GENERATE YOUR OWN LOx

Ensure your security of supply with OxyMax - an integrated solution by Benchmark International Inc.

Independence Generate your own LOx onsite, eliminating risk of supply disruptions.

No LOx Losses Recompress vapours to prevent venting and waste.

Reduce Carbon Footprint Reduce emissions with onsite generation by eliminating trucking and leveraging green energy.

Reduced Cost Avoid costly supply contracts, transportation fees, tank rentals, and minimum purchase requirements.

LEARN MORE ABOUT OUR SOLUTIONS AT osioxygen.com

By Jean Ko Din

When I think about recirculating aquaculture systems (RAS), I was always told how young the industry is. Especially on a commercial, mass production scale, it’s still in a pioneering stage.

And yet, here is a story about a farming business that found its roots 90 years ago. Three generations of trout farmers that dedicated themselves to growing the family business to what it is now. This cover story really brought home the idea that aquaculture and fish farming has always played an important function in feeding the world. And for as long as there have been fish farmers, there will be an ongoing pursuit on how we can do more, do better and do it more efficiently.

I think this is what has kept Hayashi Trout Farms growing. Soichiro Hayashi, his family and his staff talk about their aspirations of bringing RAS to more areas of Japan. They have a vision to bring this technology to more farms and they are already well positioned to do so.

If only the rest of the world can catch up. Iceland is another area of the world that seems to be joining the RAS train. For those projects, they call it hybrid flowthrough and we’ve talked about this in our Spring issue, but the technology is still the same. Whether your recirculating rate is 20 per cent or 99.9 per cent, it is all land-based aquaculture. There is room for every type of project and design, and lately, I’ve been reflecting on how I can bring more of these diverse ideas onto the pages of this magazine.

I am writing this editorial about a month after our team’s biggest project of the year, the RASTECH 2025 Conference and Trade Fair. For a small team like ours, this project is a Goliath-like undertaking. But, we believe in the conference’s mission to drive progress in the technology and in the industry by bringing everyone together.

We agonize over details of the program,

like what experts we bring to what sessions and how we create a good balance of topics. We agonize over what suppliers come to the trade show and how we can showcase a variety of solutions providers. Even in the little details, we agonize over the location, the menu, the show bag, the room setups, all because we believe that these details make up what we believe can create the perfect conditions for real collaboration.

It takes all sorts of expertise and experiences to make a facility function to its fullest potential. Similarly, it will take all sorts of expertise to get the industry moving towards the exponential growth many of the early adopters and investors have been holding their breath for. In fact, I would argue that the moment is here. There are some exciting projects happening all the time and maybe they are just in the places that we least expected.

That brings me back to my earlier thought of bringing more diverse stories. I’ve been toying with the idea of widening the scope of this magazine beyond the food production sector. There are so many places where RAS is thriving and maybe I’m not doing enough to bring those stories to the table.

Conservation hatcheries were some of the earliest adopters of RAS and partial RAS. These land-based facilities are in a race against climate change to preserve wild populations and preserve the ecology of their local watersheds.

And then, there is ornamental fish farming. Unlike farming food fish, ornamental fish farming doesn’t require acres of water or expensive equipment. You can start small and still make good profits, especially if you focus on rare species or those with vibrant colours.

That’s why St. Augustine in Florida might be the perfect location for RASTECH 2026 (May 19-21). Now that this year is done, our cycle of planning starts again and I’d love to know your thoughts. Email your ideas to jkodin@annexbusinessmedia.com.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact Angelita Potal, Audience Development Manager Tel: 416-510-5113

Email: apotal@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Jean Ko Din 437-990-1107

jkodin@annexbusinessmedia.com

Associate Editor

Sherene Chen-See 647-203-7031

schen-see@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Sales Manager Patrick Villanueva 416-606-6964 pvillanueva@annexbusinessmedia.com

Account Coordinator Barb Vowles 416-844-7106 bvowles@annexbusinessmedia.com

Group Publisher Anne Beswick 416-410-5248 abeswick@annexbusinessmedia.com

Audience Manager Urszula Grzyb 416- 510-5180 ugrzyb@annexbusinessmedia.com

CEO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

Subscription Rates

Canada $37.00, United States – $48.00 CAD, Foreign - $62.00 CAD

All prices are for 1yr subscription and in Cdn funds.

ISSN 2817-7266 - Print ISSN 2817-7274 - Online

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2025 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Made possible with the support of

Innovaciones Alumbra is launching Mexico’s first global aquaculture centre focused on warmwater, generative, and regenerative systems. The announcement was made at the 2025 UN Ocean Conference (June 9-13).

The Center for Applied Aquaculture Innovation (CAAI) is backed by a coalition of organizations, including Innovasea, Santomar, and Sol Azul, who are committed to restoring oceans, advancing innovation, and building resilient coastal economies.

“Our oceans and their resources are significantly degraded. We must move beyond efforts to do no further harm and take huge strides toward generative and regenerative outcomes. It’s time to invest significantly in advanced technologies and systems,” said Christy Walton, founder of Innovaciones Alumbra.

“Our hope is that this centre will accelerate the sector toward business models that restore ocean health and promote biodiversity while producing food and economic opportunities for communities.”

