IF YOU THINK ALL LYSOPHOSPHOLIPIDS

LONG-LASTING EFFECTS OF PALATABILITY ENHANCERS 34

Palatability enhancer benefits have been demonstrated in several fish species and applications in challenging conditions.

TECHNOLOGY FOR QUALITY CONTROL OF EXTRUDED FEEDS 17

A NATURAL ALTERNATIVE TO SYNTHETIC ANTIOXIDANTS 31

How combing intelligent quality prediction and control technology allows high-performance quality control in aquafeed extrusion. Aquafeed: Advances

Polyphenols as an efficient alternative to synthetic anti-oxidants and ethoxyquin to preserve extruded aquafeed from oxidation.

AN INGREDIENT FOR IMMUNE SUPPORT IN SHRIMP 40

Pichia guilliermondii is a novel yeast that supports immune physiology and promotes improved performance in shrimp.

CONTACT US

Editorial: editor@aquafeed.com

Editor/Publisher: Lucía Barreiro

Consulting Editor: Suzi Dominy

Technical Editors:

Peter Hutchinson, Albert Tacon, Ph.D

Assistant Editor: Marissa Yanaga

info@aquafeed.com

sales@aquafeed.com Accounts

Aquafeed Media, S.L.U., Ames, 15220 A Coruña, Spain. Copyright© Aquafeed Media, S.L.U., 1998-2022 All rights reserved. Privacy Policy & Terms of use

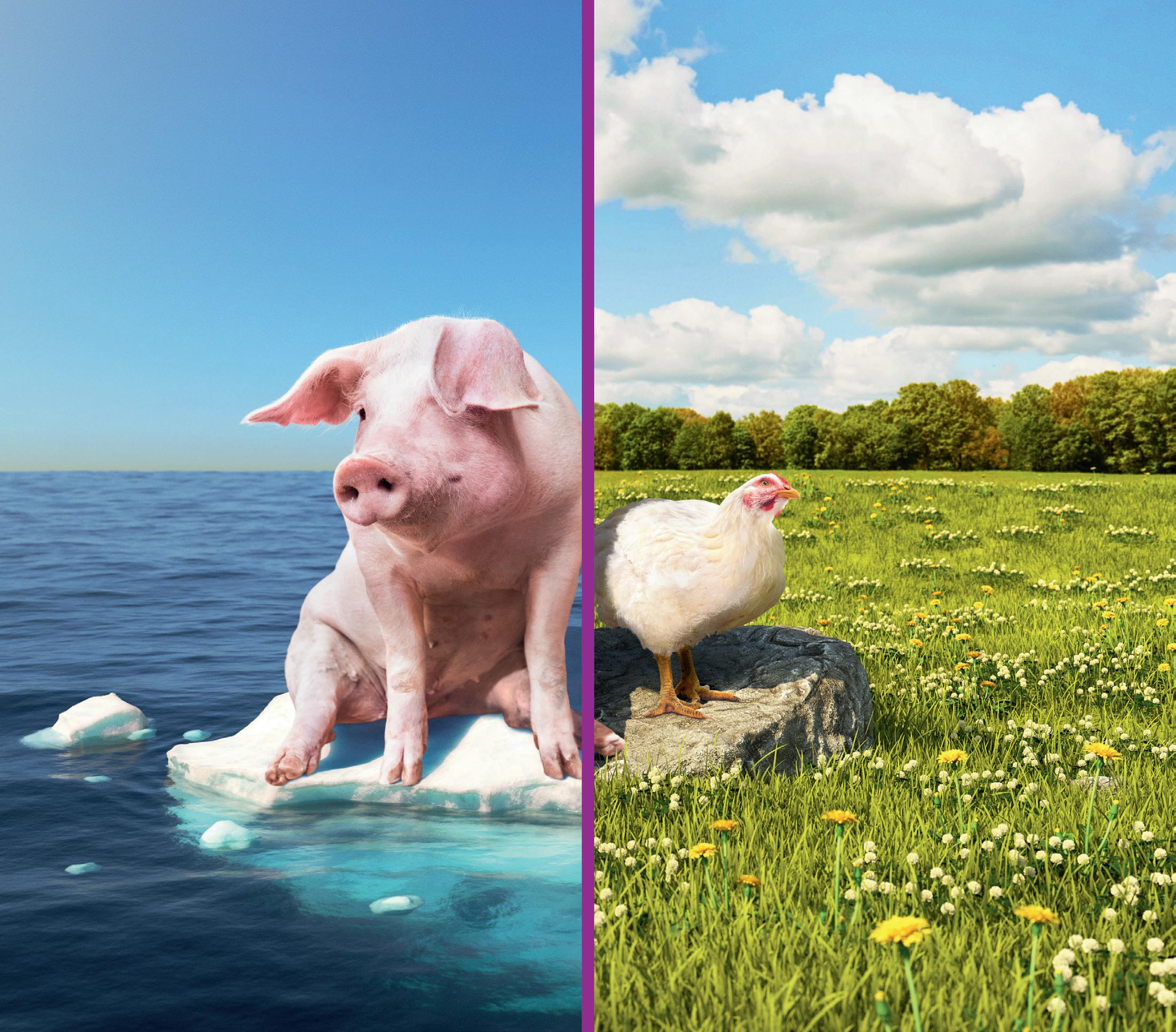

Animal feed can make a change!

Fully on track to carbon neutrality –Biolys® production in Castro, Brazil.

Reducing the carbon footprint becomes increasingly important for feed producers. With a minimal carbon footprint of 0.06 kilograms of CO2 equivalent per kilogram of product, Biolys® produced at Evonik’s Castro site helps achieving this goal. It’s nearly carbon neutral and uses over 90 percent renewable energy sources for a waste-free process – and it’s certified by TÜV Rheinland. Our next goal: full carbon neutrality.

INTERVIEW with Olivier Decamp

technical director. I was given the opportunity to work with our Innovation Department in Taiwan and our very large technical team across eight Asian countries. We work with fish and shrimp producers, ranging from small family businesses with a few ponds to very large companies.

AQ: Founded in Taiwan in 1974, Grobest has seen continuous growth throughout Asia. Where is the company today in terms of size and markets served?

Grobest has a proud history, serving farmers and the aquaculture community across the Asia region. With a mission “to feed the world by improving the health and growth of aquatic species through advanced nutrition”, Grobest today operates in eight markets across Asia, with 16 feed and pre-mix factories and more than 3,500 employees across the group. In addition to this broad presence across Asia, Grobest is also a pioneer and technological leader in an array of innovative and differentiated functional feed products. The company also provides a full range of services and technical assistance to farmers throughout Asia, including pond maintenance, water treatment, and soil and disease testing.

AQ: Apart from aquafeed, Grobest has developed a proprietary additive and premix technology. How have these products improved aquaculture farming? Does the company have new developments underway?

AQ: What has been your journey in aquafeed?

How did you get to where you are today?

OD: I started my journey in aquaculture at the Oceanic Institute in Hawaii in 2000. I worked on a superintensive shrimp production system with limited water exchange, within the team of Albert Tacon. From there, I joined INVE Aquaculture as researcher and then product manager in health products. This included health booster diets and pond management products. These two organizations gave me the bug and the love for aquaculture. I traveled extensively to aquaculture farms in Asia, Latin America, the Middle East and Europe. Feed is extremely important for shrimp and fish farmers. Joining a major aquafeed company like Grobest was the right step for me. At Grobest, I took up the position of group

OD: Grobest is a unique company in the sense that it develops and produces its own functional additives. At our Innovation Department in Taiwan, researchers continuously improve existing additives and develop new formulations to help farmers cope with their challenges. Their work does not end there. They include the upscale production of the additives in their research program. These additives are produced at our factories located in Taiwan and China, and then delivered to our feed mills across Asia, where they are incorporated in the feeds manufactured at these plants. By having the ability to produce its own additives, the company has a clear understanding of the performance of the additives, and more importantly, how these can be combined in a way that delivers the best performance. This is a huge advantage. This allows our people to recommend the best diet and the best feed management to our

customers because we are fully aware of the benefits of the different combinations of additives that we develop and produce ourselves.

Thanks to our technical team in the field, we have very detailed feedback on the challenges faced by our customers. This feedback is sent back to our innovation department in Taiwan. It allows them to improve existing additives or develop new additives that can support our farmers with their new challenges. The whole development process is quicker and more efficient because it is taking place within the same organization. For example, in Thailand, we recommend a specific diet to help farmers cope with white faces syndrome, Seahorse CCT. In Vietnam, we recently launched Super Shield EMS, a functional feed to support shrimp when challenged with AHPND/EMS.

