FUELLING LOWER EMISSIONS

Biodiesel production going strong in Welland

With an ANDRITZ Consignment agreement, you can rest easy knowing the inventory and logistics of your spare and wear parts, including repair and rebuild services, are under control. And with predictable pricing and parts you only pay for once you use them, “unscheduled” is no longer something that keeps you up at night.

Contact your ANDRITZ Territory Manager or scan the QR Code for additional details.

Phone +1 (570) 546-1253

Email: andritz-fb.us@andritz.com andritz.com/feed-and-biofuel-en

11 Changes to combustible dust

New regulations coming to B.C. industries.

18 2024 WPAC Show Guide

The official show guide of the Wood Pellet Association’s annual conference taking place in Victoria this fall.

20

Alberta is calling… and pellet producers are answering

WPAC’s Gord Cooke visits La Crete Sawmills' pellet operations in La Crete, Alta.

22

Converting landfill gas to RNG in Edmonton

The Clover Bar Landfill in Edmonton is in the early process of developing a system to convert the gas produced from decomposing landfill organics into renewable natural gas for injection into Alberta’s natural gas distribution system.

24 Pellet Gear Buyer’s Guide

Canadian Biomass’ annual Pellet Gear Buyer’s Guide rounds up suppliers of pellet production and safety equipment.

IGetting DHAs right

The top five mistakes made in Dust Hazard Analysis reports

recently had the pleasure of attending the 2024 Global Dust Safety Conference. One of the sessions that caught my interest was presented by Diane Cave, eastern lead for Element6 Solutions. Cave presented “Top five mistakes identified during external audits and reviews of incomplete Dust Hazard Analysis (DHA) reports.”

During this informative presentation, Cave offered her top five DHA report mistakes based on her 20-plus years of experience, which I wanted to share with the readership in countdown order:

#5) Too much filler

Cave identified too much filler in the DHA reports. One example she touched on was unnecessary multi-page resumes. Other examples of filler included the same information being repeated over and over; and details on the sizing of equipment. She added that DHA reports should also not be used as sales pitches or be a regurgitation of the code.

#2)

Language

Soft or weak language such as “might consider,” “should think about,” or “should consider,” should not be used in DHA reports, Cave said. Another type of language that should not be used is overly technical language. Similar to soft or weak language, non-concise language is another issue.

#1) Lacking clear recommendations and a path forward

One example is having the DHA report simply list codes and standards that have not been met without clearly explaining a path forward. Cave reminded attendees that when creating DHA reports, that they’re not about teaching all the intricacies of fire and deflagration hazards, a regurgitation of the code, or a summary of the codes that were not met. DHA reports need to review and communicate results that include defined areas of risk.

Volume 24 No. 3

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Customer Service Ph: (416) 510-5113 Fax: (416) 510-6875 Email: apotal@annexbusinessmedia.com Mail: 111 Gordon Baker Rd., Suite 400 Toronto, ON M2H 3R1

Interim Editor - Andrew Snook Ph: (416) 510-6801 asnook@annexbusinessmedia.com

Contributors - Gordon Murray, Jeannine Moyer, Derek Nighbor.

Group Publisher - Anne Beswick abeswick@annexbusinessmedia.com Ph: (416) 510-5248 Mobile: 416-277-8428

Account Coordinator - Shannon Drumm Ph: (416) 510-6762 sdrumm@annexbusinessmedia.com

National Sales Manager - Rebecca Lewis Ph: (519) 429-5196 rlewis@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick twshaddick@gmail.com Ph: (604) 264-1158 Fax: (604) 264-1367

Audience Development Manager - Serina Dingeldein Ph: (416) 510-5124 sdingeldein@annexbusinessmedia.com

Media Designer - Curtis Martin CEO - Scott Jamieson

Canadian Biomass is published four times a year: Winter, Spring, Summer and Fall. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

#4) Poor identification of hazards

Issues Cave has encountered related to poor identification of hazards include lengthy discussions on theoretical items; and identifying hazards that are not actually DHA-related hazards.

#3) Poorly organized or hard to read

This included problems like equipment being named incorrectly, and it being unclear what process is being evaluated. Reports not having pictures, or being stuck in an appendix forcing the reader to be constantly surfing through different parts of the report, is another common issue.

“You want to make sure that you give it a risk ranking or a hazard analysis, and put a number beside it. Give the people, ‘This is your problem. This is how bad it is.’ Some form of where to start,” Cave said. “These people that get the report have a million other things to do, and they're making product XYZ, and they want to know what the problem is, and then where to start, and then a rough idea of how to get there.”

Well said, Diane Cave. High-five for your top five. Stay safe everyone •

Subscription Rates: Canada - 1 Yr $58.14; 2 Yr $104.04 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $123.93 CDN; Foreign – 1 Yr $140.76 CDN

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2024 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

FSC UNVEILS LANDMARK PUBLICATION: FOREST FUTURES

The Forest Stewardship Council (FSC) recently announced the release of its flagship publication, Forest Futures. This pivotal work leverages current scientific research to assess the state of the world’s forests and explore their potential for profound change. It underscores the vital role of forest stewardship in fostering resilient and healthy ecosystems.

Forest Futures provides an in-depth analysis of today’s forests, addressing critical issues such as biodiversity loss, the ability of forests to support livelihoods, and the urgent need to tackle the climate crisis. It sheds light on the shared understanding of forest stewardship and highlights how this approach has been undervalued by many decision-makers as a viable solution to these global challenges.

ENVISIONING THE FORESTS OF THE FUTURE

To explore three potential trajectories for the world’s forests by 2050, FSC collaborated with Reos Partners, renowned for their expertise in systems-change studies and transformative scenarios

mapping. Input from over 200 stakeholders helped identify four key drivers influencing forest management, conservation, and sustainable use. Leveraging these drivers, the three distinct trajectories were outlined and mapped out. These drivers are (1) Forests & Planet, (2) People, (3) Economy & Markets, and (4) Governance. These trajectories, developed through an innovative modelling exercise, demonstrate the profound impact that different levels of commit -

ment to forest stewardship can have on our planet.

“Forests are at the heart of our environmental and socio-economic future,” said Kim Carstensen, director general of FSC. “Our flagship publication demonstrates that by embracing forest stewardship, we can unlock their potential for positive change. This is not just about preserving forests, but about enhancing their role in addressing global challenges such as climate change, biodiversity loss, and social inequity”.

FSC continues to lead the way toward a future where forests can thrive, advocating for responsible forest management practices that meet societal needs while preserving ecological integrity. Forest Futures calls for transformative change, offering a tangible strategy for achieving environmental targets. It urges governments, businesses, NGOs, and other key actors to join in creating a future where forests flourish, communities thrive, and our planet achieves harmony.

Read the full publication at: https://fsc. org/en/forestfutures.

Source: FSC Canada.

CANFOR PRESIDENT AND CEO TO RETIRE AT END OF 2024

John Baird, Chairman of the Canfor Corporation Board of Directors, announced that Don Kayne, president and CEO, plans to retire at the end of the year. Kayne has been with Canfor for 46 years and has held the position of president and CEO since 2011.

Under his leadership, the company has grown and transformed from its British Columbia roots into a global entity with operations in Alberta, the United States and Sweden. As a respected industry leader, he has been a constant champion for the forest products sector, serving in a variety of industry roles including Chair of the Forest Products Association of Canada, the BC Council of Forest Industries and the Bi-national Softwood Lumber Board.

Canfor is also announcing the appointment of Susan Yurkovich as the company’s next CEO. Currently serving as Canfor’s senior vice-president of global business development, Yurkovich brings three decades of experience working in the natural resources sector to the role, 12 of those years with Canfor. She has served in executive roles in both forestry and energy including as president and CEO of the BC Council of Forest Industries and executive vice-president at BC Hydro.

“On behalf of the Board of Directors, I would like to express our sincere gratitude to Don for his extraordinary contributions and commitment over many decades at Canfor,” said Baird. “As we transition to new leadership under Susan, I am confident we will continue to build on our global operating platform, while advancing new opportunities to innovate and expand our product offerings.”

Yurkovich’s appointment as CEO will take effect January 1, 2025. Kayne will continue in an advisory capacity through 2025.

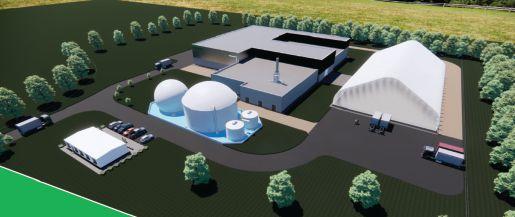

NEW WASTE-TO-RENEWABLE ENERGY PROCESSING FACILITY ANNOUNCED

IN QUEBEC

A new waste-to-renewable energy processing facility has been announced in Quebec that will utilize advanced anaerobic digestion and in-vessel composting technology to convert up to 35,000 tonnes of organic waste annually into renewable energy (biogas) and nutrient-rich fertilizer and compost.

