Moving forward towards more autonomous operations

More and more companies aim to increase the autonomy of their mill or plant operations. In an autonomous mill or plant, an autonomous system can monitor its own performance, which brings several benefits, like improved safety and efficiency, lower costs and reduced environmental impact. Digitalization and more autonomous operations also mean that there is less need for human intervention. The role of people will continue to be important, evolving towards supervising and ensuring that different process areas perform well together, and towards managing exceptions. Operations and maintenance work will become more collaborative in the future as well.

Whether you are just beginning your digital transformation journey or you’re further along in the process, Valmet’s framework helps you recognize the necessary steps and building blocks. Our experts are there to support you as you move towards more autonomous and optimized operations.

More on valmet.com/autonomousoperations

Happy anniversary, Pulp & Paper Canada!

Digging through historical archives, I came across the very first issue of the magazine which was published in May 1903. It was then known as The Pulp and Paper Magazine of Canada. The prospectus stated, “If anyone asks why The Pulp and Paper Magazine of Canada comes into existence, we give answer that such a magazine is inevitable. Canada is destined to be the greatest pulp and paper manufacturing country in the world, and naturally a country which leads the world in a special industry will require an organ of information and opinion to represent that industry.”

Sukanya Ray Ghosh Editor

Over the course of 120 years, the pulp and paper industry landscape in Canada and the world has changed drastically. What stands true from that statement, however, is that this magazine continues to represent this sector and the people in it. This magazine is for all of you – our readers and constant supporters through the years. It is fascinating to read what the major concerns of the industry were in that era. The first issue discussed Canadian pulp and paper exports to the U.S., Great Britain, Australia and China. The issue covered topics such as alternate fibres for papermaking, newly built mills, the contributions of existing mills, Canada’s forest assets, local and international pulp trade outlooks and even the latest machinery for process optimization. So much has changed since then and yet so little. Newsprint paper is on the brink of going extinct while innovations in packaging products and plastics alternatives abound. Currently, the focus is on transforming operations with the advanced technologies of today that can also complement legacy equipment and systems. Tracking the market trends locally, nationally and globally is even more important today. Fibre shortages plaguing the industry are impacting mill operations like never before. Attracting and retaining a skilled workforce has been a challenge for some years. For years now, industry stakeholders have been working hard to incorporate sustainable practices, reduce carbon footprint and take environmentally conscious decisions.

Taking a trip down memory lane, major players in this space share how their mill operations have evolved over the years, where the industry stands today and what they foresee for the future.

“Change” is the key word here. Change is inevitable. The industry is doing its best to transform itself with the times. The magazine itself has changed so much over the years. It has print and digital presence today to help reach our readers in every way possible.

It is my honour and privilege being a part of this piece of history. I truly believe that this industry and its magazine will continue to grow for many more years. Happy Anniversary, Pulp & Paper Canada!

READER SERVICE

Print and digital subscription inquires or changes, please contact Barb Adelt, Audience Development Manager

Tel: (416) 510-5184

Editor

SUKANYA RAY GHOSH

416-510-5225

srayghosh@annexbusinessmedia.com

Brand Sales Manager

SONYA HESSON

416-510-5224

shesson@annexbusinessmedia.com

EDITORIAL/SALES OFFICES

Fax: (416) 510-6875

Email: badelt@annexbusinessmedia.com

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

President/COO

SCOTT JAMIESON 519-429-5180

sjamieson@annexbusinessmedia.com

Group Publisher ANNE BESWICK 416-510-5248

abeswick@annexbusinessmedia.com

111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Phone: 416-442-5600

PRODUCTION

Media Designer EMILY SUN

Account Coordinator SHANNON DRUMM sdrumm@annexbusinessmedia.com

Print in Canada ISSN 0316-4004 (Print) ISSN 1923-3515 (Digital)

PUBLICATION MAIL AGREEMENT #40065710

SUBSCRIPTION RATES

Canada $57.50 - 1 year; $92.50 - 2 year

USA $139.00 CDN per year Overseas - $150.00 CDN per year

Occasionally, Pulp and Paper Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbusinessmedia.com

Tel: 800-668-2374

The editors have made every reasonable effort to provide accurate and authoritative information but they assume no liability for the accuracy or completeness of the text or its fitness for any particular purpose. All rights reserved. The contents of this publication may not be reproduced in part or in full without the publisher’s written permission © Annex Publishing & Printing Inc.

Sustaining member, Pulp and Paper Technical Association of Canada; Member, Alliance for Audited Media.

Paper Excellence to restart Crofton Mill’s paper operations with $50 million investment

Paper Excellence is investing around $50 million to upgrade its Crofton mill’s paper operations and towards reductions in its carbon footprint. The funds are being used to restart Crofton Mill’s C2 paper machine, putting over 100 employees back to making paper at the site. The company had recently curtailed paper operations at the mill due to weakening Chinese paper markets and escalating input costs.

The C2 paper machine will be transformed to produce stronger, water-resistant paper grades which replace single-use plastics. The investment also reduces natural gas consumption through more efficient use of waste bark fuel in the mill’s boiler.

“This investment will enhance the development of innovative products that replace banned plastics with renewable paper while significantly reducing carbon emissions,” said Stew Gibson, chief operating officer for Paper Excellence Canada, in a press statement.

Canadian Competition Bureau approves Resolute – Paper Excellence merger

The Canadian Commissioner of Competition approved the Paper Excellence and Resolute Forest Products merger. The companies jointly announced that the Canadian Commissioner of Competition has entered into a consent agreement regarding the parties’ business combination.

Once the combination is finalized, Paper Excellence’s wholly-owned subsidiary Domtar will acquire all of the outstanding common shares of Resolute stock for $20.50 per share and one contingent value right tied to potential duty deposit refunds of up to $500 million.

The consent agreement filed by the Canadian Commissioner of Competition with the Competition Tribunal on December 28, 2022, completes one of the remaining conditions for closing the transaction. The companies shared in the statement that the transaction remains on course to close in the first half of 2023, subject to the satisfaction or waiver of the other conditions to the closing of the merger.

Port Hawkesbury Paper, Unifor sign agreement

Port Hawkesbury Paper mill’s workers signed a new agreement, the first one in 10 years. The agreement allows for long-overdue gains for members of Local 972, according to a Unifor press statement.

“This group will now be aligned with the timing of negotiations across the Eastern pulp and paper Locals and we hope to see members of Local 972 benefit from future pattern negotiations,” said Lana Payne, Unifor national president.

The new four-year agreement sees a $3.50 wage adjustment to all rates for operations on January 1, a $1.50 adjustment to all rates for operations on January 1, 2024, and then 1.5 percent wage increases at the beginning of both 2025 and 2026. In addition to general wage increases, there are improvements to the Sunday premium and time-and-a-half for working holidays in addition to holiday pay.