The centre will be built in La Paz, Baja California Sur. Once constructed, it plans to offer a variety of state-of-the-art facilities, including laboratories, hatchery, technology, and open-ocean projects.

The centre plans to foster scientific and technological breakthroughs in multiple phases of the value chain for finfish, shellfish, and algae. The intent is to bring science, entrepreneurship, and ecosystem restoration experts together to build practical models for the future.

AquaCultured Seafood has permission to plan the U.K.’s first commercial-scale landbased salmon farm, but a legal challenge from Animal Equality looms.

The recirculating aquaculture system (RAS) facility, located in New Clee, Grimsby, was recently given the green light to proceed with construction to build a 5,000-tonne facility from North East Lincolnshire Council.

The U.K. High Court originally dismissed Animal Equity’s application for judicial review against this proposal in March. In the judicial review, non-profit group, Animal Equality, raised several concerns about pain and suffering from the animals being highly packed together, being attacked by sea lice, cannibalism and other mass fish deaths, high liquid waste levels in RAS, and other problems.

The charity claims that the council’s planning committee was not advised to consider animal welfare concerns and

thus, were misled.

Deputy High Court judge Karen Ridge eventually upheld the council’s decision in June to approve the salmon farm. She ruled that although the committee may have been misdirected and that animal welfare concerns could be considered in material planning, the approval was still lawful.

However, her decision pointed out that animal welfare issues could be considered in future planning decisions. This is important for future cases involving planning law and animal welfare, according to U.K. Human Rights Blog.

The project is estimated to create 300 local jobs in the region.

“The fishing industry has long been a source of employment for North East Lincolnshire residents, providing not only income, but a sense of pride and community, and we intend to ensure that it continues,” said Mike Berthet, AquaCultured director.

A new government report outlines significant challenges to British Columbia’s planned transition from salmon net pens.

The 213-page report was jointly commissioned by Fisheries and Oceans Canada and the B.C. Ministry of Agriculture to identify the feasibility of transitioning the province’s salmon production from net pen farming to closed containment and land-based aquaculture production. The assessment report was conducted by Blue Economy Consulting Group, which is made up of nine consulting partners with diverse expertise in seafood and business development.

The report concluded that this transition, which is expected to be done by 2029, requires “high initial capital costs and ongoing operating costs, which pose barriers to both entry and scaling up.”

The report identified several layers of challenges, including B.C. power supply, aquaculture licensing, and alternative marine-based technology.

Current open net pen Atlantic salmon facilities can support more than 2,500 tonnes of production per year with a target harvest size of 4-6 kilograms. Most marine-based, semi-closed and closed containment technologies have not been tested for growing salmonids to that harvest size, the report explained.

Currently, these systems focus on growing smaller smolt to a post-smolt size of 500-1,000 grams and then moving the fish to open netpens.

In order to produce salmonids profitably, efficiently, and with manageable cost in closed containment systems, farmers need the best sites with the best, most proven technology, the report said.

The B.C. salmon farming sector is trialling floating, semi-closed containment systems for growing larger post-smolts and potentially for full-scale salmon production. Semi-closed systems are an initial step towards development of marine-based closed containment farming technology,

the report indicated.

Another challenge is: key requirements for setting up semi-closed or closed systems are the same as for a recirculating aquaculture system (RAS).

“Therefore, semi-closed and closed containment projects could be in competition with RAS projects for preferred locations along the B.C. coast where cheaper shore power is available. The alternative is using more expensive diesel generators to power semi-closed and closed systems in remote areas,” the report explained.

“The key to success,” according to the report, “will be finding sites where the intersection of optimum physical oceanographic conditions, lower-cost clean power, and proximity to infrastructure all meet. Most preferred sites would be near communities with a labour force, processing plant, and service and supply companies already supporting the fish farming industry.”

Research from BioMar has highlighted some of the aquafeed challenges associated with waterborne feeding systems.

Waterborne feeding systems use underwater technology to feed fish in aquaculture tanks. It is considered to be gentler on pellets and has the potential to reduce energy consumption, microplastic pollution, and sea lice exposure.

BioMar used the ORBIT product range and POWER grower diets in its research. The company identified factors contributing to nutritional loss in feed delivered through submerged systems. These factors vary in intensi -

ty, showing the complexity of creating an aquafeed that performs consistently in waterborne feeding.

“Through our research, we have a better understanding of the complex dynamics of waterborne feeding. These insights allow us to enhance our feed

formulations and production techniques to reduce nutrient loss significantly,” said Ewan Cameron, product marketing manager of the Grower Category for BioMar.

Although the company’s work in this area is ongoing, it notes that the current results demonstrate a commitment to addressing the challenges of waterborne feeding head-on.

“Farmers can trust that we are not only aware of the challenges but are actively developing practical solutions. Our progress to-date is a significant step forward, and we’re excited to share more as we advance towards a final product,” Cameron added.

Water treatment company, BIO-UV, marks its 25th anniversary this year.

Founded in 2000, the company is celebrating how it maintained steady growth. According to a press release, the company saw €39.6 million (US$45.8 million) in revenue last year, more than half of which was generated internationally. BIO-UV is headquartered in France and now operates in over 70 countries, employing more than 160 people.

