Chemical Resistance Guide

Solutions for Tough Chemical Environments

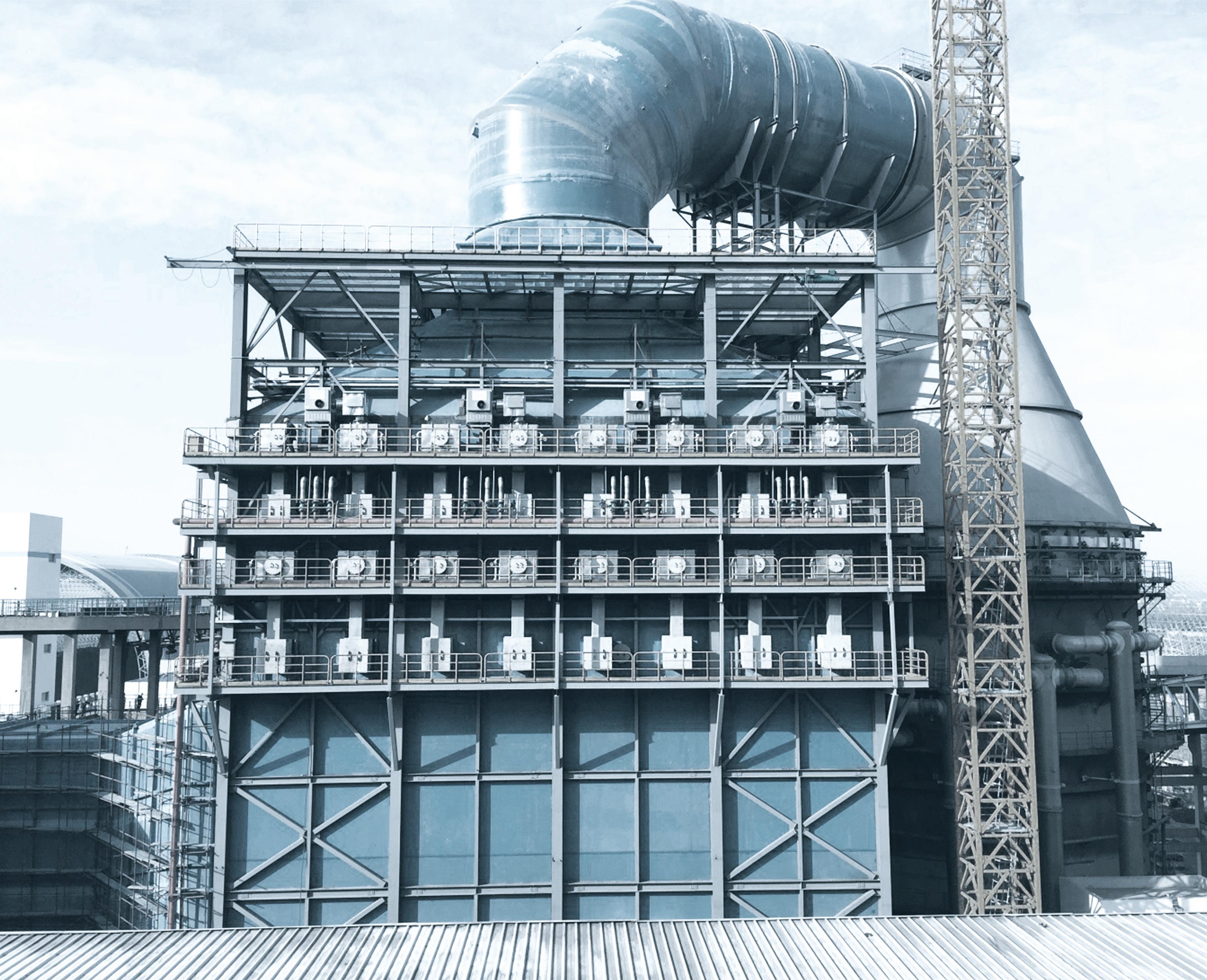

AOC is leading the composites industry in the fight against damaging and costly corrosion. Our Vipel corrosion-resistant formulations set the global standard for proven performance in fiberreinforced polymer (FRP) applications. Trust AOC for corrosion resistance in pipes, tanks, and other equipment for a wide range of chemical industries, including water and wastewater treatment, chemical processing, pulp and paper, mining and power generation. With unparalleled strength and durability, AOC formulations combat corrosion in the harshest conditions.

