CLEARLY SUPERIOR

EFFICIENCY

Maximum growth potential

• Optimum growth

• Optimum feed conversion rates

• Maximized physical and biological filter capacity

SUSTAINABILITY

Lower Nitrogen Discharge

• High pellet stability

• High fecal binding

• Lower FIFO

WELFARE

Take Care of the Health of you Fish

• Improved water quality

• Supplemented with organic vitamins and minerals

• It can be complemented with any of our health PACKS

16

COLUMNS

10 | Power Struggle

Energy efficiency is a team sport

30 | Fresh Tips

Three rules of successful depuration DEPARTMENTS

12 It takes two Philippine farm produces zero-salinity vannamei shrimp and tilapia in RAS. BY RUBY GONZALEZ

COVER STORY Waste not Converting RAS fish waste to fertilizer, biocoal, and other profit opportunities BY NESTOR ARELLANO

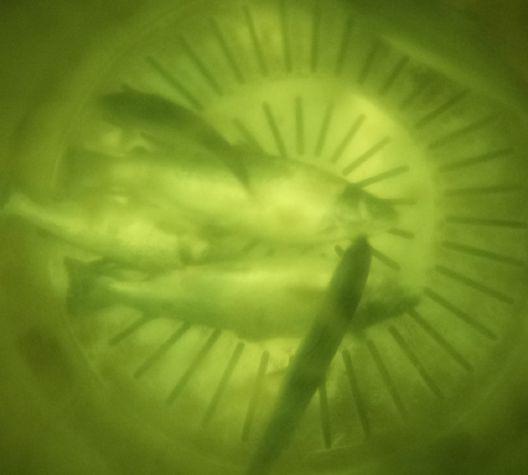

to detect fish mortalities in RAS BY KATA SHARRER AND RAKESH RANJAN, FRESHWATER INSTITUTE

Land-based aquaculture making ‘strides towards maturity’: Spheric Research BY MATT JONES

From the editor

By Jean Ko Din

Let’s talk about it

Iam writing this editorial about a month before the biggest project of my year, which is the RASTECH 2024 Conference and Trade Fair (June 5-6 in Charlotte, N.C.).

As editor of RAStech Magazine , I feel it is my duty to build a program that truly reflects the issues that are top-of-mind in the industry. My dream for this event is to bring as many of the industry’s leaders and experts in the same room to talk about the challenges and develop solutions to progress for the next year. I would consider this event a success if I hear someone say that the next big thing in recirculating aquaculture systems (RAS) happened because of RASTECH! What can I say, I like to dream big.

The RAS industry is growing every day and new applications of this technology is being tested all the time. While the community is still relatively small and young (compared to the larger aquaculture industry), it is important that the right foundations are being established now.

So after a year of consultations from trusted advisors in the industry, what do I think are the biggest topics we should address in 2024?

The first topic is on versatility and adaptability. For a few years now, it feels as though the majority of the sector focused on fully recirculating, Atlantic salmon megafarms. But recently, I think we are all realizing that recirculating aquaculture technology can be as diverse as the fish in the sea.

According to market reports, the companies that are enjoying profitability are not necessarily the highest water recirculation rates, nor are they targeting the

majority consumer market share that Atlantic salmon holds globally. This trend has led many investors and aspiring operators to truly open up their imaginations to more possibilities for a successful RAS business.

The second topic that I based this year’s conference around is the importance of good process. Many of us who observe the industry from the sidelines have seen projects crumble under the pressure of high production targets and tight deadlines. RAS technology is complicated as it is without throwing in the challenges of delayed construction timelines, political lobbying, and system failures.

So, much of the program also emphasizes the importance of planning, testing, setting guidelines, training the team, and creating necessary redundancies that derisk your overall operation.

I’m looking forward to facilitating some of these conversations, but also being a fly on the wall for many others. I’m grateful to the team of session chairs that I leaned on for their expertise. They are the ones that give me confidence that our team has developed an industry event that will move the needle in the right direction.

For those who aren’t able to attend, I haven’t forgotten about you, dear reader. I have plans to share as much of the learnings from our flagship conference as I can physically manage, so stay tuned on our website and on our LinkedIn for updates. I hope you still join the conversation in some way.

If you have ideas you’d like to share, or if you’d like to talk about the magazine, you can email me at jkodin@annexbusinessmedia.com.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact

Angelita Potal, Audience Development Manager Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107

jkodin@annexbusinessmedia.com

Associate Editor Seyitan Moritiwon 519-429-5204

smoritiwon@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Manager Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Account Coordinator Catherine Giles 416-510-5232 cgiles@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

Subscription Rates

Canada $37.00, United States – $48.00 CAD, Foreign - $62.00 CAD

All prices are for 1yr subscription and in Cdn funds.

ISSN 2817-7266 - Print ISSN 2817-7274 - Online

Publications Mail Agreement -#PM40065710

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Natural Shrimp’s water treatment trial reports success in Japan

Natural Shrimp, Inc., a biotechnology aquaculture company, says it completed a successful six-month trial in Japan with the company’s patented electrocoagulation (EC) and Hydrogas™ technologies.

According to the trial results, the tank with the EC effectively removed ammonia from the water and the shrimp growth rate increased during the presence of Hydrogas, compared to the shrimp growth rate in the tank treated only by the biofilter.

“I very much enjoyed working with the team in Japan during the installation and operation of our equipment in the Japanese shrimp research facility. The Japanese quickly learned how to operate the EC and Hydrogas equipment and shared with us the data that they collected during the trial,” said Tom Untermeyer, chief technology officer at Natural Shrimp.

Natural Shrimp said it made three trips to Japan during the trial period and continued to actively participate in the trial by remote access to the equipment between trips. However, after initial instruction by the NSI team, the Japanese team was able to independently operate the EC and Hydrogas equipment on their own.

The Japanese team collected data under varying conditions by testing different flow rates, ammonia levels, and amperage levels. Based on the results from the trial, Natural Shrimp said it’s looking to either joint venture, license, or form a business combination in Japan.

“The Japanese market is uniquely set up for the NSI technology based on its current shrimp import conditions and a robust consumption of shrimp as a primary protein source. I am excited to see where this will lead us in the future with the hope of helping them and others develop successful shrimp production systems using our technologies,” Untermeyer said.

AKVA and Laxey collaborate for RAS technology in Iceland

AKVA group has announced a new contract with Laxey to advance land-based aquaculture technology in the Westman Islands, Iceland.

The contract will focus on implementing re-use technology across the first of six grow-out modules planned for the site. Each module is designed to produce 4,500 tons of salmon annually, a total output of 27,000 tons.

“We have had excellent cooperation with AKVA group on the development of our smolt RAS facility that is now up and running. We see this contract for the growout project to be a continuation of our relationship for years to come. We are happy to keep the experience of AKVA group on board,” said Hallgrímur Steinsson, chief technology officer of Laxey.

The comprehensive delivery from AKVA group includes the design and installation of advanced oxygenation and degassing systems, SCADA and electrical systems, project management and advisory services across the entire project. The project will begin in 2024.

“I am sure that the good relation-

ship created during the execution of the Smolt RAS project will benefit this much larger Grow-out part. We have a lot of experience from previous Re-use projects that will surely contribute positively. We really look forward to continuing working with Laxey; we team up really well,” said Jacob Bregnballe, sales director at AKVA group Land-Based.

In September 2023, AKVA group and Laxey started a project to install a Recirculating Aquaculture System (RAS) for smolt in Vestmannaeyjar, Iceland.

Which the company says is the “first true RAS smolt facility in the country.” The project is supported by Laxey’s EUR 42 million financing. They plan to start production in 2024.

Laxey said it aims to reach an annual production of 27,000 metric tons of Atlantic Salmon by 2031, a significant increase from Iceland’s current production. “This project signifies a shift towards land-based salmon farming in Iceland, focusing on sustainability and environmental preservation,” a press release from AKVA Group reads.

Jacob Bregnballe of AKVA group and Hallgrímur Steinssonofn Laxey signing the contract.

PHOTO; AKVA GROUP

Aqua Founders Capital launches

The Black Cod Company

Aqua Founders Capital has launched The Black Cod Company, aiming to be the first land-based producer of black cod in Europe.

