ModulRAS is the most compact and cost-effective RAS concept in the market, constructed for use with both fresh water and seawater. Energy-efficient technology and advanced control systems ensure optimal operation, environmental friendliness and the best possible fish welfare.

• Standardized and modular

• High-quality components

• Polyurea coated surfaces

• Short construction time

• Thorough training of operating personnel

• Comprehensive operating manuals

• Control system with predictions

Kari Attramadal Head of R&D

Robert Hundstad CEO

10 | Power struggle

Happiness as a compensated

Monitoring fin condition for improved welfare and performance

VLADISLAV VOROTNIKOV

MAGIDA TABBARA

NESTOR ARELLANO

By Jean Ko Din

Awise person once told me that innocent optimist is beautiful, but optimism that has perservered through challenge and uncertainty is much more admirable. This is what I think of now when I read about new projects and new plans for expansion within the RAS industry.

Even within the pages of this Winter 2024 issue, we hear of the latest developments from some of the biggest ongoing projects worldwide. Stories like these can signal a new hope for the upcoming year and I think many in the industry are looking forward to more reasons to be optimistic about the future of the recirculating aquaculture industry.

Unfortunately, there is no rule book that simply outlines how to build a successful RAS business. There is no chapter that outlines who are the experts that you should hire onto your team to guarantee a profitable model. But, those experts are out there and they want to succeed just as much as anybody.

Hopefully, this publication continues to help in that exchange of knowledge by giving the right experts the platform. The RAS Summit (Oct. 9) was one of the many ways that we offer to provide accessible knowledge to the industry. This virtual event brought out thoughtful discussions that helped identify the current challenges that RAS faces.

In between the release of Spheric Research’s annual Land-based Aquaculture Report, Matt Craze gave attendees a midyear update with the latest data his team has gathered from hundreds of companies around the world. He provided an overview of the challenges that current projects face

and he analysed the different factors that led operating projects to succeed.

We also gathered an expert panel of operators that have long-running RAS operations. For much too long, discussions in the industry revolved around the permitting and construction phase but these panellists offer the knowledge they’ve earned through years of production experience.

Then, we rounded out the virtual event with an interesting panel with some of the biggest RAS and aquaculture investors to talk about their outlook on the market. Without people like our expert panelists, the capital funds the industry needs to grow would not exist. So, we look to them to educate professionals about what makes for a good partnership. They talked about the projects they’ve invested in and what criteria they require in order to place their full confidence in their partners.

As you can see, the RAS Summit was full of important discussions. Access to recordings for this event is exclusive to those who paid and registered before the broadcast.

The RAS Summit was a bit of an experiment for our team because we wanted to know if there was an appetitie for a mid-year virtual confeerence in between our annual RASTECH 2025 in-person conference. Not everyone is able to travel and therefore, not everyone has access to the amazing discussions that take place with some of the biggest minds in the indsutry. We wanted to provide a mid-level option with similar quality but accessible to more people. I hope we achieved that.

If there is interest in accessing the full recordings post-event or if you have more ideas on how we can be an information hub, send me an email and let’s brainstorm at jkodin@annexbusinessmedia.com.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Angelita Potal, Audience Development Manager Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107

jkodin@annexbusinessmedia.com

Associate Editor Seyitan Moritiwon 519-429-5204

smoritiwon@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Manager Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Account Coordinator Catherine Giles 416-510-5232 cgiles@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

Subscription Rates

Canada $37.00, United States – $48.00 CAD, Foreign - $62.00 CAD

All prices are for 1yr subscription and in Cdn funds.

ISSN 2817-7266 - Print

ISSN 2817-7274 - Online

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Pure Salmon Technology has acquired all of Billund Aquaculture Denmark’s intellectual property (IP) assets and secured the exclusive rights to purchase Billund Aquaculture Australia and Billund Aquaculture Chile.

The company expects this move to bolster its RAS technology offerings and provide new growth opportunities for the group. In a press release, Pure Salmon Technology stated that by integrating Billund Aquaculture Denmark’s IP, it will be better positioned to address the increasing demand for efficient, scalable RAS systems and meet the evolving needs of its clients worldwide.

“We are excited to welcome the assets of Billund Aquaculture Denmark to Pure Salmon Technology. The acquisition is a strategic move that enhances and strengthens our market leading technology capabilities,” said Kent Rasmussen, CEO of Pure Salmon Technology. “The exclusive rights to purchase Billund Aquaculture Australia and Billund Aquaculture Chile further strengthen our commitment to expanding our presence and impact in the global aquaculture sector.”

Pure Salmon has already hired several ex-Billund employees in the last few years and plans to hire more as part of the transition and implementation of these intellectual property assets. It has also acquired the technical documentation of the full Billund install base, making it possible for it to service all of Billund’s previous customers.

“Pure Salmon Technology is committed to driving innovation and sustainability in aquaculture, and this deal allows us to combine the strengths of both companies to deliver unparalleled value to our clients,” added Stephane Farouze, Pure Salmon chairman, and 8F chairman and founder. “We look forward to continuing to push the boundaries of what’s possible in aquaculture technology.”

Hima Seafood says it is one step closer to its goal of becoming the world’s largest land-based recycling aquaculture system (RAS) trout facility as it begins to build its planned facility producing around 8,000 tonnes per year in Rjukan, Norway.

“Ensuring a consistent and stable water temperature for our fish is key to producing a world-class product. Superior product quality and environmental sustainability are not just slogans for us, they are part of Hima’s DNA,” said Sten Falkum, CEO of Hima Seafood.

The facility will have the latest technology–designed by Eyvi and constructed by Total Betong–in which the fish will be hatched and grown out to a size of a maximum of five kilograms. It will also include water treatment equipment enabling 99.3 per cent of the effluent water to be cleaned and recycled.

With financing from the Tinn municipality, the company plans to build an 11-kilometre discharge pipe for the effluent water. The facility will be 320 metres long, with a floor area of about 27,000 square metres over two stories. Partial operations

are expected to commence in 2024, with steady-state operations to follow in 2025.

Hima Seafood secured financing from Foresight Group and P Capital Partners. In addition to external funding, the founders of Hima have made further investments in the facility. Together, the parties have committed NOK 2.5 billion (US$236 million).

Daniel Sachs, CEO of P Capital Partners AB said his company is partnering with HIMA Seafood because it puts sustainability at the forefront.

“We are pleased to make our first investment into land-based aquaculture, contributing to the sustainable supply of trout to meet rising consumer demand. We consider that this investment will deliver environmental benefits to the food system and offer a product to suit today’s consumer needs,” said Chris Tanner, Foresight Group LLP partner.

Hima also entered into a partnership with Villa Seafood, a Norwegian seafood distribution company that will be responsible for its sale, distribution and processing.

The “Let’s talk biology” cover story included a quote from Dr. Deborah Bouchard comparing off-flavour in catfish with off-flavour in salmon. The statement has since been retracted.

The “China’s largest eel RAS operation” story misspelled the name of Ze Hui Aquaculture as Zehui. RAStech Magazine regrets its error.

