MODERN.CLEAN.SAFE

Wood

biomass heating technology from Viessmann

Viessmann offers state-of-the-art wood biomass heating solutions for both residential and commercial applications.

Innovative combustion technology ensures high efficiency. This leads to lower fuel consumption and emissions.

Numerous automatic functions ensure comfortable, reliable, and consistently efficient system operation.

Wood biomass heating systems from 37.4 to 4265 MBH

Wood-fired biomass heating systems for

Over 80 biomass system installations across Canada

Residential & commercial applications

and commercial applications (outputs from 37.4 - 4265 MBH)

CANADIAN BIOMASS

12 DIGESTING THE BIOECONOMY

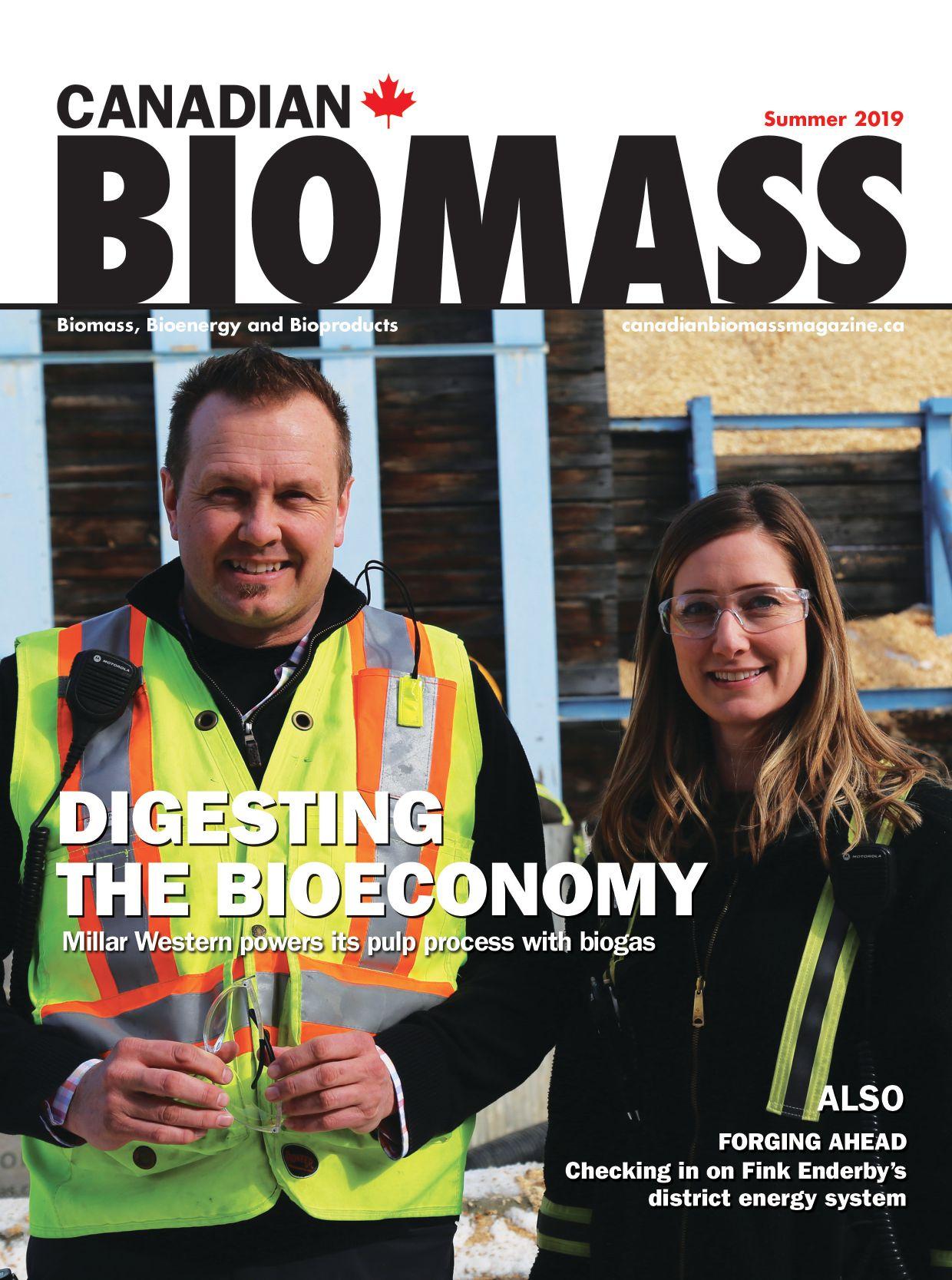

In 2017, Millar Western’s bio-energy facility at its pulp mill in Whitecourt, Alta., started production. Now, it’s among the largest anaerobic treatment systems in the world, using methane from its pulp effluent treatment process to produce green energy.

10

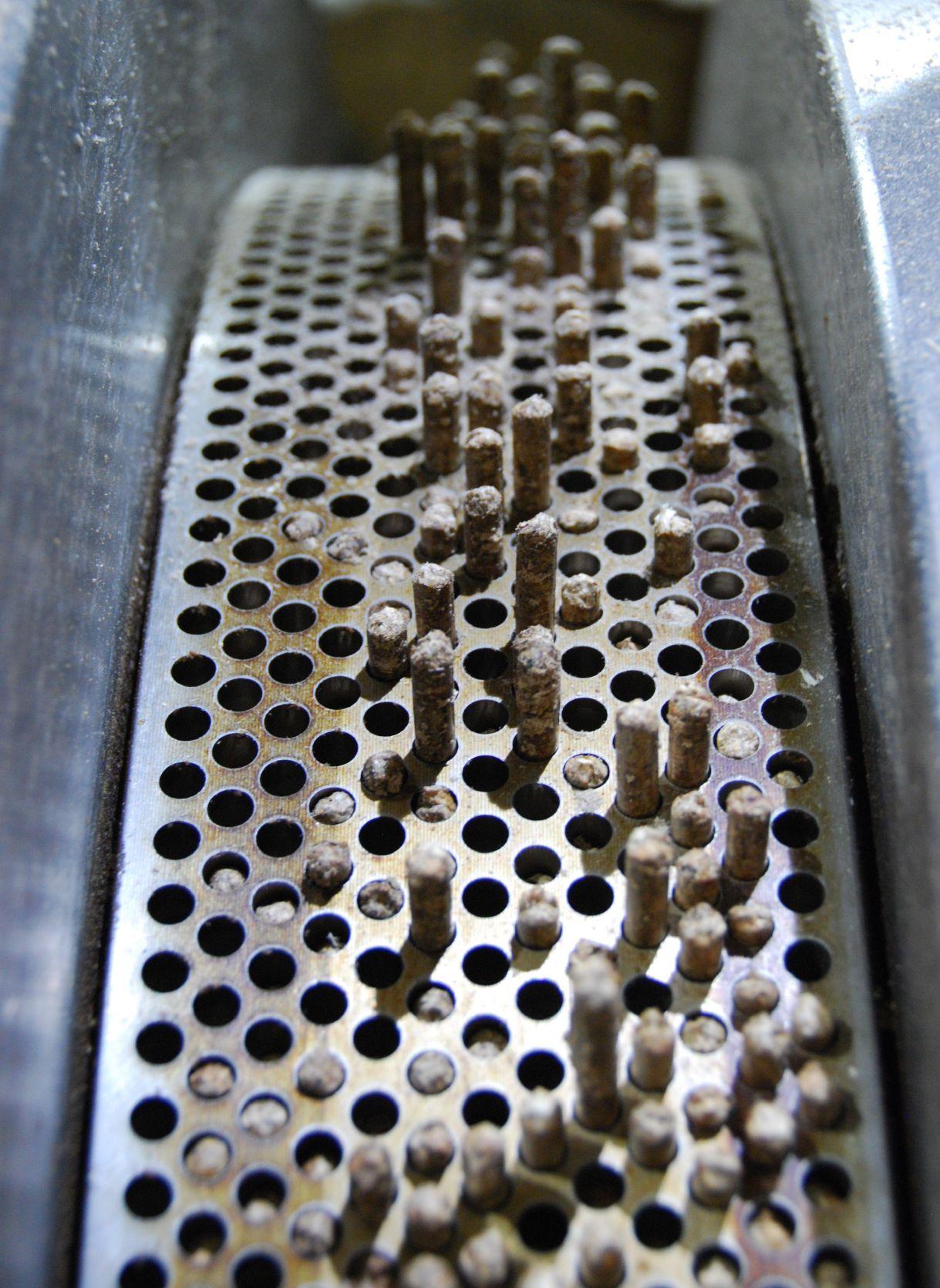

Pellets 4.0

Granules LG is moving towards Industry 4.0 with a $2.2 million investment in its Saint-Félicien, Que., pellet mill to acquire new automated equipment that will optimize its storage capacity and wood pellet manufacturing processes.

11

Serious about safety

Canadian Biomass attended the Wood Products Safety Summit in Prince George, B.C., in June, and reports some of the key takeaways.

16

Forging ahead

Canadian Biomass first toured the Fink Enderby District Energy installation when it opened in 2012. We check in with owner Burkhard Fink and manager David Dubois to see how the project has held up and discuss some lessons learned.

