Aquaculture Products and Solutions

Grow More Fish with Grundfos

A global leader in centrifugal pumping technology with a strong local presence in the United States, Grundfos offers a full line of reliable pumping systems designed to optimize your water transfer and treatment operations. Grundfos technology is widely known within the aquaculture market based on more than 20 years of global experience.

Whether your application is seawater, freshwater, water reuse, wash and clean, or temperature control operations, we have a wide selection of pumps and solutions to drive sustainability and efficiency to meet your needs.

COLUMNS

12

Think

JONES

From the editor

By Jean Ko Din

More to come

Ican’t decide whether it’s a good thing or a bad thing that we have so many aquaculture conferences and events in a calendar year. As I’m writing this editorial, I feel like I’ve just come back from RASTECH 2023 in Orlando, Fla., USA.

Of course I am biased, but I think that in-person conferences have an important role to play in driving progress within the industry. It seems to me that because the recirculating aquaculture business is so complex, it is easy to silo yourself and be completely consumed in your own project that you can forget to bring back that hardearned knowledge to the larger community. It is important to bring professionals back together in the same room, not just to network and and make deals, but also to learn from each other’s experiences. Collaboration breeds progress.

To those outside of this tight-knit industry, progress seems slow moving. We are still talking about the same problems in construction and scale that we have been talking about since before we could cry “Covid pandemic.” We are still waiting for that one rags-to-riches story that is meant to open the investor floodgates. We are still trying to establish a profitable path that will also solve all our problems with sustainability.

But I share Maddi Badiola’s sentiment in this issue’s Power Struggle column in that the industry has to fundamentally change its approach to growth.

While most of our attention has been towards massive growout projects that are popping up all over the world, our cover story explores why smolt and post-smolt RAS have become one of fastest growing

sectors. The open net pen industry is steadily adopting more land-based aquaculture technology into their value chain. It can provide more optimized growth performance and future-proofing for the mounting challenges of climate change. Maybe this sector can be leveraged as a stepping stone to the rest of the RAS industry’s larger ambitions for full scale.

In another story, we get an inside look at the work a Belgium-based research centre is doing to create a truly circular food production system. If Inagro’s model can be commercialized at scale, it could transform the food economy as whole. With rising inflation costs, it’s worth tuning in to innovative ideas like these that could bring more food closer to home.

While the outside world grows impatient about this industry’s progress, it cannot discourage us from putting our heads together to bring more ideas to the table. With diligence and thoughtful execution, the possibilities of tomorrow’s industry will come sooner than we think. Progress is boring when you’re in the midst of the work but we cannot also lose sight of the crucial process.

The horizon may seem elusive but I think there is a general agreement that it still remains bright.

Despite regulatory obstacles, economic slowdowns, skill shortages, or whatever else may get in the way of RAS’s success, I’ve learned that the industry remains persistent in its belief that the work is still worth pursuing. And perhaps, the role of this industry publication is to continue to reflect it back. I look forward to hearing from you at jkodin@annexbusinessmedia.com.

RASTECH EDITORIAL ADVISORY BOARD:

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Audience Development Manager Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Editor Maryam Farag 437-788-8830 mfarag@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Manager Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager

Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

COO

Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Made possible with the support of

Dharma Rajeswaran I Megan Sorby I Tom Sorby I Jamie Stein I Siri Tømmerås I Yonathan Zohar

SMARTFLOW

HIGH LEVEL EFFICIENCY & ACCURACY

SmartFlow connects all Vaki Smart Pumps, Graders and Counters for full overview and control of the fish handling system.

Nordic Aquafarms switch to yellowtail in Humboldt Bay

Nordic Aquafarms is switching to raising yellowtail kingfish instead of salmon at its land-based facility in Samoa Peninsula at Humboldt Bay, Calif., USA.

The proposed recirculating aquaculture system (RAS) facility was first announced in 2019 with the intention to convert a former Samoa pulp mill to a company facility that would raise Atlantic salmon. The US$500-million project was initially intended to create 80 jobs and produce 50,000 tons of salmon per year.

However, the company announced a full shift from salmon to kingfish in Norway in 2022.

Sashimi Royal, which Nordic Aquafarms took over in 2020, is the first large-scale producer of premium yellowtail kingfish in Northern Europe. In a press release last year, Nordic Aquafarms said the “newly expanded facility will also enable production of yellowtail at Fredrikstad Seafoods, preparing us for our transition from salmon to Kingfish in Norway.”

In April 2023, Nordic Aquafarms also announced its Fredrikstad Seafoods was transitioning to yellowtail after four years of successful salmon production.

The Samoa Peninsula facility is still a phased project but will “start smaller” than when the facility was intended for raising salmon, said Brenda Chandler, chief executive for the United States operations, in an interview with Seafood Source.

Oceanloop wants to build Europe’s largest land-based shrimp farm

Bavarian shrimp farmer, Crusta Nova, has partnered with aquaculture engineering company, Neomar, to form what could be Europe’s largest land-based shrimp farm.

The move will see Crusta Nova become part of what will be known as the Oceanloop Group. Under the partnership, Crusta Nova, which began shrimp farming in Germany in 2015, has rebranded as Honest Catch.

“The Oceanloop Group of companies will create Europe’s technology leader for land-based farming of saltwater shrimp,” a press release from the company said. “Oceanloop will significantly expand its farming capacity in Europe until 2027 by building the most sustainable and largest land-based shrimp farm in the world with over

2,000 tons of farming volume per year.”

Neomar has a shrimp farm in Kiel, on Germany’s Baltic coast. The facility uses the Oceanloop RAS technology for sustainably raising antibiotic-free shrimp. The company said the global warming potential (GWP) of a ton of shrimp farmed in an Oceanloop facility is up to 77 per cent lower than in open pond farms. It uses up to 49 per cent less land and up to 96 per cent less water, all with the help of 100 percent renewable energy sources such as solar and wind power.

Oceanloop Group plans to sell its products to import-dependent markets such as the Middle East, Japan, and the United States.

- NESTOR ARELLANO

PHOTO: NORDIC AQUAFARMS

Blue Star says RAS growth taking longer

Miami-based recirculating aquaculture system (RAS) producer Blue Star Foods reported US$12.8 million in revenue for 2022, but also said its plans for expansion is taking longer than previously planned.

In a financial report released April 18, the company highlighted that it “outperformed previously issued preliminary results” and achieved $1.4 million in revenue from its RAS operations. For the twelve months ended Dec. 31, 2022, Blue Star reported growth of 28 per cent to $12.8 million annual revenue. This is higher than the preliminary results previously issued of 20 per cent to $12 million. The increase in revenue was primarily due to an increase in poundage sold, according to the report.

