COMMON SCAB SOLUTIONS

Tackling the disease from multiple angles

FOR YOUR EYES ONLY.

Dedicated to Canadian potato growers. AtBASF,we’vemadeitourmissiontodeliverthemostadvancedchemistries foryears.Today,ourpotatosolutionsarenoexception.Withinnovative productslikenewSefina™ insecticideandSercadis®, themostrecentaddition toourfungicidelineup,wehelpgrowerstakeonthetoughinsectanddisease challengestheyfaceeveryday.Andthat’simportant.Afterall,yourjobis nosmallpotatoes.Learnmoreat agsolutions.ca/horticulture orcontact AgSolutions® CustomerCareat1-877-371-BASF(2273).

10 | Precision agriculture for potato production

Research is underway to develop tools and technologies for growers in the Maritimes.

By Carolyn King

Stephanie Gordon

14 | Creative solutions for common scab Researchers are tackling the disease from several angles to understand how common scab works and build effective controls.

By Julienne Isaacs

Donna Fleur y

18 | Biopesticides to fight late blight Development and commercialization of a promising biopesticide is underway.

By Donna Fleury

By Donna Fleur y

STEPHANIE GORDON | ASSOCIATE EDITOR

FORECASTING BETTER CONDITIONS

It has not been an easy year for Canadian potato growers. After having the chance to speak with growers from Manitoba to Prince Edward Island, the consensus is this year was unprecedented ¬– even for those most senior in the industry.

The hot and dry weather experienced in summer 2018, followed by brutal harvest conditions, resulted in a 2.6 per cent decrease in Canadian potato production according to the United Potato Growers of Canada. For some, almost two-thirds of their spuds were left abandoned in frozen ground.

After a particularly troubling year, it’s natural for everyone in our industry to wonder what lies ahead. This was evident in January at Manitoba Potato Production Days in Brandon, where Peter Vander Zaag, a farmer and potato scientist from Ontario, presented on the progress and challenges of China’s potato industry. The country now produces 20 times more potatoes than Canada. The leaps in progress that China had made in a short amount of time, combined with the opening of McCain’s French fry production plant in 2004, had audience members questioning how Canadian potato producers would be affected. But Vander Zaag was quick to come to the defense of Canadian producers, explaining China was having some difficulties producing the right varieties and characteristics for the French fry industry, and reaffirming the age-old saying of quality over quantity.

Despite difficult harvests and international competition, there’s still a lot of confidence in Canada’s potato producing abilities. Opportunities still exist, and continue to grow, for Canadian potato producers. Cavendish Farm’s new $360-million potato processing plant in Lethbridge, Alta., and Simplot’s $460-million processing facility expansion in Portage la Prairie, Man., are expected to be completed by the end of 2019. These encouraging news stories provided some respite when the weather wouldn’t.

The industry isn’t giving up on Canadian growers yet, and we’ve highlighted what growers can look forward to in 2019 and beyond in this issue. With a worldwide rise in demand for biopesticides, which are derived from natural animal, plant, bacteria and mineral sources, researchers are turning their focus to a promising biopesticide to fight late blight (read about this on page 18). The interest in precision agriculture has also not wavered, and precision agriculture tools for potato production are within grasp, which you can read about on page 10. Our cover story, on page 14, highlights the creative work of researchers as they test biological controls for common scab.

Finally, sometimes it’s about looking at what tools are already in your toolbox and using them to solve emerging problems. Researchers at the University of Wisconsin have investigated how effective calcium fertilizer applications are in helping tubers combat heat and drought stress, with promising results, as you’ll see on page 6.

This past growing season was an opportunity to learn and be tested, but in tough conditions Canadian producers will continue to shine. As always, we wish you a prosperous growing season.

The world has never seen a nematicide like this before.

Velum® Prime nematicide is making big news. No wonder. Now you can make yield-robbing nematodes a thing of the past, and expect more out of your crop. It even offers early blight protection. To integrate it into your potato protection program, apply it in-furrow at planting. And give your potato yield a chance at being out of this world.

Get the yield-enhancing details at cropscience.bayer.ca/VelumPrime

COOLING HEAT STRESS WITH CALCIUM

Potato tubers need more calcium under stressful conditions.

by Donna Fleury

In Ontario, the hot summer temperatures in 2018 reduced potato yields even under irrigation. A few cases of heat necrosis and/or calcium deficiency due to drought and heat stress were also reported. The hot, dry start for potatoes in many parts of Canada, combined with challenging harvest conditions that left many unharvested acres, resulted in lower overall production.

