By Mari-Len De Guzman

One of things that have changed for many of us in the industry over the last year due to the global pandemic is the way we are now interacting with our peers, locally and globally.

The cancellations and postponements of industry events all over the world have caused us to rethink our communication strategies. Just as masks and social distancing have become a social norm, technology-enabled remote work and virtual interactions have emerged as the new productivity model.

Many perhaps have silently hoped that 2021 will be the year that things “go back to normal.” But with vaccine roll-outs across countries still many months – if not years – away from reaching general populations and achieving herd immunity, and with new COVID-19 variants lurking and threatening to wreak havoc if left unchecked, it’s looking like we would have to contend with the new norm for a little while longer.

For the most part, virtual interactions and remote connections have managed to deliver a level of effectiveness. Zoom calls are now a daily occurrence. People are having more face-to-face communications now, albeit digitally, than ever before. Meeting schedules are now paired with Zoom or Skype invitations. I’m not complaining (well, maybe I am, a little) but whatever happened to just picking up the phone?

Perhaps that need for a face-to-face conversation through virtual meetings,

rather than a simple voice call, is an indication of our inherent need for connectedness. Human beings are not cut out for isolation. Connectedness and human interaction are essential to psychological and emotional well-being.

Imagine a world with no Internet capability, no way to connect virtually, in the midst of a global pandemic. Isolation and social distancing will be a much challenging feat. The ability to connect and communicate virtually through technology has made this global health crisis just a little bit easier to navigate.

This is also how our team at RAStech is able to put together some pretty amazing virtual events that allow us to provide you with great content, through webinars, virtual roundtables, and yes, virtual conferences. This year, we are putting together a trio of virtual events designed to create a venue for the industry to connect and learn through a content-rich, interactive platform. Check out our news story on page 6 to learn more.

And so we forge ahead and work with the tools we are given. Many, if not all of us, are at this point probably missing the humming and buzzing of a tradeshow or being able to sit in on a presentation and learn something new. I know I do. There’s something quite exciting about the impromptu chats and the chance meetings that lead to great story ideas. For certain, we will be able to get back to that again someday. Hopefully it will be soon. For now, see you at the next Zoom meeting.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquires or changes, please contact Urszula Grzyb, Audience Development Manager Tel: (416) 510-5180 Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Mari-Len De Guzman 289-259-1408 mdeguzman@annexbusinessmedia.com

Associate Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Coordinator Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Connecting RAS professionals virtually throughout 2021

Presented by

Join us for a series of live virtual events throughout 2021 that offer opportunities for learning and networking with the RAS community. With both live and on-demand speaker presentations and panel discussions, as well as a virtual tradeshow highlighting the latest in RAS technologies and systems, this trio of virtual events is a must-attend.

Learn from subject matter experts, connect with RAS and aquaculture suppliers and immerse yourself in this content-rich, interactive platform. The RAS Connector Series is the online venue for some much-needed networking and engagement with your industry peers.

Register early to reserve your spot for this one-of-a-kind virtual event series!

For more details and to register, visit: rasconnectorseries.com

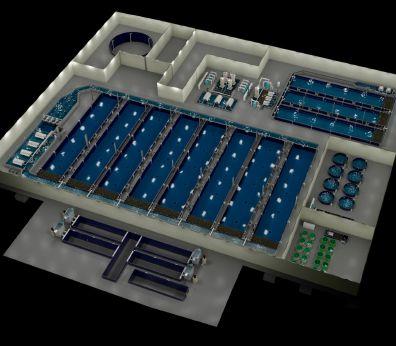

Construction of Norway-based Proximar Seafood’s RAS facility in Japan has commenced, according to the company’s RAS technology provider AquaMaof Technologies Ltd. Proximar aims to raise about 26,000 metric tons of Atlantic salmon in Yama, close to Japan’s famed Mount Fuji volcano. The facility is also less than two hours trucking distance from the country’s two largest cities, Tokyo and Yokohama.

The constructions comes after a lengthy design stage whic the AquaMaof and Proximar teams have been collaborating on since 2016.

Joachim Nielsen, chief executive officer of Proximar expressed gratitude for AquaMaof’s support and said his company is confident that the construction stage “will be carried out at the same level of proficiency that characterized the design stage.”

Earlier, Proximar initiated a private share placement valued at US$47.3 million to finance the construction project in Japan.

“We would like to congratulate the Proximar team on a successful IPO,” David Hazut, chief executive officer of AquaMaof, said in a press release. “We are pleased and honoured to kick-off the construction stage and to continue to support the Proximar team on their visionary mission.”

The facility will include a hatchery, nursery, full grow-out area, as well as management, operational and processing zones.

The continued uncertainties and varying levels of travel restrictions related to COVID-19 have led organizers of the RAStech Conference and Tradeshow to move the event date from Nov. 3-4, 2021, to March 30-31, 2022. The location, at the Westin Hilton Head in South Carolina, remains the same.

Sponsors and attendees who have already registered will be rolled over to the new RAStech 2022 conference.

Conference host Annex Business Media, which publishes RAStech, Hatchery International and Aquaculture North America, has made the decision to postpone the 2021 conference to March 2022 to ensure the health and safety of staff, attendees, sponsors and exhibitors.

“The COVID-19 global pandemic continues to bring significant challenges for hosting in-person, live events,” said Mari-Len De Guzman, editor of Hatchery International and RAStech, and part of the event organizing committee. “As much as we recognize the value of face-to-face networking with industry peers, the health and safety of all attendees is our topmost priority. We are looking forward to welcoming all professionals in the RAS sector in March 2022.”

With the postponement of the RAStech Conference and Tradeshow, Annex Business Media is hosting three, must-attend virtual events in 2021. Dubbed the RAS Connector Series, these virtual events include the following:

RAS Investors’ Forum – June 9 RAS Roundtable Discussion – Sept. 14 RAS Virtual Summit – Nov. 3

For the first time, RAStech is bringing together RAS investors, designers and producers in a one-day online event on June 9 that focuses on the opportunities, risks and the future of land-based aquaculture. Whether you’re an investor looking into this exciting and emerging sector or a producer and designer with a great business case, this virtual event will surely be an opportunity to engage and talk about the business of RAS.

“Networking is where it’s at and Annex’s new virtual event platform gives industry suppliers and attendees this ability,” said Jeremy Thain, associate publisher, about the new system for the RAS Connector Series. “Everybody will be able to interact with each other in real time. Exhibitors can engage new customers, sponsors can increase their visibility, attendees can learn more about a variety of RAS-related topics and presentations. Our RAS Connector Series is going to be where industry comes to meet.”

The RAS Roundtable, to be held on Sept. 14, will feature a panel of industry experts and thought-leaders, and the opportunity to engage with them in a meaningful discussion about the state of the industry, the challenges and the prospects for the future. More details on this and the RAS Virtual Summit on Nov. 3 will be made available soon.

Find the latest turf-related news, stories, blogs and analysis from across Canada, and access our forum . . .

www.rastechmagazine.com

Fish farm and fishing company Leroy Seafood is looking to enter the land-based aquaculture sector with a recirculating aquaculture system (RAS) in western Norway.

In its 2020 fourth quarter report, the company announced its planned RAS project in Kjærelva, Fitjar. The first module will deliver six million smolt of 160 grams. The second and third module will deliver 500-gram to 1,200-gram smolts.

“The third module may also be used for growing fish to full harvest weights,” the report said.

Total capital expenditure for the three modules is estimated at NOK1 billion (US$116 million).

The report said construction may be finalized in 2023.

The company also reported profits fell from US$91.1 million in Q4 2019 to US$65.3 million in the final quarter of 2020.

“The global pandemic COVID-19 has a negative effect on demand and has resulted in lower prices for both redfish and whitefish,” the report said. “Weaker price achievement is the most important reason for lower earnings in the fourth quarter of 2020 compared with the same quarter last year.”.

Jeremy Thain appointed as new associate publisher

Annex Business Media, publisher of RAStech magazine, has promoted Jeremy Thain to associate publisher for the firm’s aquaculture group of publications, including RAStech, Hatchery International and Aquaculture North America

Thain started his media sales career in 1999 in the fisheries and aquaculture division of the Oban Times Group in Scotland, where he is originally from. In 2004, he moved to Victoria, B.C., Canada, where he joined the team at Capamara Communications, then

NaturalShrimp is moving to buy Hydrensis Aquaculture LLC to acquire the company’s innovative water treatment technology. The company, which pioneered recirculating aquaculture systems (RAS) for shrimp production, has signed a letter of intent (LOI) to acquire the aquaculture assets of Hydrenesis for US$12.5 million.

NaturalShrimp “intends to immediately begin deployment of the technology in our hatchery and nursery systems,” said Gerald Easterling, NaturalShrimp CEO. “We expect to file additional patents around the expansion of the application and use of the combined EC (electrocoagulation) and Hydrenesis technology.”

Easterling said that the Hydrenesis technology “will have major impacts on disease control” in established and growing aquaculture segments such as salmon,

publisher of Hatchery International and Aquaculture North America. These publications were later acquired by Annex Business Media in 2017, and Thain remained as the advertising manager following the acquisition.

“Jeremy is a proven media professional, with an excellent reputation in the industry and a strong desire to make his publications even stronger,” said Todd Humber, group publisher.

In his new role, he looks forward to implementing more of his ideas to the benefit of his aquaculture industry colleagues, while further developing the growth of Annex’s aquaculture division.

barramundi and tilapia farming.

Hydrenesis’ technology uses a form of reduction-oxidation (Redox) which produces an electro-chemical reaction that reduces harmful metals in water. The technology increases oxygen levels in the water and produces a supportive environment that reduces stress levels in fish and shrimp.

“We have been exploring the application of ‘Redox’ water treatment for several years,” according to David Antelo, CEO of Hydrenesis. “Our technologies’ ability to affect water chemistry and elevate water quality is proving to have a significant impact on growth and health metrics.”

He said NaturalShrimp is “the ideal partner for extending commercialization of Hydrenesis technologies to additional species applications.”

