Canon Canada’s

November 2017

November 2017

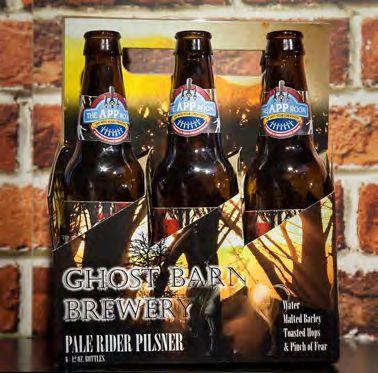

As markets become more localized, the demand for short-run packaging has increased. With innovative Océ large format printing solutions, you can produce sample packages enabling creative professionals to work efficiently to refine their designs. Océ printing solutions enable you to target short-run, niche packaging to local retailers or specialty product manufacturers and enables you to go after new markets and grow your revenue. Did you know that packaging is increasingly segmented by geography, niche, and even language? Providing this in-house printing service allows you to produce smaller runs more cost-effectively and even experiment with personalized versions for your clients. These custom packaging applications can be produced and finished using Océ’s unified print-and-cut workflow solutions to maximize short-run production efficiencies. Explore all the business opportunities that packaging applications can offer.

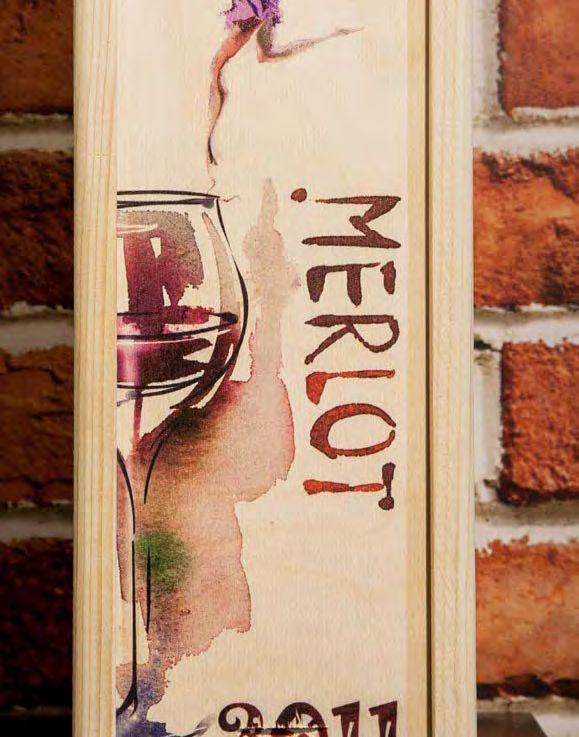

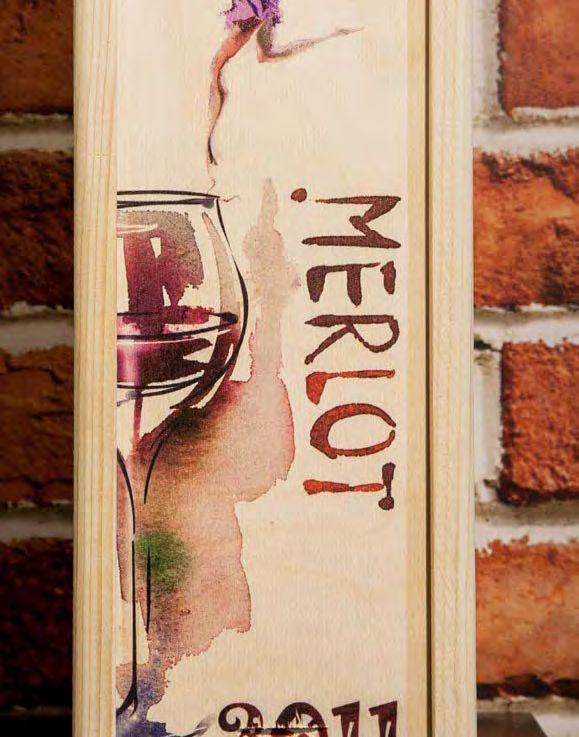

Advertising specialty applications are ideal in providing a coordinated and professional look for your customers’ products or brands. Now you can offer your customers high-quality print products on promotional items like yoyos, thumb drives, custom boxes, signage to floor graphics. With Océ large format printers, you can produce a wide variety of promotional products that can be customized helping your customer build their brand. Did you know that you can produce large customized pieces like doors, tabletops, wall panels, and more? And still have the ability to print smaller pieces from hockey pucks to plaques, to nameplates, or even dimensional printing of textures including braille.

Retailers and brand owners are demanding more graphically rich packaging to keep their products looking fresh. Their demand also includes the need for great looking POP displays as well. What this means for you is that run lengths for these applications, such as corrugated POP displays and retail-ready packaging, have shortened while the frequency for producing updated products has increased. This is a great opportunity for your business. With Océ large format printers you can efficiently take on these jobs and meet the quick turnaround demands to stay competitive. We will provide you with the right tools and knowledge to target this high-margin market.

Brand owners, retailers, and marketing executives value custom, unique packaging solutions that deliver memorable responses. Retail packaging printing services offering customized solutions based on geography, shipping efficiency, and storage requirements can drive profitability for your business. High-end packaging leads to stronger brand recognition for your customers. The innovative printing solutions provided by Océ provide you with the right tools to target this highmargin market. We can teach you how to create pop-up constructions, pull tabs, print-on, or emulate unique types of luxe materials such as plush suedes, smooth Tyvek® prints, and box toppers, all of which can deliver that unique interactive product for your customers’ consumer.