“True to our thesis on the competitive advantage of land-based aquaculture, farming Black Cod on land in the EU meets the critical strategic trifecta: a high-value species, well suited for land-based farming, deployed at an otherwise import dependant market,” a LinkedIn post from AquaFounders Capital states.

Ohad Maiman, founder and former chief executive officer of The Kingfish Company, and Thue Holm, founder and former chief technology officer of Atlantic Sapphire, formed AquaFounders Capital in 2023 to support compan -

ies that focus on innovative RAS technologies. In Fall 2023, the two shifted their business model to focus on building two companies up.

The company’s other current projects include Farm in a Box, a

plug-and-play hardware and software solution for modular land-based fish farming.

Maiman and Holm will also be keynotes at the RASTECH 2024 Conference and Trade Fair.

Ohad Maiman and Thue Hold announce new RAS venture called The Black Cod Company.

Nordic Aqua Partners reports successful first harvest in China

Nordic Aqua Partners AS has reported the successful completion of its first Altantic salmon harvest at its recirculating aquaculture facility in Gaotang, China.

The harvest marks the company’s transition to full operational status. According to a company press release, the harvest during the first three weeks will amount to 10, 20 and 30 tons respectively, before gradually increasing to stabilizing in the 70-80 ton per week range.

Stage 1 is the first step in an overall plan towards 20,000 tons. Construction for an additional 4,000-ton Stage 2 capacity was initiated in the third quarter of 2023, and preparations for the Stage 3 expansion to 20,000 tons are “well underway,” said the company.

“Our first harvest confirms the high-quality of our farmed Atlantic salmon, achieving an average weight of

approximately 5.7 kilograms LW, with mortality rates of below 2 per cent, no signs of maturation issues and a superior rate of 99 per cent,” comments CEO Ragnar Joensen in a press release.

“These excellent biological results underscore Nordic Aqua’s capability to maintain superior fish health and welfare standards, which translates into premium product quality for the highly attractive Chinese consumer market.”

“This marks a new milestone in this

pioneering story. I would like to thank Nordic Aqua who gives us the opportunity to be a trusted partner and all our employees in AKVA group who have contributed. We look forward to the further development in this project,” said Johan Fredrik Gjesdal, COO of AKVA Group Land-Based.

Nordic Aqua is scheduled to host a Capital Markets Day for investors, analysts and other stakeholders on Sept. 3 in Ningbo, China.

Innovasea expands to serve Chilean market

Innovasea, an aquaculture solutions company, has announced that it is now offering land-based aquaculture solutions to the Chilean aquaculture industry.

The company is expanding its services to better serve the growing land-based salmon farm industry in Chile, one of the world’s largest fish farming regions.

Marc Turano, vice-president of Land-Based Aquaculture at Innovasea, said “Our team in Chile includes former fish farmers who know the industry from every angle. They offer top-notch expertise and hands-on technical support to implement tailored solutions that boost fish

production, lessen environmental impacts, improve regulatory compliance, streamline operations and increase profitability.”

Innovasea’s Chilean operation in Puerto Varas opened in 2020 and has

since collaborated with Chilean aquaculture companies that have installed Innovasea’s aquaculture solutions.

The office is managed by Innovasea’s Juan Pablo Barrales, who has more than 25 years of experience working in Chile’s aquaculture industry. “Building on almost five years of supporting net-pen salmon farmers to boost productivity and profitability, I’m thrilled to be able to deliver Innovasea’s proven technology and equipment to land-based customers in Chile,” said Barrales. “Our hands-on technical support and services will ensure our customers long-term success with their hatchery and grow-out operations.”

PHOTO; AKVA GROUP

PHOTO: INNOVASEA

Nordic Aqua Partners reports successful first harvest at Goatang, China.

Innovasea’s Chilean team will be based in Puerto Varas.

Bioled and University of Maryland explore irradiance effects on Atlantic salmon

Chilean company, Bioled, has initiated a research project with the University of Maryland, USA to study how irradiance interferes with the growth and control of early maturity in Atlantic salmon ( Salmo salar ) farming in full-cycle RAS systems.

This is part of its international expansion plan and in analyzing the characteristics of land-based farming systems.

“We are very pleased and proud to conduct this research with the Institute of Marine and Environmental Technology (IMET) at the University of Maryland, located in the city of Baltimore. We are confident that this project, co-funded by the Corfo instrument ‘Consolidate and Expand’ for international validation and scaling of products, will be a milestone at both national and international levels,” said Ximena Navarro, Bioled’s R&D manager.

Ximena Navarro and the project manager of Bioled, Cristián Robles, will be travelling to the experimental facilities of IMET in Baltimore to meet with Yonathan Zohar, a researcher and institute director, who will lead this project together with Bioled’s deputy R&D manager, Ana Fernández.

Meanwhile, the equipment to be used for this research has been shipped to Maryland to begin installation and subse -

quent research. Some of this equipment will be remotely operated from Chile, thanks to the implementation of the modern Bioled Automation System (BAS).

“Working on a project with the University of Maryland is a major milestone for our company, positioning us as global experts in fish photoperiod. I thank the R&D team, who sees opportunities and seizes them promptly. I especially want to highlight the leadership and drive of our colleagues Ana Fernández, Vanessa Mella, Alejandro Sáez, and Patricia Catalán. Without them, this would not be possible,” Navarro said.

50 years of selection, innovation and precision led us here.

Premium selection of salmon ova for the specific requirements of the land-based production environment.

This product is selected for high growth and reduced early maturation (All-Female) or even complete elimination of early maturation (All-Female Triploid).

Learn more about our products bmkgenetics.com/products

Contact Harry Tziouvas Commercial Lead UK and Global Land-Based harry.tziouvas@bmksalmon.com +44 (0) 782 337 4568

Bioled has initiated a research project with the University of Maryland.

PHOTO;

Power Struggle

By Maddi Badiola

Maddi Badiola, PhD, PM, is a RAS engineer and co-founder of HTH Full Spectrum based in Basque Country, Spain and USA. She is executive director of the Florida Marine Aquaculture Coalition. Her expertise include energy conservation, lifecycle assessments and RAS global sustainability assessments. Email her at mbadiolamillate@gmail.com.

Energy efficiency is a team sport

Energy is what keeps this world moving. We are based on water and driven by energy. When we are tired, we need fuel (i.e. food).

I am a big soccer fan. Athletic de Bilbao is my team. Our philosophy relies on our team, no individualism, a Basque-rooted team. I have always been a team player and somehow, I believe that the collaborative approach and teamwork-based way of thinking applied and stated in my company HTH’s baselines come from there.

Athletic de Bilbao played the Spanish King’s Cup Final last April and I flew from North Carolina to the Basque Country to watch it with my family and friends. More than 300,000 Basque were mobilized to support them. The dream was about to become real after 40 years. The passion, the faith for our colors, was somehow transmitted to our players and they used this energy to win the championship. Indescribable feeling. Emotional tears.

Energy is neither created nor destroyed; it does not disappear. Energy changes from one form into another form, and it is transmitted in many ways. How efficiently it is transmitted makes the difference, whether it is a difference in our energy bills, the difference from one team to another, or the difference of winning or losing.

And that is the key: the team. Whoever oversees the Recirculating Aquaculture System (RAS) is crucial and critical for continuous operations. He or she needs to be capable of developing a well-trained and qualified team for the success of a commercial-scale RAS. The efficiency is covered in the design phase (i.e. defined by engineering criteria, equipment and technology). Thus, in order to meet the such efficiency, the main goal of the management team should be to operate the system within predefined criteria.

Five out of five interviewees for this article stated the energy efficiency of a RAS is directly related to its operational management. Thus, energy efficiency must become an integral part of the company’s culture. Energy management including proactive cleaning procedures, monitoring critical components (such as blowers, pumps, compressors), and ensuring those are running at optimum speed are some of the examples.

At the same time, preventative maintenance service will keep RAS components operating in their ideal conditions for best filtration removal and minimized additional work for its components (e.g. water flowing through a clean filter has much less resistance, and less effort is required to maintain turnover when compared to a dirty filter).

