Volume 51 Number 2 April - May 2025

EDITOR’S COMMENTS

Health, Safety and Quality: Factors for Successful Trade

6

GREENHOUSES AND POND LINERS

Polyculture of Genetically Improved Farmed Tilapia and Penaeus vannamei Using Biofloc Technology: A Review

12

22

ARTICLE

Sex Reversal in Tilapia: A Game Changer in Aquaculture

ARTICLE

Tilapia Lake Virus (TiLV): Understanding its Epidemiology, Clinical Signs, Diagnosis, and Prevention

26

ARTICLE

Chicken By-Product Meal as a Replacement to Fish Meal in Juvenile Abalone (Haliotis discus hannai Ino 1952) Feed

Serving the aquaculture industry for 51 years

Editor and Publisher

Salvador Meza / info@dpinternationalinc.com

Contributing Editor

Marco Linné Unzueta

Editorial Coordinator

Karelys Osta / edicion@dpinternationalinc.com

Editorial Design

Perla Neri / design@design-publications.com

Sales & Marketing Coordinator crm@dpinternationalinc.com

Sales Support Expert sse@dpinternationalinc.com

Operations Coordination

Johana Freire / opm@dpinternationalinc.com

Business Operations Manager

Adriana Zayas / administracion@design-publications.com

Subscriptions:iwantasubscription@dpinternationalinc.com

Design Publications International Inc. 401 E Sonterra Blvd. Sté. 375 San Antonio, TX. 78258

info@dpintertnatinonalinc.com

Office: +210 5043642

Office in Mexico: (+ 52) (33) 8000 0578 - Ext: 8578

Aquaculture Magazine (ISSN 0199-1388) is published bimontly, by Design Publications International Inc. All rights reserved. www.aquaculturemag.com

* Marco Linné Unzueta Associate Editor

The aquaculture sector encompasses the set of activities that originate in the use of aquatic flora and fauna resources, especially the cultivation of these resources, their processing and marketing. It is part of the economic activity of a population and is therefore of vital importance in the generation of food of high nutritional value, employment and economic income, as well as a source of inputs for the food industry and foreign exchange for a country.

Considering the opening of trade in food products at the international level and the signing of agreements in this area, the health authorities of the countries have made it a priority to establish policies to ensure the health and safety of food and its access to national and international markets, without neglecting the processes of traceability to the final consumer.

Globally, two factors have had a direct impact on the relevance and use of the concept of “animal health”: a) the risk to public health generated by consuming spoiled products, and b) the premise of being responsible for environmental contamination.

As a result of the above, health and safety have become important assets for countries to participate in agrifood trade, so they are stricter in controlling pests and diseases, in accordance with policies aimed at preserving wildlife and animal health and guaranteeing the quality and safety of food for the population. For this reason, countries exporting products must invest in increasingly rigorous control in the area of health, quality and food safety, which becomes the cornerstone for international trade to take place.

Considering the above, aquaculture is one of the fastest-growing international food production systems in recent decades, which, as a result of rapid diversification, intensification and technification, contributes to food production, foreign exchange generation and food security; however, its products must be regulated by international health and safety agencies.

At the global level, in order to address the aforementioned considerations, there must be the capacity to access any information related to production and processing systems

through registered identifications that arise in the chain, where health and safety are included as part of its food safety policy, both because of the global trend and to ensure and increase the internal marketing and export of its products.

In view of the above, and the fact that aquaculture health and safety are a priority as strategies to ensure and increase the availability of food products, both for domestic marketing and export, it is considered necessary for producers to interact with research institutions dedicated to generating relevant information on these issues. By being updated, they will be able to face the new market scenarios.

And in accordance with the above, FAO’s vision for a blue transformation (FAO, 2022) should be considered, where “The objective is to achieve further intensification and expansion of aquaculture in a sustainable manner so that global demand for aquatic food is met and benefits are equitably distributed, with attention to social responsibility, pollution and other considerations”.

Aquaculture is a rapidly growing sector, contributing to global food security and livelihoods. India ranks second in aquaculture production with shrimp and fish farming playing vital role. However, challenges like protein loss, water pollution, and reliance on fishmeal demand sustainable solutions. Biofloc technology and polyculture offer eco-friendly alternatives. Penaeus vannamei shrimp, known for high feed efficiency and disease resistance, thrive in polyculture with polyculture of Genetically Improved Farmed Tilapia (GIFT), a resilient omnivorous species. Their complementary feeding habits enhance resource utilization, improve water quality, and boost sustainability. Polyculture optimizes production by recycling nutrients, reducing costs, and creating a balanced ecosystem for aquaculture growth.

Scenario

Aquaculture is a rapidly growing sector that plays a crucial role in global food security. Despite advancements, hunger affects 811 million people, and 3 billion cannot afford a healthy diet. Aquaculture provides essential food and livelihoods to 820 million people worldwide. India ranks third in global fish production, contributing 8% of total production and second in aquaculture output. In 2020, global aquaculture production reached 122.6 million tons, including fish, mollusks, and crustaceans. The consumption of aquatic foods has grown at an annual rate of 3% since 1961 to 2019, double the global population growth rate (1.6%) for the same period. Per capita consumption of aquatic animal foods grew by about 1.4% year, from 9.0 kg in 1961 to 20.2 kg in 2020.

Aquaculture is the culture of aquatic organisms. People have been involved in different forms of aquaculture for thousands of years. Today, the practice of aquaculture spans the globe. Many of the basic goals have not changed significantly in aqua-

Aquaculture is expanding rapidly to meet the increasing global demand for fish while preserving natural stocks. However, challenges like disease outbreaks and environmental impact threaten sustainability. A promising solution is the polyculture of Genetically Improved Farmed Tilapia (GIFT) and Penaeus vannamei using Biofloc Technology. This method enhances water quality, optimizes resource utilization, and reduces pathogen pressure, creating a more sustainable and resilient aquaculture system; making aquaculture a viable solution for global food security.

culture: maximizing growth rate and minimizing production cost. A rapid growth rate minimizes the time to achieve a marketable size and decreases risk. Aquaculture faces challenges such as nutrient loss, water pollution, and dependency on fish meal and oil. Only 24%-37% of nitrogen and 13%-28% of phosphorus in aquaculture feed are converted into

biomass, while the rest is released as waste, affecting water quality and causing diseases. Frequent water exchange is required to maintain quality but contributes to environmental pollution. Additionally, the increasing demand for alternative protein and oil sources poses economic and environmental challenges.

Biofloc technology and polyculture offer eco-friendly alternatives. Penaeus vannamei shrimp, known for high feed efficiency and disease resistance, thrive in polyculture with Genetically Improved Farmed Tilapia, a resilient omnivorous species.

To mitigate these issues, technologies such as biofloc, polyculture, raceway systems and lined pond culture system have been developed.

Biofloc technology is a sustainable aquaculture method based on dense microbial communities that reduce toxic metabolites and convert waste into microbial biomass, which serves as food. This technology improves water quality, prevents diseases, and reduces feed costs. It is implemented by adjusting the carbon/nitrogen ratio and maintaining constant aeration. Proper biofloc management

prevents the accumulation of organic matter and maintains a balance between beneficial microorganisms. BFT has been successfully applied to species like tilapia and shrimp, enhancing feed conversion and reducing ammonia and nitrite toxicity.

Polyculture is a traditional fish farming practice; where compatible species with different feeding habits were stocked in a single-pond for grow out practice to effectively increase production. Polyculture involves the simultaneous farming of compatible species with different feeding habits to optimize resource utilization and improve water qual-

ity. In monoculture, excess nutrients accumulate, degrading water quality, whereas polyculture allows one species to consume the waste of another. The combination of tilapia and P. vannamei shrimp is particularly efficient: shrimp feed on detritus and organic waste, while tilapia filter phytoplankton, reducing the risk of nighttime hypoxia. Additionally, shrimp bioturbation recycles nutrients and promotes phytoplankton production. Some authors affirmed that shrimp culture has severely affected the ecosystem and concluded that integrated aquaculture practices, such as polyculture, are good alternatives for reducing contamination (Table 1).

The aquaculture term “raceway” is a highly generic name and implies little more than a water impoundment with water flowing through it. Raceways are continuous-flow water channels designed for intensive aquatic organism production. The water flow removes solids and dissolved waste, reducing effluent discharge. This technology improves water quality and minimizes environmental pollution, making it a viable solution for intensive aquaculture. Raceway could potentially address the major challenges associated with the aquaculture effluent production.

