MAYER

Crowding tips: Keeping your fish

JEAN KO DIN

MAYER

Crowding tips: Keeping your fish

JEAN KO DIN

By Catarina Muia

Hello all, my name is Catarina Muia and I’m thrilled to introduce myself as the new editor of RAStech magazine. I’m even more excited to become part of this growing community dedicated to the knowledge transfer, technology, innovation, discoveries, sustainability, and success of the recirculating aquaculture systems (RAS) industry, and its related sectors.

In my first week of starting this new role, I had the opportunity to attend our very own RAS Connector Series, held on June 9. As I sat-in on the discussion panels, I was impressed by the number of professionals that were not only in attendance, but were committed to offering their knowledge and expertise to drive forward such an important industry.

In a world where it feels like we’re constantly surrounded by complicated global situations, the RAS sector, dedicated to providing eco-friendly and sustainable solutions to rejuvenate and protect ocean life, is quickly gaining more and more attention.

The virtual event opening keynote speaker, Maggie Fried, head of the Oceans, Seafood and Aquaculture Investor Consortium (OSAIC) at CREO Syndicate, delved into the number of ways the RAS industry can be part of the solution to many challenges today, including global crises such as climate change and the COVID-19 pandemic. (To read more of Fried’s comments, visit the Event Highlights article found on page 10.)

Investors from around the world have taken notice of this, which is why the aquaculture industry in general is under-

going many new strategies, changes, and projects, as well as new solutions and products are being introduced to the market constantly, across the globe.

For example, this month’s cover story by Liza Mayer highlights how the Bakke brothers, founders of Smart Salmon in Norway, partnered with AquaMaof Aquaculture Technologies Inc. to introduce a new strategy to increase capacities and deliver big post-smolts. Read the full article on page 18.

In Finland, LIVIA College of Fisheries and Environment’s 20-year-old RAS facility underwent a major renovation project to replicate a modern learning environment with the equipment students would likely encounter in today’s leading RAS companies.

With the industry in need of specialized RAS personnel, the updated facility will allow students to gain the knowledge and expertise in managing an entire recirculating aquaculture system. Be sure to read the full article on page 14.

It’s an exciting time for RAS sector, and I’m eager to learn about the industry’s newest and most innovative projects, products, and ventures, through connecting with you, the professionals!

Is there a topic you would like to learn more about, or would like to teach your community about? Feel free to send me an email at cmuia@annexbusinessmedia. com, I would love to hear your feedback and get to know the members of our community. I’m looking forward to meeting and learning from each of you.

With that, I leave you to read, learn, and enjoy this issue of RAStech magazine.

Happy reading.

www.rastechmagazine.com

Reader Service

Print and digital subscription inquiries or changes, please contact Urszula Grzyb, Audience Development Manager Tel: (416) 510-5180 Fax: (416) 510-6875

Email: ugrzyb@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Editor Catarina Muia 519-410-0600 cmuia@annexbusinessmedia.com

Associate Editor Jean Ko Din 437-990-1107 jkodin@annexbusinessmedia.com

Associate Publisher Jeremy Thain 250-474-3982 jthain@annexbusinessmedia.com

Account Coordinator Morgen Balch 519-429-5183 mbalch@annexbusinessmedia.com

Group Publisher Todd Humber thumber@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Printed in Canada

SUBSCRIPTION

RAStech is published as a supplement to Hatchery International and Aquaculture North America.

Occasionally, RAStech will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com Tel: 800.668.2374

No part of the editorial content of this publication may be reprinted without the publisher’s written permission © 2021 Annex Business Media. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or the publisher. No liability is assumed for errors or omissions.

All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of the publication.

Made possible with the

West Palm Beach-based Blue Star Food Corp. aims to boost the production capacity of recirculating aquaculture system (RAS) farmer Taste of B.C. Aquafarms Inc., following its acquisition of the family-owned Canadian steelhead salmon producer.

The aquaculture company based in Nanaimo, British Columbia is a RAS pioneer in Canada. It has been owned and operated by the Atkinson family for almost a decade. The company’s Little Cedar Falls brand steelhead salmon has been in the market since 2013.

Blue Star aims to boost the company’s production to 21,000 metric tons by 2028.

Blue Star Foods, which processes, packages and sells globally refrigerated pasteurized blue crab meat and other premium seafood products, made a move to purchase Taste of BC Aquafarms back in December last year.

“They’ve built a proven and scaleable model and we are excited to strategically fund their next level of growth and use our sales platform to market their delicious, sashimi-grade, steelhead salmon,” said John Keeler, Blue Star CEO.

“We took a different approach than others developing RAS for salmon production. Ours is a more modular strategy that can be launched with confidence and we believe will be highly scalable,” said Steve Atkinson, president and co-founder of Taste of B.C. Aquafarms.

Stockholm-based equity fund Summa Equity has partnered with Longship Fund II of Oslo in investing on a turnkey supplier of recirculating aquaculture system (RAS) equipment.

The firms said they are investing in RAS solution provider Nofitech, which will support growth opportunities in land-based fish farming.

Nofitech, based in Trondheim, Norway, specializes in module-based RAS solutions for land-based aquaculture farmers. The company was established in 2011 by founders Geir Løvik and John Hestad.

“Nofitech provides standardized turnkey solutions and equipment, a

training program, market leading automation, a revolutionary production prediction system and no-waste solutions to be launched in the near future; we are well-positioned for further growth,” said Bernt Østhus, partner at Longship.

Longship Fund I invested in Nofitech back in 2018.For Summa Equity, its investment in Nofitech marks the company’s second foray into the aquaculture sector.

“Nofitech fits our thematic investment approach well and has a sustainable approach to enabling land-based aquaculture,” said Martin Gjølme, partner at Summa Equity.

The Kingfish Company has secured a critical permit for its planned recirculating aquaculture system (RAS) facility in Jonesport, Maine.

The approval by the Maine Department of Environmental Protection (MDEP) of a Maine Pollutant Discharge Elimination System (MEPDES) permit paves the way for the company to build a land-based aquaculture facility with an estimated output of 6,000 to 8,000 yellowtail annually, according to Kingfish Maine.

The MEPDES permit evaluates the facility’s discharge to ensure that Kingfish Maine will maintain the water quality of the area based on the location of the discharge point and the make-up of the effluent water.

The company said it will use the same technology solutions used in the Netherlands to minimize impacts of effluent.

The MEPDES permit is the second of two critical water-side permits required to build and operate its facility. The company has

already obtained the first critical permit, a submerged land lease, during 2020.

The Kingfish Company announced its intentions to build a US$110 million RAS facility in Jonesport back in November 2019. Jonesport is a lobster-fishing community of about 1,400 residents. Most of the work in the area is seasonal. The prospect of year-round jobs from a facility like the one Kingfish Zeeland is planning is welcome news to some people in the community.

The Millbrook First Nation community and the Canadian arm of Cooke Aquaculture Inc. have received the green light from the Nova Scotia Department of Fisheries and Aquaculture (NSDFA) to develop a recirculating aquaculture system (RAS) smolt facility.

The NSDFA has approved the assignment of Millbrook First Nation community’s aquaculture licence of a land-based hatchery in Millbrook to Kelly Cove Salmon Ltd., the Atlantic Canadian salmon farming division of Cooke Aquaculture.

The Millbrook facility will include a building each for grow-out, filtration, bio filter/degassing, a hatchery, and a greenhouse. The facility employs five people and engages outside suppliers on a contract basis. The hatchery and main facility use a RAS, engineered to grow 450,000 salmon smolt for Cooke’s 12 marine aquaculture sites on Nova Scotia’s Southern and Western shores.

“Farming Atlantic salmon through best practices in association with Cooke Aquaculture as a world leading company provides us with a sustainable source of nutritious salmon and employment opportunities,” said Millbrook Chief Bob Gloade. “We appreciate that Cooke is growing responsibly and thoughtfully in Nova Scotia.”

It’s another example of developing a circular economy platform for the aquaculture industry.

Land-based lobster producer Norwegian Lobster Farm is partnering with a data centre company, Green Mountain, to reuse the tech firm’s wastewater for heating up a recirculating aquaculture system (RAS) facility for lobsters.

Norwegian Lobster Farm’s current RAS facility uses advanced robotics, computer vision systems, and automatic and continuous monitoring of each individual lobster. The plan adds another layer of sustainable practice which will help the company further reduce its carbon foot print, according to a press release from the company.

• Best Efficiency Direct Gear Wheel Design with 70% Drum Submergence

•

To grow optimally, the lobster needs a temperature of 20 C in the seawater which the company says is “exactly the temperature of the seawater” that has been used to cool the IT equipment in Green Mountain’s data center. This heated wastewater will be funneled directly to Norwegian Lobster Farm’s RAS facility.

“In practical terms, this means that we can scale up production, reduce technical risk, and save both CAPEX and OPEX. In addition to the environmental benefits, of course,” said Asbjørn Drengstig, Norwegian Lobster Farm CEO.