BIO-UV’s water treatment processes incorporate ultraviolet (UV) light, ozone, salt electrolysis and advanced oxidation processes. The company’s solutions are used in more than 3,000 drinking water and wastewater systems, 6,000 public pools and over 200,000 residential pools and spas. BIO-UV treated about 717 million m3 of water in 2024 alone.

“BIO-UV Group’s 25 years stand as a testament to our dedication and know-how in water treatment,” said CEO Laurent-Emmanuel Migeon. “We have evolved, innovated, and expanded internationally to become a reference point across the industry. We are

ready to meet tomorrow’s challenges and support our clients with sustainable and efficient water management solutions.”

BIO-UV’s growth was bolstered by successful acquisitions which, in turn, further expanded its technological portfolio. These include purchasing ozone and UV specialist Triogen in 2019, and acquiring saltwater chlorination leader, Corelec, in 2021.

The group was approved by the French Ministry of Health for dechloramination in public pools in 2004. It became the first and only French manufacturer certified by the International Maritime Organization for ballast water treatment in 2013. It also

developed BIO-SCAN, a UV-C surface treatment system, in response to the COVID-19 pandemic in 2020.

BIO-UV recently launched the O’CLEAR residential pool solution, the PPO3 ozone generator, and the modular CUBIQ system for wastewater reuse, as part of its commitment to delivering sustainable water treatment technologies.

They continue to build on key strategic partnerships, including an exclusive agreement with Pinnacle Ozone Solutions to open new markets in Europe, the Middle East, Africa and Asia, and a partnership with Innovasea to drive growth in North America’s aquaculture sector.

Norway’s Ministry of Trade, Industry, and Fisheries have reopened license permitting for land-based aquaculture facilities.

The permits were suspended in 2022 due to a need to tighten regulations in the sector. As part of this announcement, the ministry is also revising its salmon facility allocation and aqua biosafety regulations, according to the government website.

The changes in salmon allocation requirements will clarify conditions for facility locations. This is to make the boundary between what is considered to be on-land and at-sea clearer, regardless of life stage.

“The government will facilitate the sustainable development of fish farming on land,” said Fisheries and Oceans Minister Marianne Sivertsen Næss, as translated from Norwegian. “There has been major technological development since the current regulations for fish farming on land were introduced. Changes have therefore been necessary. A clearer distinction between fish farming on land and in the sea will provide more predictable framework conditions for industry and management.”

The requirements will also streamline the allocation process, the ministry explained. One requirement of the new biosafety regulations is disinfection of intake water for land facilities.

“The requirement for purification of intake water is necessary to reduce the risk of spreading infectious agents to the marine facilities, and to ensure good biosafety in the facilities on land,” said Næss. “This will be beneficial both for existing players in the sea in close geographical proximity to the land plant in question, as well as the marine environment.”

The new regulations only apply to new facilities. Existing facilities that have already received permission for

land aquaculture are not covered by the new cleaning requirements, unless they are to make significant changes, the ministry indicated.

In a year plagued with division and uncertainty, it seems more important than ever to come together for the good of the industry.

RASTECH 2025 Conference and Trade Fair took place at Town & Country Resort in San Diego, Calif. on June 9-10. This year’s event welcomed hundreds of professionals from 15 countries in the world of recirculating aquaculture systems (RAS).

Some new and notable sessions included: New Projects, Investors’ Forum, RAS Hatcheries Workshop, Waste Treatment and Management, Community Development, and Navigating the U.S. Regulatory Framework.