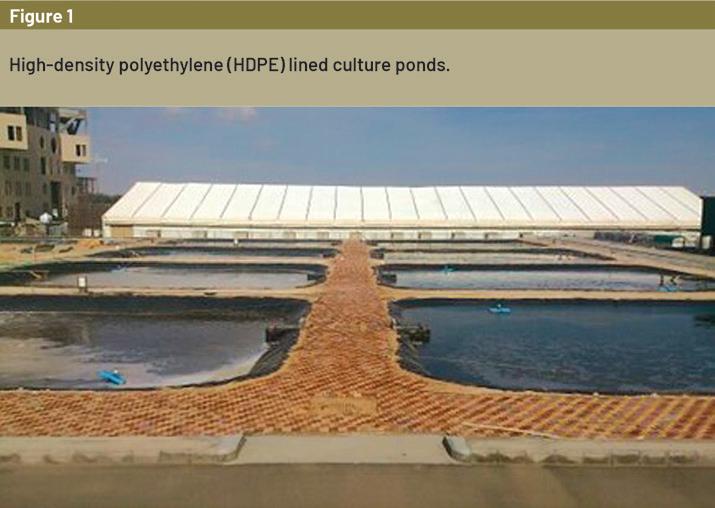

Earthen ponds are conventionally used for fish farming with some boundaries like continuous water seepage; complications with soilwater chemistry haven’t been understood with difficulties in determining the causes of physio chemical parameters related problems and organic load accretion. Hence, lining the ponds with High Density Polyethyl-

ene (HDPE) sheets has many advantages like reducing seepage, reducing pumping cost, complications due to soil-water interactions can be prevented and for undertaking advanced farming practices are more appropriate. The initial investment will be largely compensated by the huge advantages in terms of net profit. Lining materials should be long lasting and cost effective.

Biofloc systems enhance water quality by minimizing ammonia and nitrites, stabilizing pH, and reducing water exchange requirements. The adjusted carbon/nitrogen ratio in biofloc facilitates ammonia assimilation by heterotrophic bacteria. Research has shown that BFT improves feed efficiency and water quality in species like tilapia, shrimp, and carp. Additionally, this technology reduces operational costs and environmental impact. BFT is one of such novel microbial biotechnologies that have been developed with an excellent

Biofloc technology has been successfully applied to species like tilapia and shrimp, enhancing feed conversion and reducing ammonia and nitrite toxicity.

ecofriendly technology not only for higher productivity but also for sustainable development (Table 1).

Penaeus vannamei is the most farmed shrimp species globally due to its adaptability and rapid growth. Its production reached 5.8 million tons in 2020, generating over USD 33 billion annually. It is widely cultivated in Latin America, China, India, and Southeast Asia.

GIF Tilapia is a selectively bred strain of Oreochromis niloticus developed by the World Fish Centre. This lineage has demonstrated an 85% improvement in growth rate after multiple generations of selection. In many countries, tilapia is co-farmed with shrimp in polyculture systems to enhance water quality and increase productivity.

The use of biofloc and polyculture improves water quality by reducing or-

ganic waste and dissolved nutrients. Key parameters such as dissolved oxygen, pH, and alkalinity stabilize in these systems, reducing the need for water exchange. Additionally, microbial activity in biofloc degrades waste and enhances feed efficiency in fish and shrimp.

Biofloc systems stimulate digestive enzyme activity in farmers species, improving feed conversion and growth. Studies have shown that incorporating biofloc into diets enhances protease and amylase activ-

ity in tilapia and shrimp, optimizing digestibility and reducing reliance on fish meal,

Consuming biofloc improves the immune response of shrimp and fish, increasing resistance to diseases. The bacterial diversity in these systems promotes the competitive exclusion of pathogens, creating a healthier pond environment. Studies have found that species such as Bacillus and Lactobacillus in biofloc contribute to protection against bacterial infections in aquaculture,

The combination of biofloc and polyculture represents a sustainable and profitable strategy for aquaculture. These technologies optimize resource use, reduce pollution, and improve feed efficiency. Their adoption can transform the aquaculture industry into a more environmentally friendly and economically viable model.

This informative version of the original article is sponsored by: REEF INDUSTRIES INC.

This is a summarized version developed by the editorial team of Aquaculture Magazine based on the review article titled “POLYCULTURE OF GENETICALLY IMPROVED FARMED TILAPIA (GIFTILAPIA)ANDPENAEUSVANNAMEIUSING BIOFLOCTECHNOLOGY–AREVIEW)”developedby:JOSHNA,M.,AHILAN,B.,CHERYLA., RAVANESWARAN, K., CHIDAMBARAM, P., UMA, A., and RUBY, P. TamilNaduDr.J.Jayalalithaa FisheriesUniversity. The original article, including tables and figures, was published on JULY, 2024, through INTERNATIONAL JOURNAL OF BIORESOURCE AND STRESS MANAGEMENT. The full version can be accessed online through this link: DOI: https://doi.org/10.23910/1.2024.5396

Organizadores:

Organizadores Locales:

* By Nayan Chouhan, Bhavesh Choudhary, Kunal Samadhan Tayde, Suvankar Rout and Rajalaxmi Dalabehera

Introduction

The common name “tilapia” refers to cichlid species that are farmed all over the world and whose yearly production has been steadily increasing. According to the FAO (2022), Nile tilapia is presently the third most widely cultivated finfish species globally. The main characteristics that this fish apart as an exceptional aquaculture species are its omnivorous feeding habit, quick growth, tolerance to a wide range of salinity, dissolved oxygen and temperatures, as well as its ease of reproduction (El-Sayed, 2019). Tilapia also accepts inert feed immediately after yolk sac absorption. The idea of sex reversal in fish species such as tilapia has become a major change in the complex field of aquaculture, revolutionizing breeding procedures and greatly increasing production. In addition to piquing experts’ interest, this phenomenon in which fish is switch from being female to male has created new opportunities for increasing the fish production.

Male tilapia develops larger and faster than female tilapia in the population. Therefore, manual sexualization, direct hormonal sex reversal hybridization, or genetic modification is the methods used to grow tilapia for monosex. Technically, it is also possible to produce only male hybrids; however, facilities for isolation are necessary to preserve the integrity of both parental lines, and partially incompatibility between two different species often results in lower seed yield. In grow-out ponds on commercial fish farms, female tilapia is typically kept out of them to avoid overcrowding and stunting from unintended reproduction. Females can be physically removed by visually inspecting the juvenile fish’s urogenital papilla, although this method requires a lot of work. A more modern method of creating male fingerlings is called “sex reversal” or “sex inversion.” This can be accomplished by providing tilapia fry with diet that has been treated with

a male hormone prior to the females’ primordial gonadal cells differentiating into ovarian tissue. Once the testes have grown enough to maintain normal levels of endogenous hormone, the dietary hormones can be stopped.

Sex reversal has enormous potential to improve aquaculture methods, especially for tilapia production. Farmers are able to optimize production efficiency by controlling the sex ratio of their fish populations through the manipulation of environmental factors throughout critical phases of initial development. With this strategy, it is possible to produce all-male populations, which develop larger and faster than mixed-sex populations since they require less energy to reproduce. It seems that the YY male technology holds great promise for increasing tilapia yields and returns and embraces great potential for economic viability. Most likely,

The common name “tilapia” refers to cichlid species that are farmed all over the world and whose yearly production has been steadily increasing. The idea of sex reversal in fish species such as tilapia has become a major change in the complex field of aquaculture, revolutionizing breeding procedures and greatly increasing production. In addition to piquing experts’ interest, this phenomenon in which fish is switch from being female to male has created new opportunities for increasing the fish production.

the largest potential for this technology’s widespread use is in stock enhancement.

During the induction process, an optimal dose of sex steroid is administered during a specific period to reverse the physical characteristics of a genetic female, transforming them into a male. However, the genetic male remains unchanged. Currently, there are established protocols for hormonal sex reversal in numerous species utilizing steroids (Pandian and Sheela, 1995). Understanding the genetic approach to sex manipulation for the production of all male, all female, or all sterile populations involves inducing ploidy (Lakra and Ayyappan, 2003). Two processes determine how sex is expressed: (a) sex determination, which is typically set at fertilization time by combining sexdetermining genes from the paternal and maternal chromosomes in the developing zygote; and (b) sex differentiation, which is the later development of the undifferentiated primordium into male or female gonads.