A manager, together with the team that he or she builds, should have biological and hands-on skills. Employees can help improve energy efficiency by being atten-

tive to the normal operation. Any unusual sounds, changes in flow, or cleanliness of the water could signify that something is operating very inefficiently; paying attention to small changes could head-off large swings that can cause loss of efficiency.

One of the main issues in the RAS industry is that energy and its consumption have not gotten the attention it deserves. Only in the current context of rising energy prices and limited resources, energy efficiency has it become a common priority more so than it was years ago. It was a concern from an “operational cost control” standpoint. However, there has been a tendency to sacrifice long-term efficiency for short-term cost savings.

Thus, in the past, mechanical systems (e.g. pumps, fans, compressors, and motors) used to be selected based on price and availability, not based on their energy and operating costs, and were often oversized. Luckily, these same mechanical systems are now being evaluated during the design

Energy efficiency of a RAS is directly related to its operational management. Thus, energy efficiency must become an integral part of the company’s culture.

phases for their energy-saving opportunities and the return on investment (ROI) in addition to price and availability. Moreover, it is more and more common to hear about energy audits, a procedure that I have been personally advocating in the industry for the last 14 years. In an Internet of Things age where networks are capable of tracking all parameters of all technical components, audits are conducted to identify inefficiencies and opportunities for improvement. Indeed, the success of any plan to reduce energy consumption, specifically within older facilities, should begin with an energy audit. They should be part of a larger-scale operational audit when performed because the results of these audits will allow aquaculture operations to prioritize improvement projects based on the percentage of efficiency gained and the ROI of those improvements.

As such, the push for energy efficiency in land-based aquaculture operations should be a collective effort that needs to combine technological innovation with the mindful practices of the operations team. Motivated and highly skilled leader-

ship are required. But what should we be looking for in an energy manager? Which responsibilities are required?

1. To understand and support facility’s energy efficiency and energy conservation goals and objectives,

2. To establish and maintain a comprehensive understanding of the energy requirements and characteristics of aquaculture systems and equipment,

3. To develop Standard Operational Procedures that address energy efficiency and conservation on a continuous basis,

4. To assist in development and implementation of operational improvement strategies,

5. To provide technical expertise for fuel and power requirements of proposed, existing, and replaced aquaculture systems and equipment,

6. To understand and advocate automated controls that improve energy efficiency and conservation,

7. To identify and implement mainte -

nance activities to assess and maintain best operational efficiency and,

8. To develop system and equipment operating energy profiles that are monitored to ascertain unusual energy usage.

Let’s work on creating such a profile for the aquaculture industry’s benefit and more efficient systems. Aquaculture is meant to be the most efficient and sustainable industry and the future of animal husbandry. Vamos! Let’s go!

This article is a combination of ideas, experiences and expert knowledge and I would like to specially and personally acknowledge their contribution to it to Rick Elyar, director of Business Development at The Haskell Company; Dan Farkas operating manager of different RAS units and founder of HTH Full Spectrum Aquaculture; Tyler Gibsonm, operational manager of Atlantic Sapphire seawater growout and Blue Ocean nursery, and owner/founder of Blue Thumbs Consulting; Lubomir Haidamaka, CEO of Vismar Aqua; and an anonymous source at a commercial RAS salmon facility.

Innovation Beyond Measure

It takes two

Philippine farm produces zero-salinitiy vannamei shrimp and tilapia in RAS.

By Ruby Gonzalez

Mark Johnson built a greenhouse for commercial lettuce production in the Philippines but ended up with biofloc operation producing freshwater zero-salinity vannamei shrimp, which he said is “a very unique project” in the country.

Most industry players told him the freshwater vannamei concept just wouldn’t float. They warned of low survival rate, high feed conversion ratio (FCR), soft shell, bad colour, and off taste.

Then, he got in touch with a shrimp expert from the other side of the world. Fabio Higa, who lives in Brazil, told him otherwise. He has been Johnson’s consultant since that day.

Johnson’s vision has always been tied to biofloc. “The thought of intensive culture in zero water exchange was a new concept not being practiced here in the Philippines. I wondered if I could make up the small profit margins with large biomass,” he said.

The leafy vegetable production was bumped off for aquafarming because of the salinity of the deep well water at the site.

He received suggestions to go for tilapia. There was a market but price was low. He started considering high-value species that could be cultured in his deep well water salinity at about 1.6 ppt. Vannamei shrimp was a potential.

Higa’s expert advice gave Johnson the final push. “He explained to me that it was very much possible to grow in freshwater. And not only could you grow in freshwater, you could do it in very intensive levels. It was possible to culture vannamei in any model from extensive to intensive and it just depended on your management and technical abilities.”

PHOTOS: M. JOHNSON

AM Ponds owner, Mark Johnson, right, with wife, Aveen, and team members of CPF, a feeds company. At the start of operations and with his vannamei production protocols unheard of, Johnson said it was only CPF, among all the feeds companies, that entertained his queries and provided his requirements

AM Ponds Inc. had been operating for a year when RAStech Magazine got in touch with Johnson in the first quarter of 2024. Named after Mark’s wife, Aveen, and himself, the 6.5-hectare farm in the province of Iloilo has a good location. It is near the national highway. A river, which is the freshwater source, is about 700 metres away. Their major market is only about an hour away.

Year 2024 projections for the lined ponds are nine tons and 30 tons per hectare for shrimp and tilapia, respectively. Three to five tons for shrimp at 35 to 40-gram sizes, and ten to 15 tons per hectare for tilapia are expected from the earthen ponds.

“The main crop will be tilapia. This species will match the typical monoculture production volume. The secondary crop, vannamei shrimp, will be at a lower stocking as we will not be feeding them,” he said. “The overall biomass will be over the typical monoculture stocking by about 30 percent.”

Tilapia-shrimp polyculture allows them to be competitive in the market. Tilapia production costs are high. It is priced low because it has to compete with wild-caught fish in the market.

“If you polyculture with shrimp, then the production costs can go down and it then makes sense,” he said.

The species tandem likewise makes sense from a growout perspective. “Tilapia are all-around filter feeders and one of the only fish to eat blue-green algae. They can coexist with shrimp, which are bottom-eaters. Tilapia eat microalgae. Biofloc can concentrate important proteins and lipids in their waste and makes for a good fishmeal

replacement for the vannamei.

“Tilapia will also eat any morbid shrimp and help control disease from shrimp cannibalism. Tilapia will also disturb the bottom with foraging and nest building. Keeping the bottom aerated and preventing anaerobic bacteria problems,” he said. This system is expected to create a cleaner water environment.

There are four lined ponds of about 1,500 cubic metres each, 4,000 sq. m. reservoirs and five earthen ponds spread out on 30,000 sq. m. Four concrete round tanks and one round PVC tank

are used for freshwater larvae acclimation.

Getting started in aquafarming placed Johnson, who at that time was a newly retired BPO executive, in a “massive learning curve.”

There was the critical task of producing salt water for the vannamei larvae acclimation tanks. As per Higa’s protocols in Brazil, artificial salts did the work. But local salts in the Philippines, Johnson eventually found out, are either not pure or have anti-caking additives that are toxic to larvae. This was eventually solved by harvesting water directly from the sea. In the nursery tanks, the water is brought to about 10 ppt to match the hatchery salinity level.

High aggression observed in vannamei larvae in the Philippines likewise presented a big problem. In acclimating larvae to freshwater in a very confined nursery tank, he had observed them going after each other straight from the hatchery bag.

Initial stocking is at 2,000 pieces per cubic metre. In the process of acclimation, minerals are lowered every day, making the situation even worse. Average survival rate is 50 to 60 per cent. The record is at around 85 per cent.

During acclimation, he thought that keeping the animal at its shortest possible time at decreasing density before transfer would be beneficial. Introducing live feeds would also address cannibalism.

“One major advantage of freshwater culture is we can culture freshwater zooplankton, fairy shrimp, and tubiflex worms to feed the larvae,” said Johnson.