Jeremy Thain

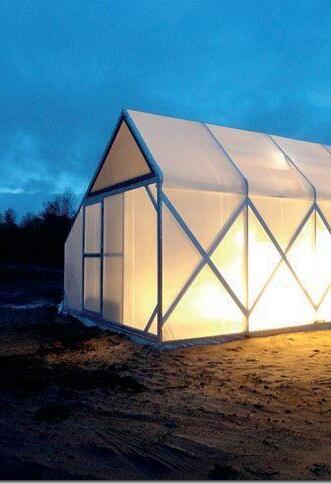

The University of Waikato Macroalgae Research Facility in Tauranga, New Zealand, has officially opened its new Facility of Aquaculture Research of Macroalgae.

The cultivation research facility is focused on the development of sustainable technologies to enable the production of marine and freshwater macroalgae for biomass applications. This will ultimately deliver on New Zealand’s national targets to diversify the local aquaculture industry.

The university partnered with Fresh By Design (FBD) to supply and build the new facility using recirculating aquaculture system (RAS). The system is comprised of two identical, bespoke algae research systems for both fresh and saltwater use. These are all housed in locally sourced greenhouses using reverse cycle heat pumps for temperature control, according to information obtained from FBD.

The RAS facility will primarily grow freshwater alga Oedogonium and sea lettuce ( Ulva lactuca ), and will conduct research on the uses of the produced biomass, with focus on incorporating algal bioproducts for human and animal health and nutrition, as well as plant health and biostimulants and other materials.

“Fresh by Design were engaged at the vision conception stage to provide preliminary guidance which progressed to high-level design, engineering and construction for all the RAS and greenhouses,” said Chris Blake, from the university’s Entrepreneurial Universities Macroalgal Biotechnology Enterprises Programme. “Their expertise was critical when working with all other contractors to make effective decisions on the wider building, plumbing and electrical requirements to support the RAS systems.”

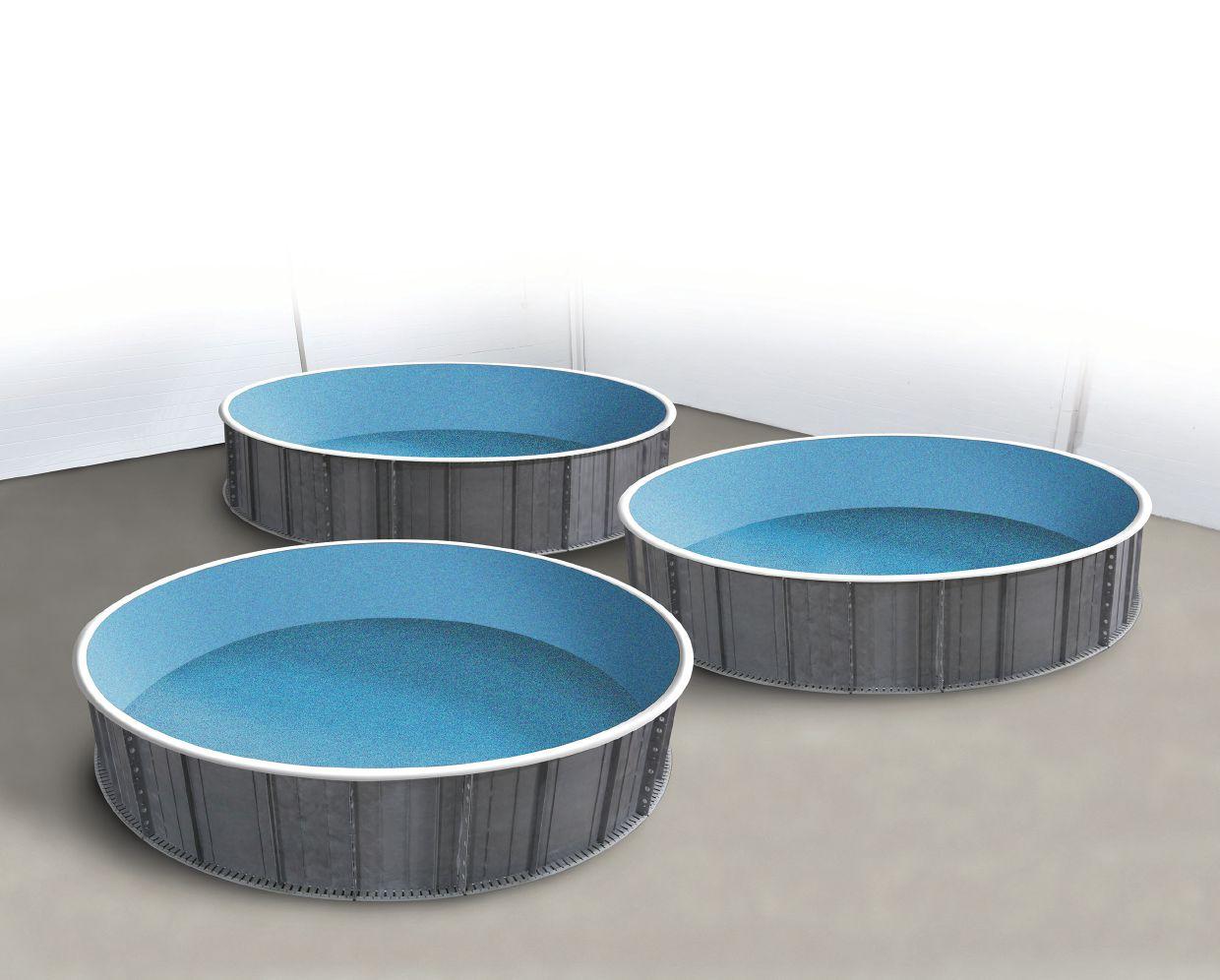

The facility has two RAS systems, each one containing six 7,000-litre high-rate algal pond tanks from Ajay

Fiberglass, and six 1,000-litre Duraplas tanks.

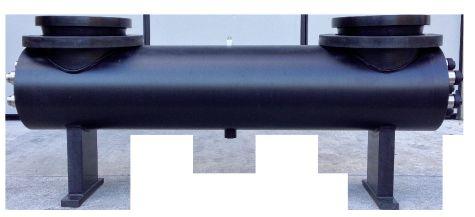

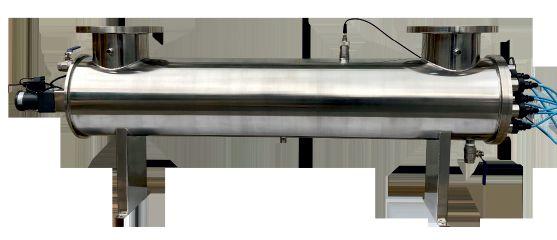

These systems include: direct CO2 control via FBD injection systems with PID control; RK2 foam fractionators; Ultra Aqua UV systems; Waterco Aquabiome filters, media filters with AFM media; Waterco pumps including built-

in and stand-alone Vacon VFD control for the main system pumps; FSI bag filters; Oasis heat pumps; and FBD oxygen cones.

The system also required a dual intake water treatment system for saltwater and freshwater – also allowing for input of various sources of wastewater to test treatment and remediation options, FBD said. These intake systems include Devan storage tanks, dechlor-

ination systems, Ultra Aqua UV units and Waterco media filters and pumps, along with bypass options.

The system is monitored and controlled via dual OxyGuard Pacific units (supplied by Technolab) measuring a number of sensors, including pressure, flow meters, pH, salinity, temperature along with ultrasonic measurement of levels in sumps and storage tanks.

Other key project partners included Aotea Electrical, Hawkins, Greenstone Group, Water Solutions and Technolab. A high level of locally sourced products were used – chillers, pumps, filters, storage tanks and sumps – along with local installation expertise.

“FBD remained proactive and solutions orientated throughout the process, which included a partial redesign building method late in the project whilst also navigating COVID-19 restrictions to get the RAS systems built and operating between May and July 2020, even though key FBD staff could not be onsite, instead utilising remote project management. We appreciate their ongoing support with the project and would be happy to work with them again,” Blake said.

AquaBounty Technologies has completed its first harvest of the genetically modified AquAdvantage salmon at its Indiana RAS facility.

“This is an incredibly exciting moment, 26 years in the making... Our first round of harvest will go on today and throughout this week,” said Sylvia Wulf, AquaBounty president and chief executive, during a virtual press conference on Feb. 23. “We are now in, or soon to be in, commercial production.”

Wulf said the company aims to produce 100 metric tons of its AquAdvantage-branded salmon from its Indiana facility. Wulf said there are “lots of inbound interest” about the fish from distributors and customers.

The company is also raising the GMO salmon in another land-based farm in Rollo Bay, Prince Edward Island in Canada.

AquaBounty initially planned to begin the first harvest of the fish in late 2020.

“The impact of COVID pushed it from December to now,” said Wulf. “But it turned out advantageous to the custom -

A German pioneer in recirculating aquaculture system (RAS) shrimp production says that its recent acquisition by private capital firm Rigeto Unternehmerkapital of Munich will pave the way for its bid to target new markets.

“We have achieved important milestones in the establishment and operation of our land-based shrimp farm, as well as in brand building and establishing longterm customer relationships,” Dr. Fabia Riedel, founder of Crusta Nova, said in a press release.

“With Rigeto, I have the right partner at my side to expand on the growth we have initiated and to now take important steps

ers and the fish.”

The company’s AquAdvantage fish program is based on a single, specific molecular modification in fish that results in more rapid growth in early development compared to conventional salmon. This means the company has the potential to raise fish to market weight in less time than its more conventional competitors.

In 2018, as AquaBounty was introdu -

cing the fish to the public, the company sold five tons of AquAdvantage salmon fillets in Canada. Yesterday, Wulf once more spoke to allay fears around AquAdvantage and said it is “safe, secure, and sustainable.”

Wulf also said the company is in the “final stages of its due diligence” in choosing a location for its second large fish farm in the United States.

in the areas of new target markets, product range expansion, digitization, and expansion of sales and marketing, among others.”

Riedel will continue to hold a significant stake in the company as managing partner.

Crusta Nova, which was founded in 2012 and based in Langenpreising, Germany, produces 30 tons of sashimi-grade

vannamei shrimp per year.

The company’s saltwater shrimp are raised in a closed system in eight breeding tanks.

Crusta Nova’s strategy involves building its land-based aquaculture operation, growing its wholesale B2B business involving retailers, and selling directly to consumers in a B2C model.

The walleye (sander vitreus) is a prized freshwater sports fish in North America. The white-meat fish also enjoys a reputation as an outstanding food fish. Now, an aquaculture startup based in Minnesota plans to develop a “sustainable, highly intensive” production of the species using recirculating aquaculture system (RAS) technology.