Partner with AOC for our superior products, industry leadership, professional expertise and commitment to quality.

This guide is designed to assist fabricators of FRP components in selecting the appropriate formulation for parts which will be exposed to highly corrosive environments. The data presented is the result of years of extensive laboratory testing and actual field exposure in North America and Europe.

System selection is determined by the chemical service and environment to which the equipment will be exposed, end-user specifications and preferences, or fabricator recommendation. AOC corrosion advisors also are available any time to answer questions.

Users frequently specify the system and laminate construction for particular applications. The requirement may be based on past experience, manufacturer recommendations, the supplier of the chemicals being handled, or the manufacturer of an equipment package. Fabricators should always confirm the source of selection and the acceptability of equivalent alternate systems.

When users depend on fabricators to recommend a system, it is critical that the user states all aspects of the application and service. Fabricators should get the following information from users:

• The common name and, when possible, the chemical name. For example, muriatic is a common name for hydrochloric acid. This information is generally contained in the Safety Data Sheet for the medium.

• Concentration of each of the chemical components.

• Specific gravity of each chemical solution or mixture.

• pH, if it is an aqueous system.

• Maximum operating temperature (not design temperature) and any anticipated temperature excursions.

• Pressure and/or vacuum conditions. For tanks, it is also important to know if filling will be by pressure, such as from a tank wagon.

• Any use in food and drug applications, where applicable.

• Length of exposure to the medium if less than continuous. For example, the laminate may need to withstand only occasional splashes of exposure.

• Process description, where a reaction such as neutralization takes place in the tank.

• Fire retardancy, where applicable, including flame spread rating and smoke requirements.

Normally a suitable formulation can be selected from the AOC Chemical Resistance Guide based on the information in the “Gathering Data” section above. A few comments on information featured in this guide should be noted:

• Temperature data presented in the guide represents the highest temperature at which the individual product has demonstrated acceptable service life in a laboratory environment or in actual field use.

• Testing of coupons is ongoing, and environments not tested may be done at the customer’s request.

• Serviceability should not be interpreted to mean the full retention of all visual and mechanical properties, but rather an expectation of how a properly designed and fabricated structure will perform.

• Short exposure periods at higher temperatures usually do not affect product integrity if the heat distortion temperature of the cured formulation is not exceeded. However, the highest temperature reached and the exposure duration at this temperature should be indicated when making inquiries.

• This list does not apply to mixtures of different media unless explicitly stated. It contains chemically declared media and some brand name chemicals, which were not precisely identified with respect to chemical composition.

• When the concentration is listed as less than 100%, the remaining product is water, unless specifically stated otherwise.

• The chemical resistance of Vipel formulations can be negatively affected by fillers or thixotropic additives, and should not be used in the corrosion barrier in most applications.

Bisphenol A Epoxy Vinyl Ester

Epoxy Novolac Vinyl Ester

Bisphenol A Fumarate Polyester

Vipel F007

Vipel F010

Vipel F013

Vipel F085

Vipel F086

Vipel F282

Lower VOC/HAP bisphenol A epoxy vinyl ester.

Excellent corrosion resistance to both acidic and alkaline environment. Suitable for equipment subjected to high static and dynamic loads.

Higher styrene bisphenol A epoxy vinyl ester. Offers the best resistance to hot caustic solutions.