According to Kevin MacIsaac, general manager of the United Potato Growers of Canada, 2018 production was reduced by 2.8 million hundred weight below the 2017 crop. Industry had placed the losses closer to 5.5 million hundred weight but this appears to have been offset by increases of 2.7 million hundred weight in the provinces of Alberta, New Brunswick, and British Columbia. Although Canadian yields per acre would appear similar to last year’s 312cwt/acre, overall total production was lower. Hot, dry drought conditions not only impacted yield, but also caused some quality issues such as smaller tuber size, heat necrosis and hollow heart dockage. One strategy to combat heat and drought stress in potato tuber development is timely calcium fertilizer applications to the root zone.

“When I started this research over 35 years ago, little was known about calcium nutrition and fertilization in potato,” says Jiwan Palta, professor in the department of horticulture at the University of Wisconsin, and pioneer calcium researcher in North America. “At that time, calcium was used primarily to correct pH levels of soil by adding lime or gypsum. Calcium is also very abundant in soils, so nobody thought it was needed as a nutrient. It is a unique element and the dominant positive cation, next to silica, in the soil. Our research over the years has shown that although calcium is abundant in many soils, it may not always be at adequate levels in available forms. Calcium in the soil must be 60 per cent of the total bases of calcium, magnesium, potassium and sodium to have a good soil for growing potatoes.”

Researchers also thought that if the potato plant (foliage) had enough calcium, it would provide enough to the tubers. However, Palta’s research work disproved that, showing that calcium is not re-localized from the leaves to the tubers in the plant. His research showed that the tubers are independent of the plant and have special roots (tuber roots, tuber-stolon junction roots and stolon roots) to transport water and calcium from the soil to the tubers. Therefore, the implications for a fertilizer program are that placement and timing of calcium fertilizer are important to enhance tuber calcium concentration and thus tuber quality.

Calcium has an important role in plant growth and development, as well as maintenance and modulation of various cell functions. It is a very important part of the membrane structure, acting like a glue in the plant cell wall and cell membrane, similar to humans and bone structures. The health of the cell membranes can only be maintained in the presence of sufficient calcium around the membranes. Should the membrane be hurt or damaged during stress, the concentration of calcium in the cell membrane can leak away, creating weakness in the membrane structure that can lead to issues such as heat necrosis or other conditions.

PHOTOS COURTESY OF JIWAN PALTA.

Early research to demonstrate that liquid, water soluble calcium can be delivered through irrigation during the tuber bulking period.

“Heat stress during the mid and late season can result in heat necrosis in tubers,” Palta explains. “Our studies have shown that giving water soluble calcium during the heat stress period can improve plant health and reduce heat necrosis in tubers. In one of our earlier studies, we showed that calcium fertilization (water soluble form of calcium) during bulking could mitigate an adverse impact of heat stress on tuber yield. We found that during the stress period the cell membrane function can be protected by having higher calcium concentration in the root zone. In a controlled environment experiment, side-by-side comparisons were made on the impact of calcium nutrition on potato plants grown at either 20 C day/15 C night cycles (normal) or 30 C/15 C (heat stress). Plants were grown in a sandy loam soil that tested at 1,500 kilograms per hectare available calcium per hectare (adequate amount of calcium for potato growth). The results showed that plants given calcium under heat stress had better plant growth and higher tuber yield, up to 30 per cent higher, as compared to plants with no supplemental calcium under identical conditions.”

Therefore, application of calcium during the stress periods should help protect potato plant health and improve tuber yield and quality. Effective method of delivery of calcium to the potato crop would depend on the soil type and if the crop is irrigated or not. It is important to provide a readily available form of calcium during the stress periods. Calcium is an important nutrient for potato production, not just for heat and drought stress, but also for other stresses such as during freezing and frost injury. Calcium deficiencies also cause conditions such as hollow heart, and other growth and development problems in tubers. Issues such bruising and injury during harvest and post-harvest handling, or storage rot can be reduced dramatically by applying calcium.

As a result of Palta’s research findings, several liquid formulations of calcium fertilizer are available, either as a water-soluble calcium nitrate or calcium chloride form. There are also many new soluble formulations that are readily injectable for later in the season, to ‘spoon-feed’ potatoes as required. In sandy soils, adding supplemental calcium during tuber bulking is very criti-

Every jug counts!

In 2019, recycle every jug.