Tilapia, a commonly farmed fish species, demonstrates notable adaptability in their sexual maturation. Tilapia, unlike mammals, can change their sex in response to environmental and social cues rather than being genetically determined. The occurrence of sex reversal, also referred to as hermaphroditism, is most com-

monly observed in species such as Nile tilapia (Oreochromis niloticus) and Mozambique tilapia (O. mossambicus). This reversal is performed by adding steroids to the diet for a short length of time during the hormonal gender reversal phase. The method for generating fry for eventual sex reversal is founded on the following primary factors:

» Tilapia sex reversal must begin before the gonadal tissue of young genetic females has developed into ovaries.

» Fry production must be synchronized with the sex reversal surgery since the hormone treatment should be commenced immediately after fry harvest and the facilities will not be accessible to receive the subsequent batch of fry for another 25 to 30 days.

» It is often preferable to sex reverse uncommon batches of large numbers of fry rather than more frequent batches of fewer fry for efficient farm management.

» Based on the foregoing parameters, the suggested technique for fry production in ponds involves a 25-to-30-day cycle (including a 2–10-day turnaround time) with a single, full harvest of fry not exceeding 14 mm total length.

In

grow-out ponds on commercial fish farms,

female tilapia is typically kept out of them to avoid overcrowding and stunting from unintended reproduction.

Several approaches have been discovered to induce sex reversal in tilapia. Hormonal manipulation stands out as the most extensively employed approach. By injecting synthetic hormones such as 17α-methyltestosterone at early developmental stages, female tilapia can be efficiently turned into males. This technique ensures a high degree of dependability and precision in sex control, permitting the generation of monosex populations with desirable features. Immersion treatment of androgen can also induce the reversal of sex in O. niloticus (Wassermann and Afonso, 2003). Non-steroidal compounds, such as aromatase inhibitors, have potential for production of monosex population in tilapia (Afonso et al., 2001).

A more modern method of creating male fingerlings is called “sex reversal” or “sex inversion.” This can be accomplished by providing tilapia fry with diet that has been treated with a male hormone prior to the females’ primordial gonadal cells differentiating into ovarian tissue.

Environmental Triggers also plays crucial role because the type and timing of therapies that are able to elicit sexual reversal differ substantially between species. Various environmental factors play a significant role in inducing sex reversal in tilapia. Treatments impacting sex determination and differentiation in fish include temperature, pH, density, exogenous hormone treatment, social variables, or a combination of these. Moreover, the gonad undergoes differentiation towards the male or female state within a certain time period known as the labile period (also known as the sensitive window or period) (Baroiller et al., 2009).

After the gonads have developed and sex has stabilized, temperature, hormones, and other treatments frequently lose their effectiveness (Ospina-Alvarez & Piferrer, 2008).

Temperature, for instance, is a crucial influence, with specific thresholds producing sex difference. Short exposure to higher temperatures was sufficient to significantly skew the sex ratio toward males in O. niloticus (Nivelle et al., 2019). Additionally, social factors such as population density and social hierarchy can influence sex reversal, illustrating the complicated interplay between heredity and environmental cues. Environmental sex reversal (ESR), results in a mis-

match between genotypic and phenotypic sex, is well reported in various fish species and may be produced by chemical exposure. Historically, research with piscine ESR has been done out with a view to improve profitability in aquaculture or to understand the processes underlying sex determination and sexual differentiation.

Although sex reversal procedures have some encouraging effects, there are drawbacks and moral dilemmas with them as well. Hormonal treatments, for instance, raise concerns over their potential environmental

impact and long-term implications on fish health. Furthermore, maintaining the ideal environment for sex reversal necessitates close attention to temperature, hormone dosages, and water quality, all of which need appropriate resources and experienced staff. Despite effective use in various aquaculture species, sex reversal of fish by hormone injection modification should be conducted with caution to prevent any unwanted effects in the fish produced, to the farmers themselves and consumers, or to the environment. For example, hormone excesses or extended duration of therapy may create malformations, or even tilt sex ratios toward the non-target sex (Beardmore et al., 2001).

Conclusion

Sex reversal in tilapia represents a fascinating phenomenon that has

transformed aquaculture methods globally. By leveraging the plasticity of tilapia’s sexual maturation, farmers may optimize production efficiency, enhance profitability, and contribute to global food security. However, the correct implementation of sex reversal technology demands careful consideration of environmental, ethical, and welfare problems. Sex-reversed tilapia exhibited superior growth rates compared to normal individuals due to the injection of androgens, which have both an androgenic and anabolic impact. As scientists continue to uncover the secrets of sex determination in tilapia, the future holds enormous promise for sustainable and resilient aquaculture systems. Continued study into the mechanisms behind sex reversal in tilapia is vital for refining existing procedures. Advances in genetics and technologies show promise for

Treatments impacting sex determination and differentiation in fish include temperature, pH, density, exogenous hormone treatment, social variables, or a combination of these.

finding genetic markers related with sex determination, enabling noninvasive alternatives to hormone manipulation. Moreover, interdisciplinary collaborations including biologists, geneticists, and aquaculture professionals can promote innovation and handle growing issues in tilapia production.

and sources

1Department of Aquatic Health & Environment, College of Fisheries, Central Agricultural University (Imphal), Lembucherra, Agartala

2Department of Aquaculture, College of Fisheries, Central Agricultural University (Imphal), Lembucherra, Agartala

Tripura, India. Email: nayan101chouhan@gmail.com

* By Aquaculture Magazine Editorial Team

The aquaculture sector is rapidly expanding, playing a key role in food security by providing quality animal protein. This industry has shifted from semi-intensive to intensive farming to increase production. Among the fastest-growing agri-food sectors, the shrimp industry has seen remarkable growth due to rising global trade. Farmers are adopting intensive systems with better biosecurity to mitigate pathogen risks. Key fac-

tors enhancing intensification include advanced nutrition and breeding programs, crucial for sustainable expansion. Balancing biological and economic aspects is essential due to the sector´s sensitivity to multiple inputs. Super-intensive systems require improved nutritional strategies and robust breeding lines tailored to demanding environments (Emerenciano et al., 2022).

Shrimp farming is a preferred practice due to its rapid growth,

short culture period, and high consumer demand. Market factors such as aquafeed costs and market access influence global shrimp production, with an expected compound annual growth (CAGR) of 4.8% in 2024, down from 5.8% (2011-2021) (Jory, 2023) (Figures 1 and 2). Fish meal and fish oil scarcity limit industry growth, as farmed crustaceans consume 30% of global fishmeal (Johannessen, 2023). The Peruvian anchovy shortage reduced global fishmeal and fish oil

As the world seeks sustainable protein sources, shrimp aquaculture is surging ahead becoming a cornerstone of global food security. Driven by innovation, the sector has evolved from traditional methods to intensive, high-tech systems that balance biology, economics, and environmental care. With rising demand, shifting market dynamics, and urgent sustainability challenges, the shrimp industry stands at a transformative crossroads, one where science, strategy, and adaptability will define its future.

supply by 10% and 30% respectively, increasing prices (White, 2023; LeBlanc, 2023; Miranda, 2023).

Sustainability challenges include environmental concerns, lack of certification, and market fluctuations. Developed nations now monitor shrimp imports for transparency. Certified, traceable shrimp from regulated farms can stabilize prices and ensure sustainable production (Asian Development Bank 2022; Villarreal, 2023).

Region-Specific Shrimp Production and Trading Activity

Global shrimp production is projected to grow by 4.8% in 2024, reaching 5.88 million metric tons (MMTs). The top five shrimp-producing countries: Ecuador, China, India, Vietnam, and Indonesia, account for 74% of global production (Jory, 2023). Increased shrimp consumption in the United States (U.S.) has driven exports up by 123%, from USD 225.21 million (2013-2014) to USD 501.57 million (2022-2023) (CAA, 2023).

Pacific white shrimp dominates the market, comprising 80% of global production due to its superior yield, shorter culture period, and disease resistance (Aquaculture Asia Pacific 2024). Black tiger shrimp production, however, is also, adding 550,000 tons in 2023 and projected to exceed 600,000 tons in 2024 (Jory, 2023). The industry faces global price declines, with Ecuador´s shrimp sector expected to decelerate to 7% growth in 2024, largely due to El Niño risks (Krishna-

kumar, 2023). Meanwhile, Asia is rebounding after a 2023 production decline, with projected growth of 4% in 2024. India´s shrimp production is set to grow 2%, while Vietnam is expected to recover with a 6% increase (Gairn, 2023).

The U.S. is investigating Ecuador, India, Indonesia, and Vietnam for anti-dumping and countervailing duties, potentially shifting imports to Thailand. China and Japan may absorb redirected exports (Arunmas, 2023).

