To maximize productivity, you need tools that allow you to keep your organization moving along smoothly. Canon’s Production Printing Solutions help to keep you better equipped for the challenges ahead, enabling you to avoid time-wasting bottlenecks. Canon’s production printing expertise and innovative print technologies are renowned in the industry and your business can rely on us to help drive growth for your business.

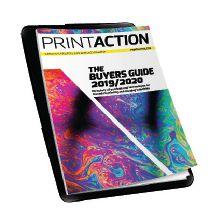

The ProStream series is a breed of fast, high-productivity continuous feed inkjet presses combining the vibrant colours of o set with the variable-data versatility of digital printing. This ink-jet printer is a great fit for commercial print as it supports a wide rage of media including: o set uncoated, matte and gloss coated, and inkjet-optimized.

1200 x 1200 dpi Up to 262 ft/minute (80 m/minute) Up to 22.23” web width (565 mm)

The VarioPrint® i-series+ sheetfed inkjet press is the solution to bridge the gap between the application flexibility and e ciency of sheetfed presses and the economy and productivity of web-fed systems, without compromising quality. Breakthrough iQuarius™ technologies, unlocks the sheetfed versatility and inkjet productivity, enabling print providers to handle new and more diverse applications— and to do so profitably.

600 x 600 dpi (perceived 1200 dpi)

Up to 294 Letter Images Per Minute

Print on o set and inkjet media up to 13.8" x 20"

Printing industry battles its way through the global coronavirus pandemic.

In packaging prepress departments, it is now possible to create prototypes that look and feel exactly like the final product.

The latest offerings from Canon, Heidelberg, HP and RICOH.

DEPARTMENTS

GAMUT

5 News, People, Calendar, Installs

NEW PRODUCTS

20 Detailing the latest offerings from SinaLite, Colortrac and Fujifilm

MARKETPLACE

21 Industry classifieds SPOTLIGHT

22 Andrew Hrywnak, President, Print Three Franchising Corp.

FROM

4 Andrew Snook

Help is on the way Feds roll out $82-billion COVID-19 Economic Response Plan

CHRONICLE

8 Nick Howard Fasten Your Seat Belts What happens after COVID-19 for print?

Unprecedented times call for unprecedented measures.

So when the coronavirus disease (COVID-19) pandemic made its way across the globe and into Canada, we needed a quick and powerful response on many fronts.

The Government of Canada’s response was to announce an $82-billion COVID-19 Economic Response Plan, which offers financial support to individuals, families, businesses and some entire sectors.

The package featured $55 billion in tax deferrals for businesses and $27 billion in direct aid.

ing costs during a period where their revenues have been temporarily reduced.

To qualify, these organizations will need to demonstrate they paid between $20,000 to $1.5 million in total payroll in 2019. Business owners can apply for support from the Canada Emergency Business Account through their banks and credit unions.

Canada Emergency Commercial Rent Assistance (CECRA)

Interim Editor

Andrew Snook asnook@annexbusinessmedia.com 289-221-8946

Contributing writers

Zac Bolan, Wayne Collins, ,Victoria Gaitskell, Martin Habekost, Nick Howard, Neva Murtha, Abhay Sharma

Associate Publisher Stephen Longmire slongmire@annexbusinessmedia.com 416-510-5246

Media Designer Lisa Zambri

lzambri@annexbusinessmedia.com

Account Coordinator

The value of the Government of Canada’s COVID-19 Economic Response Plan.

In case you’re wondering what $82 billion looks like, it’s more than three per cent of Canada’s GDP.

So what does this program look like? Well, not surprisingly, it’s extremely vast. I decided to go online and review some of the supports that the federal government is setting up. Here’s a brief list of a few of the business supports currently in place for you to peruse:

Canada Emergency Wage Subsidy (CEWS)

Found under the heading, “Avoiding layoffs and rehiring employees,” the CEWS is designed to support employers that are hardest hit by the pandemic, and protect the jobs of Canadians. The subsidy generally covers 75% of an employee’s wages –up to $847 per week - for employers of all sizes and across all sectors who have suffered a drop in gross revenues of at least 15% in March, and 30% in April and May.

The program will be in place for a 12week period, from March 15 to June 6, 2020.

Employers who are eligible for the CEWS are entitled to receive a 100% refund for certain employer contributions to Employment Insurance, the Canada Pension Plan, the Quebec Pension Plan, and the Quebec Parental Insurance Plan paid in respect of employees who are on leave with pay.

The Canada Emergency Commercial Rent Assistance (CECRA) program is designed for small businesses and will seek to provide loans and/or forgivable loans to commercial property owners who in turn will lower or forgo the rent of small businesses for the months of April (retroactive), May, and June. Implementation of the program will require a partnership with provincial and territorial governments who are responsible for property owner-tenant relationships. More details will be available soon.

Alice Chen achen@annexbusinessmedia.com 416-510-5217

Circulation Manager Beata Olechnowicz bolechnowicz@annexbusinessmedia.com 416-510-5182

Circulation bolechnowicz@annexbusinessmedia.com Tel: 416-510-5182 Fax: 416-510-6875 or 416-442-2191

Mail: 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1

Group Publisher Diane Kleer dkleer@annexbusinessmedia.com

Small and medium-sized businesses unable to access other support measures

This fund will provide $675 million to give financing support to small and mediumsized businesses that are unable to access other COVID-19 business supports, through Canada’s Regional Development Agencies.

These are only a few examples of what is potentially available of businesses in need of assistance during these strange and stressful times. More details and support programs are expected to be rolled out federally and provincially. So if you’re one of the many businesses or employees struggling due to this global pandemic, hang in there. More help will be coming.

For now, all we can do is adapt to the new reality as best we can and stay safe out there.

For more details on Canada’s COVID-19 Economic Response Plan, visit: www.canada.ca/en/department-finance/economic-response-plan.html. $82B

For employers that are eligible for both the CEWS and the 10% Temporary Wage Subsidy for a period, any benefit from the Temporary 10% Wage Subsidy for remuneration paid in a specific period will generally reduce the amount available to be claimed under the CEWS in that same period.

Applications for the CEWS opened on April 27.

