COLUMNS

Understanding

JEAN KO DIN

Understanding

JEAN KO DIN

By Jean Ko Din

It continues to be my pleasure to watch how this industry e volves into more parts of the world. I write this editorial in January and the year 2023 is still very much ahead of me.

The recirculating aquaculture industry, and the aquaculture industry at large, has had a difficult few years. Though I can’t say that the worst is behind us, I’m optimistic that there is much more to look forward to.

For example, our flagship event, RASTECH 2023 (April 20-21), is just visible on the horizon and I’m looking forward to the conversations that will take place in Orlando, Flo. for those few days.

I worked hard to pull together some of the most relevant and influential voices in all sectors of RAS. I want this event to offer the best of what this industry has to offer in research, in innovation, in business strategy and in experience.

And I hope I can do the same for the pages of this publication.

In this issue, I’d like to introduce our new editorial advisory board. Each of the five members of this board have been selected for their professional expertise and their shared goal of elevating the RAS industry in a collaborative spirt. For two years, they will serve as a trusted focus group of experts whom I can turn to for feedback and guidance.

It gives me, as editor, an enhanced assurance that the content that I curate for this publication continues to serve information that is relevant to RAS professionals. But at the same time, each of these members’ professional affiliations do not earn them any excep -

tion to the journalistic integrity and accountability of this publication.

My first responsibility will always be to deliver responsible and transparent information to you, the readers.

In this issue, we feature different voices from the industry, raising issues and sharing concerns, uncovering inspiration to solve and innovate, and a hopeful way to start out the new year.

Our cover story features InfiniteSEA CEO, Andreas Mäck, sharing his ambitions for carbon neutral RAS .

As Colin Ley writes, the surge in energy costs, which put RAS systems around the globe under intense economic pressure in 2022, “has been met with a strong response by the management team behind InfiniteSea, claimed to be the world’s first large-scale urban marine fish farm.”

In addition, this issue features Wanhe Qi, Ph.D. student at the Technical University of Denmark, investigating results of a new study which shows “a robust method with oxygen sensor to estimate the biofilter performance in freshwater recirculating aquaculture systems.”

And I had the honour of sitting down with Dianna Fletcher on RAS Talk , who shares Kingfish Maine’s experience of gaining social license in the town of Jonesport.

And just because you are not named as part of the core advisory board, does not mean you and your fellow readers have less opportunity to provide feedback and guidance to me and to the magazine. In every issue, I make a point to say that my inbox is always open for your ideas at jkodin@annexbusinessmedia.com.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Audience Development Manager Tel: 416-510-5113 Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Editor Maryam Farag 437-788-8830 mfarag@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Manager Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2023 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

SmartFlow connects all Vaki Smart Pumps, Graders and Counters for full overview and control of the fish handling system.

The Government of Norway put a freeze on approving permits for land-based aquaculture projects in the country.

The six-month moratorium is meant to allow its Ministry of Trade, Industry and Fisheries enough time to develop new regulations that will consider advancements in land-based aquaculture. Current regulations were created when there were clear distinctions between sea-based aquaculture and land-based aquaculture. These regulations do not take into account hybrid systems.

For instance, Salmon Evolution’s land-based fish farm in Indre Harøy, uses a hybrid flowthrough system.

“There has been significant technological development within concepts that seek permission for aquaculture production on land... We see that there is a need for clearer frameworks for what is to be considered aquaculture on land, as opposed to aquaculture in the sea,” fisheries and oceans minister Bjørnar Skjæran said in a press release.

There are several pending applications for land-based aquaculture projects are awaiting processing in Norway, according to a report by the aquaculture publication, Fishfarming Expert. Companies that have applied are those using recirculating aquaculture systems (RAS), flow-through systems, or those using hybrid systems. Previously there were some applications were given to “concepts with close connection to the sea,” according to publication.

“When permission is given for aquaculture on land for a facility with a close connection to the sea, such facilities can affect the sea and sea-based breeders’ opportunity for growth within the traffic light system. For the sake of the environment and other farming activities in the sea, it is important that we avoid this,” said Skjæran.

- NESTOR ARELLANO

NESIC Land Aquaculture Co. Ltd., which is part of NEC Networks & System Integration Corporation, recently celebrated the completion of its recirculating aquaculture system (RAS) facility in Yamanashi Prefecture.

The Fuji Katsuragawa Factory is NEC’s first large-scale commercial land-based salmon farming facility that will also deploy the company’s information and communications technology.

“We will contribute to the local economy in Yamanashi Prefecture through employment and sales of salmon produced at this factory,” a press release from the company said.

“In addition, by deploying this factory as a model of a digitized land-based aquaculture farm both in Japan and overseas, we will contribute to the resolution of

social issues such as preserving the marine environment and food problems.”

The facility covers 4,000 sq. m and currently has the capacity to produce 500 tons of salmon per year.

NEC said that it plans to introduce juvenile fish sometime in January next year.

In 2021, NEC also partnered with Indian aquaculture construction firm, King Infra Ventures, on a shrimp RAS proof of concept that will employ networking, sensors, artificial intelligence and Internet of Things technologies.

NEC Corp. is a US$28 billion IT and electronic company based in Minato, Tokyo. It is one of the growing number of Japanese companies that are investing in aquaculture.

- NESTOR ARELLANO

It’s all systems go for Gold River Aquafarms, a recirculating aquaculture system (RAS) company based in British Columbia, Canada, after it received an aquaculture permit from the country’s Department of Ocean’s and Fisheries (DFO).