Nordic Aqua, a land-based Atlantic salmon farmer, with operations in Ningbo, China, has entered a short-term credit facility of €5.8 million (US$6.4 million) with DNB ASA, a seafood bank.

The company stated in a press release that the facility has a term of up to four months and is intended to provide the necessary funds to support the company’s ongoing operations and strategic growth plans. The funds will be used to maintain operational stability, invest in essential capex for long-term improvements, and support its ongoing buildout until the upcoming equity financing of approximately NOK 250 million (US$23.8 million) planned for later 2024 and supported by several large shareholders.

This credit facility comes at an important time for Nordic Aqua as the company continues to implement corrective

actions in response to recent challenges in its operations. In July, the company experienced overloading of the purging unit and a high concentration of the off-flavour compound, geosmin, a naturally occurring compound known to be absorbed by fish in all recirculating aquaculture systems (RAS). The company stated in a press release that it is focused on addressing the geosmin issue that affected its production.

“We are committed to ensuring that Nordic Aqua remains financially robust and capable of delivering on our strategic objectives. This credit facility will enable us to navigate the current challenges while continuing to focus on our long-term vision of sustainable growth and a strong market position for premium quality Atlantic salmon to the Chinese market under the Nordic Pure Atlantic brand,” said Ragnar Joensen, CEO of Nordic Aqua.

The Black Cod Company, a land-based farming company developed by AquaFounders Capital has secured a site in Kamperland, Province of Zeeland, Netherlands, to commence its farming activity.

The company will focus on the full-cycle production of black cod (sablefish). The fish is primarily supplied by wild catch from western North America, and small net pen farming activity in Canada. It is also imported frozen or seasonally fresh to the E.U., Japan, and the Gulf.

“It is good to be back in Zeeland and launch The Black Cod Company at an optimal site with strong support by the province and the local community, suppliers and stakeholders. We look forward to work with Seafarm’s Adri and Dave Bout that have partnered with us in the new endeavour and are confident that we can repeat the development of The Kingfish Company with a similarly solid business case,” said Ohad Maiman, managing partner at AquaFounders Capital and founder/former CEO of The Kingfish Company.

The site includes an existing building that the company will convert into a full-cycle hatchery and initial production volume, as well as an adjacent plot of land available for additional expansion.

The company was recently granted governmental approval by RVO to farm black cod as a new species in the Netherlands and

has worked for the past year to secure the site, develop the business case, and confirm it has the in-house knowledge required for the full-cycle hatchery process.

“Having searched across the E.U., we are very pleased with the chosen site- with access to high-quality clean seawater, zoning and permits for land-based farming, and professional and knowledgable suppliers and farming personnel in close proximity, and can now move to funding and conversion of the site to a hatchery and initial production,” said Thue Holm, managing partner at AquaFounders Capital and founder/former chief technology officer at Atlantic Sapphire.

“We are delighted to partner with The Black Cod Company. With our many years of experience in sustainable fish farming and the strong reputation of Seafarm, we believe that together we can build a successful and sustainable farming of Black Cod. We look forward to contributing to this development,” said Adri and Dave Bout of Seafarm.

“It is great that the initiators of The Black Cod Company have chosen Zeeland as their business location. Fishing and aquaculture are activities that belong to our province. After previous developments by Kingfish, this is an excellent new addition. We are happy to support that,” said Zeeland fisheries representative, Jo-Annes de Bat.

8F Asset Management and Pure Salmon Technology are collaborating with Ecofisk AS, a land-based salmon farm, to develop a 7,000-tonne post-smolt facility in Espevik, Rogaland, in Norway.

The project is set on Ecofisk land, a 289,000-square-meter site secured in 2019 to produce 40,000 tonnes of salmon annually. The company stated in a press release that it plans to cultivate up to 20 million post-smolts, each weighing up to 1,000 grams.

“This initiative is crucial for accelerating the development of post-smolt capacity in Norway,” said Stephane Farouze, chairman at 8F Asset Management. “By combining our financial expertise with Pure Salmon Technology’s development capabilities, we are creating

a model that enhances production efficiency and sustainability. This facility will support the increasing demand for larger smolts and improve fish welfare by reducing the sea phase and associated treatments.”

Pure Salmon Technology will design the facility, while 8F Asset Management will provide essential financial structuring. They will offer the facility through an innovative business model that includes a flexible leasing option or shared ownership. Construction is set to commence immediately, with the first fish anticipated by 2027/2028.

“We have observed an increasing demand for larger post-smolt, up to 1 kg. By enlarging the smolts before release, we can shorten the sea phase, which leads to

better utilization of concessions. We will not operate the facility but will serve as project developers. This enhances our role as a strong partner in the Norwegian aquaculture industry,” said Michael Mortensen, chief business development officer at Pure Salmon Technology.

“We are thrilled to be onboarding Pure Salmon Technology and 8F Asset Management to our Ecofisk project at Espevik, Rogaland. Our new partners add capacities such as cutting-edge RAS technology, strong project execution track-record and financial muscles, thus combined represents a perfect strategic fit to Ecofisk unique concession, prime location and business plan,” said Lars Erik Baustad, chairman at Ecofisk.

Blumar recently celebrated its smolt facility’s first year in operation.

The facility is located three kilometres downstream from the Pilmaiquén River, which divides the Chilean regions of Los Lagos (The Lakes) and Los Ríos (The Rivers) and originates from Lake Puyehue, from which Blumar’s Puyehue smolt farm takes its name.

This is the company’s first fish farm which began with the aim of providing about 30 per cent of the company’s smolt requirement of around 4 million fish per year.

As the company’s first freshwater plant, it opened in May 2023, coinciding with Blumar’s 75th anniversary. The facility is intended to rear Atlantic salmon smolt of up to 150 grams.

This smolt farm has a total capacity of 6,000 m³, spread across 24 tanks of 250 m³ each within a 5,770 m² area. Water is sourced from the Pilmaiquén River, with permitted water rights of 7,200 m³ per hour, allowing a water renewal rate of 1.2 times per hour.

The facility is equipped with five Atlantium UV filters near the inlet, each capable of treating up to 1,440 m³ per hour, as well as four Hydrotech rotary filters after the fish tanks to further treat the effluent, with the capacity to process up to 2,900 m³/h. Finally, the water goes through UV treatment before returning to the river, to have an optimum quality.

“Each tank is fitted with an oxygenation cone that enriches the water with oxygen more efficiently. In addition, the oxygen level is continuously monitored in each fish tank, along with water temperature, pH, and turbidity,” explained Wido Martínez, Blumar’s freshwater manager.

The facility can produce 4.1 million Atlantic smolt annually. It receives fingerlings weighing 20g from thirdparty suppliers and grows them to 150 grams over four months, after which they are transferred to the company’s sea sites in the Aysén region.

Before the construction of this land-based farm, all of Blumar’s smolt were sourced from third-party suppliers.

Now, the company expects to meet nearly 30 per cent of its smolt requirements through its own production.

As the only smolt farm built in Chile over the past two years, Blumar’s farming manager, Pedro Pablo Laporte, stated that this investment provides greater stability and control over our production chain. He also noted that the Puyehue smolt farm has created 24 local jobs and reactivated several local services and businesses.