Walleye production in the United States has mainly been done using outdoor pond-type facilities. Blue Water Farms aims to build indoor RAS tanks to grow the fish.

Clarence Bischoff, founder and chief executive of Blue Water Farms as well as founder and president of the Minnesota Aquaculture Association, said the company intends to build the RAS facility in Red Wing, Minn.

“The immediate mission of Blue Water Farms is to develop a sustainable, intensive system for

production of walleye for the food market that is flavorful, nutritious, and affordable,” according to the company. “The satellite sites will also include the production of plant products using a decoupled aquaponics system.” The planned facility will also include a hatchery and processing site.

“Since we are introducing walleye to the seafood market from a RAS, we need to have a hatchery, and from the hatchery, the fish go to the growth facilities,” said in an interview with the

Brainerd Dispatch.

In December last year, the Minnesota Department of Employment and Economic Development (DEED) released US$746,295 in award money to help local startups grow, according to Kevin McKinnon, deputy commissioner of economic development for DEED.

Among the recipients was Blue Water Farms which received US$31,500.

By David Kuhn

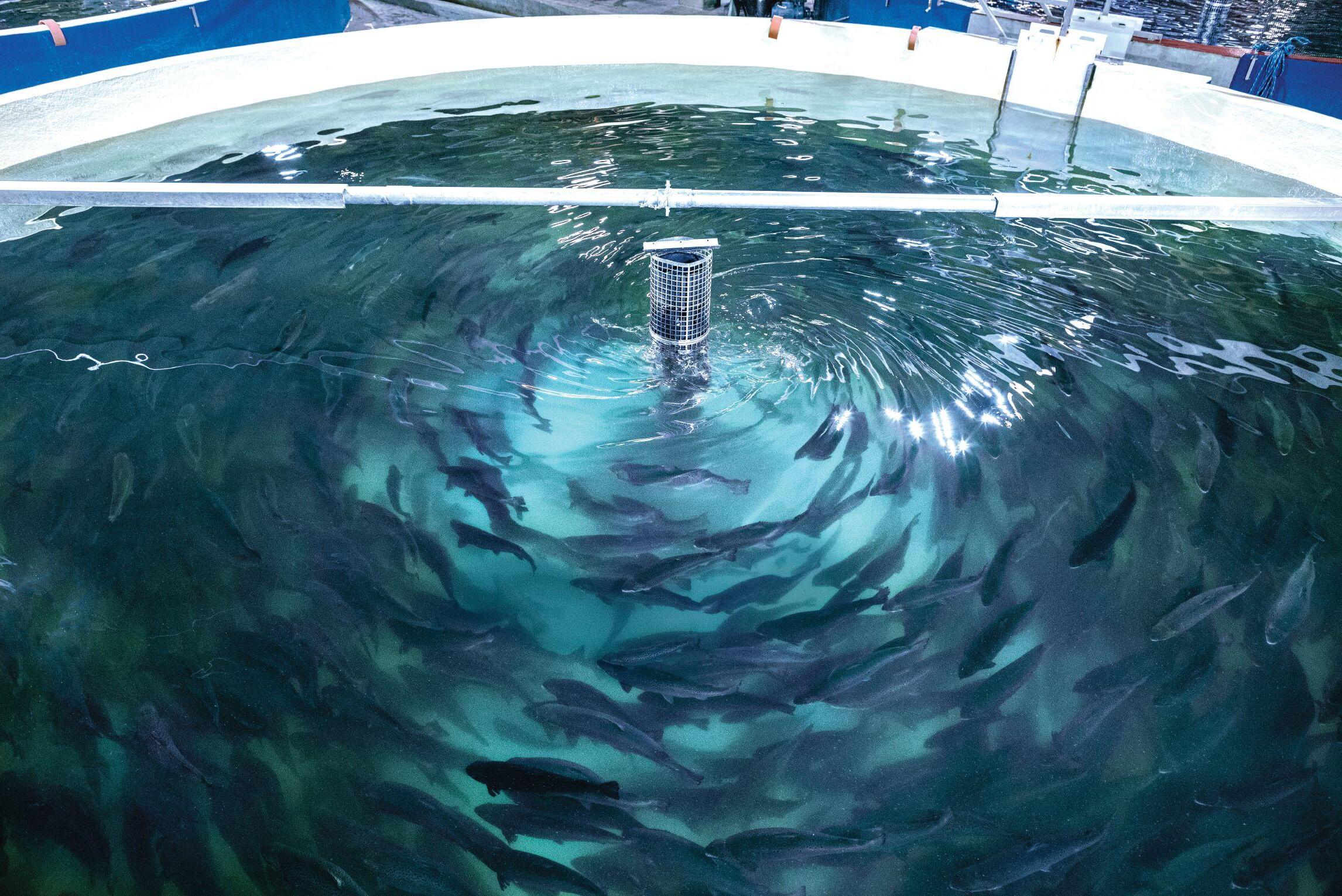

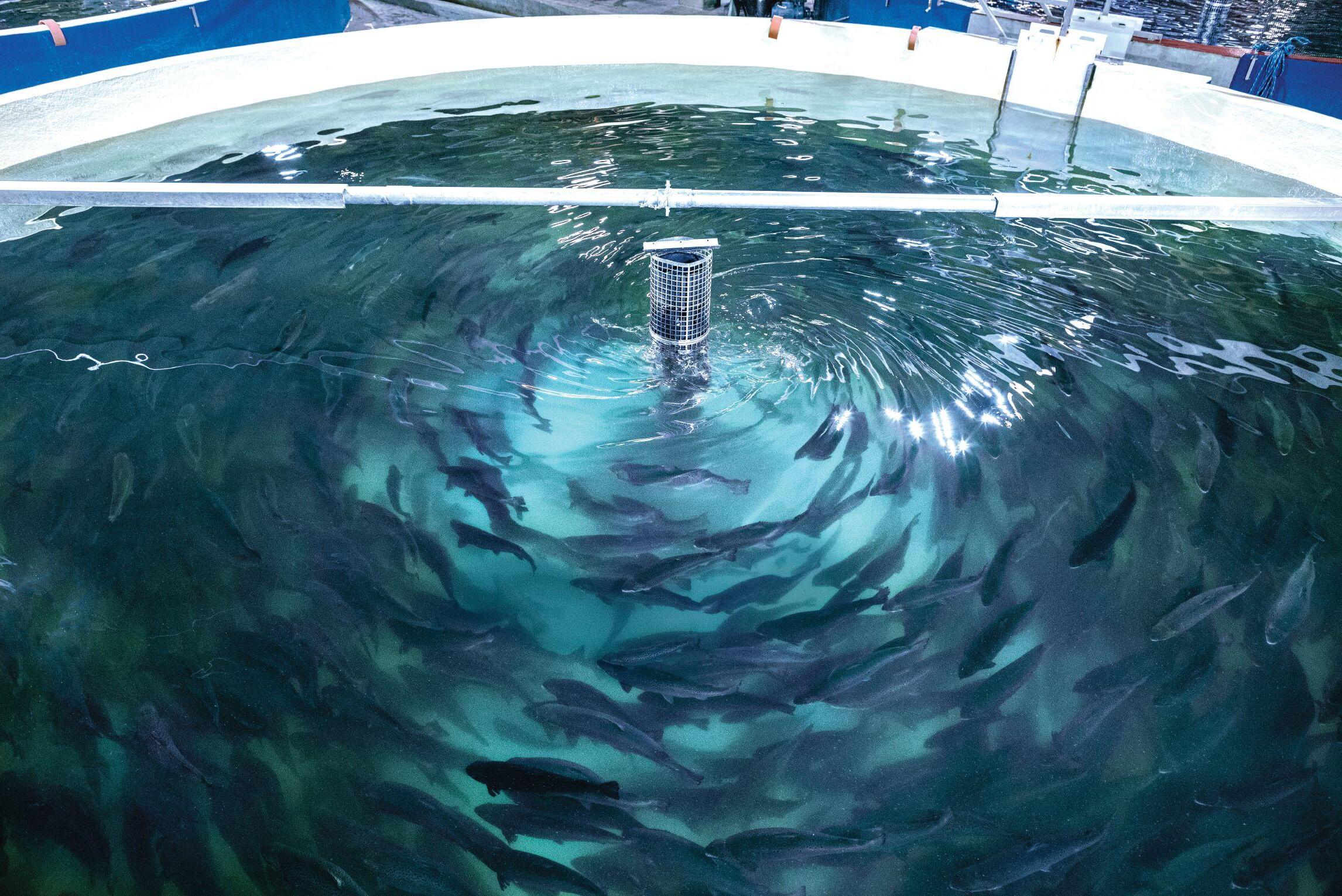

Implementing recirculating aquaculture systems (RAS) to raise fish and shellfish is an excellent strategy for maximizing water reuse while minimizing wastewater discharge. The first thing to understand is how RAS and water quality are managed. Since fish and shellfish that are cultured in RAS live in their own waste, the water needs to be consistently and constantly filtered to improve water quality. Good water quality is critical for animal welfare, health and production. Unsuitable water quality can be detrimental to the animals and the bottom-line in any aquaculture venture.

There are countless ways to design and operate a RAS successfully but they all have the same general unit operations. Solids filtration is used to remove suspended solids, uneaten feed and fecal material, from the water column. Examples include settling basins, radial flow separators, filter socks, centrifuges, bead filters and rotary drum filters. For the proteins and the smallest of suspended particles, these can be removed using protein skimmers. The efficiency of this foam fractionation process proportionately increases with the level of salinity or salt in the water. In addition to fecal material, fish and shellfish also excrete urine, other metabolites, and molecules that contain phosphorus. Toxic ammonia is converted to less toxic nitrate using biological filters such as moving bed biological reactors, trickling filters or other process units such as bead filters that contain a large surface area for beneficial nitrifying bacteria biofilms to form. Lastly, aquatic animals respire. The resulting carbon dioxide needs to be stripped from the water and oxygen is simultaneously added back using aeration, water agitation, or direct oxygen delivery.

It is critical for any aquaculture facility to have a properly designed and operated RAS

to ensure healthy animal production while providing a conditions that is conducive to a healthy wastewater management plan.