19

2019 WPAC Show Guide

The official Wood Pellet Association of Canada 2019 AGM and Conference show guide, complete with welcome letter, agenda and exhibitor list.

“It’s a pretty self-sufficient operation. We don’t need someone continuously manning it. That’s how I wanted it: effortless.”

Millar Western cut the ribbon on its anaerobic treatment facility two years ago. Lindsay Boyce, environmental process specialist, and Jeff Shipton, manager of corporate environmental services, share what makes it a success. Read the full story on page 12. Photo courtesy Alberta Forest Products Association.

Don’t ignore your gut

Take steps to ensure complacency doesn’t affect the safety of your operation

Agut feeling is hard to define and easy to ignore. I would describe it as the twinge in my stomach when I do something risky.

I most acutely felt it as I was donning a harness and bungee cord about to jump off a bridge 50 metres above a river in Whistler, B.C. A reasonable person might think twice about the experience. My 18-year-old self chose the thrill over reason.

In our day to day, the gut feeling is much less obvious, but no less present. For those in trades or operational roles, working with heavy machinery or dangerous substances, the gut feeling naturally dulls with experience. But it’s still there.

Spencer Beach, a former flooring installer from Edmonton, ignored his gut feeling once and has since committed his life to convincing others to listen to it.

Beach was the keynote speaker at the Wood Products Safety Summit (coverage on page 28), put on by the Wood Pellet Association of Canada (WPAC) and Canadian Biomass in Prince George in June. I was in the audience this year and consider myself lucky to have heard Beach speak. You know a message is hitting home when a room of nearly 100 people is dead silent as a speaker tells a story.

In 2003, Beach was removing the flooring from an under-construction home with a flammable chemical when a flash fire engulfed the house. The chemical fire reached 1,500 degrees, burning 90 per cent of his body in third- and fourth-degree burns.

Miraculously, Beach survived the incident. Months of painful recovery gave him time to reflect on where things went

wrong, and how he could have avoided it. A big step was admitting he knew the chemical he was working with was unsafe.

“How many of you have been in a situation where you have the gut feeling, and you do nothing at all?” Beach asked the audience. “But I did what all strong, hardworking people do – I took that feeling and I pushed it deep down to where it can’t be heard. And I did nothing. I chose to die.”

It’s a harsh, critical lesson for all machine operators in the biomass industry. No pellet plant, biogas facility or wood chipping operation is immune from the complacency that leads to unsafe practices.

The reality is our industry is in the business of combustible dust. And while industry practices and technology solutions for explosion prevention and protection have advanced, there is still plenty to learn, and re-learn, to prevent future incidents.

If you missed our Dust Safety Week 2019, which took place June 24-28 at www.canadianbiomassmagazine.ca/dustsafety-week, I encourage you to check out the articles and talk to managers, colleagues and employees about how your plant can step up its safety game. Don’t wait until an incident happens. Don’t ignore the gut feeling.

Beach is bringing his story and message to WPAC’s AGM, taking place Sept. 22-25 in Ottawa. Find details at www.pellet.org/ wpac-agm. •

CANADIAN

BIOMASS

Volume 19 No. 3

Editor - Maria Church (226) 931-1396 mchurch@annexbusinessmedia.com

Associate Editor - Ellen Cools (416) 510-6766 ecools@annexbusinessmedia.com

Contributors - Gordon Murray, Guillaume Roy, Peter Diekmeyer, Carsten Huljus.

Account Coordinator - Stephanie DeFields Ph: (519) 429-5196 sdefields@annexbusinessmedia.com

National Sales Manager - Ross Anderson (on leave)

National Sales Manager - Rebecca Lewis Ph: (519) 410-0332 RLewis@annexbusinessmedia.com

Quebec Sales - Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexbusinessmedia.com

Western Sales Manager - Tim Shaddick tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Alison Keba

Circulation Manager - Jay Doshi jdoshi@annexbusinessmedia.com Ph: (416) 442-5600 ext. 5124

Group Publisher - Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson

Canadian Biomass is published four times a year: Winter, Spring, Summer and Fall. Published and printed by Annex Business Media.

Publication Mail Agreement # 40065710

Printed in Canada ISSN 2290-3097

Subscription Rates: Canada - 1 Yr $57.00; 2 Yr $102.00 Single Copy - $9.00 (Canadian prices do not include applicable taxes) USA – 1 Yr $93.50 US; Foreign – 1 Yr $106.00 US

CIRCULATION

mchana@annexbusinessmedia.com Tel: (416) 510-5109 Fax: (416) 510-6875 or (416) 442-2191 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Annex Privacy Officer Privacy@annexbusinessmedia.com Tel: 800-668-2374

Occasionally, Canadian Biomass magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2019 Annex Business Media, All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication. www.canadianbiomassmagazine.ca

BIOMASS update

PINNACLE, TOLKO PARTNER TO BUILD NORTHERN ALBERTA INDUSTRIAL PELLET PLANT

Pinnacle Renewable Energy and Tolko Industries are partnering to build a new industrial wood pellet plant in High Level, Alta.

The limited partnership agreement, announced in early July, will see each company own a 50 per cent share of the new $54-million plant, Northern Pellet Limited Partnership.

The plant will source high-quality wood fibre from Tolko’s existing sawmill in High Level, producing up to 200,000 tonnes of pellets annually. The facility will be built on Tolko land, with construction to begin shortly.

“We look forward to expanding our business relationship with Tolko, growing our production platform in Alber-

ta and further diversifying our regional fibre supply,” Pinnacle CEO Robert McCurdy said. “We have established a strong working relationship with Tolko through the construction and operation of our jointly-owned Lavington, B.C. production facility, which was completed safely, on-time and on-budget. Our partnership with Tolko offers Pinnacle the ability to diversify the business further and position the company well to implement our growth strategies.”

Pinnacle will operate and manage the facility, while Tolko will supply heat energy and fibre to the facility under long-term supply agreements.

“We’re excited to once again partner with Pinna-

cle Renewable Energy on a project that promises to bring economic, environmental, and employment benefits to both companies and the community of High Level,” Tolko president and CEO Brad Thorlakson said. “When commissioned, Northern Pellet Limited will reduce our carbon footprint, secure and increase full-time permanent

employment opportunities in the area, and allow us to use all our bark, shavings, and sawdust to produce pellets for growing markets. We look forward to working with Pinnacle on the project and to a successful, on-time, on-budget completion, with start-up in 2020.”

The first wood pellets are expected in late 2020.

Enerkem announces passing of co-founder Vincent Chornet

Enerkem has announced the death of its co-founder and executive chairman Vincent Chornet at 45 following a prolonged illness.

In a media statement, the company said: “Faithful to himself, he fought this terrible disease with the passion and determination that we know him for. He has been active even in the last moments, exchanging emails last week with different members of his team. In recent

months, he has continued to chair Enerkem’s Board of Directors, with the best interests of the company at heart.”

The company credited Chornet’s entrepreneurial spirit for making Enerkem a global leader in biofuels and renewable chemicals.

“Vincent has guided our company from the founding to the commercialization of our patented technology. Today, we are setting a new standard for smart waste management and the production of biofuels and renewable chemicals, in large part thanks to him. His legacy is immense, and we now have the responsibility to continue his work and to realize his most ambitious dreams for the company,” the company stated.

Before his Enerkem days, Chornet was involved in a number of projects and start-up companies in the energy production and fine chemicals sectors, including Bioxalis Medica, Fractal Systems and Kemestrie.

“The whole Enerkem family now shares a deep sense of loss. Vincent has always been a source of inspiration for all those who have crossed his path. His memory will always be part of Enerkem’s DNA,” the company stated.

Photo courtesy Pinnacle Renewable Energy.

OVER 22M TONS OF WOOD PELLETS SHIPPED IN 2018

Global trade of wood pellets jumped more than 21 per cent year-over-year in 2018 when a new record of 22.3 million tons was shipped, according to the North American Wood Fiber Review (NAWFR).

The five major pellet-exporting countries (the U.S., Canada, Vietnam, Latvia, and Russia) have remained the top exporters for over five years. They accounted for about 69 per cent of the world’s export volume in 2018. Pellet production in the U.S. South continued at record pace, driven by a European move towards renewable energy. From the 1Q/18 to the 4Q/18, exports from the region were up almost 50 per cent, further manifesting the U.S.’s role as the world’s largest producer and exporter of wood pellets, reports the NAWFR.

Demand for imported pellets in Japan and South Korea continued a three-year growth trend in the 4Q/18 when import volumes reached new record highs of 339,000 tons and 993,000 tons, respectively.

In 2018, the total annual import volume for the two countries was just over 4.5 million tons, more than doubling in just two years. Prices for pellets landed in both Japan and South Korea have moved upward over the past three years.

Wood Resources International LLC

CANADIAN BIOECONOMY CONFERENCE AND EXHIBITION ANNOUNCES 2020 DATES

Canada’s largest and longest-running conference on the bioeconomy will be the place for industry, government, communities, and researchers to meet and discuss some of the greatest challenges facing the nation: climate change, energy security, and truly sustainable economic development.

The Canadian Bioeconomy Conference and Exhibition will take place in Prince George, B.C., June 10-12, 2020.

