in mid-April, the Bank of Canada announced it would leave the overnight lending rate unchanged at 0.75 percent, based on what it referred to as an economic “wobble” to start 2015. The news came just days before Federal Finance Minister Joe Oliver was to table his first budget, which is also the Conservatives’ last before a scheduled fall election.

The budget, therefore, is expected to address the Conservatives’ future position relative to the Liberals and New Democrats, and will be billed as a blueprint for which party can best manage a frail economy.

The Bank of Canada last week, when announcing its decision to maintain its lending rate, stated the first three months of 2015 had produced zero economic growth. This sluggish result was foretold back in January when the Bank of Canada made a surprise rate cut – a surprise even to most banks.

A few months ago, Bank of Canada Governor Stephen Poloz used the word “atrocious” when describing the predicted GDP growth for the first quarter of 2015, despite much earlier estimations of a 1.5 percent GDP growth rate. With numbers in for the first three months of 2015, Poloz’ use of the word wobble suggests the Bank of Canada believes the current stalled economy is only temporary.

Economists primarily point to what is described as an oil shock for the poor performance of economies around the globe, as countries adjust to the unexpected, long-lasting price drop. These adjustments have

editor Jon Robinson jrobinson@annexweb.com 905-713-4302

Contributing writers

Zac Bolan, Peter Ebner, Chris Fraser, Victoria Gaitskell, Martin Habekost, Nick Howard, Andy McCourt, Nicole Rycroft, Abhay Sharma, Trish Witkowski

Publisher Paul Grossinger pgrossinger@annexweb.com 905-713-4387

Associate Publisher Stephen Longmire slongmire@annexweb.com 905-713-4300

director of soul/Coo Sue Fredericks

stalled global economic growth despite positive signs in the United States.

“The Bank expects global growth to strengthen and average 3.5 percent per year over 2015-17... This is in part because many central banks have eased monetary policies in recent months to counter persistent slack and low inflation, as well as the effect of lower commodity prices in some cases,” reads the Bank of Canada’s lending rate statement. “At the same time, economies continue to adjust to lower oil prices… Strong growth in the United States is expected to resume in the second quarter of 2015 after a weak first quarter.”

In an article about the Bank of Canada’s rate, CBC reports domestic manufacturing sales slumped for a second straight month in February 2015, down 1.7 percent on a month-over-month basis. Most printers have become used to operating in this arena, but the government points to stronger days ahead, backed by a stronger U.S. economy.

The Bank of Canada’s April 2015 Monetary Policy Report suggests Real GDP in Canada will grow by 1.9 percent in 2015, 2.5 percent in 2016, and by 2.0 percent in 2017. If this holds true, the Canadian economy is only experiencing a wobble before stability returns before the end of the year.

National Advertising

Manager

Danielle Labrie dlabrie@annexweb.com 888-599-2228 ext 245

Media designer

Angela Simon asimon@annexweb.com

Circulation Nicole Cuerrier ncuerrier@annexweb.com 866-790-6070

subscription rates

For a 1 year monthly subscription (12 issues): Canada — $39.99 ($35.39 + $4.60 HST) United States — CN$69.99 Other foreign — CN$139.99

Jon robInson, editor jrobinson@annexweb.com

Mailing address

Annex Business Media 222 Edward Street Aurora, ON, L4G 1W6 printaction.com

Tel: 905-727-0077

Fax: 905-727-0017

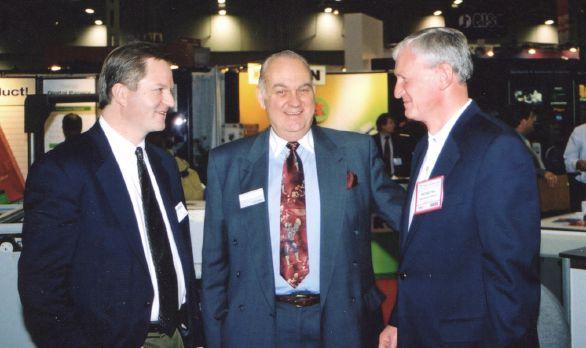

David Walker, an important figure in Canada’s printing industry for decades, passed away at age 80. Born in Toronto in 1935, Walker was well known as the long-serving President of Louson-Desonite, before eventually moving into a sales position with Heidelberg Canada.

Walker devoted much of his energy to developing Canada’s printing community as the supplier representative on the Board of Directors of the CPIA. He became President of PESDA in 1984 and worked with the organization until 2000. For several years, Walker also led the student scholarship efforts of CPISTF, which continues today. For the past 14 years, he was an active member of the Honourary Society of the Wayzgoose.

“It is difficult to find the right words defining how very influential he was for so many people,” says Willy Wilkins, former leader of the CPIA, who worked closely with Walker at Wayzgoose. “He was a mentor, a leader, an inspiration and for most of us a trusted longtime friend.”

speedpro signs Calgary north east, owned by Joanne Ruston, earned the parent company’s Franchise of the Year Award for 2014. This marks the fourth time Ruston has received Speedpro Signs’ top award. She also received the 2014 Al Crow Memorial Sales Award for achieving the top sales in the country. Ruston entered the sign business in 2001, following

proposed purchase agreement, Standard Register’s assets will be sold for approximately US$275 million plus the assumption of certain liabilities. Silver Point is an existing secured lender of the company and, in combination with Bank of America, agreed to extend US$155 million in financing in the form of a debtor-in-possession (DIP) credit facility.

May 20

Digital Imaging association meeting

Unisource, Mississauga, ON

June 3

Dscoop emea Conference Dublin, Ireland

June 6

sWob 2015 Golf tournament Doon Valley, Kitchener, ON

a 20-year career in the service industry. In 2009, she was named as one of Business in Calgary magazine’s Leaders of Tomorrow. The Speedpro parent company is headquartered in Winnipeg, Manitoba, and began franchising in 1991. Today, the company has 49 franchises from Victoria to Newfoundland.

esko, led by President Udo Panenka, acquired Minnesota’s MediaBeacon Inc., which develops Digital Asset Management (DAM) software sold primarily in the United States through direct distribution and OEM partnerships. Jason Bright, CEO and founder of MediaBeacon, is to assume the role of Chief Technology Officer, working with the Esko R&D teams.

standard register Company, led by Joe Morgan Jr., filed voluntary petitions under Chapter 11 of the Bankruptcy Code in the United States. The company planned to pursue a sale process and entered into an acquisition agreement with an affiliate of Silver Point Capital L.P., a private investment firm managing approximately US$8.5 billion in combined assets. Under the

manroland sheetfed, led by Rafael Penuela Torres, received a Red Dot Award for Product Design of its new Evolution 700 printing press, introduced in November 2014. The German-based product design competition has existed since 1954 and is regarded today as one of the world’s leading such programs. This year’s Red Dot Award program attracted nearly 5,000 entries from 56 countries. The competition’s jury was made up of designers, academics and journalists from 25 countries.

asia pulp & paper (app) plans to install in excess of 200 mega-watts (MW) of solar power capacity across eight Chinese mills, within the next three to five years, which will be linked into the national grid and generate enough energy to power more than 500,000 homes. It is anticipated to be the largest solar project within the pulp-andpaper industry, and amongst the largest rooftop solar projects anywhere in the world.

The project will result in the installation of approximately four million square metres of solar panels, the equivalent of 560 soccer pitches. The Chinese government committed to increase the overall proportion of its renewable energy to 20 percent by 2030. Bloomberg reports China is the world’s largest investor in renewable energy, spending more than $89.5 billion in 2014.

met Fine printers of Vancouver, BC, led by President Nikos Kallas, purchased certain assets and business activities of Rhino Print Solutions, including its Calgary facility, which will be integrated into MET’s operations. Senior members of the Rhino team are joining MET and all business will operate exclusively under the MET Fine Printers name.

June 10-13

pacwest Conference

Fairmont Chateau, Whistler, BC

June 11

DIa annual Golf tournament St. Andrews Valley, Aurora, ON

June 16

packex toronto Congress Centre, Toronto, ON

June 23

printaction education series, Craft of printing

Delta Markham, Markham, ON

June 24

IapHC Golf tournament Wooden Sticks, Uxbridge, ON

August 8

opIa 2015 toronto Golf Classic Angus Glen, Markham, ON

September 16-19 sign China Shanghai, China

September 25-26

Consac Imagemakers International Centre, Mississauga

September 28-30

packexpo Las Vegas, NV

October 28

printaction education series, business of printing

Delta Markham, Markham, ON

November 4-6

sGIa expo Atlanta, GA

November 12

Canadian printing awards Gala The Grand Luxe, Toronto, ON

May 31-June 10, 2016 drupa Dusseldorf, Germany

The Toronto Club of Printing House Craftsmen in mid-April recognized the Toronto Gallery of Excellence Award winners at the Duncan House. The organization also presented funding to ryeTAGA and 11 students pursuing printing and graphics arts education, including the annual Chai Tse and Graphic Challenge Awards.

toronto Craftsmen student Chai tse awards

Christophe Blythe Centennial College, Centre for Creative Communication

Kerin Bethel-John Central Technical Secondary School

Angelo Roldan George Brown College, School of Design

Marilyn Gregory Georgian College, Design and Visual Arts

Khalid Ahsan Humber College, Advertising & Graphic Design

Melissa Binsted Ryerson University, School of Graphic Management

Aeshin Yeo Seneca College, School of Creative Arts and Animation

Graphic Challenge awards post secondary

Waqas Mohammed Khan Seneca College, School of Creative Arts and Animation

Chow A. I. Khalid Ahsan Humber College, Advertising & Graphic Design

secondary schools

Helen Zhou Central Technical Secondary School

Ben DePaul Central Technical Secondary School

of excellence

toronto Craftsmen best Use of bindery

Project: CPC Empress OF Ireland 100th Anniversary Collection

Printer: Colour Innovations

ryetaGa Funds

Jessica Klien and Stephanie Murray receive funding from Bill Kidd of the Toronto Craftsmen

Heidelberg Canada best of show

Project: Until The Last Child

Printer: C.J. Graphics

taniguchi Ink Canada best

Use of Ink

Project: Large

Poster Flip Chart

Printer: The AIIM Group

Jim bailen of INX International received the NAPIM Printing Ink Pioneer Award acknowledging his achievements over more than 30 years in the ink industry. Serving as Vice President of Engineering since 1999, Bailen has been the lead project engineer for every major facility expansion and equipment installation instituted by INX over the past 20 years.