Norwegian Lobster Farm has spent several years on research and development and has secured EU funding through the Horizon 2020 Grant Agreement and the EuroStars programs. Drengstig expects being able to start construction of the production facility in 2021.

Cooling a data centre usually accounts for an additional 40-80 per cent of the electricity required to power the servers. At Green Mountain’s DC1-Stavanger, they use an innovative fjord cooling solution for this purpose. The seawater enters the facility with a temperature of 8 C and is released back into the fjord with a temperature of 20 C.

“For a long time, we have explored various methods to reuse the waste heat from our data center. Here at Rennesøy, which is sparsely populated, district heating is not a sensible alternative,” said Kristian Gyland, Green Mountain CEO. “This project, on the other hand, fits like a glove. We hope we can expand this and similar concepts to our future facilities as well.”

By Catarina Muia

As the world looks to become more environmentally-responsible, the aquaculture industry is no different, aiming to replenish at-risk natural stock in a safe, eco-friendly and cost-effective way. Because of this and numerous other reasons, companies and investors have taken recent interest in the aquaculture industry, and more specifically, in recirculating aquaculture systems (RAS).

Maggie Fried, head of the Oceans, Seafood and Aquaculture Investor Consortium (OSAIC) at CREO Syndicate, looked into a number of these reasons during her ‘RAS Reality Check’ opening keynote at the first virtual event in the RAS Connector Series, held on June 9.

Featured in the RAS Investors’ Forum, which ran simultaneous to the Danish RAS Technology Seminars, Fried’s opening remarks highlighted four driving forces behind increased RAS investments: decoupling aquaculture from ocean ecosystems; the increasingly competitive CAPEX and cost of production; benefits of local production; and ongoing proof points.

“Removing aquaculture from the ocean can eliminate the risk of mass die-offs due to unforeseen ocean changes,” said Fried. “Unfortunately, evolving conditions due to climate change will only become more problematic over time. While RAS can have its own negative externalities, it does eliminate the environmental damage to the ocean due to nutrient-loaded seabed damage

and escapes.”

Fried also highlighted several benefits of local production. With a land-based aquaculture facility, she said you can choose a location near end markets, providing yearround access to high-quality seafood and non-native species. For investors, this means accessing new markets.

Part of the RAS Investors’ Forum, the Investor’s Profile panel session gave attendees a closer look at an investor’s perspective of RAS.

During the session, host Jean Ko Din, associate editor of RAStech and Hatchery International magazines, explored several topics with three guest investors, including factors to keep in mind when investing in a RAS company or project.

For some, having a knowledgeable and experienced team is of the utmost importance. “We want to understand their experience, and assess how realistic their plan is,” said Jamie Stein, co-founder of Devonian Capital.

“With the lack of specialized RAS farmers, for us, it’s important that we start with finding the right people,” added Roy Høiås, CEO and founder of Lighthouse Finance AS. “We also take a look at who is supplying the technology. We like to see suppliers who are involved, in some sense, in the business or can provide support services for the next two to three years.”

At Nutreco, investors keep to strict guidelines and typically only consider opportunities involving species that have already

been industrialized and developed. “Atlantic salmon and shrimp are our preferred species. For us, focusing on these species lowers the overall risk profile for RAS, which is quite high, especially in early-stage companies,” said Erik Tveteraas, investment director at Nutreco.

When conducting business and having conversations with RAS producers, Ko Din was interested to hear what investors think is important for RAS producers to know. “Definitely do your homework. Know who your investors are and what level of knowledge they have on the business, otherwise you will find yourself in a challenging situation,” Høiås warned. “We see very wide knowledge differences, and sometimes we are advising our clients when they are talking to investors, to go back to the ABCs of farming. This way, the investors are really understanding the risk and opportunities.”

The RAS Investor’s Profile panel discussion continued to look at several topics, including specific areas of investor interest, current obstacles affecting the RAS sector, and promising species for RAS in North America.

Registered attendees of the RAS Connector Series can access the full first virtual event of the series, which includes a number of series concerning investors of RAS technology, as well as perspectives from product and solution providers and RAS producers. Visit the event’s On Demand section, which contains all sessions for both the RAS Investors’ Forum and the Danish RAS Technology Seminars events.

By Maddi Badiola

Maddi Badiola, PhD, is a RAS engineer and PM, co-founder of HTH aquaMetrics LLC, (www.HTHaqua.com) and project leader & RAS specialist in Alpha Aqua A/S (www. alpha-aqua.com) based in Getxo, Basque Country, Spain. Her specialties include energy conservation, lifecycle assessments and RAS global sustainability assessments. Email her at mbadiolamillate@gmail.com, mab@es.alpha-aqua.com or contact her through LinkedIn, Facebook and Instagram.

In 2018, I did a worldwide survey regarding energy usage in recirculating aquaculture systems (RAS), which showed the different types of energy sources the RAS industry used in the past. While only three years have gone by, things have changed quite a bit. We are in an era where technology is driving the industry but the COVID pandemic, which has already lasted for more than year and a half, has dramatically accelerated this situation. The worldwide lockdown in response, has pushed ‘work from home’ and online meetings now more than ever before.

We are all familiar with RAS: intensive fish production systems with reduced water and land use. We are also aware that their high energy requirement is a challenge, increasing operational costs, affecting both environmental impacts and economic costs, jeopardizing the farms’ sustainability. Recently, there has been a piqued focus on using renewable energy sources or waste heat from other industries as part of the solution to decrease environmental impacts, due to the use of fossil fuels. Nevertheless, this energy source to be employed in a particular farm is being dictated by the system’s location and accessibility.

The RAS industry is ‘immature’ compared to other protein farms which helps keep it in the public eye. The industry has been scrutinized more so than many others. This may be due to the failures experienced, but also because society is now more aware of how

we produce what we eat. This has some pros and cons; the industry has always been looking for more efficient production technologies. That said, waste heat from other industries has been promoted as a source for RAS. According to the literature and market review made by Badiola et al. 2018, this type of heat source has been used worldwide for different fish/seafood species: commercial oyster, penaeid shrimp, salmon, American lobster, catfish, and more. Some other examples include eel and salmonid fingerlings production, which uses heat from power plants, while salmonid culture uses hydroelectric waste heat. Additionally, positive results have been obtained using waste heat from thermal electric or hydro-electric power stations. One study concluded that it could offer substantial energy and cost savings to salmon aquaculture in Canada. What is something that society constantly uses? What is one of the newest additions to global infrastructure? What do we use 24 hours, 365 days each year? The answers are data and technology. At this point, anyone could guess what this main, heat releasing industry is: data centres. Heat recovery from data centres is an emerging trend that is encouraged and mandated by some government entities. Concepts such as energy reuse effectiveness allow data centres to extend the opportunity to the energy suppliers. Nordic countries are leading implementation of this new sustainability, with Stockholm, Sweden looking to use data centre

waste to heat 10 per cent of the city by 2035. What about taking advantage of them? Some investors are already watching for this, and there has been some news around this topic: Norwegian Lobster Farm, the world’s largest land-based trout farm. The common expectations are that both energy consumption and carbon footprint are significantly reduced, otherwise the energy produced by the mentioned data centres is released, wasted and lost. With the use of heat recovery technology, a fish farm will use this energy to ensure the correct fish culture temperature, with this water forwarded to the data centre afterwards. As one of the mentioned farm’s CEO pointed out, “This means that the system can be scaled-up in production, reducing technical risk, saving both CAPEX and OPEX, and gaining environmental benefits.”

This approach is important to a circular economy. A next step could be looking at how to link the technology and farmed fish. I believe this is a great opportunity. In fact, thanks to the data centre supported social media and internet, many fish producers have been able to sell much of their production during the pandemic crisis, and therefore, keeping their businesses alive.

Keep track of my next article and/or contact mbadiolamillate@gmail.com or mab@ es.alpha-aqua.com for any further questions or discussion; a RAS lover willing to spread sustainability and efficiency approach among the industry.

By Carlo Lazado & Kevin Stiller

Ozone (O3) is regarded as a powerful oxidant due to its highly unstable nature. This oxidising potential provides potent O3-related germicidal functions, making it an effective well-known strategy for water disinfection. When O3 dissolves in the water, it produces a broad spectrum of biocides destroying bacteria, viruses and cysts; hence, water treatment facilities often use O3 for disinfection.

In aquaculture, its benfits to improve water quality have been well-documented. In recirculating aquaculture systems (RAS), using O3 results in the reduction of bacterial load, nitrite, ammonia, suspended solids, and yellow substances.

However, the use of O3 is mainly limited to freshwater RAS, as disinfection by-products (total residual oxidants) can form, and are higly toxic to fish in high salinity conditions. In particular, the formation of toxic bromines, following contact of O3 with bromide in seawater, is of great concern. Therefore, a cautious attempt at using O3 in saline RAS must begin with establishing thresholds that provide a favourable environment but do not negatively affect the health, welfare and production of farmed fish.

CtrlAQUA develops technological and biological innovations supporting the adoption of closed containment systems for Atlantic salmon aquaculture. We are exploring the use of O3 in salmon production in brackish water closed systems.

