By Mari-Len De Guzman

Just a few years ago, someone touting the commercial viability of raising fish exclusively on land would have raised a lot of eyebrows. Today, the general attitude toward land-based fish farms – in various forms and sizes – is optimistic, particularly for salmon.

Analysts are predicting rapid growths in land-based aquaculture systems with production volumes expected in the hundreds of thousands. A new report from Norwegian financing firm DNB estimates up to 500,000 tonnes of salmon will be produced annually from land-based systems by 2026. While salmon seems to be the species of choice for major RAS deployments, a number of aquaculture companies are now looking at expanding their land-based operations to other species. Among them, the high-value Yellowtail appears to be yielding successful outcomes in various operations (see cover story).

What’s driving this shift are the ongoing challenges and the rising costs associated with traditional fish farming. Added to this equation is a growing number of consumers becoming more sophisticated with their buying decisions and are likely to support socially responsible organizations.

A report published by market analyst Shelton Group titled, “Brands & Stands: Social purpose is the new black,” found that 64 percent of consumers are likely to buy from companies that stand for social issues. In its 2015 Global Corporate Sustainability Report, Nielsen found 66 percent of consumers are willing to

pay more for products associated with a sustainable brand. Clearly, there is a business case for sustainable corporate practices, and consumers are poised to reward these activities through their pocketbooks.

Today, sustainability is no longer a trend but a market reality, especially in food production. The increasing global demand for food has made traditional seafood production unsustainable and driven companies to respond and adapt. Investments in sustainable aquaculture ventures have also increased in recent years, which paved the way for new projects commencing in various parts of the world that would further increase production output from land-based fish farms.

It is no longer a question of whether land-based aquaculture is commercially viable. Many ongoing and planned projects are already making the case for commercial viability. The question now is whether organizations are willing to take on this challenge and move toward a meaningful direction for long-term growth.

Investments on sustainable production are trending upward and the market is optimistic. Research and development initiatives are continuing to pursue ways and means to enhance and improve the viability of sustainable aquaculture.

The global movement toward sustainability is only going to increase. Best to catch the wave or risk wiping out.

NEXT ISSUE: Deadline is June 21st for the SUMMER ISSUE

Submit a RAS story idea or press release: Contact the editor at mdeguzman@annexbusinessmedia.com

Advertising: Contact Jeremy at jthain@annexbusinessmedia.com

www.hatcheryinternational.com

Editor Mari-Len De Guzman 289-259-1408 mdeguzman@annexbusinessmedia.com

Associate Editor Tamar Atik 416-510-5211 tatik@annexbusinessmedia.com

Advertising Manager Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Media Designer Jaime Ratcliffe jratcliffe@annexbusinessmedia.com

Account Coordinator Kathryn Nyenhuis 416-510-6753 knyenhuis@annexbusinessmedia.com

Circulation Manager Barbara Adelt 416-442-5600 ext 3546 amadden@annexbusinessmedia.com

Group Publisher Scott Jamieson sjamieson@annexbusinessmedia.com

President & CEO Mike Fredericks

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

CIRCULATION email: blao@annexbusinesmedia.com Tel: 416.442-5600 ext 3552

Fax: 416.510.6875 (main) 416.442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2019 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

As the primary external input into recirculating aquaculture systems, feed is essential to get right because we’re not only feeding the fish, but also feeding the system. It is well-known that RAS need high performance feeds in terms of physical and nutritional quality, to help the fish grow faster and healthier and to maintain the water quality in the system. The use of ingredients with high digestibility maximise nutrient utilisation for fish growth and minimise nutrient loss, while the use of patented ingredients in Skretting RAS feed ensure that the output is just as good as the input.

Read more at www.skretting.com and contact your local sales representative for more information.

Cooke Aquaculture is planning to build a US$30-million post-smolt RAS facility in New Brunswick, Canada – a plan that will enable the company to grow salmon larger on land before transferring them to saltwater net pens.

Officials at Cooke Aquaculture told members of the Chamcook Watershed Landowners’ Association about the planned facility in a presentation on Feb. 12, according to a news report from local paper, The Saint Croix Courier.

The planned facility – to be built by Cooke’s subsidiary Kelly Cove Salmon – will grow salmon to about 300 grams before transferring them to sea pens. This is more than double the typical weight of 120 grams salmon would be transferred from hatcheries net pens.

The planned RAS facility will be built in the Champlain Industrial Park in Bayside, New Brunswick, and will use the “most advanced water recirculation technology available,” the Saint Croix Courier reported.

“This type of facility fits with the existing activities of the Bayside port,” Joel Richardson, vice-president of public relations for Cooke Aquaculture, told the Saint Croix Courier. “Science shows that adding stronger, larger fish to the net pens reduces the chances of fish health issues. This new facility will help to reduce fish handling, reduce time at sea and reduce days to market.”

Kelly Cove Salmon has applied to the New Brunswick Department of Environment and local government to drill additional wells for water testing and supply in the Chamcook watershed. Instead of drawing water from Chamcook Lake, the company plans to source its water from deeper groundwater wells further into the watershed. Richardson said this approach is comparable to formerly active wells used to supply businesses in the Champlain Industrial Park, the newspaper reported.

MainStream Aquaculture and Pejo Enterprises have amalgamated their considerable production platforms to create a barramundi (Lates calcarifer) farming operation that will merge the world’s largest warm water recirculating aquaculture system farm (Hatchery International, July/August 2018) with one of Australia’s leading saltwater open pond systems.

The combined capability of this important merger will make the company a major supplier of barramundi in Australia.

“Our business model incorporates extensive knowledge in genetic selection, nutritional science and aquaculture engineering to produce a high-quality product while maintaining class leading environmental management credentials. We have aspirations to grow the barramundi sector in Australia and ultimately, internationalize a successful vertically integrated business model. Our merger with Pejo Enterprises constitutes a significant step in that direction,” MainStream’s managing director Boris Musa said.

MainStream is an industry leader in genetic selection. Improved performance traits such as conformation, growth rate and feed conversion efficiency have been a hallmark of MainStream’s position in the industry. The long-lead pioneering work in these fields has paid off and MainStream has established its

brand internationally and now exports to 24 countries on five continents from its two hatcheries.

The company recently commissioned a 1,000-tonne state-of-the-art facility alongside its existing farm. A warm water aquifer that delivers spring water at 28ºC (perfect for barramundi production) supplies both grow-out farms and the modern hatchery and distribution hub at the company’s Melbourne headquarters.

Pejo Enterprises has two Queensland-based saltwater, pond-based farms covering a total of 135 hectares and is renowned for its award-winning barramundi. It will function as a wholly owned subsidiary of MainStream Aquaculture; however, the management of both operations will remain intact. Executives from both businesses have substantial equity interests in the holding company.

Head of Pejo Enterprises, Marty Phillips, said, “I am looking forward to working with the MainStream team. We have been collaborating for some time now and this merger will catapult our combined business to the next level.”

Boris Musa said this merger would provide significant scale to the realization of MainStream’s vision to become a leading supplier of premium white fish domestically and, ultimately, internationally.

– John Mosig

The first commercial batch of salmon fingerlings have been moved from the hatchery to the feeding unit at Atlantic Sapphire’s new land-based production facility in Miami, Florida, U.S.A.

This new milestone comes months after the company reported the delivery of it first 400,000 eggs in the Miami Bluehouse hatchery in November 2018, supplied by StofnFiskur in Iceland.

Chief executive officer Johan Andreassen, in a post on LinkedIn, credits the move to a “tremendous effort” from the entire team and partners.

“These fish are swimming in crystal clear purified water from the Biscayne Aquifer,” Andreassen announced.