In 1984, Bailen joined CPS, the in-house ink division of Sullivan Graphics in Dunkirk, New York, and began work as an Electrical Supervisor in the Maintenance Department. Bailen is credited with pioneering safety devices for ink production equipment, including the Nip Guard Safety Interlock System. INX, owned by Sakata INX, is the third largest producer of inks in North America with over 15 facilities in the U.S. and Canada.

tony Denison takes over the dayto-day leadership of Simpson Print in Bloomingdale, Ontario, succeeding Martin Johanns in the role of President. Johanns, who purchased Simpson Print in 1987, remains owner and Chair of Simpson Print, which acquired Denison Print of Breslau, Ontario, back in January 2014.

John alden becomes Vice President of Sales for Toronto-based Avanti Computer Systems, which launched its new Slingshot MIS product in late-2013. Alden joins Avanti after 17 years at Xerox, where he led regional sales of the company’s production presses, including the flagship iGen line and Xerox FreeFlow software.

rick littrell becomes Vice President, Direct Hires and TechCreative Talent, for Semper International, a North American placement firm. Littrell began his career with printing-industry suppliers like Agfa, Information International and Scitex, before founding Graphics Xpress, Magicomm LLC and Littrell Associates. He will help lead Semper’s new TechCreatives initiative focusing on the intersection of creativity and technology.

Fran mayo and robert Wray, long-time industry and Nilpeter veterans, will now represent Nilpeter in the Canadian market. Mayo is to cover the Eastern Region of Canada, while Wray is to look after the rest of the country.

eric Wiesner assumes the role of Vice President and General Manager for HP’s Inkjet HighSpeed Production Solutions (IHPS) division, succeeding Aurelio Maruggi, who becomes VP and GM of HP’s new Office and Versatility division. Wiesner started with HP in 1984 in San Francisco, holding various R&D and manufacturing management roles.

A 57-inch, 7-colour KBA Rapida 145 with coater is being added to Walter G. Anderson Inc.’s facility in Newton, Iowa.The April arrival of the new press joins two existing 57-inch KBA Rapida 145 presses with coaters, which were installed over a 4-year timespan. The company’s 175,000-square-foot plant outside of Des Moines, built in 2011, now holds the single largest number of these new Rapida 145 presses in the world.

“Our first two Rapida 145 presses run round the clock and have become workhorses producing our folding-carton work,” says Marc Anderson, President and CEO of Walter G. Anderson. The company’s print work has been recognized by influential clients like General Mills, Berry Plastics, Cargill and Hormel. Its manufacturing practices are supported by participation in entities like AIB, GMA-SAFE and GFSI.

The new 7-colour Rapida 145 is equipped with a fully automatic plate changer; CleanTronic Synchro, providing simultaneous cleaning of inking rollers, blankets and impression cylinders, as well as a dedicated package for inking unit drives; and ErgoTronic ColorControl. Founded in 1950, the company also has a manufacturing facility in Hamel, Minnesota.

The independent firm installed its first 57-inch Rapida 145 in August 2011 “under wraps” prior to the press’ official debut at drupa 2012. Walter G. Anderson explains it was attracted to the Rapida 145 platform based on its high run speeds, redesign of the feeder, new delivery extension and delivery, ability to pre-set different options, and being environmentally progressive.

With an annual turnover of €50 million and 430 employees, Sweden’s Miller Graphics, claims to be the number-one prepress provider in the European corrugated sector. The company has turned to Flint’s nyloflex NExT technology, using a high-intensity UV-A LED light source for rapid crosslinking of a photopolymer surface before oxygen inhibition occurs, Founded in 1932, Miller is owned by the family business O.F Ahlmark & Co.

Ian lifshitz, Asia Pulp & Paper’s Director of Sustainability for the Americas, has been named CoChair of the Paper, Pulp and Forestry Sector Working Group for The Sustainability Consortium. With products distributed in more than 120 countries, APP has an annual combined pulp, paper, packaging product and converting capacity of over 19 million tons.

allan brown becomes General Manager of Eastman Kodak’s Unified Workflow Solutions business, which includes Prinergy technology. Brown most recently served as VP and GM of HP’s integrated workflow software unit and also held executive positions with Xerox.

Primeflex Labels Inc. of Englewood, Colorado, invested in an 8-colour Nilpeter FB-3 servo flexo press. Founded in 1997, the company, once a full Mark Andy shop, focuses on labels for food and beverages, cosmetics, consumer products, meat products, as well as flexible packaging like pouches and wrap-arounds.

Primeflex is led by two printing industry veterans with more than 50 years of combined experience, including Tom Cummings, President, and Michael Martin, Vice President, who co-founded the company. The new press is a multi-substrate, servo-driven flexo system with UV curing, running at up to 560 feet per minute. Installed in mid-March, the press features Nilpeter’s CLEANINKING chambers.

When we asked offset printers in 2007 to describe the perfect short run press solution, they didn’t mince words. The print quality needs to be as good as offset litho. Use standard coated and uncoated stocks, and load-up and off-load of sheets shouldn’t require an owners manual to figure out. The prints should be smooth, without any pile-height issues, and look and feel like an offset sheet. Prints need to be durable too, especially when using finishing equipment. And please…no more click charges.

Fujifilm’s J Press 720S technology delivers these benefits and J Press installations have produced millions of brand on demand impressions where it counts most – in the field. So why wait on the promises of new technology, when proven Fujifilm innovation can help you dominate the high-quality, short-run market today.

Seeing is believing. Visit fujifilminkjet.com today.

Last year’s May 13 blaze completely destroyed the old Ainsworth Press. With damage estimated at $10 to $12 million, including two recently installed presses valued at some $2.85 million, the fire, which razed the 50,000-squarefoot operation, was one of the worst in Ontario’s history.

Michael Quinn of Southam Graphics, which acquired Ainsworth through the December purchase of the printer’s owner Jemcom Inc., described the new facility as the “finest, most modern, state-of-the-art printing plant that I’m aware of in Canada.” Built and equipped at a cost of roughly $30 million, the 2-story plant is approximately 35 percent larger than the previous location. Ten Heidelberg Speedmaster presses dominate the facility, while equipment from Crosfield Electronics highlights its prepress area.

At the ribbon cutting are (L to r): Ken Ainlay, VP of The Ainsworth Group, don Nurse, President of Ainsworth, don Cardillo, Mayor of Kitchener, Michael Quinn, President of southam, MPP david Cooke, and sandra Brandt, Treasurer of Ainsworth.

Scitex Offers Entry-level Colour Page Make-up System

Scitex America is also in the entry-level market with the Response 100 electronic prepress system, targeted at the small- to medium-sized trade shop. It provides all the page make-up features of larger systems, such as electronic retouching and stripping capabilities, but is designed to match the production volumes of a growing company.

Priced in the $250,000 range, the system is said to be appropriate for trade shops with 10 to 19 employees and $2 million in annual sales, and commercial printer shops with 10 to 49 employees and $3 to $5 million in annual sales.

Fujifilm has developed expertise in a wide range of core technologies, including advanced material chemistry, nanotechnology, fine chemicals, software and electronics.

“I don’t want to be an output house,” says Battlefield President, Paul Theoret. “The more value-added services we can offer, the better off we are.” Battlefield created a high-end colour prepress department a little over two years ago. Then they became an early adopter of Heidelberg’s GTO-DI press. Battlefield entered the world of electronic prepress for the first time by investing in a Crosfield ColorSpace System, 9500 stripping station and Macintosh desktop computers for page assembly. Linking all the pieces is a high-throughput fibre-optic network.

from

In the last year, Battlefield has bought Kodak’s Approval digital proofing system and upgraded its DI press for laser imaging PERARL technology from PressTek. In the pressroom, the company is replacing a 25-inch, 5-colour Heidelberg with a 6-colour 29-inch model, in addition to a newly installed a 2-colour, 29-inch press.

Several proprietary technologies were achieved by Fujifilm in the creation of the J Press 720S production inkjet press:

■ Dimatix SAMBA™ 1200dpi printheads using MEMs nano-technology deliver unprecedented inkjet precision and higher drop densities in a single pass.

■ Our VIVIDIA aqueous ink system provides a consistently smooth, high-quality print with the durability and finishing characteristics of offset.

■ Our RCP in-line coating process allows the use of most standard coated or uncoated offset paper, eliminating the expense of pre-treated inventories.

the sM 52 spelled the end of the gtO, but these little gems still impact the printing world

By Nick Howard

Undoubtedly the most outstanding small-format press ever made was the Heidelberg GTO. Many printers grew their businesses with a GTO. To appreciate the impact of this little marvel, we need to go back through time, 42 years in fact, to 1972. This was the year that Heidelberg, at the drupa fair in Germany, formally presented the GTO 46. Originally only offered as a single colour in a sheet size of 32 x 46 cm (12 5/8 x 18 inches), you could also buy a modified “TO” version with sheet size of 26 x 32 cm (10 x 12 5/8 inches).

From the mid-1950s, the small sheetfed offset press market was a largely an afterthought for major machinery suppliers. Such presses tended to be less robust and none could register hairline, leaving smaller print shops without a way to penetrate more lucrative, higher quality work done on bigger presses.

The Addressograph Multigraph was a very popular press, as was the Davidson, ATF Chief 15 (known in Canada as the Gestetner Gestelith), and AB Dick. In America, Miehle marketed the larger AB Dick 380 under its marquee and Harris built a 14 x 20-inch model LUH. Neither was very exciting. Over time, small offset presses settled into the niche of Quick Printing, while being very good at stationary and envelope printing. KOVO of Czechoslovakia manufactured the Romayor, a clone of the British Rotaprint. In Japan, earlier attempts by companies like Fuji (Shinohara) and Hamada were less successful. Hamada, however, was an early exporter to North America. In Canada, Toronto Type Foundry was probably the first Hamada importer and rebranded the press as TORLITH. Canadian Linotype later controlled the agency and called it the LINOLITH.