Canada Emergency Business Account (CEBA)

The Canada Emergency Business Account (CEBA) will provide interest-free loans of up to $40,000 to small businesses and not-for-profits, to help cover their operat-

ANDREW

SNOOK, Interim Editor asnook@annexbusinessmedia.com

COO Scott Jamieson sjamieson@annexbusinessmedia.com

Subscription rates

For a 1 year

subscription (10 issues): Canada — $43.00 +Tax Canada 2 year — $70.50 +Tax United States —$98.00

Other foreign —$191.00

All prices in CAD funds

Mailing address

Annex Business Media 111 Gordon Baker Rd., Suite 400, Toronto, ON M2H 3R1 printaction.com Tel: 416-442-5600 Fax: 416-442-2230

Annex Privacy Officer Privacy@annexbusinessmedia.com 800-668-2384

PrintAction is

Memjet CEO Len Lauer passes away Len Lauer, CEO of digital inkjet technology provider Memjet, died on April 13 at age 62.

In a press release, Memjet said that Lauer passed away unexpectedly at his home in La Jolla, Calif. Lauer was named the CEO of Memjet in 2010 and assumed the role of Chairman in 2012.

“On behalf of our board of directors and employees worldwide we extend our deepest sympathies to Len’s family during this very difficult time,” said Tony Duddy, Memjet’s group president, R&D and operations and board member. “An outstanding leader, visionary, and champion for high-quality, innovative digital printing technology for all markets, Len was a tireless advocate for Memjet Technology, our employees, and for delivering beautiful precision to the OEM partnership communities we serve as and their customers. Most importantly, Len was a devoted husband, father, and friend. We all will miss his tremendous presence in our lives.”

Lauer was born and raised in Springfield, Mass., and received his Bachelor of Science degree in managerial economics from the University of California, San Diego in 1979. For over 30 years, Lauer held leadership roles with leading global technology innovators, developers and providers, including Qualcomm, Sprint, Bell Atlantic and IBM, and for the past 10 years, Lauer held the role of Memjet CEO, overseeing the company’s growth to its current status as a leader in the development of inkjet

printing technology.

Effective immediately, the board of directors has named print industry executive and Memjet board member Sunil Gupta as CEO of Memjet. Gupta joined Memjet’s board of directors in January of 2019. He has held leadership roles in major print industry businesses, including Fuji Xerox Australia, Fuji Xerox Asia Pacific and Xerox International Partners, and Xerox Corporation.

Xerox ends its hostile takeover bid for HP

Citing the current global health crisis related to the COVID-19 coronavirus, tech giant Xerox has dropped its bid to merge with competitor HP.

“The current global health crisis and resulting macroeconomic and market turmoil caused by COVID-19 have created an environment that is not conducive to Xerox continuing to pursue an acquisition of HP Inc.,” Xerox said in a March 31 statement. “While it is disappointing to take this step, we are prioritizing the health, safety and well-being of our employees, customers, partners and other stakeholders, and our broader response to the pandemic, over and above all other considerations.”

Xerox will not nominate candidates to HP’s board, and has withdrawn its offer.

“We have a healthy cash position and balance sheet that enable us to navigate unanticipated challenges such as the global pandemic now before us, while preserving strategic optionality for the future,” HP said in its own March 31 statement.

Xerox had previously led a hostile takeover bid of HP which would combine the two companies. In November 2019, HP’s board unanimously rejected the offer, arguing that it undervalued the company and wasn’t in the best interest of shareholders.

Delphax Solutions introduces “#PrintingStrong” COVID-19 recovery program for the printing industry

Delphax Solutions Inc., a digital inkjet press manufacturer based near Toronto, has introduced a “#PrintingStrong” program (www. PrintingStrong.com) to help support Canadian and U.S. printing companies during, and post the COVID-19 pandemic.

Delphax Solutions is offering qualified printers who produce more than 12 million letter impressions per year the opportun-

ity to acquire one of a limited number of Delphax Solutions’ Elan 500 HD cut sheet digital inkjet presses, for a minimum of two years with no equipment lease or purchase costs.

“This program provides access to a high availability, high productivity, and low total cost of ownership production press on a ‘pay-asyou-go’ basis without the typical financial commitments associated with capital equipment,” Richard Lee, Delphax CEO, stated. “Successful applicants will only be required to pay for consumables and support, which remain at our 2019 rates.”

For high volume users there are additional incentives available, he added.

Applications under this program are being accepted immediately.

“However, due to the current government mandated travel restrictions, companies located in the Greater Toronto and Hamilton Area (GTHA) in Canada, and the Minneapolis-St. Paul, Minn. area in the U.S. will be able to access the program and schedule installations immediately (subject to any government imposed COVID-19 restrictions),” Lee said. “Once travel restrictions relax, installations can be scheduled for other Canadian and American firms that qualify.”

Existing customers who have the additional annual production volume also qualify for the program.

The Association for PRINT Technologies (APTech) has released a free online Disaster Recovery Toolkit to help businesses manage the unprecedented COVID-19 disruption.

The toolkit provides tips and best practices along with a downloadable disaster recovery plan that can be adapted for businesses that want to develop a plan for future forward planning.

Released on April 6, the fourpart series is designed to assist businesses impacted directly and indirectly by disaster, especially when a plan is not yet in place.

“Users will learn how to create a disaster response and recovery plan, how to effectively communicate to staff and customers during a crisis, and how to do the tough work during rough times, like spring cleaning your customer base, policies, procedures and staffing,”

June 21-24

CUPMAC

Niagara Falls, Ont.

August 23-25

ISA Sign Expo Orlando, Fla.

August 24-25

Converters Expo Green Bay, Wisc.

September 10-12

Labelexpo Southeast Asia 2020 Bangkok, Thailand

September 15-17

Brand Print 2020 Chicago, Ill.

September 15-18

Digital Signage Expo 2020 Las Vegas, Nev.

September 18-19

Sign Expo Canada 2020 Mississauga, Ont.

September 24, 2020

Gala Gutneberg Montreal, Que.

September 29 to October 1

Solimar User Conference & CAC

Summit San Diego, Calif.

October 21–23

Printing United 2020 Atlanta, Ga.

November 12

Canadian Printing Awards 2020 Palais Royale Toronto, Ont.

APTech stated.

The Disaster Recovery Toolkit also offers what APTech calls, “a customizable plan to help businesses take a thoughtful approach to the many important components of recovery following a disaster without wasting time, resources or drifting from the main objective of ensuring continued business success.”

“There are many question marks along the road ahead. The suggestions in this guide are intended to help companies identify the unknowns by giving them a competitive advantage and a solid start to disaster preparedness,” said Ken Garner, senior vice-president for content creation at APTech.

To view the toolkit, visit: www. printtechnologies.org/futureforward.

