Labels as storytellers

Technology is optimizing labels for better consumer engagement and product management

Christine Yardley, president, Print Panther

DEPARTMENTS

3 Landa expands North American sales team, Print Media Centr launches the Project Peacock Network, Durst opens an incubator, and more

INSTALLS

5 Tonejet, Paragraph, and Mitchell Press

7 Paper supply: Crisis or opportunity?

NEW PRODUCTS

19 Products and solutions from HP, Gallus, Lecta, Solimar Systems, Rosas Maschinenbau

Landa Digital Printing is aggressively expanding its global team and business development infrastructure with the appointment of several new sales professionals for North America. The new hires are fulfilling a variety of roles and bringing nearly 110 years of experience. New Landa appointments include Bill Lawver, inside sales representative; Michael Weyer-

mann, regional sales manager – Northeast; Steve Smith, regional sales manager – Southeast; Danny Green, regional sales manager – Mid-Atlantic; and Michelle Weir, regional sales manager, West.

Print Media Centr announces the launch of the Project Pea-

cock Network , a video streaming platform sharing

resources with print and marketing professionals around the world, 24/7/365. The Project Peacock Network is accessible at ProjectPeacock.TV and kicks off with the series, Project Peacock: Print Production, produced in partnership with Inkish.TV. These episodes share the benefits of collaboration across creative, paper, printing, finishing and technology partners to

activities. With it, clients can identify trends, detect production bottlenecks, and gain actionable insights to help produce consistent output accurately and efficiently.

ensure printed materials achieve their intended creative and business results.

Ricoh USA integrates Ricoh Supervisor and Ricoh Pro -

cessDirector to empower clients with advanced data analytics. This integration enables visibility down to the document level, including production volume as well as printer and inserter operator

Printing United Alliance announces the recipients of the Pinnacle InterTech Awards Program. The awards recognizes best-in-class products. The Pinnacle InterTech Awards are open exclusively to Printing United Alliance supplier members and, this year, judges selected seven award recipients. They are Barbieri Electronic for Barbieri Spectro LFP qb textile edition; Canon Production Printing for Canon FLXfinish+; Design ‘N’ Buy for DesignO; Kodak for Magnus Q4800 Platesetter; Vivid Laminating Technologies for VeloTaper; W+D

North America for W+D BB1000; and X-Rite Pantone for Mantis Video Targeting Technology.

Infigo is partnering with Tilia Labs, which enables print clients to use Tilia’s Phoenix product through an Infigo storefront. Tilia Phoenix is an automated, AI-driven preproduction software for packaging, labels, commercial, and wide format. The partnership between the two companies will enable print clients to order and edit their designs online through an Infigo storefront as per usual, viewing a 3D print preview of their order, including additional post-print features, such as embossing and foil stamping.

Durst opens the “Durst Kraftwerk,” a 5,300-m 2 hall in Brixen, Italy, that will be the new home of the company’s in-house spin-offs and startups. “Durst Kraftwerk will be a powerhouse that brings together our spin-offs and start-ups and offers them a new home. In this way, we provide a creative environment where the companies can fully concentrate on their respective areas of expertise

without the ‘burden’ of integration into an established structure,” said Christoph Gamper, CEO and co-owner of the Durst Group. Kraftwerk is home to the European branch of Vanguard Digital Printing Systems.

R.R. Donnelley & Sons Company (RRD) increases its capacity for direct thermal linerless label production by approximately 40 per cent. It has installed an extra linerless press at its plant in Monroe, Wis. “In a market where businesses find themselves getting pinched by material availability, converting to linerless has presented itself as a more viable, greener, market-ready option,” said Lisa Pruett, president of packaging and labels at RRD.

Christoph Gamper and Harald Oberrauch, owner of Technicon Holding, an incubator.

Tonejet, a manufacturer of advanced electro-static drop-on-demand digital print engines, installs a new Cyclone C4+ with Tonejet Can Primer digital decoration system at Solucan, Que.

Montreal-based Paragraph installs a new Canon Colorado UVgel 64-in. printer, a suitable one for both indoor and outdoor applications. The UVgel technology delivers a large colour gamut and opens the doors to a wider range of media capabilities.

Mitchell Press of Burnaby, B.C., will be home to the first Landa Nanographic Printing Press in Canada. The Landa S10P Nanographic Printing Press offers reproduction of up to 96 per cent of Pantone colours, 6,500 sheets per hour speed, double-sided B1 (41 in.) format, and compatibility with a majority of off-theshelf substrates.