Canadian farmers recycle 65% of ag-plastic jugs. To celebrate the 30th anniversary of collection, this year we’re going for 100%. Every jug counts. Please help by recycling all your ag-plastic jugs.

To find a collection location near you, or learn about other programs, click on Programs at Cleanfarms.ca

info@cleanfarms.ca @cleanfarms.ca

cal for tuber development. Sandy soils are often irrigated two to three times a week due to their low moisture holding capacity, which continuously washes the top portion of the hill, moving soluble nutrients to the lower portion of the hill that may be available to the vegetative growth through the main root system. However, the tubers developing during late season on the upper portion of the hill won’t be able to access these nutrients, therefore, requiring a supplemental application. It is important to provide readily available forms of calcium during the stress periods. Although cultivars vary in tuber calcium concentration, 200 parts per million in the internal tuber tissue is considered desirable.

“Under irrigation, delivering liquid calcium fertilizers through the irrigation water during the bulking period is recommended,” Palta explains. “The recommended rate is for a total of 100 to 150 pounds per acre (lbs/ac), which is split into three or four applications every two or three weeks, starting at the tuber initiation stage. Some of the formulations such as calcium nitrate contain nitrogen (N), therefore the N application needs to be adjusted to get the desired total N for the season. Although initially there were some concerns that applying N later in the season would hurt tuber development, our research has shown that it does not. It actually is better for the plant and the environment to use split applications under irrigation, rather than applying all of the N at hilling in mid-June, which can be washed into the groundwater by heavy rains. If growers see a drought and heat stress period forecasted, that is a good time to plan to apply a split application.”

For dryland production, one option is to apply calcium at the last hilling time, mixing the product into the soil. In sandy

soils, because of the potential for leaching, it may be better to use less soluble products such as gypsum. In heaver soils, soluble products such as granular calcium nitrate can be incorporated into the hill. “Growers can also consider applying liquid formulations similar to how fungicides are applied and sprayed on the plant,” Palta adds. “If the application is tied together with a rain, then the rain will wash the calcium from the foliage to the top of the hill and down to the tuber. There are also special sprayers available that target the soil during application. Growers are very good at figuring out what works best in their farming system to get the calcium applied towards the top of a hill in a soluble form. One consideration is to be careful putting a salt on the plant that can burn if not washed away by rain, however, using a dilute form and in adequate concentrations is useful and can be particularly important during heat and stress periods while the tuber is developing.”

“Timely calcium fertilizer applications directed to tuber development can help address heat and drought stress conditions in any growing system,” Palta says. “Applying rates anywhere from 50 to 150 lbs/ac during the bulking period is important. Interestingly, more calcium will not hurt the crop; it is more about the cost-benefit of applying higher rates. Overall, the benefits of proper and timely calcium fertilizer applications include improved quality and yields, reductions in storage rot, reduced internal defects such as hollow heart, brown spots, black spot bruise and reduced impacts of heat, drought and cold stresses on the plant and tuber development. Remember under stress, the calcium need increases.”

Research trials being conducted with soluble calcium products at the University of Wisconsin, Hancock Agricultural Experimental Station located in the commercial potato production area of Wisconsin.

DISEASE & INSECT PROTECTION YOU CAN COUNT ON

We’ll let our product do the talking. Titan® Emesto® is the number one potato seed-piece treatment used by Canadian potato growers. The unique red formulation is easy to apply and see. It protects against the broadest spectrum of insects plus all major seed-borne diseases, including rhizoctonia and silver scurf. It also provides two modes of action against fusarium, even current resistant strains. It takes a lot of confidence to grow a healthy potato crop season after season and we’re proud Canadian potato growers keep choosing Titan Emesto to do it.

Learn more at TitanEmesto.ca

PRECISION AGRICULTURE FOR POTATO PRODUCTION

Research is underway to develop technologies and tools for growers in the Maritimes.

by Carolyn King

Variable-rate applications of crop inputs can offer significant benefits for the crop, the environment and the grower’s bottom line. So Aitazaz Farooque is leading a research program that is tackling the challenge of developing practical systems that accurately determine what inputs to apply, how much to apply and where to apply them for potato production in the Maritimes.

This research involves fertilizer, herbicide and fungicide inputs. “When we apply these inputs based on need [rather than applying them uniformly across a field], we are saving on agrochemicals. And at the same time, we are promoting sustainable agriculture since we are applying fewer chemicals,” explains Farooque, an assistant professor in the faculty of sustainable design engineering at the University of Prince Edward Island.