By Bonnie Waycott

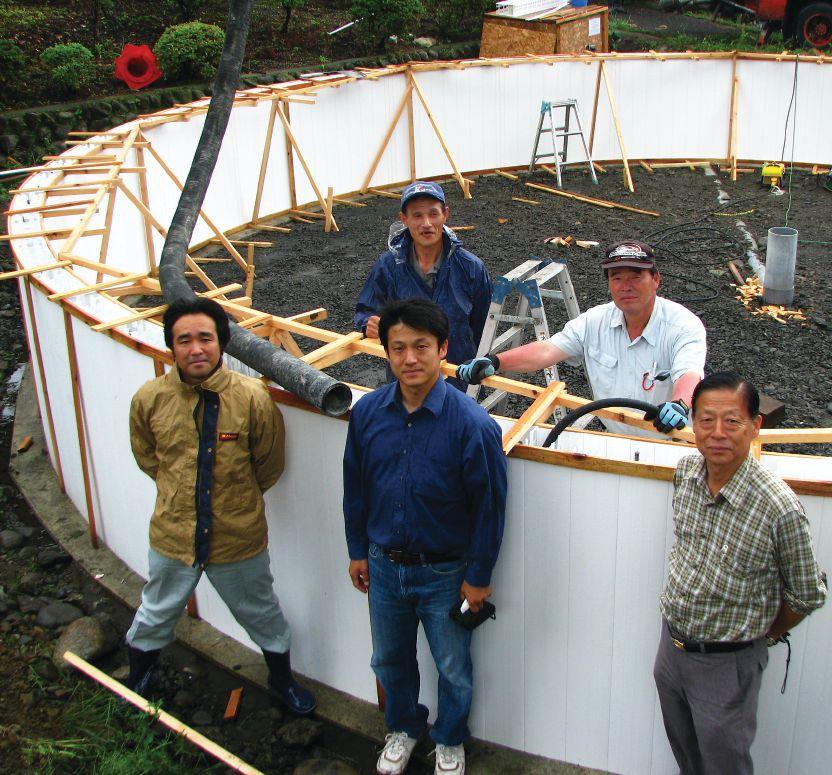

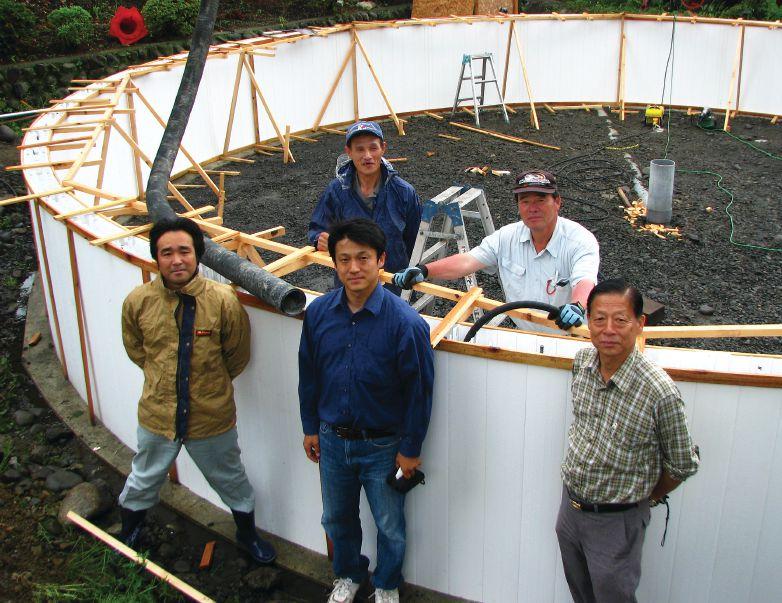

Japan may be surrounded by sea, but Soichiro Hayashi, the third-generation owner of Hayashi Trout Farm in Fukushima prefecture, is looking inland to raise the country’s most loved fish: salmon and trout.

With nearly 90 years in the land-based farming business, Hayashi Trout Farm is one of Japan’s oldest fish farms. This family-owned farm in Fukushima prefecture’s Nishi-shirakawa county has been a leader in aquaculture innovation since it started by farming 30,000 rainbow trout fry in three ponds.

Today, it farms 1,200 tons of salmon and trout across five flowthrough systems and three recirculating aquaculture systems (RAS) across Japan. Hayashi and his team are committed to producing high-quality fish with a key focus on the benefits and potential of land-based farming.

“My great-grandfather was a member of the Diet (Japan’s national legislation) in Tokyo,” says Hayashi. “Through this connection, he learned about rainbow trout farming, which was rarely practised in Japan back then, and encouraged his son, my grand -

father, to start his own business. After graduating from university and working overseas, my grandfather founded Hayashi Trout Farm in 1935. He chose the location because of its abundant spring water, which happens to be suitable for aquaculture. He was also well-aware of the need for, and importance of, food production in Japan.”

The lure inland Today, the majority of salmon consumed worldwide is farmed, with the aquaculture market dominated by countries such as Norway and Chile. But farming at sea, the most common way to produce salmon, can be a complicated prospect. The sea must be the right temperature – colder than 20 C – and only areas without strong waves and currents are suitable.

In Japan, the warm waters surrounding the country make yearround salmon farming at sea challenging and commercially unviable. Doing so is only possible between the end of November to the start of summer, said Hayashi. This short season results in smaller overall yields compared to countries such as Norway and Chile, that have more favourable conditions for year-round salmon farming.

With significant fluctuations in water temperature, changes in weather such as stronger typhoons, periods of torrential rain or no rain at all, as well as the possibility of disease outbreaks, Japan’s marine and inland fresh -

water environments are becoming increasingly difficult to farm in.

Amidst this situation, the country’s salmon sector is shifting to systems such as flowthroughs and modern, high-tech RAS, while maintaining its focus on quality and sustainability. Japan’s seafood-loving culture has also spurred interest in domestic landbased salmon production over the years.

In addition to the issues facing Japan’s marine environment, Hayashi believes that land-based farming is important for another reason. Japan needs to increase its self-sufficiency rate for edible seafood and become less reliant on imports. Farming salmon on land may be an expensive endeavour that requires lots of water and electricity, said Hayashi, but landbased farming and RAS operations are likely to help Japan significantly.

“The Japanese eat much more seafood than the rest of the world,” says Hayashi. “With other food items such as beef becoming more popular, there is currently a decline in per-person fish consumption from around 70 kilograms of fish per person. But the Japanese still consume a lot – over 40 kilograms. You’re also never far away from the sea, and Japanese culinary traditions include an abundance of fish dishes. However, it is clear that obtaining seafood from the wild is becoming increasingly difficult, which means that farmed species such as salmon are more prevalent, but this also has issues. For example,

salmon is becoming more expensive due to price fluctuations, partly because of the war in Ukraine, the cheaper yen, and the situation in the Middle East. Meanwhile, other countries such as China, India, and Brazil, which, like Japan, didn’t eat salmon until recently, are also turning to farmed salmon. Shifting to domestically produced salmon makes sense for Japan to establish a more sustainable and efficient food production system.”