The goal of RAS operators is to minimize water reuse by approaching zero water discharge. As a system approaches zero discharge, there are several waste products that accumulate and end up being the driving forces for water renewal, replacing a volume of water discharged from the system with new water. The two primary driving forces for water renewal are the accumulation of solids in solid filters and nitrate in the water column.

Solids will accumulate during normal RAS operations in solid filters. Each filter has a unique limit of how much accumulated solids it can handle. Filters that use settling as a mechanism will experience an increase in solids or sludge in the bottom of the tank. If the level of solids gets too high, the efficiency of the settling process will decrease significantly and toxic gases, such as methane, can be emitted from anoxic zones within the sludge into the water column.

Accumulated solids also have to be removed from bead filters using backwash cycles and scraped off the screen of the rotary drum as part of their routine operation and maintenance. Regardless of filter type, solids need be discharged from the RAS on a regular basis. Since these solids contain a notable amount of water, the operator is also discharging wastewater.

Nitrate accumulates in RAS as the bio-

logical filter cannot oxidize nitrate any further. It is normal to see nitrate concentrations in orders of magnitude higher than the more toxic forms of nitrogen (i.e. ammonia and nitrite) in RAS water. Nitrate toxicity varies greatly across aquatic species of fish and shellfish. For example, some marine species of finfish might be negatively impacted by 30 mg/L nitrate. Meanwhile, many freshwater species of fish can handle over 100 mg/L nitrate.

Similar to solids, as an operator of a RAS approaches zero discharge, nitrate levels will accumulate to higher levels at a faster rate. Nitrate is typically reduced by using water renewal as the primary method. All or a fraction of required water renewal amount is achieved while also removing excess solids from the RAS filters.

Aquaculture wastewater comprises of water and solids that are high in organic material, nitrogen and phosphorus. It is important to characterize wastewater for levels of suspended solids, total nitrogen, total phosphorus, pH, salinity (total dissolved solids) and ash, as well as for dissolved concentrations of ammonia, nitrite, nitrate and orthophosphate. If discharged directly to the environment it can cause great harm. Another important factor is to understand the volume and schedule of when you need to discharge wastewater. These factors combined will provide important informa-

tion, termed loading rates, that will help drive an aquaculture facility’s wastewater management plan.

The location of the aquaculture facility is critical for determining how to manage its wastewater. More specifically, what resources are available and what the local environmental regulations are.

If land area is not a constraint, a properly designed constructed wetland can be used to treat aquaculture wastewater. Wetlands use various natural processes to treat or “clean” aquaculture wastewater: quiescent pools allow suspended solids to settle out, wetland vegetation remove nitrogen and phosphorus from the water column, and organic matter can be assimilated or oxidized to carbon dioxide via naturally occurring microbes in the sediment.

If the site is located in a town or city, there may be an option to work with the local municipal wastewater treatment plant by discharging aquaculture effluent directly (or after some pretreatment) into the sewer system. Since aquaculture wastewater is different in composition compared to the typical wastewater it receives from the town

or city, they will need to make an assessment to determine whether or not they can receive it. For example, if the effluent water is from a marine RAS it will contain a lot of salt and if the wastewater treatment plant is not large enough, it may not be able to receive the aquaculture wastewater as the salt will disrupt the freshwater biological processes and could be catastrophic for its overall operations.

If discharging aquaculture wastewater to a municipal wastewater treatment plan is not an option, then alternative engineering strategies can be implemented. One strategy is to use biological reactors to digest the solids and improve wastewater quality. Types of biological reactors that are implemented include, but are not limited to, sequencing batch reactors, continuously stirred tank bioreactors, packed bed bioreactors, and membrane bioreactors.

If designed and operated appropriately, the use of biological reactors can be a great strategy for managing and improving the quality of aquaculture wastewater prior to being further reused by the RAS facility, sent as pretreated wastewater to the sewer, or

discharged to the environment as treated effluent water.

Aquaculture wastewater or spent-wasted solids from biological reactors should be dewatered prior to transportation to its final destination whether it is a landfill or used as a fertilizer (depending on local environmental regulations). Dewatering is the process of removing water content from the solids/sludge, resulting in material that is more consistent with cake.

Dewatering can be relatively low-tech. Concentrated wastewater or sludge is placed in a large, sealed bag with a tiny hole which allows the water to leave the bag but not the solids. These bags are often placed on earthen pads. More advanced technologies can also be used to dewater, such as specialized centrifuges or filter presses. Polymers may be added to the sludge to improve the efficiency of the process.

Each RAS operation is unique and producers should work with appropriate experts, engineers and local authorities to come up with a sustainable wastewater management plan that will lead to success while minimizing their impact on the environment.

By Maddi Badiola

Maddi Badiola, PhD, is a RAS engineer and co-founder of HTH aquaMetrics llc, (www.HTHaqua.com) based in Getxo, Basque Country, Spain. Her specialty is energy conservation, lifecycle assessments and RAS global sustainability assessments. Email her at mbadiolamillate@gmail.com or contatct her through LinkedIn, Facebook and Instagram.

Properly designed RAS can be the most environmentallyfriendly systems in the aquaculture industry. With credit to the blue revolution and the exponential increase of seafood consumption, these systems are meant to be the most sustainable across the food industry. They are environmentally, technologically, socially and economically sustainable. But once more, the question without the desired answer, is there: Is the industry looking deeply and taking into account energy effectiveness?

Remember that energy does not only impact the environment, it impacts the technology; more efficient systems, less energy required per kilogram produced. It attracts society awareness, as people are looking at pollution more than ever before. Carbon footprint has become a very important factor of either success or failure of many products. And lastly, linked to society, energy influences the economy of a product, making it cheaper or more expensive according to the operational costs incurred. Thus, energy is among all factors that account most in the production chain, impacting four out of four pillars of sustainability: human, social, economic and environmental.

To facilitate the process of replacing existing energy sources with sustainable alternatives and to minimize environmental impact, energy efficiency in consumer goods, building system and manufacturing systems has to be improved. This includes fish production systems and equipment.

RAS has always been seen as a loop with different components connected – a filter, biofilter, disinfection units, oxygenation, skimmer, CO2 stripper – all of them connected through pipes and valves where water flows constantly pushed by a pump. In this manner, energy consumption can be

difficult to decrease as many different pieces of equipment take part in the equation. So, let’s at these systems as a whole machine; a machine that integrates all of the equipment in to one, and a machine with a nameplate where it states the electrical power usage. Controlling one complete equipment package could be easier than controlling several smaller ones.

The nameplate indicates the worst-case energy usage estimate of a machine, while the actual energy demand will vary depending on the application of the equipment. In my previous articles, energy auditing and energy measurement have been pointed out as a requirement within the industry. Neverthelss, at the same time, it

“Using power measurement data, machines and equipment can be shut down when not needed, or turned down where possible.”

seems tedious and demanding to be monitoring each piece of equipment on the loop. Thus, what if with one measurement, monitoring the energy demand and consumption, it could be controlled?

The best way to measure and monitor the dynamics of a machine is to use a power meter, measuring the actual power consumed over the course of time. Measure power usage for each operating mode of the machine, and during all parts of the programmed process to better determine when energy consumption is the highest and identify areas for improvement. The amount of energy consumed at each production state can be determined using proper software and analysis. Through this power measurement data, the energy cost of a machine idling during production stops can be identified and reduced if found to be excessive. Monitoring power can also point to process and scheduling problems that cause unnecessary energy usage.

There are many ways machine design affects efficiency. Something as simple as supplying excess voltage to the machine can waste energy. Shut it off or turn it down. With proper power measurement and monitoring in place, effective control of machines becomes an adaptable and adjustable capability. Using power measurement data, machines and equipment can be shut down when not needed, or turned down where possible. With proper monitoring of machines and equipment, energy usage can be optimized.

Understanding where and when energy is consumed in a machine is an important step to reducing energy consumption. To better understand the energy flow and consumption of the machine, it would be beneficial to develop an energy flow map. From this map, opportunities for improvement can be identified along with energy-related features. After creating a map, models can be generated that will help predict energy consumption and allow for optimization of the machine and a more sustainable design of the machine. Also, with the proper software and networking, this data can also be pushed to operators, technicians, and management in a variety of ways. Management may see the energy-efficiency data on a report analyzing machine efficiency. Manufacturing engineers can have access to this data on their tablet or smartphone for quick analysis and action, and the operator can view the data on a local display to ensure safe operation.

In the technology revolution century that we are in, it should not be any problem to get all the production chain employees involved in such an important element as energy, the factor impacting four out of four pillars of sustainability, the factor that makes the change between technologies, the factor that could help make an industry and/or a product a success.

By Liza Mayer

The Land of Fire and Ice, as Iceland is referred to, is home to Matorka, a 3,000-tonne Arctic char and steelhead landbased farm in the picturesque fishing town of Grindavik. The fish farm uses

the country’s rich combination of volcanic geology and arctic climate to its advantage, helping enhance its energy efficiency and environmental performance.

“What we have here in Iceland which makes us a bit unique is that we have a lot of

very clean and pure groundwater that’s filtered by lava rocks. We also have a lot of precipitation both in winter and summer, giving us very large reserves of clean groundwater, which is a great asset when you’re farming fish,” Matorka CEO Árni Páll Einarsson tells RAStech.

The choice of Grindavik as site puts it strategically close to a geothermal resource and access to the transportation infrastructure and local talent pool serving the town’s fishing industry. But the foremost benefit is the access to bountiful, pristine water.

“The surrounding area is geothermally active, hence our ambient water temperature is about 9C – very warm for Iceland –all year round. This warm water gives us a very good growth rate for our fish,” Einarsson says.

The choice of partial reuse aquaculture system (PRAS) as mode of production was also deliberate. Chief operating officer and systems designer Sveinbjörn Oddsson says PRAS is absolutely not for everyone, but for

Matorka, it was ideal.

“Either you are in a situation where you could draw water with the right temperature, for example from the sea – which is possible – then you could do it. Or, if you have a source of cheap warm water, for instance from smelters,” says Oddsson.

“We’re lucky where we are, we are using the natural resources,” he continues. “There’s abundant freshwater and seawater that’s lukewarm, which is perfect for salmonids. It comes from the boreholes from the ground in the ideal temperature so we don’t have to heat it or cool it or do anything with it.” This represents massive energy savings.