Canfor permanently closes pulp line at Prince George facility

Canfor Pulp Products is permanently closing the pulp line at its mill in Prince George, B.C., resulting in a reduction of 280,000 tonnes of market kraft pulp annually, and the loss of about 300 jobs.

The decision follows an extensive analysis of its operating footprint and the long-term supply of economic residual fibre, the company said in a statement. The specialty paper facility at the site will continue to operate. Over the next few months, the company will be following an orderly wind down process. The pulp line is expected to close by the end of the first quarter of 2023.

“In recent years, several sawmills have permanently closed in the Prince George region due to reductions in the allowable annual cut and challenges accessing cost-competitive fibre. This has had a material impact on the availability of residual fibre for our pulp facilities and we need to right-size our operating platform. As a result, we have made the very difficult decision to shut down the pulp line at Prince George Pulp and Paper Mill and will continue to operate the specialty paper facility,” said Kevin Edgson, president and CEO, Canfor Pulp.

VOICES FROM THE PAST

Notes from two former editors of Pulp & Paper Canada

By Scott Jamieson

It was a stroke of luck that I began my B2B media career as an assistant editor on Pulp & Paper Canada in 1991. As an employee at Paprican (now FPInnovations), I attended the once-massive pulp and paper convention in Montreal looking to indulge my love of writing. The first person I met was long-time P&PC editor Peter Williamson, who was looking for a new team member.

Not long after, I was reporting to Peter as part of a dream team. The bulk of my training was at the hands of the thorough and passionate associate editor Sue Stevenson. Much of my early career, I owe to her. I also worked with managing editor Graeme Rodden on the Daily Reporter we handed out to Montreal convention delegates each year, to be slipped under hotel room doors by 6:30 a.m. Some readers will remember these iconic media figures. I certainly do, and fondly. They gave me a foundation that has served me well since.

deliver – action around effluent treatment, recycling, dioxins, clear cutting, forestry certification and more. These were challenging times to be in – and report on – Canada’s pulp and paper sector. Industry executives were getting “pied” by activists in downtown Vancouver, and some young trade journalists were collateral damage. The difference was I only owned the one suit. But the industry, and my wardrobe, persevered.

This was also an exciting era for investment in new mills, mostly out west, and new paper machines and technology, mostly in the east. I was privileged to visit Kruger and Tembec installations for cover stories on cutting-edge papermaking technology, and to interview industry tycoons the likes of which we no longer see.

to our operations, technical wizardry that cut proofing time by weeks. Prior to that, they were…yes, mailed to authors. I also introduced the first spell-checking software to the operation, despite serious doubts among older colleagues. Finally, we moved from manual cut-and-paste to desk-top publishing.

But in all of this, one thing never changed. The immense responsibility of caring for a piece of Canada’s magazine history, a brand covering one of our country’s primary industries. The weight of 120 years of continual publication should weigh heavy on any editor. Sorry, Sukanya. But also, you’re welcome.

My old bosses would not recognize the media landscape that P&PC inhabits. But the core job remains the same – To provide niche information and a like-minded community for all that serve this tenacious industry.

Soon after I moved on as editor of Canadian Forest Industries, and then part owner of three forestry media brands, and the rest is history. But I remember that early P&PC reporting well. My first feature was on the then-contentious issue of secondary effluent treatment. I interviewed dozens for what I wanted to be a definitive overview of treatment options and tech and took far too long to put it all together (just ask Sue), but it was an example of what trade journalists could accomplish with time, curiosity and the right mentoring.

This was also the first real barrage of environmental concerns. The public wanted – and the industry would soon

One highlight was flying with Repap’s George Petty on his private jet to cover his pioneering Alcell bio-refinery in Miramichi, NB. I was a more-than-intimidated college grad on that trip, but I got the job done, despite George’s scowls and implied threats.

We were also key partners of the Canadian Pulp & Paper Association (CPPA) Technical Section back then. We edited, prepared and published the association’s Technical Papers, serious works of engineering over which Sue and Peter presided. This was a privileged role, and they made sure I knew it. Pencil in hand, I did my best to make these dense tomes readable but still technical.

This era also saw dramatic technical changes in the media business. I witnessed the introduction of the first fax machine

Thank you for reading – then, now and in the years to come.

Scott Jamieson is the president and chief operating officer of Annex Business Media, publishers of 60 B2B media brands, and the founding editor of Canadian Biomass.

By Cindy Macdonald

Recently, a sponsored post from an environmental activist group showed up in my Twitter feed accusing Procter & Gamble of cutting down old growth trees for toilet paper. My responses were, in order: Really? Again? Still?

I’ve been involved with the pulp and paper industry off and on for almost 30 years. This public relations battle has been going on that whole time, and long before. I joined Pulp & Paper Canada just before the war

Scott Jamieson

Cindy Macdonald

in the woods, during the dioxin years in the late-80s.

At that time, the industry was being asked to control a carcinogen that had just begun to show up in testing. And we did, quickly.

Then, in no particular order, the environmental activists came after the forestry sector for logging old growth forests, various endangered species, wastewater, caribou and the Boreal forest. This industry has made tremendous gains in sustainable development, but there will always be some trade-offs between industrial development and the natural world, and someone ready to criticize our choices.

What struck me about the pulp and paper sector, even as a journalism student when I first joined Pulp & Paper Canada, was the open sharing of information. The technical papers and the conferences were quite astonishing. I have not seen the same degree of cooperation in any other industry I’ve covered: automotive repair, plastic part manufacturing, construction, engineering, retail. It’s something this industry should be proud of.

Speaking of technical papers, when I started with Pulp & Paper Canada, Sue Stevenson managed that task. The magazine was the Journal of Record for the CPPA Technical Section. She used file

folders stapled together accordion style to track the status of available papers, noting when they were edited, peerreviewed, approved by the author, and ready for publication. It was a handwritten, paper-based spreadsheet that worked flawlessly.

Eventually, Pulp & Paper Canada stopped publishing technical papers when it became easier and more common to publish such work online. This decision was made several years after I rejoined Pulp & Paper Canada as editor in 2009.

A major shift was happening during my tenure from 2009 to 2016. Biofuels, bioproducts, bioenergy were beginning to gain traction. These represented a new revenue stream for Canada’s pulp and paper industry to explore.

Driven by extraordinary individuals, Canada’s pulp and paper companies have been adaptable, innovative and resourceful. I have no doubt this sector will thrive for many more years to come.

Cindy Macdonald is a former editor of Pulp & Paper Canada (2009 to 2016)

A print issue cover of the magazine from 1989

Photo: Cindy Macdonald

Kadant is a global leader in fabric cleaning with more than 1000 traversing high-pressure cleaning system installations worldwide. The M-clean™ system uses high-pressure water in combination with an effective evacuation and air knife system. This patented method removes stickies and chemical build up from the fabric’s surface to optimize cleaning, improve operation efficiency, and increase production.