Reviews were not kind to Japanese builders in the 1960s and the American Multilith and then AB Dick machines dominated the Instant Print market. Duplicators, as these light-duty machines were called, developed their own mini-industry, with tools like PMT and electrostatic plates.

Webendorfer-Wills company in 1935

Production on the GTo, which took on the Printmaster name in the 1990s, came to end an in 2014 after 42 years of mass production.

put out an interesting little press in the 14 x 20-inch size and called it the Little Chief. It was a major break from, for example, a Multilith or a Davidson, built like a much bigger press. This press could register albeit with tumbler grippers and a push guide. The industry paid attention and after ATF bought Webendorfer-Wills Co. in 1938, Chief 20s made their way across North America. Someone did pay attention to small-format workhorses and it was Heidelberg. With the 1962 launch of Heidelberg’s first offset press, the KOR, the company’s management board likely agreed that Schnellpresse needed to accept the fact that offset printing was going to win the war over letterpress. The long-time head of Heidelberg, Herbert Sternberg, is noted as not favouring offset and was likely pressured by younger, more progressive managers.

The KOR was possibly a way to appease Sternberg as it was really a Kletterpress with bed removed and modified for offset. The KOR’s success spawned other sheet sizes, but it was also a heavy piece of machinery and probably more costly than designing from scratch. Heidelberg did go back to the drawing board in the 1960s and introduced its GTO at drupa 1972. No one had seen such a press before! The side frames were cast in one piece from lightweight aluminum alloy. Every shaft, as well as the main cylinders, ran in precise bearings –unheard of technology in the duplicator field.

Everything the little ATF Chief could

have been was found in this little GTO gem. With the thought of replacing the T Platen for applications like numbering, Heidelberg fashioned a device (referred to as PLUS) for a numbering box or even a flexo plate to number or add an additional colour.

By Drupa 1977, a 2-colour GTO with convertible perfector was released by Heidelberg. In 1979, the sheet size was expanded to 36 x 52 cm, which was welcome news and a major impetus for GTO domination. Eventually, the GTO was expanded to 4- then 5-colour models. At drupa 1986, the well-known ALCOLOR continuous dampening system was offered as an option along with Heidelberg’s range of CPC consoles.

In September 1993, Heidelberg introduced the GTO-DI (direct Imaging) press. Teaming with U.S. innovator Presstek, Heidelberg built in the Spark then PEARL laser heads. But the early days of direct imaging left many customers disillusioned with poor print quality. Undaunted, Heidelberg stuck with the GTO offset press and its platform was expanded in sheet size in 1980 to become the M-Offset. By 1974, Heidelberg had brought out the Speedmaster 72, a 52 x 72 cm press. Similarities with the GTO were evident. The perfecting device was almost identical.

Why was the GTO such a terrific press? First, it was over-built compared with duplicators of the day. Even using a push side guide did not prevent printing 4-colour in hairline register. America in the 1960s was heading toward the creation of what we now call the Rustbelt. Unions and environmental laws slowly ate away at America’s industrial strengths.

Foundries and allied industries were either reducing in size, raising prices or closing. Germany took on a clear advantage, particularly with the D-Mark exchange rate, just as theYen was increasing imports from Japan.

Almost impossible to wear out, with no serious competition and so incredibly easy to run, the GTO was the press behind many of today’s most successful printers. Even forgers loved the press. Reports suggest as many as 106,000 units were sold. My estimation (based on tracking serial numbers) suggests that Heidelberg made that many and almost 75,000 were complete machines not just printing units!

nICK HoWarD, a partner in Howard Graphic Equipment and Howard Iron Works, is a printing historian, consultant and Certified Appraiser of capital equipment. nick@howardgraphicequipment.com

tracing its roots back to working with holography and stereoscopic images, Quebec’s photogram recently stamped its position as one of north America’s leading producers of lenticular print

By Jon Robinson

hotogram Technologies Inc. of Montreal, using Epson inkjet systems, recently completed its build of what the company describes as the world’s largest tiled animated lenticular panel of wall murals. The project, produced in collaboration with AD+ Inc. of New York, was installed at the new customs facility in Texas’ Austin-Bergstrom International Airport earlier this year.

“At 1,672 square feet, [the Austin-Bergstrom project] beats the recorded Guinness World Record by 10 square feet,” says Sebastien Rouleau, co-owner of Photogram.

The project, called Time Lines, is based on the work of artist Mikyoung Kim, who ultimately directed how the work was applied in the Texas airport. She was commissioned to produce the installation through the Art in Public Places program of the City of Austin’s Economic Development Department. Kim’s art was converted into a continuously changing lenticular mural measuring over 212 feet in length and almost eight feet high.

Time Lines is designed to mimic the world’s time zones, with Austin’s location shown in the middle of the artwork.

“Manufacturing this large-format animated wall mural required technological mastery of lenticular graphic design, printing and mounting techniques,” says Pierre Gougeon, President and founder of Photogram.

Photogram describes itself as a world-leading lenticular technology special effects studio, having developed manufacturing techniques for a wide range of printing equipment, from large-format inkjet to lithographic printing. The company owns multiple patents specific to lenticular manufacturing. Its DRIP (Dense Raster Image Processor) technology is used as a 3D lenticular process. In 2007, Photogram worked closely with KBA and a 6-colour Rapida 105 to unveil what it referred to as HYPER-MOTION printing. It provided Photogram with an ability to print up to 120 frames, or four seconds of animation, which could also be applied through high-definition video on LENSTAR plastic. Today, DRIP is used for applica-

Mikyoung Kim is a

Landscape Architect with work throughout the United States, the Middle East and South Korea..

tions like POP, publishing, packaging, direct mailings, signage and displays. The company also applies its technology to cards for security access, business, gift or loyalty programs, as well as relational cards that unveil a hidden cryptogram both on print material or on any type of electronic screen.

Photogram was founded in 1998 to focus on this specialized application process and has since produced thousands of lenticular projects, building from its track record of working with holography, holograms and stereoscopic images. Using its years of expertise and patents, Photogram is focusing its lenticular printing techniques on new applications in large-scale design and architecture projects, primarily in the United States through its partnership with AD+.

“We can showcase moving images, 3D holographic type visual effects and even short video clips in large format mural printing,” explains Rouleau. Over the past year, Photogram has worked on lenticular projects for the likes of Cirque du Soleil, Walt Disney and TV Guide in the United States. In the summer of 2014, Photogram also produced lenticular work for a large-run of a DC Comics special edition.

For the Time Lines project, Photogram used a total of 70 different tiled sections of lenticular lens panels of various sizes to produce the entire mural. The printing was performed on an Epson large-format inkjet system. The team then applied its patents to construct the continuously changing wall mural.

Rouleau explains production of this particular project required a range of specialized knowledge, including understanding the way lenticular plastic extrusion and optics work; how to create complex video special effects (a form of 3D movie special effects); and quality control and troubleshooting techniques. The company also needed to understand the different existing patents for lenticular in the market.