Shrimp production in Asia fell by 3% in 2023 but is expected to grow by 4% in 2024. China´s shrimp industry benefits from greenhouse and recirculatory aquaculture systems. In India, Pacific white shrimp production declined 12% in 2023, though a 2% rebound is expected in 2024. Vietnam saw a 15% drop in 2023 but is projected to recover with 5% growth. Indonesia anticipates a 3.5% increase in 2024 after a 5% decline in 2023 (Jory, 2023).

India´s shrimp production grew 267%, from 0.322 MMTs (2023-2014) to 1.184 MMTs (2022-2023). The industry´s export value doubled from USD 348.84 to USD 697.67 million. In India, the market, valued at USD 7.3 billion in 2022, is projected to reach USD 14 billion by 2028 (IMARC, 2023). Pacific white shrimp dominates (60%) and slightly increased by 4%, followed by black tiger shrimp (30%) and others (10%) (Krishnakumar, 2023).

Vietnam is a major shrimp exporter, with 40% of seafood export earnings from shrimp. However, exports declined in 2023, with major reductions to the U.S. (-41%), Europe (-40%), and China (-70%). The total farming area is expected to reach 750,000 ha by 2025, with an export target of USD 10 billion (Giang, 2023).

China´s shrimp production grew 120% over 20 years, with a projected CAGR of 1.5-4.3% (2023-2028) (Mordointelligence, 2023). The country is expanding recirculatory aquaculture systems (RAS), biofloc technology, and greenhouse farming (Shriminsights, 2023).

Latin America is the second-largest shrimp-production region. Ecuador leads production, growing 4% in 2023 to 1.49 MMTs. However, falling global prices and reduced Chinese demand have impacted revenue, causing a USD 1 billion loss in 2023 (Molinari, 2023).

Europe ranks third in shrimp imports, led by France, Spain, the United Kingdom., Italy, the Netherlands, German and Belgium. The market is projected to grow at an 8.1% CAGR (2023-2033) (Futuremarketinsights, 2023).

Shrimp aquaculture presents both risks and opportunities. Technological advancements have improved productivity and reduced costs though market forces remain unpredictable. Aquafeed plays a crucial role in sustainability, but challenges include fluctuating ingredient quality and mycotoxin contamination. Shrimp farmers must meet strict market requirements, particularly in high-end consumer segments (Aquaculture Asia Pacific, 2023).

Intensive shrimp farming increasingly relies on recycling waste,

with successful applications in Hawaii, Florida, and Texas. Yields range from 5 to 10kg/m3 within three months. Maintaining microorganism levels and water quality is vital for indoor-intensive aquaculture (Min et al., 2009).

Shrimp aquaculture has evolved through three main phases: (1) post2011 (early mortality syndrome), (2) 2001-2011 (vertical integration and monoculture), and (3) 1988-2001 (infection spread) (Dubik, 2019). Recent advancements in technology allow for precise monitoring of feeding procedures, water quality, and production efficiency (Bostock, 2009; Parra et al., 2018).. High-tech farming reduces the need for chemicals and antibiotics, ensuring healthier shrimp. Canvas farming can increase productivity by two to three times, with a 90% success rate (Ulhaq et al., 2022).

Super-intensive shrimp farms now adopt four key strategies: (1) biofloc aquaculture systems, (2) RAS, (3) hybrid Bio-RAS, and (4) mixed trophic systems (Joffre et al., 2018; Arnold et al., 2020). The transition to Pacific white shrimp farming has been rapid, replacing black tiger shrimp due to superior breeding and disease resistance (Dastidar et al., 2013). Innovations like aerators, pond lin-

Global shrimp production is projected to grow by 4.8% in 2024, reaching 5.88 million metric tons (MMTs). The top five shrimpproducing countries: Ecuador, China, India, Vietnam, and Indonesia, account for 74% of global production.

ers, and biosecurity measures have further enhanced production efficiency (Lightner, 2005; Stentiford et al., 2012). Sustainable intensification remains key to the industry´s future growth.

Effective marketing strategies are essential for increasing global shrimp consumption. Price stability and trust in the value chain create a positive cycle, leading to higher investment and better product quality, ultimately boosting demands. Expanding demand can help mitigate price fluctua-

tions, which are primarily driven by supply growth and reduced consumption. Promotional efforts play a crucial role, especially as dietary habits evolve. However, globalization and rising food costs may temporarily hinder shrimp consumption in Europe and the U.S. Shrimp-producing countries should prioritize market saturation across all segments, including small and new consumers, rather than relying solely on expansion frequency (Responsible Seafood Advocate, 2023).

While shrimp demand in Europe and the U.S. is relatively low, China´s market remains strong, driven by advancements in hatcheries, nutrition, farms, and processing facilities. The

main factors fueling shrimp farming growth are genetic improvements and production efficiency. A coordinated marketing plan is needed, similar to pre-competitive efforts seen in beef, pork, and dairy industries, to expand the sector and stimulate demand (Wright, 2019).

India is well-positioned in the global shrimp market, with strong international demand and growth potential. However, four key challenges threaten profitability: low shrimp survival rates, increasing disease risks, limited processing capacity for valueadded products, strict traceability regulations, and environmental stress. To sustain growth, India´s shrimp sector must urgently improve feed efficiency, wastewater management, and renewable energy use. Environmental sustainability and transparency will be critical for maintaining exports, particularly to the U.S. (Rubel et al., 2020).

Ecolabelling, Traceability, Certification, and Information and Communication Technologies (ICT) in the Shrimp Industry

Seafood consumers in developed countries are increasingly aware of the social and environmental impacts of production, prompting governments to enforce regulations for sustainable and ethical sourcing. The U.S. and Europe now product traceability

to distinguish between aquaculture and wild-caught fisheries (FAO, 2007). Various ecolabels have emerged to inform consumers about production practices and environmental responsibility. The Marine Stewardship Council (MSC) pioneered fisheries management ecolabelling, while aquaculture producers have adapted to market trends due to concerns over aquaculture´s environmental impact (Islam & Bjarnason, 2008).

Leading shrimp-exporting nations, including Ecuador, Brazil, China, Thailand, Vietnam, and India, have implemented certification programs to ensure compliance with ecological and food safety standards. Examples include Brazil´s Integrated Program of Farmed Shrimp Certification (PICC), Thailand´s “Thai Quality Shrimp,” China´s Good Aquaculture Practice (GAP), and Vietnam´s Global Aquaculture Alliance (GAA) certification (FAO, 2007). Major retailers worldwide, such as Wal-Mart, Tesco, and Carrefour, support certified shrimp, aligning with global sustainability benchmarks like the Global Sustainable Seafood Initiative (GSSI) (CBI-Ministry of Foreign Affairs, 2021).

Shrimp sustainability is under scrutiny due to disease outbreaks, water contamination, and inefficient resource use. Certifications such as Best Aquaculture Practices (BAP), Global GAP, and Aquaculture Stewardship Council (ASC) are increasingly demanded by international buyers (Tran et al., 2013). Given the fragmented nature of Asian shrimp aquaculture, supply chain traceability is critical. ICT solutions now enable precise stock management, automated feeding, and real-time water monitoring, im-

Shrimp sustainability is under scrutiny due to disease outbreaks, water contamination, and inefficient resource use. Certifications such as Best Aquaculture Practices (BAP), Global G.A.P., and Aquaculture Stewardship Council (ASC) are increasingly demanded by international buyers.

proving efficiency and sustainability (Bostock, 2009; Gómez-Chabla et al., 2018). These innovations strengthen product traceability, linking final products to specific batches and feed sources for greater transparency.

The shrimp industry faces significant challenges, including environmental concerns such as sludge accumulation, chemical residues, and wastewater management. Additionally, the lack of dedicated aquaculture infrastructure forces farmers to modify agricultural systems, affecting raw material costs and global competitiveness. Disease risks, high production costs, and water quality issues further impact profitability. Shrimp consumption and processing have declines due to trade barriers and reduced restaurant demand. Some producers are lowering stock densities to cut costs while focusing on high-quality feed and efficient nutrition management to improve profitability and sustainability.

To ensure long-term viability, shrimp farming must minimize water, energy, and chemical use, enhance traceability, and embrace sustainable practices. Governments, cooperatives, and producers must collaborate to promote responsible aquaculture. Policymakers should lead in enforcing sustainability standards, food security, and social accountability regulations (Wong, 2023).

