Infused Tooling

A step-by-step guide.

A step-by-step guide.

The laminate operation (all layers and cores) can be set up in just one step.

Because of the high glass content and better mechanical properties, thinner laminates can be infused compared with other processes.

The infusion process allows for high glass content laminates with excellent mechanical properties.

Plant capabilities

The initial infused tooling setup takes time and resources.

Process capabilities

Knowledge of tooling systems and parts helps avoid common mistakes and rework.

Tool specifications

For purposes of efficiency, it is best to use infusion for tools that are one meter sq. or larger. Anything smaller will result in dimishing returns on prep time and cost.

End application

Open mold

Closed mold A side

Closed mold B side

Glass master

Laminate schedule

Gel coat

Barrier coat

Glass schedule

Cores

Frames

Tip: To select the best laminate construction for your infusion mold, AOC suggests infusing a flat panel (12”x24”) using the gel coat, barrier coat and laminate schedule created from previous discussions with our technical team.

With this panel on hand, you can evaluate the performance of the laminate, cosmetics appearance, and mechanicals properties. Also, this panel can help to determine the infusion time (and the resin gel time) for the laminate schedule selected.

Scan the QR code to contact an AOC rep about your specific tooling questions.

Before beginning the tool building process, it is critical to have a master model that is in good condition to ensure tools will have the surface finish needed to build quality parts.

You will also need the following materials:

Glass reinforcement

Two different colors of gel coat or a gel coat and a barrier coat

Resin formulation Catalyst

In addition, you will need the following consumables:

Flow media

Peel ply

Plastic tubing

Bagging material

Putty

Spray adhesive

Tack tape for patching holes

VINYL

A next-generation vinyl ester tooling gelcoat, Vibrin G910 delivers unmatched toughness, gloss, and durability for high-performance molds.

High Gloss Finish: Delivers mirror-like surface quality

Dimensional Stability: Maintains shape and integrity under stress

Porosity Resistant: Smooth, defect-free surface

High HDT: Withstands elevated temperatures

Tough & Resilient: Excellent impact and abrasion resistance

Designed for spray applications behind gelcoat, Vibrin G930 is used to enhance surface quality and structural performance.

Minimizes Glass Print: Enhances surface appearance

Thermal Shock Resistant: Withstands temperature cycling

High Elongation: Improves flexibility and toughness

MOLDTRU LPT-68001 FORMULATION

Optimized for room-temperature vacuum molding, MoldTru LPT-68001 enables faster build cycles with no post-cure required.

Faster Build Time: Rapid infusion and cure accelerate mold production

Efficient Flow: Low viscosity supports high-glass laminate wet-out

No Surface Distortion: Low shrinkage ensures dimensional accuracy

High HDT: Ideal for master mold replication and thermal stability

No Print-through: Smooth surface finish without glass pattern visibility

Start preparing your master model by applying a complete mold release system to ensure the mold releases from the master cleanly after curing.

Your master model needs to be designed with a minimum 8” flange for tubing and tack tape, and should be strong enough to support the vacuum pressure.

~10 minutes

Two workers mix the gel coat and catalyst for the master model in the background.

The next step in the process is to apply the gel coat to the master model. The gel coat is applied in two layers.

Remember to mask 2” around the perimeter before applying the gel coat, for the tack tape location.

Start by preparing the gel coat. Mix it with the catalyst according to the product specifications.

