BIGGER TANKS, SMARTER BUILDS

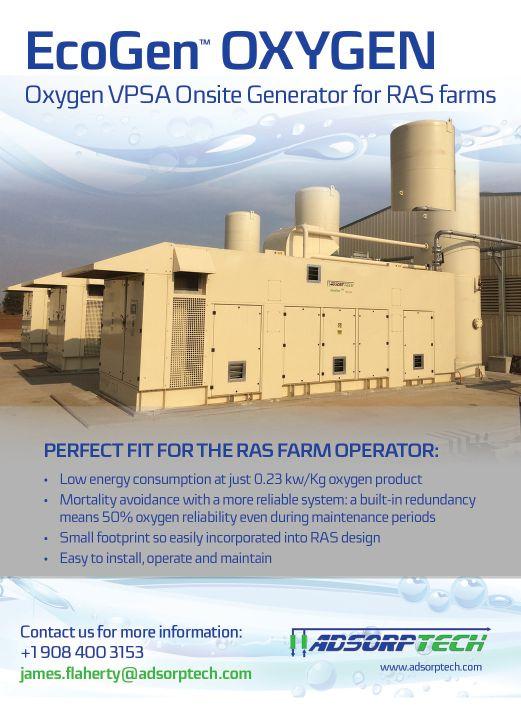

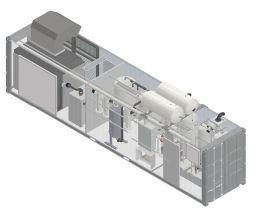

OXYMAX

NEVER RUN OUT

GENERATE YOUR OWN LOx

Ensure your security of supply with OxyMax - an integrated solution by Benchmark International Inc.

Independence Generate your own LOx onsite, eliminating risk of supply disruptions.

No LOx Losses Recompress vapours to prevent venting and waste.

Reduce Carbon Footprint Reduce emissions with onsite generation by eliminating trucking and leveraging green energy.

Reduced Cost Avoid costly supply contracts, transportation fees, tank rentals, and minimum purchase requirements.

LEARN MORE ABOUT OUR SOLUTIONS AT osioxygen.com

DEPARTMENTS

04 | From the Editor

Unity over uncertainty

06 | In the News

Latest industry updates

22 | Showcase

New products and services

Summer 2025 Vol. 8, No.2 www.rastechmagazine.com

18

COLUMNS

26 | Fresh Tips Culture tank design and setup

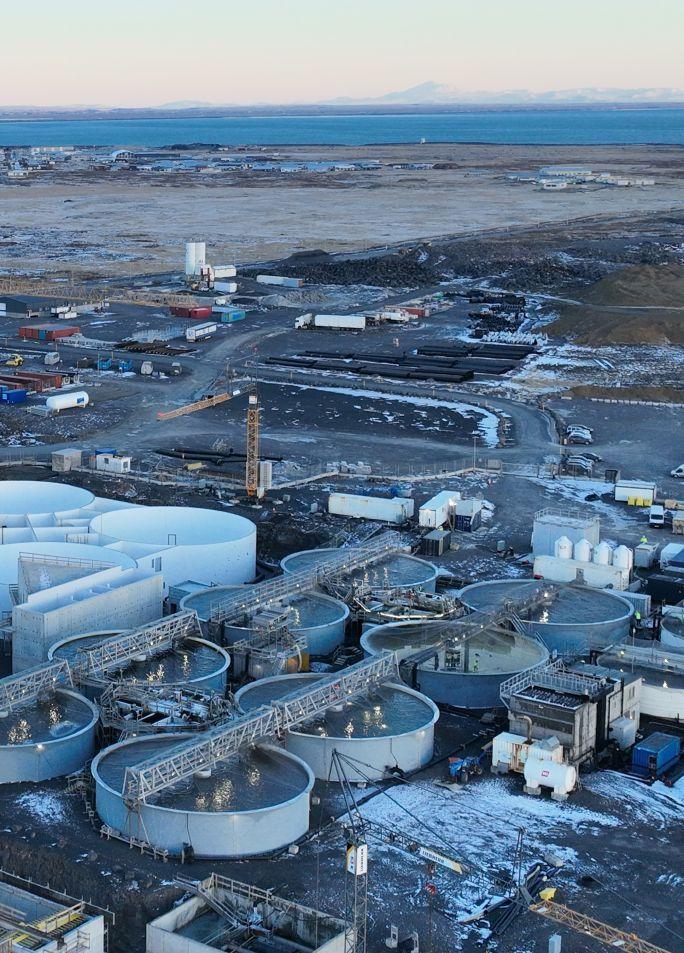

ON THE COVER Grow-out tank at Laxey in Iceland of 5,000 cubic meters, delivered by UK-based supplier A-Consult. (Photo: AKVA Group)

Riding the wave Aquafarmer gains momentum in the Russian RAS technology sector BY VLAD VOROTNIKOV 14 COVER STORY Bigger tanks, smarter builds How to address the complexities of designing and building larger tanks BY TREENA

HEIN

18

Soybean revolution A breakthrough in off-flavour management for recirculating aquaculture BY MATTHEW STROMBERG, UNIVERSITY OF MARYLAND-BALTIMORE COUNTY

RAStech is a supplement to Hatchery International and Aquaculture North America by Annex Business Media Return undeliverable Canadian addresses to: Circulation Department, 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2025 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

From the editor

By Jean Ko Din

Unity over uncertainty

Uncertainty seems to be the magic word these days. With all the political and economic volatility that is going on right now, it’s difficult to operate in any capacity with an attitude of hope or optimism. But hope and optimism is exactly what the industry craves right now.

The recirculating aquaculture sector has had a string of challenges these past several years. I don’t think I need to tell you that. It seems to be the topic of every editorial I write. People still reminisce about the optimism the RAS industry carried in 2018/2019. No project felt too big or too ambitious. Early projects held a promise of changing the way we do aquaculture. It was going to be efficient, sustainable, and controlled. But then reality sets in with the weight of inflationary capital expenditures, supply shortages that crippled construction, a knowledge gap for specialized expertise, and a regulatory infrastructure that didn’t know how to evolve with the technology.

The most frustrating part is that we know RAS works and that the land-based aquaculture model can be profitable. There are examples of this at different scales all over the world, but it doesn’t necessarily capture the headlines the way that tens of thousands of tons of Atlantic salmon once did.

Here’s what we know: the model that earlier projects have tried to execute no longer works. And so, the industry must pivot. Promising projects have emerged with other species that are more robust, more tolerant in RAS, and at a more premium price point. Projects began to innovate and find ways to streamline construction through smart design and engineering. Projects started to advocate for better fish welfare and sustainability practices, instead of bowing to shareholder pressures to chase a bottom line that favours a more shortterm return.

The lessons the industry has learned was

built on the backs of these early pioneers that tackled the challenge boldly. And instead of being dismissive of their achievements or being dissillusioned by all the different ways a new project could fail today, industry should use this history as fertile ground on which to build new foundations.

In a society that is looking to divide people through borders, through economic classes, and even through education, I challenge the industry to face these obstacles even more boldly and more creatively than that “gold rush of RAS” that people continue to be nostalgic for. Today, success will come in the form of community and cooperation. This is a small industry in the sense that everyone in the RAS space is connected to each other in some way. Hopefully, you agree that RAStech Magazine has a role to play as a glue to these connections. But ultimately, this is up to you and your own participation.