Suitable for elevated temperatures. Excellent resistance to acidic and mild alkaline environments. Performs well in a wide range of acidic oxidants and solvents.

Higher heat distortion temperature than Vipel F085. Preferred over standard epoxy novolac in chlorine and other oxidated environments.

Proven resistance to both acidic and alkaline environments. A powdered alkyd version of F282 is available.

Broad chemical resistance at moderate temperatures. Resistant to many petroleum products including kerosene, heating oils and crude oils.

Vipel F737

Isophthalic Polyester Vipel F701

Vipel F764

Vipel F774

Terephthalic Polyester

Vipel F798

Higher elongation versions of F701 used primarily where additional flexibility is important, such as in filament winding and pultrusion processes.

A high-reactivity formulation that meets UL 1746 and Steel Tank Institute requirements. Field-proven for many fuel blends.

Provides a higher heat distortion temperature while maintaining a higher elongation compared to F764. Vipel F774 also meets UL 1746 and Steel Tank Institute requirements. Field-proven for many fuel blends.

Vipel F798 is a high reactivity formulation certified to UL/ULC 1316 for single and double wall underground gasoline storage tanks. Vipel F798 provides lower HAP content and higher elongation to provide improved crack resistance while maintaining a high HDT. F798 is also suitable for corrosion applications where standard Isophthalic and Terephthalic formulations are used.

Vipel K022

Brominated

Bisphenol A

Epoxy Vinyl Ester

Vipel K026

Versions are available to achieve ASTM E84 Class I and Class II flame spread. Excellent resistance to both acidic and alkaline environments. Provides exceptional thermal and mechanical properties.

Can meet ASTM E84 Class I flame spread and smoke development without antimony trioxide. Excellent resistance to both acidic and alkaline environments. Provides exceptional thermal and mechanical properties.

Brominated Epoxy Novolac Vinyl Ester

Vipel K095

Brominated Isophthalic Polyester Vipel K733

Can meet ASTM E84 Class I flame spread and smoke development without antimony trioxide. Excellent resistance to acidic and mild alkaline environments. Performs well in a wide range of acidic oxidants and solvents. Suitable for elevated temperatures.

Versions are available to achieve ASTM E84 Class I flame spread with or without antimony trioxide. Exhibits mild corrosion resistance to acidic environments.

Vipel F010-H2O

Bisphenol A

Epoxy Vinyl Ester

Elastomeric Bisphenol A

Epoxy Vinyl Ester

F013-H2O

Vipel F017

Isophthalic Neopentyl Glycol Polyester Vipel F707-PVA

Certified to NSF/ANSI 61 standard for use in potable water applications and sodium hypochlorite. When used as directed, the fabricator does not need to perform additional testing to manufacture NSF/ANSI 61 compliant coatings.

Designed as a primer for bonding fiberglass laminates to steel, concrete and other substrates. Exhibits improved interlaminar adhesion and can be used to manufacture composites with extra flexibility.

PVC bonding formulation with broad chemical resistance at moderate temperatures.

Many of the applications and chemical services listed in the guide make reference to NOTES in the column adjacent to the chemical. These notes are an integral part of the listing recommendation and must be strictly followed. The notes will indicate those applications requiring different veil materials, cure systems, liner construction or thickness and post curing requirements.

In those instances where the specific application is not listed, the fabricator is encouraged to contact AOC. The information in the “Gathering Data” section above should be included and directed to:

Corrosion Product Leader

Phone: +1 901 854 2800

E-mail: corrosion@aocformulations.com

Number Remark

Our recommendations should not be taken as inducements to infringe any patent or violate any law, safety code or insurance regulation. The term resistance is used in the sense which is commonly used in the trade, not as the complete retention of all optical and mechanical characteristics. Refer to ASTM G 15 and ASME/ANSI RTP-1 for common corrosion definitions.

The resistance of Vipel formulations to chemical environments listed in this guide has been established according to ASTM C581 and the ASME/ANSI RTP1 standard coded “Reinforced Thermoset Plastic Corrosion-Resistant Equipment.”