Digital printing solutions provider Domino has appointed Mike Barry as key account and OEM manager, digital printing, North America.

Barry spent the past eight years in the printing and packaging industry.

Prior to joining Domino, he was with Fujifilm for seven years where his roles included business development, product marketing management and sales support. During this time, he also became an active member of TLMI, serving on the technical committee and participating in industry conferences.

“I am very excited to have recently joined the Domino team,” Barry said. “Domino is the market leader for inkjet in the label industry, and I am looking forward to working with our customers and hybrid partners as we continue to grow our business.”

Barry has a Bachelor of Science in graphics arts management from Ball State University and is currently pursuing an MBA from Benedictine University.

Recycled paper tubes and cores supplier Yazoo Mills Inc. has announced the promotion of Chris Evans to sales manager. Evans joined the New Oxford, Pa.-based company in 2017 as an outside sales representative, responsible for creating new business within the east coast.

Evans assumes his new role from Sharon Smith, who has spent more than 40 years at Yazoo Mills and will continue working as a key account manager.

Evans has a B.A. from Rowan University and over 20 years of experience in the tube and core industry. In his new role, he is responsible for driving and expanding business by directing the sales team, as well as implementing sales strategies to maximize the use of existing data in Yazoo’s systems. He will also help develop new territories and markets.

Flint Group has named Emmanuel Bareaud as president of its Narrow Web division, effective March 30, 2020. He replaces outgoing president Guillaume Clement.

“I would like to thank Guillaume for his important contribution to our company over the last seven years,” Flint Group CEO Antoine Fady said in a statement. “He has developed a strong strategy, a great product range manufactured in a world-class mother plant in Trelleborg, and a team ready to meet the challenges and win in the marketplace. Additionally, Guillaume led the step-change in Flint Group growth with international key accounts and cross-divisional solutions for customers. We thank him for his contribution and wish him well for the future.”

“I am delighted we have secured a successor for Guillaume of the quality and experience that Emmanuel represents,” added Steve Dryden, Flint Group chief operating officer. “Flint Narrow Web is an incredibly strong business and I look forward to working with Emmanuel and the Narrow Web team to continue the successful development of this business.”

In early 2020, Montreal-based Champion Imaging Group completed the installation of an Anapurna H3200i LED from AGFA. Established in 1975, Champion Imaging started as a photo lab and today is one of Canada’s leading producers of larger format colour graphics for the advertising, retail, display, and signage industries.

SinaLite of Markham, Ont. recently purchased an HP Indigo 6900 digital press for the product of roll labels. The press was installed in January 2020.

Dion Label Printing from Westfield, Mass. has acquired its third MPS flexo press, an EFA+ 430 fully automated multi-substrate press. The partnership between Dion Label and MPS began in 2008 with the purchase of an EF 410.

By Nick Howard

The entire world has entered new territory.Young or old, male or female, smart or dumb, the virus plays no favourites and not only disrupts lives but also literally kills. H.G. Wells, the English science-fiction author, probably nailed it back in 1897 when he wrote the classic War of the Worlds. But for seemingly innocuous bacteria, the Martians would have destroyed humankind. The 2003 SARS virus was never quite like this. As Toronto was a hot zone, I recall only being annoyed because very few of our international clients would travel to our plant. Foolishly, I had no idea of the implications of not containing something we can’t see or smell.

How quickly our everyday patterns of life changed with COVID-19. Once this virus is isolated and a vaccine developed, there will still be trillions of dollars left unrecoverable, along with potentially millions of shattered lives. But there are significant problems for various commercial segments of the economy: those who have been waging battles of survival for the last 25 years. One of these is of course our own printing industry.

It would be totally inappropriate for anyone (me included) to suggest how COVID-19 will play out. But I come from the printing industry and this article is read by our community. So, I must pass on what seems obvious. Whenever a catastrophe arises, and no one living has seen this latest incarnation, humans somehow adapt. The 1973 Arab oil embargo crippled supplies of gas but also changed our driving habits and the way we built our cars. Fuel efficiency was the new buzz word. Even with this inherent ability for survival, slowly, we went back to our old ways: but never exactly the same as before.

The Spanish Influenza of 1918 infected 500 million people, of which 17 to 50 million perished. I researched our museum library to see what, if anything, print publications were reporting during the period between January 1918 and December 1920. Virtually nothing -- not one line in any significant print industry publication mentioned the noticeable adverse effects this influenza was having. I also couldn’t find the words “flu” or “influenza.” The closest comment was tucked

away in 1920 by the British Penrose Annual’s William Gamble: “then there have been the deaths of a number of older workers in the trade – deaths hastened in many cases, perhaps, by the trying conditions of the times.”

H.G. Wells, the English science-fiction author, probably nailed it back in 1897 when he wrote the classic War of the Worlds.

Most of the newspapers of the period spun a completely counterfactual story that suggested because the Spanish King (Alfonso XIII) was gravely ill somehow, the virus must have emanated from Spain just as today countries looked for someone or some state to blame. Today, historians are divided on the epicenter pointing to two locations: Haskell County, Kansas, U.S. or Étaples-sur-Mer, France. The experts are, however, in agreement that the Spanish Flu had nothing to do with Spain.

But there is one remarkable difference between the influenza pandemic of 1918 and COVID-19: the ability for businesses and the general public to bypass the printed word. By the end of 1919, the market was back to normal. The Great War had ended, soldiers returned to their jobs, and the printing industry was experiencing a significant boom. Today, with so many people either working from home or laid off, unless they’re sequestered with a book, they are on their computers or watching television. Should they get hungry, they

order-in using many of the home delivery apps. But today the virus is front and centre. Unlike 1920, everybody is calling it out and not burying it as if it is someone else’s problem. One hundred years later, society has vastly more tools at our disposal, some of which can further damage print.

In the United Kingdom, there is a growing dislike by shop owners accepting cash. The chance of catching germs from paper notes and coins is a possibility, and now more than ever. So, we tend to use credit cards or our smartphones to pay for things, even a cup of coffee. How will the long-term effects of virtual cash, help the security print industry, including the manufacturers of specialized machinery? The COVID-19 virus just sped this transition from paper to digital, and it is not reversible. Even a few years ago, several countries, particularly Sweden, discouraged the use of cash, and many establishments simply refused to take it. The trend was already there before the COVID-19 boost.

