15.4COMPLETEHYDRAULICCYLINDERASSEMBLY...........60

15.4.1HYDRAULICCYLINDERREBUILDKIT..............61

15.5 ”R”PUMPASSEMBLY............................62 15.5.1”R”PUMPREBUILDKITS......................65 15.6 ”A”PUMPASSEMBLY............................67

15.6.1”A”PUMPREBUILDKITS......................70

15.7 PUMP-LINEASSEMBLY...........................74 15.7.1PUMPBASEREPAIRKIT......................75

15.8 INLETMONITORINGASSEMBLY.....................76

15.9 Y-STRAINERASSEMBLY”A”SIDE....................77

15.10Y-STRAINERASSEMBLY”R”SIDE....................78

15.11HEATERASSEMBLY.............................79

15.11.1HEATERTHERMOCOUPLEKIT..................85

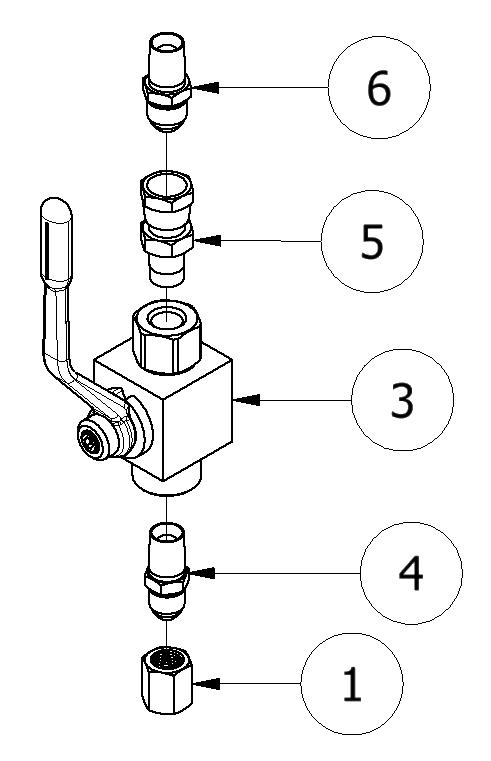

15.12PRESSURETRANSDUCERASSEMBLY..................85

15.13BLEEDVALVEKIT.............................. 86

15.14MOTOR-LINEASSEMBLY..........................87

15.15TRANSFORMERCOVERASSEMBLY...................89

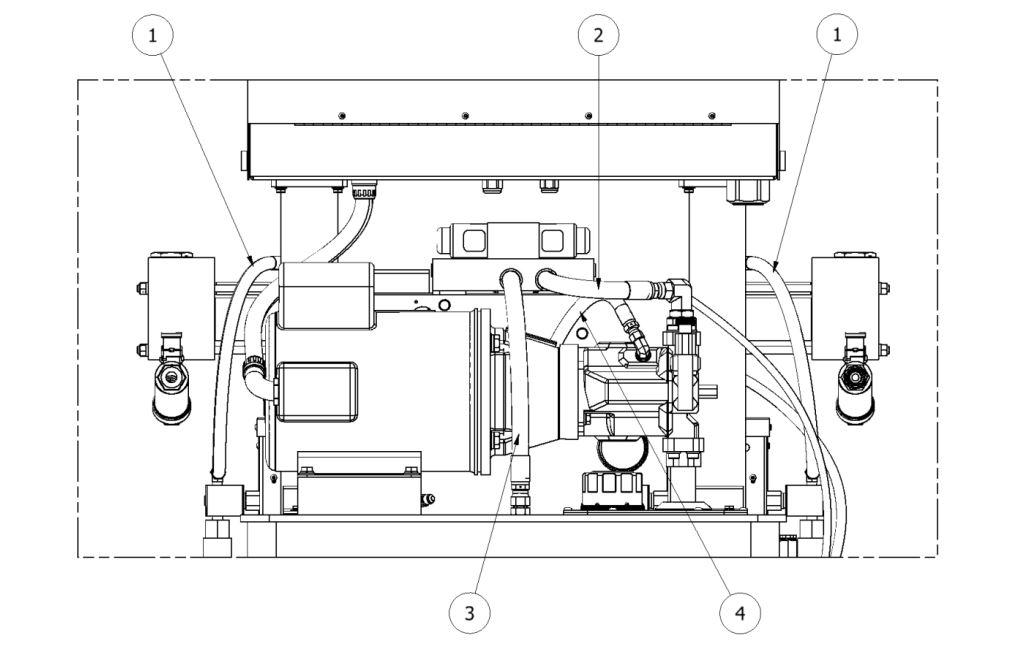

15.16FRAMEASSEMBLY.............................91

15.17FINALASSEMBLY.............................. 93

15.18PH(X)-25/PH(X)-40HOSES.........................96

15.18.1HALFINCHHOSEKIT........................96

15.19LUBEBOTTLECOMPONENTS......................97

1 WARRANTY PolyurethaneMachineryCorporation(hereinafter“PMC”)providesthis LIMITED WARRANTY (hereinafter“Warranty”)totheoriginalpurchaser(hereinafter“Customer”) coveringthisequipmentandtheoriginalPMCmanufacturedaccessoriesdeliveredwiththe equipment(hereinafter“Product”)againstdefectsinmaterialorworkmanshipoftheProduct (hereinafter“Defect”or“Defective”)foraperiodofone(1)yearfromthedateoffirst purchaseasshownontheoriginalPMCinvoice(hereinafter“WarrantyPeriod”)

IfduringtheWarrantyPeriodundernormaluse,theProductissuspectedbyCustomertobeDefectiveinmaterialorworkmanship,itisCustomer’sresponsibilitytocontact PMCandreturntheProducttoPMCasdirectedbyPMC,freightprepaid.IfPMCdeterminesthattheProductisDefectiveandthatsuchDefectiscoveredbythisWarranty,PMC willcreditCustomerforthereasonablefreightchargesincurredbyCustomerinreturning theDefectiveProducttoPMC,andPMC(oritsauthorizedagent)will,atPMC’soption, repairorreplacetheProduct,subjecttothefollowing:

1. OriginalInvoice: Theoriginalinvoicemustbekeptasproofofthedateoffirstsaleand theProductserialnumber.TheWarrantydoesnotcoveranyProductiftheOriginal Invoiceappearstohavebeenmodifiedoraltered,orwhentheserialnumberonthe Productappearstohavebeenalteredordefaced.

2. ProductMaintenance: ItistheCustomer’sresponsibilitytomaintaintheProductproperly.Seeyourmaintenancescheduleandowner’smanualfordetails.TheWarranty doesnotcoveranimproperlymaintainedProduct.

3. Non-PMCComponentsandAccessories: Non-PMCmanufacturedcomponentsandaccessoriesthatareusedintheoperationoftheProductarenotcoveredbythisWarranty.Suchcomponentsandaccessoriesshallbesubjecttothewarrantyofferedtothe Customer,ifany,bytheoriginalmanufacturerofsuchcomponentoraccessory.

4. OtherWarrantyExclusions: TheWarrantydoesnotcoveranyProductthatPMCdetermineshasbeendamagedorfailstooperateproperlyduetomisuse,negligence, abuse,carelessness,neglect,oraccident.Bywayofexampleonly,thisincludes:

• Normalwearandtear.

• Improperorunauthorizedinstallation,repair,alteration,adjustmentormodificationoftheproduct.

• Useofheatingdevices,pumpingequipment,dispensers,orotherpartsoraccessorieswiththeproductthathavenotbeenapprovedormanufacturedbyPMC.

• Failuretofollowtheoperatinginstructionsandrecommendationsprovidedby PMC.

• Cosmeticdamage.

• Fire,flood,“actsofGod,”orothercontingenciesbeyondthecontrolofPMC.

THEWARRANTYDESCRIBEDHEREINISTHEEXCLUSIVE REMEDYFORTHECUSTOMERANDISINLIEUOFALLOTHER WARRANTIES,EXPRESS,IMPLIED,STATUTORYOROTHERWISE,AND THEIMPLIEDWARRANTIESOFMERCHANTABILITYANDFITNESS FORAPARTICULARPURPOSEANDALLOTHERWARRANTIESARE HEREBYDISCLAIMED.TOTHEFULLESTEXTENTPERMITTEDBY LAW,PMCSHALLNOTBERESPONSIBLE,WHETHERBASEDINCONTRACT,TORT(INCLUDING,WITHOUTLIMITATION,NEGLIGENCE), WARRANTYORANYOTHERLEGALOREQUITABLEGROUNDS,FOR ANYCONSEQUENTIAL,INDIRECT,INCIDENTAL,LOSTPROFITS,SPECIAL,PUNITIVEOREXEMPLARYDAMAGES,WHETHERTOPERSON ORPROPERTY,ARISINGFROMORRELATINGTOTHEPRODUCT, EVENIFPMCHASBEENADVISEDOFTHEPOSSIBILITYOFSUCH LOSSESORDAMAGES.

• Non-WarrantyServicebyPMC: IfPMCdeterminesthatthesuspectedDefectofthe ProductisnotcoveredbythisWarranty,dispositionoftheProductwillbemadepursuanttothetermsandconditionsofPMC’swrittenestimateonatimeandmaterials basis.

• ContinuingWarrantyforProductsRepairedorReplacedunderWarranty: Following therepairorreplacementofaProductcoveredbythisWarranty,suchProductwill continuetobesubjecttotheoriginalWarrantyfortheremainderoforiginalWarranty Periodorforthree(3)monthsfromtherepairorreplacementdate,whicheverislonger.

• NoRightsImplied: Nothinginthesale,leaseorrentalofanyProductbyPMCshall beconstruedtograntanyright,interestorlicenseinorunderanypatent,trademark, copyright,tradesecretorotherproprietaryrightormaterialownedbyanyone;nor doesPMCencouragetheinfringementofsame.

• ExclusiveWarranty: Thiswritingisthefinal,complete,andexclusiveexpressionof theWarrantycoveringtheProduct.AnystatementsmadebyPMC,itsemployeesor agentsthatdifferfromthetermsofthisWarrantyshallhavenoeffect.Itisexpressly understoodthatCustomer’sacceptanceofthisWarranty,byperformanceorotherwise, isuponandsubjectsolelytothetermsandconditionshereof,andanyadditionalor differenttermsandconditionsproposedorexpressedbyCustomeroranyone,whether inwritingorotherwise,arenullandvoidunlessspecificallyagreedtoinwritingbyan OfficerofPMC.

2 SAFETYANDHANDLING Thischaptercontainsimportantinformationonthesafety,handling,anduseofyour PHSeriesProportioner.

BeforeinstallingthePHSeriesProportionerandstartup,carefullyreadallthetechnicalandsafetydocumentationincludedinthismanual.Payspecialattentionto theinformationinordertoknowandunderstandthe operationandtheconditionsofuseofthePHSeries Proportioner.Alloftheinformationisaimedatimprovingusersafetyandavoidingpossiblebreakdowns fromtheincorrectuseofthePHSeriesProportioner.

WARNING! Symbolispresentedinfrontofinformationto alertofasituationthatmightcauseseriousinjuriesiftheinstructionsarenotfollowed.

CAUTION! Symbolispresentedinfrontofinformationthat indicateshowtoavoiddamagetotheproportionerorhowtoavoid asituationthatcouldcauseissues.

NOTE! Symbolispresentedinfrontofrelevantinformation ofaprocedurebeingcarriedout.

Carefulstudyofthismanualwillenabletheoperatortoknowthecharacteristics ofthePHSeriesProportionerandtheoperatingprocedures.Byfollowingtheinstructions andrecommendationscontainedherein,youwillreducethepotentialriskofaccidentsinthe installation,use,andmaintenanceofthePHSeriesProportioner.Youwillprovideabetter opportunityforgreateroutput,incident-freeoperationforalongertime,andthepossibility ofdetectingandresolvingproblemsquicklyandsimply.

KeepthisOperationsManualforfutureconsultationofusefulinformationatall times.Ifyoulosethismanual,askforanewcopyfromyourPMCServiceCenterorgoon lineatourwebsite(www.polymacusa.com).

ThePHSeriesProportionerhasbeendesignedandbuiltfortheapplicationof polyureachemicalsystems,polyurethanefoamchemicalsystems,andsometwo-component epoxysystems

WARNING! ThedesignandconfigurationofthePHSeries Proportionerdoesnotallowitsuseinpotentiallyexplosiveatmospheresorthepressureandtemperaturelimitsdescribedinthe technicalspecificationsofthismanualtobeexceeded.

Alwaysuseliquidsandsolventsthatarecompatiblewiththeunit.Ifindoubt, consultyourauthorizedPMCdistributor.