The Atlantic Sapphire’s chief executive also announced the closing of its US$86-million credit facility with DNB and EKF, Denmark’s export credit agency. The debt agreement was scheduled to close on Feb. 19th of this year. This marks the completion of financing for Atlantic Sapphire’s facilities expansion in Denmark and the first phase, 9,500-ton Bluehouse operation in the United States.

The University of Southern Maine (USM) and a Maine-based aquaculture firm Whole Oceans have teamed up to offer a course on aquaponics and recirculating aquaculture systems, the university’s public affairs office said.

Whole Oceans plans to build a landbased Atlantic salmon farm on the site of the former Verso Paper Mill in Bucksport, Maine, with an initial investment of US$75 million and a phase 1 production capacity of 5,000 metric tons of salmon per year. Construction is expected to begin this year. By full project completion, the Maine RAS site will have capacity to produce up to 25,000 metric tons per year.

The course, “Practical Guide to Aquaculture,” will present an overview of aquaponic growing and RAS, taught at a lay level for non-scientists. The course will also discuss the business of land-based farming and aquaculture, as well as the global context of aquaponics and recirculating aquaculture, the university said.

Theo Willis, associate professor of environmental science and policy and course instructor, said the course material is relevant as companies begin to explore mid-coast Maine as a haven for developing these types of systems.

Whole Oceans is now the second fish producer planning to build a large-scale land-based salmon farm in the U.S. state.

Nordic Aquafarms intends to develop its site in Belfast, Maine, with production capacity of up to 33,000 metric tons.

“Because of Maine’s relatively pristine waters, the state is in a great position to take advantage of the consumer’s desire for organic foods from known origins,” Willis said. “It’s a relatively new industry and sector so there’s lots of room for entrepreneurs right now.”

More than two million metric tons of Atlantic salmon are produced globally, according to Whole Oceans – a more than $10-billion industry – yet only four percent of U.S. demand is produced domestically.

Whole Oceans estimates 50 to 60 new positions in the Bucksport area for its first phase of production, which includes a variety of positions from animal husbandry technicians and tradespeople to fish biologists and engineers.

“Workforce development is very important to us,” said Jennifer Fortier, outreach and development associate at Whole Oceans. “We want to encourage Maine residents to become trained in the skills needed for this burgeoning industry.”

Whole Oceans will play an active role in the course instruction, Willis said, with several of their senior personnel teaching modules on aspects of the land-based aquaculture business, plus technical aspects of land-based aquaculture.

Analysts at Norwegian financial firm DNB estimate around 500,000 metric tons of new planned production in the land-based salmon sector currently, more than double the figure of just two years ago, according to a report from Undercurrent News.

“We continue to see solid rationale for land-based fish farming given rising costs in – and ongoing challenges to – traditional methods,” wrote Alexander Aukner and Tone Bjornstad Hanstad in their new report. While some of the now-estimated 500,000 tonnes is delayed projects, “generally, developments have grown in number and scale,” they said.

The growing challenges in traditional fish farming and the expected increase in salmon prices are fuelling the number of new land-based aquaculture projects, which more than doubled from the estimated 150,000-tonne volume identified in 2016, the report said. A total volume of around half-a-million tons is now expected by 2026.

“Comparing current developments we identified with the numbers two years ago, we note volumes have been pushed out in time, and projects have increased in number and scale,” wrote the analysts. “We believe several of the new and revised projects are also likely to fail due to a lack of financing or other challenges.”

In Maine, on the U.S. east coast, Nordic Aquafarms is investing up to US$500 million in another land-based Atlantic salmon farm.

By Liza Mayer

Nordic Aquafarms has announced plans to build a land-based Atlantic salmon farm in California, U.S.A., to be close to the regional markets it plans to serve.

The facility will be built in Humboldt County, located about 270 miles north of San Francisco. It will be Nordic Aquafarms’ second land-based salmon farm in the United States and its first in the West Coast.

“The Humboldt location will enable us to reach more than 50 million people within a 12-hour drive or less, which reduces the cost and environmental impact of transportation while supplying the market with super-fresh, sustainably raised local fish,” said Marianne Naess, Commercial Director at Nordic Aquafarms.

The $400-million RAS facility is expected to create up to 80 new jobs and is designed to have a production capacity of 55 million lbs. The company said that a final decision on which species to raise – salmon or steelhead – will be based on market

considerations and further discussions with the local permitting authorities.

On February 11, Nordic Aquafarms through its subsidiary California Marine Investments entered into an exclusive option agreement with the Humboldt Bay Harbor District to lease 30 acres on the Samoa peninsula near Eureka in Humboldt County. Key permits such as aquaculture licences are already in place, the company said.

“This site meets all of our criteria for building a safe, clean, and sustainable fish farm, and we have been welcomed by local authorities who are excited about the many benefits this project can bring to the area,” said Erik Heim, president of Nordic Aquafarms Inc.

The company is currently building a 40-acre land-based Atlantic salmon farm in Belfast, Maine, to serve the east coast market. That project is now in the permitting phase and plan to start construction later this year.

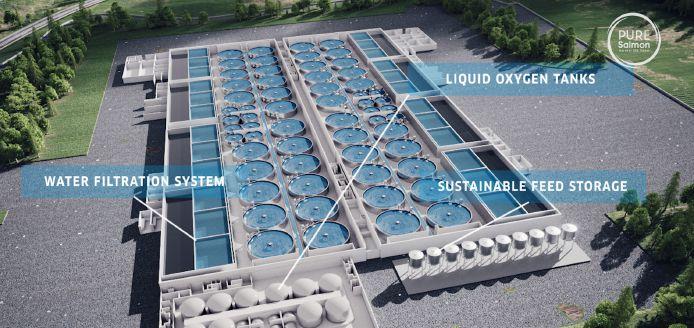

Singapore-based Pure Salmon continues its push to establish a global network of sustainable, land-based salmon farms, with the announcement of a new facility to be built in Tazewell County, Virginia, U.S.A., as well as two new potential locations in Europe.

The U.S. facility will add 20,000 tons in annual production to its existing RAS production facility located north of Warsaw in Poland, which currently produces 10,000 tons of Atlantic salmon annually. The U.S. project comes with a US$20-million financial assistance from local development agencies, according to a statement from Pure Salmon.

The company also plans to expand its European presence with two new locations being considered for development, which would contribute an additional 10,000-ton production capacity. The first site being considered is Boulogne-sur-Mer, a major fishing port on the northern coast of France with excellent connectivity within France and neighbouring countries. The second is Olbia in the north of Sardinia, Italy, a project which has attracted significant support at a national and local level, both politically and financially, Pure Salmon said.

The new European sites will be fully integrated with on-site hatcheries, grow-out systems and processing facilities.

“We’re delighted to be announcing further details of our plans to build large-scale land-based Atlantic salmon farming facilities in the U.S. and Europe,” said Stephane Farouze, chairman and founder of 8F Asset Management Pte. Ltd, a global asset management firm which developed Pure Salmon. “8F is proud to be a sustainable

investment business and we are looking to change the future of salmon farming with our ambitious growth plans for Pure Salmon around the world.”

Last year, the company announced a US$162-million investment to build 137,000-square-meter land-based Atlantic salmon farm in Japan, with production capacity of 10,000 tons per year. Dubbed, Soul of Japan, the RAS facility will be the largest of its kind to be built in Asia, according to Pure Salmon. The Japanese farm is expected to be fully operational by 2021.

The facilities in Poland, Japan, the U.S. and France/Italy are phase 1 of Pure Salmon’s roll-out plans and contribute a total 40,000 tons of production to its 260,000-ton global target, the company said.