For instance, applications that provide just enough but not too much fertilizer to meet the crop’s nutrient needs, as those needs vary across a field, would enhance crop performance and reduce fertilizer costs. And such applications would avoid excessive nutrient levels that could increase the risk of nutrient losses to the

environment that could degrade water quality and contribute greenhouse gases to the atmosphere.

“The goal of this research program is to develop technologies to characterize and quantify soil and crop variability, and then come up with the tools and options that can do that on the go for effective decision making in a sustainable fashion,” he says. “We want to find out what the needs are, and based on that, we want the decision making to improve profitability and at the same time protect the environment.”

This research program is funded by the Natural Sciences and Engineering Research Council of Canada (NSERC), P.E.I. Potato Board, New Brunswick Department of Agriculture, Aquaculture and Fisheries, Canadian Space Agency, Provincial Government of P.E.I., and other industry partners. The fieldwork is taking place across P.E.I. with sites at O’Leary, Summerside, Hamilton and Souris, and in New Brunswick at Grand Falls and Florenceville.

ABOVE: RTK-GPS is used to map the topography of potato fields, one of the data layers used in developing management zones for variable-rate applications.

Having multiple field sites over multiple years helps ensure the systems developed through this research will be able to accommodate the range in variability that could occur within individual fields and between fields, and within a single year and from one year to another. That variability can be due to variations in factors like landscape characteristics, soil characteristics, weather conditions and crop production practices.

Farooque and his research team are working with various sensors and technologies for mapping in-field variations at each site to determine which options would be best for creating prescriptions for variable-rate applications on potato fields.

For instance, they are using ordinary cameras and cameras that capture thermal imagery and multispectral imagery. These cameras are mounted on drones or field equipment, and are used in mapping things like weeds, crop health and disease, and the amount of heat emitted from the soil, which is related to moisture content.

A DUALEM sensor is another important instrument in the research. It measures electrical conductivity (EC) in the ground. “There are different studies on conductivity showing that it is related with soil moisture content, soil nutrients, soil organic matter and sometimes soil texture. So EC is a pretty handy tool,” Farooque notes. The DUALEM sensor can be dragged behind an ATV or a tractor, or it can be dragged by hand for small-plot studies.

As well, the team is evaluating technologies like yield monitors and soil moisture sensors. They are also comparing two different options for elevation and slope mapping: RTK-GPS (real-time kinematics global positioning system) and LIDAR (light detection and ranging). Both RTK and LIDAR can be used to create digital elevation models, which are helpful for things like mapping water flow across a field and for landscapes where topsoil has been eroded from the hilltops and deposited in the low areas.

Each sensor used for precision agriculture research has to be calibrated and validated for the conditions at each site. For example, the research team has to do detailed soil sampling across each field site to find out how the DUALEM data is correlated with the results from the lab analysis of the soil samples, like soil organic matter content and soil nutrient levels. They have to measure the greenness of leaf samples to see how that correlates with the imagery from the cameras; they have to compare the yield monitor data with the actual yield data; and so on.

Farooque and his team overlay the maps produced by all the different sensors and analyze how well the different layers match up with each other, and they determine which layers are the most significant ones for potato production in that particular field. Farooque says, “There are always some variables that don’t affect things as much as the others do. It really depends on the situation.” This analysis enables the team to identify management zones in the field that can then be used to guide the variable-rate control system for applying the inputs.

They are also conducting studies to figure out the appropriate rates for the nutrient inputs in each management zone. The main focus of this work involves determining optimal variablerate applications for commercial fertilizer blends of nitrogen, phosphorus and potassium. In 2019, they will be doing small-plot experiments to assess the effects of these applications on potato yields and greenhouse gas emissions. Then in 2020, they will be evaluating the effects in field-scale experiments.

In addition, they are conducting micronutrient studies, and they will be doing an experiment in 2019 to compare slow-release

nitrogen fertilizer with nitrogen fertilizer split into three applications over the growing season. They are also exploring the possibility of applying biosolids amendments. For instance, in a 2017 experiment, they applied biochar to see if it might improve potato productivity, enhance soil organic matter content, and increase carbon storage. Biochar is a soil amendment made through a combustion process that turns biological products – in this case wood chips and fish waste – into charcoal.

Farooque and his team are only two years into this innovative research program, but they are making progress. One key step forward is that they already have a good sense of how to manage nutrients based on the conductivity measurements.