Labels as storytellers

Technology is optimizing labels for better consumer engagement and product management

By Treena Hein

In this day and age, new ways to engage with old and potential customers have never been more critical. To catch the attention of the public, especially the younger generation, innovation is ramping up in area of ‘smart label’ technologies.

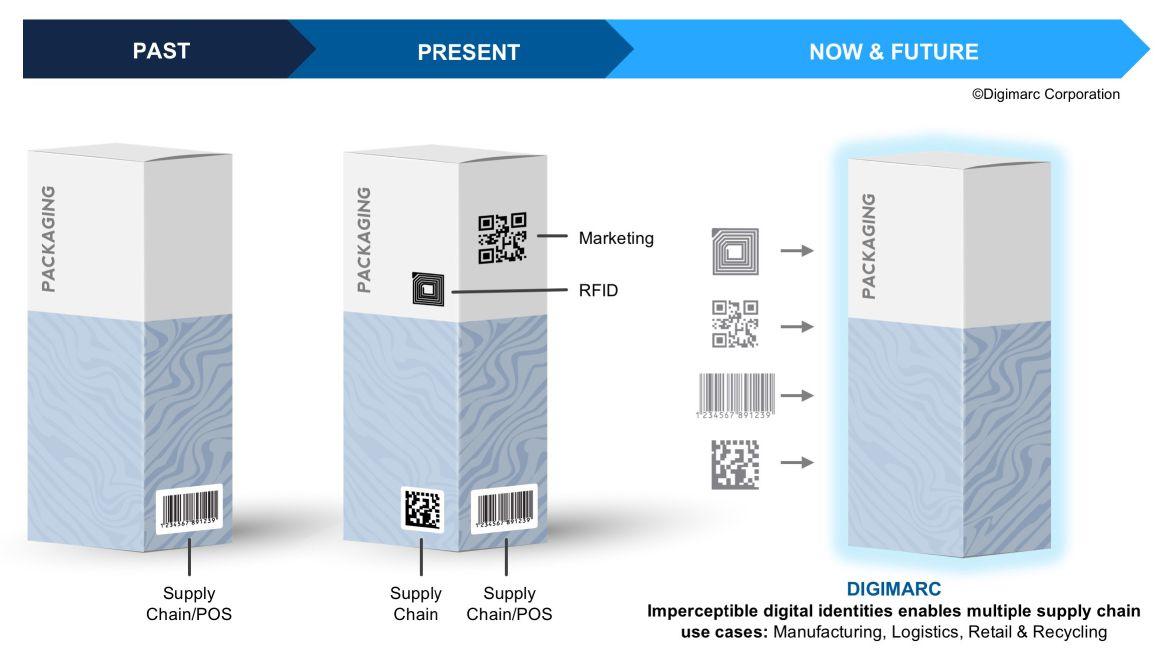

“At a time when the e-commerce channel continues to grow, the ability for brands to connect directly with consumers through digitized products is invaluable,” explains Phil Stafford, director of global channels at Digimarc Corporation. Connecting directly means that consumers not only interact with the real product physically, but also with its digital twin (a version of the product accessible solely through internet-enabled technologies).

These innovations provide consumers with dynamic and more rewarding experiences with a product, even personalized experiences that might enrich their lives in a meaningful way.

Stafford explains that as consumers become more familiar and comfortable with digitized products, they’re more willing to engage with them, “especially when the content offered is of value.”

For companies, the benefits of smart labels are obvious. When a new form of digitized product hits the market, it gets a lot of attention. The brand also becomes associated with the use of new, cutting-edge technologies, making the products ‘cool.’ However, there are other benefits in

the direct communication channels created by smart labels between companies and their customers, says Stafford. Brands receive valuable, consensual data from consumers of the product in real-time, such as when, where, and how often a product is being interacted with, even when and where consumption occurs. This direct data capture informs future marketing strategies, allows companies to identify purchasing and consumption trends, and so on.

A look back

It’s been common for a few years now

for companies to print QR codes on their labels to provide consumers with a direct link to product information. This might be date on where and how the product was made, or even traceability of ingredients.

Companies like Multi-Color Corporation (MCC) offer a variety of interactive ‘smart label’ options that include reaction to heat or cold. Another example came on the Brazil market in June 2022, when limited-edition bottles of Sol beer were released sporting labels with photochromic (light-activated) ink developed by MCC. When exposed to sunlight, the label reveals

How Digimarc digital watermarks perform on printed labels.

a hidden message to the consumer, enhancing their experience with the brand and reinforcing a connection with the brand name and the power of the sun.