– Mari-Len De Guzman

on a new role as head of the Institute of Aquaculture (IoA) at the University of Stirling in the United Kingdom effective March 1st.

Stead, who serves as a chief scientific advisor to the U.K. government, has held a number of high-profile positions during her career.

She takes over leadership of the research centre at an exciting time – with ministers recently announcing £17 million (US$22.6 million for a new aquaculture facility at Stirling.

“Joining the University of Stirling as head of the Institute of Aquaculture is a once in a lifetime opportunity that will allow me to work with staff, students and alumni, the wider university community, industry and government representatives to further enhance the centre’s outstanding reputation as a global leader in aquaculture,” Stead stated.

Under the City Region Deal, funded by the UK and Scottish governments, the university will receive £17 million for a new aquaculture facility, with a further £22 million (US$29.3 million) to be invested in the university-led International Environment Centre.

Keeping it simple: A discussion on aquaponics

NEW ORLEANS – Aquaponics was a big feature at Aquaculture 2019 held in this city March 7-11, with presenters highlighting the system’s potential for addressing the world’s food security challenges.

“We are not here because we want to know aquaponics; we are here because we want to grow food,” Urban farming expert George Brooks told attendees during his presentation.

Brooks is the founder and president of NxT Horizon Group, specializing in AgTech to build food production systems, including aquaponics.

“The world needs more fish and we think aquaponics is a way to accomplish that task. The problem is that aquaponics is fragile,” Brooks said.

Presenting the concept of ‘design thinking’ – empathize, define, ideate, prototype, test – he said this approach to producing an aquaponic system will help manage the complexity of such systems when applied to a community or urban setting.

The Interaction Design Foundation explains design thinking as a “a solution-based approach to solving problems. It’s extremely useful in tackling complex problems that are ill-defined or unknown, by understanding the human needs involved, by re-framing the problem in human-centric ways, by creating many ideas in brainstorming sessions, and by adopting a hands-on

approach in prototyping and testing.”

In his aquaponics session, Allen Patillo presented a project in Jamaica to develop a US$20,000 medium-size commercial aquaponic system. Patillo is the aquaponics technical director for the Increasing Access to Climate-smart Agriculture (IACA) project by INMED Caribbean.

The project aims to increase economic opportunities for small-scale farmers in Jamaica. It focused on making aquaponics a commercially viable technology for small and medium-scale Jamaican farmers, including women, youth and disabled farmers, while improving market access and resilience to climate change.

Training was a vital element, Patillo said. “We wanted to make sure we are picking people who are good candidates to get this thing done,” Patillo said.

The IACA aquaponic system used ebb and flow design with nine grow beds 20 feet long and four feet wide. Keeping the system simple helps keep the costs down without any expensive components to keep up with, Patillo said.

– Mari-Len De Guzman

Cape Nordic Corporation’s (CNC) project to build a large-scale land-based fish farm in South Africa just got even bigger with new plans to include the production of oysters, according to the project’s building contractor Gråkjær Aqua.

The company plans to use wastewater from the fish farm to produce up to 3.5 million oysters annually. According to a statement from Gråkjær Aqua, the facility, located near Cape Town in South Africa, is being designed to produce 1,800 tons of sea trout per year, with the capacity to expand its production to salmon in the future. The RAS facility will grow fish from eggs to final slaughter weight of 5.2 kilogram, and will contain a hatchery, first feeding, fry, a pre-smolt unit, a smolt and post-smolt unit, and a delivery tank.

An integrated multi-trophic aquaculture (IMTA) set-up will allow the facility to incorporate oyster production. Essentially, the oysters to be produced will live off the residual waste of the fish in the wastewater. The wastewater includes, for example, fish slurry, which will be utilised and converted into fertiliser, feed and energy. When the facility is completed and operational, CNC expects an annual output of 3.5 million oysters.

“Oyster production is a good business initiative, since the expanded fish production facility will enable us to produce a much-coveted, high quality product,” said Erik Rasmussen, Danish director for CNC. “The production will also generate even more local jobs, which will benefit the local community in the area.”

The company is also touting the facility’s sustainability features. Most of the power source in the fish farming plant will come from recyclable energy, Gråkjær said. The limited amount of bio-waste from production activities will be used as fertiliser for the farmland that surrounds the facility.

The government of South Africa, through the Department of Trade and Industry, provided subsidy for the project, Gråkjær said.

“We are two teams who, while sitting opposite each other, are actually on the same side of the table,” said Jens Jensen, business developer at Gråkjær Aqua, about his company’s partnership with CNC.

The project is running according to plan, the company said. Currently, on-site activities are continuing, including drilling of boreholes for water supply, soil investigations and analyses of the general conditions on and around the construction site. The CNC project team is also working on securing environmental approval and other regulatory processes, which are all expected to be in place by the summer of 2019. Construction is expected to commence in February 2020.

– Mari-Len De Guzman

The Triennial edition of Aquaculture America welcomed a record 3,500 attendees in New Orleans, Louisiana, a 65-percent growth from the previous event held in 2016 in Las Vegas. The Triennial is held in the United States every three years and combines the annual meetings of industry associations: WAS, the National Shellfisheries Association, the Fish Culture Section of the American Fisheries Society, and the National Aquaculture Association.

“Every show is getting bigger and bigger,” John Cooksey, executive director of World Aquaculture Society, said. “The only reason to account for that is that the industry is healthy, from research to production to the entire chain. A lot of people are looking to get into aquaculture. It’s definitely an indicator because if the producers are not doing well, they don’t buy equipment and the exhibitors don’t buy booths and there’s also no money going into research.”

There were 104 educational sessions at the

event, covering industry mainstays – finfish and shellfish aquaculture. But what was most notable was the strong presence and interest in emerging sectors and technology, such as recirculating aquaculture systems (RAS), offshore aquaculture, aquaponics and seaweed farming.

“Seaweed has become very popular and aquaponics is growing everywhere. We had a

workshop on aquaponics before the trade show and a lot of people attended,” said Cooksey. RAS sessions attracted a standing-room-only crowd.Participants this year are from 85 countries. (More from our coverage of Aquaculture 2019 in the May/June issue of Hatchery International) .

– Liza Mayer

By Michael Ben Timmons

In my current class teaching senior engineering students about the basics of recirculating aquaculture system (RAS) technology, I asked them if they have ever been ‘jazzed’ about something lately? You probably have used this term yourself when you were talking to a friend about something that excited you and made you passionate about something you are about to become involved in. I told my students they are about to become RASed about recirculating land-based aquaculture. I’m not sure they completely grasped this new term, but as the weeks go by in the semester the students are really starting to embrace the term.

Well, I’m all RASed up about this new technology called a mixed-cell raceway

sustainable and environmentally friendly engineering technologies.

(MCR). I wrote about MCRs in the last issue of Hatchery International. In that same issue (Vol 20 Issue 2 March/April 2019) immediately following my article was the piece, “Miami turns blue,” an update on Atlantic Sapphire’s project to construct a massive land-based salmon farm in the U.S. There were some great pictures of the project that showed the massive scale of an individual rearing tank (22x65ft or 6.7m x 19.8m with 546,000 gallons or 2,067 cubic meters). This type of tank scale volume is necessary to make the required capital investment efficient and provide competitive economic returns to conventional net pen salmon production systems. No argument here, but is this the type of system you or the fish people on your team want to work in on a

daily basis? One thing for sure is that you’d need to have plenty of safety flotation devices (life preservers) hanging all over the place in case someone accidentally tripped or slipped and fell into the 7-meter-deep fish tank.