Another important step is that they are in the process of developing a sensor that is using deep learning (a type of machine learning) to identify patches of weeds and diseased potato plants. Once the sensor has completely mastered this learning, it could be used for on-the-go targeted spraying. So, the sensor would detect plants that need to be sprayed as the operator drives through the field, and in real time, the sensor would send instructions to sprayer’s control system, which would emit the spray from the appropriate nozzles.

The results from Farooque’s research could help potato growers to make more efficient, targeted input applications that improve productivity and reduce environmental risks. Within a few years, he expects to have some technologies and tools developed, and to have them tested and evaluated at the growers’ level.

Farooque says, “At the end of the day, the idea is to work with the potato industry to solve the problems they are facing and to help the industry to be more profitable and sustainable.”

ABOVE: The DUALEM sensor is proving to be helpful in determining variable-rate fertilizer applications.

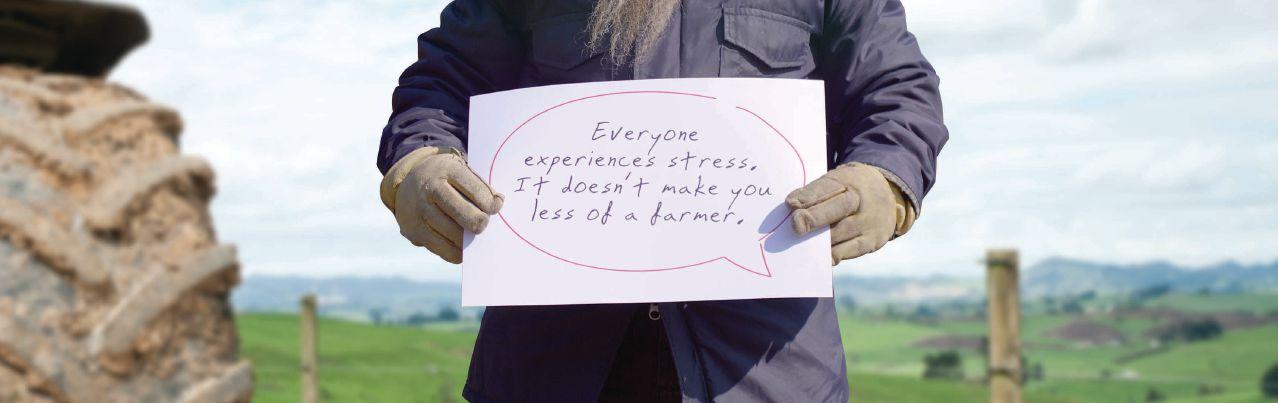

CREATIVE SOLUTIONS FOR COMMON SCAB

Researchers are tackling the disease from several angles to understand how common scab works and build effective controls.

by Julienne Isaacs

Creative solutions are needed in the battle against bacterial diseases in potato. In people, most bacterial diseases are treated with antibiotics, but due to the rise in resistant bacterial strains, that option, apart from a few exceptions, is off the table for field-scale agriculture.

But researchers are making headway against bacterial diseases such as common scab, largely in the area of biological controls.

Common scab, a cosmetic disease that is usually caused by the bacterium Streptomyces scabies, impacts growers worldwide. Except in extreme cases, common scab doesn’t result in lost yield. Instead, it causes brown lesions on the tuber’s surface that impact salability. If more than five per cent of a tuber’s surface is affected, potatoes can’t be sold to the table market; the lesions also make tubers difficult to peel, resulting in waste and lost profits when potatoes are sold to the chip and fry markets.

In Canada, the disease is responsible for at least $17 million in lost revenues annually, particularly on the East Coast, whose rainfed soils offer the right conditions for the disease.

“Irrigation is one way you can decrease common scab because

the disease likes soil conditions to be really dry,” says Claudia Goyer, a molecular bacteriologist with Agriculture and Agri-Food Canada in Fredericton.

“When it’s really wet, mobile bacteria will colonize the tuber faster, but when it’s dry, the mobile bacteria don’t have an advantage and Streptomyces scabies can get in the lenticels of the tubers,” she says.

The bacterial group Streptomyces contains at least 10 bacteria responsible for causing common scab, including but not only S. scabies; there are also other “pockets” of unrelated bacterial species that cause common scab-like symptoms, Goyer says. Adding to the problem, a large fragment of Streptomyces DNA is transferable to other species of Streptomyces, which explains why so many unrelated Streptomyces cause common scab.