Gold River Aquafarm’s (GRA) C$100-million (US$74.3-million) project aims to build a 3,000 metric ton RAS facility for raising steelhead trout. When completed, the facility will be Canada’s largest land-based fish farm, according to the company.

The facility will be built on the site of a decomissioned paper mill. GRA said it saved $15 million in capital by repurposing the mill infrastructure, including several large warehouses as well as water and power systems.

GRA also said the facility also has the potential to expand capacity to 15,000 metric tons by building into an adjacent property.

“We began the planning for this project three years ago

and have already done a lot of engineering and survey work to get to this point,” said Rob Walker, president of GRA. “Our application for regulatory approval was filed on February 2021 through FrontCounter, B.C. and we are delighted to now have the permit in hand.”

GRA says it hopes to boost the economy of the village of Gold River by helping create other start-up venture opportunities for local entrepreneurs.

Michael Mott, mayor of Gold River, said his office looks forward to working with “an environmentally responsible and sustainable industry.”

- NESTOR ARELLANO

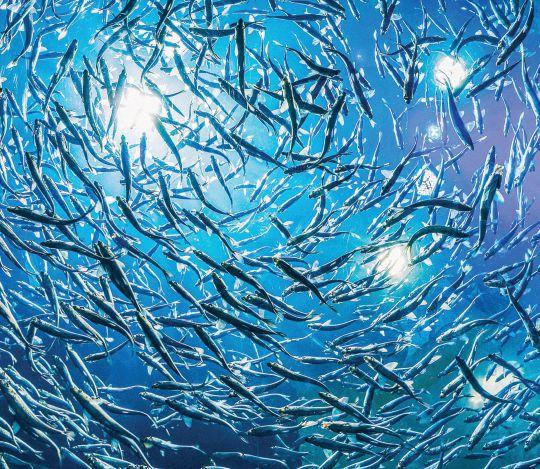

Typically a mere 25 to 50 millimetres long and its schools of young growing in coastlines and estuaries, whitebait are a tender and tasty delicacy eaten head, tail and all in various parts of the world. However, whitebait consists of fry of important fish species such as mackerel, bass, and sardines. Their harvest is not considered ecologically viable.

A New Zealand-based aquaculture company, named Manāki Whitebait, aims to change all that by building the first land-based facility designed to sustainably grow whitebait. Manāki Whitebait is owned by Tahu Whaoa Group Holdings.

The company reported that it has just come one step closer to its plans to develop a year-round commercial supply of whitebait

while helping protect the local species. Its pilot project launched at the Bluff’s Ocean Beach in Southland.In New Zealand.

Whitebait are the juveniles of five of the countrys most precious native freshwater fish: inanga, kōaro, banded kōkopu, giant kōkopu and shortjaw kōkopu.While the adult fish live in freshwater, whitebait hatch and spend the first 12 weeks living in the ocean. During their time in freshwater whitebait swim upstream to grow into adults.

The giant kōkopu, which can grow up to 45 cm in length and live for more than 20 years, is considered “vulnerable and decreasing” on the International Union for Conservation of Nature red list,” according to Manāki.

- NESTOR ARELLANO

Canadian-based steelhead salmon grower, Taste of BC Aquafarms, has submitted to the country’s Department of Fisheries and Oceans for a recirculating aquaculture system (RAS) salmon farm.

The proposed facility in Campbell River, British Columbia will have an estimated annual production of 1,500 metric tons of head-on-gutted steelhead salmon.

The proposed site is co-located with a local distillery and barley farm. The company said the 380-acre site features abundant freshwater with capacity for

future expansion. The farm will operate with zero discharge off-site by capturing the water and nutrient discharges from the facility to fertilize adjacent crops.

The facility will use Taste of BC’s module-based RAS. Construction is anticipated for spring 2023 with an investment of approximately C$35million (US$26 million).

Taste of BC Aquafarms is a subsidiary of Miami-based Blue Star Foods Corp.

In a press release, Taste of BC managing director, Steve Atkinson, said his com-

pany’s plans complement the federal government’s current strategy to transition to land-based aquaculture.

“Salmon farming is a vital part of our economy here on Vancouver Island and we look forward to being a major part of its future. This is the first of several farms we intend to build,” he said.

“Our current facility in BC has proven our technology, growing salmon since 2013 and harvesting since 2014, with an annual target of 100 metric tons. This new proposed facility will be built in modules essentially replicating what our team has done successfully over the years,” according to John Keeler, CEO of Blue Star Foods.

An aquaculture start-up planning to build Sweden’s first large-scale, land-based salmon farm has secured SEK 530 million (US$50.6 million) in funding from the lending arm of the European Union.

The European Investment Bank (EIB) reported this week that it has agreed to release the money as a venture debt investment on Re:Ocean (formerly Premium Svensk Lax) which plans to build a land-based fish farm in Säffle, in the woodlands of Värmland, Sweden.

The Säffle facility is expected to be in full production by 2025. The facility will have a production capacity of 10,000 tons of fish per year.

The land-based salmon farm,

employing cutting-edge zero-water circulation technology, according to a press release from EIB. As much as 99.999 per cent of the water is said to be used in the facility in a closed environment. The facility will also use fossil-free energy for power.