Earlier, it was demonstrated that salinity of 12 ppt improved growth, survival and welfare of salmon in RAS and was identified to be cost-efficient for prolonged land-based rearing of post-smolts before transfer to open sea cages.

The first trial aimed to identify the O3 threshold for salmon post-smolts. To isolate the effects of ozone alone, the experiment was performed in a brackish water flowthrough system. O3 was injected into a header tank, and the desired O3 concentration in each tank was achieved by mixing ozonated and non-ozonated water.

The O3 concentration in each tank was expressed in millivolts and monitored regularly. We tested five different levels of ozone: (1) control = 230 mV, (2) low = 280 mV, (3) medium = 350 mV, (4) high = 425 mV, and (5) very high = 500 mV.

This short-term exposure study lasted for 10 days. Significant mortality was found, around 36 per cent in the very high group on day six, which was above the humane endpoint set for the trial. This prompted termination of the treatment group. Mortality was also recorded in the high group, registering a cumulative mortality of around 33 per cent on day 10. The medium group’s cumulative mortality was no more than one per cent.

One of the drastic impacts of O3 application was how O3, particularly at 425 mV and higher, compromised gill health. Histopathology revealed extensive damage to branchial features, including widespread hyperplasia, lamellar clubbing and fusion, necrosis. Additionally found, was fish with compromised gill health had reduced chloride ion levels in the blood, which was a finding indicative of respiratory acidosis and a higher haematocrit level, showing the fish experienced compromised oxygen transport.

During the trial, we also documented that fish from the two high groups were schooled near the water inlet prior to observed mortality which somehow supported the hypothesis that O3 resulted in respiratory compromise. Interestingly, the skin was not significantly affected by the treatments. Therefore, based on the results from this foundational study, we concluded that O3 levels of 300 to 350 mV was the safest range for post-smolt in brackish water.

This foundational study was used to further investigate the biological consequences of continuous O3 application on post-smolts in a brackish water RAS. In a 45-day trial, we had two treatment groups: (1) a control group that did not receive ozonation and (2) a group that was continuously dosed with O3 The latter received an average O3 dose of 330 mV during the trial.

No significant differences in survival, external operational welfare indicators and

average weight at termination between the O3-treated and control groups were found. Plasma was analysed for a panel of stress status and internal organ health indicators. Cortisol, lactate, glucose, alkaline phosphatase, and lactate dehydrogenase levels, as well as total antioxidant capacity remained unaltered by the treatments. Nonetheless, the increased level of plasma creatinine in the O3-treated group at termination, suggest interference with renal function, warranting further investigation. This trial supported results from the foundational study, demonstrating the skin was less responsive to O3 than the gills. Histological and gene expression analyses showed little skin changes after O3 treatment.

Contrastingly, changes in the gills showed it was a suitable organ for assessing the impact of O3 on salmon. Quantitative histopathology disclosed that the O3 group exhibited better gill health status than the control group, particularly at the end of the trial. The number of healthy gill filaments was higher in the O3 group, while the prevalence of non-specific pathologies, such as lifting, clubbing, hypertrophy, and hyperplasia were higher in the control group.

The gene expression profile revealed the potential of O3 to induce local oxidative stress responses in the gills, as several genes affected by O3 treatment had a crucial role in maintaining redox balance and antioxidant defence.

Exploring the impact of O3 treatment on salmon response to secondary stressors provided insights into the consequences of using O3. O3 treatment didn’t alter the capability of post-smolts to respond to a secondary stressor as both the control and O3-treated groups mounted the classical adaptive respons handling confinement stress.

When optimising the RAS environment, physiological consequences of these rearing manipulations in fish should be considered. While we develop technologiesto make salmon production viable and economically feasible in closed systems, emphasis must be put on the effects on their health, welfare, and performance.

The

overhaul of an aquaculture school’s aging RAS facility provides some interesting insights By

As a young aquaculture student at the LIVIA College vocational school in late 1990s Finland, Pekka Marittinen felt very lucky to receive hands-on training in what was considered Northern Europe’s only educational recirculating aquaculture system (RAS) educational facility.

It was a delight muddled only by the system’s water which had a high concentration of solids. The clay particles of the

brackish water settled in tanks and pipes, continually messing with the water temperature and quality.

Twenty years later, Marittinen found that his career had come full circle. In 2019, as an entrepreneur and consultant at RAS-Consulting, Marittinen was hired by LIVIA College to overhaul the school’s aging RAS facility and battle his old nemesis – the brackish water that made managing the system a challenge.

The RAS renovation project was complet-

With more than 30 years of experience in fish farming and water treatment our team, including engineers and biologists, works to ensure the optimal solution for your water treatment. Our services include particle filtration, sludge treatment, disinfection and oxygenation - we are certain that we can deliver the best filtration system made for your needs.

Galaxy Skimmer

With a highly efficient venturis that works both in freshwater and saltwater. This is considered the most cost effective protein skimmer in the market.

CONTACT US NOW!

+45 2117 5600 info@cmaqua.dk www.cmaqua.dk

Hex Drumfilter

New X Series is completely rust resistant which is very reliable and need little maintenance.

ed in December 2020. Antti Forsman, lecturer at LIVIA’s College of Fisheries and Environment, says the work by RAS-Consulting has transformed the school’s RAS facility into a modern learning environment outfitted with equipment students will most likely encounter in today’s leading RAS companies.

Apart from that, according to Forsman, the renovation project provides insights on RAS construction best practices. Prior to the project, the use of RAS had been growing around the world. However, Finland was experiencing a RAS talent

crunch, says Forsman.

“We were experiencing a shortage of skilled RAS personnel,” he explains. “You know how to take care of fish, but managing the system is a challenge.”

That was when, LIVIA College made the decision to modernize its 20-year-old facility. Right from the start, the college was clear about the reason for the renovation.

“We are not into producing fish. We are into producing students that will someday become experts,” as Forsman puts it.

The aim was to build a RAS learning environment where, in addition to fish farming, all the different stages of water treatment can be studied, all factors can be monitored, and techniques can be practiced.

RAS-Consulting began drawing up plans, making equipment listings, process diagrams and investment estimates. The old system was dismantled in the summer of 2020 and construction of the new system began in autumn that year.

For Marittinen and many students, the old RAS facility was a maze.

“There were so many pipes in the old facility,” he recalled. “They snaked all over the place and we had no idea what half of them did.”

In order to manage a RAS facility properly, operators need easy access to equipment and clear visibility of components.

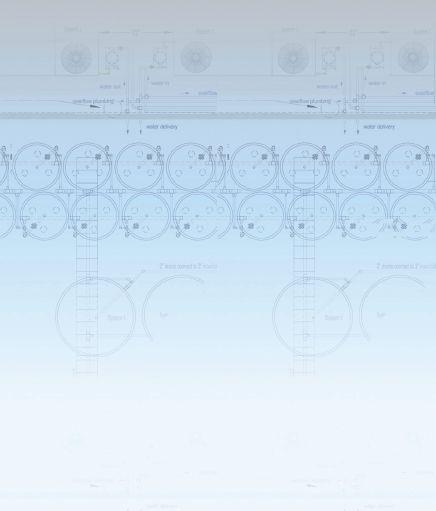

The company created a floor plan which made it easier for students to observe the different stages of the various processes involved in running the facility.

“Another challenge for the project was brackish water from the Baltic Sea and its varying quality. The water is very high in clay particles,” says Marittinen. “There would be times, especially in the summer, when you can even sea the fish in the tanks.”

The system consists of a sand filter, a protein skimmer, ozonation and UV radiation. First, the water is pumped

through a sand filter, after which the water is UV-irradiated. After UV irradiation, the water is passed to a protein skimmer to remove fine solids. The treated incoming water is led to a pump sump where it is taken as make up water for the fingerling system.

RAS-Consulting designed two different RAS systems for the plant. The incubation system operated on fresh water, while the more water-intensive fingerling rearing system had to be built on high-solids

brackish water.

From the perspective of the learning environment, this was seen as an interesting equation, according to Marittinen.

The incubation system works with fresh water (municipal water and borehole). The system includes six incubation trays, mechanical filtration (sand filter), cooling, UV irradiation and aeration.

The capacity of the incubation system is approx. 300,000 eggs per incubation batch.

