Kemira’s roots are in the pulp and paper industry and we are here to stay. Working closely together with customers, we continue to invest in R&D to create value through improved process efficiency, productivity and end-product quality. Our leading portfolio and best-in-class application expertise covers the whole process from pulping to coating.

Let’s work together to build value into paper.

www.kemira.com

Several months ago, I attended my first pulp and paper industry event, PaperWeek Canada, and I left the conference particularly inspired after one of the presentations. The Wednesday luncheon speaker was James Carr, Canada’s minister of natural resources, who delivered an insightful speech about the vibrancy of the forest products sector. He described it as an industry that is not only staying ahead of the curve, but is reshaping its future through world-class innovation.

He noted that wood fibre is presently being used in ways that would “have been unimaginable just a few decades ago” listing strengthening composite car parts, making vehicles lighter, reducing emissions, and replacing plastics and chemicals made from fossil fuels as several examples.

Alyssa Dalton Editor

“It wasn’t so long ago that this sector seemed to be on the ropes — its prospects grim, its potential limited, its practices criticized. To many, it seemed like an outdated, even dying, industry. But then something remarkable happened. Instead of wringing its hands, the industry rolled up its sleeves and began a transformation whose best chapters are still to be written,” said Carr.

He commended the industry for reaching out to its critics and making changes to its operations, as well as investing in new products and establishing new offshore markets. “Creating not just a new image but a new vision for what forest products could be. Now the forest sector has transformed itself into one of the most innovative parts of our economy, writing a success story most Canadians do not know well or hear often enough,” he continued. “And instead of patting yourselves on the back, you are focused on staying ahead of the curve.”

Carr pointed out that as the state of the softwood lumber agreement looms, we shouldn’t overlook the “underlying strength” of the forest products industry as a whole. “It is healthier than it has been in years, ideally positioned to help address four of the biggest challenges facing our country: combating climate change, driving innovation, creating economic opportunities for indigenous and rural communities, while advancing trade.”

The minister’s comments are a timely reflection of Canada’s rich history, as this year marks the country’s 150th birthday. It’s a poignant chapter in our heritage as many Canadian industries — including pulp and paper — are in the midst of great transformation.

My first foray into this industry couldn’t have been a more welcoming or enlightening experience, and I look forward to meeting many more of you. I encourage you to reach out and let me know what we should cover, whether it’s a trend, technology or one of your company’s latest successes. After all, this is your magazine too, and you should have a hand in shaping its content. In the meantime, keep innovating. PPC

Editor ALYSSA DALTON

905-713-4378 adalton@annexweb.com

National Accounts Manager LAURA GOODWIN 289-928-8543 lgoodwin@annexweb.com

Group Publisher/Director of Content and Engagement

SCOTT JAMIESON 519-429-5180 sjamieson@annexweb.com

COO TED MARKLE tmarkle@annexweb.com

President & CEO MIKE FREDERICKS

EDITORIAL/SALES OFFICES

80 Valleybrook Dr., Toronto, ON M3B 2S9

Phone: 416-442-5600. Toll Free: cda 800-268-7742; usa 800-387-0273

Art Directors

EMILY SUN

Circulation Manager

BEATA OLECHNOWICZ bolechnowicz@annexbizmedia.com

Print in Canada

ISSN 0316-4004 (Print)

ISSN 1923-3515 (Digital)

Account Coordinator

TRACEY HANSON thanson@annexbizmedia.com

PUBLICATION MAIL AGREEMENT #40065710

CIRCULATION

email: mchana@annexbizmedia.com

Tel: 416-510-5109

Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON M3B 2S9

SUBSCRIPTION RATES

Canada $53,95 - 1 year; $72.95 - 2 year

Outside of Canada - $101.95 per year

Occasionally, Pulp and Paper Canada will mail information on behalf of industry related groups whose products and services we believe may be of interest to you. If you prefer not to receive this information, please contact our circulation department in any of the four ways listed above.

Annex Privacy Office privacy@annexbizmedia.com Tel: 800-668-2374

The editors have made every reasonable effort to provide accurate and authoritative information but they assume no liability for the accuracy or completeness of the text or its fitness for any particular purpose. All rights reserved. The contents of this publication may not be reproduced in part or in full without the publisher’s written permission © Annex Publishing & Printing Inc.

Sustaining member, Pulp and Paper Technical Association of Canada; Member, Alliance for Audited Media.

“We acknowledge the financial support of the Government of Canada through the Canada Periodical Fund of the Department of Canadian Heritage.”

We are on a journey towards providing the best services experience for you. To keep your processes running smoothly and to optimize your production, explore our reliability and performance services. Our new technologies and industrial internet solutions upgrade your processes to the next level. On our Shared Journey Forward, we are committed to putting safety first, working close to you, earning your trust and providing the right solutions to your needs. Step on board at valmet.com/sharedjourney

Tembec has announced a four-year $136-million capital investment program in its Quebec facilities to improve competitiveness, centred on its specialty cellulose pulp operation at the Temiscaming manufacturing site. According to the company, this investment qualifies Tembec to benefit from electricity rebates applicable to large industrial power users under the Electricity Discount Program for Consumers Billed at Rate “L.” Tembec will be reimbursed for an amount of up to $55 million.

The program, introduced in the Government of Quebec’s 2016-2017 budget, applies to significant investments in the four-year period up to the end of calendar 2020 which increase productivity or improve energy efficiency.

Tembec says the proposed investments will cover various upgrades at the site, including the long-planned replacement of 11 existing pulp digesters. Work is already underway, with one digester replaced to date. Some of the new investment will go toward reducing greenhouse gas emissions, As well, the Temiscaming site’s high-yield pulp and coated bleached board manufacturing facilities will benefit from new investments as will the Matane high-yield pulp facility, says Tembec.

The site is supplied mainly with wood fibre from local forests and sawmills in the Abitibi-Témiscamingue region.

Resolute Forest Products has announced the immediate and indefinite idling of its paper mill located in Thorold, Ont. The facility, which employed more than 100 workers, has an annual production capacity of approximately 197,000 metric tonnes of newsprint on one machine using 100 per cent recycled furnish.

Resolute explains the decision is based on what it sees as significant decline in North American newsprint consumption, as well as with the increasing cost of recovered paper. The company had been taking downtime at the operation since mid-December 2016.

It explains it is collaborating with Stone House Investments Holdings, which is interested in converting the Thorold facility to produce an unnamed alternative product.

Resolute produces market pulp, tissue, wood products, newsprint and specialty papers, which are marketed in more than 70 countries. The company owns or operates some 40 manufacturing facilities, as well as power generation assets, in Canada and the United States.

Registration has opened for Tissue 2017 Conference and Expo, an international tissue industry event co-produced by TAPPI, an association for the worldwide pulp, paper, packaging, tissue and converting industries, and RISI, an information provider for the global forest products industry.

Scheduled for Oct. 3-6 in Miami, Fla., the new event brings together tissue industry professionals to gain insight on market trends, product and manufacturing innovations, and the latest industry challenges.

Tissue 2017 will feature sessions on the technical and operational aspects of the business to help improve efficiency and encourage innovation, said organizers, adding that several presentations will be by industry experts and financial analysts who will provide a holistic view of the market.

Attendees can also listen to an executive panel of leaders from North and South America, a customer panel that will give a buyer’s perspective, and a forum presenting the tissue industry’s latest academic and institutional research projects.

According to TAPPI and RISI, the event is expected to attract senior executives and mill operations management from major tissue manufacturers, financial analysts and investors, and machine, chemical and process suppliers.

The Alberta Forest Products Association (AFPA) said forest company leaders from across the province had a “very productive meeting” with Alberta Premier Rachel Notley in February, where they discussed Alberta’s forest sector and its trading relationship with the United States.

Meeting participants also included Deron Bilous, minister of economic development and trade, and Oneil Carlier, minister of agriculture and forestry. Topics of discussion included developing new uses for forest products in Alberta, expanding exports to Asian markets, and dealing with challenges posed by the softwood lumber dispute with the U.S. As the province’s largest export market, trading relationships with the United States are very important, explains AFPA, as Alberta exports approximately $2 billion worth of forest products, including lumber, pulp, and paper to the American market.