When we were developing the MCR concept a few years back, I asked my good friend John L. Holder, who has more than 30 years of experience working with salmonids in both raceways and net pens, what would be his ideal depth in a raceway to manage the salmon effectively. And his answer was 1.5 to 2 meters. Well, 2 meters is a lot different than a round tank that is 7 meters deep.

I was in a recent conversation with a project team leader that is building a large indoor land-based farm and we were arguing, I mean discussing, some subtle aspects

of design and tank layout. The issue revolved around being able to fit a number of MCR tanks into an existing building space and how much space was needed between adjacent MCRs for people activity, i.e., fish management activities. Basically, the discussion ended up with the age old saying of me telling the other fella, “You don’t know what you don’t know.”

New teams entering this arena of indoor aquaculture (where space is a premium) always underestimate the critical aspect of being able to effectively and conveniently conduct the day-to-day chores of managing a fish farm. If the design layout makes it difficult for the fish folks to do their job, then one or two (or maybe both) things will happen: 1) the job or task will be done poorly or at greater effort, or 2) not done at all or as often as it should be.

Using John Holder’s ‘wish’ that a tank should only be about 2 meters deep, I did a calculation (see Table 1) on the size of a MCR compared to the Atlantic Sapphire round tanks. After looking at this table and studying it some, do you see why I’m all RASed about

ROUND

Diam 65ft - 19.8m

Depth 22ft - 6.7m

the MCR? We can create the same tank volume using a conventional raceway footprint (with MCR adaptation) and still have reasonable and very manageable water depths. The only thing I really think works negatively against the MCR is that if you are going to use the shallow depth (2 m) then your floor foot print is going to be roughly double the footprint of a round tank (that takes up a square foot print, i.e., round tank diameter expressed as a square area). You could increase the depth on the MCR, but then you get back into fish management issues. But why do you need a building in the first place? Why not use tank domes? That’s another discussion for another column. Anyway, I am RASed and after reading

MIXED CELL RACEWAY

Width39ft - 12m

Depth 7.9ft - 2.4m

Length 236 ft - 72m Vol 547, 430 gallon 2,074 m3

Cells 6

this, maybe you’ll be a little RASed as well. Here is the recently published paper on the MCR tank hydraulics using CFD analytics of various configurations and operating conditions to maximize the effectiveness of the MCR design (Chun, C., Vinci, B.J., Timmons, M.B., 2018. Computation fluid dynamics characterization of a novel mixed cell raceway. Aquac. Eng. 81, 19-32; https://doi. org/10.1016/j.aquaeng.2018.02.002).

For those who want to study RAS principles a bit more or review the basic principles, let me encourage you to take advantage of a newly created distance course, www.eCornell.com/fish, or look into the Aquacultural Engineering Society’s offering of a certification in RAS design, www.aesweb.org.

By Maddi Badiola

Sustainability” and “sustainable” are popular words these days, but often misused. We understand it as producing food while sustaining natural resources and achieving it only through production systems with minimal ecological impact.

The most common relation is linking environment with sustainability. If something does not impact the environment or has a positive impact on it, it is considered sustainable. However, there are other factors that might come into play when considering a product or production system’s sustainability.

RAS as case study

We conducted a survey among different stakeholders whose opinions are critical for the advancement of the aquaculture industry. One of the questions we asked was why RASis considered “environmentally friendly” fish production methods. Responses were received from all over the world and the main reasons given were: less water usage from the environment compared to other culture technologies, such as flow through systems; decrease of the eu-

Chair: John Davidson

The Freshwater Institute & CtrlAQUA, Norway: A multi-year research collaboration on RAS-based Atlantic salmon production.

Chris Good, Director of Aquaculture Research

Integrating membrane biological reactors within RAS culturing rainbow trout – A preliminary evaluation.

John Davidson, Research Scientist

Practical problem solving and management technologies to address RAS challenges.

Curtis Crouse, Assistant Aquaculture Production Manager

Determining the effects of photoperiod regimes on growth performance, health, and maturation of Atlantic salmon in freshwater RAS.

Chris Good, Director of Aquaculture Research

Woodchip bioreactors for treating RAS wastewater: Evaluating performance, economic feasibility, and environmental impact.

Christine Lepine, Research Associate

Fillet and product quality research at TCFFI: Off-flavor remediation, harvest techniques, and humane slaughter.

John Davidson, Research Scientist

Analyzing economies of scale for land-based recirculation aquaculture systems.

Laura Bailey, Project Engineer

Stakeholder Q & A

Maddi Badiola, PhD, is a RAS engineer and co-founder of HTH aquaMetrics LLC, (www.hthaqua.com) based in Getco, Biscaye, Basque Country, Spain. Her specialty is energy conservation, life cycle assessments and RAS global sustainability asessments. Contact her at mbadiolamillate@gmail.com.

trophication potential of the outgoing water; elimination of potential disease transfer and genetic contamination of wild stocks; use of no or very little vaccines or antibiotics because of a biosecure culture environment; and the possibility of re-using discharged nutrients in agriculture.

Nonetheless, in practice, sustainability of RAS was considered uncertain and the use of energy and its environmental impact was of little concern to the respondents. In fact, concerns identified by the stakeholders included (Fig. 1): identifying alternatives to fishmeal (35%); enhancing animal welfare (i.e. increased biomass production, increased survivals and reduced maturation with the subsequent reduction of product downgrades) (26%); decreasing the feed conversion ratio (23%); decreasing the use of chemicals (11%); and decreasing the use of energy and thus, created environmental impacts (5%).

Energy plays an important role when considering the sustainability of RAS. Respondents were also asked about techniques or strategies applied in relation to energy recovery systems designed/ applied. Examples included exchanging heat between the incoming (i.e. make-up water) and outgoing water through a heat-exchanger; retaining heat based on the system’s operation/water use; controlling the energy use of CO2 stripping through pH/CO2 set-points for on/off control of blowers for energy saving and; increasing the recirculation rate through the use of denitrification technologies which resulted in energy use reduction and cost savings. Using system sludge for local farming purposes and producing energy for other nearby companies through a bioreactor supplied by sludge, guts from the processing stage and mortalities, were also mentioned.

Typical environmental benefits of RAS are less water and land use, greater control over the environmental and water quality parameters enabling optimal conditions for fish culture, and high biosecurity standards. However, there is something else beyond this. There are many other reasons to consider such systems as environmentally sustainable. RAS are located where consumers are, decreasing the transportation and thus the carbon footprint of each of the marketed products. RAS producers are committed to promote site-specific energy sources such as renewable energies and zero or near-zero impact initiatives within the local community. The recapture and reuse of waste from the system, included in a lifecycle assessment throughout the whole production cycle, make it possible to consider such systems within circular economy business models.

Aquaculture is the production of fish, the industry of the future, the (potential) engine of many communities in developing countries and the promising farming method to meet the seafood demand in

technological and economically advanced areas. Society needs aquaculture as aquaculture needs society.

RAS produces absolutely fresh products, possibly and potentially certified, available all year round. Moreover, these systems allow full traceability of the product, from egg to the table, giving consumers the confidence of purchasing a trustworthy product. The site selection by investors and/or company managers also guarantees local employment and economic development. This positively contributes to local job creation and generates ripple effects in the local supply and service sectors. RAS can promote aquaculture (and related areas) through schools, universities and research companies as well as investing in R&D with continuous feedback from stakeholders.

However, society and consumers need to be educated. The understating of what fish production is and the implications of the industry in the near and further future is crucial. RAS companies need to educate fish eaters about the benefits of sustainable

Fish meal alternatives

choices. The importance and awareness relies on the information strategies to adopt sustainable seafood choices.

