30

135

More than years projects countries

25

PEREZ-

30

135

More than years projects countries

25

PEREZ-

By Mari-Len De Guzman

In journalism, information is our bread and butter. We collect the facts from a number of credible sources, sort through the data and present an unbiased narration of the events. And, if we are doing a good job, our readers are able to gain insights from our reporting of the facts and form their own opinions.

At least, that was true back in the day, the pre-Twitter and pre-Facebook era. In today’s Internet-engulfed society, it is much harder for folks to separate fact from fiction, and easier for unscrupulous entities to dupe people into consuming false and malicious content. Legitimate industries, therefore, must be extra vigilant and more involved in propagating truths and promoting the evidence, especially where public interest is concerned.

The growing number of firms investing in RAS for large-scale production means fish farms are being located in close proximity to markets. Being closer to market also means operating near communities and interacting with residents, whose buyin is important for the success of the operation.

The state of Maine in the U.S. is a test bed for such dynamics. Over the last couple of years, at least four companies –Nordic Aquafarms, Whole Oceans, Aquabanq and Kingfish Zeeland – have announced plans to set up a land-based aquaculture farm in Maine. First mover Nordic Aquafarms, in particular, has been engaged in a battle with opponents of the project to be built in Belfast. The company is going through the steps to acquire the necessary permits to allow it to begin

To submit a story idea or press

construction, and its efforts have been met by opposition from a local group. So far, it seems the Atlantic salmon producer is gaining tiny victories along the way, and will ultimately be able to build its planned 33,000-metric-ton production facility.

Nordic Aquafarms will not be the last company to face opposition from various lobby groups. And organizations planning to go the RAS route must come prepared to argue their case not just in the judicial courts, but also in the court of public opinion. Unfortunately, misinformations and misrepresentations have become part of the opposition game and the vehicle for spreading these is just a mouse click away.

Any company doing the unconventional, no matter how noble the intentions are, must have the extraordinary ability to effectively engage the community where they will operate and win the trust of the local residents.

The aquaculture industry is just beginning to wrap its head around RAS and the whole idea of raising fish on land. The business case for this has been building for years and industry acceptance and adaption are increasing. It’s time to expand the fan base and engage the general public, the consumers of these land-grown seafood to be educated on the benefits – and risks –associated with land-based seafood production.

An educated market can have a positive impact on the business bottom line. Drown out misinformation from the loud minority and start telling the RAS story with some real evidence and in a way that would resonate with the consumer.

contact the editor at mdeguzman@annexbusinessmedia.com

For advertising inquiries, contact Jeremy Thain at jthain@annexbusinessmedia.com

www.rastechmagazine.com

Editor Mari-Len De Guzman 289-259-1408 mdeguzman@annexbusinessmedia.com

Associate Editor Jean Ko Din 416-510-5211 jkodin@annexbusinessmedia.com

Advertising Manager Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Coordinator Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Circulation Manager Barbara Adelt 416-442-5600 ext 3546 amadden@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

CIRCULATION

email: blao@annexbusinesmedia.com

Tel: 416.442-5600 ext 3552 Fax: 416.510.6875 (main) 416.442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

As the primary external input into recirculating aquaculture systems, feed is essential to get right because we’re not only feeding the fish, but also feeding the system. It is well-known that RAS need high performance feeds in terms of physical and nutritional quality, to help the fish grow faster and healthier and to maintain the water quality in the system. The use of ingredients with high digestibility maximize nutrient utilization for fish growth and minimize nutrient loss, while the use of patented ingredients in Skretting RAS feed ensure that the output is just as good as the input.

Read more at www.skretting.com and contact your local sales representative for more information.

A new land-based Atlantic salmon farm is set to begin construction in Maine, U.S.A., by 2020 and begin producing 5,000 metric tons of head-on gutted fish by 2022.

Aquabanq, a subsidiary of U.K.-based Aquaculture Management & Holding Co, plans to build an industrial-scale RAS facility in Millinocket, Maine. Its Atlantic salmon will be distributed in Boston, Montreal, New York, Philadelphia, Washington, D.C. “and everywhere in-between within hours of harvest to ensure peak freshness.”

The company’s multiphase project includes an additional five RAS units to double production capacity to 10,000 metric tons by 2025.

Commenting on the commercial profitability of its land-based salmon, Aquabanq executive AJ Shapiro said his company can “easily compete” with cage farming operators because its productions costs are on par with these conventional farmers.

However, he said, “the fish in closed-containment systems are not exposed to parasites and pollutants like sea lice and plastic, and unlike our competitors, we can guarantee a yearround production.”

Aquabanq’s production units are based on a flexible, proven, closed-loop system with optimized process logistics, low operating costs and a reduced footprint that makes them perfect for large-scale, sustainable onshore fish-farming operations, the company said. Each unit rears fish in large circular tanks with movable compartments separated in two closed-loop channels taking advantage of the circular tank’s hydrodynamics.

Aquabanq’s parent company in the U.K., Aquaculture Management and Holding Co., is projected to reach production capacity of 10 million lbs. for its Atlantic salmon and steelhead by 2021.

Maine, U.S.A.-based Whole Oceans has closed a deal to purchase a former paper mill in Bucksport, Maine. This paves the way for the company to build its planned land-based Atlantic salmon farm with a projected initial capacity of 5,000 metric tons per year.

Branzino producer Ideal Fish in Waterbury, Conn., is getting some financial boost with the completion of a significant equity investment from a consortium of US and international investors, a press release from the company revealed.

The transaction, which was completed on May 14, will provide the company with growth capital, strengthen its balance sheet and bring a new group of “highly engaged investors with significant aquaculture experience and financing resources,” the company said.

“We are delighted with the outcome of this important transaction,” said Eric Pedersen, founder and CEO of Ideal Fish. “Our new investors believe strongly in our mission and will bring many resources to the Company as we build our business together.”

Ideal Fish produces European seabass (Dicentrarchus labrax), also known as Branzino, on land using state-of-the-art recirculating aquaculture system (RAS). It is the only commercial-scale facility in the U.S. growing this species, and one of only a handful of RAS facilities in the world raising ocean-going fish in saltwater, the company said, adding it is on track to produce 175 metric tons of Branzino per year.

“We are unified in the belief that the quality and security of seafood available in the US today need to be improved. Americans should be able to enjoy higher quality fish that comes from a safer, traceable and sustainable seafood production system in this country. This includes responsible wild-catch fisheries as well as many forms of well-managed pond and lagoon, ocean cage and RAS aquaculture,” Pedersen said in a statement.

The company plans to expand significantly both within the Northeast region and nationally in the near future and expects to complete additional growth capital raises as it increases the scope of its operations.

“Through future expansion into new markets and the addition of numerous seafood species to our product line, Ideal Fish plans to play a significant role in the development of a robust, sustainable aquaculture industry in the US,” the Ideal Fish chief executive said.

The BAP-certified Ideal Fish is currently rated “Best Choice” by the Monterey Bay Seafood Watch Program.

RAS provider Billund Aquaculture is making some changes to its executive team, with several appointments that aim to “continue cementing its position as the undisputed leader in RAS systems.”

The company has announced the appointment of its new chief operating officer and business development manager Brjarne Hald Olsen, who has been working as an executive at Billund for 13 years and has 33 years of experience within the global aquaculture industry. In his new position, Olsen will continue to drive the company’s sustained growth, Billund said in a press release.

“To meet the future growth expectations, we need to be even more innovative

in our technology and get even more engaged with our customers,” Olsen said in a statement. “I can’t wait to get started in developing the business even further and getting closer to our customers.”

Billund’s success has been enhanced by the excellent market conditions and positive projections the land-based aquaculture market is currently enjoying across the globe, the company said. Market demand is on the rise for salmon smolt, post smolt, grow-out and other marine and fresh water species. Estimates are showing that by the year 2030, over 600,000 tons of different species will be produced using this technology.

The company also announced that

Fisheries and Oceans Canada (DFO), the federal agency responsible for regulating Canada’s aquaculture industry, will soon test British Columbia fish farms for foreign strains of a virus deemed harmful to fish.