Competitive challenges, including supplier power, new market entrants, and environmental concerns, necessitate industry-wide strategic changes (Prusty et al., 2011). Key strategies include improving value-added processing, increasing export transparency, leveraging technology, and investing in R&D. India, a major shrimp producer, must address low survival rates (55%), limited traceability, and environmental impact. Strengthening processing capabilities and transitioning to fully traceable, sustainable farming methods will be crucial to maintaining international market access.

Innovative indoor systems, such as biofloc and recirculatory aquaculture, could revolutionize shrimp farming by reducing disease risks and environmental strain. Enclosed systems enable higher stocking densities and better resource efficiency, ensuring long-term sustainability and market competitiveness (Ruble et al., 2020).

The future of the shrimp industry is closely tied to innovations in feed, farming technology, and sustainability. Techniques like extrusion improve feed conversion ratios (FCR) and reduce pond waste. While Ecuador has adopted such innovations, countries like India lag behind due to high costs. Only 17% of Ecuadorian farms use automatic feeders and aeration, but their adoption is expected to increase exports. However, restrictions on fishmeal and fish oil —used heavily in shrimp farming— remain a major challenge (Johannessen, 2023). Alternative protein sources like insect meal, unicellular proteins, and plantbased feeds are gaining traction (van Riel et al., 2023).

To meet growing demand, the industry must adopt recirculatory aquaculture systems and genetic selection for high-growth shrimp strains that tolerate alternative feeds. Certified, traceable production will help stabilize prices and attract investment. Enhancing breeding programs through molecular-assisted selection and disease-resistant, SPF broodstock will be key to long-term sustainability.

India, the world´s second-largest shrimp producer, is poised for growth, especially after the Coastal Aquaculture Authority (Amendment) Bill 2023. Future development will rely on eco-friendly farming using technologies like biofloc, especially in inland saline areas (Haq, 2024).

However, limited value-added capacity restricts profitability. To stay competitive and tap into global markets. India must modernize processing, enforce strict quality standards, and focus on value-added exports (Stalin and Jothi, 2022).

Frozen shrimp dominates the global market driven by lifestyle changes and increased female workforce participation. India´s low labor costs and strong processing infrastructure position it well to maintain and expand its global leadership in shrimp exports.

Enhancing genetic diversity in farmed shrimp is key to improving resilience, growth, and overall performance. Innovations like nursery systems and water reuse can further optimize grow-out technologies. Intensifying operations near consumption centers and targeting younger consumers will support industry growth. Accreditation and certification are vital as global consumers increasingly demand responsible, sustainable, and protein-rich food options. To meet these expectations, shrimp farmers are adopting advanced, eco-friendly production methods.

While value-added shrimp products offer higher profitability, many producing countries lack adequate processing infrastructure. To remain competitive, the shrimp industry must pivot from bulk frozen exports to valued-added products. This requires adopting modern processing technologies and offering convenient, innovative options tailored to evolving market demands.

Ultimately, the long-term success of shrimp-producing nations lies in developing sustainable business models focused on value-added production. Shifting from short-term gains to long-term strategies will ensure continued growth and global market leadership in the shrimp industry.

This is a summarized version developed by the editorial team of Aquaculture Magazine based on the review article titled “GLOBAL SCENARIO OF SHRIMP INDUSTRY: PRESENT STATUS AND FUTURE PROSPECTS)” developed by: MANDAL, A. and SINGH, P., Guru Angad Dev Veterinary and Animal Sciences University, Ludhiana, Punjab, India. The original article, including tables and figures, was published on 2025, through SHRIMP CULTURE TECHNOLOGY. The

* By Natan Wajsbrot

Tilapia farming has long been fundamental to global aquaculture, providing millions with an affordable and sustainable protein source. However, the industry has faced a significant threat in recent years: Tilapia Lake Virus (TiLV).

First reported in 2014, TiLV has since spread to numerous countries, causing mass mortalities in tilapia populations and posing a considerable challenge to aquaculturists worldwide. This article explores the epidemiology, clinical signs, diagnosis, and prevention strategies concerning TiLV.

Introduction

Tilapia tilapinevirus, belonging to the family Amnoonviridae, genus Tilapinevirus (TiLV) was first officially identified and reported in 2014 at the Sea of Galilee, Israel. Investigations linked the sharp decline of wild-caught tila-

Tilapia Lake Virus (TiLV) is a serious viral fish disease that affects both farmed and wild tilapia and causes high mortality in infected fish. Its fast transmission is facilitated by various factors, including the movement of infected fish, contaminated water sources, and the global trade of tilapia fingerlings.

pia in the Sea of Galilee since 2009 to an increasing presence of TiLV in wild fish populations.

Since then, TiLV outbreaks (Figure 1) have been reported in at least 17 countries, including Ecuador, Colombia, Peru, Egypt, India, Thailand, Malaysia, and the United States.

TiLV is a serious viral fish disease that affects both farmed and wild tilapia and causes high mortality in infected fish.

Its fast transmission is facilitated by various factors, including the movement of infected fish, contaminated water sources, and the global trade of tilapia fingerlings. Its ability to infect multiple tilapia species further exacerbates the challenge of containment and eradication efforts.

TiLV is transmitted both horizontally (among individuals of the same generation) and vertically (from brood-

stock to offspring). Under experimental conditions, the virus was detected in feces and contaminated water after a successful intragastric infection, suggesting an oral-fecal route of transmission. The virus can thus spread horizontally among conspecifics inhabiting the same water body.

Vertical transmission of TiLV was detected in infected broodstock and their offspring (as early as 2-day-old larvae). This means that it is technically possible to test larvae for the presence of TiLV before shipping them to farms, representing a significant opportunity to create TiLV pathogen-free larvae – a major biosecurity step.

It is also suggested that mollusks, aquatic insects, and other invertebrates are potential carriers of TiLV, though more research is needed to confirm these transmission pathways. Overall, these multiple transmission pathways make the containment of

outbreaks particularly challenging. Despite TiLV being a recently identified virus, some direct effects have already been identified as significant risk factors for its propagation, namely the presence and proximity of infected, wild, or farmed populations, and water temperatures ranging from 25°C to 31°C.

Other risk factors include any change that might affect the immune status of the fish, making them more vulnerable to the virus, either by directly altering their immunological competence or disrupting their homeostasis. The latter ones, which force the fish to energetically rebalance its physiological conditions, are referred to as immunosuppression drivers and include sub-optimal environmental parameters, increased stocking densities, and the presence of secondary bacterial and/or parasitic infection.

Identifying TiLV-infected fish is crucial for implementing timely control measures and minimizing economic losses. Clinical signs of TiLV infection vary depending on the fish’s age, size, and immune status. Common symptoms include:

1. Exophthalmia (Pop-Eye) and Unilateral or Bilateral Opacity of the Lens (Cataract): Infected fish may exhibit protruding eyes due to ocular swelling, a characteristic sign of TiLV infection (Figure 2).

2. Pale Gills: Discoloration of gills, ranging from pale to reddish-brown, is often observed in affected fish.

3. Skin Lesions: TiLV-infected fish may develop skin lesions, ulcers, or hemorrhages, particularly around the mouth and fins (Figure 3).

4. Abnormal Behavior: Affected fish may display abnormal swimming patterns, lethargy, or disorientation.

5. Reduced Feed Intake: Infected fish often show a decline in appetite, leading to reduced feed consumption and poor growth performance.

Early detection of these clinical signs is crucial for implementing quarantine measures and preventing the spread of TiLV within aquaculture facilities.

Accurate diagnosis is essential for effectively managing TiLV outbreaks and preventing further dissemination. Various diagnostic methods are employed to confirm TiLV infection, including:

1. Molecular Techniques: Polymerase Chain Reaction (PCR) assays targeting specific regions of the TiLV genome are commonly used for rapid and sensitive de-

It is also suggested that mollusks, aquatic insects, and other invertebrates are potential carriers of TiLV, though more research is needed to confirm these transmission pathways. Overall, these multiple transmission pathways make the containment of outbreaks particularly challenging.

tection of the virus in fish tissues or water samples.

2. Virus Isolation: TiLV isolation can be performed using cell culture techniques, enabling the visualization and characterization of the virus under laboratory conditions.

3. Serological Tests: Enzymelinked immunosorbent Assay (ELISA) and Indirect Fluorescent Antibody Test (IFAT) are employed to detect TiLV-specific antibodies in tilapia serum, providing valuable information on the fish’s immune response to the virus.

4. Histopathology: The most common histopathological feature found in TiLV outbreaks is syncytial hepatitis of tilapia.

Combining these diagnostic methods enhances the accuracy and reliability of TiLV detection, enabling prompt intervention measures to limit its spread.