Larvae acclimation issues had been

Freshwater zero-salinity” vannamei is still unique in the Philippines

turns totally green and followed by a sudden crash. In freshwater this may lead to shrimp mortality. Nitrite spikes bring bacterial infections and death, he explained, and they can only go to about 2.5 ppm on nitrite before major problems happen in freshwater.

“We work on this nitrogen issue with recirculation, aeration and probiotics. Transparency is measured daily and probiotics given on a daily basis. We try to keep the water to a nice brown/green. We believe that pure biofloc colour is too heavy on aeration costs and try to find a nice balance,” he said. “Over the last year, not understanding these dynamics has caused the loss of shrimp.”

Sludge accumulation is faster during summer, when cynabacteria bloom. In addition, shrimp respond well to heat and will consume causing even higher nutrient load. “Again, it comes back to aeration,” he said.

Being inland with only recirculated water creates nitrogen concerns. Nutrients and solids build up over time. Water

resolved by the second quarter of 2024 by transitioning over to 100 per cent live freshwater zooplankton for feeding larvae. “It has solved any past production problems during acclimation to freshwater of the larvae,” he said. No commercial feeds are given during larvae acclimation.

While they do biofloc, they also incorporate green water, which saves them money on electric bills. This model recirculates into a settlement pond and he vouched for its sustainability.

Consultant, Fabio Higa, right, examines the first-ever vannamei stocking of AM Ponds with owner, Mark JohnsonCaption: Consultant, Fabio Higa, right, examines the first-ever vannamei stocking of AM Ponds with owner, Mark Johnson

“There is no discharge of high nitrogen water into the environment. Even in biofloc, they got to discharge sludge waste somewhere. The current system in the Philippines is to take either river water or seawater and do massive water exchanges. They will bleach and kill off all life,” said Johnson.

“The cool part of our model is you can expand it into a green water system and live food production ponds. To create a more natural system. You just create additional recirculation ponds dedicated to

these processes,” he added.

Beyond 2024, Johnson is looking at allocating 4,000 sq. m. of the farm for green water and live feed ponds. Biofloc water and sludge will be pumped into shallow ponds with no fish or animal.

“This will make green water and the natural zooplankton thrive along with microalgae,” he said. “This would be a batch process lasting for a period of three days, when we wait for the water to go green and seed zooplankton into the pond. Monia naturally thrive here in the tropics.

LONG-LASTING AQUACULTURE PUMPS

This water would be pumped back into the grow-out ponds to feed the tilapia and shrimp, giving natural feed to the animals. Priority would be given to the ponds with the youngest fry and larvae.”

Once the farm is completely under control, Johnsons said he is keen to start a vannamei shrimp hatchery.

“This hatchery would be unique as I would promote freshwater acclimated post-larvae. I believe that freshwater culture is the future and sustainable,” he said.

Stocking one of the ponds at AM Ponds

Waste not

Converting RAS fish waste to fertilizer, biocoal, and other profit opportunities.

By Nestor Arellano

Fish sludge, the very name easily conjures images of the mess it creates. Made up of fish feces and undigested excess feed, this aquaculture waste product is a top headache for recirculating aquaculture system (RAS) operators.

Sludge is an ideal breeding ground for disease causing bacteria and it clogs up systems. Getting rid of it is expensive, and the more biomass you produce, the more fish sludge you get.

In this article, we investigate the contrasting waste conversion strategies adopted by two dissimilar companies that embraced fish waste recycling in different phases of their company’s growth.

From problem to profit

The agriculture industry has already developed advanced methods of converting animal waste however, the RAS industry is catching up, according to Abhinav Choudhury, PhD; Environmental Research Engineer; The Conservation Fund Freshwater Institute.

“Mature waste conversion technologies and business models already exist for terrestrial animal farms,” says Choudhury.

The Conservation Fund Freshwater Institute specializes in conducting research on sustainable development of the US aquaculture industry. Choud-

hury’s work focuses on a waste-tovalue program and his team is currently researching the potential of creating value from aquaculture waste for a RAS farmer.

The growing interest in the RAS around this area is driven by three key factors, according to Choudhury:

1. The potential for increased revenue or economic returns through the utilization of the organic matter and nutrients in the waste stream to offset high capital expenditure and operational expenditure of RAS farms.

2. Reduction in the environmental impacts caused by discharged wastewater into lakes other bodies of water or landfill.

3. Increased scrutiny of the public and strict government regulations to protect the local watershed.

Early converts

Todd Deligan, the general manager of the North American arm of Norway’s Salmon Evolution, would be happy if the industry could move away from

calling fish sludge, fish sludge or fish waste. Its decades-old moniker just doesn’t suit the potential that fish sludge has, according to Deligan.

“The industry really has to come up with a better name for this product that holds a lot of economical and ecological potential,” says Deligan.

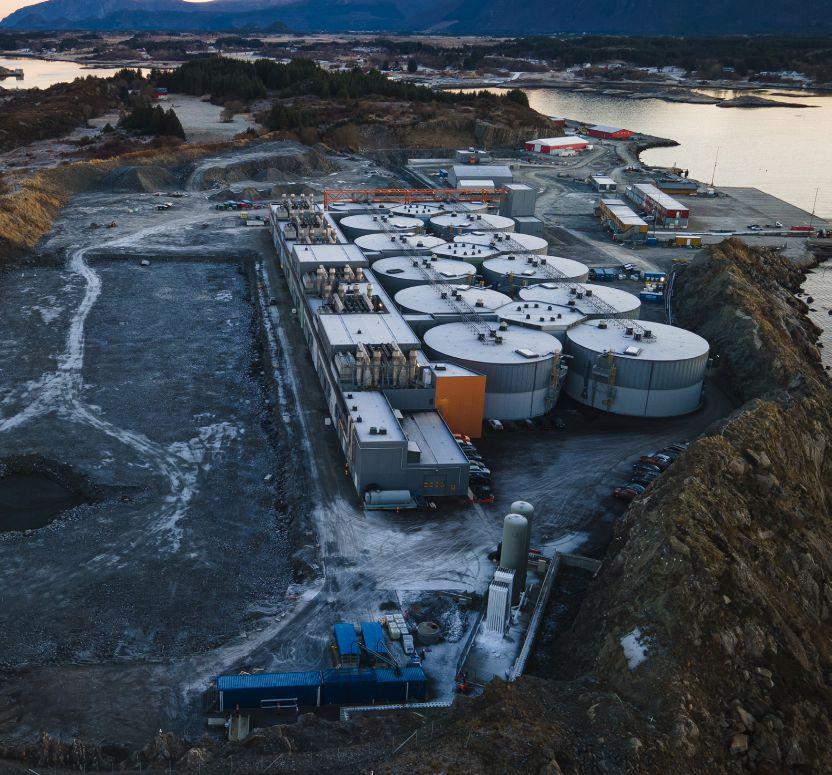

Salmon Evolution operates one of Europe’s largest land-based fish farms at Indre Harøy in the west coast of Norway. The hybrid flowthrough/RAS facility was designed for a total annual production capacity of 31,500 tonnes head-on gutted salmon.

Sustainability is a key component of company’s construction and production strategy from the get-go. For instance, Indre Harøy in fully powered by renewable electricity from a nearby hydropower plant.

“Environmental sustainability was always part of the conversation,” says Deligan. “The concept of treating effluent and being able to recycle solid waste was part of the company strategy since Day One.”

In 2021, Salmon Evolution signed a

RAS companies are looking at the potential of fish sludge as a “second harvest” for profit.

contract with Blue Ocean Technology, to provide the RAS company with a complete treatment package for washing, disinfecting, dewatering and drying sludge.

Blue Ocean Technology develops systems that users can program to convert sludge for various uses such as biocoal, fertilizer, biogas, or compost.

Salmon Evolution does not use the product directly.

“Today, we are having to pay to take the solids away to a biogas plant,” explains Deligan. “Our core business is sustainably producing high-quality salmon. For us, waste conversion is not a revenue stream. This is a cost we are willing to pay. We want to support a circular economy.”

“Treating wastewater and reusing fish sludge to produce for example biogas and

short-travelled fertiliser are among our contributions to a circular economy,” states the company’s 2022 annual report.