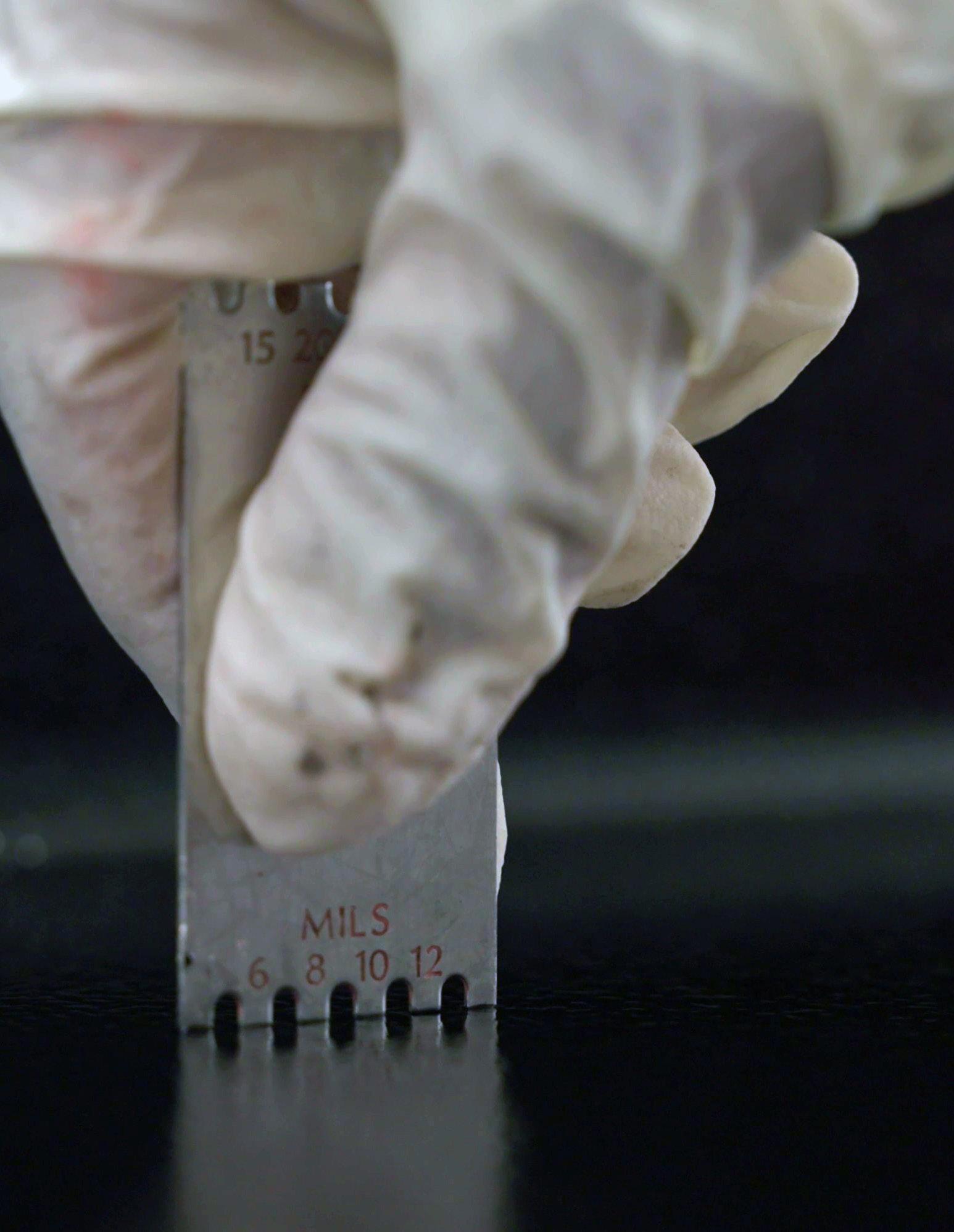

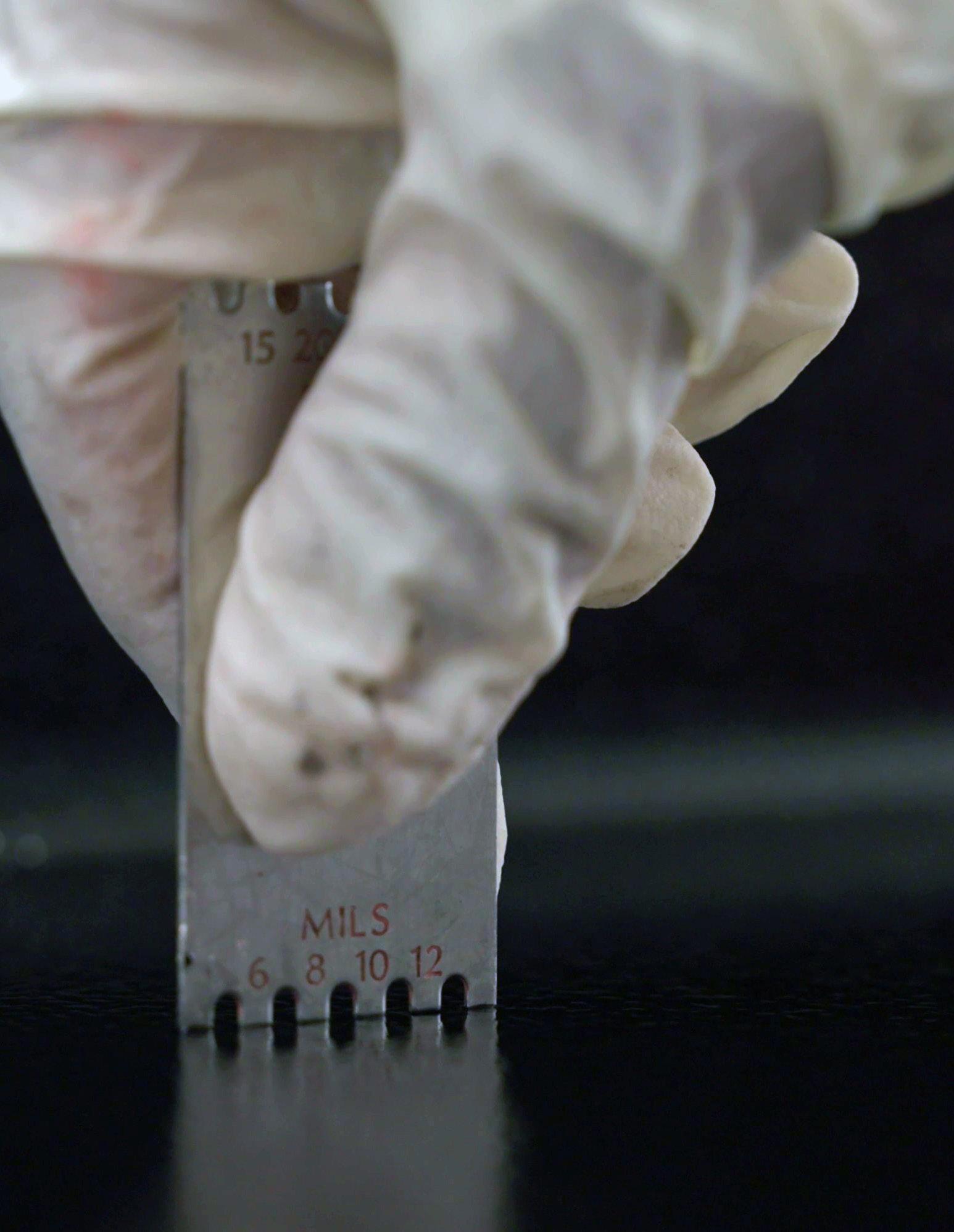

Apply the first layer of gel coat. Inspect for full cure before applying the second gelcoat layer. Once the first layer is cured, you’ll then apply a second layer of a different color gel coat, or alternatively, a barrier coat if extra protection is needed for the tool. Ensure the second layer is also applied at 20 mils thick.

Why are two different gel coat colors recommended?

Using two layers with different colors allows for visually tracking wear on the tool, signaling when rework or polishing may be needed.

~2 hours to apply and cure

After the barrier coat or gel coat is tack-free, apply a light putty on corners and radius to increase the draft angles. This step is only needed when the radius of the tool is smaller than 5mm.

Tip: If you find uncured or wet areas, allow more time OR remove and reapply the layer.

Scan the QR code to watch a short video demonstrating the gel coat application.

