WIDE FORMAT RESOURCE GUIDE

PLUS

Power of the wrap

Firsthand experience with dynamic vehicle graphics

The Wild West of large format

Colour management inroads and challenges

Commercial large-format

A stable and robust sector to realize new value

Expanded gamut

Practical guide to an emerging colour strategy

Inkjet pioneer

Bill Baxter describes the rise of Inca Digital and how it transformed display graphics

Inkjet pioneer

By Jon Robinson

In the late-60s, an engineering group called Cambridge Consultants was asked by a company to find a better way to print their carpets, without touching the material. As a result, Steve Temple and David Payton started looking at the physics of droplet ejection from nozzles. Although not initially used for printing carpets, their developments became a sudden sensation for date coding in the early-1970s when legislation required all food packaging to carry a sell-by date, creating Domino Printing Sciences. The duo then developed the original concept of drop-on-demand Xaar technology.

Bill Baxter, founder of the Inca Digital Printers, shared an office with David Payton, although they did not work together on inkjet technologies. PrintAction spoke with Baxter to find out how he helped forever change the direction of printing and what lies ahead for Inca Digital, which was purchased by Dainippon Screen in 2005 for approximately $70 million.

How did you find your way into the pioneering UK inkjet sector?

Bill Baxter: I’m a late-comer. I was working as a consultant for a company that made contact lenses, re-engineering their manufacturing line when my client said, “We’ve got about 200 OEM customers. They take daily wear, weekly wear, monthly, they have different tinted lenses, there are 60 odd powers of lenses... We have so many SKUs. Can we bring white carton board into our production line and print it right there when we know what is going in it?”

Innocently, I said, “Well, yeah, there is this inkjet thing.” So I

had a look around and, well, no one makes a printer that can do that… So I started going around initially to packaging companies and found that all you had to do was ring them up and say you want to talk about digital printing; and you instantly got a meeting with about six senior people around the table... It turned out, for technical reasons, packaging really wasn’t going to happen at that period. But, by pure accident, we met someone from the retail display industry who said, “You guys need to make a machine for retail display,” and that became Inca.

How long did it take you to create Inca?

Bill Baxter, founder of Inca Digital Printers, in front of the new Inca Onset X3, which runs at 900 square metres per hour, features up to 14 ink channels and is still recognized as the workhorse brand of wide-format.

BB: In Eighteen months – R&D, flogging around trying to get finance, because we were venture-capital backed. Also creating what became a real central pillar to our business, which was a deal with Sericol, which was later bought by Fujifilm. Sericol supplied our inks and also they had a worldwide sales network that could sell our machines. So it was a perfect marriage and it has absolutely been a bedrock of our business.

How did Inca’s engineering set such a high standard in those early years?

BB: We were a bunch of crazy engineers, very much an engineer-

ing-based company. I remember getting terribly criticized because I kept on making our own machines obsolete – “You are mad don’t do this.” But I did, because it is the right thing to do, because suddenly we found ourselves with some rather more substantial competition.

How fast was your pace of development?

BB: Typically we were introducing a new product every 18 months, which would usually obsolete the last one. It also drove some of our customers crazy – the last guy who got the old. But we are engineers and this business is engineer heaven.

How much money was being spent on R&D in the early years?

BB: Twenty-five percent of our payroll is R&D and it continues to be. And I think it will continue to be for many years.

How much has the speed and quality of display inkjet systems increased from Inca’s first Eagle 44 to today’s X3?

BB: In just over a decade the throughput of our machines has gone up by a factor of between 30 and 40, and the quality is wildly better. When I look back at the test prints that we did on those first Eagles, I am horrified – absolutely horrified – by the quality, but at the time people’s eyes popped out. They thought it was great

How has inkjet technology affected screen-printing?

BB: It was kind of a slow-motion tragedy of the screen-printing industry. It was around 2003 when it really started to have an affect. In 2003, digital’s share of production was probably less than one percent, but everyone could see the new [inkjet] kit. Not everyone wanted to buy it, but everyone saw what was happening, that it was improving and so nobody was going to invest in a screen kit that would have to be written off in 12 years – and they were right. In a few years, secondhand screen kit was going for scrap metal and the price of screen output fell drastically, because digital was starting to take a little bit of market share. There were people with all of this installed [screen] capacity who were competing for a smaller and smaller chunk of the market, as digital output was commanding an excellent price. It really is a sort of business school case that ought to be investigated.

Canadian display graphics power

Holland & Crosby Limited, one of Canada’s leading manufacturers of display graphics, recently opened a 71,000-square-foot facility in Mississauga, Ont. The company, which specializes in Point of Purchase retail-based signage programs (for some 80 years), began to operate out of its purposely-designed facility in January 2016 shortly after completing its purchase of Colormark Limited.

Holland & Crosby’s facility is highlighted by the installation of two new Inca inkjet flatbed presses purchased through global distributor Fujifilm, including the all-new Onset X3, which runs at speeds of up to 9,688 square feet per hour (180 beds), and an Onset X1. The company also installed two massive Esko Kongsberg cutting systems to accommodate the size and throughput of its new inkjet engines.

Scott

VP Sales & Marketing and co-owner

Bill Baxter, the UK-based engineering pioneer who established Inca Digital in 2000, attended the open house to help celebrate Holland & Crosby’s powerful printing platform. “As equipment makers in this field, where the pace of development is very quick, we are always coming out with the latest, greatest, most-advanced [systems],” says Baxter. “Holland & Crosby have regularly taken the very first of our machines shipped to North America and that is very important for people like us, because they really do provide a reference for our latest machines.

“I know that we have sold a lot of machines simply because Holland & Crosby have been making them work and sending the results out to clients,” continues Baxter. “We love them because of that, but we also love them because they are descent, sensible people. It has always been a real pleasure working with them.”

After establishing its digital department in 2004 with an Inca Columbia system, Holland & Crosby in 2008 became the first company in North America to install the Onset S70. In 2009, the company installed the Onset S20 and in 2010 became a digital-only shop now built around its Inca horsepower.