“While our RAS expansion plans are taking longer than previously expected, we have made efforts to identify capital resources, both from private (non-dilutive) and government sources and currently hope to execute upon those over the next few months,” said John Keeler, chairman and chief executive of Blue Star.

Net loss for the year ended Dec. 31, 2022, increased by $10.6 million, to $13.2 million, compared to $2.6 million for the year ended Dec. 31, 2021.

“The increase in net loss is primarily attributable to a decline in gross profits, increase in operating expenses and funds deployed in the RAS projects and a significant impairment loss,” the report said.

Gross loss for the year ended Dec. 31, 2022 was $600,000 compared to gross profit of $2 million for the year ended Dec. 31, 2021. This increase in losses was attributed to higher cost of goods sold compared to the cost of goods sold in the year ended Dec. 31, 2021.

“2022 was a transition year for us, for as we increased revenue, but we had to deal with higher costs of goods sold and inflationary operating expenses. With that said, we are very pleased with the progress of our RAS business. Our soft-shell crab RAS operations commenced in March 2022, generated close to $1 million in revenue and is poised for expansion,” according to Keeler.

“As we look forward in 2023, we believe we remain on track to restore our legacy business to pre-pandemic levels, with inflation cooling off our operating expenses and to advance to the next stage in the construction phase of our transformational soft-shell crab RAS facility,” Keeler said.

Washington DNR partners with Canada’s Sustainable Blue

Sustainable Blue, in Nova Scotia, Canada, will be working with Washington’s Department of Natural Resources to explore land-based aquaculture options for the American state.

The development comes six years after commercial net-pen farming was effectively banned in Seattle following a massive spill of non-native Atlantic salmon into the Salish Sea.

Although the agreement it signed with the Seattle DNR is non-binding, the Canadian aquaculture company said on its Facebook page that the development was “an exciting next step in the Sustainable Blue story.”

“We believe that in

entering into this agreement, we are testing those people who said it wasn’t possible, or that it won’t work, the costs are too high, or that it by itself will have environmental impacts that are not being considered,”

Hilary Franz, state commissioner of public lands, told the Seattle Times .

On April 7, Seattle Times reported that the state’s DNR signed the non-binding agreement to identify lands in in the state that would be ideal for landbased fish farming.

It was Franz who wrote an executive order that stopped net-pen farming in Seattle waters. This came after the state DNR terminated

Cooke Aquaculture’s net pen leases after an estimated 260,000 Atlantic salmon were released into the water

when the company’s net pen off of Cypress Island collapsed in 2016.

- NESTOR ARELLANO

UMaine secures $2.25M RAS research fund

The University of Maine’s Aquaculture Research Institute (ARI) has been awarded US$2.25 million per year of congressional programmatic funding for recirculating aquaculture systems (RAS) research.

The funding represents a significant investment, not only for the future of the RAS industry, but for workforce development as well. Several new full-time positions have been created through both the ARI and the U.S. Depart-

ment of Agriculture’s Agricultural Research Service (USDA-ARS), enhancing infrastructure at the Center for Cooperative Aquaculture (CCAR) and expanding the facility’s capabilities for cutting-edge research and development.

The money helps establish ARI as a nationally recognized RAS research facility, focusing on shellfish and finfish species. Prioritized research includes the development of domestic broodstock, sustainable alternative feeds, the impacts of climate change, innovations in waste processing, reduction of environmental impacts, elimination of off-flavour compounds like geosmin and 2-methylisoborneol (MIB), and overall more energy efficient systems at the CCAR, according to a press release from the university.

“This will allow ARI and USDA to continue work on improving Atlantic salmon reproductive inefficiencies. Low eye-up rates have plagued the salmon industry for the past 15 years. A new reproductive physiologist will be hired that will address these inefficiencies. In addition, a new fisheries biologist will be hired that will address off-flavour and water quality as it relates to salmon grown in RAS,” said Brian Peterson, director of the National Cold Water Marine Aquaculture Center.

-

NESTOR ARELLANO

RASTECH23 cashing in on collaboration

By Nestor Arellano

Collaboration and the ability to pivot rapidly are key survival tools in today’s ever changing aquaculture landscape. This was a point frequently stressed by industry experts who spoke at RASTECH 2023 Conference and Trade Fair in Orlando, Florida.

The two-day, sold-out event was held at the J.W. Marriott Orlando Grand Lakes on April 20-21. It was attended by more than 400 people from 16 countries who shared their experiences and knowledge in aquaculture and the recirculating aquaculture system (RAS) industry. Investors, board directors, farm managers, researchers, engineers and technical suppliers were among the crowds discussing how to move the industry forward.

During the first keynote session titled, “Lessons Learned,” speakers discussed strategies for dealing with crucial challenges their businesses faced. Among the panelists were Damien Claire, chief sales and marketing officer at Atlantic Sapphire; Justin Henry, owner of Henry Aquaculture Consult and aquaculture business director at University of British Columbia; Per Heggelund, founder of AquaSeed, Sweet Spring Salmon and now, Andfjord Salmon; and Sylvia Wulf, president and chief executive officer of AquaBounty Technologies.

Establishing partnerships

Panelists agreed that from dealing with supply chain challenges in a post-Covid business environment, to getting a handle

on perennial technical issues and production problems, the flexibility to quickly shift tactics and employ strategic alliances can spell the difference between floundering and thriving.

“Really establishing those partnerships, and working with your collaborators is critical,” said Wulf.

In the months following the Covid outbreak, shipping issues disrupted the delivery of electrical equipment and components needed by aquaculture companies. Prices of materials skyrocketed.In response, AquaBounty conducted weekly and monthly consultations with its contractors and suppliers.

“We were in constant collaboration with our partners to make sure we understood what the critical supplies were, when did we need them, and what was going to happen with pricing,” said Wulf.

At one time the cost of copper was shooting up. AquaBounty needed to make decisions on whether to buy the material at a higher price or wait a bit but run the risk of supply disappearing.

“Sometimes, we need to buy at a higher price than what we had planned for because we will need the product at some point in time. You got to have a plan, but you need to be flexible,” Wulf explained.

“We have really been closely working with our engineers and our subcontractors to make sure we consider every efficiency we can find.”

Collaboration also means connecting with academia, research organizations, and industry knowledge centres that can provide

your business with vital research information according to Heggelund.

“The Freshwater Institute has been the nucleus for all of us… The University of Maryland has been in the same position,” he noted.

“They may not have seen the same growth issues we’ve seen, but they still keep on working on and solving these issues. We are fortunate that we have so many institutions that can support us as we learn and move forward.”

Later on in the conference, while speaking at Business track session titled, “Creating a RAS Business Model,” Henry drilled down on the areas where a RAS business might need to find collaborators.

Henry said businesses can develop a list of areas where expertise is needed.