The Vipel Chemical Resistance Guide and its contents are the confidential and proprietary information of AOC and it may not be modified, altered, deconstructed or presented in any other manner without the explicit authorization of AOC and/or its legal counsel.

Abbreviations

1 Contact our corrosion specialists NR Not recommended.

2 Double synthetic veil should be used in the chemical resistant barrier

“ALL” in concentration column refers to concentrations in water.

3 Double C-glass veil should be used in the chemical resistant barrier “100” in concentration column refers to the pure chemical.

4 Acid resistant glass should be used in the chemical resistant barrier

5 Chemical resistance barrier thickness should be 5 mm

6 Benzoyl peroxide/amine cure system is recommended (for chemical resistant barrier)

7 Acid resistant glass recommended in the structural wall

8 Post cure recommended for improved service life.

9 Satisfactory up to maximum stable temperature of stored component

10 Stored chemical can discolour in contact with FRP laminate

11 Vipel® F013 series should be used instead of Atlac® F010 series.

12 Safety Data Sheet of specific chemical required

13 Stored chemical can discolour in contact with Novolac Vinyl Ester FRP laminates

14 Vipel F764, Vipel F774 or Vipel F798 resins are preferred products over Vipel F701.

15 Only F010, F007, F013, F015, F701, F737 and F764 are suitable for FDA/USDA applications.

16 Vipel K022 or K026 preferred

“SAT'D” in concentration column refers to maximum dissolved solute in water at a given temperature/pressure.

anhydride

Acetone : Methylethyl ketone: Methylisobutyl ketone : H2O

Acetonitrile

Acetyl acetone 100 NR NR NR NR NR NR NR NR NR NR NR NR

Acetyl

Acrolein (= Acrylaldehyde)

Acrolein (= Acrylaldehyde) 21 - 100 NR NR NR NR NR NR NR NR NR NR NR NR NR NR

Acrylamide

Acrylic acid 1

Acrylic acid

Acrylic latex

Acrylonitrile 100 NR NR NR NR NR

Ammonia (wet gas) See Ammonium hydroxide

Ammonia, liquified

bisulfite black Liquor

Ammonium hydroxide (aq. ammonia)

hydroxide (aq. ammonia)

Ammonium hydroxide (aq. ammonia)

Ammonium hydroxide (aq. ammonia)

Ammonium thioglycolate

thiosulfate

Aqua regia (HCl : HNO3 = 3 : 1)

Benzene : Ethyl benzene

Benzyl alcohol (= hydroxy toluene)

Benzyltrimethylammonium chloride

Biocides

Biodiesel/FAME (max

methanol)

Black liquor (pulp mill)

Bleach, Calcium hypochlorite

Bleach, chlorine dioxide

Bleach, chlorine water

Bleach, Lithium hypochlorite,

Bleach, Sodium hypochlorite

Borax (Sodium tetraborate, Sodium borate)

Boric acid

Brine, chlorinated

Brine, salt

Bromine, liquid

Bromine gas, dry

Bromine gas, wet

Bromine Water

Butanediol (all isomers)

Butanol (n-) (= Butyl alcohol, all isomers)

glycol

Butoxyethanol (2-)

Butoxyethoxyethanol (2,2-)

acetate

Butyl acrylate

diglycol

Butyl stearate (5% in mineral spirits)

See Calcium hypochlorite

See Chlorine dioxide

See Chlorinated water

See Lithium hypochlorite

See Sodium hypochlorite

See Chlorinated brine

See Sodium chloride

Cane sugar liquor & sweet water

Carboxy

Caustic

Chlorine / Hydrochloric acid, wet

Chlorinated brine,

Chlorinated brine, pH 2.5 - 9

brine, pH > 9

Chlorine

Chloroacetic acid (Monochloroacetic acid)