The announcement was made by the Convertus Group (Convertus), which, along with Énergère, a leading energy services company in Quebec, plans to design, build, finance, and operate a cutting-edge organic waste processing facility in Saint-Étiennedes-Grès, Que., under a 20-year operating contract.

“We are excited to contribute to the sustainability goals of Mauricie Region’s communities by providing an innovative organic waste management solution,” said Michael Leopold, CEO of Convertus Group. “Our full-service approach to designing, constructing and operating new organic waste processing facilities across North America ensures maximum resource recovery while minimizing environmental impact.”

The new facility is scheduled to receive its first waste in 2026, and will “address the increasing environmental challenges associated with organic waste disposal in Mauricie Region,” according

YATSUSHIRO BIOMASS POWER PLANT STARTS UP OPERATIONS IN JAPAN

Image: Convertus.

to a Convertus press release. The company intends to supply the biogas to Enercycle’s onsite gas upgrader where it will be further processed and compressed into RNG.

“We expect 48,900 (GJ/yr) of biogas, which will be delivered to the existing Enercycle gas upgrading system and will be upgraded to RNG for grid injection,” said Ann-Marie Cooper, human resources and communications manager for Convertus.

Construction will begin in spring 2025 and commissioning is expected to take place in mid-2026. The company stated that the GHG emissions that could be reduced through the use of this technology range from 1,500 to 2,500 tCO2/yr.

“Each step in reducing greenhouse gases is a victory for our planet,” stated Mario Geoffrey, director of biomethanization at Énergère.

CHAR TECH ANNOUNCES PRODUCTION MILESTONE AT THOROLD FACILITY

Toyota Tsusho Corporation (Toyota Tsusho) recently announced that Kumamoto Forest Generation, jointly invested by Toyota Tsusho Group company Ene-Vision Co., Ltd., Chubu Electric Power Co., Inc., and Toho Gas Co., Ltd., completed construction on the Yatsushiro Biomass Power Plant with commercial operations starting up on June 16, 2024. The 75,000-kW power plant is fuelled by wood pellets and wood chips (mainly unused wood from Kumamoto Prefecture), and is expected to generate approximately 480 million kWh annually. Construction on the power plant began on April 18, 2022.

“Through the operation of the power plant, Kumamoto Forest Generation will continue to promote initiatives toward carbon neutrality and contribute to the realization of a sustainable, recycling-based society,” the company stated in a press release.

CHAR Technologies (CHAR Tech) has announced the “imminent commencement” of a production of 500 tonnes of pelletized biocarbon, which will be shipped to a variety of heavy industrial facilities, including ArcelorMittal sites to fulfill a portion of the company’s previously announced biocarbon offtake agreement. The company stated that this is an important production milestone in the ongoing commercial upgrades at CHAR Tech’s Thorold facility in Thorold, Ont.

“Pelletization of biocarbon is a critical step in meeting the specifications, including physical properties, of met coal to allow for direct drop in-replacement,” stated Andrew White, CEO of CHAR Tech. “It can also be a tricky step with a number of different operational factors at play to be able to create a pelletized material that can be used in heavy industrial applications, and that can withstand handling, transportation and weather.”

CPM ACQUIRES INNOVATIVE PELLETING SOLUTIONS GMBH

CPM recently announced that it has acquired Innovative Pelleting Solutions GmbH and its high-capacity, direct drive pellet mill technology invented by Graf Equipment GmbH. The company stated that the purchase brings new technology to the CPM biomass portfolio, including a high capacity, direct drive pellet mill capable of processing various biomass feedstocks, and that the acquisition demonstrates CPM’s commitment to its customers looking for higher-capacity, more energy efficient biomass machines.

With CPM’s biomass equipment portfolio now including three types of pellet mill solutions, the company stated that is can offer customers the flexible options they need to plan their optimal processing operation. The CPM biomass portfolio now offers a full range of technologies including Direct Drive, Gear Drive and Belt Drive pellet mills.

The company stated that the all-new Direct Drive technology is beneficial for several reasons: the force from the pellet mill motor is directly driven to the machine which reduces the need for other mechanical components thus offering a smaller footprint and simplified maintenance; and higher torque produces denser pellets.

The technology is also desinged to be more sustainable as it lowers the use of grease due to its low vibration and low die speed which also preserves the longevity of machine parts.

FSC CANADA NAMES NEW PRESIDENT AND CEO

The Forest Stewardship Council (FSC) Canada has announced that Monika Patel will succeed François Dufresne as president and CEO of the FSC, effective January 1, 2025. Patel is currently the director of communications and marketing for FSC Canada. She will start her transition into the new role by first taking on the role of deputy president, starting on July 1, 2024. Dufresne will remain with the FSC as a special advisor throughout 2025.

“It has been an honour to serve as president of FSC Canada, and I am confident that Monika will continue to drive our mission forward. Her leadership and vision are exactly what FSC Canada needs to thrive in the coming years,” Dufresne said.

APowering sustainability

The role of biomass in electrification

cross Canada and around the globe there’s an electrification revolution. Reducing our reliance on fossil fuels and shifting to emissions-free electricity to propel our cars, heat our homes and run our factories will require doubling, or possibly tripling, the amount of power we make now.

According to the Public Policy Forum’s Project of the Century: A Blueprint for Growing Canada’s Clean Energy Supply – And Fast, Canada must build more electricity generation in the next 25 years than it has over the last century to support a net-zero emissions economy by 2050.

Powering the shift from fossil fuels to clean, renewable and responsible energy will require new innovations and solutions. Biomass and wood pellets have a critical role to play in the transition to a greener and brighter future.

While there are varying opinions on what technologies will be needed, one thing everyone can agree on is that achieving our goals will require smart combinations of renewable resources and effective policies to reduce emissions. We’re also not the only nation grappling with this catch-22 scenario of both establishing an emissions-free grid and expanding current grid capacities.

In 2012, Sweden reached their target of 50-per-cent renewable energy eight years ahead of schedule on their 2040 goal of 100-per-cent fossil-free renewable electricity production. They achieved this

By Gord Murray

by leveraging their natural assets, using a combination of wind, bioenergy, and solar. Like Canada, Sweden has a rich supply of moving water and biomass, which contributes to the country’s high share of renewable energy. The largest source of bioenergy in Sweden is the forest.

The Swedes have proven what many of us have long believed: bioenergy isn’t just good for our bottom lines; it’s also good for our forests. In Sweden, 37 per cent of its energy is from biomass; and since 1990, they have doubled their bioenergy consumption while increasing their standing timber volume by 40 per cent; resulting in a 70-per-cent reduction in GHG emissions. Imagine the potential for bioenergy in Canada with 367 million hectares of forests compared to Sweden’s 28 million hectares. This combined with

"The Swedes have proven what many of us have long believed: bioenergy isn’t just good for our bottom lines; it’s also good for our forests."

the fact that we still leave tens of millions cubic metres of forest residuals on the ground following harvesting or natural disturbances – residuals that could go towards bioenergy, keep communities safer and reduce carbon emissions from fires. Talk about a missed opportunity!

This September, WPAC will host its annual conference in Victoria, B.C. from September 17 to 18, where we will gather experts from across the country and around the globe to explore the role of biomass in electrification, and what we need to do to help our sector reach its highest potential. One such expert that you won’t want to miss at our conference is longtime CBC reporter and author Bob McDonald, who believes that humans have already invented everything they need to solve the climate crisis. However, he says transitioning to a greener economy will require political will, economic investment and public acceptance. McDonald is the author of The Future Is Now: Solving the Climate Crisis with Today’s Technologies and the host of CBC Radio’s award-winning science program, Quirks & Quarks.

The BioNorth Energy biomass power generation facility in Fort St. James, B.C. Photo: Arrow Group of Companies.

As McDonald rightly points out, there’s no silver bullet. A green future will use solar, biofuel, wind, wave, tidal, geothermal, nuclear, fusion and hydrogen power. But there is still much to do. According to McDonald, green energy is still a fringe component of our energy supply, with wind accounting for only 3.5 per cent of our energy and biomass providing a mere 1.4 per cent. The good news is that bioenergy from our forests is gaining traction in remote communities across Canada, the Maritimes and even in provinces once known for their abundant supply of hydroelectric power. Our sector, long respected across Europe, the U.K. and Japan is quickly making its mark at home.