“Not only will Re:Ocean’s new facility provide the Swedish population with domestically and sustainably produced salmon, but it will also do so in an innovative and climate-friendly way, employing cutting-edge zero-water circulation technology. In addition, food supply has become an important part of the critical infrastructure of any economy and the Säffle salmon facility will strengthen Sweden’s food self-sufficiency and resilience,” said Thomas

Östros, vice-president of EIB.

Swedes eat an average of 12 kilograms of fish per year. Currently, Sweden imports nearly all of the salmon consumed in the country.

“The EIB investment is a strong signal of trust and a cornerstone for other investors in our new, sustainable food production concept, and a result of 12 months close cooperation,” said Katarina Klingspor, chair of Re:Ocean. “This process also verifies our team’s and partners experience within the industry, our highly advanced solutions and new technology, that will enable consumers to enjoy clean, healthy locally produced salmon while safeguarding our environment.”

- NESTOR ARELLANO

By Maddi Badiola

Maddi Badiola, PhD, PM, is a RAS engineer and co-founder of HTH Full Spectrum (fullspectrumaquaculture.com; HTHaqua.com) in Basque Country, Spain. Her expertise include energy conservation, lifecycle assessments and RAS global sustainability assessments. Email her at mbadiolamillate@gmail.com.

We are living in the era of technology, however, it may be coming to an end.

One lesson to be learned is that the marketplace for online communications, entertainment, and news media has never been and doubtfully will ever be stable, and the most powerful players can be dethroned, power is (luckily) limited.

Russia’s invasion of Ukraine was the most important happening of the Year 2022. Nobody – except maybe the government intelligence departments – would have ever imagined that this could happen. Millions of Ukrainians were crossing the borders and running to safety, fighting and surviving with no food, heat, electricity and/or water. The rest of the world began to react to “the first truly global energy crisis, with impacts that will be felt for years to come” due to price volatility, supply shortages, security issues and economic uncertainty (International Energy Agency, IEA).

Nevertheless, the myriad consequences of an ongoing global energy reboot means there may be some positive developments, too.

The IEA defines energy security as the uninterrupted availability of energy sources at an affordable price. “What a joke!” many of you would say to this. The high energy bills for households have created the debate around turning on the heat or eating protein.

Big companies have reduced their working loads to reduce energy costs, and not to mention that many small businesses have shut down because they are not being able to overcome increasing operational costs.

Putin’s threat to shut off Russia’s oil and gas pipelines is pushing another global rethink about energy security. Nevertheless, experts suggest that the crisis in Ukraine is not the main driver for the unprecedented increase in gas prices, but rather a result of a continuing trend to scale back production among oil producers (i.e., produce less at a lower cost to get high returns). This is mainly driven by the need of their power to run the world, or in any case the fear of losing it.

Energy security is about diversity in supply, to have the ability to substitute one supply easily and quickly for another. The inevitability of a growing shift away from hydrocarbon toward more sustainable energy sources is making the powerful people realize that their power might become limited.

How has all this has affected the RAS aquaculture industry? It seems obvious that the industry has been impacted for higher energy prices and the change of trade flows and supply shortages.

One of the particularities of RAS is the need for power 24 hours, over 365 days of the year and if the cost of such increases with no increase (or even decrease) on sales, the math is clear.

I come from a region (the Basque Country) where the average fish consumption is one of the world’s highest, 37.2 kilograms of fish per person, per year. However, in the last two years, this has been depleted to around 32. Families cannot afford to eat fish as the prices go up due to the need of producers to survive. So, yes, this situation has affected the RAS industry.

But, Charles Darwin, with his evolution theory results, said, “Weaknesses become virtue, failures are opportunities.” This situation will make the industry think twice about energy and power consumption. It must push companies toward renewable energy sources and total monitoring and efficiency of the systems.

High investments due to high-tech systems and feed costs have always been setbacks of the industry, but with time, we are seeing that all passes through energy. Existing RAS companies should rely on energy audits to increase their efficiencies and to build systems that look for renewable energies as its main (but not the only) energy supply. In the variety is the spice!

Fish is the most sustainable animal source protein food produced. In parallel, RAS is the most sustainable way of producing it. Should not these two statements be enough to focus on improving the efficiency and limiting the power of energy on RAS? I leave the answer for discussion in RASTECH 2023 in Orlando, FL, U.S.