I firmly believe that the future of RAS lies in the continued openness and support among different project teams and other professionals. This is the quality that I’ve always admired about the industry. I understand there is extra pressure for these projects to start to produce results and prove the concept to RAS critics. But, I would also like to warn of a siege mentality that I am seeing pop up these days. Farm comes first, yes. But, is there room to step away for a few days to share what you know?

I admit that the RASTECH 2025 Conference and Trade Fair is around the corner and so, that is what is top of mind for me. But, even in attending other conferences this year, there has been a different mood. Uncertainty is forcing us all to second-guess the progress we’ve gained so far. But I urge you to stay the course. The person that gets hurt on a roller coaster is often the one who tries to get off early, before the ride is finished.

I’d love to know your thoughts at jkodin@ annexbusinessmedia.com.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Audience Development Manager Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Editor

Seyitan Moritiwon 519-429-5204 smoritiwon@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Coordinator Catherine Giles 416-510-5232 cgiles@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

Subscription Rates

Canada $37.00, United States – $48.00 CAD, Foreign - $62.00 CAD

All prices are for 1yr subscription and in Cdn funds.

ISSN 2817-7266 - Print ISSN 2817-7274 - Online

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2025 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Made possible with the support of

Atle Eide steps down as executive chairman of Nordic Aqua Partners

Nordic Aqua Partners’ executive chairman has stepped down.

Atle Eide announced his decision to leave the company after two years via a LinkedIn post titled, “A Time for Transition.”

“It has been an honour to serve as executive chairman through these defining years. At the same time, the role has been demanding and all-consuming, and with retirement age now behind me, this is the right moment to step down,” he said.

Eide plans to focus on his own investments, a few selected board positions, and mentoring related to “new technology” founders/start-ups.

He also said it’s been an experience witnessing the growth of Nordic Aqua – from construction to production, and from egg to smolt, growout, processing, and now seven-kilo, large premium salmon. He attributed the success to Ragnar Joensen, CEO of Nordic Aqua Partners and his team.

Eide has been a part of different companies, including Skretting, SalMar, Benchmark Holdings and more.

“And last, I look forward to reflecting – maybe even publicly – on the future of our fantastic industry and the urgent need for enhanced new technology development, supported by the entire salmon industry,” Eide added.

Kingfish Maine wins permit case for Jonesport facility

The Kingfish Company, a land-based producer of yellowtail kingfish, has won a court case in Maine that upholds the state permits for its Kingfish facility.

The state’s Supreme Judicial Court denied the most recent appeal from opponents of Kingfish Maine’s combined Site Location of Development Act (SLODA) and Natural Resources Protection Act (NRPA) state permit.

Kingfish Maine was first introduced to the Jonesport community in 2019. The permit to build an 8,500-ton production facility was initially issued by the Maine Department of Environmental Protection in 2021. But opposition groups appealed the permit decision to the Maine Board of Environmental Protection and the Maine Superior Court. Both appeals were denied. This has delayed the design and construction process.

“This has been a multi-year battle with a small group of

opponents which worked to stop our project,” said Kingfish Company CEO, Vincent Erenst. “Due to this opposition, our project was delayed by almost four years.”

Maine’s Supreme Judicial Court has now denied the opponent’s appeal of the Maine Superior Court decision, upholding the original Maine Bureau of Environmental Protection decision. So, Kingfish Maine remains fully permitted with all required local, state and federal permits.

“Our construction timeline for the Jonesport facility was, unfortunately, significantly delayed by several years due to the multiple appeals by opponents. Now, with the appeals behind us, the project timeline will be determined by current economic and financial conditions, which we are assessing at this time. This is a win for Maine and the United States with regard to seafood production,” added Erenst.

Founder of Billund Aquatech reveals new company name, Globaq Solutions

The founder of the former Denmark-based company, Billund Aquaculture, Christian Sørensen, has founded Globaq Solutions to advance RAS technology and sustainability in global aquaculture.

According to a press release, Sørensen is bringing his over forty years of experience, expertise, and vision to this new company, which will focus on delivering solutions for responsible fish farming.

This comes after a 2024 announcement that Billund Aquaculture would file for bankruptcy. In the same year, Sørensen created a new company, Billund Aquatech, to “drive innovation in aquaculture projects worldwide.” It is now operating as Globaq Solutions.

“Our transition to Globaq marks an exciting new chapter,” said Sørensen,

founder of Globaq Solutions. “Our mission is clear: we develop recirculating aquaculture systems (RAS) that support responsible fish farming –today and tomorrow. We have years of hands-on experience and a dedicated team. We work side by side with our clients to develop tailored solutions that improve efficiency, protect the environment, and help shape the

future of a more sustainable aquaculture.”

The company was reported to be working over the past few months to build a foundation with the right organization and processes in place. Globaq Solutions will offer services, including RAS design, turnkey project execution, retrofits, and system upgrades.

AquaBounty reports 68% revenue drop in 2024

AquaBounty Technologies Inc. has released its 2024 financial reports, stating that it ended the year with a revenue of US$789,000, 68 per cent lower than the 2023 numbers.

The company sold its Indiana grow-out farm in July 2024 and began to wind down its fish-rearing operations at its two Canadian farm sites in December; They have now been designated as discontinued operations.

The land-based aquaculture company’s net loss for the year increased to $149.2 million compared to $27.6 million in 2023. This included asset impairment charges of $129.8 million related to its Indiana Farm, Canadian

Farms, Ohio equipment assets, Ohio farm construction site and corporate intellectual property. Cash, cash equivalents and restricted cash totalled $230,000, as compared to $9.2 million in 2023.

“AquaBounty entered 2024 with the goal of raising new funds to allow for the recommencement of construction activities at our Ohio Farm Site, but ultimately our efforts were unsuccessful,” stated David Frank, chief financial officer and interim CEO.

Even though the company sold assets to generate money, it didn’t make enough to maintain operations.

“Thus, we had no alternative but to

close down our remaining Canadian Farms operations in December and reduce our staff,” Frank added.

On Feb. 11, 2025, the company completed an auction of certain Ohio equipment assets for net proceeds of $2.2 million. And on March 3, it completed the sale of its Canadian Farms and Corporate IP for net proceeds of $1.9 million.

“We plan to continue to work with our investment banker to assess strategic alternatives for our Ohio Farm Project, and we will continue to market and sell available Ohio equipment assets to generate cash,” Frank said.

PHOTO: GLOBAQ

Kristoffer Lund, chief operating officer and Christian Sørensen, CEO and founder of Globaq Solutions

Proximar Seafood harvests 322 tonnes in Q1 2025

A production update from Proximar Seafood AS shows that at the end of Q1 2025, the company had a standing biomass of 1,126 metric tonnes.

This number is up from 1,058 metric tonnes at the end of Q3 2024. It recorded a gross biomass growth of 456 tonnes, including 388 metric tonnes (live weight) of harvested biomass.

This is the company’s seventh production update since it started producing Atlantic salmon in its Oyama facility in Japan in October 2022 and the trial harvest in September 2024.