Chloroacetic acid (Monochloroacetic acid)

Chloroacetic acid (Monochloroacetic acid)

Chloroethylene (1,1,1-)

Chloroform

Chloroparaffin

Chloropyridine (tetra)

Detergents,

Di 2-ethylhexyl phosphoric acid (in kerosene)

Dibutyl sebacate

Dibutylamine (n-)

Dichloroacetic acid

Dichlorobenzene

Dichloroethane

Dichloroethene

Dichloromethane (= Methylene chloride)

Dichloropropane

Dichloropropene

Dichloropropionic acid

Dichlorotoluene

Diesel fuel, Aromatics, Methanol

Diesel fuel, No Aromatics, No Methanol

Diethanol amine

Diethyl amine

Diethyl aniline

Diethyl benzene

Diethyl formamide

Diethyl maleate

Diethyl

Diethyl sulfate

Diethylene glycol

ether

Dimethyl acetamide

Dimethyl amine (DMA)

Dimethyl aniline (= Xylidine)

Dimethyl formamide (DMF)

Dimethyl morpholine (2,6-)

Dimethyl phthalate

Dimethyl sulfate

Dimethyl sulfide

Dimethyl sulfoxide (DMSO)

Dinonyl phthalate

Chemical Substance

phthalate

Dioctylsulfosuccinate sodium salt

Dioxane (1,4-)

Diphenyl ether (Diphenyl oxide)

Dipiperazine sulfate

Dipotassium phosphate (Hydrogen phosphate)

Dipropylamine (n-)

Dipropylene glycol

Disodium phosphate (Hydrogen phosphate)

Chemical Substance

Ethylenediaminetetraacetic acid, EDTA

Ethylene dibromide

Ethylene dichloride

Ethylene glycol

Ethylene glycol monobutyl ether (2-Butoxyethanol)

Ethylene oxide

Ethylhexanol (2-)

Ethylhexylacrylat (-2)

Eucalyptus oil

Fatty acids (C12 or

Glycolic

Gypsum Slurry

Isobutanol (= isobutyl alcohol)

Isopropanol (Isopropyl alcohol)

Isopropylamine See Propylamine

Isopropyl myristate

Limestone slurry See Calcium carbonate

Mercury (I) chloride) (Mercurous chloride)

Mercury(II) chloride (Mercuric chloride)

Mercury(II) nitrate (Mercuric nitrate)

Methyl bromide, gas

Methyl ethyl ketone

Methyl isobutyl ketone (MIBK)

Methyl methacrylate

Methylamine

Methylcellosolve

Methylchlorophenoxyacetic acid (MCPA)

Methylchlorophenoxypropionic acid (MCPP)

Methyldiethanolamine

Methylene bromide

Methylene chloride See Dichloromethane

Methyleneblue salts pH 2-5.5, aqueous

Methylpentanol (2-)

Methylstyrene

Molasses and Invert molasses (2 < pH < 9)

Monochloroacetic acid See Chloroacetic acid

Monochlorobenzene See Chlorobenzene

Monoethanol amine

Muriatic acid

Octanoic acid See Caprylic acid

Octylamine (all Isomers)

Oils (grease, lube, Vegetable)

Pentanedioic

Pentanol See Amyl alcohol

Pentasodium triphosphate See Sodium

Phthalate esters

Piperazine dihydrochloride

Plating solution, Cadmium

(3.2% Cadmium oxide, 10% Sodium cyanide, 1.2% Sodium hydroxide)

Chemical Substance

Plating solution, Chrome

(18.5% Chromic acid, 0.6% Sodium fl uosilicate, 0.01%

Sodium sulfate)

Plating solution, Gold (23%

Potassium ferrocyanide, 0.2%

Potassium gold cyanide, 0.8%

Sodium cyanide)

Plating solution, Lead (8% Lead, 0.8% Fluoboric acid, 0.4% Boric acid)

