Quebec City apartment block heats with biomass.

Documenting and evaluating the implementation of a wood biomass heating system on a small to medium-sized farm.

Consensus at the annual PFI conference was that the European market will provide the next growth phase for pellet producers.

Protecting against fire in pellet production facilities.

Prevention of dust explosions in pellet plants benefits from new research.

he generation of dust never gives up and can only be fought with diligence.”

It may seem a bit over-dramatic, but the risk of dust explosions in pellet manufacturing plants is serious business and must be treated as such.

Recently, the Wood Pellet Association of Canada (WPAC) released a report that outlines steps pellet mills can take to assess and minimize the risk of dust explosions in their facility and it concluded with the above quote.

Penned by research director Staffan Melin, Determination of Explosibility of Dust Layers in Pellet Manufacturing Plants looks at dust explosions in the pellet industry and outlines a dust management scheme that would eliminate much of the risk at a minimal cost. The report also discusses risk assessment, dust sampling and categorization methods.

in. Based on lab testing, the report offers pellet plant operators information to evaluate the necessary safety precautions that need to be taken as it relates to “housekeeping” or controlling dust levels.

According to the report, keeping upto-date records, using the correct methodology to record dust accumulation and sharing this information with everyone in the plant are key to a successful plan to control dust explosions. “Whoever is assigned the responsibility of controlling the dust level in a manufacturing plant should be equipped with methodology to record thickness of dust accumulation in layers and spaces where dust is continuously suspended in the air. Inspections and recordings need to be done at preset intervals. This should be done every time just before vacuuming takes place.”

Volume 5 No. 5

Editor - John Tenpenny (905) 713-4351 jtenpenny@annexweb.com

Associate Editor - Andrew Macklin (519) 429-5181 amacklin@annexweb.com

Editorial Director/Group Publisher - Scott Jamieson (519) 429-3966 ext 244 sjamieson@annexweb.com

Contributors - Gordon Murray, Isabelle des Chenes, André Dumont, Rob Cruickshank, Andrea Kent

Market Production Manager

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

National Sales Manager

Ross Anderson Ph: (519) 429-5188 Fax: (519) 429-3094 randerson@annexweb.com

Quebec Sales

Josée Crevier Ph: (514) 425-0025 Fax: (514) 425-0068 jcrevier@annexweb.com

Western Sales Manager

Tim Shaddick - tootall1@shaw.ca Ph: (604) 264-1158 Fax: (604) 264-1367

Media Designer - Kelli Kramer

Canadian Biomass is published six times a year: February, April, June, August, October, and December.

Published and printed by Annex Publishing & Printing Inc.

Printed in Canada ISSN 2290-3097

Circulation

Carol Nixon

e-mail: cnixon@annexweb.com P.O. Box 51058 Pincourt, QC J7V 9T3

In pellet manufacturing plants, cleaning and monitoring dust levels hasn’t always received the attention it deserves, as the priority is usually keeping the plant operating and producing revenue. “Cleaning of floors is a nuisance since the generation of dust never stops but it is as important as regular maintenance of machinery,” states the report.

However, it offers a methodology for evaluating how much dust on floors, girders and beams is acceptable in order to ensure a safe working environment.

While there are published guidelines on the subject, most aren’t specific to the kinds of dust produced in pellet plants, and that’s where the WPAC report comes

A well-kept record of thickness measurements seems to be the best approach, concludes the report: “A well calibrated thickness meter and well-kept record of measurements could eliminate much uncertainty and disputes regarding safe operating procedures and eliminate poorly designed operating equipment and procedures.”

This method also promotes collaboration amongst employees at all levels, keeping the issue of dust explosions and their prevention top of mind. Dust will continue to fall in pellet plants, just as the industry’s diligence to-

John Tenpenny, Editor jtenpenny@annexweb.com

Subscription Rates: Canada - 1 Yr $49.50; 2 Yr $87.50;

$9.00 (Canadian prices do not include applicable taxes)

Occasionally, Canadian Biomass magazine will mail information on behalf of industryrelated groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.. No part of the editorial content of this publication may be reprinted without the publisher’s written permission ©2012 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

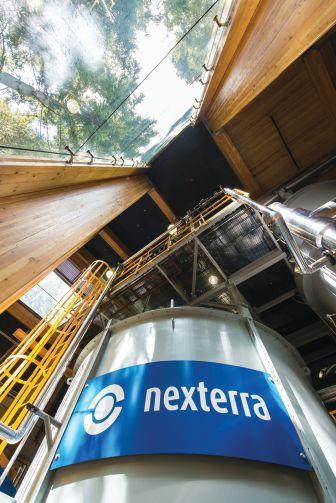

Nexterra Systems Corp., the University of British Columbia and GE celebrated the successful completion of an energy-fromrenewable-waste combined heat and power (CHP) system located at UBC’s Vancouver campus.

The system that combines Nexterra’s gasification and syngas conditioning technologies with one of GE’s high-efficient Jenbacher internal combustion engines.

GE’s Jenbacher gas engine will produce 2 MW (megawatts) of clean, renewable electricity that will offset UBC’s existing power consumption, enough to power approximately 1,500 homes. The Nexterra system will also generate 3 MW of thermal energy, enough steam to displace up to 12 percent of UBC’s natural gas consumption. This will reduce UBC’s greenhouse gas emissions by up to 5,000 tonnes per year, which is the equivalent of taking more than 1,000 cars off the road.

Using Nexterra’s gasification technology platform and gas clean-up and thermal cracking solution, the system converts locally-sourced waste wood into a clean, reliable gas that is suitable for use in a highefficiency, industrial-scale gas engine to produce heat and power.

“This project represents a significant milestone for Nexterra and we are thankful to our partners for helping to make this a tremendous success,” said Mike Scott, President and CEO of Nexterra. “We are seeing significant interest in this next-generation solution from around the globe. We look forward to further proving the system out at UBC and then replicating this system worldwide.”

The Wood Pellet Association of Canada (WPAC) has released a report that outlines steps that pellet mills can take to assess and minimize the risk of dust explosions in their facility.

Penned by research director Staffan Melin, Determination of Explosibility of Dust Layers in Pellet Manufacturing Plants, looks at dust explosions in the pellet industry and outlines a dust management scheme that would eliminate much of the risk at a minimal cost. The report also discusses risk assessment, dust sampling and categorization methods.

Part of the problem, says the report, is the limited understanding of the complex behaviour of dust explosions among plant operating personnel as well as corporate management. The report concludes that

a successful dust management scheme is built upon a sharing of responsibility among management, operations and maintenance personnel and a robust safety record as the basis for safety inspections and audits.

The allowable dust level is determined by a model and inexpensive instrumentation, which can be used by plant operating personnel and is based on characterization of the dust by scientific means.

As a guideline, the report states that, “without knowing the Minimum Explosible Concentration (MEC) and dust bulk density the safety rules for a production plant and safety management becomes a guessing game. A safety margin policy of 50% or better should be established for any pellet manufacturing plant.”