The significant energy required by landbased fish farms using recirculating aquaculture systems (RAS) is seen as a limitation of this mode of production. But by using PRAS, Matorka reduces its energy use further because water is pumped into the raceway only once, then water flows through the entire system just by the pull of gravity.

Energy use was Oddsson’s main consideration in the system design. “My goal was to create a system where you use as little energy as possible to run it. I’m always calculating the kilowatt per kilo produced. That’s always the main target: what can we do to decrease the amount of kilowatts used.”

In his latest calculation, Oddsson says the farm consumes 2.6 kW per kilogram of fish. Its electricity supply costs US$0.07 to US$0.08 per kWh.

To put this into context, Atlantic Sapphire’s Miami Bluehouse uses 8 kW per kilogram of salmon produced. “The environmental advantages of this way of farming have a much bigger impact than the consumption of energy, but we will also move towards using more and more renewable energy,” a spokesperson for Atlantic Sapphire tells RAStech

Oddsson, a trained fish biologist and environmental science specialist, got his feet wet in aquaculture as a teen in the early 1970s. Born in Iceland, he developed his industry expertise in both land-based and ocean-based aquaculture operations locally and in Norway, Chile, Australia and Indonesia. His experience and industry observations made him shun the use of biofilters – at least for now. He believes the use of biofilters to clean the water, as is done in RAS operations, is where complications begin.

“Our main design principle is to reuse the

water up to the point where you would otherwise need a biofilter. That’s when you stop. And the reason for that is that biofilters and whatever comes with them create more risks in the operation.”

The company’s original licence allows for 3,000 tonnes annually, but a new licence granted in November 2020 allows for 6,000 tonnes of live biomass at any given time. When production ramps up, Oddsson sees the potential to start using simple biofilters.

“Our design has already allowed for the

use of biofilters and a higher degree of recirculation should it be needed later. But it’s good to be able to start with the partial reuse system initially so that by the time that you start to increase the complexity of the operation, you have competent staff on site. And you will have already mastered everything else, such as fish transfers.

“I think another reason why people (in RAS facilities) have had problems is that they throw everybody into the deep end from day one. They start with a system that’s complex,

•

•

•

•

•

•

•

and especially in these days when so many new facilities are being built, I don’t know where they’re going to get enough people to run them.”

He says Matorka’s system is not unique, nor its use of geothermal energy. Fish farming in Iceland accounted for 5.4 per cent of the

total geothermal heat use in 2019, according to Iceland’s Renewable Energy Cluster, citing data from the Icelandic Energy Authority.

“There’s nothing unique under the sun when it comes to fish farming. Somebody has tried something somewhere else,” says Oddsson. “This module system where one tank is below the one before, you can find

these in rainbow trout farms in Turkey from the 1920s and in many places, they have these earthen ponds or raceways. I basically just went back to the basics but added to it state-of-the-art water purification system, CO2 removal, oxygenation system and drum filters to remove all the sludge from the centre drains. Ours simply is a 100-year-old system brought to the modern times. But I don’t know if anybody is doing this in a modern farm.”

The company’s operations encompass the whole fish farming cycle – from hatching eyed eggs to harvesting, filleting, packaging and exporting. Production goes mostly to overseas markets, mainly the United States, Canada, Sweden, Germany and France. Arctic char accounts for roughly 75 per cent of production, while steelhead accounts for the rest.

In 2020, the Grindavik facility produced only half of its production target of 2,000 tonnes for that year. “Arctic char is quite a big restaurant and catering item so we’ve produced lower volumes than what we would have liked to see. As soon as the American airspace was closed off back in March, that’s when we reduced our budget for the year and slowed down our production process,” says company CEO Einarsson.

“Once we get out of this surreal and difficult environment and challenging markets brought about by the pandemic, we’re planning on significant growth. Immediately in 2021, we’ll be doubling our production. We foresee that we will fully utilize the 3,000-tonne in 2022. In the long run, we aim to take the production levels of this company up to 10,000 tonnes,” he says.

“We are breaking records daily,” adds Oddsson. “Every day we have more biomass than we had the day before. By March or April, we expect to be up to 1,500 tonnes.”

For now, Oddsson is working on securing Arctic char eggs. It and other Arctic char farmers in Iceland source their eggs from Hólar University, which is the premium source for good quality stock.

His wish list includes making Matorka even more sustainable than it already is. “Although we have not implemented everything yet, we’ve so far been able to use even less water than we were planning to. The plans were to use 450 to 500 litres per module but we’ve been able to reduce it down to 300 litres. The CO2 degassers are working better than I expected. The growth has been faster than I expected. The setup works. I’m proud of that.”

What Matorka has so far accomplished in terms of sustainability is no mean feat. Aquaculture investment firm AquaSpark recognized that. The Netherlands-based impact investor holds roughly 25-per-cent stake in the operation.

“We are in very good shape to facilitate growth in the next few years. Pandemic aside, the industry is seeing a significant demand for increased production, not only in terms of increased quantity, but also in terms of better quality, cleaner product that don’t rely on chemicals or antibiotics. And that is where we fit into the picture,” says Einarsson.

By Nestor Arellano

If you happen to talk with Mordi Laloush you’ll get the idea that he believes recirculating aquaculture systems (RAS) and barramundi (lates calcarifer) are a match made in heaven. Except in the case of the chief executive officer of Aquatech Fisheries, it would be more like a match made in the dessert.

The barramundi is also known as the Asian sea bass. The fish is prized for its tasty white meat. It’s fished and raised in aquaculture systems in Australia, Singapore, Malaysia, Thailand, the Philippines, Vietnam, Indonesia, Saudi Arabia, Poland, The United Kingdom, the United States, and Israel.

Aquatech runs the only large-scale inland fish farms raising barramundi in a strip on Israel’s Negev Dessert bordering the Gaza Strip and the Mediterranean. And the operation is thriving.

The company made deliveries of about 800 tons of barramundi in 2020 despite dealing with the challenges of the COVID-19 pandemic.

“We want to get those number up to 900 tons in 2021 and 2,000 tons in 2023-2024,”

says Laloush. “RAS is the future for us.”

Things weren’t so rosy with Aquatech’s early white fish RAS foray.

In 2012, Aquatech commissioned AquaMaof to design and build a RAS plant that

would have an annual production of 1,925 tons of seabream. Since sea bream need saltwater to survive, the facility needed to have high salinity. It also needed to have near zero discharge because there were concerns that the saltwater run-off could contaminate the aquifer water.

Good circulation is decisive for profitable aquaculture. Do you want unequalled operational reliability, energy savings, and operating efficiency many years ahead?

in corrosion-

Unfortunately, the system was unable to deal with the scale of biomass produced. High nitrate concentration killed off hundreds of thousands of sea bream, according to Laloush. In two years, Aquatech managed to harvest only 153 tons of sea bream out of the 1.3 million fingerlings which the company seeded.

“We decided that if we can’t grow sea bream, then we had to find out what fish would work,” says Laloush.

Aquatech conducted tests with several other species such as striped bass and mullet. In the end, the company decided to switch to barramundi.

Hardiness and productivity are key factors for RAS operators considering barramundi, according to Spencer Gowan, general manager of Great Falls Aquaculture, based in Turner Falls, Massachusetts. The company bought the farm from Australis Aquaculture in 2018 when the latter pulled out of the barramundi industry in the U.S.

“With Australis, production would be up and down. It could be as high as 25,000 tons and down to 15,000 tons,” says Gowan, who also used to work in the farm when it was still owned by Australis. “With Great Falls, we’re steadier – around 17,000 tons, post pandemic.”

Great Falls is currently the biggest barramundi grower in the U.S., according to Gowan.

“Barramundi is well-suited for RAS because the fish performs very well in high-density environment,” Gowan explains. “Fish pay rent. The longer they stay in the tank the more you feed them and spend money on them.”

Barramundi is farmed in RAS facilities using freshwater of brackish water systems, and a combination of physical and biological filtration.

Another advantage is that barramundi can reach harvest size – 350 grams to 3 kilograms – in six months to two years.

A single female barramundi may produce 30 to 40 million eggs. This means farmers will only need small numbers of broodstock to obtain enough larvae for a large-scale hatchery operation.

Barramundi broodstock are typically commercially available baitfish, but juveniles and grown fish also feed well on pelleted diets.

The growing demand for sustainably produced, healthy food is one of the drivers of the growth of the aquaculture industry.

In the case of barramundi, it helps that the fish has a flavour profile that appeals to a wide swathe of consumers.

“Barramundi meat is quite sweet, and it doesn’t have the fishy (taste) that turns off some people,” says Gowan. “It’s the kind of fish that even people who don’t eat fish would enjoy.”

The absence of any over-powering flavour also make barramundi a very versatile fish that’s “great for the backyard grill or as a gourmet dish,” adds Gowan.

Then there’s the omega-3 content. Compared to salmon, the barramundi has a higher ratio of omega-3 to fat.

What’s in a name?

The name barramundi originated from the Australian Aboriginal word for “large-scaled fish.” The genetic differences between the Asian sea bass and barramundi are not big enough to consider the two distinct species.

However, in the 1980s, the name barramundi was ascribed by Australian growers to their fish, to differentiate from those grown by other countries.

Dr. Paul Harrison, co-founder of Mainstream Aquaculture, explains that buyers of barramundi have come to associate the fish with the regulated Australian barramundi aquaculture environment geared to producing quality fish.

The Queensland-based Mainstream Aquaculture is one of the largest producers of barramundi in Australia. The company also provides approximately onethird of the world’s supply of barramundi seed which it exports to 25 countries.

Around 5,000 tons of barramundi come from local aquaculture, anywhere from 12,000 to 15,000 tons are imported.

“They come from South Asian countries such as Vietnam, Indonesia and Thailand. Often produced in subsistence farms in villages where there are likely lower standards,” says Harrison. “If barramundi is labelled as premium, then it is sold as premium. But if barramundi is lumped with Asian sea bass its status suffers.”

That’s why robust marketing and continuous education of consumers, chefs, food trend influencers and buyers are vital, he says.

Despite these advantages, raising barramundi is not a piece of cake, says Sasha Dyer, fish health manager at Great Falls.