Hayashi Trout Farm operates in eight locations throughout Japan with a total area of over 100,000 square metres. Five of the fish

farms are located in northeast Japan and produce approximately five million fish from eggs to adults.

The fry are raised in groundwater from the moment they hatch until they reach around five grams. Thereafter, river water is used continuously to grow the fish to adulthood. The water temperature is around 1 C in winter and can reach as high as 25 C in summer, depending on the year.

Meanwhile, a total of approximately one million fry are hatched and reared at Hayashi Trout Farm’s three RAS facilities. The rearing systems automatically control and recirculate dissolved oxygen (DO), water temperature,

pH, CO2, and ammonia levels to maintain optimal environments for the fish. All this offers a sustainable alternative to traditional net pen farming, says Hayashi. Flowthrough systems and RAS facilities are promising pathways, yet for Japan, there are still numerous uncertainties. In addition to high costs and energy consumption, the limited availability of land in the country is a constraint. Land-based facilities must be suitable for local areas and production methods, and be able to withstand the Japanese environment, such as high humidity levels during the summer which could impact farming equipment and machinery.

However, Hayashi believes that the advantages of land-based farming outweigh the challenges, as production volumes can be increased, while better control over water quality and rearing environment means that higher yields can be produced more stably and efficiently. Hayashi has also spent some time working with companies and organizations outside of Japan to learn more about land-based farming and forge international connections. Such

efforts continue to this day.

“We realized very early on that Japan’s marine environment isn’t suitable for farming salmon and trout at sea,” says Hayashi. “This has been an extremely difficult endeavour for many farms since the Year 2000, which is around the time that the summers begin to get hot and we begin to see more torrential rain and stronger typhoons. We have also experienced these environmental challenges ourselves – los-

ing all our fish to flooding and extremely high water temperatures. This is why we decided to look abroad to come up with new ways of farming.

“Today, we supply eggs and fry to fish farms in Japan through a 30-year business relationship with Troutlodge. We have also partnered with aquaculture equipment manufacturers and designers in the United States, France, Germany, Canada, Norway, and Denmark.”

In 2011, Hayashi’s work changed with the March 11 earthquake and tsunami and subsequent meltdowns at the Fukushima nuclear power plant.

Selling to people within Japan became a struggle, while exports were no longer possible. Monthly inspections by Fukushima prefectural authorities found no unsafe levels of radioactive substances in seafood, but that did little to reassure consumers.

With fears about the safety of food from Fukushima still remaining, Hayashi believes that land-based fish farming systems like flowthroughs and RAS can make key contributions by providing consumers with safe fish, thanks to full control over the farming process. Fish from Hayashi Trout Farm could also be branded as local specialties and help develop industry growth in the region. Hayashi himself regularly takes part in promotional events to boost local industries, showcase advancements in Fukushima prefecture, encourage local communities, and attract businesses, investment, and talent to the region, fostering a more vibrant local economy.

Blending tradition with innovation, aquaculture remains central to Japan’s seafood supply. As it continues to grow, Japan is solidifying its role as a leader in seafood production. Having overcome

various hurdles from natural disasters to technological challenges over the last 90 or so years, Hayashi Trout Farm is a powerful example of dedication and resilience, demonstrating a strong will to persevere, says Hayashi.

Meanwhile, Japan’s reliance on seafood imports necessitates a focus on ways to boost domestic salmon and trout production and reduce the seafood sector’s vulnerability to external factors. In this sense, expanding land-based farming will be a significant priority for the country going forward.

“There are always unexpected challenges and last-minute alterations when it

comes to farming fish on land, so I’d like to see land-based salmon farming become even more stable than it is today,” says Hayashi. “RAS technology has already contributed to this stability and it would be great to see this continue while the various barriers surrounding RAS, like high initial investment costs and managing complex systems, can be addressed. My ultimate aim is for Hayashi Trout Farm to play a key role in reducing Japan’s reliance on seafood imports and increasing the country’s seafood production … Together with other fish farms, I hope to play my part in developing sustainable solutions in Japan for many years to come.”

By Ruby Gonzalez

As the saying goes, give a man a fish and you feed him for a day. Teach a man to fish and you feed him for a lifetime.

But what if giving a fish and teaching to fish are done at the same time and in the literal sense? This turned out to be the combination that paved the way for putting up AquaTribe, a recirculating aquaculture system (RAS) facility owned by a farmers’ group in the Philippines.

Samahan ng Magbubukid ng Manaul (Farmers Association of Manaul) successfully implemented the tilapia RAS program during its first year of operation in 2024, with stock posting an 80 percent survival rate. As the group look into 2025 and beyond, among the goals is scaling up production and operation.

“Once our team is confident and proficient in the system, we intend to transition into shrimp and prawn farming, recognizing their significantly higher revenue potential compared to tilapia,” says association president,

Michael Buque. They are likewise looking at agri-tourism.

Manaul is an upland district in the town of Mansalay, located in the province of Mindoro Oriental.

“However, we are also aware of the critical challenge. The growout system for shrimp is far more sensitive and requires a higher level of technical precision and care,” Buque admits. “With the right support and preparation, we believe this shift will strengthen the sustainability and profitability of our aquaculture initiative.”