“Since the first conference in 2004, the Canadian Bioeconomy Conference and Exhibition has developed a reputation for being one of Canada’s leading conferences on the topic, providing a venue for community leaders, industry members, and policy makers from across Canada

FANSHAWE RECEIVES $2M TO ESTABLISH BIOECONOMY RESEARCH HUB

Fanshawe College in Ontario has received nearly $2 million over five years from the federal government to establish a research hub focused on the agri-food industry.

The Centre for Bioeconomy will be established with the college’s recently opened Centre for Advanced Research and Innovation in Biotechnology (CARIB).

“While federal and provincial policy looks to grow the agri-food production sector, producers face barriers to innovation that hamper growth, such as delayed technology adoption and insufficient support for product development and commercialization. Fanshawe’s Centre for Bioecon-

omy will help to address these barriers,” the college stated in a news release.

The centre will focus on plant and soil health, food innovation and turning agri-food waste into bioproducts, with the goal of accelerating product development and commercialization, as well as improving knowledge diffusion and technology adoption.

and around the world,” said Rob van Adrichem, chair of the CBCE Board of Directors.

The bioeconomy involves the sustainable production and use of materials, energy, fuels, chemicals and industrial and consumer products from renewable resources instead of fossil fuels. B.C. communities are already at the forefront of the bioeconomy given their local expertise related to forest management and manufacturing capacity for advanced wood building products and bioenergy.

“As the world works to develop economies that are less carbon-intensive and wasteful, the bioeconomy is a tremendous opportunity for B.C. and for Canada,” van Adrichem said. “It has special significance for rural, remote and Indigenous communities,

as it uses a readily available resource to create local jobs, energy security, and build economic development.”

The Canadian Bioeconomy Strategy reports that more than 21 million metric tonnes of raw biomass was transformed into bio-products in Canada in 2017 alone. Of that total, 60 per cent came from forestry. Total revenues in 2017 surpassed $4 billion.

The conference host region, North-Central B.C., has a long history as a leader in developing the first generation of the industrial bioeconomy in Canada, including the country’s largest pulp and paper cogeneration sector, the first and largest wood pellet-producing industry, and multiple district energy systems, which have virtually eliminated greenhouse gas emissions from the buildings they heat. With projects such as the groundbreaking Canfor-Licella biofuels project, the industry is now moving quickly toward

new technologies and new innovations in wood-based products that are fuelling the new bioeconomy.

“Our conference will feature speakers and exhibitors that will showcase the companies and communities that are at the forefront of a global market for bio-based products,” van Adrichem said. “We will continue to bring expertise from around the globe to share knowledge and best practices with Canadian industry members, and to demonstrate B.C.’s leadership role in the Canadian bioeconomy.”

“Prince George is one of the most diversified and important forestry communities in Canada and continued innovation and leadership in this sector is critical to our economic development,” said Prince George Mayor Lyn Hall. “We’re delighted to again be hosting the Canadian Bioeconomy Conference and Exhibition next June.”

AAdvocacy and market support

WPAC makes progress promoting key priorities

By Gordon Murray

s WPAC’s executive director, I prepare a business plan and budget each year for approval by our board of directors and membership during our AGM. The business plan guides our direction for the ensuing year. Of course, from time to time, unforeseen priorities arise, and we need to adapt.

Key business plan priority areas for 2019 included advocacy and market support, safety, and research and technical development. Here is a progress report of our efforts so far this year:

ADVOCACY IN JAPAN AND EUROPE

In January, we took JJ Ruest, CEO of CN, and other senior company executives to Japan. We visited the Keihin Biomass Power Plant and met with our Japanese customers and other participants in the wood pellet supply chain. WPAC met with the Japanese Ministry of Economy, Trade and Industry (METI) and also began co-operating with JCOAL, a Japanese joint industry-government research study, to justify a seismic increase in wood pellet consumption by Japanese coal power plants. We took JCOAL representatives on tours in B.C. to educate them about our industry and to meet with government and pellet sector representatives.

In May, WPAC sponsored the annual CMT Biomass Pellet Trade and Power Conference in Japan. We were accompanied by Diane Nicholls, assistant deputy minister and chief forester of the province of British Columbia. WPAC helped set the conference agenda, providing seven speakers. We also visited the Sakata Biomass Power Station that uses Canadian wood pellets. We met again with METI and JCOAL.

Meanwhile, in Europe, I am continuing to participate as a board director of both the European Pellet Council and Bioenergy Europe trade associations. WPAC also supplied speakers for the European Pellet Conference in Wels, Austria and the Argus Biomass Conference in London. Presentations were intended to reinforce Canada’s reputation as a reliable supplier of high-quality, sustainably-produced wood pellets.

WPAC has also made progress on the project to harmonize European and Canadian boiler pressure standards. We’ve met with European boiler manufacturers and national and European trade associations to formulate strategy. Through the Austrian Boiler Association, we have submitted a CETA complaint to the European Commission that is now on the agenda for the November meetings between Canada and the EU. We have met with the Canadian Standards Association and joined their boiler standards committee. And we have had significant correspondence and many conversations with Canadian government representatives about this issue.

ADVOCACY AT HOME

At home in Canada, WPAC has raised external funding and begun work on a Canadian wood pellet market study. We will be carrying out another social media campaign in the fall.

In March, WPAC met with B.C.’s deputy minister of forests to ask for improvements to fibre supply access and security. We filmed the B.C. government burning useable wood fibre and, in April, met with B.C.’s chief forester and her team in an attempt to stop this egregious practice by the B.C. government. WPAC is continuing to engage with the B.C. government in this regard.

WPAC is also participating on the Canadian Clean Fuel Standard Technical Committee and the Solid Fuels Subcommittee in an attempt to ensure that wood pellets are properly integrated into Canada’s proposed Clean Fuel Standard regulatory framework. A main issue for us is the proposed framework does not provide for the generation of carbon credits for fuel switching between heating oil and wood pellets.

In June, WPAC travelled to New Brunswick to lobby for a change to an RFP for a boiler for the City of Moncton to allow for wood pellets. We succeeded in delaying the RFP and in gaining approval for one boiler to be specified for pellets.

Canada had strong representation at the CMT Wood Pellet Conference in Japan. Starting third from left: Vaughan Bassett, President, WPAC; Diane Nicholls, ADM and chief forester, Province of B.C.; and Katsunori “Tiger” Takamitsu of Pacific BioEnergy. Photo by Fiona Pun, Center for Management Technology.

SBP REFORM

WPAC has continued to be engaged in the governance reform of the Sustainable Biomass Program (SBP). WPAC president Vaughan Bassett has joined the board of directors, while I have been appointed as a member of SBP’s standards committee. WPAC will host the next round of SBP meetings in the fall when we will be visiting forest operations, sawmills and pellet plants in B.C.’s southern interior.

We are also working on SBP regional risk assessments for B.C. and New Brunswick. When those provinces are complete, Nova Scotia and Alberta will be next. WPAC is making progress on a computer information system to manage the wood pellet chain of custody through Westview and Fiberco terminals in compliance with PEFC and SBP.

PROMOTING SAFETY

In January, WPAC prepared and publicly released a 2019 safety work plan. Since then, we have held monthly safety committee conference calls as we implement the work plan and monitor progress.

WPAC’s safety committee’s work has gained an international reputation. In February we accepted an invitation to give presentations on the Canadian wood pellet safety journey and on combustible dust management at the Nordic Pellet Conference in Sweden.

WPAC also planned and executed a workshop on silo fire prevention and response in February and the Wood Products Safety Summit in June. In June, the safety committee also met with WorkSafeBC for one of our biannual sector safety performance reviews.

RESEARCH AND TECHNICAL DEVELOPMENT

On April 1, Dr. Fahimeh Yazdan Panah replaced director of research and technical development, Staffan Melin. Fahimeh has continued WPAC’s participation with ISO Technical Committee 238 on developing international standards for mechanical and chemical testing and the safe handling of wood pellets. Fahimeh has also started a new research project in response to concerns expressed by the Maritime Safety Committee of the International Marine Organization, which involves examining potential conditions under which wood pellet off-gassing may become flammable and thus hazardous to ocean shipping.

Finally, WPAC and the University of British Columbia Biomass and Bioenergy Research Group successfully applied to Agriculture and Agrifoods Canada for $1.8 million in funding over four years to research biomass densification issues.

2019 AGM AND CONFERENCE

We are looking forward to this year’s AGM and conference, which will be held at the National Arts Centre in Ottawa during the week of Sept. 22. We are including a golf tournament, pre-conference workshops on quality and sustainability certification, as well as biomass research; a two-day conference, the AGM and a board meeting; and a two-day tour of pellet plants, sawmills, forests, and port facilities in New Brunswick. You won’t want to miss our opening party, featuring Nova Scotian sisters Cassie and Maggie MacDonald’s blend of traditional and Celtic music. It’s going to be fun! I hope to see you all there! •

WOOD PELLETING PLANTS

The latest pellet mill type 65 – 1500 with 630 kW drive power reaches up to 12 t / h high quality level. It is the largest industry proven wood pelleting press in the market today.