AQ: Another example is 360 Turbo Nutrition, recently launched in China, Vietnam, and Indonesia. What does this new strategy consist of?

OD: Our most recent innovative products launched in the key markets China, Vietnam, and Indonesia are defined as Grobest Horizon products. We applied the 360 Turbo Nutrition solution to the Grobest Horizon products. This means that we optimized the formulations and added high doses of our propriety functional additives to strengthen the performance. As a consequence, the quantity of excess nitrogen in the water is greatly reduced, minimizing pond contamination, also improving shrimp farmers’ productivity. This impressive breakthrough is the proud result of our technological knowledge of aquatic nutrition and our deep understanding of farmers’ needs.

AQ: Diseases are one of the main challenges for shrimp farmers in Southeast Asia. How Grobest is tackling these issues?

OD: Based on the information gathered by our technical service when they visit farms, we make recommendations on feeding management and the rearing protocol. As mentioned before, Grobest has developed a range of functional feeds with a focus on improving immunity and other on enhancing the growth rate. When faced with diseases, farmers have a range of options. We recommend the most cost-efficient protocol, permitting the farmers to get a profitable crop despite the challenges.

AQ: Some Asian countries are moving to more sustainable shrimp production systems. How do you see this change and how does Grobest plan to support it?

OD: At Grobest, we are promoting and supporting a move towards more sustainable production. Looking at Vietnam, we have set up GroFarm, a platform where we work with farmers who decided to improve their farm infrastructure including their water treatment process. The aim is to lower the risk of failure (and associated waste resources) and reduce the organic waste in the surrounding environment through improved feeding management and more effective water management protocols.

Over the past few years, our knowledge of aquatic animal nutrition requirements has been advancing through the many research and experiments conducted. We are continuously optimizing the marine-based protein, animal protein and plant protein usage ratio in feeds to reduce the reliance on marine resources, increase efficiency, reduce feed cost, decrease carbon footprint and decrease waste released into the environment. The ongoing laboratory and field trials on several novel ingredients that Grobest has conducted are showing promising results for further scale-up application in commercial feeds. More recently, the use of a novel ingredient in shrimp feed showed good performance in the field. This encourages us in developing more sustainable feeds in the near future.

AQ: Apart from shrimp, Grobest has a diversified portfolio of products and services for different warm water species. What are the current major markets and most demanded services?

OD: Indeed we are producing feed for shrimp, warm water marine and freshwater fish. Currently, 60% of our feed production is aimed at shrimp and high-value marine species. We are market leaders in eel feed in China and Taiwan. Our key fish markets are in China, Taiwan and the Philippines. We provide technical support to all our market, according to their needs.

AQ: The development and expansion of new farming models, such as RAS, require new feed developments. Is Grobest developing feed lines for these new systems?

OD: Grobest is closely working with farmers applying new production methods. I would like to take two examples to document the actions of the company. The first one is in Taiwan, where we are the front runners in hybrid solar farming. The sites are used to simultaneously produce electricity with solar panels and farm fish or shrimp. This requires revised feed formulations and/or feeding management. Through our pioneering work, we have taken a leading position in the segment. Another area of interest to us is indoor shrimp farming. An example is a collaboration with Universal Aqua in

Singapore. Grobest will work closely with UniAqua to develop a next-generation feed that is tailored for the particular model developed by UniAqua called Hybrid Biological Recirculation System™ to facilitate all its technological advances. The cooperation between the two companies comes at a time when Singapore is pursuing the goal of 30% home-grown food by 2030.

AQ: With the current price volatility and issues in the commodities value chain, which has been the main measures adopted to avoid an increase in the final feed price? What are your expectations for the next 12 months?

OD: We took measures across the group to keep producing feed that gives the best value to our customers. We expect the coming months to remain challenging in terms of raw material prices. Our innovation and procurement teams work closely together to ensure we produce feed that gives the best value to our customers. Our close collaboration allows us to be agile in responding to market situations.

The Future Awaits

Built on partnership and innovation, Wenger is providing more opportunities for client success.

For almost a century, Wenger has delivered extrusionbased innovations to our partners. We’ve worked alongside you to develop new processing solutions and better products, providing our industry-leading expertise and ongoing support every step of the way. We don’t plan on stopping any time soon.

Wenger’s global food processing family is growing, and we look forward to the exciting opportunities that lie ahead. We will continue to deliver even more innovations and technologies to benefit companies that share our vision of tomorrow.

Aboitiz sells Gold Coin Feed Mills

BioMar, Síldarvinnslan to build a net-zero aquafeed facility in Iceland

BioMar Group and Síldarvinnslan have signed a memorandum of understanding to build a modern high-tech aquafeed production facility in Iceland. Through this move, BioMar will become the only global feed company in the Icelandic market. The venture will build a facility that will achieve net-zero within its own operations.

Aboitiz Equity Ventures Inc. (AEV) has exited the Sri Lankan market with the sale of 100% equity interest in Gold Coin Feed Mills (Lanka) Limited to New Anthoney’s Farms (PVT) Ltd. “The exit from Sri Lanka is aligned with the Aboitiz Group’s plans to grow its animal feed business in other parts of the Southeast Asia and China markets,” the company said.

Nicovita to open a shrimp research center in Ecuador

Nicovita signed an agreement to build the first experimental center for the development of shrimp aquaculture technology (CEA Tecnológico) in Ecuador. The center will mimic real conditions for shrimp production and be dedicated to the validation and continuous improvement of existing and new technologies.

New aquafeed mill to support demand from East Africa's growing aquaculture industry

Maxim Agri Holding, Victory Farms Ltd, and Gatsby Africa partnered for a joint venture, Samakgro, an aquafeed mill that will produce high-quality and affordable aquafeeds to meet the demand from East Africa's growing aquaculture industry. The feed mill will be managed by Maxim Agri. Construction of the environmentally friendly high-tech feed mill facility is already ongoing in Naivasha, Kenya.

New partnership unveils insect-based feed for land-based shrimp

Förde Garnelen, Aquafeed Germany, Protix, neomar and Crusta Nova have joined forces to launch a new shrimp feed: SHR EX. The feed has been exclusively designed for the needs of European land-based shrimp farms as they increasingly move towards greater sustainability. SHR EX replaces marine proteins with locally produced insect proteins. The product will be sold by Aquafeed Germany.

Mobile NIR spectroscopy solution adds applications to aquafeeds

trinamiX GmbH, a provider of mobile spectroscopy and wholly owned subsidiary of BASF SE, now enables customers to receive on-the-spot nutritional insights into aquafeed and feed ingredients. Applications range from efficient quality checks of ingredients and raw materials processed at feed mills and integrators to the precise formulation of diets on the farm.

Chilean company sets a new standard for fishmeal production

FoodCorp, operating in the Biobío region in Chile, recently made an important contribution in the effort of validating the company´s sustainable management of biomass and processed products. FoodCorp became the first pelagic fish producer in the world to validate the traceability of the raw material used for its fishmeal production through ORIVO´s laboratory test-based program.

Adisseo opens 180,000-ton liquid methionine plant in China

Adisseo began operations at BANC2, the 180,000ton liquid methionine project that the company has built in Nanjing, China, becoming the facility with the largest liquid methionine production capacity in the world. The facility brings a more significant competitive edge on costs and will have more space and flexibility to optimize its capacity allocation, cushioning the impact of fluctuations in raw material and energy prices.

F3 Challenge winners announced

The F3 – Future of Fish Feed announced that three animal feed manufacturers – Star Milling Co, Empagran and Jiangsu Fuhai Biotech Co, Ltd. – each won a USD 100,000 grand prize in the F3 Challenge - Carnivore Edition in the categories salmonid, shrimp and other carnivorous species, respectively. Aquafeed.com spoke with the winners to get some insights on the challenge.

U.S.-based Star Milling Co. won for its non-GMO plant-based feed that contains omega-3 DHA-rich algae and heart-healthy flax oil for rainbow trout. Paul Cramer, VP/general manager of Star Milling Co., said that fish-free feeds performed better than conventional diets with no palatability issues and superior final fillet quality. But Cramer mentioned that "right now, it is cost prohibitive." He said that "utilizing terrestrial animal proteins and fats would bring the overall price down and be more appealing for other species producers to trial."