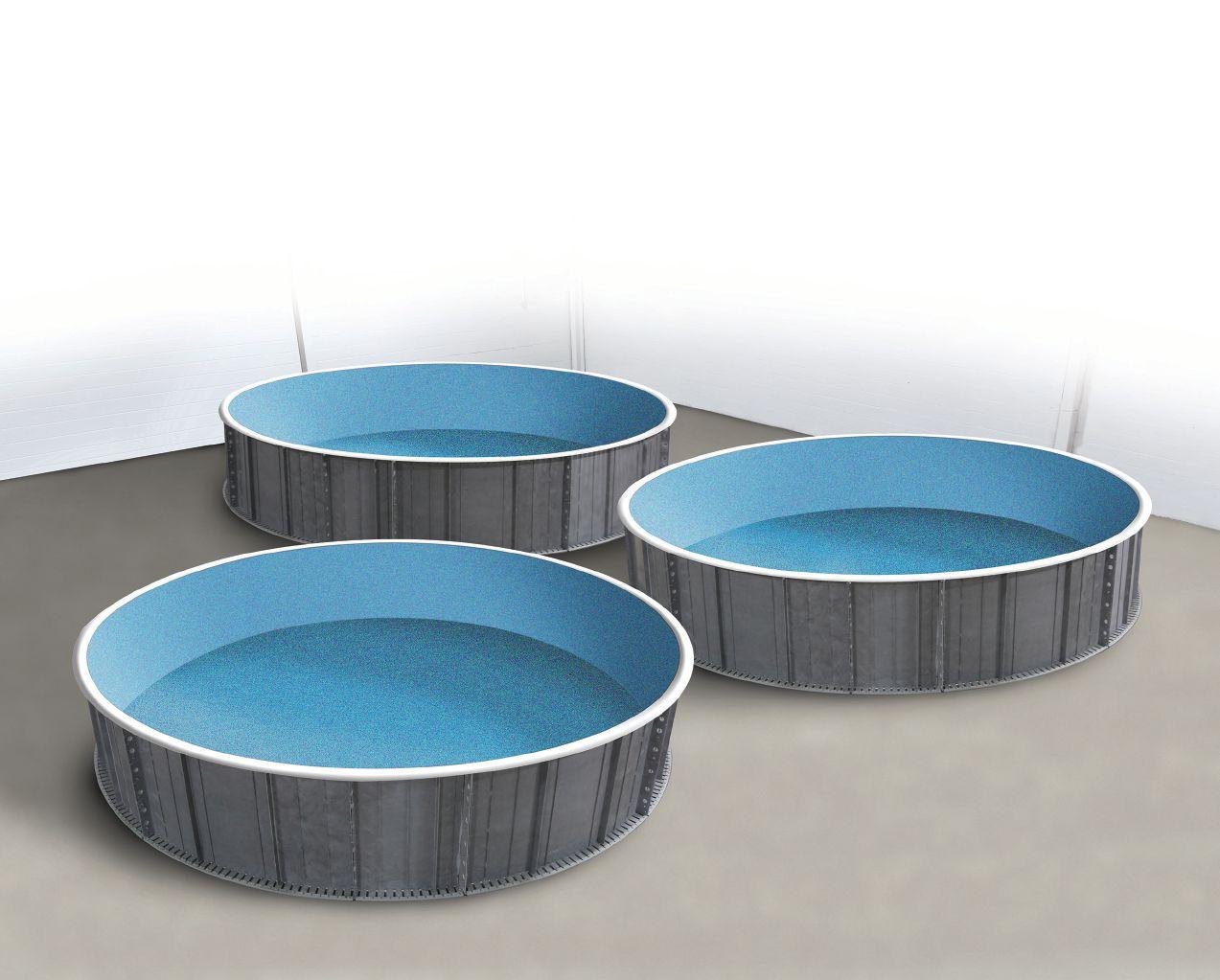

blutanQ™ epoxy‐coated steel tanks help land‐based aquaculture producers accelerate production and protect yields.

We offer:

• An unrivalled product portfolio

• Exceptional service levels

• End to end customer support

• A dedicated engineering resource

As a design and manufacturing company we take full responsibility for our products, so you don’t have to deal with intermediaries.

The temperature of the incubation water is kept between seven and 12 C.

In the upper water tank, the water is aerated, and oxygen, pH and temperature are measured from the water with online sensors.

The fingerling system operates with brackish water (0.5 per cent salinity). The system includes 12 rearing tanks, mechanical filtration (drum filter and bead filter), biological filtration (bead filter and moving bed bioreactor), aeration, UV irradiation and oxidation.

The feeding capacity of the system is about 12 kilograms of feed a day and the production capacity is about 100,000 -150,000 fingerlings per year.

The need for make-up water is about 1,000 litres per kilogram of feed.

This past December, work on LIVIA College’s RAS facility was finished.

“The project went well and the first batches of whitefish, rainbow trout and sea trout are currently growing in the system,” Marittinen proudly says.

Forsman is also very hopeful that word of the successful RAS renovation will attract more students to LIVIA.

“The RAS system has now been operational for the first spring season and we have been pleased with the operation of the plant as both a RAS and a learning environment,” according to Forsman. “Much remains to be learned about running a facility, and that’s just the right signal from a learning environment perspective.”

Norwegian brothers jump on RAS bandwagon, and they’re confident they have the trump card.

By Liza Mayer

Brothers Stig and Ole Bakke were partners in a salmon farming venture in Norway in 2014 when they met the founders of AquaMaof, the Israel-based specialist in recirculating aquaculture system (RAS) technology.

That meeting would prove fateful.

“We were fascinated with the technology,” Ole says of what he saw during that visit at AquaMaof’s RAS tilapia farm in Poland.

Although the RAS specialist would later abandon tilapia pro -

duction in favour of higher-value Atlantic salmon, it was by no means a measure of the technology’s weakness. If anything, the market-driven decision points to the flexibility of the technology, says Ole.

“It functions with tilapia very well and in other species, such as salmon. They have improved the production of salmon in landbased facilities over the past few years, and there have been no accidents. That’s important,” he says.

Just a few months following that meeting, the Bakke brothers would decide on a new direction for themselves. They believe they could help solve a long-standing problem of Norwegian salmon farmers – the inadequate supply of big post-smolts – by producing smolts year-round in a closely controlled on-land facility using AquaMaof’s RAS technology.

“We have been in fish farming since the ‘80s and we’ve noticed there’s a problem in getting big post-smolts,” says their younger brother and co-founder, Petter.

“Over the last 10 years, we have only been able to release 120gram smolts, but we see the advantages in releasing bigger smolts. The industry is screaming to get it.”

In recent years, salmon farmers have been raising smolts longer in land-based facilities before moving them to ocean cages where they will grow to market size. This means the fish spend less time in the sea where they are more exposed to risks, such as inclement weather, fluctuating

water temperatures and sea lice. This also reduces salmon farming’s environmental footprint due to less need for sea lice treatments and reduced sludge deposited into the sea.

But the average size of smolt in Norway today is only 175 grams, says Petter. “So, if everybody is going to have 500gram smolts, the smolt capacity has to be tripled.

In 2015, the brothers proceeded with the many steps required to launch a new business venture, which they would later call Smart Salmon. While still running their existing company full time, the brothers spent the next five years securing the required licences, networking with investors, and searching for equipment suppliers and people to work for the company.

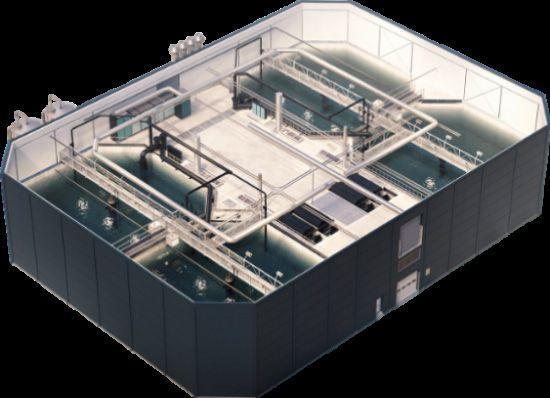

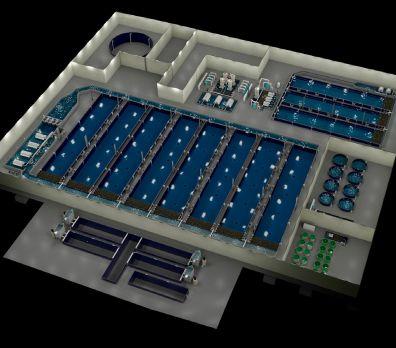

In late 2020, Stig and Ole sold the other company to focus fulltime on Smart Salmon. A 45,000-sqm land in Smørhamn in Bremanger, two salmon farming licences, and a preliminary design for the facility are now in place.

Meanwhile, work on securing licences to build a 10,000-tonne land-based facility in France that would produce full-grown salmon for the local market, is underway.

The Bakke brothers believe that Smart Salmon is well placed to tap opportunities in the farmed salmon industry. Bremanger is located in Vestland county, which is centered around the city of Bergen, often referred to as Norway’s aquaculture capital. Farming giants Mowi, Lerøy and Grieg Seafood are located in the area.

Smart Salmon plans to supply 500-gram smolts to salmon producers of all sizes, including major salmon producers whose in-house production of smolts is not enough to fill their needs. Small salmon farmers that do not have the

ability to have their own smolt farms are also their target.

Smart Salmon will build up capacity in two phases: the first entails building a 2,500-tonne facility that will produce 500-gram smolts, and the second phase will scale up that production by an additional 5,000 tonnes.