I hope you’ll be able to join our conference this year as we examine the global demand for clean energy solutions and discuss our sector’s state of readiness. We will explore trending safety initiatives like process safety management to ensure our sector is not just ready to grow, but to do so safely. We will learn from First Nations leaders who are advancing Indigenous-led approaches to sustainability using ancestral wisdom and hear about modern tools to demonstrate compliance with emerging trade requirements. Together we will also examine the future of AI in achieving our sector’s full potential. I look forward to seeing you in Victoria, B.C. •

Combustible Dust Specialists

Allied brings 49 years experience to help you meet current NFPA Standards with: system design/documentation, spark detection, isolation, grounding, PLC, venting, blast path management, clean-up systems and duct audits — CWB certified and member SMACNA.

Sawmill – Biomass – Boardplants – Pulp & Paper – Power Generation – Mining 50 years of Industrial Air Systems www.alliedblower.com ◆ Phone: 800-576-3611

Surrey,BC ◆ Vernon,BC ◆ WilliamsLake,BC ◆ Edmonton,Alberta ◆ PrinceAlbert,Sask ◆ Mobile, Alabama

1:51

OPG biomass power plant in northen Ontario.

Photo: WPAC.

HARGASSNER: 40 YEARS OF COMFORTABLE HEATING WITH RENEWABLE HEAT

Competence, innovation, sustainability, family business - these are the values that stand for an international heating company with 185,000 customers worldwide and 1,250 employees today. The company is already represented in more than 43 countries and the export rate is 79%. This is how the “Hargassner” brand is recognized today.

It all began in 1984 with the promise of biomass pioneer Anton Hargassner Sr. to his wife: “I’ll build you a heating system that you’ll never have to refill by hand again”.

This meant that he had to develop an automatic filling system for the family’s wood chip heating boiler. On the way to becoming a global player Anton Hargassner Sr. acquired many patents for these innovations. These developments remain the foundation of the company’s success today.

Stefan Kopp, CEO, Hargassner North America

“Hargassner has been committed to the North American biomass heating market for more than 20 years. Last year we invested in an official company headquarters, warehouse space and local staff in Toronto to better support Hargassner’s growing base of customers, dealers and contractors across North America. This year, we are proud to announce that our new website, hargassner.com, has just gone online.” Stefan Kopp, CEO, Hargassner North America

BIOMASS SAVES MONEY VS FOSSIL FUEL

Facing rising fuel costs, customers are searching for sustainable heating options for their homes and businesses. Using wood pellets, wood chips or wood logs as a fuel source is not only more cost effective

than burning oil or gas, it also supports the local economy and recycles residual wood in a sustainable manner. Further advantages include the fact that the biomass fuel for Hargassner’s boilers is exempt from the carbon tax, and buyers benefit from a 30% federal investment tax credit.

TAILORED BIOMASS HEATING SYSTEMS FOR EVERY NEED

The company offers an individual biomass boiler system scaled to meet almost every level of demand - from single-family homes up to larger-scaled installations for farms, greenhouses, hotels and industry. Hargassner produces solutions from 23 kW (78,500 BTU/h) to 330 kW (1,125,000 BTU/h) and in cascade set-ups (multiple boilers connected) up to 2 MW (6,700,000 BTU/h).

COST EFFECTIVE AND EASY TO OPERATE

The company guarantees the lowest possible maintenance requirements and long operational life for its full range of equip-

ment. With the remote control via phone or tablet, customers can easily change settings on their biomass boiler or even check its status. The user interface is simple and intuitive to operate. Importantly, the company’s biomass boiler systems are officially certified and approved by the U.S. EPA and the CSA.

Changes to combustible dust

New regulations coming for B.C. industries

By Andrew Snook

In British Columbia’s forestry sector, there has been no year filled with more preventable tragedies than 2012.

In January of 2012, the Babine Forest Products sawmill in Burns Lake suffered an explosion that resulted in the deaths of two workers while injuring 20 others. A few months later in April 2012, about a 2.5-hour drive from Burns Lake in B.C.’s Northern Interior, the Lakeland Mills sawmill in Prince George exploded, killing another two works and injured 22 more people. The investigations into these explosions found one culprit responsible for both tragedies: combustible dust.

Since that time, regulations have been tightened to ensure better management of combustible dust throughout the province.

B.C.’s management of combustible dust was the topic of the closing keynote presentation for the 2024 Global Dust Safety Conference, which took place earlier this year. The presentation, “Upcoming release process for the proposed British Columbia regulations for combustible dust. Why they are needed and what it means for industries in B.C.,” was presented by Rodney Scollard, senior policy and legal advisor, and Mike Tasker, CRSP occupational safety officer with WorkSafe BC.

They reviewed proposed upcoming regulation changes regarding combustible dust in the province of British Columbia; provided a background on what drove regulation change in BC over the past decade; the timeline for the new regulations to come into effect; the roadmap to combustible dust hazard assessment and management provided in the regulations; and what these changes may mean for industries in B.C.

BACKGROUND

When the sawmill explosions took place in 2012, WorkSafe BC had enacted Workers Compensation Act policies related to the general duties of employers, workers and supervisors in relation to how they identify and manage the risk associated with wood dust. The proposed regulations expands on the policies related to wood dust.

“The provisions we have currently around combustible dust, and controlling the hazards associated with it, is very limited, and not very detailed,” Scollard explained. “So, there’s been this drive now to introduce specific dust-related regulations within our occupational health and

safety regulation. And in doing so, these new regulations will ultimately replace those three current policies that were introduced after the 2012 incidents.”

REGULATION CHANGES

While the focus of WorkSafe BC has understandably been on regulations related to combustible wood dust, the proposed regulations would expand the types of dusts within the regulations.

“Most of our focus from a regulation perspective has been devoted to combustible wood dust. Certainly, that is an issue that we needed to address. So, under the proposed regulation, it’s been greatly expanded to any dust that is handled or

The currently proposed regulations expands on the policies related to combustible wood dust. File photo.

generated at the workplace,” Tasker said. “That ‘handled or generated’ is an important aspect. We’re not talking about the dust that might accumulate on a windowsill. We’re talking about dust that is either handled or generated. So, handled or generated through pulverizing processes, grinding processes, material size reduction processes, and that sort of thing. Handled meaning things like conveying it, moving it, storing it, those kinds of examples.”

The type of dust within the proposed regulation could include wood dust, agricultural dust, plastic dust, manufactured powders and lint.

“If it’s combustible, then it’s covered by the regulation,” Tasker said.

Dust that is in sealed commercial packaging is excluded from the proposed regulation.

“A sealed bag of shavings for a rabbit cage in a pet store is not covered by this regulation, it’s excluded,” Tasker said.

While the current version of the proposed regulation on the WorkSafe BC website, “Part 6, Substance Specific Requirements: Combustible Dusts,” is not the finalized approved version of the regulation, Tasker said that he believes it is very close to a final version.

“We don’t know exactly what the final version of the regulation is going to look like. However, I think, in my personal opinion, we’re getting pretty close to that,” he told attendees. “We’ve been working through the consultation process now for over a year, where we’re pretty clear on what has been recommended and what has

been adopted. So, I don’t foresee a lot of significant changes. But we just want to make it clear that the version of the regulation that you may access from our website is still a working draft, until it actually gets finalized and approved by our Board of Directors, and then moves forward through the rest of the approval process.”

When putting together the proposed regulations, Tasker said they tried to find a balance between performance-based regulation and prescriptive-based regulation.

“Because this regulation is intended to

cover workplaces that are both simple and complex, very large to very small, we had to strive to find a scalable regulation that could be applied across the board, regardless of the size or complexity of your operation,” he said. “In order to do that, we had to find a balance between those two regulatory methodologies.”

To address the performance-based aspect of the regulation, they expanded the requirements around conducting a risk assessment, so the risk assessment takes into consideration the characteristics of the dust, as well as the machinery and equipment that exists at a given workplace. It also expands the requirements for employers that have combustible dust, to have a combustible dust management program, Tasker explained.

“We also have a section that is more specific, more prescriptive in nature, that stipulates specific control measures that must be in place for particular risks or particular types of equipment. And it does provide some guidance specifically to those,” Tasker said.

An assumption clause has been put into the proposed regulations to help address

Photo: Adobe Stock/rsooll.

a notion of understanding about particular dusts, while reducinig costs for employers.

“For every employer to take representational samples of every dust they have, and to send it to a lab for testing, paying the money for that, and all the associated costs with it, was just overly burdensome, especially for small and medium sized employers,” Tasker said. “We also recognize that some dusts are easily recognizable as combustible. We don’t need to conduct those tests in order to understand and manage those dusts.”

To simplify things for employers, the assumption clause states if a workplace handles or generates a dust, employers must assume it’s ignitable and deflagrable, unless they do one of two things: test the dust or show evidence that it is not combustible.