Jonathan Wilkinson, minister of DFO, said screening for the non-native Icelandic and Norwegian strains of piscine orthoreovirus (PRV) at BC hatcheries is part of a proposed risk management policy that aims to protect wild salmon and the health of farmed fish.

“Science tells us there are different strains of PRV around the world, and that the one in BC is naturally here and benign. Requiring farmers to test for foreign strains of this virus is a responsible approach,” said the BC Salmon Farmers Association (BCSFA), in response to the news.

The association added that its members are already testing for a number of known pathogens before smolts are transferred from hatcheries to the saltwater environment. “Testing for this additional virus will now be part of an already rigorous process,” it said.

The public has 60 days to comment on the DFO proposal, called Framework on the Transfer of Live Fish.

In the interim, DFO said that as a precaution, it will be requiring enhanced testing and reporting of any instances of heart and skeletal muscle inflammation (HSMI) and jaundice syndrome in fish farms.

It said it will also invest additional resources to test farm sites to ensure proper and enhanced monitoring of farmed fish health.“The

Steffen Busk Jespersen will be Billund’s new CEO in Denmark as of August 1st.

“I am very happy and excited to get this unique opportunity to represent such an important company, one that has earned a privileged position in the competitive RAS market. I’m excited to be part of this successful team and to contribute in taking the company to the next level,” Jespersen said.

Jespersen is the former managing director for the Swedish operations of packaging and insulation group BEWiSynbra. Before that, he was co-owner and CEO of industrial group AH Industries A/S. He has also held several leadership positions in a variety of companies in countries such as Denmark, China, USA, Germany and the UK.

“This new structure is a very important step towards securing the management team the company needs to meet its future development needs, focusing heavily on structure, technology development and a strong control over project implementation,” said Christian Sørensen, chairman of the board at Billund Aquaculture. Sørensen will remain in his role as chairman of the board and will continue to be fully involved in daily operations, “with a strong emphasis on design, technology development and project implementation,” Billund said.

Government of Canada is committed to following the precautionary approach, which recognizes that the absence of full scientific certainty shall not be used as a reason for postponing decisions where there is a risk of serious or irreversible harm,” DFO said in a statement. Two new studies released early this year have suggested that the PRV is not as harmful as some believe).

– Liza Mayer

By Colin Ley

We’re very new, very young and very small, said Dougie Allen, CEO of Great British Prawns (GBP), a Scottish business that has built what it claims to be the world’s first sustainable land-based, clean water king prawn production unit.

Located at Balfron, Stirlingshire, the new farm is the result of five years of planning, investment and development by a team of six directors and a farming staff of 12.

Drawing on a range of combined skills, including salmon and sea bream production, aquarium construction and use, general engineering and big business management, the new prawn venture is equipped with its own self-built recirculation system, rather than one bought ‘off the shelf’.

“We built our own RAS system partly because we knew we had the in-house talent and experience to enable us to do so,” Allen told RAStech. “Another reason for doing it ourselves, of course, was the high cost of buying in a ready-made system.”

For anyone hoping to see and learn from GBP’s design and build, the company’s management team is currently keeping its RAS secrets to themselves – at least until the new unit has had a chance to prove itself.

“I’ve worked in aquaculture engineering for more than 25 years and this project is truly setting a worldwide precedent that will change the way prawns are farmed in the future,” said Dr. Andrew Whiston, technical director for the project.

“Focusing on getting our RAS exactly right, along with mimicking the precise conditions required for optimal prawn development, has been a precision project that has required painstaking research and engineering. The outcome is an approach that impresses in its engineering, as well as its sustainability and humane methods.”

Working with an input of more than 300 tonnes of water, the new unit is designed to hold up to one million fresh prawns, which will be grown to an average 25 grams. These prawns are targeted for restaurants and hotels within a two-hour distribution radius of the Balfron location. That includes selling at £23 (US$26) a kilogram to chefs in Glasgow and Edinburgh, with the farm’s first prawns due to be delivered to buyers this summer.

“Our design allows us to effectively plug into any suitable potable water source, with no need to be near a river or the sea. We can take supplies from the mains and do whatever is necessary to make sure any water entering our system is suitably clean,” Allen said.

“Having a circular system like this means we can control the various, and often challenging, factors involved in other forms of production, such as the weather, the risk of disease coming in and so on. It’s all about driving risk out of the business, a process which comes at a cost, of course, but which we believe is worth it.”

By being able to choose their location without too much concern about water sources, the company’s objective was to achieve the highest possible level of sustainability, while having minimal impact on the surrounding environment.

That involves using sustainable energy from an anaerobic digester, located on a neighbouring dairy farm, while also applying high levels of insulation and bio-filters to clean and recycle its waste.

As a result, GBP says the new farm’s ‘constantly improving design’ will allow any future facilities they build to be virtually waste free. In addition, by using a closed filtration system, they’re convinced they won’t require antibiotics or other medication, chemicals or manual handling, to produce their ‘uniquely clean, fresh prawns’.

Having only opened a few months ago, the key challenge for 2019 is to make sure the Balfron unit performs as intended. Even so, the company is already committed to building other UK units in the future, Allen said.

Water treatment specialist Pentair Plc is exiting the aquaculture business and selling related units to focus its strength on the residential and commercial pool segments.

A spokesperson for the Minneapolis-headquartered company said the firm will sell the Vaki business unit under the Aquatic Eco-Systems Division, which is specialized in aquaculture-related products and services. Vaki specifically provides fish handling, counting and grading solutions. Pentair will also divest itself of the Chile operations and the online catalog operation.

“While we believe the aquaculture business offers attractive long-term opportunities, the short term business model does not meet our

expectations. Pentair will not have any business related to aquaculture once the sale process is complete,” spokesperson Rebecca Osborn told Aquaculture North America (ANA).

About 35 employees in the Pentair Aquatic Eco-Systems Division are being let go as soon as June 5 as a result of the decision.

“We plan to operate business as usual as we navigate through the sale process. We are dedicated to ensuring a smooth transition for our customers, and will be communicating with customers,” Osborne added.

Reacting to news of Pentair’s departure from the industry, the executives at Aquatic Equipment and Design (AED) gave assurance to the market it still has “a partner in aquaculture

supplies and design.”

AED was formed after the Pentair merger with Aquatic Eco-Systems (AES) in 2012, and provides aquaculture equipment and designs to aquaculture companies worldwide. AES was established in 1978 by Robert “Bob” Heideman, a former Navy SEAL. AED co-owners Amy Riedel-Stone and Huy Tran, president and vice-president, respectively, both learned the business from Heideman, prior to establishing AED.

“Huy and I are proud to have been able to learn from Bob and continue his mission and values today,” Riedel-Stone said in a statement. – Liza Mayer

A new US$7-million, 27,000-square-foot land-based eel production farm is set to break ground in Maine this summer.

American Unagi, a Maine-based company cultivating and selling live, locally-sourced Maine eels throughout the United States, announced it will begin construction of Maine’s first land-based eel aquaculture facility to be located in the Waldoboro Business Park in Waldoboro, Maine.

The company said it has received planning board approval in January and has now secured all necessary environmental and building permits.

“We are shovel ready,” said Sara Rademaker, American Unagi’s founder and president. The company will employ up to 14 staff and produce 240 metric tons of eels at the new facility.

The recirculating aquaculture systems (RAS) facility will be the first of its kind in the U.S. to grow Maine eels to market size, the company said. Its stateof-the-art equipment solutions have been designed by Netherlands-based ACE, an aquaculture design-build RAS specialist with 30 years in the industry.

“We chose ACE because of its commitment to innovation and efficiency,” Rademaker said. “They’ve assisted us in designing a farm that outperforms competing products and allows us to scale up to meet the strong demand for our eels.”

Demand for U.S. cultivated eels is strong because the majority of eels im-

ported into the U.S. market are not traceable. American Unagi’s “fisherman-tofarm-to-table” approach, along with eel’s culinary diversity on the plate, make the product very popular among US chefs, especially within the sushi industry. Additionally, consumers like the health benefits of eels because they have high amounts of vitamin D, the company added.

“Our traceable method of production, which makes our eels popular with chefs and consumers alike, is unprecedented in the industry. Our goal has always been to create the most transparent and traceable product possible,” Rademaker said. “We believe domestic production of eels will produce a better product and result in more U.S.-based jobs.”