“We greatly appreciate the dedication of Premier Notley and her government to this very important file,” said Paul Whittaker, AFPA president and CEO. “By working closely together, we can ensure a strong future for the forest sector and the thousands of Albertans who work in it.”

B.C. announces $150-million reforestation investment to help fight climate

B.C. Premier Christy Clark has announced $150 million for the Forest Enhancement Society of British Columbia to plant tens of millions more trees, which she says will help fight climate change and create more than 3,000 jobs in rural British Columbia.

“This is an investment in our forests, in B.C.’s rural communities and the world’s clean air,” Clark said. “This initiative is another example of how we do business in B.C., striking a balance between environmental protection and economic priorities.”

The investment will be transferred in the 2016-17 fiscal year as a lump-sum payment to the society to advance environmental stewardship and, in particular, focus on reforestation initiatives throughout the province. The government previously allocated $85 million in 2015-16 to the society.

“Since 2005, we’ve invested over $445 million in reforestation through Forests for Tomorrow,” said Forests, Lands and Natural Resource Operations Minister Steve Thomson. “[This] funding will build on those efforts and ensure our children can enjoy the environmental and economic benefits we enjoy from our forests.”

“The rehabilitation and reforestation of damaged forest stands will provide significant greenhouse gas benefits and increase the use of low-quality fibre,” added Jim Snetsinger, vice-chair, Forest Enhancement Society of British Columbia. “The society is pleased to receive this funding and we will work with government agencies, First Nations, forest licensees and stakeholders to achieve these important objectives.”

Publicly traded Catalyst Paper goes private Catalyst Paper Corp. has announced it is no longer a publicly traded company.

The common shares of Catalyst were delisted from the Toronto Stock Exchange (TSX), and following recapitalization, the company is now privately owned by three major shareholders: Oaktree Capital Management, Mudrick Capital Management, LP. and Cyrus Capital Partners, LP.

According to the company, the move improves its financial strength and reduces its financing risk by wiping out its US$125-million debt without “adversely impacting” trade vendors and other suppliers.

The company explains it also obtained an order from the British Columbia Securities Commission confirming that, upon the effectiveness of the recapitalization and the privatization transaction, Catalyst ceased to be a reporting issuer in each of the provinces of Canada under applicable Canadian securities laws.

Pierre Lapointe, president and CEO of FPInnovations, has been recognized by the Royal Swedish Academy of Engineering Sciences and The Royal Canadian Geographical Society for his contribution to science both nationally and internationally.

“For me, this honour is much more than a personal recognition by The Royal Canadian Geographical Society and Royal Swedish Academy of Engineering Sciences,” he said. “It is recognition of the national and international stature of the Canadian forest sector and the worldclass achievements it has realized over the past decade.”

Lapointe was elected as an International Member of the Royal Swedish Academy of Engineering Sciences, the world’s oldest engineering science academy, as well as the College of Fellows of The Royal Canadian Geographical Society for his commitment to Canada and its remarkable geography.

household

Cascades is launching a new consumer line of tissue paper, consisting of three

varieties of toilet paper and two varieties of paper towels.

According to the company, the new products are “among the softest and strongest” on the market and will gradually replace the current generation of their Cascades counterparts.

“This will give consumers the comfort and performance they’re looking for in a product, while protecting the environment. We believe that through these new and improved products, Cascades will be chosen by a growing number of families across the country thereby increasing our market share,” said Mario Plourde, Cascades president and CEO.

Jean Jobin, president and COO of Cascades Tissue Group, said the research and development team have worked for more than two years reviewing each step in the construction process before arriving at the “superior quality” of Cascades Fluff and Cascades Tuff products. “No detail was overlooked in improving families’ experience — from the manufacturing formula of the paper to its embossing and packaging,” he said.

The company says the Fluff and Tuff brands are now available in grocery stores and pharmacies in Quebec as well as in many stores across Canada.

“MANAGING

“Each unit chose ambassadors to raise awareness of the cause. We owe this feat to their dedication and involvement, and also to the company’s decision to increase its contribution this year by generously matching the sum raised by the region’s employees,” said Jean Morin, first-time manager of Cascades’ Centraide Centre-du-Québec campaign. “Over the last few months, I’ve had the opportunity to see just how wonderful and charitable the people in this organization are, and how much they do for the good of the entire community.”

Ajay Vashisht – Evonik

Tim Jarvis – ERCO Worldwide

Drew Lyon - OVAL International

Apparel giant VF Corporation has released its first ever Forest Derived Materials Policy, which sets formal guidelines for its purchasing preferences and use of sustainable forest materials and products.

Mike Trivett – Valmet

Jason McCulloch - Kemira

“Deforestation and forest degradation continue to be a global issue affecting climate change and human rights,” said Letitia Webster, VF’s vice-president of global corporate sustainability. “This policy provides clear guidance across our many purchasing categories and it enables us to play our part in protecting the world’s forests.

*H.R. MacMillan Trophy for BEST MILL PAPER

*RUNNER-UP for full length paper (open to consultants and researchers)

*BEST SUPPLIER PAPER

*BEST NOVICE PAPER for first presentation by author

*BEST STUDENT PAPER

The policy aims to avoid the issues associated with deforestation and forest degradation, explains VF, including the loss of ancient and endangered forests, loss of biodiversity and habitat, use of forced labour in making forestry products and loss of indigenous peoples and local community rights. Emphasizing the use of products made with recycled fiber when possible, the policy also promotes the use of Forest Stewardship Council (FSC) certified paper and fiber, while striving to elevate all third-party forestry management certification systems.

Join us at:

Cascades said the management’s leadership on this has also been “remarkable, getting behind the cause year after year,” as well as “incredibly supportive and generous in encouraging employees to collect money from their co-workers.”

BC

WEDNESDAY, JUNE 7

INDUSTRY MEETINGS:

*PAPTAC Councillors (TBC)

“Cascaders should be proud of the difference they are making in thousands of people’s lives each day. When they give to Centraide, they are supporting a communal reciprocity movement that seeks to improve the lives of those in the greatest need,” added Mario Plourde, company president and CEO.

*Mill Managers & Sr. Executives

*Maintenance Managers RT

* Energy Reduction Steering Committee

* Alkaline Pulping Committee

*Papermaking Technology Committee

*Short Courses:

To network with peers, industry leaders and technical experts. Enhance professional development learning about new technologies, process improvements and what’s being showcased for the latest industry challenges.

The units’ ambassadors organized activities and put together testimonials to increase awareness of the cause. Within Cascades, more than 1,000 employees make weekly donations to Centraide Centre-du-Québec, for an average weekly contribution of $4.60. The organization’s mission is to end the cycle of poverty and isolation by taking action in areas that are likely to result in lasting and significant improvements in people’s lives, in partnership with local organizations.

We are also pleased to present a full Spousal Program

- Mechanical Reliability

- Pulp Bleaching

*Trade Fair

THURSDAY, JUNE 8

*Conference Forum Moderated

- Rod Albers, West Fraser & featuring

- Carlo Dal Monte, Cat alyst Paper

“Donating to Centraide means helping the less fortunate regain control over their lives. Life has its hardships. And everyone goes through tough times,” said Isabelle Dionne, executive director of Centraide Centre-du-Québec.

VF partnered with a number of NGOs and external stakeholders, including Canopy, a Canadian not-for-profit environmental organization dedicated to protecting forests, species and climate. Forest Derived Materials Policy supports the CanopyStyle initiative, which has a goal to eliminate the use of ancient and endangered forests in the production of forest derived fabrics, such as rayon and viscose, from the apparel and fashion industries by the end of 2017.

