YOU’LL NEVER FEEL OUTNUMBERED AGAIN

Ultimate fly and litter beetle control for your barn

When it comes to pests, there’s no such thing as too effective. Agita’sT advanced second-generation insecticide is residue free, so it’s strong and safe. It is also easy to apply, and comes in two special formulas to target flies and litter beetles. Select AgitaT 1 to effectively control flies in your poultry, swine and dairy barns and AgitaT 10 to manage beetles in your poultry operations.

IT’S TIME TO TAKE BACK YOUR BARN.

Reducing Floor Eggs

How to do it in a community nest system By David Engel, Cobb Technical Service Manager – Eastern

RESEARCH: Canadian Connection

Canada’s role in the Laying Hen Housing Research Project By

Leslie Ballentine

FEED: Cargill’s Nutrition System

New cutting-edge software feed decision system provides real-time access to growing amount of data By

Treena Hein

PRODUCTION: Getting Started

New entrants share their stories By

Karen Dallimore

Changing

McDonald’s Our Food. Your Questions. platform shows the importance of transparency By

Karen Dallimore

Antioxidants in Raw Egg Yolk Extracts Research shows that antioxidant activity in eggs is increased six to 10-fold after digestion By Nerine T. Joseph, PhD.

Karen Dallimore

FROM THE EDITOR

BY KRISTY NUDDS

Keep the Momentum Going

In anticipation of high-level negotiations in the Trans-Pacific Partnership (TPP), which took place in Hawaii the last week of July, supply management once again found itself under attack. That round of negotiations was widely rumoured to be the final round, where the TPP’s 12 member countries sealed the deal on the world’s most ambitious — and largest — free-trade agreement.

Advocates of the TPP hope that the agreement, which seeks to eliminate or reduce tariff and non-tariff barriers to trade, will boost economies of the member nations, which together account for nearly 40 per cent of the global economy.

It’s been no secret that the United States, and New Zealand in particular, want access to Canada’s dairy market. News reports will have you believe that Canada’s refusal to budge on tariff rates for dairy is the primary reason the talks fell apart. Not true –although an important point of contention amongst some of the TPP countries, news reports cite disagreements over intellectual property rights and duties on automobile manufacturing between the U.S., Japan and Mexico as the most significant barriers to reaching a conclusive deal.

Nonetheless, the perception that Canada’s dairy industry is hindering TPP progress persists. Although it’s not known when talks will resume, don’t expect much of a break in the supply management bashing.

Now is not the time for Canada’s poultry and dairy sectors to breathe a sigh of relief. With a federal election approaching in Canada and the U.S. gearing up for an election in 2016, there is pressure on the countries’ leaders to finalize the TPP, or at the very least achieve bilateral deals. This will keep supply management in the news, and it provides a great opportunity for the dairy and poultry sectors to take a proac-

tive, rather than a defensive, stance.

In anticipation of the July TPP meeting in Hawaii, the Dairy Farmers of Canada (DFC) put together a great campaign to educate consumers on the benefits of supply management to Canadian dairy farmers and milk production. Called the “Milkledown Effect,” the DFC sought to give consumers information on supply management and its benefits via a website (www.milkledowneffect.ca).

It’s the best campaign showing consumers the benefits of supply management I’ve seen. The reason I feel it’s effective is it keeps the message simple, and touches upon issues that are important to consumers – food safety, the economy, local food production, and family values.

Towards the end of the TPP meeting in Hawaii (July 30) the national poultry boards and the DFC jointly released “Farmers Fight False Information About Supply Management” (available on our website, www.canadianpoultrymag.com), which was full of great information on supply management for consumers and media.

But it was sent out late in the game, and didn’t receive as much coverage as I would have liked to see. One advantage of the Milkledown Effect is that it is housed on its own webpage, separate from DFC’s main website. This is key because it allowed the DFC and dairy farmers to promote it heavily on social media networks.

I hope that the feather boards and DFC create a website that houses the fighting false information article for easy access. In the meantime, find it on Google or our website and promote in your own blogs, websites and social networks. Keep the momentum going – and don’t wait until the TPP looms again. The benefits of supply management need to be promoted 365 days a year. n

SEPTEMBER 2015 Vol. 102, No.7

Editor

Kristy Nudds – knudds@annexweb.com 519-428-3471 ext 266

Digital Editor – AgAnnex Lianne Appleby – lappleby@annexweb.com 226-971-2133

Sales

Catherine Connolly – cconnolly@annexweb.com 888-599-2228 ext 231 Cell: 289-921-6520

Account Coordinator

Mary Burnie – mburnie@annexweb.com 519-429-5175 • 888-599-2228 ext 234

Media Designer

Brooke Shaw

Group Publisher

Diane Kleer – dkleer@annexweb.com

Director of Soul/COO

Sue Fredericks

Mailing Address

P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5

Publication Mail Agreement #40065710 RETURN UNDELIVERABLE CANADIAN ADDRESSES TO CIRCULATION DEPT., P.O. BOX 530, SIMCOE, ON N3Y 4N5. email: subscribe@canadianpoultrymag.com.

Printed in Canada ISSN 1703-2911

Circulation email: subscribe@canadianpoultrymag.com Tel: 866-790-6070 ext 201 Fax: 877-624-1940

Mail: P.O. Box 530, Simcoe, ON N3Y 4N5

Subscription Rates

Canada – 1 Year $30.00 per year (with GST $31.50, with HST/QST $33.90)

GST – #867172652RT0001

USA – 1 Year $ 66.00 USD Foreign – $75.00 per year

Occasionally, Canadian Poultry Magazine will mail information on behalf of industry-related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above. No part of the editorial content of this publication may be reprinted without the publisher’s written permission. ©2015 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

OptiGROW

More Weight with Less Wait

1 2 3

easy as 1, 2, 3. and still maintaining exceptional litter conditions.

Got Lubing? Contact your local Lubing Distributor for more detailed information.

Glass-Pac Canada

St. Jacobs, Ontario

Tel: (519) 664.3811

Fax: (519) 664.3003

Carstairs, Alberta

Tel: (403) 337-3767

Fax: (403) 337-3590

Tel: (519) 657.5231

Fax: (519) 657.4092

As

1) Large bottom pin that holds a drop of water to attract day old birds to nipple / great starts / average first week mortality below 1%.

2) Greater side flow with minimal triggering force allows all birds to easily trigger the nipple and get off to a great start. Great Starts = Fantastic Finishes!

3) Both, vertical and side action, deliver the Opti-mum flow rates and ability to grow a 4 lb small bird up to a 10 lb Jumbo bird with the same nipple. After hundreds of house updates, customers are consistently seeing improved weight gains of up to 1/2 lbs/bird with dry litter conditions!

Cowansville, Quebec

Tel: (450) 263.6222

Fax: (450) 263.9021

Alberta

Tel: (780) 963.4795

Fax: (780) 963.5034 J. Dean Williamson Ltd.

O Unlocking Canola’s Potential WHAT’S HATCHING HATCHING

ne of the keys to unlocking the full potential of canola as a feed ingredient for livestock is understanding and capturing the hidden nutritive power of dietary fibre, says Dr. Bogdan Slominski of the University of Manitoba, a featured speaker at the International Rapeseed Congress, held July 5-9 in Saskatoon.

A leading expert in carbohydrate chemistry and new feed ingredient evaluations, Slominski says three key approaches include breeding for superior yellow-seeded canola, utilizing new dehulling options and harnessing the power of new multi-carbohydrase enzyme formulations designed to break down fibre and enhance nutrient utilization for monogastric animals such as pigs and poultry.

The main advantages of

canola meal typically include good protein content, good amino acid profile, high oil content and a complex carbohydrate matrix, along with good selenium and phosphorous content.

However dietary fibre is also a significant component that presents an ‘X Factor’ with implications for nutritional value, processing approaches and feeding strategies, says Slominski.

However science and technology advances are set to help manage this component, to support higher demand and value for canola meal, says Slominski.

Superior quality characteristics of newly developed yellowseeded B. napus canola and canola-quality B. juncea mustard have been demonstrated, he says. Although canola meal from these sources is significantly lower in dietary fibre, studies have shown similar growth performance parameters in

broiler chickens and turkeys to those fed conventional canola meal and soybean meal, when diets were formulated based on digestible amino acids and available energy contents.

“This indicates that all types of canola meal could effectively replace soybean meal in poultry rations,” says Slominski.

One of the most promising and fresh areas of advancement is the new higher power of certain feed enzyme formulations to unlock more nutrients from otherwise indigestible fibre, says Slominski. “Recent studies and literature reviews show that substantial gains in nutrient utilization are possible for all species with properly formulated and applied enzyme supplementation. Also,this approach can make feasible the use of full-fat canola or off-grades of canola seed that can represent an economic,well-balanced source of protein.”

Control zone removed

The Canadian Food Inspection Agency (CFIA) removed the first avian influenza control zone in Ontario

on July 20 and the second was removed on July 29 following 21-day waiting periods after disinfection of three infected premises (IP’s) in two neighbouring counties.

As of July 29 permits are no longer required for the movement of birds and bird products in Ontario.

Removal of Avian Influenza

Immune-boosting treatment receives funding

Canada’s poultry industry will be able to address a significant productivity issue thanks to a $400,000 investment from Western Economic Diversification Canada.

This investment will enable the University of Saskatchewan’s Western College of Veterinary Medicine (WCVM) to develop and commercialize a novel technology that delivers an

immunity-boosting aerosol protectant to chickens as an alternative to antibiotics.

The funding will allow WCVM veterinary pathologist Dr. Susantha Gomis to realize nearly 10 years of avian immunity research and develop a novel, non-antibiotic, nonvaccine aerosol that can be used at the hatchery to protect birds before they are shipped to farms.

This project supports a multi-

Control Zones is a Canadian domestic measure and has no impact on export of poultry or poultry products.

A 3-month enhanced surveillance period following the cleaning and disinfection of all IPs is required by the World Organisation for Animal Health (OIE) before a zone will recover its avian influenza free status.

regional partnership with poultry farms based in Saskatchewan and British Columbia, and engages highly qualified personnel in Saskatchewan, Alberta, and British Columbia as well as industry associations from both Alberta and Saskatchewan.

CFO launches Artisanal program

Chicken Farmers of Ontario (CFO) has announced a portfolio of new programs that will support expanded business opportunities for chicken farmers and offer Ontario consumers even more choice in accessing locally grown, high quality chicken. The new business opportunities were developed following the CFO’s recent farmer, public and industry “Allocating Growth” consultations, and includes an “Artisanal Chicken” program which will appeal to smaller, independent, family farmers looking to meet local markets.

The new portfolio of programs were developed by CFO following six months of extensive consultations and reviews during which CFO and its Team Ontario partners solicited input from a wide range of stakeholders including farmers, the chicken processing industry, the retail and food service sectors, and members of the public.

The new ‘Artisanal Chicken’ program is directed at those farmers who are interested in growing between 600 and 3,000 chickens annually (through a production licence) for select target markets such as local farmer markets. Details on a new ‘Local Niche Markets’

SEPTEMBER 2015

September 15-17, 2015

Canada’s Outdoor Farm Show, Canada’s Outdoor Park, Woodstock, Ont. For more information, visit: www.outdoorfarmshow.com

September 29, 2015

Science in the Pub, Shakespeare Arms, Guelph, Ont. For more information, visit: www.poultryindustrycouncil.ca

OCTOBER 2015

October 6-8, 2015

Poultry Service Industry Workshop, The Banff Centre, Banff, Alta. For more information, visit: www.poultryworkshop.com

NOVEMBER 2015

November 18, 2015

Canadian Poultry Sustainability

Symposium, Best Western Plus Lamplighter Inn and Conference Centre, London, Ont. For more information, visit: www.cpsustainability.com

program for farmers wishing to raise more than 6,000 birds will also be announced in coming months along with other program updates. These new CFO market opportunities will be supported by a portion of future production growth allocated to Ontario through the national supply management system.

In addition, the existing CFO small flock program for those farmers growing under 300 birds per year has been renamed the ‘Family Food’ program in order to better reflect the intention of the program. The current average “Family Food’ chicken farmer in Ontario grows approximately 65 birds a year.

November 19, 2015

Poultry Innovations Conference, Best Western Plus Lamplighter Inn and Conference Centre, London, Ont. For more information, visit: www. poultryindustrycouncil.ca

JANUARY 2016

January 26-28, 2016

International Production and Processing Expo (IPPE), World Congress Center, Atlanta, Georgia. For more information, visit: www.ippexpo.com

WHAT’S

HATCHING HATCHING

Aviagen increases feed mill

Aviagen announced that growing demand for its poultry breeding stock has led the company to increase the capacity of its Athens, Ala., feed mill by 66 per cent. The Athens mill services more than 100 Aviagen breeding stock farms in Northern Alabama and Tennessee.

As part of its most recent $3 million expansion, the company installed the world’s largest Hygieniser, a state-of-the-art

pellet feed system that thermally treats feed to eliminate pathogens. Installed in June, the custom-built Hygieniser features the latest innovations for pathogen prevention and joins another existing Hygieniser, which also was the world’s largest when Aviagen installed it here in 2010. Now with two Hygienisers, the Athens facility has increased its maximum capacity from 30 to 50 tons per hour.

Connecting with Research

oultry industry representatives had an opportunity to connect with the researchers whose discoveries help their industry at a mid-July barbeque held at the University of Guelph.

A joint venture of the University of Guelph, Livestock Research Innovation Corporation (LRIC),Poultry Industry Council (PIC), and the Poultry Health Research Network (PHRN), the poultry industry barbeque brought together industry leaders from the poultry commodity groups and industry with University of Guelph leaders.

In welcoming the group,

January 28-30, 2016 Pacific Agriculture Show, Tradex Exhibition Centre (Abbotsford Airport), Abbotsford, B.C. For more information, visit: www. agricultureshow.net

MARCH 2016

March 9-11, 2016

B.C. Poultry Conference 2016, Westin Bayshore, Vancouver, B.C. The four feather boards in B.C. are hosting a joint conference that will feature breakout sessions, trade exhibits, each commodity’s annual meeting and keynote speakers. For more information, e-mail: office@ bcchickengrowers.ca

APRIL 2016

April 6-7, 2016

London Poultry Show, Western Fair District Agriplex, London, Ont. For more information, visit: www.londonpoultryshow.com

Ed Verkley, a director with Chicken Farmers of Ontario and chair of the Poultry Industry Council, noted just how important research is for the industry.

The poultry industry is incredibly important to the economy, said UofG president Dr. Franco Vaccarino as he addressed the group.

“Knowledge in action is so very important,” he noted, “and this partnership is an example of that.” He added UofG is doing research at all levels from molecular to production and the questions researchers address often come from the industry.

We welcome additions to our Coming Events section. To ensure publication at least one month prior to the event, please send your event information at least eight to 12 weeks in advance to: Canadian Poultry, Annex Business Media, P.O. Box 530, 105 Donly Dr. S., Simcoe, ON N3Y 4N5; email knudds@annexweb.com; or fax 519-429-3094. Please write ‘Event Submission’ in the subject line.

Remarkably Clean

Virkon BioSentry 904 Dupont

Management FloorReducingEggs

Tips on how to do it in a community nest system

by David Engel, Cobb technical service manager – Eastern Canada

Floor and slat eggs can be a huge problem in a breeder flock. Not only do they lower hatch and production for the hatchery, but they also lead to poorer chick quality. More importantly for the farmer, this leads to lower profit and increased work picking up these eggs.

Many management techniques are used to help reduce this problem. These are some of the ideas that have been used by many producers.

BODY CONDITION

SHARING IDEAS

The most important factor in reducing floor and slat eggs is simply — if it were really that simple —to have the birds in the proper condition at light stimulation. This means having them developed with the correct fleshing and fat reserve. This will be a key factor to the birds developing the natural instinct to go to the nest to lay their eggs.

David

Engel, Cobb

technical service manager for Eastern Canada shares some ideas on reducing floor eggs.

Having the birds in the right condition at lighting is heavily influenced by ensuring the correct bodyweight gain from 16 to 20 weeks of age has been achieved. We are looking to have the birds gain 33-35 per cent in bodyweight from 16 weeks to 20 weeks old. By doing this we are likely to have the correct fleshing and adequate fat reserve. Often with flocks over the bodyweight standard at 16 weeks, we are tempted to try and control the weight gains from that point and have the birds on the target at 20 weeks. This results in the birds not gaining enough weight relative to their 16-week bodyweight

and therefore not being in the proper condition at 20 weeks of age.

When deciding what the correct bodyweight is, you need to keep two things in mind: What line of females you are using, and when will the birds come into production. The line of the female is important as different lines have different bodyweight targets for lighting. For example, the Cobb 500SF requires a heavier bodyweight at lighting than the Cobb 500FF. Typically, flocks that will be coming into production during decreasing day lengths also require a heavier bodyweight at lighting.

Another aspect to consider, especially when moving into a solid wall production barn, is the amount of natural light coming into the barn. You may be keeping the birds on eight hours of light after transfer believing you are not light stimulating the flock. In reality, in many cases, so much light is leaking into the barn that the females are light stimulated from the day of transfer. Even though these birds may be moved at a time that technically they are “in season” flocks and would normally be on a lower bodyweight standard, because of the early light stimulation they should be reared on a heavier, ‘out of season’ standard. This will help make sure the birds are ready for the light stimulation and ready to go to the nest. This is especially important for the Cobb 500SF.

Having the birds in the correct condition means meeting some guidelines for fleshing and reserve. To check this we need to pen up enough females (around 50) to get a good idea

of the condition of the flock. In scoring the females, we want to see 95 per cent of the birds scoring a 3 or 4 on fleshing and at least 90 per cent of the birds with pelvic fat. If we have this, the flock should be ready to receive light and ready to go to the nest. If the females are not in the proper condition, then you need to delay light stimulation on this flock.

TRAINING

While having the birds in the right condition is the top priority, there are many other things that we can do, or items to look at, that will help ensure the females go to the nest. Training the birds begins in the pullet barn. This is done by placing something in the pullet barn to simulate jumping up on to the slats, such as a perch rail or actual slat section for the birds to get up on. This should be done early, between the ages of three and four weeks to give an early brain imprint that jumping up is allowed.

The training of the birds continues after they are moved to the production barn. Once there walk the birds slowly to encourage them to get up out of the scratch area and onto the slats. Many have been hesitant to walk the slats but this will help move the birds to the nest when done correctly, especially on wider slats. Walking should be done on the outside edge of the slats in a slow manner that will encourage the birds to

move toward the nests. After the birds are light stimulated, some customers walk the birds as much as once per hour to train them to go to the nest.

NEST SPACE

Having the proper nest space is also very important. If there is not enough space to easily accommodate the birds, they will look for a place outside the nest to lay their eggs. The minimum amount of nest space needed is one square meter of nest space per 100 birds. Another way to express this is 200 birds per nest segment of four nest openings of a 2.4 m long nest unit.

Opening the curtain at the nest entrance — while these curtains are there to shade the entrance to the nests, opening them will help get the birds into the nests. Many producers have seen that if they are having a problem with the birds just standing at the entrance to the nest, they can open these curtains to encourage the birds to go inside. They open the curtains by taping or clipping them to the top of the nests. While some have waited to see how the birds go to the nest before making the decision whether to open the curtains, many producers will start this practice when the flock is housed and the nests are opened. The recommendation is to open every other curtain. This allows the females to more

Training females to go into the nest begins in the pullet barn. Stimulating jumping by placing something such as a perch rail (shown here) will work, but it has to be done early, when the birds are between three and four weeks old.

Management

FLESHING CONDITION IN FEMALES

Many producers have observed that if birds are just standing at the entrance to the nest, opening every other curtain can encourage them to go inside.

easily see inside the nests and seems to make them more curious about going inside. These curtains can then be gradually lowered once it is seen that the majority of the birds are going to the nests. On certain nest systems, producers have opened the entire top of every other nest as an alternative to just opening the curtain. Some producers have opted to install a winch system allowing them to raise all the

nest tops at the same time. They will not open them fully, just enough to allow the birds more space to enter into and see into the nest.

LIGHTING

Having the right intensity and even light distribution plays a big role in how the flock comes into production

and where the hen wants to lay her egg. We want to see a minimum of 60 lux at bird level, and minimize the difference in distribution across the barn — this needs to be less than 20 per cent. Having this minimum light intensity and even light distribution will help eliminate shadows and dark areas that would encourage the birds to lay their eggs outside the nest.

EGG BELT

The egg belt should not be visible to the hen when she enters the nest. If the hen can see the moving belt, she is more likely to be scared out of the nest. Having the belt shielded properly will prevent the hen from seeing the belt. Small, plastic movable flaps are installed for this purpose.

LITTER DEPTH

Placing very little shavings in the barns helps to discourage the birds from laying eggs in the floor; 2-3 cm of shavings in the scratch area is sufficient. Additional shaving can be added to the

scratch area post peak, if desired, but is normally not done due to the litter build-up giving additional litter depth.

EQUIPMENT LAYOUT

Drinker lines should be close enough to the nest entrance to help draw the birds to the nest. This distance is normally 60-70 cm from the nest entrance. Never place all the feed lines in the floor. Having part of the feeders on the floor and on the slats encourages the birds to use both areas. Spacing should be such that the birds can easily utilize the water line and all feed lines. Also, feeder height should be high enough so that the birds can move freely underneath the feed lines — approximately 20cm to the bottom of the feeder. Another option is to raise the feeder lines with an electric winch after the feed has been consumed. This is more important for pan feeder equipment placed on the slats, which tends to give more shaded areas. Chain feeder lines are normally placed directly on the slats and a bracket is used to keep the troughs horizontal.

WATER FLOW RATE

A low water flow rate will increase the time the birds have to spend at the drinker lines. A minimum flow rate of approximately 60-80 ml/min is desired. A low flow rate will cause a wall of birds between the hens trying to get to the nest and the nests themselves. If the hens cannot get to the nest because of this wall, they will simply lay their eggs outside the nest or drop them close to the drinker line. Many broken eggs are found under the slats at the drinker line area. While there are many items that contribute to where the hen chooses to lay her egg, taking care of the basics goes a long way towards making sure the eggs do end up in the nest. n

Research

Canadian Connection

Canada’s role in the Laying Hen Housing Research Project

BY LESLIE BALLENTINE

When we think of poultry research we tend to think of single-issue, controlled studies conducted in academic facilities. In the first of its kind, a multi-flock, multi-aspect study designed to evaluate and compare a range of sustainability elements in a commercial setting is just winding up. Final results were released earlier this year.

The Coalition for Sustainable Egg Supply (CSES) is a multi-stakeholder group which collaborated on the Laying Hen Housing Research Project. Facilitated by the U.S.-based Center for Food Integrity, CSES formed in 2010 to evaluate the sustainability of egg production under three different scenarios: the conventional cage, enriched colony and cagefree aviary laying hen housing systems. The three-year study simultaneously assessed five elements of sustainability by evaluating the impact of each type of housing on; animal health and wellbeing, food safety and quality, environmental impact, worker health and safety, and food affordability. Co-led by top researchers in each of the five areas, the purpose of the one-time project was to provide meaningful science-based data to help inform future egg production and egg buyer decisions.

The Coalition is made up of 29 leading animal welfare, food safety and environmental scientists, economists, academic institutions, non-government organizations, egg suppliers, and major food retail and restaurant/foodservice

HOUSING AND SUSTAINABILITY

A three-year study simultaneously assessed five elements of sustainability by evaluating the impact of conventional housing, enriched cages and aviaries on animal health and well-being, food safety and quality, environmental impact, worker health and safety, and food affordability.

companies from the U.S. and Canada. Canada has been well represented with the involvement of Egg Farmers of Canada, B.C. and Ontario Egg Producers, the University of Guelph, and Burnbrae Farms. The $6 million study was funded through coalition members.

In a telephone interview with Burnbrae Farms representatives shortly following release of the CSES final report they said their farm’s involvement is just one more step in developing alternative housing systems that first began with Burnbrae’s introduction of free-run loose housing in 1998.

“We were quite interested in participating for a number of reasons” said Craig Hunter, Executive Vice President of Poultry Operations and Producer Relations. “As a farmer we were interested in getting some much needed documented unbiased research.” He explained that while there has been research done in the EU on cage sizes and design, none of it has ever been as extensive as this research. “So we here in North America said let’s do research based on elements of sustainability.” Hunter notes that the five elements the Coalition identified have

92% of Canadians say they prefer Canadian eggs

Supply management ensures Canadians get the fresh, local, high-quality eggs they want.

KEEP THE “EH!” IN EGGS

92 % des Canadiens veulent des œufs canadiens

Le système de la gestion de l’offre permet aux Canadiens d’avoir accès à des œufs frais, de haute qualité et produits localement.

C’EST AVANTAGŒUFS

eggfarmers.ca

producteursdoeufs.ca

since become the standard for many of those involved in the North American supply chain.

What makes this study different is that it is the first study done on a large commercial setting and the first time that there has been a combined look at all five sustainability elements of housing systems by bringing together multiple disciplines. The Coalition is quick to point out that the study was a snap shot of production systems: Done with one breed, one type of equipment in one part of the country, using one set of management.

Ian McFall V.P., Industrial & Foodservice Sales, explained that there is a particular need for this information among the food service and ingredients side of the food business where buyers have had to make decisions about one housing type or another.

Research

“Grocery retailers can sell a variety of eggs under various housing types and then see what kinds their customers buy in the store. But Quick Service (fast food) Restaurants have to decide which way to go.” Prior to CSES there was little research done on a commercial scale for the customers to rely on, he said.

Hunter says the project was timely because food companies were just beginning to adopt sustainability as a core element of Corporate Social Responsibility and yet there was no good definition of sustainably at the time. “So CFI and CSES defined it under these five elements which have become the basis of most company definitions today.” Because there are still different interpretations of “sustainability” such as organic or environmental or animal housing, he said,

“the coalition definition accounts for five elements and it’s the relative importance of these elements that has to be considered.“

Both men agreed that there were no big surprises in the findings saying they basically confirmed some of the things they had seen through their own experiences in the field. But now these findings are documented by independent experts. “One is that scratch pads in the furnished housing have more downsides than benefits,” said Hunter. The birds don’t use them for scratching but rather use them as a resting place and so they become very dirty, are difficult to keep clean and result in dirty eggs. On the other hand, he noted the birds did use the nests in the enriched cages with up to 97% of birds using them and that perches were also used to a

Research

high degree, especially at night. “A small surprise in this study was that the birds performed a bit better in enriched cages than conventional cages, although we haven’t found any difference in our barns.”

The economic findings were not surprising. Hunter pointed out that the performance from flock to flock between conventional and enriched is very stable; whereas the variability of performance of aviary production can change from flock to flock.

Labour costs found in the study were higher than anticipated and Hunter speculates that could be due to more time spent by employees initially learning how to manage the enriched and aviary systems and that those barns have a larger footprint in order to accommodate the same number of birds so more time needs to be spent in the barns.

He said it is also important to recognize that due to economies of scale and the competitive nature of the business the US production model is based on large flocks which require hired staff with more birds per person at a lower wage rate than smaller Canadian farms which are mostly managed and run by the farm owners themselves. He said this “personal” involvement means that Canadian facilities tend to be more productive. Burnbrae’s own experience is that the two alternative systems can raise labour costs by about 50% for enriched systems and by as much as three times for cage-free aviaries.

The biggest costs are associated capital costs of providing the extra space while the equipment such as nests and perches is a smaller part. The study found in total and driven largely by higher feed, labor, pullet, and capital costs, the aviary system was 36% more expensive to produce eggs in than the conventional cage system, while the enriched colony system was 13% more expensive than conventional, primarily due to capital costs per dozen.

MULTIFAN FIBREGLASS CONE FANS

• Maximum air performance

• High efficiency, high durability

• Optimal aerodynamic air intake

• Low noise level

• Easy to maintain, install and clean for optimal hygiene

• Lifetime bearings

V-FLO FAN

• Optimal air distribution in the poultry house with the purpose to create an ideal climate

• Create an active microclimate at animal level

• Control humidity level

• Constant low airspeed at animal level

• Reduction in energy costs through vertical airflow with a special aerodynamic shaped conical outlet

• Exacon’s brand name since 1987

• Available in sizes 12” to 60”

• White or Black polyethylene flush mount housings

• Designed to meet the rigorous demands of farm/agricultural ventilation

• Energy efficient Multifan, MFlex or North American motors

• Fiberglass housings available in 50” and 60” diameter

RECOV-AIRE HEAT EXCHANGERS

• Recovers wasted heat from exhaust and transfers to incoming air

• Reduces humidity and improves air quality for improved livestock performance

• Large tube type heat exchange core vs plate type stays cleaner longer and is, fully accessible for easy cleaning

• Many installations in poultry, swine and commercial applications have proven these models are cost efficient and effective

• Recovers in excess of 50% of wasted exhaust heat

• New split core for ease of cleaning

SELECT DOSER AND SELECT DOSER MAX

• Select Doser dispenses products accurately into low and high pressure watering systems through it’s tubing via compression and peristalic action.

• Aggressive products and powders never pass through the pumps mechanism that can cause premature wear and maintenance.

• New improved Model 640 is now simple to use with one tube size

• New Select Doser Max can now operate in high pressure and volumes

interface

• Navigates like an I-Pad by simply touching, swiping or dragging on a 7” or 10” touch screen

• Available with up to 8 variable stages and between 15 to 30 on/off relays

• A slave is available to expand to 50 on/off relays

•

•

McFall explained that they have been providing updates and results to their major buyers and will continue to communicate those results. He said that generally the reaction has been very positive because buyers have been looking for this sort of information. Some buyers, he said, may have been hoping for clear cut results that would identify the “best” type of housing although that was never the intent of the project.

The purpose of the research was to identify the trade-offs in all three types of housing that retailers can use to determine for themselves the housing system that offers them the benefits they are looking for. According to both men, while some grocers and fast-food companies have offered a small percentage of alternative eggs to appease their critics still 94% of eggs in Canada are raised in conventional cages and it will take time to change housing methods even if the marketplace demands it.

The study provides opportunities to not only better communicate with buyers but also points to opportunities to do further research on some identified issues. “It really is a good basis for explaining to the average customer what the decision points are and what the issues are and at the same time laying some ground work for further studies,” said McFall. Hunter added that it could prove to be useful information in the Code of Practice update currently underway and for future policy changes by marketing boards.

Perhaps most important, this new multidiscipline research model may be useful for other segments of animal agriculture. Buyers are asking for similar research for other animal products now that the egg study has been completed, said Hunter who also sits on the CFI board. Commercial-scaled research that is consistently based on five recognized sustainability criteria can only help the food supply chain make decisions down the road. n

CPRC Update

Why is AIV so difficult to control?

Although only viruses of the Influenza virus A genus are known to infect birds, the complexity of this genus is increased by the possible combinations of the subtypes present, based on the antigenicity of surface glycoproteins hemagglutinin (HA) and neuraminidase (NA). Each virus consists of one of the 18 identified HA antigens and one of the 11 NA antigens, generating a large number of virus subtypes.

Avian Influenza (AI) is classified based on the severity of the disease caused; highly pathogenic AI (HPAI) and low pathogenicity AI (LPAI). HPAI is restricted to strains with H5 and H7 subtypes exhibiting a multi-basic cleavage site (MBCS) at the precursor of the HA molecule. HPAI is a ‘dead-end infection’ in certain domestic birds and its effects are variable in domestic waterfowl and feral birds, in which it may or may not cause clinical signs and mortality. Viruses belonging to subtypes without the MBCS are maintained in feral bird populations and serve as an ever-present source of the virus. A large portion of the influenza gene pool is present in waterfowl whereas shorebirds and gulls maintain a number of isolated subtypes of the virus. These viruses cause LPAI when introduced into domestic bird populations.

Several mechanisms result in the virus mutating to HPAI once the LPAI (H5 and H7 subtypes) is introduced into poultry. However the factors that bring about this mutation are not fully understood and can occur at any time. It is therefore imperative that both LPAI and HPAI should be controlled.

The complexity of the variants of the virus, their omnipresence in nature and the ability to mutate to a highly pathogenic strain from a low pathogenic strain all contribute to the challenge that this

virus presents to the poultry industry. Transmission of the virus between birds is poorly understood, although research suggests that bird-to-bird transmission is extremely complex and determined by the virus strain, bird species and environmental factors. Studies also show that the virus is present in considerable quantities in bird feces, to the extent that the virus can be isolated from untreated lake water in waterfowl habitats. Nonetheless, the primary route of introduction of AI virus in domestic poultry occurs through direct or indirect contact with infected birds affirming that implementation of biosecurity measures at the farm level can prevent AI infections.

CPRC has been funding AIV studies since 2006 and has committed almost $520 thousand to 11 research projects with total research budgets of more than $2.5 million. This research has looked at a range of issues associated with AIV. The issues studied included:

• Identifying the molecular determinants that confer a bird’s immunity to the virus and the immune system cells that recognize these determinants. The project was also aimed at determining the dynamics of immune system cells in response to AI virus infection and the genetic pathways that control that response.

• Three related-research projects from the first Poultry Science Cluster investigated adaptation of AIV from its natural reservoir in wild fowl to domestic poultry, how avian influenza is transmitted to domestic poultry and the bird’s immune response to AIV. These projects provided information that is important to developing AIV controls and responses.

• AIV vaccines are difficult to create because the virus is prone to change

that interferes with a vaccine’s activ ity. Researchers investigated the use of RNA interference (RNAi), a natural mechanism present in many animals including birds, that can decrease the activity of specific cellular genes and has been shown to serve as a natural antiviral response. This research could lead to improvements in a bird’s natural immunity.

• An ongoing series of projects have been moving toward development of an effective AIV vaccine and delivery system to provide poultry with broad protection delivered efficiently and effectively. This research is being con tinued in CPRC’s second Poultry Science Cluster and has already provided patent able results.

• Present approaches to testing for expo sure to avian influenza for the national surveillance program are based on tak ing blood samples from birds and send ing them to a laboratory for analysis. CPRC is supporting research that will evaluate a standardized test to use eggderived immunoglobin for screening of antibodies to avian influenza to avoid the stress and cost associated with han dling birds and taking blood samples. CPRC and its member organizations will continue to support research on this important threat to Canadian poultry pro duction in its ongoing research activities.

CPRC, its Board of Directors and member organizations are committed to supporting and enhancing Canada’s poultry sector through research and related activities. For more details on these or any other CPRC activities, please contact The Canadian Poultry Research Council, 350 Sparks Street, Suite 1007, Ottawa, Ontario, K1R 7S8, phone: (613) 566-5916, fax: (613) 241-5999, email: info@cp-rc.ca, or visit us at www.cp-rc.ca.

Cargill Nutrition System

New cutting-edge software feed decision system provides real-time access to growing amount of data

BY TREENA HEIN

Cargill has launched a new proprietary feed formulating platform called the Cargill Nutrition System (CNS). It combines nutrient analysis of feed ingredients from all over the world, and is updated constantly with the latest feed research and Cargill ingredient sourcing – all to provide livestock producers with clarity and consistency in making feed decisions.

The database behind CNS is comprised of over 2 million nutrient samples, covering more than 200 ingredients and 10 million annual nutrient predictions, explains Dr. Jason Shelton, Cargill Animal Nutrition global technology application director. “This data is combined with the knowledge and experience of Cargill Animal Nutrition’s 18,000 employees, including more than 500 research and development professionals,” he says. “It’s all about providing customers with certainty in feed application to achieve the desired results, rather than just a ‘best guess.’”

What stands out about the CNS is that wherever producers are located in the world, and no matter what their production target goals, they will receive unique feed formulations. The system accounts for climate factors, nutrientcontent requirements and cost considerations of available ingredients.

IN-DEPTH ANALYSIS

A new proprietary feed formulating platform combines nutrient analysis of feed ingredients from all over the world.

Vitamin D and Omega-3 ingredients are included in the system. Shelton says that the specificity of CNS can help farmers achieve similar or better production results at a lower cost, at the same time reducing nitrogen and phosphorus supplementation with a consequent excretion reduction anywhere from 10 to 40 percent. Better for producers and better for the planet.

Recently, poultry customers in Indonesia went through a CNS review process. It was discovered that by

decreasing levels of crude protein and changing amino acid and fiber levels in the feed, farmers would see improved animal performance along with better feed cost per unit of production. The wetness of the litter was reduced as well when the feed changes were made. CNS was also instrumental in a recent trial in Switzerland, where a reduction in calcium and phosphorus levels and an increase in phytase in broiler feeds led to better feed costs per unit of production and easier compliance with local

Nutrition

environmental legislation. The amount of phosphorus declared on the label of the feed was reduced by more than 10 percent, which allowed farms using the feed to meet government regulations

relating to having a balanced nutrient input/output.

CNS is also built into Cargill’s MAX modelling system to provide producers with alternative options, if for example,

a major crop failure occurs or the price of common ingredients like corn or soy spikes, Shelton explains. “In the U.S., Canada and Mexico, CNS employs the MAX modeling system in pork and beef in the U.S. and Mexico, and for dairy and pork in Canada,” he notes. “It is now being rolled out for poultry globally. A Canadian pilot project will begin late this summer/early fall and is slated for full deployment across North America during summer 2016.” Shelton says the MAX modeling system matches availability of supply for ingredients, with farm needs or predicted needs to meet production goals. “So, if you have this or that ingredient mix, MAX will give you the price change and the performance prediction change,” he explains. “It’s the CNS with a prediction model.” For its part, Cargill provides its own feed (under the Purina

The CNS allows for a reduction of the total protein that is fed to animals, resulting in better utilization of nitrogen, reducing emissions.

and Nutrena brands) and pre-mixes (under the Provimi brand) in every province, and all Cargill feed products are now being developed using CNS.

In addition to MAX modelling, CNS also supports ‘Reveal,’ a system that analyzes ingredient variability and nutrient content. It’s useful for farmers who make their own feed, which is gaining in popularity among Canadian poultry producers. It’s estimated that the percentage who make their own feed is as high as 30 to 40 percent, depending on the region. “The customer could have ten different corn meals, or ten different soybean samples for example,” Shelton says, “and using the analysis results, is assisted with choosing ingredients for his or her own formulations.” ‘Reveal’ is also licensed to feed mills.

In terms of specific environmental

Nutrition

or regulatory issues in Canada that CNS helps solve, Shelton says that “By implementing CNS in Canada, emissions of nitrogen to the environment can be reduced. This is because CNS allows for a reduction of the total protein that is fed to animals, resulting thus in better utilization of dietary nitrogen, even with better performance of animals.”

“Reductions in nitrogen and phosphorus excretion are two important environmental concerns,” adds Dr. Bruno Marty, director of nutrition for Cargill’s animal nutrition business in Canada. “Excessive nitrogen excretion in poultry primarily results from an amino acid imbalance between feed supply and animal demand. Through the more accurate description of digestible amino acids, CNS reduces these imbalances and consequently waste.”

Marty says the same concept applies to phosphorus, where contribution from plant-based feedstuffs is poorly digested by poultry. For this nutrient, CNS additionally estimates the quantity of phosphorus liberated by the application of phytase enzyme technology which enhances phosphorus digestibility and thus nutrient efficiency.

Marty agrees that every region in Canada faces specific feed challenges which change with shifting ingredient market conditions and CNS is designed to help with that. “A CNS analysis might find the best value may come from the use of non-traditional feedstuffs and by-products,” he says. “It’s all about helping producers to more accurately assess for digestible nutrients to support animal performance and long-term business goals.” n

Production

Getting Started

New entrants share their stories

BY KAREN DALLIMORE

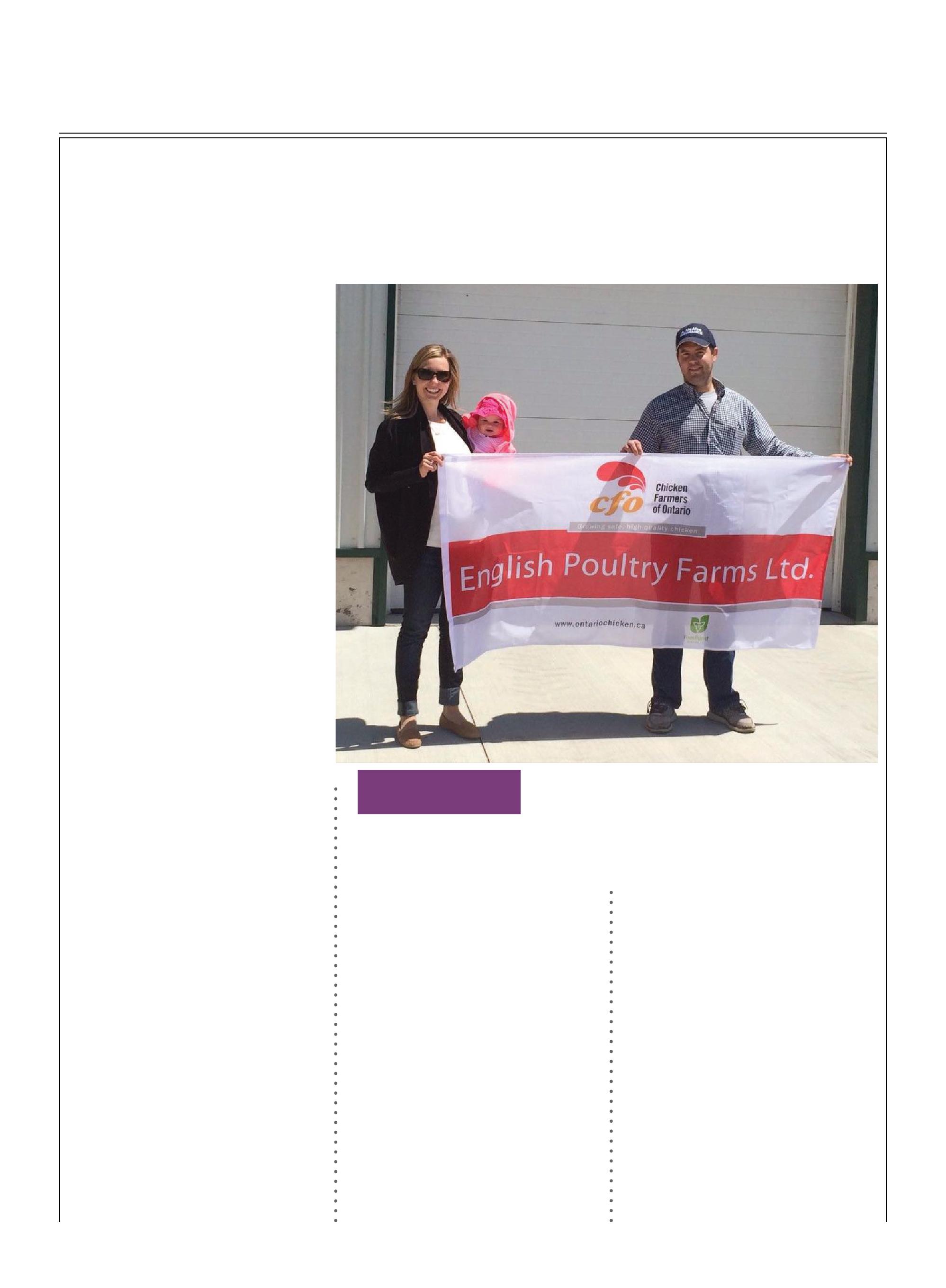

Getting into the chicken industry under the Chicken Farmers of Ontario (CFO) New Entrant Program is a long-term commitment, but for Jamie and Melissa English of Alliston, it was exactly the opportunity they wanted.

Both Jamie and Melissa had grown up on a family farm. Their parents relied heavily on outside jobs for income. Melissa’s parents ran a cow-calf operation and worked for the Ministry of Transportation Ontario; Jamie’s parents farmed potatoes and grains before moving into the logistics industry. For these farm kids, their challenge was to find a way to get back into farming and they found it through the New Entrant Program.

It was 2012 when the young couple first heard about the program. They started researching the industry, talking to farmers to find out what was involved. “We wanted to make sure this was what we actually wanted to do… what the industry was like.”

Under the program formula, new farmers were required to buy 4,000 units of quota and borrow the other 10,000 units from the CFO to meet the minimum production requirement of 14,000 units. The market sets the quota price, making it difficult to predict the eventual total investment. Between five and fifteen years the 10,000 units are paid back to the CFO under a timed schedule.

The application process involves presenting a business plan to an industry panel of financial and farming experts that evaluates the application and makes recommendations to the CFO Board of

Farm kids Jamie and Melissa English wanted to find a way to get back into farming and they found it through the Chicken Farmers of Ontario’s New Entrant Program.

Directors. Successful applicants have up to 18 months from the date of approval to execute their business plans.

The next step was to get a business plan together. The application was handed in on the 31st of October and the green light was given in March 2014. Jamie and Melissa were very excited to be one of two farms chosen and soon began construction on their new facility. “There was a lot of red tape with setbacks and also with Nutrient Management, so those were a few challenges,” said Jamie. They knew they only had one chance to build, going with a 16,500 square foot barn, large enough to capture future growth but small enough to manage costs.

Jamie really focused on the equipment because that’s where he felt he’d get good payback. They went with a system of what he called ‘back-end brooding’ - where the birds were kept to a smaller area for the first 10 days so that the humidity and temperature could be controlled. He added extra drinkers to give the birds a really good start and extra heaters help to keep the temperature even.

Their first transition crop was in October 2014 and Jamie admitted they “had a bit of a learning curve.” That first flock had five percent mortality but they met their weight targets; their second flock had 3.2 percent mortality and their weights were a little over, held back a day

NEW ADVENTURE

Production

on the processing end. These first two flocks seeded the barn with good bacteria to help the next flock to fight disease naturally; their next flock will be meet full RWA (Raised Without Antibiotics) criteria.

Jamie gives thanks to the many farmers and other people in the industry that continue to give them a lot of help and advice and leadership. “A lot of people were very open; local farmers helped out immensely.”

Overall Jamie is a huge fan of the quota system, knowing that he’s building something that he can pass down to their children. “We’d be crazy if we ever had the chance to lose it and didn’t make sure we did everything we could to hang onto it.”

As Jamie prepares for his next flock, he continues to work off farm as well, but for his family, “it’s good to get back to where our roots are and into something we’re passionate about. For that we’re really fortunate to be part of this program - it’s helped us to get into something that we really wanted to do.”

The story was similar for Joannette and Jim Van Hemert, only for them it was a new adventure as egg farmers.

Jim Van Hemert is a Ridgetown graduate and obtained his B.Sc. in Ag. Business at the University of Guelph before taking positions as an account

manager at TD Canada Trust, then RBC, but his real passion was in farming. He grew up on a poultry farm in the Fraser Valley of British Columbia. His wife Joannette grew up in Norwich and shares a similar strong financial background - the McMaster graduate obtained her CA designation in 2010.

They combined their business savvy to analyze several different options to get into farming, deciding in 2011 to buy a turkey breeder operation in Ingersoll. Not long after moving in, Jim began growing turkey poults at a rented property in Thorndale, bringing them in as day olds, growing them until they became mature breeding stock before transferring them to the Ingersoll farm.

It was around the same time that they started asking questions about the New Entrant Quota Loan Pool (NEQLP) program. It was an opportunity to diversify their operation from being solely reliant on a contract with Maple Leaf Foods as well as enabling them to take advantage of the benefits of supply management: reduced price risk, increased stability and long term sustainability. As for the business side of the equation, it was also a means of reinvesting cash flow into the company.

The Egg Farmers of Ontario NEQLP program, now in its fifth year, lends up

to 10,000 units of quota split between two new entrants every year according to the needs of their business plan. The quota is lent on a 1:2 ratio, meaning that one unit must be purchased for every two units loaned. After 10 years, the quota is returned to the EFO in ten annual installments. Overall it is a 20-year commitment.

The application consisted of forms and a business plan – a 10-page written report - that were both submitted in May 2012. It was a long wait until September to hear they were finalists and a one-hour interview would be arranged. The interview was successful; it was now November 2012. They had 18 months in which to begin production and there was a lot of work to be done. Where would they build a barn? What systems would they use? How large would the barn be? Would there be quota available to purchase?

Their original projections were for 12,500 hens. That quickly rose to 15,000. With that number in mind, details of the actual project started to surface, such as finding the right building contractors and deciding which equipment to install?

Due to disease transmission concerns with the turkey operation they needed to seek a new location for their 290’ x 30’ layer barn, finding a 70-acre property within a short drive of their farm where they could build. They decided that traditional cages would be the most cost effective and efficient system to install. The enriched cages represented additional costs without benefit, and free run was considered too labour intensive.

By July 2013, Bright Horizon Farms announced their open house in the paper. With some help from the industry that included Clarke, New Life, Burnbrae and McKinley Hatchery, their first flock arrived in the new red and white barns on July 16, 2013. Despite some trouble with cracked eggs, Joannette considered that first flock a success.

Looking back, Joannette sees the NEQLP program as an opportunity to farm with the stability that was lacking in the turkey breeding operation. Without it, they wouldn’t be layer farmers today. n

Jim and Joannette Van Hemert (shown here with their children (L-R) Jayden, Tyanna and Cory).

Consumers

Changing Perspectives

McDonald’s Our Food. YourQuestions. platform shows the importance of transparency

BY KAREN DALLIMORE

McDonald’s comes face-toface with nearly three million Canadian consumers every day at more than 1,400 restaurants across Canada. The quick service food retailing giant knows that it’s the consumer that drives sales, and those consumers apparently have a lot of questions.

The company launched Our Food. Your Questions., an online digital platform that has provided answers to over 23,000 questions from consumers since its launch in 2012. “We have nothing to hide,” said Sherry MacLauchlan, Director Government Relations & Sustainability with McDonald’s Restaurants of Canada Limited, who admits that sometimes the questions can get tough. Where does your food come from? What’s in it? How is it processed? How do you prepare it? Some questions have been challenging, but the company is committed to transparency and answers with openness and honesty.

For farmers, MacLauchlan realizes that direct link with consumers isn’t always obvious but said that the Our Food. Your Questions. model could be re-shaped in different ways to be effective, perhaps through grocers or food service companies at point-of-purchase. Her advice? “Be brave; be bold,” MacLauchlan told the audience at the

TRANSPARENCY MODEL

The Our Food. Your Questions. model could be re-shaped in different ways to be effective, perhaps through grocers or food service companies at point-of-purchase.

Photo courtesy of Sherry MacLauchlan.

Farm & Food Care 2015 AGM in Milton, Ont. “Get comfortable being uncomfortable.” When consumers ask questions, you have to tackle them head on to reach your goal of putting people at the core. Take brand action then advertise it, putting the brand in the hands of the consumer, all while maintaining a casual tone.

Many of the questions are about the food chain and farming, and as she told the room, “that story comes from you. We get a halo when we talk about our association with farmers.” Answers are provided in text, video or image format. Taking the time to answer questions isn’t about selling; it’s about changing perspectives. MacLauchlan hears fixed perceptions about their brand, but finds that as soon as you give a little information,

people walk away with an enlightened view. “Our task was not to say something new. It was to say what we had been saying for years, but to say it in a way that stopped people in their tracks.”

It’s working. The campaign has generated a dramatic 53 per cent change in the public perception. As for the critics, the new transparency has changed that dialogue too but MacLauchlan admits that while McDonald’s will always be a “bullseye”, the campaign is an opportunity to set the record straight by providing the real facts. “We’ve got big shoulders,” she said, and although the dialogue sometimes gets uncomfortable, “we build our case around science and evidence, hoping that a rational approach will appeal, stating facts and correcting misinformation.” n

Research

Antioxidants in Raw Egg Yolk Extracts

Research has shown that antioxidant activity in eggs increased six to 10-fold after digestion

BY NERINE T. JOSEPH, PH.D. LIVESTOCK RESEARCH INNOVATION CORPORATION ON BEHALF OF THE POULTRY INDUSTRY COUNCIL

Arecent study led by Dr. Jianping Wu of the University of Alberta has found antioxidants in raw egg yolk extracts. Antioxidants can improve public health by reducing the risk of chronic diseases like inflammation, diabetes, and cancer.

The Canadian egg industry contributes approximately $1.4 billion to the economy annually and that egg consumption is increasing. The industry continues to work proactively to develop eggs with additional nutritional and nutraceutical attributes.

“Research to explore the presence of health-promoting components in eggs is essential to reinforce the positive image of eggs,” explains Dr. Wu.

The objective of Wu’s study was to further characterize the presence of antioxidants in eggs and determine the effects of cooking and digestion on their formation and activities.

“Eggs are a protein-rich food commodity; it is very likely that antioxidant amino acids and peptides may be generated during gastrointestinal digestion to further enhance the antioxidant activity of eggs,” he explains.

The research commenced in 2012, and included quantifying and

ANTIOXIDANTRICH

A UofA study has characterized the presence of antioxidants in eggs and determined the effects of cooking and digestion on their formation and activities.

characterizing the total antioxidant activity of egg yolk extracts and determining the effects of cooking methods and subsequent simulated gastrointestinal digestion on the antioxidant activity of the eggs.

Results showed that free amino acid and carotenoids were the major antioxidants found in raw egg yolk, and that the free amino acid content of egg yolk is approximately 10-fold higher than that of egg white.

Cooking in general reduced antioxidant activity of the egg yolks, whereas simulated gastrointestinal digestion substantially increased the antioxidant activity by releasing free amino acids and peptides. The carotenoids

remained stable after digestion.

Overall, the eggs antioxidant activity increased six to 10-fold after digestion.

“Peptides released from proteins are the major contributor to the increased antioxidant activity in cooked digested eggs,” says Wu. “These findings will have a significant impact on the current welldefined knowledge on egg nutrition and may give rise to a paradigm change in the nutritional evaluation of eggs.”

This research was funded by Egg Farmers of Canada, Alberta Egg Producers, Agriculture and Food Council of Alberta, Food for Health Initiative, Burnbrae Farms Limited, Natural Sciences and Engineering Research Council, and Poultry Industry Council. n

Industry Speaking up for Agriculture

How to tell your story

BY KAREN DALLIMORE

You’re not just a farmer; you are the voice of farming. There are people who want to hear your story. Are you ready to tell it?

Bern Tobin likes to tell stories. As a journalist and videographer, it’s what he does best, and he’s good at it. Now he’s added another skill to his resume: teaching farmers to tell their story through a training campaign called Speaking Up For Agriculture, started in 2014 by the Farm and Food Care Foundation.

Ten years ago, no farmer would sit for a day in a classroom to learn how to tell their story. “The world is different now,” Tobin told the audience at the Farm and Food Care AGM in May 2015. So far, over 170 farmers had done just that: dedicated a day to honing their presentation skills, learning what to say and how to say it with confidence.

It turns out that farmers are well positioned to tell their story to the general public. Statistics gathered by Farm & Food Care indicate that information from farmers ranks third in believability, after information from a university environmental science professor and an environmental engineer for environmental issues, and second after veterinarians for animal welfare issues.

It’s up to farmers to help the public shape their perception of agriculture, said Tobin, instead of allowing others to fill that void. Either they hear straight from the horse’s mouth, so to speak, or they tune in to Dr. Oz, activists or the mainstream media.

WHAT TO SAY

Journalist Bern Tobin shares his expertise on how to tell their stories and answer questions at a Speaking Up for Agriculture event in May.

But what do you say? Who will listen? What happens when you are faced with difficult questions? Those are the kind of questions that the Speak Up For Agriculture training will answer, helping you to tell your own story.

Aaron Stevanus has taken the course. He did a mock presentation to the “Lions’ Club in Waterloo” - actually the audience at the AGM – to show what a presentation could look like. He took out the jargon and made a connection with the audience by inserting photos of his own farm and family in slide templates that were supplied as resources in the program. He didn’t have to worry about the format; he just had to fill in the blanks.

The young 4th generation farmer told us about the corn, soybean and wheat rotation, the bees that give them honey and pollinate the crops, and the CSA program that feeds 100 families that they run from their incorporated family farm. He joked that there wasn’t a slide big enough to show all of the crops that they grow. As a farmer in the Grand River Watershed, he talked about using to notill cultivation, continuously evolving his land stewardship by rotating crops, using cover crops, and fertility testing

Industry

the soil to ensure that it is “alive”.

“I love being a steward of the land,” Stevanus told us, sharing his passion and pride in creating a positive environment in which the fifth generation of his family could grow.

It was obvious that the Speak Up training agenda had given Stevanus the tools he needed to address a group: an understanding of the public perception of food and agriculture, templates and resources to back up his discussion points, and the confidence to tell his personal story to the public. The audience could be the local Lion’s Club, or a high school class, Municipal council or Chamber of Commerce, but whoever they were, he would be prepared.

What if the questions got tough?

Tobin drew on his advice as a journalist to tackle that issue. He called the technique “blocking and bridging”, a technique often used by Steven Harper as a prime example. “It’s a great skill,” said Tobin, which involves turning the discussion back to familiar ground, speaking about what you know.

It helps to know your audience too. Polling has indicated that there are 11 percent of people at either end of the agricultural knowledge spectrum, firmly negative or positive, but it’s the 78 percent of people in the middle that form the most receptive audience. “Spend your energy in the middle,” said Tobin, ”there’s tremendous opportunity.”

Make that connection, said Tobin, and tell your story at the dentist’s office, on the bus, anywhere there is an opportunity to dispel myths and share facts. Many consumers are just looking for someone to trust. They’re just regular people with many of the same values. As he said, “It’s our industry, your business, and your children’s future.”

For more information on the Speak Up For Agriculture program or to sign up, contact Farm & Food Care at info@ farmfoodcare.org. Several sessions are already being planned for the fall of 2015. n

HERE’S THE POINT

BY LESLIE BALLENTINE, BALLENTINE COMMUNICATION GROUP

From Bad Egg to Good Egg

It has taken nearly 40 years for U.S. government nutritional guidelines to catch up to Canada. In February, the top nutrition expert panel in the U.S. lifted its warning about consuming cholesterol. The recommendation comes from the Scientific Report of the Dietary Guidelines for Americans Advisory Committee.

In its regular five-year review of dietary guidelines the Advisory Committee recommended lifting restrictions on consuming cholesterol, saying it is “not a nutrient of concern for overconsumption.” This important recommendation will be considered by the U.S. departments of Health and Human Services (HHS) and Agriculture (USDA) as they develop the 2015 edition of the Dietary Guidelines for Americans.

It’s a move that reverses nearly 50 years of U.S. government warnings about cholesterol-rich foods and whose guidelines influence millions of people. The recommendation validates what research and the egg industry have long been saying.

The announcement is also a significant win for the Canadian egg industry, who has battling cholesterol scare since the 1970s, when research studies began reporting that high-cholesterol foods, especially eggs, raise blood cholesterol levels leading to a higher risk for heart disease. And, as egg farmers know, when people began to think of an egg as a cholesterol time-bomb. That thinking took hold and by the 1980s and ‘90s, food manufacturers were labelling their products as “cholesterol free.” The change in the U.S. recommendation reflects a new evaluation of the existing data that show diets high in saturated or trans fat, not dietary cholesterol, are mostly responsible for increases in blood cholesterol levels.

average of one egg per day does not increase the long-term risk of heart disease. Some studies have shown the same to be true for double that intake. Sadly, the “eggs are bad” myth survives where the exact opposite may be true.

In fact, avoiding or restricting egg consumption due to cholesterol concerns may actually be harming not helping us. One large egg contains no trans fat, 70 calories, six grams of high-quality protein and five grams of total fat, most of which is the healthy, unsaturated type that lowers “bad” cholesterol. Ironically, eggs also provide benefits that may actually help to protect heart health. These include antioxidants like the vitamins A, D and E, carotenoids like lutein and zeaxanthin, as well as B vitamins like folate, B6 and B12. Egg yolks are a significant source of iron which, as with the iron in meat, is highly bioavailable. Iron together with folate and vitamin B12 are important for healthy blood.

Nutritionists who’ve commented on the new report say that health warnings about cholesterol all these years may have also caused people to shift to foods high in carbohydrates and sugar which are known to increase heart disease and obesity.

Avoiding or restricting egg consumption due to cholesterol concerns may actually be harming not helping us

In a complete 180, eggs are now entering the “functional foods” category. A functional food is one that provides health benefits beyond its basic nutrient content. One recent study by a Purdue University nutrition researcher found that adding boiled eggs increases the carotenoid absorption from raw vegetables. Prof. Wayne Campbell, concluded that: “Americans under consume vegetables, and here we have a way to increase the nutritive value of veggies while also receiving the nutritional benefits of egg yolks.”

Scientists have long concluded that the earlier link between eggs and blood cholesterol was largely exaggerated. Health Canada and the Heart and Stroke Foundation have recognized that dietary cholesterol has little impact on blood cholesterol in the general population. But in the U.S., government dietary guidelines continue to advise limiting egg consumption and other cholesterol containing foods. This advice has perpetuated the myth that eggs are bad for your heart.

In general, studies show that for healthy people with no history of heart disease, diabetes or high blood cholesterol, eating an

And according to new research from the University of Eastern Finland, egg consumption may actually lower the risk of type 2 diabetes. In some studies, high-cholesterol diets have been associated with risk of type 2 diabetes. That is why diabetics are still advised to limit their egg consumption. The Finland study found that men who ate approximately four eggs per week had a 37 per cent lower risk of type 2 diabetes than men who only ate approximately one egg per week.

Here’s the Point: It takes science to refute science and science takes time.