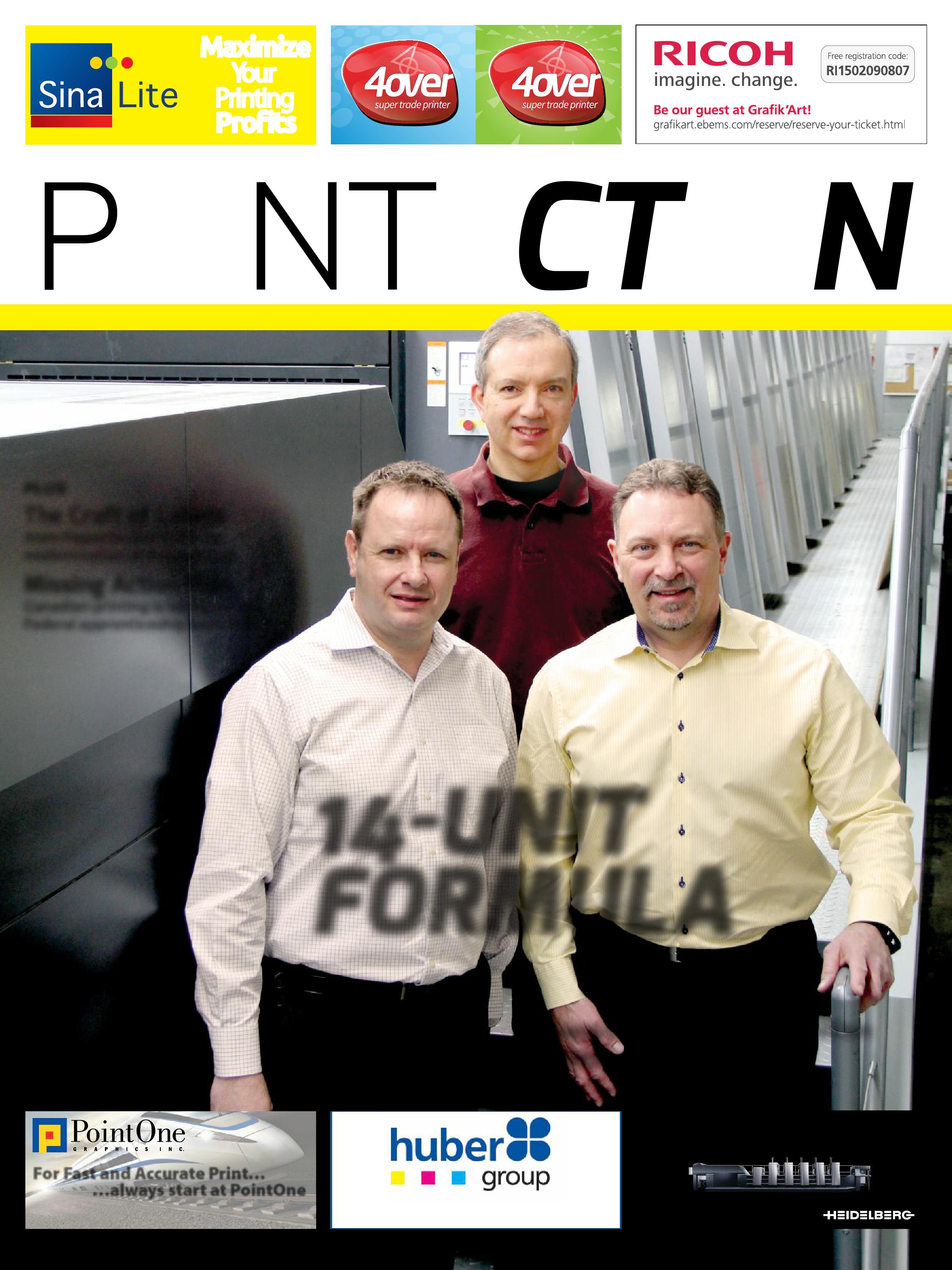

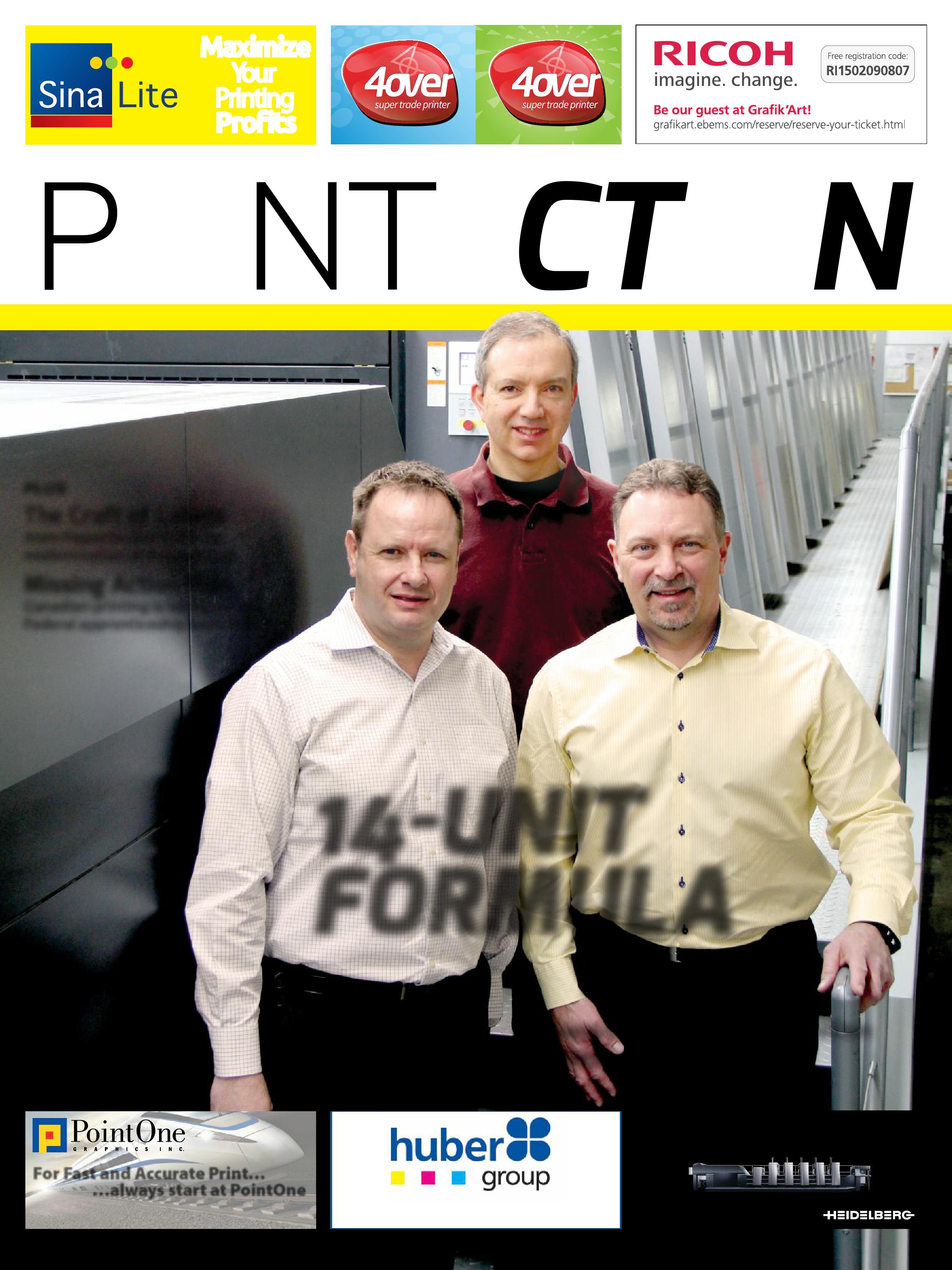

A look inside MM&t cenveo and its $6 million investment in a Heidelberg XL 106 duo press to produce cutting-edge baby-formula labels

By Jon Robinson

cenveo McLaren Morris & Todd is home to some of the most knowledgeable technicians, managers and salespeople in Canada’s printing industry. Nearly three years ago, one of these key assets, Steve Hanley, set out on a career-defining journey with one of his key sales clients aiming to mass-produce a groundbreaking babyformula label

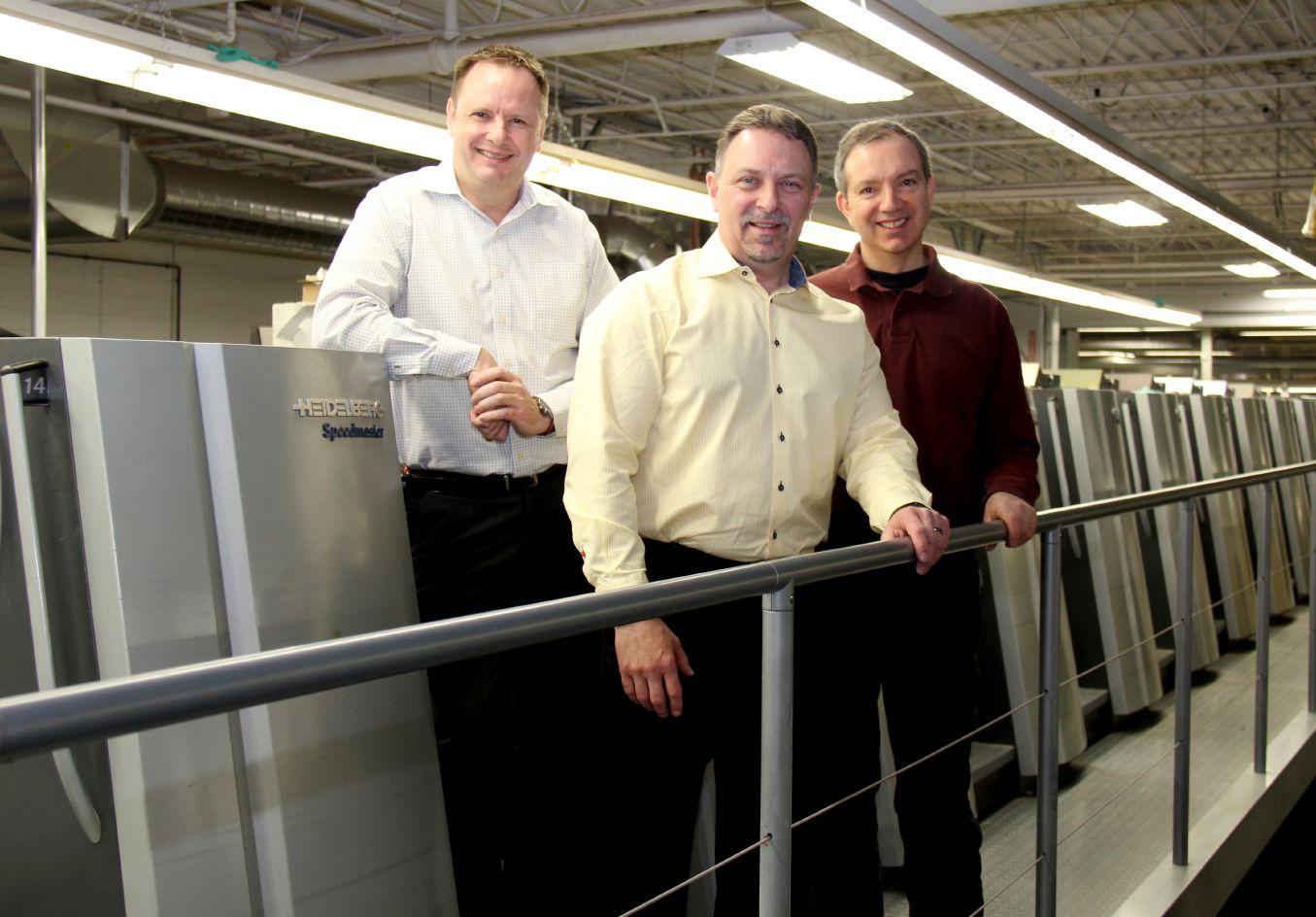

After months of collaborating with the client, testing inks and coatings in Germany, covering financial plans with corporate, Hanley and Cenveo MM&T’s journey materialized in late-2013 with the installation of a 14-unit Heidelberg Speedmaster XL 106 sheetfed press. The more than $6 million investment, unique in its printing configuration and auto-

mation, is rivaled in approximation by only a handful of such high-end presses in North America.

Holding one of the most interesting histories in Canada’s printing industry, from its origins of producing Hallmark Cards to its role in establishing the worldwide phenomenon of the Trivial Pursuit board game, the new 14-unit Heidelberg press is pushing Cenveo MM&T along an impressive growth path in pharmaceuticals, where packaging is often as important as the formula.

MM&T was acquired by Cenveo, then operating as Mail-Well, 17 years ago, adding yet another important marker to its 59-year history in the Canadian printing industry. Headquartered in Stamford, Connecticut, Cenveo is a $2-billion company operating in the management

Karl Cox

to

regional Vice President, sales and operations; steve Hanley, Vice President; and Peter Zamos, Technical Manager, with the Heidelberg XL 106.

and distribution of print and related offerings. The company is overseen by one of modern printing’s most dynamic businessman, Robert Burton Sr., who has been Cenveo’s Chairman and CEO since September 2005 – with sons Mike Burton serving as Cenveo’s COO (June 2014) and Rob Burton as President.