The Prince Rupert Port Authority announced it has approved Pinnacle Renewable Energy’s Westview Terminal Redevelopment Project, which will ship up to two million tonnes of wood pellets a year. According to PRPA, the Pinnacle terminal project represents an estimated capital investment of $42 million in Prince Rupert, 90,000 hours of construction work, up to 24 direct jobs in terminal operations, and a significant increase in the municipal tax base.

Millar Western has announced it will spend $42 million to build a biogas power generation facility onto the effluent processing stream of its pulp mill in Whitecourt. With with the one-year provincial permitting process completed, construction of the anaerobic effluent processing plant at Millar Western’s pulp mill will begin in September. When it finishes in late 2013, it will provide 5.2 MW of power to the combined pulp and saw mill, reducing the compound’s power consumption by almost seven per cent.

The Centre for Research and Innovation in the Bio-Economy (CRIBE) announced it is providing $467,212 to a partnership with Confederation College to develop the Bio-Energy Learning and Research Centre (BLRC) that will contain a fuel testing lab, demonstration space, and a separate 150 kW boiler dedicated to research and learning with associated emissions monitoring equipment. CRIBE is also providing $70,839 in funding to Atikokan Renewable Fuels (ARF) to begin testing various natural additives to wood pellets (to be used for biomass) to improve their performance in co-operation with Lakehead University. It is an important first step in helping ARF produce highquality pellets that will feed biomass energy facilities, said CRIBE.

Biofuel from biomass one step closer to reality thanks to discovery by University of Georgia researchers to manipulate ‘hot’ microbes.

The single most important barrier to the use of lignocellulosic biomass such as switchgrass, populous, sorghum and miscanthus for production of biofuels is the resistant nature of the biomass itself. The problem lies in the conversion or degradation of complex biomass to make products of interest.

New research from scientists at the University of Georgia who are members of Department of Energy’s BioEnergy Science Center (BESC) provides a genetic method for manipulating a group of organisms, called Caldicellulosiruptor, that have the ability to use biomass directly at temperatures over 160 Fahrenheit. The ability to modify the microbes to make the needed fuel products is a required first step for modern industrial fermentations. This allows researchers to combine the natural ability to consume renewable plant materials with an altered, improved ability to make what is needed.

“The most formidable barrier to the use of biomass, such as switchgrass, to biofuels is the ability to break down the biomass,” said Janet Westpheling, a microbial geneticist in the department

of genetics in the UGA Franklin College of Arts and Sciences and a scientist of BESC. “Plants have evolved over millions of years to resist degradation by microbes, and that is exactly what we want to do. The ability to manipulate the genetics of organisms that can use biomass directly is essential to making them useful. We began with a group of bacteria that can use biomass for growth and will use genetics to teach them to make ethanol.”

Abellon Energy Inc. Canada has announced the acquisition of Canadian bio-pellet manufacturer Trebio Inc. Abellon, the wholly-owned subsidiary of India-based Abellon CleanEnergy, said Trebio has one of the largest pellet plants in Canada with a capacity of 130,000 MT/year, with the potential to increase capacity to 250,000-300,000 MT/year.

Commissioned in August of 2011, it is the only plant in North America that is ENPlusA1 certified.

The company has good access to fibre from nearby sawmills and dedicated, assured access to forest fibre through a timber licence from the Quebec Ministry of Forestry for at least the next 25 years that is managed in compliance with sustainable forestry practices and norms.

Other advantages, according to a press release from Abellon, include a strategic location with good rail and port access, highly experienced and professional management operations teams and a strong and credible stakeholder base.

Abellon says the acquisition is a significant step for both companies, and will harness its unique strategic advantages and complementing strengths to help expand collective reach, and enabling the collaborative entity to take up a global position in the pellet industry.

“In Abellon, Trebio gains an experienced partner with proven selling, operational and project related capabilities,” stated the release.

“Which can help the company quickly scale up to its full potential. The current team at Trebio will continue to manage the company, with strategic inputs from the global team.”

According to Abellon, it has been strongly committed to establishing a base in Canada, and this partnership is one more step towards enhancing its presence in the country, as well as contributing to bilateral trade and investment between Canada and India.

Canada’s forest biomass sector changes daily. Keep up at www.canadianbiomassmagazine.ca, through our weekly Bio-Blast enews, and on Twitter @canadianbiomass.

By Gordon Murray

anada’s new regulations for reducing greenhouse gas (GHG) emissions from coal-fired electricity were released by Environment Minister Peter Kent on September 5, 2012. As a result of a year of the electrical industry and the provinces lobbying both Environment Canada and the Prime Minister’s Office, the new regulations are weaker than those initially proposed in 2011. Despite this, Canada’s wood pellet producers have an opportunity to grow the domestic pellet market by supplying coal power plants and by helping them to meet their emissions requirements.

The final regulations for coal-powered plants stipulate they can emit no more than 420 tonnes of greenhouse gases per gigawatt hour of electricity generated, which, according to Environment Canada, is the emissions intensity level of Natural Gas Combined Cycle technology. This number is significantly higher than the 375 tonnes per gigawatt hour originally proposed.

The new regulations also stipulate that coal-powered plants must be shut down after 50 years of operation. It was 45 years

1

2

5

8

9

in previous draft regulations. Power stations commissioned before 1975 will have to shut down after 50 years or at the end of 2019, whichever comes first.

The provinces have the opportunity to opt out of the federal regulations if they adopt provincial regulations that deliver an equivalent environmental outcome. Alberta, Saskatchewan, and Nova Scotia – the three largest coal-consuming provinces – are all pursuing equivalency agreements with the federal government. Ontario – once Canada’s largest coal consumer – is phasing out coal completely by 2014.

Coal-powered plants have several options to reduce emissions: they can implement carbon capture and storage (CCS) technology or the plants may co-fire with natural gas, biomass, or a combination of both. Under the regulations, only emissions from fossil fuels are considered. Thus emissions from biomass do not count toward the 420 T/MWh cap. Interestingly, the coal power industry has indicated interest in combined co-firing of coal, natural gas and biomass.

So there is now an opportunity for

Canada’s pellet producers to convince the coal-power industry of the benefits of wood pellets. To that end, the Wood Pellet Association of Canada is working on two projects: (1) a $200,000 biomass co-firing study in co-operation with the Canadian Clean Power Coalition (funded in part by B.C.’s Forestry Innovation Investment) to help the power industry understand in detail, the economics of biomass co-firing; and (2) an $800,000 wood pellet emissions study in co-operation with Environment Canada (funded by the Government of Canada) to gain actual emissions data for wood pellet co-firing on an industrial scale to be used in support of government policy.

