ject to heat evacuation at temperatures up to 180 piece, etc. Trying to initially force the sensor out degrees Celsius (356 degrees Fahrenheit). The fluid is a gamble, with the high probability of breaking and new components of the electric vehicle are in the sensor. direct contact. The fluids must be compatible with

Once the sensor has been removed, be sure to different types of materials in order to avoid the clean the bore to remove any rust or other debris. following consequences: swelling, breakage, corLightly lube the new sensor’s metal jacket before rosion, etc.

Copper is a fundamental material for these applications. Its high electrical conductivity makes it the main critical component used for electrical appendages, wiring, snaking, encircling, and windings. The 5.1 fluids are formulated and developed with excellent copper compatibility.

Brake service notes Brake fluid type and condition is critical to brake system operation. In general, brake fluid should be changed every 2 years due to ambient air moisture entering the system (as glycol brake fluid is hygroscopic and absorbs moisture, thus lowering the fluid’s boiling point). Below is an overview of the dry and wet boiling point minimums for various fluid grades.

DOT 3 4 5 (silicone) 5.1 DRY BOILING POINT 401 deg F 446 deg F 500 deg F 518 deg F

WET BOILING POINT 284 deg F 316 deg F 356 deg F 374 deg F (The above figures represent a minimum standard. Depending on the brand and formulation, some fluids offer higher boiling points.)

Do not confuse DOT 5 with DOT 5.1 fluid. DOT 5 is silicone-based, and is not compatible with glycol fluids. While DOT 3, 4 and 5.1 fluids are hygroscopic (glycol based and absorbs atmospheric moisture), DOT 5 is silicone based and is hydrophobic (it does not absorb moisture).

Also, remember that since glycol brake fluid is hygroscopic (will absorb airborne moisture), avoid adding brake fluid from a container that has once been open and stored for a long period, as the brake fluid, even though “new,” can begin to absorb moisture once the bottle has been opened. Excess moisture contamination will lower the boiling point. Only use fresh brake fluid when topping off, filling a new system or when flushing and filling the system. Keeping partially filled bottles of brake fluid on your shelf is just asking for trouble.

A note concerning DOT 5 silicone brake fluid is in order. While silicone brake fluid is popular among owners of vintage/restored/classic vehicles because silicone fluid is not harmful to painted surfaces, silicone fluid should never be used in a brake system that features ABS. When hard braking is applied and the ABS actuator attempts to 44

Avoid using old brake pad spring spreader clips. In the example shown here, the spring clips are designed to apply slight outward pressure to pull the pads away from the rotor surface to avoid dragging and glazing. Use only new clips.

regulate braking pressure, the rapid operation of the ABS valves can cause silicone brake fluid to aerate and foam, which can greatly reduce braking efficiency. Always use the DOT grade brake fluid specified by the automaker.

Hoses and lines Whenever servicing any brake system, closely inspect all flexible rubber brake fluid hoses and hard lines. Old, dried-out flexible hoses, or hoses that are soft and spongy should be replaced. Hoses can deteriorate from the outside or inside. If the hose appears to be hardened and/or features small cracks, or is too easy to compress, or shows signs of rubbing against a nearby surface is a clear indication that failure is imminent. Considering the relatively low cost of new hoses, advise the customer of the need for replacement.

Inspect all hard lines for signs of corrosion. Granted, some brake line materials are more resilient to corrosion, but especially in areas that experience winter weather and road salts/brine, brake line inspection is critical. Also, if the brake fluid is old and contains a high level of water, line

Especially when pads have become worn very thin, the caliper pistons have been located further out of their respective bores, and corrosion/debris may have accumulated deep inside the bores. When thicker new pads are installed, the pistons must be pushed back into their bores, likely resulting in piston drag and/ or leaking piston seals. If the caliper pistons have been exposed to riding far out of the bores, it may make more sense to replace the calipers with new or reman units to avoid these issues.

deterioration from the inside of the line can occur, weakening the wall strength, even if the outside looks fine. A weakened metal line can rupture under braking pressure. If the engine dies, the vehicle becomes immobile and the driver may be able to pull to the side of the road. If the brakes fail and the driver is unable to stop, obviously this becomes a much more critical safety issue.

Clean is as clean does Whether you’re dealing with new or used brake rotors, the disc surfaces must be clean prior to installing the pads. The pads need a clean and properly machined surface in order to be able to transfer pad material to the rotor. While a spray brake cleaning solvent is good for removing the bulk of surface contaminants, the best cleaning approach is by using hot water and Dawn dish washing liquid and a soft scrub brush, followed by a hot water rinse, followed by a cold water rinse.