The clear benefits of embracing software have a startling effect on jobs, too. Banks used to be nothing but bricks and mortar with ridiculous closing times, such as 3:30 p.m. That’s why everyone joked

about “banking hours.” Tellers, long the only connection to your money, are vanishing and replaced with machines and online banking (which is the most profitable).The same is happening in our stores and supermarkets. Self-service checkouts are an everyday thing. News now flows in a continuous stream 24/7, and we are not only hooked, but extremely comfortable paying our bills or buying a new

1920 by the British Penrose Annual’s William Gamble:

“then there have been the deaths of a number of older workers in the trade – deaths hastened in many cases, perhaps, by the trying conditions of the times.”

pair of shoes with our smartphones. Gone are the early days of E-Commerce when we were scared to leave credit card information on a website. For the porn industry, print versions were systemically wiped off the face of the earth by the internet. The printing of porn was something few printers were proud of, but it sure put a lot of their kids through college and made millionaires of more than a few.

Add the excellent fortune of enhanced and more abundant data, and no wonder businesses increasingly want to become not only paperless but also cashless. This nasty virus is merely clearing the path faster than anyone expected. Today there is not only a wish for streamlining business but an actual need. As of this writing, most restaurants are closed, as are coffee shops that have seating. Effectively, these businesses cannot survive unless they have drive-thru or can deliver. Each step forward means one step back for print. Our ecosystem just got a whole lot smaller.

COVID-19 now makes it even more difficult to at least sustain the small slice of the communication pie. During the early stages of a mass shutdown, many print clients had no choice but to reassess how they could maintain marketing campaigns without the need to print anything.

A most explicit example of this about-turn is in companies now communicating how they are coping with disruptions and encouraging customers to follow them on social media or company websites. Staff working from home linked by cloud-

based software: Voila! No changes at all to how we serve you. Perhaps you noticed your suppliers had communicated lately only via social media or email?

Conceivably, packaging is immune. Oddly the “eyeball” sector of signage, banners, and point-of-sale should be safe. Eyes don’t reach out and touch signage as fingers do a magazine or envelope. Besides, we will be excited to get outdoors, and guess where most of the large format is? Outside.

For everyone else, we have reached another setback. With so many people impacted by COVID-19, anything that can be transacted remotely will be. No building can be completely sealed to prevent vermin from finding a way inside. So, it is with technology. The moment a better or cheaper way is invented, humans will find it. I’m less concerned with COVID-19, more worried about how we charge back. Fasten your seat belts, our mighty print industry will need to be brilliantly creative to win some of it back.

NICK HOWARD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment.

nick@howardgraphicequipment.com

Printing industry in the midst of yet another battle, as it fights its way through the coronavirus pandemic

By Andrew Snook

The printing industry has never in the past century been without its share of challengers and doubters.

When radio became a popular choice of households in the early 1900s, many people predicted the fall of print. It never happened.

In the post-war era of the 1950s, when television became a staple in homes around the world, print was again predicted to die off. Not only did it stay alive, but it continued to share in a healthy slice of the marking and advertising pie.

When the internet’s popularity took off in the late 1990s and early 2000s, many experts again predicted that many aspects of print would disappear. The new digital world certainly made a significant impact on the printing world in many different

segments (possibly none more than the newspapers industry) and is still creating new challenges for the industry to overcome. That said, many companies in the printing industry have found ways to adapt and continue to run profitable operations, introducing new services and technologies to their businesses.

If things were not challenging enough for many in the industry, enter the COVID-19 coronavirus pandemic, which has hit a countless number of industries fast and without mercy across the globe.

Canadian companies in all sectors have had to find ways to adapt and be agile in our new reality, which includes stay-athome orders, social distancing, supply line challenges and a great deal of personal protective equipment.

Although the printing sector has been allowed to continue its operations, since it

After considering all the factors — including the small footprint of the Elan 500 HD, its powerful throughput, a larger format sheet-size, super efficient workflows, a low power consumption, aggressive total cost of ownership (TCO) profile - we made your decision an easy one.

With our #PrintingStrong program, we’re making this decission even easier by providing qualified companies such as yours the opportunity to secure this press with no capital acquisition costs

#PrintingStrong program which allows for:

• Qualified companies printing 12 M or more letter impressions per year the opportunity to secure an Elan HD for a multi (2 to 5) year, no capex or lease payment program.

• The only expenses required are day-to-day running costs, a true “Pay as You Print” program.

Elan Highlights:

• 500 impressions per minute

• Up to 18”x26” sheet size

• CMYK inkjet press

• 94% + availability

• Self or factory maintenance

• Canadian Designed and Manufactured

was identified as an essential service, many companies have needed to be extremely agile and change directions on its operations to keep their doors open. Add to this, the complexity of trying to keep your workers safe and adhering to constantly changing health and safety policies, and the industry may be in its biggest battle to date.

Although managing operations around the pandemic is a new and fierce challenge for Canada’s printing industry, some companies do have experience with being deemed an essential service during a state of emergency.

One of those companies is CJ Graphics Communications Solutions (CJ Graphics) in Mississauga, Ont., which was deemed an essential printer going back to when the massive northeast blackout occurred in 2003, knocking out power throughout a large part of Ontario, as well as the northeastern and midwestern United States. CJ Graphics provides a variety of labelling products for the pharmaceutical and food and beverage industries as part of its operations. So when the pandemic hit, the company already had some safety procedures prepared for dealing with a state of emergency.

“We are used to stringent rules,” says Jay Mandarino, president and CEO of CJ Graphics. “The first thing we did was shut our building down, nobody could come from the outside in.Then, only people who could get a drive here could come. Anybody that took transit or anything else was not allowed in the building, because they couldn’t control where they were coming from. People have to abide by the rules at home. Here, in every part of the building we opened all the inner doors everywhere, we have stations and tissues everywhere that people can use. They get masks and gloves in reception. And, of course, we

customers

see products

MET Fine Printers has partnered with a brewery and is producing 5,000 bottles of its own hand sanitizer that it plans to distribute among frontline workers. Photo: MET Fine Printers.

have sanitizing hand gel at every workstation and every desk.”

The company also had to shut down its shipping and receiving area but uses a sensor for when drivers are coming to offload materials, so no employees need to have direct contact with them.

“Front reception directs everybody,” Mandarino says. “If somebody has to come in and pick something up, we have a separate table in a vestibule.”

Social distancing practices (everyone working a minimum of two metres away from each other) and other work safety policies are also being practiced.