According to Sasha, barramundi growers should watch out for several key factors:

• consistent feeding formulation

• proper water chemistry

• signs of disease

• cannibalism

“High CO 2 levels tend to make fish lethargic and sick,” says Dyer. “If their metabolism is low, fish tend to bloat. This means food will literally rot inside them and kill them slowly.”

Barramundi are predator fish. During the early stages of growth, larger, more aggressive barramundi will feed on their smaller counterparts.

“Grading takes a lot of time. But we grade our fish once a week when they’re small and gradually ease down as they

grow bigger,” says Dyer.

Back in 2001, when Mainstream started its land-based RAS operation, the company began raising different species such as Murray cod, golden perch, and barramundi. But things started to take off for the company when it decided to concentrate on barramundi.

“We’re focused on making barramundi the white salmon,” declares Harrison.

Salmon is a global aquaculture success story. However, the market for a farmed white fish remains wide open and full opportunity.

“At the moment, there is no industrialized white fish that can fill the ‘white flesh’ category adjacent to salmon worldwide,” says Harrison. “The world needs an industrialized white fish – I am optimistic it will be barramundi.”

Danish Salmon CEO Kim Hieronymus Lyhne has embraced the demands of recirculating aquaculture and is determined to ride the company’s planned waves of growth.

By Jennifer Brown

As a pioneer in the world of recirculating aquaculture operations, Danish Salmon’s chief executive officer Kim Hieronymus Lyhne lives and breathes the RAS business 24 hours a day, seven days a week — and he revels in the challenges it brings.

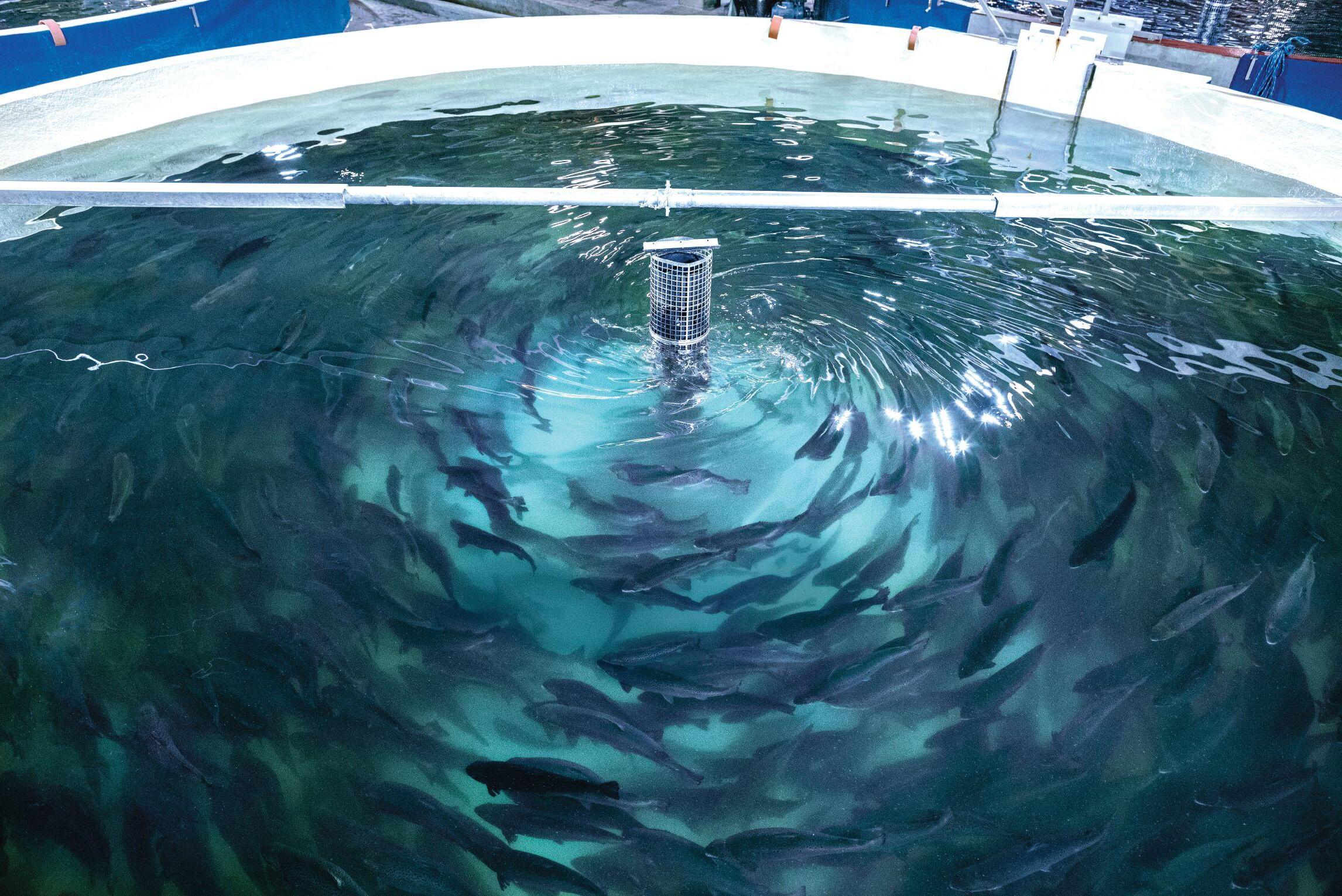

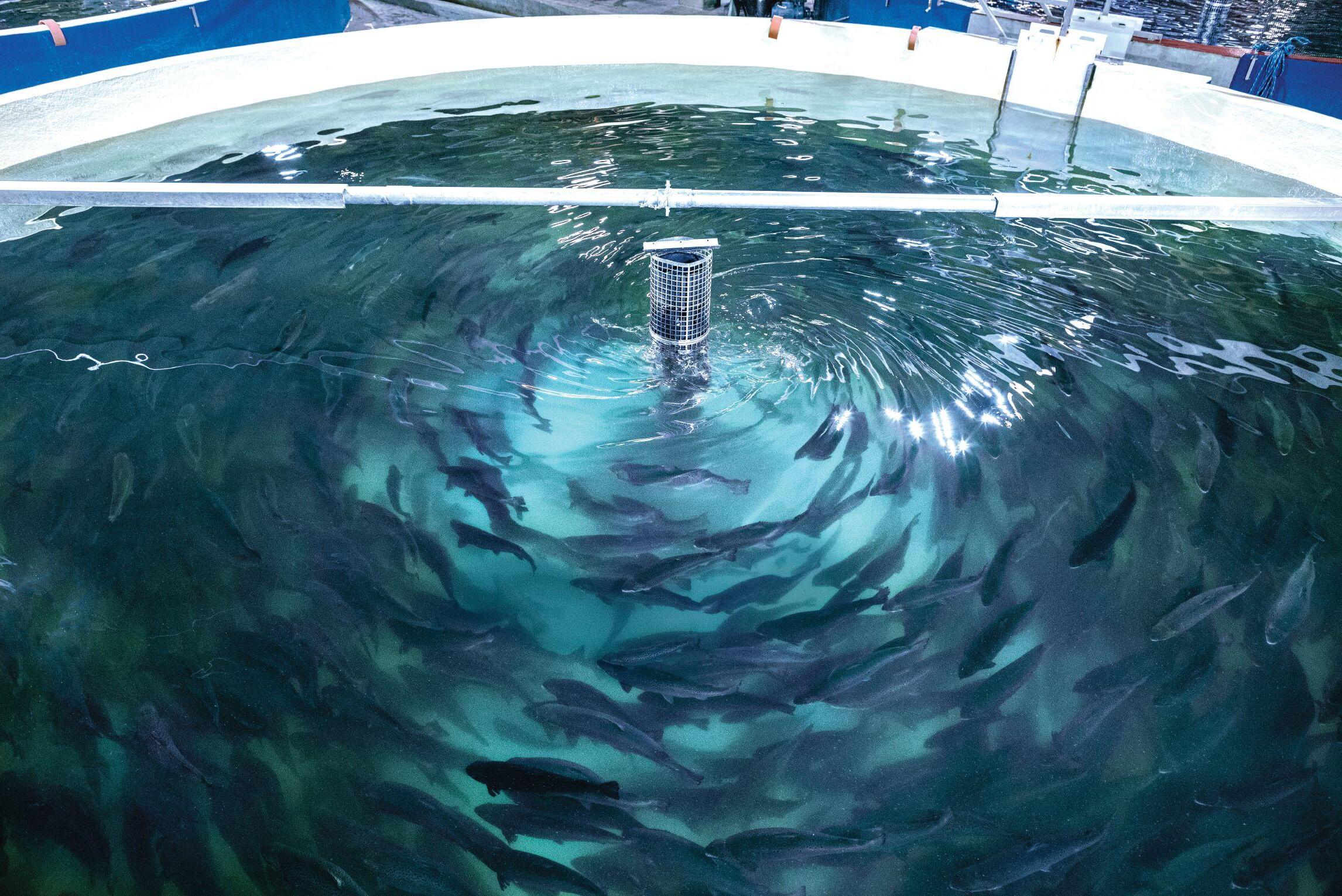

Danish Salmon started constructing its initial facility in 2012 and harvested its first batch of Atlantic salmon raised in its land-based recirculating aquaculture system in 2015. At the time, they were one of a small handful of other fish farmers doing land-based, closed recirculated systems. Over the years, Hieronymus Lyhne says the key has been to troubleshoot issues as quickly as possible and applying the lessons learned.

“It’s about avoiding problems and dealing with instability,” says Hieronymus Lyhne, who has worked with Danish Salmon, based in Hirtshals, Denmark, since 2014. In 2017, he became the company’s CEO.

This year, Danish Salmon is projected to produce 1,200 metric tons of live salmon. Through 2022 and into 2023, the company will increase its production, and in early 2023 it is expected to increase production to 2,750 metric tons (live weight).

“The current facility can produce 1,200 metric tons, but the construction of our new facility should be ready in March/ April 2022. As soon as that is ready, we should have full production by the end of 2022/2023,” he explains.

The biggest market for Danish Salmon is Europe, and in particular, they are fo -

cused on keeping it local in Denmark. They process and ship fish in 24 hours and partner with Nordic Seafood which has sold its salmon locally and in Europe since it launched in 2015.

“We don’t focus on the United States market, China, Russia or South Africa because the whole idea is you produce the fish local instead of transporting it,” he says.