- Christian Pérez-Mallea

The Hydrotech Drum Filter Value series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost.

Let us help you! Call +46 (0)40 42 95 30, or visit www.hydrotech.se

By Maddi Badiola

Maddi Badiola, PhD, PM, is a RAS engineer and co-founder of HTH Full Spectrum based in Basque Country, Spain and USA. She is executive director of the Florida Marine Aquaculture Coalition. Her expertise include energy conservation, lifecycle assessments and RAS global sustainability assessments. Email her at mbadiolamillate@gmail.com.

After years of studying, working hard, prioritizing my profession, along with my family and friends, but giving up fun plans, parties, and other joyful moments, I am seeing the light at the end of the tunnel as they say. I am harvesting the fruits of my effort.

It was 25 years ago when the film, Armaggedon, was released. I watched that movie nine times at the theatres (my mom knows it well). I was crazy about it. And now, and after people have asked me numerous times ”When and why did you realize that you like it here in the U.S.? That you wanted to become American?” I think I know the answer.

Twenty-five years fighting for what I have achieved. I am officially a permanent U.S. resident (in three years I will apply for the blue passport!). I have a family here, I am making friends everyday, I got a brand new car (half of it still belongs to the bank), and I have just become tenant of a tiny, but super cozy and beautiful apartment in Hendersonville, North Carolina.

I am happy and happiness brings positive things. Good vibes are shared with the ones that are around you and all of that attracts and makes everything better. Same happens in RAS aquaculture, same happens with fish, and consequently, with fish farmers/managers and investors.

Happy fish will keep systems running smoothly (and vice versa) and this will have two positive outcomes: 1) better tasting product for consumers, and 2), efficiently performing systems. This means that among other things, lower energy consumptions. Inherently, both of these will make farmers happier, as they will see their marketed product being sold and their energy costs go

down.

But what makes a fish happy? How can a farmer make his/her animals feel comfortable so they grow according to the planned production plans?

Environmental enrichment can help to reduce stress and improve health and wellbeing of the fish. This leads to better results (i.e. better product and profits). Healthy farmed fish are advantageous as fish farmers depend on high survival rates and marketing healthy fish in order to keep businesses operating.

Fish nutrition, feeds, and feeding

management play important roles in increasing the productivity of aquaculture RAS farms. A nutritionally balanced feed and adequate feeding are important factors that maximize fish production and profitability.

Another important aspect playing a major role in overall fish health and performance is achieving and maintaining good water quality through all stages of production. We could say that water quality is one of the most (if not the most) important factor affecting fish health and performance in aquaculture

production systems. Fish are totally dependent on the water in which they live.

And what makes a fish farmer happy? People that know me call me minimalist. I do not need many things to be happy. I do not like overusing resources without the real need and I like to know for what I am paying for. I guess a farmer should be the same: knowing where the energy is used well.

Using less energy means paying less for it, right? It is true that terms like “energy consumption”, “energy efficiency”, “energy management” are more openly and commonly used by vendors at tradeshows for example. Reflecting on my year of attending and hosting RAS-related conferences, I have to admit that energy is still the forgotten cost. And I am starting to think that I am becoming a bit annoying with this topic!

Yes, we, as an industry, may be more aware than years before but still, the importance is not there. At the RASTECH 2024 conference, several presentations posed the importance of data. Measuring as many parameters as possible, knowing our systems to the very tiny detail, being able to react to any sudden change, is crucial for a system’s (and the fish’s) healthy performance.

As American business theorist, W. Edwards Deming, said only that which is measured and recorded can be improved. Only the numbers are the proof of our performance and will give the answers to our investors’ questions. And at the end, is it not investors’ happinness and serenity that will keep us working? And so, among others, would it not be better to be

• 100% Titanium Heat Exchangers

• Hot & Cold Water Loop Systems

• Available with Tube Sheet, Helical Coil, or Plate

• Compact Designs

• Easy Installation

• Salt & Fresh Water Safe Chiller & Heat Pump Packages

A happy fish will result in a healthier, good-looking product, resulting in better profits, and a happy farmer.

paying less in energy, decreasing operational costs, and thus having more margin for profits?

As I mentioned in my last article, and according to the law of conservation of energy, energy is neither created nor destroyed. It changes from one form into another and is transmitted from one body/object to another. The same happens with happiness. A happy fish will result in a healthier, good-looking product, resulting in better profits, and a happy farmer will treat and look for his/her fish with more care producing happier fish.

Every effort in life, sooner or later, is paid. Let’s make this industry more efficient and less resource consuming. Aquaculture is very important to the future of the food industry and our successors will pay for our efforts.

By Vladislav Vorotnikov

While recirculating aquaculture systems (RAS) facilities are still a rarity in the Baltic region, the exceptional journey of SIA Akva Agro, a sturgeon farm in Salaspils, not far from Riga, stands as a beacon of potential in this corner of Europe.

The history behind SIA Akva Agro is rather unique, recalls Vasiliy Krasnoborodko, a SIA Akva Agro minor shareholder. Having built several RAS farms in other countries, Krasnoborodko embarked on the ambitious journey of launching his own project. His quest led him to the main financial street of Old Riga, where he sought investments and equity participation for his

future fish farm, instead of a traditional loan.

Despite repeated rejections, Krasnoborodko’s unwavering determination eventually led to a fortuitous encounter in a bank, where he met a well-known Latvian entrepreneur who shared his vision.

“That’s how a man from the street came to the bank and left with a partner and an investor,” Krasnoborodko said.

The partners found a site near Salaspils and secured support from European funds to construct a sturgeon farm for growing sturgeon for black caviar.

“I designed everything myself,” Krasnoborodko claimed. “I also supervised the construction and participated in the equipment installation.”

Strictly speaking, however, Krasnoborodko was far from being a man from the street. By then, he had likely already acquired more experience in RAS technology than anyone else in Latvia could boast of. He was engaged in over 20 RAS projects in different countries, some of which were state-of-theart facilities.

Krasnoborodko’s portfolio involves projects on opposite sides of the globe, implemented in extreme weather conditions, such as hot tropics or harsh frosts of the Polar Circle.

“I built a RAS farm in Thailand to grow sturgeons, where it is always summer and hot for sturgeons. Sturgeons do not like temperatures above +25 C, and it is usually

hotter in Thailand,” Krasnoborodko unveiled.

Even more peculiar was a project in the Yamal Peninsula — the Russian part of the Arctic caught in permafrost. Keeping the farm running in such conditions is associated with some outstanding challenges.

“In Salekhard (a Russian city in the Arctic), everything underground is frozen and turned into ice 100 metres down. It is impossible to drill a well or a borehole. The water in the well would freeze immediately,” Krasnoborodko stated.

All the water in that farm was brought from the outside. The owner even had to buy a 20 m3 water truck to ensure uninterrupted water supply to his farm.

Krasnoborodko noted that the high cost

of delivering water was compensated with relatively low electricity and heating costs, as the Yamal Peninsula is rich in natural gas.

The strong local population’s purchasing power also helped the farm generate profit, as the monthly salary in this part of Russia is close to €2,000 (US$2,204) — almost twice the country’s average.