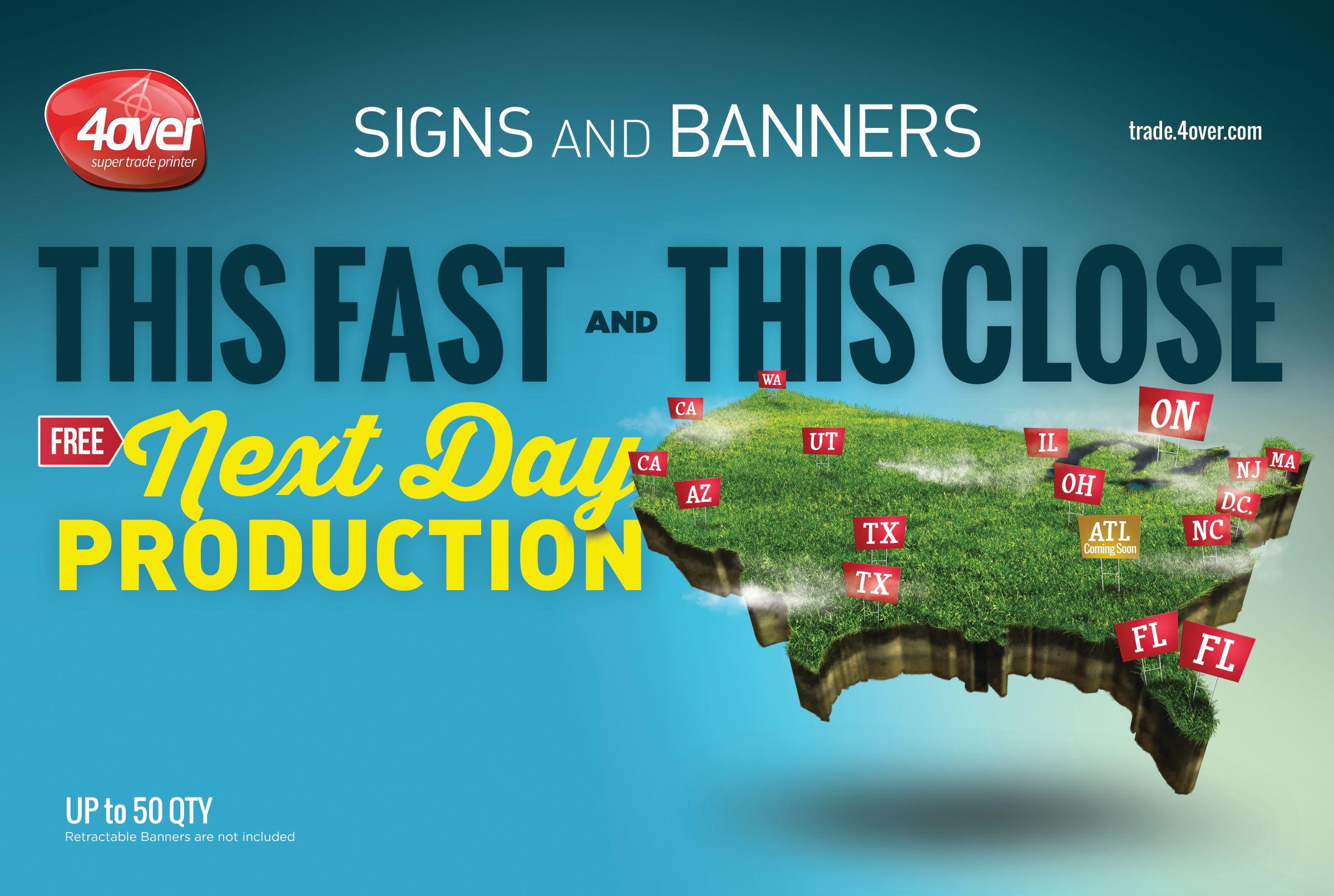

FASTSIGNS AND EPSON EXTEND

PARTNERSHIP TO OFFER FRANCHISEES

NEW PRINTER TO INCREASE EFFICIENCY AND DRIVE SALES

FASTSIGNS International, Inc., the leader in signs, graphics and visual communications, and Epson America, a global leader in printing technology, have announced a partnership to offer franchisees the all-new Epson SureColor® S60600 roll-to-roll solvent printer. All 600 franchisees in the FASTSIGNS network will be able to integrate the high-speed, highproduction printer into centres, which boasts substantial technological enhancements to save centres time and money while producing some of the highest quality output available today. Currently, three locations have the new printer installed, with 33 new FASTSIGNS centres expected to open this year with the new printer.

SureColor S80600 is now shipping

Epson is proud to announce that the new Epson SureColor S-Series 64-inch production, roll-to-roll, solvent printer line is now shipping. Poised to become the new benchmark in high-performance solvent printing, the SureColor S-Series, including the flagship

SC-S80600, leverages advanced imaging technologies to provide exceptional levels of productivity and image quality, plus improved reliability, to the signage, vehicle graphics, and fine art reproduction markets. The SC-S80600 joins the complete line of SureColor S-Series printers, including the SC-S40600 and SC-S60600, and is now available for purchase through authorized Epson Professional Imaging S-Series resellers.

“The SureColor S80600, our flagship signage printer, delivers on all the features our customers consider important when seeking a quality, production-grade solvent printing machine,” said Matt McCausland, product manager, Professional Imaging, Epson America, Inc. “Innovations in imaging technology, coupled with the latest Epson UltraChrome® GS3 ink system, provide the ultimate combination of performance and photographic quality to enable print shops of any size to get the job done, on time and beyond expectations.”

SOLVENT PRINTING.

WATCH

WATCH Printing on Adhesive

THE ALL-NEW SURECOLOR ® S-SERIES FAMILY

Three new models, starting at $21,595 †

Introducing the all-new SureColor S-Series family of sign printers, an innovative line of solvent printers that significantly outperforms anything that has come before them. The industry’s first solvent printer with same-day lamination capabilities – it’s about time.

Learn how we beat the clock at epson.ca/solventprintingsolved

Commercial large format printing

The drupa Expert Article Series looks at the growth in large-format inkjet as a technologically stable sector experiencing growth for commercial printers to realize new value

By Sophie Matthews-Paul

Developments in inkjet technology allow single systems, such as Epson’s SureColor series, to produce a range of printed products.

Not so many years ago wide-format inkjet printing was still in an experimental stage and could not be considered a serious contender for most commercial environments. Advances in technology have been rapid and inkjet has become the preferred process for many display applications. Where wide-format has scored, complemented by advances made in associative software and available materials, is by bringing versatility and flexibility to all industry segments where the digital revolution has opened doors to low volumes, one-offs, versioning and variable data.

As the growth in wide-format print continues, it is noticeable that users of machines are moving to new niche and specialty areas where digital technology can realize jobs that, formerly, were not feasible. The ability to experiment with inkjet and different materials is simplified because of fast-set-up and changeover, the ease of the prepress process and the viability of producing one-offs.

Historic print service providers face new challenges from recent entrants that opt to take on a niche or specialist segment, rather than merely become a me-too operation focused on speed. Versatility is still key to the throughput benefits of inkjet and diversification can often prove to be the key factor that drives better margins and greater profitability. Ergo, effective workflow is as important as the throughput rates of a particular print device, and investment must be quantified against expected daily volumes, diversity and variability of work.

“We know many of our customers are using our printers to produce a wide variety of products on a range of substrates to meet the needs of their customers and to maximize ROI. So one printer can be used to produce everything from retail POS graphics, pop up banners and self-adhesive decals and labels to wall coverings, external displays and vehicle wraps,” says Richard Barrow, Senior Product Manager, Epson Europe.

Mike Horsten, General Manager Marketing EMEA at Mimaki, concurs: “I believe that diversity in the offering is the key to success. For the most part, a single production type of print company no longer exists. Offering a diverse series of printing products is making the one-stop-shop a reality.” Flexibility is now encouraged by

technologies developed to minimize downtime during job changeover and the ability to produce applications that are right the first time.

Advances do not lie only in the print engine’s design and construction; of increasing importance is the benefit of an efficient end-to-end workflow plus integration with onward services like print-to-cut environments, MIS and JDF compliance. “It is fairly obvious to calculate how a company can increase its throughput and its profits by printing more work on a wider, faster printer,” says EFI’s VP of Inkjet Solutions, Ken Hanulec. “But it is too easy for companies to overlook the ways they can also get better results with a better workflow. So it is definitely a way to gain a competitive edge that needs to be recognized.”

Mimaki’s Horsten, explains, “If you are a large print house with multiple printers the workflow is crucial to survival. Without a good MIS system or an automated workflow the amount of work would kill any company in the long run. On the other hand, the demands for perfect workflow are not so important if you are a small company and you know your entire customer base.”

Agfa’s Paul Adriaensen endorses the relevance of workflow in today’s print operations: “Good throughput means that the machine outputs correctly the first time and every time, job after job. Workflow automates input file and data processing, colour management, printer and finishing settings in order to avoid delays during the entire production process.” Today’s users of wide-format printers can come from any

background, whether they happen to be designers, former specialists in typesetting or repro, sign makers or screen printers. But every print service provider should look at the bottom line and not just production costs.

Horsten emphasizes: “There are still companies that don’t calculate the entire workflow cost before adding margin. If they can look at the whole cost structure of their business they would know the profitability for the work carried out.”

Growth in the wide-format segment is based on machine technologies and reliability, running costs, diversification in application type and balancing volume against the versatility of low numbers and one-offs. But device flexibility is proving to be a key factor in future investment where fewer print engines can generate the right volumes across a range of applications. “Diversity is one of the reasons customers like using our hybrid roll/flatbed printers. Many of our customers need to be able to print as many different types of jobs as possible, from corrugated displays printed to traditional banners to everything in-between,” says Hanulec.

Since drupa 2012, inkjet developments have continued apace, with new inks and faster machines, automated material handling, print-to-cut and LED curing. New chemistries include water-based UV-curable formulations, the challenge presented by latex chemistries and the capabilities of aqueous, solvent and UV-curable options that continue to be used in everyday environments.

Evolution of Wide Format Printing

THINKING CREATIVELY TO IMPROVE YOUR ROI

he wide format printing industry is constantly evolving in response to customers’ habits and expectations, technology, and media selection. Rapid advances in technology allow for more flexibility, versatility, and business opportunities than ever before. And with the continuous increase in printable substrates, it’s clear that with the right printer and a little creativity, any business can not only survive, but thrive.

REINVENTING YOUR BUSINESS

In the Canadian graphics marketplace, the use of flatbed printers has grown exponentially. The right flatbed printer can increase production efficiencies and profitability while eliminating workflow manpower steps and reduce both turnaround times and material costs.

At the Professional Printing Solutions Group (PPSG), a division of Canon Canada, we see innovation every day in the vast array of applications produced by our customers. For many, the addition of a flatbed printer has completely reinvented and rejuvenated their business. With the ability to print on almost any relatively flat surface of up to 2” thick, and with options such as white ink, varnish, and roll-media, customers can increase their current profitability by keeping more projects in-house. Less outsourcing also means more control over quality, schedule, and pricing while opening the door to new business.

Here’s how some business segments reinvented themselves to increase revenue and ROI while capitalizing on cost-effective, new opportunities.

DIGITAL PRINTERS

WHY: Early adopters of flatbed technology looking for efficiencies and new opportunities

HOW: Capitalized on market shift to on-demand, low, and medium runs. Transitioned to offering unique substrates and specialty applications to upsell current customers

WHAT: POP graphics, in-store signage, event graphics, and specialty one-offs

SCREEN PRINTERS

WHY: Dominant suppliers of large scale printed graphics. Challenged with maintaining profits as jobs trend toward shorter runs

HOW: Adding a flatbed made hybrid screen/digital printing possible, creating short run profitability and workflow efficiencies

WHAT: Print on pre-manufactured items such as binders, containers, footwear, doors, and more

REPROGRAPHERS

WHY: Traditional business declining due to shift from large, paper plots to digital documentation

HOW: Smooth transition to flatbed printers as profitable extension to current business

WHAT: Typical services now include retail and outdoor graphics

EXHIBIT MANUFACTURERS

WHY: Focused on custom production and challenged with maintaining profitability in one-offs and short runs

HOW: Adding a flatbed printer allowed for high quality printing on a wide range of rigid and flexible substrates with uncompromised productivity

WHAT: Freedom to design using media such as MDF wood panels, metal, acrylics, and textiles

COMMERCIAL PRINTERS

WHY: Conventional print volumes are shrinking and new profit avenues are needed

HOW: Expanding into wide format utilized core business while complementing current production capabilities. Output on an Océ Arizona flatbed is comparable to offset and allows for split runs between press and digital, depending on volume demands

WHAT: Use similar media (paper, card stock and banner media) to create POP signage, packaging, and retail products

BEYOND JUST A PRINTER

Since first introducing the Océ Arizona® flatbed printer in 2006, PPSG has been dedicated to showing customers how to reinvent their business. We believe that the backbone to reinvention is a solid understanding of your printer’s capabilities and how you can best use these to leverage productivity and undiscovered customer needs. By building a strong relationship with our customers we strive to become true partners who can offer valuable advice and unique application ideas. Our professionals ensure that customers are fully educated on their system’s capabilities, up-to-date on new developments, and understand all media options available. We are confident that with the right equipment, knowledge, support, and a little imagination any business can thrive in the evolving wide format market.

WINDOW GRAPHICS

Check out our Flatbed Printer Application Guide, specifically designed to show you the potential in your business. The newest issue includes application recipes, Canadian case studies, interviews and much, much more.

The Quality and Speed You Need Today. Easily Expandable in the Future.

Onset X Series wide format printers provide you the best of both worlds. Onset’s reputation of delivering one of the industry’s highest ROI is well-known. Now with 21 available press configurations, you can choose the exact quality, speed and price point today, knowing an upgrade path is built-in for future business growth. And an even better lifetime ROI.

The secret to this unprecedented flexibility is the innovative Inca Scalable Architecture design of the Onset X. Want to start with CMYK and max-out to 14 color channels next year? No problem. Need to increase speeds from 40 beds per hour to up to 180 beds per hour? We’re ready. One call and we’ll install the components needed to upgrade your Onset X machine onsite. And as new color and printhead technologies evolve, so will Onset X’s upgrade potential.

To learn more how Onset X can multiply your return on investment, visit fujifilminkjet.com today.

The Wild West of large format

By Angus Pady

In the world of large-format printing, we do not have the same targets as we do in commercial printing. This can be a good thing and a bad thing as it allows for more variation in the process and it makes it difficult to implement a process control action plan. In commercial printing we have lots of targets to aim for and to control the process, such as GRACoL, Fogra and ISO, and I recommend that you use the same standards and specifications in large-format printing. This way we create consistency between offset and large format.

The first step is to understand where you are starting.You have a couple of options when evaluating colour. If you have an inhouse proofing device, you could print a visual reference to compare your large-format device to a known standard such as GRACoL.

I use a test image that shows me a lot of great information about how a device is printing. (Please email me for a copy, angus@ colourmanagement.ca). I first look at the solid ink densities starting on the left of the image. In large format, the magenta is the weakest ink. If you have a densitometer from your press, measure the CMYK values. For most decent medias, you should achieve the following density: Cyan 1.30 - 1.70; Magenta 1.30 - 1.60; Yellow 0.90 - 1.10; and Black: 1.60 - 1.90.

If your numbers are lower, consider going back to look at how your per channel ink limiting in your RIP was set up. If, for example, your magenta is too low, at around 1.10 to 1.20, then you will have a tough time achieving a decent red. Next, I evaluate the images across the top of my test image that will show you all the primary and secondary colours, as well as the transitions to darker regions as the colours move into the shadows. The dark transitions are often where ICC profiles fall apart and posterize and can make an abrupt transition.

Next, I focus on an image of a grey bottle, which is very important. Grey is the one colour that we can agree on as to how it should look. If your grey a magenta or green cast, for example, then your ICC profile is not going to reproduce colours accurately. If this is the case, consider re-calibrating your device or building a new output profile and linearization. Remember, this grey image is being printed with four colours but must look neutral. The circular blend behind the

bottle must not have any discolouration and it must be smooth. Look at this image next to a window (i.e. daylight) and you may see a big colour shift when compared to office lighting. This can be an indication that you need to increase the GCR and/or start with the black earlier in your profile build.

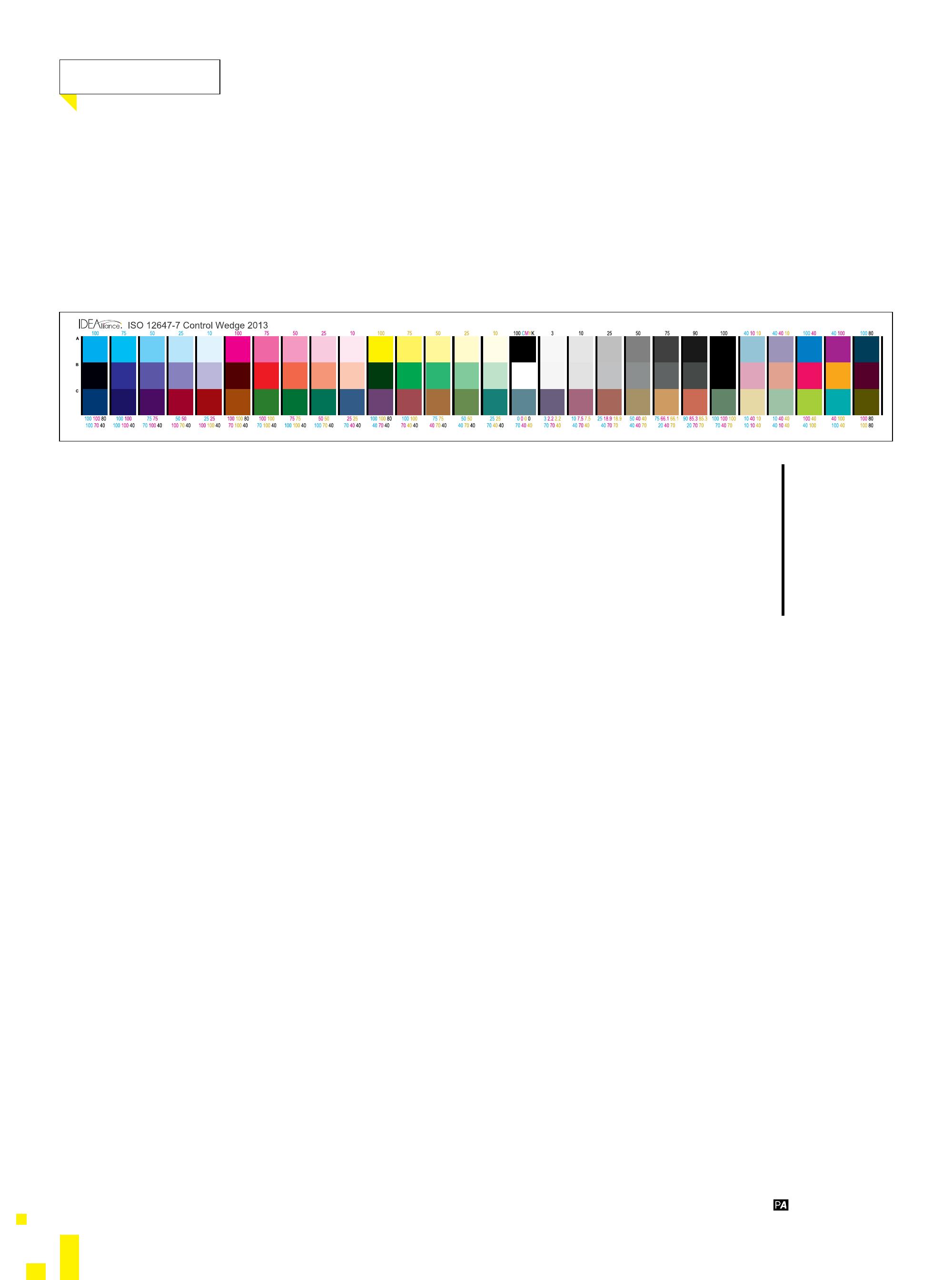

The ISO 12647-7 control wedge is one of the best options when measuring process control and colour verification.

Other than a visual inspection there are a number of tools to verify colour when using a measurement device. The ISO 12647-7 control wedge is the best option when if comes to process control and colour verification. The bar can be measured with an i1 device from X-Rite but you will need software to calculate and compare the measurements to known values. Another cool option is the SpectroPad from Barbieri. This device can be placed directly onto the surface of the print and the top head slides across the colour bar. You are guided by a laser to ensure you are properly aligned. Once the measurements are completed, the device will perform the calculations and show on screen the pass/fail Delta e values. The device can send the measurements via WiFi to a computer.

So what can you do, if after measuring and analyzing your device, you find that you are not matching to GRACoL? First, determine what is not matching. Is it simply the difference in paper white or is it the actual colour. I try to remind people that white is the fifth colour in printing and, unfortunately, the only one we cannot adjust. If it is a difference in colour then you may need to create a new ICC profile for your device.

Some RIPs make this process fairly simple while others make you read a 60-page manual. Regardless of what RIP you are using, the steps are always the same and it’s the first step that is most important. Aside from naming and setting up the parameters of the profile, the first chart you print is the “per channel ink limits.”

This is where you limit the individual ink channels (CMYK) to the optimum levels. And this is where a lot of profiles are too limited too as a result of inexperience. In summary, first evaluate your current printing condition either visually or colourimetrically, determine if changes need to be made, then monitor it daily or weekly to ensure that things have not drifted.

CMYK + OGV Spot Colours

CMYK

Expanded gamut printing

By Abhay Sharma

Commercial printers should start working to understand the evolution of expanded gamut printing, as more of the industry’s biggest technology providers are developing substantial products in this area. In general, we have printed for a long time using four process colours – CMYK – and when a customer needed something more colourful we created a separate spot channel plate and ordered ink or requisitioned the ink from the in-house mixing lab. This is the way we have worked for many years in offset and flexography. Digital devices, such as the HP Indigo, are also able to print with extra colour units and Indigo customers throughout North America order their spot colour toner from a lab in Rochester. In this type of usage, the spot colour channels did not expand the overall gamut per se, they just sent some colours to the separate plates or printing units.

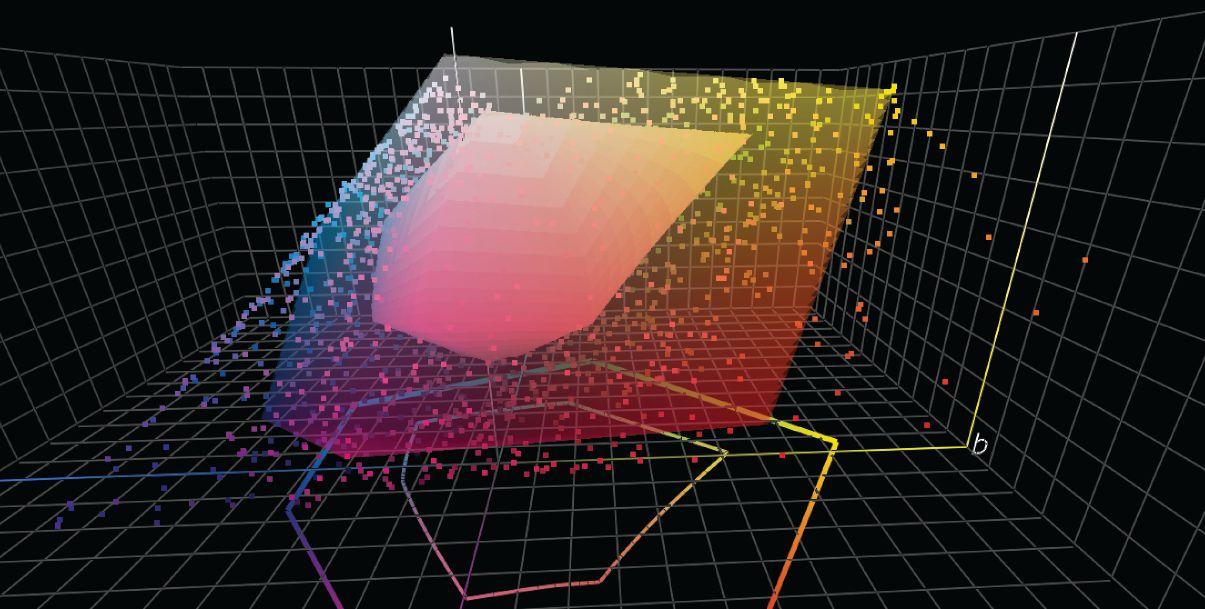

Expanded or extended gamut printing is a paradigm shift in terms of colour and colour gamut. In expanded gamut printing, we move from four-colour printing to seven-colour printing and our base set of process colourants is now seven colour, which can be different for different systems. For example, the new PANTONE+ Extended Gamut swatch book is printed using CMYK plus Orange, Green and Violet (OGV). The Xerox iGen5 has a 5th toner station and can extend the colour gamut with CMYK plus Orange, Green or Blue (OGB). The swatch book is available as a traditional swatch book as well as in software – PANTONE Color Manager – and shows how spot colours would be reproduced in seven colours (CMYK+ OGV).

We can create an ICC colour profile for this extended gamut process and analyze the extent of the expanded gamut using colour management tools. One indicator of the increase in gamut size and volume is to assess how many more spot colours can now be accurately reproduced by mix of the CMYK+OGV ink set. The big advantage is that we can reproduce many more spot colours without using separate spot colour printing! In other words, we do not need to make spot colour plates and order spot colour inks to accurately reproduce many spot colours. In addition, we have the benefit of just keeping the press running

with this expanded colourant set and no press wash-ups. Only the most colourful of spot colours with the most exacting and highpaying client would now warrant traditional spot colour treatment in making a separate plate and ordering a spot colour ink.

In an extended gamut printing process, many more spot colours will now be in gamut of a seven-colour process. An important new requirement is that software tools need to give you an indication of the accuracy with which the process can reproduce any given spot colour. Every colour management vendor at the Phoenix conference was showing new software that enabled users to gauge their seven-colour-process ability.

The small squares generated in this colour gamut by the author are the 1,729 spot colours of the new PANTONE+ Extended Gamut swatch book. A CMYK+OGV and a CMYK gamut are simulated by the larger and smaller volumes in this L*a*b* diagram. It is clear that a CMYK+OGV process can simulate many more spot colours using seven inks, and for the majority of spot colours contained within the volume there would never be the need to make a separate spot colour plate.

The new world of expanded gamut printing also needs to consider proofing. We still may need to create inkjet proofs for the customer. The inkjet proofer must be able to accurately proof the CMYK+OGV press sheet. An inkjet proofer does not need to have exactly the same OGV colourants as a press, but it does need to have the ability to print the increased gamut, so typically the Epson Stylus Pro 7900 has CMYK + OG, while the Epson Stylus Pro 11880 has Vivid Magenta to try and keep up with a CMYK+OGV press. It may be non-intuitive, but there is no requirement for the inkjet proofer to have cartridges that match the units on the press it is trying to simulate. An inkjet proofer can use any inks as long as it can create a sufficient colour gamut to proof the press colours.

There are pressures on commercial printing today to increase colour gamut and reduce costs. Using an expanded gamut set meets both of these requirements. It is more economical to use an expanded gamut ink set rather than wash up of spot colours for individual jobs. Based on the tools and technologies coming to market, from all the major companies, expanded gamut printing is here today and growing tomorrow.

Innovative

systems, Unsurpassed productivity.

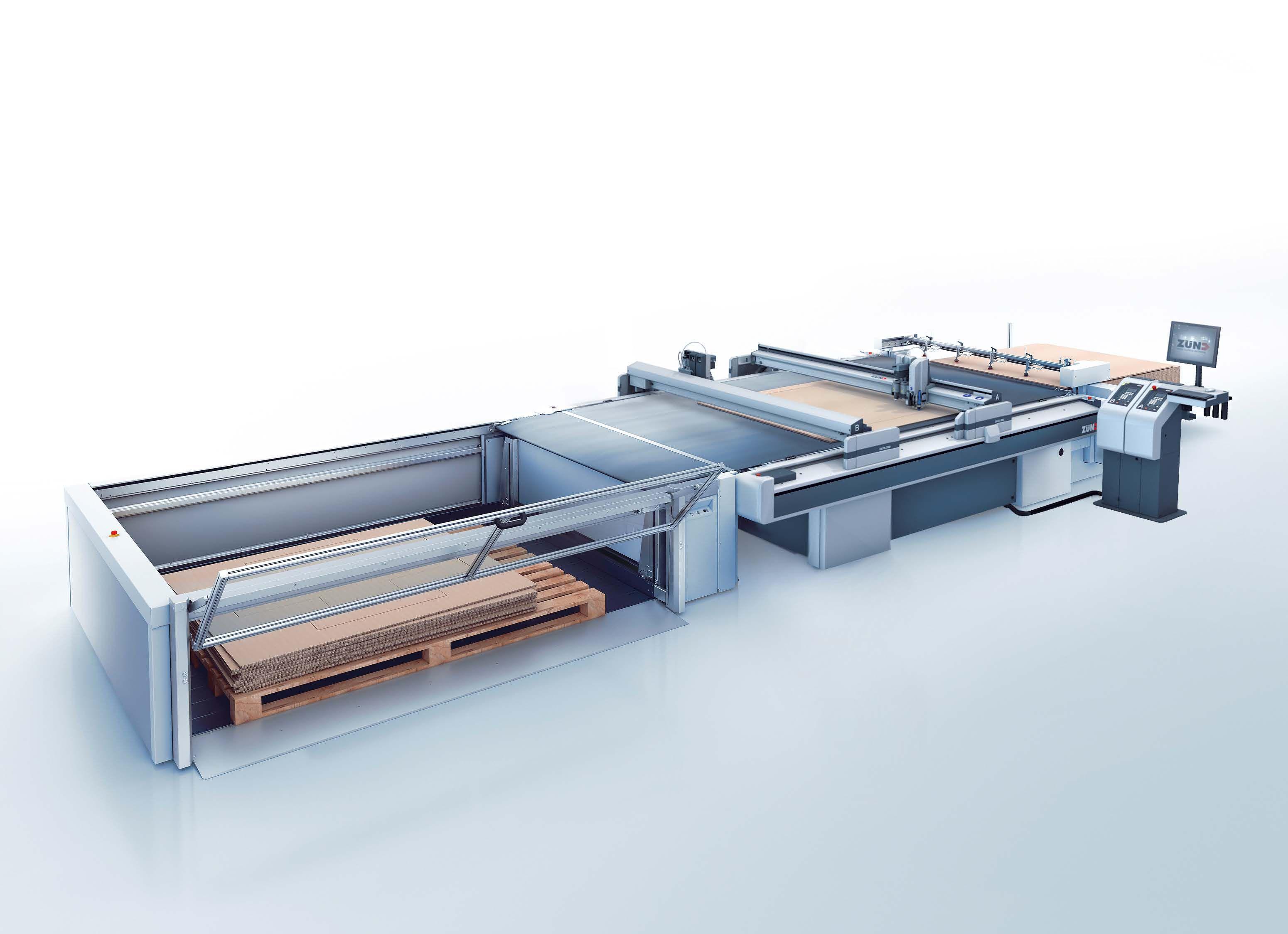

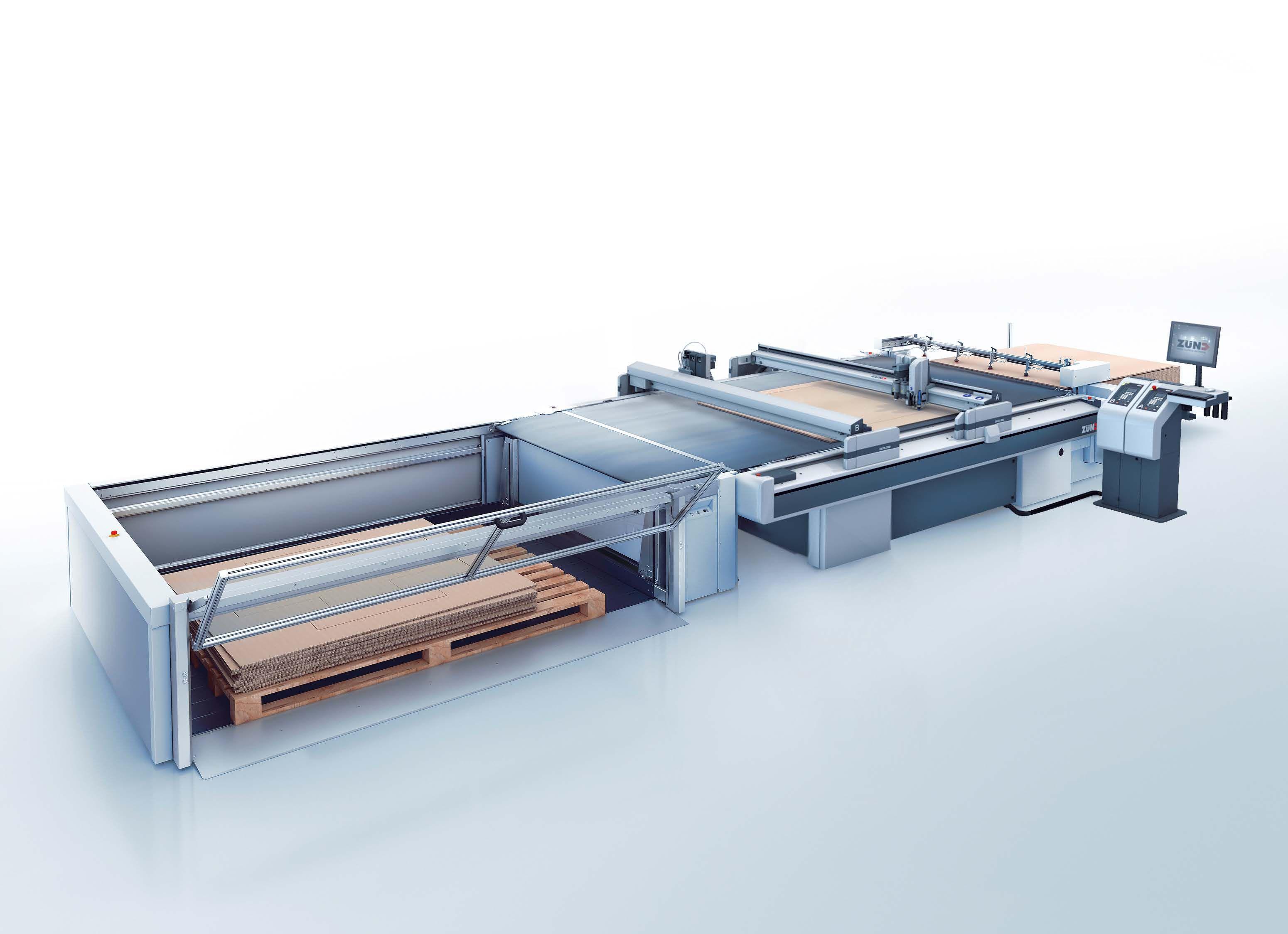

NEW dual-beam Zünd D3:

• Capable of doubling the throughput

• 3 different modules/tools on each beam

• Modular tooling, material handling automation

• Easy integration in existing production workflows

• Proven G3 technology, precision, reliability

Click here to preview the Zünd D3 showing at SGIA, Sep 14 - 16, Las Vegas

Why Zünd?

• State-of-the-art cutting solutions

• Widest range of tool & automation options

• Modular, upgradeable, easy to use

• Reliable non-stop cutting/finishing

• Unsurpassed ROI & longevity

Proving the power of the wrap

By Wayne Collins

Probieren geht über studieren is a mantra that has guided me through much of my career. These are the words of one of my greatest mentors for the past 30 years, Peter Madliger, VP of Prepress at Hemlock Printers in Burnaby, BC – roughly translated, Proving it is better than studying it!

I have accomplished so much by remembering this phrase when implementing new ideas. There comes a time when one has to move past due diligence and roll up your sleeves to see what works, which is what many of us love about printing.

The Graphic Communications Technology program at BCIT, where I serve as program head, recently surveyed business owners who identified large-format imaging to be a common growth sector. We had some equipment donated, did some major renovations to create training facilities, and reached out to the community for help, guidance and resources. The response was an incredible plethora of giving that has topped $6 million. Esko is our Platinum Sponsor with over $4 million provided in hardware, software, and resources that will flow into our program over the next five years.

When I reached out to 3M Canada for support of the program, I also asked their biggest challenges were in marketing consumables for the large-format printing sector. The response was immediate: “Fully qualified installers that know our materials, and how to apply them.” Before the call ended, we came up with a creative proposal to have 3M trainers deliver a series of installer workshops to our students, as well as a scholarship plan for top students to proceed to the next level of 3M installer training. The goal is to have six fully qualified installers from our

graduating class each year.

We first embarked on this training with Brandon and Vaughan Blancher, brothers who have been fully licensed 3M installers for decades. Their father was an installer, and the brothers often win international competitions. They are a dynamic duo as instructors because, not only do they finish each other’s sentences in the technical lectures, they are grace personified when demonstrating perfect installation techniques. They capped the training session by pulling their rental car into our Graphics Lab, divided students into teams, and coached them with a hands-on session.

Brandon and Vaughan Blancher, certified 3M installers, show BCIT students how to wrap a car, following a major commitment by 3M and other members of the Canadian printing industry.

The Blanchers said it was the first time 3M had trained college students. Usually their workshop is full of veteran sign installers. These students were keen, coachable, and enthusiastic. They made the training fun for the instructors, but the passion the instructors injected into our students was life altering. Most of them are practising installations on our floor models daily, in preparation for the next level of 3M training.

3M signed a commitment to grow this idea in our school over the next five years. No one predicted the enthusiasm and passion of these students. I am honoured to have industry partners like 3M, Brandon and Vaughan mentoring these young apprentices in our industry. I left a message in my former boss’s voice-mail: “Peter, I want you to know that Probieren geht über studieren is still alive and well in our industry.”

Detailing new large-format imaging technologies from Agfa, Canon, Drytac, Durst, Gandy Digital, EFI, Epson, Esko, Fujifilm, GMG, HP, Inca, Mimaki, Mohawk, Mutoh, ONYX Roland, SPGPrints and Zund

Roland TrueVIS

In May 2016, Roland DG launched what the company describes as its most advanced printer/cutter ever in the TrueVIS VG-640 and VG-540. These printer/cutters are equipped with four newly developed Roland DG FlexFire print heads to deliver droplet placement in three sizes and a 25 percent wider print swath compared to previous models. The combination of the new FlexFire head and new TrueVIS INK provides print speeds of up to 34.8 m2/hr in dual CMYK ink configuration.

Available in 64-inch and 54inch models, TrueVIS VG Series ink comes in 500-cc pouches that fit into reusable cartridges, sliding into a hidden ink bay. In dual CMYK configuration, up to one litre of ink can be loaded for each colour for high-volume, unattended production.

HP Latex 500/1500

In April 2016, HP introduced its Latex 500 and Latex 1500 series, aimed at medium to large display print service providers with increasing print

volumes. The new 64-inch HP Latex 560 and 570 printers include more unattended printing capabilities with a new spindle-less pivot table and automatic skew adjustment to load rolls in one minute or less, as well as a status beacon for real-time production monitoring from a distance. It holds print speeds up to 23 m2/hr (248 ft2/hr) at indoor mode HP explains users can produce highly saturated prints with new vivid print modes that apply 50 percent more ink density. A new wiper roller can be leveraged for high-quality results on low cost banners and self-adhesive vinyl.

The 126-inch (3.2-metre) HP Latex 1500 printer is described by the company as a robust super-wide solution for a range of indoor and outdoor applications, including PVC banners, self-adhesive vinyl,

textiles and double-sided prints. It prints at speeds up to 74 m2/hr (800 ft2/hr) in outdoor production mode and up to 45 m2/hr (800 ft2/hr) in indoor mode. The system leverages 1,200-dpi HP Thermal Inkjet print heads, auto nozzle replacement, an optical media advance sensor (OMAS), as well as an embedded spectrophotometer.

Epson SureColor P10000

Epson’s new 44-inch SureColor P10000 inkjet system is aimed at the upscale retail display graphics market and fine art photography printing. Joining the 64-inch SC-P20000, the new SC-P10000 leverages an 8,000 nozzle PrecisionCore MicroTFP print head, a new media feeding system, and a reformulated Epson UltraChrome PRO nine-colour pigment ink system. The company explains, when compared with other Epson systems on the market, the new SureColor P10000 is capable of producing quality output at up to 2.8 times faster.

The SureColor P10000 utilizes an all-new 2.6-inch-tall 10-channel PrecisionCore

MicroTFP print head capable of printing output at resolutions of up to 2,400 x 1,200 dpi. Epson explains, when this print-head capability is combined with the new Epson UltraChrome PRO nine-colour pigment ink system, the SureColor P10000 provides strong colour and black density. Epson continues to explain UltraChrome PRO is the first pigment ink set to feature fourlevels of grey ink technology.

HP PrintOS

In late-February, HP unveiled its new HP PrintOS technology as a cloud-based operating system to manage print production for its Scitex and Latex technologies, as well as other systems. PrintOS features what HP describes as a suite of Webbased and mobile applications with cloud connectivity for customers to monitor print status remotely as well as track and improve production performance over time.

PrintOS applications include Box, a tool simplifying job onboarding through nonautomated channels like email and file transfer services. The Site Flow application combines automated order submission, prepress and shop floor management capabilities to, according to HP, fulfill hundreds, thousands or tens of thousands of individual, personalized print orders.

Fujifilm Uvistar

Hybrid

320 UV

Fujifilm’s new Uvistar Hybrid

320 UV system is a 3.2-metre combination flatbed and roll printer, capable of producing output at speeds of up to 2,100 square feet per hour. The inkjet system uses Fujifilm Dimatix Q-Class print heads and Fujifilm Uvijet inks. The eightchannel configurations delivers CMYK, Lc, Lm, Lk and orange inks. A nine channel configuration is available to add white.

The Versa-Drop technology of the Dimatix Q-Class print heads allow the press to image in greyscale with droplet sizes ranging from 10 to 30 picoliters. The Uvistar Hybrid 320 also leverages what Fujifilm describes as a patented tri-lobal belt and six-zone vacuum system. Additionally, Fujifilm explains a dancer bar with spreaders keeps difficult roll media from wrinkling before entering the imaging area.

Durst Alpha

In March, Durst unveiled its “Durst Water Technology” and its new WT printer class, which starts with the Rho WT 250 HS for advertising media and POS displays. Durst’s new Alpha multi-pass machine for textile printing provides one-step pigment inks and automatic material pretreatment for producing home textiles, clothing and upholstery coverings. The Alpha series offers print widths from 190 to 330 cm.

HP Scitex 9000

In March, HP unveiled the new Scitex 9000 system rated to produce up to 90 beds per hour with full automation, while operator-dependent manual

media handling is targeted at around 60 beds per hour. This relates to a 500,000 m2 per year duty cycle for a range of applications like point-of-purchase signs and displays. Additionally, the Scitex 9000 press is upgradeable, allowing customers to scale production according to their quality and productivity needs.

SPGPrints JAVELIN

In June 2016, SPGPrints launched its new JAVELIN designed as an entry-level textile printing system for production of up to two million metres per year, as opposed to its existing PIKE printer (launched in 2015) rated to produce up to 13 million square metres per year with an array of 43 Fujifilm

make proofing simpler, OpenColor calculates high-precision profiles and then transfers them to GMG ColorProof for printing.

Mimaki TS30-1300

In April 2016, Mimaki introduced the TS30-1300 dye sublimation printer for light production environments. This 54-inch wide, roll-based model is a dedicated dye sublimation transfer paper printer aimed at first-time users or design shops producing short-run pieces, samples and custom work for transfer to textiles or hard surfaces. The TS30 printer is an entry-level model best suited to just-as-needed production of apparel prototypes and custom goods. The printer is purpose built for easy operation with features and functionality specifically for sublimation transfer printing.

Agfa Anapurna M2540i FB

In October 2015, Agfa Graphics introduced the new Anapurna M2540i FB as a 6-colour plus white UV-curable flatbed system. It reaches printing speeds of up to 93 m2/hr (1,001 ft2/hr). Agfa explains the M2540i, with its moving gantry flatbed, is well suited for both step-and-repeat work and for printing on a range of media sizes at one time. This can include indoor and outdoor medias, as well as uncoated rigid media like corrugated boards, plastics, Plexiglass, mirrors, exhibition panels, wood, aluminum, MDF, stage graphics, and advertising panels.

Epson SureColor S-Series

Samba print heads. PIKE holds an 1,850-mm print width delivering variable dot sizes (from two to 10 pl) at a resolution of 1,200 x 1,200 dpi.

GMG OpenColor 2.0.4

In May 2016, GMG released version 2.0.4 of its multichannel profiling software called OpenColor. The highlight of GMG OpenColor 2.0.4 is the ability to create separation profiles which can be exported to other applications. Following shortly afterwards, GMG OpenColor 2.0.5 offers dot proof profiles for GMG proofing solutions. The variety of printing technologies, spot colours, substrates and inks provide challenges for proofing, GMG explains, especially with overprinting behaviour and the interplay of inks. To

The TS30 printer is bundled with Mimaki RasterLink6 RIP software for a quick start to production immediately after installation. It utilizes variable dot imaging along with Mimaki Advanced Pass System (MAPS) that applies ink in gradations over several passes using a blending mask pattern. This unique imaging technology reduces banding and uneven color printing. It can reach print speeds of up to 211 square feet (19.6 square metres) per hour in four-colour mode.

In January 2016, Epson launched its most-advanced line of SureColor S-Series rollto-roll solvent printers – the 64-inch SureColor S40600, S60600 and S80600. The new series leverages fourth-generation Epson UltraChrome GS3 solvent inks, an all-new mediafeeding system, and what the company brands as Dual-Array PrecisionCore TFP print heads – aimed at signage, vehicle graphics and fine-art reproduction markets. Developed over a four-year period, the SureColor S-Series’s GS3 solvent inks are formulated for fastdrying. The SureColor S80600 inks a new GS3 Red ink, as well as optional White or Silver ink.

ONYX Graphics Thrive

ONYX Graphics recently released version 12 of Thrive, which the company describes as a full featured, scalable workflow based on the Adobe PDF Print Engine. Thrive v12 provides automation with what ONYX brands as Quick Sets, designed to eliminate manual steps. Also included is Thrive Production Manager, which

provides a real-time, browserbased dashboard into print production from any location.

ONYX Connect, a JDFbased interface, is available as an optional module for Thrive. The open system provides what the company describes as a simple developer interface to connect current business workflow to ONYX software. It also includes the ability to automate job submission through JDF and hot folders.

Canon Océ Arizona 2200

In May 2016, Canon unveiled the Océ Arizona 2200 Series of UV flatbed printers, which builds on the Arizona 600 series to deliver sellable prints at speeds of up to 63.4 m2/hr. The system also produces high quality work with the system’s new six colour Océ VariaDot grayscale printing technology. The Arizona 2200 also features pneumatic registration pins for loading and the Automated Printhead Maintenance System for completely hands-free

print head cleaning in less than 25 seconds per colour.

Patented Active Pixel Placement Compensation technology employed by the system is designed to provide uniform print geometry across both the flatbed table and roll media option. A new UV curing system reduces heat output reduced by 15 percent, expanded the range of heat-sensitive flexible media, including thin film and self-adhesive PVCs.

Fujifilm Acuity Select 20

In March, Fujifilm launched its new Acuity Select 20 Series of wide-format systems as a replacement line for the existing Acuity Advance Select series. The new UV flatbed printer series reaches print speeds of up to 362 square feet per hour (33.6 square metres) working with substrates of up to 2 inches thick (50.8 mm). Acuity Select 20 Series also now includes the option of using light cyan and light magenta, aimed at reproducing fine art or photographic images. As well, Fujifilm explains the addition of a pneumatic pin registration system delivers easier media loading, while new UV lamp technology allows for thinner media to be printed.

The Select 20 Series is also available with an optional automated printhead maintenance system. Acuity Select 20 Series now features what Fujifilm describes as an improved highpressure vacuum system, designed to reduce the need for

masking of the bed for easy loading of media. It will also be available in both the standard 98.4 x 49.2 inch (2.5 x 1.25 metre) and X2, 98.4 x 121.3 inches (2.5 x 3.08 metre) printbed sizes, with a roll option available for both.

Mutoh ValueJet 1628X

Mutoh’s new X series of ValueJet printers, including the 54inch ValueJet 1324X, 64-inch 1624X, and 104-inch 2638X, expand on its current Eco-Ultra line of printers. Denoted by the letter W in the model number, ValueJet 1624WX and 2638WX also expand the company’s dye-sublimation line. The new X series of printers include Mutoh’s newest Smart Printing Technology, DropMaster, designed for dot placement accuracy. DropMaster also eliminates the need for individual head adjustments per individual media type. The new Eco-Ultra branded printers are aimed at vehicle wraps, labels, decals, stickers, banners, trade show graphics, while the dye-sublimation models produce soft signage, flags, custom apparel and interior design products.

Roland VersaUV LEF-300

In January 2016, Roland DGA introduced the new and larger VersaUV LEF-300 to its line of benchtop UV-LED flatbed printers, which also includes the existing LEF-12 and LEF20 models. To accommodate greater quantities and larger-

Roland’s new and larger VersaUV LEF-300 has a print area 30 inches wide by 13 inches long.

sized items, the LEF-300’s printing area has been expanded to 30 inches wide by 13 inches long, which equates to an imaging area 50 percent larger than the LEF-20.

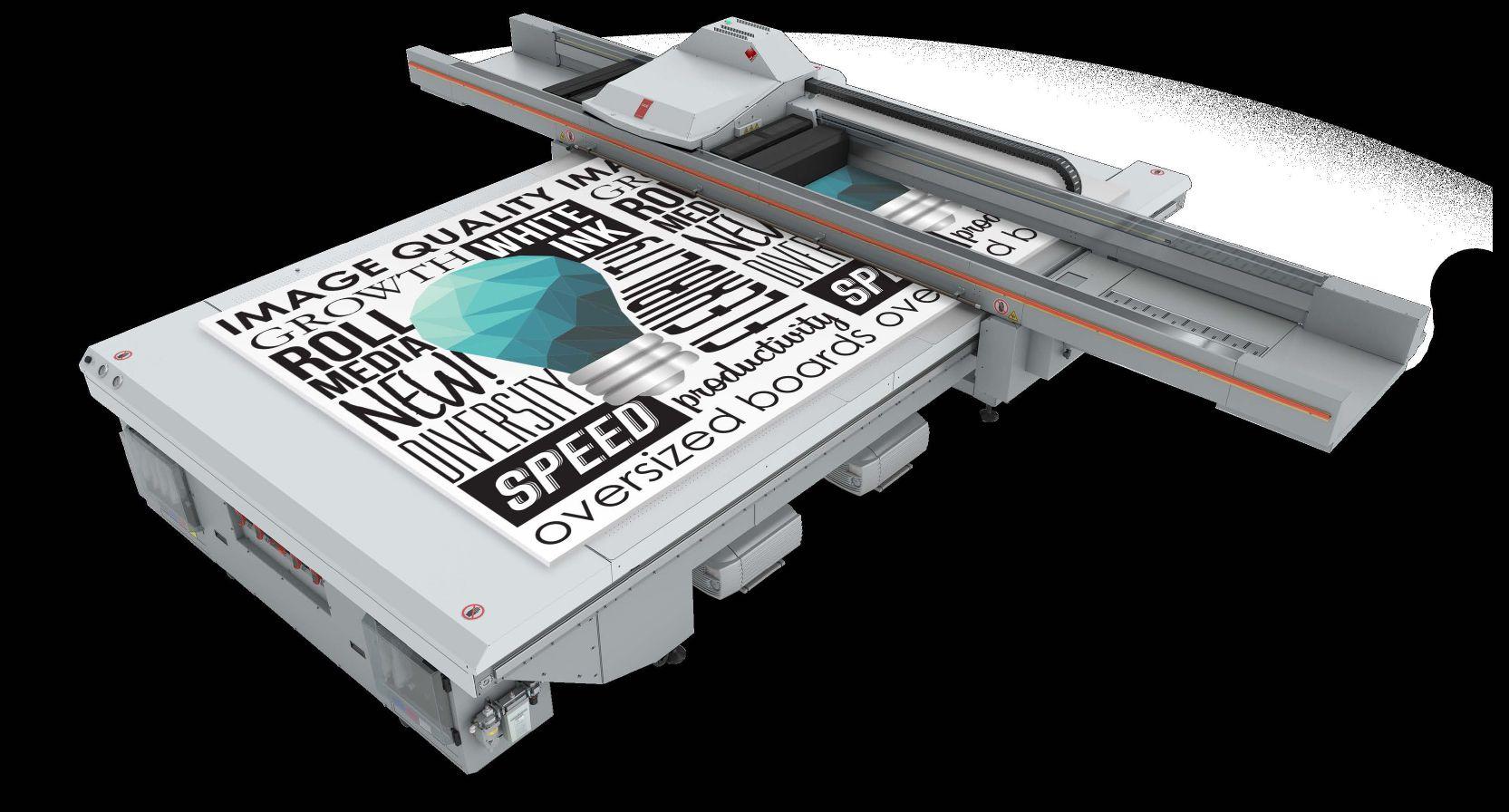

Inca Digital Onset X Series

In October 2015, Inca Digital unveiled the new Onset X Series of large-format flatbed inkjet printing systems, sold globally by Fujifilm. The Onset X Series is described as Inca’s fastest-ever printer, reaching speeds of up to 900 m2/hr (9,687 f2/hr). The systems also leverage a 25-zone vacuum table and UV control to help eliminate masking, and a carriage that can incorporate up to 14 ink channels. Users can start out with the Onset X1, which runs at up to 560 m2/hr (6,027 f2/hr), producing 112 full-bed sheets per hour. The high-end Onset X3 runs at 900 m2/hr produces up to 180 beds per hour. The Series handles substrates in sizes up to 3.22 metres (126 inches) x 1.6 metres (63 inches) and thicknesses up to 50 mm.

Drytac JM55 Force

In January 2016, Drytac introduced its JM55 Force as part of its new JetMounter model of wide-format roller laminators. Described as a heavy-duty, entry-level laminator, Drytac explains JM55 Force is designed for users who require durability and functionality over the long term. JM55 Force has a maximum laminating

width of 55 inches (1,397 mm) and is described as being well suited for mounting, laminating and decaling pressuresensitive materials.

EFI VUTEk FabriVU

The new 3.2-metre EFI VUTEk LX3 Pro hybrid roll/ flatbed LED inkjet printer is rated for a throughput of up to 3,420 square feet (318 square metres) per hour.The aqueousink soft-signage printer also offers grayscale imaging and LED technology. The Quantum LXr LED printer, a dedicated roll-to-roll printer, described by EFI as an economical alternative to latex printers, features 7-picoliter imaging and print resolutions up to 1,200 dpi in four colours with optional white.

The 65-inch H1625-SD is an entry-level UV hybrid production printer that uses EFI SuperDraw UV ink for nearphotographic imaging direct to thermoformable substrates. The printer runs four colours plus white with grayscale imaging. The EFI VUTEk FabriVU 340 is a 3.4-metre dispersed dye-sublimation ink printer developed by EFI Reggiani, which EFI acquired in 2015. The new FabriVU product line, which is also available in a 1.8-metre size, runs waterbased inks and is aimed at soft signage and banner applications.

Agfa Jeti Automation

In April 2016, Agfa Graphics demonstrated new automation

and feature enhancements for its Canadian-made Jeti Tauro and Jeti Mira UV inkjet printing systems. The Jeti Mira UV inkjet printer will be demonstrated with a dockable RTR system that attaches to the front of the flatbed table, Agfa explains, reducing the distance the media needs to travel (less media waste) and further decreasing the chance of skewing while also improving accuracy.

The 105.9-inch (2.69 metre) Jeti Mira flatbed printer features a moving gantry for industrial workloads and produces work in six colours plus white, with optional primer or varnish. With six vacuum zones, Agfa explains the Jeti Mira’s Print & Prepare mode reduces downtime and increases productivity by allowing operators to load one side of the table as the other side is printing.

The hybrid Jeti Tauro printer, designed for high-end sign and display printers, features media tables, an integrated RTR system and can be upgraded with a semi-automated board feeder and stacker. The system’s Automatic Board Feeder, explains Agfa, can drive productivity gains in some cases by more than 30 percent. The 98-inch (2.5 metre) Jeti Tauro features six colours plus white and/or primer option and is designed for 24/7 printing on both rigid and flexible material with speeds up to 2,960 square feet per hour. It also features a

vacuum-belt drive for motion control that, explains Agfa, results in high dot accuracy.

Zünd D3

The Zünd D3 cutter is a new dual-beam system, largely based on the G3 series, aimed at high-volume, industrial applications. The company explains D3’s gains in productivity are primarily due to the series’ dual-beam construction: twin beams operating simultaneously in one production workflow, with each beam carrying up to three different tool modules.

The D3 systems are available in four different sizes ranging from the D3 L-3200 with a working area of 1,800 x 3,200 mm (71 x 126 inches) to the D3 3XL 3200 with a working area of 3,210 x 3,200 mm (126 x 126 inches). D3 cutters allow for the addition of new tools, modules or automated load/off-load devices. The system also leverages the Zünd Cut Center for production workflow.

Gandy Gladi8tor

In mid-2015, Gandy Digital of Mississauga launched its Gladi8tor UV flatbed inkjet printer, featuring what the company refers to as an inline 8-blade print head configuration, which allows for a double CMYK set-up to deliver twice the speed – up to 240 m2/hr –relative to the company’s Domin8tor and Pred8tor models. The Gladi8tor provides double white inking to address density issues on transparent or non-white substrates. It also offers a new layered print option for the production of multi-layered colour images and white. Gandy explains the Gladi8tor’s ability to sandwich white or doubled-sided banners with white and black between images, allows for the production of new applications like backlit jobs.

Mohawk Inkjet Portfolio

In January 2016, Mohawk introduced a major expansion of its wide format inkjet portfolio, which previously consisted of six items. The new Mohawk portfolio expands to 112 items, with 32 different product lines such as backlit, lightblock, black polyester, adhesive, Dupont Tyvek and tear-resistant fabric. Mohawk’s inkjet portfolio now handles aqueous inks, Memjet inks, solvent or eco-solvent inks, latex inks and Ultra Violetcured inks.