“As part of Salmon Evolution commitment to a truly sustainable production and circular economy, waste is filtered and collected, before being transported to a recirculation plant where it is converted into fertilizer, biogas or similar.”

This strategy will be part of Salmon Evolution’s business model for its unfolding North American expansion, according Deligan.

Home and garden approach

Great Falls Aquaculture, in Turner Falls, Mass., is one the biggest RAS grower of barramundi in the U.S.

Keith Wilda and business partner James Malandrinos own Great Falls. The two men

also own Blue Stream Aquaculture-New Hampshire which produces trout, and Blue Stream Aquaculture-Cape Cod, a trout hatchery in West Barnstable, Massachusetts.

All three companies do not only sell fish, they also produce and market a whole line of organic soil supplements and fertilizers for lawns, gardens, farms, and orchards. Source from various mixtures of nutrient-rich RAS sludge, fish scraps and organic ingredients, the products are sold under the brand Fish Brew. Fish Brew branded t-shirts and baseball caps are even available from the website for fans.

Great Falls Aquaculture was bought by its current owners in 2018, and Fish Brew became part of the business just around 2021. However, using waste to help plants grow was something facility workers had been

Recycling the solid waste at Salmon Evolution’s Indre Harøy facility has been part of the company’s strategy from Day One, said Todd Deligan.

doing even before then, according to Spencer Gowan, general manager at Great Falls since 2018. Gowan also worked as a production manager from 2015 to 2019, when Australis Aquaculture was still the owner of Great Falls Aquaculture.

“You would always hear stories of employees collecting sludge, solid waste or fish scraps and using it in their home gardens,” said Gowan. “They would often come back to share their massive squashes, tomatoes and other New England veggies.”

Gowan attributes the start of the eventual development of what would be known as Fish Brew to Walker Wright-Moore, current nursery manager at Great Falls Aquaculture.

Wright-Moore was working as a fish culture specialist for Australis Aquaculture when he began developing a fish hydrolysate, a product for promoting plant growth.

“He was building a garden bed, and he began researching regenerative gardening,” recounts Gowan. “Then he started asking people about their use of fish scraps and fish waste as fertilizer.”

Regenerative gardening is an ecosystem-based approach to gardening. It seeks to improve plant resilience and growth through by improving soil health and water quality, improving biodiversity, and reducing synthetic inputs.

Wright-Moore began developing a fish

hydrolysate, by putting dried-up fish scraps into a meat grinder and adding other ingredients such as rice wash, probiotic and sugar.

“He came us with a product that had good NPK value,” says Gowan.

NPK stands for nitrogen, phosphorous, and potassium – the three macro nutrients used by plants. NPK numbers indicate the percentage of these three elements in a fertilizer. The higher number of a one of these elements indicate a greater concentration of this element in the fertilizer. Different plants and soils require different NPK combinations.

“Wright-Moore approached Australis with his product, but they didn’t have time for it. They just allowed him to collect more scraps,” says Gowan. “It was only when Great Falls Aquaculture came under new ownership that Wright-Moore got the help to further develop the product, determine the proper enzymes to use and streamline production.”

“We are also found out that each of our farms produced different nutrients, algae, beneficial fungi and bacteria,” Gowan adds. “If we alter the mixture, we can produce different products that provide different benefits.”

Today, the Great Falls Aquaculture sells Fish Brew Hydrolysate along with Fish Brew Epic FLO probiotic for hydroponic growth; Fish Brew Pro FLO probiotic, and Rise and

Thrive, soil conditioner.

Currently, Great Falls Aquaculture wastewater goes through a water treatment and solids treatment system. A series of drum filters to separate solid waste from the water. The solid waste from all three fish farms is combined. Part goes to the municipal treatment plant and some are added into the Fish Brew products.

Great Falls Aquaculture will soon purchase a screw press to compact this nutrient-rich solid waste into cakes which it intends to sell for farm use or for creating compost.

The company also plans to install an anaerobic digester to convert sludge into bioenergy.

The next step

Anaerobic digestion is used to generate bioenergy for terrestrial farms, a liquid fertilizer to meet nutrient requirements for crops, and a solid product that is either composted and sold, or used on-site as bedding for the animals, says Choudhury.

Anaerobic digestion involves a series of biochemical processes where microorganisms break down sludge, without the use of oxygen.

“I have not seen a whole lot of technologies like anaerobic digestion deployed commercially for converting aquaculture waste into valuable products,” he adds. “Simple waste treatment solutions like mechanical filtering,

Dr. Abhinav Choudhury examining samples of MBR at the Freshwater Institute’s research facility.

gravitational thickening or addition of coagulants for solid separation, and sludge drying are more common.”

These solutions are effective at reducing sludge volume, but they rarely utilize the organic matter and nutrients in the waste to generate additional value for a RAS farmer, says Choudhury.

“Understanding the knowledge gaps to adapt these technologies to aquaculture waste is the first step, according to the scientist. The next step would be to develop innovative fresh solutions specific to aquaculture waste so farmers can have a plethora of options to choose from to meet the specific requirements of their farms,” says Choudhury.

Word to the wise

Waste conversion is still in its pilot stages in the RAS industry.

Companies interested in checking it out could benefit from this advise from Choudhury:

Plan – Waste conversion/management should not be an afterthought. Creating a sellable product from the waste may help offset operating costs. When planning the project, hire or consult waste experts in

addition to fish experts.

Permitting pain points – RAS is a recent technology and regulators in many jurisdictions may still be investigating how to classify waste streams from RAS farms. Make sure you begin discussions with local natural resources protection departments in your area of operation. They can help you identify the applicable waste management practices for your facility and the accompanying required

permits.

Loans and grants – Investigate sources of government loans, grants, and other support for waste conversion technologies and programs.

Track trade-offs – Different waste conversion strategies come with their own associated trade-off. A simple waste treatment solution may look attractive initially but could result in higher expenses (stricter regulations, increased cost of transportation, higher landfill costs, etc.). Conversely, a complex waste conversion technology could be challenging to operate, and a competent operator may be necessary to ensure its longterm successful operation.

Data sharing – Sharing experiences and challenges with both waste and fish researchers or experts can also lead to the development of farm-specific solutions.

Choudhury, Gowan and Deligan agree on one thing: Never ignore waste.

Regulations around aquaculture waste are becoming more stringent. RAS farmers need to be proactive in their waste management efforts. The industry should start seeing waste as an opportunity rather than a problem.

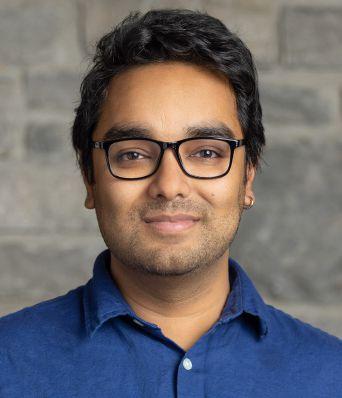

Abhinav Choudhury

Using AI to detect fish mortalities in RAS

Introducing Freshwater Institute’s new MortCAM AI technology. By Kata Sharrer and Rakesh Ranjan, Freshwater Institute

When raising fish for food, as broodstock, or for conservation purposes, a farm’s biomass or stock is highly valuable. Any sudden increase in mortality can be devastating. Unforeseen losses can significantly impact fish populations and production outcomes, whether occurring during early rearing stages or when fish are ready for harvest. Mortality patterns can serve as early warning signs of fish health and welfare issues or operational failures within aquaculture systems. Failure to recognize these signs promptly can lead to mass mortality events. Therefore, integrating tools for continuous mortality monitoring

and alerting operators to unusual or sudden changes is essential for identifying root causes and taking action to prevent escalation.

Well-designed recirculating aquaculture systems (RAS) are engineered to provide optimum rearing conditions for the cultured species. Environmental stressors are minimized by removing solids and CO2, converting ammonia to nitrate, adding oxygen, and maintaining consistent pH for water reuse. However, higher rearing densities associated with RAS production can exacerbate conditions for biotic and abiotic stresses on the fish. As the scale of RAS operations increases, mortality incidents in larger tanks can result in greater losses.