“If you believe that the dust that you have at your workplace is not a combustible dust, you can send a sample to a lab, follow [WorkSafe BC’s] methodology and confirm that it is, in fact, not a combustible dust,” Tasker said. “Because we understand that there’s access to published data on various dusts, if you believe that your dust at your workplace is not combustible, you can rely on that objective published data, provided that it’s been derived from the prescribed testing method that’s indicated in the regulation.”

RISK ASSESSMENT

Once a company has dealt with the assumption clause, they can proceed to the next step in the process, which is to begin a risk assessment. Every employer in B.C. that has a combustible dust at the workplace is required to conduct a risk assessment in con sultation with a qualified person.

“Within the regulation, it outlines the risk assessment pro cess that needs to be followed the types of things that need to be considered in order for it to be a valid risk assessment. And we also provide language as to when that risk assessment has to be reviewed and updated,” Tasker said. “For example, if there’s a change in materials or machinery or processes, then there’s a re quirement to go back and review and update your risk assessment to reflect those changes.”

For the definition of a qualified person used by WorkSafe BC for the proposed regulation, the organization adopted the univer sal definition of qualified that WorkSafeBC relies on in Occupa tional Health and Safety Section 1.1.

“We didn’t come up with a specialized definition of qualified for the purposes of combustible dust,” Tasker explained.

After a risk assessment is completed and combustible dust has been identified in a workplace, the next step is to develop a combustible dust management program. The combustible dust management program should outline how to manage that risk, and what controls need to be put in place.

“Those controls can be many, can be few, depending on the on the nature of the workplace and the nature of the risk,” Tasker said. “This program is a written program that has to be developed by the employer, and once again, under consultation with a quali fied person. And within the regulation, we also stipulate the basic elements of a combustible dust management program in order for it to be considered adequate to manage the risk.”

THE FIVE FACTORS

The risk assessment and specific requirements that flow from within the proposed regulation are aimed at tackling these factors: What is the type and amount of fuel (dust) that’s present at the workplace? How much of it and what type is it?

What sources of ignition are around in that workplace that could ignite the dust?

What degree is there potential is for confinement of the dusts? What is the possibility of the dust being dispersed or suspended in the air?

And to a lesser extent, what amount of oxygen is present?

“That’s really what a lot of the provisions and requirements in the draft are flowing from, and what they’re aiming towards is having the employer control those five factors at their workplace,” Scollard explained.

TIMELINE

At the time of this article’s publication, the proposed regulation was still undergoing consultation in its draft format and is subject to change. Feedback was being accepted until May 17, 2024. “Part 6, Substance Specific Requirements — Combustible Dusts” is available to download at the WorkSafe BC website at: www.worksafebc.com/en/resources/law-policy/discussion-papers/part-6-substance-specific-requirements-combustible-dusts-2024-may?lang=en. •

DRYER CONTROL, PRODUCT QUALITY & MORE

MoistTech’s near-infrared moisture sensor allows manufacturers the ability to adjust moisture levels based on real-time information lowering raw material and fuel costs, prolonging equipment lifecycle and increasing product quality & production efficiency.

www.moisttech.com 941-727-1800

Fuelling lower emissions

Biodiesel production going strong in Welland

By Andrew Snook

Back in May 2019, Verbio Diesel Canada Corporation (a subsidiary of German company Verbio Vereinigte BioEnergie AG) purchased Atlantic Biodiesel Corporation’s biodiesel plant in Welland, Ont., which is designed to produce crude glycerin and biodiesel transportation fuel derived from canola and soybean oil. The acquisition assisted Verbio in pursuing its internationalization strategy focusing on the growing biofuels market in North America.

Five years since the purchase, Canadian Biomass decided to reach out and get an update on the status of the company from Verbio’s founder and CEO Claus Sauter.

How have operations at the Welland plant changed since Verbio acquired the facility? Since we took over the plant in May 2019, we have run the plant

Since Verbio took over the Welland facility in May 2019, it has run continuously seven days a week, 24 hours a day.

Verbio’s founder and CEO Claus Sauter. Images courtesy of Verbio.

continuously – seven days a week, 24 hours a day.

Our expertise from running biodiesel plants in Europe since 2001 helped increase the efficiency and production capacity of the plant while reducing costs significantly.

What is your current annual production at the Welland plant? What are your long-term production targets?

The plant has an annual production capacity of approximately 150,000 tons of biodiesel and 18,000 tons of raw glycerin. However, renewable energy markets are subject to the regional and global market conditions.

We have been pleased with the results being achieved by our Welland plant. In the past years, we have developed readily executable plans to increase production capacity, produce higher value by-products and use lower grade feedstocks.

As one of the leading global renewable energy companies, Verbio has always been reviewing plans for potential expansion and/or upgrades of its existing facilities as well as investigating options for new projects. However, current market conditions tied to regulatory uncertainty are delaying decisions for numerous renewable energy companies.

With clear sets of governmental and regulatory guidelines, Verbio will be able to make decisions on long-term investments.

The energy business has always been and will continue to be very capital intensive. Therefore, certainty and stability are desired in the market to ensure long-term success for its shareholders and employees.

Can you describe in detail the production and quality control processes used in the Welland operation to produce crude glycerin and biodiesel? For our biodiesel and glycerol production we use renewable sources like vegetable oil and methanol. The chemical process called “transesterification” is catalyzed by a caustic catalyst. This process is very efficient, using very little energy and producing nearly no waste or wastewater. Biodiesel produced in Welland is defi-

nitely an environmentally friendly and CO2 emission-saving biofuel.

Has sourcing feedstock for the Welland plant been challenging? Sourcing feedstock for the Welland plant so far has not been a challenge. It is actually quite the opposite. A major advantage of the plant is its connection to the railway infrastructure, which makes it easier for us to bring in raw materials.

How many people are currently employed at the facility? Has finding qualified staff been difficult during the labour shortages taking place over the past few years?

We currently employ 33 people at our plant in Welland, and we can say that it is not easy to find qualified staff in the Welland region. Therefore, we invest a lot in training our employees and providing a good working environment to avoid fluctuation.

With countries and companies looking to meet more aggressive carbon emissions reduction targets, how do you see facilities like the Welland plant and Verbio playing a significant role in helping them meet their targets?

All of what we do at Verbio is based on the principles of sustainability. Not only are we using an innovative approach to continuously optimize our use of resources, we also have steadily expanded our range of climate-friendly products that are created in an energy and CO2 efficient manner.

The raw materials we apply are almost completely utilized in multiple production steps. This steadily increases the efficiency of our production processes and reduces our own carbon footprint. With the products we supply, we drive decarbonization, especially in the industry and mobility sector.

Our customers are able to increase their carbon handprint goals and save a significant amount of GHG emissions.

To learn more about Verbio Vereinigte BioEnergie AG Welland biodiesel facility and other ongoing projects, visit: verbio-north-america.com. •

PRESSING FOR PROFITS

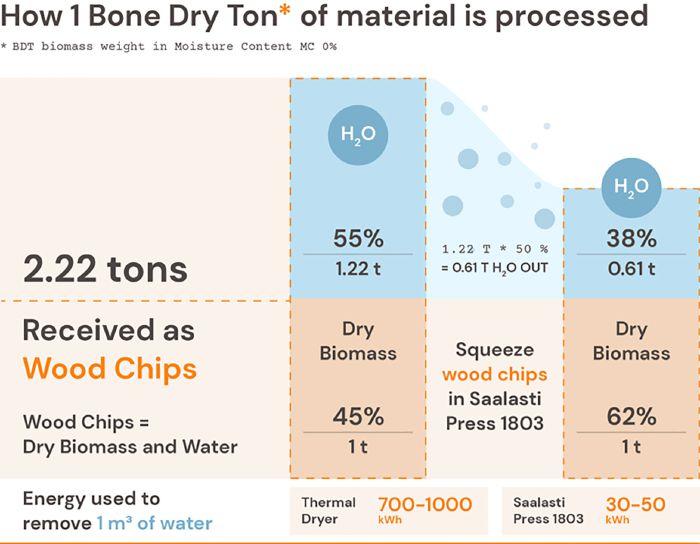

Wood pellets are too seldom the focus of innovative technology. It’s even more rare to see a novel solution that can both save money and reduce a pellet plant’s environmental impact. When it happens, it’s worth taking a closer look.

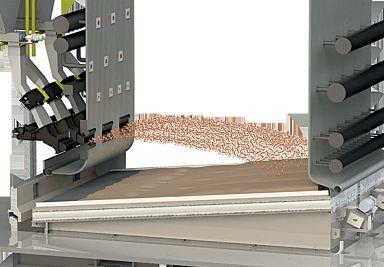

Mechanical dewatering of fibrous biomass is offering to shakeup the traditional pellet plant flow, with its ability to lower demand at both the dryer and the hammer mills. A high-pressure press installed before the dryer can squeeze out up to half the water of fresh wood chips, sawdust, hog fuel or any fibrous biomass.