2016 HR MacMillan Trophy for BEST PAPER presented to BARRY HIRTZ, Canfor Pulp by Chair, KELLY PARFITT & Program Chair, GORD START

(Outline)

- Mats Nordgren, Valmet

- Paul Saunders, Winstone Pulp Int’l

- Shannon Huntley, FP Innovations

*Pulp Machine Superintendents

*Maintenance Managers RT

*2 Technical Sessions/Panels

*Trade Fair

Catalyst has launched Bistro, describing it as a diverse line of uncoated food service papers.

For inclusion in the Program, abstracts must be received by March 31st 2017 with paper completion by MAY 14th

Selection of papers is based on several criteria, including originality, technical merit and mill relevance

“When an apparel giant like VF expands its forest commitment with a policy like this, it adds incredible momentum to global forest conservation and climate efforts,” said Nicole Rycroft, executive director of Canopy. “From hang tags, to packaging to fabrics, some of America’s favourite global brands are protecting the world’s forests and the species that call them home.”

- Biotechnologies

- Process Control

- Recovery

- Brownstock Operations

- O2 Delignification Operations

- UBC Student Presentations

FRIDAY, JUNE 9

*5K Fun Run

*Trade Fair

Produced at the FDA-compliant Powell River mill in B.C., Bistro Wax, Bistro Foil and Bistro Bag — the first entrants to the new line — are “specially-designed” bleached grades for a range of food service applications, including wrappers, basket liners, deli papers, and flat and pinch bottom bags.

*Pulp Machine Superintendents

*Maintenance Managers RT

Time limit for presentations is 20 minutes with 5 minutes for Questions & Answers

Available in 15 to 40 pound basis weights (lbs. per 3,000 ft2), the brands are U.S. Food and Drug Administration (FDA) compliant and sustainably produced with available chain-of-custody certification under both the Programme for the Endorsement of Forest Certification (PEFC) and Sustainable Forestry Initiative (SFI) standards.

*5 Technical Sessions/Panels

* Keynote Feature Luncheon Speaker

should be submitted to PACWEST 2017 Program Chair: Steven Bull - Domtar Steven.Bull@domtar.com

This year, Cascades’ Kingsey Falls, Victoriaville and Drummondville units held an outstanding fundraising campaign to support Centraide Centre-du-Québec. Cascades and its employees managed to raise $525,000 for the organization, a whopping $165,000 more than last year.

The Western Producer is reporting that Sustaina-Pulp Canada intends to build its first straw-to-pulp mill in Belle Plaine, Sask. According to Les Schaevitz, company president, the process will convert cereal and flax straw into pulp suitable for making paper.

www.pacwestcon.net

Todd Hirsch – Chief Economist

ATB Financial

*Awards Dinner & Dance

The company hopes to build at Belle Plaine this year and be in production by late 2018. According to the media outlet, Sustaina-Pulp Canada plans to eventually build six plants in Western Canada — each would require about 500,000 tonnes of straw a year and save the equivalent of two million trees.

SATURDAY, JUNE 10

Annual Golf Tournament

JUNE 7 - 10, 2017

PROGRAM Committee:

Gord Start - West Fraser-Hinton Pulp

Steven Bull – Domtar

Surendra Singh – Alberta Newsprint

Kerry Morton – Zellstoff Celgar

IBMP ORGANIZING Executive:

Ajay Vashisht – Evonik

Tim Jarvis – ERCO Worldwide

Drew Lyon - OVAL International

Mike Trivett – Valmet

Jason McCulloch - Kemira

*H.R. MacMillan Trophy for BEST MILL PAPER

*RUNNER-UP for full length paper (open to consultants and researchers)

*BEST SUPPLIER PAPER

*BEST NOVICE PAPER for first presentation by author

*BEST STUDENT PAPER

2016 HR MacMillan Trophy for BEST PAPER presented to BARRY HIRTZ, Canfor Pulp by Chair, KELLY PARFITT & Program Chair, GORD START

TECHNICAL SESSIONS (Outline)

- Biotechnologies

- Process Control

- Recovery

- Brownstock Operations

- O2 Delignification Operations

- UBC Student Presentations

To network with peers, industry leaders and technical experts. Enhance professional development learning about new technologies, process improvements and what’s being showcased for the latest industry challenges.

We are also pleased to present a full Spousal Program

For inclusion in the Program, abstracts must be received by March 31st 2017 with paper completion by MAY 14th

Selection of papers is based on several criteria, including originality, technical merit and mill relevance

Time limit for presentations is 20 minutes with 5 minutes for Questions & Answers

should be submitted to PACWEST 2017 Program Chair: Steven Bull - Domtar Steven.Bull@domtar.com www.pacwestcon.net

WEDNESDAY, JUNE 7

INDUSTRY MEETINGS:

*PAPTAC Councillors (TBC)

*Mill Managers & Sr. Executives

*Maintenance Managers RT

* Energy Reduction Steering Committee

* Alkaline Pulping Committee

*Papermaking Technology Committee

*Short Courses:

- Mechanical Reliability

- Pulp Bleaching

*Trade Fair

THURSDAY, JUNE 8

*Conference Forum Moderated by:

- Rod Albers, West Fraser & featuring:

- Carlo Dal Monte, Cat alyst Paper

- Mats Nordgren, Valmet

- Paul Saunders, Winstone Pulp Int’l

- Shannon Huntley, FP Innovations

*Pulp Machine Superintendents RT

*Maintenance Managers RT

*2 Technical Sessions/Panels

*Trade Fair

FRIDAY, JUNE 9

*5K Fun Run

*Trade Fair

*Pulp Machine Superintendents RT

*Maintenance Managers RT

*5 Technical Sessions/Panels

* Keynote Feature Luncheon Speaker

Todd Hirsch – Chief Economist ATB Financial

*Awards Dinner & Dance

SATURDAY, JUNE 10

Annual Golf Tournament

Cellulose nanomaterials will contribute to everyday life is the theme for TAPPI’s 2017 International Conference on Nanotechnology for Renewable Nanomaterials, to be held June 5 to 8 in Montreal, Que. TAPPI Nano 2017 brings together the scientists and product developers who are incorporating these materials into applications that touch all of our lives, in products such as cement, drug delivery vehicles, water filters, flexible electronics, battery separators and more.

The wide interest in cellulose nanomaterials can be attributed to their unique properties, and the fact that they are a renewable resource, an attractive quality for companies looking for alternatives to fossil-fuel based polymers. As well, these materials are “new,” offering companies an advantage to creating new products.

While the paper industry has been leveraging the strength of cellulose nanomaterials in paper fibres for decades, these versatile materials boast unique properties that appeal to nearly every industry. Despite the fact that many products and applications that use cellulose nanomaterials are kept confidential, a steady rise in patents and technical papers are a testament to the growing interest in these materials. At Nano 2017, producers of cellulose nanomaterials will share application studies and new product grades.

Returning to Canada for the fourth time, Nano 2017 will present its firstever end-user panel. Representatives from Cabot, Ford Motor Company, Schlumberger and L’Oréal are scheduled to attend. Organizers say this session is expected to be of wide interest, as scientists and producers alike will learn about the requirements and issues end-users

Submitted

by FPInnovations

Themarket for printing and writing (P&W) paper is becoming increasingly competitive with declining demand. As a result, papermakers are paying more attention to performance in the pressroom. Researchers from FPInnovations’ Web Performance group were recently asked for help from a member company that was facing curl issues for its P&W paper. In addition to poor appearance of printed paper, curl may cause converting issues at the pressrooms, thus leading to customer complaints and significant production loss. FPInnovations’ expertise was requested in order to develop a uniform, accelerated curl test to be used by the member company in an attempt to implement a reliable, predictive method for quality control at the company’s mills. The approach first consisted of understanding the key requirements for a curl testing method to be successfully used at the mills. Following consultation with mills of the member company, it was

identified that the curl method should require minimal resources, provide results that are less operator-dependent, and be a strong predictor of end-use curl performance.