Pellets 4.0

Granules LG invests $2.2 million to modernize pellet facility

By Guillaume Roy Translated by Peter Diekmeyer

Granules LG is investing $2.2 million in new equipment, storage capacity and manufacturing processes at its Saint-Félicien, Que., wood pellet facility. The goal for the company is to move towards a “smart” pellet plant, complete with data-optimized and artificial intelligence-controlled operating systems.

The effects of the company’s investments are expected to be seen quite rapidly in the plant’s production numbers. The next step is for artificial intelligence technologies to completely manage the plant, which could happen within a few years.

The pellet mill in the northern Lac-Saint-Jean region of Quebec currently produces 120,000 tonnes of softwood and hardwood pellets annually, 40 per cent of which is exported overseas.

A recently installed inventory tracking system that keeps track of pallets via GPS was a key upgrade from the $2.2-million investment. “We are already able to label each pallet and follow it with our GPS system,” says Alain Paul, president of Granules LG. “(They) can be stored in the yard and we can track exactly how much of each of the 18 products we make are in stock.”

The production process is managed by a central system. However, data related to humidity, compression and the temperature of the pellets remain partly controlled by humans. “Soon we will have too much information to control,” Paul says. “Artificial intelligence will help us optimize our operations.”

The $2.2 million investment has also gone into a truck dumper system, a new outdoor storage surface for green fibre, and pellet silos.

In the next few years, Granules LG wants to leverage new pellet export facilities, which are slated to be built in GrandeAnse, N.B. The company also plans to develop an optimized bulk delivery network to reduce its production of bagged pellets, and to capitalize on the local domestic pellet market.

GOVERNMENT SUPPORT

Canada Economic Development for Quebec Regions supplied Granules LG with $400,000 in loans to help finance the modernization project.

Paul says he fully supports the Quebec and Canadian government’s increasing focus on the green economy, a shift he describes as “very important.”

Granules LG has boosted annual wood pellet production from 75,000 to 120,000 tonnes during the past five years, which is evidence of growing wood pellet markets both domestic and abroad. But maintaining that growth rate requires significantly

Granules LG currently produces 120,000 tonnes of softwood and hardwood pellets annually, 95 per cent of which is bagged, while the remaining five per cent is sold as bulk.

more investments in automation, storage capacity, packaging, production processes and working capital.

The recent upgrades will enable Granules LG’s 60 employees to better serve both future and existing customers, particularly its Italian clientele, which buys 40,000 tonnes of pellets each year from the Quebec producer.

Richard Hébert, Member of Parliament for Lac-Saint-Jean, says he is a big believer in the company’s future. “Granules LG, which specializes in forest biomass, produces much more than pellets and energy logs,” Hébert says. “It is 100 per cent Aboriginal-owned and stands out for the economic, social and environmental benefits that it generates.”

Granules LG was also among the first wood pellet manufacturers in Canada to hold the ENplus certification, which it received in 2016, and is currently one of six Canadian producers with an active certificate.

Yet, even with the global pellet export market forecast to grow, Mélanie Paul, vice-president of Granules LG, sees opportunities for the company at home in Quebec where 220,000 homes continue to use oil heating. Migrating some of those homes to using locally produced green energy, instead of fostering reliance on imported fossil fuels, would boost the province’s economy and reduce its carbon footprint, she notes. It would also reduce the company’s supply lines and dependency on exports.

The Lamontagne family founded Granules LG in Saint-Félicien in 1995. The company’s present owner, Groupe ADL, will celebrate the plant’s 25th anniversary next year. •

Serious about safety

Best practices, reality checks at Wood Products Safety Summit

By Maria Church

Despite frequent laughs shared by attendees at the annual Wood Products Safety Summit held in Prince George, B.C., in June, it was clear safety is serious business for the industry.

Nearly 100 attendees came to the event, which covered many bases, from ways to create a safety culture, to technical combustible dust presentations, and a powerful keynote on working in an unsafe environment.

SAFETY CULTURE

The idea of a creating a company safety culture is nothing new, but how to go about effectively doing that has its challenges. Pinnacle’s director of health and safety, Steven Mueller, gave the summit’s first presentation on how the pellet producer created a culture of “owning safety.”

Key to their success, Mueller said, is their in-house Safety Champions Academy program that aims to build and reinforce safety culture from the ground up. The program recruits safety leaders for safety training in Prince George. By the end of 2019, nearly 60 safety champions will graduate from the program.

WorkSafeBC’s Gordon Harkness also spoke about building a corporate safety culture, which he says always begins with management. “Safety culture is either driven or dragged by senior management,” he said.

Harkness offered ways to assess corporate safety culture:

• A workplace health and safety climate survey, which measures immediate employee feelings towards safety.

• An evaluation of OHS practices, which involves site tours, program reviews, and document and compliance reviews.

• And direct commentary from the workforce, in the form of written responses or interviews from the employees.

TECHNICAL UPDATES ON SAFETY

Kevin Ericsson with Cariboo Biomass Consulting has been involved in several incident investigations on dryer fires. His presentation on best practices for managing combustible gas offered warnings for typical maintenance mishaps or oversights that can lead to a fire.

Dryers are at the greatest risk of explosion, he said, when there is a sudden, unexpected power outage; during a scheduled shutdown process; when dryer components fail; when there is faulty fire protection equipment; or when there are distracted operators.

Formal training is needed for dryer operators on the fire safety systems, Ericsson said. Suppliers should provide the documents, but operators should be able to prove they’ve learned the material.

SAFETY PROCESS

Cherie Whelan with the BC Forest Safety Council presented on

challenges and methods to get to “lessons learned” as an industry.

An important step is for companies to assess and determine which workplace incidents qualify as “serious injury fatality potential” or SIFp. To identify SIFp, companies can follow an incident management process that involves four steps: notification and reporting; assessing risk and consequences; investigation and causal analysis; and corrective and preventative actions, follow-up and lesssons learned.

REALITY OF UNSAFE PRACTICES

The summit’s guest speaker offered attendees a cautionary story of the consequences of an unsafe work environment.

Spencer Beach, a flooring installer in Edmonton, was removing linoleum from an under-construction home with a strong, flammable chemical when the house was engulfed in a flash fire. The chemical fire reached 1,500 degrees, burning 90 per cent of his body in third and fourth degree burns.

Beach said he knew, deep down, working with that chemical was unsafe. “How many of you have been in a situation where you have the gut feeling, and you do nothing at all?” he asked the audience. “But I did what all strong, hardworking people do – I took that feeling and I pushed it deep down to where it can’t be heard. And I did nothing. I chose to die.”

Beach impressed upon the crowd the importance of creating not just an organizational safety culture of policies and procedures, but also a compatible workers’ culture.

The Wood Products Safety Summit is presented by WPAC, along with Canadian Biomass, Canadian Forest Industries and Pulp & Paper Canada magazines. Find the full-length article and photos from this year’s summit at tinyurl.com/yxzdj46t. •

The Wood Products Safety Summit held in Prince George, B.C., in June welcomed nearly 100 attendees.

Digesting the bioeconomy

Millar Western is powering its pulp process with biogas

By Maria Church

It’s been two years since a pulp mill in northern Alberta cut the ribbon on what is likely the largest anaerobic treatment facility of its kind in the world. Now that the proverbial dust has settled, the real benefits of the facility are crystal clear: reduced environmental impact, higher pulp production and lower costs.

Millar Western’s bioenergy facility at its pulp mill in Whitecourt, Alta., is using anaerobic hybrid digesters (AHDs) to remove organic material from the mill’s wastewater stream and convert it to biogas that is then used to generate power. Steam from the process is captured and used in the pulp drying process.

At its current capacity, after two years of running successfully, the bioenergy plant can generate 10 per cent of the mill’s electricity requirements – a significant offset for a facility that is a major power consumer.

“The bioenergy project was an opportunity for Millar Western to utilize more of the energy that’s in the wood we harvest,” says Jeff Shipton, manager of corporate environmental services for Millar Western. “We’re able to take a waste stream from the mill and turn it into a green energy source that we can use to generate power and steam on our site and thereby reduce our utilization of power from the

grid and natural gas consumption.”

As the first application of this technology in a pulp mill setting, the project presented a steep learning curve for the Millar Western team, Shipton says. The scale of the facility and the northern Alberta climate were unique challenges.

“We’re moving a lot of wastewater through the system, generating a lot of gas and removing a lot of hydrogen sulphide; and doing it in a northern climate has its own challenges,” he says.

How was it done successfully? “First,” Shipton says, “we had a great group of people. Millar Western dedicated the right number of staff to this project and

From left, Lindsay Boyce, environmental process specialist, and Jeff Shipton, manager of corporate environmental services, are key team members who help make Millar Western’s bioenergy facility at its Whitecourt, Alta., pulp mill a success. Photo courtesy Alberta Forest Products Association.

let us focus on start-up and optimization.

“We also had the benefit of a good business environment. There’s a lot of cutting edge technology here. All the pulp and paper companies in the province are leading edge, committed to reinvesting in their businesses to improve their performance.”

Shipton notes that all levels of government were supportive, with the project receiving funds from Natural Resources Canada’s Investments in Forest Industry Transformation (IFIT) program and from the Alberta ecoTrust program. “This project was a good example of how governments and industry can come together to solve some of these greenhouse gas issues,” he says.