Prevention Strategies

Preventing the introduction and spread of TiLV in tilapia farms is paramount for ensuring the sustainability of the aquaculture industry. Key prevention strategies include:

1. Biosecurity Measures: Implementing strict biosecurity protocols, such as controlling the movement of fish, disinfecting equipment, and monitoring water sources, helps minimize the risk of TiLV introduction into aquaculture facilities.

2. Health Screening: Regular health monitoring and screening of tilapia populations enable early detection of TiLV and other pathogens, allowing for prompt intervention and containment.

3. Genetic Resistance: Breeding programs aimed at developing tilapia strains with increased re-

sistance to TiLV can reduce susceptibility to infection and mitigate the impact of outbreaks.

4. Education and Training: Educating aquaculturists about the risks associated with TiLV and providing training on disease management practices promote proactive measures and rapid response to outbreaks. By adopting a multifaceted approach that integrates biosecurity, surveillance, and genetic improvement, stakeholders can effectively mitigate the impact of TiLV on tilapia farming operations.

5. Vaccination Against TiLV: A promising approach for disease management.

As the aquaculture industry grapples with the challenges posed by TiLV, the development of effective vaccination strategies emerges as a promising avenue for disease management. Vaccination offers a proactive approach to bolstering tilapia health, reducing susceptibility to TiLV infection, and minimizing economic losses associated with disease outbreaks.

Efforts to develop TiLV vaccines have gained momentum in recent

years, driven by the urgent need to safeguard tilapia populations against this viral pathogen. Researchers have explored various vaccine formulations and delivery methods to elicit protective immune responses in tilapia. These include:

1. Inactivated Vaccines: Inactivated TiLV vaccines contain whole or fragmented viral particles that are rendered non-infectious but immunogenic. Tilapia are vaccinated with inactivated virus preparations to stimulate the production of specific antibodies, providing immunity against subsequent TiLV exposure.

2. Recombinant Vaccines: Recombinant TiLV vaccines employ genetically engineered viral proteins or antigenic fragments to induce protective immune responses in tilapia. Recombinant protein subunits or viral vectors carrying TiLV antigens are administered to tilapia, triggering the production of antibodies and cell-mediated immune responses.

3. DNA Vaccines: DNA vaccines encode TiLV-specific antigens within plasmid DNA molecules, which are delivered into tilapia cells to

Preventing the introduction and spread of TiLV in tilapia farms is paramount for ensuring the sustainability of the aquaculture industry.

stimulate immune responses. DNA vaccination offers advantages in terms of stability, scalability, and cost-effectiveness, making it an attractive option for TiLV vaccine development.

Despite progress in TiLV vaccine development, several challenges persist, including regulatory approval, vaccine delivery logistics, and costeffectiveness. Collaborative efforts among researchers, industry stakeholders, and regulatory agencies are crucial to overcoming these obstacles and advancing TiLV vaccine technologies.

This article is sponsored by: PHIBRO ANIMAL HEALTH CORPORATION

The total production of abalone accounts for only a far smaller proportion of aquaculture production compared to fish; however, it is considered as one of the most expensive seafoods for its scrumptious taste and nutritive value, particularly in China, Korea, and Japan. Growing demand for abalone brings about a drop in wild stocks as well as an increase in cultured abalone production. China currently produces the largest quantity of abalone in the world, with 203,485 metric tons of abalone production in 2020, followed by Korea, with 20,059 metric tons in the same year (FAO, 2021).

The approach of using waste products to bring about a feed ingredient, as part of the circular economy, contributes to the reduction of the carbon footprint of ingredients utilized in aquafeed formulations. Especially, by-products derived from animals to replace fish meal FM in aquafeeds have recently received considerable attention.

Chicken by-product meal (CBM) mainly composed of chicken heads, bones, feathers, and feet is predominantly produced from chicken processing plants and considered as waste. CBM is inexpensive but contains an appreciable amount of crude protein and lipid. Here is presented research that evaluates the use of CBM as an ingredient replacer to FM as feed for juvenile abalone (Haliotis discus hannai) in terms of growth, survival, and carcass chemical composition.

This study aims to assess the effect of replacing anchovy meal with chicken by-product meal (CBM) in juvenile abalone (H. discus hannai) feed. Five diets were formulated to contain 0 (CBM0), 25 (CBM25), 50 (CBM 50), 75 (CBM75), and 100% (CBM100) CBM in replacement to 24% fish meal (FM) (Table 1). Dried Saccharina japonica, which is the natural food for this species of abalone was also prepared. Each diet was fed to triplicate groups of abalone. 1,260 abalone assigned

It is urgently needed to search for an alternative source for fish meal (FM) because the current production of FM is not sufficient to satisfy its increased demand for aquaculture production. This article presents the results of a study that aimed to assess the effect of replacing anchovy meal with chicken by-product meal (CBM) in juvenile abalone (Haliotis discus hannai) feed.

into eighteen cages were fed for 16 weeks. After the 16-week feeding trial, 30 abalones from each cage were exposed to air for 24 h, and survival was monitored for 7 days.

Results

The content of dry matter, crude protein, crude lipid, and ash in each diet

was significantly (p < 0.0001) affected over time, and their significant (p < 0.0001) interaction was observed. The highest lost dry matter content was observed in the CBM100 diet among formulated diets throughout the 48-h observation period.

The highest lost crude protein content was observed in the

CBM100 diet among formulated diets throughout the 48-h observation period. The highest lost crude lipid content was observed in the CBM100 diet among formulated diets within the same time measured.

The lost ash content of the CBM0 (5.8%, 7.1%, and 14.9%, respectively) diet was significantly (p < 0.05) lower than that of the CBM100 (7.8%, 9.9%, and 16.1%, respectively) diet and the S. japonica (14.7%, 21.0%, and 23.6%, respectively) throughout the 48-h observation period after seawater immersion. The highest lost ash content was observed in the CBM100 diet among formulated diets within the same time measured.

Survival of abalone ranging from 89.0% to 94.3% showed no significant (p > 0.2) difference among the experi-

mental diets (Table 2). Weight gain and SGR of abalone fed the CBM0 (185.4 ± 12.83% and 0.93 ± 0.040%/ day, respectively) diet were significantly (p < 0.04 for both) higher than those of abalone fed the CBM100 diet (139.0 ± 6.36% and 0.78 ± 0.024%/day, respectively), but not significantly (p > 0.05) different from those of abalone fed the CBM25 (175.7 ± 5.41% and 0.91 ± 0.017%/day, respectively), CBM50 (162.1 ± 8.69% and 0.86 ± 0.030%/day, respectively), and CBM75 (158.4 ± 6.19% and 0.85 ± 0.021%/day, respectively) diets.

The survival of abalone fed all formulated diets showed no significant (p > 0.1 for Log Rank and Wilcoxon tests) difference throughout the 7-day post observation period after 24-h air exposure (Figure 1).

It is urgently needed to search for an alternative source for FM because the current production of FM is not sufficient to satisfy its increased demand for aquaculture production (Wu, Yu, et al., 2022b; Yu et al., 2022). CBM containing relatively high crude protein, especially in essential amino acids including arginine, leucine, phenylalanine, and threonine (Ha et al., 2021) can be highly regarded as a good substitute for FM in an abalone diet as well. Comparable weight gain and SGR of abalone fed the CBM75 diet to abalone fed the CBM0 diet in the present study might indicate that FM (anchovy meal) up to 75% could be replaced by CBM without compromising the growth performance of abalone. However, further increased

Chicken by-product meal (CBM) mainly composed of chicken heads, bones, feathers, and feet is predominantly produced from chicken processing plants and considered as waste. CBM is inexpensive but contains an appreciable amount of crude protein and lipid.

replacement levels of FM with CBM in the CBM100 diet led to inferior weight gain and SGR of abalone compared to the CBM0 diet. Therefore, CBM seemed to be a sustainable and cost-effective protein replacer for FM in an abalone diet. Similarly, Ha et al. (2021) reported that diets substituting FM up to 50% with CBM, which is the same CBM used in this study achieved comparable growth performance and feed utilization of olive flounder to fish fed a 65% FM-based diet when fish were fed with a 65% FM-based diet or one of the diets replacing 10%, 20%, 30%, 40%, and 50% FM with CBM for 8 weeks.

Growth performance of abalone fed all formulated diets outperformed abalone-fed S. japonica in this study, being consistent with the previous studies demonstrating that abalone fed a nutrition-balanced diet outperformed the growth of abalone fed macroalgae. This could be elucidated by the fact that poor nutrient content (crude protein: 11.5% and crude lipid: 1.1%) in the S. japonica restricted the

growth of abalone because of relatively high dietary protein (25%–30%) (Mai et al., 1995b) and lipid (2%–5%) (Lee, 2004) needs for normal growth of abalone.

Inferior growth performance (weight gain and SGR) of abalone fed the CBM100 diet compared to abalone fed the CBM0 diet in the present study might indicate that an excessive amount of FM substitution with CBM in abalone feed may bring about reduced growth performance. Analogous results were also observed in other studies (Falaye et al., 2011; Kim et al., 2021; Wu, Zhang, et al., 2022) showing that high substitution level of FM with CBM in diets led to the reduced growth performance of fish.

Lower lost content of dry matter, crude protein, crude lipid, and ash throughout the 48-h observation period after seawater immersion in CBM0 diet compared to the CBM100 diet in the present study might suggest that CBM0 diet were more stable than the CBM100 diet. This can partially explain why abalone fed the CBM0 diet out-

Comparable weight gain and SGR of abalone fed the CBM75 diet to abalone fed the CBM0 diet in the present study might indicate that FM (anchovy meal) up to 75% could be replaced by CBM without compromising the growth performance of abalone.

performed the growth of abalone fed the CBM100 diet in the present study, being consistent with the previous study (Lee et al., 2017) demonstrating that abalone-fed diets with higher water stability could produce better growth performance.

Significantly longer shell lengths and wider shell widths of abalone fed the CBM0 diet compared to those of abalone fed the CBM75 and CBM100 diets were observed in this study. In considering combined growth and shell growth including shell length and width, FM up to 50% could be made with CBM in abalone diets without compromising growth performance. Improved shell length and width of abalone fed the CBM0 diet compared to that of abalone fed the CBM75 and CBM100 diets appeared to be closely related to the growth rate of abalone, agreeing with other studies (Dai & Cho, 2022a; Lebata-Ramos et al., 2021; Luo et al., 2013; Zhao et al., 2018) explaining the positive relationship between shell growth and carcass weight versus growth rate of abalone.

In considering combined growth and shell growth including shell length and width, FM up to 50% could be made with CBM in abalone diets without compromising growth performance.

Abalone subjected to air exposure lowered immune response, but increased vulnerability to bacterial infection, and subsequently led to decreased survival (Malham et al., 2003; You et al., 2018). Nevertheless, no remarkable difference in the survival of abalone during the 7-day post-observation period after the 24-h air exposure in the present study might indicate that substituting FM with CBM in diets did not cause any negative effect on the

survival of abalone subjected to air exposure.

Conclusion

Chicken by-product meal successfully substituted for fish meal (anchovy meal) up to 50% in formulated abalone diets. It exhibited similar growth performance, shell length, and width, and survival response to juvenile abalone subjected to a 24-h air exposure after an experimental duration of 16 weeks.

This is a summarized version developed by the editorial team of Aquaculture Magazine based on the review article titled “CHICKEN BY-PRODUCT MEAL AS A REPLACEMENT TO FISH MEAL IN JUVENILE ABALONE (HALIOTIS DISCUS HANNAI INO 1952) FEED” developed by: DAI, Q. and HWOAN CHO, S. - Korea Maritime and Ocean University. The original article was published, including tables and figures, on MARCH, 2023, through WORLD AQUACULTURE SOCIETY. The full version can be accessed online through this DOI: 10.1111/ jwas.12973

* By Sambhu Chithambaran and Samy Al Deen

Market Overview for Jumbo Shrimp (Over 84 Grams) in Global Aquaculture

The Pacific white shrimp (Litopenaeus vannamei) is a globally significant aquaculture species valued for its rapid growth, adaptability, and high market demand. Jumbo shrimp exceeding 84 grams (U10-U15 size category) represent a premium, highvalue segment in the global seafood industry. These shrimps are highly sought after due to their impressive

size, superior texture, and versatility in gourmet cuisine. Demand for this product is particularly strong in markets with high disposable incomes and a preference for luxury seafood, such as the United States, European Union, Japan, the Middle East, and China.

» United States: One of the largest consumers of jumbo shrimp, with demand driven by fine-dining

restaurants, high-end supermarkets (e.g., Whole Foods), and seafood retailers. Jumbo shrimp are commonly used in shrimp cocktails, grilled dishes, and gourmet seafood platters.

» Europe: Southern European countries like Spain, Italy, and France favor jumbo shrimp for premium seafood dishes such as paella and shrimp Provençal. Sustainability certifications like ASC or BAP play a role in purchasing decisions.

The Pacific white shrimp (Litopenaeus vannamei) is a globally significant aquaculture species valued for its rapid growth, adaptability, and high market demand. In semi-arid regions like Saudi Arabia, shrimp farming faces challenges such as limited freshwater resources and extreme environmental conditions. However, semi-extensive culture systems using high-density polyethylene (HDPE)-lined ponds offer a sustainable solution to optimize water use and enhance production efficiency.

» Japan: A seafood-centric culture values large shrimp for sushi, sashimi, and tempura, with premium quality standards influencing imports from Vietnam and Thailand.

» Middle East: Dubai and Saudi Arabia have a growing demand for jumbo shrimp in luxury hotels and high-end dining, catering to an affluent and international consumer base.

» China: While a massive shrimp market overall, jumbo sizes are in demand among wealthy consumers in major cities like Shanghai and Guangzhou, where they are used in hot pot and banquets.

Jumbo shrimp command significantly higher prices than standard sizes due to limited supply and high consumer demand. Prices fluctuate based on market conditions, sourcing (wild vs. farmed), and regional factors:

» Japan: One of the highest-priced markets, with wholesale rates of USD 15.00–18.00 per pound and retail prices exceeding USD 25.00 per pound.

» Middle East & China: Prices range between USD 11.00–20.00 per pound, with luxury hotels and fine dining establishments paying premium rates for top-quality jumbo shrimp.

The viability of producing jumbo shrimp depends on factors like feeding strategies, growth cycles, and environmental conditions. Given rising demand and premium pricing, targeted production of jumbo shrimp could offer significant profitability for aquaculture producers. However, production challenges, including longer growth periods and higher feed conversion ratios, must be managed effectively.

Jumbo shrimp are not just a highend seafood option—they are a statement of quality and prestige in global markets. As demand grows in fine dining, premium retail, and luxury hospitality, aquaculture producers who can optimize production for larger shrimp sizes will be well-positioned to capture lucrative opportunities in this elite market segment.

In semi-arid regions like Saudi Arabia, shrimp farming faces challenges such as limited freshwater resources and extreme environmental conditions. However, semi-extensive culture systems using high-density polyethylene (HDPE)-lined ponds offer a sustainable solution to optimize water use and enhance production efficiency. This study evaluates the feasibility of producing jumbo-sized L. vannamei in such systems over a 330day period at the University Fish Farm

Demand

for jumbo shrimps is particularly strong in markets with high disposable incomes and a preference for luxury seafood, such as the United States, European Union, Japan, the Middle East, and China.

in Obhur, Jeddah. By assessing growth performance, survival rates, feed conversion efficiency, water quality, and shrimp quality, the research aims to develop a cultivation strategy tailored to arid environments, contributing to economic development and food security in water-scarce regions.

The study was conducted in three HDPE-lined ponds (300 m² each) over 330 days (47 weeks) at the University Fish Farm in Obhur, Jeddah (Figure 1). Ponds were cleaned and sun-dried for one week before water culture. To promote algal bloom (40–50 cm Secchi disc transparency), seawater (30% salinity) was introduced, and ponds were fertilized with urea (400 g), molasses (1.5 L), and diammonium phosphate (200 g) on days 1, 4, and 8, with water levels increased to 60% and 100% before the second and third doses, respectively. Two 1-hp aspirator aerators (Force-7, Acquaeco, Italy) were installed in each pond at a 40 cm depth and 35° downward angle. To enhance heterotrophic bacterial growth, soya hull and molasses (2 kg) were applied as carbon sources every three days. On day 12, healthy, uniform-sized juveniles (mean weight: 1.21 ± 0.2 g; mean length: 3.7 ± 1.8 cm), produced at the farm hatchery, were stocked at a density of 25 individuals/m² (hapa survival > 95%). Shrimp were fed a standard fishmeal-based pellet feed (35% protein, NAQUA, Jeddah) three times daily at 7:00 a.m., 1:00 p.m., and 6:00 p.m., following a standard feed table.