So how big is this opportunity? By 2015, when the regulations come into effect, it is expected that there will be 34 operational coal-power units in Canada with 9,200 MW of capacity, consuming some 44 million tonnes of coal annually. Of these, nine units will be affected by the new regulations within the first five years the regulations are in force. (Table 1)

Coal power units in Table 1 will use some 5.6 million tonnes of coal annually. Assuming an average coal emissions factor of 1,050 tonnes of CO2 per MWh must be reduced to 420 T/MWh, this means that coal consumption must be reduced by 3.3 million tonnes annually (assuming 25 GJ/T), and if replaced entirely by wood pellets (assuming 19 GJ/T) would require 4.4 million tonnes annually. To put this into perspective, current annual Canadian wood pellet produc-

Gordon Murray is executive director of the Wood Pellet Association of Canada. He encourages all those who want

wood pellet industry to join. Gordon welcomes all comments and can be contacted by telephone at 250-8378821 or by e-mail at gord@pellet.org.

CBy Isabelle des Chenes, Vice-President Market Relations, FPAC

arbon dioxide, that simple chemical compound of two oxygen and one carbon atom, has been rebranded as the greenhouse gas believed to be a major culprit in causing global warming and climate change. The forest products industry has a complex relationship with carbon – on the one hand storing it in the forest ecosystem and on the other spewing it out when burning fossil fuels at its mills. Now, as part of its environmental leadership, the industry is working hard to rebalance that equation to limit its carbon footprint and help mitigate climate change.

The Canadian forest products sector is globally recognized for its accomplishments on the environmental front: having the most third-party certified forests in the world by far; regenerating forests; attempting to maximize the value of every tree harvested; reducing greenhouse gas emissions and using cleaner energy. The forest products industry is

a leader in co-generation, also known as combined heat and power, which is far more efficient than conventional electricity generation because smaller amounts of fuel are required and fewer greenhouse gases are emitted.

To top it off, the industry has set a new bar for environmental responsibility and action on climate change by pledging to be carbon neutral through the life cycle of its products by 2015, without the purchase of offset credits. Achieving carbon neutrality generally involves three steps: measure the existing carbon footprint; develop targeted goals to reduce emissions; and buy offsets to achieve zero net emissions. Canada’s forest products sector has completed the first step, is working on the second step – and aims to avoid the third.

In 2007, FPAC commissioned the National Council for Air and Stream Improvement to produce a groundbreaking research report, The Greenhouse Gas and Carbon

Profile of the Canadian Forest Products Industry. Canada’s forest industry became the first in the world to assess its total carbon profile throughout the entire value chain.

Investigators analyzed direct emissions from mills, most resulting from the combustion of fossil fuels. They also explored indirect emissions associated with the purchase of electricity, as well those related to harvesting and transporting raw materials and products. They looked at carbon sequestration, both in the forest products industry value chain and in carbon stored in forest products.

The carbon profile has provided FPAC, its members and its partners with a roadmap on how to reduce emissions and store more carbon through the entire carbon cycle – from the forest to product manufacturing to end use through to disposal. This includes reducing greenhouse gas emissions by switching to renewable energy sources in mills or by improving transportation networks. In the forest, carbon storage may be increased by planting faster growing trees, or through alternative harvesting and planning techniques that consider carbon along with other values such as biodiversity.

As emerging economies improve the standard of living and quality of life for their citizens, demand will increase for many wood-based products. This will exert even greater pressure on global ecosystems.

However, markets can be comforted by the fact that forest products from Canada come from an environmentally responsible industry striving to be carbon neutral. And Canadians walking in the woods can feel proud that Canada’s forest products industry is a world

Clean Alternative to Incineration

Feedstock Flexible without Equipment Changes

Commercially Vetted with Over 40,000 Operating Hours

Scalable for Small and Large Projects

Industrial Grade Downdraft Gasification

Eliminate Landfill Costs And Transportation Expense

Find out more... and contact us for an initial benefit analysis and to discuss feedstock options.

community in downtown Quebec City is setting the standard for energy efficiency, including a four-boiler biomass combustion system to heat the dwelling and domestic hot water.

There are very few properties in the Quebec City core large enough to accommodate the construction of new housing, especially since preserving green spaces has become a top priority. The obvious solution is to combine living space with green spaces, which is precisely what SSQ Financial Group has done with La Cité Verte (The Green City).

The project site, a 93,000 m2 parcel of land in the Saint-Sacrement district (near the intersection of Chemin Sainte-Foy and Avenue Saint-Sacrement), has a rich history; it has been home to the Saint-Vincent-dePaul crèche, Hôpital de la Miséricorde (mercy hospital) and the École de puériculture (childcare nursing school). SSQ Financial Group (a Quebec-based insurance, investment/retirement and real estate services institution) acquired the property from the Congrégation des Soeurs du Bon-Pasteur de Québec in 2005.

One of only a handful of such projects in Canada, La Cité Verte takes the concept of sustainable development a step further – to minimize the environmental impacts of a major real estate development project and demonstrate that state-of-the-art technologies and environmental protection can go hand in hand for the well-being of our society and future generations.

La Cité Verte, the first large-scale, multi-residential project in Quebec, comprises green, intelligent buildings. There are more than 800 housing units – including condos, townhouses, apartments and affordable housing – intermingled with community features such as green spaces, stores and services to encourage pedestrian movement and social interaction. The result is a welcoming urban environment that exists in harmony with its natural surroundings.

La Cité Verte currently employs the most advanced biomass district heating system in North America for its space heating and domestic hot water (DHW) needs. It offers proof that biomass heating is not only a feasible solution for rural areas, but it can also be implemented effectively within an urban setting.

The heating network uses wood pellets, a byproduct from Quebec’s forest industry, as fuel. Wood is a local staple and independent of wide price fluctuations; it is harvested with minimal energy input and contributes to the regional economy. The combustion of premium wood pellets is a clean and environmentally friendly process and, as a carbon-neutral source of energy, it does not contribute to the greenhouse effect.

At the heart of the system is a boiler plant housing four Viessmann Pyrotec KPT-1250 wood-fired boilers (each rated at 1,250 KW) in a 5 MW cascade system. The cascade arrangement provides maximum boiler plant efficiency with

LEFT MAIN: La Cité Verte employs a biomass district heating system for its space heating and domestic hot water (DHW) needs.

FROM LEFT TO RIGHT: The heating system uses local wood pellets and also has an integrated system that monitors the energy consumption data collected from individual units and district substations; At the

a high turndown ratio (1:16) that precisely matches load. The Pyrotec hot water boilers have met their published performance ratings for combustion efficiency (up to 85%) since the biomass heating system went online in October 2011. A 5.2 MW natural gas boiler provides emergency backup for the biomass boilers, and a 650 KW diesel generator will ensure continuous operation of the entire district heating system in the event of an electric power failure.

The boilers heat two 22,000 L buffer water tanks before heated water (90°C supply/50°C return) is distributed through a highly efficient, low-temperature hydronic heating network for district DHW and space heating. Pre-insulated underground piping in the 2.2 km system ranges from 8 in. in diameter exiting the boiler plant to smaller pipes feeding row houses (1 in. diameter) and other buildings throughout the site.

Substations in each Cité Verte building distribute the appropriate amount of heat and calculate fuel bills for the individual units. Water flow throughout the network is driven by a 25 HP pump in the winter and a 5 HP pump during the summer, when space heating requirements are significantly reduced.