The Ecuadorian company Empagran won for its vegetarian recipe using Veramaris’ algal oil rich in EPA & DHA for Pacific white shrimp. "We have tested our vegetarian diet (zero marine and animal ingredients) with no major differences in yields up to 4 MT per hectare compared to standard diets," Pablo Intriago said. But he sees an issue with the price. "The price of replacing traditional ingredients such as fishmeal and oil with biotechnological products is much higher. Convincing farmers and wholesalers that this product is worth a better price is a real challenge," Intriago said.

China-based Fuhai Biotech uses its unique Fatide® product with dehulled full fat soybean fermented by microbes and enzymes for its largemouth bass feed. Jinfeng Yu, aquaculture director at Fatide Biotech Co.

Ltd., told us that the company found no difference compared to commercial feeds. The diet has been tested in rainbow trout and shrimp with good performance as well. "Our formulas are cost-effective and competitive with standard feeds, sometimes even cheaper when the soybean supply allows it.

Japan-based Dainichi Corporation also received an Honorable Mention Award, a USD 25,000 prize for their breakthrough feed for red sea bream.

Redefining aquaculture feed processing plants

Kim Larsen, SKIOLD

By introducing an innovative horizontal plant design, aquaculture feed processing specialist SKIOLD redefines the traditional construction of aquafeed processing plants, offering an extensive range of benefits for fish feed producers.

Based on more than 140 years of experience in designing feed milling plants, Danish specialist SKIOLD is renowned as a pioneer within their field and for reinventing the global feed industry with unique technologies and innovative solutions. Now the time has come to reinvent and optimize aquafeed manufacturing as well.

Nutritious feed for various fish species

SKIOLD aquafeed extrusion plants are designed to produce a versatile range of sinking, slow sinking, or floating pellets with superior durability and water stability. Properties, that prevents dissolving as well as diverse physical properties, in terms of shape and density amongst others. In short, nutritious feed that

meets the need of various fish species, match fish feeding habits, and ensure optimum health and feed conversion rates.

Modular concept for aquaculture feed production

SKIOLD aquafeed processing plants are made up of flexible scalable modules, which combined provide complete and customized solutions, covering every phase of the production process – from fine milling to mixing, extruding, drying, coating, and cooling of feed pellets. SKIOLD’s own developed plant automation and control systems, keep track of production data. This ensures full traceability and tracking of raw materials and feed ingredients resulting in optimum fish farm productivity and food safety.

Horizontal design for improved performance

Contrary to the typical aquafeed facility, that towers high above the landscape, SKIOLD aquafeed processing

plants are designed horizontally. It comprises onelevel buildings that provide fish farmers and fish feed manufacturers with a wide range of advantages, which optimize plant performance, ensure operational reliability, and produce a high return on investments. This concept has been proven by SKIOLD customers for

Site lay-out increases efficiency

The horizontal site lay-out yields various benefits for aquafeed manufacturers. Primarily, the site lay-out simplifies the overall layout of the plant, increases the efficiency of daily operations, and ensures easy access between control room, points of operation, and inspections. It is as simple as it sounds: by keeping all plant facilities and machinery at ground level, it is significantly easier to operate and maintain the facility on a daily basis, optimize procedures, establish a logic product flow throughout the plant, and consequently, ensure a consistent feed quality that guarantees the health of the farmed fish, and the productivity and revenue of the fish farmer.

Easy-to-build solution

The horizontal plant design also offers a substantial financial advantage, as one-level constructions are not as demanding and expensive to build as complex multiple-level tower constructions. Consequently, this will have a positive influence on the return on investments mainly due to lower civil costs. Furthermore, the modularized SKIOLD plant concept offers reduced construction time and a relatively uncomplicated building process. Therefore, the construction project can be managed by local civil contractors. On the contrary to popular beliefs, the horizontal SKIOLD construction does normally not take up more land space than an equivalent vertical construction, due to the compact, space-saving, and modularized design we offer.

Agile and flexible production

In combination, the modular concept and the one-level plant design additionally ensures an agile and flexible production, that is easily upgradable or adjustable to meet changing or growing market demands. Thanks to the one-level plant design, plant modules can easily be replaced or upgraded to ensure an efficient production.

Aquafeed: Advances

Ultimately, this increases the feed output, and/or meet the feed and nutrition requirements of other fish species or even other animal types.

Safer work conditions –improved employee satisfaction

To ensure continued growth and increased productivity, aquafeed manufacturers are highly dependent on skilled workforce. In a global labor market, where skilled workers are in high demand, it has never been more important to focus on employee retention and on reducing employee turnover. The horizontal SKIOLD design that keeps all plant facilities at ground level, improves aquafeed manufacturers’ ability to attract and retain a skilled workforce by simplifying daily work tasks, improving overall work conditions, and ensuring a safer work environment.

New SKIOLD feed production plant in Vietnam

Close to Hanoi in Vietnam, Nam Viet Group is looking forward to reaping the benefits of their new SKIOLD feed processing plant, Pilmico Feed Mill Plant. The plant

will be put into operation later this year. The new plant has been developed in a close partnership with Nam Viet Group.

“We are proud to reinvent the production of aquaculture feed in close cooperation with SKIOLD and look forward to further improve our performance when we put our new plant into operation,” said Nguyen Van Dich, director from Nam Viet Group. The final project includes four pelleting lines for production of animal feed, with an output of 4 x 15 tons pelleted feed per hour and one extruder line for production of aqua fish feed with an output of 10 tons per hour. Apart from the production lines, the plant also includes a warehouse for storing of raw material as well as packing facilities.

More information:

Kim Larsen Project Sales Manager

SKIOLD

E: kla@skiold.com

Aquafeed ingredients that drive the industry forward.

Our innovative ingredients include:

• EncompassTM fishmeals – customized marine protein solutions

• EmergeTM barley protein concentrate—nutrient-dense, high phosphorus bioavailability, supports cleaner water quality

• Sustainable and ethically sourced solutions

Steam and enzyme dosing units for De Heus in Asia

has become one of the top 3 in its sector, with eight factories strategically distributed across Vietnam. Recent acquisitions have since increased this number to 16 factories.

“The success of De Heus in Vietnam, where our regional Asian headquarters are located, has encouraged us to develop our business in the region. In addition to Vietnam, we now successfully operate three feed mills in Myanmar, we've built a feed mill in Cambodia and with the acquisitions, we can now enter the promising Indonesian feed market”, says Gabor Fluit, regional director of Royal De Heus Asia.

Late last year, Dick Wesselink, production & technical director for Asia, was in the Netherlands where he paid a visit to IVS. During the meeting, it emerged that some things were unclear about how the steam sets previously delivered to Royal De Heus Asia worked. We looked deeper into this question in the original customer request, how we responded to it, and what was eventually delivered and installed. It became clear in the meeting that there was potential to optimize the equipment to provide both the client and the animal feed producer with the perfect equipment for its production line.

This company visit by Wesselink showed once again how important it is for the customer and supplier to stay in contact and that personal contact is often essential; something that was unfortunately virtually impossible during the COVID-19 pandemic.

Indonesia has a population of 260 million people and it is the largest consumer market for protein in Southeast Asia. Demand for animal protein in Indonesia will continue to grow as a result of rising incomes, population growth, and changes in dietary preferences. The animal feed market is expected to continue to expand in 2022 from 19 million tonnes to 22 million tonnes.

In 2009, De Heus acquired an animal feed company in Vietnam, marking its entry into the Southeast Asian market. Nine years later, De Heus Vietnam

IVS Steam Dosing Units

The visit to IVS led to an order for various equipment including two new IVS steam dosing units for a press line with a capacity of 23 t/h and another with a capacity of 28 t/h. The dosing units are equipped with a Prowirl steam flow meter, which allows the steam flow to be controlled consistently. The press line can now start up very quickly, from 0 to 100% in just a few minutes. The dosing units will be shipped to a new factory that is scheduled to open in October

2022 on the Indonesian island of Java. This factory will produce poultry feed.

IVS Enzyme Dosing Units

IVS is supplying two enzyme dosing units that can dose liquid enzymes for the same PT Universal production location. A complete dosing system consists of a pump set mounted in a stainless steel structure with a drip tray that can accommodate an IBC tank and a dosing cabinet that ensures the correct dosing. These dosing systems are connected to the two batch coaters at the production location and work independently of each other, permitting different volumes to be dosed simultaneously or independently of each other.

Installation

Production work is currently in full swing at our factory in Veghel. This great order will be delivered to the tropical island of West Java within a few months, after which an IVS service technician will commission the installations. This will be done to ensure that the products we supply are installed correctly and will also be used correctly by the customer. With this, we can guarantee that the system works perfectly and produces the very best finished products. Our aim is to provide the benefits of our product knowledge and improve the use and optimization of our dosing systems. That is why customer experience and cooperation are at the heart of our mission and vision objectives.

For more information, contact Elze Tutelaers, e.tutelaers@ivs.nl or visit www.ivs.nl.

Extruded aquafeed: New technology for quality control

Yang Chen (Michael), FAMSUN GroupAs we all know, some processing parameters in extrusion, such as water addition amount, temperature, pressure, and screw speed have a direct and critical effect on the quality of extruded products. These parameters determine the starch gelatinization level of feed melt in the extruder, the shearing effects on it, the expansion ratio of floating pellets, the viscosity and cohesiveness of the sinking ones, and their bulk density and water durability.

With the awareness of productivity, cost, animal health and well-being, and environment sustainability increase, aquaculture farmers pay much more attention to such feed quality as bulk density, oil/fat content, water durability and the leaching of oil and other nutrients in the water. They ask for feed with more “precise” or “customized” nutritional and physical quality to grow their products and aim for more economical and sustainable benefits.

This is a big challenge for the aquafeed industry. For most existing aquafeed mills, the quality control of products and the adjustment of processing parameters always depend on the skill, knowledge, and experience of extruder operators. Before launching a new product onto the market, skillful extruder operators must take lots of trial and error to develop the most suitable production solutions for the new formula, including the parameter adjustment practices of extruders. That means much time, labor, and energy investment and a lot of material and water waste in trials.

A big if

The diversified feed demands and the precision farming trends call for more future-fit aquafeed production technologies. At Famsun, researchers have a big assumption: If a group of reliable mathematical models is available to predict the product quality of an extrusion system, the costly trial production will not be a necessity

anymore, and producers will be able to find the best processing parameters to produce their new products efficiently as soon as the new formulas created. The only thing to do is to define the quality parameters for the new products. With the quality prediction models, producers will be able to accelerate the pace of new products onto the market, become more flexible with different (customized) formulas, and achieve the best Overall Equipment Effectiveness (OEE) and Yield (YE) for their aquafeed mills as well.

In 2021, Famsun R&D experts successfully developed a group of mathematical regression models based on solid statistical theory and rich experience in the application of big data technology. The experts used the ANOVA multi-parameter coupling method to perform regression on the processing parameters of the Famsun twin-screw extruders. Combined with quality indicators, such as bulk density, gelatinization level, and water durability, researchers obtained many mathematical models to predict the quality of extruded aquafeed produced by the twin-screw extrusion system. The prediction models are classified and stored in Famsun’s quality prediction model database according to the feed formula, screw configuration, and the diameter of the die hole. As more data on the best aquafeed-production practices are used in model creation, the database grows and benefits more Famsun extruder users.

The regression models were proven to be able to predict extruded product quality precisely and reliably in Famsun partners’ feed mills. The quality parameters of the product produced by the extruder are the same as that predicted according to the actual processing parameters. On the other hand, by inputting the product quality requirements, the backstage database will calculate the recommended prediction models automatically, and provide the best proposal on start-up parameters for new productions.

The quality prediction models allow feed manufacturers to respond to customer demands quickly and target excellence in operation.

Quality control practices on FAMSUN H Series Twin-Screw Extruder

Launched in 2018, FAMSUN H Series Twin-Screw Extruder (Fig. 1) is highlighted by excellent production stability, outstanding formula adaptability, and simple operations. So far, there have been over 100 sets of H Series extruders creating success stories in FAMSUN customers’ feed mills in Vietnam, Thailand, South America, and other main aquaculture markets of the world.

The collaboration between Famsun and H series extruder users on the research, tests, trials, and application of the aquafeed quality prediction

and control technology now has achieved its firstphase goals. The researchers worked out many regression models by using the ANOVA multiparameter coupling method to test the quality data of extruded products and the corresponding processing parameters, and by taking an influencing factor of p<0.05 and its coefficient. With MATLAB contour surface graph, the relationship between feed quality and extrusion processing parameters is described visually. For critical quality indicators, such as bulk density, gelatinization level, water durability, and water absorption capability, the regression process is performed separately, and the regression model only describes the relationship between an individual quality indicator and the processing parameters. All prediction models are classified and stored in the database according to the feed formula and die holes.

For new productions, once the targeted product quality is defined and input, the backstage database will calculate the recommended prediction models and provide the best production control proposal on melt temperature in extruder and steam and water addition amount in conditioning, which ensure aquafeed production in a high-efficiency, low-consumption, and less waste way.

Table 1 shows a group of quality prediction models of the Famsun H series extruder that Famsun researched, tested, and verified in cooperation with an aquafeed mill in Zhejiang, China. The feed mill produces feed for four kinds of aquatic species. It is available in three or four quality prediction models for each species that cover quality indicators of bulk density, gelatinization

level, water absorption capacity, and water durability, taking an influencing factor of p<0.05 and guaranteeing the R2>0.95.

x, y respectively represents the melt temperature in extruder and moisture content of feed in the conditioner, the value is (-2: 0.05: 3), and the corresponding processing parameter of temperature and moisture content are shown in Table 2.

With MATLAB 3D contour surface graph, the visualized relationship between the bulk density of seabass and the processing parameters of melt temperature and moisture content is shown in Figure 2. Melt temperature and bulk density show a positive correlation first and then a negative one. While moisture content of conditioned feed mash shows a negative correlation with bulk density first and then a positive correlation. For starch gelatinization level, it is negatively correlated with melt temperature first then positively correlated, and its relationship with moisture content presents the opposite situation (Fig. 3). It is obvious the relationships of gelatinization level with melt temperature and moisture content are opposite to that of bulk density with melt temperature and moisture content, which verifies the extrusion expertise that a high gelatinization level always results in a high expansion ratio and low bulk density of the extruded product.

All prediction models are classified according to formula first, and then formulas for the same fish species are further classified according to the die holes. With MATLAB calculation, the database will search for the recommended models automatically according to product quality parameters. After defining the targeted quality such as bulk density, gelatinization level, water absorption capacity, water durability, etc., the backstage program will calculate automatically according to the recommended prediction models and output proposal on start-up parameters for the extruder (Fig. 4). The quality prediction and control database is now available in Famsun Extruder Automatic Control System. With this function, operators can have the proper processing parameters to produce qualified products as soon as possible, avoiding losing production time in trials and such demanding quality tests as water absorption capacity and water durability. In addition, the intelligent function helps reduce the dependence on experienced operators and promotes scientific and economical production in feed mills.

Conclusion

By combing intelligent quality prediction and control technology with high-level automatic control based on state-of-the-art extruders, Famsun aquafeed extrusion solutions allow quick start-up, full-automatic steamwater addition, and high-performance quality control in aquafeed extrusion. It helps to simplify operations and provide the producer with powerful capability, flexibility, and efficiency to meet farmers' demands today and tomorrow.

More information:

Dr. Yang Chen (Michael) Senior Mechanical Engineer FAMSUN Group E: sysucy06@famsungroup.com

E: sysucy06@famsungroup.com

FEED PROCESSING

Providing improvement options for pelleting shrimp feed

Steven Goh, DelstAsiaThere has been much hype about the efficiency of extruded feed by 15-20% of improved feeding value and pellet integrity when compared to the pelleted feed for shrimp. Extrusion is a short-time highthermal processing method that involves progressively increasing pressure, heat, mechanical shear and highly moistened material which helps to break down the structure of starch and proteins of processed feed effectively. This results in higher starch gelatinization and unfolding of proteins for better digestibility and growth performance, and good pellet integrity to prevent nutrient leaching into the pond water system. Many studies on feeding extruded feed to livestock have shown consistent effects in feed efficiency due to the enhanced energy and nutrient digestibility. However, the extrusion process needs to be properly controlled as excessive thermal processing may reverse any beneficial effects of extrusion.

Feed extrusion also has a downside as the drying process can cause starch retrogradation which results in resistant starch and is destructive to vitamins. Whether you are debating over the need to change to extrusion feed processing and the high capital cost that comes with it, the most important aspect of the conundrum with pelleted feed is that starch and protein is not well processed at all.

The industry has fallen further into a quagmire of confusion that is hard to escape because there is no easy solution to improve pelleted feed quality. Feed pelleting is a complex, semi-dry thermal processing, rendering it impossible to deal with the objective of processing starch and protein effectively without the dreaded Maillard reaction problem.

The industry has been working under the notion that the feed has been processed well enough, but now with the help of feed imaging, it reveals the underlying problems in feed. Feed pelleting is merely

a forced feeding of hot-moist conditioned mash through a die, and at best, only the pellet surface is anywhere close to being better cooked, due to high surface moisture and the searing effect from the hot die surface.

Hence, Pellet Durability Index (PDI) is merely a measure of the strength of the outside of the tube (integrity of the pellet surface). Putting a knife through a pellet often reveals a brittle exterior and a very loosely bonded center (Fig. 4). This is the reason PDI improves when there is more surface moisture in the hot mash and with the higher die compression used for shrimp feed production.

What can possibly go wrong with the following production parameters?

• Pulverised grinding

• High water added at the mixer

• Long mixing time

• Very long conditioning dwell time

• Extra postconditioning

• Small pellet size 1.2-1.8mm

• High die compression – 24-26 (die thickness over pellet size)

With the above parameters, pellet formation and quality should be perfect. However, we are seeing abnormally high issues with the starch in processed pellets. The whitish spots and rough pellet surface are good indicators that things are not quite right. These problems are clearly observed on all feeds under microscope. Some obvious factors, such as high protein ratio over starch, higher ratio of alternative soy protein over native protein, high-temperature processing, and high die compression, make things worse.

In a very different context away from the current industry norm, the main objective of feed processing should be to induce positive chemistry changes in starch and protein, and minimize the negative chemistry

changes caused by the Maillard reaction. Using these fundamental principles, the next steps are to deploy the science needed to get the job done correctly and optimally.

This article focuses on a patented concept, Mash Hydrolysation™, which is a biochemical approach to getting moisture into the feed chemistry that addresses the root cause of poorly processed pellet feeds.

Feed imaging

Forensic Feed Science™ (FFS) is a tool that exposes problems that could well explain the issues with questionable feed quality, pond water quality, diseases,

poor farm productivity, and low survival rate. FFS also provides much better post-mortem insights into the quality of processed shrimp feed over current analysiswet chemistry analysis for starch gelatinization, PDI and water stability tests. Feed imaging shows up accurate visual macro details for assessing the processed feed quality and if starch and protein are processed well (Fig. 3, 4).

Poor processing of starch/protein affects pellet binding, energy value and feeding value. The feed pellet could be very stable in water, but if intra-particle bonding is poor in the entire pellet, bits and crumbs can easily fall off while the shrimps are feeding. Leaching of nutrients and uneaten feed particles contaminate the water, and will certainly affect the pond water stability and health of the ecosystem.

Maillard reaction is a reaction of lysine and some other amino acids with reducing sugars such as glucose (Fig. 2). This reaction impacts protein quality which is critical for shrimp nutrition. Certainly, we know that the Maillard reaction binds lysine, making it non-reactive, and interferes with the transport of stored nutrients to the muscle for growth.

Whether the Maillard compounds have any negative effects on the hepatopancreas general function (metabolism of lipids and carbohydrates, energy for molting, regulation of immune response) has yet to be fully understood. However, there are likely effects on absorption and storage of nutrients, synthesis, and secretion of digestive enzymes for food digestion.

is poorly processed with birefringence, the moisture not penetrating the starch granules; (ii) High degree of visible crystalline starch indicating a lack of moisture hydrating the starch granules. When sufficient moisture penetrates the granule, the amorphous regions of the granules absorb the moisture and swell, resulting in the separation of the starch chain from the crystallites. Sufficient water lowers the starch melting point and results in the quick melting of the crystallites at high temperatures; (iii) Poor particle bonding; (iv) Darkened color indicating browning from Maillard reaction. Sufficient moisture prevents the breakage of glycosidic bonds holding glucose to carbohydrates.

Mash hydrolysation

The whole science around feed pelleting is centered around the proper hydrolysis and cooking of starch and protein. For this to happen, moisture needs to get into the feed chemistry. However, the polarity of water molecules alone is insufficient to disrupt the hydrogen bonding of starch and protein structures.

DMX contains divalent cations termed “structure breakers” with a high charge density having the ability to disrupt hydrogen bonds of starch and protein. These cations also possess high polarity, thus attracting water molecules strongly. With the disruption of hydrogen bonds, moisture can penetrate freely into the starch granule, leading to swelling, rupture, and the melting of amorphous and crystalline starch, leading to irreversible starch gelatinization.

This biochemistry solution is important for activating moisture in the feed chemistry in the semi-dry feed pelleting process. In the current low moisture scenario, water molecules do not easily penetrate the starch granules.

Structure breakers act as gate-openers into the native protein structure. It breaks the native structure and forms a new structure. The presence of DMX ions also reduces electrostatic repulsion that prevents gel formation of the negatively charged proteins and helps aggregates the denatured protein, connecting them into a desirable network instead. This can be observed under SEM Imaging and Feed Imaging (Fig. 5, 6).

Moisture plays a very important role in feed processing. It is one of three elements involved in cooking food – heat, moisture, and time. An effective moisture management technology determines if moisture will be used “functionally” by drawing moisture into the feed chemistry for proper hydrolysis of starch and protein, contributing to positive chemistry changes to starch and protein, which greatly determines production efficiency and processed feed quality.

Durability on the pellet surface (from high die compression/searing/use of pellet binder) help with water stability. However, we need to be concerned about the content inside the pellet. The feed can crumble and disintegrate as the shrimp are eating.

Conclusions

Mash Hydrolysation™ provides great economics in feed processing efficiency, improved production

yield, lowering feed formulation costs, producing good quality performing pellet feed with good chemical stability and extended shelf-life in post-production. What’s more important, a well-processed feed could well provide important answers to current issues relating to pond water quality, growth performance, diseases, and survival rate. With very limited information on the Maillard compound affecting the shrimp hepatopancreas, it would be sensible to produce feed without the dreaded Maillard reaction as

The onus now lies with shrimp feed producers making the change to bring the processed feed to the next level. After all, there is great economics favoring both feed producers and shrimp farmers.

More information:

Steven Goh Managing Director DelstAsia Sdn. Bhd. E: steven@delstasia.com

History of fish nutrition

Part III (2000-2022)

Ronald W. Hardy, Distinguished Professor Emeritus, Aquaculture Research Institute, University of Idaho

Environmental and sustainability concerns

During the second phase in the history of fish nutrition, production of established farmed fish species, notably salmon, catfish and tilapia, increased greatly and more species were added to the list of farmed fish and shrimp. Formulating feeds to meet newly discovered nutritional requirements significantly reduced losses due to nutritional deficiency and, as an added bonus, improved nutrient retention and feed efficiency. The adoption of extrusion pelleting enabled the production of high lipid feeds for salmon and trout, also improving feed efficiency. However, the growth and intensification of aquaculture production raised new concerns related to feeds, namely overdependence on fishmeal and fish oil, environmental effects of wastes released from fish farms and the possibility of elevated organic contaminants in farmed fish products. These concerns ushered in the third phase of fish nutrition research which involved in-depth evaluation of alternative protein and oil sources, development of low-pollution feed formulations, and investigations of levels and sources of contaminants in farmed fish. Continued exploration and refinement of the nutritional requirements of fish to support rapid, efficient growth and optimum health were the foundations for these efforts.

Reducing dependence on fishmeal and fish oil

Historically, poultry and piglet feeds contained fishmeal as a source of unidentified growth factors. Over time, the nutrients in fishmeal responsible for growth benefits in poultry and piglets (mainly ultra-trace elements) were identified, enabling feed formulators

to decrease and eventually eliminate fishmeal from their feeds. Aquaculture feed production increased during the 1990s and consumed a steadily increasing percentage of annual global production of fishmeal and fish oil. Although fish nutrition researchers investigated alternate protein and oil ingredients for decades, recognition that the amount of fishmeal and oil used in fish feeds would exceed global production within a decade unless levels in feeds were reduced became more widespread in the scientific community and the media, highlighted by Naylor et al. (2000).

Research on alternative fish feed ingredients expanded in the 1970s when production of fishmeal and fish oil dropped sharply in Peru and Chile when an El Niño event reduced landings of anchovies. Catfish feeds in the USA switched from fishmeal to soybean meal as the main protein source in feeds with negative consequences for the catfish industry. Feed producers formulated feeds to meet crude protein levels rather than essential amino acid requirements because requirement levels were incomplete. When soybean meal replaced fishmeal in feeds, growth performance and feed efficiency suffered. Nutrition research identified the quantitative amino acid requirements of catfish and available amino acid levels in soybean meal and other alternate protein ingredients. This information enabled feed formulators to develop nutritionally balanced feeds using other protein sources rather than just fishmeal.

Research on alternate protein and oil sources continued after anchovy landings returned to normal levels but, from time to time, feeds containing alternative protein sources to replace fishmeal caused

significant fish health problems, highlighting the lack of knowledge in the fish feed and nutrition field. For example, in the early 1980s, salmon feed containing high-ash fishmeal produced from fish processing byproducts caused millions of juvenile salmon in the western USA and Canadian hatcheries to develop bilateral cataracts. Canadian and US researchers discovered that interactions in feeds between phytic acid and bones in high-ash fishmeal interfered with zinc digestibility (Richardson et al., 1985; Hardy & Shearer, 1985). Cataracts, a clinical sign of zinc deficiency in salmonids, developed even though zinc levels in feeds were well above the reported zinc requirement of juvenile salmon and trout. Increasing zinc levels in trace mineral premixes used in salmonid feeds eliminated the cataract problem.

Another striking example of the perils of simply replacing fishmeal with alternate proteins without complete knowledge of the nutritional requirements of farmed fish involved taurine and farmed marine species. A prolonged, cyclical crash of the Japanese sardine population around Japan led to the wholesale replacement of sardines and sardine meal with soybean meal in feeds for yellowtail. Even though amino acid levels in soy-based feeds were adequate, fish grew poorly and exhibited a condition called ‘green liver syndrome’. After years of research, low available taurine levels in soy-based feeds were identified as the cause of the syndrome. Prior to this problem, taurine was not known to be an essential nutrient for fish because fishmeal-based feeds contained sufficient taurine. Fishmeal is an excellent source of taurine whereas taurine is absent in plant-based ingredients. The dietary need for taurine only became evident when low fishmeal feeds were fed to marine fish. Antagonistic interactions with constituents in soybean meal may have contributed to taurine deficiency under some circumstances by reducing available taurine levels, illustrating the complexity associated with using alternate proteins in fish feeds.

Rising costs of fishmeal, especially in 2007-2008 when global production was relatively low and China purchased huge amounts, highlighted the need to reduce fishmeal and oil levels in feeds. Fish nutrition researchers used several standard approaches to evaluate alternative ingredients. First, researchers measured the digestibility of protein, amino acids and

essential dietary minerals, mainly phosphorus and zinc, in feed ingredients. Measuring digestibility with fish is more difficult than doing so with chickens, swine or rats because of the challenge of collecting feces from aquatic animals. Fish feces collection methods fall into two general categories – stripping or dissection of feces from the fish or collecting naturally-expelled feces using settling systems. Each approach introduces errors in digestibility determinations. Stripping inevitably results in contamination of collected feces with endogenous material (urine, intestinal enzymes, intestinal cells) whereas settling inevitably results in loss of soluble minerals and amino acids. Consequently, stripping leads to underestimates of digestibility and settling leads to overestimates.

The magnitude of under- or overestimations can be minimized by diligent control of experimental variables and by including a standard, refined ingredient, such as casein, in digestibility trials. This provides a common, baseline standard that facilitates comparisons of digestibility results from different laboratories. Researchers at Guelph University refined the settling method, known as the ‘Guelph System’. It has been used by other labs leading to more reliable digestibility values, at least for salmonids. Guelph researchers were also early leaders in the development of low-pollution feeds, using many of the same approaches involved in studies of alternate protein sources.

After the levels and digestibility of nutrients in alternate protein ingredients were known, ingredients were evaluated in feeding trials using experimental feeds in which fishmeal was replaced by an alternate ingredient at incremental levels. Fish weight gain and feed efficiency were the primary measurements used in feeding trials to determine suitable fishmeal replacement values. Very few alternate protein ingredients are as nutritionally complete or as free of antinutrients as fishmeal, and as replacement levels increased, growth performance generally decreased proportionally. Amino acid imbalances in alternate ingredients were then corrected in feeds by amino acid supplementation and/or by combining alternate ingredients that complement each other’s amino acid profile. Nutrition research also focused on plant antinutrients that affected fish, followed by the development of ways to remove or inactivate them.

Nutritional values of animal protein ingredients were

improved by lowering drying temperatures during production, especially for blood or meat meals, including poultry byproduct meal. Air-classification to reduce the content of indigestible components, i.e., cartilaginous material, feathers or fiber, was also found to improve and standardize the nutritional quality of land animal proteins and produce plant protein concentrates, such as pea protein.

The role of feeds on the environmental impacts of fish farms

Fish farm effluents affect streams and rivers by releasing phosphorus and total suspended solids from indigestible material in feeds excreted in feces and metabolic wastes that are excreted in urine and through the gills. Excreted material originates from feeds; therefore, reducing levels of enriching nutrients in effluents involves fish nutrition research. The focus of research is on nutrient digestibility in feed ingredients and on the refinement of dietary requirements of essential nutrients. Feed formulators use this information to set upper and lower limits on essential nutrient levels in feeds to increase the retention of nutrients for tissue growth and minimize the excretion of dietary nutrients present in excess of required amounts.

Phosphorus levels in fish farm effluents became the number one target of regulatory agencies because phosphorus is the limiting nutrient for freshwater algae and macrophyte growth. Phosphorus digestibility values in feed ingredients are not always additive when ingredients are combined in feeds. Fish nutrition researchers eventually worked out how digestibility values vary in different feed formulations. Indigestible phosphorus in feeds mainly comes from phytate phosphorus, the storage form of phosphorus in grain and oilseed protein concentrates, and from bones in land animal proteins. Fecal solids containing phosphorus can be removed from effluents using screens and settling systems. However, excess available phosphorus in feeds excreted as soluble phosphorus in urine cannot be removed from fish farm effluents.

Reducing phosphorus excretion in fish, therefore, involves formulating feeds to contain the minimum required amount of available phosphorus to meet dietary requirements while also limiting total phosphorus levels to minimize fecal excretion. Grow-

out feeds constitute over 90% of the total feed used to raise fish to harvest size so refining dietary phosphorus levels in grow-out feeds is the key to reducing phosphorus losses from fish farms. When low pollution feeds were being developed, there were no dietary phosphorus requirement values for fish during the grow-out stage of production, just values for fry and fingerlings. Fish nutritionists found that the dietary phosphorus requirement of post-juvenile fish was lower than that of fry and fingerlings and thus were able to reduce available phosphorus content in lowpollution feeds to account for this difference.

Other nutritional strategies to reduce the environmental impacts of fish feeds involve processing ingredients to improve digestibility. Although crude protein digestibility of plant protein concentrates is generally similar to that in fishmeals, phosphorus in plant protein concentrates is present as phytate phosphorus, a form that is indigestible by monogastric animals, including fish and humans. Treating plant proteins or high plant-protein feeds with microbial phytase releases phosphorus from its phytate form, making it available for absorption. Nutritional research explored other approaches to improve feed ingredient quality including heat treatment, solvent or aqueous extraction and air classification to remove fiber or indigestible bony material as mentioned above.

Fish nutrition research continues to focus on novel alternate protein ingredients, such as insect meals and single-cell protein meals. Both present challenges to fish nutritionists due to issues with digestibility and nutritional content compared to fishmeal or conventional alternate proteins. A positive result of research to develop low-pollution feeds is that information developed through detailed characterization of feed ingredients makes it possible to formulate precision feeds. This has increased feed efficiency across the aquaculture industry, including in countries where environmental concerns are secondary to production goals

Safety and quality of farmed fish products

In the early 2000s, several papers reporting elevated levels of persistent organic pollutants (POPs) in farmed salmon appeared in the scientific literature. While there were some significant flaws in these papers related to where fish used in studies were obtained and the

lack of transparency regarding chain of custody prior to analysis, they received a large amount of media attention and highlighted the potential for fish feeds to be a source of POPs in farmed fish products. Although subsequent studies did not confirm that farmed salmon contained elevated levels of POPs, researchers did identify fish oil as the primary source of POPs in fish feeds, notably fish oils from the Northern Hemisphere. Fortunately, POPs can be economically removed from fish oil using carbon filtration, and this is now a standard practice in fish oil production from fish landed in the North Sea and other areas where POP pollution is elevated. POP levels in farmed fish remain well below levels of concern, in contrast to levels in wild fish caught in contaminated areas, such as portions of the Great Lakes in the USA and the eastern Baltic Sea. The fact that feeds are the source of contaminants in farmed fish provides a clear path for researchers to develop feeds with low contaminate loads and thus guarantee the safety of farmed fish to consumers.

Future directions for fish nutrition

Conventional wisdom is that the past is a guide for the future. Applying this aphorism to fish nutrition suggests

that efforts to develop a wider range of protein and oil sources for fish feeds will continue to be a priority. Although acute losses of fish due to nutritional deficiencies are rare, nutritional imbalances associated with the use of alternative protein and oil ingredients are a continuing problem that lowers the efficiency and productivity of the aquaculture industry, especially in the marine sector. Applying advances in salmon feeds to marine fish feeds does not always result to healthy fish and efficient growth. The diverse feeding habits of marine fish suggest that further nutritional research is necessary to develop efficient feeds to support optimum fish growth and health. Fortunately, high throughput ‘omics’ provide new tools to investigate the effects of essential nutrients on cellular metabolism as well as on whole-animal performance. The ‘one nutrient-one disease’ approach of the past 100 years in animal and human nutrition has been replaced with a more comprehensive approach to nutritional research. Effects of dietary nutrients on immune function and functional ingredients on the microbiome are examples of new areas of opportunity for fish nutrition research that will support a new and productive era of fish nutrition research.

ANDRITZ EXTRUDER MICROFEED SYSTEM THE

A natural alternative to synthetic antioxidants for aquafeed preservation

Amine Chaabane, Laboratoires PhodéAntioxidants are widely used in aquaculture today. These compounds have the ability to limit the effect of oxidative stress, which is the consequence of high oxygen metabolism within the animal’s body, causing the appearance of Reactive Oxygen Species (ROS, also called free radicals). The latter interfere with cell signaling and tissues, leading to damage and dysfunctions inside the organisms. Antioxidants are also naturally included in feed to prevent them from oxidation and degradation, maintaining the quality of the feed compounds at their maximum. Through high exposition to oxygen and ROS, antioxidants scavenge those free radicals and reduce them by giving them a hydrogen atom: these new compounds are harmless to the feed and oxidized antioxidants are considerably less reactive.

Ethoxyquin was suspended by the European Food Safety Authority to be used as an antioxidant. Alternative solutions are then being sought by the industry to produce high-quality aquafeeds with more sustainable products compared to synthetic antioxidants.

Polyphenols are known to be very efficient antioxidant molecules thanks to their phenol groups. Among natural polyphenol sources, grape seed and skin extracts are widely used as they contain high content of polyphenols, particularly condensed tannins. Among condensed tannins, procyanidins, and more specifically oligo-procyanidins (OPC), are one of the most powerful antioxidants known.

The aim of this study, conducted in the Innocon experiment center in Chile, was to evaluate the potential of an OPC-rich feed additive, Olpheel Anti-Ox, on feed preservation against oxidation.

Accelerated oxidation test

To evaluate the antioxidant effect of Olpheel Anti-Ox (OAO), accelerated oxidation of the feed assay was carried out. It consisted of subjecting an extruded feed to a temperature of 90°C and 6 bar of oxygen for 18 hours in Oxitest® equipment. Through this, the induction time was determined: it corresponds to the time necessary for primary fat oxidation reactions to begin to occur in the sample. The longer the time, the more resistant the feed matrix is to oxidation.

To measure the efficiency of the antioxidant, four treatments have been assessed:

• Control -: feed without antioxidants

• Control +: control feed + 500 ppm of TBHQ (tertiary butylhydroquinone) + 300 ppm of BHT (Butylated hydroxytoluene) + 1,300 ppm of Vitamin E

• OAO 50 ppm: control feed + Olpheel Anti-Ox at a 50-ppm inclusion

• OAO 125 ppm: control feed + Olpheel Anti-Ox at a 125-ppm inclusion

Regarding feed oxidation (Fig. 1), both 50 and 125 ppm Olpheel Anti-Ox dosages displayed similar results (6.47 and 6.18 hours respectively for oxidation to start) compared to the positive control (6.67 hours, blend of synthetic antioxidants), showing higher feed preservation compared to the negative control (without any antioxidant).

Effects on the shelf life

To push further these primary results, the effect of Olpheel Anti-Ox on the shelf life of the extruded type feed was evaluated in a second experiment. Another oxidation analysis was carried out in Oxitest ® at 90, 100 and 120°C, determining the induction time at these temperatures with an oxygen pressure of 6 bar. As there was no significant difference in the oxidation induction time between Olpheel Anti-Ox at 50 ppm and 125 ppm, the 50-ppm dosage was the best between the two regarding cost efficiency. To carry out this second test, a 30-ppm dose was chosen to be tested, as lower doses of the product are known to be efficient too. The induction time values at 90, 100 and 120°C obtained with the Oxitest were plotted and the shelf life of the extruded type feed at 25°C was calculated by extrapolation of the curve. For this purpose, the Oxisoft® software of the Oxitest® equipment was used. Results showed that the use of the Olpheel Anti-Ox at a 30-ppm dosage could lead to a 141-day shelf life value for extruded feeds stored at 25°C (Fig. 2), corresponding

to the time necessary for oxidation to start during storage. This duration is considered high as extruded feeds are consumed quickly during salmon or shrimp farming, showing that the use of the Olpheel Anti-Ox could be an efficient strategy for feed preservation.

Conclusions

The use of Olpheel Anti-Ox, a grape seed- and skinbased antioxidant, has resulted in similar protection of feed against oxidation to synthetic antioxidants. These results indicate the use of Olpheel Anti-Ox as an efficient alternative to synthetic anti-oxidants and ethoxyquin to preserve extruded feed from oxidation.

More information:

Amine Chaabane

Aquaculture

Product & Species Manager

Laboratoires Phodé

E: achaabane@phode.fr

Long-lasting effects of palatability enhancers on fish zootechnical performance are more visible in challenging conditions

Mikaël Herault, Paul Seguin, Eduardo Hurel Nacer, Arnaud Rossignol, Symrise Aqua Feed

Palatability enhancer benefits have been demonstrated in several fish species and applications.

., 2021) but also to Atlantic salmon, which industry is already very well optimized (Fournier

More recently, it has increased tilapia and butter Ompok bimaculatus) feed acceptance with topcoated dietary protein hydrolysate supplementations ., 2022), resulting in much lower farm feeding costs. Freshwater fish species are known require less diet nutritional compositions, or palatability. Today, new results are available, and they highlight the long-term benefits of dietary PE supplementations in marine carnivorous fish species, despite significant

A 2% liquid PE makes a fishmeal-free diet palatable to European seabass juveniles

Over the past three years, Diana Aqua, recently renamed Symrise Aqua Feed, has issued several articles demonstrating the benefits of protein hydrolysatesbased palatability enhancers (PE) for aquafeed.

First, a wide range of applications has been illustrated in marine carnivorous fish species, and performance has been shown to be improved when using dietary PE: fishmeal replacement, medicated feed, environmental or husbandry stress mitigations (Seguin et al., 2020).

Top coating application and a specific PE formulation, including marine protein hydrolysate, permitted to reduce its cost in use making it scalable to all fish growth stages, from larval to grow-out diets. Specific PE applications were successfully extrapolated to Asian

Feedback from the industry tells us marine carnivorous fish juveniles are usually fed with 20-25% fishmeal (FM) diets while grow-out fish are fed with 10-15 FM diets. These figures seem to be confirmed by a recent review made by Naylor et al. (2021).

In a recent study, Symrise Aqua Feed evaluated the long-term impact of a 2% liquid PE supplementation, when top-coated on European seabass juvenile practical diets, with six graded levels of FM. Experimental diet formulations are presented in Table 1. All experimental diets were nutritionally balanced to meet seabass requirements and were iso-nutritional for dry matter, crude protein, crude fat, and energy (CP: 44+/- 0.4%, CF 15.1+/- 0.2%; Energy: 5.2+/-0.07Kcal/g).