ZERO WASTE

Millar Western’s Whitecourt operations – a two-hour drive northwest of the company’s Edmonton headquarters – include a sawmill, a pulp mill and woodlands operations. The company has a second sawmill in Fox Creek, Alta., and a remanufacturing facility in Acheson, just outside Edmonton. In all

operations, Millar Western’s goal is to use the whole tree with zero waste.

Logs are supplied to the Whitecourt mill site from woodlands certified to the SFI sustainable forest management standard and the PEFC and FSC chain-ofcustody standards. The sawmill produces 330 million board feet of lumber annually, with all by-products used to create valuable products: wood chips are used in the company’s adjacent pulp mill and at a neighbouring newsprint facility; wood shavings and other residuals are transferred to a regional medium density fibreboard plant; and bark and other remaining wood waste is sent to a nearby biomass-fired power plant for conversion to green energy.

The pulp mill produces around 320,000 air-dried metric tonnes per year. Millar Western launched the bioenergy project to utilize even more potential from the wood chips used in the pulp manufacturing process, and to further reduce the environmental impact from discharge of the pulp mill’s treated effluent into the Athabasca River.

“Alberta has some of the most

stringent regulations when it comes to industry effluent discharged back into the environment,” says Lindsay Boyce, environmental process specialist with Millar Western. Producing power from the effluent is a way to make use of material in the process that would otherwise go to waste, she says.

“We use water in our process and we need to treat that water before it’s discharged into the environment. So we take organics that are in the wastewater and we use bacteria to treat the organics to bring the wastewater up to a quality that exceeds our permit requirements and minimizes impacts on the receiving waters. In the process of doing that, these bacteria produce methane. We take the methane gas and produce energy that we can use in the mill,” Boyce says.

Millar Western cut the ribbon on the bioenergy project in late 2016. While the technology has been used in the oil and gas industry for some time, it was a novel application in a pulp mill, and is one of the world’s largest anaerobic digester treatment systems of its kind.

PROCESS

The pulp manufacturing process uses about 10,000 litres of water a minute. The wastewater treatment process begins at the AHD tanks – three glass-lined, 10,000-cubic metre tanks running parallel to each other. Bacteria of different varieties are present at various stages in the digesters.

“There are different types of bacteria that all work together. It’s a step-by-step process. You have one type of bug that takes the organics and converts it to a simpler form that the next bug can use. And the final step is the bugs that create the methane that we can burn in our engines,” Boyce explains.

The digesters create 600-900 cubic metres per hour of methane, which then flow to the 8x45-metre aerobic biological scrubbers. The scrubbers remove hydrogen sulphide from the gas and generate about 700-1,100 cubic metres of biogas each hour, which is sent to the GE Jennbacher engines equipped with power turbines.

The entire process has the capacity to generate 6 MW of power, as well as three tonnes per hour of steam from Cain Industries heat recovery steam generators.

The steam is used in the pulp drying process, which means less natural gas is burned at the dryers.

ADDED BENEFITS

Sending the wastewater to the anaerobic digester process ahead of the mill’s existing aerobic effluent treatment system has further reduced the “organic loading” in the mill’s final effluent, as well as the volume of water discharged back into the Athabasca River, Shipton says. It has also reduced the mill’s fresh water intake and chemical consumption, and cut greenhouse gas emissions.

On top of the environmental benefits, the increased capacity of the new treatment system has also eased a previous bottleneck at the mill. “We’ve been able to raise our pulp productivity by over 20,000 tonnes a year,” Shipton says.

More capacity also means more flexibility in the pulp grades produced, he says. “That has allowed us to adapt to changing market requirements. We’re able to shift our focus and create different grades for different end users.”

FUTURE STEPS

Now that the path has been forged to introduce AHD technology to the pulping process, the future is full of possibilities for Millar Western and other forest product companies.

“We’re utilizing as much of each tree that we harvest as we can. This is the first step in terms of biofuels and the bioeconomy. We’re taking the waste stream and converting it into biogas, into methane. The next step for the forest sector is to look at higher-valued commodities – turning it into liquid biofuels, biopharmaceuticals or other bio-products,” Shipton says.

For now, the Millar Western team continues to study methods to optimize the process and resulting biogas and power generation.

“We generate a lot of data and making sense of it all is a lot of work. There’s a lot of sitting down and analyzing. It’s a work in progress, and we’re always looking for the next advancement,” Boyce says. •

*With files from the Alberta Forest Products Association.

ALWAYS INNOVATING

AT PETERSON WE NEVER STOP DEVELOPING THE ULTIMATE INDUSTRY LEADING EQUIPMENT.

For over 35 years, we’ve built our business around building the most productive mobile chipping and grinding machines in the industry. Day after day, we partner with our customers by giving them the best tools for the job and exceptional support when they need us.

Visit us at www.petersoncorp.com today and see why Peterson is the industry leader for disc and drum chippers, horizontal grinders, blower trucks, screens and stacking conveyors.

Get the right sized product, sort it out, and stack it higher with Peterson!

Let us know how we can help grow your business!

Forging ahead

Checking in on Fink Enderby’s privately owned district energy system

By Maria Church

According to the International District Energy Association, there are at least six biomass-fuelled district energy systems operating across Canada as of May 2019. That number is likely higher with a handful of small First Nations communities in B.C., Yukon and the N.W.T. installing these systems over the past few years.

All are owned and operated not for profit either by universities, municipal governments or residential developers to economically heat their own buildings – save one.

Fink Enderby District Energy is successfully running as a private for-profit mini-utility for a handful of nearby customers in Enderby, B.C.

Canadian Biomass first toured the Fink Enderby District Energy installation when it opened in 2012 as the first privately funded biomass district energy system in western Canada. The project was hailed as a benchmark for speed and affordability compared to the typical cumbersome process to approve, design and install a biomass-fuelled system. Operating as a private

utility under 1 MW registered by the British Columbia Utilities Commission, Fink Enderby originally served eight commercial, municipal and residential customers.

Seven years later, we wanted to check in with project owners and managers to see how the system has held up, and share their lessons learned about biomass district heating in Canada.

Fink Enderby District Energy is owned by and sits on the property of Fink Machine, a bioenergy equipment supplier in Enderby, B.C. Owner Burkhard Fink says, regardless of the financial success of the district energy system to date, it’s the education that has had the most impact.

“The biggest obstacle to bringing district energy to Canada is doubt about the reliability. Often the fear is that these systems are not reliable, therefore they price them out of this world with expensive manufacturers. It’s not necessary. We just needed them to learn from existing systems,” Fink says. Fink Enderby was built for that very reason.

Walking to the Fink Enderby site, I’m struck by how inviting it

Burkhard Fink stands in front of Fink Enderby District Energy’s facility in Enderby, B.C. – Canada’s only privately owned for-profit utility offering customers district heating fuelled by biomass.

looks. An engineered timber structure custom-designed by Fink houses the entire Fink Enderby system. Support beams holding up the roof over the open-air infeed room are cross-laminated timber panels from Penticton, B.C.’s Structurlam. Floor-to-ceiling glass windows in the main boiler room allow sunlight to stream in, and those outside to easily see in.

And the inside doesn’t disappoint. Much of the original infrastructure is still in place, including the Viessmann Vitoflex 300-RF (Pyrot) wood-fired boiler, walking floor, augur, backup gas boiler, and the piping.

Today the utility serves 11 customers, the most recent of which is the new Splatsin community centre.

“The timing worked out well because we were involved in the design stage so we could put the right things in there to prepare for it. These things are harder after the fact,” Fink says.

Connecting a building to the district energy system involves installing three-inch insulated Urecon PEX pipes. Those pipes –buried four feet down to avoid heat loss – are connected to the district energy system’s main lines, bringing heated water to the buildings and cooled water back to the district energy building. A heat transfer station at each client’s building regulates the water inflow and outflow. The water system is closed loop, which means zero wasted water from the process.

AUTOMATED PROCESS

The boiler is running continuously through the year, ramping up and down as required. Wood chips from two or three local sawmills fuel the system, delivered up to once a week depending on the time of year and required fuel load. Chips are stored in a bunker that can hold up to 60 tonnes. From the bunker, chips are automatically fed into the boiler using a walking floor and augurs, all of which were built in-house by Fink Machine.

The boiler is a Viessmann Vitoflex 300-RF (formerly called the Pyrot) wood-fired boiler, rated at 540 kW. At maximum output, during the coldest days of the year, the boiler consumes 4.5 tonnes of chips a day. A triple-pass heat exchanger in the boiler converts the heated gases into hot water, which is then piped into

DISTRICT ENERGY LESSONS LEARNED

Not all of Fink Enderby’s lessons learned have been rosy; some have been harder lessons, says David Dubois, Fink Machine’s manager of business development.

“There’s an evolution going on right now. And like most businesses, we have to react to them,” Dubois says.

Here’s his definitive list on what to bear in mind if considering a district energy system:

Fibre availability

“Going into this project, we knew what our fibre basket looked like in our area, but that doesn’t mean that we haven’t changed suppliers andencounteredchallenges,” Dubois says.