By Colin Ley

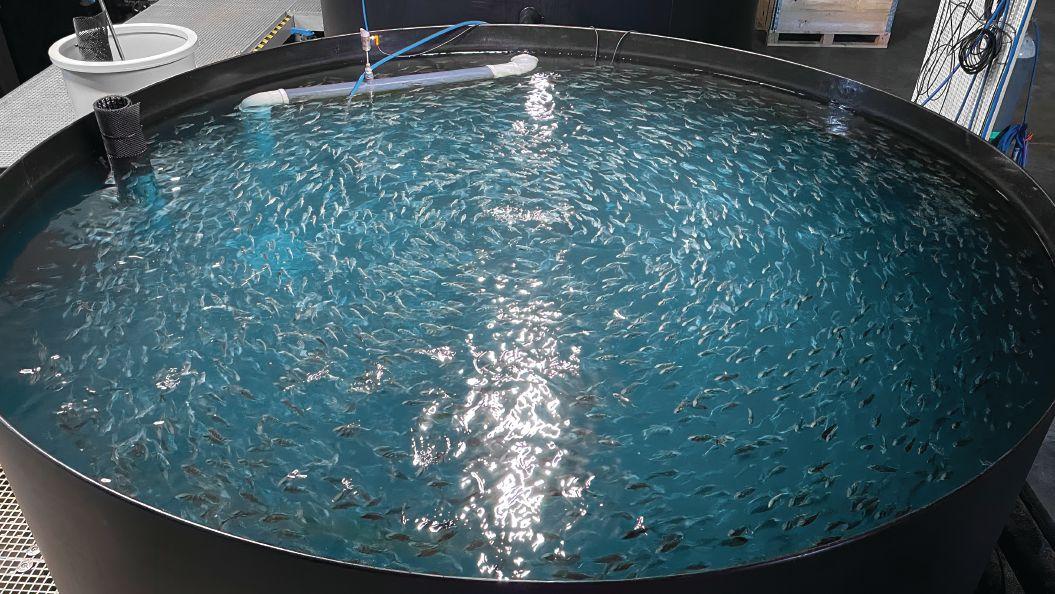

The surge in energy costs, which put RAS systems around the globe under intense economic pressure in 2022, has been met with a strong response by the management team behind InfiniteSea, claimed to be the world’s first large-scale urban marine fish farm.

Located at Völklingen in the middle of Germany, a very long way from the nearest ocean, the InfiniteSea business is 12 months into a redevelopment programme which will ultimately see the company’s RAS structure producing 800 tonnes of Yellowtail kingfish and amberjack annually.

The venture will be deemed a success if that level of output is delivered at a markedly lower energy-toend-product ratio than many RAS systems have traditionally achieved. In addition, with the farm progressively benefitting from its “state of the art” energy consumption, the business will also become economically profit-

able, which is always the ultimate goal.

“Working with other companies in the past I’ve been aware that energy consumption within RAS systems is generally relatively high, often running at six kWh per kilo of fish produced, or more,” said Andreas Mäck, CEO of InfiniteSea, to RAStech Magazine . “While this level of energy usage hasn’t been a major issue in the past for businesses in regions with low electricity costs, such as the north of Norway, it’s a totally difference equation in central Europe, especially following the recent price rises.”

Prior to joining InfiniteSea in 2020, Mäck was part of a research team at the German aquaculture technology company SENECT, a specialist manufacturer of fish farming equipment, with a strong commitment to the development of new RAS technology.

Recognising that a high energy/output ratio is one of

the major economic bottlenecks attached to RAS systems globally, he became involved with SENECT colleagues in a three-year production efficiency project.

Funded by a grant from Germany’s Federal Ministry of Economic, the project was launched in 2018, long before Russia invaded Ukraine.

Today, of course, with the impact of the war in Ukraine resulting in an 11-fold increase in energy costs for InfiniteSea during 2022, lessons learned during the efficiency project are being

put to good use as part of the redevelopment of the Völklingen enterprise.

“Our objective here is to examine all the different aspects of our existing RAS structure to ensure they are each working at optimum efficiency, very much in line with the core aspects of the SENECT-based project,” said Mäck. “This includes energy usage, which has become an increasingly important consideration for us over the past 12 months.”

Key focus points to date have involved seeking

improvements in the Völklingen unit’s water treatment processes, adaptive control systems, drum filters, degassing procedure, and more.

“We began by establishing a small pilot unit consisting of three 2-cubic-metre tanks,” he said. “These were stocked with Arctic Char, a deliberate choice of species which allowed us to avoid running into output limitations caused by high stocking densities.

“Across our work so far, we have seen that the farm’s energy consumption can be reduced by 20-50 per cent, despite continuing to use already developed technology.

“Admittedly, some RAS equipment suppliers claim that one kWh per kilo of fish is achievable, but I’ve never seen

that sort of performance being delivered under real commercial conditions, and I’ve visited several ‘low use’ operations to look for myself.”

Adding that many such ultra-low energy claims possibly fall into a :marketing category,” Mäck agreed there were several non-design/non-technology reasons why RAS-based units have an energy/output imbalance which doesn’t add up in terms of saleable fish production.

“Our own business here, for example, was built to produce 600 tonnes a year, but it never reached even half of that figure,” he said. “A similar gap between potential capacity and achieved commercial output is no doubt being repeated elsewhere, resulting in an industry average which is nearer 50-60 per cent of the expected production capacity than we’d like to admit as a RAS community.”

Clearly not content with their own site’s limited production, as recorded in the past, the management and ownership team behind InfiniteSea embarked on a total system rebuild in 2022, aligned with the goal of equipping the site to produce a total of 800 tonnes of Yellowtail kingfish and amberjack a year.

“Having gone back to basics in order to start again, we had to settle for an output of just 50 tonnes in 2022, all of which was kingfish,” said Dr Mäck. “We’re currently on schedule to install a

capacity of 400 tonnes this year, however, and are well placed to achieve 800 tonnes in 2024.”

Achieving their longer-term production goal will be governed by emerging equipment supply challenges, of course, with one ordered item already subject to a 52-week delivery date, imposed by the provider.

“Progressing through the rebuild in annual steps, however, has given us an easier ride on energy costs so far than would otherwise have the case,” he said. “At the point when the first major surge in costs took effect, for example, we were only utilising about one quarter of our site so only had one quarter of our previous energy requirements to fund. While our costs will inevitably rise as output builds, we are at least able to plan ahead and adjust our systems in line with the farm’s energy efficiency goals.”

The Völklingen site already benefits from being well-equipped with solar panels, a resource which covers all the farm’s core electricity needs during daylight hours, after which the unit switches to night-time grid supplies.