Another example is the personal ‘Reel Label’ used by British Columbia-based Jones Soda. These labels have images of real customers on them, and other customers can learn the story behind the moment captured in the label through Augmented Reality (AR) videos on the Jones Soda app.

sumers hold up their smart phones and the label comes to life. We haven’t

2017

seen these platforms grow at the same level as some of the other smart packaging options, but the brands that have introduced this technology have been quite successful.”

In 2017, Australia-based Treasury Wine Estates became the world’s first wine company to use an AR platform across its portfolio.

“We see customers utilizing these [types of smart labels] for promotional products and high-engagement campaigns,” says Kimberly Flynn, marketing project manager at MCC. “For AR and virtual reality, we have a number of customers who have launched very successful campaigns where con-

This has certainly been the case for Australia-based Treasury Wine Estates. In 2017, it became the first wine company in the world to use an AR platform across its portfolio. For example, through a company app available in over 90 countries, consumers hover their smartphone over the label of the firm’s ‘19 Crimes’ bottles and are introduced to the associated real historical criminals. This innovation helped in achieving doubledigit growth of the 19 Crimes brand in the US, and netted Treasure Wine Estates a prestigious Super Reggie marketing award.

Digimarc digital identities on labels/packaging support traceability initiatives.

Now, AR ‘smart labels’ have become truly interactive. The first Internet of Things packaging platform, recently developed by MCC and a company called Talkin’ Things, combines AR with near field communication (NFC)

technology on the labels for an imaginary brand called ‘Black Beer.’

As explained by MCC, when the Black Beer smart label is scanned (again, using an app), “the skull displayed on the label engages in interactive dialogue with the consumer.

Digimarc on packaging allows products to be tracked throughout the supply chain journey from manufacturing, retail to consumer and recycle, resale or reuse.

The facial recognition feature detects if the customer is happy or sad and customizes the next part of the dialogue. Variable AR scenarios are also launched, depending on answers provided to questions asked by the skull.” The product also recognizes when the product has been opened, which changes the responses of the skull. Operation and supply chain benefits

Other smart packaging and smart

labelling applications, notes Flynn, are more operational, such as RFID and electronic article surveillance (EAS) tag inlays for product tracking and inventory management.

“The increase in online shopping has expedited the use of passive tags to manage operations and product tracing,” she says. “We see a larger growth in this segment of the market.

Retailers are developing policies that consumer packaged goods brands are answering with tags applied either onto the container or onto the label before the container.”

For product security, among its other technologies MCC offers secure QR codes, a new kind of QR code containing public and private data. Consumers scan the tag to instantly receive a message confirming the authenticity of their purchased item. The public data can be read by any reader such as a smart phone. The private data is encrypted and protected with a password that can only be unlocked with a proprietary scanner. The technology provides product tracking, traceability, and anti-counterfeiting applications.

started exploring the use of watermarks for consumer-facing packaging and labels, which would carry the same Global Trade Item Number as a UPC/EAN code and be scanned by a retailer ‘point of sale’ device. They are being used in North America for brand protection purposes, parts matching, supply chain improvements and front of store efficiency.

Digimarc currently offers digital watermarks, which are created by subtly modulating the pixels in the label artwork design at a very low level, so that there is no perceptible structure to it such as what’s seen with an EAN or QR code. They came about seven years ago, when Digimarc

Digital watermarks were created by Digimarc founder, Geoff Rhoads, who is also an astronomer. “The concept arose from his work removing noise from digital photos of deep space imaging,” says Stafford. “The science behind watermarking is quite amazing and by using proprietary Digimarc software, any printed image can have an imperceptible watermark embedded into it, and yet, be easily scanned by a mobile phone app or device that uses our decoding software.”

Phil Stafford

Digimarc can also combine digital watermarks with QR codes, or RFID or NFC tags. “Using dual-factor authentication, brands now have the strongest defense possible in the fight against counterfeiters,” says Stafford. “This product is supported by our product cloud that allows brands to track every product item through the supply chain, customs inspection and onshelf via brand inspection agents.”

Improving recycling

Digimarc’s digital watermarks are also durable (i.e. able to be scanned in difficult environments). This means they can be used to collect information about package recycling. When the watermarks are scanned at a recycling depot, the system can access unlimited information, including characteristics of the packaging such as type of plastic or the presence of components that are problematic for recycling. Digimarc has recently part-

nered with Canadian company Winpak to test this, as part of the Circular Plastic Taskforce initiative.

“This technology can better help material recovery facilities understand what materials are coming in and how better separate them to make ‘cleaner’ bales,” explains Winpak Director of Corporate Sustainability Phillip

Crowder. “The information gathered can also help a brand to understand how much of the packaging is being recycled, and how they can perhaps improve that rate.”