Mortality in RAS is typically monitored through human observation or, in some

cases, with the help of monitoring equipment such as an underwater camera. These two common methods are usually limited to when workers are on site, and even then, only intermittently, when attention is on this task. Compounding the issue are the unique characteristics of each farm, which may include deep tanks, low lighting, or cloudy water, making observation challenging. Therefore, continuous monitoring of mortality trends is crucial for effective risk mitigation.

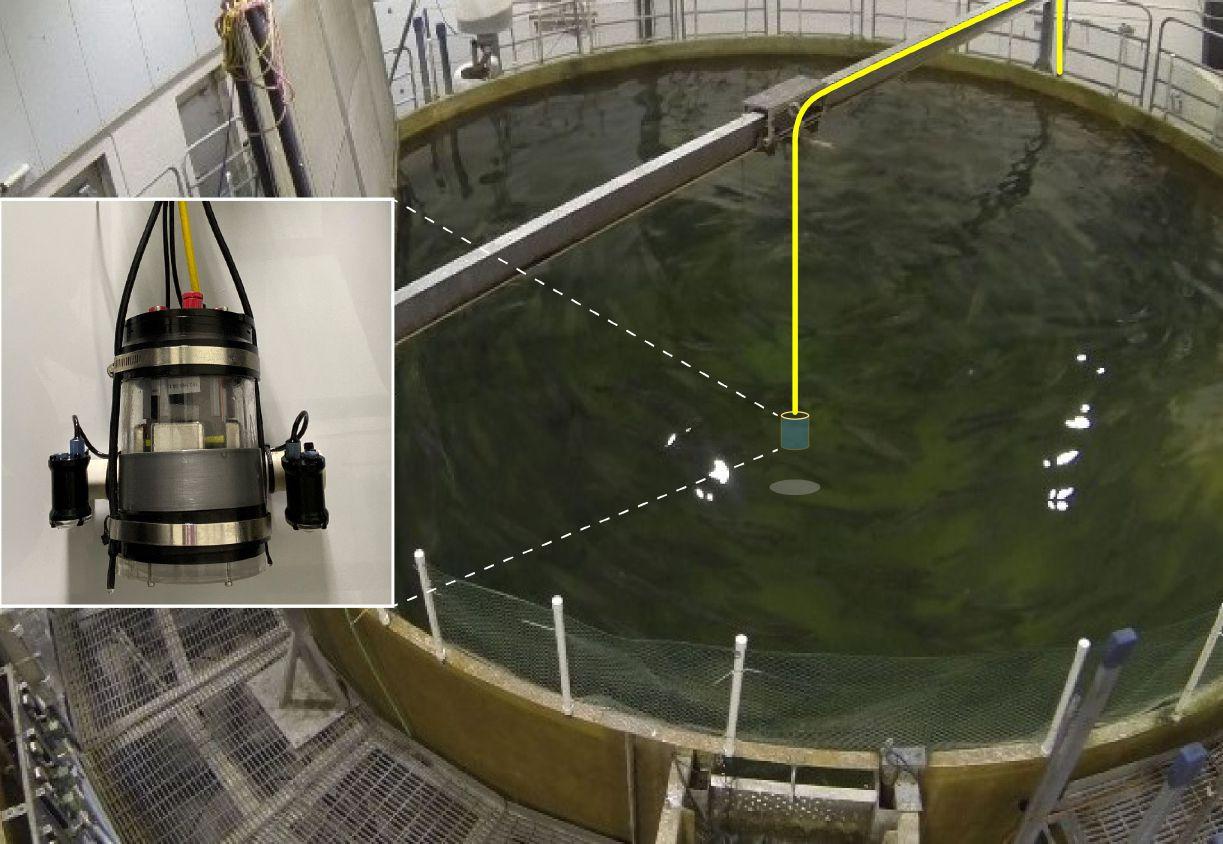

With these challenges in mind, the Precision Aquaculture team at the Conservation Fund’s Freshwater Institute (TCFFI) developed and evaluated MortCam AI, a mortality monitoring tool that utilizes Artificial Intelligence (AI) to provide near real-time mortality tracking. Using the Internet of Things (IoT), the

The MortCAM is positioned above the drain plate in the Freshwater Institute’s growout tank.

device generates email and text alerts with counts and photo evidence to inform the farm manager and staff of unusual mortality trends.

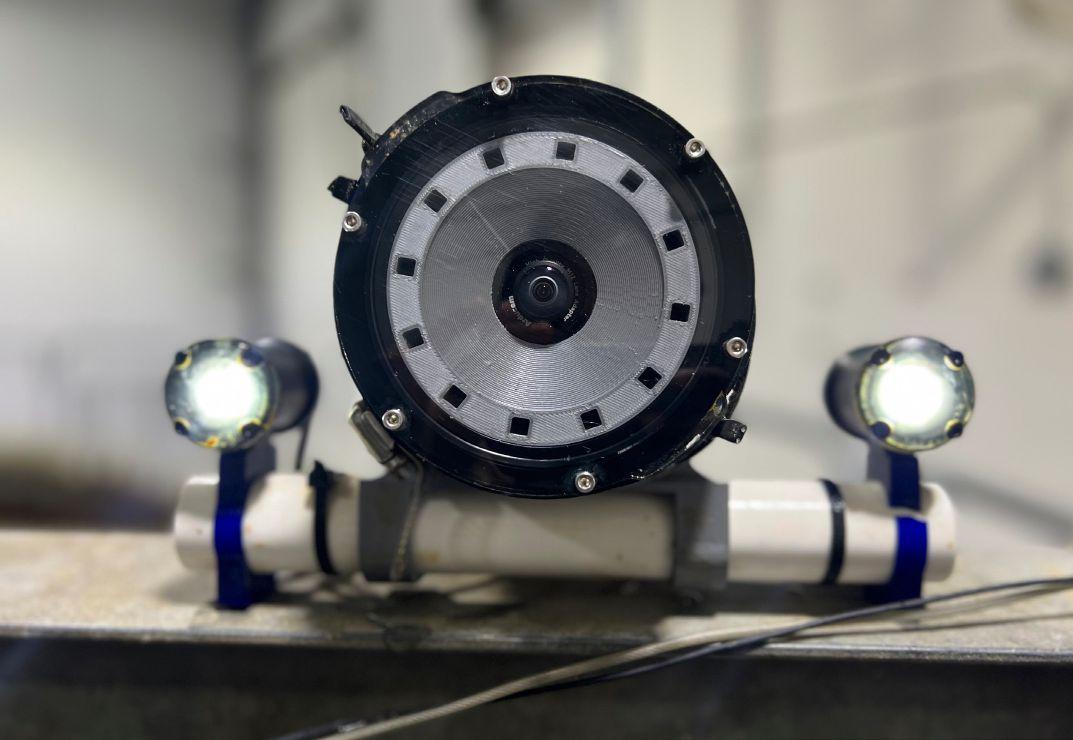

MORTCAM AI

MortCam AI was developed using off-theshelf components, including a Raspberry Pi 4 single-board computer, RGB camera, underwater enclosure, and power-overEthernet (PoE) HAT board. MortCAM development occurred over two phases: 1) image collection and model training and

2) evaluation of the deployed model and notification system. The device was deployed 0.6 m above the bottom drain in TCFFI’s 150m3 semi-commercial scale RAS growout tank, operating with a flow rate of 4,169 liters per minute. During image collection, the tank was stocked with approximately 5,000 Atlantic salmon (Salmo salar) with an average fish weight of 1.63 kg, and a tank density of 50 kg/m3.

MORTALITY MODEL

To develop a robust mortality detection

model, training data was collected in two tank light conditions: ambient roof lighting and LED-supplemented lighting. MortCam was programmed to capture training images at 15-minute intervals for each light condition over a three-month period. The acquired images were sorted and uploaded to an online AI model training platform for annotation, model training, and visualization. During annotation, each image was manually assessed for the object classes of interest: 1) alive and 2) dead fish in the frame. Bounding boxes

The MortCAM AI was developed to provide robust mortality detection data and identify trends.

were used to select and classify each visible fish instance in the image. One thousand images were used to train the mortality model, and performance was analyzed in terms of mean average precision (mAP) and F1 score, two widely adopted performance metrics.