The company’s expanded facility is part of a long-term strategic plan developed with a diverse group of industry and business experts.

Visit us online

We’re online! Now, you can get more RAS-related content anywhere, anytime.

www.rastechmagazine.com

By Michael Ben Timmons

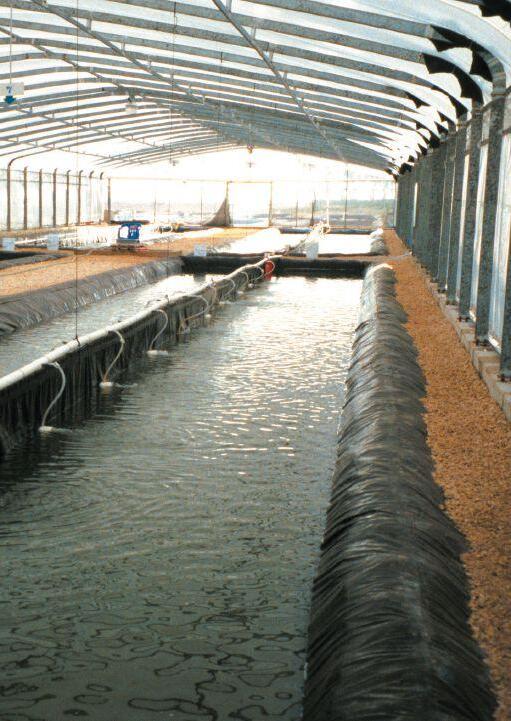

Ihope your summer is off to a good start. Mine is. I’m involved in a large indoor project producing 400 tons per year of salmon using mixed cell raceways (see my article in the RAStech 2019 spring issue). But my focus for this article will be aquaponics.

For the last 30 years (until about five years ago) I used to roll my eyes when anyone would mention aquaponics and the great results they were obtaining. According to these early aquaponics zealots they were getting more growth, better tasting plants, longer shelf life, better color, etc. Often, these comments would be from someone who was taking my hands-on short course (now available as a distance course, wee www.eCornell. com/fish). Since I try to be a polite and kind person, I would not ‘laugh’ out loud when hearing these comments. But, generally responded with some comments or questions such as, “Did you have any replications or controls to compare your results against?” Always, the answer was “Well no…but… my aquaponics plant production is just fabulous!”

Cornell has been one of the leaders in Controlled Environment Agriculture (CEA) for 50 years. The engineering professor (Dr. Lou Albright) and plant science professor (Dr. Robert Langhans) would always agree on

one thing: if you take two complicated systems (RAS and hydroponics) and you put them together (aquaponics), then you have a really complicated system. And that no one in their right mind would do this.

Well, that all changed for me about six years ago.

I started conducting replicated and controlled research under commercial scale conditions. The hydroponic growing condition re -

quires very careful and precise control of pH (around 5.8) and the macro and micro nutrients. RAS conditions generally target a pH value of 7.0. The problem is that if you were to run the hydroponic system at a pH of 7.0, you would cause very significant decreases in nutrient availability for many of the key elements. Well, surprise, surprise to all of us. Our results for bibb lettuce, spinach, and now

strawberries are showing no significant differences in productivity between the aquaponic and hydroponic (pH 5.8) conditions. But the hydroponic system that operated at pH 7.0 had typical reductions in productivity of ~25 per cent. We have yet to figure out why. Our initial hypothesis was that it was the living microbial community from the RAS being given to the aquaponics plants that was providing

the compensation to normal growth we had observed.

Being good scientists, we then ran a trial where we compared hydroponic (pH 5.8 and 7.0), aquaponic water, and sterile aquaponics source water (we auto-claved the fish water). Again, to our surprise (it seems this happens a lot to me), the hydroponic pH 5.8 and both aquaponic water conditions (autoclaved and non-autoclaved) all performed the same. (The hydroponic pH 7.0 again had very poor performance). So there apparently is some bacterial action that makes the nutrients more bio-available to the plants, but this conditioning occurs before the water is introduced to the plants. This makes running decoupled aquaponic systems totally available to the design team and farmer. (Decoupled aquaponics is

where the plant system and the fish system do not recirculate water between the two systems.)

We are really happy with our strawberry aquaponic research. We are testing aquaponic vs. hyroponic using day-neutral strawberries (Albion and Monterey) since it is hard to compete in the summer with field grown berries, but in the winter the grower could obtain premium pricing. One of our student team leaders, Jessie Powell, senior in Biological and Environmental Engineering, Cornell University, on the strawberry project is shown in the image. Here are the papers we have recently published on aquaponics.

REFERENCES: Vandam, D.A.; Anderson, T.S.; de Villiers, D.; Timmons, M.B. Growth and Tissue Elemental Composition Response of Spinach (Spinacia

oleracea) to Hydroponic and Aquaponic Water Quality Conditions. Horticulturae 2017, 3, 32.

Anderson, T.S.; Martini, M.R.; de Villiers, D.; Timmons, M.B. Growth and Tissue Elemental Composition Response of Butterhead Lettuce (Lactuca sativa, cv. Flandria) to Hydroponic Conditions at Different pH and Alkalinity. Horticulturae 2017, 3, 41.

Anderson, T.S.; de Villiers, D.; Timmons, M.B. Growth and Tissue Elemental Composition Response of Butterhead Lettuce (Lactuca sativa, cv. Flandria) to Hydroponic and Aquaponic Conditions. Horticulturae 2017, 3, 43.

Wielgosz, Z.J., Anderson, T.S., Timmons, M.B. Microbial effects on the production of aquaponically grown lettuce. Horticulturae 2017, 3(3), 46.

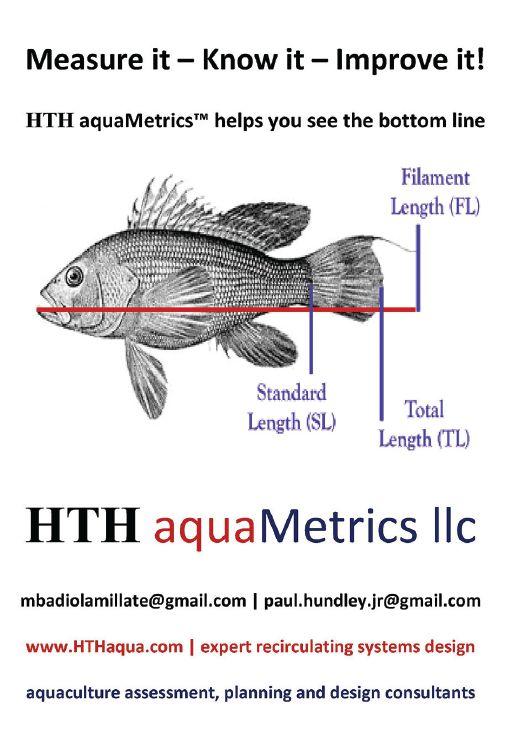

By Maddi Badiola

Maddi Badiola, PhD, is a RAS engineer and co-founder of HTH aquaMetrics LLC, (www.hthaqua.com) based in Getco, Biscaye, Basque Country, Spain. Her specialty is energy conservation, life cycle assessments and RAS global sustainability asessments. Contact her at mbadiolamillate@gmail.com.

Following my previous article, the consideration of RAS sustainability should be analyzed from different angles. In general, sustainable product, sustainable communities and/or sustainable systems claims are often based on a single feature, disregarding other possible characteristics –being energy-efficient or recyclable, for instance.

Sustainable development is one of the greatest challenges of our time. It brings together a number of global problems. Thus, different descriptions of sustainability sometimes compete with one another. Use of the term is often misused. Moreover, as mentioned in earlier articles, sustainability should be assessed from four different directions: social, environmental, technological and economical.

The first two have already been explained, so let’s continue with the last two aspects.

Industry development, an inherently technological evolution has played an important role in creating the problems that we face, but will also play an important role in solving them. The reason is not that sustainable development is a technological mission; rather, sustainable development is the mission for the whole of society.