“We are very pleased to observe how the Fuji Atlantic salmon continues to experience great demand and price achievement. In the quarter, the fish has been sold in several 5-star hotels in Japan. In addition, we announced the first exports of the Fuji Atlantic salmon into the Taiwanese market,” says Joachim Nielsen, CEO of Proximar.

Proximar announced in Q4 2024 that the

reduced feeding following two biofilter incidents affected growth rates and average harvest weights in the quarter. However, it is undergoing some repair works, and the last biofilter is expected to be operational in early May.

It currently has 21 batches and about 2.1 million individuals in production. The

targeted long-term harvest level for Proximar is 5,300 tonnes head-on-gutted (HOG) per year in Phase 1, and based on the performance, it is on track to reach the target utilization in 2027.

The company also harvested 322 tonnes of salmon HOG, in line with its anticipation. It expects an H1 harvest of about 800 tonnes.

Innovation Beyond Measure

Riding the wave

Aquafarmer gains momentum in the Russian RAS technology sector

By Vlad Vorotnikov

For over ten years, Aquafarmer LLC, a Moscow-based engineering firm, has been building RAS farms in Russia and across the post-Soviet space. In addition to its core business, Anton Pelcher, Aquafarmer CEO, is now also running a popular YouTube channel about RAS technologies, calling to popularize this still nascent segment of aquaculture in Russia and abroad.

The Russian fish farming industry has been riding a roller-coaster ride in the last few years, with trends like import replacement and moving towards technological sovereignty essentially determining the local agenda. However, for the RAS segment, the turn of the tides happened long ago. The first sanctions imposed against Russia by the European Union and the U.S. in 2014 and 2015 became a gamechanger for the RAS market landscape, which, prior to

that crisis, relied almost exclusively on foreign technologies, Pelcher recalled.

“[In the mid-2010s,] Russian ruble’s exchange rate against Euro plummeted nearly twofold, making the economic feasibility of building a RAS farm with imported equipment far less attractive than before,” Pelcher said.

In the years before the sharp ruble devaluation, Pelcher specialized in importing RAS equipment, primarily from Europe, but in the emerging economic reality, he decided to grasp new opportunities and invest in equipment localization. Now, a decade later, Pelcher says his bet clearly paid off.

Since its launch in 2015, Aquafarmer has designed blueprints for over 100 RAS farms from sunny Bulgaria to Magadan, a cold, remote location in the Russian Far East, nearly 10,000 kilometres away from Moscow.

“Of course, not every draft eventually was realized - some projects remain only

in the drawings. This is how things are in our business,” Pelcher said, estimating that only around 50 farms have actually been built using his drafts.

Recalling the Magadan farm as one of the most distant projects ever implemented, Pelcher also highlighted the region harsh climate and logistics problems. This project, he noted, was a testament to Aquafarmer’s expertise and resilience in the face of adversity.

In Karelia, the heart of the Russian salmon industry on the border with Finland, where fish farming has grown by leaps and bounds in recent years, the environment is also somewhat unfriendly to RAS farms. Here, the key obstacle to building land-based facilities is associated with rocky soil. “It is almost impossible to dig deep underground, where you need to place some treatment facilities. You practically need to use dynamite to perform the necessary works,” Pelcher indicated.

Lagging behind Europe

Although the RAS farm construction picked up in Russia in recent years, the country still lacks industrial-scale projects, Pelcher admitted.

“I’d say we are 10 to 15 years behind Europe in terms of the RAS sector development,” Pelcher said, adding that the industry is catching up quickly. “The projects are growing bigger every year, and local businesses get a better understanding of how this is also functioning. Contractors and customers are growing more conscious and more experienced.”

The Russian RAS sector has been on a steady growth track in recent years, owing to the fact that there are no viable alternatives for meeting the domestic demand, Pelcher emphasized.

“Everyone would be happy to grow fish in Karelia in cages since it would be easier and cheaper, but the problem is no suitable fish farming areas have been left. Those still available are located in the middle of nowhere, with no physical access,” Pelcher noted.

The last few years have brought tremendous changes to Russian aquaculture.

“Before 2022, around 80 per cent of fish feed on the Russian market was of European origin and only 20 per cent of local origin. Now, it is the other way around,” Pelcher said. “Quite a few new players emerged in this segment.”

While the Russian aquaculture has made significant strides towards self-sufficiency, Pelcher emphasized that the industry still lacks broodstock and fertilized eggs, highlighting the remaining gaps that need to be addressed.

In the RAS farm equipment segment, on the contrary, the last few years brought almost no tangible changes. In

NOVAIR Oxygen Generators

Built for Aquaculture Excellence

Tailored Solutions – For your oxygen flow and pressure needs. For Oxygenation and Ozone Feed Gas – Reliable and efficient. Compact Design – Fast installation, minimal space.

Reliable & High-Performance – Uninterrupted oxygen supply. Eco-Friendly – Sustainable, zero emissions.

Contact NOVAIR today contact@novair.fr www.novairindustries.com www.novair-usa.com

Aquafarmer CEO Anton Pelcher runs a popular YouTube channel about RAS technologies.

the past, European engineering companies, primarily from the Netherlands, Denmark and Germany, built some farms in the country, but this business has nearly come to a halt after 2015.

Aquafarmer also manufactures RAS equipment at a network of its own and partner locations across Russia. According to Pelcher, all equipment is manufactured on a turn-key basis, so the growth prospects in this area fully depend on the state of demand in the market.

Investing in public image

In addition to engineering and building RAS farms, Pelcher is also running a YouTube channel, which has recently hit 35,000 subscribers. With particular videos gathering around 150,000 views, the channel is likely the most popular platform of its kind in the Russian aquacultural industry.

Launched nearly four years ago, the channel sheds light on the peculiarities of running RAS farms, the most common mistakes of newcomer farm managers, and what needs to be done for the business to

THE NEW POLARIS C

run profitably.

In addition, Pelcher shares some information about unique projects, such as converting an old abandoned barn into a modern RAS farm.

“This is all about trust,” Pelcher said, explaining the rationale behind running the channel. “It represents an opportunity to provide value and educate my auditorium, including potential clients and show them what we do. I would say that this project is combining business with pleasure.”

Aquafarmer CEO Anton Pelcher hopes to popularize reicrculating aquaculture technology in Russia.

However, the YouTube channel remains only an application to the Aquafarmer’s core business – Pelcher said he has no intention of trying to turn it into a commercial venture any time soon.

“We harbour plans of reaching out to new markets in Africa and the Middle East,” Pelcher said, praising the YouTube channel for making Aquafarmer’s services popular in other emerging markets where the RAS industry is also still in embryo. “We see a growing interest in RAS projects in the world and hope to grasp opportunities provided by some countries, especially those friendly to Russia.”

Growing market

In 2015, Aquafarmer was a trailblazer in the RAS farm engineering in Russia. Now, the number of companies providing a similar set of services in the country is growing, and competition in the segment is getting fiercer.

“I really like that the industry is growing and more players emerge on our field,” Pelcher said.

However, Pelcher called to distinguish the companies engaged in building industrial-scale farms, like Aquafarmers, and those primarily focused on smallscale operations. Only a handful of firms still can deal with large projects.