Should technology and the economy also be considered when defining the sustainability of RAS? Learn about sustainability and the circular economy, which radically limits the extraction of raw materials and the production of waste, recovers and reuses as many of the products and materi-

Animal welfare enahncement

Energy use-environmental impacts

Decrease of FCR

Chemical usage decrease

als as possible, in a systemic way, over and over again.

The prevailing model of production and management of resources that promote short-term consumption is leading the planet to an unsustainable outcome. In contrast, the circular economy is a “make/ remake – use/reuse” economy that offers substantial improvement.

By Christian Pérez Mallea

Highly prized for sashimi, sushi, nigiri and Peruvian recipes, such as ceviche and tiraditos, the Yellowtail (Seriola lalandi) has found a great ally in recirculating aquaculture systems (RAS), which seems to be a perfect match for rearing this species on land.

In addition, since these fish are farmed in closed-containment systems, their meat is free of parasites, making them an optimal choice for raw fish consumption.

Recognizing this potential viability, several companies producing Yellowtail are investing millions of dollars worldwide to scale up their operations and meet the requirements of a growing global demand.

As additional attribute, the production of S. lalandi in RAS systems is regarded as sustainable by international non-profit

organizations such as the Monterey Bay Aquarium, which has included this farmed fish in its Seafood Watch Program as ‘Best Choice’ in its ‘Green List’, or the Good Fish Foundation, which has recommended it as a ‘Green Choice.’

The Argentinian Institute for Fisheries Research and Development – called, INIDEP, by its initials in Spanish – started farming S. lalandi in 2016, with a team of four skilled professionals (Facundo Bernatene, Pablo Javier Martínez, Pedro Camilo Menguez and Mariano Spinedi) working on its Yellowtail RAS project. In just two years, they have reared its own breeders from eggs hatched in Mar del Plata.

Facundo Bernatene, head of the breeding program of S. lalandi within the above-mentioned team, describes this

initiative as the most innovative and ambitious aquaculture project that has taken place in the country.

“Currently, we have a new breeding stock of breeders obtained from captivity-born individuals, which are reproductively active and producing viable eggs,” Bernatene explains. “To validate the last and final stage of our proof of concept, we have scheduled an official tasting with an expert panel of recognized chefs that will evaluate the sensory qualities of the product.”

Right across the Andes, Acuinor began a similar project a few years earlier in Chile. In less than 10 years, the company has been able to create a genetic program with land-based reared breeders, weekly egg production and a 2018 harvest of 10 tons, which is expected to be doubled this year. Following a recent US$4-million-investment in its RAS farm, the company

capacity close to 520 tons per year, Kingfish Zeeland plans to grow that capacity to 1,000 tons this year, and to 4,000 ton by 2020, Kloet tells RAStech sister publication Hatchery International in an earlier interview. The company also plans to establish a production facility in the United States (see ‘Yellowtail borne from research to RAS’ in Hatchery International, Volume 20 Issue 2).

With close to 6,000 tons in capacity per year, the Australian company Clean Seas is the largest producer of this fish outside Japan, where three Seriola species (S. quinqueradiata, S. dumerili and S. lalandi) count for around 180,000 tons annually.

While Kingfish Zeeland’s 5,000-square-meter RAS farm was born with technology from Billund Aquaculture, Sashimi Royal relies on its sister company Maximus, which has produced marine fingerlings for the past 25 years in its 3,000-square-meter

indoor production facility (with more than 35,000 cubic meters in outdoor production tanks). High control and pure-quality water are a common theme in these environments.

On the other hand, the RAS systems used by the Argentine team are of the team’s own design. “We have been following the evolution of RAS for more than 15 years, but the worldwide jump to the third generation was the key for us,” Bernatene says.

“The systems with Moving Bed Biofilm Reactor (MBBR) of fluid bed were a fundamental part of this evolution. The MBBR is a complete mix and continuous flow process that achieves greater process stability, greater efficiency per cubic meter, favors the elimination of solids without leaving dead zones, and does not have the need for periodic backwashing. In addition, it allows working with low pressure systems, reducing energy costs,” he explains.

The Argentine head of the Yellowtail

breeding program points out that this species has a high growth rate, excellent feed conversion rate and are optimal for RAS technologies. “It has a great adaptability to be farmed in RAS systems at high densities,” Bernatene adds.

Similarly, Acuinor has designed its own RAS systems. “This technology has been developed given the knowledge we have acquired in the cultivation of this species, having determined its optimal conditions of photoperiod, temperature and nutrition, among others. This knowledge has allowed us to know precisely the requirements of this species, their demands and emissions, as well as their behavior,” says Muriel Teixido, development manager at Acuinor.

Difficult access to skilled personnel has also required additional efforts from these South American producers of RASgrown Yellowtail. For example, in Argentina there is no aquaculture college degree in local universities. “We have had the good fortune to be trained in countries

such as China, Japan, South Korea, Chile and Brazil, besides working for more than 15 years developing new technologies of sustainable culture of marine fish in RAS,” Bernatene says.

Although Chile has an extensive aquaculture industry – thanks to salmon farming – Acuinor’s Teixido says as far as production is concerned, rearing of marine fish is still in its early stages of development. It demands specific techniques and knowledge, “which has required us to train collaborators in this particular trade,” she explains.

One of the largest challenges for Yellowtail producers has been feed quality. Kingfish Zeeland, for example, began with 100 percent organic feed, but given some issues with product quality, have now moved toward 60 percent non-organic feed and 40 percent organic feeds.

The Argentine team has conducted a thorough analysis of experiences around

the world with regard to fish feed performance in RAS with the Yellowtail species. These analyses were combined with their own practices.

“With the raw materials available, we formulated a specific diet for this species,” Bernatene says. This feed was manufactured in cooperation with one of the three largest freshwater fish feed companies in Argentina (Paku Téko, Chaco).

“So far, a specific feed supplier is not available and probably until an industry

develops, nor will there be one. However, Argentina has raw materials of excellent quality, such as fishmeal and fish oil that are obtained from cuts derived from the processing of the local fishing industry. In other words, we use a by-product or waste, and we transform it into a premium fish,” he adds.

Even though the Chilean salmon industry is well supplied by large feed manufacturers present in the country, these suppliers are not covering the Yellowtail needs. “Since our farming volumes are still low, it is not of great interest to feed suppliers since they do not manufacture small batches of feed,” says Teixido.

This is why Acuinor has also been contributing in the production of their own feeds. “We have been working on the development and improvement of diets for our fish, which will be a work of continuous improvement over time and in the development of this industry,” she adds.

By Bonnie Waycott

As the global demand for quality seafood rises, fish farmers are recognizing the need to gain greater control over their operations. More farms are exploring ways to create smarter, more sustainable operations and land-based aquaculture is emerging as a viable way to reduce risk and maximize profitability.

Swiss Alpine Fish, a land-based salmon farm in Switzerland, embarked on its journey toward sustainable production nearly four years ago. It is among the early adapters of RAS2020, a modular recirculating aquaculture system (RAS) design developed by Veolia Water Technologies.

Tapping Krüger Denmark to deliver this new system to its facility in Lostallo village, Swiss Alpine Fish started construction of its new state-of-the-art farm system in 2015.

The company’s CEO, Julian Connor, explored the best technologies in the

market to farm salmon and RAS2020 became the obvious choice, explains Thomas Hofmann, farm manager at Swiss Alpine Fish.