In other words, it’s a complicated disease – but Goyer’s team is tackling it from several angles, attempting to understand how common scab works in order to build effective controls.

ABOVE: Claudia Goyer in a common scab infested field at the Fredericton Research and Development Centre where the study took place.

PHOTO COURTESY OF JULIE ROOT, AAFC.

Soil conditions

In early 2018, Goyer’s team published a paper offering conclusions on a study that ran from 2013 to 2014 looking at factors that influence common scab pathogens in the soil – how the pathogen populations change between the rhizosphere and the surface of the tuber over time on two susceptible (Green Mountain, Agria) and two resistant (Gold Rush, Hindenburg) cultivars.

“What we saw was that some of the susceptible cultivars were harbouring a greater number of the pathogens overall compared to the resistant cultivars,” Goyer says.

Goyer believes the different varieties have different root exudates, or exuded different substances from the root, and the quantity and composition of the exudates differs between varieties, attracting different pathogen communities in the soil microbiome.

What this means is that the cultivars themselves influence common scab pathogen growth conditions. It also means producers planting susceptible varieties are perpetuating a common scab problem in the soil over the long-term.

“At the end of the field season when the tubers are harvested, the roots are left behind, which means that susceptible cultivars leave five to 10 times more pathogens that cause common scab in the fields, compared to tolerant cultivars,” she explains.

Somaclonal variation

Goyer has another project examining the use of somaclonal variation, the plant’s natural ability to change its tissue culture, to increase resistance to common scab in common potato varieties Shepody and Red Pontiac.

Somaclonal variations use the natural ability of a plant to change under stress. Somaclonal variation can rapidly introduce genetic variability using tissue culture, including random mutations in target plant species, creating genetic variants. These lines are then screened using a toxin from the target pathogen to find variants with enhanced resistance. Two years ago, Goyer’s team planted out 50 variants each from Shepody and Red Pontiac, and found about 10 variants with improved resistance to common scab.

promising results.

“What we’re hoping to have is something that will be better than the parental line, and to see over time which ones are more consistently resistant to common scab compared to the parental line. We need to ensure that it’s stable, so whatever this natural change is doesn’t revert to the parental line,” she explains.

Goyer’s program needs to run two more years of assays before new varieties are available to producers.

Disease management

Currently, says Goyer, producers have very few chemical options to control common scab. The best controls available to producers come down to management: producers are advised to use clean seed and to avoid letting soils reach a pH above 5.4, because the pathogen prefers soil with more neutral pH.

In summer 2019, Goyer plans to start a new project in Manitoba and Prince Edward Island looking at which management practices are effective in controlling common scab.

In Manitoba, the project will run in partnership with Tracy Shinners-Carnelley, vice president of research and quality at Peak of the Market; in P.E.I. the project will run in cooperation with Cavendish Farms.

“We’ll be looking at the effects of agricultural practices in these two provinces to understand the mechanism, why some agricultural practices work to reduce common scab and some do not,” she says. The project will take into account environmental and soil factors – including rainfall, temperature and soil physico-chemical properties – as well as management practices.

218_083_Range_CAN_8,58x12,70_DG_0[1].pdf 1 2019-02-21 12:06 PM

LOOKING BEYOND THE HORIZON

“We then took those variants and multiplied them and planted them in 2018 to see whether the effect held,” Goyer says. “We’re still crunching the numbers, but some of the variants are showing

such as agriculture, construction, and OTR, as well as transport and agro-industrial applications.

BKT Tires (CANADA) Inc. (905) 641-5636 (514) 792-9220 (604) 701-9098

PHOTO COURTESY OF CLAUDIA GOYER.

ABOVE: Sampling of potato rhizosphere by AAFC technician Sean Whitney.

TRAINING TECHNOLOGY TO WORK IN THE FIELD

Researchers are

advancing

studies on cost-effective digital tools for precision management applications.

by Donna Fleury

Researchers are investigating the use of digital sensor technology and machine learning for precision management applications and integrated pest management programs for potato growers. Combining digital cameras and computer algorithms to train sensors to identify crops and crop pests can help improve application efficiency, economics and environmental sustainability.