“You will need finance expertise, you will need expertise in regulatory framework for the location you want to operate on, you will need RAS technology expertise, you will need operational expertise, RAS design expertise, sales and marketing expertise,” Henry said.

This could require “several people, several groups of people, or just one person” but it will mean collaborating.

Rapid reaction

Asked for his advice on what companies can do when met with a challenge such as a pandemic, Henry said you can either fall back temporarily or meet the hurdle head on.

“For a lot of the projects in the last one or two years, the answer was maybe a bit of a slowdown. Scaling down was the solution of some people who were forced into a decision,” he explained. “What we’ve done [at West Coast Salmon] was to take this opportunity to focus on design.”

He said they looked at things such as minimizing the use of highcost materials and reducing footprint.

Like most aquaculture operations, the Miami RAS arm of the Norwegian company Atlantic Sapphire suffered supply delays and rising materials cost, according to Claire.

“Pre-Covid we had a budget of US$225 million which we had to revise to $270 to $300 million, which is quite significant,” said Claire.

To cut cost, Atlantic Sapphire shifted strategies by changing the design of its RAS tanks.

“In our Phase Two construction, we actually moved the fish from steel tanks to concrete tanks,” he said. “Cost is the main reason for the change.”

Following some “setbacks” with its Phase One Miami facility, Atlantic Sapphire also decided to change RAS partners.

Collaboration powers design

“We are still working on fixing some of those issue a couple of years later,” according to Claire. “Our biggest lesson was we decided to move with a new construction team.”

Instead of an integrated RAS designer, Atlantic Sapphire chose to partner with a local engineering firm that specializes in water treatment.

“What we learned in Miami is that very strong local partnership with water treatment experts is what we need for Phase Two,” according to Claire. “Water treatment is very similar to RAS. Ultimately, we are a very big water treatment plant with fish in it.”

AquoBounty also sought outside help in deciding the design for its three North American facilities.

Wulf said the water filtration system of her company’s Indiana facility was designed by the Freshwater Institute while the technology used at the Prince Edward Island location came from Innovasea.

“We are using the Indiana facility and technology to train, improve

and retain out talent pool and the PEI technology we are designing into our Ohio facility,” she said.

Jamie Stein, co-founder of international land-based aquaculture investment firm Devonian Capital, summed up the importance need for collaboration and sharing of knowledge in the RAS industry.

During the Investor’s Forum, he said the RAS industry is a fingerling that has just hatched “but it’s not a zero-sum game.”

“Every project we invested in, we worked with talent, experience and hard work from a whole bunch of people,” he said. “We can provide capital but there’s only so much we can do. Collaboration is critical. Every failure hurts us all, and every time we share experience, we grow the pie.”

RASTECH 2023 gathered more than 400 industry professionals from 16 countries to Orlando, Fla., USA. (Photos: Jean Ko Din, RAStech Magazine)

and Ian Roberts, Director of Communications at MOWI Canada, Scotland, Ireland

with Mari-Len De Guzman, Aquaculture Writer and Editor

Presented by

Sponsored by

Power Struggle

By Maddi Badiola

Maddi Badiola, PhD, PM, is a RAS engineer and co-founder of HTH Full Spectrum (fullspectrumaquaculture.com; HTHaqua.com) in Basque Country, Spain. Her expertise include energy conservation, lifecycle assessments and RAS global sustainability assessments. Email her at mbadiolamillate@gmail.com.

Think smaller and be smarter

The first quarter of the year has already gone by. It has been a very busy year in terms of meetings and conferences. Last year, the first one after the pandemic, people showed their willingness to be back in a normal situation (the new normal) but in my opinion, this year has been the one really showing that.

As incredible as it may seem, this year has been the first one I have not been “afraid” of hugging or kissing someone (and believe me I am not a hysteric of the virus at all). I have learned quite a bit about the latest technologies, have networked and contacted lots of people, and of course, had a lot of fun. But, I must admit that I have a bittersweet taste it after all.

The sweetness

Since I like seeing the glass half full instead of half empty, talking with others about energy and being asked about it is already a big achievement.

Here are some examples/happenings over the last year:

• Someone working in one of the biggest salmon producer companies reached out to me requesting my expertise in order to conduct energy audits in their systems.

• There is technology being developed with energy saving algorithms for degassers.

• Some of the vendors and equipment suppliers are aware of the energy importance, and are putting effort in trying to make more efficient devices.

During RASTECH 2023 in Orlando, I spent some time with one of my industry colleagues working on a spreadsheet with regards to energy costs, energy savings, different equipment comparisons. This made me extremely happy. Also, in the Spring issue of this magazine, I was gladly surprised that energy related news was on the front page.

The bitterness

Unfortunately, not all is positive. It is a bit disappointing seeing that the industry has kept on with the same ideas over the years, even though we keep failing (or not having at least the predicted results). “Why are we trying to make the largest farm in the world?” I keep reading this headline in the news.

So far, I may have seen four or five very large farms being built (if not more) and sorry to say, but only one of those could have that title or honour. I wonder if this “size matters” has something to do with men being the ones running the industry? Could be.

Jokes aside, instead of making the largest, what about proving that smaller scale is feasible and profitable? Sustainable is equal to being realistic – realistic with numbers. How many farms are out there projected to produce X number of fish and not being able to achieve those production goals? Should not this be a reason to switch our vision?

Operational expenditure most of the time is not real because, for instance, energy costs surpass any prediction. Also, I have recently learned, that for every pound of fish or seafood produced (or predicted) on the order, US$2 in regulatory issues are required in the United States. Has anybody realized this? Such a number could kill any business plan.

Technical improvement

I guess the most important improvement, and so the most realistic approach, will be taking into account energy as one of the main issues in RAS. Until we internalize that, we will not advance. Other aspects that could help in those savings would be:

• Investing in an area where, on average, the optimum environmental conditions (e.g. temperature) are naturally available for the species planned to be produced.

• Improving both the system design

and management of equipment, such as finding a compromise between an optimal design for water circulation and water oxygenation of the airlift and the backwash and operation of the bio-filters.

• Minimizing height differences between RAS components (i.e. low head RAS). RAS should be designed to minimize lifting of water when possible.

• Land or building prices may outweigh the advantage of spreading out horizontally. However, more “vertical” systems may come at the expense of higher pumping costs.

I realize that the last two bullet points are difficult. Land is either expensive or missing. CAPEX wise this is something that should be studied; maybe investing more in land would help decrease OPEX which is really what makes farms struggle. Some would say investing in land is less risky than investing in RAS technology.