“All the office people and salespeople that can work from home, work from home,” Mandarino says. “We were 230 people, now we’re 60 people over multiple shifts, so it’s like a ghost town… and of course, anybody who doesn’t want to be here we encourage to stay home. We don’t want anyone to feel unsafe. Maybe they’re susceptible to someone else, maybe they’ve got older parents, we’re really trying to control the environment.”

To keep the environment safe for workers at Burnaby, B.C.-based Hemlock Printers, president Richard Kouwenhoven says his company has been following the guidelines put forward by public health officers of B.C. since March.

“We do a full disinfecting of our workplaces and workspaces both by our staff and our cleaners,” he says. “At the same time, we started putting together daily protocols to keep the facility clean. That is managed by our production manager. Daily cleaning of desks, computers, all the touchpoints in the building, any workspaces being shared.”

Management also downloaded the various safety guidelines options off the Government of Canada website and printed out them out, along with their own safety signage, and placed the materials throughout their entire building.

“By mid-March, we closed our two U.S. sales offices, around the same time California was issuing its stay-at-home orders,” Kouwenhoven says. “In mid-March, we asked salespeople to work from home, they were the first to get to work from home.We started accommodating work from home for other staff after that.”

The company had recently upgraded its some of its systems, which allowed various departments to work remotely, including the accounting, sales and marketing deparments.

“At the same time, we closed the main facility to visitors.The only people that can come in were people to service the equipment, if absolutely needed,” Kouwenhoven says.

For internal meetings, Hemlock is doing a lot of its meetings on Microsoft Teams.

Due to a combination of the current economic conditions and new work-fromhome policies, the company had about half of its employees in the building.

“Because of the economic impact, our workload has dropped so we’ve implemented work sharing through the federal program and are waiting to hear back if they get approved,” Kouwenhoven says. “We’re able to scale our capacity down to the workload we have now, and less people coming in, less travel, less people in our building, which is what the government is looking for.”

Implementing the new social distancing policies at Hemlock has been challenging to implement simply due to human nature and being used to a different routine, but Kouwenhoven says everyone at Hemlock is following the rules.

“It’s the nature of our business, we’re working in groups a lot,” he says. “At the presses – with the exception of our small press – we have two people on them. We’re trying to have this crew work at a distance. But they’ve been working, in some cases, for decades without that. So, we’ve had to separate some people.”

The PDI Group in Kirkland, Que. has also been closely following all of the guidelines being brought forth by the federal and provincial governments for keeping employees and customers safe during the pandemic.

“We have implemented all the government recommendations regarding the prevention of COVID-19 in the workplace,” says Jamie Barbieri, president of PDI Group. “We have closed our reception area and limited any outside visitation to essential services only – those visitors are required to wear mask and gloves when entering the building and are screened prior to entry for symptoms and recent travel.

MET Fine Printers in Vancouver has also reduced its office staff, allowing employees to work remotely at home, keeping only a skeleton crew in rotation.

“The plant has a day shift 12 hours a day, three days a week, then another shift comes in for three days, and we do regular full sterile cleanses of the workplace,” says Nikos Kallas, president of MET Fine Printers. “We’ve also installed a heat detection camera to scan anyone coming into facility to check for fevers.”

Scott Gray, vice-president of sales and marketing at Mitchell Press in Burnaby, B.C. says the majority of the staff there are also working from home.

“Sales teams have been working remotely, and I’d say probably close to 60 per cent of our production coordinators and admin staff, so we have mitigation plans in play,” he says. “But the work has dried up pretty dramatically. So, we’re trying to figure out how to square that circle,”

Many companies are scrambling and attempting to change at least part of their product focus in an effort to create products that will help frontline workers in their battle against COVID-19.

CJ Graphics is busy producing a wide variety of products for companies deemed as essential services.

“One of the most popular products we’re making for COVID-19 are what we call social distancing guards – we have four models,” Mandarino says. “Basically, one is just a blank special plexi, another one has a transaction window, one is a tabletop version and the other one is a larger tabletop version.We have them in hotels, condo buildings, reception areas.”

Another unique product to come from CJ Graphics is the production of hospital beds, which the company got approval for in early April. It is in the process of finalizing the costs on those and has plans to ship across Canada and into the U.S.

The company is also producing face guards for frontline workers.

“Most of these things we’re not really making any money on them, we’re doing them at cost to give back and keep some people busy here,” Mandarino says.

At Hemlock Printers, to ensure that customers are still receiving the same level of service that they’re accustomed to, the company has implemented video conferences for quality control where customers can see products and talk with operators.

“The client is able to see a job on press using a tablet and they can talk to the operator,” Kouwenhoven says, adding that they’re promoting this new service through a blog on the company website. “That’s a way for us to continue operating and supporting some of the things that they typically do with us while complying with the distancing rules.”

To help frontline workers in B.C.’s Lower Mainland, Hemlock is providing infographic signage created by federal and B.C. provincial governments.

“Any organization in the Metro Vancouver area can order from us batches of this signage to put up – whether it’s a grocery store or a public space somewhere, where they want to communicate the distancing rules or hiking rules,” Kouwenhoven says. “We’re printing those with no charge with support from HP, because we’re printing it on our Indigo [press],and Spicers [Canada] is donating paper, and a local courier is doing free delivery. We’ve pulled together a small group of companies to make that possible and we’re seeing some orders come in, which is nice.

In an effort to aid frontline workers, PDI Group has been able to tweak some of its equipment in order to manufacture personal protective products such as facial visors and countertop deflectors.

“Also, we have been doing a lot of COVID prevention signage and printing,” Barbieri adds.

MET Fine Printers partnered with a brewery and is producing 5,000 bottles of its own hand sanitizer that it plans to distribute among frontline workers.

Mandarino says the biggest challenge is adjusting to a new reality filled with uncertainties.

“Who knows what’s coming up? Are we getting subsidized? We’re a larger company, so originally the funding that was available didn’t apply to us, now I hear that it does. But by the time you get it, when you get it, there are just so many questions that haven’t been answered yet,” he says. “This is catastrophic. It’s not just Toronto, it’s not just in Ontario, it’s not just in Canada, it’s the whole world.”

Mandarino says that the coronavirus pandemic will generate serious financial challenges for many companies.

“We have to really figure out how that’s going to play into cash flows and dealing with banks,” he says. “We do a lot of retail stuff and, unfortunately, we’ve have a few retailers who were already in tough times and will likely go under because of this. We’ve already received information from people saying that, ‘Unfortunately, due to the economic hardships of these times, we’re unable to pay our bills at this time.’