This five-year project was initiated in 2017 using soybean and weeds to test the capability of training sensors for recognition. In 2018, researchers advanced to focus specifically on potato plants and added diseases and insects to the project along with weed management. “We spent the second growing season in 2018 collecting data for weeds, diseases and insects in potatoes,” explains Andrew McKenzie-Gopsill, weed scientist with Agriculture and Agri-Food Canada (AAFC) in Charlottetown. “We started working with lamb’s quarters and potato, and were pleased that the sensors were able to accurately and reliably detect those plants in the field over 90 per cent of the time. We also focused on collecting data and training sensors for early blight disease and Colorado potato beetle.”

Other significant advancements in 2018 include a new method for processing data collected. “My collaborator Aitazaz Farooque, assistant professor in engineering at the University of Prince Edward Island (UPEI), has advanced the development of the machine learning system, which is now much less labour intensive,” McKenzie-Gopsill says. “At first, we needed thousands of images at various stages to train the sensors to identify the crops, but with this more advanced machine learning system, we only need 20 or 30 images to reliably detect whatever our target is. The only restriction is the system must be able to visually see the target for detection, so disease symptoms must be fully visible to be detected.”

The priority is to develop a system that will be cost-effective for growers. Therefore, the system is designed to use standard small RGB digital cameras with a cost of $30 or $40, and to be compatible with precision farming computer systems. The sensors, combined with algorithms and machine learning, are able to take the images from these cameras to train the machine to identify the characteristics of the potato crop versus everything else for example. For weed management, the goal is to train the system to learn to always recognize the potato and bare ground and then target anything else that is not. In some cases, the system may also be trained to learn specific weed or other pest targets along with the potato crop.

“For precision spraying applications, the image data being col-

lected by the cameras or sensors will be transferred into the onboard sprayer computer system that will relay this information for variable-rate application,” McKenzie-Gopsill explains. “The information relayed into the variable-rate controller can then turn nozzles on and off, or vary the pesticide application rate on the go,” he adds.

“Another one of our goals is to train the system to detect soil variability. Currently, a large percentage of herbicides for potatoes are applied as pre-emergent applications. Therefore, if we can train the sensors to detect soil variability in soil organic matter and soil moisture, then the system may be able to vary the pre-emergent applications and improve efficacy of those products. In some situations, pesticide use may be able to be reduced quite a bit.”

The next steps in 2019 are to continue more intensive data collection for the various weeds, diseases and pests and the potato crop, and to continue to develop and integrate technologies and systems to identify variations within a field. Farooque has also been working on a new buggy system for image data collection that will make it easier to move through the fields and collect the image data required.

“We expect by the end of the project to have developed costeffective, integrated sensor and smart technology digital tools for precision management applications in potatoes and other crops,” McKenzie-Gopsill says. “Overall our goal is to reduce pesticide use to only apply what is needed, to do it more sustainably and save farmers money.”

Data and image collection in field plots with potato, lamb’s quarters and bare soil.

PESTS AND DISEASES

BIOPESTICIDES TO FIGHT LATE BLIGHT

Development and commercialization of a promising biopesticide is underway.

by Donna Fleury

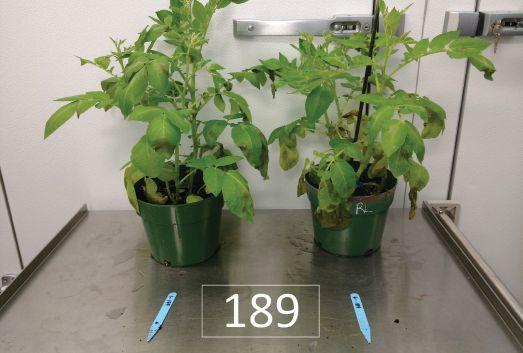

Late blight disease, caused by the pathogen Phytophthora infestans, continues to be one of the most serious disease concerns for potato growers. Over the past few years, new genotypes of P. infestans have emerged creating new management challenges for commercial potato growers. These challenges have led Agriculture and Agri-Food Canada (AAFC) scientists to investigate naturally-occurring bacteria for their potential use as biological pesticides (biopesticides). The use of biopesticides has been of interest in recent years for their ability to produce powerful antifungal compounds and to induce systemic resistance in host plants.

“There are disease forecasting tools in place and registered fungicides for control. However, there are reports of P. infestans genotypes that have become more resistant to those fungicides and new genotypes are emerging,” says Sue Boyetchko, research scientist with AAFC in Saskatoon. “We wanted to investigate potential alternative control options and to reduce our carbon footprint.”