RAS is a technology-based system. Nowadays many are 100 per cent monitored where every single value, data or modification can be seen or watched online, as a big brother’s eye. In terms of technological sustainability, the technology designed by engineers (with the aid of the managers in charge) could be analysed using these questions:

What characteristic of sustainable development informed the design process? What sustainability impacts or effects are caused by the technology? Who or what was affected, where and when? Could the designer have foreseen these consequences? How did the designer judge and anticipate them? How was societal interaction dealt with during the design process?

In general, the sustainability assessment begins in the farm, but how the technology was produced or how much waste is generated by such technology is important as it is also part of the product production.

RAS are expensive, usually require costly indoor spaces and have continuous and substantial operational requirements beyond less intensive methods. Moreover, the costs of labor and energy can be prohibitively high depending on the location. The production location influences the competitiveness of the aquaculture farm by conditioning environmental impacts and economic expenditure factors. For instance, any comparison between different RAS productions may not be realistic

as many factors (e.g. species, country, production volumes and policies) affect the results obtained.

A clear dimension and perspective of economies of scale needs to be considered if affordable operational costs and consistent marketable final product prices are intended in the given location of the system/company. We are looking for a balance between operational costs and production benefits.

RAS management and understanding affect their performance and, consequently, industry success. Moreover, the investment required and the long pay-back periods seem to be the greatest constraints. Thus, a good market study is required in order to plan an affordable and realistic production goal. Nonetheless, the first requirement would be a reliable operation, followed by low operating costs.

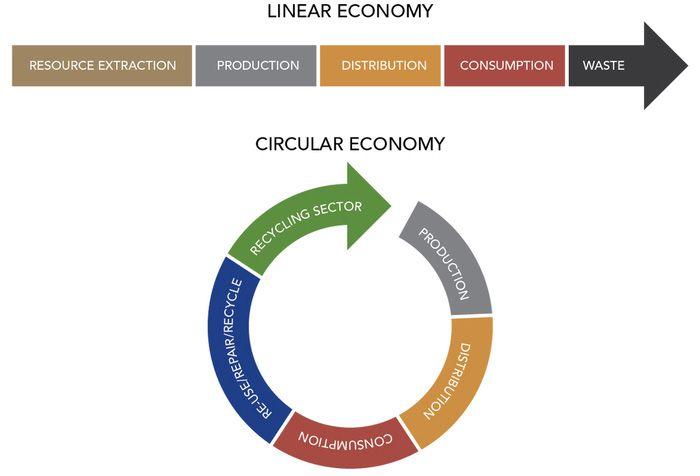

The latest economy model concept has interests on global markets, with growing environmental issues where the food sector has a major importance. The circular economy aims to redefine growth, focusing on positive society-wide benefits. It entails gradually decoupling economic activity from the consumption of finite resources, and designing net waste out of the system. This “re-thinking progress” is based on three principles: (i) design out waste and pollution, (ii) keep products and materials in use and, (iii) regenerate natural systems.

The model distinguishes between technical and biological cycles. Thus, consumption only happens in biological cycles, where food and biologically-based materials are designed to feed back into

the system through processes like composting and anaerobic digestion. These cycles regenerate living systems, such as soil and RAS solid waste, which provide renewable resources for the economy. Technical cycles recover and restore products, components, and materials through strategies like re-use, repair, remanufacture or recycling.

Doesn’t all that perfectly fit into the RAS way of thinking? Doesn’t RAS try to generate the least waste possible? Isn’t one of the main objetives to re-use all the waste for any other purpose, such as agricultural manure and/or biogas production? If you want to know the answers to some of these make sure you read the next article.

Are we on a good path? The know-how is there; let’s make a more profitable industry with less costs and resource use. As a rule, the challenges of sustainable development will be different in specific settings.

In aquaculture, and RAS in particular, energy, water and waste are the three encompassing challenges. Although it will be challenging to design the most innovative, productive, efficient, profitable and environmentally friendly RAS in the future, it will not be a single measure that will lead to the widespread success of commercial RAS. Rather, the commercial success of this industry will require the need to genuinely focus on the combination of all aspects of these types of ventures.

In reality, rethinking such productions with an integrated mindset will help with holistically tackling the simultaneous challenges of energy demands, management matters, consumer preferences, and system efficiency.

Follow me on LinkedIn, Instagram and/ or Facebook. I’m happy to answer questions, have an enjoyable chat or assess a RAS.

Good circulation is decisive for profitable aquaculture. Do you want unequalled operational reliability, energy savings, and operating efficiency many years ahead?

By Mari-Len De Guzman

The increasing popularity of RAS is paving the way for other sustainable production models to gain traction in the industry.

What used to be a “backyard hobby farming” project, aquaponics is evolving to become a sustainable – and profitable – alternative to food production.

Aquaponics blends aquaculture and hydroponics (soilless plant cultivation) and creates a natural system of producing food, without the use of artificial fertilizers or pesticides. It’s an integrated multitrophic system, mimicking the environment of a natural ecosystem, explains Nick Savidov, senior research scientist at Lethbridge College in Alberta, Canada, in an earlier interview with this writer.

“The natural ecosystem does not have waste,” he says. “Everything is getting utilized, so that waste product of one component – such as fish manure – become feed stock for another component, which are beneficial microorganisms such as bacteria, fungi, protozones, so forth… and then of course the plants are fed by the water, then

the water goes back to fish. So, the cycle is complete.”

Regarded as Canada’s “Yoda of aquaponics,” Savidov has been involved in aquaponics research for well over a decade. He says one of the most important features of aquaponics is that it does not produce any waste.

“Recirculating is the key word,” Savidov points out. “Water becomes not just a habitat for plants, fish and the nutrients and microorganisms. Water becomes a carrier, a link which ties together all those components. That is why water is so important.”

Aquaponics has huge potential over traditional methods of farming, says Savidov. “It’s naturally produced, no chemical used, environmentally friendly, sustainable.”

Any fish species that can be grown in RAS can be reared in an aquaponic system, but everything boils down to the business plan, says Ryan Chatterson, founder and president of Aquaponic Engineering and Design based in Florida, U.S.A.

“Can you line up the eggs? Can you line up the harvest schedule, and everything that

it takes to do that? Can you maintain water temperature? These are all just numbers on a table: you pick the fish, you set the requirements, and then if you have to do a 30-degree change in the water (temperature) from the fish to the plants, then in that plan you add kilowatt hour. It’s going to tell you whether it makes sense or not,” explains Chatterson. Before starting his own aquaponics farm and then launching his aquaponics engineering company, Chatterson worked for 10 years at Aquatic Ecosystems. Seeing the potential for aquaponics, he eventually set out on his own, establishing first a R&D farm in Florida serving as a test bed for his designs and to evaluate various crops in different growing conditions.

The bottom line, when selecting the species and the crops, is the bottom-line. Choose a fish that would be profitable in a RAS and that has a good market demand in the area where you are choosing to locate the aquaponics farm, Chatterson advises.

One of the most attractive features of aquaponics, both from a sustainability and prof-

itability standpoint, is the ability to build these farms closer to market. This eliminates the huge expense of long-haul transport and reduces the products’ carbon footprint.

In St. John’s, Newfoundland, Canada, a 120-acre family farm is reaping all the benefits of aquaponics farming, providing farmto-table fresh produce to the local community. Lester’s Farm has installed an aquaponics system to grow lettuce and other leafy greens alongside tilapia fish.

Rearing warm water species in an area where temperatures can go down to doubledigit degrees below freezing is not an easy feat, according to Wasiim Kader Bathia, aquaponics specialist and managing director at Aquaflora Aquaponics in Vacoas, Mauritius. Bathia worked with engineering firm Silk Stevens Limited, in New Brunswick, Canada, to design and install a facility that will house the aquaponics farm, including a greenhouse.

“At the time when we were designing the project, we had very few design data regarding aquaponics, especially with regards to… the design of the system itself, managing the greenhouse environment, and especially the temperatures,” Bathia recalls.

“In Newfoundland, it can get to minus 30 degrees Celsius… and we were using warm water species so we had to heat the water, heat the air inside the greenhouse and the fish building, and insulate everything.”

The farm currently uses conventional coupled aquaponics, where the fish and vegetable are produced in a single loop system. This system works well when both fish and plant species generally require the same level of water temperature, explains Onassis Sanchez, civil engineer at Silk Stevens, who worked with Bathia on the Lester’s Farm project.