The second-phase facility is licensed for growing full-size salmon; hence, the Bakke brothers refer to it as a “flexible farm.” The intent is to raise roughly a thousand tonne market-size (5 kg) fish a year just so they could learn and refine the RAS technology in preparation for the 10,000-tonne growout facility they plan to build in France.

If all go according to plan, the 2,500-tonne facility will start delivering big post-smolts to clients in 2023, says Petter, while the 5,000-tonne facility could start delivering big post-smolts in 2024.

Ole noted that one of the many advantages of focusing on big post-smolts, is there’s little competition because there’s not a lot of third-party suppliers like them.

Risk reduction is another. “There is less risk to produce a 500-gram fish than a five-kilo fish because you don’t need to have it in the facility for that long,” says Petter.

In their calculation, there’s also more revenue to be had in producing big post-smolts compared to market-size salmon. The sales price of a post-smolt is almost NOK 100 (US$11.60) a kilo, compared to a full-grown salmon which

is, on average, NOK 60 (US$6.95) kilo, he says.

“When you sell full-size salmon, you sell it gutted, which means you lose 17 per cent of the fish. But if you sell postsmolt, you sell it whole. So, if you compare the weight to a full-grown slaughtered fish, the kilo price for postsmolt is around NOK 90-100 (US$1011).”

Besides, the price for post-smolt is stable throughout the year and from year to year, he notes. “It’s like infrastructure for the sea farming industry.”

Smart Salmon’s business model appeals to investors. Three equity financing rounds to date have netted NOK 47 million (US$5.3 million) from 80 deep-pocketed backers who believe in

the company’s potential. It also has secured a NOK 220 million loan (US$25 million).

Investors include biologist and fish farming pioneer Bjørn Myrseth, as well as Olav Refvik, a self-described “fisherman and investor” but also a Wall Street legend known for his savvy in the US fuel commodities market.

Petter notes that Smart Salmon investors are mostly Norwegian. Myrseth is not merely investing money but also offers time, expertise and advice on the design and building of the facility, he says.

AquaMaof is also an investor. It holds a 7.3 per cent stake. As tech supplier, its involvement continues long after the technology’s sale is concluded. Such

arrangements – where tech providers become a part of the value chain with their clients – may hold the key to de-risking RAS, explains a financier who was involved in early land-based RAS facilities built in Scandinavia.

Under the deal with AquaMaof, an expert from its Global Training Centre in Poland will be stationed in Norway to serve as adviser/co-manager during the first year of Smart Salmon’s operation. Smart Salmon staff will be trained in AquaMaof’s indoor fish production platform at the Polish training centre.

“We are in the middle of the biggest fish farming clusters in Norway so there’s a lot of skilled people we can tap

here from both sea-based farming and land-based smolt facilities. We also have the opportunity to send people to Poland, to the R&D centre, which we will do even before the facility’s construction is finished,” says Ole.

Ask any land-based salmon farmer their biggest fear, it would undoubtedly be mass mortality of fish. Saltwater has naturally high sulphate content, which could reach toxic levels and turn into poisonous hydrogen sulphide (H 2 S) if not detected early. The toxic gas has recurrently figured in mass mortality events in salmon RAS facilities, in recent years.

AquaMaof technology has low risk for hydrogen sulphide toxicity, says Ole. “There’s been no H 2 S accidents in AquaMaof facilities. H 2 S is what causes the big catastrophes in RAS.”

The use of a sedimentation tanks instead of drum filters, which requires water to be forced through with powerful pumps, is key in the stability of the technology, says Petter. “Less can go wrong when the water does the job in the filter itself,” he says, noting that the use of technology that includes drum filters to purify water for reuse have caused biological challenges in Norwegian RAS facilities.

Energy use is a major consideration in AquaMaof’s system design. Ole says it will take 3 KWh to produce 1 kg of fish, including the production of oxygen. For fish production alone, the energy usage is approximately 2 KWh to produce a 1 kg fish.

Water use is minimal. “AquaMaof technology was developed in Israel, where they have very little water. They are only allowed to fill the water tanks

once a year or at least release water once a year. So, they have been forced to develop a technology that uses minimal water, which could also be reused almost 100 per cent.”

Depending on how the Norwegian operations turn out, the Bakke brothers are planning a third facility, in France. It will be in collaboration with local fish farmer Arild Lokøy, who holds a 20 per cent stake in Smart Salmon France. Lokøy could help ease Smart Salmon’s entry into the French market, notes Petter.

“France is the second biggest market in the world for farmed salmon. The aim is to go to France and produce full size fish in the market. It is a very

patriotic market and they like products made in France. They’re willing to pay extra for domestic products and they like sustainable products,” he says.

The facility will be designed to adopt a circular production model, where sludge from the fish will be used as a resource for biogas and greenhouse production. It will also capture CO 2 for use in the greenhouse.

“We see a big opportunity in France to produce a completely environmentally friendly fish, ideally zero carbon emissions, with less transporting and the possibility to brand it,” says Petter.

Smart Salmon is expected to have the license for the French operations by next year. In Norway, construction of the first-phase facility is scheduled to start this autumn.

Ensure sustainable disinfection that meets the highest standards for your recirculating aquaculture system

By Jean Ko Din

Yonathan Zohar believes that in order for recirculating aquaculture system (RAS) technology to truly become the future of food, then stakeholders must work together to ensure the success story.

Zohar has earned global recognition for his more than 40 years of research and development in the global aquaculture industry. Starting from his early days at the National Center for Mariculture in Israel, Zohar says the priorities of his research have always been to identify what he calls “bottlenecks in the industry” and develop technologies to open them up. He has made notable contributions to fish reproductive biology and endicronolgy, broodstock management, hatchery technologies and land-based aquaculture.

He now serves as professor and chair at the Department of Marine Biotechnology, as well as director of the Aquaculture Research Center in University

of Maryland Baltimore Country. He is also program leader of the Recirculating Aquaculture Salmon Network (RAS-N) which he helped found in 2018.

In RAStech Magazine ’s latest podcast episode of RAStalk, co-host Brian Vinci sits down with Zohar to talk about RAS-N and what the future of the industry holds through innovation.

RAS Talk: Tell us why you decided to pull together RAS-N and what you hope the outcomes will be.

Yonathan Zohar: The initial NOAA Sea Grant came up with a request for proposal for collaborative research that would help aquaculture in the United States. And this was about three years ago. At the time, we started to see the boom in land-based Atlantic salmon production in the United States. There were all these investments and growth in the industry and we have, I think, a

collective responsibility to make sure that it will be a success story.

So that so the idea is to combine researchers, engineers, educators, extension people to look at the industry and identify gaps in knowledge and barriers to success. RAS-N is stakeholder-based so it’s a public-private kind of partnership with many of the main producers, growers involved. And it’s all about working and thinking.

We’re going to do two things. Number one, we’re going to develop a white paper that will review the history of the industry, that will look at all those core aspects that I just mentioned – the biology, the technology, the economy, they’re the extension, public relationship, workforce development, all those kinds of things - and identify priorities for research and development.

And this will all lead to a strategic plan or a roadmap that will end up putting all these recommendations together. Most importantly, it will

“I think RAS is all about maturing now, which is a combination of engineering and biology.”

recommend to the federal government, to state governments, to the industry, to foundations, which areas of R&D should be developed, what are the priorities and where to spend the dollars to help overcome these barriers. So that this industry can deliver on its promise and be as successful as and as stable as possible.

RAS Talk: As one of the peer reviewers of the CtrlAQUA program, do you think RAS-N will develop into larger research efforts similar to that?

Zohar: I was very inspired by CtrlAQUA. I think it’s a very beneficial program to the industry, much larger than what we are. Yes, we do intend to grow the program. But right now, RAS-N is mainly about its building capacity so it’s not a lot of hands on research.

But what we want to do is take the deliverables of RAS-N and develop it and implement it and go much… Real-

ly taking whatever RAS-N will recommend and convert it to real R&D, opening this bottleneck, overcoming those barriers on everything – technology, biology, extension, outreach, education, workforce development, economic feasibility.

So fingers crossed, we put in a very strong and long proposal (to the USDA Agricultural Research Service). We worked on it for months and months, and we will know by September. And this is really, this really will take us to the level of what CtrlAQUA is, and where we want to be in this country.

RAS Talk: You mentioned researching and overcoming the challenges that the industry is facing. What research is your group currently working on at the Institute of Marine and Environmental Technology (IMET)?

Zohar: Many of us are working on different aspects related to aquaculture with the mantra of environmental

• 100% Titanium Heat Exchangers

• Salt & Fresh Water Safe

• Available with Tube Sheet, Helical Coil, or Plate

• Hot & Cold Water Loop Systems

• Compact Designs

• Easy Installation

• Incubator Rack Systems

• Gas Boilers

responsibility. We continue to do a lot of work on group stock management, year-round sea production, which I think is very important for the Atlantic salmon industry in the U.S. to be independent and to develop our own broodstock year-round. They are available from overseas, which is great and great quality but I think we need to also think about having them domestically.