TECHNOLOGIES AT TAPPICON 2023

TAPPICon 2023 is focussing on breakthrough technologies and strategies to improve bottom line performance in pulp and paper mills

By TAPPI

Pulp and paper mills today grapple with concerns such as competition, high costs, product quality and sustainability. TAPPICon 2023, taking place from April 22 to 26 in Atlanta, Georgia, is offering a platform to discuss innovative solutions to many of these challenges.

The event is a valuable resource for the latest technical knowledge available in the industry. TAPPICon draws mill, paper and packaging professionals from around the world year after year. The comprehensive technical program provides fundamental knowledge for both young professionals new to the industry and seasoned professionals needing a refresher. Each session provides valuable, hands-on information attendees can implement back at their mills.

With the theme, “Three Rings of Success: Vision • Technology • Action,” the conference offers over 200 expert-led presentations, panels and roundtable discussions delivered within eight distinct program tracks: coating and graphic arts; papermaking additives; papermaking fundamentals; papermaking technology and operations; PIMA management; process control; recycled paperboard; and tissue.

Spotlight on presentations

There is a wide-ranging selection of topics to attend, many of which focus on timely, topical issues such as:

1. “PFAS-free Barrier Solutions for Food Service Molded Fiber Applications” by Christopher Dilkus, Solenis. Attendees will hear about a new PFAS-free solution which can provide oil, grease and

water resistance across a wide range of furnish types for use in the food service market space.

2. “Multi-Functional Barrier Coating Systems Created by Multi-Layer Curtain Coating” – Don Ventresca, Trinseo. This presentation will highlight waterbased barrier coatings (WBBC) for oil and grease (OGR), water, water vapour (MVTR) and oxygen barrier performance. Attendees will learn about coated systems that can achieve more than one barrier property, using multilayer curtain coating (MLCC), in one application step.

3. “Fundamentals of Wet End Chemistry” – Larry Anker, Solenis. Attendees will learn the fundamentals of water chemistry and how these fundamental properties impact the additives as well as the finished product quality and production efficiency.

4. “QCS Control Handbook Tutorial” –Tim Murphy, ABB, Shih-Chin Chen, retired (ABB), and Seyhan Nuyan,

retired (Valmet). Experts will review key chapters within the Handbook that focus on optimization and transition controls for a paper machine, characteristics of paper machine colouring process and fundamentals of colour measurement, and paper machine QCS control and applications. Complete program tracks are available on the TAPPICon website.

Additional resources

TAPPICon's exhibit floor brings together over 100 suppliers where they showcase their latest developments in products and services. Attendees can join the New Technology Showcase taking place Monday, April 24 and Tuesday, April 25, an event that highlights exciting new technologies for the mills of today and tomorrow. Attendees can also participate in multiple social events, career advancement and training opportunities, and committee meetings throughout the four-day conference.

Photo:

TAPPI

A conference in progress at TAPPICon 2022

TALES OF TRANSITION

On the magazine’s 120th anniversary, pulp and paper companies share how the industry is evolving and embracing changes that come its way.

By Sukanya Ray Ghosh

Amajor contributor to the Canadian economy, the pulp and paper industry has endured through years of drastic changes in the market. It was a leading global producer of newsprint paper once upon a time, as well as a major pulp producer. With the evolving times, Canadian mills have embraced the needs of the hour. Today, the focus is on pulp and paper alternatives to plastics, packaging products for the highly demanding e-commerce industry and adoption of sustainable practices.

In this special anniversary feature, five stakeholders of the Canadian pulp and paper industry share how they have evolved and their vision for the future.

Paper Excellence

Established in Canada in 2006, Paper Excellence expanded its operations through acquisitions from a single mill to a group producing 2.5 million tonnes of paper and pulp. The group recently acquired Domtar and is on the path to complete its acquisition of Resolute Forest Products. Despite the many challenges plaguing the industry as a whole, including Paper Excellence, the company announced a $50 million investment to restart operations at its Crofton mill.

Davis Chiu, director of innovation at Paper Excellence Canada, shares that the mill is converting one of the paper machines to make new products that can replace plastics. Chiu explains that this is

one of the many trends in the industry that the company is embracing to move ahead. However, the difficulty in trying to replace plastics right now is that most of the solutions made from pulp fibres are usually more expensive and probably don't have the same performance as their plastic counterparts. Another trend, Chiu says, is the focus on carbon emissions. He shares that the Canadian pulp and paper industry started its carbon reduction journey way before it was “cool” to do so.

“At Paper Excellence, we're roughly at 80 percent renewable energy usage. The remaining 20 percent is still fossil fuels. So, we're looking at opportunities to reduce that last 20 percent,” he says.

Over the years, eucalyptus pulp producers have established their prominence in the global markets. Canadian NBSK pulp still remains in high demand, however, especially where the reinforcing fibre is required, according to Chiu.

In the near future, Paper Excellence is looking to expand on digitalization and automation at its mills.

“We currently have the computational power to start leveraging all of the data that we're collecting, and start developing

things like model predictive control and using that to optimize how we operate,” says Chiu.

As an example, Paper Excellence is planning to deploy a digital twin in one of its mills.

“We can use this digital twin to test out various events, process control philosophies and to see what the overall impact could be on our facility. This gives us a roadmap to see what we can do from a control standpoint and understand what the relative impact is on the thermal efficiency of the facility,” Chiu explains.

Chiu foresees the industry as a whole and Paper Excellence, in particular, working harder on being more sustainable. While the technology is not there yet to convert all processes in mills, Paper Excellence continues to look for innovative ways to progress further on its sustainability goals.

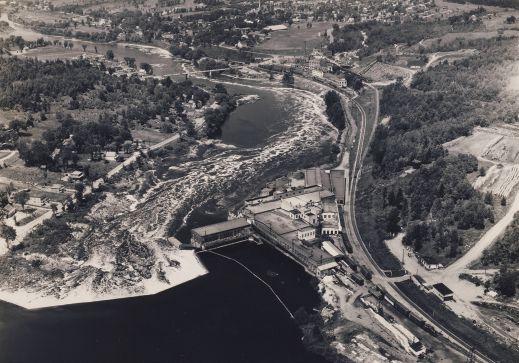

Domtar

Domtar, as a company, is celebrating its 175th anniversary this year. With its roots in Europe, the company first established its operations in Canada in 1903. Over the years, it diversified its

Paper Excellence’s Howe Sound Pulp and Paper mill was commissioned in 1909.

Photo: Paper Excellence

portfolio, adding paper and packaging to the mix.

In paper, Domtar has adapted to the market to ensure its long-term success, matching capacity and demand. In pulp, strategically combining technical insights from Engineered Absorbent Materials (EAM) with its pulp business allows the company to deliver a full suite of absorbent materials for hygiene products globally. The company is also entering the packaging market with the conversion of its Kingsport mill to high-quality containerboard.