WhenworkingwiththePHSeriesProportioner,itisrecommendedthattheoperator wearsuitableclothingandelementsofpersonalprotection,including,withoutlimitation, gloves,protectivegoggles,safetyfootwearandfacemasks.Usebreathingequipmentwhen workingwiththePHSeriesProportionerinenclosedspacesorinareaswithinsufficient ventilation.Theintroductionandfollow-upofsafetymeasuresmustnotbelimitedtothose describedinthismanual.BeforestartingupthePHSeriesProportioner,acomprehensive analysismustbemadeoftherisksderivedfromtheproductstobedispensed,thetypeof application,andtheworkingenvironment.

Topreventpossibleinjurycausedbyincorrecthandlingofthe rawmaterialsandsolventsusedintheprocess,carefullyread theMaterialSafetyDataSheet(SDS)providedbyyoursupplier. Dealwiththewastecausedaccordingtocurrentregulations.

Toavoiddamagecausedbytheimpactofpressurizedfluids,do notopenanyconnectionorperformmaintenanceworkoncomponentssubjecttopressureuntilthepressurehasbeencompletely eliminated.

Usesuitableprotectionwhenoperating,maintainingorbeing presentintheareawheretheequipmentisfunctioning.Thisincludes,butisnotlimitedto,theuseofprotectivegoggles,gloves, shoesandsafetyclothingandbreathingequipment.

Theequipmentincludescomponentsthatreachhightemperatures andcancauseburns.Hotpartsoftheequipmentmustnotbe handledortoucheduntiltheyhavecooledcompletely.

Topreventseriousinjurythroughcrushingoramputation,do notworkwiththeequipmentwithoutthesafetyguardsinstalled onthemovingparts.Makesurethatallthesafetyguardsare correctlyreinstalledattheendoftherepairormaintenancework oftheequipment.

3 CHARACTERISTICS ThePHSeriesProportionerhasbeendesignedandbuiltfortheapplicationof polyureachemicalsystems,polyurethanefoamchemicalsystems,andsomespecifictwocomponentepoxysystems.

3.1 PRINCIPALHEATINGSYSTEM TheProportionerconsistoftwo(2)independentMaterialHeaterswithoutinternal seals.EachheaterforthePH(X)-40Proportionerhassix(6)HeatingElementsratedat1,250 1,500or1,750wattseach,givingtheProportioneratotalheatof15,000,18,000or21,000 watts.TheMaterialHeatersystemsforallPHSeriesProportionerscontainthenecessary controlandsafetycomponentsfortheirpreciseoperation.TheMaterialHeaterdesignallows atemperaturedifferential(DeltaT)of90oF(32oC)andmaterialapplicationtemperatures ofupto190oF(88oC)undernormalambienttemperatures.

3.2 HOSEHEATINGSYSTEM ThePH(X)-40Proportionerisdesignedwitha5kVA(120V)IsolationTransformer thatenableseffectiveheatingofuptoatotalhoselengthof410feet(123meters).Both systemsincludeaninnovativehoseheatingconceptinwhichthecontinuousbraidtinnedcopperjacketisdistributedevenlyaroundthecircumferenceofthehoseprovidingauniform heatingwattdensityandprecisecontrolofthematerialapplicationtemperature.Thishose heatingelementdesignisextremelyresistanttofatiguefailure.

3.3 DOUBLEACTINGOPPOSEDPISTONMETERINGPUMPS TheopposeddoubleactingPumpLineisdrivenbyadualrodHydraulicCylinder.Thein-linepumpsystemwithopposedpistonpumpsprovidesaconstantvolumeand guaranteesuniformpressuresinbothdirectionsofpumpmovement.Differentsizedpumps allowforvariousvolumetricratiostobeachieved(1:4to1:1to4:1)betweenthechemical componentsusedintheprocess.

3.4 PRESSUREBALANCECONTROLSYSTEM ThePressureBalanceControl(PBC)systemperformsanautomaticshutdownwhen achemicalimbalanceoccurs.Whenthesystemisturnedoff,theProportionerwillperform asifthereisnoPBCsystemandwillcontinuepumpingmaterial.Whenthesystemis turnedon,itwillcontinuallymonitorthepressurebetweenthetwochemicals(knownasthe pressuredifferential).Ifthepressuredifferentialbecomesequaltoorgreaterthanthe maximumallowablepressuredifferential,thepumpswillbeshutoff.

ThePressureBalanceControlsystemcanbesimplifiedintoalogicboxdiagram withinputsandoutputs.Therearefiveinputs:thepowersupplyfromthemainconsole,the pressurereadingsfromeachchemical,themaximumpressure,andthemaximumallowable pressuredifferential.Insidethelogicbox,theactualpressuredifferentialofthechemicalsis comparedtothemaximumallowablepressuredifferential.Dependingonthecircumstances ofallfiveinputs,thereareonlytwopossibleoutputs:eitherthepumpswillcontinueto pressurizeandmovematerial,orthepumpswillshutoffandflowwillbelost.

Figure1:PressureBalanceControlLogicDiagram

4.1 PH(X)-25ELECTRICAL

PH(X)-25,SinglePhase,208-240V

2,000PSI(PH-25)

3,000PSI(PHX-25)

PH(X)-25,ThreePhase,208-240V

2,000PSI(PH-25) 3,000PSI(PHX-25)

PH(X)-25,ThreePhase,400V

2,000PSI(PH-25) 3,000PSI(PHX-25)

MaterialHeaterPower PowerConsumption

4.0kW/side(2x2,000W/side) 8.0kW

5.0kW/side(2x2,500W/side) 10.0kW 6.0kW/side(2x3,000W/side) 12.0kW 7.0kW/side(2x3,500W/side) 14.0kW

HoseTransformer PowerConsumption

ElectricalMotor PowerConsumption

PH(X)-25 3hp

CAUTION! InsidetheconsoleisaTerminalStripforconnectingthemain power(wirenotsupplied)tothePHSeriesProportioner.Thiselectricalconnectionmustbemadeonlybyaqualifiedelectrician.

4.2 PH(X)-40ELECTRICAL PH(X)-40,SinglePhase,208-240V Pressure

12.0kW(6.0kW/side)

2,000PSI(PH-40)

3,000PSI(PHX-40)

PH(X)-40,ThreePhase,208-240V Pressure

2,000PSI(PH-40)

3,000PSI(PHX-40)

PH(X)-40,ThreePhase,400V

2,000PSI(PH-40)

3,000PSI(PHX-40)

MaterialHeaterPower PowerConsumption

6.0kW/side(3x2,000W/side) 12.0kW

7.5kW/side(3x2,500W/side) 15.0kW

9.0kW/side(3x3,000W/side) 18.0kW 10.5kW/side(3x3,500W/side) 21.0kW

HoseTransformer PowerConsumption

ElectricalMotor PowerConsumption PH(X)-40 5hp

CAUTION! InsidetheconsoleisaTerminalStripforconnectingthemain power(wirenotsupplied)tothePHSeriesProportioner.Thiselectricalconnectionmustbemadeonlybyaqualifiedelectrician.

4.3 PH(X)-25MECHANICAL 120Pumps 80Pumps

MaximumWorkingPressure 2,000PSI(14MPa,138bar) 3,000PSI(21MPa,207bar)

MaximumProduction 25lb/min(12.5kg/min) 1.4GPM(5.6L/min) @1,500psi @1,750psi

MinimumProduction 2.0lb/min(1kg/min)

GallonsperCycle 0.0312gal/cycle(0.1182L) 0.021gal/cycle(0.0786L)

Cyclesper55gal(200L)Drum 1,763cycles 2,619cycles

MaximumHoseLength

3kVATransformer 310ft(93m)

5kVATransformer 410ft(125m)

ApproximateWeight

HydraulicTankEmpty 420lbs(190kg)

HydraulicTankFull(20gal) 594lbs(269kg)

OverallDimensions(WxDxH) 40inx29inx52in(100cmx73cmx133cm)

4.4 PH(X)-40MECHANICAL 120Pumps 80Pumps

MaximumWorkingPressure 2,000PSI(14MPa,138bar) 3,500PSI(24MPa,241bar)

MaximumProduction 40lb/min(14kg/min) 2.5GPM(1.0L/min) @1,000psi @2,500psi

MinimumProduction 2.0lb/min(1kg/min)

GallonsperCycle 0.0312gal/cycle(0.1182L) 0.021gal/cycle(0.0786L)

Cyclesper55gal(200L)Drum 1,763cycles 2,619cycles

MaximumHoseLength

3kVATransformer 310ft(93m)

5kVATransformer 410ft(125m)

ApproximateWeight

HydraulicTankEmpty 420lbs(190kg)

HydraulicTankFull(20gal) 594lbs(269kg)

OverallDimensions(WxDxH) 40inx29inx52in(100cmx73cmx133cm)

PH(X)-25/PH(X)-40SERVICEMANUAL 4TECHNICALSPECIFICATIONS

Figure2:ProportionerDimensions

Figure3:ComponentIdentification-Front

A. ControlPanel -ControlsandregulatestheoperationofthePHSeriesProportioner.

B. Isocyanate(Iso,A)MeteringPump -MeterstheIsocyanatematerial.

C. Polyol(Poly,R)MeteringPump -MetersthePolyolmaterial.

D. Isocyanate(Iso,A)Heater -HeatstheincomingIsocyanatetoatemperaturesetby theoperator.

E. Polyol(Poly,R)Heater -HeatstheincomingPolyoltoatemperaturesetbythe operator.

F. HoseHeatingTransformer -SuppliestherequiredvoltageformaterialHeatedHoses.

G. HydraulicPressureGauge -IndicatesthepressureintheHydraulicDriveSystem.

H. Isocyanate(Iso,A)PressureGauge -IndicatesthepressureintheIsocyanatesystem.

I. Isocyanate(Iso,A)SafetyPressureSwitch -Disablesthepumpcircuitintheevent ofexcessivepressureintheIsocyanatesystem.

J. Isocyanate(Iso,A)Thermocouple -ProvidestemperaturereadingoftheIsocyanate chemical.

K. Polyol(Poly,R)PressureGauge -IndicatesthepressureinthePolyolsystem.

L. Polyol(Poly,R)SafetyPressureSwitch -Disablesthepumpcircuitintheevent ofexcessivepressureinthePolyolsystem.

M. Polyol(Poly,R)Thermocouple -ProvidestemperaturereadingofthePolyolchemical.

N. HydraulicPressureControl -Allowsthepressureofthehydraulicsystemtobeincreasedordecreased.Turnclockwisetoincreasethepressureandcounterclockwise todecrease.Toregulatethepressureofthehydraulicsystem,theNORMALorRETRACTPumpSwitchpositionmustbeselected. Figure4:ComponentIdentification-Back

O. Isocyanate(Iso,A)InletMaterialStrainer -Screens(60mesh)materialfrombulk supply.

P. Polyol(Poly,R)InletMaterialStrainer -Screens(60mesh)materialfrombulk supply.

Q. MainPower -TurnsONandOFFmainpowertothecontrolpanel.Itmustbeturned ONforanyoperationtobeperformedwiththeunit.WhenturnedON,theredpilot willlight.

R. EmergencyStop -InterruptsthePHSeriescontrolpowercircuittostopallmotion andheating.

S. ControlPower -TurnsONandOFFthecontrolpowertothecompleteelectricalcircuit includingHeatersandHoseHeaters.

T. HeaterTemperatureZones:A(Iso),R(Poly),HOSE -TurnsONandOFFpower tothespecificHeaters.Seepage27fordetailedTemperatureControllerinstructions. TheHoseHeatControllerautomaticallycontrolstheHoseHeateronlywhenusingthe TSU(TemperatureSensingUnit)probe.

U. CountDownCounter -Usedtosettheamountofcyclesrequiredtopreventthe chemicaldrumsfromrunningdry,themachinewillshutdownwhenthepresetcycle expires.ThereisandON/OFFswitchtoactivate/deactivatethisfeature.

Figure5:FrontPanelDescription

V. CycleCounter -Indicatesthenumberofpumpcyclestocalculatematerialusage.

W. MotorSwitch -TurnsOnandOFFtheElectric/HydraulicMotor.WhenturnedON theswitchwillbelit.Intheeventofamotoroverload,thepilotlightwillturnOFF andthemotorwillstop.

X. PumpSwitch

OFF -Removespowerfromthepumpcircuit.Thedirectionalindicatorlightswillnot belit.

NORMAL -Activatesthenormaloperationofthemachine.WhentheswitchisON thedirectionallightcorrespondingtothestrokedirectionwilllight.

RETRACT -SetsthePistonRodoftheA(Iso)meteringpumptotheretractposition andpreventscrystallizationofA(Iso)onthePistonRod.Turntheswitchtothe RETRACTpositioneverytimetheunitisstoppedbytheoperator.(see11,page32)

Y. DirectionIndicatorLight -IndicatesthedirectionofmovementoftheMetering Pumps.Ifexcessivepressureoccursinthesystem,thepumpcircuitwillbedisabled andthedirectionallightswillturnOFF.

Z. HeaterTemperatureSwitch:A(Iso),R(Poly),HOSE -TurnsONandOFF powertotherespectivespecificHeaters.

AA. AutoShutDownSwitch -TurnsONandOFFpowertotheAutoShutDownunit.

BB. PressureBalanceControl”FAULT”Light -Indicatesthethepressuredifferential isequaltoorgreaterthanthemaximumallowable.

CC. PressureBalanceControl”ON”Light -IndicatesthatthePressureBalance Controlsystemisonandfunctioning.

DD. PressureBalanceControlKnob -Usedtosetthemaximumallowablepressure differential(PSI)betweentheA(Iso)andR(Poly)pumps.Seepage26formore information.

6 INSTALLATION WARNING! UsesuitableprotectionandfollowtherecommendationsintheSafetyInformationenclosedandprovidedbymaterial supplierswheninstallingorworkingwiththeProportioner.

CAUTION! Makesurethepowercableisdisconnectedfromthe mainpowersourcebeforeconnectingtotheTerminalStripinthe Console.

NOTE! ToensurethePHSeriesProportionerworkscorrectly,the electricalsupplymustmeetthespecificationsindicatedontheSerialNumberPlacardaffixedtotheElectricalConsole.

1. Insertthemainpowercablebypassingitthroughthewirestopatthebottomofthe electricalconsoleandconnectasshowninthediagramabove.

2. FilltheHydraulicReservoirwith20gallons(76Liters)ofapprovedhydraulicfluid. Seepage56forhydraulicoilspecifications.

NOTE! Donotfillthetanktomaximumcapacity; usetheVisualLevelIndicatoronthetanktomake suretheamountofhydraulicfluidisnotmorethan 20gal(76L)or80%ofthetanksmaximumcapacity.

3. TocheckthelevelofthehydraulicfluidintheHydraulicPumpCase,disconnectthe HydraulicHosefromthe90degreefittingandremoveFittingfromHydraulicCase. Addfluidasrequired.ReattachFittingandHydraulicHose.Turnthehydraulic pressurecontrolknobcounterclockwiseuntilitstops,thatisthelowesthydraulic pressuresetting.

Figure6:ElectricalInstallation

Figure7:ComponentIdentification-Misc

CAUTION! Ensurethattheemergencystopisnotengaged.

4. ThreePhaseProportionerOnly: ChecktheElectricMotortoensurerotationis clockwisewhenviewingtheendoftheElectricMotor.Acounterclockwiserotation indicatestwooftheincomingpowerleadsneedtobereversed.

CAUTION! EnsureMainPowerSwitchisOFFandincomingpowerislockedOFFbeforereversingpowerleads.

RecheckrotationbeforeproceedingwithInstallation.

5. FilltheLubeReservoirwithPMCPumpLubeorsuitabledilutents.Itisnotnecessary toprimethesystem.

6.1 HEATEDHOSEINSTALLATION CAUTION! ThematerialdeliveryHeatedHosesarecolorcoded RedandBlue,allowingtheusertorecognizethem.TheRedcorrespondstotheIsocyanate(Iso,A)andtheBluetothePolyol (Poly,R).Toavoidconnectionerrors,theCouplingConnectionsof theIso(A)andPoly(R)HeatedHosesaredifferentsizestoensure correctorientation.

NOTE! ThematerialdeliveryHeatedHosesarecappedatthe endstopreventabsorbingmoisture.Donotremovecapsuntil theHeatedHosesaregoingtobeinstalledontheProportioner.

1. LayoutalltheHeatedHoseassembliesendtoendaligningtheIso“A”(red)andPoly “R”(blue)andconnecttherespectiveCouplingConnectionsusingtheappropriate sizedopen-endwrenchafterensuringHeatedHoseassemblieslayflat.

CAUTION! Takecaretonotcross-threadorover-tighten theCouplingConnections.ThreadsealtapeorcompoundisnotrecommendedforthesetaperedseatCouplingConnections.

2. ConnectthematerialHeatedHosestotheoutletsoftherespectiveHeatersi.e.Iso (A)HeatedHosetotheIso(A)HeaterandthePoly(R)HeatedHosetothePoly(R) HeaterensuringHeatedHoseassemblieslayflat.(Forhalfinchhoseassemblies,all requiredfittingsandinstructionsareincludedinkit200212)

3. ConnectAirHoseCouplingConnections.

4. ConnecttheHeatedHosepowerwirestothe“Fast-Lock”Connector(Part#KT00029A)comingfromtheHoseHeatTransformerasfollows:

(a) LoosentheSocketHeadSetScrewtoallowinsertionoftheHeatedHoseelectrical wireTerminal.

(b) InserttheTerminalintothe“Fast-Lock”ConnectorBody.

(c) SecurelytightentheSocketHeadSetScrew.

(d) InstallelectricaltapearoundConnectorBody.

NOTE! Agoodpracticeistoaddsomedielectricgrease (Permatex67VRorequivalent)totheoutsideofthe Terminal,wheretheelectricalconnectionismade,prior toinsertion.

5. Repeattheabovestepstoconnectthe“Fast-Lock”Connectorsthatyouwillfindon allHeatedHosepowerwire.

CAUTION! EnsurethepropermechanicalandelectricalconnectionsoftheHeatedHosesaremadetoavoid possiblematerialleakageandHoseheatproblems.

6. ItisrecommendedtheTSUbeinstalledbetweenthelastsectionofHeatedHoseand theGunWhip.Carefullystraightenthesensingwire,insertingitintheIso(A)Heated Hoseandtightenfluidfittingswithappropriatesizedopen-endwrenches.

CAUTION! ToprotecttheTSUsensor,youmustpay specialattentionnottokinkorexcessivelybendthe HeatedHoses.DonotcoiltheHeatedHoseswitha diameteroflessthan4feet(1.22Meters).

Figure8:TemperatureSensingUnit

(TSU)Part#EL-51A-4

ReplacementSensorPart#EL-51A-2

CAUTION! ConnectingtheTSUbetweenthefirstand secondsectionofHeatedHoseresultsintheTSUsensing thematerialtemperatureexitingtheHeaterandnotthe insideoftheHeatedHoseneartheSprayGun.

7. EnsuretheManualValvesareCLOSEDandconnecttheCouplingBlocktotheHeated GunWhip.

CAUTION! ExcessiveforceclosingoropeningtheManualValvesmayresultindamagetotheManualValves and/orCouplingBlock.

8. ConnecttheTransferPump/HeatedHoseAssemblies/AirSupplyandAirDryersystemsasrequired.ReviewtheInstallationInstructionsforeachtoensureproperset-up andoperation.

9. InstalltheMaterialTransferPumpsasfollows:

WARNING! IfTransferPumpshavebeenpreviouslyused,pay specialattentiontoconnecteachPumptoitsspecificmaterial. InadvertentlychangingtheTransferPumpswillcauseachemical reactionrenderingthemuseless.

NOTE! PlacingatapeofthesamecolorasoftheMaterialDeliveryHoses(redfortheIso(A),blueforthePoly (R))oneachTransferPumpwouldbeagoodmethodfor minimizingerrorsinconnection.

a. MakesurethattheInletValvesontheProportionerareclosed.

b. ConnectoneendofthePolyol(R)MaterialDeliveryHose(3/4”thread)tothe ProportionerPolyol(R)InletValveandtheotherendtothePolyol(R)Transfer Pump.

c. ConnectoneendoftheIso(A)MaterialDeliveryHose(1/2”thread)tothe ProportionerIso(A)InletValveandtheotherendtotheIsoTransferPump.

d. ConnecttheairhosetotheTransferPumpsafterensuringeachTransferPump Shut-OffValveisCLOSED.

NOTE! Toavoiderrorsinconnection,theCouplingconnectionsoftheIso(A)andPoly(R)MaterialDelivery Hosesaredifferentsizes,makingitdifficulttoswapconnections.

10. GroundtheTransferPumpasrecommendbythematerialsupplier.Themovementof productinsidetheHosescancausestaticelectricityandproduceelectricaldischarges.

11. Connectairtotheairlinecomingoffthefirstsectionofhose(90-110psi,6-8bar)

6.2 HOSEHEATTRANSFORMER TheHoseHeatTransformerofferstheabilityofconnectingtodifferentoutputvoltages dependingonthetotallengthoftheHeatedHoseinuse,maximizingtheheating abilityoftheHeatedHose.Thefactorysettingis18voltsforusewith60feet ofHeatedHose.BeforestartingtheProportioner,ensurethesettingmatchesthe HeatedHoselengthinstalled.IfHeatedHosesectionsareaddedorremoved,theTap settingshouldbechangedtoasettingwhichwilllimitthemaximumamperageinthe HeatedHoseto52amps.Thesuggestedsettingsarelistedinthetablebelow.

RECOMMENDEDTAPSETTINGS Figure9:Transformers

*90Vtransformers(shownabove)allowforamaximumhoselengthof310ft(94.5m).120V transformersallowforamaximumhoselengthof410ft(125m).

7 PROPORTIONERPURGING WARNING! UsesuitablePersonalProtectionEquipment (PPE)andfollowtherecommendationsintheSafetyInformationprovidedbyproductsupplierswheninstallingorworking withtheunit.

WARNING! DonotturntheTemperatureControllersON untiltheProportionerpurgingprocedureiscompleteandthe PrimaryHeatersandHeatedHosesarefilledwithmaterial.

NOTE! BeforeusingtheProportioneritisnecessarytopurge theentiresystem,includingHeatedHosesofmineraloilleft overfromQualityControltestingandair.Thefollowingprocedureisalsofollowedtopurgeairentrappedbyrunningout ofmaterialinthesupplyDrum/Reservoirsresultinginasignificantindicatedmaterialpressureimbalanceasindicatedby thePressureGaugesandsprayedmaterial.

1. Ensurethefollowingbeforeproceeding:

a. AirsupplytoTransferPumpsis90-110psi(6-8bar).

b. ProportionerinletballvalvesareCLOSED.

c. Allconnectionsaretight.

d. Materialshouldbestoredtothematerialsuppliersrecommendedtemperatures.

e. Sprayguncouplingblockisinstalledandmanualvalvesareclosed.

2. SlowlyOPENthePoly(R)TransferPumpAirShut-OffValveallowingPumptocycle slowlyasitfillstheMaterialDeliveryHosetotheProportioner.Checkforleaks.

3. OPENPoly(R)CouplingBlockManualValveoverawastecontainer.

4. SlowlyOPENProportionerPoly(R)InletValveallowingTransferPumptomove materialthroughthesystem.Whenallspittingofairstopsandalltracesofmineral oilhavedisappeared,CLOSEPoly(R)CouplingBlockManualValve.CleanCoupling Block.

5. Repeatsteps2to4forIso(A)side.

CAUTION! Properlydisposeofallwastechemicalsinaccordancewithallapplicablelocal,stateandfederalcodes.DO NOTturnontheAutoCountdownSwitchorthePressure BalanceControlSwitch.

6. TurnHydrualicPressureControl(ItemN,Figure4)fullyCOUNTERCLOCKWISE.

7. TurnONMainPower(ItemQ,Figure5).

8. TurnONMotorPower(ItemW,Figure5).Buttonwillturngreenwhenactivated.

9. ActivatePumpPower(ItemX,Figure5).Thebuttonwillturngreenandthepumpwill activate.TurnHydraulicPressureControlCLOCKWISEincreasingmaterialpressure to400psi(28bar).BothMaterialPressureGauges(ItemsH&K,Figure3)should approximatelyreadthesame.CheckallHeatedHoseCouplingconnectionsforleakage.

10. CheckallTSUand”Fast-Lock”connectionsforleaks.

11. BundleallHeatedHoseConnectionsensuringthatthereareNOkinksintheTSU CableorAirHose.WrapwithElectricalTapetosecurelyholdallcomponentsinplace andminimizeplacesforbundletosnagontojobsiteprotrusions.

8 PRESSUREBALANCECONTROL ThePHSeriesProportionerhasbeendesignedwithapressurebalancecontrolsystem.This systemwillgivetheoperatorofthismachinetheabilitytocontrolapressureimbalance withincertainpredeterminedparameters.

8.1 OPERATION Positiontheselectorswitchononeofthethreeoptions:

Thesystemconsistsof:

SelectorSwitch FaultLight OnLight

ControlUnit

PressureTransducers Relay

• PressureDifferentialNumber -theseconsistof300,400,500,600,and700PSI. SelectinganyofthesenumberswiththeswitchwillactivatethegreenONlight.While thepressuredifferentialnumbersareselected,thecontrolboxwillcontinuallymonitor pressureonbothsidesoftheProportioner.Intheeventthatthepressuredifferential betweenbothsidesoftheProportionerisequaltoorlargerthantheselectednumber, afaultisgiven(theredfaultlightisturnedonandtheactivegreenlightisturnedoff) andshutsdown.

• Off -iftheselectorswitchisplacedinthisposition,theProportionerwilloperateas thoughthereisNOPRESSUREBALANCECONTROLSYSTEM(neitherthered faultlightnortheactivegreenlightwillbelit).Theoverpressuresystemwillremain activeforthemachineandpersonnelprotection.

• Reset -intheeventofapressureimbalance,resolvetheProportionerimbalance, positiontheselectorswitchonresettoclearthefaultlightandrestorepowertothe Proportioner.Afterthefaulthasbeencleared,positiontheswitchineitheraPressure DifferentialnumberorintheOFFPositiontocontinueoperations.

9 DIGITALTEMPERATURECONTROLLER ThePHSerieshasthreeDigitalTemperatureControllerstomanagethetemperaturesfor thePrimaryHeaters(Iso(A),Poly(R))andtheHeatedHose.TheHoseHeaterController isprogrammeddifferentfromtheIso(A)andPoly(R)Controllersandthereforenotinterchangeablewiththem.

WARNING! DonotturntheTemperatureControllersON untiltheProportionerPurgingprocedureiscompleteandthe PrimaryHeatersandHeatedHosesarefilledwithmaterial.

EATONCONTROLLER 1. EnsureMainPower(SeeFigure5onpage16)isON,ControlPower (SeeFigure5onpage16)isONand 01 Displaylightislit.

2. PressandreleaseXbutton.Thedisplaywillread SP1.

3. Pressandreleaseupordownbuttontodisplaythe currentmaterial temperatureset-point

4. Pressandholdtheupordownbuttonto increase or decrease the materialtemperatureset-pointtothedesiredvalueasdeterminedby thematerialsupplierorapplicationconditions.

5. Pressandreleaseupanddowntogethertoreturntothe actualmaterial temperature inthePrimaryHeater/HoseHeater.

NOTE! TheTemperatureControllernormallydisplaystheactualmaterialtemperature.Whenlit,the“01”displayinthe upperleftindicatespowerissenttothedesignatedheating system.The“01”displaygoesoutwhenthematerialtemperaturehasreacheditsset-point.The“01”displaywillcontinue tocycleonandoffindicatingtheControllerismaintainingthe materialtemperatureset-point.

OMRONCONTROLLER 1. PressandholdtheUPorDOWNkeysto increase or decrease, respectively,thematerialtemperatureset-pointtothedesiredvalue asdeterminedbythematerialsupplierorapplicationconditions.

2. Thesmaller green numbersinthebottomrightsideofthecontroller displaythesetpoint.Thelarger white numbersinthecenterofthe controllerdisplaytheactualtemperatureofthematerialasreadby thethermocouplesinthePre-HeaterandTSUassembly.Seetheimage belowfortheOMRONHeaterControllerdisplay.

3. TurntheHeaterTemperatureSwitch(SeeFigure5onpage16)tothe right toturnONeachheater.

NOTE! TheTemperatureControllerdisplaystheactualmaterialtemperatureandtheset point.TheYELLOWboxwith thewordOUTindicatesthatthe heatersarebeingpowered.

WARNING! TheControllersarefactoryprogrammedandare notfieldre-programmable.Ifaproblemisencountered,contact yourPMCDistributor.Donotattempttochangeanyofthe programmedparameters.DonotsubstituteaControllerfrom analternatesupplierasitsusemayresultinequipmentdamage and/orbodilyinjury.

10 START-UP NOTE! Followtherecommendedprocedureintheordershown.

CAUTION! TheStart-upproceduresassumethatallstepsinProportionerpurginghavebeenperformedandnoproblemswere found.

1. Checkthehydraulicfluidlevelandserviceasrequired.

2. Makesurethematerialshavebeenstoredatthemanufacturer’srecommendedtemperature.Askyourmaterialsupplierforinformation(MaterialSafetyDataSheet)on theminimumstoragetemperature.

3. Y-Strainerscreensshouldbecheckedroutinely.

4. ConnectairsupplytothetwoTransferPumpsandensureAirValvesareinthefull OPENposition.OPENbothProportionerMaterialInletBallValves.

CAUTION! RemoveallHeatedHosesectionsfromcoiledstorage andlayflattoeliminateheatbuild-upandpossibleHeatedHose failure.

5. TurnONMainPower(SeeFigure5onpage16).

6. TurnONControlPower(SeeFigure5onpage16).

7. TurnONHoseHeater(SeeFigure5onpage16)andconfirmmaterialset-pointtemperatureasrecommendedbythematerialsupplierorapplicationconditions.

CAUTION! ToavoidexcessivepressureintheProportioner,wait fortheHoseHeatertoreachitsset-pointtemperaturebeforecontinuing.

8. TurnONeachPrimaryHeaterandconfirmmaterialset-pointtemperatureasrequired bythematerialsupplierorapplicationconditionshasbeenreached.

9. TurnONMotorPower(Seefigure5onpage16).

10. SetPumpSwitch(SeeFigure5onpage16)toNORMAL.OneoftheDirectional IndicatorLights(SeeFigure5onpage16)willilluminate,indicatingtheMetering Pumpdirection,andtheMeteringPumpShaftswillbegintomove.

NOTE! TheMaterialPressureGaugesshouldbeapproximately equalandremainconstantthroughouttheMeteringPumpcycle. Ifnot,refertoTroubleShootingsection.

NOTE! DirectionalIndicatorLightsmustindicateMeteringPump directionwhenPumpSwitchisintheNORMALposition.Ifnot, refertoTroubleShootingsection.

11a. UsingtheHydraulicPressureControl,adjusttotherequired stallpressure andcheck eachMaterialPressureGauge.

12a. AutoShutDownCounter- Ifthisfunctionisnotneeded,leaveitintheoff position. TosettheAutoShutDownCounter:

a. Turntheswitchtotheonposition,thegreenlightwillilluminate.

b. InsertthenumberofcyclesdesiredtodisablethePHmachinebypushinginonthe whitetrianglestosetthecyclecount.Pushinontheredbuttonuntilthedata isreplicatedonthetoprow,thetoprowwillcountdown.

Model PumpSize CyclesperGallon

PHX-2(3,000PSI) 61 55Cycles

c. Whenthecountercountsdowntozerothemachinewillstopandthepumpdirectionallightwillbeoff,pushinontheredbuttontoreset.

13a. ProceedwithInstallationandStart-upoftheSprayGunaspertheGunmanual.

Stallpressure: WhenmaterialsareatrecommendedapplicationtemperatureandMetering Pumpsarepressurizedbutnotmoving.Thispressureisnormally100–200psi(7-14Bar) greaterthanthedevelopedspraypressureasrecommendedbythematerialsupplier.

NOTE! DirectionalIndicatorLightsmustindicateMeteringPump directionwhenPumpSwitchisintheNORMALposition.Ifnot, refertoTroubleShootingsection.

11b. (SeeFigure5onpage16)- Ifthisfunctionisnotneeded,leaveitintheoff position. TosettheAutoShutDownCounter:

a. InputthenumberofcyclesdesiredtodisablethePFmachineontotheAutoShut DownCounterbypushinginonthegraybuttonstosettheCountdownValue.The bottomrowof green numbersidentifiesthesetpoint.Thetoprowofnumbers identifiesthenumberofcycleslefttocountdownandwillinitiallybecolored red beforetheCountdownValueisset.Eachbuttoncorrespondstoaspecificdigit. Forexample,inordertosettheAutoShutDownCountertoavalueof136asseen intheimagesbelow,pressButton1(6)times,Button2(3)timesandButton3 (1)time.Seetableonpage30forapproximatecyclesrequiredpergallonorliter.

b. Pressthegray“RST”buttononthebottomleftofthedisplaytosetthecountdown value.Thetoprowofnumberswillnowbecome green.TurnthePumpSwitch (SeeFigure5onpage16)to Normal.Thetoprowofnumberswillcountdown by1aftereachcycleofthePumpLineiscompleted.

c. AfterthePumpLinehascompletedthesetnumberofcycles,theCountdownValue willread“0”andchangecolorto red,thePumpLinewillstopintheRetract position,andthePumpSwitch/IndicatorLightwillnolongerilluminate.

d. Tomakethemachineoperationalagain,resettheCountdownValuebypressing the“RST”buttonwiththenextdesiredCountdownValueorbyshuttingoffthe AutoShutDownCounter.

12b. ProceedwithInstallationandStart-upoftheSprayGunaspertheGunmanual.

11 SHUT-DOWN 11.1 SHORT-TERM Followtheprocedurebelowfortemporaryshut-downs,suchas lunchbreaks:

1. SetPumpSwitch(SeeFigure5onpage16)totheOFFposition.

2. Turnboth“A”and“R”HeatersOFF.HoseHeatershouldremainON.Neverleave ProportionerONifunattended.

3. CLOSESprayGunManualValves.

CAUTION! ExcessiveforceopeningorclosingtheManualValves mayresultindamagetotheManualValvesand/orCouplingBlock.

11.2 LONG-TERM Followtheprocedurebelowforshut-downswhenworkis stoppedfortheday:

1. SetPumpSwitch(SeeFigure5onpage16)totheRETRACTposition.

2. SprayofftheapplicationsurfaceuntilMaterialPressureGauges(SeeFigure3onpage 14)readingsbegintofall.

CAUTION! ToavoidpossibleProportioningPumpSealweepage, andmoisturevapordriveintotheHeatedHoses,thesystempressureshouldnotbereducedtozero.Itisrecommendedtolower thesystempressuretoaminimumof400psi(28bar).

3. CLOSEtheSprayGunCouplingBlockManualValves.

4. TurnOFFMotorPower(SeeFigure5onpage16).

5. TurnOFFtheAandRHeatersandHoseHeater(SeeFigure5onpage16).

6. TurnOFFtheControlPower(SeeFigure5onpage16).

7. TurnOFFtheAutoShutDownSwitch(SeeFigure5onpage16).

8. TurnOFFtheMainPower(SeeFigure5onpage16).

9. DisconnecttheairsupplytothetwoTransferPumpsandCLOSEtheProportioner MaterialInletValves.

CAUTION! ExcessiveforceopeningorclosingtheManualValves mayresultindamagetotheManualValvesand/orCouplingBlock.

12 TROUBLESHOOTING ThisPHSeriesProportionerhasbeendesignedandbuilttowithstandsevereworkingconditionswithahighdegreeofreliability,providedthatitisusedinasuitableapplication byaproperlytrainedoperator.Thischaptercontainsinformationonpossiblefaultsthat mayinterrupttheoperationofthePHSeriesProportioner.Theinformationprovidedwill serveasaguidelinetodetectandresolveproblems.Inanycase,feelfreetocontactyour authorizedPMCdistributor,whereaqualifiedtechnicianwilladviseyou.

WARNING! Onlyqualifiedpersonnelshouldperformtroubleshooting;unqualifiedpersonnelmaycausedamagetotheunitandput theoperatoratrisk.

Topreventpossibleinjurycausedbyincorrecthandlingofthe rawmaterialsandsolventsusedintheprocess,carefullyreadthe MaterialSafetyDataSheet(MSDS)providedbyyoursupplier. Dealwiththewastecausedaccordingtocurrentregulations.

Toavoiddamagecausedbytheimpactofpressurizedfluids,do notopenanyconnectionorperformmaintenanceworkoncomponentssubjecttopressureuntilthepressurehasbeencompletely eliminated.

Usesuitableprotectionwhenoperating,maintainingorbeing presentintheareawheretheequipmentisfunctioning.Thisincludes,butisnotlimitedto,theuseofprotectivegoggles,gloves, shoesandsafetyclothingandbreathingequipment.

Theequipmentincludescomponentsthatreachhightemperatures andcancauseburns.Hotpartsoftheequipmentmustnotbe handledortoucheduntiltheyhavecooledcompletely.

Topreventseriousinjurythroughcrushingoramputation,do notworkwiththeequipmentwithoutthesafetyguardsinstalled onthemovingparts.Makesurethatallthesafetyguardsare correctlyreinstalledattheendoftherepairormaintenancework oftheequipment.

12.1 HEATERS WARNING! Onlyqualifiedpersonnelshouldperformtroubleshooting;unqualifiedpersonnelmaycausedamagetotheunit,personnel, orpropertyandputtheoperatoratrisk.TheHeatersarecomponentsthatreachhightemperatures;youmustwaituntiltheycool beforehandling.

NOTE! TheThermalLimitSwitchisasafetyswitchincontactwith theHeaterBody.Ifthesurfacetemperatureexceeds220◦ F(109◦ C) theLimitSwitchwillshutofftheHeaterpower.TheLimitSwitch willnotre-setuntilthetemperatureintheHeaterisbelow190◦F (88◦ C).Thesystemisdesignedthatincaseofanovertemperature, acontactorlocatedintheconsolewillopenanddisablepowerto bothHeatersandtheHose.

Followtherecommendedprocedureintheindicatedordertosolvetheproblemandavoid unnecessaryrepairs.MakesureallSwitchesareinthecorrectpositionandIndicatorLights ONbeforedeterminingtheexistenceofafault.

FrequentHeaterProblems Primaryheaterdoesnotheatandthedisplayonthecontrollershowsambienttemperature. Page35

Primaryheaterdoesnotheatandthedisplayonthecontrollershowsan errormessage(SbEr,EEPE,CjEr,AdEr). Page36

Primaryheatercontrollershowsexcessivetemperatureandthecircuithas turnedoff. Page36

PrimaryheaterTemperaturedropsexcessivelywhilespraying. Page37

• Problem: Primaryheaterdoesnotheatandthedisplayonthecontrollershows ambienttemperature.

Solutions:

1. Checkthatthelightontheon/offswitchislitwhentheheateristurnedon,if notreplacetheswitch.

Ifthelightison,movetothenextstep.

2. Checktheheaterbreakerinthemainconsoleandresetthebreaker.Ifitcontinues totrip,wrapanAmpClamparoundoneofthewirescomingoffthebreaker.If theAmperagereadingdoesnotexceedtheratingofthebreaker,thebreakerneeds tobereplaced.Ifthebreakerdrawsmorethanitsratingthemostlikelycauseis thatoneormoreofthefirerodslocatedintheheaterareshorted. Ifthebreakerisnottripped,moveontothenextstep.

3. Opentheconsoletopandlocatethesolidstaterelaysfortheheaters,lookingover theconsoletopfromthefrontofthemachine.Therearetworelaystotheleft bottomoftheconsole,theonetothefarleftisforthe“A”heaterandtheoneto therightisforthe“R”heater.Withtheheateron,looktoseeifanLEDlightis litontherelay.

IfthereisnoLEDlightonthesolidstaterelay,movetothenextstep.

4. WithaDCvoltmeterreadacrosspositionA1andA2onthesolidstaterelay (smallerwires)ifyouhaveareadingof4-6voltsDCandtheACreadingacross L1andL2(Heavywires)reads208-230voltsACreplacethesolidstaterelay. With4-6voltsDCatA1andA2theproperreadingshouldbe1voltACacross L1andL2.Adefectiveovertemperatureswitchwillopenacontactordisabling bothHeatersandtheHose.

IfthereisnoDCvoltagetotherelay,movetothenextstep.

5. ChecktheM1contactortoensureitisactivated.Ifnot,inspectthecontactorfor failure.

IftheM1contactorisactivated,movetothenextstep.

6. UsingaDCvoltmeter,onanEatonControllermeasureacrossposition5and9on thebackoftheheatercontroller.OnanOmronControllermeasureacrossposition 5and6onthebackoftheheatercontroller.Thisistheoutputofthecontroller andsendspowertothesolidstaterelay.OnanEatonController,yourreading willbe4-6voltsDC.OnanOmronController,yourreadingwillbe12voltsDC. Ifthereisnoreadingchecktomakesurethatthesettemperatureofthecontroller isabovetheactualtemperaturereadingonthecontroller.Beforereplacingthe controllerreadacrossposition1and2tomakesurethatthecontrollerispowered up,yourreadingwillbe208to230voltsAC.Ifthereisnovoltagedetected;check forloosewiresoramalfunctionoftheheatercircuitbreaker.

• Problem: Primaryheaterdoesnotheatandthedisplayonthecontrollershowsan errormessage(SbEr,EEPE,CjEr,AdEr).

Solutions:

1. Checkposition6and7ontheheatercontrollerforloosewires. Ifthewiresaretight,movetothenextstep.

2. Removetheheatercoverandcheckthatthethermocouplewiresaresecuretothe harnessgoinguptothecontroller. Iftherearenolooseconnectionsreplacetheheaterthermocouple.

• Problem: Primaryheatercontrollershowsexcessivetemperatureandthecircuithas turnedoff.

CAUTION! Theheatermustbeallowedtocooldownbefore continuing.

Solutions:

1. Setthecontrollersetpointatleast20degreeslowerthanthetemperatureshown onthecontroller.BrieflyturnontheheaterandlookfortheLEDlightonthe solidstaterelaytobeon. Ifthelightison,replacethecontroller. Ifthelightisoff,replacethesolidstaterelay.

• Problem: PrimaryheaterTemperaturedropsexcessivelywhilespraying.

Solutions:

1. Temperatureofthechemicalinthecontainersistoocold.

2. Exceedingtheflowratespecificationofthemachine.Useasmallermixingchambertoreduceflow.

3. Disconnectpowertothemachine. Oneormoreofthefirerodsintheheaterhave malfunctioned.Removetheheatercoveranddisconnectthewirestomeasurethe resistanceacrosseachrod.Installingasmallermixingchamberinthegunmay allowyoutosprayuntilanewrod(s)isinstalled.

CAUTION! Iftherodthatisusedinconjunctionwiththe thermocoupleisdefective,donotoperatetheheateruntilthe rodisreplaced.

IndividualOhmMeasurement

1250WATT 37OHMS

1500WATT 31OHMS

1750WATT 27OHMS

12.2 HYDRAULICDRIVESYSTEM FrequentHydraulicDriveSystemProblems HydraulicPumpdoesnotdeveloppressureandtheelectricmotorisnot running. Page38 HydraulicPumpdoesnotdeveloppressure. Page39 LoworzerohydraulicpressurewithunusualHydraulicPumpnoises. Page39

Followtherecommendedprocedureintheindicatedordertosolvetheproblemandavoid unnecessaryrepairs.MakesureallSwitchesareinthecorrectpositionandIndicatorLights ONbeforedeterminingtheexistenceofafault.

WARNING! Onlyqualifiedpersonnelshouldperformtroubleshooting;unqualifiedpersonnelmaycausedamagetothe unit,personnel,orpropertyandputtheoperatoratrisk. TheHeatersarecomponentsthatreachhightemperatures; youmustwaituntiltheycoolbeforehandling.

CAUTION! ExcessiveforceopeningorclosingtheManual ValvesmayresultindamagetotheManualValvesand/or CouplingBlock.

• Problem: HydraulicPumpdoesnotdeveloppressureandtheelectricmotorisnot running. Solutions:

MotorContactorSafetyorMotorBreaker- The ElectricMotorisprotectedfromexcessivecurrentbyan OverloadSafetySwitch.AfterallowingtheMotorto cool,opentheControlPanelandresetMotorContactor Safety.

• Problem: HydraulicPumpdoesnotdeveloppressure. Solutions:

NOTE! HydraulicpressureisnotgeneratediftheMotorPower Switch(SeeFigure5onpage16)isOFForthePumpSwitch(See Figure5onpage16)isintheOFFposition.

HydraulicPowerPackage- WiththePumpSwitchintheNORMALposition,the failureoftheHydraulicPumptodeveloppressureislossofpumpsuction(prime).To ensurepositiveprime,checkthefollowing:

a. MotorRotation.

b. HydraulicReservoirisfilledtothecorrectlevel.

c. HydraulicPumpCaseisfilledwiththeproperhydraulicfluid.

d. LooseInletPlumbing:CheckthatallinletplumbingtoHydraulicPumpistight ensuringnoairleakageintothehydraulicsystem.

• Problem: LoworzerohydraulicpressurewithunusualHydraulicPumpnoises.

Solutions:

1. Theuseofanincorrecthydraulicfluidcanresultisunusualnoisesfromthepump, excessivewear,andmoistureabsorption.Ensurethehydraulicoilusedisfrom thelistonpage56.Inaddition,continuousexcessivehydraulicoiltemperature aswellasfailuretochangethehydraulicoilonayearlybasiswillcausetheoilto failandresultinexcessiveHydraulicPumpwearandunusualnoises.

2. LooseInletPlumbing:CheckthatallinletplumbingtoHydraulicPumpistight, ensuringnoairleakageintothehydraulicsystem.

12.3 METERINGPUMP-LINE Figure10:MeteringPump-Line(PL-1A/PL-2)

FrequentPump-LineProblems Meteringpumpsdonotchangedirectionandthepressuresonbothof chemicalgaugesarelowerthannormal.

Page40

Cavitation. Page43

PressureLoss:Discharge/InletBall. Page43

Followtherecommendedprocedureintheindicatedordertosolvetheproblemandavoid unnecessaryrepairs.MakesureallSwitchesareinthecorrectpositionandIndicatorLights ONbeforedeterminingtheexistenceofafault.

• Problem: Meteringpumpsdonotchangedirectionandthepressuresonbothof chemicalgaugesarelowerthannormal.

Solutions:

1. TheMeteringPumpLinehasReversingPlateswhichactuatestwoProximity Switches(EL-153),oneateachendofthestroke.TheProxSwitchesinturn actuatetheappropriateDirectionalValveSolenoid(HI-05003).Failuretomake contactwitheitherProxSwitchmaybecausedby:

a. DeformationoftheReversingPlate.

b. ForeignmaterialpreventingtheReversingPlatefromcontactingtheProx Switches.

2. PassingoftheReversingPlatebeyondtheProxSwitchmaybecausedby:

a. FailureoftheProxSwitchandrelatedcomponentsonthesideoftheover-run.

b. FailureofacomponentoftheDirectionalValve.

c. MountingPlateand/orProxSwitchisoutofadjustment.

NOTE! IFTHEDIRECTIONALINDICATORLIGHT(Q,Page 16)ISONCHECKTHEREVERSINGVALVECOILONTHE SIDETHATTHELIGHTISON.IFYOUHAVE24VOLTSDC ATTHEPLUGCHECKTHEOHM’SRESISTANCEOFTHE COIL,ITSHOULDREADAPPROXIMATELY19OHM’s,IF NOTREPLACETHECOILORREVERSINGVALVE.IFTHE DIRECTIONALLIGHTISOFFPROCEEDBELOW.

NOTE! BEFORETROUBLESHOOTING,THEREVERSING PLATEMUSTBEMOVEDAWAYFROMTHESWITCH.

d. Bleeddownthechemicalpressures.

e. EnsurePumpSwitch(P,section5)is OFF

f. Turnonthemotor(X,section5).

g. GototheDirectionalValveandlocatetheActuationCoils.Locatedinthe middleofeachcoilisasmallroundtabthatcanbepushedintomanually shiftthespooltomovethepumps.IftheReversingplateisallthewayto theleftpushinontherightsidecoil.Ifit’sallthewaytotherightside,push inontheleftsidecoil.

WARNING! THEMOTORMUSTBEOFFANDTHEPUMP SWITCHINTHENORMALPOSITION.

h. Takeasmallscrewdriverorathinpieceofmetalandmoveitacrossthefront ofeachProxswitch.Aredlightonthebackoftheswitchshouldilluminate. Ifnot,replacetheswitchthatdoesnotlight.

i. IftheProxswitcheslightup,turnoffallpowerandcheckforcontinuityon bothoverpressureswitches,pin1and2.Ifthepressureswitchesaregood, gotothetwosolidstaterelaysinsidetheconsoleandinterchangethem,they canbepulledfromtheirhousing.Poweruptheunitwiththepumpswitch inthenormalpositionandthemotor OFF.Ifthedirectionallightcomeson replacethedefectivesolidstaterelay.IfnotreplacetheLatchingrelay.

3. SafetyPressureSwitch-EachMeteringPumphasaSafetyPressureSwitchsetto 2,200psi.for#123pumps,3,200psifor#61pumps.Whenthematerialsystem reachesthispressure,theSafetyPressureSwitchwillremovepowerfromthe DirectionalValveandDirectionIndicatorLights(Q,section5).LackofDirection IndicatorLightsalongwithhighpressureindicatedononeorbothofthematerial PressureGauges(E,F,section5)isanindicationofanover-pressurecondition. TheSafetyPressureSwitchesareamomentarydesign;whenthepressurebleeds offtheMeteringPumpLinewillresumenormaloperation.However,thecauseof theover-pressureshouldbedeterminedandcorrected.Themostcommoncauses are:

a. CavitationsoftheMeteringPumponthe low pressuresidecausinghigh pressureontheoppositeside.

b. ArestrictionintheSprayGunonthe high pressureside.

4. Pressure/MaterialImbalance-Troubleshootingthisproblemrequirestheapplicatorto:

a. KnowwhattheNORMALspraypressuresarefortheapplicationinprogress.

b. DeterminewhatmaterialisNOTexitingtheMixingChamber.

c. ReadthePressureGaugeontheproblemsideandinterpretthereading.

MaterialCondition ”A”GAUGE ”R”GAUGE • Problem: Cavitation.

Solutions:

1. CavitationsoccurwhentheMeteringPump(BorC,section5)requiresalarger volumeofmaterialthanthesupplysystem(TransferPump)canfurnish.This createsa”void”ofmaterialintheMeteringPump.Themostcommoncausesof cavitationsare:

a. Materialtemperaturetoolowcausingincreasedmaterialviscosityresulting intheinabilityoftheTransferPumptomaintainsufficientsupplytothe MeteringPump.Thisismostcommonwithtoday’sblowingagents.Ensure thematerialtemperatureinthedrumsisnolowerthanthematerialsuppliers’ recommendation.

b. FailuretoventthematerialdrumwhiledrawingmaterialoutwiththeTransferPumpcausesavacuumandcavitationsintheTransferPump.Ensurethe drumisventedtotheatmosphereoraDesiccatedAirDyerKitisinstalled asrecommendedbythematerialsupplier.

c. InsufficientairvolumeforTransferPumporapartiallyclosedTransferPump AirValvewilllimittheabilityoftheTransferPumptooperateatitsmaximumcapability.

d. InletMaterialScreen(M,section5)obstructed(SeeMAINTENANCEsection,page48).

e. MeteringPumpInletBalldoesnotseatproperlyallowingmaterialtoflow backintotheMaterialDeliveryHosewhentheMeteringPumpisonthe ”Discharge”stroke.ThiscausesthevolumeofmaterialonthatMetering Pumptobelessonthedischargestrokeresultinginintermittentoff-ratio materialandPressureGaugefluctuation.

• Problem: PressureLoss:Discharge/InletBall.

Solutions:

1. SimultaneousobservationofthematerialPressureGauge(E,F,section5)and DirectionIndicatorLight(Q,section5)isnecessarytodeterminewhichdirection theMeteringPumpfailstomaintainpressure.Refertothecharttodetermine problem:

LeftArrowDirectional IndicatorLightON

RightArrowDirectional IndicatorLightON

IsoPressureGauge FALLS

PolyPressureGauge FALLS

IsoInletBalldoesnotseat properly

PolyDischargeBalldoesnot seatproperly

IsoDischargeBalldoesnot seatproperly

PolyInletBalldoesnotseat properly

InmostcasesthecauseofaleakingInlet/DischargeBallisforeignmaterialpreventing theBallfromseatingproperly.Iftheabovestepsdonotresolvetheproblem,replacethe appropriateBall.ForserviceseeMAINTENANCE:METERINGPUMP-LINE(page52).

12.4 HOSEHEATING WARNING! Beforecorrectinganykindofdefect,makesurethe MainPowerSwitchisOFFandincomingpowerislockedOFF. NEVERaccesstheinsideoftheControlPanelwiththeProportionerpowersupplyON.TheHeatedHosearecomponentswhich reachhightemperatures;youmustwaituntiltheyhavecooledbeforehandling.

CAUTION! ExcessiveforceopeningorclosingtheManualValves mayresultindamagetotheManualValvesand/orCouplingBlock.

HoseHeatingProblems HeatedHosedoesnotheatandthedisplayonthecontrollershowsambient temperature. Page44

Hosedoesnotheatandthedisplayonthecontrollershowsanerrormessage (SbEr). Page45

Heatedhosecontrollershowsexcessivetemperature. Page46

Hosewillheatbutdoesnotcomeuptosettemperature. Page46

Hosedoesnotheatandthedisplayonthecontrollershowsanerrormessage. Page46

Followtherecommendedprocedureintheindicatedordertosolvetheproblemandavoid unnecessaryrepairs.MakesureallSwitchesareinthecorrectpositionandIndicatorLights ONbeforedeterminingtheexistenceofafault.

• Problem: HeatedHosedoesnotheatandthedisplayonthecontrollershowsambient temperature.

Solutions:

1. Checkthatthelightontheon/offswitchislitwhentheheateristurnedon,if notreplacetheswitch.

Ifthelightison,moveontothenextstep.

2. ChecktheHoseHeatbreakerinthemainconsoleandresetthebreaker.Ifit continuestotrip,wrapanAmpClamparoundoneofthewirescomingoffthe breaker.Ifitdoesnotdrawmorethantheratedvalueofthebreaker,thebreaker needstobereplaced.

Ifthebreakerisnottripped,moveontothenextstep.

3. Checkthecircuitbreakermountedonthetransformerandresetthebreaker. Ifitcontinuestotrip,wrapanAmpClamparoundoneofthewiresfromthe transformergoingtotheheatedhose.Ifitdoesnotdrawmorethantherated valueofthebreaker,thebreakerneedstobereplaced.

IftheAmpDrawislessthantheratedvalue,moveontothenextstep.

4. Checkthatthetapsettingonthetransformerissetfortheproperhoselength. Ifitissetcorrectly,movetothenextstep.

5. Tocheckthesecondarysideofthetransformer,youmusttakeanACvoltreading acrossthetwoleadscomingoutofthetransformerthatareconnectedtothe “A”and“R”hoseleads.Ifyouarereadingvoltage(yourvoltreadingwillvary dependingonwhattapsettingisused),mostlikelytheproblemisintheheated hose.Eitheraconnectorhascomelooseorthereisabrokenwire.

6. Becausethegunwhiptakesthemostabuse,itismostlikelythewhipthathas failed.Disconnectthecrossoverwiresonthemachineendofthewhiphoseand connectthetwowirestogethercomingoffthe50’section.Turnonthehoseheat andseeifthehoseheatcircuitisoperating;ifsoreplacethewhip.Totakea continuityreadingthroughtheheatedhose,oneoftheleadsfromthetransformer tothe“A”or“R”heatedhosemustbedisconnected. Ifnovoltageiscomingoutofthetransformertotheheatedhose,move ontothenextstep.

7. Opentherightsideofthetank(wherethetransformerislocated)andlocatethe solidstaterelayforthehosecircuit(EL-35).Withthehoseturnedonandthe LEDlightilluminatedontherelay,takeavoltmeter(setonDC)andmeasure acrosspositionA1andA2;yourreadingshouldbe24volts.ThentakeanACvolts measurementacrosspositionL1andL2(heavywires).Withtherelayfunctioning properlyyoushouldhavea1voltReading.IftheReadingis18to90voltsAC, therelayhasmalfunctionedandneedstobereplaced.IftheACReadingacross L1andL2is.025voltschecktheovertemperatureswitchesintheheaters.A defectiveovertemperatureswitchwillopenacontactordisablingbothHeaters andtheHose.

Ifthereisnolightonthesolidstaterelay,movetothenextstep.

8. UsingaDCvoltmeter,measureacrossposition5and6onthebackofthehose controller.Thisistheoutputofthecontrollerandsendspowertothesolidstate relay.Yourreadingwillbe 4-6voltsDC.Ifthereisnovoltage,checktomake surethatthesettemperatureofthecontrollerisaboveambienttemperature. Beforereplacingthecontroller,readacrossposition1and2tomakesurethatthe controllerispoweredup;yourreadingwillbe208to230voltsAC. IfthereisnoDCvoltagetotherelay,movetothenextstep.

• Problem: Hosedoesnotheatandthedisplayonthecontrollershowsanerrormessage (SbEr).

Solutions:

1. Checkposition6and7ontheheatercontrollerforloosewires. Ifthewiresaretight,movetothenextstep.

2. Removethetransformercoverandcheckthatthethermocouplewiresaresecure totheharnessgoinguptothecontroller.Iftherearenolooseconnections,disconnectthewirefromtheTSUandconnectitdirectlytothethermocoupleharness

comingoutofthehosetransformer.

Ifthecontrollerstillshowstheerrorcode,replacethehosethermocouple.Iftheerrorcodegoesawayandtemperatureisnowshownon thedisplayofthecontroller,thenalltheTSUharnessesfromtheTSU tothetransformerneedtobecheckedforlooseconnectorsoroneor moreoftheharnessesaredefective.

• Problem: Heatedhosecontrollershowsexcessivetemperature.

Solutions:

1. Setthecontrollersetpointatleast20degreeslowerthanthetemperatureshown onthecontroller.Brieflyturnonthehoseandlookfortheledlightonthesolid staterelaytobeon.

Ifthelightison,replacethecontroller. Ifthelightisoff,replacethesolidstaterelay.

• Problem: Hosewillheatbutdoesnotcomeuptosettemperature.

Solutions:

1. Checkthetapsettingonthetransformertoensurethatthecorrectpositionhas beenselectedforthelengthofhosebeingused.Dependingonthemachines incomingvoltage,youmayhavetomovethetapsettinghigher(upone).

CAUTION! Donotexceedthetripvalueofthetransformerhose breaker.

WARNING! Beforecorrectinganykindofdefect,makesurethe MainPowerSwitchisOFFandincomingpowerislockedOFF. NEVERaccesstheinsideoftheControlPanelwiththeProportionerpowersupplyON.

• Problem: Hosedoesnotheatandthedisplayonthecontrollershowsanerrormessage.

Solutions:

1. Checkposition9and10ontheheatercontrollerforloosewires. Ifthewiresaretight,movetothenextstep.

2. Removethetransformercoverandcheckthatthethermocouplewiresaresecure totheharnessgoinguptothecontroller.IftherearenolooseconnectionsdisconnectthewirefromtheTSUandconnectitdirectlytothethermocoupleharness comingoutofthehosetransformer.

Ifthecontrollerstillshowstheerrorcode,replacethehosethermocouple.

Iftheerrorcodegoesawayandtemperatureisnowshownonthedisplayofthecontroller,thenalltheTSUharnessesfromtheTSUtothe transformerneedtobecheckedforlooseconnectorsoroneormoreof theharnessesaredefective.

12.5 PRESSUREBALANCECONTROL IfthePressureBalanceControlboxisnotworkingproperly,followthesestepstoresolvethe potentialissue:

1. WiththeMainPower ON,checkthePower/RunlightontheControlUnit:

a. IfOFF,theControlUnitisnotgettingpower.Checkforlooseorpoorwire connections.IfthePower/Runlightstilldoesnotturnon,contactyourauthorized PMCdistributor.

b. If SOLID,theControlUnithaspowerbutnoprogram.Contactyourauthorized PMCdistributor.

c. If BLINKING,theControlUnithaspowerandisprogrammedproperly.Proceedtothenextstep.

2. WithMainPower ON,turntheRotarySwitchtoaPressureDifferentialNumberand checktheAmberlightonCR1:

a. If OFF,CR1isnotactivatingproperly.Checkforlooseorpoorwireconnections betweentheControlUnitandCR1.

b. If ON,CR1isactivating,butthemechanicalswitchinsidetherelaymaynotbe functioningproperly.Ifthesystemhasfaulted(i.e.apressureimbalanceexists, theONlightturnsoff,andtheFAULTlightturnson),butthepumpsdonotshut off,checkforcontinuitybetweencontacts11and12onCR1.Ifthereiscontinuity, contactyourauthorizedPMCdistributor.Ifthereisdiscontinuity,proceedtothe nextstep.

3. ContactyourauthorizedPMCdistributorforfurtherassistance.

13 MAINTENANCE ToachievemaximumoutputfromthePHSeriesProportioner,adailyorregularmaintenancescheduleisrequired.

Topreventpossibleinjurycausedbyincorrecthandlingofthe rawmaterialsandsolventsusedintheprocess,carefullyreadthe MaterialSafetyDataSheet(MSDS)providedbyyoursupplier. Dealwiththewastecausedaccordingtocurrentregulations.

Disconnecttheunitfromthepowersupplybeforecarryingout anyoperationinsidetheelectricalconsole.Theelectricalmaintenanceofthemachinemustonlybeperformedbyaqualified electrician.

Toavoiddamagecausedbytheimpactofpressurizedfluids,do notopenanyconnectionorperformmaintenanceworkoncomponentssubjecttopressureuntilthepressurehasbeencompletely eliminated.

Usesuitableprotectionwhenoperating,maintainingorbeing presentintheareawheretheequipmentisfunctioning.Thisincludes,butisnotlimitedto,theuseofprotectivegoggles,gloves, shoesandsafetyclothingandbreathingequipment.

Theequipmentincludescomponentsthatreachhightemperatures andcancauseburns.Hotpartsoftheequipmentmustnotbe handledortoucheduntiltheyhavecooledcompletely.