Danish Salmon employs 16 people, including biologists, fish farmers, maintenance, managers and technical staff. Hieronymus Lyhne has a Master’s degree in business administration and applies his business knowledge to evolving the operation.

“With fish farming, and in particular with recirculating systems, you can spend 24 hours a day with the fish — it’s a lifestyle.

I love that it’s non-stop 365 days a year, 24 hours a day,” he says.

Hieronymus Lyhne has developed a keen sense for knowing when things aren’t going well for the salmon in his care.

“What we’ve learned is that if we don’t provide the environment the fish need, they simply will not grow. Salmon is a very unforgiving animal — it simply will not eat, and if a fish doesn’t eat, it loses weight rapidly, so if you don’t provide the environment the fish need, it won’t grow,” he says.

Unlike livestock on a farm that shares the same environment with humans, he says it’s harder to tell if fish are experiencing adverse conditions in their environment.

“The only way we can talk to the fish is

through behaviour analysis and the way they feed. For salmon, in particular, their only purpose in life is to eat and grow, so if they are not eating, that’s the fish telling you there’s something wrong – it doesn’t like its environment,” he says.

“Some of the things we have learned in terms of fish health is the need to address any issues early on, and it starts with feeding. You cannot rectify health problems a year into the production cycle of the fish, you need to do it immediately, so what we really focus on is feeding,” he says.

With so many technology vendors reaching out to RAS farmers with solutions to help their operations, Hieronymus Lyhne says it can be overwhelming.

“RAS is a funny business because technology is huge, and it’s about to blow up even more. Technology suppliers are coming up with crazier ideas, and what they keep forgetting is that you’re farming fish; you’re not farming nuts and bolts. It’s live animals that you can’t communicate with – it’s about how do you know every single day that this fish is doing alright?”

While technology plays a significant part in recirculating aquaculture systems and Danish Salmon is trying to use artificial

can’t do it 24/7, so we need help to do that,” he says.

“If AI (artificial intelligence) can provide what we believe it can provide and what the suppliers we are developing it with tells

The

Hieronymus Lyhne says Danish Salmon has the first 95 per cent of salmon production under control at its facilities – the rearing environment, the oxygen, temperature and monitoring of water levels.

“All of that is what all the sensors do. But it’s the last five per cent that is human action that makes the business or breaks the business,” he says. “With RAS, if you do something wrong, even five per cent wrong, you will have 100 per cent loss – you can’t do anything wrong when it comes to feeding in RAS systems.”

“What we have learned with technology suppliers is that we need to be more skeptical about it – you really need to be asking the simple questions when it comes to technology. How was it designed and why was it designed and how did they come up with this idea, and what do they know about it?”

While demand for Danish Salmon’s product was affected by the pandemic, Hieronymus Lyhne has resolved that it’s an industry issue everyone must deal with.

“That’s the entire seafood industry,” he says. “We have to accept that market conditions are tough, but the market will bounce back at some point.”

He says staffing and people management are among the

SAVE TIME ON DATA COLLECTION AND MANAGEMENT

Polaris C has a Bluetooth function that guarantees e cient data transfer. To make things even more smooth, we are introducing NFC tags. The tags are mounted on fish tanks, pens or cages to make identification of the location accessible. Just scan the tag and measure - Polaris C will do the rest.

Preorder now

most significant issues facing RAS facilities right now.

“The biggest issue was financing, but now that these projects are coming online, they need staff, and it takes at least a year for staff to know even 50 per cent of what they’re doing; and in three years, you’re 90 per cent there. I think that’s the steepest learning curve I’ve experienced – every step you take has a consequence.”

When it comes to staffing, Hieronymus Lyhne says the RAS sector needs more people who are trained in managing the systems. Many employees for RAS facilities come straight out of university. When they come on board, they have a good understanding of biology and chemistry; however, what they teach at school doesn’t include managing the various challenges a system can experience.

“It would be nice to have a RAS education line of programs and have people come out of school having done RAS farming,” he says.

Denmark is one of the heaviest regulated countries globally in terms of wastewater and pollution, especially nitrogen pollution, so Danish Salmon is regulated on a discharge permit based on a specific amount of tonnes of nitrogen that can be discharged per year.

“For us to operate on the vision we have of 2,750 tonnes, we will need to filter more than 80 per cent of our effluent away, which makes us 80 per cent more sustainable in terms of nitrogen discharge than a kilo of salmon produced at sea,” he says.

He says that’s what also makes RAS interesting in terms of sustainability and environmental impact.

“We have seen that we can talk about environmentally sound production. You can measure what goes in and what goes out. The amount of feed you put in produces X amount of nitrogen and X amount of solids, and we filter it away and measure every single kilo of sludge disposal we drive away from the farm. There’s no escaping here – every single kilo of feed you pollute your system with has to go somewhere, and it cannot just go to the sea; it needs to be filtered.”

It’s another example of how RAS facilities like Danish Salmon are leading the way in providing a brighter future for the production of land-based fish for consumers who want a product produced locally and sustainably.

Andfjord Salmon’s Atlantic salmon farm puts a twist on land-based aquaculture.

By Mari-Len De Guzman

This spring, a Norwegian Atlantic salmon producer is set to commence its pioneering land-based farm using technology that

promises to address some of the biggest challenges in both traditional oceanbased farming and RAS production, by taking the best of both these worlds.

Andfjord Salmon is relying on the natural advantages that Northern Norway offers to build an Atlantic salmon farm on shore and underground using flowthrough technology, but with a twist.

Traditional flowthrough systems –typically used in hatchery operations – involve setting up the fish tanks on land attached to pipes that pull water from a nearby water source into the production tanks. The process of lifting the water from

the source up to the ground to reach the tanks require a considerable amount of energy consumption.

Andfjord’s concept takes the production tanks underground below sea leavel, so that seawater directly flows straight into the tank or pool, resulting in much lower energy costs.

“The concepts represent the best of traditional sea-based salmon farming and combined with advantages of being on land,” says Andfjord Salmon CEO Martin Rasmussen, in an interview with RAStech. “We have a very unique location… and if you want to have 100 per cent flow-through system, you have to have a very good location.”

Andfjord Salmon’s farm is being built in Andoya, on the northern tip of Vesterålen. This part of Norway offers optimal water temperatures for salmon farming in the Arctic region.

“Our flow-through system gives a continuous supply of fresh water, and the water has two key functions: to transport

oxygen into the pool and transport CO 2 and other metabolism products out of the pool,” explains Rasmussen.

Unlike in a recirculating aquaculture system, where up to 99 per cent of water is recirculated and reused in production, Andfjord’s system has seawater flowing directly in and out of the pools where the fish are growing. “We only utilize that water once, compared to others… where you reuse it. So it means that .. since we don’t have to lift it, because when you’re using a RAS system you have to lift it to release the CO2, we have a very low energy usage with our methods,” Rasmussen says.

Norway is the world’s second largest exporter of fish and fish products, owing to its vast 83,000-km coastline and pristine waters ideal for fisheries and aquaculture. The face of fish farming in Norway has evolved over the years, with an increasing number of land-based aquaculture projects being announced in recent years. Of the 23 land-based projects in the pipeline in Norway, only 13 are RAS while 10 will use flow-through systems, according to data from The Land-based Salmon Handbook.

One of the appeals of RAS facilities is the ability to locate the production farm closer to market, which scores some points on sustainability. Andfjord Salmon’s technology is likewise vying for some sustainability points but from a different front.

While Andfjord’s location cannot claim strategic benefits for being close to market, it is making up for it with what it expects to be lower energy costs when the farm is in commercial production.

“Since we have good water quality, with temperature profile, salinity profile, and also clean water, we can also have very simple and non-complex technology,” explains Ramussen. Andfjord Salmon will have two sources for water intake: the gulf stream at 160 metres, and the coastal water at 30 metres. The farm will access coastal waters in the summer, while the gulf stream will provide the warm water for the fish during winter seasons.

“That means we can have a very even temperature profile all year round, to have very good growth, and also I don’t have to use energy to cool down the water or heat it up.”

Another area for energy saving is in the design of the system, where water flows through directly from the sea right into the underground fish tanks or pools. Square-shaped pools, rather than circular tanks, will achieve a steady, laminar water flow, with no turbulence.

“Imagine that you have a vault in the sea and you just drill a hole in it, it will just automatically fill with water. And the same will happen with our pools. We have built it in the same level as the sea. So when I open up the pipes, it will flow water into the pool. So we are not using energy to lift the water, we are just using energy to create a river through the pool,” Rasmussen explains.

An important parameter in any sustainable aquaculture operations is fish health and welfare. The Andfjord Salmon CEO says the farm’s location and the natural resources that come with it, combined with the design of the facility will ensure the fish are given the best life throughout their lifecycle.

“It’s a very unique and genius technol-

ogy because we can provide the fish with very good biological conditions, since we have a very even distribution of oxygen in the water and you get very homogenous environment in our pool.”

By installing the fish pools below sea level, the company is also hoping to address another important challenge with farming Atlantic salmon in traditional ocean net pens: sea lice.

Majority of the sea lice generally occur on the upper layers of the water column. By placing the production pools below sea level, fish can be kept away from these menacing parasites above.

“It means that we don’t have to use a lot of energy, resources and cost to treat the fish,” explains Rasmussen.

The flow-through system and the pools installed below sea level are all designed to keep operational costs down and the fish happily swimming in consistently clean water.

“We don’t need biological filter system to clean the water. One of the main problems with technology used today in RAS is that when it works, it works very good. But it’s very (reliant) on humans, the operators, and there’s always a big risk for something with fish. But with a very stable, (less) complex technology, we don’t have the same risk factor as the RAS system,” Rasmussen explains.

The company is currently in the last stretch of phase one construction of the Atlantic salmon farm in Andoya, which involves the commissioning of the first of a total of 70 pools, once all phases of the project are complete. In February, the company reported it has successfully hooked up its water inlet pipeline and its

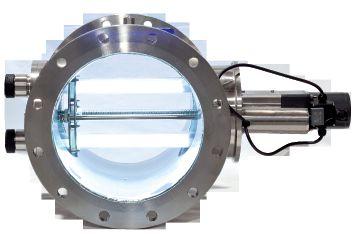

Ensure sustainable disinfection that meets the highest standards for your recirculating aquaculture system

flow-through system has been connected to the ocean water source.