Finnish-based Saalasti has been a producer of high-pressure presses since the ’80s and has introduced a new model – the Saa-

lasti Press 1803 – that uses 30 to 40 kWh to remove one cubic metre of water from fresh wood chips. Thermal drying, by comparison, uses 670 kWh for the same result.

Based in Finland and representing pellet customers globally, Saalasti’s chief sales officer Markus Rekonen says moisture content is a common challenge affecting the efficiency and quality of pellet production, leading to higher energy consumption and longer thermal drying times.

“The Saalasti High-Pressure Press addresses this issue by significantly reducing mechanically the moisture content in biomass, enhancing drying efficiency, saving energy, and improving the overall quality of the pellets produced,” Rekonen said in an email. Additionally, a more even mois-

ture content during thermal drying can help lower dust safety risks at the dryer.

To date, 13 Saalasti presses have been installed in B.C. in both pellet plants and pulp and paper facilities. Brent van Halderen, general manager of B.C.-based engineering firm PE Tech Ltd., has worked closely with Saalasti’s Nanaimo, B.C., office on those projects. He likens the Saalasti Press to a pulp machine.

“These [Saalasti] machines by design have a narrow nip so the pounds per square inch are significantly higher with the load you’re putting on it. They can get a higher pressure on that material.”

While each project is unique, van Halderen says they follow a similar flow. An in-feed conveyor evenly distributes incoming

material to each press and screw conveyors feed it up and into the machines. The pressed material is then collected and conveyed to next destination – a dryer, boiler or hammer mill – depending on the application.

Not only does the material coming out of the presses have a lower moisture content than what went in (depending on the type of material), it has also been crushed, increasing its evaporation surface for the dryer and conditioning it for the grinders. All of this serves to reduce wear and bottlenecks at the downstream machinery.

Ideally, material heading through a press should be as homogenous as possible. “If you stick a big chunk of something through, it’s going to open the jaws up –it’s got a pressure set limit – and the rest of the material around that isn’t going to compress as well,” van Halderen says. He suggests that different in-feed materials run through conditioning equipment to ensure the material compresses efficiently.

Tero Toikka is the president of Saalasti’s Nanaimo office in B.C. He says a 100,000-tonnes-per-year pellet plant would likely need three or four of the modular 1803 presses. Multiple presses allow for redundancy during downtime to ensure material is still being pressed before the dryer.

“If you’re throwing the same material in [the boiler] all the time at the same moisture profile, it provides consistency to inconsistent material.”

Saalasti recently introduced a larger model of the 1803. The original single press, designed to run continuously, has a yearly capacity of 40,000 tonnes of finished pellets. The newly launched 1803L model doubles capacity at 80,000 tonnes. The larger press is still modular, but designed for the larger output on a single machine. It goes without saying that the less energy needed to remove moisture from fibre, the better the environmental footprint. Beyond that, mechanical dewatering directly reduces a plant’s carbon dioxide and VOC (volatile organic compounds) emissions. Squeezing out half the water also removes half the suspended solids in the fibre sent to the thermal drying process. Despite re-

ducing the VOCs, the process has no measurable impact on the completed pellets’ BTUs, van Halderen says.

Toikka says a common question for pellet plants exploring mechanical dewatering is what to do with the effluent. The solution will always be unique to each site, he says.

“When we take out water, it has to be treated somehow,” he says. “We have several different options available depending on the rules and regulations to release and clean effluent. The easiest way is to spray the logs if you are in a sawmill. You could have an evaporation or settling pond, and those don’t cost anything to operate.”

One unique solution Toikka has seen permitted is for the water to be sprayed over an unused hog pile. The large surface area of the fibre pile allows the water to evaporate naturally, fast enough to keep up with the output.

Reflecting on the completed projects, two of which are on the coast, van Halderen says the biggest benefit those customers have seen is consistency.

“With hog especially, being here on the coast, it’s full of salt and full of garbage, the presses and the preconditioning make the outgoing material so much more consistent for the boiler,” he says. “If you can imagine, throwing wet material in your fireplace is going to bog down the fire and not give you a consistent flame. If you’re throwing the same material in all the time at the same moisture profile, it provides consistency to inconsistent material. You can now start to predict your process and tighten up boiler efficiencies.”

Government grants, particularly in B.C., Toikka says, encourage energy savings and are a route for faster ROI on a press project. “If we have government grants in place, it drops the payback time in half,” he says.

Saalasti’s office in Nanaimo offers turnkey mill upgrades, including MCC, conveyors, structures, automation integration, site services and supervision and labour.

“Saalasti is really great in that they will be on site with you and if there is any sort of site-specific challenges, they’ll work on site with you to solve those,” van Halderen says. “That’s key. Even though the general installation idea is the same, it’s never the same.”

For more information, visit saalasti.com

The Saalasti Press 1803 can remove approximately half of the water from fresh wooden material.

SHOW GUIDE

It gives me great pleasure to invite you to join us at the Wood Pellet Association of Canada’s 2024 Annual Conference in Victoria, British Columbia. This year, we will gather from Sept. 17-18 at the Delta Hotels Victoria Ocean Pointe Resort in Victoria’s picturesque inner harbour.

Across Canada and around the globe, there’s an electrification revolution. Powering the shift from fossil fuels to clean, renewable and responsible energy will require new innovations and solutions. Biomass and wood pellets have a critical role to play in the transition to a greener and brighter future.

Each year, our conference attracts a global audience of nearly 200 participants. We expect another year of record attendance from pellet producers, customers, First Nations and government officials, policy makers and regulators at every level, researchers, safety specialists, logistics personnel, and equipment manufacturers.

Join us as we hear from experts on a range of trending topics, including:

• Drivers, opportunities and challenges behind the green industrial revolution.

• The role of biomass in electrification with leading examples from the U.K., Asia, New Brunswick and remote and rural communities across Canada.

• Solving the climate crisis with today’s technology with Bob McDonald, CBC Radio’s host of the award-winning science program Quirks & Quarks

• Market outlook for wood pellets: supply and demand.

• The latest safety initiatives in Canada; as well as sharing key learnings from safety incidents in Japan.

• The role of biomass in forest health and climate change, and new tools for traceability in the EUDR.

• Advancements in technology and AI in the biomass sector.

Don’t forget our pre-conference activities on Sept. 16. Join us for a game of golf at Bear Mountain Resort. Alternatively, we invite you to participate in our workshop, where we will hear from First Nations involved in Canada’s forest sector to understand how our industry can support their goals for their communities and develop climatefriendly solutions for future generations.

Don’t forget to sign up for the post-conference tour and learn about British Columbia’s coastal forest industry: its history and how it’s transforming to meet the needs of new markets and future generations. Highlights include

the Indigenous-owned Malahat Skywalk, a tour of working forests and discussions around First Nations partnerships, new approaches to old growth forests, and carbon credit initiatives. The tour wraps up with a stroll among the towering 800-year-old trees in Cathedral Grove.

I’d like to acknowledge that none of this could happen without our sponsors and extend a huge thank you for your support. It’s not too late to become a conference sponsor. Please contact Rebecca Lewis at rlewis@ annexbusinessmedia.com.

PLATINUM SPONSOR

GOLD SPONSORS

SILVER SPONSORS

Welcome everyone! All the best, Gordon Murray Executive Director Wood Pellet Association of Canada

PELLET BBQ SPONSOR OPENING RECEPTION SPONSOR

SHOW GUIDE

AGENDA

WPAC Conference

Powering Sustainability: The Role

of

Biomass in Electrification

Sept 17-18, 2024, Delta Hotels Victoria Ocean Pointe Resort, Victoria

MON, SEPT 16, 2024

PRE-CONFERENCE

8:00 AM – 5:00 PM Golf Tournament

- Bear Mountain Golf Club

9:00 AM – 4:00 PM

Workshop: Indigenous Perspectives on the Role of Biomass in Building Better Partnerships, Stronger Communities & Tackling Climate Change

- Delta Hotels Victoria Ocean Pointe Resort

6:00 PM – 9:00 PM

WPAC Opening Reception

- Delta Hotels Victoria Ocean Pointe Resort

TUES, SEPT 17, 2024

CONFERENCE DAY 1

7:30 AM – 8:30 AM Breakfast and Registration

8:30 AM – 9:00 AM Opening Remarks

Moderator: Gordon Murray, Executive Director, WPAC

9:00 AM – 10:00 AM

Session #1: The Electrification Revolution

Moderator: Gordon Murray, Executive Director, WPAC

Revolution Drivers

• Leading the Charge in Canada

• Leading the Charge in BC

• Q&A

10:00 AM – 10:30 AM

Coffee Break – Networking in the Exhibit Area

10:30 AM – 12:00 PM

Session #2: The Role of Biomass in Electrification

Moderator: Dr. Fahimeh Yazdan Panah, WPAC

• United Kingdom, Asia, New Brunswick

• Rural and Remote Solutions

• Q&A

12:00 PM – 1:15 PM

Lunch and Networking in the Exhibit Area

1:15 PM – 2:15 PM

Keynote: Solving the Climate Crisis With Today’s Technology, Bob McDonald

Moderator: Vaughan Bassett, Senior VicePresident, Biomass Sales and Logistics, Drax Group

2:15 PM – 2:45 PM

Session #3: Ready, Set, Go?