FPInnovations experts used their proven, 20-hour in-house curl method to efficiently predict and solve curl issues, as a basis for developing the accelerated curl test. Through modification of the existing method and validation of results, FPInnovations was able to provide an accelerated three-hour testing method by measuring curvature of paper strips upon ambient humidity cycling, without compromising accuracy. Several hours of brainstorming and pooling expertise led to the development of a device that could adapt to various mill situations, while performing efficiently and being cost effective. FPInnovations also offered on-site training and provided support for successful implementation of the method. Benchmarking of papers col-

will have when producing commercial products with cellulose nanomaterials.

Several sessions will be devoted to advances in paper and packaging applications. For several years, scientists have reported that cellulose nanomaterials can be used in papermaking to improve paper properties, enhance barrier properties, and add functionality for smart packaging.

Two lunch keynotes from prominent Canadian organizations will be featured this year. Trevor Stuthridge, FPInnovations executive vice-president, is the lunch speaker on June 6, while John Kozij, director of general policy, economics and industry for the Canadian Forest Service, will take the stage June 8.

To read the rest of this article, written by Colleen Walker, Ph.D., technical director of TAPPI, visit bit.ly/2o3p3q5. PPC

lected from each mill of the member company validated the accelerated curl testing method and identified further curl improvement opportunities using the new curl testing method.

To date, the testing units have been delivered and installed at two beta sites, leading to an important reduction in customer claims. The two sites are now using this method on a daily basis and the results are very positive. Installation at a third mill is in progress.

For more information, please contact Javad Saberian, researcher in FPInnovations’ Web Performance group, at javad.saberian@fpinnovations.ca. PPC

By Richard Walker, senior director, communications and public affairs, Forest Products Association of Canada

Canada grows on trees. As Canadians across the country gear up to celebrate the nation’s sesquicentennial on July 1st, the forest products industry is celebrating our storied past and bright future.

Since before Confederation, the forest sector has played a vital role in Canada’s history and is leading the way towards a prosperous future. Our industry has provided jobs to sustain our economy and has helped define Canadian culture. For example, did you know that in 1875, at the first organized indoor hockey game, not only were the sticks made of wood but they ditched the traditional ball and used a “flat round piece of wood” — the first iteration of the puck we know today?

Forestry was already in full bloom when our nation was just a seed. It fuelled the economy and provided the materials

that our new homeland was built on. By transforming the physical terrain to get products to market, villages, roads and railways sprang up in its wake.

To this day, the forest products industry remains a vital part of the Canadian economy, providing direct jobs for 230,000 Canadians coast to coast and a million indirect jobs while operating in more than 200 communities, primarily in rural or northern parts of the country.

Our industry is recognized by the federal government and customers from around the world as an environmental leader for how sustainably we manage our forests. Canada has 166 million hectares of sustainably managed, third-party certified forests, representing 40 per cent of the world’s certified forests.

We are embracing new technologies to expand our markets and are developing

innovative world-first products and many mills are now powering themselves through biomass.

New uses of wood are being discovered everyday — from cellulose being used in cosmetics, to lignin acting as a substrate for 3D printers, to rayon fabrics made from dissolving pulp that have a smaller environmental footprint than synthetics like polyester.

Canada’s forest products industry is clean, green and growing. We’ll be here for the next 150 years as Canada’s renewable industry provides jobs, products and prosperity for Canadian families. PPC

By Julie Copeland

Workplace safety initiatives are essential when it comes to maintaining a work environment that is both safe and productive. However, the safety programs you put into place don’t mean much if employees aren’t inspired to change old behaviours. So, how do you get your workers motivated?

The first step is taking a close look at what not to do:

• Disciplinary action: Not only does this require constant supervision, but it’s ineffective. In fact, this course of action could incite hostility and defiance.

• Slogans and posters: If safety isn’t your No. 1 priority, a sign saying otherwise doesn’t belong in your workplace. Safety signage is only effective if what it’s saying is true and lived up to. If not, it becomes a joke.

• Incentives: Focusing on the number of accidents as a way to reward employees sends the wrong message. They may be

afraid to come to you with an issue, which results in an unsafe work environment.

The fact is, there’s no one answer. Real and lasting change requires doing many things the right way.

The following workplace safety motivation tips are designed to engage employees in developing workplace health and safety, from establishing core values to making safe choices on the job.

Before any environmental health and safety program takes effect, it’s important to first establish the right goals and message. Motivation begins by engaging your employees’ hearts and minds. What is important to them about workplace safety? Take your employee feedback and turn their sentiments into a company slogan with real value.

By establishing a clear company vision, your strategic plan has a foundation. That’s where the big picture goals begin to build and take shape. Once long-term strategies have been developed, short-term tactics can be formulated. This

kind of planning paves the way to certainty about what, exactly, is expected from every employee.

When everyone is on the same page, there’s a sense of certainty about how processes should be carried out. Then, it will be much easier to implement a management system that holds employees accountable for safe behaviour.

A confused employee is an ineffective and uninspired employee. If your company is held to any number of accredited national or international safety standards, the expectation is your business must operate under a variety of procedures and practices. When different people manage these compliance areas, it creates dangerous compatibility gaps.

By aligning the common elements of all safety standards, it’s possible to set up a compliance process to work from one system. By having as little bureaucracy as possible in your management system, employees gain a better understanding of what is expected and conduct themselves accordingly.

What is your company’s current approach to developing a safe work environment? Opportunities to learn should not be used as a privilege or punishment. Workplace safety requires more than just giving your employees some information and leaving it at that. You have to create a safety learning culture at your organization.

• Training programs: Teach your employees how to apply and practice what they’ve learned about workplace safety and apply it to their daily decision-making.

• On-the-job coaching: Treat every incident or mistake as a learning opportunity rather than finger pointing and punishing employees. This sort of feedback and support fosters continual improvement among your team members.

When you create a learning culture around safety, your employees feel cared for rather than scolded. This approach encourages commitment, accountability and responsibility and creates a much more motivating environment than being forced to comply with safety rules out of obligation or fear of reprimand.

You might remember what it was like to be in their shoes — always being told what to do. This course of action, while necessary in many cases, may be met with resistance or outright defiance. To inspire employee involvement in workplace safety initiatives, gather input from your workers. Ask them how they want to create their own safety system and account for the results and search for opportunities to bring them into the fold. You must also pay attention to the issues they bring forth.

At the end of the day, your employees care about their own personal safety, health and well-being. Providing them with a means of engagement and ownership of your company’s safety initiatives shows them a level of respect they respond to.

Incentive programs designed to reward a worker with the least number of safety infractions can send the wrong message. A better way is to reward someone when you see them carrying out a safety measure, right then and there. But what

should you reward them with?

Your sincerity goes a long way. A faceto-face “thanks” has more power than you might think. This is best received when the recognition is personal to the individual and comes from his or her own manager. Of course, more tangible incentives of some kind can also help spark some motivation. Following up your heartfelt thanks with a little letter, bonus or gift, especially if their positive behaviour continues, is the most effective way to use incentives as motivation.

With specific departments, you should periodically round everyone up to revisit the safety initiatives you’re putting into practice. This is a time to update your team with any new information regarding workplace safety and a great chance for employees to give their vital feedback so you understand what is and isn’t working.

You might be asking yourself, “How is this motivational?” In addition to getting employees involved, you can demonstrate how and why the safety process is work-

ing. When people begin to see the positive results of eliminating workplace injuries — that there’s proven success — they’ll be even more motivated to get on board.

Fear of fault finding and the subsequent retribution is what keeps a lot of employees from speaking up about safety issues. When employees aren’t reporting safety infractions, it prevents you from knowing exactly how safe or unsafe your workplace really is.

You have to encourage an environment where those who bear the risks are respected for bringing safety issues to your attention. To give this some structure, set aside one day a week for any employee to bring issues to the table without fear of negative consequence. Review each item, find a resolution and document its completion.

Let’s face it: The reason for all the intense focus on workplace safety is because your employees’ health and well-being are at

stake. Although workplace safety is very serious business, it’s that very seriousness that also creates an obstacle for getting people to engage with it.