“Some customers just want to play with RAS technologies to see how it works. They order small farms with a capacity of around one to two tonnes per year. There are players who assemble such mini-farms. On the one hand, this is good since it gives customers a sense of what RAS is without investing billions. On the other hand, investors oftentimes burn their fingers on such ventures since the economic feasibility of small farms is questionable.”

The wide presence of such practice is a double-edged sword, as small companies also try to popularize RAS technologies, but their efforts also

form a prejudice that running an RAS farm is not profitable and essentially senseless, Pelcher stated.

In general, Pelcher forecasted that the Russian RAS industry has a good chance to take off in the coming years. In particular, he expected new industrial farms with a capacity between 500 and 1000 tonnes per year to be increasingly built in the country in the course of the coming years.

Growth is primarily expected in the European part of the country, but the construction of new industrial farms in the Far East is also not off the cards, Pelcher added.

Aquafarmer has designsed blueprints and manufactures its own RAS equipment for more than 100 Rusiian farms.

Bigger tanks, smarter builds

How to address the complexities of designing and building larger tanks that function efficiently and protect fish welfare

By Treena Hein

The current trend towards larger RAS systems means many different elements come into play when designing and constructing larger-scale tanks. While each project will be unique, there are overarching best practices that help appropriately address the complexities of these projects, avoiding even small pitfalls. While these best practices are still being developed, “meticulous planning and collaboration with all stakeholders are crucial,” notes Callum Graham, business development manager at Octaform in B.C., Canada.

“A detailed work plan should be developed for all aspects of the build, including pipe penetrations, equipment integration and access points to prevent costly modifications later,” he adds.

Regarding the size of tanks, Jacob Bregnballe, (director of land-based sales in AKVA Group in Denmark) has seen the scale of RAS projects grow over the last three decades, but he also explains that for many years, very large tanks have already been in use. In Icelandic production of Arctic char, for example, there are already tanks 26 metres across holding a water volume

of 2,500 cubic metres. And more recently in Iceland, Bregnballe says Laxey has now built individual salmon tanks that each have a volume of 5,000 cubic meters.

“Looking at it from a fish perspective,” he adds. “We’ve gone from land-based operations that produced a total 250 tons per year in 1990 to systems today where just one tank produces more than 500 tons in a year. How do we handle harvest? How do we remove mortalities? It’s a totally different ballgame, and you are designing an entirely different system at these scales.”

Thorsten Vammen, general manager at FREA Solutions in Denmark, also notes that very large tanks present particular challenges with how to harvest a portion of the tank efficiently without having to crowd (and therefore disturb) all the fish. Similarly to Bregnballe, he flags efficient removal of dead fish as another challenge.

“Large tanks have large biomass, so if something negative happens, it has a big impact,” he says.

As RAS facilities get larger, the construction and design of large tanks have also become more complex.

Standard shape

Circular or octagonal shapes are the rule in large tanks, explains Bregnballe, as they provide the structural stability to withstand the water pressure. Raceways, in his view, do not give the required stability when higher depths are required, and he adds that circular/octagonal tanks are basically self-cleaning compared to the raceway type.

FREA makes raceway tanks for trout RAS systems, and today’s tanks can hold up to 700 cubic metres of water. Vammen notes that “there is no limitation of how many raceway tanks you could have. Their shape also avoids wasting floor space and construction efficiencies, in that raceway tanks can be placed beside each other and share a wall.”

Circling back to circular tanks, Bregnballe adds that the physics of water also works well in these tanks in that the water rotates well, and you can achieve high velocities.

“You want to design a large tank so that the water speed is appropriate for the size of the fish and their preferred swimming speed, and also so that there are different velocity lanes, if you will,” he says. “This way, the fish have a choice in their environment and can get exercise, which makes better meat quality.”

Whatever the exact shape, going deeper lowers the footprint and keeps costs down. Bregnballe says a ratio of height to diameter of 1:3 is normally employed in circular tanks, but a ratio towards 1:2.7 is now being used in some cases.

Software power

To ensure larger tanks will function properly, it’s a must to use software programs with the capability to analyze computerized fluid dynamics (CFD).

“We might have two or three or even a maximum of four inlet pipes as tanks get larger,” says Bregnballe, “And with the software, we can get calculations about the risk of vortex in the middle with different numbers of inlets, and how else that might be mitigated. We can also map different water speeds according to the angle of the inlet pipe adjustments. You can also look at adding outlets on the side of the tank to get better fluid dynamics, or you can choose just to have a main outlet at the centre.”

Vammen also believes it’s crucial to use CFD analysis in large tank design, with another use to determine the right water velocity for the tank shape to ensure the fish waste moves to the outlet instead of settling at the bottom of the tank.

“With mortality collection, the software needs to predict where the dead fish will be and how they will move in the water,” he adds. “This is tricky to do today, but as the CFD models get better and better, this will be better simulated in the future. The models are becoming more and more intelligent in their ability to predict how fish will move in the water using different tank designs.”

Bregnballe also points to the achievement of efficient daily mortality as “increasingly difficult” to achieve as tanks get larger. “As with fish exit for harvest, the velocity in the mortality pipe at center needs to be high enough to bring morts up to tank side for disposal,” he says. “All these calculations need to be right before we actually build.”

In addition, Bregnballe flags efficient tank depletion as another critical aspect that needs attention, ensur-

ing water levels are kept adequate to protect fish welfare. Indeed, he stresses that “this important part of tank design has much too often been forgotten.”

Tank construction tips

Graham cautions that materials selection should go beyond upfront costs and consider long-term durability.

“RAS tanks endure significant wear and tear from operational and maintenance cycles, making it crucial to choose a system with a permanent liner that eliminates the need for reapplication,” he explains. “Conventional concrete tanks often need coatings, and mistakes

in their application can be expensive to fix.”

In most instances, AKVA recommends coating and lining the inside of concrete, which Bregnballe explains that in addition to protecting the tank from tear and wear, the coating and lining “will create a more hygienic environment as dirt does not adhere easily to a smooth surface.”

Graham also highlights the hygienic characteristics (for example, prevention of biofilm buildup) of plastic liners (Octaform uses PVC plastic). Bregnballe adds that the surface smoothness of plastic liners – which in some cases

even have hydrophobic properties, such as those made from polyethylene plastic – also improves water hydraulics.

Logistics is another major factor to consider in tank construction. Graham says delivering large-scale tanks can be costly and complex, and shipping lightweight flat-pack components that are assembled on-site reduces costs, particularly for remote locations. This also allows for a higher ratio of trade assistants to senior construction personnel, accelerating installation. Vammen also notes that using pre-cast concrete is often very cost competitive and installation is fast, but “other materials like

Installation of a central outlet pipe in a 2,000-cubic-metre tank for post-smolt production in a RAS in Norway

PHOTOS: AKVA GROUP

composite are getting better, so this is certainly also an alternative to concrete.”

Graham adds, however, that “additionally, if a facility is being built in phases, noise impact should be considered. Concrete helps attenuate noise, reducing stress on fish and promoting better growth conditions.”

Octaform uses stay-inplace concrete formwork, which promotes optimal concrete hydration and therefore avoids quality issues.

“Independent studies have shown that this controlled curing process leads to improved concrete hardness and increases in both compressive and flexural strength,” he says, “contributing to overall structural dur-

ability and seismic resilience.”