Lastly, I could not end this article without mentioning the popular topic of artificial intelligence (AI). Not very keen on it but sufficient to know that processing intense AI algorithms not only needs copious amounts of electricity, but also tons of water to cool the data centres. It is not a secret that training AI algorithms requires insane amounts of energy and uses up an absurd amount of water. Could not be there a connection between new RAS farms and AI facilities?

Recent studies show that in the Basque Country, where I come from, summer days have gone from 90 to 145 degrees F, showing the harsh reality of climate change. This is one of the many examples. It is in our hands to make a change. Don’t just think big, think smartly and efficiently. The investors are here to make money and farmers to produce fish. Size may not be giving profitable results, so let’s think smaller, be smarter.

EVONIK’S SOLUTION FOR RAS: EPA-REGISTERED VIGOROX® TRIDENT REDUCES PATHOGENS IN WATER WITH FISH PRESENT

Fish farmers can now reduce fish pathogens (bacteria and viruses) in their recirculating aquaculture systems (RAS) without removing the fish, thanks to Evonik’s VIGOROX® Trident peracetic acid.

The solution has been registered by the U.S. Environmental Protection Agency (EPA) for use in RAS — and it’s effective. “VIGOROX® Trident is one of the best biocides in terms of combating a wide range of fish pathogens — bacteria and viruses — in water,” says Philip Block, Technology Director at Evonik’s Active Oxygens business line, which produces VIGOROX® Trident. “Our new label from the EPA allows us to apply peracetic acid in the RAS tank with fish present. This will make it much easier for the farmer to treat the water and reduce fish pathogens.”

Peracetic acid has a long history of being used effectively in other industries, including poultry processing and municipal waste water treatment. And Evonik has a long

track record of producing peracetic acid: It has been manufacturing the substance since the 1940s.

CONVENIENT APPLICATION

“Many biocides that have historically been used in aquaculture leave byproducts or degradants in the aquaculture system after use,” said Philip Block. But VIGOROX® Trident breaks down into only water, oxygen, and acetic acid.

In addition, not having to ferry the fish from one tank to another to clean the water is a big time and money saver for RAS operators.

“It’s a lot better than any compound that we can use to treat the water in fish farming, and it’s perfectly designed for RAS systems,” said Dave Straus, from the Agricultural Research Service at the U.S. Department of Agriculture (USDA).

Pavel Korzinek, Business Manager for Specialties at Evonik Active Oxygens, said

there’s another potential benefit in using VIGOROX® Trident over other technologies, including ozone, to clean the water: less electricity usage.

“Using ozone can be very energy consuming, so using VIGOROX® Trident peracetic acid may also save energy,” said Korzinek.

ADDING IT TO WATER

“Typically, VIGOROX® Trident would be added to the water three to four times a week for somewhere between 30 and 45 minutes,” said Block. “It is an ongoing treatment to inhibit the growth of fish pathogens in the RAS water.”

“Evonik works closely with farmers early on in the process, evaluating system needs and requirements, running tests, and determining dosage, as well as providing equipment and ongoing operational support. The product works well in both fresh and saltwater environments, but it does decompose a bit faster in salt water,” explained Korzinek.

He added that Evonik offers continuous technical services and support to farmers to ensure the product works as designed, and that changes are addressed as they occur.

“One of things that Evonik can do is actually sample the RAS water, analyze it in our microbiology labs, and recommend the optimal dosing strategy based on the water quality and the VIGOROX® Trident decomposition rate.”

“It’s not as simple as dosing peracetic acid into the system,” Korzinek explained, noting that a number of factors need to be considered, including flow rates, recycle rates, water quality, and the ratio of fish to water.

“Not every RAS system is the same.”

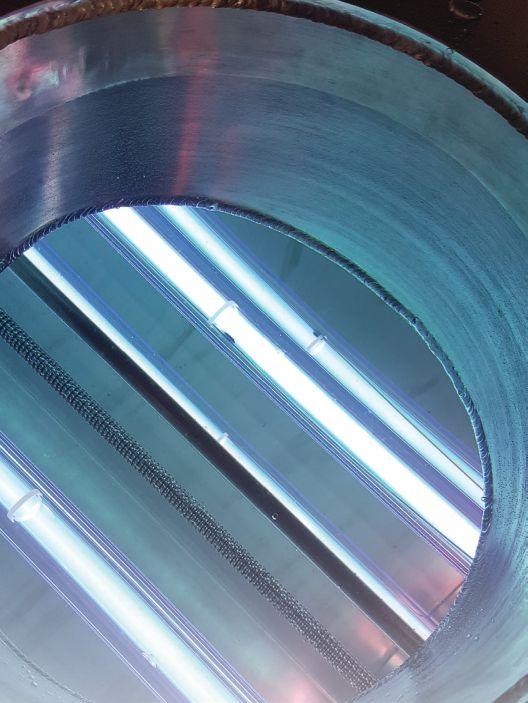

Another advantage of VIGOROX® Trident is that it can be used in tandem with other technologies being used by farmers, such as ultraviolet light (UV).

“It’s not uncommon for fish farms to use both peracetic acid and UV systems,” said Block. “Peracetic acid does not negatively affect UV systems, so no additional maintenance is required in order to use both.”

MEASURING THE LEVELS

Measuring the amount of peracetic acid in the water is a simple process for farmers, said Block.

There are two ways, essentially, to monitor the levels. The first, which is the most common, is with a handheld unit that takes a sample of the water and runs an analysis

— a process that takes about five minutes.

“It’s accurate down to 0.2 parts per million,” he said. “It’s very simple to use.”

A second method is to use a submersible probe that can measure the level of the acid. These probes are very accurate but require a fair amount of maintenance, so most farmers use the handheld unit, remarked Block.

THE SCIENCE BEHIND IT

Chris Good, Director of Research at The Conservation Fund’s Freshwater Institute, said there was a lot of research conducted to ensure VIGOROX® Trident was effective.

“We wanted to see how efficacious it is against specific fish pathogens in the RAS water,” he said.

The Freshwater Institute worked to assess the impact of VIGOROX® Trident on specific fish pathogens and demonstrate how much concentration, and time, it took to sufficiently reduce fish pathogen numbers in the water.

“I think farmers will really benefit from having this in their tool chest. Especially RAS operators: because anything you put in the water in a recirculating system — if it’s going through the biofilter — might kill your biofilter,” he said.

Once the upfront work is done, ensuring

that the dosage is calculated and administered properly, Good said farmers will “quite like” peracetic acid as a supplementary method for reducing fish pathogens in water.

He noted that a different biocide compound previously used to treat water is a human carcinogen and is “relatively biofilter unfriendly.”

“Peracetic acid is expected to replace current water treatment technologies, and farmers will really like it once they’re able to establish their own protocols,” said Good, who said he was pleased Evonik is willing to work with customers in guiding the application of VIGOROX® Trident in their systems.