MODEL PERFORMANCE

The mortality model trained with images captured in ambient light conditions performed best among the models, achieving the highest mAP of 95.5% and an F1-score of 0.92. The performance of the model trained for supplemental light conditions achieved a mAP of 88.7% and an F1-score of 0.86. The glare produced by LED lights on the bottom train plate likely contributed to the degraded model performance in supplemental light conditions. Interestingly, when the performance of the mortality model trained for a certain light condition (e.g., ambient light) was tested in another (e.g., supplemental light) and vice versa, the perform-

ance of models declined considerably. This finding suggested that the model wasn’t robust for varying imaging conditions typical in real-world scenarios and may benefit from diversifying the input training data. Therefore, a mixed mortality model was trained by including images from both ambient and supplemental light conditions, and model performance was tested to further explore this idea. As expected, the mixed model was more versatile and better able to accurately predict the classes in varied conditions, achieving a mAP and F1 score of 93.4% and 0.89, respectively.

MORTCAM ALERT SYSTEM

MortCam AI offers customizable alert settings, allowing users to specify the mortality threshold for triggering email and text notifications. In the validation phase, MortCam was configured to send alerts to authorized users once the threshold of three mortalities was reached. Email and text alerts pinpointed

the tank reported with abnormal mortality and provided the mortality count along with the date and time. The alert generated by MortCam attached photo evidence in the email to verify the death count. Any unusual mortality event alerts generated by MortCam can be used to take immediate corrective action to avoid mass mortality events. MortCam also logs daily and cumulative mortality. This enables farm managers to create mortality metrics and benchmarks, which they can use to recognize unusual patterns and identify root causes of fish mortality.

WHAT’S NEXT?

The developed mortality monitoring system is a Research prototype. Our aim is to eventually commercialize this technology for use by RAS farmers. The mortality model is trained to detect Atlantic salmon mortality within a specific RAS configuration. Generalizing the mortality model to encompass various fish species and RAS configurations

Example training images of drain plate in ambient light conditions

MortCam will generate email and SMS alerts to notify the operator of high mortality.

would enhance the system’s commercial adaptability. We are extending discussions with our industry partners to explore the commercialization potential and market feasibility of MortCam AI. We believe that the sooner this technology can be used across our industry, the more reliable our production systems become.

For in-depth details on this research, you can refer to the open-access journal article, accessible here.

Land-based aquaculture making ‘strides towards maturity’: Spheric Research

By Matt Jones

Spheric Research, in conjunction with Undercurrent News, released its 2024 Land-Based Aquaculture Report (LBAR). The report outlines key impacts on the proliferation and success of land-based aquaculture systems.

The report posits that RAS aquaculture has been subject to the Gartner Hype Cycle. Identified by research firm Gartner, the cycle follows as the emergence of a new technology leads to a peak of inflated expectations, when the new technology promises to revolutionize their industry. Often, though, that hype doesn’t become reality and the second generation of projects using that technology must suffer through the disillusionment that followed the first generation. Eventually, however, a more balanced understanding of the benefits of the technology emerges and it can be better appreciated without the hype.

In this case, the report specifically cites Atlantic Sapphire’s Bluehouse in Miami, Fla. as a cause of disillusionment. With the belief that the company had discovered the secret to successfully producing salmon in RAS as a commercial enterprise, the project led to a goldrush-like fever among investors and a brief US$1 billion evaluation for Atlantic Sapphire on the Oslo Stock Exchange. As the project began to experience setbacks in 2021, however, the “trough of disillusionment” began to impact the sector.

As a result, investors were less inclined to continue providing capital for many of the first generation of RAS projects. The report

cites notable examples from 2024 such as AquaBounty halting construction of a 10,000 tpy (throughput yield) facility in Ohio and Washington’s Sustainable Blue going into receivership.

On the other hand, while large-scale RAS projects appeared to experience setbacks, hybrid RAS solutions – those that incorporate both recirculating and flowthrough technology – have shown promise. Norway’s Salmon Evolution is cited as a success which led to increased investor focus on hybrid RAS farms in Norway and Iceland. Because of those successes and others, the report notes there will be more emphasis on hybrid approaches and less on traditional RAS.

The successes of that hybrid model (and second-generation traditional RAS approaches that have learned from the experiences of the first generation) appear to be contributing to the ‘slope of enlightenment’ phase of the Garner Hype Cycle. The report notes that second-generation RAS and hybrid approaches have rekindled hopes that using RAS to raise adult salmon on land can be proven as a business model, quoting comments by Anne Hvistendahl, head of seafood for Norway’s DNB bank.

“This is an interesting year,” Hvistendahl is quoted as saying at the Aquasur conference in Chile. “We will see proof of concept for recirculation but also the full flow-through. If you get proof of concept, we think there will be much more of this. Flow-through seems to be the most successful, but let’s see where this will take us.”

With trout becoming a larger portion of the RAS sector, the 2024 LBAR has listed trout as a separate category for the first time. Ten operating trout RAS companies were identified and Finland’s Finnforel expanded their capacity to over 3,000 tpy. The Hima Seafood project in Norway was also cited as an influence. Four arctic char RAS projects were cited as well, including Sapphire Springs in Canada.

Trout RAS is becoming a larger portion of the sector, the report says.

These growing sectors of the RAS market have Spheric asking whether the industry should have started these efforts with a species other than salmon.

“The appearance of some success stories in growing other salmonid species raises the counterfactual question of whether recirculating aquaculture should have initially focused on trout and Arctic char before tackling the daunting challenge of growing a delicate species like Atlantic salmon,” states the report. “Trout takes less than 18 months from egg to harvest, compared to more than two years for Atlantic salmon. Even coastal salmon farmers are struggling to boost salar output with mortality rates at some net pen operations approaching 20 per cent.”

Looking beyond salmonid species, the report also highlights increasing efforts in growing species such as yellowtail. While most North Americans will only know Nordic Aquafarms for their well-publicized legal issues in Maine, the company has quietly moved forward with establishing a 3,000 tpy yellowtail farm in California. Indoor shrimp farming, while still not yet proven at commercial scale, is also seeing a proliferation,

with the report recognizing 26 indoor farms operating around the world, with 13 more proposed farms at various stages of progress.

On the topic of RAS smolt and growouts, the report notes that in 2023, salmon farming companies “added more biomass capacity by way of RAS smolt facilities than the sum of the RAS capacity currently dedicated to

growing harvest weight salmon.” While this has been a growth area for the industry, some Norwegian companies have scaled back such projects due to a 2023 resource tax.

Overall, the report states that the landbased aquaculture industry is still in its relative early days, but the industry is making significant strides towards maturity.

HOSTED BY Ian Roberts, Director of Communications at MOWI Canada, Scotland, Ireland

Success of Salmon Evolution’s hybrid model has lef to increased interest in other hybrid RAS projects.

Fuel Tech Inc. and Royal Caridea unveil results of gas infusion system trials

Shrimp farm technology company, Royal Caridea LLC, worked with engineering technology company, Fuel Tech Inc., on a trial to determine the effects of growing Pacific whiteleg shrimp (Litopenaeus vannamei) in a raceway system using its patented gas infusion system.

“The research shows that high post-larval shrimp stocking, combined with reliable dissolved oxygen (DO) dosing with DGI, can dramatically increase total production compared with traditional aeration methods,” the company’s press release states.

The comparative trial occurred in back-to-back growth cycles on a raceway with high species stocking and low-salinity water at Royal Caridea’s aquaculture farm in Arizona, U.S.A. Trademarked DGI®Dissolved Gas Infusion, Fuel Tech said the technology enables higher stock densities.

“Demand for shrimp is increasing globally and shrimp farming is an important source to help meet the growing demand and reduce overfishing of the marine environment,” said Bill Decker, vice-president of water and wastewater treatment technologies at Fuel Tech.

In the first growth cycle, traditional bubble aeration using the venturi principle was used until the oxygen demand of the water could

no longer be met. This required that the shrimp be partially harvested to ensure acceptable DO concentrations were maintained for those remaining.