Synergies at play?

While there are many challenges with employing large tanks and operating larger RAS systems in general, economies of scale will continue to move the sector in this direction. Large tanks require less wall material, fewer valves, less instrumentation and so on.

“The larger the tanks the lower, the cost of each cubic meter of production volume,” says Bregnballe. “There will be a limit for sure, but I am not sure we have hit the roof yet.”

But while we won’t know how large the largest RAS tank size will be, best practices for tank design and construction will continue to be honed. Stay tuned.

Long-term

Ask the Experts

By Matthew Stromberg & Yonathan Zohar, University of Maryland, Baltimore County - Institute of Marine & Environmental Technology

Soybeans revolution

A tradesman turned academic, Matthew J. Stromberg, has transitioned from a full-time blacksmith to an engineering doctoral student at the Institute of Marine & Environmental Technology. Matthew is co-advised by Yonathan Zohar and Upal Ghosh. His research focuses on both the removal technologies for off-flavour and the underlying mathematical end-engineering processes that control their operations.

A breakthrough in off-flavour management for recirculating aquaculture

When seafood connoisseurs turn away from a perfectly prepared salmon filet because it tastes like “pond mud,” recirculating aquaculture system (RAS) farmers feel the pain not just in their pride, but in their pocketbooks. Off-flavour compounds –primarily geosmin (GSM) and 2-methylisoborneol (2-MIB) – have emerged as the single most challenging obstacle facing America’s growing land-based fish farming industry.

“In 2019, industry stakeholders ranked product off-flavour as the top barrier to the success of salmon RAS ventures in the U.S.,” explains Yonathan Zohar, professor and chair of the Department of Marine Biotechnology at the University of Maryland, Baltimore County. “This isn’t just an occasional inconvenience. It’s a persistent problem that threatens the economic viability of the entire sector.”

The issue is particularly troublesome because of the deceptive potency of these compounds. Humans can detect them in water at vanishingly small concentrations, as little as 5 ng/L. In fish flesh, studies have demonstrated detection at 400-450 nanograms per kilogram, though that it is broadly thought to be closer to 200-250 ng/ kg. To put that in perspective, that’s equivalent to detecting a few drops in an Olympic-sized swimming pool.

What makes these compounds so problematic is their lipophilic nature. As most farmers and distributors are aware, these compounds readily accumulate in fish tissue even when present at extremely low concentrations in the water. Any farm regardless of size can develop this problem, and once present, its hard to resolve.

The current (costly) solution

Today’s standard approach to addressing

this issue is depuration – essentially, purging the fish in clean water before harvest. Fish are transferred to separate tanks with continuously flowing fresh water and held without feeding for days to weeks to allow the off-flavour compounds to be excreted.

While effective, this method comes with substantial drawbacks that undermine the very advantages that make RAS attractive in the first place.

A moderately sized depuration system consumes approximately 2,300 kilowatt-hours per month just for basic operation, with additional energy needed for water treatment and temperature control. Facilities using municipal water may use up to 30,000 cubic metres monthly for depuration alone.

Beyond the resource intensity, depuration creates significant operational challenges. The process delays harvesting, increases costs, and results in weight loss due

to the fasting period. For a 10,000-metricton land-based salmon farm, annual losses from biomass reduction during purging can reach approximately US$1.5 million.

The off-flavour arsenal

The aquaculture industry hasn’t been sitting idly in the face of this challenge. Over the decades, researchers have explored numerous approaches to addressing off-flavour issues, each with varying degrees of success.

Physical adsorption methods, particularly activated carbon in both powdered and granular forms, have shown promise due to their high surface area and adsorption capacity. However, their performance significantly deteriorates in the presence of natural organic matter, which competes for adsorption sites.

In practical applications, these systems require frequent replacement and are

The magical thing about using waxes is that represent an alternative lipid for the off-flavour compounds instead of the fish.

prone to clogging, making them expensive and maintenance-intensive for commercial-scale operations.

Advanced oxidation processes (AOPs), such as combined ozonation processes, UV/TiO2 photocatalysis, and UV/H2O2 systems, can degrade GSM and 2-MIB into less odorous by-products. However, these energy-intensive methods often produce toxic intermediates requiring additional treatment. For example, ozonation systems face high oxidant demand due to reactions with organic matter, significantly increasing operational costs.

Biological filtration systems leverage microbial degradation to remove off-flavour compounds. While effective under controlled laboratory conditions, these systems struggle with maintaining stable microbial communities in the dynamic environments found in commercial RAS operations. Ironically, biofilters themselves are often sources of GSM and 2-MIB production, potentially exacerbating the very problem they’re designed to solve.

“Despite decades of research, depuration remains the industry’s fallback solution,” notes Zohar. “It works, but it’s resource-intensive and costly. The industry has been searching for a more elegant solution for years.”

A waxy innovation

In our research at the University of Maryland, Baltimore County’s Institute of Marine and Environmental Technology, we’ve discovered an unexpected hero in the fight against off-flavours: soybean wax.

We were looking for a sustainable, efficient solution that would overcome the limitations of existing technologies. In our search for lipid-based materials that could effectively capture these compounds, we found that soybean wax demonstrates a remarkable capacity for removing geosmin and 2-MIB from water.

Unlike activated carbon, which relies solely on surface adsorption and is prone to clogging, soybean wax maintains its effectiveness through a dual mechanism of adsorption and partitioning that allows the off-flavour compounds to diffuse into the wax matrix.

The magical thing about using waxes is that represent an alternative lipid for the off-flavour compounds instead of the fish. It creates an almost perfect natural affinity—the compounds want to move from the water into the wax, allowing us to extract them efficiently from the system.

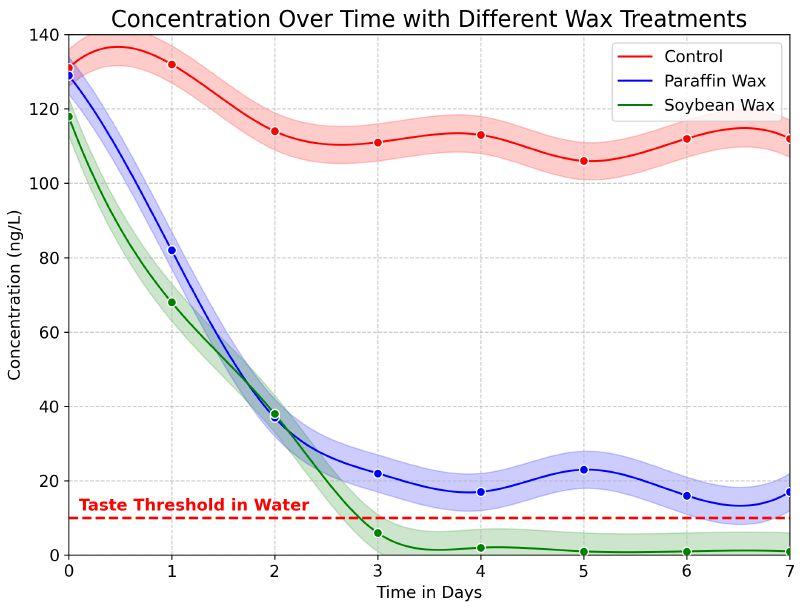

In head-to-head laboratory comparisons, soybean wax achieved 99 per cent geosmin removal within just four days, significantly outperforming petroleum-based paraffin wax, which managed only 87 per cent removal under identical conditions. This performance advantage held consistently across various water conditions, including freshwater and brackish environments.