Lighten things up a little by adding some creativity or variety to get people involved. An example of making things more fun is a “safety wheel.” If an employee makes a suggestion for safety that you use, they get to spin the wheel and win a prize. Games like these breathe life to an otherwise somber topic.

Motivating employees and empowering them to take ownership of your safety programs are important steps in building a culture of safety within your organization. The tips outlined in this article are a good starting point and will help inspire your employees and increase engagement. PPC

As CEO of Arbill (www.arbill.com/arbillsafety-blog), Julie Copeland provides strategic direction, builds its global manufacturing platform, evaluates emerging market opportunities and oversees daily operations to ensure Arbill meets its customer, financial and operating commitments.

Moving the annual shutdown to every 18 months

By Martin Fairbank, ph.d.

When a kraft pulp mill has to shut down for 10 to 14 days every year for scheduled maintenance, millions of dollars are spent, and millions more in revenue from lost production are not coming in — resulting in a significant impact on cash flow and a company’s quarterly results. There is enormous pressure not only from management, but also from investment analysts, to complete these shutdowns on time and on budget.

But what if that annual outage could be extended out to every 18 months or even longer?

At PaperWeek Canada this past February in Montreal, Que., a session was held on shutdown strategy, featuring three mills that presented their experience with extending the period between major shutdowns. The panel was hosted by Eric Ashby, general manager of Domtar’s Windsor, Que., mill and newly appointed chair of Paptac’s executive council.

First to present was Ryan Kazakoff, maintenance superintendent and shutdown coordinator at Domtar’s Kamloops, B.C., mill. He told the audience that four to five years ago, the shutdown budget and costs at his mill were not under control. In spite of meetings held year after year on how to improve the shuts, the same items came up each time.

He decided it was time to change their approach. They did some benchmarking within Domtar, with other pulp mills in the industry and even in other industries, to compare shutdown cycles and documented some best practices. One of the

first follow-ups was to instill better discipline in their planning, execution and improvement cycles.

While the benefits of a shutdown that is planned and executed efficiently are easy to understand, an intriguing idea emerged from looking at some other mills — extending the period between shuts from 12 months to 18 months or longer. Intuitively, one would think this is more risky. With a longer period between scheduled shuts, there might be more breakdowns, necessitating unscheduled downtime. But if it’s backed up by better predictive and preventive maintenance, these risks can be mitigated. Looking at historical records of unscheduled breakdowns, Kamloops determined through Pareto analysis that 80 per cent of the risk comes from 20 per cent of the equipment. Typically, the two pieces of equipment in a kraft mill that drive the critical path

for a shutdown schedule are the recovery boiler and the continuous digester. And Kamloops’ analysis showed that the actual time used during the annual shuts for working inside these two pieces of equipment amounted to only 50 per cent of the shutdown window for the recovery boiler and 20 to 25 per cent of the shutdown window for the digester. This means the length of the scheduled shutdown does not necessarily have to be longer when it is held less often.

Kamloops’ expectation was that with a longer period between shutdowns, over a three-year cost cycle, the cost of industrial cleaning and mechanical, electrical and instrumentation repairs would go up. On the other hand, with only two shuts instead of three over a three-year period, the cost of several other items would subsequently decrease, including scaffolding, rental of equipment and trailers, contractor overhead, training and chemicals.

Special Mill Program and Discounts

Get more details at PaperCon.org

Be part of PaperCon 2017 as a Sponsor and/or Exhibitor

See available opportunities at PaperCon.org

© Career Advancement and Tutorial Sessions (with CEUs)

© Networking Opportunities with industry professionals and experts

© Young Professionals Program and Couch Pit University

© Comprehensive, peer-reviewed Technical Program

© Latest Technological Advances and Processes impacting the industry

© New Technology Showcases

© Hot Topics Breakfast Roundtables

© Expert-led Panel Discussions with insight into future trends

© Poster Session highlighting new ideas and solutions

Papermaking • Coating & Graphic Arts

PIMA • Young Profes sionals

The second presenter was Bob Ostaff, kraft pulp production manager at Resolute’s Thunder Bay, Ont., mill. They were looking for ways to become more costcompetitive, and since the annual outage has a large impact on costs, they looked at how to move to an 18-month cycle without incurring additional risk. At first, they faced a lot of skepticism from operators, whose reaction was: “The equipment is not being taken care of now, and you’re going to do less maintenance?” But the message from the corporate level was: “A lot of mills in the industry are doing it already, so why can’t you?”

Resolute selected the Thunder Bay mill to pioneer the 18-month process, because in this case, a shutdown not only meant lost revenue from pulp production, but also from the sale of renewable power to the Ontario grid. Resolute decided the benefits of a successful implementation would be high.

In the last couple of shutdowns, the mill had not hit the targeted budget or timeline, so they had to develop a plan. They set up a review process using personnel from the mill, the corporate office, suppliers and regulatory agencies to look at what they did in the past and what would need to be done in the future. In the past, they had never really had a shutdown planning group, so that was one of the first changes made — three employees now do nothing but plan the 18-month shuts using a more rigorous approach.

One advantage of this new approach is that they are now able to prepare detailed job packages, with pictures, procedures,

Communication with employees about the how, when and why of a new strategy is very important, as it helps gain employee buy-in, ensuring its success.

and safety and environmental information. These packages are sent out to contractors for quotes, and the mill now has the power to negotiate better prices on these contracts, because both sides know exactly what the job being quoted on involves.

Thunder Bay’s vision of success for this exercise includes reduced maintenance spending on shuts, with production risks mitigated, improved reliability, and important lessons that can be transferred to other Resolute sites.

One of the barriers that had to be overcome to implement the new strategy at all the mills presenting at PaperWeek was the effect on employees. When the annual shutdown was traditionally held in spring, employees planned their lives around it, and it was a good fit with the spring thaw season, when log trucks are regulated to carry lighter loads. With an 18-month schedule, a shutdown could take place in the spring, or sometimes in the fall, or not even in a calendar year at all. Having a shutdown in the fall could require some employees to be on site when they traditionally take vacation for hunting season. Communication with employees about the how, when and why of a new strategy is very important, as it helps gain employee buy-in, ensuring its success.

Benefits Potential risks

• Increased number of operating days

• Less shutdown costs over three years

• More time to implement changes to shutdown planning, execution and improvement cycle

• More time available for training

• Increased shutdown complexity

• Shutdown date is more movesensitive

• Higher dependency on availability of specialized skills and equipment

• Assets are under-maintained and have a decreased life span

• If a shutdown is skipped, others may be longer and more expensive

The process of moving away from an annual shutdown requires a lot of patience and dedication. Ostaff stated a five-year plan as a requirement, and Kazakoff opined that it will take six to seven years to fully evaluate and optimize the longer time cycle.

The third speaker at the session was Vincent Charbonneau, assistant maintenance superintendent at the Domtar Windsor mill. He is planning the mill’s first 18-month shutdown for October 2017. To support the longer period between major shuts, Windsor uses a “pit-stop” strategy of shorter shuts for cleaning when production rate is decreasing due to bottlenecks, approximately every six months. For example, they use short pit-stops of two days to descale the lime kiln. They also take advantage of these pit-stops to carry out non-destructive testing inside the digester.

A risk of moving to less frequent major shutdowns is the possibility of a major failure occurring to a pressure vessel, such as the recovery boiler or the digester due to corrosion. Pulp mills have to persuade their insurers that they are taking all necessary steps to mitigate this risk, by performing predictive and preventive maintenance. Non-destructive testing, such as ultrasonic inspection of welds and boiler tubes, is a useful tool, as well as vibration testing and oil analysis of rotating equipment. Physical inspection is important too. Ostaff mentioned “rats in the digester” — it turned out he was not discussing rodents but Remote Access Technology, a company that inspects and services difficult-to-access areas through technicians who use ropes and harnesses to get to these areas, saving pulp mills from having to erect scaffolding.