AquaTribe was initiated through government funding. The association, also known as SaMa Manaul, wants to eventually be self-funded. “The team expects to complete the experimental phase this year, with the goal of making the project fully self-sustaining by 2025.” Buque says.

The Provincial Agriculture Government Office (PAgO) of Mindoro Oriental, in collaboration with AGRITEKTURA, RAS system

provider, facilitated the provision of essential infrastructure and equipment.

PAgO also supplied vital production inputs, including fingerlings and fish feeds, and has committed to continue providing fingerlings for the succeeding production cycles. They also conduct regular site monitoring to ensure operational efficiency and compliance with aquaculture standards.

“The support from the Provincial Agriculture Office is ongoing and multi-faceted. PAgO played a key role initiating the project by identifying high-performing community organizations, such as SaMa Manaul, as viable beneficiaries,” says provincial agriculturist, Christine Pine.

For their part, SaMa Manaul invested in land prep, and facilitated water access and processing of government-required documents.

The 87-cooperative membership is composed mostly of local Mindorenos and members of the Indigenous group, Mangyans. Until venturing into aquaculture, activities were focused on small-scale agriculture,

such as vegetable farming and livestock, and handicrafts.

The first tilapia harvest was done at the start of August 2024, followed by staggered harvests within each of the following months. By Jan. 1, there was a total of 16 harvests amounting to about 710 kg.

SaMa Manaul uses the Circular portaSHIP (CPS) Model, a closed-loop aquatecture model that maximizes resource efficiency and production volume.

Built for bulk harvesting, the CPS is structured to support community- or organization-based operations, which makes it ideal for cooperative-led production networks, says Ran Quijano, technology inventor and owner of AGRITEKTURA.

The model was identified by the PAgO as a model that fits in the community.

“The CPS aligns seamlessly with community-based livelihood and food sustainability programmes because it enables high-volume, high-efficiency production within a compact and adaptable system,” Quijano explains.

“It was specifically designed to meet the scale requirements of community organization, helping them produce enough yield to support both consumption and commerce.”

The pond has a diameter of 10 metres, depth of 1.5 metres, and capacity of 110 cubic metres. The system has 10 filter tanks. Portable in design, the entire system was set up in two days.

The structure’s frame uses Schedule 40 steel pipe with steel matting wall support, turnbuckle top support and flatbar bottom support. The pond is made of high-grade tarpaulin with net cover. Filtration uses stone filter composed of filter cloth, filter brush, Japanese mat, K1 media, and stone filter.

For aeration, there are Venturi bottom aerators and support top aeration using smart aquapumps and a degas aerator.

With most of the members having no previous exposure to aquaculture, they had to start the project on ground zero.

AGRITEKTURA made transfer of knowledge and technology accessible by providing them with hands-on training using Basic Operational Forms. The training was complemented by the PAgO providing foundational training on fisheries and farms operations.

“This made the transition to smart farming more accessible and

less intimidating,” says Quijano.

To ensure that operation runs smoothly, the group learned the importance of feeding protocols, regular cleaning of filter tanks, water quality monitoring, and proper record keeping. Members follow a strict feeding and cleaning schedule with general and partial cleaning of the 10 filter tanks, adhering to protocols provided by AGRITEKTURA and PAgO.

Quijano explained how operational success

hinges on focus and delegation. “While the portaSHIP is engineered for ease, maintaining strict adherence to protocols — especially in feeding, water quality monitoring, and harvest schedules —is essential to ensure consistent, high-quality output. Each member of the cooperative must be diligent and accountable in their designated roles to uphold system integrity.”

All members are actively involved in the project.

The SAMA Manaul Leadership Team implemented a weekly rotating schedule to en-

sure shared responsibility and continuous engagement. Each group is led by a designated team leader, who oversees daily operations and submits regular reports.

“This system has empowered even the Mangyan Indigenous members to actively operate and manage the smart aquafarm facility, highlighting the project’s inclusive approach and its commitment to capacity-building within the community,” says Buque.

Getting the group’s feet wet was not without challenges.

“Lack of prior experience in fish farming led to initial tilapia mortality. There were logistical issues with electricity and water location,” Buque says.

With RAS-grown tilapia still considered a unique product in the locality, the product had to be introduced to the market. Social media and visual impact did a good job.

Interested parties are allowed to go to the tank, where they see healthy fish in a clean environment. Fish is sold on site. There is a catch-your-own-fish option.

Consumers said the fish tasted fresh and had none of the earthy, off-taste that is not unusual with the species. One of the best feedback received was that, when fried, it tasted like fried chicken. There were people who, because of biases, had never had tilapia before. Those who tried AquaTribe tilapia were converted.

Based on collated data from consumer preferences of size, medium is the most popular because of ease of preparation. It fits well in the pan; no chopping prep is needed before cooking. Big fish is preferred for grilling. There are also those who buy big tilapia to use as stock in their own ponds.

Buyers come not only from Mansalay but from other towns as well. Supply is not enough to cater to the demand. Additional tanks are needed to keep up, Buque cites in the co-op’s annual report.

Solar power would also contribute in growing the farm, he notes. In both fair and foul weather, power supply in the area is said to be unreliable, compromising operation. The farm’s electric power bills likewise represent a major bulk of expenses.