A Viessmann boiler control system integrates seamlessly with Smart Heat Network controls developed by Regulvar and project engineers Génécor and Poly-Énergie. The integrated system monitors the energy consumption data collected from individual units and district substations along with boiler data to optimize efficiency throughout the district.

Each dwelling is equipped with a monitoring unit that provides information on daily energy consumption to raise residents’ awareness of their energy usage and encourage energy conservation in the neighbourhood.

Residential units in three renovated buildings and one new structure constructed during the first phase were completed in late autumn 2011. The first residents moved into the renovated buildings at the beginning of December. The construction of new buildings in Phase 2 will begin in 2013.

Representing over $300 million in investments, La Cité Verte has demonstrated the feasibility of taking an environmentally responsible approach to urban development by addressing urban densification,

rainwater management, energy efficiency of buildings, waste sorting, transportation management and the preservation of green spaces. When completed, the project will use 30% less energy than conventional developments, and the consumption of potable water will be cut in half – representing a reduction of 131,000,000 litres of water per year, or the equivalent of 52 Olympicsized pools.

A $22.7-million investment by the Quebec government, a $4.7-million grant from Natural Resources Canada’s Clean Energy Fund and financial assistance from Hydro-Québec affirm the vision and forward thinking of the Quebec community regarding sustainable development. By integrating aspects of sustainability and green technologies in the initial planning stages, La Cité Verte has become a model for future developments in the province and the first green technology showcase in Eastern Canada. The site is also expected to inspire new planning strategies and play a leading role in the adoption of sustainable development

This article was submitted by Viessmann Manufacturing Co. Inc.

A unique district heating project is serving residents of a small B.C. community.

By John Tenpenny

WHENimplementing a district energy system, speed is not always the first thing you think of. Add in biomass and some people become even more skeptical about undertaking such a project. But in the case of Fink District Energy in the Okanagan in British Columbia, the reality was quite different.

After Burkhard Fink, founder and owner of Fink Machine Inc. in Enderby, B.C., got the go ahead in 2011 from the city to implement the first privately-funded biomass district energy system in western Canada, only eight months passed between groundbreaking and the system becoming operational.

Stephen Bearss, a renewable energy representative with Fink Machine, calls it a “benchmarking system. “Some people, especially when they hear biomass and district energy, think it can be a long and drawn out process because of the technology, but the reality is when everyone is on board, the systems themselves can actually go together

relatively quickly,” he says. “It’s a cost incentive from a construction standpoint that it doesn’t take two years to build.”

Fink Enderby District Energy is the first privately-funded biomass district energy system operating as a Private Utility under 1 MW in western Canada (it is registered with the British Columbia Utilities Commission). The district system currently serves eight commercial, institutional and residential customers, including the local Lions Pool, which was the first building connected to the system and Fink Machine building. Three more customers will be online by the spring of 2013, while there remains capacity for future growth. (The hotel is currently only using domestic hot water, but they intend to add space heating in the near future.)

A KOB Viessmann Pyrot 540 wood-fired boiler (rated at 540 kW) is the primary source of space heating, domestic hot

water and pool heating for district customers. The fully-automatic Pyrot utilizes the an advanced combustion technology, triple-pass heat exchanger and modulating output control to achieve an efficiency of 85 percent while keeping emissions to a minimum. Continuous gasification is carried out on the moving grate with minimal primary air. The combustible gases rise into the rotary combustion chamber and are mixed with secondary air that had been diffused by the rotation blower and given spin impulse. This guarantees a perfect mixture of secondary air with the combustible gases.

A monitoring system and safety equipment ensure safe and reliable operation, while a 300 kW gas-fired boiler provides backup and additional capacity during peak loads, which Bearss says hasn’t

happened yet. The district lines are made by Urecon and installed by Fink Machine Inc., while Ocana Construction of Armstrong, B.C., poured the concrete foundations.

A timberframe energy centre, constructed by Fink Machine Inc., includes a district fuel bunker with a capacity of 50 tonnes, which allows two 53-foot trailers to unload and depart. (The building’s laminate beams were supplied by Structurlam Products of Penticton, B.C.) An automated walking floor delivers fuel from the storage bunker to the Pyrot’s feed auger. When fuel gasification and combustion are complete, an automated deashing system extracts ashes from the combustion chamber and transfers them to an ash bin.

An ash removal auger extracts the ashes into a large external container once they have cooled.

The Pyrot boiler feeds an 8,400 L water buffer tank before distributing heated water to transfer stations and customers through a 640-metre main line consisting of three-inch insulated Urecon PEX pipe.

Fink Enderby District Energy’s carbon neutral wood biomass fuel is supplied by local sawmills and wood product manufacturers, including a window shim plant. It also receives pulp chip screenings from a mill in Revelstoke. Bearss says their fuel costs average $25-50 per tonne. Wood

waste is also being diverted from landfills and businesses within a two-hour transportation radius.

According to Bearss, area landfills are now having to seriously look at modifying their material recycling facilities to create wood biomass fuel or run out of landfill.

“We’re working with the City of Vernon’s landfill trying to get them to streamline their wood waste stream by clean wood, like pallets and construction demolition debris, and sorting and separating the nails and anything that’s not wood biomass out of that steam so we can use it in our boiler.”

He says that Fink is hoping the city will move ahead and order the proper material recycling equipment to sort and separate out the waste that isn’t wood. It would be a prime use of wood biomass in the local area and it may be something that [the City of Vernon] will actually pay Fink Enderby District Energy to take potentially, because “for them it’s a necessity to make space.”

The system is expected to consume 800 tonnes of renewable wood fuel annually while helping to mitigate approximately 425 tonnes of greenhouse gases.

Users are reporting savings of 10 to 18 percent just on efficiency improvements over their old systems compared to the energy transfers they’re getting from the district energy line now, says Bearss.

This has created some interest both from local business joining the system and other communities looking at implementing their own district energy system.

“What we’re finding is that people before that weren’t interested for whatever reason, now realize from talking to their neighbours that are on the district energy grid and learning about its advantages and are wanting to learn more about getting on board themselves,” says Bearss.

“We have some potential clients that have talked to us about tying into the district energy grid. Hopefully people in the community will become involved and tie into the grid because they find it an advantage to them in many different ways.”

One advantage, Bearss points out, is operational maintenance because continual maintenance is no longer required on previously installed boiler or heating systems and they can then

For the separation of particulate matter, centrifugal separators for pre-separation and dry electrostatic precipitators for final cleaning represent the best available technology. Take advantage of our single source system solutions.

Single and multi-field ESPs

Fabric Filters in combination with Dry Sorption Processes

Our extensive industry experience ensures the most reliable design and economical operation.

Scheuch Inc. 2351 Huron Street, Unit 1 London, Ontario, N5V 0A8, Canada Phone: +1 (519) 951-7700 I Fax: -7711 office@scheuch.ca

become a back-up or stand-by.

“[The energy district system] is set it up so that it’s a cost-savings advantage for people to do business with us,” adds Bearss. “Even though it’s small, rural system, it does have the three fundamentals of district energy – space heating, domestic hot water and process heat.”