And what do you do? Now we become a bank. There’s only so much cash flow people have, so it’s really strenuous that way.”

Hemlock’s Kouwenhoven says the biggest challenge is keeping staff and customers informed.

“Keeping our stakeholders informed in an environment that is changing so fast is a challenge. You have to formalize your response and communicate it,” he says.

PDI Group’s Barbieri agrees.

“One of the most difficult challenges we have had is dealing with the large volumes of information that are communicated

publicly – interpretation, accuracy and facts are hard to handle and getting access to answers is even more challenging,” he says, adding that the reduction and adjustment in the workforce has also been difficult to manage, as has the lower demand in services. “As we have obtained a designation to remain open in support of our customers who are deemed essential servi-

“Keeping our stakeholders informed in an environment that is changing so fast is a challenge.”

ces, we have had to modify our communications methodology and workflow to accommodate those of our customers and employees working from home.The access to technology tools and workflow automation systems and networks are a challenge for those working from a home computer and many security issues have arisen. The overloading of internet bandwidth and teleconferencing systems have also proved to be an issue lately.”

Kallas at MET Fine Printers says that keeping morale up during the pandemic, while managing through the decrease in business present the biggest challenges. That said, his company has faced adversity before.

“Our company burned down two years ago in Vancouver and we adapted and worked through that. We’ve been through a very challenging time before, so we’ve built contingency plans,” he says, adding that those plans allowed for employees to work remotely relatively seamlessly. “We kind of forced ourselves into it when our company burned down. We got everyone on laptops to get them on our systems and put them all on cellphones.”

Although uncertainty is certainly part of the new post-pandemic reality for Canada’s printing industry – and some companies will more than likely be forced to close their doors – many companies plan on toughing it out, adapting to their environment, and continuing to generate much-needed products and employment for their employees.

“So far we’re lucky, we haven’t had to lay anybody off – and it’s not our intention to do that – so anything we do is as a team,” says Gray at Mitchell Press. “Whether we take advantage of work share or some of the new programs being rolled out by the government – we’re still waiting to find out more information on it – we spent so many years trying to get this team together that we don’t want to let anybody go. Everybody is in it for the long haul together.”

It is now possible to create prototypes that look and feel exactly like the final product.

In

packaging prepress departments, it is now possible to create prototypes that look and feel exactly like the final product.

By Erik Schmitt

In most packaging prepress departments, proofing and prototyping is a particular challenge, especially considering the needs of brand colour expectations matching. Given the complex nature of conventional (lithographic or flexographic) print variables such as ink viscosity, dot gain, screening, packing materials, and many others, there is no wonder it can be confusing to clearly communicate expectations to demanding brand owners.

How do you demonstrate colour-accurate proofs on unusual substrates like films, foils and adhesives? It is difficult enough to control your own in-house processes and the wide variety of print production variables; never mind proving to customers that you can do it.

Previous solutions could create prototypes that only resembled the final product.

Now it is possible to create prototypes that look and feel exactly like the final product. By connecting superior colour management software to extended gamut digital printers, anyone can produce exceptional, colour-accurate prototypes on a wide variety of substrates. It closes the gap between traditional prototyping and contract quality proofing.

With the increased use of multi-colour printing and different combinations of inks types, substrates, screening, and finishes, package and label printing involve a lot of press fingerprinting, ink drawdowns and file manipulation. Fingerprinting, or press/printer profiling, is difficult to do and, conducted by experts, can cost many thousands a day.

For the first time ever the Buyers Guide will be included within our October issue print and digital editions, as well as enhanced online listings NEW for 2020/2021 edition.

Deadline for display ads and enhanced online listings is August 31st

All processes, whether conventional or digital, are affected by dynamic changes in environment and printing conditions.The goal is to create a repeatable “golden state” that can be maintained. This is all possible. Using the latest profiling technology, a print provider can easily predict press performance and determine quality characteristics. From past live jobs, with minimal input like a colour bar, or a few measurements from known referenced live areas, a knowledgeable service provider can create an exceptionally accurate brand colour or target press reference. Different printing technologies, and the variety of service providers and end output printing conditions lead to deviations.

‘Please match to previous’ is now more common regardless of your printing pro-

cess. By leveraging spectral data profiling and conversion technology—which precisely predicts the overprinting of process and spot or gamut expanding colours— users can avoid lengthy correction loops on press before running a job. Printing process, substrates, and finishing enhancements are taken into consideration. If parameters are similar enough, an accurate prediction proof, separation strategy or direct-to-production material prototype can be quickly calculated without the need to reprofile your end output device— whether conventional flexo, offset, or the wide variety of digital reproduction technologies available.

With the right combination of process controls, profiling software and procedures, it is possible to precisely and repeat-

edly predict the colour appearance of any combination of inks, substrate, and finishes of the final desired product. Combinations of spot colours or gamut expanding inks with conventional CMYK can be accurately reproduced before the job gets to press. Once a press fingerprint or printer profile is finalized, the prediction of output device behaviour can be accurately predicted to ensure that customer expectations are met. All involved in the project can be satisfied that brand colours are attained, and we all are able to profitably meet our objectives.

In choosing a device that can reproduce a job without going to production equipment, the Epson SureColor S80600 solvent printer is an interesting option. While satisfying the need to reproduce vivid colour, it is equally nimble in its ability to cover the wide gamut of colour to demonstrate accurate proofs, from paper to finished product prototypes. Many different materials are available, including sealable pouch films, shrink wrap films, metallized foils, folding carton boards, and laminate heat transfers to actual printing material.

The printer can be calibrated within tight tolerances to ensure consistent performance and colour reproduction stability. It bridges the gap between a contract colour proof on inkjet paper and direct-to-substrate laminated simulations from the past, with faster print speeds. All of this can be done with simple integration into a supported colour proofing system. Because of the printer’s small droplet size, even halftone dots can be replicated. This is not a simulation, but the exact dots from the same final files that existing workflows ultimately image to plate. Potential problems such as moirés and incorrect trapping settings are visible in advance, via the proof.

Leaving creation of colour accurate prototypes to itself

Based in London, Ontario with a production facility in Fayetteville, Arkansas, Autumn Graphics Ltd. is a privately-owned company providing pre-media production, plate production, brand management, 3D packaging development, print production technical services, and packaging lifecycle workflow tools. It has served consumer product companies, converters, printers, and advertising agencies since 1982. By continuing to invest in technology, people, processes, and research and development, Autumn Graphics secures the ongoing success of both itself and its customers.