“It would be good if we get to operate using solar power, even partially, for our operation

to minimize our expenses and increase the revenues,” he says.

They had a start with solar power through a foundation grant, which provided portable systems to a number of members. Buque has submitted a proposal to a government agency for a more extensive solar power system.

The maiden year’s production of about 710 kilograms didn’t reach the system’s optimum capacity of 1.2 tons. Quijano said the output was good, considering the group was still on a trial stage. Another contributing factor was starting with broken sizes of fingerlings.

By keeping track and looking for solutions on pre-production factors, causes of mortality, growth rate, and other performance indicators, AquaTribe is batting to hit maximum production volume by year-end.

“They’re currently focused on mastering and refining the use of RAS technology. This is particularly important since most of their workers lack a background in aquaculture. Despite this, their recent harvests have shown very promising results, suggesting that with continued training and process optimization, self-sufficiency is within reach,” Quijano says, the last note referring to SaMa Manaul fully weaning themselves from external fundings.

The RAS programme has not only brought another revenue stream for the group.

Elaborating on this, Buque says, “Members, including Indigenous Mangyan families, have gained hands-on experience in operating a modern recirculating aquaculture system, which is an opportunity that was previously out of reach.

“The system has generated additional income, improved food security, and increased community confidence in adopting technology-driven solutions. It has also fostered a sense of pride and ownership, as members are no longer just recipients of aid, but active innovators in their own right.”

Recognizing the “successful implementation and promising outcomes,” the PAgO is currently advancing a proposal to scale the adoption of the portaSHIP system to other cooperatives

“The vision is to position our community organization as a model site. This demonstrates how innovative agricultural technologies like aquaculture can be integrated to diversify local livelihoods. By showcasing various agri-based commodities, we aim to create additional income streams and promote sustainable development that directly supports the needs and aspirations of the community,” Buque says.

South-Tek Systems now offer compressors, dryers, and filters alongside their trusted nitrogen generators. This is the latest in the company’s expansion into full-spectrum compressed air solutions.

South-Tek is a leader in nitrogen generation solutions, and their compressors are designed for continuous uptime and low maintenance. Their air systems help maintain water quality and fish health. They offer simplified system design and support from expert engineers.

With this expansion, South-Tek Systems now offers a one-stop solution for industrial end-users, distributors, and original equipment manufacturers seeking reliable and high-performance compressed air systems, said the company in a press release. The addition of

compressors, dryers, and filters complements South-Tek’s existing nitrogen generators, providing customers with a complete solution for their air and gas needs.

“This launch marks a significant step in our mission to provide unmatched control, performance, and expertise,” said South-Tek Systems CEO, Jens Bolleyer. “As the leading single-source provider of gas generation and compressed air solutions, we now offer a comprehensive product suite under one brand, giving our customers the confidence of relying on one vendor and exceptional support for all their needs.”

South-Tek Systems’ new line of compressors is designed for maximum efficiency and durability, offering reliable performance and low maintenance costs. The addition of dryers and filters ensures clean, dry air, protecting equipment and optimizing system performance.

UV technology is a proven, reliable, efficient method for removing pathogens from water. This can help avoid costly virus and bacteria outbreaks.

For best results, the system needs to deliver the exact UV dose required. For long-term reliability, it also must withstand harsh operating conditions and offer the capacity and flexibility to meet your business needs.

The AquaShield and AquaDose UV systems from DESMI aim to deliver just that.

Regarding dose: “When we design a water treatment solu-

tion for an aquaculture customer, we are able to calculate the UV dose very accurately, even at high dose levels,” explained Hans Christian Thisen, product manager at DESMI.

“You don’t just get the treatment dose you need; you also get a fairly accurate estimate of the power consumption of your plant.”

DESMI systems can handle a wide range of capacities, from 35 to 3,500 cubic metres of water an hour.

In addition, “all AquaShield and AquaDose systems are available in super duplex steel,

making them completely resistant to salt water,” said Thisen. “You can get a DESMI solution that will keep running for years in any salinity and temperature.”

They can be bundled with filtration and cleaning systems, and remotely monitored, the company said.

“We have the technology and know-how to deliver effective, reliable water treatment solutions for your application – but more importantly, we have the expertise and the mindset to understand your business and give you what you specifically need,” concluded Thisen.

Compact Design – Fast installation, minimal space.

Reliable & High-Performance – Uninterrupted oxygen supply. Eco-Friendly – Sustainable, zero emissions.

By Curtis Crouse Fresh Tips

Applying low-dose ozone to a recirculating aquaculture system (RAS) can improve water quality. Benefits include reduced dissolved metals, nitrite-nitrogen oxidation, lower suspended solids concentrations, and improved water clarity. These improvements are associated with possible growth advantages for Atlantic salmon and rainbow trout (Figure 1).

Ozonation consists of generation, transfer, and contact. Assuming appropriate purity, the oxygen already required for intensive culture in RAS can be used as the feed gas for on-site ozone generation. Once generated, ozone gas must then be transferred to the RAS water for reaction. Efficient gas transfer to the liquid is critical for an effective process.

At the Freshwater Institute, ozone gas is added to the air space of the low-head oxygenator (LHO). Following transfer, an appropriate contact time in the LHO sump is maintained to allow the ozone to react with the constituents in the water and decompose without residual entering the culture tank.