According to Bearss, the cost to “cookie cutter” this system in a similar install setting is approximately $1.2 million, which he says has caused many in the public sector to rethink their approach because until “our system came online consulting firms were estimating systems similar to ours for communities at nearly seven times the price. Since the beginning of the year this installation has resulted in two communities who have selected Fink Machine to install a similar system in their communities.”

By utilizing biomass fuel, an energy source largely independent of today’s wide energy price fluctuations, says Bearss, Fink Enderby District Energy can provide customers with economical, safe and environmentally responsible heating

Three years down the road, the Vitrine biomasse (Biomass Showcase) project is revealing the true nature of an industry that has barely started to tap into Quebec’s endless supply of wood biomass.

By André Dumont

both wood and greenhouse vegetables is what Luc Verrier has been doing for most of his career. At Les Serres Verrier, in Saint-Joachim-deCourval, forestry and agriculture go hand in hand. And now that biomass is the new buzzword in the greenhouse industry, Verrier may be the company others look to for an inspiring business model.

Three years ago, the Syndicat des producteurs en serre du Quebec (provincial greenhouse growers’ union) chose Verrier to install a new biomass heating system on his farm, as part of the Vitrine biomasse project (Biomass Showcase). The goal was to document and evaluate the implementation of a wood biomass heating system on a small to medium-sized farm, where other producers could go to obtain hands-on information.

A final report was filed to the Bureau de l’efficacité et de l’innovation énergétiques (BEIÉ – provincial energy efficiency

agency) last March. Canadian Biomass magazine met with Verrier and forestry engineer Jean Gobeil, who managed the project, to find out about the lessons learned and to reflect on the current state of biomass use in Quebec’s greenhouse industry. The monitoring and tweaking of the boiler is still ongoing and the first harvest of fast-growing willows will only occur this coming fall, but the project is already providing useful insight for other growers.

Verrier operates 12 greenhouses totalling 2,500 m2 north of Drummondville. He grows tomatoes, cucumbers and lettuce year-round. The produce is sold in supermarkets within a 40-kilometre radius.

There are countless acres of forest across the province that need to be cleaned if they are to yield quality lumber, says Jean Gobeil.

The Vitrine biomasse project was done in partnership with the Syndicat des producteurs en serre (Quebec Greenhouse Growers), the Quebec ministry of Agriculture (MAPAQ), the Bureau de l’efficacité et de l’innovation énergétiques (provincial energy efficiency agency), the Centre d’information et de développement expérimental en serriculture (greenhouse research centre), grower Luc Verrier and forestry engineering firm Jean Gobeil & Associés Inc.

“I have always heated with wood (logs), but I could never measure anything,” Verrier says. Now, everything about his heating system is being measured: the quantity of wood chips, their humidity level, as well as the efficiency of the boiler, hot water storage tank and hot water distribution network. His

550-kilowatt boiler is from Quebec manufacturer Transfab Énergie. It can burn chips with up to 35% humidity.

Being able to use wet biomass in such a small system is one of the two innovative features of this project. The other is the planting of 20 hectares of fast-growing willows, in order

to secure biomass self-sufficiency. With the first harvest yet to come, only a few tests with purchased willow chips we have conducted.

Harvesting 10 hectares per year could provide Verrier with 50% of his energy needs. “We still need to measure the plantation’s yield, its heating power and to what extent the chips need to be dried,” Gobeil says.

Planting willows for biomass would make more business sense in areas where corn and soybean can’t be grown, Verrier reckons. Willows could also be planted and harvested on buffer strips along streams and rivers or in areas where the soil needs to be decontaminated, he suggests.

The greatest advantage of growing part of your boiler’s feedstock is not having to depend on only one source of biomass, Verrier says. The prices of all types of fuel tend to vary over time and the same could happen with wood chips. Verrier currently harvests his own wood by thinning the Forêt Drummond, a public plantation only kilometres away from the farm.

Wood biomass may be one of Quebec’s most important untapped sources of energy. The Ministry of Natural Resources (MNRF) has estimated that 8 million m 2 of residual wood biomass could be collected annually from the province’s forests. Currently, less than 10% of trees or parts of trees with no commercial value are used as fuel.

According to Gobeil, there are countless acres of forest across the province that need to be cleaned if they are to yield quality lumber. A lot of abandoned farmland that was reforested in the 1970s is ripe for thinning. “The only use for that type of wood is biomass for energy production,” Gobeil says. “Just by taking care of these forests, we have years and years of supply.”

New business models will need to be invented if we are to collect this biomass, he adds. Things will need to be done on a smaller scale, with a lot less long-distance hauling than what we currently see in the lumber industry. “If in Europe, they are able to do it and to make money, we should also be able here.”

Perhaps biomass users will be the ones taking charge of biomass harvesting. This has been Verrier’s way of life for years.

His greenhouse complex sits next to what looks like a lumber operation. The piles of round lumber come in part from trees he cuts on private lots, leaving them clean for replanting, or in better condition for the best trees to grow better. Harvesting biomass like this becomes a service to landowners.

The wood biomass sector in Quebec is still in its infancy and this was reflected in the Vitrine biomasse project. While there is an ample supply of biomass, there remains a great lack of expertise among boiler manufacturers and equipment suppliers.

Boiler manufacturers can only provide clients with an approximation of their products’ performance and efficiency, Gobeil notes. In the case of Verrier’s boiler, it appears to be more

powerful than the 550 kilowatts it was expected to deliver. Considering that a boiler’s efficiency is at its best when heating at its highest capacity, Verrier’s boiler may actually be too big for his 2,500 m 2 of greenhouse. “It is essential that boiler manufacturers be able to certify their products properly regarding energy output and environmental regulations,” Gobeil says.

There also seems to be an absence of expertise in Quebec about hot water distribution networks and hot water storage. To this day, Verrier’s tank does not work properly. “Storing hot water is meant as a buffer that allows you to have a much smaller boiler,” Gobeil says. “The system has to be well configured. It’s not as simple as one could think.”

In other words: unless they purchase technology from far away, Quebec growers are not able to get precise and proven information about the performance and optimal configuration of a biomass heating system. In Europe, manufacturers provide extensive data about their boilers and also offer quality followup service once installed, adds Gobeil.

Despite his system still needing significant adjustments, Verrier is a happy farmer. “Heating with wood biomass requires a lot more involvement than heating with natural gas,” he says. But for him, handling wood with his farm machinery and feeding it into his chipper is the fun part of the day.

As part of the Vitrine biomasse project, Les Serres Verrier remains open to visitors, from both forestry and greenhouse sectors. Two fact sheets have been printed on implementing a biomass heating system for a greenhouse farm and on the types of wood biomass and their advantages. Two more fact sheets

are in the works: one on technical aspects of biomass heating and the other on financial considerations.

So far, the Vitrine biomasse has inspired five new projects, four of which are waiting for public funding from the BEIÉ. The agency’s budget has run out and the next available funds will come in 2013.