Climate plays a role even in RAS operation. In Thailand, despite the challenges of the tropics, there have been unexpected benefits to operating in a warm climate.

Fish mature more rapidly in warm weather than in their native chilly north. In Russian Siberia, the growth is much slower.

Originally graduated from the Moscow Physics and Mathematics Institute as a specialist in the physics of sea and oceanol-

ogy, Krasnoborodko studied fish farming in Israel and RAS technologies in the U.S.

The Soviet-era marine technology school was really strong, offering some of the best education available in the world around that time.

“When humanity was crazy about space in the 1970s, there were enthusiasts who turned their gaze not to the clouds, but down, to the depths of the sea,” Krasnoborodko recalled.

“I have loved fish since childhood. I have always had aquariums at home, and now at home, I have a large aquarium for 1.8 m3 of fresh water,” Krasnoborodko stated. “By the way, an aquarium is also a RAS.”

Over the years, Krasnoborodko experimented with using RAS to grow different

seafood species, including shrimp, catfish, eels, crayfish, sturgeons, trout and even sea sharks.

At the Salaspils site, Krasnoborodko helped build a large fish farm consisting of three buildings with a total area of 3,300 m2.

“We have about 60 metric tons of sturgeon broodstock. We can get two metric tons of caviar per year, which is about 40 kilograms of caviar per week constantly and continuously per year,” Krasnoborodko explained.

“We mainly get caviar from fish without killing the females. We milk the eggs and release the females to the fattening workshop so they can continue to live, gain weight, and produce new eggs.”

From the beginning, the investors envisaged an opportunity to double production performance by adding the second floor.

“I specially built a high building, six

meters high, for this,” Krasnobodko said.

The farm has been running smoothly for nearly 15 years. In general, Krasnobodko says, “to set up a machine that would work uninterruptedly for 15 years” is quite a challenge. However, it would be wrong to say that the SIA Akva Agro’s operation was entirely cloudless.

“The main difficulties we encountered were sales and energy costs,” Krasnobodko revealed.” We planned to sell [caviar] to Russia and Belarus since Latvia shares borders with these countries and sturgeon is a traditional food out there.”

Sturgeon, often referred to as the royal fish, has seen a resurgence in popularity, with increasing demand for its meat and black caviar in Europe and Latvia. ‘Our sales are growing every year,’ Krasnoborodko proudly stated.

Since sturgeon is a heat-loving fish, the farm runs two 120 kW gas boilers. Also, to simulate winter and spring—to milk fish

eggs—the farm uses water cooling with an 80-kW chiller. In this context, energy efficiency has come to the fore in recent years.

“We now need investments to install solar panels and make heating with a heat pump, not a gas boiler,” Krasnobodko said.

To overcome the energy crisis, Krasnoborodko believes the Baltic countries need to revive the nuclear energy development program, which was shut down more than a decade ago when plans for the construction of the Ignalina nuclear plant in Lithuania were scrapped.

In a bid to further streamline operations, Krasnoborodko is now looking into opportunities offered by artificial intelligence (AI). In particular, he revealed that he had designed a program for automatic fish counting in a pool.

“I use a neural network for the detection task. This neural network finds a fish and draws a rectangle around it. Then, a small algorithm tracks the detected object,” Krasnoborodko explained.

Even if the neural network has lost the fish, the tracking algorithm remembers it for a minute, and as soon as the lost fish appears in the frame again, it will have the old ID number assigned when it was first detected, Krasnobodko stated. This technology has already proved its value.

“It is possible online, using another neural network that performs the segmentation task, to count the area occupied by fish and from there calculate their total weight; to determine the size, use the dimensions of the pool, namely the diameter of the pool. And this, in turn, allows you to calculate the feed coefficients,” Krasnoborodko claimed.

The future holds great promise. Krasnoborodko revealed that he found a new investor from Kazakhstan to build a new trout pond with a capacity of 500 tons per year. Krasnoborodko stated that the project worth €5 million (US$5.5 million) got a €3 million (US$3.3 million) subsidy from European funds.

Despite becoming increasingly busy, Krasnoborodko is not planning to abandon RAS. Aside, from SIA Akva Agro he also works as a project manager in engineering company Akva Ferma. “Through, this firm I keep building RAS worldwide,” he added.

Will collaboration trump competition in Iceland’s landbased salmon hub?

By Nestor Arellano

In a windswept expanse of Iceland’s southern coast where some of the country’s most enterprising players in the land-based aquaculture space have staked their claim, it appears the word competition is losing its edge.

In recent years, Þorlákshöfn, a town in the Municipality of Ölfus, has been a magnet for companies in Iceland’s nascent land-based aquaculture industry.

Executives of three companies building large salmon farms in the town of on a coastal strip that earned the name Laxabraut (Salmon Row) say they are keener on working together rather than becoming industry rivals.

Halldór Ragnar Gíslason, managing director of Thor Landeldi, says having competitors just a stone’s throw from his facility will keep his company on its toes but “maybe we can help each other when problem arises so we can minimize the risks.”

Eggert Þór Kristófersson, CEO of First Water hf., agrees. “We see clear opportunities in working together going forward.”

“Of course, we don’t necessarily characterise them as competitors,” according to Jens Þórðarson, CEO of GeoSalmo. “These are colleagues of ours in the industry.”

Thor Landeldi, First Water, and GeoSalmo are three of the five land-based fish producers with operations in Þorlákshöfn Laxabraut. The other two are Ísthór ehf, which is owned by Icelandic Salmon subsidiary Arnalax; and Fiskeldi Austfjörður, which was formerly known as Laxa.

What’s so special about Þorlákshöfn?

The municipality is in the Reykjanes peninsula, close to the capital Reykjavik. In its 2023 report titled “The

State and Future of Aquaculture in Iceland,” the country’s Ministry of Food, Agriculture and Fisheries cited the peninsula as “one of the most optimal sites for landbased aquaculture.”

“The geology of this area is very different from others in the world. Almost unique,” according to Gíslason. “You hardly had any tress or grass. It’s almost like being on the moon.”

After 800 years of quiet, a series of eruptions in 2021 in the Reykjanes peninsula jogged Icelanders’ memory of the volcanic activity beneath their country. Sporadic eruptions have since occurred, including one in August 2024 before this article went to press.

This destructive force is also responsible for the volcanic rock bed beneath Þorlákshöfn.

“There are no rivers or lakes. All water is underground where the dried-up lava acts as a natural filter providing us with clean freshwater perfect for land-based salmon production,” Gíslason explains. “The estimate is that every second 800 litres of freshwater flows to our spot. So, we have lots of water for smolt productions.”

Gíslason’s company is about one and a half years into its project of raising Atlantic salmon in Þorlákshöfn. Thor Landeldi is aiming for an annual production of 20,000 metric tons. The company’s site spans 25 hectares.

Thor Landeldi has contracted a nearby geothermal plant to sell the company five megawatts of power for the first and second phases of the project. The power will be enough for the smolt facility and for producing the first 5,000 tons of salmon. The company has option to purchase five megawatts more in the near future.