“As for our further planned efficiency steps, we’re working on improvements to the control system which drives the entire RAS structure,” he said. “We’re also looking to reduce our reliance on aeration, which requires a lot of energy

input and which we believe isn’t the way to go in the future, or at least that it can be done better than is currently being achieved.

“Another major focus is degassing, which is highly demanding in energy and cost terms. By using adaptive control algorithms, we’re convinced that our degassers can be operated much more effectively than they have been to date. As for the question of how much

energy in total we can save once the redevelopment is complete, we’ll have a positive answer once we hit our 800-tonne target.”

No matter how difficult managing the individual parts of the Völklingen rebuilding programme may prove to be, however, the idea that rising energy costs could prevent RAS technology from having a role in the future of fish farming, isn’t even being considered.

“Moving away from RAS, either as a business or an industry, isn’t a realistic option,” said Mäck. “The current rise in energy costs is obviously asking questions of the sector which haven’t been faced before, at least not to the present extent. As an industry, however, there is no way we can even begin to question whether or not the RAS approach to fish production in general has become too expensive.”

Pointing out that net pen fish farms are not necessarily low energy operations in themselves, taking ship and barge infrastructure into account, he added that a typical RAS structure could

also have greater renewable energy po traditional RAS benefits linked to dis “The challenge, therefore, is to fine

Utilizing

Wanhe Qi, is a Ph.D. student at The Technical University of Denmark, DTU Aqua. His Ph.D. project, “Bacterial activity in biofilm from RAS”, is part of the RASHealth project, led by the Norwegian food research institute Nofima.

By Wanhe Qi, Nofima

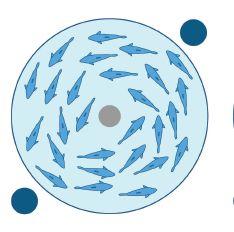

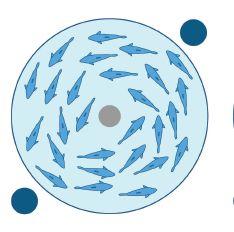

Results of a new study show a robust method with oxygen sensor to estimate the biofilter performance in freshwater recirculating aquaculture systems (RAS). The method is based on the use of oxygen sensor to monitor oxygen consumption rates of biofilter elements.

RAS are an indoor aquaculture system and operated under controlled environ-

mental conditions. Water in RAS is recycled and reused after a series of water treatment processes with mechanical and biological filtration, disinfection, oxygenation and degassing. With the advantages of high-degree water reuse (>90 per cent of the culture water), reduced waste discharge and shorter transport distances to the markets, RAS are regarded as an environmentally sustainable system for fish production.

Land based aquaculture using Permastore’s Glass-Fusedto-Steel bolted tanks is quite possibly the most economic and sustainable solution for fish farming - due the durability and longevity of Permastore’s tanks.

Permastore offers solutions, with storage typically ranging from 150m3 to 28,500m3 with capacities that can exceed 50,000m3 or 13,200,000 US Gallons.

In RAS, biofilter is a fundamental water treatment unit and plays an important role in maintaining sufficient water quality for fish growth with the help of biofilm. Biofilm is defined as the aggregates of microorganisms that are attached on the surface of biofilter elements. Microorganisms need carbohydrates, fats, proteins, metals, and vitamins to survive, just like fish. By taking advantage of the features of microorganisms, the undesirable nutrients in

RAS water for fish, such as ammonia and nitrite, can be removed or converted into their non-toxic form by biofilm.

Hence, biofilter performance is an important parameter for monitoring, operating, diagnosing and managing biofilter. It is generally evaluated based on ammonia or nitrite concentration decrease rates, which are obtained through feeding known concentration of ammonia or nitrite to the sampled biofilter elements.

For instance, to get information of biofilter performance in terms of ammonia removal, the bio-elements collected from RAS biofilter were placed in a batch reactor following ammonia spike. Then, the reduction of ammonia in the batch reactor over time reflects the ammonia removal performance of biofilter. However, this method is time-consuming and laboratory equipment required. It seems unsuitable for on-site application in a RAS facility. Instead, both processes are oxygen-consuming processes. That means they require oxygen for reactions in the ammonia and nitrite removal pathways and for respira-

tion. By means of this, biofilter performance in RAS might be also assessed through monitoring the oxygen consumption following ammonia or nitrite spike.

In their study, researchers developed a custom-made platform equipped with oxygen sensor, which allows high throughput, non-invasive oxygen measurement without disturbing biofilm integrity. The method was tested with three different commercially available bio-elements from moving bed biofilm reactors in a common freshwater RAS, and is compared to the general method for biofilter performance assessment.

Results showed the biofilter performance evaluation with oxygen sensor was in satisfactory accordance with the values from substrate degradation batch kinetic tests for all three tested bioelements, confirming the feasibility and robustness of the developed method as a means to assessing biofilter performance.

The developed method can potentially be used to quantify the impacts of relevant biotic and abiotic conditions on biofilter

performance in RAS, such as salinity changes, disinfection, increased feed loading, altered flow, etc. Furthermore, the proofof-concept platform proposed can be miniaturized to reduce the sample volume and be easy to carry, which shows promising prospect for lab analysis and industrial application.

The study was carried out by researchers at the section for aquaculture, DTU Aqua, Technical University of Denmark in the RASHealth project, led by the Norwegian research institute Nofima. The work was funded by the Research Council of Norway, Young Research Talent Program. The application of this method is being validated at Nofima RAS facilities in Tromsø in collaboration with Nofima researchers. More results are expected in 2023.