Crowder adds that on the consumer side, these watermarks can also communicate to consumers the environmental attributes of packaging and where to best recycle it, let alone all kinds of information to the consumer about the product itself such as nutritional information and meal preparation ideas.

With more and more innovations like this, it seems smart labels, and the companies that use them, are getting smarter all the time.

Rellable, customizable workflow automation, from prepress to dispatch – Semi- to fully automated and robotic material handling, incl. loading/off-loading, picking, sorting, placing

IoT solutions for monitoring, analyzing, and maximizing productivity

Christine Yardley/ President/ Print Panther

Earlier this year, Print Panther, Oakville, Ont., won multiple Gold Leaf Awards from the Foil & Specialty Effects Association. In the Category of Best Foil/Coatings Selection Guide, Print Panther was awarded the Gold Award for the “Konica Minolta Extreme Digital Guide – Capturing the Feel of Creativity”. It also earned a Best in Show Honorable Mention. The award-winning project was a labour of love for Christine Yardley, president of Print Panther, and her production team.

For 24 years, Yardley has led Print Panther whose clientele is largely international. An industry veteran with a global perspective Yardley has some interesting thoughts to share about the state of the Canadian printing industry.

What is the state of the print industry today, in your opinion?

CY: I think everyone is looking for

ways to increase business opportunities. It doesn’t matter where you are or what business you are in. I think high value, exciting, innovative print is a leader in helping companies, especially smaller and luxury brands, regain market share and position. Print allows brands to communicate on a tangible level. I think that is paramount after the last 18-24 months. It is difficult to imagine a post-pandemic world, but history proves innovation and creativity prevail during difficult times. From direct mail to packaging, tactile, meaningful print will be at the forefront when we come out of this digitally saturated period of history.

What attracted you to the print industry?

CY: I have always been involved in the broader industry. I have always been attracted to the printed page in some form. My background in typography,

graphic design and marketing uniquely positions me to create beautiful print that legitimately helps my clients connect with their customers. My love of print has been an organic flow of ideas and design, a life-long love affair, really.

How can the industry attract more young people?

CY: Like any industry, there are ebbs and flows. I think we all, no matter our age, suffer from some sort of digital fatigue. When someone enrolls in a program at Toronto Metropolitan University [Toronto] for example, they are taught design needs to cross over

High value, exciting, innovative print is a leader in helping companies, especially smaller and luxury brands, regain market share and position. 24

between print and digital. Print is a large part of the curriculum. Further, successful brands need print. I am not sure if there is truly an issue with attracting young people. I can tell you that everyone working for me is about half my age, and they love it.

In such a competitive landscape, how can printers win more sales?

Christine Yardley has been president of Print Panther for 24 years.

CY: I do not think the industry has become more competitive than previous years. Having said that the industry is not only competitive, but also turbulent. I think printers need to embrace new technologies. It is our job to show customers what they can do to help elevate their brands and support their businesses. During times of crisis, opportunity is everywhere. Just

think: you can provide a small company a custom brand colour that’s fresh and different. With metallic and fluorescent inks, foils and spot varnishes, the opportunity to make a product and/or service standout is at our fingertips, literally! We must help managers and others who help promote companies and products understand the positive impact of innovative printed solutions.

What

are some of the

biggest

opportunities in the print industry?

CY: We should all see opportunity as the world re-opens. Everyone is craving some sense of normality. Every business will be looking at ways to move forward. With the holidays upon us, it is the perfect time to reconnect

with clients with a wonderful, printed piece. I love receiving cards; it never gets old. Getting something physical and personal is more meaningful than a “pop-up” on a website. Print creates a touchpoint with customers.

What do you think is the most exciting thing about print today?

CY: I think print is exciting and beautiful. We need the tactile experiences that only print can provide. Quality has never been better, thanks to new digital printing capabilities. The technology has transformed design. We are seeing more customized and personalized print products. I love foils and bright inks.

Bright colours, clever bindery and textured papers for creating tactile, sensory products are certainly going to lead in 2022.

Yardley’s responses were edited for length. For more Q&A Spotlight interviews, please visit www. printaction.com/profile.

Celebrate your Brand’s Inner Beauty

Celebrate your Brand’s Inner Beauty with Envi PC 100 Performance Board + Hemp Envi® Performance Board

Built for Brands unwilling to compromise, Envi PC 100 Performance Board + Hemp Envi® Performance Board are the seamless integration of beauty, performance and sustainability.