Thor Landeldi has started the groundwork for a smolt facility that will have a hybrid flowthrough system ca -

pable of reusing 65 to 70 per cent of water.

The company expects to receive its first eggs in January or February 2025. The facility will produce 80 to 130-gram smolts. The first harvest is expected about six months after delivery of the eggs.

About 200 metres away, the company will build a growing facility capable of producing 5,000 tons annually on the site known as Thor’s plot where an earlier salmon farm existed from 1988 to 1991. Thor Landeldi expects its first tank to be operational by January 2025.

Tests from boreholes indicate that saltwater has ideal salinity and water temperature for growing salmon. “Levels of nitrogen, oxygen and CO2 are very good,” according to Thor Landeldi. “We are confident that the seawater quality on Thor’s plot and in the

surrounding area is excellent and at good temperature for on growing of salmon.”

According to the latest report from Radarinn, the Icelandic Dashboard of Fisheries and Aquaculture, the value of Iceland’s aquaculture products have hit a record high. Aquaculture exports have reached ISK 27.3 billion (US$197.8 million) in the first seven months of 2024, an increase of almost 20 per cent.

The report says much of this is attributed to salmon farming in the country, which accounts for about 82 per cent of Iceland’s total aquaculture export value. The value of Iceland’s farmed salmon has increased by about 28 per cent (ISK 22.4 billion, US$162.3 million) in value compared to the same period in 2023.

First Water, formerly known as Landeldi hf., has already harvested 1,500 tons of salmon from its 52-hectare farm in Þorlákshöfn. The company is targeting an annual production of 8,000 tons by the end of its Phase 1 in 2025.

The company hopes to achieve total production of more than 50,000 tons and complete the six-phased project in 2029.

The company uses a hybrid flowthrough system which uses 33 per cent of new lava rock-filtered seawater sourced from boreholes, and 67 per cent of water that is filtered and recirculated from existing water in the tank.

Apart from the lava-filtered water of the region, First Water’s Kristófersson also sees access to the market a big plus for operating in Þorlákshöfn. The town is also home to one of Iceland’s largest export seaports.

“At Laxabraut we have the perfect environment for salmon farming on land and we are close to an international harbour and Keflavík airport,” he says.

First Water’s facility is about three kilometres from the area’s international seaport, and 85 kilometres from the international airport.

From Iceland’s land-based salmon hub, the United States is just six to seven hours away by plane or six to seven days away by ship. Getting to Europe takes three to four hours by plane or three to four days by ship. This proximity to the airport and seaport gives Laxabraut land-based fish farms direct access international seafood markets in both continents.

Reykjavik is also just a 45-kilometre drive.

In addition to the Þorlákshöfn natural and transport route advantages, Þórðarson of GeoSalmo is also thankful for the Municipality of Ölfus’ approach attitude towards businesses and sustainability.

“The municipality is very open to new projects, constructions, and new economic developments. They made it quite attractive for companies to come to the municipality and set up their operations here,” says Þórðarson.

He says he’s not talking about tax breaks or financial assistance but rather deftness in handling of permits and applications. “It’s just general positivity in terms of planning, the allocation of plots

of land for companies, and such…Moving relatively quickly, making decisions quickly.”

The company broke ground at Þorlákshöfn in January 2023.

GeoSalmo is building a land-based salmon farm with a planned annual production of 24,000 metric tons. Artec Aqua is building the company a hybrid flowthrough system that recirculates up to 65 per cent of water volume.

The farm will have an on-site smolt facility, a growout facility, and a processing plant.

The initial phase of the project will produce roughly 7,500 tons and the first products are expected to launch in 2027.

Þórðarson believes that opportunities for cooperation among the various aquaculture companies in the Laxabraut are plentiful.

“I see the possibility of some form of collaboration in operational areas,” he says. “We have a lot of companies here. We share the cost of building a larger oxygen facility.”

“On the downstream side, we can also pool resources in the treatment of sludge. We can also work together in converting waste into energy of fertilizer,” according to Þórðarson.

The conversion of sludge into fertilizer or biogas, is already a project that First Water is involved in.

The company is working on the very stage of Terraforming LIFE, a project funded by the Environment and Climate Program of the European Union. Members of the joint project include First Water; The Farmers’ Association of Orkidea; the Olfus Cluster, a Þorlákshöfn-based group focused on promoting and supporting economic growth in the region using blue and green economy as a guiding principle; SMJ from the Faroe Islands; and associates Blue Ocean Technology from Norway.

Kristófersson of First Water believes collaboration among

Laxabraut aquaculture companies in the areas of processing and hatchery operations can help cut cost and minimize risk for everyone.

The idea of some form of collaboration in the processing is also attractive to Gíslason.

“I would be very interested in cooperating in the processing area,” says the Thor Landeldi executive. “It probably makes more sense to have access to multiple processing areas instead of just one.”

The same goes for smolt production, according to him. “Smolt production is open to a lot of risks. Maybe we can help each other when problems arise. If you have access to multiple supplies, you can minimize the risk.”

Sourcing experience and well-trained workers will be one of the challenges for growing operations in the area.

Gíslason believes that land-based fish farms can collaborate with schools and universities to develop a potential talent pool. He says the area has a traditional fish farming community here. Aquaculture companies can work together with schools to provide practical experience and training to students.

“We have lot’s resources here that we can share. We can work together…The salmon market is three to four million tons a year. There is a large market for everyone,” says Gíslason

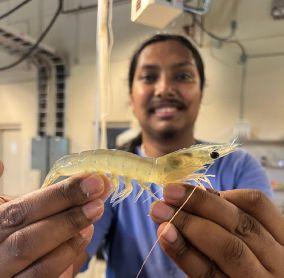

Shrijan

By Magida Tabbara

Pacific white shrimp, also known as Litopenaeus vannamei, has been leading aquaculture production as the most produced species since 2020, according to the latest FAO report. More than 6.8 million metric tonnes was produced in 2022.

Despite the increased quantities produced, optimizing shrimp culture conditions remains a field open for exploration and testing.

Like in many other sectors in aquaculture, increasing production is caused by three main drivers: optimizing culture conditions, meeting the nutritional requirements of the animals, and operating in the most cost-effective manner.

Research within the field has offered some solutions through recirculating aquaculture systems (RAS). Shrijan Bajracharya is a young scientist with great passion for aquaculture.

Born and raised in Bhairahawa, Nepal, the young scientist travelled more than 11,000 kilometres to come to the United States in December 2019 to pursue a Master’s

degree in aquaculture at Kentucky State University. He believes through his study, he can contribute to the betterment and advancement of shrimp aquaculture in RAS.

A holder of a Bachelor’s degree in Agriculture with a mini thesis in Aquaculture, Bajracharya believes that culturing fish and shrimp will help feed the world. But first, it’s important to understand the needs of the animals before raising them to fulfill our needs for affordable food.

“I hadn’t even seen a live shrimp before coming here,” says Bajracharya, who now has experience culturing Pacific white shrimp to be as big as the palm of his hand.

Bajracharya’s studies focused on developing a new culture system with great potential for application in hatcheries.

“The research was a follow-up on a previous work from the same laboratory that compared raising Pacific white shrimp in clearwater versus biofloc,” he said.