Cenveo encompasses more than two-dozen entities in over 100 facilities. It employs more than 270 sales associates in North America, with additional entities in the Dominican Republic, India and Thailand – 8,100 employees in total. It acquired a Canadian printing gem with the acquisition of McLaren Morris & Todd, co-founded in 1958. One of those original builders, John McLaren (in association with Harry Morris and Art McLaren), secured greeting-card producer Hallmark as a massive customer for its sheetfed presses. Greeting-card production would come to represent 25 percent of total company revenues by the early 1960s.

After being purchased by Southam in 1967, which brought in web-offset presses for direct-mail and advertising work, MM&T would soon enter the spotlight by working closely with the creators of Trivial Pursuit, Chris Haney and Scott Abbott, to manufacture their world-record board game. (Today, more than 100 million copies of the game have been sold in 26 countries.) The original Trivial Pursuit had 6,000 questions on 1,000 cards – a printing risk with a world of potential benefit. MM&T’s early involvement with Trivial Pursuit led to an expansion of the facility to a total of 115,000 square feet.

Building on its greeting- and Trivial Pursuit-card knowledge, and moving with the 1980s boom in collector cards, MM&T shifted its expertise into label work. This application direction was emphasized after John Morris and Alan George purchased MM&T from Southam in 1995. In 1998, they sold their company to Mail-Well, which, after combining with acquisitions led by Robert Burton Sr., became Cenveo in 2004 –resulting in Cenveo MM&T (CMM&T).

A year later, CMM&T installed its first 10-colour flexographic press to dive deeper into label printing. This was soon followed by the installation of a 7-colour full web Goss press. The newest direction for the facility is positioned squarely at feet of the Heidelberg XL 106.

Before the Heidelberg XL 106 was purchased, Hanley visited Germany on three separate occasions to test out the printing units, twice with Heidelberg and once with KBA. The CMM&T team sent over specific inks and did thorough press testing on behalf of their client before pulling the trigger.

“Part of the testing in Germany was to prove it to Cenveo’s corporate leadership,

‘Here is where the client wants to go, here is where I got them, and this is the press that is going to do it,’” Hanley recalls. Hanley himself established the protocols for how the files should be tested, which took place on three different substrates in each of two main application categories, cartons and labels. “Heidelberg was very excited about the project too, because it highlights what they do.

“KBA is a very capable press as well,” explains Hanley, who was impressed with both high-tech factories, but the XL 106 better fit CMM&T’s application and long-standing experience with Heidelberg machines.

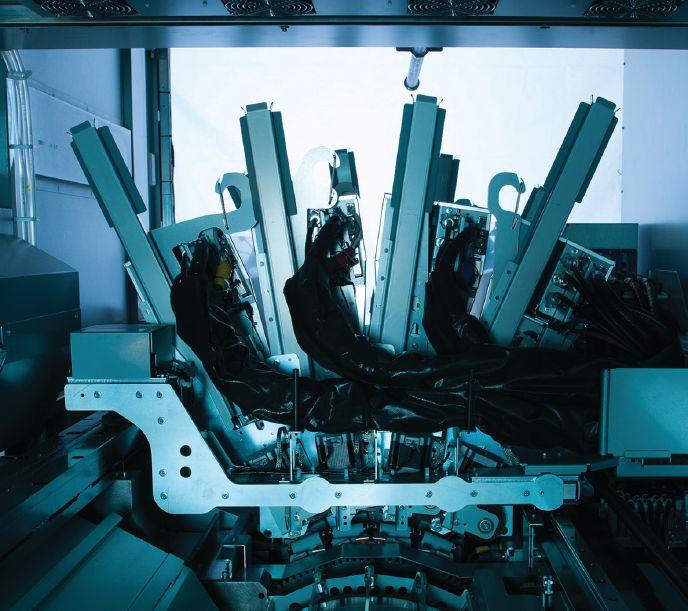

The purchase of the press was based on the baby formula producer signing a 5-year printing contract with CMM&T. It was the first such press configuration that Heidelberg has produced. “It is a duo press with flexo and offset capabilities, 14 units, all UV capable, extended dryer. It is a very unique packaging press in the world,” says Hanley. “We had faith in Heidelberg to deliver the product.”

The Heidelberg press arrived in Mississauga literally by 17 tractor-trailer loads. “Heidelberg knows what they are doing, so there were no issues with it at all,” says Peter Zamos, who has been with MM&T for 31 years and led the technical implementation of the press into the plant. Leaving the feeder, sheets first travel into a flexo unit where a premium liquid silver foil is applied, which is key to reaching the client’s graphic goals for its new baby-formula label design. “The advantage of putting it on in the first unit is then you can tint it and it will look like foiling.”

This immediately raises technical challenges in a press run, but the liquid foil is a highly efficient route for long-run label production, as opposed to applying traditional mylar (metallized polyester film) or other forms of foil. The baby-formula work is now produced in a single pass at very high speeds. “There is an unknown factor with a raised plate when you are trying to marry it to a lithographic plate in the next units,” explains Zamos, describing fit and trapping issues when breaking from the conventional wisdom of putting the opaque colour down last.

Zamos feels the capabilities of the Heidelberg press are almost like a return to the craft of printing, including the file preparation of Autumn Graphics, a specialized flexographic prepress house from London, Ontario. Autumn Graphics has been working with CMM&T and this client for approximately 20 years. “You are trying to fit transparent ink around an opaque shell without having a visual problem,” he says. “From a client’s perspective, there is a craft to that.”

Leaving the flexo unit, sheets travel through two drying stubs before reaching the offset units, coating and drying units. Karl Cox, who took over as the lead of

a UnIt by UnIt breaKDoWn oF CenVeo mm&t’s HeIDelberG speeDmaster Xl106

14 UnIts / DUo press teCHnoloGy / eXtenDeD DelIVery

Unit 1 – Flexo Unit

Unit 2 – UV Drying Unit

Unit 3 – UV Drying Unit

Unit 4 – Offset Print station

Unit 5 – Offset Print station

Unit 6 – Offset Print station

Unit 7 – Offset Print station

Unit 8 – Offset Print station

Unit 9 – Offset Print station

Unit 10 – Offset Print station

Unit 11 – Flexo Unit

Unit 12 – UV Drying Unit

Unit 13 – UV Drying Unit

Unit 14 – Flexo Unit

CMM&T’s facility at the beginning of 2015, agrees with the artistic value that the new press brings. “The art aspect of it is not only in how we look at the colour and how we get to the quality, but how we run the press efficiency at its maximum speeds,” he says, continuing to point to how business flows into the press, scheduling its run and labour to meet the expectations and needs of the facility.

During his early research, Hanley also had to consider how the printed labels would fit into the client’s packaging line. “A key challenge is to run at high speeds and to reach the proper coating gloss levels to have it run smoothly through the customer’s lines at high speed,” he explains. The production team is targeting a superior gloss level of 90 and is currently just below this high standard, while also committing to run with a delta E of two or less (well below the normal standard of delta E 3).

“This was Steve’s passion. He believed this is what this organization needed and went for it – the proof is that he got it right,” says Cox, Regional Vice President, Sales and Operations at CMM&T. “It is exceeding the ROI that we positioned for the press when we brought it in. We are ahead of schedule. It has been a massive success for us as an organization.” Cox explains the press has already attracted new clients and he expects more. “We first wanted to perfect our art as a business with the press, before taking it to market for new opportunities. We are really at that point now.”

This strategy fits well with CMM&T’s historic approach of working with highend, demanding clients. “We used to print for Hallmark Greeting Cards. It was our first account and Hallmark has always been a very quality-oriented company,” says Zamos. “If you are going to buy a

card for $6 you want it to be perfect and their quality levels are almost at pharmaceutical levels... Really, it is nothing new for us.”

In addition to closed-loop colour, the Heidelberg XL 106 includes auto inspection cameras with pharmaceutical-specific PDF architecture to capture an image of each sheet – and dreaded hickeys –at press speed, to mark and pull errors from the run.

Cox joined Cenveo in January 2014 to implement structural change at the Clixx Direct Marketing facility in Scarborough, which Cenveo purchased in 2010. After more than a decade of Cenveo’s growth through acquisition, Cox is tasked with consolidating processes and to capitalize on individual assets at CMM&T. Cenveo is divided into three groups: Packaging, which includes CMM&T; commercial print; and the envelope group, as a result of the Mail-Well acquisition. After acquiring the assets of National Envelope in 2010, Cenveo became the largest envelope manufacturer in North America.

“We are starting to see an improvement in mailing,” Cox says. “That provides us with huge opportunities... We can essentially print in this facility and then add variable aspects at the Clixx facility. The two facilities work very well together.”

One of Cox’ first moves at CMM&T was to bring in a lean manufacturing black belt to drive further efficiencies. The facility has been deeply involved with both external and internal auditing processes since 1996, when a client’s new Request For Proposal approach required partners to be

Good Manufacturing Practices (GMP) certified.

“We took it on very aggressively… and we passed every audit they could throw at us,” says Hanley, noting the baby-formula market has higher standards than most pharmaceutical sectors. “It really highlights the importance in the quality of printing and in every aspect of the quality of that product.” Concern for quality control in the sector came to a head about five years ago when several infant deaths in China were tied to contaminated baby formula products of the country’s domestic suppliers.

“We have a platform that we can grow with a lot of different products and services that meet the needs of our customers,” says Cox. “That is what really impressed me [about CMM&T]. We have a great team here.”

Hanley is one of the top salespeople in the Canadian printing market and he sees an enormous opportunity ahead, because of the new 14-unit Heidelberg press. “This is the defining moment of my whole career,” he says. The packaging industry is still largely comprised of small entrepreneurial businesses and Hanley expects many mergers and acquisitions are ahead, mirroring the past decade in commercial printing.

“There are some challenges on the commercial side from a margin perspective and there are different types of challenges in packaging,” says Cox. “We have opportunities for margin and growth potential through the development of new products, the installation of new presses, and in the innovation that we have brought to market with this press. That is where we see opportunity.”

red seal trades can access $100 million in new Federal apprenticeship loans

By Victoria Gaitskell

Canadian Prime Minister

Stephen Harper on January 8, 2015, visited the British Columbia Institute of Technology and Vancouver Community College on Annacis Island in Delta to announce the official launch of the Canada Apprentice Loans program. These loans, similar to the ones already available to college and university students, are expected to provide an estimated 26,000 apprentices registered in Red Seal trades across Canada with access to over $100 million annually.

