IC

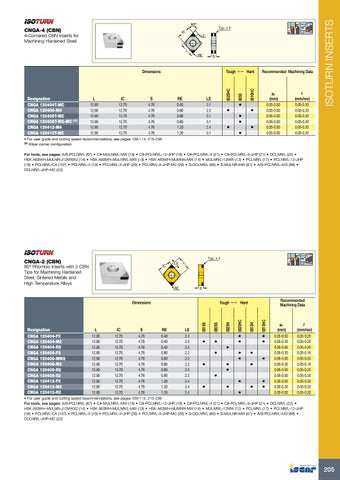

4-Cornered CBN Inserts for Machining Hardened Steel

95º

Typ. x 4

95º

95º

LE

L RE

S

Dimensions

S

RE

LE

12.90 12.90 12.90 12.90 12.90 12.90

12.70 12.70 12.70 12.70 12.70 12.70

4.76 4.76 4.76 4.76 4.76 4.76

0.40 0.80 0.80 0.80 1.20 1.20

3.1 2.2 3.1 3.1 2.4 3.1

• •

• • • •

Recommended Machining Data

IB10HC

IC

IB55

L

IB25HC

Designation CNGA 120404T-MC CNGA 120408-M4 CNGA 120408T-MC CNGA 120408T-WG-MC (1) CNGA 120412-M4 CNGA 120412T-MC

Hard Tough 1

ap

• •

f

(mm)

(mm/rev)

0.05-0.50 0.05-0.50 0.05-0.50 0.05-0.50 0.05-0.50 0.05-0.50

0.05-0.20 0.05-0.20 0.05-0.20 0.05-0.20 0.05-0.20 0.05-0.20

ISOTURN INSERTS

80º

CNGA-4 (CBN)

• For user guide and cutting speed recommendations, see pages 109-114, 215-238 (1) Wiper corner configuration For tools, see pages: A/S-PCLNR/L (87) • C#-MULNR/L-MW (13) • C#-PCLNR/L-12-JHP (18) • C#-PCLNR/L-X (21) • C#-PCLNR/L-X-JHP (21) • DCLNR/L (22) • HSK A63WH-MULNR-J12MWX2 (14) • HSK A63WH-MULNR/L-MW (13) • HSK A63WH-MUMNN-MW (14) • MULNR/L-12MW (12) • PCLNR/L (17) • PCLNR/L-12-JHP (18) • PCLNR/L-CA (107) • PCLNR/L-X (19) • PCLNR/L-X-JHP (20) • PCLNR/L-X-JHP-MC (20) • S-DCLNR/L (85) • S-MULNR-MW (91) • A/S-PCLNR/L-X/G (88) • DCLNR/L-JHP-MC (22)

IC

LE

L

RE

95º

95º

S

Dimensions

Recommended Machining Data

LE

12.90 12.90 12.90 12.90 12.90 12.90 12.90 12.90 12.90 12.90 12.90

12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70 12.70

4.76 4.76 4.76 4.76 4.76 4.76 4.76 4.76 4.76 4.76 4.76

0.40 0.40 0.40 0.80 0.80 0.80 0.80 0.80 1.20 1.20 1.20

2.3 2.3 2.2 2.2 2.2 2.2 2.2 2.2 2.4 2.4 2.4

•

• •

• • •

• • • •

• • • •

• •

IB10HC

RE

IB10H

S

IB20HC

IC

IB05S

L

IB10S

Hard Tough 1

IB20H

80° Rhombic Inserts with 2 CBN Tips for Machining Hardened Steel, Sintered Metals and High Temperature Alloys

Designation CNGA 120404-F2 CNGA 120404-M2 CNGA 120404-R2 CNGA 120408-F2 CNGA 120408-MW2 CNGA 120408-M2 CNGA 120408-R2 CNGA 120408-S2 CNGA 120412-F2 CNGA 120412-M2 CNGA 120412-R2

95º

Typ. x 2

CNGA-2 (CBN)

• • • •

•

•

• •

ap

f

(mm)

(mm/rev)

0.05-0.50 0.05-0.30 0.05-0.50 0.05-0.30 0.05-0.50 0.05-0.30 0.05-0.50 0.05-0.50 0.05-0.50 0.05-0.30 0.05-0.50

0.05-0.20 0.05-0.20 0.05-0.20 0.05-0.18 0.05-0.20 0.05-0.18 0.05-0.20 0.05-0.20 0.05-0.20 0.05-0.20 0.05-0.20

• For user guide and cutting speed recommendations, see pages 109-114, 215-238 For tools, see pages: A/S-PCLNR/L (87) • C#-MULNR/L-MW (13) • C#-PCLNR/L-12-JHP (18) • C#-PCLNR/L-X (21) • C#-PCLNR/L-X-JHP (21) • DCLNR/L (22) • HSK A63WH-MULNR-J12MWX2 (14) • HSK A63WH-MULNR/L-MW (13) • HSK A63WH-MUMNN-MW (14) • MULNR/L-12MW (12) • PCLNR/L (17) • PCLNR/L-12-JHP (18) • PCLNR/L-CA (107) • PCLNR/L-X (19) • PCLNR/L-X-JHP (20) • PCLNR/L-X-JHP-MC (20) • S-DCLNR/L (85) • S-MULNR-MW (91) • A/S-PCLNR/L-X/G (88) • DCLNR/L-JHP-MC (22)

205