The main difference between the present research and what was done previously was trying to find a happy medium between both culture systems that could be efficient and easy to use in hatcheries and small farms.

The novelty of this work came from the ability to explore the addition of sugar as a carbon source, and an alternative salt mixture that a farmer might want to substitute to make his business more profitable without compromising shrimp

growth.

Both factors were studied in tandem with comparing two intensive culture systems, and evaluated from a growth perspective, as well as water quality and shrimp physiology.

The young researcher employed two interesting choices of resources.

For the salt, he prepared an “inhouse” low-cost salt mixture based on his laboratory’s recipe. The salt formulation was made by the research team in his laboratory at Kentucky State University, with special attention to calcium, magnesium, and potassium levels.

“Those elements are essential for appropriate osmoregulation and survival of marine organisms, especially Pacific white shrimp,” says Bajracharya.

The low-cost mixture had seen light several years before he joined the program, and because of its effectiveness, shrimp farmers across Kentucky are already using it as an alternative to conventional marine salt mixtures.

As for the carbon source, Shrijan relied on table sugar additions.

“Table sugar was our choice of carbon source only for its ready availability in grocery stores close to the laboratory,” says Bajracharya.

“But from my experience, molasses can do an equally good job as table sugar as a carbon source for building a good floc,” the researcher added.

It is worth noting the difference

in carbon content of table sugar and molasses, being ~41 per cent in the first but ~24 per cent in the latter.

But in terms of expenses, molasses is more cost effective, bearing in mind that the feed that will be offered to the shrimp will add carbon to the system and complement the molasses.

In terms of research, simplicity is a must. The present work tested for three important factors simultaneously, offering good results and expanding horizons with op -

tions backed with experience.

“We could’ve added a pure biofloc system as an additional factor, but that would have complicated the research design without bringing more information to the table.”

The young researcher advises to keep the system simple, and the same applies to any experimental design that researchers are planning to apply.

Having experience with various shrimp culture systems, Bajracharya draws atten-

tion to several key factors one should consider when diverting from traditional culture systems towards more cost effective ones.

“Hybrid systems like this one are good and can be used successfully for shrimp culture. However, hybrid systems do not contain as much floc as conventional biofloc systems, so you may need to keep an extra eye on water quality.”

The scientist emphasizes the importance of water quality, regardless of the system used.

“Without proper water quality manage -

ment, no system will allow you to raise quality animals, even if it’s part biofloc.”

Bajracharya also reminds that maintaining good water quality means also taking care of turbidity, which must be maintained within a reasonable range in hybrid and pure biofloc systems.

“I am biased towards hybrid and pure biofloc systems,” he says.

The scientist doesn’t deny that clearwater systems can be used successfully to raise shrimp but draws attention to how expensive they would make the production operation. For clearwater systems, various expensive filtration systems would be needed to maintain optimal culture parameters for the shrimp, especially in startup farms.

Some people rely nowadays on culturing shrimp at low salinities after research has demonstrated that Pacific white shrimp grow well at salinities as low as 5 g/L. But when asked about it, Shrijan referred to raising shrimp at low salinities as a double edged sword.

“Low salinity works and helps save

money but can easily backfire if nitrite levels start rising.”

The scientist advises to culture shrimp at salinities between 10 and 15 g/L. The shrimp will have no problems growing at such salinities, but it would give the farmers an edge to manage water quality in case of nitrite spikes.

“If anything, the low-cost salt mixture can help decrease production cost rather than risking very low salinities,” he says.

Bajracharya continues his doctoral studies at Auburn University. He works on optimizing the nutritional requirements of Pacific white shrimp as well managing culture conditions mainly in biofloc systems but occasionally in clearwater systems.

“I love working with shrimp. From my experience raising them in biofloc system so far, I say you can rely on the floc and let it do its magic,” says Bajracharya.

After completing his degree, Bajracharya would like to pursue a career in academia as a research and extension professor, helping farmers in the U.S. and

Full article citation: Bajracharya, S., Fisk, J. C., Fleckenstein, L. J., & Ray, A. J. (2024). Salt type, sugar addition, and system type in intensive RAS for Pacific white shrimp ( Litopenaeus vannamei ) production. Aquaculture, 586, 740755.

FAO, 2024. The State of World Fisheries and Aquaculture.

Fleckenstein, L. J., Tierney, T. W., Fisk, J. C., & Ray, A. J. (2022). Using alternative low-cost artificial sea salt mixtures for intensive, indoor shrimp ( Litopenaeus vannamei ) production. Aquaculture Reports, 24, 101147.

around the world culture cost efficient but big and healthy shrimp.

Tierney, T. W., & Ray, A. J. (2018). Comparing biofloc, clear-water, and hybrid nursery systems (Part I): Shrimp ( Litopenaeus vannamei ) production, water quality, and stable isotope dynamics. Aquacultural Engineering, 82, 7379.

Ace Aquatec has launched its A-Biomass® camera to the Japanese market at the Japan International Seafood and Technology Expo in Tokyo.

A-Biomass® is an underwater camera designed to measure biomass and distributions of a range of fish species more efficiently. The camera uses machine learning and artificial intelligence for real-time millimetre accuracy, which could transform the way fish farmers monitor and grade their fish stock.

It has been rolled out in several regions, Ace Aquatec now has its sights set on the East Asian market with the

company’s chief sales and marketing officer Tara McGregor-Woodhams, head of sales Ben Perry and technical sales and partnerships manager Tom Cryans, sharing insights into the company’s products with delegates.

“Our A-Biomass® cameras are helping farmers optimize feed and growth rates and transform the way they monitor their salmon stock. Over the course of our visit to Japan, we hope to not only nurture our connections in this crucial region but also introduce the A-Biomass® device to a new market, in line with our ambitions of bringing Scottish technology to the aquaculture industry on a global scale,” said McGregor-Woodhams.

The

Water ApS has been delivering the patented GAIA ozonation system and UV water cleaning systems. And over the past five years, both segments of the company have experienced steady growth.

As a result, Director Richard Martin together with the board, decided to split the company into two individual companies, effective August 2024, to maintain a dedicated focus on the development of each system.

Tritonlux will specialize exclusively in UV cleaning systems for aquaculture, aquariums, drinking water, swimming pools, ventilation systems, and wastewater. Camilla Cetinkaya has been appointed as the CEO of the company. Before this, she worked at CM AQUA Technologies for seven years as branding and communications director and as

the company’s Denmark director.

Cetinkaya will lead the company in prioritizing production with high-quality components and fully customizable systems, enabling seamless integration into water-cleaning systems of all sizes.

Aquaintech Inc. has found that using its specific Bacillus species, PRO4000X can be beneficial in RAS farms.

Nitrification and denitrification are critical for ensuring that nitrogen-based metabolites are kept at levels that do not adversely impact the production systems. The microorganisms are added directly to the biological filters, typically as spores in a tableted form. The spores germinate and the Bacillus colonize the substrates and become a component of the biofilms, where they degrade organic matter, ammonia and other

nitrogen-containing compounds, and increase oxygen levels.