“Construction took 14 months. It began in September 2015 and fish were in the system by November 2016. Not only does the RAS2020 provide great performance, it’s also reliable and respects the environment and fish welfare. Its advantages are its low footprint, innovative design and the warranty to have optimal water quality,” Hofmann says.

For Swiss Alpine Fish, the RAS2020 has provided a turnkey solution to farming salmon in the Alps, while Veolia’s

expertise in water and technical support has been an integrated part of the company’s success.

Founded in 2013, Swiss Alpine Fish receives batches of 50,000 salmon eggs every 10 weeks from Stofnfiskur in Iceland. It operates on a 24-month- production cycle, from the egg stage to 4 kilograms. Fish are given Biomar feed free of ethoxyquin each day through an automated feeding system, with rations adjusted according to fish size and appetite. An average of 1.3 to 1.5 tons of feed is given each day depending on standing stock in the system, while water quality is checked daily.

Best suited to species like salmon, trout and sea bass, the RAS2020 is designed to reduce capital and operating costs, maximize production and improve sustainability in land-based aquaculture. Based on recirculation, it includes water treatment technology that can optimize growth, reduce feed conversion ratio (FCR) and improve survival.

Two circular tanks are positioned around a central tank that has a platform and contains a biofilter. The two circular

tanks are divided into a number of sections by permeable grids to separate different groups of fish. Flow markers allow water exchange in each tank section in under a minute and adjust flow rate to the most optimal level for the fish. Parameters such as oxygen, pH, CO2 and temperature are kept at optimal levels with an advanced control system.

The maximum feed load is 4,200 kilograms of feed per day, and the system can produce 1,000 to 1,800 tons of fish each year, depending on the species and

production logistics. The RAS2020 comes with a tank volume of 6,400 cubic meters and a system flow of 10,000 cubic meter per hour.

Fish enter one of the sections in the inner of the two circular tanks as juveniles. A grader installed on the central platform grades them as they grow, before they are transferred to another section in the outer circular tank once they have reached a preferred size. As they grow in the outer tank, a tank separation grid expands the section they are in to create more room. The fish are then transferred to the next section of the outer tank followed by the next until they reach the tank’s last section at harvest size. This section is connected to two purge tanks, 385 cubic meters each, allowing the fish to be moved easily without pumping. They remain there for several days until harvest.

“One of the RAS2020’s unique features is the possibility of moving fish through the system using moveable grids, reducing stress significantly,” says Dr. Michael Bech, project developer at Krüger Denmark, a business unit of Veolia. “Another is the adjustable water velocity and uniform flow pattern, which gives an even distribution of fish, reducing competition and stress.

“The RAS2020 is cheaper and faster to build than a conventional farm of the same capacity because it’s very compact with a footprint of 3,340 square meters, and designed with four concrete channels and no additional piping under the concrete floor. Our aim is to deliver safe, sustainable aquaculture solutions with the highest standards for biosecurity, fish welfare and water quality.”

Water quality is vital to success in salmon farming, farm manager Hofmann says. “It’s the key to producing healthy fish and achieving an optimal performance on the farm. On average, our CO2 levels are 6mg/L, ammonia is 0.3mg/L, turbidity is 0.7NTU, and pH is very stable across the entire system at 7.3,” he notes.

The RAS2020 has multiple probes inside the tanks that can continuously measure and monitor water parameters. The probes are connected to an alarm

The Sustainable Aquaculture programme offers a range of part-time, e-learning, postgraduate-level modules, including recirculating aquaculture systems (RAS). Students may study individual modules from the postgraduate programme, allowing students to focus their studies on specific areas of interest. The credits for each module completed successfully can contribute towards a postgraduate qualification (PG Certificate, PG Diploma, MSc) at a later date.

The modular course in Recirculating Aquaculture Systems trains students to apply RAS techniques to modern sustainable aquaculture using a series of online lectures, tutorials and assignments.

• Water quality

• Biofiltration

• Treatment of solids

• Gas transfer

• System design

• System operation

• System management

• Financial aspects of installing and operating RAS

The objective of the course is to provide students with the knowledge necessary to design and operate their own RAS systems.

APPLY

Visit www.thefishsite.com/learn or email Dr Neil Hazon, Course Director at nh1@st-andrews.ac.uk

system that can generate emergency alerts and allow the staff to quickly respond if problems occur.

Reared in freshwater with 24-hour light, it takes up to one year for the salmon to reach a weight of 150 grams, and another 10 to 12 months before they reach an optimal harvest size of 3.5 to 4 kilograms. Once they’ve reached this size, they are processed at Swiss Alpine Fish’s processing plant, electrocuted and bled before gutting.

Although mainly head-on, gutted fish is sold, the company has recently established its own onsite smokehouse, where 20 percent of its fish is smoked before being sold online at the farm shop and to retailers and distributors.

Strict biosecurity measures are in place in the facility. Color-coded tools and gear are used in each part of the production process, all equipment and fish tanks are cleaned and disinfected continuously

and the use of footbaths and hand sanitizers are enforced. Water is disinfected as much as possible through multiple UVs within the RAS2020.

Good waste management is among the most important drivers for companies to adopt smart RAS technologies. Veolia’s state-of-the-art wastewater treatment system allows Swiss Alpine Fish to discharge clear water to a nearby river, and meet Switzerland’s toughest and most restrictive quality standards for water discharged into local rivers. Through the RAS2020 system, fish waste is also collected before being sold to a local biogas facility.

“The flexibility and simple design of the RAS2020 is another great feature,” says Thomas. “We can adjust all parameters with the click of a button. For example, water flow can be adjusted so the fish swim hard in our tanks. This gives us an excellent growth rate and good flesh quality. Our fish are performing extremely well. By 2021, it’s said that the

RAS2020 will be producing up to 8,000 tons of fish on land. That’s very promising.”

RAS is emerging at a good time to meet the changing needs of land-based aquaculture and the growing demand for seafood. New, innovative systems will allow companies to increase operational performance and give producers the advantage of being able to promote what they say is a clean, sustainable approach to farming fish.

Polyethylene. High-density polyethylene is more effective in challenging terrains such as heavy soil, but there can be a lot more difficulties with polyethylene as the pipes age.”

If a sprinkler system is providing inadequate coverage, he suggests trying a two-headed sprinkler system for more efficient watering. One must also consider how much water is available and how long the system should run.

balanced with essential nutrients and be highly digestible, be of excellent physical quality, and improve faeces quality for easy removal from the system. This article will mainly focus on faecal quality derived from dedicated RAS diets.

In any RAS, the first step of waste removal should be the separation of the faecal solids and uneaten feed from the rearing water. This is easily achieved with high efficiency by mechanical filtration and sedimentation. However, both are dependent on faecal structure, integrity and size. Sedimentation is also dependent on the buoyancy and

settling properties of the faeces. To ensure proper maintenance of solids removal efficiency, the faeces must be as robust and as large as possible. If the faeces are not effectively removed from the system, because they are too small or disintegrate too easily, it can have a snowball effect on the rest of the system and on the fish (Table 1). Residual organic solids can greatly impact biofiltration, degassing and aeration, efficiency of microparticle treatment (such as protein skimmers and contact filters) and microbial control. An excess of nutrients in the water will represent an additional load to the biofilter and can accumulate in and mechanically damage the gills, re -

sulting in poor oxygen uptake by the fish. This can, in turn, lead to a fish that is less robust and more susceptible to disease.