“The plants require high temperature in the water and this is the main reason why tilapia was chosen because tilapia can grow at high temperatures, around 25 to 30 degrees Celsius, which is what that plants need to grow,” Sanchez says.

Some modifications have been made to the design of the Lester’s Farm system, however, to allow for future conversion to a decoupled aquaponics system, in case the farm’s operators decide to grow a different species of fish that may require lower water temperatures that may not be conducive to growing healthy plants and vegetables, Sanchez says.

Decoupled aquaponic is an integrated system that involves separate functional units for fish and plants, with individual water cycles that can be controlled separately.

Now in full operation, Lester’s Farm delivers year-round produce to the local community, including lettuce, Asian vegetables and various herbs, as well as fresh tilapia every week.

Commercial deployment of aquaponics around the world has been gaining ground over the last decade. An international survey published in the journal Aquaculture in 2015 looked into the profitability of commercial aquaponics over a 12-month period. According to the survey, 69 per cent of aquatic animals commonly raised in commercial aquaponics is tilapia, followed by ornamental fish (43 per cent), and catfish (25 per cent). Other species raised, according to the survey, are perch (16 per cent), bluegill (15 per cent), trout (10 per cent), bass (7 per cent), and other aquatic animals (18 per cent).

The most frequently raised plants among commercial aquaponics producers, on the other hand, are basil (81 per cent), salad greens (76 per cent), non-basil herbs (73 per cent), tomatoes (68 per cent), lettuce (68 per cent) and kale (56 per cent). Other plants raised include chard, bok choi, peppers and cucumbers.

Based on 257 respondents surveyed – 81 per cent of which are from the U.S. – the

median quantity of fish harvested by respondents was 23 to 45 kg/year. And the median quantity of plants harvested was 45 to 226 kg/year.

Thirty-one per cent of respondents reported that their aquaponic operations were profitable in the previous 12 months, while more than half (55 per cent) predicted profitability in the next 12 months.

While most commercial aquaponics operations in the world are in the small to medium-scale range, Superior Fresh in Wisconsin, U.S.A., is proving the business case for large-scale investment.

The farm sits on a 720-acre native restoration property and is the largest facility of its kind, raising Atlantic salmon and steelhead from egg to about 4 kilograms, and a variety of leafy greens.

Using a proprietary decoupled aquaponic system, Superior Fresh’s current operations include nearly six acres of production facilities. Plans are underway to expand production capacity, according to Steven Summerfelt, chief science officer at Superior Fresh.

“Right now our Atlantic salmon and steelhead production is just about 200 tons (per year), and we are between 5 and 10 times that in leafy greens, depending on what we produce,” Summerfelt says.

The company is currently adding new grow-out facilities that would expand its fish production output to 600 tons or approximately 1.3 million lbs. New greenhouse

facilities are also being added to expand its production footprint to 14 acres by next year.

With continued daily harvest for leafy greens, and weekly harvest for fish, Superior Fresh is able to bring its produce to local markets within a 400-mile radius.

As the former director of aquaculture systems research at the Freshwater Institute, Summerfelt knows first-hand the power of aquaponics to produce food sustainably.

“Aquaponics is being focused on as a more sustainable production (method), and it really is because we are able to have zero discharge from our production and processing systems,” the Superior Fresh chief science officer says, adding that by having the plants remove nutrients from the water and returning clean water to the fish tanks, the farm is able to recycle 99 per cent of the water.

“That is incredible; instead of having zero waste capture from net pens, we have 100 per cent waste capture. And we are actually reclaiming it so that 1.1 tons of fish food produces 1 ton of salmon and 5 to 10 times that of leafy greens.”

Summerfelt explains the advantages of having a decoupled system – and much of it has to do with scale.

“In our case we have a fully functioning state-of-the-art recirculating aquaculture system for salmon, and another for steelhead. We also have a fully functional recycle system for the plants – and these two connect,” he says.

“We are focused on revenue stream from the fish, separate from the revenue stream from the plants. They are both critical for the economic performance of our business,

and with the decoupling and the ability to focus on salmon RAS, we are able to scale to very large RAS facilities.”

One of the significant advantages of an aquaponic system over a traditional aquaculture RAS, is that by adding leafy greens to the production output, profit margins can increase significantly. While Atlantic salmon takes two years to grow to harvest size, it only takes about seven weeks for leafy greens to grow and be ready for harvest, Summerfelt points out.

Despite its significant promise, aquaponics is still a relatively expensive investment at this point. A small to mid-size scale aquaponics farm would entail an initial investment of between $100,000 and $300,000, according to Chatterson at Aquaponic Engineering and Design. But, he adds, the return on investment can be achieved in about two to three years.

According to that 2015 survey, greenhouses are the most popular building facility used for aquaponics. However, getting the services of your friendly neighbourhood greenhouse contractor may not be as easy you think, Chatterson says.

“I find there is a lack of greenhouse construction companies,” he says. “You’d think any general contractor would be able to take that job up, but that’s not the case. I’ve been dealing with this for years now. It seems like people are scared when you say the word ‘greenhouse’ and they run the other way.”

Because of that, he says, the price of getting a greenhouse installed can skyrocket.

Sanchez of Silk Stevens Limited agrees

that the most expensive portion of the initial capital cost is the physical structure. So he is an advocate of the principle of starting small and then scaling up.

“Some aquaponic systems are very complex,” he says, and that means likely sourcing materials and equipment outside of your local vicinity, which does not promote the concept of ‘buying local’ and can have a significant cost attached to it – defeating the spirit of aquaponics, says Sanchez.

“That, in my opinion, is the beauty of aquaponics – where you have local products that can be built locally, and can be consumed locally, and it can be handled and operated locally.”

For aquaponics to grow mainstream, the industry also needs to produce a fresh breed of aquaculture experts with the skilled knowledge of aquaponic systems that are specifically designed for large-scale, complex operations.

“I don’t think the traditional aquaponic training is adequate in preparation for a large, decoupled, cold water aquaponics facility,” Summerfelt says. “It’s breaking new ground in every way, and it’s not easy to implement.”

Chatterson agrees, and he is helping to build a future generation of aquaponics experts. Through his company, he has helped install an aquaponic demonstration unit at a community college in North Carolina. An upcoming project is also underway to install a similar unit in a middle school in Virginia.

“If we are going to have an aquaponics industry, we have to have people going to school and getting motivate to get careers in those areas if the industry is ever going to have long-term viability,” he says.

A smolt farm in Chile is using aquaponics to transform itself into a sustainable food production system producing fish and vegetables on a commercial scale

By Christian Pérez-Mallea

Astrategic partnership between the private sector and academia is rethinking and redesigning the already existing Lago Sofía smolt farm in Chile. Circular economy is the main concept being implemented with the aid of aquaponics. This would be the first large-scale aquaponic production in the country.

Located within the urban limits of Puerto Montt, this facility is intended to rear salmon smolts for third-party companies and leafy greens for the local community, in a sustainable manner and with a low carbon footprint.

Likewise, the plan is not only to provide jobs but also to become a training and research center for both, the neighbors and the scientific world.

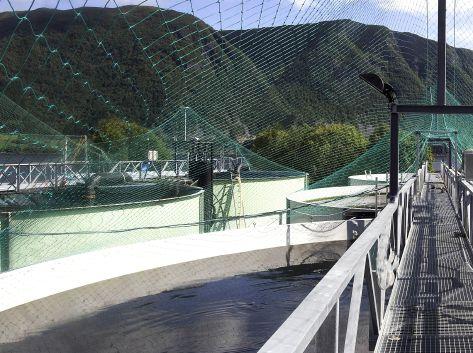

The Lago Sofia smolt farm is a 4,400-cubic-meter facility located 12

kilometers south of downtown Puerto Montt. It has a maximum production capacity of 2,200 tons per year. That means 22 million Atlantic and Coho salmon pre-smolts (30-50 grams) and smolts (150-200 grams).

There have been several investments here in recent years and once the current expansion stage concludes, the facility is expected to reach a capacity of 8,000 cubic meters.

The water intake comes from two wells and a watershed located within the premises.