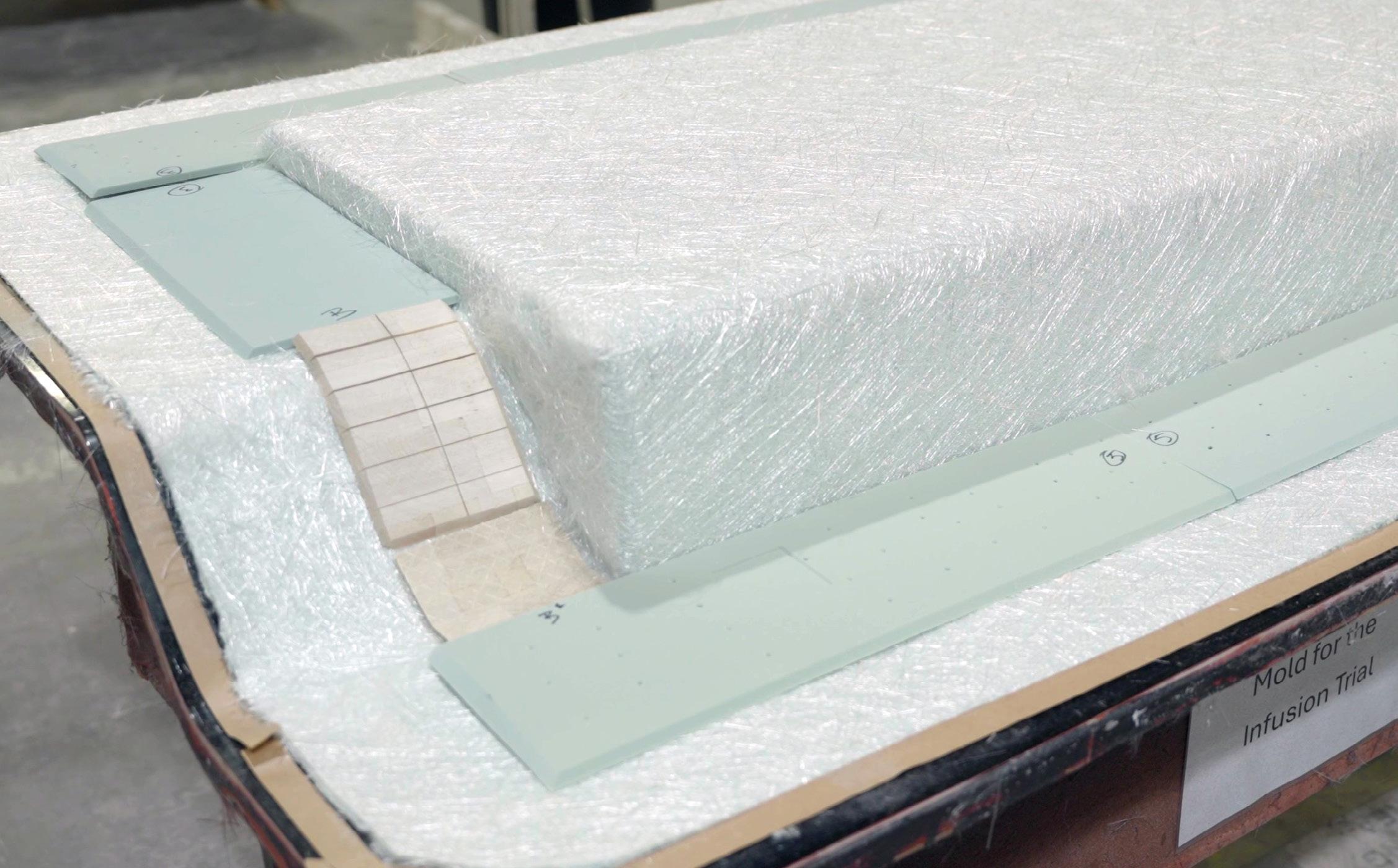

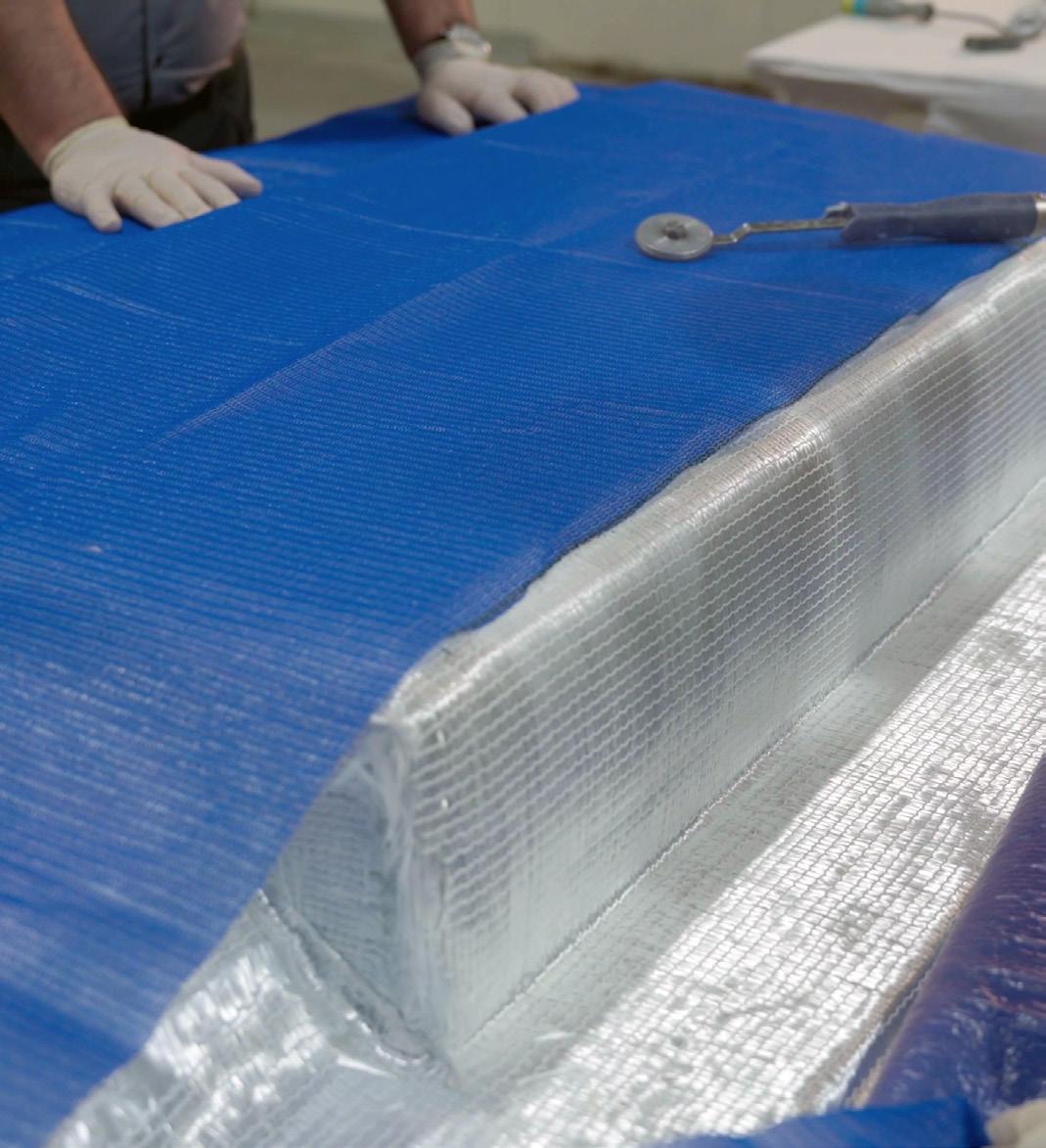

Apply the tack tape around the perimeter of the master model. Then, begin the glass loading process.