Dave Straus noted that peracetic acid is produced from acetic acid, hydrogen peroxide, and water, along with a stabilizing agent. It has greater reactivity and lipid-penetrating properties than hydrogen peroxide alone and is not deactivated by catalase and peroxidase like hydrogen peroxide would be.

GETTING STARTED

To learn more about VIGOROX® Trident and how it can be used in your system, contact Pavel Korzinek: pavel.korzinek@evonik.com.

Not an offer for sale.

Not an animal drug.

Not intended for use in the diagnosis, cure, mitigation, treatment, or prevention of disease in fish or fish eggs, or to affect the structure or function of the fish or fish eggs.

Intended only to control disease pathogens in water, not in or on the fish or fish eggs, consistent with the EPA-approved instructions provided on the product label.

To smolt or not

Is smolt and post-smolt RAS the answer to production efficiency?

By Matt Jones

Post-smolt growing has been intrinsically tried to the development of recirculating aquaculture systems (RAS).

In the past decade, post-smolt growing efforts have become increasingly popular among aquaculture practitioners. For the uninitiated, post-smolt growing refers to keeping young fish in RAS for longer before transferring them into open-net sea pens to

continue their maturation. This technique is intended to have the benefit of allowing the fish to become larger, heartier, and more resilient to diseases and other impacts they could experience in the net-pens. In just the past year alone, there have been multiple examples. Norway’s Aker purchased 25.3 per cent of Gaia Salmon, which looks to produce around 7,200 tonnes of salmon per year at a new post-smolt facility. After being delayed by the COVID-19 pandemic, Grieg Seafood’s plans to build a large post-smolt

facility in Newfoundland, Canada appear to be back on track. And in New Brunswick, Cooke Aquaculture was approved to develop a C$72 million (US$53.3 million) post-smolt facility.

“Hybrid systems, involving a mix of land and marine-based fish farming will continue to be part of our future,” said Cooke Aquaculture vice-president of public relations, Joel Richardson, in a news release. “Innovative scientific technologies bring a new opportunity for greater production in ocean waters by

shortening time Atlantic salmon spend in marine cages.”

RAStech Magazine spoke with several researchers and practitioners to find out more about why the technique is becoming increasingly popular and what benefits the producers have seen.

A GRADUAL DEVELOPMENT

More than 20 years ago, in the early days of the Chilean salmon industry, RAS systems were developed after the country’s environ-

mental regulators would not permit flowthrough systems.

In 2011, the Norwegian aquaculture industry also started to adopt the technology after a regulatory change. In the decade that followed, the industry became more profitable, and the Norwegian companies started using some of those profits to build post-smolt facilities.

“In Norway, the regulations are such that if you can speed up sea pen cycles, you can start (your production cycle) all over again. Over the course of several years, you’ll achieve more production,” says Matt Craze, founder and head researcher at Spheric Research.

“You can’t do that in Chile because there’s a calendar system for stocking fish.”

Craze publishes an annual “Land-Based Aquaculture Report” that provides a detailed data analysis on the development in landbased projects around the world. The report collects data from about 190 projects from around the world, plus a database on 100 post-smolt facilities.

“In Norway, there’s a very significant advantage to adopting a post-smolt strategy,” Craze explained. “And then when you think of the sea lice problem in Norway, especially in southern Norway, taking fish up to say 500 grams will allow you to avoid having the fish in the waters for two summers and therefore, you don’t have to apply as many treatments and you don’t have to handle the fish as much.”

Åsa Maria O. Espmark is a senior scientist and RAS expert at the Norwegian Institute of Food, Fisheries and Aquaculture Research, also known as Nofima. She adds that Norway is intending to grow their aquaculture production dramatically over the next 20-30

LONG-LASTING AQUACULTURE PUMPS

years, but the consensus seems to be that it cannot happen in open water.

“If they’re going to grow, then the growth needs to be somewhere else in different systems,” says Espmark. “And that is where the semi-closed system comes in, which I think has huge potential.”

All of which explains why the technique gained traction in Norway and Chile, but why has it proliferated to other parts of the world? Craze posits that it has to do with the variety of biological challenges faced across the world.

“In Eastern Canada, you’re dealing with quite cold water, especially in the winter months. It allows these farmers to take more control of the biological parameters of the fish into a later stage,” says Craze. “It’s part of a strategy of growing fish in very challenging environments, whether it’s been disease issues, temperature variation, it’s basically taking the risk of these fish being out at sea into their own hands and having more control.”

WHAT ARE THE BENEFITS?

Water temperature control has also been a big benefit for northern European countries, says John Davidson, research scientist at the Freshwater Institute.

“My understanding is that (Norway) has had a history of increased mortalities when they transfer the fish from their land-based systems to their sea cages,” he says. “So by growing larger smolt, the understanding is that those fish are more robust, less likely to succumb to the change of environment and less likely to be affected by sea lice.”

Miguel Portus, CEO of Lago Sofia in Chile, says that their company is 100 per cent dedi-

An aerial shot of Lago Sofia’s post-smolt Atlantic salmon RAS facility in Chinquihe, Chile.

cated to providing quality smolt for its customers and made investments into infrastructure, technology, monitoring, and control due to a belief that the industry should go for bigger, stronger and more robust smolts. The technology, he says, has been perfected over the last decade, making it very attractive due to biosecurity and flexibility.

“The smoltification stage has been brought closer to sea sites, significantly reducing handling and movements, lowering freight costs and above all improving the sanitary condition of the fish, making

each batch safer and more robust to face sanitary challenges from sea,” says Portus. “Lago Sofia facilities have permits and spaces available to grow and increase production on land.”

Davison’s prior word choice – “the understanding” – should be noted, however. While many have touted the benefits of post-smolt growing as it relates to fish health, it has yet to be proven by research. In fact, Craze notes that some scientists in Norway have claimed that the fish actually do better in older flowthrough systems in colder water. But regardless of that aspect, having the fish in the water for less time is advantageous for many other reasons.

“There’s different viewpoints out there,” says Craze. “But we’ve run analysis on a company like Lerøy (Seafood), that was having pretty significant difficulties in its farms in southern Norway. And they made themselves completely self-sufficient with very large smolt coming from very modern RAS facilities. They did seem to hit a slight production bump when these things come online, but not much. It may just be that they’re offsetting potential declines in population as the sea lice problem gets worse.”

Espmark says, however, that as much as these systems have developed significantly in the past, they may evolve to the point where they could have more wide-ranging benefits in the future.

“At the moment, they don’t prevent some other diseases, but the systems are quite new, only 10 or 15 years,” she says. “We’re working on ways to make water treatments and effluent treatments cheaper to make them more suitable for people to use.”