Perfect for lifestyle, cosmetic and personal care, confectionery, liquor and entertainment brands, recyclable Envi Performance Boards offer unparalleled printability, durability and eco-benefits.

Made with the environment in mind. FSC® Certified, manufactured carbon neutral (VERs) and using 100 percent renewable Green-e certified wind powered electricity (RECs) under a third-party certified ISO 14001 Environmental Management System.

Discover the complete range of sustainable performance packaging boards and exceed expectation on your next project. Call your local Spicers Sales Consultant for more information. 877 790 2335 | spicers.ca

Gallus launches new digital inkjet label press

Gallus unveils its first fully digital label press, the Gallus One. The press has been specifically designed to remove the total cost of ownership barrier for the adoption of reel-to-reel digital labels with some of the industry’s highest levels of automation and cloud-based technologies. The Gallus One is built on the Gallus Labelmaster press platform. It is a 340-mm wide roll-to-roll UV inkjet digital inline labels press with print speeds of up to 70 mpm.

HP unveils new press for paper-based packaging

HP launches the HP PageWide T700i Press, a new 67 in. (1.7 m), digital web-fed platform for the production of digital single-face lamination, corrugation, and folding carton applications.

The HP PageWide T700i Press, which is expected to be available for installation in late 2023, will be configurable to meet specific customer and market needs and includes a variety of in-line options for manual or continuous unwinding, priming, varnishing, and delivery in both roll and sheet format. Select configurations will be capable of up to 1,000 ft per minute (300 m/min) supported by HP’s single-pass Thermal Inkjet technology with water-based inks for printing packaging. The new press will feature the next generation HP Thermal Inkjet printheads.

Lecta unveils paperboard for luxury packaging

Lecta creates a range of SBS graphic paperboard with a silk finish: Diva Art (one-side coated) and Diva Art Duo (two-side coated). This range is suitable for finishing processes such as screen printing, stamping, flocking and dry embossing.

Diva Art and Diva Art Duo have been developed for offset, flexo and digital printing. They are ideal for creative graphics, communications and packaging projects, including book covers, folders, labels, postcards and greeting cards, or packaging for cosmetics, perfumes, premium beverages or chocolates and sweets.

The HP PageWide T700i Press is a web-fed platform for the production of folding carton applications.

The Gallus One is Gallus’ first fully digital label press.

Lecta unveils a range of SBS graphic paperboard with silk finish for packaging projects.

Solimar releases version 9.2 of it PDF optimization software, ReadyPDF.

Solimar releases ReadyPDF 9.2

Solimar Systems releases version 9.2 of its PDF optimization solution, ReadyPDF Prepress Server. ReadyPDF 9.2 offers many enhancements to its current features and new additions to boost functionality and improve user experience. These improvements include a streamlined configuration, additional discard object options, ReadyPDF job property variables, expanded optimization settings, pre-defined modes for various activities, greater optimization report functionality, and the addition of a new preflight mode.

Rosas

Maschinenbau introduces

new

products

in label converting

Rosas Maschinenbau launches two new products for the label converting market: the Infinity 4K line scan camera and its second-generation Gazelle high-speed bidirectional rewinder. The Infinity 4K line scan camera is designed for tabletop rewinders that handle web widths of up to 520 mm. It features AI-based print inspection technology providing label checking capability similar to that of a human operator with decades of experience. The second-generation Gazelle high-speed bidirectional rewinder is useful for imprinting a variety of label types. The company collaborated on the development with Graph-Tech USA, which incorporated their EZ 202 DOD colour inkjet head based on Epson S3200 technology. This inkjet head and complementary UV LED curing system enables the machine to deliver real-time database serialization at 1200 dpi in full colour at production rates of up to 50m/min.

The new NC ink series is designed for all kinds of flexible packaging.

Siegwerk launches new generation of NC inks

Siegwerk is now offering a new generation of NC inks for flexible packaging applications. The formulations have been optimized to match both latest production technologies and current market trends. The new NC ink series includes colours and clears and is designed for gravure and flexo printing of all kinds of flexible packaging.

The Infinity 4K line scan camera is designed for tabletop rewinders.

There’s a better way.

We get why solvent is king. It’s been around for a while, and other options have not been able to compete with its quality. But that’s changed. Improved water wash technology has arrived, and Flenex plates are the proof. They process 3x faster than solvent and 1.5x faster than thermal, and the gradation and superior print quality with the ability to hold a 1%, up to 99% dot.

No more disposing of nasty chemicals. No more waiting on drying time. Just 30 minutes of total processing.

Learn more and transform your plates at www.print-us.fujifilm.com/products/flenexwater-wash-plates/.