Load the glass reinforcement onto the tool. Carefully position the glass according to your tool design. Use spray adhesive to keep the glass in place and tight to the surface, especially if multiple layers are needed for added strength. If required, core material like balsa or foam can be used to increase mold stiffness without adding excess weight.

~1 hour

Tip: Remember to reinforce the flange and maintain the center flexibility.

Scan the QR code to watch a short video showing how the glass reinforcement is added.

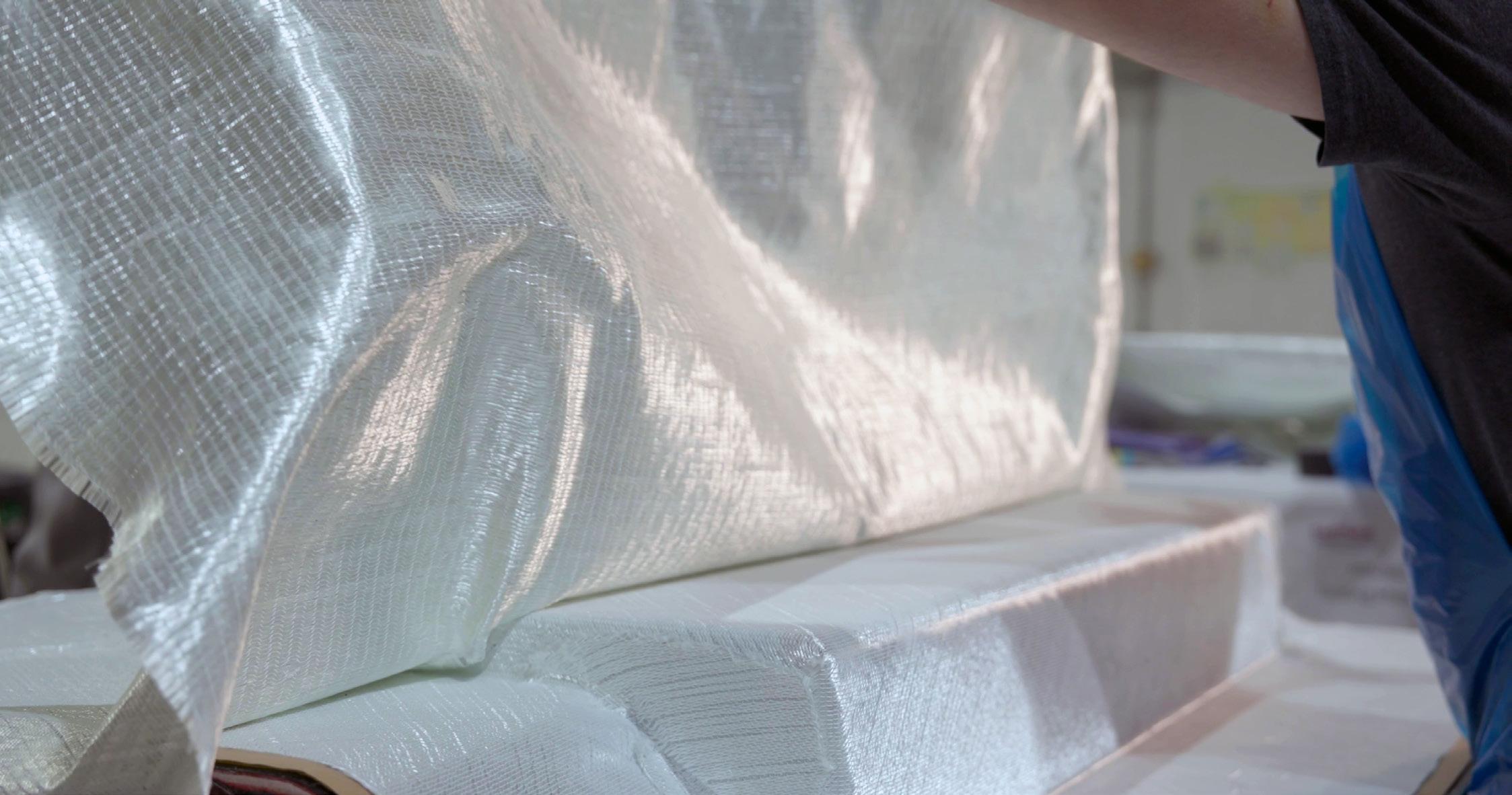

Put down the peel ply, followed by the flow media, covering the surface of the master model. The flow media ensures consistent wetting of the glass and an even cure. Then, locate the resin and vacuum feed lines. The format of these consumables will vary depending on the size and shape of the tool and infusion strategy setup.