While it’s good to have long-term suppliers, it’s not always possible. Major suppliers aren’t typically looking for small 300 to 400-tonne per year contracts, so if they are able to supply feedstock, it may be temporary.

“We just have to make sure we’re aware of the

larger market so when things change we are able to react and identify new suppliers,” he says. “That industry awareness is a key piece of what we need to do.”

Utility regulations

“When we first started we really weren’t on the radar of utilities here in B.C. We still aren’t, but they have recognized small-scale energy systems do fall within their mandate. There is this ongoing process and evolution,” Dubois says.

That evolution led to questions around registration, filings and ways to ensure they are staying within regulation parameters. Municipalities are exempt, but because Fink Enderby is privately owned they are under certain constraints.

“It’s a bit of a moving goal post and there have been changes since we started that had the potential to impact us, so it was important we stayed on top of those,” Dubois says.

Canada’s leading supplier of commercial biomass heating systems

ASME and CSA certified

100 kW – 12 MW (0.3 MMBTU – 36 MMBTU)

Over 100 energy efficient systems installed

Emissions testing

There has been some recent movement in Canada around emissions regulations that may impact biomass district energy systems. Emissions are provincial jurisdiction, but there are efforts underway to standardize the marketplace on the national level.

Regulations aside, in the spring of 2018 Fink Enderby made the decision to install a cyclone filter on the boiler flue gas system to bring its emissions down even lower.

“We recognize we’re also part of a community,” Dubois says. “It wasn’t needed or

inspired by any comments or concerns, but that’s us being a good, proactive corporate citizen.”

Public facing

Fink Enderby regularly hosts open houses to welcome the community into the facility to learn what they’re all about. The importance of the larger community was a lesson they learned quickly, Dubois says.

“Within the industry we’re known, but not necessarily by the general public. We all have the tendency to fly beneath the

an 8,000 litre buffer tank where it becomes a thermal heat sink. From the buffer tank the water flows to a hot water manifold and is then divided into the main lines, which feed client’s pipes.

“It’s a pretty self-sufficient operation. We don’t need someone continuingly manning it. That’s how I wanted it: effortless,” Fink says. As a result, the entire system requires very minimal staff

radar, but we really need to make sure that we are educating people about what it is we do,” he says.

The open house also helps them maintain a strong relationship with the local government. “We have learned to appreciate that what we’re doing has an impact on our community and having the support of the local government is a key piece. That can be a surprise sometimes for a private enterprise.”

Flexibility

Central to Fink Enderby’s

success is their ability, as a private company, to remain flexible to all these challenges and jump on opportunities as they are presented, Dubois says.

“Our decision-making matrix is very compact, very simple, due to our knowledge and experience. We can say, ‘Yes, we can do that,’ and that’s all we need. We’ll do our due diligence, of course, but we don’t need a 45-page report from three different engineering companies. We can do our own calculations to find out what will work,” he says.

interaction and oversight. Fink measures and monitors each building’s usage remotely via a district energy management program from Schneid, an Austrian company that specializes in HVAC building management systems with a focus on district energy.

CLIENT FOCUSED

Fink expects they could see new clients coming on board shortly, which would require them to upsize the boiler from 540 kW to 720 kW. More clients mean the system’s efficiency goes up.

“If you have a long main line with only two clients, you have heat loss from A to B. If you have more customers on that line the heat loss is divided up between all those customers,” Fink says.

Fink Enderby offers its clients a fixed rate equal to what they are currently paying for their natural gas. Customers are saving by not having any combustion losses. For customers with older heating system that are only 80 or 85 per cent efficient, the result is 15-20 per cent less energy usage, and the resulting dollar savings.

SUSTAINABLE BUSINESS

After seven years of maintaining this small private utility model, the company has managed to stay in the black in spite of the fluctuations in gas prices across Canada. “With these low gas prices right now, it’s pretty much at the break-even point. There is not a lot of money in it as is. But, because I’m running it so efficiently without a lot of overhead, it’s successful,” Fink says.

The real incentive for Fink is to showcase that his system makes sense in Canada. “Yes, we’re in the black, but the important thing was education. There are a lot of situations out there where these systems get priced to death in the design stage so they don’t even come off the ground. We proved that you don’t need $5-10 million for a small system like this.”

The list of municipalities, First Nations and education institutions that have since installed wood boilers and district energy systems are the real testament to Fink Enderby’s success.

“We’ve definitely been able to create business through our show system. Around four or five clients have installed district energy,” Fink says. •

WOOD PELLET

www.pellet.org/wpac-agm

JOIN US IN OTTAWA!

MUCH HAS HAPPENED in our industry since the last time we met in Vancouver. It’s been a busy year, testing us in many ways and giving rise to new challenges and new opportunities alike. Our annual general meeting and industry conference in Ottawa from Sept. 22-25 is a chance for us to catch up with one another and to get ourselves caught up on the latest issues, trends and ideas in our industry.

Our “stronger together” culture in the Canadian wood pellet industry has made us formidable global suppliers. It’s important to our customers, our suppliers, our service providers, and our people that we continue to flourish. The Wood Pellet Association of Canada conference provides important tools to enable that progress, but this time in a venue that allows us to interface with another key stakeholder in our industry: the federal government.

This year’s conference theme is “Leading Canada’s low carbon economy.” The conference is taking place at the National Arts Centre in downtown Ottawa. WPAC has partnered with the Lord Elgin Hotel, located directly across the road from the National Arts Centre. Book before Aug. 28 to secure a deeply discounted rate of $259+ per night.

The conference kicks off on Sunday, Sept. 22, with a golf tournament at the Loch March Golf and Country Club from 10 a.m. to 6 p.m.

Pre-conference workshops on Monday, Sept. 23, will cover ENplus, CANplus and Sustainable Biomass Program certification. Monday will also see a full-day BioFuelNet business meeting and workshop.

The annual Pellet Party, taking place at Mill Street Brewery, will round out Monday night. We’re looking forward to the live entertainment by Nova Scotian sisters Cassie and Maggie. Tuesday is a full-day conference program, and Wednesday is a half day of sessions, adjourning at 12:30 p.m.

This year’s post-conference tour will bring a small number of early registrants to pellet plants in New Brunswick. Book early as seats are limited and fill quickly.

Register at www.wpac.org/wpac-agm. I look forward to meeting up with you all in Ottawa in September.

Vaughan Bassett President Wood Pellet Association of Canada

AGENDA

> SUNDAY, SEPT. 22

9:15 a.m. to 6:45 p.m.

Golf Tournament - Loch March Golf & Country Club

• Bus from Lord Elgin Hotel to Loch March G&CC and back

• Coffee and rules explanation

• BBQ and prizes

> MONDAY, SEPT. 23

8:00 a.m. to 5:00 p.m.

Certification Workshops - Lord Elgin Hotel

8:00 a.m. to 12:00 p.m.

Morning Workshop - Wood Pellet Quality Certification Workshop leaders:

Gilles Gauthier, General Manager, European Pellet Council

Luut Brink, Operations Manager, Control Union & Administrator of ENplus/CANplus for WPAC

1:00 p.m. to 5:00 p.m.

Afternoon Workshop - Sustainable Biomass Program Workshop leaders:

Carsten Huljus, CEO, Sustainable Biomass Program

Brenda Hopkin, Professional Forester, Hopkin Forest Management

Nicolas Blanchette, President, INCOS Strategies

9:00 a.m. to 5:00 p.m.

BioFuelNet Business Meeting and Workshop

- Lord Elgin Hotel

9:00 a.m. to 12:00 p.m.

Business Meeting

1:00 p.m. to 5:00 p.m.

BioFuelNet Workshop

6:00 p.m. to 8:00 p.m.

Pellet Party: Celebrating 152 Years of Sustainable Energy in Canada

Mill Street Brewery with live entertainment by Nova Scotian sisters Cassie and Maggie.

> TUESDAY, SEPT. 24: CONFERENCE DAY 1

Chair: Gordon Murray, Executive Director, WPAC

8:00 a.m. to 9:00 a.m.

Breakfast and Registration

9:00 a.m. to 9:30 a.m.

Opening Remarks and Welcome

Vaughan Bassett, President, WPAC

Beth MacNeil, Assistant Deputy Minister, Canadian Forest Service

9:30 a.m. to 10:40 a.m.

Global Markets

Moderator: Vaughan Bassett, President, WPAC

John Bingham, Director, Hawkins Wright: Global Wood Pellet Market Overview

Dr. William Strauss, President, FutureMetrics: A Biomass Tour of Japan

Rick Taylor, Head of Fuels, Drax Power: Wood Pellet Supply Dynamics in Europe

10:40 a.m. to 11:10 a.m.

Coffee and Networking Break

11:10 a.m. to 12:30 p.m.

Ensuring Sustainability and Quality

Moderator: Andre Bedard, Director of Sales and Marketing, Granules LG

Carsten Huljus, CEO, Sustainable Biomass Program: Recent Developments with SBP

Brenda Hopkin, Professional Forester, Hopkin Forest Management: Regional Risk Assessments in Canada

Nicolas Blanchette, President, INCOS Strategies: (1) Quebec’s Regional Risk Assessment, (2) Tracking Biomass Suppliers through the Supply Chain

Gilles Gauthier, General Manager, European Pellet Council: The Argument for Wood Pellet Quality Certification

12:30 p.m. to 1:30 p.m.

Lunch

1:30 p.m. to 3:10 p.m.

Managing Safe Operations

Moderator: Scott Bax, COO, Pinnacle Renewable Energy

Keynote Speaker: Spencer Beach, Forged in the Heart of Fire

Scott Bax, COO, Pinnacle Renewable Energy: Combustible Dust Management

Fahimeh Yazdan Panah, Director of Research and Technical Development, WPAC: Silo Fires: Prevention and Response

3:10 p.m. to 3:40 p.m.

Coffee and Networking Break

3:40 p.m. to 4:20 p.m.

Government Supporting Industry

Moderator: Gordon Murray, Executive Director, WPAC

Catriona Armstrong, Manager, Market Development, Canadian Forest Service: Expanding Wood Pellet Export Opportunities

Nicole Knox, Senior Technical Advisor, Industry Relations and Innovation Programs Division, Canadian Forest Service: IFITFacilitating Forest Innovation

4:20 p.m. to 5:00 p.m.

Focus on New Brunswick and Quebec

Moderator: John Arsenault, Director, Wood Pellet Group, Quebec Wood Export Bureau

Nicholas MacGougan, General Manager, JD Iriving - Grand River Pellet: New Brunswick’s Newest Wood Pellet Operation

Michel Vincent, Director, Economics and Markets, Quebec Forest Industry Council: Quebec’s Forest Fibre Supply Situation

5:00 p.m. to 7:00 p.m.

Cocktail Reception

John Swaan, the grandfather of wood pellets and FutureMetrics pellet operations expert, will be cooking his world famous pelletsmoked ribs.

> WEDNESDAY, SEPT. 25: CONFERENCE DAY 2

Chair: Gordon Murray, Executive Director, WPAC

8:00 a.m. to 9:00 a.m.

Breakfast and Networking

9:00 a.m. to 10:30 a.m.

Growing Canada’s Pellet Heating Market

Moderator: Rene Landry, Director, Wood Pellet Operations, Shaw Resources

Luc Lefrancois, Director, Resomasse Inc: Biomass Boiler Projects in Quebec

Lindsay Veinotte, Product Marketing Strategiest, Shaw Resources: WPAC’s Efforts to Grow the Canadian Pellet Heating Market

Dr. Harry “Dutch” Dresser, Consultant, WPAC: Situation UpdateHarmonizing Canadian and European Biomass Boiler Standards

Dr. Jamie Stephen, Managing Director, Torchlight Bioresources: How will the New Canadian Clean Fuel Standard Impact Wood Pellets?

10:30 a.m. to 11:00 a.m.

Coffee and Networking Break

WOOD PELLET

11:00 a.m. to 12:15 p.m.

www.pellet.org/wpac-agm

Panel Discussion: Pellet Producers and Power Utilities

Moderator: Gordon Murray, Executive Director, WPAC Panelists:

Vaughan Bassett, Senior Vice-President, Pinnacle Renewable Energy

Rene Landry, Director, Wood Pellet Operations, Shaw Resources

John Stirling, President, Pacific BioEnergy

Rick Taylor, Head of Fuels, Drax Power

Henry Pease, Biofuels Trader, RWE Supply & Trading

Fabien Mehu, Head of Biomass Trading, Engie

12:15 p.m. to 12:30 p.m.

Wrap-up and Adjournment

Gordon Murray, WPAC: Summary and Wrap-up

1:00 p.m. to 2:30 p.m.

Annual General Meeting

Open to all WPAC members. Lunch will be served.

Board meeting to follow AGM from 2:30 p.m. to 3:30 p.m.

*Agenda is subject to change

FUEL | AIR | GAS | ASH

EXHIBITORS

AIREX ENERGY

Airex Energy develops, manufactures and markets torrefaction systems that convert biomass into torrefied pellets –a clean, renewable alternative to coal. Benefits over industrial-grade pellets include: superior energy content, one similar to that of coal; superior energy density, therefore reducing transportation and handling costs; water-resistance, allowing the pellets to be stored in a pile; and easily able to integrate into existing systems for handling and grinding coal.

www.airex-energy.com

ANDRITZ

Andritz provides a comprehensive product portfolio for biomass industries all over the world. With its technologies and service solutions, Andritz is the world leader in wood processing, biomass handling, and wood pellet production facilities. Process technologies, equipment, plants, and systems – Andritz is your complete process partner. www.andritz.com

BIOMASS ENERGY LAB

Biomass Energy Lab (BEL) provides analytical testing services for the biomass and pelletized fuel industry. As an ISO 17025 accredited lab, BEL specializes in certifications for export shipments and offers testing per CEN/EN methods as well as ASTM methods. Along with testing services, BEL also provides auditing services for both the Pellet Fuels Institute and the ENplus fuel certification programs. www.biomassenergylab.com

BIOMASS ENGINEERING & EQUIPMENT

Biomass Engineering & Equipment specializes in material handling solutions for forest products industries across the globe. BE&E engineers and installs complete systems for receiving (lumber and bulk material), debarking, chipping, storage, reclaim, transfer, and load out. BE&E is best known for its SMART Conveyors, the most advanced drag conveyor available. Designed for low operational costs and less downtime, SMART Conveyors set the bar for performance and efficiency. www.biomassengineeringequipment.com

BLISS

Bliss Industries has been involved in the development and advancement of biomass fuel since the early 1990s. Bliss equipment has been installed in pellet facilities worldwide, with hundreds of Eliminator hammermills and Pioneer pellet mills utilized in biomass applications. Bliss Industries has continued to prove its reliability through dependable operation and production through the years. The highly rated service department helps keep your equipment functioning and performing the work it has been engineered and sized to do.

www.bliss-industries.com

BRUKS SIWERTELL

Bruks Siwertell is a market-leading supplier of dry bulk handling and wood processing systems. With thousands of installations worldwide, Bruks Siwertell machines handle your raw materials from forests, fields, quarries and mines, maintaining critical supply lines for manufacturers, mills, power plants and ports. The company designs, produces and delivers systems for loading, unloading, conveying, storing, and stacking and reclaiming dry bulk materials, alongside equipment for chipping, screening, milling and processing wood for the biofuel, board, saw mill, pulp and paper industries.

www.bruks-siwertell.com

BRUNETTE MACHINERY COMPANY

Brunette Machinery Company is an independently owned and operated company serving the North American forest industry since 1942. Brunette’s long history of manufacturing experience guarantees its customers an unsurpassed level of quality and leadingedge technology built into every single one of Brunette’s innovative products. Brunette’s commitment to quality gives customers an important advantage as they compete in an ever-changing global economy.

www.brunettemc.com

CONTROL UNION

Control Union are the experts in handling and analysing the biofuels and biomass you trade to ensure sustainable added value. Control Union’s presence throughout the entire supply

chain makes them the right business partner to manage your product quality, safety and certification needs. With a presence in over 70 countries, Control Union Certifications is uniquely placed to manage today’s challenges. www.certifications.controlunion.com

CPM GLOBAL BIOMASS GROUP

CPM has been a leader in biomass pelleting for more than 20 years. With the formation of the Global Biomass Pelleting Group, the company can now call on all its resources worldwide to ensure you receive the highest quality equipment and support.

www.cpm.net

DANSONS

Dansons Industrial Bulk Lubricants proudly supplies high quality greases to pellet mills across Canada. Working in tandem with the plants, Dansons aims to maximize cost effectiveness as well as efficiency while continuously providing superior results. When it comes to finding a true partner for your pellet mill, look no further than Dansons Industrial Bulk Lubricants. www.dansons.com

FIKE

Fike offers a full range of explosion protection solutions ¬– explosion vents, flameless explosion venting, explosion suppression and explosion isolation systems. With a team of inhouse engineers, scientists and application specialists, Fike can help you mitigate the risk of explosions. Fike also offers a wide range of explosibility tests at its state-of-the-art testing facility.

www.fike.com

FWS

Established in 1953, FWS is a fully integrated design, engineering and construction firm providing single source turn-key services across multiple industries for both greenfield and retrofit industrial projects. Recognized as one of Canada’s best managed companies and a leader in LEAN construction, FWS places safety, quality and efficiency at the forefront of all operations. As a result, FWS has earned a reputation for delivering projects safely, on quality, on time and on budget, providing

clients with peace of mind and unparalleled return on investment. www.fwsgroup.com

KAHL GROUP

The five companies of the KAHL Group offer sophisticated solutions for process engineering, machine and plant construction as well as the erection of complete factories for many industries. Research, planning, and development are essential functions of the companies. The most important machines and plant components are fabricated in the central factories in Germany. More than 800 motivated employees of the group guarantee smooth and perfect service. www.akahl.de/en

MOISTTECH

MoistTech Corp. is a world leader in moisture measurement and control utilizing near-infrared technology to develop world-class sensors. Insensitive to material variations such as particle size, material height and colour, the sensors provide continuous, reliable readings without maintenance, and one-time calibration with a non-contact, non-drift optical design, which allows for immediate process adjustments. www.moisttech.com