This is especially applicable to new rotors which may have a protective film of rust-prevention grease that may have been applied prior to packaging. Even if the rotor has a rust prevention coating that isn’t greasy, giving the rotor a bath in hot water and Dawn will assure that any surface contaminants, and even fingerprints, are removed. Achieving a clean and dry surface gives the pads a fighting chance to properly seat and mate.

The interaction between the brake pads and rotor disc requires the pad material to initially transfer to the disc. This cannot take place if the pads or rotor are contaminated with oil or grease. When handling these components during the entire brake job, make sure that neither the rotors or pads come into contact with anything except a clean surface. Don’t lay pads or rotors on the floor or on a dirty workbench, and keep your hands clean when installing the pads and rotors. Wash your hands or wear clean latex gloves to avoid transferring oils, grease or other contaminants to the pad and rotor surfaces.

These are simple and obvious precautions, but mistakes can easily happen when rushing a job.

Preventing leaks If the brake job involves using new brake lines that you have flared in-house, depending on the quality of your flare, you may have a small fluid leak at flare-to-fitting/flare-to-port connections. This is especially a concern when dealing with harder stainless steel lines, which can be more challenging in terms of creating a quality seal. If you find a leak during pressure testing/bleeding, crack the fitting loose and re-tighten. Sometimes this may require several repetitions to establish a proper seal.

When brake calipers feature a banjo-style bolt (at the line to caliper connection), make absolutely certain that the orifices in the banjo bolt are clean and free of debris. Whenever possible, always use a new banjo bolt, and always install new crush washers on each side of the connection (bolt head to fitting and fitting to caliper). Copper or aluminum crush washers are designed for one-time use. Paying attention to details will prevent unnecessary comebacks.

These tips certainly do not cover the entire braking system or all system design variants. But following a few basic precautions and installation procedures will help to both satisfy the customer and avoid unwanted comeback complaints. ■

New Autel ADAS calibration system is portable Autel’s MaxiSys MA600 ADAS Calibration System folds and disassembles easily, enabling technicians to calibrate advanced driver assistance programs in multiple locations. Stored in a flight case for secure handling, the unit features a twoline and five-line laser leveling process for new vehicle squaring, faster frame centering placement and one-person set-up within two minutes. The MA600 is compatible with the following tablets: MS906BT, MS906TS, MS908, MS908P, MS908S, MS908SP, MSELITE and MSADAS. A video library of training support for the MA600 is available.

AUTEL INTELLIGENT TECHNOLOGY CORP. WWW.AUTELTECH.COM

Continental unveils ClearContact premium wiper blades The full line of ClearContact premium beam windshield wiper blades enables shops to carry 14 part numbers to cover more than 94% of cars and light trucks. Continental Commercial Vehicles and Aftermarket says ClearContact wiper blades do not require adapters and come fitted with the correct connection for the vehicle. ClearContact wiper blades are available for front and rear wiper applications. The front blades feature an all beam design and are available in 14 part numbers covering lengths from 15 to 28 inches. The rear wipers are offered with 19 part numbers in lengths from 10 to 16 inches.

CONTINENTAL COMMERCIAL VEHICLES AND AFTERMARKET WWW.CONTINENTAL-AFTERMARKET.COM

New Rein oil pan kit simplifies service The new Rein Automotive Oil Pan Kit (P/N ESK0172) from CRP Automotive is designed to simplify service on a wide range of European vehicles by allowing technicians to place one order 46

and receive all the necessary parts for a complete oil pan replacement. The Rein Oil Pan Kit comes complete with oil pan, gasket, drain plug and aluminum torque-to-yield bolts, along with the torque specs. The kit covers a wide range of applications on many BMW engines from 2007-2013 as well as a variety of models from Audi/VW, Mercedes-Benz/Smart, Mini, Saab and Volvo. CRP Automotive is part of CRP Industries Inc.

CRP AUTOMOTIVE WWW.CRPAUTOMOTIVE.COM

Raybestos expands rotor coverage Brake Parts Inc LLC (BPI) has added rotor part numbers for the 2019 Ram 1500 and Chevrolet Silverado 1500 to its R-Line and Specialty line. Created for everyday driving conditions, Raybestos R-Line rotors are designed to deliver the most complete application-specific line on the market. They match OE fit, form and function as well as meet SAE standard for tensile strength. Specialty line rotors provide application-specific designs with enhanced metallurgy to keep brakes cooler in demanding situations and severe duty use, the company says.

RAYBESTOS WWW.RAYBESTOS.COM

Mahle updates A/C service units The latest Mahle Aftermarket air conditioning service units are equipped with an automatic leakage test function designed to prevent refrigerant from escaping. In addition, the new A/C service units are available with special connector couplings that completely eliminate the risk of escaping refrigerant, according to Mahle GmbH. The new units also offer more options for workshop connectivity. Refrigerant analysis units from Mahle recognize all common types of refrigerants, making it possible to recycle them by type.