In 2013, Boyetchko and collaborator Patrice Audy, research scientist with AAFC in Quebec City, initiated a three-year project to begin screening for potential biopesticide organisms of a bacterial nature. Researchers also investigated the different genotypes that were common in North America, as well as upcoming genotypes forecast to become a problem. Several naturally occurring bacterial strains isolated from Canadian soils were discovered and showed great promise in controlling the late blight disease on potato under laboratory and greenhouse conditions. The top bacterial candidates were observed to suppress or inhibit the disease on potato by more than 90 per cent.

The team took the top six candidates and focused additional research on further screening and narrowing down the biopesticide candidates to the top one: Pseudomonas sp. strain 189, Boyetchko explains. “The good news is this organism actually produces a suite of a family of chemical compounds that contribute to its biopesticide control. Therefore, the

chances of resistance developing is probably reduced. If used judiciously together with other methods of disease management, it should mitigate the risk of resistance occurring in the biopesticide. We are not using the biopesticide as a silver bullet, but wish to implement it in a diseasemanagement system.”

The project team is now focused on strategies for scale-up and the commercialization of the biopesticide. Priorities include developing an ideal formulation for spray application in the field, maximizing bacterial survival and shelf life during storage, and developing an efficient and economic fermentation process for mass-producing the bacteria. “There was a lot of interest in our early results from several industry companies, particularly as late blight is a global disease,” Boyetchko says. Recently the team has identified an industry partner to work with, but the commercialization process will take a few years.

Researchers will also investigate agronomic practices for using the biopesticide as part of an integrated pest management program for potato growers. They want to make sure this new potential biopesticide will work with other synthetic fungicides and cultural control practices growers are currently using to manage the disease. If commercialized, this biopesticide will be an additional pest management tool in the tool box for growers.

“Our goal is to make sure our Canadian farmers benefit from our new technology introductions,” Boyetchko adds. “Most importantly, through this process we have also developed a template or roadmap for how to pursue other potential biopesticide projects, and how to collaborate with other industry partners and expertise to bring new biopesticide control options to growers.”

ABOVE: Potato plants sprayed with only the pathogen Phytophthora infestans (left) compared with a potato plant sprayed with biopesticide Pseudomonas sp. strain 189 and the pathogen in greenhouse trials (right).

ADMIRE® /// ALIETTE ® /// ALION® /// BETAMIX® ß /// BUCTRIL® M /// CALYPSO® /// CONCEPT® /// CONVERGE® FLEXX /// CONVERGE XT /// Country Farm Seeds /// Croplan® /// DECIS® 5EC /// DEKALB® /// ELITE /// ENVIDOR® /// ETHREL® /// FLINT® /// FOLICUR® EW /// General Seed Company ® /// GENUITY® ROUNDUP READY ® 2 YIELD ® SOYBEANS /// GENUITY VT TRIPLE PRO® RIB COMPLETE® CORN /// INFINITY® /// Legend Seeds Canada /// LUNA SENSATION™ /// LUNA TRANQUILITY ® /// /// Maizex Seeds /// MOVENTO® /// Northstar Genetics /// NORTRON® SC /// OBERON® /// OPTION® LIQUID /// PARDNER® /// PICKSEED /// Pride Seeds /// PRIWEN® /// Prograin /// PROLINE® /// PROPULSE ® /// PROSARO® XTR /// PROSeeds /// PUMA® ADVANCE /// REASON® /// ROUNDUP READY ® 2 CORN /// ROUNDUP READY 2 XTEND ® SOYBEANS /// ROUNDUP XTEND® /// SCALA® /// SeCan /// SENCOR® STZ ///SENCOR480///SENCOR 75DF /// SERENADE ® SOIL /// SERENADE OPTI /// SIVANTO™ PRIME /// SMARTSTAX ® RIB COMPLETE® CORN /// STRATEGO® PRO /// TITAN® ///TITANEMESTO® /// TRILEX® EVERGOL® /// TRILEX EVERGOL SHIELD /// VELUM® PRIME /// VIOS® G3 /// VT DOUBLE PRO® RIB COMPLETE® CORN /// XTENDIMAX®

Coragen® insecticide delivers extended residual control of European corn borer and Colorado potato beetle, protecting the quality of your potato crop. If your Colorado potato beetle seed/in-furrow treatment breaks down, Coragen® insecticide can keep your crop on track. It’s also easy on bees, beneficials and pollinators*. Mission accomplished.

* When applied at label rates. In line with Integrated Pest Management and Good Agricultural Practices, insecticide applications should be made when pollinators are not foraging to avoid unnecessary exposure.