Prior to inkjet prototypes, Autumn Graphics used transfer systems to provide proofs on a substrate. They were looking for a solution that would enable them to increase prototype quality for complex packaging designs and achieve a better

colour match for the final print result.

“By transitioning to 100-per-cent inkjet proofing rather than lamination systems, we determined we could produce more efficient, cost effective, and accurate prototypes,” says Ben Abray, president of Autumn Graphics.

“We wanted to grow our inkjet proofing options rather than other systems, and determine what tools could simulate as many types of printed results as possible,” adds Hugh Wilson, Autumn Graphics technical services manager. “The ability to more accurately simulate print conditions without requiring press trials would be really helpful. A graphic trial on press, of course, is the best way to prevent surprises—dealing with issues from ink, anilox, etc. However, if we could use a good predictive model to represent what may happen down the road, that would be very useful.”

Autumn Graphics invested in GMG colour management technology about seven years ago. While they rely on its colour accuracy, another important piece was the remote proofing. They can send accurate colour files to remote calibrated devices anywhere in the world.

“GMG ColorProof was reasonably straightforward to implement,” recalls Wilson. “The GMG OpenColor learning

curve took just a little longer because it is very different than typical colour tools. Its fingerprinting takes advantage of sophisticated, proprietary spectral prediction technologies.”

Autumn Graphics invested in its Epson SC-80600 a bit less than a year ago. Its colour gamut was large enough and output was reasonably fast enough, so they could create prototypes on a wider range of substrates. It allowed them to remove slower, non-inkjet proofing options and replace them with more efficient technology to create colour-accurate prototypes.

Autumn Graphics had worked with an outside service for prototypes, but it cost a significant amount of money.

“Prepress proofs have always been accurate. However, the accuracy of prototypes has taken a step forward,” Abray says. “It lets us produce more prototypes, more efficiently, on specialty substrates without the same subsequent increase in human resource and production costs.”

Creating customer expectations is something you don’t do in production.

“With prototypes, one of the challenges is that we have to send, fairly quickly and inexpensively, a sample with reliable colour. We produce any proof or prototype with colour management based on the profile we created from the actual flexo or

Autumn Graphics Ltd. has served consumer product companies, converters, printers, and advertising agencies since 1982.

offset press that will run the job, accurately representing process and spot colours,” Wilson notes.

Using the new process not only has cut production costs, but has also reduced shipping costs and timelines.

“It has given us the ability to achieve compressed deadlines for proofs that require different substrates,” Abray says. “In the past, we would have planned for longer lead times to generate our prototypes. But now we expect shorter lead times, condensing time to market.”

While the cost of one prototype is not prohibitive, imagine if a brand owner wants to see a number of sample prototypes that, ultimately, do not go to market.

“Our system offers the brand considerable savings. And, the ability to produce accurate prototypes really helps take the surprise out of the process,” Wilson says.

“Our responsibility is to show samples that represent what can be produced on the press, so that the customer does not have unachievable expectations,” Arbay says. “Many brand owners still need to see what a physical prototype looks like. Now, they can see it in accurate colour.”

Erik Schmitt is GMG director of sales for Canada.

– Over Cutter Camera OCC system for high-speed registration

Dual-beam D3 series for twice the throughput and productivity – Cut & Seal LM-100W Laser module for one-step fabric finishing

340

Combining the latest digital printing technology with the benefits of conventional printing and further processing technology, the Gallus Labelfire 340 is a complete in-line solution handling digital, flexo, cold foil, rotary screen, and die-cutting from start to finish – all from a single machine. Jointly created by Heidelberg and Gallus, the Labelfire is run by Heidelberg’s Prinect Digital Front End, which includes spot colour matching, the PDF Toolbox, and Prepress Manager. The Labelfire enables shorter runs and lead times while still printing at 1200x1200 dpi resolution and running at 50m/min. www.heidelberg.com

HD with HP Brilliant Ink

The HP PageWide Web Press T250 HD with HP Brilliant Ink for high-volume production inkjet web presses is here to

power your aspirations with uncompromising offset-class quality and impressive ROI. The new HP Brilliant Ink enables efficiencies while delivering a more vivid colour gamut with outstanding results across a broad range of substrates, including offset coated and uncoated media, and more. Enjoy the benefit of one press that enables all applications –commercial, direct mail, publishing, and transactional. This versatility allows you to meet your customers’ demands. And it’s upgradable to keep you on track to deliver every new trend for many years to come.

www8.hp.com

The award-winning RICOH Pro VC70000 is a is scalable, field-upgradable Continuous Feed Inkjet Printer that delivers all the benefits of digital printing and powerful data-driven communications without sacrificing the affordable

Heidelberg-Gallus Labelfire 340

HP PageWide Web Press T250 HD with HP Brilliant Ink

media choices, image integrity and speed of offset. It gives commercial printers the ability to produce demanding high-quality applications, such as catalogues and magazines.

The RICOH Pro VC70000 has new extended gamut inks that make it possible to print onto a variety of different types of stocks, including offset coated and uncoated papers, without pre- or post-coating.

Other key features include media support for offset coated, IJ coated, IJ treated and uncoated papers from 40 to 250 gsm; Ricoh’s latest generation stainless steel printheads; dynamic drop technology at the image level to render fine details, consistent half-tones and optimized ink usage on high coverage areas; production volumes up to 40 million impressions per month; repeatable print lengths of up to 54”; and output speeds up to 492 ft/min; RICOH Pro VC70000 advanced drying and

cockling correction technologies, which are required when printing on lightweight papers; and RICOH TotalFlow Print Server R600A Digital Front End (DFE) for powerful job and data processing with support for multiple data streams, access to colour management and additional job tools; and technical and field support.

www.ricoh.ca

The Canon ProStream is a web-fed inkjet production print engine developed with the requirements of premium direct mail and high quality commercial print applications in mind. It’s been designed from the ground up to combine the

best technologies in digital and offset printing. This engine will put printers ahead of the curve. Especially in demanding applications where existing printing technologies run into limitations; run lengths become too short for offset to operate profitably, overall volumes are beyond throughput levels of toner engines, and media latitude is beyond that of existing inkjet presses.

Utilizing Canon’s ColorGrip and unique polymer pigment ink technology, the ProStream prints on uncoated, inkjet-optimized, and matte, silk, or gloss coated standard offset stock achieving superb quality and productivity required for the commercial print space. www.csa.canon.com

same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

Wholesale trade printer SinaLite recently introduced social distancing floor graphics, and health and hygiene decals. Both products come with pre-designed artwork.

1x Mitsubishi 40” 10 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Perfector with AQ

3x Mitsubishi 40” 6 Colour with AQ

2x Heidelberg Printmasters

3x Saddle Stitchers / 1 Perfect Binder / 10+ MBO Folders

Over 75,000 sq ft plant housing state-of-the-art nishing and bindery

Personalized account management and complete control over production

24/7 Production with fully automated and barcode controlled plant

FSC / PEFC / SFI certi ed

SinaLite’s new floor graphics feature five designs to choose from. Printed on vinyl stock with anti-slip properties, these removable 13-mil. vinyl adhesives are safe and scratch-resistant. They can be applied to surfaces such as tiles, wood flooring, carpets, and more.

SinaLite has also introduced decals to promote healthy hygiene practices. Launched on April 9, these 4-mil. removable vinyl decals come in four sizes and feature 11 different designs to choose from. Designs include decals that promote hand washing, covering coughs, and avoiding handshakes.Both products take two to four business days to produce, and can be blind shipped either to the reseller’s address or directly to the reseller’s client.

Paradigm Imaging Group has made updates to Colortrac scanning software. Colortrac has made it easier to combine a Colortrac scanner with a wide format printer. Colortrac scanners range in size from 25” to 44” with either CIS or CCD technology. The SmartWorks Pro intuitive

graphical user interface (GUI) can be operated through either mouseor touchscreen-enabled displays, providing simple and rapid access to the wide range of new full colour and image quality editing features. Updates to Colortrac SmartWorks Pro V1.9.7.0 have added the new Canon imagePROGRAF PRO series printer drivers for Canon PRO-2100, PRO-4100, PRO-4100s, PRO-6100, and PRO-6100s, and can be installed over the top of previous versions. Previous updates to Colortrac SmartWorks Pro V1.9.3.0 software added both the Canon series printer drivers and the Océ ColorWave printer drivers. Also added was the long PDF enhancement – single page per scan long PDF file generation has been improved to remove the separate pages that existed in the previous version.

Fujifilm ColorPath SYNC now supports X-Rite i1Pro 3 spectrophotometers

Colour science and technology providers X-Rite Inc. and Pantone have announced that Fujifilm’s ColorPath Sync cloud-based color management tools now support the new i1Pro 3 family of spectrophotometers. Print providers will be able to quickly and easily create ICC profiles using the i1Pro 3 devices and align production devices to a designated colour target using ColorPath Sync.

It simultaneously measures M0, M1, and M2 in a single pass while accounting for optical brighteners. Prepress and print operators can quickly predict how colours printed on optically-brightened substrates will look under different lighting conditions. The i1Pro 3 Plus features a larger 8mm aperture to support additional materials and substrates used in digital printing applications. It also supports transmission scanning for backlit film and materials used in signage.

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO/KORD64

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size

(newer model)

Polar: any size/older or newer models

(66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

In this era of global competitiveness, very few companies have the opportunity to celebrate significant milestone anniversaries. But Concord, Ont.-based Print Three has been able to defy the odds, celebrating its 50th anniversary in 2020. At the heart of these types of success stories are the people that make them possible. One of those people is Print Three’s president Andrew Hrywnak. PrintAction recently had the opportunity to chat with Andrew about the milestone, some of the future plans for Print Three and how it has managed its way through the current pandemic. Here’s what he had to say.

Print Three is celebrating a big milestone this year with its 50th anniversary. Can you share a little about the history of the company and hitting 50 years?

The original founder of the company stated the business with one location downtown [Toronto] and expanded to three locations. Since then, they thought about franchising, so some of the people working in the business ended up buying a location and we started franchising across Canada. We have locations coast to coast. The strength in our network is we have many owners that have been with us for 25-plus years. It’s very rare that a Print Three location goes for sale. Typically, they’re passed down into the family. The family will continue running the business, so kids get involved in running the businesses. Everyone that we’ve had as a franchise owner has renewed to stay in the franchise so they can pass that legacy down, or they’ve simply retired and, at that point, sold their business and we’ve started with a new generation of franchise owners.

Can you share any plans for the future of Print Three?

In the last five years we’ve looked at expanding the network again, but we’re doing it through bringing on independents. Right now, we’re really picky in terms of who’s going to be part of the Print Three network. We’re looking and reaching out to independents and other resources that we don’t currently have in the network to join our brand and our network, so that we can offer a full range of services to our customers. We’ve developed from being just Print Three to becoming a true one-stop shop marketing arm that has built in it, during this period, a full-fledged marketing and advertising company called Eden Advertising. We have a full-fledged technology arm that builds our proprietary web products.

We also have a web company called Bloomtools Canada, which builds websites and social media marketing… we’ve come a

How has Print Three been able to navigate through the COVID-19 pandemic?

Print Three is celebrating a big milestone this year with its 50th anniversary.

Everyone is in survival mode right now, but we’ve been fortunate enough that we’re so diverse. We are doing work for first responders. We are building safety shields. We are doing signage. We are printing for companies that are building ventilators. People have reached out to us knowing that we’re still around and we’re still open and have these capabilities. We’ve diversified on the print side of it, obviously, because our business is really B2B. Ninety-five per cent of what we do is B2B, we do very little retail whatsoever.

We’ve been affected, our stores have been affected, by this slowdown. So, the locations that have diversified into some of those other areas have been really helpful. Prime Data (a recently acquired direct mail company), as an example, is still working with some of our customers because they’re trying to get mail out to their client base letting them you know what their status is: how they’re operating and what they’re doing. We’re still building websites, updating websites, getting involved in

creating social media advertising for some of our clients as well. There are other things we’re involved in because we’re so diverse. But if it was just the print side, it would be a problem.

What would you say is the biggest challenge during this pandemic?

The challenge of when our business is going to get back to normal.

We’re looking at volumes and I can tell you, we’ll more than likely be less than 50 per cent of what we were doing the previous year. That’s going to be a big challenge for all of us. And it’s just a matter of working with the government programs that are available, so that we can focus and try to maintain staff levels and keep staff employed, because it’s a family. Our concern is not just for the owners, but all of the employees that work for the owners as well; and how we keep them engaged in these trying times so that they know that they’re still part of the family.

In our role now, it’s as much giving out information to our network as it is sending out information to our customers – letting them know that we’re still open and we can help in different ways.