About 40 people work in this freshwater site, which originally opened in the 1980s – making it one of the oldest smolt farms in the region.

Circular economy is the core concept in this project; that means minimizing every waste and optimizing all resources. Through the aquaponic system, Lago Sofía plans to utilize the nutrients

present in the water flowing out of the fish production system to produce leafy greens for its nearby community. The Agronomy School of the Pontifical Catholic University of Chile (UC) is a close partner in this project.

According to the chief growth officer of Lago Sofía, Miguel Portus, humidity in the sludge from the farm processes is reduced by 70 to 80 percent.

“We dehydrate the sludge to the driest possible matter. The excess water, which is the wastewater from the process, enters the roto filters again to eliminate all suspended solids that may remain. An ozone filter then clarifies and oxidizes all microparticles and solids that may have remained in the process. After all this movements and treatments, we take part of that water that should return to the environment to generate a vegetal production,” he explains.

A very important motivation is the absence of drugs or antibiotics in this

facility processes, he points out.

“Additionally, all cleanings, sanitary dryings and disinfections are performed with biodegradable products that allow us to work in the most sustainable way. Besides, in all the water characterizations, samples and profiles, we have not found any relevant issues that might be telling us that the project is not viable. By contrast, we realize and convince ourselves every day more and more, that this is a nice alternative to improve the situation of the water discharges,” Portus says.

The UC’s Agronomy School contributes its knowledge on aquaponics and vegetable farming. Once the production plan is completed, the farm expects to start producing leafy greens at a small scale by the end of 2019.

Francisco Albornoz and Fernando Bas, academics and researchers at the Chilean university, say the analysis performed at Lago Sofía indicates that the water obtained after the processes of sludge separation and ozone filtration are suitable for all types of fruit and vegetable cultivation. “The main nutritional contribution is phosphate,” they say.

“The production of vegetables will not be limited by the quality of the water, but by the environment that is generated inside the greenhouse,” the researchers explain. “The most critical months will be June, July and August, when daytime solar radiation and nighttime temperatures are low (winter time in the Southern Hemisphere). This will require the implementation of heating and artificial lighting equipment, which are currently being evaluated. The intention is to select

• 30 years in Aquaculture

sales and after sales service

those species that maximize the cost/ productivity ratio.”

Both scientists expect to have the greenhouse operational within nine months. The plan is to invite different stakeholders within the community and educate them on this food production model.

“Our intention is to encourage other fish farming companies to incorporate these systems, that will allow them to generate a circular economy in their productive processes,” they say.

The creation of a closer link with the community of Chinquihue in Puerto Montt is one of the main objectives of everyone involved in this project. Portus is eager to see the interaction and relations that may develop between the residents of the community and those people working on this project.

“We will be able to have students from

a technical high school or a community college here, who will perhaps be working side by side and exchanging opinions and experiences with people who may be doing a PhD or an undergraduate thesis at the UC,” he says.

Portus believes the freshwater pro -

duction sector of the Chilean salmon aquaculture industry could potentially benefit from all the environmental, social and economic advantages of an aquaponic system, since there are no technical barriers to adoption. However, it would require willingness from

those other companies.

“The only limitation is whether (they would) want to do it or not, because it means getting into another business,” he says. “Maybe this kind of project will become more attractive once there is a product, with a different added value.”

According to the chief growth officer, the next steps for the Lago Sofia project once production begins and the final product is achieved would be “how to position it, where to position it, what vegetables to produce and how much to produce.”

He also points out the environmental impact of such a circular food production system.

“Through urban farming, it is possible to grow vegetables in the middle of the cities, in order to produce locally, in a sustainable manner and with a carbon footprint as low as possible and at the most competitive cost,” he says, adding that aquaponics could be key for remote fish farms, since these systems can pro -

vide products that are not easily accessible, such as leafy greens, in the southern Patagonia.

Circular economy has been a primary goal of the government of President Sebastián Piñera, says Klaus Kosiel, regional delegate (Seremi) of the Chilean Environmental Ministry. Far from that goal, he sees lots of challenges in the region of Los Lagos.

“In this region we have big problems with the waste of our productive and domiciliary processes. There are problems about where to dispose them, we have the inland sea of the Chiloé island with many sectors contaminated with plastic waste, buoys, pens, etc.,” he says.

He believes the concept of circular economy is already gaining traction in the world, although recognizes that it is still avant-garde.

“France, for example, traced its road map to the circular economy in 2017. In

that sense, Chile wants to be a pioneer in South America and stop talking about waste and garbage, to refer to raw materials. Here, several elements enter the scene, such as the Law of Extended Responsibility of the Producer and Promotion to Recycling, which require the recovery and valuation of priority elements (batteries, tires, packaging, boxing, etc.) with goals of up to 10 years,” he explains.

Finally, when referring to the environmental performance of the aquaculture industry in Chile, he acknowledges there is still so much to do.

“It has a fairly large historical debt in terms of sustainability, but it is evident that they have made progress in implementing sustainable measures.

“Lago Sofía is a good example, since they are reducing impacts on the environment while contributing with production of vegetables in the process,” he says.

By Matt Jones

It all began as a backyard science project: entrepreneurship student Paul Shumlich and environmental science student Kevin Daniels started experimenting on the property of the home Shumlich was renting.

“We just wanted to know more about where food is being grown, who was growing it and how to get involved,” says Shumlich. “We just kind of stumbled upon the concept of aquaponics and it really spoke to us.”

The idea developed more and more over as they brought their idea to a variety of business pitch competitions, “similar to Dragon’s Den, but in the post-secondary setting,” says Shumlich. As the idea for what would become Calgary’s Deepwater Farms developed into a business model they felt comfortable moving forward with, they obtained an angel investment and the rest is history. It all comes back to their fascination with the sustainable nature of aquaponics.

“It’s the closed-loop concept – being able

• 100% Titanium Heat Exchangers

• Salt & Fresh Water Safe

• Available with Tube Sheet, Helical Coil, or Plate

• Hot & Cold Water Loop Systems

• Compact Designs

• Easy Installation

• Incubator Rack Systems

• Gas Boilers

to take waste from one stream and turn it into valuable input for another,” says Shumlich. “I like the idea that it’s organic by nature. It’s a living breathing ecosystem.

“Aquaponics is completely organic because you’re using composting and living, breeding bacteria that is just naturally found in the soil. I really like the idea that, opposed to using chemical fertilizers, there could be this natural way of unlocking fertilizers and nutrient solutions for the plant.”

Developing their farm and their process was a long effort involving a great deal of trial and error. There are very few large-scale aquaponics operations in existence, so there were few businesses whose successes and failures could be learning opportunities. None of the members of their team are specialists, but they are very science-minded.

“We’re kind of trailblazing it,” says Shumlich. “We’re making mistakes and learning from the mistakes, because there’s nobody we can learn from. We’ve worked with Lethbridge College on aquaponics and different people like that who have been very helpful for us, but when it comes to commercialization and running the business, there wasn’t really anyone.”

Deepwater Farms’ facility has 25,000 sq. feet of grow space in vertically stacked layers, with eight grow-out tanks and around 10 nursery tanks that hold about 30,000

gallons of water. The farm produces around 2,000 lbs. of sea bass every month and between one and two thousand lbs. of greens each week – baby arugula, mixed baby kale and mizuna mustard greens, as well as a spring mix.

“As a business, we sell mostly plants, but as an operation, we’re more of a sustainable fish farm,” says Shumlich. “The techniques we use, the fish farming is pretty cut and dry recirculating aquaculture. We stocked to organic standards, we seed by hand. We have a purge system to ensure the fish quality is there as we go to market. We do all our netting by hand and grading and counting as passively as possible.”

While everything on the farm is currently done by hand, Deepwater Farms’ system was designed with the future in mind as well – Shumlich says that the system is flexible enough that once they have felt that the business model has been proven enough, they can begin to layer in automation and

improve their processes.

Deepwater Farms’ offerings are largely driven by their clients, which include a number of chefs at restaurants around Calgary. Shumlich says they are not in a rush to scale out their product offerings – more product offerings mean more complexity –but are looking to scale up the customer base.