The key to faeces management is to develop diets that promote good quality faces for removal and good growth. One way to achieve this is by utilising indigestible ingredients that bind the faecal matter. The use of faecal binders is not new in the nutritional world, and ensuring low dosage in the formulation of diets is key to their effectiveness. Binding of faeces must occur in a way that nutrient digestibility and uptake is not compromised, while also ensuring that the indigestible fraction of the diet leaves the fish in good integrity. This way, leaching of nutrients from the faeces in the system is minimised, while ensuring the faeces are taken out of the system in a quick and gentle way. As water quality is enhanced, fish grow better and healthier, and the production capacity of the system may be increased.

Another consequence of being able to remove faecal components more easily is that the effluent treatment is simplified. In most of the places where RAS are located, strict regulations about release of nutrients (N, P, organic matter) into the environment have been implemented. The task of treating the

solids is easier with good faecal physical quality. Good faecal physical quality will also assist in harvesting nutrients for further valorisation as manure, energy, etc. For instance, more nitrogen and more phosphorus will be faeces-bound when adding faecal binders, thus improving the potential recovery of these nutrients for other applications (Table 2). Likewise, less of these nutrients will be leached into the system, which will have a retroactive effect in fish and system performance.

Faeces that are easier to handle will greatly reduce costs associated with effluent treatment. When such faeces are produced, the waste stream flow is reduced, and the waste treatment reactors and processes will become more efficient.

Skretting introduced dedicated RAS diets into the market back in 2009 – an industry first. Since then, we have introduced a specialised concept dedicated to RAS, RecircReady, which takes

into account growth and waste predictions, nutrient recycling solutions and health monitoring in addition to tailored feed solutions using patented faecal binders. Skretting has been investing research resources into RAS

over many years, with three dedicated RAS-based research facilities across the world, each with a unique focus to support the growth of the land-based industry.

AKVA group Scotland has appointed David Peach as its new commercial director, replacing Douglas Johnson, who has retired after a lengthy career in aquaculture.

Peach has more than 25 years’ experience in the marine industry and arrives at AKVA from a senior position as group sales director at 3Si, Safety and Survival Systems International.

“I’m delighted to be joining the AKVA team and building strong relationships with customers and developing a robust sales team, along with ensuring that excellence in customer service and the supply of innovative, and high-quality products, is

THORILEX Ltd. has launched several new products for the aquaponics market. The three new products include: the Automatic Vertical THORILEX Hydroponic System (THORILEX AVHS) ; Multiuse THORILEX Hydroponic basket; and the Self-cleaning THORILEX fish tanks

THORILEX products uses quality materials such as stainless steel, the company said, and are design for easy construction and transportation around the world similar. All these products are currently being used and tested at the THORILEX Aquaponics farm as part of a two-hectare glasshouse area. The data evaluation is expected until the end of the year.

The Automatic Vertical THOIRLEX Hydroponic System is made from the stainless

maintained,” said Peach.

With AKVA in Scotland now employing more than 70 people, David’s role will be to lead the commercial organization in delivering profitable sales while upholding customer service and support standards. In addition, he will actively explore new commercial opportunities for AKVA group Scotland and seek to monetise these over the coming period, the company said.

“David’s strong sales background will bring great value to AKVA group Scotland as it continues to develop and thrive within the U.K., industry, as well as allowing us to develop our international business,” said

steel and yields up to nine times higher production, easier harvesting and better climate for the plants. The system can be up to eight

meters in height provides options for different growing boxes by species of plant. It is also equipped with a special spraying system operated through a control and security system.

The THORILEX Hydroponic reusable basket is uniquely designed to last longer, with modified bottom and made with stiff material for easy and fast plant removing without damaging the root system.

The THORILEX Fish tank is made from stainless steel and uses hydrodynamic water flow to remove the fish waste. It has the capability to regulate the height of the water and is designed to accommodate an automatic feeder system.

The products are highly modular for easy packing, delivery and installation, the company said. THORILEX is currently accepting advance booking to purchase these products at introductory prices. www. thorilex.com

Nordic Aquafarms Inc., the U.S. subsidiary of Nordic Aquafarms, a global player in land-based aquaculture, has appointed Brenda Chandler of Auburn, Maine, as its full-time chief financial officer. She is now working out of the company’s corporate headquarters in Portland, Oregon.

“We are very pleased that Brenda has chosen to join the company as we are proceeding with our plans in the U.S.,” Erik Heim, company president, said. “I also want to thank Thomas A. Brigham, who has been assisting us as acting CFO in the start-up and transition phases.”

Chandler, who most recently was responsible for the global Corporate Real Estate program at ON Semiconductor in South Portland, has a varied and successful finance career in the technology and paper industries. She has had progressive experience in treasury, risk management, finance, accounting and most recently corporate real estate.

A Maine native with family roots in Belfast and Jonesport, Chandler began her career working for small wood products companies and later joined the Rumford paper mill where she worked in several accounting roles. In 1999, she joined Fairchild Semiconductor and was

Aller Aqua has introduced a new feed technology called PowerRAS.

This new feed system has been developed to meet the requirements for RAS feed in terms of efficiency, optimal water quality and fish growth.

“The PowerRAS concept has been developed based on many years of research,” says Aller Aqua product manager Dr. Robert Tillner. “We have kept up with the increasing

promoted through several financial leadership positions, culminating in senior director and assistant treasurer roles. In 2016, Fairchild was sold to ON Semiconductor.

Chandler holds B.S. and A.S. degrees from the University of Maine Augusta. She and her husband, Tony, live in Auburn on an 18-acre farm and between them have six children and six grandchildren. The couple’s latest adventure is the start-up WillowsAwake Winery in Leeds Maine, a 67-acre farm and forest turned vineyard and winery.

Chandler currently serves as board president of Wayfinder Schools and was formerly on the supervisory committee of the Maine Solutions Credit Union. www.nordicaquafarms.com

sophistication of RAS, whilst focusing on the benefits for the RAS farmers.”

As RAS farming becomes more common in the global industry adding more fish produced in RAS to total aquaculture production, Aller Aqua says feed is an essential factor in optimizing water parameters and fish biomass in RAS technology.

The company says its new feed takes a number of aspects into consideration,

We are your source for professional aquatic and aquaculture products and services.

Our hands-on experience allows us to offer practical solutions to your situation, big or small.

We have years of experience in retrofit and new construction and understand your needs.

Contact us today to learn more!

Phone: +1 407 995 6490 Web: AquaticED.com

including: nutrient digestibility and palatability, faeces quality, fish metabolism and DP:DE ratio, technical quality of the feed, and feed functionality.

The findings are now commercialized and represent the latest addition of RAS-optimized feed technology by Aller Aqua. www.aller-aqua.com

- Permanent PVC concrete form

- Maintenance free

- No paint or membrane required

- Low transportation costs

- PVC respects drinkable water requirements

- R-value insulation option to reduce energy costs.

75 De Vaudreuil, Boucherville, Quebec Canada J4B 1K7 - Ph: +1 (450) 449-6400 www.dc-inter.com dctank@dc-inter.com

Some of the most influential companies and organisations in global aquaculture have come out to support the 2019 Aquaculture Awards, according to award host Aquaculture UK.

The awards, to be presented on May 29th in Edinburgh, Scotland, cover eight categories and have attracted interest and entries from all corners of the globe.

2019-02-25 3:38 PM

The Applied Research Breakthrough category is sponsored by Lloyd’s Register, and open to any research project involving collaboration between the industry and academic sectors.

Mowi is sponsoring the Technical Innovation award, to be presented to the developer of new hardware or software that has, or is projected to, improve performance of an aquaculture sector.

The Animal Welfare category, sponsored by Benchmark, recognizes an initiative that has improved the welfare of the farmed animals and/or the wildlife they interact with since January 2018. Initiatives can cover a range of factors, including genetic, pharmaceutical and technological innovations, or improvements in husbandry and farm management protocols.