One of the fastest growing segments is custom and short-run packaging. Driving this growth are the brand owners. Brand owners and retailers are constantly fine-tuning their marketing and product messaging. Creating custom and short-run packaging is now practical as well as profitable, a direct result of Océ innovative printers along with our digital cutting solutions. Since there is virtually no setup required, compared to offset, you can produce cost-effective, limited runs of custom packaging supporting memorable events such as weddings and award ceremonies. You can also offer shortrun packaging to meet the demands of private labels, test markets, sporting events, and more. Personalization is easy providing your business the ability to support variable data on a box-by-box basis.

Packaging today is so much more powerful and valuable than a mere receptacle. It is a shortcut to consumer decision-making and a communicator of a brand’s overall message. Because the demand for, and the rise of bespoke, innovative, engaging, beautifully designed or environmentally friendly packaging has become a mainstay of our day-to-day lives, packages have become a legitimate part of the customer experience themselves. The total digital package and label printing market is forecast to grow at a rate of 20% every year until 20241. It’s an industry on the rise; both in terms of size and prominence.

For brands and retailers today, the proliferation of media channels, changing demographics and multichannel shopping has made it harder to grab people’s attention and predict their purchasing behaviour. While marketers are adapting to an increasingly fragmented audience through the use of digital campaigns to identify and target customers, this also has implications for the packaging industry.

40% of global print production is accounted for by packaging and labels

By 2024, the total digital printing market will be 225% of its size in 2013

Label printing is set to grow at 4.7% between 2014-20181

A well-designed or innovative packaging solution is an increasingly important differentiator for brands and one which can have a disproportionately positive effect in driving sales. Advances in digital and smartphone technologies have significantly transformed consumer behaviour and their expectations. Product packaging is at the centre of these developments in the consumer retail experience and it should come as no surprise that the packaging market is growing strongly. The luxury market alone for example, is expanding by 4.4% per annum and the packaging printing market by almost the same amount over the period 2014-20181.

Since the birth of barcodes, digital technologies have continually been tested to bring reforms to retail experience. The rise of the Internet of Things (network connectivity of everyday objects) and advances in mobile computing, RFID, augmented reality and biosensors have not only shaken up the retail landscape – they’ve increased the scope of packaging from something to simply protect a product to something to genuinely connect with consumers. In addition, the latest innovations in digital printing have opened up possibilities in the production process that never previously existed.

Integrated into the production process, these new technologies allow for truly customized print and frequent design changes whilst cutting down the time from design to production. Many printing procedures are now suitable for both small and large quantities, enabling manufacturers to respond quickly

to changing markets or customer demands. With so many powerful opportunities, digital print is creating new values and growth within a wide range of industries, with minimized risk and cost. For retailers, brand owners and marketers, this should come as no surprise.

more demand for smaller household products and services aimed at the solo consumer4.

By 2050 two billion people will be aged 60 and over2

The global population is ageing and the number of single person households is growing dramatically. The rise of the ‘senior’ generation (defined as 60+ by the UN) is outstripping overall population growth3 and this trend looks set to continue for at least the next 25 years. By 2050, two billion people will be aged 60 and older. The implications for packaging and product design are immense. How will brand owners address this? Larger print and easy-to-open packaging are two considerations that spring to mind.

In parallel, single person households are already the most common household profile in Western Europe4 and North America. While couples with children prevail in emerging markets, single person households will increase here too in line with shifting cultural attitudes and rising female employment. Euromonitor predicts that this trend will equate to

As customers and their needs grow increasingly diverse, customizing packaging has become a surefire way to gain traction. Mass customization is an attempt to deliver this heightened consumer experience without adding cost and complexity to operations. For retailers managing different markets for global brands in particular, it is both a useful and cost-effective strategy. Every retailer knows that successful packaging depends on the consumer. Packaging loved by customers in Germany may be interpreted differently in France. Green packaging may suggest ‘eco-friendly’ or ‘healthy’ in the UK, but it is unacceptable in Egypt due to religious reasons. Now that print runs can be as short as a single product, customization can even trickle down to individual users. A recent campaign for Heinz Tomato Soup, for example, allowed consumers to personalize a can on the brand’s Facebook page and send it to a friend as a gift. Similar campaigns from other FMCG (fast moving consumer goods) brands such as HP Sauce and Coca-Cola, as well as luxury brands, such as American Express, are ushering in an era of design where big brands aim to engage their customers with packaging specifically designed to appeal on a personal level. As digital printing technology becomes more affordable and wide-spread, short print runs will continue to increase and personalization will be one of the main tools brands use to differentiate and attract customers.

TETRA PACK FRANCE, a leading food processing and packaging solutions company created an app in 2014 aimed at getting consumers to recycle more. The packaging brand is one of the few to step out of the B2B sector to communicate directly with consumers. Predominantly aimed at children, the mobile app illustrated the benefits of recycling through a variety of augmented reality games.

Convenience packaging

It is not enough for brand owners to meet consumers’ existing needs. They should be anticipating their desires and providing them with a product that goes beyond what’s already on the market. One area that’s ripe for packaging innovation is convenience packaging, targeting increasingly on-the–go, time-poor consumers. Unit-dose packs for example, have achieved wide acceptance in some categories such as laundry detergents. Other examples of new convenience packaging include Robinsons Squash’d, a plastic squeezable pouch designed to dispense fruit cordial into water bottles on the go.

Smart packaging

Innovations over the last 20 years have been able to take packaging’s interactions with consumers one step further. A recent example of technology shaping packaging is Heineken and Strongbow’s interactive bottle features. Heineken’s ‘Ignite’ bottle used micro sensors and wireless networking technology to sense when people clinked the bottles

together. These motions triggered certain effects that would light up the whole bottle and when left idle, fade away.

Packaging can also boost the environmental credentials of brands. British start-up Graze developed eco-friendly packaging made of corrugated cardboard which was biodegradable and could be turned into sustainable punnets for growing plants and herbs5. Subsequent research into new materials and optimal and sustainable solutions is a continuing trend with eco-friendly packaging playing a significant role in affecting consumer choices. Some 52% of global respondents in a recent Nielsen survey6 said their purchase choices are partly dependent on the packaging. They check the labelling before buying to ensure the brand is committed to positive social and environmental impact.

OPPORTUNITY FOR PRINTERS

Research7 into what the drivers towards digital printing are for packaging companies identified cost savings as the main factor – 49% are interested in reducing the cost of short runs, 37% want to be quicker

to market and 29% wish to reduce packaging inventory. Only 25% aren’t looking into digital printing at all.

Printed packaging companies need to deliver more packaging variations than ever before to meet the wants and needs of retailers that are simultaneously shaping and responding to consumer demands and expectations. Brands need to provide new shapes, new materials, more colour, more distinctive and shorter-runs to differentiate from the competition and attract consumers. All of which needs the right technologies. Digital print is the answer to changes in supply chains and consumer behaviour. With digital package printing, brand owners can enhance the value they offer and their role in the process.

The opportunities for printing professionals are immense. Analogue packaging is predicted to grow by 28% in the 2008-2018 period while all digitally produced material will increase by 375% for the same period to reach $9.4bn (€8.5bn) by 2018, according to a report by Smithers Pira1.

One of the biggest changes to the

25% of men and 35% of women said their buying choices were influenced by how recyclable the packaging was.

publishing industry was the advent of print-on-demand which allowed books to be printed singly or in small quantities. While build-to-order has been an established business model in many other industries, printon-demand developed only after digital printing because it was not economical to print single copies using traditional printing technology.

Print-on-demand scenarios have enormous potential to reduce costs and are particularly well suited for market-specific products in small batches. As a result, it seems certain that packaging will follow the same route with the same opportunities for printers and print service providers.

Early digital printers were all developed largely for pages, making them realistically too small to work for packaging or indeed anything bigger than A3. However, recent developments in wide-format print have the power to slowly change this. German company puzzle & play GmbH creates personalized puzzles in personalized packages for thousands of customers from its offices in Bavaria, Germany.

The chosen puzzle motifs are printed on 1.9 mm puzzle cardboard with the latest digital printing technology, and punched and packed in a secure plastic foil before being placed in an individually designed box printed with the customer’s puzzle motif. The jigsaw puzzles can range from 1001,000 pieces and turnaround is under two weeks.

What seems certain is that digital, print-on-demand, label and package printing is meeting current lean

manufacturing initiatives as well as creating opportunities for increasing customization and targeted marketing. This sort of capability gives brand managers a powerful tool for attracting new customers.

Printing on demand means less waste, ensuring that new designs or changes don’t result in redundant stock. One-off customization becomes just as possible as

traditional long production runs. Technological developments in inkjet and electrophotography are making digital print increasingly accessible and cost-effective for all kinds of companies, big and small. In short, digital is enabling businesses to work in totally new ways.

Makes short-run and customized packaging economical – ensuring that new designs or changes don’t result in redundant stock

Creates opportunities for working differently

Gets products to market faster

Helps to streamline supply chains

Enables customization

Generates less waste –printing on demand, to order, means the end of long print runs and unused packaging. The green and cost implications are compelling

Despite all of the advantages on offer, there has historically been reluctance in the industry to adopt digital printing processes on a large scale. A general lack of knowledge in the sector coupled with a perception that the process is expensive and difficult to manage has meant digital printing has evolved slowly in the past. However, more companies need to consider digital print to avoid being left behind in this fast-moving market. With three quarters of the print industry7 researching digital print packaging options, opting out seems like a risky option.

For printing professionals looking to make the move to digital printed packaging, the first step is to figure out what the benefits of digital printed packaging are, acquainting yourself with how others are using it innovatively. Before you can communicate its benefits to your customer base, it’s essential you yourself are convinced of its merits and potential to add value. The next step is to discuss the opportunities of digital printing with your client base. Understanding their customers and what’s important to them: the joy of unboxing, transparency, authenticity, green issues and balancing this with what their brand stands for will go some way to making a convincing case for the value of digital print.

The beauty of packaging is that it is everywhere! PSPs should go out and see how packaging is being used by businesses in multiple sectors and of multiple sizes.

How does it differ by product volume? What materials are being used? Is it functional, decorative or both?

How is it working with other POS products that could also be an opportunity for print?

PSPs should ask themselves which of their current services could be utilised in the packaging sector and what new areas or concepts they’re able to deliver within the capabilities of their business.

Can key trends such as prototyping, customization and the social ‘unboxing’ experience be taken advantage of?

Which of your customers already has a requirement for packaging that you can leverage?

With your knowledge and Canon’s support, how can you show them the new possibilities?

Packaging is a technically demanding, knowledge hungry application but the rewards are there for those that invest the time.

How can your skills and the skills you can acquire, service the packaging supply chains at any level?

Do you have in-house skills that could be re-purposed or built on to deliver value in this sector?

Are there new applications that you would like to offer?

Knowledge is key – if you recognise areas where additional expertise would be useful, an investment in training or applications development, however modest, could pay large dividends. PSPs need to start small and see what offers they can make to support existing customers or businesses. The learning experience could be key to developing further in these markets.

Take the proactive approach – What showcase materials or samples do you need in your portfolio to highlight what you can do for retail?

Consider working with other suppliers or customers in your network who already service packaging markets.

Get creative – Can you find an innovative niche that sits perfectly within your businesses capabilities and services the needs of your customers?

Find the right print partner – Our product specialists, application experts and account managers are here to help. They represent one of the largest wide format portfolios in the industry and can help you learn the skills needed to push the boundaries of packaging.

COMPANY NAME

i-Pack

Sarpsborg, Norway SERVICES

Digital wide format printing, packaging, POS, display graphics, commercial print, design and composition, finishing, product assembly WEBSITE

http://i-pack.no/

Expand business to become leader in POS solutions.

• Canon analysed business strategy and best solution to enable customer to add printing to service offering

• Canon and Océ Arizona technology was recommended by new business partner for new digital division

• Canon invited company to pre-launch of the Océ Arizona 6000 series in Vancouver

• Demonstration of productivity and versatility across wide range of media for short-run packaging, display and commercial applications

• Canon supported installation and integration with existing finishing line

• Provided business support to help transition into in-house printing for end-to-end production

Océ Arizona 6170 XTS and Onyx Thrive

i-Pack – based in Sarpsborg, Norway – has always excelled at creating display graphics and packaging solutions for the Point-of-Sale (POS) market. Operating under different names and owners since its founding in 1997, the company has worked with a number of leading packaging companies in Scandinavia and other European markets.

By 2013, however, its founder – Atle Andreassen – felt the company was not fulfilling its potential. “We had lost our identity,” comments Andreassen. Functioning as more of a local sales organisation for its parent company, Andreassen led a successful buyout to bring the business back to its roots. Rebranded as i-Pack AS, the specialist’s new strategy was to revert back to supplying, and, more importantly, producing high quality POS materials and special packaging. The long-term goal was to be the best in its field.

A key part of this new business strategy was winning business in the short-run promotional graphics and packaging market. However, as Andreassen explains, the company did not possess the capability to print in-house: “Financial restrictions and a lack of vision by our previous owners hindered investment in our own printing technology. We had always outsourced our printing to production sites in Sweden and Denmark.”

This was an inadequate process. Not only slow and onerous, the costs involved in ordering and shipping

printed sheets from a third party were expensive too. “The process also undermined our control over the quality of the end product,” comments Andreassen. “There was no way to guarantee that the customer’s approved PDF file would look the same once it was printed externally.”

that,” comments Andreassen. With customer demand for faster job turnaround and more flexibility from their suppliers to facilitate reactive marketing campaigns, i-Pack knew it was time to invest in digital printing technology and offer end-to-end production.

“Sometimes you get a request on a Friday for a short-run POS campaign that goes live on the Monday,” elaborates Andreassen. “The old process of outsourcing the work to be offset or screen printed was neither fast enough nor a financially viable option. We required a way to produce samples and judge the quality inhouse, rather than order 200 from a third party printer only to find that it is not to the standard we, or the customer, expected.”

In addition, i-Pack’s core customers – fast-moving, brand-conscious marketers – like to see samples to inspect their product first hand. “Our customers like to take samples to internal meetings so they can visualise how the final display would look in-store. We lacked the prototyping capability to do

Soon after the buy-out, i-Pack worked with a local print service provider (PSP) to set up a new division, i-Pack Digital. This arm would be a production site that combined i-Pack’s expertise in packaging design with the PSP’s understanding of the print market.

By 2014, i-Pack recognised the division required a partner to support its transition and propel its strategy forward. The owner of i-Pack’s PSP partner, Jan Tore Hall, was very forthcoming in his praise about his experience with Canon and its Arizona technology.

“Jan spoke very highly of working with Canon and the performance of its technology,” recalls Andreassen. “Both of these were important factors. This was our first big investment in digital printing technology, so we had to consider all the variables. Would it provide

plan, the company was invited to Vancouver for the exclusive pre-launch of Canon’s new high productivity Océ Arizona UV flatbed series. “In Vancouver, they explained the economics of printing in-house and were quick to dispel our concerns about future potential ‘hidden’ costs via maintenance and servicing issues that could undermine our profitability,” explains Andreassen.”

The company also knew that the Océ Arizona was the right technology to enable it to produce short runs of quality

“Our business can now produce eyecatching POS and packaging solutions from concept to execution that capture the imaginations of our customers, and that we can charge a premium for. All of this has been galvanised by our investment in Canon and the Océ Arizona technology.”

a return on investment (ROI), would it suit our business needs and integrate with our existing finishing line, would the supplier understand our business vision to become the leading supplier of POS materials nationwide and beyond?”

Based on Hall’s recommendation, i-Pack approached Canon. After analysing the specialist’s business

and eye-catching POS work to grow its business. “We would have the capability to bridge the gap in our production line and make us very competitive,” adds Andreassen.

i-Pack’s in-house printing service has cut 50% of its outsourcing costs and reclaimed complete control of its

short-run production, while laying the foundations for rapid business expansion.

Capable of swiftly responding to on demand customer orders –turnaround time has been cut by 30% on some orders – the company has increased monthly volumes by over 300%, from an average 4,000m2 to 12,000m2 per month.

“Vast quantities of output, around 40%, is going through the Océ Arizona and, on average, we’re running it for 15 hours a day nonstop,” comments Andreassen. “We

We printed more output in the first three months of the machine being installed than we did during the whole of 2014 combined!

printed more output in the first three months of the machine being installed than we did during the whole of 2014 combined! We have experienced minimal teething problems and the technology runs very smoothly.”

The company is also being more economical with its substrates. Depending on the size of the application, the Océ Arizona is capable of printing multiple orders from just one unit of media. “We can also produce a whole display application, often comprising many parts, in one pass. This makes us very efficient and ensures the end product is visually consistent from every angle.”

Significantly, the impact of the investment in Canon has accelerated i-Pack’s long-term strategy to

be a leader in the field, with the evolution of four distinctive business divisions. Joining ‘i-Pack’ and ‘i-Pack Digital’ is ‘i-Pack Design & Communication’ and ‘i-Pack Plast’. The former operates as a

“We’re aiming to grow volumes by 25% by end of 2015, and by additional 15% by 2016. Thanks to Canon’s support and technology, we’re well on our way to achieving our business objectives”

small advertising agency that works with customers to create original campaigns, while i-Pack Plast cuts and prepares materials such as wood,

plastic and steel for a broader range of innovative applications that can be printed on via the Océ Arizona technology. All of these divisions serve their own core customer bases, but also integrate for end-to-end production of POS promotional campaigns.

“Our business can now produce eye-catching POS and packaging solutions from concept to execution that capture the imaginations of our customers, and that we can charge a premium for,” concludes Andreassen. “All of this has been galvanised by our investment in Canon and the Océ Arizona technology. On back of this investment, we’re aiming to grow volumes by 25% by end of 2015, and by additional 15% by 2016. Thanks to Canon’s support and technology, we’re well on our way to achieving our business objectives.”

Enhanced delivery time for Just-In-Time proposition – from three weeks to one week for some applications

Increased monthly volumes by 300%

Aiming to grow volumes by 25% by end of 2015 and an additional 15% by 2016

Underpinned the establishment of newly developed i-Pack Digital division and further expansion with i-Pack Plast for wood, plastic and steel applications, and i-Pack Design & Communication for original campaign design

If you liked this article, check out the rest of our free, 76 page guide specifically created to help you explore the different application ideas, industry trends, and opportunities for your business

• A wide range of production models with print speeds up to 1,668 ft2/hour

• Product scalability with post installation upgrade options for white or varnish ink

• Fast Automated Print Head Maintenance System enables colour independent, hands-free cleaning

• Pneumatic registration pins enable double-sided prints in perfect alignment

• Up to 40% reduction in ink/printing costs compared to other competitive technologies

• A wide colour gamut, comparable to that of EcoSolvent inkjet printers

The Canadian print industry is changing. It’s no longer about compromise but about saying ‘yes’ to your customers. It’s about adapting and seizing new opportunities. Canon will work with you to overcome challenges, exceed your customer expectations, and explore bold new ideas and cutting-edge techniques. Plus, with the widest print portfolio in the industry and unique heritage in imaging technology, we’re able to push boundaries, offer pioneering solutions and challenge the pre-conceptions of print to help your business stay ahead of the curve – and the competition.

• Up to 1,389 ft2/hour

• 11" to 42' media roll width

• Up to 6 rolls = 13,650 ft2 of media online

• Océ MediaSense technology enables printing on media up to 32mil thick

• Multiple finishing options including stacking and folding

• All-in-one productive print, scan, and copy system

• 42" wide print path

• Print speed up to 12"/second

• 30,000 ft2 of production per shift

• 6 auto switching rolls

• Efficient 1.4 picoliter inkjet technology

• Robust finishing options such as rewind unit and folder

• Dry and immediately stackable prints

The Professional Printing Solutions Group (PPSG) is a division of Canon Canada. Formed in January 2014 after Océ-Canada Inc. was amalgamated by Canon Canada Inc., PPSG is the leading provider of printing solutions for professionals. PPSG’s product offerings include digital presses, high speed digital production printers, wide format printing systems and workflow software for transaction, direct mail, graphic arts, technical documentation and colour display graphics.

Canon Canada Inc., a wholly owned subsidiary of Canon U.S.A., is a leading provider of consumer and businessto-business digital imaging technology solutions. Innovation and cutting-edge technology have been essential ingredients in Canon’s success. Its parent company, Canon Inc., ranks among the Top 4 in US patents registered since 1994. Canon ranks among the world’s Top 30 brands and is one of Forbes’ Magazine’s World’s Most Admired Companies. Canon Canada Inc. is committed to the highest level of customer satisfaction and loyalty, providing 100 per cent Canadian-based service and support for all of the products it distributes. Canon Canada Inc. is dedicated to its Kyosei philosophy of social and environmental responsibility.

Professional Printing Solutions Group (PPSG) 8000 Mississauga Road, Brampton, ON L6Y 5Z7 Océ, Océ Arizona, Océ ProCut, Océ VarioPrint, Océ ColorWave, and Océ Colorado are