MAHLE AFTERMARKET WWW.MAHLE-AFTERMARKET.COM

TI Automotive offers brushless in-tank fuel pump kit The new brushless in-tank fuel pump kit, BKS1000, from TI Automotive can support up to 1,000 horsepower applications. The kit includes TI Automotive’s in-tank brushless screw pump and a stand-alone pump controller with simple power and ground connectivity designed to provide optimal output of the in-tank screw pump. The kit also comes with an inlet filter, wiring harness, instruction sheet and wiring diagram to assist with user installation. TI Automotive is part of TI Fluid Systems PLC.

TI AUTOMOTIVE WWW.TIAUTOMOTIVE.COM

Nucap expands NRS galvanized brake pad line Nucap Industries has added 57 SKUs to its North American-made NRS galvanized brake pad lineup to provide coverage for an additional 1,600 vehicle applications. The offering covers Honda, BMW, Ford, GMC Trucks, Nissan and more. NRS Brakes’ galvanized brake pads feature mechanically attached friction on a galvanized steel backing plate. Mechanical retention has been specified by OE manufacturers on many medium- and heavy-duty applications, the company says. In addition, the pads include technology such as the company’s noise-cancelling piston insert.

NRS BRAKES WWW.NRSBRAKES.COM

Arnott has new rear air spring for Cadillac XTS Arnott Inc. has released a new rear aftermarket air spring for the 2013-2019 Cadillac XTS (Epsilon II) with automatic level control and with or without all-wheel drive. The rear air spring, A-3233, for the 2013-2019 Cadillac XTS features a cross-axis, multi-ply, Firestone air sleeve engineered for extended service life. Arnott says the air springs are assembled with Tier 1 components including heavy-duty crimp rings, high-impact resin top and piston and a new 4 mm air line fitting.

ARNOTT INC. WWW.ARNOTTINDUSTRIES.COM

Clore has new flashing power supply and battery charger Clore Automotive Inc. has added the Pro-Logix PL6100, a 12-volt 100A flashing power supply and 60/40/10A battery charger, to its Solar product line. The PL6100 is designed to provide stable power, on demand up to 100 amps, to a vehicle electrical system to support module reprogramming. It also provides full-service battery charging capability from 10 to 60 amps, to service everything from small vehicle batteries to Group 31 batteries. Features include a voltage output range of 13.1-14.9V, adjustable in 0.1V increments, notes the company.

CLORE AUTOMOTIVE INC. WWW.CLOREAUTOMOTIVE.COM

Martins Industries has tire cages for pickup trucks Martins Industries Inc. has introduced two models of pickup truck tire cages, Pickup Tire Xpeditors MPTX-50 and MPTX-100. The MPTX-50 is built to carry up to 50 tires of 17 inches in outer diameter, while the MPTX-100 can carry up to 100 of them with its overhead section on top of the cab. Both models fit most 6.5- and 8-foot pickup truck beds, including those of the Ford F-150, GMC Sierra and Chevy Silverado and many others. Both models use stainless steel clamps to fix the cage to the bed.

MARTINS INDUSTRIES INC. WWW.MARTINSINDUSTRIES.COM

Instant information from ASP advertisers AD INDEX

You’re mere seconds away from receiving free product information. Just go to the website(s) listed to the right of each advertiser below and you’re there! Instant product information at your fingertips.

Advertiser Page Website

Aftermarket Auto Parts Alliance Inc. 5 www.alliancetakesthehill2021.com

Aftermarket Auto Parts Alliance Inc.

AUTEL

Bartec USA 25

3, 9, 13

15 www.partsmastersynthetic.com

www.autel.com

www.bartecusa.com

Clore Automotive

Continental Corporation

Continental Corporation

Interstate Batteries

Lang Tools 37

11

IBC

IFC

33 www.cloreautomotive.com

www.redi-sensor.com

www.vdo.com/usa

www.interstatebatteries.com/racing

www.langtools.com

Mighty Auto Parts

NAPA Auto Parts

O’Reilly Auto Parts 7

OBC

29 www.mightyautoparts.com

www.napaonline.com

www.firstcallonline.com

www.VDO.com/USA

Cars are happy to see VDO OEM Direct Parts.

VDO OEM Direct Parts are genuine OEM parts direct from the manufacturer – that’s us! They’re the same high quality original equipment parts manufactured by Continental, affordably priced to keep you competitive. We offer exceptional coverage for air control valves, electronic throttle valves, flex fuel sensors, fuel modules, fuel injectors, temperature controlling water pumps, door lock actuators, MAF/MAP sensors, wheel speed sensors, and washer pumps. Why settle for parts that claim to be OE quality when you can have the genuine OEM parts?

800-564-5066 salessupport-us@vdo.com