Promised in the Federal government’s Economic Action Plan 2014, the new loans are available for up to $4,000 per period of technical training to help cover the costs apprentices typically incur dur-

during a press conference at the British Columbia institute of Technology, stephen Harper announces the large-scale Canada Apprentice Loan program is now “open for business” for red seal trades.

ing technical training, including educational fees, tools, equipment, living expenses, foregone wages, and support for their families.

Harper considered this news so important that he brought along no fewer than eight of his Parliament Hill colleagues to help him deliver the message: Jason Kenney, then Minister of Employment and Social Development (the portfolio actually responsible for the new loans); Kerry-Lynne Findlay, Minister of National Revenue and MP for the college’s own riding; Minister of Industry James Moore; Minister of State for Seniors, Alice Wong; Senator Yonah Kim-Martin, and MPs Nina Grewal, John Weston and Dan Albas.

Similar press conferences took place through January with Transport Minister Lisa Raitt at Sheridan College in Oakville, Ontario; Tim Uppal, Minister of State (Multiculturalism) at Keyano College in Fort McMurray, Alberta; and Jason Kenney again at Assiniboine Community College in Brandon, Manitoba.

Canada’s new Apprentice Loan program actually forms part of a larger Federal initiative under way since at least 2007 to help those already apprenticing to complete their training and to encourage more Canadians to pursue a career in the skilled trades.

Related measures include 500,000 government-issued grants worth nearly $700 million, Employment Insurance benefits, tax credits and deductions for apprentices; and an Apprenticeship Job Creation Tax Credit for their employers.

I was initially encouraged when the Apprentice Loans announcement came less than a month after I had written an article in PrintAction’s December issue about the efficient apprenticeship system that helped transform Germany into a worldclass manufacturing economy. The system is being leveraged by some of the printing industry’s largest printing-press manufacturers. With over six years of experience as a recruiter, I am convinced of the increasing difficulty faced by Canadian printers when trying to hire skilled

operators because of the growing shortage of job candidates with these skills.

Yet a thorough review of the terms for Canada Apprentice Loans shows that, to be eligible, apprentices must be registered in a Red Seal trade, a designation bestowed by the Red Seal program operated by the Federal Red Seal Secretariat, a branch of Employment and Social Development Canada.

The Secretariat’s current list of Red Seal recipients comprises 57 skilled trades, including bakers, bricklayers, carpenters, electricians, gasfitters, heavy equipment operators, ironworkers, machinists, painters, plumbers, sheet metal workers, and truck mechanics. But printing-related functions are nowhere to be found on the list, making both printers and their apprentices ineligible for the Federal apprenticeship benefits outlined above.

In Canada, developing an apprenticeship program requires the trade to be certified by a Provincial or Territorial Ministry of Training, Colleges and Universities (MTCU), which is the branch of government responsible for apprenticeships. After reaching out the Ontario MTCU, Linda Mackay, Manager, Issues and Media Relations, explains in an e-mail: “An apprenticeship trade means that the majority of training takes place in the workplace. There is usually a theoretical training component typically delivered at an Ontario college of applied arts and technology. There must be broad industry support to develop an apprenticeship program.”

Additionally, each province and territory in Canada has its own regulatory body in charge of examining and certifying journeypersons trained in MTCU apprenticeship programs by issuing Certification of Qualifications (licenses, essentially). These regulatory bodies are diversely named and include, for example, the Industry Training Authority in British Columbia, Apprenticeship and Industry Training in Alberta, the Ontario College of Trades in Ontario, or the Centre administratif de la qualification professionnelle in Quebec.

To establish an apprenticeship program, therefore, a trade must be designated by both the MTCU and the regulatory body of a particular province or territory. If a trade has demonstrated broadenough industry support to become designated for apprenticeship and certification by both the MTCU and regulatory body in at least five provinces or territories, the trade can then ask one of the regulatory bodies to evaluate and sponsor

“To our knowledge, the ministry has not been approached by this sector...” - Linda Mackay, MTCU

their request to become a Red Seal trade. This request is made to the Canadian Council of Directors of Apprenticeship (CCDA), the group responsible for administering the Red Seal Program operated by the Red Seal Secretariat. If successfully granted to the trade, the Red Seal endorsement enables certified journeypersons in the trade to practise anywhere in Canada where the trade is designated without having to pass further examinations. It also entitles both employers and apprentices in the trade to the Federal apprenticeship loan benefits.

In the quest for trade designation, both Federal and Provincial civil servants have assured me that no one particular group is entitled to represent a particular trade. Either employers or employees can approach their local provincial or territorial authorities to initiate the process. As things now stand, in addition to printing’s absence from the Red Seal list, the Ontario College of Trades confirms that no trades specific to the printing industry are currently designated in Ontario, the Canadian jurisdiction with the largest concentration of printing companies. Mackay adds that: “To our knowledge, the ministry has not been approached by this sector about developing an apprenticeship program.”

Why does printing not appear on the lists of

$4,000

Amount of the interest-free loan that Red Seal trade apprentices can apply for per training period

designated Ontario and Red Seal trades, especially considering that Canada is home to so many printing trade associations, most of which advertise not only the betterment of the industry but also government advocacy (either on their own or through a parent organization) as cornerstones of their mandate?

The sole national association, the Canadian Printing Industries Association (CPIA), based in Ottawa, was founded in 1939, 13 years before the founding of the Red Seal Program, also in Ottawa, in 1952.

The numerous provincial associations showing evidence of recent activity in various other spheres include: British Columbia Printing & Imaging Association (BCPIA), The Northern Alberta Printers Association (NAPA), Printing and Graphics Industries Association of Alberta (PGIA), Saskatchewan Graphic Arts Industries Association (SGAIA), Manitoba Print Industry Association (MPIA), Ontario Printing & Imaging Association (OPIA), the Toronto chapter of the International Association of Printing House Craftsmen (IAPHC), Association Québécoise de l’industrie de l’impremé (AQII), New Brunswick Printing Industries Association (NBPIA), Nova Scotia Printing Industries Association (NSPIA), and the Atlantic Printing Industries Association (APIA).

Additionally, from its founding in 2006, the Canadian Printing Industries Sector Council (CPISC) received substantial operating and project funding from the Federal government. This included $1.5 million and then $1.8 million in its 2009/2010 and 2010/2011 fiscal years, respectively. The funding continued until 2013, when the government cut funding to CPISC and all industry sector councils involved in the program.

In CPISC’s 2008 document (still extant on line), called Charting Our Course:The Skills and Technology Roadmap for the Printing and Graphic Communications Industry, CPISC described itself as: “A national forum that brings together printing and graphic communications industry employers and employees, educators and representatives of unions and governments to create and implement innovative approaches to skills development for current and future industry workers. In doing so, CPISC enables all players in the printing and graphic communications industry to work together in partnership to improve

the quality of the industry’s labour force.”

Besides the above document, CPISC’s other products included national skill standards lists, occupational profiles, labour market information, an online HR toolkit, and the Career Focus Program, intended to help companies attract new people to the industry. CPISC’s 7-year proceedings, however, seem to have completely ignored the need to have printing formally recognized by Canada’s most basic Provincial and Federal structures for trades and apprenticeships, the same structures on which the development and continuation of a formally trained, skilled labour force depend.

Meanwhile, printing’s lost opportunities continue to grow: Since January, at least two Liberal Provincial governments, although frequently Harper’s political opposites, have demonstrated renewed support for apprenticeships.

In April 2015, Ontario Premier Kathleen Wynne announced a $55-million boost for her province’s apprenticeship programs, including an Apprenticeship Enhancement Fund that helps colleges train more people more effectively by investing in equipment, space, and technologies ($23 million over two years); a Pre-apprenticeship Training Program that helps people considering a career in the skilled trades to develop job skills and work readiness ($13 million over two years); and a funding increase for colleges and other recognized training organizations for equipment upgrades and increased lab time for apprenticeship sessions ($19 million over three years).

The Globe and Mail also reports that the British Columbia Liberals under Premier Christy Clark are linking 25 percent of their funding for colleges and universities to training for in-demand jobs in health care, engineering and trades; and plan to poll recognized trades regularly on which jobs are going unfilled.

If it will help correct the omission of printing as a provincially and nationally recognized trade, I would be happy to share the list of helpful government and regulatory contacts I have amassed while researching this article to anyone who is serious about establishing printing as a Red Seal trade in Canada. Present and future printers need and deserve the practical benefits that would follow.

Agfa Anapurna M3200i W

Agfa describes its mid-range Anapurna M3200i RTR as one of its most successful wide-format-inkjet models. When the Anapurna M3200-i RTR was first launched at Fespa, it was only available in a 6-colour version. The system introduced last month, Anapurna M3200i W, is a new version with a 4-colour + white architecture, well suited for applications like coloured self-adhesive vinyl, PVC banners or backlit film. The Anapurna M3200i’s application of highdensity white is based on Agfa’s thin ink layer technology (also applied to the new Jeti Tauro and Mira, page 24), which allows for UV-curable inks to print on a range of flexible materials, as well as front- and backlit graphics.

Agfa explains the Anapurna M3200i W can print white underneath colour, white on top of colour

or colour/white/colour. The system also allows for high-density colour printing (colour on colour) without the need to print in double-strike mode. The Anapurna M3200i RTR is an available option for printing on mesh without liner and simultaneous dual rolls of up to 1.52 cm (60 inches). It also leverages Agfa’s Asanti workflow designed for the sign and display market, with colour management and automatic preflighting, as well as the optional Asanti StoreFront Web-to-print system.

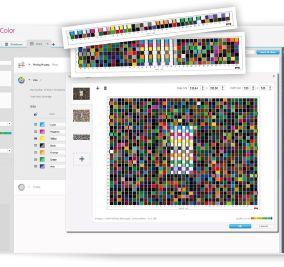

GMG of Tuebingen, Germany, adds to its unique OpenColor software with the release of version 2.0, which has a new interface, colour correction tools and a test-chart generator. The new version is designed for easier use by smaller printing and packaging operations.

You print packaging for your clients to sell more products. We provide the tools and resources to keep your client’s happy and grow your business.