Speaking with Rasmussen in December, the chief executive said his firm expects that the first batch of smolt will be released by spring 2021.

Currently, Andfjord Salmon has a production licence for up to 10,000 tonnes. The plan is to ultimately acquire licence for 70,000 tonnes of maximum allowed biomass, Rasmussen says.

“So we have all the land areas. We have already done this (licence application) in the first facility, so we will try to copy this for the next facility when it’s done.”

Anfjord Salmon worked with SINTEF, an independent research organization in Norway, to verify the technology it will be using for its farm. For the first phase of the project, the company received NOK14 million (US$1.6 million) funding from Innovation Norway.

Eventually, Andfjord Salmon will have the ability to release smolt during wintertime, with water intake at the depth of 160 metres, which ensures optimal winter temperatures for salmon

farming, the company said in a press release.

Once all phases of the project are complete, the facility will have 70 pools in total, according to Rasmussen. The company is using the experiences learned during phase one construction to make the succeeding project phases go more smoothly.

“We assume the next construction will go as the first one so we have very good track record on the first building.

As for the risk factors when you come into operational phase, when you look at the technology, we have tested the technology in a scale of 1 to 200 and it works; we tested in scale of 1 to 100, it works; and we had tested it in scale 1 to 20, and it works,” he explains.

The steady laminar flow of water in the production pools allow for the fish waste to drop to the botton of the pool for proper collection.

Andfjord Salmon is partnering with a neighbouring company, Andøytorv, to

collect and process the salmon farm’s waste materials. Andøytorv will use the nitrate, phosphate and other nutrient salts from the farm to produce peat moss, used in agriculture.

Research from the Norwegian Institute of Bioeconomy Research (NIBIO) has confirmed the potential of dried fish sludge from Andfjord’s land-based facility to be converted to organic fertilizer for agriculture and horticulture. This potentially provides another revenue stream for the Atlantic salmon producer.

The NIBIO report was developed on behalf of Andøytorv and Andfjord Salmon. The research institution explored both opportunities and limitations related to the use of fish sludge from Andfjord Salmon as a CO2-reducing component in products like growth media, soil improvers and fertilizer products for agriculture, gardening and other relevant areas of application, a press announcement from Andfjord indicated.

“We take care of all the waste to make sure of a very circular economy,” Rasmussen says.

www.freshbydesign.com.au

By Jean Ko Din

To say that 2020 was a rebuilding year for NaturalShrimp seems like a massive understatement.

Just days after the World Health Organization declared a global COVID-19 pandemic, a fire erupted at the company’s La Coste, Texas, facility in the late hours of March 18, 2020.

Tom Untermeyer, chief technology and chief operations officer, got a phone call with news that the whole building was up

in flames. By the time the fire department arrived, nothing could be salvaged.

The company was in the middle of construction. The pilot plant was being retrofitted with its latest electrocoagulation (EC) technology. After 18 years of research and development, NaturalShrimp was getting ready to commercially scale its proprietary RAS but the fire rendered those plans to ash. At least, for a short while.

Fast forward a year later and the LaCoste facility was rebuilt bigger and better than

before. The brand new fish tanks were restocked with postlarvae shrimp this February as the staff get ready for its commercial production this year.

The company has also made strides to expand. Last December, it acquired a 270,000-sq.-ft. facility in Iowa which is now also being stocked with shrimp. As the company now prepares to acquire Hydrenesis, it was announced in January that a new Florida facility will be built that combines both companies’ proprietary technologies. Untermeyer also hints further plans to look at more opportunities in California, Georgia and Puerto Rico.

Untermeyer connected with RAStech to reflect on NaturalShrimp’s whirlwind year and what the company has learned from the experience.

RAStech: Take us back to the night of the fire. Where were you when it happened?

Untermeyer: I actually live in San Antonio. It happened about midnight. I just got a call from our guy that lives on site. He was asleep

when his dog started barking and so he got up to look out the window. He saw a glow from the building and by time he got down there in 15 minutes, it had already taken up most of the building. Luckily, no one was in the building at the time and no one got hurt. It happened pretty fast. There really wasn’t any time to put it out.

When I got there the next morning, it was basically totally destroyed. It was a 30,000-sq.-ft. building and the roof had collapsed. And it was pretty obvious everything inside was destroyed, the tanks melted and the equipment we had in there was destroyed.

Fire investigators came in to search it. They went through the remnants and they kept coming back saying (the cause of the fire) was inconclusive. We even hired our own investigator to come in and he came up with the same conclusion. It was basically too intense of a fire to be able to pinpoint the cause.

RAStech: What was it like to deal with the aftermath?

Untermeyer: Yeah, it’s shocking. It takes a couple days. Like a car accident or something, it’s a shock to your system. We all put a lot of time and energy into that one building. We were getting ready for production, actually. We had stock and shrimp in there and they were growing. So I guess, at first, it was disheartening.

I spoke to Gerald Easterling (president and CEO) that day and I wasn’t sure how he was gonna react. But I was really happy. He said, “Well, just know that we have insurance on the buildings so we can go on and regroup.” So, he didn’t hesitate.

At the beginning, people, our employees, were wondering what’s going to happen to them. We held on to a couple people and we had to let some of our technicians go because there was basically nothing to do at that point. We actually are starting to bring some people back now and it’s good to see them back.

RAStech: When you were first renovating the old building, you had to make a lot of accomodations for the existing infra-

There is more to RAS aquaculture than the RAS itself: A proven fast delivery concept. NEWS:

Alpha Aqua A/S builds the full production unit at the factory site to ship it as one delivery. Installed on a standard flat concrete slab offering a variety of advantages for the customer:

Pre-test by FAT (Factory Acceptance Test)

Adaptable to existing buildings or dedicated ones

Faster construction - no fixed concrete structures implying better Return on Investment (ROI)

Floor mounted tank system – no underground pipes or specific concrete foundations in the system

High flexibility to adapt to the market changes

Want to know more?

After 10 years of research and development, Blue Unit Solutions introduces its all-in-one solution for water quality surveillance.

Blue Unit is designed to collect 13 vital water quality parameters from up to 12 locations in a RAS farm simultaneously. The data is collected in a visualization system and compared with benchmark values from producers across the globe.

Biologist David Owen began developing the first centralized monitoring system in 2010 with the hope of using his 25 years of RAS

experience to equip fish farmers with crucial trust measurements that create the best conditions for growth.

“Blue Unit Solution gives an early warning showing where, when, and why there is a change happening in water quality, which thereby ensures optimal conditions to watch over critical parameters and optimize water quality on the best possible foundation,” says Owen. “In the long term, it means less waste of fish feed, reduced expenses, better animal welfare, and greater profit.”

Blue Unit is operated with a subscription-based software that collects data and gives 24/7 insight into the farm’s status.

Special designed censors measure the

PR Aqua promises 40 times greater oxygen saturation levels with its newest product.

The Pressurized Packed Column, or PPC, is a highly efficient, on-demand oxygenation system that is designed to generate “oxygen-supersaturated water” from a mediapacked pressure vessel.

The PPC is made up of the pressure vessel and media, a high-pressure water pump, VFS, oxygen injection valve and system controls. When low dissolved oxygen (DO) levels are detected, the control system triggers the

device to blend water and oxygen at pressures from 30 to up to 110psig (8.2 BAR).

The high pressure allows for supersaturated DO in small flows, reducing the size of distribution plumbing.

The device can be installed on a one PPC to one culture tank basis or a centralized basis where one PPC serves multiple culture tanks through distribution plumbing. It can be easily installed in pre-existing facilities with minimal disruption.

www.praqua.com

following water quality parameters: pH, O2, opaqueness, conductivity, redox, rH (redox less pH), salt contents, temperature, totally dissolved matter, available CO2, total CO2, H2S, non-carbonate alkalinity (surrogate of ammoniac)

About 2,700 datapoints are uploaded to the cloud daily and can be accessed though external units. A built-in alarm system also notifies users of critical levels.

www.blue-unit.com

Transparency Market Research, based in Albany, N.Y., suggests that as the aquaculture industry moves to more sustainable production, widespread demand for eco-friendly, high-end media filters will grow. The report projects that the global bio filter market could garner an annual growth rate of up to US$3 billion by 2027.

As more aquaculture producers look to the efficacy of recirculating aquaculture systems (RAS), bio filter manufacturers must ramp up research and development for cost-effective solutions. The high cost of RAS discourages many small fish farmers from adopting this technology, so the report says manufacturers must be conscious to meet this demand.

The report claims that fish farmers in export regions, most notable in Africa and Asia, lack knowledge of the capabilities of advanced filtration media. This has caused a “restrained potential for the global bio filter market.” However, as government bodies and non-profit organizations continue to encourage sustainable aquaculture production, the market could soon open up.

The 150-page report analyzed the bio filter market growth in more than 30 countries, including the United States, Canada, United Kingdom, France, Italy, Russia, Poland, Benelux, Japan, India and South Korea. www.transparencymarketresearch.com/ bio-filter-market

Currently, Salmon Evolution is building an extensive land-based fish farm at Indre Harøy on the Norwegian west coast. When finished in 2028, the site will have an annual capacity of 36.000 tons of sustainably produced high quality salmon. A-Consult provides concrete tanks for the project.

The salmon will be raised in seawater inside huge concrete tanks, each with a capacity of 5,000m3, or two Olympic sized swimming pools. Due to a hybrid flowthrough system, 65 per cent of the water can be reused, and 35 per cent is new supply in the form of filtered fresh seawater. Combining clean and fresh seawater with reused water means, that energy consumption for pumping and heating of water is minimized. Waste and feed residues from the production are collected and used as raw material for biogas production and fertilizer. An impressive project combining rational operation with fish welfare and minimal environmental impact.

Therese Høy is the administrative project manager at the fish farm of Salmon Evolution. She works at Artec Aqua – the turnkey supplier of the plant. She is very satisfied with the progress of the project:

- Right now we are on track, and I feel confident

we will keep the overall time schedule. We have blast away the rocks, prepared the area for the concrete foundation and are currently focusing on the foundation works.

Therese explains that the first stage of the fish farm is expected to be finished during 2022 and comprises 12 fish tanks. A-Consult has had the assignment to deliver these 12 tanks, due to their extensive experience in the field: