PRINTACTION

WIDE FORMAT RESOURCE GUIDE

PLUS

The material of inkjet growth

Tips on working with unique substrates

Force of the Jeti

Building wide-format in Mississauga

New products

25 key technologies introduced in 2015

PLUS

The material of inkjet growth

Tips on working with unique substrates

Force of the Jeti

Building wide-format in Mississauga

New products

25 key technologies introduced in 2015

Craig Riethmacher of Middleton discusses high-speed inkjet

DIGITAL SUPPLEMENT

By Jon Robinson

The commercialization of wide-format-inkjet printing in the 1990s signaled the beginnings of a technological evolution into what is today one of the printing industry’s most intriguing and fastest growing sectors. Leveraging the maturation of inkjet systems and inks, materials science is now a key driver of the dipslay graphics market, pushing incredible and effective new applications and business models.

These advances in wide-format technologies have developed the out-of-home advertising field for the betterment of print. Jeffrey Uzbalis, National Distribution Accounts for 3M Commercial Graphics, describes a related summer 2015 project using 3M films to display Smirnoff ads on the brick and concrete walls aroundToronto’s BMO soccer pitch, catering to a key demographic of 19 to 34 year olds. “Everybody is so focused on social media and mobile that what they often overlook is physical graphics actually get results,” says Uzbalis. “If you put a floor graphic in a supermarket that say Chips Ahoy! you can actually influence consumer behaviour at the point of decision making.”

Uzbalis explains 3M now commissions audited studies to generate hard data points to illustrate the cost effectiveness of largeformat print to marketers. It is part of the company’s massive R&D investment in the sector to tap deeper into one of the strongest printing opportunities.

“People shouldn’t think this is a mature market or that it is too late – it is not. It is growing and there are a million things to do,” says Brian Phipps, Vice President and General Manager, Mutoh America. “The media companies are driving this a lot with the different materials that are coming out.”

An 18-year veteran with 3M’s Commercial Graphics division,

Uzbalis is a true subject-matter expert on wide-format printing. He has seen the evolution of substrates mirror the digital revolution from his position with arguably the world’s most-powerful adhesives company, which generated revenues of $32 billion in its most recent fiscal year with some 90,000 employees.

3M’s introduction of Controltac graphic film around 20 years ago, for example, marked a significant step forward for vehicle graphics. Labeled by 3M as adhesive performance, Controltac allowed users to move away from heavy permanent adhesive that was slow and expensive to use. “Controltac really revolutionized the industry because the adhesive wouldn’t stick immediately,” explains Uzbalis. “You could move it around, slide it around, position it and then apply it with a squeegee.”

In addition to its earlier advances with Controltac (repositioning), Comply (air release) and Envision (stretch and temperature latitude), 3M recently introduced adhesives to apply Envision films to textured surfaces like brick, concrete and block walls.

3M’s second major wrap innovation came around a decade ago with the introduction of Comply air-release technology, based on micro-replication science that was developed to make better stamp paper. The technology was applied to wrap material to make a special liner with a series of ridges.

When the liner is pulled away from the back of Comply film it leaves impressions in the adhesive, which provide routes for the air to escape ahead of an application squeegee – preventing the formation of bubbles. 3M’s newest film advancement, called Envision, adds material stretch and a wider operating temperature to the innovations of Comply and Controltac.

“Really, for [commercial printers] it should be about wrapping in general, whether it is the side of a building or a glass curtain wall or the windows and floors, in addition to vehicle wraps, because there is a well-established vehicle wrap business out there,” says Uzbalis. Images of the amazing artistic work of vehicle-wrap specialists can be seen across every social media platform, which is intimidating for commercial printers thinking about entering the sector. This is compounded by the fact that print is not the most significant component of such projects. “It is not just a printer, it is a department,” says Uzbalis. “With wide-format printing, once you have printed [the job] it is only the beginning. Now that graphic has a second life… it has to be applied to somebody else’s private or public property. It has adhesive on the back of it and this is a key difference – it often has to be removed.”

Commercial printers, however, are becoming more accustomed to valueadd business models, where print is not the sole revenue source within a communications project, whether this means data management, specialty finishing, installation or some other tangible expertise.

“There is certainly an art to both the design and the application if you are doing a full vehicle wrap,” says David Hawkes, Group Product Manager, Sign Products and Textile Printers, Roland DGA. “There are plenty of third-party providers out there who would be more than happy to wrap vehicles for you; and do it under your name… there are ways to put your toe in that market to see if there is interest in your customer base.” Hawkes emphasizes vehicle wraps are often just a component of a client’s overall promotional needs, which may also include out-of-home products like signage, apparel or more standard collateral work.

Commercial printers thinking about entering the display graphics sector must consider their most viable investment route. “The good news for commercial printers is that they are used to spending a million or half a million dollars and they see our printer for $15,000 or down as low as $6,800,” says Phipps. “So, at least it is not a shock from the cost standpoint. It may be from the learning curve.” ,

BRIAN PHIPPS Vice President and General Manager, Mutoh America

“My advice is to get the right equipment up front. Do not go with cheap versions, because the whole chain of equipment needs to be of good quality or the last piece that you might have saved a few dollars on is going to ruin all of your good work.”

“Spend the $700 to get the training. Fly to another city if you have to. Get trained by the professionals in the market whether it is 3M, Avery, us, whoever… it will save you so much time in practice and wasted material because this stuff is not cheap to print.”

JEFFREY UZBALIS

National Distribution Accounts, 3M Commercial Graphics

“It doesn’t matter what type of printer you are running. We really advocate understanding the application that the client wants, what is it going to go on — is it short-term or long-term, indoor, outdoor and what is the surface — and then doing both adhesion and removability testing.”

THINK OF IT AS A DEPARTMENT:

“It is not just a printer, it is a department. You need a laminator. You need a cutter. You need all of the software. You need skilled and experienced people and you have to train your sales staff.”

DAVID HAWKES Group Product Manager, Sign Products and Textile Printers, Roland DGA

“I often see a lot of printers say, ‘Yeah, I will give you that design’ and [clients] do not actually pay for the work that they put into it. If you have done a really good job on the design, people will want to use it other places.”

“You get what you pay for. I see people who have tried to do a wrap with calendared vinyl instead of cast vinyl. Calendared vinyl has memory and over time those corners peel up… if it doesn’t hold the image well, if it doesn’t last well in UV, if it doesn’t hold up to the environment then you have to redo that wrap in a year.”

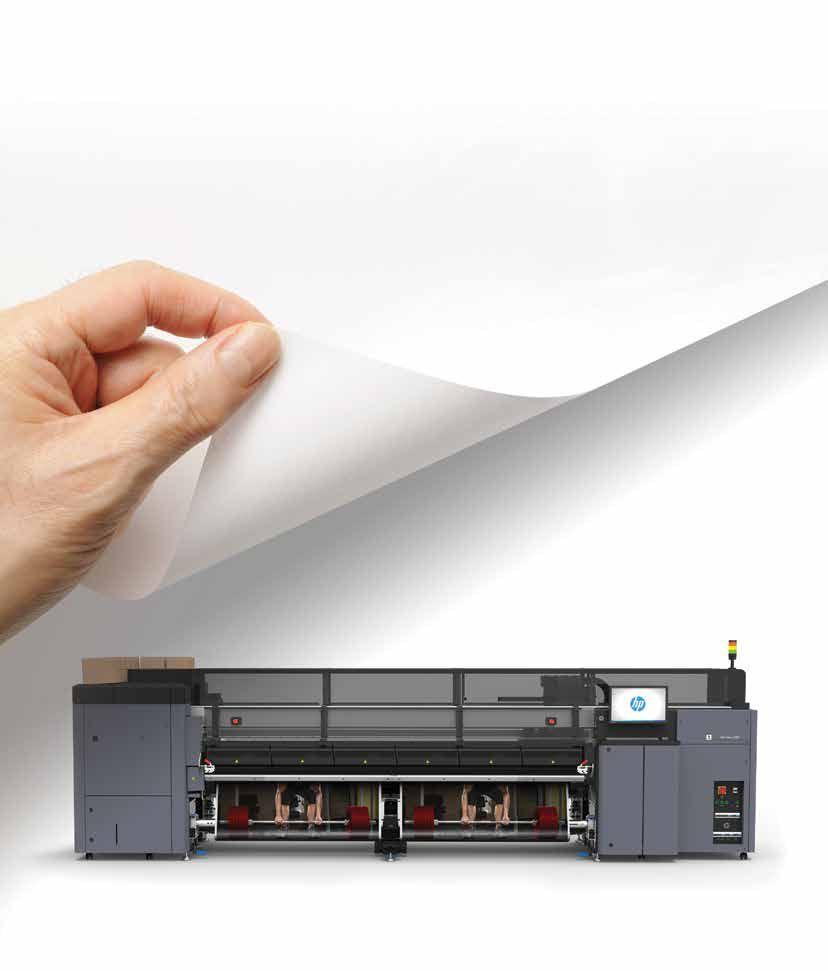

Since inventing the pen plotter in the late 70’s, HP has been a leading innovator in large-format printing. Today, HP has a robust line-up of products to help you meet and exceed your customers’ demands. Driving the digital transformation of large format printing with a versatile portfolio of industrial presses, HP Scitex and HP Latex are equipped with the latest technologies in digital printing. From sign and display to POP/POS and corrugated packaging solutions, HP has what you need to capture attention and achieve streamlined production.

HP Scitex Industrial Presses takes digital productivity to the next level.

The suite of presses can help you meet specialized market demands allowing you to expand your offering all the while reducing workflow complexities and improving your bottom line. Stay ahead of competitors by meeting demanding turnarounds with the quality you need. Plus, you can rely on end to end support from HP.

HP Scitex 11000 Industrial Press: Outstanding versatility and productivity

Expand opportunities and grow profits with application versatility and agility. You can improve margins with the industrial productivity and quality offered by the HP Scitex 11000 Industrial Press. Confidently convert more projects to digital with ongoing press enhancements, tools, and support services.

Additional features include:

• More than one million m2/year production capacity

• HP Scitex HDR printing technology enables small ink drops for quality and large drops for speed

• HP Scitex Smart Coat Technology provides surface durability and flexibility

• HP HDR Scitex inks offer exceptional media versatility—from paper to plastics Visit us at www.hp.com/go/scitex11000 to arrange a product demo with an HP Product specialist.

Expand your expertise and be unstoppable with HP Latex printers.

From building wraps and POP to wallcoverings and canvas applications, large-format print service providers around the world are turning to HP Latex Printing Technologies to expand their capabilities, shorten turnaround times and differentiate their prints and their business while keeping costs low. HP Latex printing can generate higher profit than eco-solvent—with advantages including wider application versatility and prints that come out completely dry, allowing same-day delivery. Buy in at an affordable price, and keep your running costs low.

What is the latest in the HP Latex Portfolio?

The newly launched HP Latex 3500 Printer incorporates a new level of efficient production with heavy-duty roll handling and 10-liter ink supplies leading to increased production capacity and reduced costs.

Additional Features Include:

• Heavy duty roll handling—up to 300 kg (650 lb) and 40 cm (16-in) diameter

• HP 3M 891 10-liter Latex Ink Cartridges

• Dual-roll split spindles

• HP Latex In-line Slitters

• LED Proofing Lights

• Printer Status Beacon

*Note: For a detailed list of our products please visit us online at www.hp.ca.

See the latest in the HP Latex Portfolio by clicking on the video: https://www.youtube.com/watch?v=--uvSWYjVUQ Call us at 1-866-828-3649 or visit us at www.hp.com/go/latex3500 to arrange a product demo with an HP Product specialist.

There’s nothing to lose but cost.

• Increased capacity with heavy-duty rolls and 2.6-gallon ink supplies

• Longer runs with up to 12 continuous, uninterrupted hours

• Faster proofing with in-line LED proofing lights

• Quicker turnaround times using in-line slitters for edge trimming

• Higher productivity with unattended printing with the HP Latex Mobile App

• Improved profits due to reduced media, ink and finishing waste

By Jon Robinson

Agfa Graphics purchased the Gandi Innovations facility in 2009 to cement its inkjet interests. Over the past six years, manufacturing in this 115,000-square-foot plant has evolved from early entrepreneurial pursuits to disciplined processes and meticulous quality control.

Mark Schnittke, Agfa’s Director of Inkjet Site Operations, has led much of this transformation, having joined Gandi in 2006 to ramp up its production, which peaked at around 60 machines per month. Shortly after purchasing the operation, Agfa narrowed down the more than 10 products being built in Mississauga to instead focus in key future platforms.

This meant dropping solvent inkjet systems and some successful roll-fed machines to concentrate on flatbed UV, creating what became known as the Jeti

Titan. In 2015, Agfa introduced two new Jeti systems, including the modular Tauro and the Titan-inspired Mira, manufactured out of the Canadian plant. Schnittke spoke with PrintAction about building world-class printing systems in Mississauga.

How did Agfa change this facility after purchasing Gandi Innovations?

Schnittke: We have undergone a massive transformation... We really didn’t outsource too much, but we slowly realized that we need to rely on the experts in various aspects of materials fabrication.

How has the manufacturing of systems changed?

Schnittke: We went to a cellular build [with] a centralized stockroom. All of our inventory comes in and goes through incoming inspection to a dedicated stockroom and

we pick the components that we actually need and allocate them to a specific unit or serial number and bring it to the machine. It created a lot more flexibility on the floor. We have approximately 18 to 20 work cells we can build any one of our new products in those particular work cells, at any given time.

How long on average does it take to build an inkjet machine?

Schnittke: Our lead-time is about 45 days to the marketplace. The actual build is somewhere between 20 and 25 working days. We have extra time in there because of the make to order to get the product flowing and obviously if we receive 10 orders today we cannot start all 10 machines tomorrow, so there is a bit of a queue.

We have had a larger than average order intake recently. The last four to five months

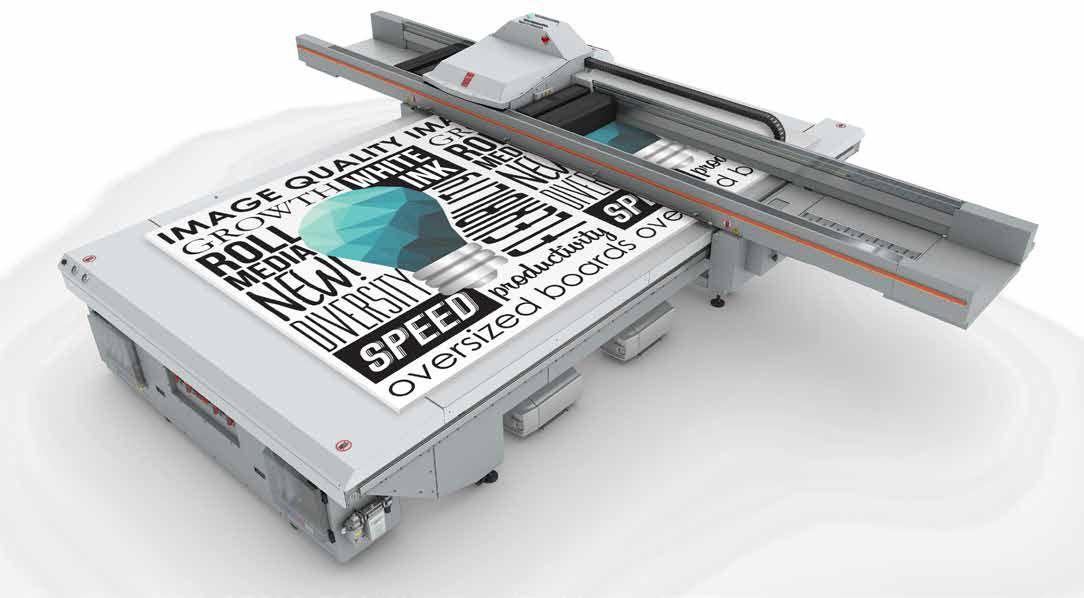

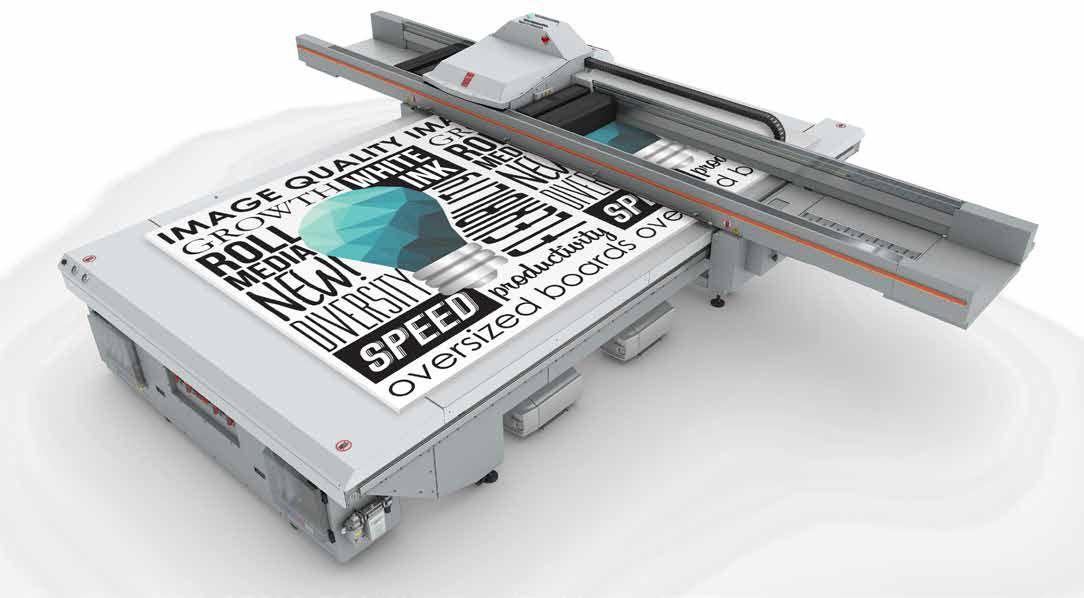

• Impressive print

productivity and versatility – six-color plus white UV flatbed

• Reduces downtime and increases productivity – Agfa’s ‘Print & Prepare’ mode and a moving gantry – allows media loading on one table side while the other is printing

• Perfect for large or small boards, objects and double-sided images

• Printing speeds up to 206 m²/hour, a table size of either 1.6 x 2.7m or 2.7 x 3.2m and one or two rows of print heads

Choose Duratex media when quality and consistency matter to your customers!

When we asked high-volume wide-format printers what it would take to upgrade to Onset, they quickly shared their wishes. Give us a more affordable option without compromising Onset’s renowned speed and quality – and while you’re at it, provide us an upgrade path for the press that increases throughput as our business grows. Wish list granted.

Now for little more than you’d invest in a mid-range press, the Onset R40-LT will deliver press productivity to up to 40 5'x10' full-size beds per hour. Plus, there’s an easy upgrade path to grow as your business grows.

The first upgrade boosts output to 58 beds an hour by adding bi-directional printing, and the second upgrade increases capacity to 80 beds by adding one of three automation options.

The Onset R40-LT comes loaded with everything you need to produce crisper images, finer lines, sharper text and smoother tonal gradations for your clients. Drop-on-demand printhead technology offers precise ink drop placement. Inca’s iNozzle technology allows the press to maintain Onset print quality like the day the press was first commissioned. Automated nozzle mapping finds and compensates for any deviated nozzle – giving you dependable print quality. You can also choose four- or six-color configurations, including white – and achieve faster job changeovers with our patented 15 zone vacuum bed.

To learn more about how Onset quality and productivity is now right within your reach, visit fujifilminkjet.com today.

Upgrade as you grow!

have been quite strong for us. Hence the lead-time is running at that 45 days. We are aggressively trying to do things to reduce that no one want to wait that long for their printer.

What Agfa machine is seeing the strongest demand right now?

Schnittke: We had a very strong first half with the Titan. We had a good year last year with Titan and it has been steady. Now with the introduction of both Tauro and Mira, those orders have been coming in quite strong.

How did Jeti Mira create different manufacturing needs?

Schnittke: Dominiek [Arnout, VP, Inkjet, Agfa Graphics] has been a driving force of this. We have really tried to establish engineering building blocks with the Titan... very robust systems, very reliable. We have adopted those systems into the Mira.

For instance, the entire ink system is adopted from the Titan; the entire carriage assembly that feeds the print heads is tied in from the Titan; the Ricoh gen 5 heads are from the Titan; and the UV system is also from the Titan.

Why is Tauro described as your first true modular system?

Schnittke: The Tauro was designed in Belgium, in Mortsel at headquarters, by an extremely strong engineering team. Where we had an advantage for that product was that it was a ground-up design, whereas the Titan has been a build off of several generations of product.

[With Tauro] we had a lot more input from a manufacturability perspective and the people in this facility really drove the need for the modularity in the design… When you look at the Titan and Mira everything is built up off of a frame or a standard platform, so everything gets added to it… you limit your flexibility, you increase in many cases your work in process, as well as your manufacturing lead time, because everything happens sequentially.

When you have something that is modular you can prebuild the modules on their own and then integrate them together. So your sequential activity is the actual integration not the build up of

all of those modules. Our factory value add has evolved from simple assembly tasks to precision alignments, system set up and image quality optimization.

How early was this facility involved in Tauro’s design?

Schnittke: Belgium was working on the concept of the machine and how things were going to work... We said, ‘On a Titan there are 800 piece parts. Well, ideally on a Tauro, I would like seven to 10 modules and those modules can be individually built and tested so that when they come together we know they already work.’

We also wanted the modules to be plug and play so the cabling comes from one module to the next and you plug it into the appropriate slots, turn it on, and you start. This concept was completely supported by the engineering team and that is what we have now.

How much pressure is there to deliver for an imaging giant?

Schnittke: Dominiek [Arnout] and his management team have faith in us, that we can deliver, but continue to put pressure on us to perform at high standards.

I think we have stepped up… we have made a lot of changes and improvements and through the years we have proven that we design, manufacture and support world-class products.

We put pressure on ourselves to perform at that level, because we worked hard to get here and we are not wiling to take a step back. And with my management style it is not an option. You can maybe slow down a little bit but you cannot take a step back you cannot degrade your quality. Quality is first and foremost for Agfa and we take great pride in it. We will not accept anything less.

How does Mira and Tauro change things?

Schnittke: The introduction of two new products in a very tight timeframe adds to the pressure obviously. There are more things at stake than just this facility. There are a lot of people who are depending on the growth of this business and the growth of the new product lines. But the team here has shown its commitment to the quality focus.

The Onset R40-LT delivers industrybest inkjet productivity and quality to your shop at near the price of a midrange press with an easy upgrade path as your business grows.

The incredible production speed of the Onset flatbed UV press platform is made possible through many proprietary technologies from Inca and Fujifilm, including:

n Full-width Print Array – Onset printheads cover the full width of the print bed, printing an edge-to-edge graphic image and eliminating banding commonly associated with scanning head technology found on many midrange presses.

n Inca Vision – A unique support service that allows Inca engineers to remotely monitor an Onset, and in many cases, prevent issues to maximize uptime and minimize down time.

n Fujifilm Uvijet OW Ink –Specifically developed for the production speeds of the Onset, Uvijet OW features Micro-V dispersion technology to maximize pigment loading to deliver superb dot reproduction, bright vivid colors and excellent finishing characteristics.

fujifilminkjet.com

he wide format printing industry is constantly evolving in response to customers’ habits and expectations, technology, and media selection. Rapid advances in technology allow for more flexibility, versatility, and business opportunities than ever before. And with the continuous increase in printable substrates, it’s clear that with the right printer and a little creativity, any business can not only survive, but thrive.

In the Canadian graphics marketplace, the use of flatbed printers has grown exponentially. The right flatbed printer can increase production efficiencies and profitability while eliminating workflow manpower steps and reduce both turnaround times and material costs.

At the Professional Printing Solutions Group (PPSG), a division of Canon Canada, we see innovation every day in the vast array of applications produced by our customers. For many, the addition of a flatbed printer has completely reinvented and rejuvenated their business. With the ability to print on almost any relatively flat surface of up to 2” thick, and with options such as white ink, varnish, and roll-media, customers can increase their current profitability by keeping more projects in-house. Less outsourcing also means more control over quality, schedule, and pricing while opening the door to new business.

Here’s how some business segments reinvented themselves to increase revenue and ROI while capitalizing on cost-effective, new opportunities.

WHY: Early adopters of flatbed technology looking for efficiencies and new opportunities

HOW: Capitalized on market shift to on-demand, low, and medium runs. Transitioned to offering unique substrates and specialty applications to upsell current customers

WHAT: POP graphics, in-store signage, event graphics, and specialty one-offs

WHY: Dominant suppliers of large scale printed graphics. Challenged with maintaining profits as jobs trend toward shorter runs

HOW: Adding a flatbed made hybrid screen/digital printing possible, creating short run profitability and workflow efficiencies

WHAT: Print on pre-manufactured items such as binders, containers, footwear, doors, and more

WHY: Traditional business declining due to shift from large, paper plots to digital documentation

HOW: Smooth transition to flatbed printers as profitable extension to current business

WHAT: Typical services now include retail and outdoor graphics

WHY: Focused on custom production and challenged with maintaining profitability in one-offs and short runs

HOW: Adding a flatbed printer allowed for high quality printing on a wide range of rigid and flexible substrates with uncompromised productivity

WHAT: Freedom to design using media such as MDF wood panels, metal, acrylics, and textiles

WHY: Conventional print volumes are shrinking and new profit avenues are needed

HOW: Expanding into wide format utilized core business while complementing current production capabilities. Output on an Océ Arizona flatbed is comparable to offset and allows for split runs between press and digital, depending on volume demands

WHAT: Use similar media (paper, card stock and banner media) to create POP signage, packaging, and retail products

Since first introducing the Océ Arizona® flatbed printer in 2006, PPSG has been dedicated to showing customers how to reinvent their business. We believe that the backbone to reinvention is a solid understanding of your printer’s capabilities and how you can best use these to leverage productivity and undiscovered customer needs. By building a strong relationship with our customers we strive to become true partners who can offer valuable advice and unique application ideas.

Our professionals ensure that customers are fully educated on their system’s capabilities, up-to-date on new developments, and understand all media options available.

We are confident that with the right equipment, knowledge, support, and a little imagination any business can thrive in the evolving wide format market.

Check out our Flatbed Printer Application Guide, specifically designed to show you the potential in your business. The newest issue includes application recipes, Canadian case studies, interviews and much, much more.

By Jon Robinson

Craig Riethmacher grew up surrounded by the business of large-format printing, with his father being one of the founding shareholders of Middleton Group back in 1952. Middleton today is a unique printing operation in Canada, based on its move into merchandising more than a decade ago and the company’s continuing drive to deliver the rich quality of screen printing through two massive 4-colour UV-enabled inline presses, and four single colours.

Middleton was also among the country’s first screen printers to dive into wide-format inkjet printing, taking on a 4-bed-per-hour Inca Eagle 44 press in 2005, followed three years later by a 10-bed-per-hour Columbia Turbo. In late-2010, Riethmacher led Middleton’s purchase of a huge Agfa M-Press Tiger press, which produces up to 170 beds per hour.

In March of this year, Middleton replaced its Columbia Turbo, after running it for seven years, with Canada’s first Inca Onset R40-LT UV inkjet press. Before touring the company’s impressive 50,000-square-foot printing plant, Riethmacher sat down with PrintAction to discuss the growth and direction of Middleton Group.

What was the largest technology jump for Middleton?

Riethmacher: When I worked on the presses we switched from solvent-based inks to UV inks. That was a really big jump, because it just changed everything. It changed all of our equipment and all of our processes.

What were the early days of digital like?

Riethmacher: The speed was horrible compared to screen-printing, so it was really limited in the beginning... But it was beautiful when it came out – just so slow. The biggest bonus was the lack of prepress compared to screen.

Why did you invest in the new Inca?

Riethmacher: The Inca is so good for us because of the type of work that we do; having to do those thick substrates and edge-to-edge printing and now we can do whites and spot gloss clears, so it is a really good press and it fits our shop.

How much has printing white advanced?

Riethmacher: It is great. We are screen printers so we have had that luxury of doing digital and putting a screen ink on the back or vice versa, but you still run into some weird curing issues... We went through a good amount of R&D on that, so to be able to just send in a sheet and have it come out with white on is great.

Will digital inkjet replace screen?

Riethmacher: Ten years from now if they keep going as they have in the last 10 years, we are going to be running some pretty speedy digital presses. I don’t think you will ever replace screen 100 percent, but it will get close. I do feel there will always be a place for screen.

What percentage of your work is screen versus inkjet?

Riethmacher: We do more digital. I would say probably 60/40. It is very much quantity related too. Larger jobs that are over 500-plus sheets tend to go screen – depending on what the job

One of Middleton’s 4-colour screen lines in its 50,000-squarefoot printing plant.

looks like. Sometimes we will look at the artwork and realize it is going to be very difficult to produce screen, like some jobs with fine light colours that have really low percentage tones where we are going to pull our hair out trying to achieve colour, so we just put them on the digital press.

How important is print today at Middleton?

Riethmacher: We are definitely not just a printer anymore with all the permanent display work we do, but we still like to boast that we are a pretty darn good printer. We always have been and I think we always will be about quality. We will take the extra step to make sure our quality is well above average before it goes out the door.

Do you feel the competition of commercial printers getting into wide-format inkjet?

Riethmacher: Yes – when we were just screen-printing, it was just us and three or four other big competitors. That became five or six as digital started and now there are people with [digital] in their garages, nipping away at things. There are so many types of digital. So, what we tried to do here was not become a so-called digital shop where we have other processes like roll-to-roll. We buy digital equipment that compliments our screen print and it makes us a better large-format printer – better at what we do best and what we sell best.

Will you scale up the R40-LT over time?

Riethmacher: We have the M-Press, which really pounds out the prints and it wasn’t that we were looking for another print pounder… The LT was perfect for us because it is four times faster than the Turbo. Even at the base model and quality is exactly the same whether you have the full R40 or not. We will definitely be looking to scale up the press moving forward.

How much of your sales is from merchandising versus print?

Riethmacher: I would say about a 60/40 split with printing still being higher… Print is very competitive. We are going to get what we can, but if we really want to grow our business we have to grow it on the merchandising side, while still being a great print provider. That is really where our focus is... helping the bottom line.

STEP UP YOUR SOLVENT PRINTING WITH THE SURECOLOR® S30675

Capable of producing high-quality output hour after hour, the Epson SureColor S30675 could be the perfect entrylevel sign printer. Utilizing some of our most advanced imaging technology – including our unique PrecisionCore® TFP® printhead, along with UltraChrome® GS2 solvent ink – the SureColor S30675 delivers unmatched value for any size print shop. To learn more about SureColor S-Series signage printers, visit PROIMAGING.EPSON.CA

SureColor S30675 is designed for use exclusively with Epson inks and cartridges.

Released April 2015, the ColorWave 500 is a 42-inch-wide monochrome and colour sys tem in one footprint. It features the Océ ClearConnect Panel (touchscreen), as well as Color Image Logic software for en hanced colour and scanning, while the system’s workflow can prepare, produce and man age complex files ranging from AEC and CAD up to large graphic files. Canon explains Océ CrystalPoint technology is designed for robust, waterfast prints with sharp lines, high readability of fine details and smooth area fills. A space-saving top delivery tray provides for organized document delivery and stacking. Canon describes the ColorWave 500 as a sustainable printing technology that can print on recycled medias, emitting no ozone, odour or dust.

ClearConnect Panel and CrystalPoint technology. The

common in higher-volume routing applications.

The latest release of the Zund Cut Centre (ZCC) software offers a range of new features including tool usage monitoring, user-definable register marks, edge-detection for rolled materials, and a userfriendly nesting option. Helping to eliminate guesswork and

Drytac’s ReTacDuo allows for repositioning wall graphics.

system is ideally suited for central print rooms and reprographers wanting to offer new large-format services like posters, pop-up banners, artistic canvas and wallpaper.

Released April 2015, the ColorWave 700 is described as a versatile all-in-one printer featuring Océ MediaSense technology to support medias up to 32-mil thick. The system, for finishing and scanning, also leverages the Océ PowerSync controller to scan, print, and copy at the same time from the cloud, USB or flash drive to hardcopy. It includes automatic cutting, instant drying of prints, and 6-roll capacity. Like the 500 model, ColorWave 700 includes

To be released October 2015, Automatic Router bit Changer (ARC) is integrated with the Zünd Cut Center workflow for the company’s G3 cutting/ routing systems. It offers the user a magazine that can hold a selection of up to eight bits for different thicknesses and/or routing tasks. The system automatically selects the appropriate bit for the job and material at hand, helping to reach optimal results and eliminating the potential for operator error

waste, ZCC now lets the user know when a given bit/blade has reached the end of its expected life. After each automatic roll feed, ZCC now detects any shifts in the material and compensates accordingly. It can now also capture any shape the user has pre-defined as a register mark.

Released May 2015, ReTac Duo, a clear double-sided wall adhesive, transforms most photos, posters, maps, or news clippings into removable wall and window decals. It has a 1-mil clear polyester carrier and features a permanent adhesive on one side and ReTac removable adhesive on the other. The ‘ReTac on the Back’ adhesive, affixes graphics in

place while, according to Drytac, allowing them to be repositioned as needed without leaving behind residue or damage during removal.

Released March 2015, Polar is an 80-micron (3.2-mil) premium polymeric self-adhesive print vinyl with a gray cross linking acrylic adhesive and a high opacity, which provides a consistent print surface and strong white point. It is available in matte and gloss finishes with permanent and removable adhesive versions. Permanent adhesive is suited for outdoor applications such as general purpose signage and construction barricades; while removable adhesive is best suited for advertising graphics and point-of-purchase displays.

Introduced April 2015, the SureColor S-Series of solvent inkjet printers consists of three models: S30675, S50675 and S70675. Designed and manufactured by Epson from the ground up, the SureColor S30675 and 50675 feature the Epson PrecisionCore TFP print head and UltraChrome GS2 ink with a newly formulated Cyan ink for what the company describes as enhanced durability and per-

formance. The S70675 leverages the UltraChrome GSX ink set with newly formulated Cyan and Light Cyan, plus an all-new Orange Plus ink for an expanded colour gamut.

Released April 2015, Agfa explains the Jeti Mira and Jeti Tauro are ideally suited for print environments requiring a combination of both high quality and high productivity. The Mira is a 6-colour plus white system that prints up to 206 square metres per hour. It is well suited for printing boards, objects and double-sided imaging with two table size options. Jeti Tauro is a 2.5-metre wide, high-end hybrid 6-colour system, plus white or primer, that features multiple automation options. Both systems are powered by Asanti workflow and manufactured in Mississauga, Ont.

Released October 2014, the VersaUV LEJ-640FT flatbed UV printer is described as an industrial-strength flatbed UV printer incorporating new generation print control tech nology, CMYK, White and Clear Coat inks, and an what Roland describes as an unprecedented printing clearance that allows the system to print

directly on substrates up to 6-inches thick and weighing as much as 220 pounds. The system is also equipped with a

rigid all-steel frame, adjustable pinpoint guides for registration, and a zoned vacuum bed for keeping substrates of different sizes flat.

Released October 2014, the Texart RT-640 dye-sublimation printer is a 64-inch system engineered to optimize sublimation output while minimizing running costs. It includes ErgoSoft RIP software, and a choice of 4- or 8-colour ink configurations. Roland states a newly designed feed adjuster, in combination with a powerful fan and the TU-3 take-up system, provides for stable and

accurate printing at speeds of up to 351 square feet per hour. In March 2015, Roland introduced new Texart Sublimation Transfer Paper as a 95 gsm substrate suited for applications like sublimated apparel, home décor and trade-show signage.

Released April 2015, ValueJet 628X is an Eco-solvent printer with a small footprint, which Mutoh describes as packing a lot of punch for the dollar. The 24-inch printer is designed to fit on a desktop. It is now available in three ink configurations, offering up to eight colours including CMYK, Lc, Lm, white and metallic inks. With the ability to produce 1,440 dpi resolution, Mutoh states the system is suitable for photographic output, custom banners, indoor and outdoor signs or custom labels and stickers.

Released April 2015, ValueJet

1628X is a 64-inch wide-format system featuring four ink configurations with up to eight colours, including CMYK, Lc, Lm, white and metallic inks. It prints 1,440-dpi output for producing similar applications suited for the 24-inch desktop model. It features Mutoh’s Drop Master print automation technique for dot placement accuracy, while also helping to eliminate the need for individual head adjustments per individual media type. With Mutoh edition FlexiPrint SE RIP software, the 1628X hits speeds of up to 500 square feet per hour.

Released in early 2015, HP explains the Scitex 11000 Industrial Press allows customers to increase versatility and productivity for high-volume indoor signage and display applications. It includes new HP Scitex Smart Coat Technology to provide surface durability without an additional overcoat. This technology places a thin, invisible layer on top of the image, explains HP, to enhance rigidity and to protect against

rubs, without compromising on application flexibility.

Introduced May 2015, the 3.2-metre (126-inch) HP Latex 3500 and 3100 printers join more than 26,000 HP Latex printers already installed worldwide. With heavy-duty roll handling up to 300 kg (660 lbs) and 10-litre ink supplies, the printer is capable of unattended, overnight printing. The machines also hold dualroll split spindles for what HP describes as safer handling of oversized rolls; as well as inline slitters to reduce bottlenecks in finishing; and built-in LED lights to support on-the-fly proofing.

Released May 2015, the Onset R50i flatbed UV printer, distributed worldwide by Fujifilm, features 14-picolitre Fujifilm Dimatix Spectra print heads and an 8-channel, dual CMYK configuration. The new system prints at 600 square metres per hour with automation. It is positioned between what Inca describes as the high-quality

6-colour Onset R40i (400 square metres per hour) and the high-speed Onset S50i, which runs at up to 720 squametres per hour. The new Onset R50i, Inca explains, is designed for firms who produce a mix of graphics for long

The Onset R50i prints an apparent resolution of 1,000 dpi onto substrate sizes up to 3.14 x 1.6 metres and 50 mm (two inches) thick.

and short-distance viewing, as the system provides both quality and speed.

In May 2015, Esko unveiled a new range of Kongsberg tools, on top of the more than 100 existing cutting blades, router bits and accessories. Some of

Psaligraphy knife tool cuts out fine details in paper and folding carton.

the newest tools include a psaligraphy (paper cutting) knife tool, perforation wheel and braille tool. All three tools are available for use on the Kongsberg XN, Kongsberg V and Kongsberg XL Series of finishing systems. The tables are suitable for both packaging and signage applications, using a range of substrates like foam, plastics and vinyl, as well as paper, corrugated board and folding carton.

In mid-2015, Sihl introduced its newest banner material, called 3275 TexBanner Xtrem white 145, which the company describes as an economical alternative to existing highquality products. TexBanner 3275 is a 100 percent synthetic, non-woven material coated

with Sihl’s water-fast matte inkjet formulation. The company explains it holds a high tensile strength and tear resistance. These factors, combined with an ability to be stapled, sewn or used with grommets, make it well suited for both indoor and outdoor banners.

In mid-2015, Kornit Digital, which focuses on the development of textile printing technology, launched a new-generation discharge ink for the Kornit Avalanche DC Pro direct-to-garment system. Kornit states the ink produces printed garments with a natural feel, which is suitable for highfashion applications. The discharge ink does not require special handling or mixing, according to the company, and remains stable in print heads for up to a year. The Kornit Avalanche DC Pro has two additional print heads by which the new discharge ink is ap-

Kornit Avalanche DC Pro can print CMYK over discharge, CMYK over white, or CMYK over a discharge and white combination.

plied to bleach the dye molecules of dark garment, thus providing a base for CMYK printing.

Released April 2015, the 72inch Rhotex 180 TR dye sublimation textile printer is equipped with Durst’s patented QuadroZ print head technology and employs what the company describes as ecofriendly, water-based, odourfree dispersion inks that are

free of volatile organic compounds (VOCs). Durst explains the Rhotex 180 TR is suitable for polyester and polyester blends, sportswear, home textiles, and various POP display/soft-signage output.

Launched March 2015, Mimaki’s ES3 inks – black, cyan, magenta, yellow, light cyan and light magenta – are designed for its JV300, JV150, CJV300 and CJV150 Series printers. These JV printers provide eight ink channels and can be configured to use ES3 inks in a double-CMYK configuration for printing at up to 1,140

printer during FESPA 2015 in Cologne, Germany.The system features what the company refers to as an inline 8-blade print head configuration, which allows for a double CMYK setup to deliver twice the speed –up to 240 square metres – relative to the company’s Domin8tor and Pred8tor models. The new Gandy Gladi8tor provides a double white ink

ber along), material requirements, edge sealing, grommet placement, ink coverage, square inch/feet calculations, and substrate utilization to optimize workflow. The company explains the software accounts for all aspects of grandformat production, including tiling, handling multiple rolls across the bed, ganging, as well as logistics like finishing, assembly, installation, and multilocation shipment. Slingshot is to also add rules-based Gang Run Tools using the Automated Press Sheet Optimizer.

square feet per hour. Described as a fast-drying, eco-solvent and low-ordour product, Mimaki ES3 inks are compatible with a range of media types from indoor posters to outdoor signs.

In May 2015, Gandy Digital of Mississauga launched its new Gladi8tor UV flatbed inkjet

capability to address issues of white ink density on transparent or non-white substrates. It also offers a new layered print option for the production of multilayered colour images and white.

Released September 2015, Avanti Computer Systems of Toronto, which develops Print MIS software, added a new Grand Format Estimating module for its Slingshot MIS platform. The module leverages complex algorithms to consider unique imposition/ layouts (number across/num-

GTI’s luminaires utilize Graphiclite 100 lamps, aluminized high-efficiency reflectors, and spectrally neutral non-yellowing diffusers to provide what the company describes as precise and balanced D5000 output. Key features and options of GTI’s Vertical Wall Viewing Systems include the use of a parabolic lens and geometry design, wireless remote control, LiteGuard II System monitoring for maintenance, custom-sized wall panels, and the flexibility to order as a single source, dual source or custom multi-source fixture.

In mid-2015, Colter & Peterson began to offer five versions of Microcut retrofit kits, which allow the automated backgauge control system to be used with most any brand of cutter sized between 20 and 150 inches. The retrofit versions include Microcut COLOR WS, Microcut Plus, Microcut JR, Microtrack II and B-65. Microcut memorizes cutting sequences instantly so the back-gauge will automatically position itself to deliver an accurate cut within 1/64th of an inch.

Introduced in 2014, GTI’s Vertical Wall Viewing Systems are designed for large-format production, configured as an ISO 3664:2009 D50 system.

Introduced May 2015, the VUTEk HSr is a productionclass roll-to-roll printer, described by the company as its fastest such machine. The VUTEk LED/UV Pin & Cure imaging press is a 3.2-metre system that targets the replacement of older solvent printers. It runs at up to 2,400 square feet per hour (223 metres) in 600 dpi, grayscale and lightsmoothing modes, for applications like fleet graphics. For high-volume jobs, in what EFI classifies as production mode, the system runs at 3,600 square feet per hour (334 metres). It features 6-colour imaging plus white ink with multi-layer print capability for the production of day/night backlit graphics. The HSr press features EFI 3M SuperFlex HSr ink and backs graphics with the 3M MCS Warranty.