GROWING THE FUTURE

While there are so many benefits, it may be tempting to label postsmolt growing as the future of the industry. However, as Portus notes, the future of the industry will most likely not be defined by any one specific technique, even if post-smolt growing will present a very useful solution to a variety of environmental and regulatory challenges in certain markets.

“The production of fish to harvest in (land-based systems) is a very ambitious objective for many companies, great steps have been taken through innovation and technology,” say Portus. “There are experiences that have been more successful than others but without a doubt

Post-smolt Atlantic salmon in a research tank at Nofima

they already mark a path towards the implementation of these technologies in the short term.”

Portus also sees bringing production closer to destination markets and contributing to an abundant local market is a good way to reduce emissions, bring consumers closer and to reduce logistic effort.

Espmark also agrees that post-smolt rearing will likely remain just one of the many tools in the aquaculturist’s toolbox, rather than the new standard. It’s most likely use case will be determined by factors such as geography, water temperature, water access, numbers of sea lice and other issues.

“This variation will continue for a long time because I think that most farmers find their own way to do things,” says Espmark. “I’m not 100 per cent sure how widespread it will be to just keep on post-smolt because there are so many unanswered questions. In Norway, you have the hypothesis that this would improve the welfare of the fish – and it still may do that, but there are so many unanswered questions of how to do it correctly that I’m unsure what will happen when we have all the answers.”

For aquaculture practitioners who are interested in exploring the possibility of incorporating a post-smolt aspect to their operations, Espmark recommends reaching out to institutes such as Nofima or the Freshwater Institute.

Davidson says that the technical know-how to work with postsmolt facilities is mostly an extension of the knowledge that the producers already have. The biggest salmon farmers are already using RAS systems at least to some degree, but there are several questions that should be asked before barreling forward.

“I think if you were to change your approach, you would certainly have to have a different bio plan or different engineering design that supported more production on land, so that would be a pretty big shift,” says Davidson. “To grow larger smolts on land will require more tanks, potentially more water, which RAS can help with by conserving water. If you’re just starting from scratch and don’t have any experience with RAS, that’s a different story. Moving from flowthrough to RAS is a big change in terms of understanding the technology and how to operate it and how to benefit from that technology.”

Nofima researchers Per Brunsvik and Åsa Espmark at the Sunndalsøra facility

Towards circular aquaculture

Belgium’s Inagro research centre is using RAS to build a more integrated food production system

By Stefan Teerlinck and Edson Panana, Inagro

Aquaculture research began at Inagro in 2008 in search of new sustainable and alternative ways to produce animal protein in Belgium, as the pig and chicken industry was becoming less profitable due to over production. To do this, Inagro built the aquaculture applied research centre for the development of freshwater fish production in recirculating aquaculture system (RAS) in Belgium.

Today, Inagro is a multi-disciplinary

research centre located in RumbekeBeitem, Belgium with more than 50 years of experience and a current staff of more than 200 employees, performing applied research and transferring knowledge to the stakeholders within the agrifood chain.

The centre’s focus is how to make freshwater fish production in RAS more sustainable. In Europe, we believe fish production should go from a linear to a circular approach. This is to reduce the input of ingredients coming from non-sustainable origins and to reduce the

pollution of our waters due to effluents from fish production.

Facility specs

This facility has a total surface area of 700m² for a total water volume of 160m³. It was designed to conduct pilot-scale research and to operate as a professional farm. Thus, all phases of fish production in RAS are present, from egg to market-size fish.

It has a broodstock chamber with controlled climate (20m³, today for pikeperch (Sander lucioperca)) and a hatchery

PHOTOS: INAGRO

Agrotopia is the rooftop greenhouse at Inagro.

system with twelve 225-litre tanks self-cleaning tanks for larval rearing and larval research.

It also has a juvenile system to produce 100,000 fingerlings (about 10g final body weight) and growout system for large feed and growth trails for all kind of freshwater fish up to two kg body weight (twenty 1.8m³ tanks).

The facility also has a fish storage system made up of four 8m³ tanks where our researchers can look to the performance of +2 kg fish, such as large pikeperch and salmon, in RAS. We also have a specially designed RAS for testing alternative new in-

gredients in aquafeeds (twelve 750-litre tanks) where fish growth performance and apparent digestibility of diets and ingredients can be tested.

All systems have computer-automated feeders and professional backups to secure constant production (emergency oxygen, electricity production, 24-hour watch). We use online probes for real-time monitoring of pH, dissolved oxygen, water temperature and conductivity on each tank. The systems have the flexibility to operate with groundwater, rainwater, tap water, or if needed, a mixture of them.

Smarter, stronger, more economical drum filters

The Hydrotech Drum Filter Value series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost.

Let us help you!

Call +46 (0)40 42 95 30, or visit www.hydrotech.se

Inagro conducts its fish production research raising pikeperch in 1.8m³ indoor tanks.

Research interests

Our first goal at Inagro was to develop the pikeperch (Sander lucioperca) production in RAS. Today, we control all the phases of the pikeperch production cycle from egg to one-kilogram-sized fish. In this frame, Inagro manages the European Percid Fish Culture (EPFC) group, a platform that gathers people from industry and research involved in percid fish. Within the EPFC group, courses are organized by Inagro for pikeperch producers from all over the world.

As Inagro has a wide range of applied research fields, we started to integrate on-site fish production with other available productions representing the Belgian food production sector, such as greenhouse vegetable production, arable crop production, insect production, duckweed production and many others.

Protein booster

Several research departments at Inagro make their productions circular and contribute to aquaculture.

Our researchers are currently working

Innovation Beyond Measure

Results Beyond Expectation

• 100% Titanium Heat Exchangers

• Hot & Cold Water Loop Systems

• Available with Tube Sheet, Helical Coil, or Plate

• Compact Designs

• Easy Installation

• Salt & Fresh Water Safe

• Chiller & Heat Pump Packages

• Electric Heaters & Gas Boilers

on these projects:

• Production of black soldier fly (Hermetia illucens), mealworm (Tenebrio molitor) and crickets (Acheta domesticus); these animals are champions in converting waste streams into proteins and fat.

• Development of single-cell protein production on methane coming from our in-house biogas installation where all kinds of waste streams are anaerobically fermented

• Duckweed ( Lemma mino r) production on manure and wastewater

• Production new local proteins, like soybean and peas

These potential raw materials are used in the aquaculture project, Protein Booster. We formulated an innovative trout feed for a local trout producer (B-trout), together with a local feed company (Lambers-Seghers) and an insect producer (Nusect). Our goal is to replace at least 50 per cent of the protein sources by Belgian circular proteins: insects, single cell, poultry products. During this project, several trials are conducted at Inagro in our growout system.