PORT OF BELLEDUNE

Port of Belledune is a modern, yearround marine transport facility and deep-water point of access that is innovative in developing its services and facilities to the fullest. The port has proven itself capable of handling any and all goods, offering flexible services, creative solutions and excellent rates. Additionally, the port specializes in the handling of bulk and break-bulk cargoes and is the only existing point of export for wood pellets on Canada’s east coast. www.portofbelledune.ca

PROCESSBARRON

ProcessBarron is a leader in the design, manufacturing, installation, maintenance, and repair of bulk materials handling, air handling and ash handling equipment for a variety of heavy industrial applications. All of ProcessBarron’s products are proudly made in the U.S. at its Alabama facilities. www.processbarron.com

PRODESA

Prodesa designs and provides comprehensive tailor-made solutions for the production of pellets, being a technological and innovating leader in the international arena. Prodesa covers all technological stages in the development of industrial plants such as design, manufacturing and supply under the concept of “turnkey” or “EPC” projects. www.prodesa.net

SGS Canada

SGS is an independent third-party inspection and auditing services provider in Canada since 1948. The company has a presence in all major ports and inland market areas across Canada and is known and respected for its people and services. SGS wood pellet quality certification and testing services includes ENplus Wood Pellet Certification and Wood Pellet Quality Testing. SGS sustainability audits are completed by qualified auditors proficient in agriculture and harvest practices. SGS is the world’s leading inspection, verification, testing and certification company. www.sgs.com

SHW STORAGE & HANDLING SOLUTIONS

For almost 50 years SHW Storage &

Handling Solutions has delivered installations for storage (silo and underground bunker), discharge, transportation, processing and feeding systems of special bulk materials, which are difficult to handle. The design, production and installation are carried out by SHW-SHS from one source. www.shw-shs.com

SINTO

Since 1991, Sinto has designed and distributed high performance lubrication products maximizing performance, protection and durability of mechanical equipment. The HT2 grease is the only grease built specifically for pelletizers, and helps Sinto promote its mission: to improve customer’s efficiency. www.sintoexpert.com

WELLONS

Wellons Canada, a member of the Wellons Group, is located in Surrey, B.C. Specializing in the design, manufacture and turnkey installation of biomass and gas-fired thermal energy systems, and lumber drying kilns. Wellons has the unique in-house ability to offer its clients a total project solution from concept to completion. www.wellons.ca

*Exhibitor list at press time

Dust Safety

Dust collection and suppression systems for pellet producers Staff Report

FAGUS GRECON

Sparks or embers are created during the processing of biomass through drying, shredding, granulating and pelletizing. These hazards are quickly transported along production through conveying systems and can ignite combustible dust, causing fires and explosions. GreCon Spark Detection and Extinguishing Systems are a cost-effective preventative system, which detects sparks and embers, then activates countermeasures before they can cause fire or dust explosions. GreCon Spark Detection Systems

are Factory Mutual Approved and can reduce your risk of fires and dust explosions in transport and collection systems, as outlined in NFPA 69, 654, and 664 standards.

www.fagus-grecon.us

ADVANCED CYCLONE SYSTEMS

of less than 10μm, achieving emissions as low as 30mg/Nm3

www.advancedcyclonesystems.com

REMBE

Advanced Cyclone Systems (ACS) is a company exclusively dedicated to the development and commercialization of high efficiency cyclone systems worldwide.Thanks to its superior efficiency, ACS cyclones are a viable alternative to ESPs and Bag Filters for emission limit compliance in both biomass dryers and boilers. Hurricane cyclones are able to capture very fine dust with a Volume Median Diameter (VMD)

MAINTAINING DUST SAFETY EQUIPMENT

Operating and maintaining dust safety equipment and systems is just as important as designing them correctly. We’ve rounded up the top maintenance tips for spark detection and extinguishing systems, as well as mechanical dust collectors, courtesy of GreCon and ProcessBarron.

Spark detection and extinguishing systems:

• Check the spray nozzles for excessive wear, material build-up and proper operation.

• The Y-strainer screen should be flushed clean on a regular basis and replaced if needed.

• During months in the freezing

weather, ensure heat tape and insulation is installed and working properly to avoid any pipes freezing.

• After maintenance, ensure any supply ball valve that was closed for maintenance is then opened for normal operations.

Mechanical dust collector:

• Yearly casing inspection and cleaning: This includes evaluating the condition of all of the tube assembly parts for possible replacement. Every inlet/ outlet tube should be free of any plugging. Guide vanes are the most common wear item and each one should be reviewed. Any inlet/outlet

Rembe has the expertise as an innovator of flameless venting for indoor/outdoor explosion protection (Q-Box/ Q-Rohr); a comprehensive line of Rembe explosion panels and TARGO-VENT that can help manage precious outdoor space utilization by reducing safety zones without compromising safety; and Q-Flap NX and EXKOP isolation systems to prevent explosion propagation. Whether you handle/produce pellets, wood chips, particle boards, MDF, OSB and/

tubes with holes must be replaced. Any holes in the tubesheets or casing must be patched, as the dirty and clean compartments must be kept airtight and separate. Make notes on any material build-up in a particular area or unusual wear patterns.

• Yearly hopper inspection and cleaning: This includes looking for evidence of fires and verifying no clinker build-up. Holes in the sidewalls must be patched and cracks in the welds must be repaired. Every time the access door is opened, the seal gasket material must be replaced. If a poke hole opening is present it must always be capped off and sealed while the unit

or operate a sawmill, careful consideration needs to be given to proper explosion protection, venting and isolation. Think dust collectors, dryers, cyclones, screens, silos, and mills. Rembe Inc. will work with you to determine your specific requirements, develop a plan of action and assist in implementation to minimize downtime while keeping your plant and employees safe. www.rembe.us

FIKE

With over 70 years of field experience in providing dust explosion protection systems, Fike’s team of engineers, application specialists and combustion researchers understand the complexities of plant processes, relevant code compliance and the critical nature of plant operation. Fike works closely with its customers, in many cases starting with safety audits and dust testing. The company then will design explosion protection solutions. Fike offers venting, suppression and isolation systems to ensure the safest and most effective solutions for plant and employee protection. Whether it is a passive (venting) solution or an active suppression solution, you can be comfortable knowing that Fike has designed

is being operated.

• Yearly inspection/rebuild of the hopper rotary feeder/double dump valve: This includes the internal and external components. Every time an access panel is opened, the seal gasket material must be replaced. On typical biomass-fired boiler applications it is recommended that the airlock devices be rebuilt every two years.

• Monitor the pressure drop: Use instrumentation to confirm the pressure drop across the unit (inlet flange to outlet flange) is near the original design conditions. Mechanical dust collectors operate at optimum efficiency when sized for a pressure drop between 2.5 to

the optimum Explosion Protection system for your facility. www.fike.com

FLAMEX

The Flamex Spark Detection and Extinguishing system is a cost-effective solution for the prevention of dust collector fires and explosions in the woodworking industry. Flamex has announced the introduction of the new YMX 5000 Detector series, which represents a unique and technologically advanced generation of infrared spark sensors for industrial applications. An industry exclusive self-monitoring optics feature provides “through the lens” testing for each detector in real time to immediately alert the user of lens contamination. The YMX 5000 Spark Detector is suitable for installation in an extremely wide range of operational temperatures (-40 F up to 221 F). FM Global Approved. www.sparkdetection.com

SONICAIRE

SonicAire fans are industrial fans designed to proactively eliminate overhead combustible fibre and dust in

4.00 inches WG. A sharp increase in the pressure drop usually indicates internal plugging has occurred.

• Regularly evacuate hoppers: One of the most critical aspects to successful mechanical dust collector operation is making sure the hoppers are properly (and continually) evacuated. If a single hopper on a multiple hopper application plugs, the unit’s efficiency can be reduced by up to 50-75 per cent. If possible, hoppers must be monitored on a daily basis to ensure there is no plugging. Air-in leakage through hopper access doors, hopper flanges, and the airlock devices are the primary causes of hopper plugging.

Every year, millions of tons of industrial waste are turned into millions of dollars of reusable materials. CPM and Di Più Systems help make that happen.

We’ve joined forces to bring you the world’s best mechanical and hydraulic briquetting technology.

Together, we’re taking the fossil out of fuel.

your facility. Not only will employees enjoy a cleaner, healthier and safer work environment, but cleaning costs will be dramatically reduced.

Overhead dust control fans also help keep a facility in compliance with OSHA and NFPA regulations. Airmax Systems is Western Canada’s leading distributor of SonicAire fans. Airmax works with Canadian pellet manufacturers, sawmills and pulp mills to eliminate fugitive dust. The company is now offering the new SonicAire XD2 fan, certified for Class II Div 2 Hazardous Areas. www.airmaxsystems.ca or www.sonicaire.com

BENETECH

Benetech’s dust suppression systems provide a low maintenance, cost-effective, and reliable solution to combat pervasive problems that interfere with

all aspects of your business. For over 35 years, Benetech’s engineering team has been dedicated to the design, fabrication and installation of dust suppression systems. Benetech’s approach has resulted in hundreds of satisfied customers who are now able to achieve year-round dust control. Through engineered innovations and tested and tried dust suppression agents, Benetech has become the leader in dust suppression products and services worldwide.

www.benetechglobal.com

PROCESSBARRON