In Canada, Domtar’s Windsor Mill has been in existence since 1864. The initial unit built in Windsor by Angus & Logan was a soda pulp mill, the first wood-pulp mill in the country and the second on the continent, shares the Domtar team. Other units were added through the years as the operations evolved and expanded. In the 1980s, Domtar decided to build a completely new mill with high-technology systems. The mill today features robots (Automatic Guided Vehicles) to bring paper rolls to the sheeters, an automatic warehouse, several performance monitoring environmental systems and other modern equipment. Domtar had been invested for 35 years to create a safe workplace, to maintain high productivity and to increase the environmental protection.

As with every player in this space, Domtar’s Canadian operations do not remain unaffected by the constantly evolving industry.

Katie Zorn, vice-president of marketing, product management and strategic planning at Domtar, says, “Coming out of the pandemic, we see continued decline in demand for communications papers in short-lived, low-value end uses and applications. But we see strong usage, and even resurgence, in high-value applications and important documents that require deep thinking, where there is benefit from physical interaction and continued use. There is no good substitute for paper and print where important information and messages are concerned. We are excited to see more efficient and economical printing techniques and technologies moving forward.”

She further adds, “Another trend is in paper-based packaging, where consumers generally feel that paper is a very sustainable option, especially when it can be easily recycled. We envision more and more paper-based packaging solutions that have new functionality for containing, protecting and preserving everyday items. Paper remains a sustainable choice, easy to use and easy to recycle.”

Kruger

Kruger started as a paper distribution company in 1904. In 1950, the founder’s son Gene Kruger acquired the company’s first newsprint mill in Bromptonville, Québec, kick-starting a journey of acquisitions, expansions and growth. Many mills that Kruger acquired along the way have been in operation for 100 years or more. The Wayagamack mill was built in 1912 (acquired in 2001). The Crabtree mill, also nearly a century old, has been a part of Kruger since 1997. The Trois Rivieres mill was built in 1923 and became a part of Kruger in 1973.

François D’Amours, executive vice-president and COO at Kruger, explains that since the acquisitions, Kruger has invested heavily in them over the years, to modernize them, make them competitive, update product lines and adapt them to current market demand. The company has evolved from a publication paper company to a diversified company with nine distinct activity sectors.

D’Amours shares that the creative and courageous leadership of company chairman and CEO Joseph Kruger II has contributed heavily to the tremendous growth and expansion of the company in recent years. Acquiring the Scott Paper Canada assets in tissue was a bold move for Kruger as it ventured into a completely different area from publication papers. The 2008 recession, as well as the current one, accelerated Kruger’s transformation journey, prompting it to further diversify product lines.

Kruger believes in technology investments. The company invested in AI technology to improve operations and supply chain efficiency at its Sherbrooke facility. Kruger regrouped automation practices on its central engineering to address labour shortage challenges in its mills. The company is also implementing Robotic Process Automation for its clerical and administrative work to allow employees to focus on more valueadded tasks.

Looking at future trends, D’Amours says that the industry is moving towards innovative alternatives to plastics. Kruger is well-positioned for this with its containerboard and specialty paper businesses. D’Amours adds that ESG is the next major trend for the industry. As a company, Kruger believes in being responsible to its stakeholders, its customers, its employees and the communities it serves.

“The Canadian industry is resilient. But, in order to be there tomorrow, we need to adapt. We need to transform. We have

The Domtar Windsor mill in 1950

The Trois Rivieres mill under construction in 1922

Photo: Domtar; Kruger

the fibre. We have good people and good resource centres. These are excellent tools for success. We need to continue to adopt the best technologies to keep innovating and transforming,” says D’Amours.

Mercer International

Mercer International’s purchase of the Castlegar, B.C., mill in 2005 marked its entry into the Canadian pulp and paper scene. Now known as Mercer Celgar, the mill was established in 1960. After Mercer took over, it expanded the mill's pulp production in 2007 and then in 2009 invested in the Green Energy Project to produce renewable energy for the marketplace. Mercer took over the Peace River mill in Alberta in 2019. Originally established in 1990, the mill produces both softwood (NBSK) and hardwood (NBHK) pulp. The Peace River mill purchase also resulted in joint ownerships of the Cariboo Pulp and Paper mill with West Fraser.

Bill Adams, vice-president of sustainability and innovation at Mercer shares that over the years, the market shift resulted in the decline of the printing and writing grades of paper. While the fear was that the shift would hurt the pulp market as a whole, demand has in fact increased. Tissue paper, packaging and specialty applications are on the rise in the industry, prompting Mercer to focus on these products.

Another challenge is that newer mills built in the last two decades have higher production capacities. They produce hardwood pulp and are low-cost operations. Adams shares that Mercer has worked hard to secure its place in the market with its high-strength softwood products. He adds that Canadian mills that have pivoted to a certain degree to start producing renewable energy are tasting more success in recent times.

“We’ve really seen that from our operating strategies – making sure you’ve got the most efficient mill possible. You use as little energy internally to produce the pulp and then you take all that extra energy that comes from the biomass and direct that towards electrical energy, selling that into the market,” explains Adams.

Over the last decade, Mercer has also focused heavily on sustainability and environmental performance. The carbon footprint and overall environmental impact of the mills are strong considerations when

making decisions, says Adams.

Looking into the future, Adams notes that investment in decarbonization technology will be essential for the industry to maintain its social license to operate. In April 2002, Mercer’s GHG emission targets were validated by the Science Based Target initiatives. The most significant opportunity will be to replace fossil fuels with biogenic fuels in lime kilns. Mercer is also focused on expanding its portfolio of bioproducts and biochemicals that include turpentine, methanol and ligninbased materials. These bioproducts will enable Mercer to capture increased value from the harvested wood, says Adams.

AV Group

AV Group’s journey in Canada started with the acquisition of an NBSK mill in Atholville, New Brunswick in 1998. The Atholville Mill was originally built in 1930. On taking charge, the AV Group converted it from an NBSK mill to a dissolving grade pulp mill. The group later acquired a comparatively newer kraft mill in Nackawic, N.B. in 2005. The Nackawic mill, which originally produced photographic paper, was converted to dissolving grade pulp in 2008. The Terrace Bay Mill in Ontario was the third Canadian mill to join the AV Group, purchased in 2012. The mill produces NBSK pulp for the tissue and graphic paper markets.

The escalating energy costs have been posing a challenge for mill operations in recent years, notes Mike Legere, director of government relations and communications at AV Group Canada. As a result, the mills have sought investments to be more

self-reliant on energy production. Stricter effluent regulations in recent years have impacted mill operations. Legere explains that the industry as a whole is working hard to meet the current requirements. In the context of sustainability, Legere says that dissolving grade pulp needs different types of certifications when it comes to wood procurement and sourcing. These factors, combined with the industry’s focus on sustainability have influenced operational decisions at AV Group’s mills.