Moderator: Vaughan Bassett, Senior VicePresident, Sales and Logistics, Drax Group

Supply and Demand

2:45 PM – 3:15 PM

Coffee Break – Networking in the Exhibit Area

3:15 PM – 4:30 PM

Session #4: Safety is a Shared Responsibility

Moderator: Bill Laturnus, Senior Safety Advisor, British Columbia Forest Safety Council

Importance of Safety in Our Sector at Home and Abroad

• Review of Sodegaura City Biomass Power

• Plant Silo Fire

• WPAC Commitment to Growing Safely

• WorkSafeBC, Trending Safety Initiatives

5:00 PM – 7:00 PM

Wood Pellet Barbecue and Reception

John Swaan, the grandfather of wood pellets and FutureMetrics pellet expert, will serve his world-famous pellet-smoked ribs.

WED, SEPT 18, 2024 CONFERENCE DAY 2

7:30 AM – 8:30 AM

Breakfast and Networking

8:30 AM – 10:00 AM

Session #5: Waste Not, Want Not

Moderator: Karen Brandt, Brandt Strategy Inc.

• Climate Change and Sustainable Forest Management

• The Swedish Approach

• The British Columbia Approach

• Advances in Traceability & Geolocation

10:00 AM – 10:30 AM

Coffee Break – Networking in the Exhibit Area

10:30 AM – 11:30 AM

Session #6: Powering The Future Through Technology

Moderator: Dr. William Strauss, President, FutureMetrics

• Using AI-Enhanced NIR Technology to Optimize Feedstock Sorting

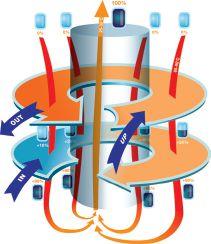

• Optimizing Efficiency: LowTemperature Drying with Waste Heat Utilization

• From Wet to Pellet: Efficient Material Preparation Techniques

• Wood Waste to Energy: Efficient ORC Heat Solutions

• Q&A

11:30 AM – 11:45 AM Conference Wrap Up

Wed, Sept 18 – Fri, Sept 20, 2024

POST-CONFERENCE TOUR

Take a scenic drive from Victoria to Parksville, ending in Nanaimo. Learn about BC’s coastal forest industry. Tour a working forest and learn about co-management with First Nations. Discuss old growth forest initiatives and the potential for carbon credits. Visit Cathedral Grove. *Agenda is subject to change

Alberta is calling… and pellet producers are answering

Afew months ago, the phone rang. It was Alberta, inviting me to visit and talk about pellets. Of course, I jumped at the chance. After all, this is a province that leads the country in forecasted economic growth, that has attracted nearly $43 billion in private equity investment over the last decade, has the highest real GDP per hour worked of Canada’s largest four economies, is investing in people and local communities and supporting clean energy development.

It’s also Canada’s fastest growing province. According to Statistics Canada, as of January 1, 2024, Alberta’s population was 4.8 million, an increase of 202,000 over the previous year – the largest increase on record. It also broke a national record in 2023 for interprovincial migration, with a net gain of 55,107 people.

Clearly it was time for WPAC to spend some time in this province, connect with our members and learn more about Alberta’s direction and opportunities for the pellet sector. The invitation from the Peace Region Economic Development Alliance (PREDA) to speak at their Value-Added Forestry Conference on June 27 in Peace River provided the ideal opportunity for my colleague Dr. Fahimeh Yazdan Panah (director of research and technical development) and I to hit the road.

We flew into Grand Prairie, the closest commercial airport to where the conference was being held. Our first stop was to visit WPAC member La Crete Sawmills. The town of La Crete is located in

the southern end of Alberta’s Mackenzie County, an 81,000-sq.-km. area bordering the Northwest Territories to the north. With a population of just 21,600, the Mackenzie Region – an area larger than the Czech Republic – is Canada’s 2024 Forest Capital. Locally owned and established in 1989, La Crete Sawmills Ltd. began with four employees hired for the initial construction of the mill with a focus of marketing its products into Japan. Over the course of the last 25 years, their market has expanded to cover North America as well as overseas.

Today, with 160 dedicated employees, La Crete operates a two-line sawmill with

two dry kilns, a planer, and a remanufacturing facility; with a total capacity of 110 million board feet. It also began operating a pellet plant in 2003 and today can produce up to 150,000 tonnes of pellets annually.

Our tour hosts included John Unger, recently retired president and CEO; Abe Klassen, newly recruited CEO who has a long history with the mill; and Barney Wiebe, sales director. John told us that since its inception in 1989, La Crete Sawmills has aimed to do good by people, communities and the world at large. The plant runs nine pelletizers and two drums, with 60% of their pellets sold in bulk for

La Crete produces 150,000 tonnes of pellets each year. Photo: WPAC

Gordon Murray, Executive Director, Wood Pellet Association of Canada

primarily for export; and 40% as bagged pellets primarily for domestic markets.

La Crete is the biggest pellet supplier to the Northwest Territories, with nearly 25,000 tonnes to support northern communities. They’ve been key to the transition to biomass in the NWT. Today, biomass is one of the main sources of primary energy in public buildings in Yellowknife. In fact, 33% of territorial government buildings in the city are heated with wood pellets, playing a significant role in reducing greenhouse gas emissions and saving

cation and innovation in the forest sector. These include supporting forestry jobs by securing access to wood fibre, increasing fibre supply over time, maintaining the forest land base by investing in sustainable forest management, and ensuring an open and competitive process for companies to bid and purchase fibre.

An important part of Alberta’s wood products sector is its exports to Asia with easily accessible rail lines into B.C. and through to ports in both Vancouver and the Port of Prince Rupert. A key part of

Forty per cent of La Crete’s production is domestic. Photo: WPAC

Converting landfill gas to RNG in Edmonton

Jeannine Moyer, on behalf of the Canadian Biogas Association

The Clover Bar Landfill in Edmonton recovers landfill gas to generate renewable energy. The site has been recovering and converting the gas into electricity since 2005 and is currently early in the process of developing a new system to convert the gas produced from decomposing landfill organics into renewable natural gas (RNG) for injection into Alberta’s natural gas distribution system.

The overarching goals of the project are to increase the environmental sustainability and economic viability of the facility through the reduction of greenhouse gas (GHG) emissions. It will also help advance Edmonton towards its goal of being carbon neutral as a municipality by 2050. Initial project planning began in 2020 and work to scope, design and procure the project is underway.

The landfill gas produced by the Clover Bar Landfill is presently co-owned by the City of Edmonton and Capital Power. For 16 years, Capital Power has worked collaboratively with the City, managing the landfill gas collection system to produce electricity, retaining 100 per cent of the sale of electricity and sharing a portion of the GHG credits with the City. Project stakeholders include the City of Edmonton, Emissions Reductions Alberta and Capital Power, who is also the construction project manager. Capital Power would also invest in the eventual RNG conversion facility and would share the profits generated from the sale of the RNG and environmental credits produced.

Working to achieve the project goals of reducing GHG emissions while enhancing the environmental sustainability and economic viability of landfill gas management, the group has divided the scope of the project into three phases:

Phase 1: Landfill gas collection – replace and improve landfill gas collection and recovery system for the Clover Bar Landfill.

Phase 2: Upgrade landfill gas to RNG – improve collected landfill gas to pipeline quality natural gas.

Phase 3: Supply RNG to the natural gas network – inject RNG into the natural gas grid through interconnection piping.

LESSONS LEARNED SO FAR

While the transition from producing electricity to RNG from landfill gas is still in its early stages, project stakeholders have learned a few lessons along the way.

Lesson #1. The importance of synergizing private and public sector procurement and decision-making approaches

This RNG project relies on working with and combining various levels of government with private sector companies at every step of the way. Project managers learned early in the process the importance of engaging everyone in a productive manner, including prioritizing communications and establishing a streamlined decision-making process. A thorough understanding of regulations and trade implications, including competitive policies, free trade agreements and compliance requirements is essential to each partner.