For greenhouse growers, a biomass heating system must pay for itself within three years, Gobeil says. Without subsidies, this cannot be achieved. “There is plenty of interest from grow-

Last February, Quebec greenhouse farmers awarded forestry engineer Jean Gobeil with the Méritas RollandHarnois for “showing faith in the development of (local) greenhouse production and believing in the potential of our businesses and their work force.”

Jean Gobeil has been involved in several greenhouse biomass conversions. Last year, he advised Quebec’s most important propagator, Sylvain Lefort, in an $8-million project to heat 6.5 hectares of greenhouses using two sixmegawatt boilers.

Consensus at the annual PFI conference was that the European market will provide the next growth phase for pellet producers.

By John Tenpenny

MOREthan 200 delegates attended the Pellet Fuels Institute (PFI) annual conference and expo held at the MGM Grand at Foxwoods over two days in Connecticut to take in a variety of presentations on the pellet industry.

Day one was highlighted by a presentation by Seth Walker of RISI, who provided an outlook for the pellet fuels industry and told the audience that most of this growth will come from the growth of the industrial export market.

He predicted that by 2017 the North American wood pellet industry will be exporting more than 10 million tonnes, with nearly half of that coming from Canada.

Walker said that 1.2 million tonnes were exported from B.C. in 2011 and noted the industry is trying to figure out if it can utilize the beetle kill stands for production. Walker said many believe that it’s not cost-effective or sustainable in the long term and a lot will depend on demand from the Asian market.

Wood pellet exports from eastern Canada were 100,000 tonnes, according to WPAC, said Walker and they are expected to increase, especially to the European Union. Walker noted that the region has a fibre availability advantage, but not a price advantage.

When is comes to export costs, Walker said that B.C. has the advantage in terms of wood cost, but when is comes to ocean freight costs, the U.S. south pays significantly less.

He also noted that there is potential growth in the export market to Asia, specifically Japan and South Korea. The Japanese government is mandating an increase in the use of renewable energy and this could help increase the market for B.C. wood pellets. According to Walker, 5% of Japan’s coal capacity equals 6.5 million tonnes of wood pellets.

His predictions for the European export market were not so rosy and he said the continued weakening of the euro will further tighten margins for the pellet trade.

Speaking about inventories, Walker noted the fact that, according to their latest survey, inventory levels were 50% higher in June 2012 compared to June 2011. This was mostly due to a warm winter, but it is something to monitor down the line if it persists.

Promoting the wood pellet industry and reaching customers is about increasing value and letting people know about it, a group of experts told the audience in another highlight of the program.

In a session titled “Marketing Strategies for the promotion of the industry: determining and reaching target audiences” several speakers discussed how to use social media as well as getting value from the wood pellet product by increasing product performance during production, while at the same time decreasing production costs.

John Nelson, of BBI International, told the audience that social media is something “you need to be doing,” but added, “remember, it’s just one tool in your tool belt.”

However, according to an informal survey he conducted prior to the event, not everyone is there yet. A check of conference attendees by Nelson revealed that only 47% have a LinkedIn account.

That’s something that has to change, he said, as social media is trending up, while other means of marketing communication, such as e-mail, are headed in the other direction.

“Where are people online? I need to be there,” Nelson said.

He shared five social media tactics with conference attendees, including the need to combine content marketing with a social media strategy, using Q&A forums to get known as an expert in your field and leveraging your customers’ connections on LinkedIn by joining groups.

The use of video was also touched upon by Nelson, who emphasized its importance

by noting that a video is 50 times more likely than a text page on the same topic to appear on Google’s first page of search results. Michael Holloway of Certified Labs told the conference that value comes from production and product – “they’re one and the same.”

He said high performance and low cost equals value. And for wood pellet producers that means they must remain consistent in performance or quality of their product, with things such as density, size and percentage of water content. Producers must also have “recognized value” in customers’ eyes, for such things as lower emissions.

Holloway also touted social media, telling attendees to “promote your value.”

“If you change your company, you can change your industry.”

In his presentation on day two as part of a series on developments in international wood pellet markets, Gordon Murray, executive director of the Wood Pellet Association of Canada, said there is the potential for the wood pellet export market to the European Union to grow by 300% by 2020.

Murray noted that if just 15% of the coal currently used was replaced, it would mean

a market of 200 million tonnes of wood pellets annually. This growth could come, he said, from the fact that only five of 27 member states are currently co-firing.

The main markets in Europe for North American pellets remain the U.K., along with Belgium and the Netherlands. Future growth outside of Europe will come from Asia, particularly Japan, which has recently introduced a generous feed-in tariff for renewable electricity generation.

Despite recent hype about the South Korean market, Murray told the audience that he’s not sure when it will open up, although he was optimistic that four million tonnes of wood pellets could be exported by 2020.

Interestingly, Murray noted that for the first time the U.S. has surpassed Canada in the export of pellets to Europe, according to data from the first six months of 2012.

Prices for wood pellets are currently higher in the U.S. than in Canada, said Murray, most likely due to higher shipping costs in this country.

Murray also updated attendees on the status of the Tilbury plant in the U.K., which suffered a devastating fire earlier this year, affecting the export market, since it was expected to have used 2.5 million tonnes over the last 18 months. Murray said it was hoped the plant would be back on line in August.

There are challenges ahead, particularly

recent efforts to discredit biomass as being dirtier than coal.

“The wood pellet industry exists because bioenergy is carbon neutral,” said Murray, and “regardless of facts, if society comes to disbelieve that, then our industry will be in grave jeopardy.

“We need to counter misinformation and support positive information campaigns.”

Murray said WPAC is working on a project to research biomass emissions that will be scientifically peer reviewed and should be released later this year. Carbon Debt Project participants include: WPAC, USIPA, European Pellet Association, the Danish Energy Association, along with Drax, Elec-

By Rob Cruickshank

is no doubt that pellets provide huge opportunities to reduce our reliance on traditional fossil fuels, such as oil. Biomass pellets deliver a unique opportunity to increase the use of renewable energy, and cost about 60% less than heating oil, according to the AEBIOM (European Biomass Association). In Canada, this industry continues to grow but there are a number of safety hazards associated with it, including the risk of fire and explosion. Fires in biomass pellet plants are increasingly common. However, the appropriate fire protection system can have a significant impact on mitigating risks.

Here is a sampling of the most common fire risks and tips to reduce your exposure:

Large quantities of solid or liquid fuel are often stored close to the incineration plant, and the heat generated by microbial activity builds up and can cause the fuel to ignite. The simplest way to avoid this is to ensure that the fuel bunker is constructed in fire-resistant, steel-reinforced concrete and is more than 15 m away from the main process building. This ensures that a fire in the fuel bunker will cause minimal local damage and not spread to the main processing plant. Operating procedures and stock control measures should include turning the biomass fuel over at least once a week to keep the fuel aerated and cooled, which minimizes the chance of self ignition.

Shredders run the risk of a dust explosion; thus, shredders and the enclosures should be designed to resist blockages in the chutes where the waste can absorb water and expand.

The furnace unit may include a fossil fuel burner head – if it does, it must include adequate combustion controls such as flame failure detection, air purge controls and fuel double valve isolations. There should be sprinkler heads over the furnace burner heads to protect against fuel spills that could ignite.