Starting with a screening trial where 5,000 trout of 100 grams are divided in 20 tanks. Five sustainable diets are compared against two control diets (traditional trout feed formulations). Out of the first trial, the best two experimental diets (better fish growth performance) are taken into the second trial where trout will grow for 20 weeks starting at one kilogram. In the third trial, we look at the performance of fish starting at three kilograms, and the effect of these sustainable diets in fillet quality traits.

Harnessing aquaponics

Inagro has a greenhouse (9,000m²) where vegetables are grown in a state-ofthe-art production facility. Since 2014, Inagro has been conducting research on aquaponics as a solution in the integration of plant production and fish production.

In the INAPRO project and the Aquavlan2 project, the fish production was done with the rainwater coming from the greenhouse and the fish farm effluent water was used to maximally replace the rainwater and artificial nutrients in the

Where Water Drives Innovation.

Stefan Teerlinck is head of research and insect production at Inagro.

greenhouse production.

While most of these experiments are performed using model fish such as tilapia and carp, Inagro opted for the use of effluent water coming from our pikeperch production. When quantity of the fish production is calculated towards the rainwater capture on the roof of the greenhouse, you should even be able to produce the fish next to the tomato production without extra water usage and no effluent to discharge from the fish culture.

For a tomato production of one hectare, this could result in 25 tons of fish next to the expected tomatoes, and this with up to 20 per cent reduction of artificial nutrient use in greenhouse. Not to mention that to some extent, we could see healthier plant growth in the gutters where the tomatoes got aquaculture effluent water.

At the same time, the aquaculture sludge was fed into our biogas installation resulting in combined heat and power used

Scientists and technical staff celebrating the opening of the rooftop greenhouse, Agrotopia, in 2021.

in the aquaculture and greenhouse facility closing the loop of productions even more.

New methods

Inagro is also working on the combination of insect and vegetable production,

blutan

The recent award of BSI Kitemark Certification for customer service reinforces our promise of customer care from start to finish.

• Unique and protected epoxy coated steel tanks

• BSI Kitemark certification for customer service

• Added value warranties and regular inspection options

• 40‐year track record

with a new term we call this entomoponics.

Intensive vegetable production in greenhouses results in large amounts of waste (rutinary pinch out of the crops). Our current trial looks at the suitability of various byproducts from greenhouse

farming as a food source for mealworms. Mealworms need a moisture source in addition to a dry feed source (standard wheat bran). In the trial, the most common residual streams produced in greenhouses are tested, such as rejected cucumbers, tomatoes, strawberries and peppers, but also bell pepper leaves, green parts of the cucumber plant and even roots of lettuce grown on hydroponics.

Currently, limited differences in growth rates can be observed between these different moisture sources. None of the moisture sources lead to significantly higher mortality rates, from which we can conclude that they are not toxic.

In the near future, we are looking to close the circular loop in our production fish, insect and vegetable model. We aim for the co-creation amongst sectors. In this way, we would be able to couple production systems where the waste of one company can be utilized as a source of nutrients, energy or feed for another.

For example, rainwater can be first collected and used to produce fish in RAS. The effluent water, rich in nutrients, can be directed to our greenhouse and utilized for vegetable production. The byproduct of these crops can be used as feed for mealworm. This insect, rich in protein and fat, can be directly used as partial replacement of aquafeed or used to produce insect meal.

Finally, the sludge produced in the Quality products supported by certified customer care Since blutanQ was launched, most major RAS developers have taken advantage of our support services that cover design, technical, commercial and construction project input.

Tomatoes fed to mealworms grown in trays beneath the tomato culture.

RAS (and to some extend it is the same for insect manure, called frass, can be potentially used in different processes such as: 1) mineralization via bacteriological processes to recover important nutrients, such as phosphorus, 2) used as bio- fertilizer for the grow of crops, 3) to

produce energy in biogas reactor and 4) when possible by European law, an alternative ingredient for the insect production.

With our new ENOLL (European Network of Living Labs) approved “living lab circularity” and all the necessary pilots

in situ like aquaculture and insect production, greenhouse, duckweed, biogas, Inagro develops methodologies – brainstorms, co-creation sessions, learning networks and workshops – to bring aquaculture to a future-proof circular level.

Frass separated from insects with a sieve

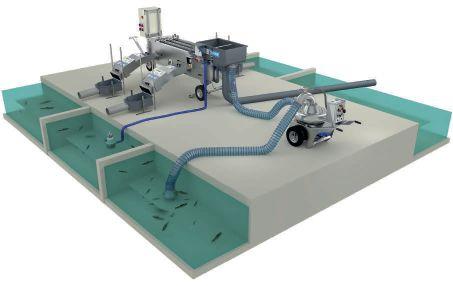

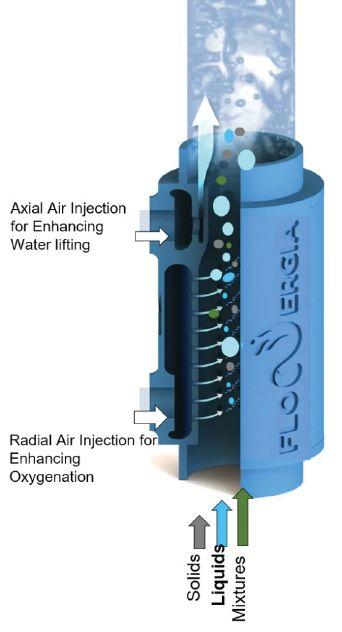

FloNergia chooses Emvees Wastewater Treatment as exclusive distributor in UAE

FloNergia Inc. announced the appointment of Emvees Wastewater Treatment LLC, part of Emvees Water Group, as Exclusive Distributor for the company’s complete line FloMov airlift pumps in the United Arab Emirates.

FloNergia’s FloMov airlift pump technology is used in many markets for water circulation and aeration. FloMov pumps helps improve water quality and reduce energy costs associated with pumping/ aeration systems by 50 to 70 per cent.

FloMov pumps have been proven to perform several functions including disrupting thermal stratification, improving oxygenation, stripping carbon dioxide and

facilitating the recovery of solid waste.

“We are very pleased to add Emvees to our global family of Exclusive Distributors. Their expertise in wastewater innovation and their network throughout the region will help us to introduce our energy efficient FloMov pump technology to more customers in the area,” said Brian Polowniak, vice-president of sales and marketing at FloNergia Inc.

“We wanted to make it easier for our current and future customers to get access to our technology to help them reduce their energy footprint and improve their profitability.”

www.flonergia.com

ENROLL NOW

•

Your Partner for Ozone and Oxygen Systems

Authorized Dealer:

• In-house fabrication allows us to build custom or engineered packages for any size aquaculture application.

• We specialize in turn key solutions, certified to any required global standard.