A Collaborative Approach

Business should be based on relationships - not transactions. At Anderson & Vreeland, we do not simply sell products to the flexo market; we work with our clients and vendors to introduce new, innovative technology that improves the efficiency and quality of flexographic printing.

The flexo industry is evolving and so are the demands of the market. Today, everything is a rush and perfection is demanded. As a printer, you need a partner that offers more to keep your clients happy. Call Anderson & Vreeland to find out how we can help you and your business grow.

OpenColor tackles the interplay of inks for creating predictive profiles for overprinting, among more common colour management operations.

GMG explains a project-based view in its new GUI provides more flexibility in handling measurement data and creating profiles, while at the same time allowing for more safety in terms of data control and transparency. Each packaging product can be managed via a project folder, which holds all related information in one place. Also new to version 2.0, a centralized data management system provides for

openColor’s multi-channel test chart generator.

more accurate and consistent results across multiple sites. GMG explains OpenColor 2.0 offers more control in terms of publishing functionality so that only approved data and profiles proceed into production.

GMG OpenColor 2.0 comes with new correction tools for determining potential sources of error, optimizing measurement data and editing profiles. All corrections are visualized in a live preview. The new GMG OpenColor multi-channel test chart generator is a tool to create individual test charts for all packaging applications. GMG explains virtually any number of patches can be defined in various overprinting combinations and with full control of the separations. All test charts created with GMG OpenColor can be measured within the application, with the software supporting the most commonly used measuring devices in the industry.

HP in early April introduced its new portfolio of HP PageWide XL

printers with what the company describes as the fastest large-format production printing available in colour and black-and-white. HP explains the PageWide XL machines are up to 60 percent faster than the fastest monochrome light-emitting diode (LED) printer.

HP explains the PageWide XL printers are designed to enable reprographic houses, print service providers , and enterprise reprographic departments to also produce computer-aided design

(CAD) drawings. The system also opens up new business opportunities with geographic information system maps, point-of-sale applications and posters.

To be made incrementally available between November 2015 and January 2016, the HP PageWide XL portfolio includes four models, the dedicated 8000 printer, and three multi-function machines in the 5000, 4500 and 4000. The PageWide XL printers are HP’s first products introduced under its new

PageWide sub-brand, which the company expects to disrupt the $1.3 billion market dominated by dominated by monochrome LED.

PageWide consists of more than 200,000 nozzles on a stationary print bar.

Drytac released its new Polar polymeric PVC with a gloss and matte finish, as well as permanent and removable adhesive versions. Including gray cross linking acrylic adhesive, the company explains Polar provides a high opacity and strong white point. The material technology can be used on eco-solvent, UV or latex wide-format inkjet printers. Drytac states Polar is suitable for 3-plus years with both indoor and outdoor applications.

Last month, Drytac also launched what it describes as an optimized adhesive coat weight and new formulation for its Interlam Pro over-laminating films, which can now be used on inkjet printed output. Drytac explains the new development provides a strong bond, the elimination of tenting around raised inks and easy flow characteristics that minimize the chance of silvering when applied at room temperature or an optimum temperature of 110°F (43°C).

The technology provides Drytac’s standard finishes of Glossy, Matte, Lustre, and Emerytex (pebble-textured) to enhance colours and provide protection against scuffs and abrasions. UV stabilizers are added, Drytac explains, to prevent discoloration and degradation of both the film and adhesive.

Canon introduced its Poster Designer Plus software for use with its imagePROGRAF product line of inkjet printers. Poster Designer Plus is Web-to-print plug-in software that adds a large-format poster design engine, shopping cart and checkout functionality to an existing Website. This cloud-hosted printing storefront, explains Canon, gives print service providers

tools to take advantage of the emerging trend for the online ordering of wide-format printing. Canon points to a recent study by InfoTrends, which predicts the online print business will double to US$70 billion by 2017.

Heidelberg announced its Speedmaster XL 75 Anicolor press is now also available as a long perfecting press with UV capabilities. At drupa 2012, Heidelberg unveiled the Speedmaster XL 75 with an Anicolor inking unit, following the 2006 introduction of its smaller 13.78 x 19.69-inch Speedmaster with the same Anicolor technology. The Speedmaster SX 52 Anicolor has been available as a perfecting press since 2008 and as a UV press since 2010. The Speedmaster XL 75, running a maximum sheet size of 530 x 750 mm (20.87 x 29.53 inches), reaches production speeds of up to 15,000 sheets per hour.

TRESU Digital Solutions of Kolding, Denmark, launched a range of proprietary water-based and UV-curable overprinted varnishes (OPVs), called iVarnish, for what the company terms as digitally printed folding-carton applications. The TRESU iVarnish range is spe-

Your Superior choice for Print Finishing and Lettershop Ser vices

Heavy boards, plastics, laminations or digitally printed works up to 30 pt can now die crease, fold and even glue in-line.

ONE-STOP SHOP — Die Cutting, Bindery, Data & Lettershop.

2. SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

new Markets In: Labe L s, packag I ng & MaIL Intr Oduc I ng the ins Ign Ia ser I es-a new c Lass Of fLexO-MagnetIc

e

- The IS5 is a new rotary die cutter performing diecutting, kiss-cutting and cut-scores on a range of stocks up to 22pt. thickness. With run speeds of up to 5K sph, ease of operation and literally just minutes for changeover, the IS5 is surprisingly affordable for companies entering the packaging and label markets.

fOr MOre I nf Or MatIOn vI s It rOLLe M usa.c OM/dI ecut Or caLL us tOday at 1-800-272-4381 - Two models: IS5 - 20 x 15” and the IS7 - 24 x 30” sheet capacity with an in-line gluer/folder for complete box production - Ideal for: folded cartons, labels, promotional items and much more

cifically formulated for use with TRESU’s iCoat and TRESU Pinta flexo coating systems, which offer inline spot and flood varnish applications, following the printing stage.

TRESU describes iVarnish properties as providing strong slip angle for easy feeding of the substrate, rub resistance for brand integrity, and viscosity characteristics for optimized curing and drying at speeds of up to 5,000 sheets per hour on board substrates ranging from 180 to 500 gsm. The iVarnish OPV range includes UV-curable and water-based high-gloss, gloss and matte varnishes.

In April, Sappi Speciality Papers introduced atelier as a brand-new concept in folding boxboard (FBB), being made at its Maastricht mill in the Netherlands. Sappi explains the product broadens its offering in terms of both width and depth of coated virgin fibre carton boards for the packaging market. atelier is a hybrid FBB product that exceeds current market standards, according to Sappi, available in weights from 220 gsm to 350 gsm.

atelier is a multi-ply board produced on a single-wire board machine, which the company states is feature that no other paper manufacturer has ever achieved. Sappi also points to the product’s brightness, purity and gloss combined with a silk touch and feel. With a brightness level of 99 percent on its topside, atelier is described as exceeding the market standard in brightness compared to what Sappi states is the industry top value of around 92 percent. On the reverse side, atelier offers a brightness factor of 98 percent to accommodate an increasing demand for printing on both sides of the board. Sappi entered the carton board market 10 years ago with it Algro Design family of SBB carton board.

On April 28, Quark Software

launched a new major version of QuarkXPress, noted as version 2015. The layout tool for print and digital publishing features a new 64-bit architecture among a range of new tools. It will also continue to be sold as a perpetual license.

New key features in QuarkXPress 2015 include: 64-bit performance, verified PDF/X-4 output, larger page sizes, dedicated orthogonal line tool, fixed layout interactive e-books, custom paper sizes and relinking of any picture in the usage dialogue.

More new tools include collect for output for complete project, user-definable shortcut keys on Mac, table styles, format painter, automatic footnotes and end notes, a faster tool for Excel integration with table styles, text variables for automatically populating reoccurring fields (running headers), Tool Palette, Measurement Palette and Palette Group Docking on Windows.

Color-Logic technology is now available for integration on the Ricoh Pro C7100 series printers with white ink. Color-Logic explains this allows printers, who select the white ink option and Color-Logic integration, to produce 250 metallic colours and an unlimited number of special effects, when applied to metalized or pearlescent substrates.

Launched in September 2014, the Ricoh Pro C7100 press, offering a fifth colour station for applying either white or clear ink, prints at speeds of up to 80 A4 pages per minute. The press produces what Ricoh rates as a 1,200 x 4,800-dpi resolution, supports paperweights of up to 360 gsm in both simplex and duplex, and holds a maximum sheet size of 13 x 19.2 inches. Ricoh’s new vacuum feed LCT option enables oversized prints of up to 27.5 inches in length.

Durst in mid-April introduced its new 72-inch Rhotex 180 TR dye sublimation textile printer. It is equipped with Durst’s patented QuadroZ print-head technology and employs what the company describes

as eco-friendly, water-based, odourfree dispersion inks that are free of volatile organic compounds (VOCs). The company explains the system is suitable for polyester and polyester blends, sportswear, home textiles, and various POP display/soft-signage output.

Mimaki in March launched its new ES3 inks – black, cyan, magenta, yellow, light cyan and light magenta – for its JV300, JV150, CJV300 and CJV150 Series printers. These JV printers provide eight ink channels and can be configured to use ES3 inks in a double-CMYK configuration for printing at up to 1,140 square feet per hour.

Described as a fast-drying, eco-solvent and low-ordour product, Mimaki ES3 inks are compatible with a range of media types from indoor posters to outdoor signs. The company states the inks are scratch resistance for high-traffic applications such as transit advertising, window graphics, static clings, magnetic signs and other uses when over-lamination is not desired. Mimaki states these low-odour inks can be used in a commercial office, mall storefront or other shared working

environments without requiring special ventilation.

Muller Martini in February introduced new Variable Data Printing (VDP) modules for integrating onto its SigmaLine finishing systems. The technology is aimed at more complex commercial book segments like healthcare, financial, brochures, and customized textbooks. The VDP modules are branded under Connex, Muller Martini’s proprietary data and process management workflow system.

The new Connex modules include: Variable-Production, which enables products with different content or page counts to be produced in one run. The signatures are tracked using barcodes, and Connex monitors the production process. Connex Variable-Imposition is the system’s digital page assembly component (PDF and PDF/VT), in which barcodes are placed on every signature for tracking and automatically reproducing missing products following the production run. Variable-Bundle pre-bundles books selectively in the SigmaCollator.