2019-02-27 2:51 PM

5M Publishing Ltd. Pg.23

Adsorptech Pg. 15

Advanced Aquacultural Technologies Inc. Pg. 7

Aquacare Environment Inc. Pg. 21

Aqua Logic Inc. Pg. 26

Aquanetix Pg. 30

Aquatic Enterprises, Inc. Pg. 31

Aquatic Equipment & Design Inc. Pg. 29

The Most Promising New Entrant award – which recognises the best people, companies or products that arrived in the industry since January 2018 – is sponsored by Primer Design.

The International Impact award, sponsored by BioMar, aims to promote companies and/or new initiatives with a truly international impact. Projects that promote cross-industry collaboration and/or make their results freely available for the greater good of the sector will be viewed favourably.

The Sustainability award – sponsored by Cargill – is being presented to the organisation that is able to demonstrate the consistency of its contribution to the environmental, ethical and economic sustainability of the industry. All entrants will need to highlight ways they are addressing each of the three E’s.

Finally, the Scottish Aquaculture Innovation Centre (SAIC) is sponsoring the Diversity award – which will be presented to the employer that has done the most to promote diversity in their workforce and/or the sector in general since January 2018. www.aquacultureawards.com

Benchmark Instrumentation & Analytical Services Pg. 17

Billund Aquakulturservice A/S Pg. 33

Biomar A/S Pg. 2

BIO-UV GROUP Pg. 15

Cornell University Pg. 24

DC International Pg. 30

Delta Hydronics Inc. Pg. 31

Faivre Sarl Pg. 27

Fresh By Design Pg. 24

Freshwater Institute Pg. 14

Innovasea Systems, Inc. of Boston, Massachusetts, U.S.A., has acquired all of the outstanding shares of land-based aquaculture system technology firm Water Management Technologies Inc. (WMT) of Baton Rouge, Louisiana.

WMT will become a new business unit within Innovasea, named Land Systems, and operate alongside the existing Farm Systems, Instrumentation and Fish Tracking business units. Terry McCarthy, president of WMT, will lead the new Land Systems business unit as vice-president and general manager.

For 25 years, WMT has designed and supplied Intake, Effluent and Complete Recirculating Aquaculture Systems (RAS) to commercial fish farms, aquaculture research entities and government hatcheries worldwide.

Innovasea Systems enables sustainable use of ocean and freshwater ecosystems. Through its

Farm Systems, Instrumentation and Fish Tracking business units, Innovasea is creating a comprehensive, sustainable solution for open-ocean aquaculture, the company said.

“With the vigorous growth underway within the recirculating aquaculture systems sector, becoming part of the Innovasea team will significantly broaden our capability and also provide the needed resources to grow and capitalize on the opportunities presently in the marketplace,” McCarthy said.

The acquisition of WMT will add nursery and hatchery solutions to Innovasea’s existing open-ocean grow-out systems, said David Kelly, CEO of Innovasea, citing WMT’s “expertise” in both freshwater and saltwater systems.

“This enables Innovasea to provide complete egg to harvest solutions for our clients,” Kelly said. www.innovasea.com

InnovaSea Land Systems Pg. 13

Integrated Aqua Systems Inc. Pg. 9

KSK Aqua ApS Pg. 31

A/S Pg. 8 MAT FİLTRASYON TEKNOLOJİLERİ AS Pg. 11

MDM Incorporated Pg. 12

OxyGuard International Pg. 28

Systems Inc. Pg. 30

Aquatics Pg. 29 Reef Industries Pg. 18

RK2 Systems Inc. Pg. 20

Sivat Services Pg. 18

Skretting North America Pg. 5

Trome vof Pg. 22

Veolia Water Technologies (North America) Pg. 34

Veolia Water Technologies AB - Hydrotech Pg. 20

Given the unique nature of each RAS facility, maintaining a catalog of Standard Operating Procedures (SOPs) specific to your site is helpful. SOPs describe how essential routine tasks at the facility should be performed to meet quality standards. Up-to-date SOPs are a useful tool for training new hires and are a guide for continuity and quality assurance between staffing changes and work shifts.

When deciding to implement SOPs at a facility, include fish production staff in the process to solicit input and increase cooperation. Prioritize essential tasks, such as maintaining biosecurity, disinfecting equipment, or waste water discharge permitting, as the first SOPs to be written. The overall format of SOPs is flexible but should consist of the following sections.

A SOP catalog should have a master table of contents with individual SOPs identified accordingly. A descriptive title allows the user to quickly identify the SOP they may need. An efficient identification system allows easy access to the documents in the SOP catalog. To improve work flow, maintain a set of SOPs in an office area as well as in the working areas for quick reference.

The SOP should begin with a scope or purpose statement that describes the need for the procedure and the intent of the document. A short, few sentence, summary of the method helps a user confirm that they are referencing the correct SOP. This section should be brief, as the procedure will be described in depth later in the document.

A short list of definitions for industry or facility specific jargon ensures that users fully understand the methodology of the SOP without having to reference other materials or use context clues to follow along. It is helpful to write this section after completing

the SOP as only terms that appear in the document need to be defined.

Any potential risks to human or animal health should be stated to alert staff. These risks may include possible falls, injury risk from machinery, exposure to chemicals or gasses, and many others.

This section identifies the intended audience, and accordingly, the SOP should be written so that staff with the minimum suggested training would be expected to understand and successfully complete the procedure.

A list of necessary equipment allows all items to be gathered or procured prior to beginning. This prevents interruptions and may save time and resources from having to repeat a procedure.

When developing a SOP, the author should perform the task, taking note of important details to be included in the method. Further, receiving input from other staff members may yield more efficient techniques that still meet quality standards. When describing the procedure in an SOP, it should be presented in a numbered or bulleted list of step by step instructions. This makes the document easy to quickly read and interpret. Use bold or underlined fonts to highlight critical steps or warnings. Be specific enough that the directions can be followed by someone unfamiliar with the procedure but avoid lengthy explanations with overly complicated details. Including images can quickly illustrate proper technique or point out locations of important equipment using overlaid arrows. Use only high-resolution, expanded images that clearly illustrate techniques, locations, or equipment. Relevant flow charts or tables are other useful tools. Include a suggested time allocation to guide the required effort

to complete the procedure.

A record of procedure completion should be maintained, and the Data and Records Management section describes how this should be done. This often takes the form of check lists that ensure tasks are completed in regularly scheduled intervals and can prevent duplicated effort from staff. Effective record keeping can also provide feedback if a task should be performed more often or if equipment is failing.

Include any references to documents used to formulate the SOP. These may include any online and print sources or equipment operation manuals. Any SOPs referred to in the Procedure section should also be listed in the References section using the aforementioned identification system.

After authoring any SOP, allow staff to review or try to use the document to perform the task and incorporate any helpful feedback. A final draft of the SOP should be given final approval from essential staff. When a procedure is amended, or associated equipment is replaced or modified, the SOP should be updated to reflect the new procedure or retired and archived. At minimum, SOPs should be reviewed annually to ensure they are up to date and representative of the work done on site. Well written SOPs are a helpful tool when properly implemented and ensure quality standards at the facility.

To see an example SOP, visit the Publications page at FreshwaterInstitute.org.

Our RAS technology saves more than 99,5% of water use, enabling production under optimal controlled conditions, making it the most efficient and environmentally friendly solution for land-based fish farming.

Gold Sponsor

Come

13-14, Washington, DC.

Veolia’s

are Ready to Help You

Our team of global aquaculture experts will help you maximize fish quality and production yield, while delivering a cost-effective and biosecure facility.