The experimental design consisted of six practical diets with FM levels graded from 0 (fishmeal-free diet) to 25% (most conservative diet), top-coated -or notwith 2% liquid PE (Extrapal). These 12 dietary groups were randomly allocated to 2 tanks of 100L capacity, supplied with thermoregulated filtrated seawater (20+/1°C, 250% renewal rate). Fish were fed ad libitum with automatic feeders (Arvotech, Finland) for 37 days while feed waste was daily quantified to adjust feeding rates. Growth results are presented in Figure 1 and 2 while FCR values are illustrated in Figure 3.

Long-lasting benefits of palatability enhancers

These results show that 2% liquid PE is enough to significantly improve European seabass juvenile growth rates at all tested FM levels. Supplementing a fishmeal-

free diet with only 2% liquid PE allowed it to yield the same growth performance as a 20% FM diet, in seabass juveniles. This implies promising possibilities in terms of cost savings and reduction of carnivorous fish diet environmental footprint and FIFO, including the more demanding nursery phase. The trial duration was 37 days, which means observed benefits are long lasting and are assumed to remain over the whole fish growth cycle. This statement can be supported further by the fact that FCR was not negatively impacted over this duration for PE-supplemented dietary groups. Thus, the worst observed FCR average values for PE-supplemented dietary groups was approximately 1.26, which corresponds to the FCR normally observed, in lab conditions, for the non-supplemented FM20 dietary group.

As expected, modeled growth curves (Fig. 2, 3) confirm that the growth gain, resulting from the use of a PE, will be proportionally higher at lower dietary FM contents. Extrapolating, we may assume this gain could be lower, and less significant, above 27-30% FM contents. This can be explained by the fact that, at these high FM levels, using a mix of standard and premium FM, diet

palatability is already optimal, and fish cannot eat or grow any further when reared in optimal conditions.

Interestingly, under challenging conditions, it seems possible to further enhance palatable diets containing high levels of quality FM. We will see that with another trial done in European seabass but under cold water conditions.

Dietary palatability can mitigate stress perception and the resulting adverse effects

A 21-day feeding trial was implemented in Symrise Aqua Feed testing facilities with European seabass juveniles (mean weight: 13.0g). Three graded FM levels were tested (10, 20 and 40%), with or without 2% liquid PE supplementation, top-coated. Feed formulations

were like the ones presented in Table 1 with FM mixes being partly replaced with a mix of plant protein and crystalline-free amino acids. The experimental design is therefore very similar to the previous one, except it was implemented at 11.7°C (natural seawater temperature) instead of 20.0°C (thermo-regulated). Each dietary group was randomly allocated to 3 tanks of 100L

capacity. Fish were fed ad libitum to maximize dietary palatability performance and the resulting growth performance is illustrated in Figures 4 and 5.

Fish growth rates were logically impacted by temperature reduction as values were approximately 65% lower than in the previous feeding trial. Also, all PE-supplemented groups yielded a significantly higher growth rate compared to their basal dietary benchmarks, and again, the observed gap was higher for lower dietary FM contents than for higher ones. Nevertheless, contrary to what occurred at 20°C – i.e. optimal rearing conditions – feed acceptances were not at their physiological maximum for higher dietary FM contents and they could therefore still be further enhanced with PE supplementation. Thus, fish fed the

FM40 diet showed growth rates 10.5% higher with PE supplementation (p-v<0.001). Modeled growth curves, illustrated in Figure 5, show that, under challenging environmental conditions, there is no more a growth plateau observed at higher dietary FM contents and that 2% PE supplementation will result in approximately 0.15%/d more growth at equivalent dietary FM contents (as calculated by the difference between two growth curves constants).

This feeding trial, combined with other unpublished results (available upon request), confirms that dietary PE, especially when formulated with marine protein hydrolysate and specific palatable ingredients, can play a significant role in mitigating environmental, or husbandry, stress perception by fish and reduce their adverse effects on zootechnical performance.

Conclusions

Marine carnivorous fish are generally the most profitable aquaculture segments, but they are also the causes of greater challenges for feed formulators, such as higher macro/micronutrient requirements, FM replacement need for a lower environmental footprint, possible palatability issues resulting from plant protein uses – or novel proteins – and marine fish susceptibility to environmental, or husbandry, stressors increasing disease outbreak risks.

Symrise Aqua Feed results demonstrate its liquid palatability enhancer, when used at low dosages (1 to 2% depending on pellet size), can be a cost-effective solution. Thus, dietary supplementation with Extrapal, a PE specifically designed for marine carnivorous fish species, resulted in long-lasting enhanced growth and feed performance. The differential gains were even higher, proportionally, under challenging conditions, either dietary or environmentally speaking.

References available on request.

More information:

Mikaël Herault

R&D Performance

Measurement Manager

Symrise Aqua Feed

E: mikael.herault@symrise.com

A unique ingredient for immune support in shrimp

Sarah Cooper, Pancosma, ADM Animal Nutrition François Jégou, Delphine Weissman, Yoav Rosen, ADM Animal NutritionPichia guilliermondii, a novel yeast

Different types of yeast and their extracts are used as alternative feed ingredients in aquaculture because of their nutritional value and/or bioactive compounds. Pichia guilliermondii is a novel yeast with unique morphology, structure and consequent activity that has recently shown potential in shrimp. The differences in the morphology and physical characteristics of P. guilliermondii and Saccharomyces cerevisiae, the most commonly used yeast in animal feed applications, have been assessed in a side-by-side study (Peisker et al., 2017). There are significant differences between them: P. guilliermondii yeast cell is smaller, and as a result, has a greater surface area to volume or weight ratio. It is also significantly more hydrophobic compared to S. cerevisiae. Additionally, the distribution of glycoproteins in the yeast cell wall varies, suggesting

that P. guilliermondii has a different cell wall structure and composition to S. cerevisiae. These particularities may be associated with significant differences in how the two yeast cells behave when used in aquaculture feeds for functional benefits.

Pichia guilliermondii supports immune physiology and promotes improved performance in shrimp

The association between the use of P. guilliermondii in the diet of shrimp and beneficial impacts on parameters related to shrimp immune physiology and performance has been explored in a number of studies.

A primed immune system

A study performed in a research facility in Thailand evaluated critical immune parameters in shrimp before and after an experimental challenge with

Vibrio harveyi, comparing shrimp supplemented with P. guilliermondii to those without supplementation. At the end of the 28-day feeding period, shrimp from both the supplemented and control groups were sampled to measure the concentration of total and granular hemocytes. Following this, shrimp from each group were infected with V. harveyi by intramuscular injection and then three hours later the number of V. harveyi cells remaining in the hemolymph of each group was measured to assess the efficacy of bacterial clearance.

Whereas the level of total hemocytes remained unchanged between the two groups, the granular hemocyte count was significantly increased in the hemolymph of shrimp fed P. guilliermondii (P<0.05; Fig. 1). Hemocytes are invertebrate blood (hemolymph) cells that are involved in critical shrimp immune defense processes such as coagulation and phagocytosis of invading microorganisms. Although total hemocyte count is used as an indicator of overall shrimp health status, granular hemocytes contain the primary humoral defense factors that are released during a pathogen invasion. An elevated proportion of granular hemocytes amongst total hemocytes may therefore indicate primed immune capabilities, and consequently a more effective response to pathogen challenges.

The P. guilliermondii-fed shrimp, having a greater proportion of these granular hemocytes, were then found to have a significantly lower number of V. harveyi cells remaining in their hemolymph when measured three hours following the challenge (P<0.05; Fig. 2).

Improved survival under infectious challenge

Two further studies were conducted to examine the potential impact of P. guilliermondii supplementation on shrimp performance during infectious challenges with two highly significant global pathogens: White Spot Syndrome Virus (WSSV) and Vibrio parahaemolyticus, etiological agent of Acute Hepatopancreatic Necrosis Disease (AHPND). Both studies took place in a wet laboratory in Peru and were similar in design, having three study groups within each study: the unchallenged control group was fed the basal diet; the two other groups were both challenged and fed on the basal diet, but only one of these groups received P. guilliermondii supplementation at 0.1% in the diet. In both studies,

the groups supplemented with P. guilliermondii had significantly improved survival compared to the challenged control groups: 84% greater survival in the WSSV challenge (P<0.05; Fig. 3), and 76% greater survival in the V. parahaemolyticus challenge (P<0.05; Fig. 4).

Better growth