Next, set up the bagging system. Keep in mind that the bagging material should be three times the amount of material needed for the developed area of the final tool. This should be done by creating pleats, to allow the vacuum to pull the material tight and conform to the master model’s contour.

Once everything is in place, perform a vacuum drop-down test to check for holes or leaks in the bagging. Use ultrasound equipment, vacuum gage, or manual checks to detect leaks. Ensure the vacuum pressure is consistent, with no more than one inch of mercury per 5 minutes.

Any gaps or holes should be sealed with tack tape to prevent vacuum loss.

~30 minutes

Scan the QR code to watch a short video showing peel ply and flow media being added.

Mix the resin formulation with catalyst according to the product specifications and gel time needed. Once ready, open the infusion tubes to begin the formulation flow. As the infusion starts, monitor closely for any leaks and repair them as needed.

Once the infusion has completely filled the tool, clamp the feed line and keep the vacuum flowing. Continue the vacuum until the laminate is cured. It is recommended to leave the mold to cure under vacuum overnight. Next, stop the vacuum and remove the consumables, revealing the completed backside of the tool. It should appear completely white, indicating the process was successful.

~30 minutes for infusion, with overnight cure.

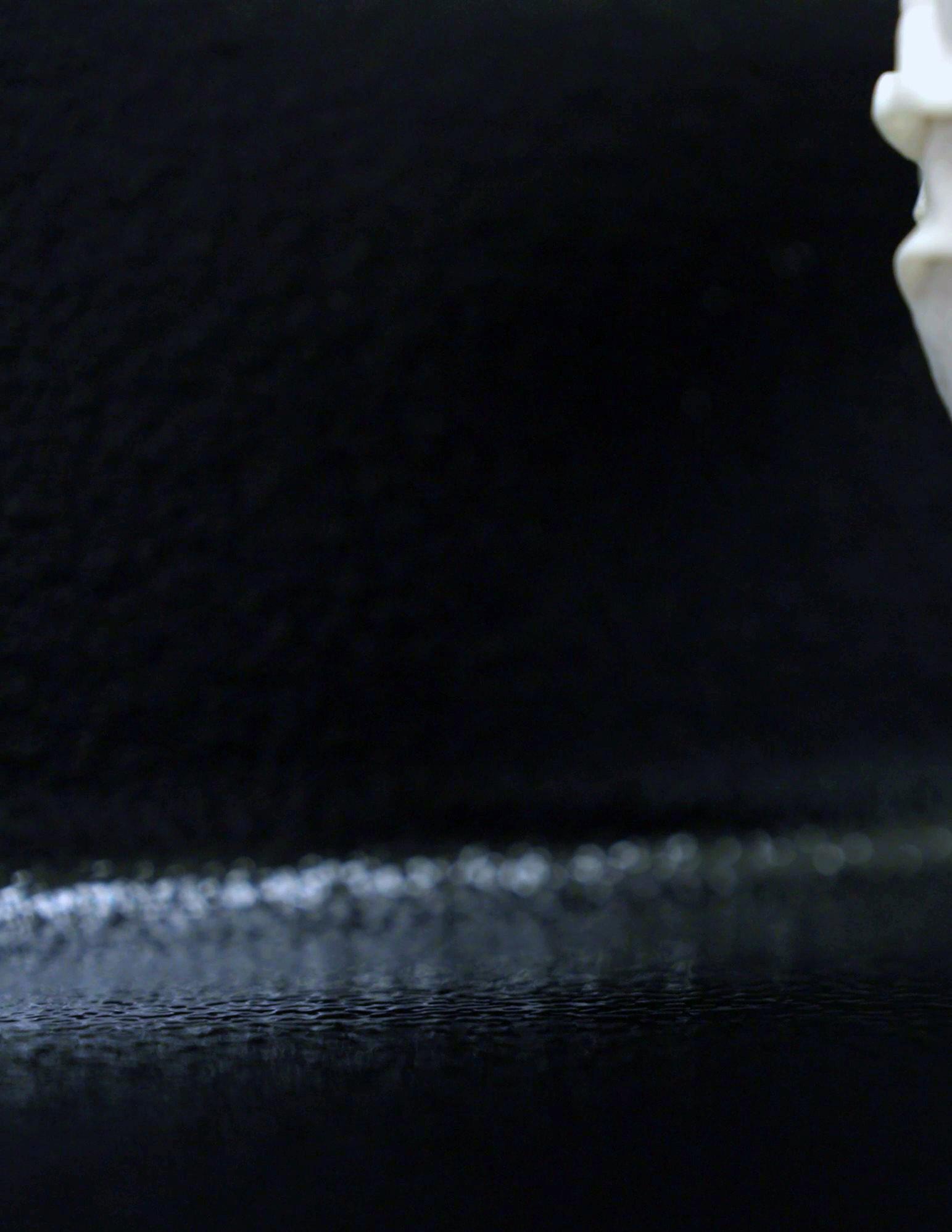

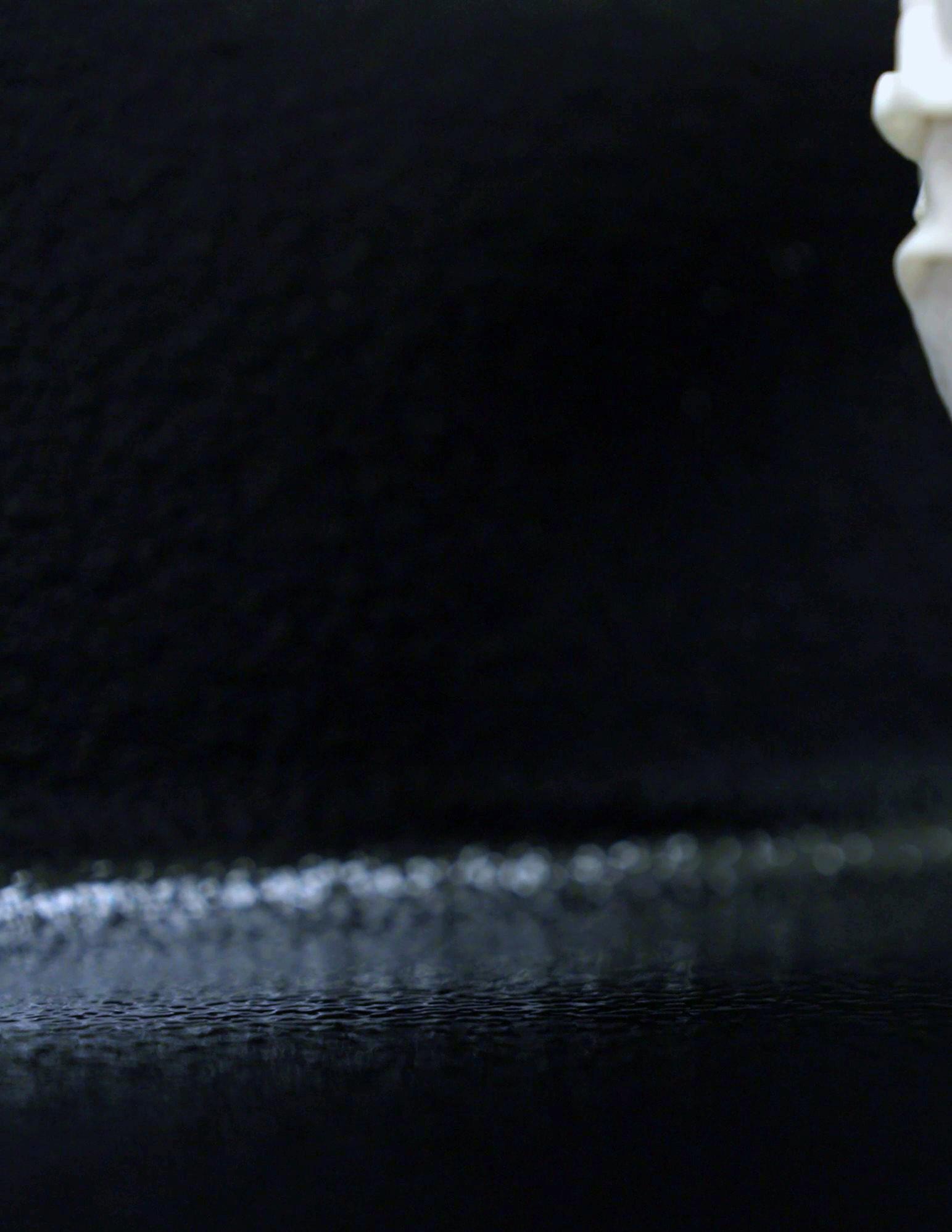

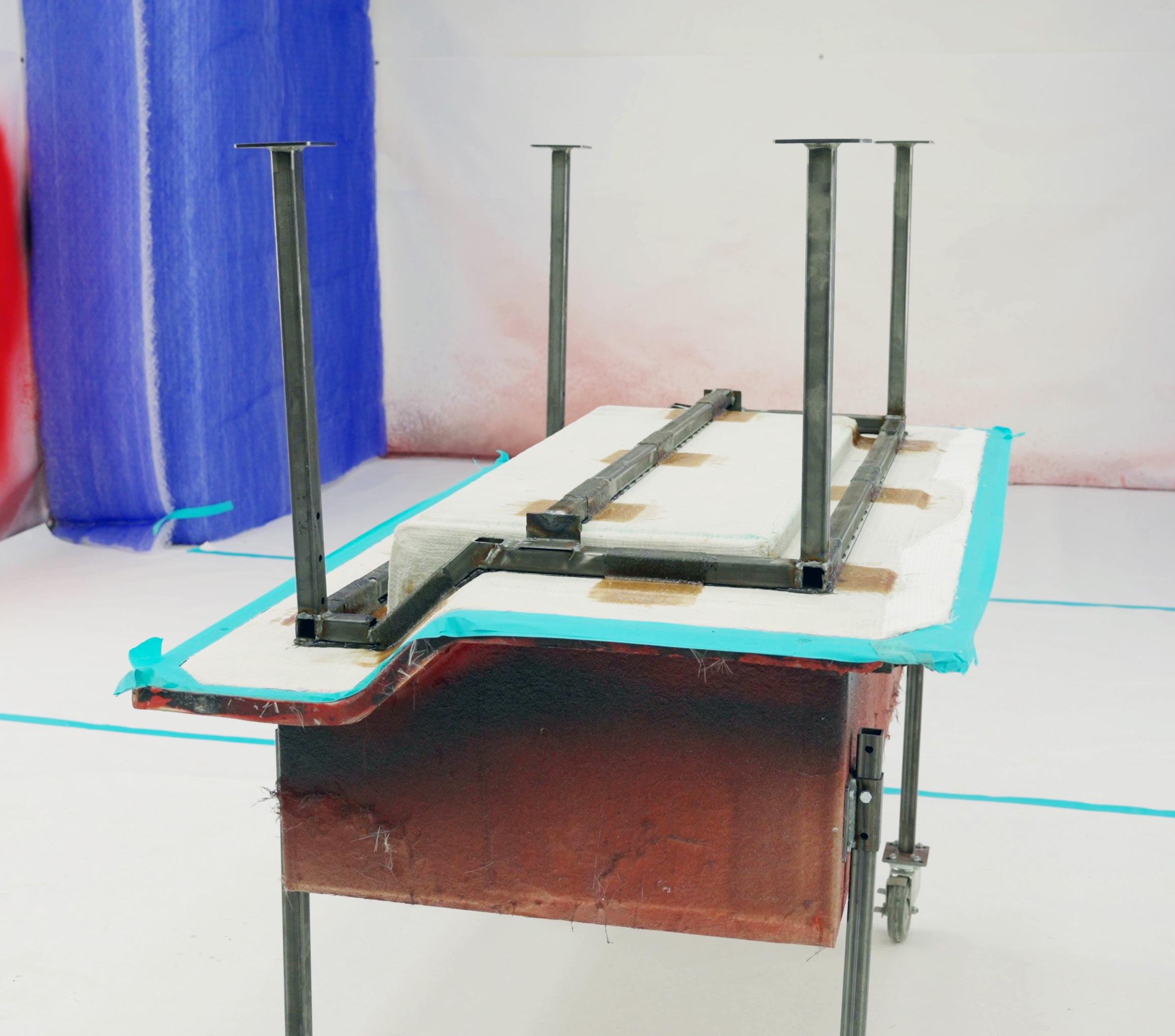

A fully-infused tool.

A fully-infused tool after it’s cured, with the bagging removed.

Scan the QR code to watch a short video showing the infusion process.

The next step is to apply a frame to the backside of the tool. To reduce torsion during the demolding process, we recommend applying a steel frame around the tool. Secure the frame at multiple points using adhesive and laminate for stability.

Adhesive is applied to the mold... ...then laminate is added to the frame.

Scan the QR code to watch a short video demonstrating the frame application.

Finally, it’s time to demold the tool. Using wedges, work around the perimeter and pull the tool off the master model. With the tool now demolded and inspected, your composite tool is ready for use or additional processing.

~30 minutes

The final results.

Scan the QR code to watch a short video showing the demolding process.

Americas

+1 866 319 8827 americas@aocformulations.com

Europe, Middle East, Africa

+41 52 644 1212 emea@aocformulations.com

China

+86 25 8549 3888 china@aocformulations.com

Asia Pacific

+41 52 644 1212

asiapacific@aocformulations.com

AOC is a registered trademark of the AOC group of companies.

The information contained in this publication is based on laboratory data and field experience. We believe this information to be reliable, but do not guarantee its applicability to the user’s process or assume any liability for occurrences arising out of its use. The user, by accepting the products as described herein, agrees to be responsible for thoroughly testing each such product before committing it to production.

The AOC name, the AOC logo, and the Trusted Solutions logo are registered trademarks of the AOC group of companies.

Nothing herein is to be construed as granting permission to use, or inducing or recommending the use of any patent or resulting invention without a valid license.

The information and recommendations contained herein are to the best of our knowledge accurate and reliable, but no rights whatsoever may be derived by any party other than those expressly agreed to with a selling entity of the AOC group of companies in a legally binding agreement. AOC hereby makes no warranty of any kind, express or implied, including those of merchantability and fitness for purpose. Unless explicitly agreed to in writing by AOC otherwise, all offers, quotations, sales and deliveries of AOC products are subject to the general conditions of sale of AOC.

© 2025– AOC Group of Companies

For more information email: americas@aocformulations.com visit: aocformulations.com