• We integrate complete ozone or oxygen packages into either new or existing projects.

info@vekenvironmental.com or 780-886-6916 www.vekenvironmental.com

Commercial Filtration Systems

Customized for your fish farm, hatchery or research operation! Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• De-gassing towers

• Wide variety of flow rates

• Flow control valves

• Protein skimmers

• Variable frequency-drive pumps

• Temperature management

our systems are pre-plumbed and fully water tested prior to shipping.

Tips

By Curtis Crouse, Freshwater Institute

Considerations for induced smoltification

As anadromous fish, Atlantic salmon undergo a physiological change as they migrate from freshwater to seawater. This process, known as smoltification, prepares the fish for the seawater environment and leads to a fast growth phase of life. Knowing the smoltification status of young Atlantic salmon is critical for farming operations to properly time the movement of stocks from freshwater nursery systems to sea cages or saltwater grow out systems.

Young Atlantic salmon can be provided with a short artificial winter photoperiod (AWP) to control the timing and synchronization of smoltification leading to better fish health outcomes when moved to seawater. AWP is also a useful tool to create out-of-season salmon smolts for consistent production volume.

The Freshwater Institute (FI) has demonstrated the feasibility of raising Atlantic salmon from eyed egg to market size exclusively in freshwater. Despite remaining in freshwater, Atlantic salmon at FI are typically provided with an AWP to induce smoltification, though several previous cohorts have performed well and smoltified normally without the benefit of an AWP. When providing AWP for smoltification, there are several considerations for successful application.

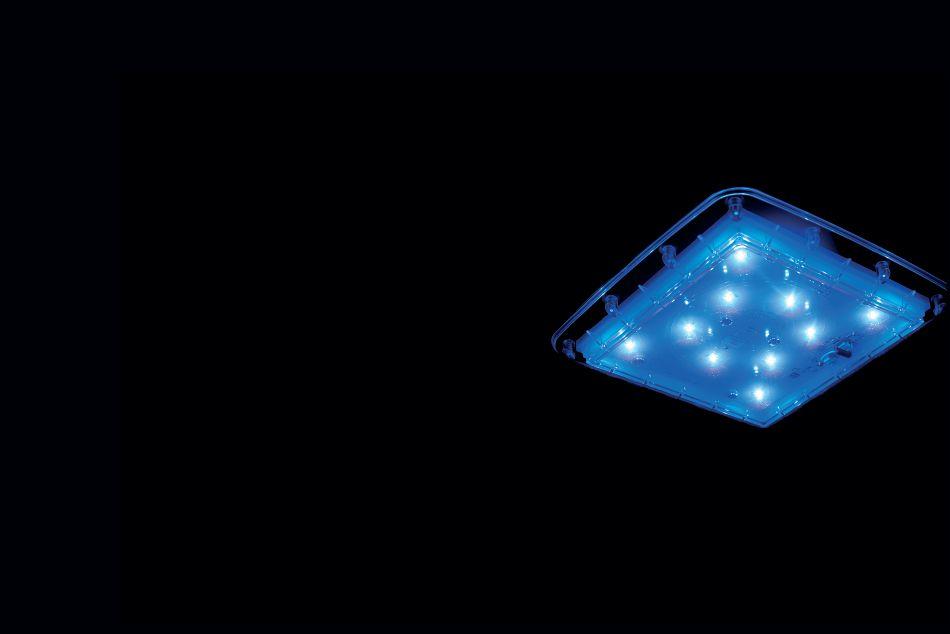

Lighting

Each nursey tank at FI has a dedicated dimmable 5,000K LED light suspended approximately three feet above the tank surface. Newly ponded fry are provided a 24-hour light photoperiod from the first feeding to the onset of the AWP. The AWP typically begins when fish reach approximately 40 grams of average weight. The light over the nursery tank is then programmed to provide 12 hours of light and 12 hours of dark for 6-8 weeks, followed by a return to 24 hours of light.

It is important that the tanks are only receiving light from the dedicated source during the AWP. At FI, each nursery tank is enclosed with a lightproof tent to prevent overhead ambient room light from influencing the intended photoperiod. Tanks could also be fitted with a lid or other cover or situated in a dedicated room with its own overhead light. In any scenario, make sure that light cannot penetrate the enclosure or shine through seams or joints in materials or walls.

When deciding on a lighting control system there are several features to consider. The first attribute should be ease of use. A second consideration is the number of channels available.

The farm’s bioplan, may dictate a need to provide several tanks with different photoperiods at the same time. A single light controller with multiple channels can be programmed to provide the desired photoperiod when needed. A good light controller should also be capable of gradually increasing and decreasing light intensity at the start and end of daylight hours.

The gradual change in intensity can reduce startle reflexes and stress associated with the light abruptly turning on and off from full intensity. A compatible dimmable light is needed for this feature. Fade up and down should occur over a 30- to 60-minute time block. Customizable on and off times also allow farms to sync daylight hours of

the AWP with work schedules so that health observations, tank maintenance, and cleaning can be completed while the tank is illuminated, and dark hours are not disturbed by opening enclosures.

If a light intensity logger is not available, it can be helpful to schedule on-time at the start of a shift or off-time at the end of a shift so that technicians can confirm that the lighting is turning on and off as intended.

Feeding

Salmon reared at the FI are typically fed around the clock with equally spaced feeding events administered with automatic feeders. Waste is monitored with collection in an external settling tank to gauge fish satiation. The external settling tank allows technicians to assess waste feed and feces production without having to open the light-proof enclosure. While under the AWP, feed programming is adjusted to deliver feed during light hours only, as feeding during dark usually results in excessive feed waste from reduced capture efficiency. Feeding is also avoided in close proximity to lights turning on and off each day. Salmon are still fed to satiation while under AWP, however, the abbreviated feeding window typically results in a reduced total daily ration compared to fish fed over the full day.

Handling

At the completion of the AWP, pay close attention to the fish as this can be a stressful transformation, especially when seawater-ready fish are to remain in freshwater. In this case, FI refrains from moving or handling newly smolted fish for at least six weeks after the completion of the AWP. To prevent unnecessary fish handling during this time window, begin with an appropriate fish stocking density, such that the growing fish do not exceed the carrying capacity of the tank when the AWP and resting period are complete.

An Atlantic salmon parr (top) and an Atlantic salmon smolt (bottom)

Advanced Oxygenation

Increase tank capacity and yield with Linde technology for aquaculture. Our SOLVOX® oxygenation systems work in both saltwater and freshwater to create a healthier environment for growing fish. Our range of low-maintenance dissolution and distribution solutions outperforms traditional air-based systems, providing better efficiency, utilization, and hydrodynamic conditions inside the tank. Linde experts can develop a system customized to meet your specific needs. Contact us today.

lindeus.com/aquaculture