Establishing a fair and transparent procurement process also needs to include significant input from every partner.

Lesson #2. Scoping of procurement to ensure operational efficiencies

When it comes to undertaking such a complex project, a firm understanding of the existing landfill is essential. In the case of the Clover Bar Landfill, having a high level of confidence and understanding of the landfill gas quality and composition is required. The project team has an advantage in this situation, having managed the landfill gas for the production of electricity. The team already has an intimate understanding of the importance of gas quality, or rather, the implications unknown gas quality can have

Still in the early stages of the project, a new system is being developed to convert the gas produced from the landfill into RNG for injection into Alberta’s natural gas distribution system.

on available technology options and final product output. That’s why they will be prioritizing a flexible design to incorporate a range of gas qualities and expandability as required. They have considered the operations and cost implications and as a result, have designed a collection system that has enough flexibility to fine-tune and optimize gas quality and flow.

Lesson #3. Flexibility and adaptability for risk management, identification and mitigation

Just like any other project, the ability to be flexible and adaptable is essential. The project management team quickly realized these skills were especially important in the early stages of the design and construction sequencing when dealing with delivery and supply chain impacts. The team also learned the importance of interdisciplinary cohesion and how to balance solutions with boundary limits of design integrations.

INVESTING IN GREEN ENERGY PROJECTS

In alignment with the City of Edmonton’s objectives, its Waste Services branch is focused on leveraging its resources while reducing its carbon footprint and has invested in a variety of projects that complement the future RNG generation facility.

REFUSE-DERIVED FUEL FACILITY

At Edmonton’s Refuse Derived Fuel plant, garbage is processed

and turned into refuse-derived fuel (RDF), or “garbage fluff.” Making RDF involves: mechanically separating municipal solid waste that cannot be recycled or composted; removing inert contaminants; removing precious metals that can be recycled; shredding remaining waste into approximately 40-mm pieces; and drying the shredded waste.

The City’s expertise in developing RDF has potential applications in various waste-to-energy processes.

The City recently entered into an agreement with Varme Energy to generate green electricity and industrial heat while enabling the diversion of at least 150,000 tonnes of residential garbage from landfill per year beginning as early as 2027.

This type of waste-to-energy facility combusts garbage to produce steam that either generates electricity or provides heat for industrial processes.

This facility will complement the work done at the Edmonton Waste Management Centre to sort and process residential waste. By putting residual garbage to use as a fuel source, the City can keep more waste out of the landfill and contribute to Edmonton’s green energy transition. •

The information in this project snapshot has been provided by project stakeholders, partners and managers to educate the public and municipalities about the benefits of RNG production. More Project Snapshots can be found at: www.municipalbiogas.ca/projects.

From size reduction to the perfect finished pellet, Schutte Hammermill has the system to meet your needs. From single units to complete turnkey systems, our custom configured hammer mills and pelleting equipment provide precision, energy efficiency and a superior finished product. Contact us today to find out how we can help you improve your process!

Revolutionary low temp dryer with counter-rotating discs optimizing air saturation for increased performances

PELLET GEAR BUYER’S GUIDE 2024

CATEGORIES

BAGGING & PALLETIZING

Amandus Kahl Gmbh & Co. Kg (SARJ Equipment Canada)

Bulldog Bag Ltd.

Möllers North America Inc.

Nvenia (Formerly HamerFischbein)

Premier Tech Chronos

Primary Packaging

Rethceif Packaging

Trinity Packaging

CHIPPERS & GRINDERS

Bandit Industries

Jacobs Global

DIES & ROLLS

Amandus Kahl Gmbh & Co. Kg (SARJ Equipment Canada)

CPM Dorssers Inc.

CPM Global Biomass Group

Jacobs Global

Münch-Edelstahl Gmbh

Salmatec Gmbh

DRYERS

Amandus Kahl Gmbh & Co. Kg (SARJ Equipment Canada)

Andritz Group

Anhydro Inc. (Spx Flow Technology)

Baker-Rullman

Buettner Energy And Drying Systems North America, LLC

Dieffenbacher North America, Inc

Dryer One

Earth Care Products, Inc.

Energy Unlimited Inc.

Gea Canada

Münch-Edelstahl Gmbh

Player Design, Inc.

Prodesa Group

Siempelkamp Energy Systems Gmbh

Solagen Inc.

Stela Laxhuber Gmbh

TSI Dryers

Uzelac Industries Inc.

DUST SAFETY &

PROTECTION

Airplus Industrial

EXPLOSION

Biomass Engineering & Equipment

Concept-Air

CV Technology, Inc.

Fagus Grecon, Inc

Fike Canada Inc

Flamex, Inc.

Fna Inc.

LEP Technologies

Rodrigue Métal Ltée

Sonic Air

ENGINEERING & CONSTRUCTION

SERVICES

Andritz Group

Biomass Engineering & Equipment

Buskirk Engineering

Dieffenbacher North America, Inc

Earth Care Products, Inc.

Energy Unlimited Inc.

Hargassner North America Inc.

Law-Marot-Milpro Inc.

Mid-South Engineering Stolberg Group

Player Design, Inc.

Process And Storage Solutions

Prodesa Group

Solagen Inc.

FIRE/SPARK DETECTION & SUPPRESSION

Airplus Industrial

Allied Blower

Amandus Kahl Gmbh & Co. Kg

(SARJ Equipment Canada)

Clarke’s Industries, Inc.

Concept-Air

CV Technology, Inc.

Fagus Grecon, Inc

Fike Canada Inc

Firefly AB

Flamex, Inc.

FNA Inc.

IEP Technologies

Rodrigue Métal Ltée

Sonic Air

HAMMERMILLS

Amandus Kahl Gmbh & Co. Kg

(SARJ Equipment Canada)

Andritz Group

Bruks Siwertell

Brunette Machinery Company Inc.

Buskirk Engineering

CPM Bliss Industries, LLC

CPM Global Biomass Group

CSE Bliss Manufacturing LLC

Dieffenbacher North America, Inc

Gemco Energy

Jacobs Global

Jeffrey Rader – Terra Source

Law-Marot-Milpro Inc.

Münch-Edelstahl Gmbh

Prodesa Group

Schutte Hammermill

West Salem Machinery Co.

HANDLING EQUIPMENT

Bandit Industries

Bid Group

Biomass Engineering & Equipment

Bruks Siwertell

Law-Marot-Milpro Inc.

S. Huot

USNR

INSPECTION, VERIFICATION AND TESTING

Biomass Energy Lab

Sgs Canada Inc.

Timber Products Inspection

Twin Ports Testing Inc.

LUBRICANTS

Jacobs Global

Sinto

MOISTURE ANALYZERS

Döescher Microwave System

Gmbh

Fagus Grecon, Inc

Jacobs Global

MoistTech Corp

Tews Of America Corp.

PELLET MILLS

Amandus Kahl Gmbh & Co. Kg

(SARJ Equipment Canada)

Andritz Group

Buskirk Engineering

CPM Bliss Industries, LLC

CPM Global Biomass Group

Münch-Edelstahl Gmbh

Pelleting Technology Netherlands

Prodesa Group

Salmatec Gmbh

PNEUMATIC CONVEYING

Allied Blower

Amandus Kahl Gmbh & Co. Kg

(SARJ Equipment Canada)

Baum Pneumatics Inc.

Clarke’s Industries, Inc.

Concept-Air

Coperion K-Tron

Continental Conveyors

Fox Venturi

Jeffrey Rader – Terra Source

Koger Air Corporation

Rodrigue Métal Ltée

Walinga

PORTS

Port Metro Vancouver

Port of Belledune

Port of Halifax

Port of Montreal

Port of Quebec

Port of Trois-Riviéres

Port Saguenay

Prince Rupert Port Authority

QUALITY CONTROL EQUIPMENT & SERVICES

Amandus Kahl Gmbh & Co. Kg

(SARJ Equipment Canada)

Biomass Energy Lab

Fagus Grecon, Inc

Münch-Edelstahl Gmbh

Timber Products Inspection

Twin Ports Testing Inc.

SCREENS & COOLERS

Amandus Kahl Gmbh & Co. Kg

(SARJ Equipment Canada)

Andritz Group

Baum Pneumatics Inc.

BM&M Screening Solutions

Bruks Siwertell

Brunette Machinery Company Inc.

Buskirk Engineering

CPM Bliss Industries, LLC

CPM Global Biomass Group

CSE Bliss Manufacturing LLC

Dieffenbacher North America, Inc

Jacobs Global

Jeffrey Rader – Terra Source

Law-Marot-Milpro Inc.