We’ve tested this in everything from deionized water to halfstrength seawater, and the technology maintains its effectiveness across the salinity ranges used in commercial aquaculture.

DESIGN | EQUIPMENT | SOLUTIONS

Commercial Filtration Systems

Customized for your fish farm, hatchery or research operation!

Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• De-gassing towers

• Wide variety of flow rates

• Flow control valves

• Protein skimmers

• Variable frequency-drive pumps

• Temperature management

From lab to commercial reality

Moving from laboratory proofof-concept to practical implementation, we designed a prototype soybean wax reactor that could be integrated into

existing RAS configurations.

The reactor’s strategic placement immediately after the biofilter – where off-flavour producing bacteria primarily reside – enables it to intercept these compounds at their

chemical properties –their affinity for lipids – to effectively remove them from the system.

The system requires minimal energy input and maintenance compared to alternatives. And because it’s capturing the compounds directly from the water, potentially before they accumulate in the fish, it can reduce or potentially eliminate the need for traditional depuration, saving farmers both time and money.

Creating new value for U.S. farmers

Beyond the obvious benefits for aquaculture producers, the technology creates an intriguing new market opportunity for American soybean farmers. The Soy Aquaculture Alliance, which supports research into expanding the use of U.S. soy in aquaculture, has recognized the potential synergy.

source before they can bioaccumulate in fish tissue.

When we implemented the prototype in our pilot-scale RAS containing salmon, we saw over 95 per cent removal of off-flavour compounds within seven days under real-world operating conditions. This wasn’t just a laboratory curiosity anymore – we were seeing dramatic improvements in a realistic, aquaculture environment. The technology is deceptively simple in its elegance. A plug-and-play fluidized bed reactor, similar to a small moving bed bioreactor, is all it takes.

What impressed us most about this approach is how it addresses the fundamental chemistry of the problem. Rather than trying to destroy the compounds through complex and energy-intensive processes, we’re using their own

“This technology creates a perfect circular economy story,” Zohar observes. “American soybeans already provide substantial protein for aquaculture feeds. Now, soybean wax – a valuable derivative –could help solve one of the industry’s most persistent challenges.”

The potential market is substantial. Farms raising 5,000, 10,000 or 30,000 metric tons of salmon per year would need 200, 400, or 1,200 metric tons of soy wax. Collectively, this would spur the raising of approximately 10,800 metric tons of additional soybeans. While this still represents a significant investment, a simplified finishing process represents huge cost savings in nearly every facet of production.

Moreover, it represents a potential paradigm shift in environmental and permitting

When we implemented on a pilot-scale RAS, we saw over 95 per cent removal of off-flavour compounds within seven days under real-world operating conditions.

concerns for RAS facilities associated with the entire purging process. As RAS technology expands to other species beyond salmon, including various freshwater fish and potentially shrimp, the market for soybean wax could grow exponentially.

The future of flavour management

As our research team continues refining this innovation in partnership with the Soy Aquaculture Alliance, we’re focusing on optimizing the technology for commercial implementation.

Current efforts include fine-tuning the wax formulation to maximize adsorption capacity, developing scalable reactor designs for easy inte -

gration into existing RAS configurations, and conducting extended trials under various commercial conditions.

We’re at a pivotal moment for land-based aquaculture in America. The industry is poised for tremendous growth, with projections indicating the worldwide RAS market will expand to approximately US$10 to 13 billion by 2030 with a compound annual growth rate of between nine to 11 per cent. But that growth depends on solving fundamental challenges like off-flavour management.

The soybean wax technology represents more than just an incremental improvement –it’s a potential paradigm shift in how the industry addresses one of its most persistent challen-

ges. By eliminating or dramatically reducing the need for resource-intensive depuration, it aligns with the sustainability promise that makes RAS attractive in the first place, while potentially improving product consistency and reducing time to market.

What excites us most is that this is an environmentally friendly, sustainable solution that creates value across multiple industries. It connects American agriculture with American aquaculture in a way that benefits both, while helping to secure our domestic seafood production capabilities.

“I’ve been working in aquaculture technology development for decades,” says Zohar. “And it’s rare to find an innov-

ation that so elegantly addresses a major industry problem while also creating new value from existing agricultural products. This is exactly the kind of cross-sector solution we need for sustainable food production in the 21st century.”

As consumers increasingly demand sustainable, domestically produced seafood, technologies like soybean wax off-flavour mitigation may prove crucial in helping the U.S. recirculating aquaculture industry reach its full potential.

The humble soybean – already a cornerstone of American agriculture – might just hold the key to solving one of aquaculture’s most persistent challenges, turning muddy-tasting fish into a problem of the past.

Smarter, stronger, more economical drum filters

The Hydrotech Drum Filter Value series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost.

Let us help you!

Call +46 (0)40 42 95 30, or visit www.hydrotech.se

RainHarvest Systems launches new ozone generator lines for water purification

RainHarvest Systems, a company that specializes in water harvesting, treatment, and reuse technologies, has released new ozone generator product lines.

The Pro series ozone generators are engineered for demanding applications and deliver ozone by venturi side stream injection to achieve precise dosing and maximum output. The generators are available in three sizes and produce up to 30 grams of ozone per hour.

The Pro Series is said to integrate seamlessly with other systems for variable load applications, excel in treating reclaimed or low-quality incoming water and support high-demand environments and ensure safety in applications with significant human contact.

The M Series are suitable for smaller-scale needs. The compact M Series is available in

three sizes and delivers up to five grams of ozone per hour through a diffuser stone. As an alternative delivery option, the venturi side-stream injection system can be added.

Some features include easy installation near water storage tanks using standard 120v electrical outlets and providing reliable purification for stored water, ensuring superior water quality in storage applications.

RainHarvest Systems has over 50 years of expertise in ozone technology and has designed six products specifically for water purification.

BIO-UV Group appoints aquaculture market sales leader

Water treatment company, BIO-UV Group, has appointed Roy Charsley as aquaculture market sales leader.

He’ll be working in the newly created role, driving commercial growth in the global aquaculture market, identifying new opportunities for the company’s advanced water treatment technologies, solutions, and supporting the development of a global go-to-market strategy.

Charsley has over 25 years of experience in the aquaculture industry, particularly in recirculating aquaculture systems (RAS). He previously worked as the operations and general manager for a multinational aquaculture producer, where he oversaw the U.K.’s largest RAS facility and led a multi-million GBP capital development project.

At BIO-UV, he will help to

double turnover within five years by expanding its reach in high-growth industrial markets.

“It’s an exciting time to join BIO-UV Group,” said Charsley. “I’m looking forward to helping build on its strengths in UV, ozone, and AOP disinfection by applying my practical experience and industry insight to support sustainable fish farming operations worldwide.”

Charsley also has international experience providing technical due diligence and consulting services in Europe, Africa, the Middle East, and the Americas. He has led production teams, developed new hatchery and site concepts, advised investors, and introduced innovative standard operating procedures and biosecurity standards across diverse geographies and regulatory environments.

Innovasea adds RAS specialist Miguel Martin to design team

Innovasea, an aquaculture technology provider, has hired Miguel Martin to join its RAS design team.

Martin brings nearly a decade of aquaculture experience as a facility manager and RAS designer. He received his master’s degree from the Technical University of Denmark (DTU).

He’s worked at Nofitech and Pure Salmon Technology, where he contributed to projects covering salmon production processes for farms.

“Miguel brings invaluable experience in designing large-

scale systems for salmon production,” said Innovasea managing director, Juan Pablo Barrales. “We are excited to welcome him to the team and leverage his insights.”

Martin will join the Innovasea team in designing and delivering freshwater and saltwater RAS tailored to the needs of each site. He will operate out of Innovasea’s Chilean office.

“I am thrilled to be part of such a talented, detail-oriented team,” said Martin. “I love the challenge of understanding and solving each farm’s unique needs

Miguel Martin

with a custom solution to help them achieve their goals. The Chilean market represents an

incredible opportunity for aquaculture growth, and I’m excited to help drive that progress.”

Alan MacLeod joins Ace Aquatec as chief financial officer

Aquaculture technology company, Ace Aquatec, has appointed Alan MacLeod as its chief financial officer (CFO) to support with its global growth strategy.

MacLeod has more than 20 years’ experience in various financial leadership roles across technology, construction, energy and oil and gas settings. Most recently, he worked as a director within the advisory section of investment firm, N4 Partners.

Before that, he was chief financial officer and board director at Allrig, where he completed several successful sales and realised additional asset sales internationally.

“Joining Ace Aquatec at such a pivotal time in its growth journey is incredibly exciting. The company’s commitment to innovation and ethical aquaculture is something I deeply admire, and I’m eager to contribute to its continued

success,” MacLeod said. “As demand for sustainable solutions rises worldwide, I see immense potential to expand our

impact while ensuring financial resilience. I look forward to working with the team to drive smart, strategic growth and cement Ace Aquatec’s position as a global leader in this space.”

MacLeod joins Ace Aquatec at a time when the demand for humanely harvested fish and accurate data about average weight, distribution, and growth trends is high.

“Alan’s wealth of experience in financial leadership across multiple industries makes him an invaluable addition to our team. As we continue to scale globally, his strategic insight will help us navigate new markets and sustain our momentum,” said Nathan Pyne-Carter, CEO at Ace Aquatec. “His track record in driving international growth aligns perfectly with our ambitions, and I look forward to working closely with him to shape the future of Ace Aquatec.”

JLH CONSULTING

Welcome to JLH Consulting! We’re here to provide farmers with a Recirculating Aquaculture System (RAS) that runs without a problem while still being economical to build and maintain. Our professionals have years of experience in designing and building land-based RAS as well as aquaponics. As one of the leading companies in the industry, we’re always working on new design techniques and manufacturing processes. Get in touch and learn how we can help.

Alan MacLeod

BRIMER AS

Storehølvegen 9, 6065

Ulsteinvik, Norway

www.brimer.no

BRIMER THE PROTECTORS

Brimer has been a supplier of GRP (Glass fiber Reinforced Plastic) products for over 50 years, and our products are known for their long lifespan and durability. We specialize in sustainable and corrosion-free solutions that last for ages and are for all practical purposes maintenance free. Brimer’s headquarter is in Norway and have production in Norway and Latvia combined with production partners both in Asia and North America.

Brimer offer a wide range of products and services across various market areas, including water and sewage, land-based aquaculture, closed aquaculture systems in sea, land-based process industry, and the subsea energy market. Brimer are The Protectors meaning that we protect and preserve wheater it is securing optimal tank hydraulics and fish welfare for the fish in a circular fish tank, secure clean and healthy drinking water for the population through our water storage solutions, or protect critical infrastructures from being damages from accidental loads.

For the Aquaculture market we supply tanks and tank-related equipment for land-based aquaculture all the way from fry to grow-out fish. We have delivered to more than fifty different land-based fish farming projects including RAS, flow through and hybrid solutions. Typically, we are chosen for reasons like corrosion free solutions, minimum maintenance required, superior lifetime, low lifetime costs, optimum tank hydraulics, etc.

Further, we produce semi-closed sea cages for marine aquaculture, combining advanced technology with sustainable materials. These solutions reduce the risk of escape and environmental impact while ensuring an optimal farming environment.

At RASTech 2025 in San Diego Brimer will be represented by Lauritz Skeide, VP Sales & Marketing, and our CEO Havard Haanes.

SITA srl

Via Rivarolo 59, 16161

Genova Italy

Tel: 0039 010 7406848

info@sitauv.com www.sitauv.com

With more than four decades of experience in UV disinfection, SITAUV represents quality, innovation, and reliability.

For over 20 years, our UV systems have been supporting the aquaculture industry around the world, delivering safe and efficient water treatment solutions across a wide range of applications.

We produce over 9,000 UV systems per year, entirely designed and manufactured in Italy using premium materials and strict quality controls.

Our portfolio ranges from compact units to large-scale systems treating up to 4,000 m³/h with a single unit and up to 72 kW of installed UV power.

We offer UV solutions with lamps from 80 W to 12 kW, ensuring flexibility and performance at every scale.

In aquaculture, maintaining optimal water quality is essential — and SITAUV provides chemical-free, reliable disinfection and biosecurity. Our systems are built to last, easy to maintain, and tailored to the specific needs of each facility.

To ensure local support and availability in the U.S. market, SITAUV collaborates with Integrated Aqua Systems as our exclusive American partner.

By Curtis Crouse

Culture tank design and setup

Good RAS design is a key factor in an operation’s success. Accordingly, emphasis is placed on selecting and designing RAS water treatment processes. While maybe not as commonly discussed as other components of the RAS, a well-designed fish culture tank can benefit fish behaviour and performance and work in conjunction with other unit processes for optimal function.

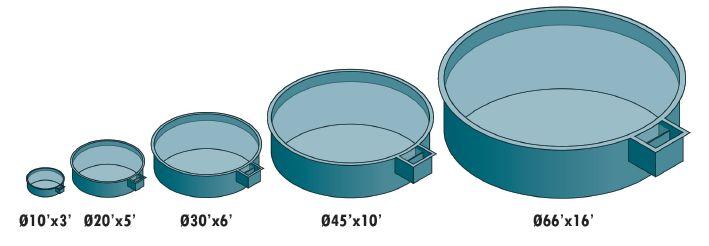

One common design is a circular dual-drain tank with a bottom center drain and a sidewall drain near the top of the tank’s water column. This style of tank can offer several advantages when set up correctly. One such advantage is good mixing that creates uniform water quality over a large tank volume. Fish will spread evenly in the tank when the total volume of appealing environment is maximized. The dual drain tank is not only self-cleaning; the two drains can fraction the settleable solids into two streams with very different concentrations. This can have implications for the design of solids removal on the RAS treatment loop or discharge at the site. Finally, the circular tank can provide a rotational flow around the tank that provides fish with health and welfare benefits.

Circular dual drain tanks come in many sizes and can be constructed from many materials. Production goals, stocking plans, costs, and risk tolerance can help determine the volume and number of tanks needed. Large farms trending toward larger culture tanks demonstrate scalability. However, the diameter-to-depth ratio dimensions impact hydrodynamics. Tanks with diameter-todepth ratios of 3:1 to 10:1 have been successfully used, though ratios of 4:1 to 6:1 are recommended for good self-cleaning and mixing.

A self-cleaning tank will concentrate settleable solids toward the bottom center

drain, and the drain must be designed to remove the solids effectively. The flow through the bottom drain of a dual drain tank typically falls in the range of 5 to 20 per cent of the total flow into the culture tank. The exact flow required will depend on the hydraulic retention time (HRT) of the culture tank and the area of the tank bottom, with a longer HRT and a larger bottom area requiring more flow. Bottom drain plates should be sized to at least 10 per cent of the tank diameter with slots or perforations that exclude the fish and with enough open area that velocity through the drain will not impinge the smallest fish in the tank (typically 2-4 body lengths per second). The relatively small bottom drain flow can have solids concentrations as much as 10 times higher than the other 80 to 95 per cent of the flow leaving the tank through the side wall drain. The concentration and fractionation of the solids provide more options for solids treatment in the RAS loop.

The final element of culture tank design is the inlet. Proper flow injection helps maintain the self-cleaning and mixing properties discussed earlier. It can also confer health and welfare benefits by generating an appropriate rotational current for the fish to swim in. Target rotational velocity will be

species-specific and can be accomplished by combining designed water pressure and inlet jet orientation. The inlet for a culture tank should consist of evenly spaced holes that cover the entire depth of the water column. The size of the inlet holes should be such that the smallest expected fish in the tank cannot enter the inlet structure. Once a hole size is selected, the number of holes needed for the designed inlet flow can be determined by solving for the area in the orifice equation (Q = Cd) A √2 g h) using a coefficient of discharge (Cd) estimate of 0.6 and a target head loss of 0.6 to 1.2 m. The total area can then be divided by the area of one hole to determine the needed total.

Inlet structures can be incorporated into the tank wall or as a separate feature, such as a capped pipe that extends into the water column. Fixed inlets in tank walls can be equipped with female threaded fittings, and head loss or direction can be adjusted by capping orifices or installing threaded elbow fittings to change the direction of the jet flow. A capped pipe style inlet can be plumbed with a flange to allow the jets to rotate. The rotational velocity is adjusted by directing the flow into the tank wall for a slower current and tangentially to the wall for an increasingly swifter current.

MAXIMIZE UPTIME & EFFICIENCY IN YOUR RECIRCULATING

SIMPLICITY UNRIVALED

• EASE OF MAINTENANCE

• CLOSE COUPLED - NEMA JM & ISO MOTOR FRAMES

• UNIQUE ANSI/ISO FLANGE SYSTEM

• ANSI B73.1

• ISO 2858

INNOVATION UNPARALLELED

• TRUE BACK-END PULLOUT

• THROUGH-BOLT DESIGN

• PROPRIETARY POLYESTER & VINYL ESTER FOR WARM SEA WATER & CORROSIVE

• ENCLOSED IMPELLER DESIGN

• 84% PEAK EFFICIENCY

• RESIN RICH INTERNAL HYDRAULIC PASSAGES

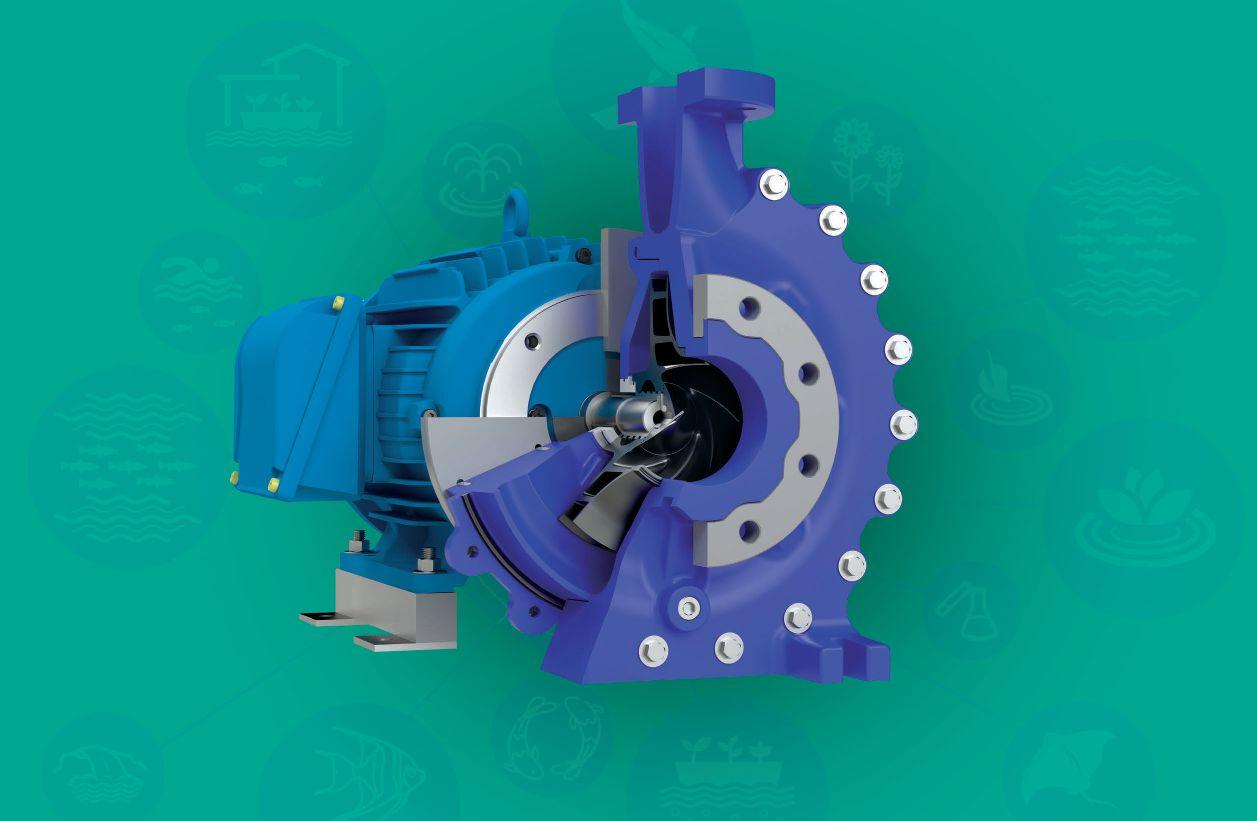

B73LEAN ® : SUPERIOR DESIGN FOR MAXIMUM EFFICIENCY

Experience industry-leading efficiency with MDM Pumps’ B73lean® Technology. This advanced solution not only ensures that inlet and discharge ports are interchangeable with existing metal and plastic pumps conforming to ANSI/ASME B73.1 and ISO 2858 specifications, but it also offers exceptionally low lead times, setting new standards in the industry. B73lean® is designed to close-couple various NEMA and IEC motor frame designs, significantly reducing acquisition costs and minimizing the overall footprint compared to outdated, long-coupled pump and motor configurations.

SCAN THE QR CODE TO LEARN MORE ABOUT THE NEW GENESYS® LINE OF PUMPS EFFICIENCY UNMATCHED