The AV Group, which is celebrating its 25th anniversary this year, is embracing technology to drive growth. It has implemented automated processes in its mills to reduce costs and improve efficiencies. Legere shares that the group is looking at the prospects for full digitalization of the mills.

“It speeds everything up. It permits the collection of big data. And data will allow us, in the future, to implement artificial intelligence and other predictive tools so that we can predict and address issues before they happen,” says Legere. This is paramount in the pulp business to address reliability issues and prevent cost escalations.

Legere says that the AV Group is no more just a pulp and paper business. The focus, he says, is now on how to derive full value from the harvested wood. The group’s facilities produce different grades of dissolving pulp that have applications beyond the pulp and paper industry.

Legere says that resiliency comes from the ability to pivot. The AV Group has been able to successfully adapt to changing market trends and conditions and will continue to do so in the future.

Mercer Peace River being built in 1989

Photo: Mercer International

D I G I T A L SER VICE S FOR PULP AND PAP E R M ANU F ACT UR E R S

The science of papermaking –The power of data

By combining chemistry and application expertise, monitoring and control capabilities and predictive analytics, we enable a new, data-driven way to manage and optimize the papermaking process.

Our KemConnect™ services provide the visibility, predictability, and insight that you need for running efficient and sustainable processes, every day of the year

HALL OF FAME

Presenting the inspiring winners of Pulp & Paper Canada’s 2023 Hall of Fame contest.

By Sukanya Ray Ghosh

The inspiring leaders at the helm of the Canadian pulp and paper industry have set impressive benchmarks for success for the newer generation of the workforce. They have contributed to ground-breaking innovations through their deep commitment to and passion for growing the sector.

Pulp & Paper Canada’s Hall of Fame contest celebrates and honours three such legends annually. Read how these changemakers have helped the industry evolve positively through their hard work and zeal.

J. DAVID MCDONALD

Consultant and adjunct professor, Chemical Engineering department at McMaster University

J. David McDonald has spent 45 years in the pulp and paper industry with AbitibiPrice, Paprican and FPInnovations as a scientist, manager and executive. He is currently a consultant and an adjunct professor in the Chemical Engineering department at McMaster University.

McDonald’s application for a job opening as a Mathematician with the Abitibi Paper Company at their research centre

in Sheridan Park west of Toronto marked his entry into this industry.

While at Abitibi, currently a part of Resolute, he developed an on-line computer system for measuring the quality of paper rolls on the winder, a mathematical model to significantly reduce calender barring and pressing and drying strategies to reduce linting, all of which were applied company-wide.

McDonald later joined Paprican as a scientist working on paper machine pressing. Working with Ivan Pikulik, he helped identify the press section factors that affect paper quality. In addition, by means of unique pilot paper machine experiments, they identified the mechanism of paper adhesion to press roll materials which supported the transition from granite to ceramic and metal rolls. With Dick Kerekes, he challenged the conventional picture of press dewatering which led to a practical model currently used by machine builders, consultants and papermakers, worldwide.

McDonald gained experience in management, first leading a small group in calendering and winding which did seminal research in minimizing paper defects and web and roll handing. Later, as the program manager of Paprican’s Mechanical

Pulping Program, he managed 25 people and transformed the group from one that produced good science to one that applied their discoveries in commercial applications.

McDonald was selected for executive positions at Paprican and later, FPInnovations. As vice-president of research and education of Paprican, he directed Paprican’s research program with line responsibility for 310 research staff. As vice-president of university programs and strategic partnerships of FPInnovations, he formulated the vision for the Transformative Technologies Initiative.

McDonald has written 87 peerreviewed publications of which 28 were published in Pulp & Paper Canada Of those published in PPC, two have received the I.H. Weldon gold medal for best overall paper, the Jasper Mardon award for the best papermaking paper and John Bates award for the best paper presented at a branch meeting.

He received the highest technical awards, the John Bates Gold Medal from PAPTAC and, the Gunnar Nicholson Gold Medal from TAPPI, for his major contributions in research and leadership. In addition to being a fellow and life member of both organizations, TAPPI

J. David McDonald

John Mullinder

Alain Lemaire

recognized him with the Aiken Prize for outstanding contributions to research and development as well as the Engineering Division Award and Beloit Prize.

JOHN MULLINDER

Former executive director, Paper and Paperboard Packaging Environmental Council (currently retired)

John Mullinder led Canada’s national environmental council for the paper packaging industry (PPEC) for 30 years, from 1990 to 2020. He worked closely with the country’s packaging mills and converters, identifying their environmental requirements and providing them with timely information and intelligence. He has been prolific in educating the industry, its customers, governments and the general public on paper’s sustainability story through online blogs, letters to the editor, and on the PPEC (and more recently his own website: johnmullinder.ca).

He has also published two books on industry issues, educating readers on the facts of deforestation, and evaluating current environmental buzzwords and exposing greenwashing where it occurs: Deforestation in Canada and Other Fake News (2018) and Little Green Lies: From “Ancient” Forests to “Zero” Waste (2021).

Mullinder represented the industry on Canada’s National Task Force on Packaging between 1991 and 2000; participated in various Canadian Council of Ministers of the Environment (CCME) committees and stakeholder groups; chaired the innovative Boxboard Task Group; and was a director on the boards of both the Recycling Council of Ontario and Waste Diversion Ontario for several years.

In the early 1990s, most of old boxboard ended up in landfills. Mullinder chaired and steered the efforts of the innovative Boxboard Task Group committee of packaging mills and their brand owner customers that led the world in further recycling old boxboard. Working with brand owners, PPEC undertook pilot trials at Strathcona Paper and Paperboard Industries. It developed a Food Packaging Protocol to give the brand owners confidence that re-using residential boxboard in new food packaging would not be a health concern. Mullinder then worked to persuade other mills such as Atlantic Packaging to use old boxboard as filler material in their manufacture of corrugated board.

While at PPEC, Mullinder initiated several North American or world “firsts.” PPEC was successful in promoting the introduction of activity-based costing to industry-funded Blue Box programs across the country. PPEC was the first paper packaging association in the world whose entire mill membership was independently third-party certified to internationally recognized “chain-of-custody” standards. PPEC was also the first packaging association in Canada to publicly call for landfill bans on the type of packaging material its own members produced.

The contributions of J. David McDonald, John Mullinder and Alain Lemaire to the industry are lasting and transformational.

“I like to dig for the facts, to understand the situation as best I can, and often there are several sides to a story. The industry has a major education job ahead of it. I mean, one environmental group is telling people today that paper packaging is mostly made from market pulp taken from 1,000-year-old trees. For a start, most trees in Canada are under 100 years old. And secondly, most paper packaging in Canada is already 100 percent recycled content,” says Mullinder.

ALAIN LEMAIRE

Cofounder and executive chairman of the board of directors, Cascades. Alain Lemaire learned the importance of material recycling and recovery from a young age through his involvement in his family’s household waste recovery business. He developed the profoundly human values that underpin Cascades’ international growth today. Lemaire’s actions, and those of the company he co-founded with his brothers Bernard and Laurent in 1964, are guided by the values of respect, teamwork, fierce determination and communication combined with a deep-seated belief in sustainable development.