Plating solution, Nickel (11.3%

Nickel sulfate, 1.4% Nickel chloride, 1.1% Boric acid)

Plating solution, Nickel

(43.7% Nickel sulfate, 3.5% Ammonium chloride, 3.5% Boric acid)

Plating solution, Silver (3.9% Silver cyanide, 6.5%

Potassium cyanide, 1.6%

Potassium carbonate, 4.5% Sodium cyanide)

Plating solution, Tin Fluoborate (18.3% Stannous fl uoborate, 7.4% Metallic tin, 9.1% Fluoboric acid, 2.3% Boric acid, 0.1% Naphtol)

Plating solution, Zinc Fluoborate (49% Zinc

fl uoborate, 4.4% Ammonium chloride, 5.9% Ammonium fl uoborate)

Plating solutions (other types)

Polyacrylamide

Polyester resins (styrenated)

Potassium pyrophosphate See Tetrapotassium diphosphate

Sodium bicarbonate :

carbonate (15%:20%)

Sodium borate

Sodium

(active

Sodium phosphate See Mono-, Di-, Ortho-, Tri-

Sodium polyacrylate

Sodium sulfhydrate See Sodium hydrosulfide

Sulfamic acid

Sulfated detergents See Sulfonated detergents

Sulfanilic acid

Sulfonated detergents

Sulfur

Sulfur trioxide gas, dry

Sulfur trioxide gas, wet FUMES

Sulfuric acid >80

Sulfuric acid (= Oleum)

Sulfuric acid : Ferrous sulfate

Sulfuric acid : Phosphoric

Sulfurous acid 10 120 /

Sulfuryl chloride

Sulfite/ Sulfate liquors (Pulp mill)

Sulfonyl chloride, aromatic ALL

Superphosphoric acid

acid

Tetrachloroethylene (Tetrachloroethene)

Tetrachloropyridine

Tetrapotassium pyrophosphate (Potassium pyrophosphate)

Tetrasodium ethylenediaminetetraacetate (Na-EDTA)

Tetrasodium pyrophosphate

(tetrahydrofuran)

(tetrahydrofuran) >

Thioglycolic acid See

Thionyl chloride

Tobias acid (2-naphthylamine - 1-Sulfonic)

Toluidine (0-, m-, p-)

(Ester

Tributylamine -N

Trichloroacetaldehyde

Trichlorobenzene

Trichloroethane

Trichloromonofluormethane

Trimethylene

Tripotassium phosphate (K5O10P3)

Trisodium

Tritolyl

Americas +1 866 319 8827 americas@aocformulations.com

Europe, Middle East, Africa +41 52 644 1212 emea@aocformulations.com

China

+86 25 8549 3888 china@aocformulations.com

Asia Pacific +41 52 644 1212

asiapacific@aocformulations.com

AOC is a registered trademark of the AOC group of companies.

The information contained in this publication is based on laboratory data and field experience. We believe this information to be reliable, but do not guarantee its applicability to the user’s process or assume any liability for occurrences arising out of its use. The user, by accepting the products as described herein, agrees to be responsible for thoroughly testing each such product before committing it to production.

Vipel® , the AOC name, the AOC logo, and the Trusted Solutions logo are registered trademarks of the AOC group of companies.

Nothing herein is to be construed as granting permission to use, or inducing or recommending the use of any patent or resulting invention without a valid license.

The information and recommendations contained herein are to the best of our knowledge accurate and reliable, but no rights whatsoever may be derived by any party other than those expressly agreed to with a selling entity of the AOC group of companies in a legally binding agreement. AOC hereby makes no warranty of any kind, express or implied, including those of merchantability and fitness for purpose. Unless explicitly agreed to in writing by AOC otherwise, all offers, quotations, sales and deliveries of AOC products are subject to the general conditions of sale of AOC

© 2026 – AOC Group of Companies

For more information email: americas@aocformulations.com visit: aocformulations.com