Shrimp Improvement Systems, a company that sells genetically improved Penaeus vannamei broodstock, uses Aquaintech’s tableted blend of Bacillus spores, PRO4000X, in their RAS nucleus breeding center. They reported that the Bacillus strains degrade accumulated organic matter and that their use is an important component of ensuring a healthy, consistent production environment. In addition to cleaner water, the company re-

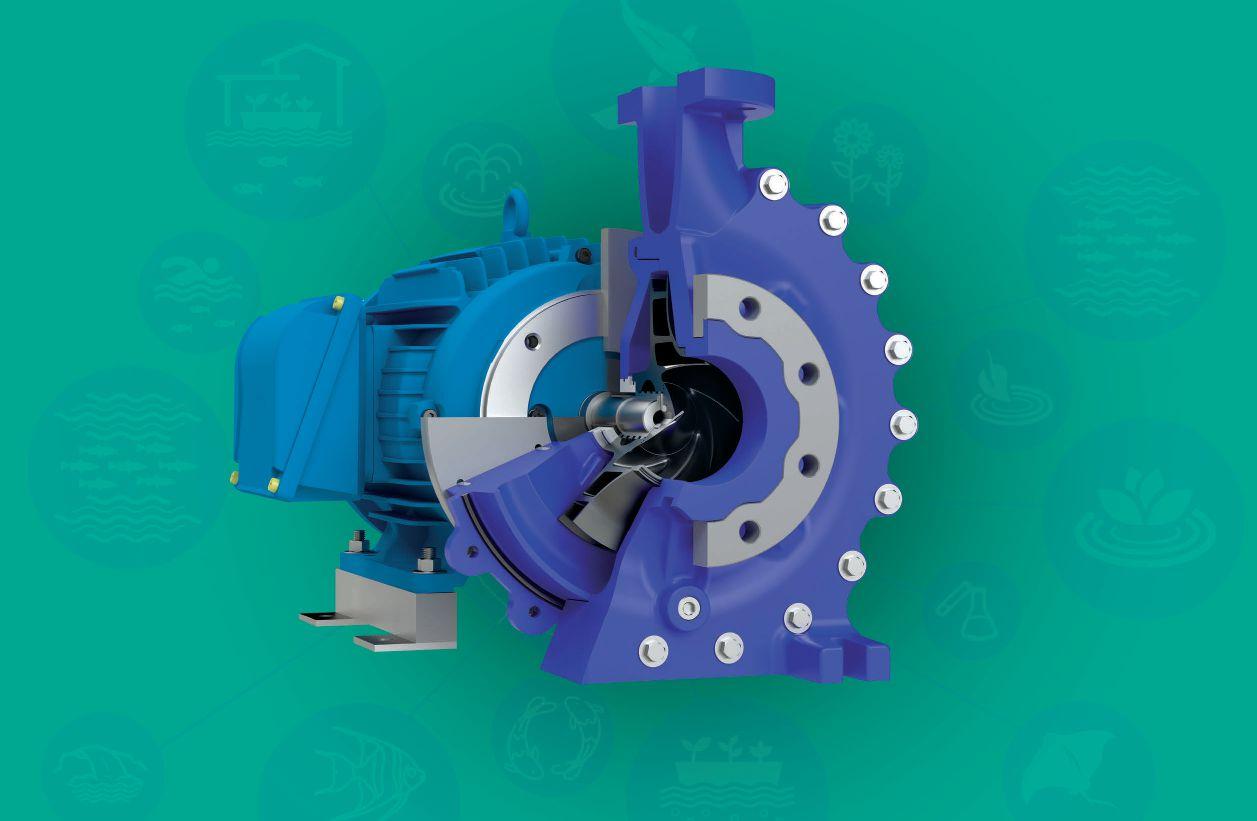

MDM Pumps, an advanced pump solutions company, has launched its recessed impeller technology. This addition to the Genesys line is designed to meet the specific needs of industries that require delicate handling of biological materials.

It has applications in algae culturing and microplankton harvesting.

The new recessed impeller technology has a low-shear design, enhanced efficiency and versatile applications, from LSS applications to Aquaculture, this technology is adaptable to a wide range

of uses.

MDM’s recessed impeller technology ensures the integrity of sensitive biological structures during the pumping process. This feature is particularly crucial for industries involved in algae culturing, where maintaining the viability of algal cells is essential. The technology allows for the efficient harvesting of algae from bioreactors without compromising cellular integrity.

Genesys Pumps can be customized to meet the needs of the company’s customers.

ported an improvement in the animals’ health in the system.

Trials with a modified formulation of PRO4000X have shown that adding the spores to the biofilter daily reduced the colony forming unit (CFU) of pathogenic bacteria by more than 95 per cent. This impact was also consistent with lower levels of application. As with the shrimp hatcheries, an application rate of

1 ppm daily was shown to be highly effective.

“We expect that a similar impact would also be observable under fish pens that are operating in relatively shallow areas. This product readily replaces the use of antibiotics and other problematic approaches towards microbiome management,” a press release from the company states.

KR Group, a steel fabrication and installation company, has secured a third contract with Nofitech to provide steel and cladding for the final phase of a new recirculating aquaculture system (RAS) at Applecross in Wester Ross, Scotland.

The project, which has received a £49 million (US$ 63 million)investment from the Scottish Salmon Company (SSC), will begin in the coming weeks. The three contracts have generated £3 million (US$ 3.8 million)for the Newburgh-based construction and engineering business, KR Group, a report from Project Scotland stated.

“I am incredibly proud of our diligent team who have been working in Wester Ross through all weather conditions constructing the first two RAS buildings and helping to bring this vision to life. Being part of this project from start to finish has been immensely rewarding for KR Group, knowing that we have contributed to a larger sustainability story,” KR

Group’s business director, Nicola Fraser.

“A key focus for our business is sustainability and we have several initiatives in place to ensure that we are playing our

part in caring for the environment. This includes our on-site wormery and rainwater harvesting system, as well as achieving carbon neutral certification.”

B.C. salmon farmer, Cermaq Canada is working with ReelData to install and test its AI technology solutions at two of Cermaq’s freshwater land-based facilities.

The trial will run for several months and will be used to assess improved feeding efficiency care of ReelData’s, ReelAppetite system. Automated average weight and weight distribution measurements will be collected via ReelWeight, an AI camera system designed for land-based systems with individual fish recognition.

“We are very satisfied with the progress of the trial. From the onset, we were able to establish clear goals, expectations, and timelines for the trial. The highly professional team of engineers from ReelData seamlessly integrated their equipment into our complex RAS systems, and we look forward to starting the next phase of

the trial,” said Janusz Wicikowski, freshwater director for Cermaq Canada.

“The freshwater team at Cermaq are already producing phenomenal biological results and we’re happy that they’re open to work with us to consider AI technology to help refine further their processes and production accuracy,” said Gareth Butterfield, the commercial director for ReelData.

“Our ReelAppetite system is designed to optimize feed delivery ensuring fish have the maximum opportunity to feed, whilst simultaneously reducing uneaten feed. This can lead to significant benefits in FCR reduction and growth. We’re also seeing through the ReelAppetite system a benefit of improved water quality and a reduced coefficient of variation in the population, which we expect to get picked up through our AI biomass camera, ReelWeight,”

Butterfield added.