All these mills have learned that a longer shutdown cycle requires a much more effective shutdown planning, budgeting and execution strategy. Equipment reliability is of paramount importance to reach their goal of more production days over a three-year cycle. PPC

Heat and CO2 from the Resolute pulp mill will power one of the most efficient greenhouses of the country, the Toundra Greenhouse

By Guillaume Roy

48.65 ° North. It’s -10 °C outside and a foot of snow already covers the ground. An intense orange light has appeared in the Northern Lac Saint-Jean skies just over a month ago showing some signs of industrial development. But forget about any forestry or aluminum development like the region is used to. This time around, it’s all about cucumbers.

And it’s big — a $38 million greenhouse project spreading over 8.5 hectares of land. Inside, state-of-the art Dutch technology produces amazing results: 360 cucumbers growing per square metre, much more than the forecasted 275 per square metre.

“It is now the most productive greenhouse in Canada,” states Eric Dubé, Toundra Greenhouse general manager, who compares the productivity to Quebec’s (80 cucumbers per square metre) and Canada’s (200 cucumbers per square metre) average. This means the production that started in November should reach a much bigger figure than the 45 million cucumbers projected.

At the greenhouse’s inauguration on Dec. 14, 2016, everybody was celebrating the creation of 200 new jobs in this rural area. Local investors, Eric Dubé, Caroline and Bertrand Fradette, are particularly thankful to Richard Garneau, CEO of Resolute Forest Products, who not only believed in the project, but also convinced his board to invest in the project to become a 40 per cent shareholder of Toundra Greenhouse.

Quebec Premier Philippe Couillard, who is also the local MP, was also a key player in the project.

“The government officials never saw a

project like that before and all doors were closed at first, even when I was asking,” said Dubé. “We need to learn lessons and use this story as a case study to be more open to innovation, because we have great opportunities to innovate in rural areas.”

Indeed, the project had to go through many phases and countless problems before the first cucumber was harvested in November.

When I moved to St-Félicien, Que. in 2008, the Agrothermic Park dreamt by the local mayor, Gilles Potvin, was already a latent project looking for a promoter.

Potvin started dreaming about this in 1989 when he was the town’s industrial commissioner. Back then, wood residues were a problem and people were looking for ways to use them to create value.

That’s when a co-generation plant idea came up. The plan: turn the wood residues into power. A good but kind of wasteful idea when we know that 80 per cent of the power generated is lost in the form of heat.

Potvin then came up with the idea of an Agrothermic Park. The extra heat could be used as an industrial economic development lever to develop a 30-hectare greenhouse hub and a 20-hectare industrial area for forest products.

At first, the project looked perfect, but as time went by, wood residues gained value and became scarce as more projects arose. From $5/ton when the plant was built in 2000, the wood residue price reached $18/ton in 2006. And since the co-generation plant negotiated a 25-year deal with Hydro-Québec at 6 cents per kWh, the plant’s future was shaken up.

In 2009, St-Félicien received a $5-million subvention to build the heat-transfer

turnup performance and reduce dusting and linting at the same time. Collaborate with the Ingredion Idea Labs™ experts.

infrastructure from the co-generation plant to a 28-hectare field they bought across the street.

Many promoters evaluated the project but nothing serious came out of it. Who would make a big greenhouse investment that relies on an uncertain energy source?

But everything changed when a new guy in town, Dubé — a Royal Bank investor from Montreal — moved to the region when the bank was heavily investing in agricultural lands. When accused of land grabbing, the bank stopped its plan, but Dubé stayed in the region to invest in a potato business and other agricultural projects.

When he met the mayor, he learned about the Agrothermic Park, a big and ambitious project he liked right away. He then met local investors, Bertrand and Caroline Fradette, who owned a lumber mill back in the 1970s, who also had interest.

In 2015, the co-generation plant was for sale and they prepared to make an offer, but Enel Renewable Energy sold their 21-megawatt power plant to Greenleaf Power.

To find a reliable source of thermal energy they decided to look away from the co-generation plant. Who was the other industrial partner with heat available nearby? The answer: Resolute Forest Products, with its pulp mill 15 kilometres away from the downtown area.

When Dubé asked for a meeting with Garneau, Resolute’s CEO, in February 2014, he was offered only/just 10 minutes for his pitch.

“We ended up spending an hour together. This was the beginning of a successful relationship,” Dubé recalled at the greenhouse’s opening ceremony.

Stunned by the proposal to make a business partnership to grow cucumbers, Garneau readily asked, “Is there a market?” because he needed this kind of information to convince the Resolute board to jump in. And Dubé provided it quickly. By July, he came back with a promise from grocery retailer Sobey’s to buy all their cucumber needs after meeting with Yvan Ouellet, the company’s procurement and merchandizing vice-president.

From then on, Resolute agreed to be a 40 per cent partner in the project and to allocate a field close to the pulp mill, but Garneau stated his conditions. Local partners had to come up with a good business plan and use an efficient and recognized technology. The municipality also needed to be a partner and the workforce should be found locally.

“We believed in this bold and crazy project. And today, cucumbers produced here can be found in 450 points of sale in the province,” Dubé said.

Sobey’s commitment helped find the funds, but the hardships were not over. For example, the agricultural zoning had to be changed. Local acceptability was challenged when the mayor proposed to invest millions of dollars in the water-diverting infrastructure. Construction workers also protested when Dutch workers came to build the greenhouses.

But in the end, the project was completed according to the planned schedule and budget. This is in part due to the worldrenowned greenhouse-making experience of Kubo and Stolze, the Dutch consortium in the venture, which made projects in cold areas like Russia, Finland and Alberta. AAB, a Dutch consulting company, also supervised all stages of the projects.

“We are able to provide the world’s best technology because

we have so much experience and knowledge,” notes Peter van der Kraan, Kubo’s financial director. “We can provide the highest productivity at the lowest cost. We can also realize a project like this one very fast.”

Kubo — which has also worked on other projects across Canada — received a $10-million contract with Toundra Greenhouse.

In the greenhouses, an integrated computer system controls more than 700 environmental parameters, ranging from lighting, humidity, fertilizers, and CO2 level controls. To improve plant growth, extra CO2, coming from the natural gas combustion is injected in the greenhouse, increasing the concentrations from 340 ppm to 800 ppm. But that’s not all, since CO2 solutions, a carbon capture specialized business, will build its first commercial $7.4-million project to feed the greenhouses with 30 tons of CO2 per day captured from the pulp mill – the equivalent of 2,300 cars off the road. To do so, CO 2 Solutions, who already has a 10-ton per day demonstration unit in function, uses an enzyme-based proven technology, says Evan Price, the company’s president and CEO. The project will be completed in 2018.

And that’s not the only byproduct coming from the mill, since 25 per cent of the energy comes from the heat released in the pulp-making processes. The remaining energy comes from TK Topboiler natural gas boilers.

Another particular aspect in the greenhouse is that the plants grow off ground on a stone wool artificial substrate, used primarily as a physical support. Those plants, which receive 20 hours/day of lighting, are irrigated and fertilized simultaneously — a process called fertigation — and all elements not absorbed are recycled.

Likewise, 98 per cent of the water is recuperated from precipitations stocked in basins or recycled through the recirculation system. Toundra Greenhouse does not use pesticides and prefers to do integrated pest management. All of this is just the first phase of the $100 million project covering 34 hectares planned over the next years.

More good news for them: Subway just signed a contract to supply all 600 of Quebec’s and 250 of Eastern Canada’s restaurants with Toundra’s cucumbers. Another step to increase the proportion of locally made cucumbers on the market, previously at five per cent before the Toundra project.

For Potvin, this project exemplifies the birth of a new ecological industrial era, where waste can become huge opportunities for others. PPC

This feature was previously published by Canadian Biomass.

By Alyssa Dalton

Mark your calendar for PacWest 2017 (www.pacwestcon.net), an annual gathering of the Canadian pulp and paper industry for three days of technical and businessoriented sessions. Organized by mill executives from West Fraser, Domtar, Alberta Newsprint and Zellstoff Celgar, along with the IBMP, an organization of industry suppliers, this year’s conference will run June 7 to 10 at the Fairmont Chateau Whistler in beautiful British Columbia.