Lemaire studied at the Institut des pâtes et papiers (pulp and paper institute) in Trois-Rivières. By keeping close to operations and focusing his actions on efficiency, he expanded his expertise in

business development and recovery. In 2003, he was the third and last Lemaire brother to take the helm at Cascades.

An experienced leader and extremely logical thinker, Lemaire orchestrated the development of the Fine Papers Group and the continued growth of Norampac, which is now known as Cascades Containerboard Packaging. In 2006, under his leadership, Cascades proceeded to buy back Domtar’s stake in Norampac (Cascades Containerboard Packaging).

“My brothers entrusted me with the task of consolidating two cultures and achieving the expected synergies. By selecting the best elements, we were able to build a winning team. It was an exciting success! This entity later became a full-fledged Cascades property,” shares Lemaire.

He also participated in the development of Cascades’ most important investment to date: the Greenpac mill, a modern mill featuring the latest technologies in paper manufacturing.

Lemaire, along with his brothers, is a North American pioneer in recovery and recycling. Thanks to their vision, in the 1960s, Cascades began manufacturing paper from recycled fibres. They made their business model a system they called “the closed loop” which consists of recovering old paper and giving it a second life by making new recyclable paper. They were practicing circular economy decades before the concept was born and popularized.

Throughout his career, Lemaire has spent a lot of time on the plant floor. He knows the equipment, the work methods and the names of many employees and their families. His operating skills have served him well in plant acquisitions. He has repeatedly demonstrated his ability to acquire and make assets profitable. He was able to breathe new life and innovation into Cascades’ processes and, more globally, into the entire pulp and paper industry.

“What still motivates me are the people around us who, through their involvement, encourage us to do more and do better. These employees dedicated on all levels have at heart customer satisfaction, especially in terms of service quality. These are the same people who, through their skills, leadership, empathy and communication skills, will make a difference and will define the industry’s success,” says Lemaire.

LET’S TALK

Nova Scotia committee keeps tabs on forestry’s social license

By Maria Church

Aforester, fisherman, millworker, environmentalist, mayor, councillor, woodlot owner and equipment supplier walk into a firehall.

No, it’s not a joke, but rather the makeup of a committee meeting I recently sat in on in Pictou, N.S.

The firehall where we met neighbours the shuttered Northern Pulp mill that closed in January 2020, crippling the province’s forest sector that relied on the mill as a high-paying consumer of lowgrade wood.

The pulp mill, having passed through a handful of owners since its opening in 1967, has a problematic environmental legacy in Boat Harbour, known in Mi’kmaq as A’sek, that wore away at public trust.

Its current owner, Paper Excellence, is behind the meeting of the Environmental Liasson Committee – ELC for short. The ELC formed as an independent committee at Northern Pulp’s request to provide a platform to concerned citizens to better

understand what it will take to re-establish a pulp mill in their community.

With so many perspectives at play within the ELC, one common sentiment is clear among members, says ELC chairperson and former mill employee, Kimberly MacLaughlin: “None of the members here want the mill at any cost – we want the best mill you can get.”

After two years of meetings with community stakeholders, the committee has learned that, to improve public opinion of the forest sector, companies and individuals need to do more than recite the facts; they also need to listen to and understand the problems.

By sharing their story, lessons learned and battles won, committee members hope to help other jurisdictions in Canada that may face similar uphill battles to repair damaged social license.

Defining the purpose

The committee, established in September 2020, has grown to 16 members in an array of sectors. The ELC makes it clear

these members are not meant to be sector representatives, but rather independent voices drawing on their experiences.

The ELC’s initial goal was to brainstorm, without limitations, what the perfect mill would look like to them and the community. The committee heard and identified the issues after many meetings with the community and then proceeded to narrow them down. Committee member David McMillan, a forest manager and woodlot owner, describes their initial meetings as a room full of flipcharts. “We spent three or four meetings where every possible pie-in-the-sky idea about how this mill could be the best in the world, we defined,” he says.

An engineering firm in Montreal then reviewed the dream checklist, explored all available technology worldwide, and determined nearly all requests were possible with the right budget. “The price tag attached to that was approximately $365 million,” McMillan says.

The committee then took a hard look at their purpose and acknowledged that

Members of the Environmental Liasson Committee visit the McMillan’s woodlot in Nova Scotia.

Photo: Jill McMillan

they needed to define their goals. The resulting terms of reference document laid out their objectives as such:

• Attempt to identify, review and prioritize potential environmental, forestry, marine and community engagement issues and solutions related to Northern Pulp’s operations.

• Monitor Northern Pulp’s plan for a mill restart, including every aspect of community engagement, planning, communications and its building of mutually beneficial relationships with its stakeholders.

• Aid Northern Pulp in the identification and initial development of mutually beneficial relationships with its stakeholders by facilitating open and honest two-way communications with stakeholders committed to finding mutually beneficial solutions.

• Provide findings and feedback to the [court-appointed] monitor and Northern Pulp for further action related to the company’s operation.

More plainly put, “Our job is to pull in public perception,” McMillan says. “What does the public feel both for and against the mill. Our job is to pull those groups in, have an evening with them and listen to them – whether they be positive or negative – capture the essence of their arguments and put that together for Northern.”

The ELC is not a mouthpiece for Northern Pulp. They’re not tasked with promoting the mill or changing anyone’s mind. They’re an independent body and their sole purpose is to listen and understand the public’s concerns.

In doing so, they’re hoping to rebuild a broken relationship between a mill and its community.

Lessons learned

Over the course of two years, more than 50 guests have accepted ELC invites.

“We’ve had a variety of guest speakers, and we’ve had open frank discussions, it’s been respectful, and questions go back and forth,” MacLaughlin says. “It’s always been very meaningful conversations. Hard conversations – there have been fists slammed on the table at times – but it’s always good. And, at the end of the night, I think everyone has learned something from that.”

ELC vice-chair and forest manager Julia McMillan says members have found

it difficult at times since everyone has their biases, but through the process they’ve all learned a lot about how to have meaningful conversations based on peoples’ values.

“I don’t think it’s about science anymore. It’s about morals and beliefs of people. And the trust and differences and teaching. We’ve learned a lot about how to turn a conversation around and to really listen to what they are saying,” Julia says.

ELC member Nick MacGregor says the committee is continuously looking for new members with unique, perhaps conflicting perspectives to have the most impactful discussions about their community’s future.

“The ELC is trying to have productive conversations instead of a clean split and divide among groups. That didn’t work before, and it won’t work this time. So, we’re trying to find a different way to do things,” MacGregor says.