Münch-Edelstahl Gmbh

Pelleting Technology Netherlands

Vibroscreen

West Salem Machinery Co.

TRUCK DUMPERS

Airoflex

Bruks Siwertell

Phelps Industrial

Wolf Material Handling Systems

AIROFLEX EQUIPMENT

www.airoflex.com

563-264-8066

AIRPLUS INDUSTRIAL

www.airplusindustrial.ca

866-291-6855

ALLIED BLOWER

www.alliedblower.com

604-930-7000

AMANDUS KAHL GMBH & CO. KG (SARJ EQUIPMENT CANADA)

www.akahl.de

905-806-6837

BID GROUP

www.bidgroup.ca

250-564-4385

DelTech has a proven, long-standing reputation for designing and manufacturing continuous/ batch kilns, biomass-fuelled energy system technologies, and pellet plant manufacturing. We provide specialized start-to-finish energy solutions for the entire forestry sector.

BIOMASS ENERGY LAB

www.biomassenergylab.com

218-461-2579

ANDRITZ GROUP

www.andritz.com

457-216-0300

ANDRITZ offers an extensive line of equipment and complete plant solutions for the production of high-quality feed and biomass products. From brown or greenfield site projects to upgrades at existing facilities, your exact specifications will be met at the lowest possible total cost of ownership by leveraging our extensive processing expertise and experience. AND with the industry’s most trusted services, we are always there for you.

ANHYDRO INC. (SPX FLOW TECHNOLOGY)

www.spx.com/en/anhydro/ 704-752-4400

BAKER-RULLMAN

www.baker-rullman.com

920-261-8107

BANDIT INDUSTRIES

www.banditchippers.com

989-561-2270

Bandit manufacturers a variety of disc and drum style whole tree chippers to serve a variety of biomass applications. Each unit is manufactured with the highest of quality components efficiently creating high quality chips with reduced operating and maintenance costs.

BAUM PNEUMATICS INC.

www.baumpneumatics.com 604-945-4507

BIOMASS ENGINEERING & EQUIPMENT (BE &E)

www.BEandE.com

250-564-4385

Biomass Engineering & Equipment provides construction management for turnkey pellet plants and manufactures bulk handling equipment for all types of biomass. With decades of experience in forest-product manufacturing, our team has developed advanced drag conveyors that address the challenges associated with handling wood. Our SMART Conveyors™ are dust tight, fully compliant with NFPA® codes, and boast some of the best efficiencies available. BE&E also offers individual systems for receiving, storage, metering, and trailer load-out. We’ve recently added the VibraPro™ line to our offering. A long-standing leader in in vibratory conveyors.

BM&M SCREENING SOLUTIONS www.bmandm.com 800-663-0323

BRUKS SIWERTELL www.bruks-siwertell.com 770-849-0100

BRUNETTE MACHINERY COMPANY INC. www.brunettemc.com 604-522-3977

BULLDOG BAG LTD. www.bulldogbag.com 800-665-1944

BUSKIRK ENGINEERING www.buskirkeng.com 260-622-5550

BUETTNER ENERGY AND DRYING SYSTEMS NORTH AMERICA, LLC www.buettner-energy-dryer.com 704-910-0162

CLARKE’S INDUSTRIES, INC. www.clarkes-ind.com 541-343-3395

CONCEPT-AIR www.concept-air.ca 866-644-0041

Successful solutions for aspiration systems and industrial processes. Our dust collectors are designed to efficiently treat a variety of particle types. We offer a turnkey service that meets the most demanding standards in the industry!

COPERION K-TRON www.coperion.com 785-825-1611

CONTINENTAL CONVEYORS LTD. www.continentalconveyor.ca 418-338-4682

Continental provides a full range of mechanical bulk handling and storage equipment including en-masse chain conveyors, screw conveyors, belt conveyors, disc screens as well as storage and reclaim solutions. Robust designs coupled with over 50 years of wood industry and related experience assures quality conveying systems for pellet, biomass, fuel, and wood processing industries. Contact us to see how we can help you move your bulk materials.

CPM BLISS INDUSTRIES, LLC www.bliss-industries.com 580-765-7787

CPM DORSSERS www.dorssers.com 519-676-8113

CPM GLOBAL BIOMASS GROUP www.cpm.net 800-428-0846

CSE BLISS MANUFACTURING LLC www.csebliss.com 580-749-4895

CV TECHNOLOGY, INC. www.cvtechnology.com 561-694-9588

DIEFFENBACHER NORTH AMERICA, INC www.dieffenbacher.com 519-979-6937

COMPANY INFORMATION

DÖESCHER MICROWAVE SYSTEM GMBH

www.moisturemeter.eu

510-420-1716

DRYER ONE

www.dryer-one.com

011 32 87 440 110

The low temperature Dryer One™ dryers deliver the solution for large-scale wood biomass processing plants where Safety, Energy Efficiency and Cost Effectiveness are of primary importance.

EARTH CARE PRODUCTS, INC.

www.ecpisystems.com

620-331-0090

ENERGY UNLIMITED INC.

www.energyunlimitedinc.com

608-935-9119

FAGUS GRECON, INC.

www.Fagus-GreCon.com

704-912-0000

Fagus GreCon the leader in Spark Detection and Extinguishing Systems for 50 years, helps eliminate early causes of fires and explosions. InfraRed sensors detect sparks/embers and then automatically trigger countermeasures.

FIKE CANADA INC

www.fike.com

800-363-8116

FIKE - WORLD LEADERS IN EXPLOSION

PROTECTION - DFI™ A flap valve you can trust. The Dual Flap Isolation Valve (DFI™) is Fike’s new explosion isolation flap valve. Available in a range of sizes from 4” to 40”, Fike DFI™ fits in nearly all pipe geometries. It can be installed close to bends in horizontal and vertical pipes and closer to the dust collector than other valves due to fast closing, lightweight flaps. Full scale tested and proven. Available in SST and C/S.

FIREFLY AB

www.firefly.se

011 46 08 4492500

FLAMEX, INC.

www.sparkdetection.com 336-299-2933

FNA INC.

www.fnainc.net

514-501-3352

With over 50 years of experience, we are a world leader in providing the wood and pellet industry with premium fire prevention and protection systems, utilizing the latest advanced technologies and best practices to ensure top-tier safety and reliability.

FOX VENTURI

www.foxvalve.com

973-328-1011

GEA CANADA

www.gea.com 819-477-7444

GEMCO ENERGY

www.agicogroup.com 011 86 372 5965148

HARGASSNER

www.hargassner-northamerica.com 437 837 2300

Hargassner offers the technological edge and the best heating technologies from our own development in the field of biomass boilers for pellets, logs and wood chips.

IEP TECHNOLOGIES

www.ieptechnologies.com 855-793-8407

JACOBS GLOBAL www.jacobscorp.com 800-831-2005

JEFFREY RADER – TERRA SOURCE www.terrasource.com 514-822-2660

KOGER AIR CORPORATION www.kogerair.com 800-368-2096

LAW-MAROT-MILPRO INC.

www.lmmequip.com 800-461-6276

Law-Marot-Milpro is a leading North American manufacturer of pellet cooling, pellet cleaning and material handling equipment. Our sturdy equipment has been in operations for over 50 years across North America.

MID-SOUTH ENGINEERING STOLBERG GROUP www.mseco.com/stolberg 604-273-1915

MOISTTECH CORP www.moisttech.com 941-727-1800

MoistTech manufactures the diamond standard in moisture sensors. Providing continuous, reliable readings with zero maintenance, one-time calibration, and non-drift optical design, allows operational line adjustments based on real-time measurements.

MÖLLERS NORTH AMERICA INC. www.mollersna.com 616-942-6504

MÜNCH-EDELSTAHL GMBH www.muench-edelstahl-gmbh.de/en 011 49 02103 58996

NVENIA www.nvenia.com 763-231-0100

PELLETING TECHNOLOGY NETHERLANDS www.ptn.nl 011 31 07354 98472

PHELPS INDUSTRIAL www.phelpsindustries.com 501-375-1141

PLAYER DESIGN, INC. www.playerdesign.net 207-764-6811

PORT METRO VANCOUVER www.portmetrovancouver.com 604-665-9000

PORT OF BELLEDUNE www.portofbelledune.ca 506-522-1200

PORT OF HALIFAX www.portofhalifax.ca 902-426-8222

COMPANY INFORMATION

PORT OF MONTREAL

www.port-montreal.com

514-283-7011

PORT OF QUEBEC

www.portquebec.ca 418-648-3640

PORT OF TROIS-RIVIÉRES

www.porttr.com

819-378-2887

PORT SAGUENAY