The flip side of the coin is reproductive sterility and we can talk about it later is extremely important for aquaculture in general, and for land-based RAS technologies as well, to understand the problem that is still there in early maturation.

RAS Talk: What do you think is next for RAS?

Zohar: I think it’s all maturing now. And I think it’s the maturing is a combination of engineering, but also the biology. I think we were able to manage the life cycle in RAS. We’re able to start dealing with early maturation, high-efficiency feeds and so on. But I think we still have challenges and several of them.

If I had to list our main challenges, what will be the biggest one and the one that comes up again and again and again, is the off-flavour. And so I think we’ll need to study much more. And we will need to totally understand it and hopefully, if we get the USDA fund, we’re going to collaborate more on that (with the Freshwater Institute).

But the idea is to understand what are the sources of the geosmin and MIB, which bacteria and what are the environmental conditions that help them thrive, or will actually help eliminate them.

The purging water now is is a big headache, because our challenge they have to release now huge amount, they cannot use it as new water in the system to the recycling, though, so we need to find technologies to mitigate and overcome off-flavours.

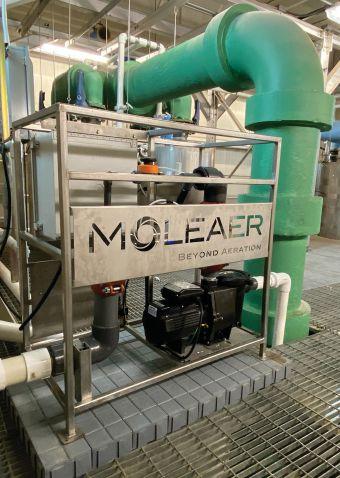

Nanobubble tech company, Moleaer, has raised US$9 million in its Series B Round of financing. This is the company’s largest financing round yet and could mark continued global expansion.

The funds raised have been led by S2G Venture’ Oceans and Seafood Fund, along with ADM Capital’s Enterprise Fund and Energy Innovation Capital.

Moleaer is one of the first companies to receive funding from S2G’s newly formed Oceans and Seafood Fund, which is focused on advancing sustainable solutions in the

aquaculture industry.

Moleaer has also recently appointed a new chief operations officer, Bryan Brister.

Moleaer has installed more than 1,000 nanobubble generators that have treated more than 225 million gallons of water per day in agriculture, aquaculture, surface water and natural resources.

The company claims to have proven an increase the biomass of salmon by 22 per cent, a 60 per cent reduction in oxygen usage and 42 per cent reduction in electricity consumption. www.moleaer.com

Laren Enz is the new vice-president of sales in the United States for the The Kingfish Company.

Enz brings more than 20 years of experience in seafood sales and leadership experience.

She previously served as vice-president of business development at Mark Foods and director of seafood purchasing at Darden Restaurants.

“The addition of Lauren Enz, as VP of Sales US, is the next step in our strategic

The Luke Natural Resources Institute in Finland is developing a passive water treatment method that is deisgned to recharge effluent to pristine intake water. Its patented solution includes a passive woodchip denitrification followed by constructed wetland and a sand filtration.

The passive water treatment field is meant to offer affordable, low-maintenance effluent treatment and water source solutions for RAS farms. The concept is meant to make fish farming possible in new locations where water shortage or environmental limitations have previous-

roadmap towards building significant production capacity in Maine for the US market,” said Ohad Maiman, CEO of The Kingfish Company.

The Kingfish Company has recently expanded its retail reach last year with the launch of a line of retail-ready, fixed weight drozen IVP portions with Whole Foods Market in the United States and a new fresh retail MAP retail product with Albert Heijn in the Netherlands. www.the-kingfish-company.com

ly prevented the growth of the business.

The water treatment system has received patents in Finland and national applications are being filed in Canada, China, Europe, India, Russia and the United States. www.luke.fl

Customized for your fish farm, hatchery or research operation!

Our Commercial LSS Packages are custom engineered to meet your specific needs.

• Marine and Freshwater

• Mechanical filtration

• Chemical filtration

• Ultraviolet disinfection

• NEMA enclosed controls

• Bio-filter towers

• De-gassing towers

• Wide variety of flow rates

• Flow control valves

• Protein skimmers

• Variable frequency-drive pumps

• Temperature management

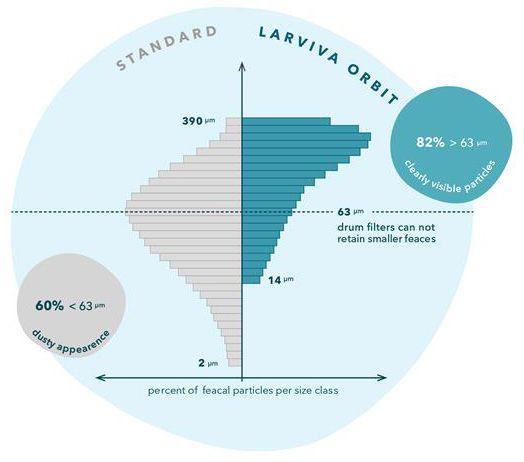

BioMar looks to target a bottleneck in marine nurseries with the introduction of its new RAS feed concept, Larviva Orbit.

The company positions this new feed as a response to the increased need of land-based fry production in the Mediterranean area. This is the company’s first feed concept designed for RAS and has been made available to customers since June.

“We understand how challenging RAS operations can be, as this farming technology demands skilled manpower, extra attention to the fish, the system and the importance of specially designed feeds to accommodate the requirements and ultimately the success of RAS technology,” said Joana Amaral, product manager for marine fish hatcheries at BioMar.

The new feed is an optimised recipe for improved physical pellet quality that claims to have a proven impact on faeces stability and reduction of small solids.

The feed formulation includes the probiotic Bactocell and BioMar’s own yeast-based additive, B-WYSE. It comes in 25-kilogram plastic bags.

• Recirculation System Design, Supply and Construction.

Commercial Farms, Hatcheries, Aquaponics, Research Labs, Public Aquariums, Live Holding Systems – we do it all!

Representing leading RAS equipment manufacturers.

“Our years of experience have shown us that the dialogue between the hatchery staff and our BioFarm technical advisors is very important to achieve success,” Henrik Aarestrup, vice-president of LATAM, Shrimp & Hatchery at BioMar Group.

“That is why ‘let’s do RAS together’ is our way of telling our customers that they are not alone when adapting to changing business conditions or when implementing new technologies.” www.biomar.com

Send

company news and press releases to jkodin@annexbusinessmedia.com to be considered in the next issue.

Airlift pumping systems company, FloNergia Inc., has named GLOBALTECH Automacão, Manutencão E controle industrial LTDA as its exclusive distributor in Brazil.

GlobalTech will now carry the company’s complete line of FloMov airlift pumps, which are being used in many markets for water circulation and aeration. FloMov pumps are designed to reduce energy costs associated with pumping and aeration systems by 50-70 per cent when compared to conventional systems.

The company also claims to have proven performance in disrupting thermal stratification, improving oxygenation, stripping carbon dioxise and facilitating recover of sold waste.

“(GlobalTech’s) expertise systems management and their connections to industry throughout Brazil will help us to introduce our energy-efficient FloMov to more customers in Brazil,” said FloNergia CEO Paul Subject in a press release.

FloNergia has also recently named Professional Aquaculture Services Inc. and Northwest Fisheries Enhancement as exlusive distributors in specific states in the United States. www.flonergia.com