Topreventseriousinjurythroughcrushingoramputation,do notworkwiththeequipmentwithoutthesafetyguardsinstalled onthemovingparts.Makesurethatallthesafetyguardsare correctlyreinstalledattheendoftherepairormaintenancework oftheequipment.

CAUTION! Allrepairsperformedbyunqualifiedpersonnelor theuseofpartsotherthansuppliedbyPMCmaycausedamage totheunitandputtheoperatoratrisk.

13.1 INLETMATERIALSCREENS InspectionoftheInletMaterialScreensonadailybasisisnolongernecessaryaslongasthe followingconditionsaremet.

1. Materialdrumsarestoredwithintherecommendedmaterialstoragetemperaturerange anddrumsarenotopenedpriortoinstallingtheProportionerMaterialTransferPumps.

2. Desiccantairdryersareusedtodryreplacementairasmaterialisremovedfromthe drumstotheProportioner.

3. Consolidationofoldmaterialintoacommondrumforuseisminimized,especiallythe Iso(A).

Iftheaboveconditionsaremet,inspectionoftheInletMaterialScreensmaybedoneona bi-weekly basis.

NOTE! InspectandcleanInletMaterialScreensbeforeProportionerstart-up.Theyshouldnotbecleanedafterthedays’ operationastheProportionershouldbepurged(seepage24) immediatelyafterinspectionandcleaning.Thisistoreduce theriskofmoisturecontamination,contaminationthrough thereactionwiththesolventusedinthecleaningoperation, andcross-overattheSprayGunduetoairentrapment.

CAUTION! MakesuretheMainPowerSwitchisOFFand incomingpowerislockedOFF.

1. CLOSEthePoly(R)ProportionerInletValve.

2. PlaceasuitablecontainerundertheMaterialInletStrainertocollecttheresidual material.CarefullyloosentheStrainerPlugtodrainmaterialintothecontainer.

3. CompletelyunscrewtheStrainerPlug.

4. RemovetheSeal,SpringandScreenandcleanthemwithasuitablesolvent.Drythe partsandensuretheScreenisnotobstructed.ReplacetheScreenifmorethan20% oftheScreensurfaceisobstructedbyresidue.

5. ReinstalltheScreen,SpringandSeal.ScrewontheStrainerScrewandscrewinPlug.

6. OPENthePoly(R)ProportionerInletValve,pressurizetheMaterialTransferPump, checkforleaksandwipeY-strainerclean.

7. RepeatabovefortheIso(A)side.

8. ProceedwithProportionerPurgingoperation(Seepage24).

13.2 ISOLUBRICATIONSYSTEM DAILY: ChecktheconditionofthePMCLubeOilintheIsoLubeReservoir. ReplacethePMCLubeOilifyouseesignificantchangesinthecolororsignsof solidification.EnsureinsideofReservoiriswipedclean.

ToreplacetheLubeOil,proceedasfollows:

1. RemovetheLubeReservoirfromitssupport,unscrewtheLidandremovetheCheck ValvefromtheSuctionHose.

2. EmptythecontaminatedLubeOilinawastecontainerandrefittheCheckValvein theSuctionHose.

NOTE! Valveisdirectional.

3. CleantheReservoir,refillwithLubeOil,andscrewontheLidandplacetheReservoir initssupport.

Thesystemisauto-suctionanddoesnotneedpriming.

13.3 HYDRAULICDRIVESYSTEM WARNING! Beforeperforminganymaintenance,makesurethe MainPowerSwitchisOFFandincomingpowerislockedOFF. TheHydraulicUnitisacomponentthatworksunderpressure.Do notopenanyconnectionorcarryoutmaintenanceoncomponents subjecttopressureuntilallpressurehasbeenbledtozero.

Thehydraulicunitshouldbeservicedyearly:

1. CompletelydraintheTankofhydraulicfluid.

2. CleantheTankToptopreventforeignmaterialfromfallingintotheTankwhenthe Coverisremoved.

3. UnscrewtheSuctionPipefromitsconnectionwiththeHydraulicPump.

4. RemovetheCoverandSuctionPipefromtheHydraulicTank.Takecarenottodamage TankCoverGasket.

5. InspectthebottomoftheTankforsedimentandcleanasrequired.CleantheSuction Pipeanditsconnections.

6. FilltheTankwith10gal(37L)ofapprovedhydraulicfluid(Seepage56forrecommendations).

7. InserttheSuctionPipeintotheTankCoverandinstalltheCover.Again,takecarenot todamageTankCoverGasket.ConnecttheSuctionPipesecurelytotheHydraulic Pump.

8. EnsuretheHydraulicPumpCaseisfulloffluidandproceedwiththenormaloperation.

13.4 METERINGPUMP-LINE WARNING! Beforeperforminganymaintenance,makesurethe MainPowerSwitchisOFFandincomingpowerislockedOFF.Allowmaterialtemperaturetocoolbelow80◦ Fandbleedallmaterial pressuretozero.

Weekly: WhentheProportioningPumpsarefunctioningproperlyitisnotunusualfora smallamountofPoly(R)materialtoappearonthePumpShaft.Thismaterialshouldbe wipedawaysodirtdoesnotaccumulateonthePumpShaftandthePumpShaftPackings arenotdamaged.

Yearlyorasrequired: ItisnotunusualforthosewhousethePHSeriesProportioneron aregularbasistorebuildtheProportioningPumpsonayearlybasisandservicetheHydraulicDriveSystem(Seepage51)atthesametime,whiletheProportionerisoutofservice.

13.5 PUMPBASESERVICE 1. CLOSEappropriateProportionerInletMaterialSupplyValveandremoveAirLine fromtransferpump.

2. EnsureallmaterialpressureintheProportionersystemiszeroandremoveappropriate RetainerNut.

3. ForInletBall:

• RemoveInletBallwithamagnet(DONOTuseanysharpobject),cleanBalland BallSeat,andinspectforforeignmaterialandanydamageontheInletBall.

• UsingsuppliedBallSeatTool(TL-02),checkforproperBallSeatGasketcompression.SnugSeatupto1/4turnmaximum110ft-lbs(149Nm).

4. ForDischargeBall:

• RemoveCageandSpring.

• RemoveDischargeBallwithamagnet(DONOTuseanysharpobject),cleanBall andBallSeat,andinspectforforeignmaterialandanydamageontheDischarge Ball.

• UsingsuppliedBallSeatTool(TL-02),checkforproperBallSeatGasketcompression.SnugSeatupto1/4turnmaximum30ft-lbs(41Nm).

13.6 PUMPSEALREPLACEMENT NOTE! RefertoPartsIdentificationforreference.

• WhentheIso(A)ProportioningPumpCylinderisdisassembledforservice,allparts includedinthePumpRebuildKit(KT-07000,KT-07002,KT-07004,KT-07006)should bereplaced.

• WhenthePoly(R)ProportioningPumpCylinderisdisassembledforservice,allparts includedinthePumpRebuildKit(KT-07001,KT-07003,KT-07005,KT-07007)should bereplaced.

• WhenassemblingProportioningPumplubricateallSeals,PistonRodandPumpCylinderwith#1LithiumGreasetoassistinassemblyandminimizeSealdamageduring re-assembly.

• WhenthePumpLineEndBlockisdisassembledforservice,allO-ringsincludedin theO-ringKit(KT-05009)shouldbereplaced.

• AfterreassemblyoftheProportioningPumpstorquetheAssemblyBoltsto30ft-lbs (41Nm).

CAUTION! Usewoodenorplastictoolsorabrassbrushforcleaning.Donotusemetalorabrasivetoolsthatcanscratchthecontact surfaces.

13.7 METERINGPUMPREMOVAL NOTE! WhenremovingthePolysidepump,skipsteps3and4.

1. Putmachineinretractposition.

2. Turnoffmainpoweranddischargeallpressuregaugestozero.

3. DisconnectthebottomelbowontheIsolubecylinderanddrainallIsolube.

4. DisconnectthetophosegoingtoIsolubecylinderthenuninstallredplug.

5. Removeclevispin.

6. Disconnectthehoseonthepumpflange.

7. DisconnecttheY-strainerfromelbow.

8. Carefullyremovethefourboltsandwasherswhileholdingthepumpinplace.

13.8 MATERIALHEATER WARNING! Beforeperforminganymaintenance,makesurethe MainPowerSwitchisOFFandincomingpowerislockedOFF. NEVERaccesstheinsideoftheControlPanelwiththeProportionerpowersupplyON.TheHeatersarecomponentsthatreach hightemperatures;youmustwaituntiltheyhavecooledbefore handlingandbleedallmaterialpressuretozero.

13.8.1 THERMOCOUPLEREPLACEMENT NOTE! TheThermocoupleisassembledintotheConnectorBody withaFerruleandNut.OnceinsertedintotheBodyandtheNut istightened,theFerrulelockstotheThermocoupleanddoesnot allowittoberelocatedormoved.ThelocationoftheThermocoupleisveryimportantandmustbedonecorrectlybeforetightening theNut.

1. UnscrewtheNutthatholdsthedefectiveThermocoupleandremovefromtheBody. DisconnectThermocouplewiringlocatedundertheTopCoveroftheHeater.Remove Bodyanddiscard.

2. InstallHeatingElementandSpringifalsoremoved.

3. InstallConnectorBodyintoHeaterusinganopen-endwrenchandtightentoprevent leakage.TeflonTapeorappropriateThreadSealantshouldbeused.

4. SlidetheNutandtheFerruleovertheThermocoupleandinsertthisassemblyinto theConnectorBodyuntilitcomesinto positivephysicalcontact withtheHeating Rod.MakesuretheSpringdoesnotpreventtheThermocouplefrommakingcontact withtheHeatingRod.

5. SlowlytightentheNutusinganopen-endwrench,ensuringtheThermocouplemaintainspositivephysicalcontactwiththeHeatingRod.

6. ReinstalltheThermocouplewires.

WARNING! Beforeperforminganymaintenance,makesurethe MainPowerSwitchisOFFandincomingpowerislockedOFF. NEVERaccesstheinsideoftheControlPanelwiththeProportionerpowersupplyON.TheHeatersarecomponentsthatreach hightemperatures;youmustwaituntiltheyhavecooledbefore handlingandbleedallmaterialpressuretozero.

ToreplaceadefectHeatingRod,proceedasfollows:

1. EnsureMainPowerSwitchisOFFandincomingpowerislockedOFF.Depressurize proportionerandremovetheCoveronHeater.

WARNING! IftheHeatingRodtobereplacedistheonein contactwiththeThermocouple,itisnecessarytoremovethe Thermocouplefirst.DonotloosenortightenThermocouple Body.

2. DisconnectthesuspectHeatingRodfromthewireconnectionsandtesttheHeating Rodagainforproperelectricalresistance.

3. UnscrewtheHeatingRodandremovefromtheHeaterBlockalongwithitsSpringand inspect;itmustbesmoothandshinyinappearance.Ifitisblackenedorhasmaterial adheredtoitreplacetheHeatingRod,evenifohmreadingisacceptable.

4. ApplyTeflonTapeorappropriateThreadSealanttotheHeatingRodthreadand assembleHeatingRodandSpringintotheHeaterBlock.Tightensecurelyto110 ft/lbs(150Nm).

5. Ifnecessarycarefullyre-installThermocoupleensuringpositivephysicalcontactwith theHeatingRod.MakesuretheSpringdoesnotpreventtheThermocouplefrom makingcontactwiththeHeatingRod.TightenNutwithopen-endwrench.