Two seats at the table are officially reserved for members of Pictou Landing First Nation (PLFN), whose land – Boat Harbour – was subjected to effluent pollution from the mill from 1967 to 2019. Invitations have been sent to meet with PLFN leaders to talk about the new effluent plan, but ELC members say they can understand their decision to decline, and that trust needs to be rebuilt first.

One approach proven to be particularly effective in building credibility is for ELC members to stick around after Northern Pulp’s town hall meetings to chat with community members about their concerns.

“They really valued us staying behind. Sometimes we were up to an hour afterwards talking about the issues … just having a conversation with them. And they truly appreciated that we did that. That evolved from an idea to a very productive process,” MacLaughlin says.

The conversations are candid, both sides speaking honestly about their perspectives on the mill. “There was a different trust level with the ELC members than with Northern Pulp,” Julia adds.

As the ELC provided Northern Pulp with feedback about those community concerns, the company’s presentations improved to address them.

The ELC is continuing to issue invites and meet regularly with community stakeholders. But those stakeholders need

to be willing to meet, and it seems, for some, there was too much harm done in the past to consider the future yet.

Uncertainty is certain

The future of the ELC, like the future of Northern Pulp, and indeed the entire forest sector in Nova Scotia, is unclear. There is also no alternative for the forest industry’s low-grade wood, which has led to a noticeable contraction of the sector. A possible path forward is for Northern Pulp to pass the Class 2 Environmental Assessment – the current regulatory hurdle to the mill reopening.

At this stage, even if the pulp mill were to reopen, McMillan says there likely wouldn’t be enough logging contractors still operating to supply the mill. “The supply chain is collapsing because of what’s happening at Northern,” he says. “There’s not enough loggers in Nova Scotia.”

Committee member Ian McKay, a now-retired environmental consultant, says he sees a disconnect in Nova Scotia – people do not understand how closely all industries in the province are tied to resource industries, and resource industries don’t typically understand the importance of public values.

“It’s not jobs at all costs, there has to be a balance,” McKay says. “Businesses need to understand that they have to be active and contributing members of society so that people know what good you are offering.

“If you want to gain social license, I think, it needs to be a continuous, nonstop educational experience as to what forestry looks like in Canada,” he says.

Julia says companies’ traditional approach of one-way outreach is becoming ineffective. “People don’t talk and communicate anymore very well. Social media has its rants and misinformation. But if this group can – and I’m hopeful – bring in enough people and have face-to-face dialogue we can come to a consensus,” she says.

ELC member Jack Lewis says their work will be worth it if the mill is able to reopen with accountability to the community. “I don’t say this lightly, but I truly believe that if you could restart the mill with the post-transformation deal, we collectively will have made it a better place with those changes and have a more environmentally friendly mill,” he says.

RELIABLE MILLS

Achieving success in equipment and mill operation reliability in 2023

By Treena Hein

Equipment reliability in every sector is reaching unprecedented levels each year, thanks to advances in software, sensors and much more. As Jeff Smith explains, “right now, the global pulp and paper sector is undergoing a technological transformation.”

Smith is the corporate head of asset reliability at Paper Excellence, and he has written extensively on reliability engineering.

There’s already been a huge shift in how equipment reliability and asset management are viewed across the pulp and paper sector and other sectors, from a reactive stance to a much more proactive stance in terms of maintenance regimes. Smith urges everyone in the pulp and paper industry to understand that ‘you can’t maintain your way to reliability.’

As with any industry transformation, there are early adopters, visionaries and those who are lagging behind right now. Here are seven critical aspects of reliability that all pulp and paper stakeholders should consider in 2023.

1) Use a company-wide strategy

Making sure all company plants are ‘on the same page’ with reliability means that equipment reliability and operational continuity at all locations will be brought up to the same high level. In its use of new technologies and digital tools to support business continuity and in planning, production and preventive maintenance to optimize operations and prevent downtime, leaders at Resolute Forest Products say aligning all facilities with the same systems and processes has been their “biggest achievement.”

Company leaders say “the lessons learned in making this change was the importance of a broad knowledge-based team, a good plan – including a plan for the change – strong execution, and support from leadership that includes adequate governance for the change.”

2)

Ensure cybersafety

Vijay Veeramisti, general manager of maintenance and engineering at AV Group’s Terrace Bay mill (AVTB) in Northern Ontario, stresses that “even though the world has embarked on adopting the Industry 4.0 standard, the view of our

team is to ensure its robustness and provide due consideration for cybersecurity. With so many mills in the world getting affected by ransomware attacks, critical processes and policies need to be followed to ensure that the systems are immune to these attacks. Cybersecurity protection using ISA 99/IEC 62443 standards has to be adopted to address and mitigate future security vulnerabilities in industrial automation and control systems.”

3) Use lessons learned

Other sectors, most notably petrochemical and mining, are ahead of pulp and paper with reliability, but Smith says smart companies are benefiting from that experience.

“The constraints are strong and the margins are razor-thin in pulp and paper, and we need to be the best of the best,” he says. “For example, at mines, the trucks already automatically report potholes so that transport is continual and both truck and road reliability stays high. The focus has transitioned from failure modes (the loss of function) and early detection of failures to managing the physics that

Photo: Paper

induce the failures. This transition is enabled by our ability to manage strain, stress and thermal cycles etc.”

4)

Build internal competencies

To build greater operational reliability, instead of completely relying on outside vendors, mills should strive to create higher levels of internal and independent competence in equipment monitoring interpretation, diagnostics and decisionmaking. Because mills operate 24/7, having more self-sufficiency in overseeing systems and troubleshooting rather than having to reach vendors across time zones and outside normal business hours is an important reliability consideration.

5) Understand ‘digital natives’

Comprehending the outlook of the digital native, says Smith, is absolutely integral to achieving reliability of equipment and operation. Digital natives are young people who have never known life without the internet and technologies such as digital data capture, storage and transmission.

“We must put the focus on people. We must create a new workforce culture to attract digital natives and support them to be successful. We have to ‘gamify’ training and tasks and do so much more,” he says.

Many pulp and paper firms are capturing the equipment and process reliability knowledge of older workers who are retiring and preparing it for transfer to digital native employees. Paper Excellence will be transferring its video content to augmented reality form. In parallel with these systems, Paper Excellence is also developing simulators to train younger workers in how to operate a mill.

6) Automate reliability

At the same time we address the digital natives, Smith says we must also have a focus beyond human labour. “We need to redefine what best practices are, and understand data to information, information to knowledge, knowledge to action, automatic feedback loops between cause and effect to achieve reliability,” he explains.

Smith notes that with rule-based diagnostics, a process anomaly or something like a known failure like an amperage spike in the wall of a clarifier, machines can be enabled to automatically set up their own work requests. “And that process anomaly,” he says, “is added to the AI’s knowledge base.”

7) Innovate with new tools

AVTB mill has many aging and obsolete systems. The mill's team is therefore using the most innovative ideas and technologies to enhance the plant’s reliability and performance.