More information of the study can be found in the peer-reviewed Aquaculture journal. The study was titled “Estimation of nitrifying and heterotrophic bacterial activity in biofilm formed on RAS biofilter carriers by respirometry” and published in December 2022.

U.S.-based RAS shrimp producer, NaturalShrimp Inc., is making plans for a proposed merger with black check company to support further plans of expansion.

According to a press release, Texasbased NaturalShrimp plans to merge with Nevada-based Yotta Acquisition Corp., founded by Hui Chen.

Yotta Acquisition Corp. will issue 17.5 million of its common shares (current valuation of US$175 million) to the security holders of NaturalShrimp. In

addition, the stockholders of NaturalShrimp are entitled to receive an additional five million common shares (worth approximately US$50 million) based on achieving certain revenue targets for 2024 and five million common shares (worth about US$50 million) based on achieving certain revenue targets for 2025.

NaturalShrimp recently announced the launch of its online ordering, home delivery program and e-commerce website, www.naturalshrimpharvest-select.com. The online retail store includes fresh harvested heads-on

shrimp, unique NaturalShrimp sauces and spices, recipe books, and instructional videos for the home cook.

“This launch creates a tremendous opportunity to further our mission to provide the freshest shrimp and seafood to local markets everywhere,” said Gerald Easterling, CEO of NaturalShrimp.

“This direct-to-consumer expansion diversifies and complements our commercial distribution strategy including our planned U.S. facility expansion, partnership with U.S. Foods, South Texas area, and the continued success of our live shrimp sales program.”

Dianna Fletcher shares Kingfish Maine’s experience of gaining social license in the town of Jonesport.

By Jean Ko Din

Kingfish Maine will soon break ground on its 94acre, land-based recirculating aquaculture system (RAS) facility for growing Yellowtail kingfish (Seriola lalandi) in Jonesport, Maine. The company’s journey to permitting has not been easy, but it was well-earned through consistent communication with its local supporters.

Dianna Fletcher, communications consultant to Kingfish Maine, was a recent guest

to the RAS Talk podcast where she talked to co-hosts, Jean Ko Din and Brian Vinci, about how gaining social license became key to the company’s success.

RAS Talk: Can you give us a quick summary about Kingfish Maine’s last hurdles of the permitting process?

Dianna Fletcher: Yes, I’m thrilled to say that we have received our building permit from the Jonesport Planning Board. And that’s really the last piece of the puzzle that

was needed for Kingfish to move ahead with construction of the site in Maine.

We have all of our state and federal permits. We’ve worked on those over the past couple of years. And you know, it’s been a rigorous process, as it should be, for a project of this size. And all of that involves a lot, or I should say, more than a whole lot. It’s constant contact with the community and community building. And clarifying and educating the public about what’s going on with the project. So, this has been a huge step that we’ve just received. I’m very excited.

RAS Talk: One of the reasons we wanted to invite you onto the podcast is to learn more about how Kingfish Maine captured the industry’s attention last July, as it faced a proposed aquaculture moratorium. Can you give us a bit of background of what happened there?

Fletcher: First, the great news is that we won and that the aquaculture moratorium was defeated. But in terms of when it was introduced in Jonesport, it was to look into putting a six-month moratorium on any aquaculture projects that were before the town and the town planning board.

And when that was brought up, of course, we were a little surprised. But for us, we doubled down on our effort in our community relations. Since 2019, when Jonesport was first selected as a site for a main location,

we had already been working with the community. We’ve actually had 25 plus, different types of meetings with the community –whether it was Coffee with Kingfish, educational library sessions, or going to the fire station during the pandemic, socially-distanced, to meet with people. So this has been ongoing public outreach.

When the aquaculture moratorium was introduced to the town for a vote, we really doubled down on our efforts to take that misinformation, directly talk about it. We reached out to people who had questions about what that misinformation was, what were some of the lingering questions about our project in the community.

And the end result was, it was the largest voter turnout ever for the town of Jonesport for an election or a town meeting. This was during a town meeting. And the community defeated the aquaculture moratorium in a two-to-one one vote, 201 to 91. And it was really a clear message from the residents that they wanted aquaculture projects to come into the community for economic development. And it was a very, very clear, and I

think a very decisive message that was sent to the town and to the opposition groups, as well.

RAS Talk: When did you come on with Kingfish Maine?

Fletcher: In 2019, when their search was underway, I was working with a nonprofit economic development group in the State of Maine that helps businesses who are looking

to locate in the State of Maine whatever it may be, not just aquaculture, but different types of industries. I had met Kingfish through this company and was able to travel to Jonesport and meet with some of the groups there, as well.

And then we actually put together that meeting, which was the end of November, in the local library. I can distinctly remember all of the holiday decorations in the library and it was all ready for Christmas. It was standing room only, people coming in with the town leaders. They had their focus group they had first work with, but then we invited the whole town to come in and hear about the project.

At that meeting, they had an informal straw poll to see who was interested in learning more and moving forward, and every single person in the room raised their hands, with the exception of two.

RAS Talk: You’ve been in Maine long enough to see some of the other projects proposed and go through various trials. Do you think there’s any common thread with

Smarter, stronger, more economical drum filters

The Hydrotech Drum Filter Value series focuses on reduced maintenance, increased component quality and simplified operation – all to give your plant maximum filtration performance at a minimum operational cost.