6. ReconnectwireconnectionsandreplaceCover.

7. EnsureHeaterisfullofmaterialpriortoelectricaltesting.

14 HYDRAULICOILSPECIFICATIONS RecommendedHydraulicOilSpecification: ISO/ASTMViscosityGrade32 Viscosity: 28.8–35.2SSUat104◦ FRustandOxidationInhibited

14.1 MANUFACTURERS • MobilDTE24(Recommended)

• Cook’sAlbavis8

• Ashland-ValvolineAW15

• Shell–Tellus32(25)

• SunOil-Sunvis706

• ChevronISO32

• AmericanOil&Supply–PQIso32

• GulfOil–Harmony32AW(43AW)

• AtlanticRichfield–DuroAWS-150

• BPOil–EnergolHLP-C32

• Exxon–NutoH-32(44)

• Margolis–T.I.P.100-15-7

• FiskeBros.–LubriplateHyd.#0

• SW–AlemiteHydraulicHD#0

• Texaco–RandoHD32(HDA0)

• White&Bagley–EPHyd.150

Figure13:HydraulicCylinderAssembly(HI-05025A)

1 1 -

2 1

3 2

2

5 2 - HYDRAULICSEALASSEMBLY(SEEPAGE57)

6 2

7 4

8 7

9 1

Figure14:CompleteHydraulicCylinderAssembly(HI-01)

1

15.5 ”R”PUMPASSEMBLY Figure15:”R”PumpAssembly(PU-05002-XXX)

1

”R”PUMPASSEMBLY 4 1 HI-05016 3/4NPTMX3/4NPTFSW

5 1 HI-05038 1/4NPTX9/16-18JIC90DEG

6 2 HI-05067 PIPEPLUG1/4-18,7/8TAPER

7 2 OR-00011A O-RING-014,CROSSOVERTUBE

8 2 OR-00046A O-RING-133,VITON,90D

14

15

1 PU-03013

1 PU-03012

1 PU-03011

16*

17

SHAFTBEARING,40PUMP,RSIDE

SHAFTBEARING,60PUMP,RSIDE

SHAFTBEARING,80PUMP,RSIDE

1 PU-03010 SHAFTBEARING,120PUMP,RSIDE

1 PU-05011-40 PUMPSHAFTASSY,40PUMP

1 PU-05011-60 PUMPSHAFTASSY,60PUMP

1 PU-05011-80 PUMPSHAFTASSY,80PUMP

1 PU-05011 PUMPSHAFTASSY,120PUMP

1 PU-05012-40 CYLINDER,40PUMP

1 PU-05012-60 CYLINDER,60PUMP

1 PU-05012-80 CYLINDER,80PUMP

1 PU-05012 CYLINDER,120PUMP

1 PU-05014-40 FLANGE,40PUMP

1 PU-05014-60 FLANGE,60PUMP

1 PU-05014-80 FLANGE,80PUMP

1 PU-05014 FLANGE,120PUMP

18 1 PU-05017 CROSSOVERTUBE

19 1 PU-05018 PUMPBASE

20 1 PU-05019 SEAT,INLET

21 1 PU-05020 BALL,INLET

22 1 PU-05021 SPRING

23 1 PU-05023-1 GASKET,PUMPRETAINERNUT

24 1 PU-05024 SEAT,DISCHARGE

25 1 PU-05025 BALL,DISCHARGE

26 4

27 4

28 4

NUT 29 1 PU-05029-40 PIN,40PUMP 1 PU-05029-60 PIN,60PUMP 1 PU-05029-80 PIN,80PUMP 1 PU-05029 PIN,120PUMP 30 1 PU-05030-40 SNAPRING,40PUMP 1 PU-05030-60 SNAPRING,60PUMP

1 PU-05030-80 SNAPRING,80PUMP 1 PU-05030 SNAPRING,120PUMP 31 1 PU-05031-40 CLEVIS,PISTON,40PUMP

1 PU-05031-60 CLEVIS,PISTON,60PUMP

1 PU-05031-80 CLEVIS,PISTON,80PUMP

1 PU-05031 CLEVIS,PISTON,120PUMP 32 1 PU-05032-40 FLANGE,PACKINGRETAINER,40PUMP

1 PU-05032-60 FLANGE,PACKINGRETAINER,60PUMP

1 PU-05032-80 FLANGE,PACKINGRETAINER,80PUMP 1 PU-05032 FLANGE,PACKINGRETAINER,120PUMP

33 1 PU-05044 BEARING,PISTON,40PUMP

1 PU-05043 BEARING,PISTON,60PUMP

1 PU-05042 BEARING,PISTON,80PUMP

1 PU-05041 BEARING,PISTON,120PUMP

34 1 TN-04186 GREASEFITTING

15.5.1 ”R”PUMPREBUILDKITS 40”R”PUMPREBUILDKIT(KT-07007)

QTY PARTNUMBER DESCRIPTION

1 KT-01016A-004 PISTONSEAL,40PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A O-RING-133,VITON,90D

1 OR-00051B O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029-40 PIN,40PUMP

1 PU-03013 SHAFTBEARING,40PUMP

1 PU-05044 PISTONBEARING,40PUMP

1 PU-03003 TRIPLELIPSEAL,40PUMP

1 PU-03023 BULLET,40PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A O-RING-028,VITON,90D

1 PU-01003-IG GASKET,DISCHARGEBALLSEAT

1 PU-01003-DG GASKET,INLETBALLSEAT

1 PU-05023-1 GASKET,PUMPRETAINERNUT

60”R”PUMPREBUILDKIT(KT-07005)

QTY PARTNUMBER DESCRIPTION

1 PU-01016A-006 PISTONSEAL,60PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A O-RING-133,VITON,90D

1 OR-00051B O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029-60 PIN,60PUMP

1 PU-03012 SHAFTBEARING,60PUMP

1 PU-05043 PISTONBEARING,60PUMP

1 PU-03002 TRIPLELIPSEAL,60PUMP

1 PU-03022 BULLET,60PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A O-RING-028,VITON,90D

80”R”PUMPREBUILDKIT(KT-07003)

QTY PARTNUMBER DESCRIPTION

1 PU-01016A-008

PISTONSEAL,80PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A

1 OR-00051B

O-RING-133,VITON,90D

O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029-80 PIN,80PUMP

1 PU-03011 SHAFTBEARING,80PUMP

1 PU-05042 PISTONBEARING,80PUMP

1 PU-03001 TRIPLELIPSEAL,80PUMP

1 PU-03020 BULLET,80PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A O-RING-028,VITON,90D

1 PU-01003-IG GASKET,DISCHARGEBALLSEAT

1 PU-01003-DG GASKET,INLETBALLSEAT

1 PU-05023-1 GASKET,PUMPRETAINERNUT

1 PU-05030-80 SNAPRING,80PUMP

120”R”PUMPREBUILDKIT(KT-07001)

QTY PARTNUMBER DESCRIPTION

1 KT-01016A-012 PISTONSEAL,120PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A O-RING-133,VITON,90D

1 OR-00051B O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029 PIN,120PUMP

1 PU-03010 SHAFTBEARING,120PUMP

1 PU-05041 PISTONBEARING,120PUMP

1 PU-03000 TRIPLELIPSEAL,120PUMP

1 PU-03019 BULLET,120PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A O-RING-028,VITON,90D

1 PU-01003-IG GASKET,DISCHARGEBALLSEAT

1 PU-01003-DG GASKET,INLETBALLSEAT

1 PU-05023-1 GASKET,PUMPRETAINERNUT

1 PU-05030 SNAPRING,120PUMP

15.6 ”A”PUMPASSEMBLY Figure16:”A”PumpAssembly(PU-05001-XXX)

”A”PUMPASSEMBLY (PU-05001-40)/(PU-05001-60)/(PU-05001-80)/(PU-05001-120) ITEM QTY PARTNUMBER DESCRIPTION

1 1 200220 SLEEVE,PUMPBASE

2 1 202221 RETAININGNUT,PUMPBASE

3 1 202228 O-RING-218,TEFLON,55D

4 1 HI-05016 3/4NPTMX3/4NPTFSW

5 1 HI-05038 1/4NPTX9/16-18JIC90DEG

6 2 HI-05067 PIPEPLUG1/4-18,7/8TAPER

7 2 OR-00011A O-RING-014,CROSSOVERTUBE

8 1 OR-00020A O-RING-136,VITON

9 2 OR-00046A O-RING-133,VITON,90D 10 1 PU-01003-DG GASKET,INLETBALLSEAT 11 1 PU-01003-IG GASKET,DISCHARGEBALLSEAT 12 1 PU-01013A GASKET,CYLINDERFLANGE

15

16

1 PU-03000

1 PU-03008

1 PU-03007

1 PU-03006

1 PU-03005

1 PU-03017

1 PU-03016

1 PU-03016

1 PU-03015

17

TRIPLELIPSEAL,80PUMP

TRIPLELIPSEAL,120PUMP

SHAFTBEARING,40PUMP,ASIDE

SHAFTBEARING,60PUMP,ASIDE

SHAFTBEARING,80PUMP,ASIDE

SHAFTBEARING,120PUMP,ASIDE

RETAININGRING,40PUMP,ASIDE

RETAININGRING,60PUMP,ASIDE

RETAININGRING,80PUMP,ASIDE

RETAININGRING,120PUMP,ASIDE

1 PU-05011-40 PUMPSHAFTASSY,40PUMP

1 PU-05011-60 PUMPSHAFTASSY,60PUMP

1 PU-05011-80 PUMPSHAFTASSY,80PUMP

1 PU-05011

PUMPSHAFTASSY,120PUMP

15.6.1 ”A”PUMPREBUILDKITS

40”A”PUMPREBUILDKIT(KT-07006)

QTY PARTNUMBER DESCRIPTION

1 KT-01016A-004 PISTONSEAL,40PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A O-RING-133,VITON,90D

1 OR-00051B

O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029-40 PIN,40PUMP

1 PU-03008 SHAFTBEARING,40PUMP

1 PU-05044 PISTONBEARING,40PUMP

1 PU-03003 TRIPLELIPSEAL,40PUMP

1 PU-03023 BULLET,40PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A O-RING-028,VITON,90D

1 PU-01003-IG GASKET,DISCHARGEBALLSEAT

1 PU-01003-DG GASKET,INLETBALLSEAT

1 PU-05023-1 GASKET,PUMPRETAINERNUT

1 PU-03017 RETAININGRING,40PUMP,ASIDE

2 OR-00020A O-RING-136,VITON

1 OR-00044A O-RING-024

1 PU-03021 SEALTOOL,ASIDE

1 RA-00065A PLUG,PUMPCYLINDER

60”A”PUMPREBUILDKIT(KT-07004)

QTY PARTNUMBER DESCRIPTION

1 KT-01016A-006 PISTONSEAL,60PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A

1 OR-00051B

O-RING-133,VITON,90D

O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029-60 PIN,60PUMP

1 PU-03007 SHAFTBEARING,60PUMP

1 PU-05044 PISTONBEARING,40PUMP

1 PU-03003 TRIPLELIPSEAL,40PUMP

1 PU-03023 BULLET,40PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A O-RING-028,VITON,90D

1 PU-01003-IG GASKET,DISCHARGEBALLSEAT

1 PU-01003-DG GASKET,INLETBALLSEAT

1 PU-05023-1 GASKET,PUMPRETAINERNUT

1 PU-03016 RETAININGRING,80PUMP,ASIDE

2 OR-00020A O-RING-136,VITON

1 OR-00044A O-RING-024

1 PU-03021 SEALTOOL,ASIDE

1 RA-00065A PLUG,PUMPCYLINDER

80”A”PUMPREBUILDKIT(KT-07002)

QTY PARTNUMBER DESCRIPTION

1 KT-01016A-008 PISTONSEAL,80PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A

1 OR-00051B

O-RING-133,VITON,90D

O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029-80 PIN,80PUMP

1 PU-03006 SHAFTBEARING,60PUMP

1 PU-05042 PISTONBEARING,80PUMP

1 PU-03001 TRIPLELIPSEAL,80PUMP

1 PU-03020 BULLET,80PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A O-RING-028,VITON,90D

1 PU-01003-IG GASKET,DISCHARGEBALLSEAT

1 PU-01003-DG GASKET,INLETBALLSEAT

1 PU-05023-1 GASKET,PUMPRETAINERNUT

1 PU-03016 RETAININGRING,80PUMP,ASIDE

2 OR-00020A O-RING-136,VITON

1 OR-00044A O-RING-024

1 PU-03021 SEALTOOL,ASIDE

1 RA-00065A PLUG,PUMPCYLINDER

1 PU-05030-80 SNAPRING,80PUMP

120”A”PUMPREBUILDKIT(KT-07000)

QTY PARTNUMBER DESCRIPTION

1 KT-01016A-012 PISTONSEAL,120PUMP

2 OR-00011A O-RING,12X12MMID

2 OR-00046A

1 OR-00051B

O-RING-133,VITON,90D

O-RING-218,AFLAS,80D

1 PU-01013A GASKET,CYLINDERFLANGE

1 PU-05029 PIN,120PUMP

1 PU-03005 SHAFTBEARING,120PUMP

1 PU-05041 PISTONBEARING,120PUMP

1 PU-03000 TRIPLELIPSEAL,120PUMP

1 PU-03019 BULLET,120PUMP

2 TN-04199 SHCS,3/8-24X2.50

2 OR-00045A

O-RING-028,VITON,90D

1 PU-01003-IG GASKET,DISCHARGEBALLSEAT

1 PU-01003-DG GASKET,INLETBALLSEAT

1 PU-05023-1 GASKET,PUMPRETAINERNUT

1 PU-03017 RETAININGRING,40PUMP,ASIDE

2 OR-00020A O-RING-136,VITON

1 OR-00044A O-RING-024

1 PU-03021 SEALTOOL,ASIDE