Picking up on the event theme, Managing Resources for Success, the technical program will offer sessions on process control, bio-products and energy, recruitment challenges, emerging technologies, kraft pulping, pulp and paper making, and more. For junior employees, the conference committee says the short courses will help delegates improve their technical skills, connect with new contacts, and problem solve with industry colleagues. As well, senior personnel can engage in discussions that contribute to a greater focus on the challenges ahead and the keys to overcoming them. The committee says delegates often report they have gained an idea or solution to a problem that was well worth the cost of attendance.

PacWest will also host roundtable discussions for mill managers, maintenance managers, and pulp machine superintendents, enabling participants to come together and discuss common, industryspecific issues.

“Although this is a very competitive business, there is a strong co-operative atmosphere that pervades the meetings and conference discussions,” says Kerry Morton, second vice-chair. “There is an understanding that by sharing the experiences and solutions to industry challenges collectively we are all more sustainable.”

Delegates can hear from a diverse mix

of industry experts scheduled to speak, including: Carlo Dal Monte, Catalyst Paper; Mats Nordgren, Valmet; Paul Saunders, Winstone Pulp International; and Shannon Huntley, FPInnovations.

According to conference co-chair, Gord Start, this year’s forum speakers either work directly for the industry or are a consultant or supplier “with considerable experience,” and will be able to provide insight into the tools and resources required to keep the industry competitive, innovative and viable.

Also on the schedule are presentations by UBC students, a staple of the conference agenda for the past several years. The trade fair, highlighting some of the industry’s latest innovations, will run during the first three days of the event.

Todd Hirsch, ATB Financial chief economist, will take the stage on Friday as the luncheon keynote speaker. For more than 20 years, he has worked as an economist at Canadian Pacific Railway, the Canada West Foundation and the Bank of Canada.

There are several social events planned for the week, including the 5K Fun Run/ Walk on Friday morning. A cocktail reception, followed by the awards dinner and dance, conclude the program that evening. On Saturday, attendees can unwind with a golf tournament and BBQ. A full spousal program is also offered.

Couldn’t make it to the 2016 event? Visit bit.ly/PacWest2016 to read our highlights. PPC

Increase strength with less fiber as you reduce your reliance on synthetics. New starch solutions from Ingredion Idea Labs™ sciencebased problem solving help you improve your current packaging and create super strong, lightweight products.

KSB Pumps has introduced new members of its Movitec series of high-pressure pumps. According to the company, the new models are designed to be mounted in a horizontal arrangement, with the inner threaded inlet nozzle parallel to the axis of the pump and the outlet nozzle positioned to feed a vertical or horizontally aligned outlet pipe. Available in five sizes with different numbers of stages, the new pumps offer a maximum flow rate of 26 cubic metres per hour and the maximum discharge head is 195 metres. Fluid temperature can range between -20 C and 140 C. KSB says the H pumps, like other members of the Movitec family, are engineered to reduce energy costs through the use of efficiency-optimized stainless steel stage casings and impellers. Suitable for a range of applications, the pumps are ideal for water distribution, water treatment, cooling water supply, boiler feed and pressure boosting. www.ksb.ca

Severe service valve task force created to establish new standards

Last fall, an interest group led by CGIS president Ross Waters presented their request for a new standard practice — on defining reliable principles and parameters for what separates a severe service valve (SSV) from a general purpose valve) — to the Manufacturers Standardization Society of the Valve and Fittings Industry (MSS). A MSS technical committee determined the proposal would be a beneficial project to pursue and as a result, an official task force was created, to be

led by Waters.

The task force will now determine the minimum requirements a valve needs to be able to perform to when faced with extreme conditions, whether from pressure, temperature, toxicity, solids or usage.

“By creating a rigorous standard for severe service valves to adhere to, we can ensure end-users can protect both their workers and the environment,” Waters said. “We’ve seen countless examples where general purpose valves were used in a severe service situation, which led to high operating costs, loss of process containment and control, and significant damage to the environment. This task force was created with the goal to drastically lower these statistics.”

Along with providing objective principles and parameters on how to define and identify SSVs, the proposed standard practice will also provide the basis of a definition that is currently being referred to in other MSS work, like Special Leak Test Methods and Procedures for Valves.

Over the upcoming year, the task force aims to determine a “clear and measurable definition and identification process” with the end goal of having a standard practice for end-users and manufacturers to follow, adding that this resource will be “critical” for selecting the right valve for the application going forward. www.cgis.ca

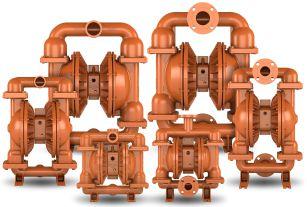

Wilden has released ductile iron versions of its Advanced FIT air-operated doublediaphragm (AODD) pump, which it says is specifically designed to be direct replacements for existing pump installations, boasting bolted product containment, easier maintenance and more efficient operations. Available with a range of elastomer options for severe applications, the pumps are offered in sizes from 38 mm (1-1/2 in.) to 76 mm (3 in.). Wilden says the pumps fit bolt-to-bolt and pipe-to-pipe in existing fluid-handling piping systems

that utilize competitor pumps or Wilden Original or Advanced pump models. Promising “superior flow rates and easier installation compared to other brands,” the pumps come equipped with the FIT wetted path that claims to minimize the number of fasteners and allows for single socket reassembly for “faster, easier maintenance.”

www.wildenpump.com

Gate valves designed for difficult and abrasive media

DeZURIK says its KGO O-Port gate valves are designed to be used on virtually all types of liquids, slurries and dry materials, adding that they are specially constructed to handle high-consistency paper stock, wood chips and fly ash, as well as slurries with high solids content and highly viscous fluids. Available in sizes 2-24 in., the KGO-CST valves feature a cast body rated to 150 psi CWP. Metal or resilient seats are available in 316 Stainless Steel, Terpolymer of Ethylene, Propylene and A Diene (EPDM), PTFE or Reinforced PTFE. www.dezurik.com

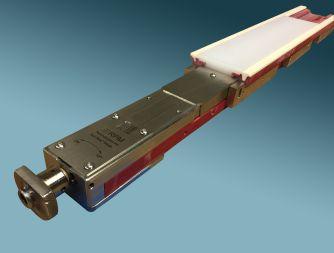

Kadant Solutions has launched its Conformatic AL creping holder, describing its as a next-generation holder that incorporates the “latest technology bringing improved blade holder performance to the tissue market.” The holder is suitable for use in all Yankee doctor positions including cutoff, creping, and cleaning, says Kadant. According to the company, upgrades to the holder’s adjustability were achieved with a proprietary adjustment mechanism promising “precise control” of the holder profile across the entire Yankee face without the need for edge fingers. The “robust construction” is designed for today’s highperformance tissue machines and features a self-conforming liquid tube, a backup blade, and a quick removal feature that allows the holder to be removed for cleaning and maintenance. Optional smart features can be integrated to provide realtime process feedback such as vibration and load. The holder is available in new doctor systems or as a retrofit to existing Conformatic holders. www.kadant.com

SDT has announced its latest innovation in ultrasound technology. Aimed specifically at solving problems related to machinery lubrication, LUBExpert promises to be a unique solution to the most misunderstood maintenance task — bearing re-lubrication. LUBExpert boasts strong measurement capabilities and clever user interface to create the Onboard Lubrication Assistant. An intelligent, algorithm driven assistant guides you to a “perfect lubrication,” says the company, adding that with only a few machine parameters, LUBExpert monitors each stroke of grease and its effect on bearing friction and temperature. Lubricant levels are reported with “Good,” “Bad,” or “Suspect” status report for each bearing. The unit features Ultranalysis Suite

(UAS) integration, which includes: six node trees define asset location; userdefined databases and surveys; alarms and analysis with 4CI; before/after condition report; and grease consumed report. www.sdtultrasound.com

Meridium and Beamex combine capabilities to optimize calibration practices

GE Digital’s Meridium has partnered with Beamex to combine its asset safety and data analytics capabilities with Beamex CMX calibration software.