The Freshwater Institute typically uses one of two strategies to apply low-dose ozone to RAS water. The first method relies on a solenoid valve to direct the flow of ozone gas from a continuously running generator to either the RAS LHO or an ozone destruction unit. The second strategy uses one pathway from the ozone generator to the LHO, where ozone generation is stopped and started as needed. Only purified oxygen feed gas enters

the LHO when the ozone generator is stopped.

In both strategies, the addition of ozone is controlled with oxidation reduction potential (ORP) probes. The ORP probes are an indirect measure of ozone and stop the addition of ozone when a target set point of 290-320 mV is reached.

While effective, ozone can present potential risks to equipment, livestock, and personnel that must be managed. Ozone gas is corrosive, requiring resistant materials for implementing ozonation. At the Freshwater Institute, stainless steel tubing is used to transfer ozone gas into the LHOs of the RAS. However, the material of the receiving vessel should also be accounted for during design or when considering adding ozone to an existing RAS.

For example, some fibreglass resins are more resistant to ozone exposure than others. In one case, extensive corrosion was observed in the first chamber of a fibreglass LHO supplied with ozone gas (Figure 2).

Depending on the control strategy, the solenoid and metering valves must also be made of ozone-resistant seals and bodies. Failed seals on an incompatible solenoid could cause a valve to stick open or cause leaks into the airspace of the tank room.

Ozone residuals in the water can be toxic to the fish at 0.9 mg/L and can have chronic effects at concentrations as low as 0.002 mg/L for salmonids. Toxic compounds can also be formed by interaction with bromide ions in brackish and saltwater RAS. Pre-

venting over-ozonating the RAS is critical for the health and welfare of the fish. Avoiding failed equipment through proper material selection is a first precaution.

In addition to the stuck valve example previously mentioned, another potential scenario where excess ozone could reach the RAS is a poorly maintained ORP probe creating a false reading in the feedback loop. Be sure to follow manufacturer recommendations for probe care and expiration.

When managing the system, consider long supply line runs from the generator. Ozone gas in the supply lines downstream of the generator could continue flowing to the LHO after reaching the desired ORP setpoint in the RAS water.

Low-dose ozone approaches can rely on contact time and reaction with the water for decomposition instead of incorporating a dedicated destruction measure to prevent ozone residuals. Consider factors like temperature and organic concentrations in the water that could shift the required contact time.

For example, when feeders are turned off, the Freshwater Institute stops ozone production and RAS dosing. Without feed, fewer solids and constituents could be present in the water to

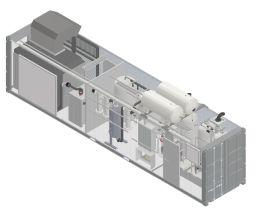

Customized for your fish farm, hatchery or research operation!

Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• De-gassing towers

•

react with ozone in the LHO sump.

A good safety practice when using ozone is to include a high ozone or ORP set point that will send an alarm call to staff. This setting should be programmed to prevent nuisance alarms from the monitoring system but give staff enough time to correct a potential problem in a timely manner.

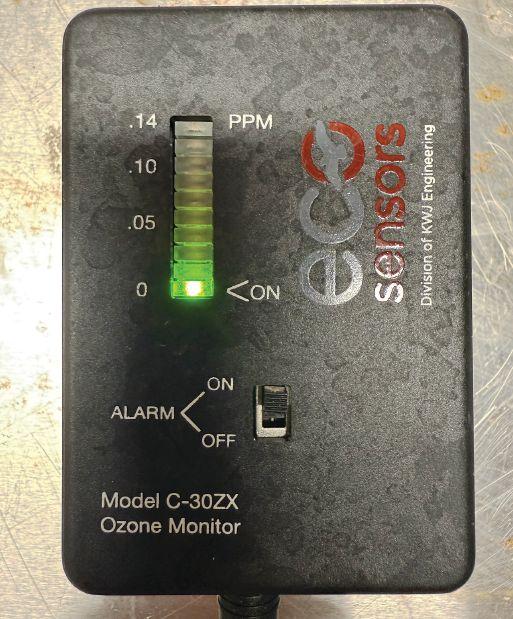

Applying ozone in RAS also carries a human health risk. The 15-minute exposure limit for worker safety is 0.3 ppm, and the 8-hour exposure limit is 0.1 ppm. Ozone gas can enter the building atmosphere through leaky fittings in supply lines or improperly managed water levels at the LHO distribution plate or off-gas tube.

Ozone could also enter the building atmosphere via the LHO off-gas port if ozone is not completely transferred to the water in the LHO. For this reason, off-gas port exhaust should be run through a destruct line and be vented out of the building when using ozone. Other safety measures include audible ozone alarms mounted in strategic areas around the facility to alert staff to potential hazards (Figure 3).

Suitable locations include areas most likely to leak, including around the LHO distribution plates, sumps, or off-gas ports, and areas with many valves, rotameters, or fittings. If an ozone alarm is triggered, staff should evacuate the area.

If the alarms do not automatically do so, use external controls to manually shut down ozone production and turn on exhaust fans to ventilate the area before re-entering. Re-enter the area cautiously by using a portable sniffer to confirm that the area is safe.