The lube oil used to maintain the temperature and conditions of the bearings can spray over the hot steam turbine casing and cause a fire. It’s often not the fire itself that causes the most damage, but isolating the lube oil in the turbine. Installing fireresistive cables for the electrical lube oil supply pumps is one way to minimize risks. Lube oil sprays can be minimized by using pipe standards that include minimum flanged pipelines, positioning spray guards over flanges to control any lube oil spray,

Shredders run the risk of a dust explosion and should be designed to resist blockages in the chutes where the waste can absorb water and expand.

and installing high-pressure (supply) lube oil pipelines within low-pressure (return) lube oil pipelines. In addition, all areas beneath the turbine generator operating floor that are subject to oil flow, oil spray or oil accumulation should be protected by an automatic sprinkler or foam-water sprinkler system.

Oil filled transformers, which are typically associated with turbine generators and old units, are riskier than dry resin units because the oil can burn or explode. It’s recommended that fire protection systems include blast walls or, in some cases, appropriate spatial separation, and complete water spray impingement on all exposed exterior surfaces, providing a water density of 10.2 mm/m2

Fires in electrical, control and cable rooms are often limited to small material losses but can mean significant interruptions to the business. Fire protection systems should include adequate compartmentalization of cables and installation of cable sealing through the walls. Cable sealing material used should be fire-resistant cement. Thermographic camera inspections should be carried out annually to identify hot spots on cables or electrical cabinets. Air-aspirated early warning smoke detection systems are an option for control and electrical rooms

– this system is very sensitive to smoke particles before the fire fully develops, giving an operator a chance to extinguish the fire before it starts. Automatic sprinkler systems designed to a density of 12.2 mm/min. are recommended.

Diesel generators have the potential for fire, mainly due to crank failure. It’s recommended that the generator be installed in a location where there is little opportunity for a fire to spread – often, the only option is a fire-resistant enclosure.

Biomass Handling Equipment

Complete Engineered Systems

Pulverized Coal Boiler Conversions

CFB Boiler Feed Systems

Cooling towers can be susceptible to fire if a wooden construction dries out during a maintenance period. The cooling tower should be made of non-combustible steel or concrete, or should be separated either by spatial separation of approximately 15 metres or by a fourhour firewall.

Fuel gas handling systems are critical to the combustion process, and combustible elements are typically minimal. If the incineration operation and the fuel

gas handling system have been properly designed, there should be no issues.

All construction materials used in pellet production plants should be non-combustible, including all composite panel insulation. Composite panels should be rated for two-hour fire resistance using mineral wool rather than fire retarding foam. The walls separating fuel storage from the rest of the plant should

The new Morbark ® Advantage 3™ high-performance chipper drum gives you improved biomass fuel chip quality, reduces your costs, and is backed by a limited three-year warranty. It comes standard on most new Morbark drum chippers and can be retrofitted to most Morbark units without modification. Either way, you get three significant advantages:

– The Advantage 3 is wider, has higher inertia, and incorporates Babbitt-style counter-knives, so it produces better, more consistent chips.

– The drum’s AR 400 heat-treated steel skin, enhanced knife design, and recessed pockets provide wear-part and maintenance cost savings of more than 70%.

– The Advantage 3 comes with a limited three-year warranty, and is supported by Morbark’s extensive dealer network for unsurpassed peace of mind.

The exceptional Morbark Advantage 3 chipper drum comes standard with most units in our full line of heavy-duty industrial drum chippers. Learn more at www.morbark.com or call 1-800-831-0042.

be concrete, providing two-hour fire separation.

All plants should include a combination of passive fire protection, which attempts to contain the fire or slow the spread, and active fire protection, which typically includes a fire detection system such as an automatic fire

The Woodsman 730 Brush Chipper is a compact, drum-style brush chipper. The 18” wide by 15” high infeed opening allows material with multiple limbs and

wide and offers two full knife pockets with two knives per pocket. This design produces a smaller, more consistent chip, which effectively helps to compact the material in your trailer. The 730 model weighs approximately 5,200 lbs, which makes it easy to tow and an excellent unit for brush crews in commercial and municipal applications. The simple design makes the machine extremely easy to operate, and combined with the advantage of being small, also makes the 730 a great unit for landscapes and rental industries. The Woodsman 750 Brush Chipper is an

and municipal agencies, which need to chip larger material. Numerous features such as a reverse auto feed, feed wheel lift cylinders, height adjustable dis-

The dual hydraulic drive motors operate the feed wheel and eliminate the need for various bearings, bushings, chains and sprockets. This is a great way to save

less maintenance, the Woodsman 750 operates simply and easily with a large chipper opening, which drastically reduces chainsaw work.

with environmental regulations and maintain good relationships with its commercial neighbours. The large-scale DustBoss DB-60 unit from Dust Control Technology replaces a smaller design from another manufacturer that proved inadequate for the size of the operation, while

than 20,000 square feet (1,858 square metres) with a dense, dust-trapping mist. Since the unit was placed in service, the facility has not received a single dust-related complaint, achieving excellent control of fugitive particles, while avoiding over-saturation of the compostable material. Designed with a series of 30 specially designed brass nozzles to atomize water into droplets 50-200 microns in size, the DB-60 uses a powerful 25 HP motor that generates 30,000 CFM minute. The atomized spray has a throw of more than 200 feet (approximately 60 metres) on a calm day, yet the standard carriage-mounted device is completely porthrow angle from 0-50-degree elevation, and when equipped with the 359-degree oscillation option, it can cover more than 125,000 square feet (over 11,600 square by a 60-kilowatt generator, with municipal water supplied by a 1.5-inch hose.

Uniconfort biomass boilers will now be available in Western Canada, thanks to an agreement between Alternative Energy Solutions and Canada Powerhouse. Alternative Energy Solutions International Inc. (AESI) and Canada Powerhouse, (the Technical Sales Division of Exclusive Boilers, Burners & Controls) (EBBC) has announced that they have established and are proceeding with an important agreement for representation throughout British Columbia, Alberta, Saskatchewan, North West Territories and the Yukon. “Uniconfort and AESI,Inc, have over 5,000 installations operating worldwide,” said David Daniels, president and CEO

direction. Together, we will create an optimal sales and service model for the very important, emerging and growing biomass industry in Canada.” According to Dale Mazur, general manager of EBBC, AESI and Uniconfort are a game changer for the 2 and NO x emissions. “Coupled or stand-alone with our co-generation -

and the environment wins. EBBC receives a considerable number of requests for district heating, cogeneration, and emission reduction requests; we looked very hard at other technologies and realized that Uniconfort and AESI had a proven track record focused on very key areas often overlooked. We further evaluated their business approach and were extremely pleased to discover that the technolo-

the customer to determine what level of involvement they prefer. No question that the company made the right decision to move forward with AESI and Uniconfort.”

company says the new look was designed to invoke the progressive history of the orga-novation is what will continue to make us successful and enable us to provide the groundbreaking products that our customers are asking for. The new website had to demonstrate that commitment, while also highlighting our past successes,” said Martin Engineering USA managing director Mark Huhn. The overhaul includes many practical elements, such as an enhanced website experience that adds a zoom function to product photos, with multiple product

redesigned web site, with other locations and languages following throughout the year.

the new site offers more robust product information, case studies and data sheets. The redesign features a visually sharper, more organized appearance that makes its features more easily accessible to prospective customers and casual browsers. Designed using Drupal, a community-supported content management system, all landing pages are extremely user-friendly for mobile devices. Drupal powers millions of websites and applications from all over the world, helping contributors publish information to their websites and assisting developers in deploying new sites and updates.