❏ Enter data once and use it many times

❏ Enhances client service

❏ Work smart, work efficiently

❏ Increases speed - accuracy from estimates to invoices

❏ Eliminates duplication of effort

❏ Saves time and resources

In April, EFI released version 8 of its Digital StoreFront Web-to-print and e-commerce application, which fits into the company’s Productivity

UV and IR Dryers

Pump Rebuilds

Machine Shop capabilities

Welding On and Off Site

Suite of workflow tools. The upgraded Digital StoreFront includes new EFI DirectSmile options that extend the types of variable-data and personalized direct-mail campaigns that corporations can create online. With the Web-to-print software’s new Enterprise Model, print providers can subdivide a client’s single Digital StoreFront license into different interfaces to serve different franchises or subsidiaries within client’s organization.

Digital StoreFront v8 also includes a new marketplace sales offering that can incorporate content partners like copywriters, photographers and graphic designers, in a single online ordering interface. EFI explains the software also streamlines the Web-to-print ordering process with single sign-on (SSO) authentication for multiple users within the same organization, more-accurate shipping estimating using UPS CONNECT rate lookup tools, and support for online purchasing of e-books or other electronic content.

In mid-April, Agfa Graphics introduced two new Jeti Tauro and Jeti Mira large-format inkjet systems, as well as new features in Asanti 2.0 software and new UV inks. The 98inch (2 1/2-metre) Jeti Tauro is positioned as a high-end hybrid UV inkjet press – for both rigid and flexible material – with 32 print heads in a 6-colour system, in addition to an optional white or primer. Jeti Tauro offers optional semi or full media load/unload automation.

Jeti Mira is a 6-colour and white UV inkjet flatbed printer with optional varnish or primer. Also aimed at high-end production, it features moving gantry architecture and six vacuum zones with automatic and independent control of the front and back vacuum zones. Jeti Mira is available in two table versions: 2.7 x 1.6 metres and 2.7 x 3.2 metres (8’

9” x 5’2”/10’5”). Agfa explains its Print and Prepare feature makes the Jeti Mira unique for printing on both small objects or larger board sizes.

The new UV inks, leveraging what Agfa refers to as thin ink layer technology, for Jeti and Anapurna systems target flexible applications, special substrates and outdoor signage printed on polypropylene

or styrene media types and provide image longevity. Asanti version 2.0 also features new options for printing white on transparent substrates. The software provides for file handling, colour management and preflighting, while also working with the Asanti StoreFront Web-to-print application.

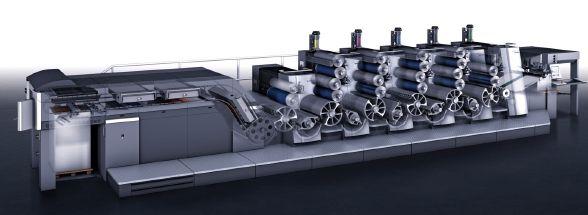

In April, KBA unveiled a new medium-format sheetfed offset press model, called the Rapida 105 PRO, scheduled for launch this June. Compared to the Rapida 105, which is still available, the new press runs at up to at 17,000 sheets per hour in a slightly higher level of performance. The Rapida 105 PRO also holds a larger standard sheet format of 740 x 1,050 mm.

One of the Rapida 105 PRO’s key features, according to KBA, is its full preset capabilities: All of the settings at the feeder and delivery can be stored according to job type, which can be leveraged with repeat jobs or orders printed on the same substrate. Options include DriveTronic SRW, CleanTronic Multi and CleanTronic UV.

larGe Format DIGItal prInt operator anD FUlFIllment

manaGer

Full time dayshift position available. Must be fluent in English and have 2-3 years Large Format Digital (LFD) print production and shipping experience.

Qualifications:

• Understanding of various substrates and their use in LFD equipment and production.

• Strong MAC and PC skills – with a thorough understanding of PDF workflow.

• Excellent quality control skills.

• Ability to multi-task and strong problem solving skills.

• Ability to read and interpret LFD production dockets.

• Facilitate fulfillment processes that focus on production and quality metrics.

• Utilize computer programs to initiate all in/outbound shipping processes, including reporting and tracking.

• Ability to prioritize workload under deadline constraints.

• Ability to work independently and as part of a team. reply to interview0905@gmail.com

Looking for a full time Pressman to run four colour GTO with CPC. Willing to be flexible and run our two and single colour presses as well. Be able to run own plates from Agfa Platemaker and be able to run Polar Cutter. Friendly no pressure shop situated in beautiful town in the north. email for more info.email resume to mark@integraphics.ca

osHaWa, prIntInG HoUse, bUsIness, aCCoUnts, eQUIpment anD bUIlDInG

$330,000

The Seller will hold financing with 35% down at an attractive rate. Call dave watkins re/max First ltd. Brokerage 905 432-6300

CUstomer serVICe representatIVe

10+ years production/customer service experience in printing industry, at least 5 years in a packaging (folding carton) setting. Degree/Diploma in Graphic Arts Communications or equivalent education and experience. Understanding of sheet-fed offset

printing and finishing for packagingdiecutting/gluing, embossing, etc. email resume to: hr.canada@cenveo. com

pre-press operator

Enthusiastic Prepress Operator needed with experience in the printing industry: digital - sheet fed – LFD Working knowledge of Adobe CC, email, FTP, bindery, Macintosh and Windows operating system. Prepare plates for printing presses; construct file layouts; prepare Raster files with Prepress workflow and Imposition programs; impose and output on digital copier. Previous experience with Xerox digital, wide format, and Sierra software is an asset. e mail resume to: admin@captainprint.com

sales estImator

Experienced Sales Estimator needed for a busy downtown print shop - digital, offset and wide format Solutions oriented sales approach; Create price quote estimates for clients,manage ongoing client accounts, develop opportunities within existing customer relationships and manage

consumer orders within the order fulfillment process. Experience with Printsmith software and Adobe CC is a strong asset. e mail resume to: admin@captainprint.com

prepress operator / aFternoon sHIFt

Prepress Operator / Afternoon Shift

Candidate must have solid knowledge of Prinergy workflow including Preps7. Looking for self motivated individual handling Prepress work from Preflight to making plates with our Magnus 800 Platesetter. send cover letter and resume to: hrd@hemlock.com

Heidelberg: K-Line/S-Line/Speedmaster/GTO/MO

Komori: 1, 2, 4 or 5 colours & any size

Adast: 714/715/724/725

Mitsubishi: Any model

Ryobi: 2800CD/3200CD-MCD/640K

Itek: 960/975/985

Hamada: 600/700/800/E47/RS34

Shinohara/Fuji: 66/65 1,2 or 4 colours

Sakurai: 1, 2 or 4 colours and any size (newer model)

Polar: any size/older or newer models (66/72/76/78/82/90/92/107/115)

Horizon-BQ: 220/240/260/440/460

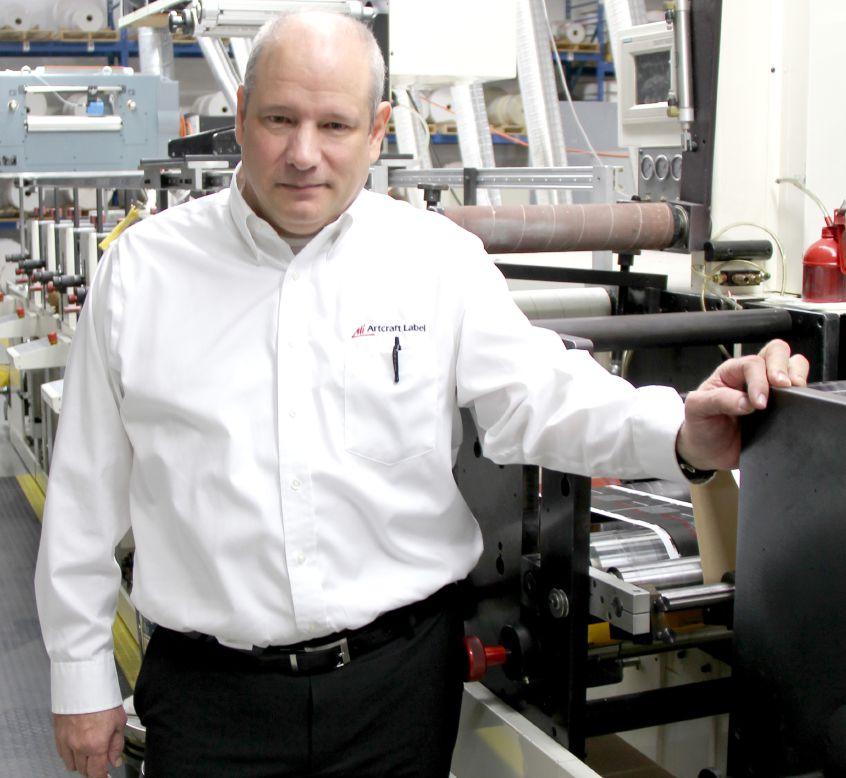

Alain Paquette, together with a silent partner, purchased Artcraft Label three years ago and set out to modernize the operation, leveraging its experienced team and position as a producer of high-quality pressure-sensitive labels. Founded in 1977, Paquette took over the operation from John and Edna Robinson, who grew Artcraft from a sticker business to an award-winning prime-label manufacturer.

Stepping away from his established career with technology suppliers, Paquette saw huge potential in Artcraft’s strong market position to institute significant operational changes to drive out costs. With his own background in lean manufacturing, investments were made to improve all aspects of the business, from the shop floor to the entire IT system.

Paquette focused heavily in establishing Artcraft’s prepress department, through Esko’s HD Flexo system, including a CDI imager and powerful new imaging software. The move adds more control over Artcraft’s high-quality printing platform housed within a 20,000-square-foot facility. The plant is meticulous in its cleanliness and order and primed for the future, which is likely to include contracting out prepress work, which currently accounts for a very small percentage of Artcraft’s revenue.

what potential did you see in Artcraft?

AP: I realized the market was changing so we came up with a plan to really optimize it… everything top to bottom… all of the software, computers, everything was all redone. We reinvented the whole ERP system. All of our stock is barcoded, for example.

How much cost have you driven out of Artcraft?