Let us help you!

Call +46 (0)40 42 95 30, or visit www.hydrotech.se

those other projects that that have had some trials? What are some of the things that you think you’ve seen that the projects need to absolutely do to be as successful as Kingfish?

Fletcher: Every project is very different, and every community is very different. I can just tell you from my own our own personal standpoint for the Kingfish team, asking Jonesport if they can be part of that community was really the first step. Each community has a different way of communicating. And I will say that in Jonesport, it’s face-to-face communications. Yes, we have a supporter email list where I’m constantly talking to our supporters, but they want to see you in-person. During the pandemic, we had to make find ways to make that happen in socially-distanced areas.

So I think that it’s just constant communication, transparency, being open about the process from the very beginning. And also, just being connected to the community in any way you can.

I talked about kind of the Lunch and Learns that we did, the Coffee with Kingfish. We also work with the high school on an aquaculture program. In 2020, we brought in a 400-gallon mini RAS system for the students at the high school to raise fish. It turned into an aquaponics program the next year. This year, that class harvested the fish, used the vegetables from the aquaponics program, and made fish tacos for the entire school. That is a service that we are giving to the high school and working with the high school. So that’s another touch point that we’ve had over

the past couple of years.

So, I think to answer your question, what can projects do? Community involvement is important is required as part of the state permitting process in the state of Maine to have these public hearings, but really, constantly be part of the community and be open to their questions and their concerns.

RAS Talk: Are there some ‘don’ts’ you could also recommend?

Fletcher: One thing we really have avoided is we do not have a Facebook presence, because the questions that arise are very technical. Something like that can’t be drilled down to a Facebook post.

For us, if folks in the community have questions about our project, and very specific questions, we want to answer those faceto-face, or in a phone call, or on a zoom call, rather than ask a question on Facebook, because it’s technical. I mean, I’m sure both of you realize how easy that can devolve when it’s on Facebook, when you can’t really get to the meat of what you’re talking about.

So I think there’s one tip I have, that was my one of my big things from the very start. During the state hearing process – part of the permitting is that we have to do public hearings - we post it, let them know that we’ve filled our permit and that we have a set date for a public hearing. We had COVID, we had the pandemic, and we we’re in the midst of it. And so, we were told by the DEP (Department of Environmental Protection) that we could just do this online but that wasn’t good enough for us.

We knew that not everybody in that community felt comfortable going online to listen to our presentation, so we did a socially distanced public hearing in the town’s fire station. The chairs were six feet apart, everybody was wearing masks, and we did it online, as well. We realized that, at least for that community, that the way that people really want to connect is in-person. And that was very important for us.

RAS Talk: Do you have any best practices for how projects might address misinformation or anti-aquaculture sentiment?

Fletcher: For us, we had been through the process over the past two years of being completely transparent. Talking about the project, it did not change from the start. But we decided to take on the misinformation head-to-head. We would have those informational meetings at the library and we would have a PowerPoint presentation that says, “This is what you’ve heard. This is in fact false. And this is why it’s false.” And we would go step-by-step on each and every piece of myths, misinformation that was out in the public.

This actually helped bring more supporters to us because it was a matter of distorting facts, at least that’s what the opposition is doing. And the people who sat in those meetings, understood everything completely as we were spelling it out. We also launched a Jonesport Fish Facts website, where it was just basically, these are the facts about our project in bullet points, make it as simple as possible. And that was very important to do as well. And we would have handouts at all of the meetings, as well.

High Volume Oxygen has introduced a new oxygen generator that is modular and designed for critical applications.

The Pro Plus Oxygen Generating System is the company’s new product. It is designed to enable higher pressures and increases litres-perminute (LPM) output while prioritizing ease of use and reliability. The system is cloud-enabled to provide monitoring and notification features that can be accessed on the company’s Seeing Eye web platform on any web browser.

The Pro Plus has a touchscreen display with real-time information, configured with wifi. When equipped with the new TITAN compressor, the

tank can be pressurized up to 175 psi / 12 bar, and store as much as 3,600 litres of oxygen while providing flow rates of up to 280 LPM / 10 CFM / 17 m3/h.

Accompanying the Pro Plus, High Volume Oxygen has also launched the new 5-Outlet Smart Relay. This device remote controls a bank of oxygen concentrators and sends this data to the cloud. It is designed to energize individual outlets using a configurable delay to prevent breaker switches from being tripped. It also

features an on-board audible alarm to signal amperage and temperature out-of-range conditions. www.highvolumeoxygen.com

Luminis Water Technologies launched a range of microbiome sampling kits designed for sample collection and storage anywhere in the world.

The sample would be sent in to the Luminis lab for Next Gen sequencing and AI-driven metagenomic analysis. Results can be ready within two days.

The AquaGENius kit works with both freshwater and seawater samples. The SwabGENius kits can sample guts, biofilm, K1 media, lesions and more.

Final client reports include species-level information about seven areas: microbiome imbalances, biodiversity, cyanobacteria, probiotics, pathogen species present and overall load, algae and parasites.

Microbiome analytics provides risk management, diagnosing mystery problems, early disease detection, water body planning, optimising inputs, and testing quarantined stock for pathogens and diseases.

The microbiome forms the foundation of health in all aquatic settings. By

We

Customized for your fish farm, hatchery or research operation!

Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• De-gassing towers

• Wide variety of flow rates

• Flow control

• Protein skimmers

• Variable frequency-drive pumps

• Temperature management

Adsorptech has repackaged and improved the process efficiency of its EcoGen VPSA Oxygen Generator product line, capacities of four tons per day and larger.

The EcoGen generator model redesign helps offset some of the past two years’ high component, labour, and shipping inflation.

According to Adsorptech, the EcoGen power efficiency was already globally best in class, and the current technology development increases power efficiency another 10 per cent, achieving 0.75 kW/100 cubic foot, 0.28 kW/Nm3, of product. www.adsorptech.com

From Curtis Crouse, The Freshwater Institute

Feed and feeding management programs can encompass many components and considerations including feed formulation, ordering logistics, proper storage, and feeding procedures. Ultimately, the success of a feeding program hinges on striking the balance between under and overfeeding to maximize fish growth and prevent excessive waste.

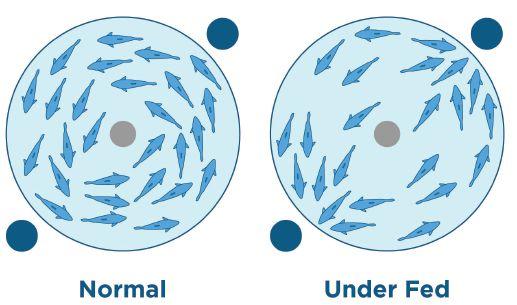

Many feed vendors provide guidance on appropriate pellet size and ration for different size fish reared at different temperatures. These recommendations are a helpful starting point when beginning to offer feed to a newly stocked tank of fish. Careful observation of fish behaviour between and during feeding events can uncover key signs to help culturists fine tune the feed ration.

One key observation to make is the positioning of the fish in the culture tank. Assuming good water quality and health, satiated fish should be spread evenly around the culture tank. Underfed fish are likely to crowd around areas of the tank where feed is introduced or stack up underneath feeders waiting for the next meal. In this case, the next step is to determine why the fish are exhibiting this behavior. The solution may not be as simple as increasing the feed ration. Watching fish as they mouth feed pellets can provide important clues to the suitability

of the feed. For example, fish spitting pellets back into the water and ignoring them could indicate a problem with palatability stemming from factors including diet formulation or improper storage.

In this case, check expiration dates or try feed from another lot number if available. Spitting paired with head shaking or gill flaring behaviors and continued attempts at the spit pellet could indicate that the pellet size is too large for the fish ingest. In this case, continue feeding a smaller pellet and mixing the two pellet sizes when transitioning to a larger size.

With feed suitability confirmed, observing a feeding event can inform decisions to increase or decrease the feed ration. When feed is introduced to the tank, satiated fish should continue to hold even spacing throughout the tank and exhibit normal swimming behavior while capturing feed pellets as they come into range.

Near the end of a feeding

event, fish should begin to ignore feed and a few waste pellets may fall to the bottom of the tank. If early into a scheduled feeding event fish are ignoring feed pellets and allowing them all to pass to the bottom of the tank, they may be over fed. In this case, culturists may need to reduce the feed ration to prevent waste. Fish that rush to the surface of the water or circle back several times against normal swimming direction to capture pellets, especially near the end of a feeding event, are likely underfed and need their ration increased.

More extreme behaviors such as fish breaking the water surface or non-bottom feeding fish retrieving feed from the bottom of a tank indicate a larger discrepancy between ration and appetite. Not only is this detrimental to optimal growth but can be stressful or cause injury to the fish. These extreme behaviors could be a sign of other problems.

For example, a failed or

underperforming feeder or user programming errors could result in the equipment delivering less feed than expected and a growing appetite in the tank. To check if this is the case, collect and weigh the feed released from a feeder for a known time interval and compare it to calculations in the feed control programming.

Additionally, inadequate feed distribution around the tank or feeding at too fast of a rate could lead to capture issues where feed drops to the bottom of the tank faster than the hungry fish can consume it. In this case, increasing the ration will not help and a better feed delivery approach would be necessary. Try slowing down the feed rate, adding more feeders or daily events, or broadcasting the feed over a larger area of the tank.

At the conclusion of a regularly scheduled feeding event, fish should theoretically be satiated. This is a great opportunity for culturists to hand feed additional pellets to gauge the feeding response of the fish and make final decisions on feed ration size. In some cases, it is necessary to withhold feed from a tank for sampling, moving, or harvesting. When reintroducing feed, behaviours typical of underfed fish are expected to be on display. These events are a great opportunity to familiarize oneself with typical underfed behaviors to identify and correct them if they are observed unexpectedly in the future.

APRIL 20 – 21, 2023

JW Marriott Orlando, Grande Lakes I Florida, USA

Whether it’s raising fish juveniles, smolt or full-harvest size, this event covers the latest innovations and research in Recirculating Aquaculture Systems (RAS) technology. Learn more from global RAS experts and network with your fellow RAS operators, designers, engineers, contractors, consultants, researchers and investors.

Engage with over 80 RAS technology & product providers in our trade show and listen to the latest product showcase presentations.

Come on a RAS Farm Tour!

Increase tank capacity and yield with Linde technology for aquaculture. Our SOLVOX® oxygenation systems work in both saltwater and freshwater to create a healthier environment for growing fish. Our range of low-maintenance dissolution and distribution solutions outperforms traditional air-based systems, providing better efficiency, utilization, and hydrodynamic conditions inside the tank. Linde experts can develop a system customized to meet your specific needs. Contact us today.

lindeus.com/aquaculture