Shumlich describes chefs as being at the heart of the grassroots movement in food trends, and having a local and sustainable option for purchasing greens or whole fish has been appealing to many of the chefs they work with.

The development of their fish sales, however, has been an interesting challenge. They always knew that there was a strong demand for the greens, but not necessarily the fish. Like many aquaponics operations, Deepwater Farms was initially envisioned as a 90/10 split between the greens and the fish, but slowly and steadily the fish has become a larger and larger part of their sales.

“When we first started, fish were really hit or miss amongst restaurants,” says Shumlich. “But we found out some of the restaurants that are really kicking off right now were actually buying white fish bones to

make fish broth or buying different parts of the fish.

“One of the restaurants really wanted the guts to make a fermentation out of and these different things. So we’ve been able to find the restaurants that wanted a whole fish. It was a challenge, but now it’s paying off. Every single week, all our fish are sold.”

Deepwater Farms currently offers delivery to restaurants and distribution partners around Calgary. They want to concentrate on the market as close to their farm as possible, though they do have product delivered to areas such as Canmore, Banff and Lake Louise in Alberta.

A larger goal is to become the premiere supplier of baby greens and fresh sea bass in Western Canada, but Shumlich says the long-term goal isn’t to ship fish to wider areas from their Calgary site.

“We want to build farms all over the world, to expand nationally and internationally,” says Shumlich. “We’d like to see our farms in as many places as possible and addressing major food security issues. We want to export farms, not food.”

by Bonnie Waycott

Recirculating aquaculture systems (RAS) have been developing for many years and the extent of their adoption has been growing progressively, particularly in the hatchery phase. RAS can play a significant part toward the production of healthier fish in an ideal environment.

In traditional salmon farming, RAS is a valuable technology at the start of the fish’s lifecycle, when fry are kept in land-based tanks until they reach smolt stage (80 - 100g) before moving them to open net pens to grow to harvest weight of 4 to 5 kg.

There is a growing trend in the salmon farming industry to keep smolts in landbased tanks for a longer period of time, to decrease grow-out time in the ocean and reduce biological exposure. This can also cut the risk of parasites and disease, reduce the possibility of exposure to micro plastics, algal blooms and predators, and address issues such as escapes and untreated fish waste. It can also positively affect the valuation of companies, with less biological risk, predictable results and more stable production.

One organization that’s moving in this direc-

tion is CtrlAQUA, or Control in Aquaculture

Production, a center for research-based innovation that was established in 2015 by the Research Council of Norway. Its focus is on the first seawater phase, or so-called postsmolt stage, the most sensitive phase for salmon in the production cycle.

“RAS is a growing production technology for aquaculture because it uses very little water compared to traditional flow-through systems,” said Åsa Espmark, senior scientist at Nofima and director of CtrlAQUA. “It allows for more controlled water quality and makes aquaculture possible in places where access to water is limited.”

According to Espmark, the attention toward the development of RAS science and technology has increased. This is because there are multiple things to consider in such systems, such as biofilters required for cleaning the water, issues with salt/brackish water in the systems, and the differences in water quality requirements compared to flow through systems, he said.

CtrlAQUA’s research is carried out in the center’s Sunndalsøra RAS facility, which is home to 0.9m3, 3.3m3 and 107m3 tanks with a total rearing capacity of 1,100m3. Oxygen, pH, redox, water level, flow and temperature are monitored automatically, while 98 per cent of sludge generated is collected directly from the tanks and later in the loop by belt filters. Commercial feed (pellets) are given with belt feeders or spreaders in the facility’s largest tanks. All tanks are cleaned mechanically and chemically, with the majority of

farmers using peroxide-based disinfectants.

CtrlAQUA’s researchers focus on producing salmon up to 1 kg. Hans Bjelland, research manager at SINTEF Ocean AS in Trondheim, Norway, is supporting their work.

“If we can let salmon grow big on land before they’re transferred to sea, we can reduce the time spent at sea, from 16 to 18 months, to 10 months, which means we can also avoid the two most severe winter months,” Bjelland said. “Every third salmon that escapes does so during bad weather, and bad weather is more prevalent in winter.

CtrlAQUA is also investigating health and production efficiency in fish farming to produce smolt that can survive the transition to a more demanding, open sea environment, he noted. “We need even more robust smolt that can survive this, and the postsmolt stage will allow us to obtain them.”

Growing salmon on land before they reach a weight of 1 kg can significantly strengthen the fish’s robustness, health and well-being, according to Espmark.

“The main idea with post-smolt RAS fa-

cilities is that the longer you keep the fish on land, the less time you are exposing them to sea lice and the less risk there is of escapes at sea. With RAS, it’s possible to produce robust smolts because you can monitor and adjust water quality parameters to better control production,” she said.

Another benefit is the ability to capture and potentially recycle any nutrients contained in the sludge from tanks.

“However, it is difficult to conclude which is more financially viable: full grow-out or post-smolt,” she said. “Logically, it’s more expensive to keep the fish on land anyway, mainly due to energy costs. The cheapest, but unfortunately not the most sustainable, is to put the fish in open net pens.”

Jacob Bregnballe, sales director of AKVA Group in Denmark, and Jesper Lund, senior sales manager of Aquatec Solutions, a wholly owned subsidiary of AKVA Group, are firm believers in the potential of post-smolt applications in RAS. In 2017, Aquatec Solutions signed a contract with Tytlandsvik Aqua to

build a new post-smolt facility in the Hjelmeland municipality of Rogaland, with an overall tank volume in excess of 15,000m3. Aquaculture giants Grieg Seafood, Bremnes Seashore and Vest Havbruk then became part of the effort, and the new facility opened its doors in June 2019, capable of producing 3,000 tons of post-smolt each year for delivery to fish farms.

Hopes are high that the facility will raise harvest volumes of up to 100,000 tons in 2020, with the goal of better fish welfare and survival, lower environmental footprint per kilo, and lower costs.

“The facility has been designed with our unique Zero Water Change technology,” Lund said in 2017 when the project was launched. “In addition to more traditional recycling technology, further steps are included in water treatment that removes nitrate and phosphorous from the water. The greatest benefit of our technology is that it allows for full sterilization of the raw water that’s added to the facility. Today, a smolt facility manages enormous values, and it’s extremely important that we do everything

Rotron Regenerative Blowers offer a reliable solution for moving large amounts of air at low to medium pressures throughout your RAS operation.

Made in the USA and distributed globally to the aquaculture market by Sivat Services, these blowers include:

• Options for multiple electrical configurations and for extreme duty special coatings.

• Large line of accessories: intake filters, inlet/outlet mufflers, sound attenuation cabinets, pressure regulators, moisture separators and VFD’s

Invest in the best equipment for your RAS facility.

• Degas Towers • Sand Filters

• Fractionators • Pumps

• Bio Filters • UV Sterilizers

• Ozone Systems

• Instrumentation & controls

• Heating & Cooling

• Bead Filters • Valves

• Blowers and more!

www.sivatsi.com

in our power to maintain biosecurity.”

Extensive trials on the production of large, seawater-adapted smolts by AKVA Group customers have yielded promising results. According to AKVA Group, some trials have shown that land-based production of postsmolts in recycled seawater leads to less infection by sea lice, lower mortality and faster growth. The company is now hopeful that there will be further opportunities to optimise post-smolt production on land.

“Pre-ongrowing of fish in recirculation systems to reach larger sizes before releasing them into sea cages is a way of increasing profitability,” said Bregnballe. “Smolts are typically 100g today when released in cages. Increasing this figure, for example to 300g, will improve health and growth rates significantly, until harvest at market size of typically 4 to 5 kgs.”

The main point, he said, is that small fish grow faster than large fish. They gain more weight over the same period of time than larger fish, and convert feed at a better rate.

“Growing faster and utilising feed more

efficiently will lower production costs when calculated per kilo of fish produced. Postsmolt applications in RAS pay off because you can keep the optimal temperature at 14°C, the fish will grow by 2 to 3 per cent per day, and you›ll maximize production timewise.

“Not all fish produced can be small fish, so the potential for growing them is limited. But when discussing what to produce in RAS, the answer is small fish. It makes sense to invest money in that.