“AVTB mill has a multitude of control systems and currently acquiring the data from DCS systems to process information is quite easy. But, this mill utilizes older technologies and innovation, therefore, plays a greater role,” explains Veeramisti. “AVTB in partnership with an India-based software firm developed protocols to acquire data from obsolete single-loop controllers and older-generation PLCs. This provides visualization for the process team to support operators in decisionmaking. The daily logs and reporting were also digitized so that it could ease tasks for the operators.”

In addition, because there are still many obsolete pieces of equipment still in use at this mill, 3D printing “has helped vastly” to maintain existing assets. “It helps to develop models to test parts,” says Veeramisti, “and then we can fabricate the spare parts with those.”

The team at AV Group’s Atholville mill also continuously explores opportunities to innovate for higher reliability. Built in the late 1920’s, the mill still has many pieces of the original equipment still in operation such as the can dryer sections of both pulp machines. “Although modern can dryer construction is similar, these dryers run on plain journal bearings with a bronze liner or ‘shell,’ lubricated by saturated grease ‘socks,’” explains maintenance and engineering manager Jamie Reinsborough. As lubricant is exhausted, the shells are exposed to increased wear and the risk of potential bearing housing or even journal damage goes up.

The team has tested shells machined from a composite material called Ryertex in the most demanding positions and found they work extremely well. “The Ryertex is able to withstand extended relubrication intervals, and to date, they have outlasted the bronze over five times the typical life,” says Reinsborough. “It’s a good example of how modern composites can extend time-based maintenance cycles for less machine downtime and lower maintenance cost.”

CONSTANT MONITORING

CLOSED

IMMEDIATE IMPROVEMENTS

FOCUS ON PROCESS OPTIMIZATION

Voith releases a new design of its OnQ FormingSens

The new design of Voith’s OnQ FormingSens focuses on solid, low-vibration construction, as well as a simplified electrical design. Voith’s experts reworked the mechanical mount so that the operator can fine-tune the penetration depth from outside the machine via waterproof mechanical gear. The sensor holder can be flexibly positioned on various existing dewatering elements in the former.

The permanently installed application is designed for higher safety as no direct contact between the operator and the forming fabrics is necessary. Improved sensor housing ensures higher long-term stability. The new generation OnQ FormingSens is installed to a nearby terminal box. It can be serviced by Voith experts via a service connection. This allows the solution to be better connected to customers’ existing infrastructures, such as the process control system.

OnQ FormingSens is used by paper manufacturers of different grades. With microwave technology, the solution measures fluctuations in water weight in realtime. Papermakers can use this information to systematically improve their settings, achieve a stable dry content at the end of the forming section and utilize the maximum dewatering capacity in the press section. For maximum user-friendliness and reliability, Voith experts have now further optimized the design of the solution.

Based on the measurements of OnQ FormingSens, the control loop can be closed with the fully automatic dewatering control OnC.Dewatering. The control system defines and stabilizes the dry content of each layer produced. voith.com

Valmet releases new lime kiln flame profile application for pulp mills

Valmet’s new flame profiling application is designed to enable real-time flame detection and monitoring in a pulp mill’s lime kiln environments. Valmet has also improved its Boiler Diagnostics Systems offering with updates to its Furnace Imaging System, IR. It now includes new optics and a port rodder, allowing for enhanced image quality and more accurate metrics.

The new flame profiling software is an add-on application for Valmet’s Visible Thermal Imaging System. The software detects the flame, measures its relative size and provides distance measurements from the end of the detected flame to user-defined markers.

The software is used in conjunction with the Valmet Visible Thermal Imaging System and is ideally suited for lime kiln applications. The system is engineered for durability and longevity and delivers visual and thermal analysis for optimizing fuel combustion and lime quality in lime kilns.

With the new updates to Valmet’s Furnace Imaging System, IR, the infrared camera system provides online visual analysis to see through flue gas and fly ash. It enables a comprehensive observation and analysis at full load. The new port rodder makes cleaning the camera more effective, according to the company. valmet.com

ABB’s QCS program to provide new features for pulp and paper mills

ABB’s new QCS Automation Software

Maintenance (ASM) program is designed to allow system evolution from older versions to the latest. It also provides continuous improvements between versions through access to regular software updates. The new program is designed to help pulp, paper, packaging and tissue mills to maximize their system investment.

With the new QCS ASM, when maintenance managers upgrade a system, they will benefit from a new system and will also have continual access to the latest attributes and releases of the current version of the software. Previously, these ongoing, incremental enhancements were not easily accessible, leaving mill managers locked into the ‘status quo’ of the day-of-implementation version of a specific system.

The new program also enables costefficient, proactive system management by offering multiple program levels to align with different customers’ needs. The new Maintain Plus level opens firsttime opportunities for customers with the latest version of QCS800xA to access the continuous software updates, new features, cyber security enhancements and patches within their current version whenever they want them. The Maintain & Evolve level caters to mills with classic or heritage QCS800xA systems that need to upgrade between system versions.

Both tiers include access to premium system documentation via myABB, ABB’s customer portal for managing their installed base, where licenses can be viewed and managed. Plus, both tiers include updates to any firmware-related devices within the QCS System.

QCS ASM is designed for customer maintenance managers, production managers and system engineers in all markets. new.abb.com

Photos: Voith, ABB, Valmet

GIVING BACK

The latest community outreach initiatives from the pulp and paper industry

The Canadian forest products sector is passionate and devoted – not just to the industry itself, but also to its local communities. Here we share the initiatives of pulp and paper companies working to make positive social, environmental and economic impacts across the country.

Excellence

Cascades’ Laurent-Lemaire Shared Services Centre team organized a mini Christmas market to benefit Centraide Centre du Québec, raising $1,100 through the sale of the team’s own creations.

the

generously

Alberta-Pacific Forest Industries completed a successful Fill-A-Box campaign in December 2022, with a total of 121 filled boxes collected for the Athabasca

Samaritan Food Bank and St. Albert Food Bank.

Let us help you share your successes. Tag @PulpPaperCanada or use #PPCGivingBack on Facebook or Twitter, or send an email to the editor at srayghosh@annexbusinessmedia.com. We’d love to hear from you!

Mercer Peace River Pulp team members donated

to the mill’s annual food and toy drive in December. The team shared

donations between the Peace River and Grimshaw Food Banks.

Paper

Canada donated $50,000 to the Canadian Red Cross to support emergency management operations in British Columbia and Saskatchewan.

Good

Photos: Cascades Facebook; Paper Excellence; Mercer Peace River Pulp Facebook; Alberta Pacific Forest Industries Facebook

Our standardized approach saves time and reduces regulatory scrutiny for the pulp, paper, tissue, packaging, converting and biomass industries

▶ Basic Orientations

▶ Customized Site Orientations

▶ Customized Employee Orientations

▶ Customized Truck Driver Orientations

▶ GateCheck Real-Time Verification

▶ Digital Badging