OCTOBER 14-17, 2012 • International Symposium on Biomass and Bioenergy Vancouver, British Columbia www.csche2012.ca

OCTOBER 17-19, 2012 • Timber Processing and Energy Expo Portland, Oregon www.timberprocessingandenergyexpo.com

OCTOBER 22-24, 2012 • The World Energy Forum Dubai, United Arab Emirates www.worldenergyforum2012.org/index.php

OCTOBER 23-25, 2012 • Expobioenergia Valladolid, Spain www.expobioenergia.com/en/frontpage

OCTOBER 28-30, 2012 • USIPA 2nd Annual Exporting Pellets Conference New Orleans, Louisiana www.theusipa.org/conference

OCTOBER 29-31, 2012 • Advanced Biofuels Markets 2012 San Francisco, California www.advancedbiofuelsmarkets.com

OCTOBER 29-31, 2012 • BioCycle Renewable Energy from Organics Recycling St. Louis, Missouri www.biocycleenergy.com/2012/index.html

NOVEMBER 29-DECEMBER 1, 2012 • RENEXPO Salzbury, Germany www.renexpo-austria.at/index.php?id=7&L=1

DECEMBER 3-5, 2012 • 9th Annual Canadian Renewable Fuels Summit Ottawa, Ontario www.greenfuels.org/en/industry-information/summit.aspx

DECEMBER 5-6, 2012 • Agri Innovation Forum Calgary, Alberta www.agri-innovationforum.com

FEBRUARY 13-15, 2013 • Montreal Wood Convention Montreal, Quebec www.montrealwoodconvention.com

APRIL 8-10, 2013 • International Biomass Conference and Expo Minneapolis, Minnesota www.biomassconference.com

Emerging technologies are expanding our clean burning fuel options.

By Andrea Kent

he results of agricultural innovation are everywhere – on the kitchen table, in manufacturing, in cosmetics and pharmaceuticals, and even our gas tanks. And while Canadians have become increasingly familiar with clean burning, renewable fuels like ethanol and biodiesel, new technologies are emerging that are expanding our crop options as well as our fuel choices.

In Canada, our advanced biofuels industry is developing both processes and equipment technologies that can effi-

miscanthus and switchgrass. The core of the process is GreenField’s Modified Twin-Screw Extruder technology, able to produce 20 litres more ethanol per tonne of biomass compared to other cellulosic ethanol technologies. At the core of the outcome are huge economic benefits for Ontario.

GreenField has an accelerated commercialization plan that seeks to fully validate its Modified Twin-Screw Extruder on a continuous basis by the end of this year. In 2013, pre-commercial validation and design engineering will be scaled-up so that construction of a new commercial plant can begin in 2014.

“Government initiatives that encourage private sector investment are critical to building sustainable development capability.”

ciently deliver cellulosic ethanol and other ‘green’ chemicals from a wide range of agricultural residues and energy crops –including feedstock that would otherwise be disposed of as waste materials. It’s an industry capable of growing exciting new technology, using energy crops that can be grown on marginal lands.

One such example is GreenField Ethanol’s Cellulosic Ethanol Program, which has been operating in Chatham, Ontario since 2007. GreenField is finishing work on a pre-treatment technology that recovers the highest and purest amount of the available sugars from a variety of homegrown biomass feedstocks including agricultural residues such as corncobs and corn stover as well as a variety of purpose-grown energy crops such as

However, technology is but one key to successful commercialization. Equally important is developing a sustainable biomass supply chain – the full infrastructure from farm to plant gate – to support a commercial scale operation such as this. A viable supply chain will offer a ‘win-win’ result for Ontario farmers, who will have the potential to generate additional revenues from both agricultural residues and energy crops.

To better understand the agricultural requirements and potential, GreenField and Ontario farmers are working together to develop techniques to harvest cobs and stover and to grow purpose-grown energy crops – much of which can be grown on the sandy soils of the Tobacco Lands.

In addition to offering a huge opportunity for incremental farm income, these efforts will also improve soil conservation

and regeneration and farming practices. And, in addition to these significant benefits for area farmers, it also creates new high tech jobs in the province and paves the way forward for the export of our home-based technologies around the world.

Projects such as this offer further proof that there are tremendous opportunities to capitalize on Canada’s resource development potential for renewable fuels; however we also have intense competition from other technologically advanced countries and foreign markets. This is why government mandates and initiatives that encourage private sector investment, like SDTC’s NextGen Biofuels Fund and Ontario’s Innovation Demonstration Fund, are critical to building sustainable development capability in Canada.

Governments should be encouraged to continue to take needed steps that lower the risk for capital investors and build on the past success of operating incentives to stimulate the creation of biofuels plants for next-generation ethanol producers – both of which have been proven to grow the Canadian jobs market and can return significant additional tax benefits.

We might not know yet the full scope of what “new fuel” will and could be but we do know that collaborating with government and fostering private sector investment is the best way to find it. As we have seen in Chatham, energy may very

Andrea Kent is the Director of Communications for the Renewable Fuels Association (CRFA). The CFRA is a nonof renewable fuels for transportation through consumer awareness and government liaison activities.

Call

FEATURES OF BEAST® RECYCLERS: PATENTED CUTTERMILL SYSTEM AVAILABLE AS TRACK OR TOWABLE UNIT KNIFE SET-UP FOR CHIP PRODUCTION ALSO AVAILABLE WITH ELECTRIC MOTOR THROWER ATTACHMENT FOR END-LOADING

Experience for yourself the economic benefits that the Beast® can bring. No other grinder offers the versatility and range of end products like the Beast! The uniformity of the product is a result of the Beast’s unique patented cuttermill system, which allows you to cut, split, grind or chip material in a single pass. A more uniform product means lower fuel production costs! Drive one of our track Beasts to the material, and drive down your biomass fuel costs. With four models to choose from and engine options up to 1,200-horsepower, you can’t go wrong.

When it comes to the grind, don’t get left behind. Find out why Bandit horizontal grinders outperform the competition everytime.

Quality. Reliability. Durability. Performance.

Introducing our new integrated high-capacity debarking and chipping system that takes in-the-woods pulp chip production to a whole new level!

The Magnum Force Flail 604 design that provides the highest volume debarking and production level while reconsumption. The independant Tigercat -

Our Flail is designed to work in unison with our new Magnum Force Disc Chipper 754.rator and bark discharges on the opposite side parallel to the chipper. Each unit is built to be -