Water quality parameters, including transparency, temperature, dissolved oxygen, pH, and salinity, were recorded daily, while ammonia (unionized), nitrate, nitrite, orthophosphate, and alkalinity (as CaCO₃) were measured weekly. Shrimp growth was assessed biweekly by sampling 200 individuals per pond, with feed quantities adjusted after each sampling. At harvest, survival, biomass, and shell quality (hard, loose, and soft-shell percentages) were recorded for both treatment and control ponds.

The average body weight (ABW) of L. vannamei exhibited a sigmoidal growth pattern over the 330-day culture period, with significant differences (p < 0.01) between sampling days (Figure 2). Growth was rapid in the first quarter (0–120 days), with an average body weight (ABW) approximately 40 g, reflecting optimal conditions and efficient feed utilization. Between days 120 and 210, growth slowed, with ABW reaching 60–70 g, possibly due to changes in water

quality or feed conversion efficiency. From day 210 onward, growth stabilized, with ABW plateauing at 80–85 g, aligning with the final harvest weight of 84.6 ± 4.3 g (Figure 3). The average weekly growth (AWG) rate was 1.9 ± 0.7 g, and the net weight gain was 83.4 ± 3.9 g. The maximum recorded length and weight was 22.1cm and 88.0 g respectively, confirming the success of achieving jumbo-sized shrimp (Figures 4 and 5).

The survival rate was 83 ± 12%, and the feed conversion ratio (FCR)

The

viability of producing jumbo shrimp depends on factors like feeding strategies, growth cycles, and environmental conditions.

was 2.3 ± 0.71, indicating efficient feed utilization. Total biomass per pond averaged 529 ± 22.1 kg, equivalent to 17,639.5 kg/ha, demonstrating high productivity for a semi-extensive system in an arid region (Table 1). Water quality remained within acceptable ranges for shrimp culture. Transparency averaged 47.17 ± 8.1 cm, temperature 27.30 ± 4.76°C, dissolved oxygen 5.82 ± 0.47 mg/L, pH 8.81 ± 1.14, and salinity 41.20 ± 1.52 g/L. Alkalinity was 143.00 ± 8.0 mg/L, nitrate 1.68 ± 0.70 mg/L, nitrite 0.03 ± 0.01 mg/L, orthophosphate 1.41 ± 0.12 mg/L, and unionized ammonia 0.14 ± 0.08 mg/L (Table 2). These stable conditions supported the observed growth performance. Post-harvest analysis revealed an average sludge accumulation of 98 ± 12 kg at the center of

This pioneering study demonstrates the feasibility of producing jumbosized L. vannamei in semi-arid Saudi Arabia using HDPE-lined ponds, potentially marking the first comprehensive effort to achieve such high biomass yields (17,639.5 kg/ha) under these conditions.

culture ponds, likely due to higher organic input from feed and carbon sources. Shrimp quality tests showed that shrimp had better taste and color. The percentage of hard-shell shrimp was 89.1%, with loose shell at 5.5% and soft shell at 5.4% indicating superior shell quality of shrimp.

Discussion

Conclusion

This study represents a groundbreaking advancement in aquaculture, being among the first of its kind to successfully cultivate jumbo-sized L. vannamei in semi-arid regions of Saudi Arabia using a semi-extensive system with HDPE-lined ponds. The strategy yielded a biomass of 17,639.5 kg/ha, a survival rate of 83%, and an average final weight of 84.6 g, offering a sustainable model for shrimp farming in water-scarce areas. These findings pave the way for economic growth and food security in arid regions. Future research should focus on optimizing sludge management

This pioneering study demonstrates the feasibility of producing jumbosized L. vannamei in semi-arid Saudi Arabia using HDPE-lined ponds, potentially marking the first comprehensive effort to achieve such high biomass yields (17,639.5 kg/ha) under these conditions. The sigmoidal growth pattern, with rapid early growth and stabilization at 84.6 ± 4.3 g, aligns with typical shrimp growth dynamics under controlled conditions. The high survival rate (83%) and reasonable FCR (2.3) reflect the efficacy of the feeding regime and water management practices, including aeration and carbon supplementation to support heterotrophic bacteria. Stable water quality parameters, despite the arid environment, underscore the suitability of HDPE-lined ponds for water conservation and shrimp culture. The superior shrimp quality in treatment ponds highlights the benefits of the cultivation strategy, particularly for premium markets valuing jumbo-sized shrimp with excellent taste and shell integrity. However, the higher sludge accumulation in treatment ponds suggests a need for improved waste management to enhance sustainability.

and exploring cost-effective feed alternatives to further enhance scalability and sustainability, building on insights from recent studies advocating for minimal water exchange and integrated systems in shrimp aquaculture .

References and sources consulted by the author on the elaboration of this article are available under previous request to our editorial staff.

* Sambhu Chithambaran Faculty of Marine Sciences. Kong Abdulaziz University, Jeddah, Kingdom of Saudi Arabia.

*Professor-Aquaculture, Email-sambhu@kau. edu.sa

Samy Al Deen Faculty of Marine Sciences. Kong Abdulaziz University, Jeddah, Kingdom of Saudi Arabia.

The importance of

* By Antonio Garza de Yta, Ph.D.

Recently I have been involved in several discussions where the importance of increasing domestic markets in countries where aquaculture is being developed has been mentioned. Of course, this depends very much on the size of the population and the objectives of the different countries. Countries with populations of more than 100 million, such as Mexico and Brazil, or, in the superlative case of India, with populations of only a few million, such as Honduras or Oman, cannot be categorized in the same way. Although aquaculture is a relevant activity in all these countries, they live in completely different realities.

Let’s talk first about countries with a population of less than 20 million inhabitants, such as several relevant aquaculture producing countries, such as Ecuador and Chile, or countries whose activity is consolidating, such as Honduras or Oman. These countries cannot focus all or a large part of their production on domestic consumption and must focus

increasing domestic markets in countries where aquaculture is developed is increasingly discussed. However, it is necessary to take into account their own realities, as they are completely different.

mainly on exports, which can be a great source of foreign exchange for the country, but can also be a major weakness, especially in a world as volatile and changing as the one we live in today.

This strategy depends on completely external factors, such as possible tariff barriers or a decrease in the purchasing power of the markets in which they are accustomed to sell their products. It is also susceptible to the competition that can be generated with other countries with a depreciation of their currency, allowing their exports to be more competitive in international markets. I am not saying that this is an exclusive characteristic of these countries, all producers competing for a global market are exposed to these risks, but if you do not have a domestic market that can absorb a large production of fish or any other product, this risk is extremely high.

Let’s take the case of countries like Mexico or Brazil, with populations of more than 100 million people, where seafood consumption has not yet

reached the levels recommended by the World Health Organization. These giants, which also have an impressive potential for the development of aquaculture, have a historic opportunity to fill this huge gap that exists, not only with imports, as is unfortunately the case in Mexico, which is the second largest importer of white fish fillets in the world, but also with a solid development of their aquaculture industry. Obviously, to achieve this, the strategic support of the institutions and leaders of the sector will be necessary, so that the activity can be consolidated and possibly grow exponentially. Let’s not talk about the case of India, which would need 1.3 million tons of fish and seafood per capita per year to meet this quota, just by increasing its per capita consumption of fish and seafood by 1 kg. If I were a producer in any of these three countries, I would be more focused on increasing the domestic market for all seafood than on seeking new horizons for exporting my product. Especially in today’s world, where globalization is experiencing major

Countries with a population of less than 20 million inhabitants, such as several relevant aquaculture producing countries, such as Ecuador and Chile, or countries whose activity is consolidating, such as Honduras or Oman, cannot focus all or a large part of their production on domestic consumption and must focus mainly on exports.

setbacks, local markets are crucial for the development not only of aquaculture, but of the economies of nations in general.

Again, as on other occasions, I would like to raise the issue of tariffs on imported products, which I believe should be applied only to those products that sell water for fish, because it is not possible to pay the same for 1 gram of fish as we pay for 1 gram of water. As I have said on many other occasions, tariffs should be directly related to the percentage of glazing of a product, be it shrimp, tilapia or any other seafood product sold domestically, because it is not possible for 1 kg of any aquaculture or fishing product to compete at a complete disadvantage with 700 g of imported product.

Another great way to make the competition between local producers and imports fair would be to indicate on the label or at the point of

sale the percentage of glaze in each product, so that the consumer knows how much drained mass is contained in the various options and can decide in an informed way what amount of product he is really buying with the value of his money. I mention Mexico because it is a case I know first-hand, but I am also aware that the same problem occurs in many other parts of the world.