Utilizing the Meridium software with Beamex CMX Calibration Connectivity, Meridium’s APM Calibration Management application populates the CMX calibration software with asset hierarchy, calibration profile and, in turn, receives calibration results and other intelligent device data from Beamex CMX. This solution delivers the benefits of the best of both APM and calibration management functionality in an integrated solution for an expanded view of asset health with metrics on time-based performance as well as dashboards for high-level statistics such as per cent of pass/fail based on hierarchy location, they say. A user can analyze and determine the most important measurements in their site based on Meridium’s APM asset criticality analysis that aligns with the risk-based approach defined in ISO 9001-2015.

The solution, according to the parties, claims to enhance the ability of organizations to obtain precise calibrations for reduced risk and compliance with industry standards. It also promises to broaden the scope of assets that can be calibrated and includes customizable calibration reports to improve analysis and documentation of asset status. As well, it can help manufacturers comply with industry regulations such as ISO 9001:2015, 21 CFR Part 11, and IEC 61511. www.meridium.com; www.beamex.com

Elevate coverage to achieve uniform coating and improved print quality with PEN-COTE® D coating binder. It’s nature-based, ready for use and engineered to perform. Get Ingredion Idea Labs™ science-based problem solving.

Chesterton introduces 442C cartridge split mechanical seal

Chesterton describes the 442C cartridge split seal as the latest innovation in mechanical split seal technology, combining “superior seal performance with the ease of installation of a cartridge seal.” The split seal technology addresses the inherent limitations found in conventional cartridge split seal designs by minimizing installation complications and excessive leakage, says the company, adding that it offers easy installation and replacement without the need for teardowns. The 442C design also offers “maximum installation flexibility” with its short axial length and flexible gland positioning. According to Chesterton,

the 442C simplifies split mechanical seal repair by using a standard spare parts kit, enabling users to lower inventory costs to maintain operations. The split seal can be installed without checking for face alignment or touching the sealing elements — the deal faces align themselves and do not have to be handled or worked, adds Chesterton. chestertonrotating.chesterton.com

Solenis says its new ClearPoint Biofilm Detection & Control program will help identify and prevent biofilm growth in extensive and complex cooling water systems. According to the company, the ClearPoint program merges equipment, chemistry and service into a single, integrated solution that detects the early onset of biofilm and intelligently doses the right combination of proprietary Solenis chemistries to help remove it. Use of the program, it explains, can help promote improved heat transfer performance, lowered water usage and reduced

corrosion and equipment damage caused by biofilm fouling.

It’s estimated that 20 per cent of corrosion comes from microbial sources, leading to pitting, deposit formation and premature repair and replacement of plant equipment, says Solenis, adding that biofilm is four times more insulating than typical mineral scale, greatly reducing heat transfer efficiency and increasing operational costs.

The program includes: an OnGuard 3B analyzer for real-time, in-situ monitoring using an ultrasonic probe; Biosperse microbiocides, biopenetrants and dispersants for biofilm removal and prevention; and service.

www.solenis.com

Coldwater Group has announced the acquisition of RPM Technologies, a supplier of drainage equipment and drainage process solutions for more than 14 years with a product line that includes the patented Acu-Pulse and Acu-Step products. According to RPM, the Acu-Pulse blade is the only adjustable pulse generating forming element of its kind offered to the paper industry. Its design allows for on-the-run adjustment which enables the papermaker to optimize from grade to grade without having to change blades, it says. Meanwhile, the Acu-Step blade allows for on-the-run accurate vertical adjustment of the blades surface to the elevation of the forming fabric, it notes.

“The acquisition of RPM’s innovative and value-driven drainage products and services makes Coldwater’s industry leading drainage product line even stronger,” said David Withers, Coldwater president.

The parties say all RPM operations will be transitioned to Coldwater facilities in either Appleton, Wis., or Atlanta, Ga. www.coldwaterseals.com

The Valmet Chip ‘n’ Bark moisture analyzer (Valmet CBA) promises to offer pulp mills a new tool to advance productivity and efficiency. According to the company, the tool replaces “time-consuming” oven-dry lab measurements by using microwave technology to continuously measure chip, bark, forest residue biomass or recycled wood moisture. A sample flow is taken from the conveyer chute, pushed through the unobstructed measurement chamber and then returned to the chute. Continuously measuring wood chip moisture provides the means to control cooking liquor to chip mass ratio for improved digester operation, says Valmet, adding that when applied to monitor biomass moisture, better boiler efficiency is enabled by the continuous

indication of heating value to optimize fuel feeding control and supplementary fuel use. A combination of microwave resonance, Q-value and sample temperature is used to measure moisture content from 0 to 70 per cent and optional heated screw tubes are available where the possibility of ice or frozen material exists. With Industrial Internet functionality, measurement data, alarms and diagnostics are all remotely accessible. www.valmet.com

Greycon has released Greycon Suite 9.0, the third iteration of X-Trim front-technology in 30 years. In addition to the front-end migration, X-Trim now promises to be 15-per cent faster on difficultto-solve problems, thanks to advances in the underlying Gurobi mathematical programming libraries, says the company. Further improvements to the pattern reduction algorithms show an increase of the reductions from 23.6 per cent (version 8.9 as compared to 8.3) to 24.0 per cent (version 9.0), it adds. The opt-Studio product also contains “significant” changes

CO2 Solutions, a provider of enzymeenabled carbon capture technology, has hired independent Canadian consulting engineering firm BBA to support its first commercial installation, the Saint-Félicien, Que., pulp mill and greenhouse carbon capture project.

Last August, CO2 Solutions signed an agreement with Fibrek General Partnership, a subsidiary of Resolute Forest Products, and Serres Toundra, for the deployment of a carbon capture unit at the Saint-Félicien pulp mill and the commercial reuse of the captured CO2 by the adjacent Serres Toundra greenhouse facility. The project, budgeted at $7.4 million, involves the capture of up to 30 tonnes-CO2/day from Resolute’s softwood kraft pulp mill in Saint-Félicien and its transportation to Serres Toundra’s neighbouring vegetable greenhouse, which was commissioned last November. The parties say the project will help reduce the carbon footprint of the pulp mill while

improving the yield at the greenhouse.

“BBA is a first-class engineering firm, and we believe the right partner to provide the support for the construction of our first commercial project, as well as lay the blueprint for future commercial projects,” said Evan Price, CO2 Solutions president and CEO. “Additionally, this collaboration will enable BBA to present our carbon capture process to their customer base, thus creating an interesting market opportunity for our technology.”

“We are very excited to play such a key role in deploying CO 2 Solutions’ first commercial installation of this breakthrough technology,” added André Allaire, BBA president. “This is an important project for us, for Quebec and for Canada that, we believe, reflects a great opportunity to help industry meet increasingly strict carbon reduction targets, while remaining competitive.”

The project is scheduled to be completed by the end of the year.

in 9.0, including an aspect requested by clients: comparing the schedule against a baseline scenario, typically set a week earlier. This will show, at a glance, any changes to customer service. www.greycon.com

ABB’s Measurement & Analytics business has launched the K-TEK LMT Series magnetostrictive level transmitters. Aiming to make measurement easy for customers, the LMT series is designed to further advance the ease of use, safety and reliability of the AT series of transmitters, says ABB. By adopting the ABB two-wire common transmitter design combined with advanced signal processing, LMT boasts “reliable measurements with integrated easy setup menu, advanced diagnostics with waveform display and signal conditioning,” says the company, adding that these advances allow the user to “ensure optimal performance and increased uptime with no need for additional tools or equipment.” www.abb.com/measurement

Cascades to upgrade Cabano biomass boilers

Cascades and the Quebec government are investing $11.3 million in two residual forest biomass boilers at the Cascades Containerboard Packaging Cabano plant in Témiscouata-surle-Lac, Que.