ReelData said deployments in the U.K., Chile, and Tasmania are currently being discussed.

Innovasea has announced that it’s expanding its landbased aquaculture systems to Iceland.

This move is happening through Thor Salmon, installing Innovasea’s Gas Management Towers (GMT) at its Icelandic smolt facility. The GMT leverages gravity, not pressure, to move water. This innovative solution to oxygenation can cut energy costs by up to 77 per cent compared to a pressurized oxygen system, a press release from the company states.

“We are excited to bring our expertise, equipment, and engineering know-how to the area,” said Innovasea’s vice president, Marc Turano. “Iceland has shown a commitment to sustainable aquaculture, and we are proud to help advance this mission.”

Innovasea’s GMT combines a low-head oxygenator and a degasser into a single unit. By offering an all-inone gravity-based solution, facilities gain a more compact, safer, and simplified alternative to pressurized systems.

Thor Salmon will use three GMTs, several dissolved oxygen sensors, and an automated control panel, to better efficiently monitor and control changing oxygen levels remotely in its smolt facility currently being constructed in Thorlakshofn, South Iceland.

“Our collaboration with Innovasea offers us an efficient, state-of-the-art gas

management solution that will play an important role in producing outstanding salmon smolts in our smolt facility. This is part of our journey of producing 20,000 metric tons of salmon annually,” Thor Salmon cofounder Jonatan Thordarson explained.

Innovasea’s Icelandic operations will be conducted out of its Norway office, and the company has partnered with the Iceland-based technology company KAPP to deliver its solutions to Iceland.

“This is an exciting time for Iceland’s aquaculture industry,” added KAPP’s chief technology officer, Valthor Hermannson. “KAPP has been a leading force for Icelandic fishing, aquaculture, and other industries. Now, by partnering with Innovasea, we’re making the latest technology available to drive our industry forward. Servicing and supporting our customers is our number one priority.”

By Curtis Crouse

Poor fin quality from damage or erosion is more than an aesthetic issue.

Fin quality is an important welfare indicator that will present potential risks and financial ramifications, if ignored. Increased likelihood of infection is one such risk factor. The damaged epithelium is an easier route of entry for pathogens with infections causing loss from decreased performance, cost of treatment, or mortality.

Poor fin condition can also negatively impact product quality or acceptability for live or head-on gutted markets, reducing sale price or the number of repeat customers.

The first requirement of an effective monitoring program is attentive husbandry.

Early stages of fin erosion are subtle and won’t be noticed by casual observation. This is especially true when observing fish from above the water surface or when damage is occurring to pelvic or anal fins.

Because assessing fin condition can be difficult, producers should take full advantage of opportunities when their fish are removed from the water for sampling events, procedures, or moves to larger tanks by adding fin scoring to their data set.

Consider also opportunities to examine mortalities for patterns of fin damage, though only observing moribund or dead fish may introduce bias to the data. Objective scoring can be a helpful tool that helps the farm set actionable thresholds or track welfare over time.

When scoring fin condition, differentiate between active and healed damage. A

severely damaged fin from a past injury that has healed over may be less of a concern than minor erosion that is actively inflamed or irritated by a present environmental stressor.

Damage from faulty, misused, or inappropriate equipment is one cause of deteriorated fin condition. The walls of culture tanks and the submerged features should be designed with smooth surfaces, roundhead or countersunk bolts, and without pinch points or sharp edges. This will reduce the risk of rubbing and acute injure to fins.

Typically, RAS grown fish swim in a predictable circular pattern, so observing injury or erosion to specific fins, always on the same side of the fish could indicate a detrimental feature of the tank. Broken fin rays or fin splitting could indicate a rough surface or poorly joined connection in a fish pump hose or incorrect dip net material or mesh size.

Monitor fish for these types of injuries during a move, so that adjustments can be made. Poor water quality could be a direct irritant to fins or allow proliferation of pathogens in the RAS environment. Unlike injury or erosion from equipment, water quality related risk factors may impact all fins more uniformly.

Stocking density is a key metric for fin quality management. The optimal density will be species and life stage specific.

In general, more aggressive species and younger life stages will require lower stocking density. Exceeding a maximum density threshold for a given species or life stage increases the number of interactions between fish and the potential for

nipping or other aggressive behaviour. Noticing nipped fins is a possible indicator of density aggression. Further, high stocking density may displace fish to less desirable areas of the culture tank like the wall or surface where fins can rub or ride above the surface of the water.

While high stocking density is likely to garner more attention, some species may also nip and display aggression at low densities.

Stocking density is constantly increasing as fish grow, and fin damage scores are likely to increase with time. Knowledge of the species being raised and careful bioplanning that projects to reach an appropriate stocking density at the target harvest date can help preserve fin quality of the final product.

Manipulating the formulation of fatty acids, amino acids, vitamins, or minerals in feed can results in better fin condition outcomes for the fish.

When observing deteriorating fin quality, first ensure that the diet has been stored properly and used prior to expiration dates. A different or over-formulated diet may improve fin quality, especially if culture conditions have recently changed.

No matter the diet, feeding fish to satiation will reduce aggressive fin nipping and interactions that occur when hungry fish compete for feed below the feeder during mealtime. The risk factors discussed above are not the only contributors to poor fin health, and culturists should keep in mind that factors can interact with each other to exacerbate a problem. However, by monitoring fin condition as a key performance indicator, increased prevalence or severity of fin damage is a sign that something is less than optimal and should be addressed.

Last page.. But first step into the future of aquaculture

MAXIMIZE UPTIME & EFFICIENCY IN YOUR RECIRCULATING

SIMPLICITY UNRIVALED

• EASE OF MAINTENANCE

• CLOSE COUPLED - NEMA JM & ISO MOTOR FRAMES

• UNIQUE ANSI/ISO FLANGE SYSTEM

• ANSI B73.1

• ISO 2858

INNOVATION UNPARALLELED

• TRUE BACK-END PULLOUT

• THROUGH-BOLT DESIGN

• PROPRIETARY POLYESTER & VINYL ESTER FOR WARM SEA WATER & CORROSIVE

• ENCLOSED IMPELLER DESIGN

• 84% PEAK EFFICIENCY

• RESIN RICH INTERNAL HYDRAULIC PASSAGES

B73LEAN ® : SUPERIOR DESIGN FOR MAXIMUM EFFICIENCY

Experience industry-leading efficiency with MDM Pumps’ B73lean® Technology. This advanced solution not only ensures that inlet and discharge ports are interchangeable with existing metal and plastic pumps conforming to ANSI/ASME B73.1 and ISO 2858 specifications, but it also offers exceptionally low lead times, setting new standards in the industry. B73lean® is designed to close-couple various NEMA and IEC motor frame designs, significantly reducing acquisition costs and minimizing the overall footprint compared to outdated, long-coupled pump and motor configurations.

SCAN THE QR CODE TO LEARN MORE ABOUT THE NEW GENESYS® LINE OF PUMPS EFFICIENCY UNMATCHED