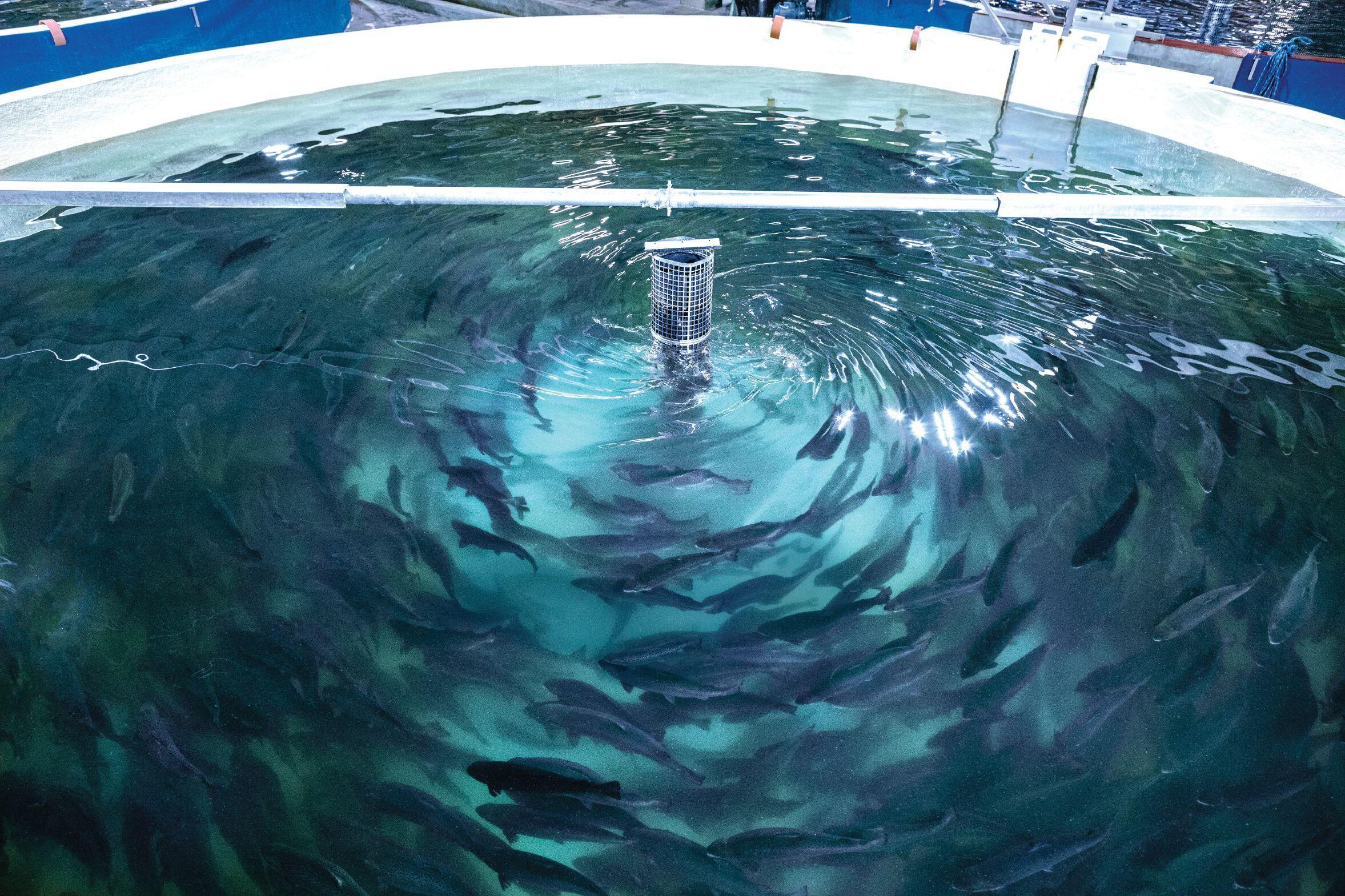

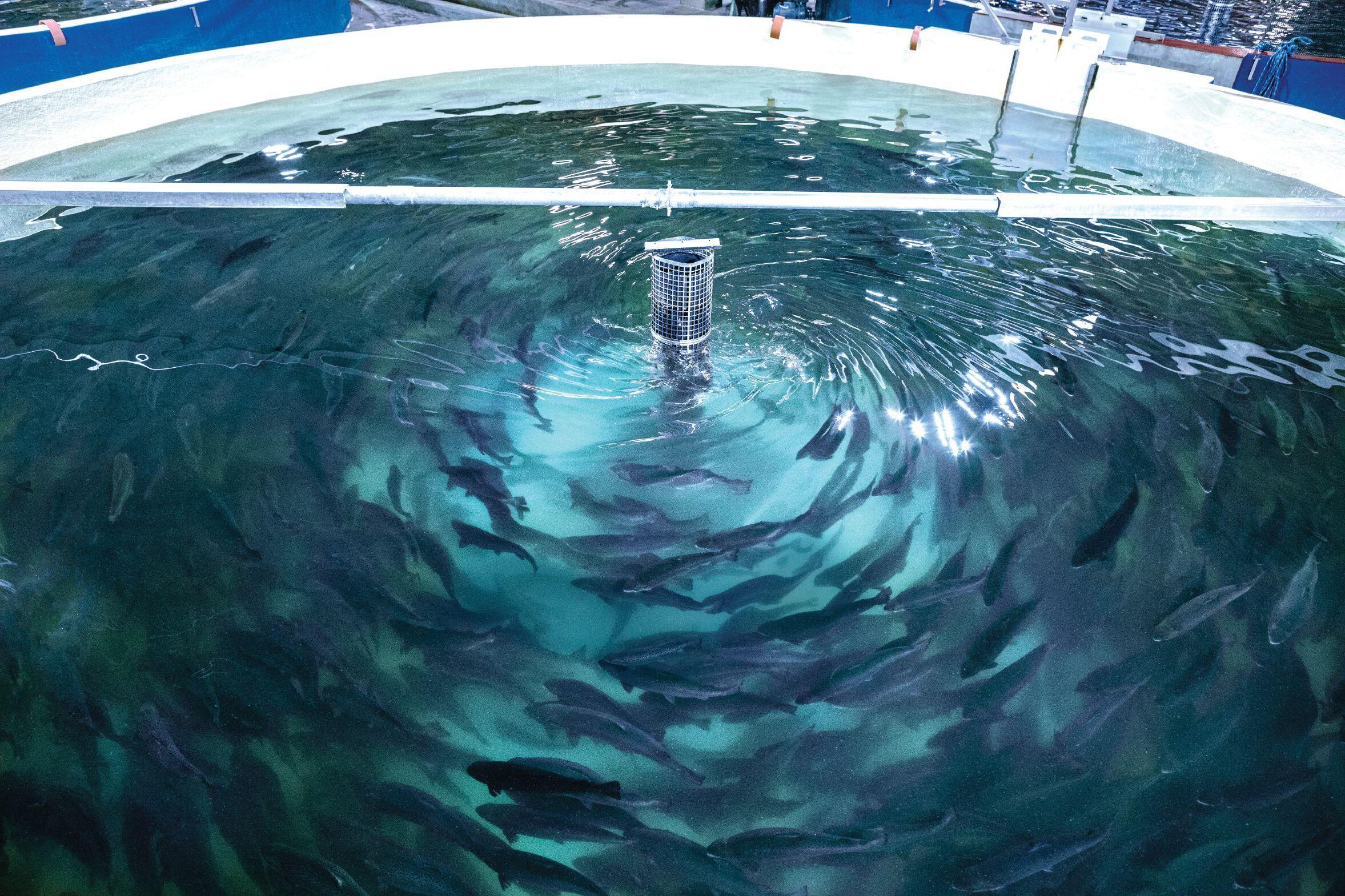

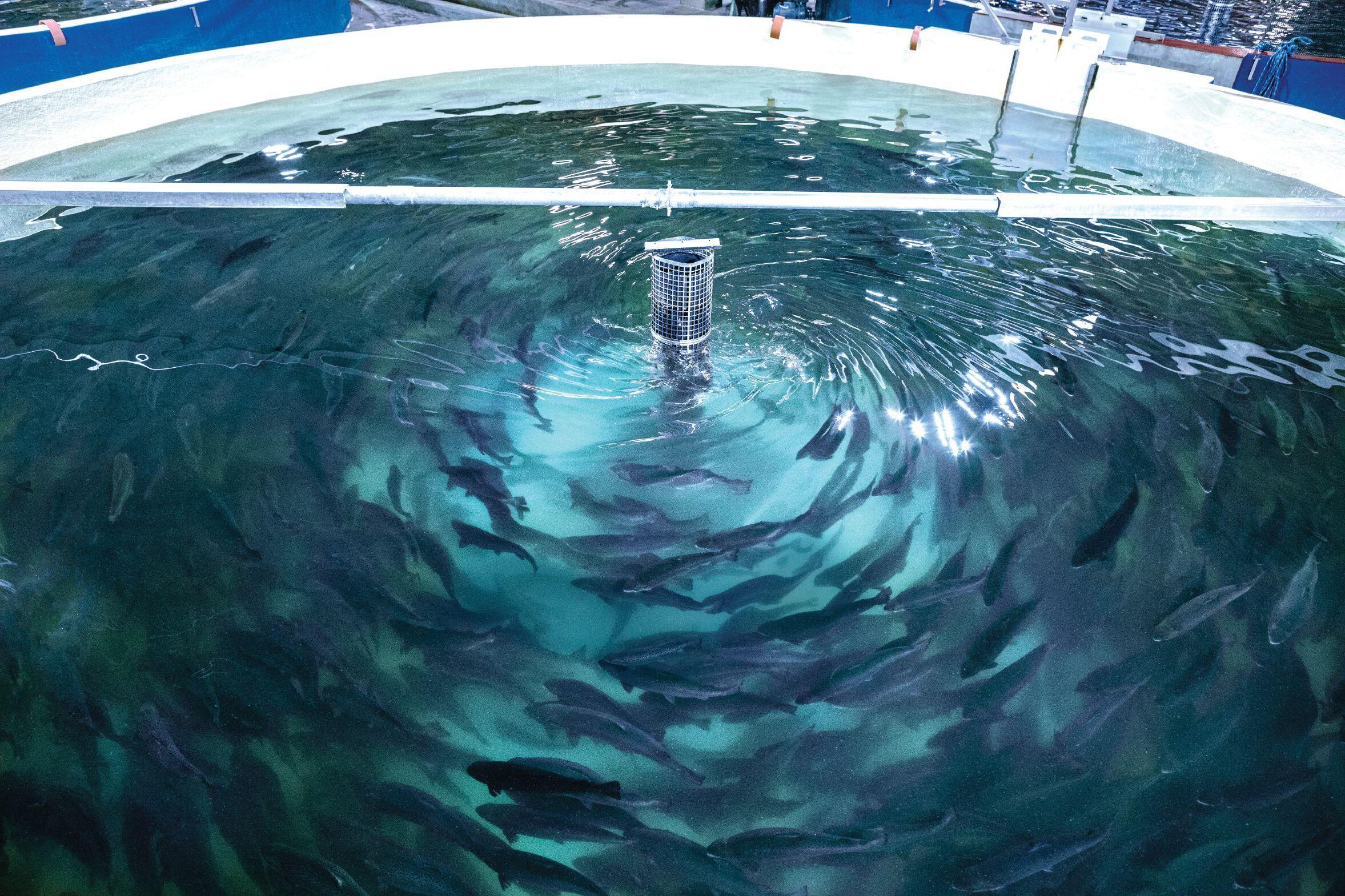

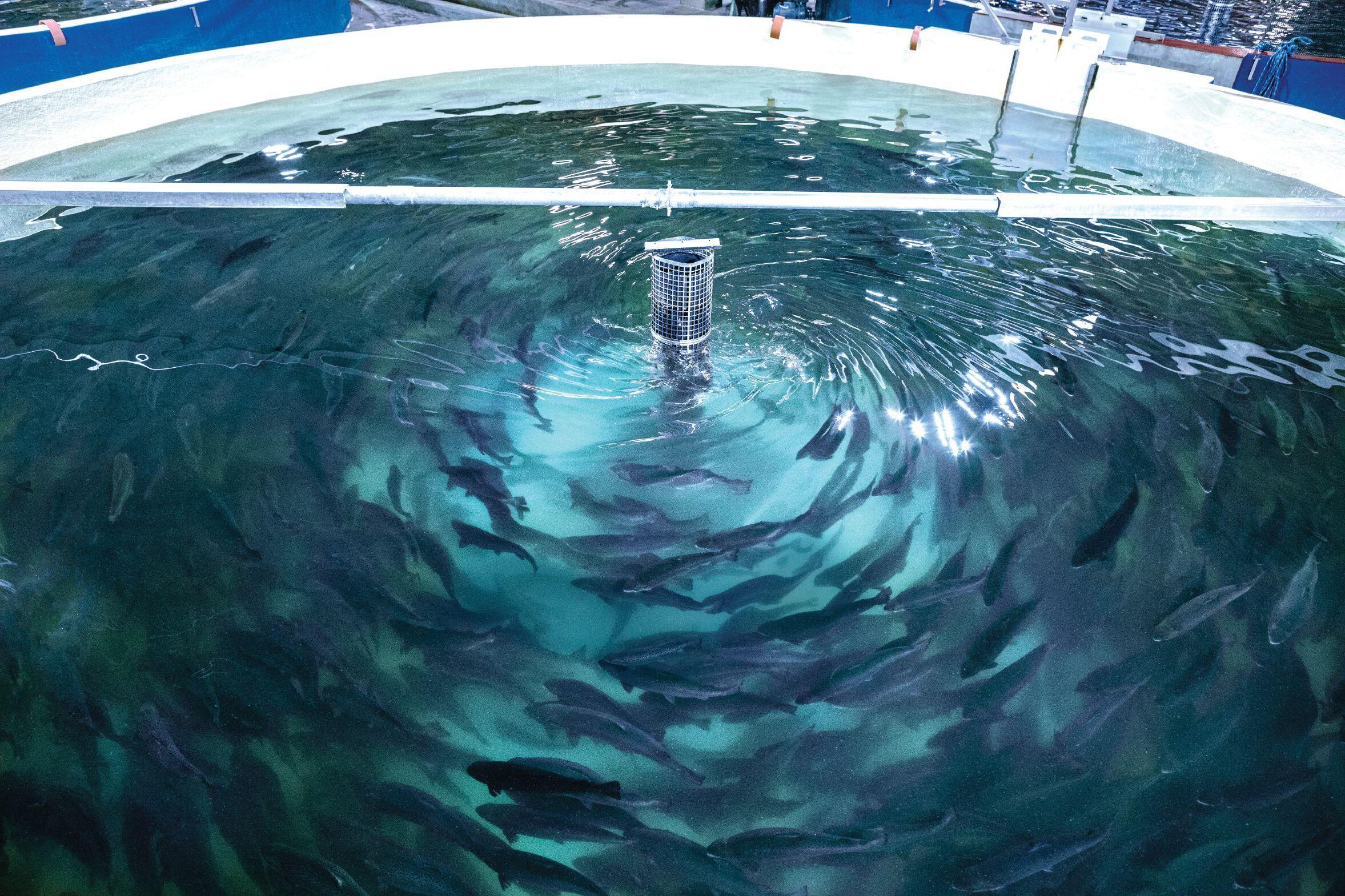

Customization

In the event of a fish harvest, move, or sampling procedure, RAS operators may find it necessary to crowd a tank of fish with a divider screen or seine net. While useful for the operator, crowding a tank is stressful for the fish and should be done with care.

It is important to select or adjust the divider screen, “crowder” slot spacing, or net mesh opening size to prevent excessive numbers of fish from passing through or becoming ensnared, leading to injury or death.

In preparation for a crowding event, check crowding equipment for damage that could include holes, cracks, bends in support structures, failing hoists or suspension cables, damaged hinges, or fraying pull ropes. Equipment failure while deployed in the tank will disrupt work and could present a major challenge for removal from the culture tank. Inspect nets for tears or frays and mend them prior to deploying into the tank. Confirm that any in-tank equipment such as probes, cameras, or plates are removed or in a safe position to prevent the crowder from becoming snagged.

Placing a crowder screen or net into a tank is an acute stressor that can cause fish to defecate while avoiding the equipment. Increased solids can degrade water quality and create an even more stressful or even hazardous environment. Withholding feed for 24 hours before a crowding event reduces solids production and minimizes fouling of the culture tank, holding tank, transport equipment, or sampling water.

Place crowding equipment into the tank gradually, holding tow ropes securely in rapid water currents. Slower introduction will be less stressful for the fish and allow them to move away from the working area to prevent being struck or trapped beneath

equipment. When pulling the crowder or net tight, do so at a slow pace and consider giving the fish short breaks to acclimate to the smaller area and higher density. While crowding a tank closely monitor fish behavior for signs of stress.

If fish begin surface piping, rolling, or burrowing against crowder equipment, the fish should be given a break to acclimate, or they are crowded too closely and should be given more space. Likewise, monitor water quality parameters, particularly dissolved oxygen, while crowding a tank of fish. Increased activity and confinement to a smaller volume will cause fish to consume available oxygen faster. Consider increasing dissolved oxygen levels in the tank immediately prior to the start of crowding with normal oxygenation systems and if dissolved oxygen begins to fall to unacceptable concentrations, further increase output or activate back up diffusers. This will offset increased oxygen demand until dissolved oxygen concentrations increase and become steady.