In the second growth cycle, Fuel Tech’s innovative DGI™ technology provided DO concentrations at 150 per cent of atmospheric saturation. This allowed for more shrimp to reach maturity within the raceway, along with likely health improvements for the shrimp.

Each shrimp achieved a mean weight of 42 grams in about 100 days. The growth curves for individual shrimps showed no significant change from the trial when selective early harvesting was necessary to manage the high biomass loading.

Fuel Tech reported that the DGI trial showed no evidence of trimethylamine odour, oxidation, speedy metabolism, osmotic shock, or gas bubble disease.

This suggests that maintaining DO levels above saturation in low-salinity water, without bubbles, increases the yield while minimizing any detrimental effects of high oxygen levels.

Royal Caridea shrimp farm warehouse interior

Nuvonic’s UV technology receives NVI approval

Nuvonic, a global UV technology solutions provider has received approval from the Norwegian Veterinary Institute (NVI), a biomedical research institute specializing in biosecurity.

The NVI has a mission to give research-based advisory and knowledge support to Norwegian Authorities in addition to supporting innovation and development of sustainable bioeconomic production and has approved Nuvonic’s range of USEPA-validated Proline PQ IL (Inline) units.

Nuvonic said after it underwent rigorous testing and provided comprehensive validation results, technical data, and capacity tables to meet strict aquaculture biosecurity standards, these units now fall under the ‘RASline’ banner.

The company has six RASline models designed for efficient water treatment.

Using medium-pressure UVC lamps, the UV systems are compact and energy-efficient. They can be customized to target specific microorganisms and precise dosages.

Danny van Kuringen, regional sales manager - Central Europe, Nuvonic, said, “We’re honoured to receive endorsement from the Norwegian Veterinary Institute. Nuvonic’s NVI-approved UV systems empower aquaculture businesses by providing USEPA-validated UV equipment to prevent fish diseases. This means our systems offer precise UV treatment control, enhanced effectiveness thanks to multi-wavelength lamp tech, space-saving designs, energy efficiency, and efficient management of high water flows. It translates to healthier aquatic life, sustainable processes and a more successful aquacultural venture.”

PHOTO:

Nuvonic’s UV water treatment system

Ace Aquatec appoints new sales and service manager in Chile

Ace Aquatec has appointed Constanza Fontaine as sales and service manager in Chile.

Fontaine joins Ace Aquatec with 12 years of experience in aquaculture solutions’ commercial and technical aspects. She previously worked at ScaleAQ as a service and aftersales manager in Chile, head of commercial at Badinotti, and head of services and operations at Akva Group Chile.

Fontaine said she plans to develop and expand Ace Aquatec’s presence in Chile.

“Aquaculture is a vital industry in Chile, and I am ex-

cited to further build on and expand Ace Aquatec’s profile here. This role offers a rare opportunity to combine my expertise with Ace Aquatec’s innovative product portfolio, and commitment to creating a more sustainable, ethical future for fish farming. I’m looking forward to helping the company and its technology break new ground in this region,” she said.

Fontaine added that her primary responsibility will be to advance Ace Aquatec’s technology products in Central and South America.

“Constanza brings a wealth

of experience to Ace Aquatec, including crucial connections and local knowledge, which will help us to further our mission of revolutionizing aquaculture technology in Central and South America. We’re thrilled to welcome

her to the team at an exciting point in time, both for us as a company and the sector more widely,” said Tara McGregor-Woodhams, chief sales and marketing officer at Ace Aquatec.

Smarter, stronger, more economical drum filters

The Hydrotech Drum Filter Value series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost.

Constanza Fontain new sales and service manager, Chile

By Curtis Crouse

Three rules of successful depuration

Depuration is the most common method to remediate accumulated off-flavour compounds, like geosmin and 2-methylisoborneal (MIB), in the edible portions of RAS-produced fish.

Depuration involves holding fasted harvest-size fish in partial reuse or flowthrough systems flushed with water containing low concentrations of off-flavour compounds. While effective, depuration requires large volumes of water and can lead to fish weight loss. Research from the Freshwater Institute has characterized the results of some alternative management approaches that operators could consider fine-tuning their depuration processes.

Water use

Reduced water use is one key characteristic of RAS production that provides advantages for strategic site selection, waste capture, and targeted sustainability metrics. Allocating a relatively high volume of water exclusively for depuration may not be practical or even possible at some RAS facilities.

One way to reduce the total water volume needed at a site would be to reuse the discharged water from the depuration system as makeup water for the rest of the facility. The water quality of depuration discharge from a partial reuse system stocked with Atlantic salmon was recently characterized (Davidson et al. 2022).

Water samples collected every six hours of a seven-day depuration cycle revealed initial spikes in suspended solids, phosphorus, and ammonia. By Day Two, concentrations of solids and phosphorus were near their lowest measured levels, 87 per cent and 92 per cent lower than the peak measurements during the spike, respectively. However, ammonia decreased only 58 per cent from the peak due to continued catabolic processes of the fish while fasting.

The results suggest that reused depuration water should be introduced before mechanical and biological filtration of the RAS. Further, fasting fish before a move to depuration systems for at least two to three days could reduce the solids and phosphorus spike in the depuration discharge.

Cleaning

Research and semi-commercial scale RAS at FI are routinely brushed to remove biofilms and settled solids from tank and sump walls.

A case study at FI measured geosmin and MIB concentrations in the water of two RAS before and after a 10-minute culture tank brushing. Off-flavour compounds spiked during the first hour after brushing and returned to near or below initial concentrations within 24 hours (Figure 1).

Several FI studies have demonstrated that off-flavour compound concentration in salmon flesh can be experimentally increased by introducing concentrated levels of the compounds to the water for as little as three hours (Davidson et al. 2022).

Because even a short-duration exposure to increased off-flavour concentrations can lead to increased concentrations in fish flesh, operators may need to be strategic about the timing of RAS cleaning. For example, avoid scheduling routine brushing in the days immediately before depuration but close enough to harvest to minimize accumulating biofilms that could be disturbed by equipment, such as a crowder, that contacts the culture tank walls. Either of these scenarios could lead to an unintended spike in off-flavour compounds and fish with higher initial concentrations that require a longer depuration.

Feeding in depuration

In a typical depuration process, feed is withheld from the fish to allow them to

completely purge the gut, maintain high water quality, and prevent excreted waste from feeding bacterial growth in the depuration system. However, fasting leads to weight loss which can have dramatic impacts on the overall revenue of a RAS facility selling whole, uncut fish to processors.

In a FI research trial (Davidson et al., 2023), salmon were fed a low-level ration for the first four days of depuration followed by fasting for the final two for gut purging. Delivering feed to recently handled market-size Atlantic salmon in a relatively shallow depuration tank proved difficult as evidenced by wasted feed observations. However, the fed fish lost only 0.3 per cent of their initial body weight compared to 1.1 per cent in salmon fasted for the entire six-day cycle.

Feeding fish during depuration did not negatively impact off-flavour depuration and could be a way to prevent weight loss in this final step before harvest. In instances where depuration time greater than six days is required, it should be verified that feeding won’t promote early bacterial colonization or increased off-flavour production.

Further, feeding during depuration could produce a different discharge water quality profile than earlier discussed and it should be considered before reuse as make-up water for the RAS facility.

References

Davidson, J., Schrader, K., May, T., Knight, A., Harries, M. (2023) Evaluating the feasibility of feeding RAS-produced Atlantic salmon (Salmo salar) during the depuration process: effects on fish weight loss and off-flavor remediation. Journal of Applied Aquaculture.

Davidson, J., Redman, N., Crouse, C., Vinci, B. (2022) Water quality, waste production, and off-flavor characterization in a depuration system stocked with market-size Atlantic salmon salmo salar. Journal of the World Aquaculture Society.

A New Dimension of Optimization

Linde can help make the most of your aquaculture process. Our SOLVOX® oxygenation systems work in both saltwater and freshwater to create a healthier environment for growing fish. Our low-maintenance pure oxygen delivery systems provide better efficiency, utilization, and hydrodynamic conditions than traditional air-based systems. Linde experts can develop a system customized to your needs.

Enter a new realm of oxygenation performance. Learn more at lindeus.com/aquaculture

Making our world more productive