A

conversation with Sylvia Wulf, CEO of AquaBounty

With extensive experience in the consumer-packaged goods industry, Sylvia Wulf knows a thing or two about understanding and responding to the needs of consumers. Now at the helm of a company that is redefining sustainable food production through biotechnology, Wulf is taking AquaBounty and the world’s first genetically-engineered seafood – the AquAdvantage salmon – to full commercial production.

Wulf delivered the keynote presentation at RAStech 2019 in Washington, D.C., stressing the importance of RAS and biotechnology in solving the world’s growing food supply challenges.

RAStech caught up with Wulf in an exclusive interview where she offered her thoughts on RAS and the role of science and technology in sustainable food production.

RAStech: Could you give us an update on commercial production of your AquAdvantage salmon?

Sylvia Wulf: We will have two farms – Indiana (U.S.A.) is one, which is about a 1,200-metric-ton facility that we bought from Bell Aquaculture and have retrofitted. We have conventional or non-transgenic salmon being grown in that facility since last June. We expect to put our AquAdvantage salmon in by the end of (May 2019), so we will be growing those to market weight in Indiana.

We are just completing another grow-out facility that is 250 metric tons on Prince Edward Island (Canada). We will be putting AquAdvantage salmon into the pre-grow out area at the end of (May) as well.

We are not farming conventional salmon in Canada. So both farms will be producing AquAdvantage by the end of May.

Once we harvest the conventional salmon that we have in Indiana we will concentrate solely on AquAdvantage.

PEI is a grow-out facility. We are constructing a broodstock facility as well. It will have both a hatchery, grow-out and broodstock facility on Prince Edward Island. The grow-out facility will be completed in August. We have fish in the pre-grow out tanks by end of (May), and then the

broodstock facility we expect to complete sometime next year.

RAStech: It’s been a 30-year journey for AquaBounty to finally get regulatory approval for the first genetically-modified seafood in the market. What has been the learning experience throughout that last decade for the company?

SW: I think the journey has been the learning around the regulatory process for something that we’ve never done before. We are the first approved bio-engineered animal in the world. When we went to apply for approval, there was no process for that at the FDA (U.S. Food and Drug Administration). So we helped them create that testing protocol, all the research that was required – and similarly in Canada.

Because we started from scratch, the learning has been how to apply that process for other species, so we will be thinking about things like shrimp and trout, and others that can be genetically edited or modified.

It’s how we take our regulatory expertise and apply it to other products that will require approval.

RAStech: The success with the regulators is half of the battle for AquaBounty; the other half is winning over the public and gaining public support for what you are trying to do. What is your company’s strategy for changing the public’s perception about genetically modified seafood in general, and AquAdvantage in particular?

SW: The science is sound. The challenge is consumers don’t understand when scientists speak to us. We have the two leading regulatory agencies in the world who have approved this from a safety (perspective) – safe for consumer, safe for the fish, safe for the environment. And 20 years of research studies prove that safety. What we have to do is help consumers understand, not just that it’s safe, but the benefits associated with genetic modification. Because as I said yesterday, if we continue to limit ourselves to conventional methodology – wheth-

Customized for your fish farm, hatchery or research operation!

Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• De-gassing towers

• Wide variety of flow rates

• Flow control valves

• Protein skimmers

• Variable frequency-drive pumps

• Temperature management

a Novel Oxygenation System

• Low energy consumption by operating at low water pressure

• Designed for the demandoriented oxygenation of your fish tank

• Operation ready for new and existing farms

• Brings up to 6 kg/h oxygen –4.3 kg O2 /kW

info@aqua-sander.de Phone +49 5173 971 0

NOVEMBER 11–13, 2019

Tired of Gimmicks? Register now for our upcoming joint Commercial Aquaponics Workshop at Auburn University which includes a full day at Southern Organics, a commercial aquaponics farm! Visit AquaticED.com for more information.

NEW WEBSITE WITH ONLINE ORDERING New products being added daily! If you don’t see what you need, let us know. There is nothing we can’t source! Subscribe to our newsletter to receive updates.

er it’s with fish or crops or whatever – we’re shutting the door on being able to feed people and have a positive effect on the environment.

That’s the concern I have with the anti-GMO lobby. It’s that they don’t understand that the science is designed to solve global challenges; but when consumers understand the benefit of genetic modification and gene editing, they immediately get it because those global challenges are much more important. And as long as it’s safe, they’ll eat it.

RAStech: The aquaculture industry is being touted for having the potential to help solve the world’s food supply challenges and to do so in a sustainable manner. The AquAdvantage salmon is AquaBounty’s response to that challenge. As a pioneer in genetically engineered seafood, what insights can you provide for other companies intending to go this route?

SW: Number one. Make sure that your science is sound and that there is research to support that science. This is peer-reviewed by experts in the field that have no vested interest in our company. So, the first thing I would say is make sure that the science is sound. Make sure that the research is published. And then work with the regulatory authorities to make sure that they have what they need so that they can make an approval with confidence.

That’s the first thing. The second I would say is be active in engaging consumers, to help them understand why you’ve applied science to solve a problem. I would urge companies to think about the consumer benefits of this science that they are pursuing at the same time that they are building the data to ensure that it’s safe.

RAStech: How important is transparency for a company such as AquaBounty that is pioneering a consumer seafood product never seen in the industry before?

SW: I think transparency is going to be critical. When I think about recirculating aquaculture systems, one of the benefits to that is you have traceability and complete transparency. It really lends itself to the trend of transparency and traceability. So, we will be completely transparent with the consumers.

RAStech: You spoke about the potential of RAS for sustainability. What role do recirculating aquaculture systems have in your company’s overall objectives?

SW: The AquAdvantage salmon was really designed to grow in landbased RAS farms. Our fish was designed to operate in that kind of a system. And why we like it is because you can put them anywhere there’s good water and decent utility cost and you can locate them close to consumers. So it capitalizes on the local trend, it capitalizes on the transparency and traceability trend, and that’s the beauty, to me, of RAS. You are minimizing the impact on the oceans, whether it’s wild-caught or ocean cage farming, both of which are viable production methods but – and I am speaking about salmon specifically – if the demand for salmon far outstrips the supply, land-based RAS is the answer. You can locate it close to the population; positive benefits for the environment, positive benefits for the consumer. It really is the future.

RAStech: In your keynote presentation, you addressed the “Franken-fish” term, which some media reports have used to refer to the GMO salmon. Please expound.

SW: Anybody that has read the story of Frankenstein understands that what he was trying to do was solve a problem. And an uneducated mob killed what they deemed a monster. That, to me, is indicative of what is going on today because they don’t understand that the science is solving a problem. We need to educate consumers so that we don’t reject something that can really solve some substantial global challenges. So that’s what I mean by that. The more that consumers understand how science can be used the better off we are.

The genetic modification took place 30 years ago. We have been conventionally breeding with our breed of salmon. Salmon spawn, eggs get fertilized, we don’t continually genetically modify. We took a gene from a Chinook salmon and injected it into the egg of an Atlantic salmon. There’s 44,000 genes and we took one of a salmon. So, when you think about that, it’s not like we took a tomato and injected it into a salmon. We took a salmon (gene and injected it) into a salmon to help it grow faster and withstand certain conditions.

- Permanent PVC concrete form

- Maintenance free

- No paint or membrane required

- Low transportation costs

- PVC respects drinkable water requirements

- R-value insulation option to reduce energy costs. DC INTERNATIONAL 75 De Vaudreuil, Boucherville, Quebec Canada J4B 1K7 - Ph: +1 (450) 449-6400 www.dc-inter.com dctank@dc-inter.com

Since that point in time, we’ve been raising it just like you raise every other salmon. And I don’t think consumers understand that. We’re breeding AquAdvantage salmon with conventional breeding practices just like we do for any other strain of salmon.

My point is, we can’t allow ourselves to be afraid of progress and afraid of science. To me that was the key learning in Frankenstein. The fact that you don’t understand creates fear. Take the time to learn.

Adsorptech Pg. 20

Advanced Aquacultural Technologies Inc. Pg. 15

Aquacare Environment Inc. Pg.18

Aqua Logic Inc. Pg. 22

Aquanetix Pg.32

Aquatic Enterprises, Inc. Pg. 31