Remember that increased fish respiration will lead to increased carbon dioxide production and a potential need to increase fan speed through degassers to prevent dissolved carbon dioxide concentrations from becoming too high.

Pull the crowding equipment only as

tight as is necessary to complete the work. As fish are removed from the tank, the crowder or net can be pulled increasingly tighter to continue working at an efficient pace. Aim to complete the work in a timely manner so the crowding equipment can be removed, and the tank returned to normal operation as quickly as possible. If a break is needed while fish are crowded, pull back on the equipment to allow more space for the fish while away and pull the equipment tight again upon return to work.

Remove the crowding equipment promptly when work with the crowded tank is complete. Take care that no fish are trapped in the crowded area or in the equipment while removing it from the tank. Once the tank is returned to normal operating conditions, continue to monitor the behavior of the fish to confirm that they begin swimming normally, are not crowding water inlets, and are not clamped closely to the bottom of the tank.

Fish should return to normal feeding soon after the crowding event is over. Observe a feeding event to confirm fish are actively consuming feed. Fish may require an increased ration over the next day to achieve satiation and return to the expected feeding ration. While monitoring feeding look closely for signs of abrasion or injury from the crowding event. Damaged fish after a crowding event could indicate the crowding was too tight or a hazardous element exists on the equipment that requires repair. Damaged fish provide feedback to the operator to make improvements for future events.

RAS operators should consider preventative treatments in the event of fish sustaining excessive abrasions or exhibiting abn ormal behaviors following crowding. Preventative treatments for overly stressed fish can mitigate opportunistic pathogen outbreaks and preserve fish health.

Increase tank capacity and yield with Linde technology for aquaculture. Our SOLVOX® oxygenation products deliver pure oxygen to help ensure an optimal growing environment. The expansive range of dissolution and distribution solutions is designed for high efficiency, excellent utilization, and peak hydrodynamic conditions inside the tank. Linde experts can develop a system customized to meet your specific needs. Contact us today.

lindeus.com/aquaculture