FEATURES

ISSN 1481 9287. PrintAction is published 12 times per year by Annex Business Media. Canada Post Publications Mail Agreement No. 40065710. Return undeliverable Canadian addresses to: Circulation Department, P.O. Box 530, Simcoe, ON N3Y 4N5. No part of the editorial content in this publication may be reprinted without the publisher’s written permission. © 2016 Annex Publishing & Printing Inc. All rights reserved. Opinions expressed in this magazine are not necessarily those of the editor or publisher. No liability is assumed for errors or omissions. All advertising is subject to the publisher’s approval. Such approval does not imply any endorsement of the products or services advertised. Publisher reserves the right to refuse advertising that does not meet the standards of this publication. Printed in Canada.

More than 200 industry leaders, students and family members gather in Toronto to recognize the achievements of dozens of students and the CPISTF

A range of business and technological developments in 2016, both domestic and international, impact the Canadian printing industry

GAMUT

5 News, People, Calendar, Dots, Installs, Globe, Archive

NEW PRODUCTS

20 Detailing the newest technologies from Bobst, callas, Canon, DALIM, EFI Heidelberg, Kodak, Roland, Propago, Sydney Stone, Touch7 and Xaar

MARKETPLACE

25 Industry classifieds

SPOTLIGHT

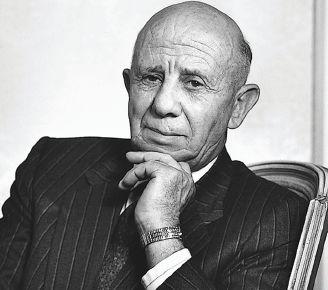

26 Phillip Crawley, Chief Executive Officer and Publisher, The Globe and Mail Inc., Toronto, ON

FROM THE EDITOR

4 Jon Robinson

Industrie 2030 plan

Canadian Manufacturers & Exporters writes a letter to Justin Trudeau about Donald Trump and its new action plan

DEVELOPMENT

10 Dave Fellman

Finding the right words

When dealing with print buyers it is important to assume they do not understand your industry

ENVIRONMENT

11 Neva Murtha

The customer is always right

North America’s largest corporations are starting to realize and record sales increases based on purchasing positions 14 12 20 26

The Canadian Manufacturers & Exporters in early November wrote a two-page letter to Prime Minister Justin Trudeau to discuss how Canada should move forward following the election of Donald Trump as President of the United States. During his campaign Trump put forward his ideas for changing or outright scraping NAFTA, the latter of which, of course, would be a monumental task.

competitive environment in which to manufacture, innovate and grow. Many of these recommendations are in line with the Federal government’s own previously stated goals.

In building its Industrie 2030 plan, the CME engaged individual companies through a 2016 Management Issues Survey, with 553 respondents from across Canada.

1.7M

Canadian Manufacturers & Exporters estimates Canada has 90,000 manufacturing companies that employ 1.7 million people, as the country’s largest business sector generating 28 percent of all economic activity.

The Canadian Manufacturers & Exporters (CME), however, needs to be out front the Trump administration’s potential policy changes given that the U.S. is vital to the health of Canadian manufacturing – the single largest business sector in Canada, directly and indirectly representing 28 percent of all economic activity and 27 percent of all employment. CME estimates Canada has 90,000 manufacturers employing 1.7 million people.

More than 75 percent of Canada’s trade is with the U.S., according to CME, and Canada is the top export destination for 40 U.S. states. CME explains the twoway flow of goods, services and people between the United States and Canada is critical for the innovation and economic growth of both countries, particularly within a complex global economy.

At the same time, CME points out that Canada directly competes for business investment with the U.S. and without a modern national manufacturing strategy there is great concern Canada will fall completely out of the picture as a location of choice for global manufacturing investment. To this end, the organization must consider Canada’s worldwide manufacturing position without becoming sidetracked with bombast and rhetoric. Last year, Canadian manufacturers exported nearly $350 billion in value-added goods – accounting for a full two-thirds of Canada’s total international sales.

Throughout 2016, CME conducted a national discussion about the future of manufacturing with the goal of creating an action plan to double Canada’s manufacturing output and value-added exports over the next 15 years.This initiative is called Industrie 2030 and, after a series of roundtables and consultation, CME in mid-October released its plan as recommendations for the Federal government to take action, noting it is ever more important given the result of the U.S. election.

CME’s recommendations for growth include developing a skilled workforce, supporting innovation and commercialization, increasing investment in, and leveraging, new technologies, opening new markets globally, and ensuring a

The CME explains most companies viewed a lower exchange rate as a positive development, although a significant 29 percent disagreed. Despite the attractiveness for export, a weaker Canadian dollar also impacts a manufacturer’s ability to create innovation through technology and research investment.

Survey respondents also reported that business conditions have grown more challenging over the past three years. Nearly 58 percent reported that the general cost of doing business has risen, while 38 percent also stated that challenges surrounding the attraction and retention of skilled labour have worsened. The CME also points out that many businesses noted that foreign competition is growing fiercer, both in the Canadian market and abroad.

In general, CME reports manufacturers are more bullish about their future, particularly around growth prospects with the United States. Close to 60 percent of Canada’s manufacturers expect domestic sales to increase over the next three years, while 62 percent expect higher sales to the U.S. Nearly a quarter of respondents expect at least 10 percent growth in U.S. sales over the next there years.

In its Industrie 2030 report, CME outlines many general issues facing Canadian printers, that the cost of doing business in Canada is rising as the rest of the world becomes more competitive and innovative. “These trends are threatening not only the long-term sustainability of manufacturing, but the millions of middle-class Canadians whose livelihoods are directly and indirectly tied to the sector,” writes Matthew Wilson, Senior Vice President of CME. “Policies that focus on middle-class growth and innovation need to recognize that is it manufacturing that drives innovation and creates middle-class jobs. Without that underlying economic driver, Canadians and their governments cannot achieve their desired policy outcomes.”

Editor Jon Robinson jrobinson@annexweb.com 905-713-4302

Contributing writers

Zac Bolan, Wayne Collins, Peter Ebner, Victoria Gaitskell, Martin Habekost, Nick Howard, Angus Pady, Nicole Rycroft, Abhay Sharma, Trish Witkowski

Publisher Paul Grossinger pgrossinger@annexweb.com 905-713-4387

Associate Publisher Stephen Longmire slongmire@annexweb.com 905-713-4300

Director of Soul/COO Sue Fredericks

Media Designer Lisa Zambri

Circulation Manager Barbara Adelt badelt@annexbizmedia.com

Customer Service Angie Potal apotal@annexbizmedia.com Tel: 416-510-5113 Fax: 416-510-5170

Mail: 80 Valleybrook Drive, Toronto, ON, M3B 2S9

Subscription rates

For a 1 year monthly subscription (12 issues): Canada — $40.95 Canada 2 year— $66.95 United States — CN$71.95 Other foreign — CN$140.00

Mailing address

Annex Business Media 222 Edward Street Aurora, ON, L4G 1W6 printaction.com Tel: 905-727-0077 Fax: 905-727-0017

Mimaki celebrates its new Toronto facility with a Kagami Biraki ceremony.

Mimaki USA celebrated the opening of its new Toronto Branch, the company’s first in Canada and seventh in North America, at a grand opening event featuring a traditional a Kagami Biraki ceremony, which culminates with the lid of a sake barrel being broken open by a wooden mallet and the sake being served to everyone present. Mimaki explains the ceremony represents an opening to harmony and good fortune. Located at the intersection of Jane Street and Highway 7 in Toronto, Mimaki’s new Canadian location includes an 11,000-square-foot technology centre for running demonstrations of its wide-format imaging technologies. Lucas Crossley, Canada Sales Manager for Mimaki, will lead the new location.

Seiko Epson began construction of a new factory in Shiojiri, Japan, which is scheduled to begin operations in the first half of its 2018 fiscal year. The facility will produce PrecisionCore print heads, the core devices in Epson’s inkjet printers, launched in 2010 with as many as 15 million units sold worldwide as of June 2016. The facility will roughly triple Epson’s current PrecisionCore production capacity.

Agfa-Gevaert NV released a public statement that has been approached

by CompuGroup Medical SE to purchase all of the issued shares of Agfa by way of a voluntary conditional public takeover offer. The statement comes amid a report by Belgian financial paper De Tijd that Agfa has been in talks with a potential buyer. Based in Mortsel, Belgium, Agfa notes there is no certainty as to whether a public offer for all issued and outstanding shares of Agfa will materialize.

Rochester Institute of Technology opened its 3,200-square-foot Additive Manufacturing and Multifunctional Printing (AMPrint) Center, located on the school’s Henrietta campus. The facility is described as being among the first research labs in the world to focus on development of next-generation multi-functional 3D printing technologies, materials and devices. Denis Cormier, an expert in 3D print technologies, is Director of RIT’s AMPrint Center and the Earl W. Brinkman Professor in RIT’s Kate Gleason College of Engineering.

Sun Chemical and its parent company, DIC Corporation, acquired Gwent Electronic Materials Ltd., a manufacturer of conductive inks, pastes and powders for the printed electronics market. With the acquisition of the United Kingdom-based company, Sun Chemical states Gwent’s European-based production sites will enhance Sun Chemical’s global conductive ink, paste and powder manufacturing capabil-

ities while allowing further penetration into developing markets. Founded in 1988, Gwent is a major world supplier of pastes and other ancillary materials for the bio-sensor and biotechnology markets, in addition to automotive and display product sectors.

Electronics For Imaging of Freemont, California, in its goal to become a $1 billion company by the end of the current fiscal year, continues to report record quarterly revenue results. For its third quarter of 2016, ended September 30, 2016, revenues reached US$245.6 million, an increase of seven percent compared to third quarter 2015 revenue of US$228.7 million. For the nine months ended September 30, 2016, EFI reported revenue of US$725.4 million, up 16 percent year-overyear compared to US$626.0 million for the same period in 2015.

Heidelberger Druckmaschinen AG is partnering with IT service provider Dimension Data and other companies in the NTT Group to create a scalable IT infrastructure focusing on LAN, WAN and communication services for some 110 sites and branches in just under 40 different countries. The German press manufacturer explains the move is key to its efforts to speed up digital transformation for its customers, which includes access to a network of over 10,000 presses connected to its central service centre. The company will provide big data analysis to predict potential failures and to also analyze performance trends.

Ultimate TechnoGraphics of Montreal, a developer of imposition and finishing software tools, has formed a new alliance with Canon Solutions America aimed at improving the prepress workflow of commercial printers. More specifically, the two companies explain Ultimate TechnoGraphics’ Impostrip imposition intelligence, combined with Ultimate Bindery JDF automated finishing hub, offer the automation requirements needed to empower a complete workflow for all types of

commercial print and book productions. Ultimate’s software technologies will be offered to Canon’s digital press customers.

Alliance Franchise Brands LLC , based in Plymouth, Michigan, acquired the Canadian franchise organization KKP Canada, based in Richmond Hill, Ontario. The agreement adds 50 franchise locations to Alliance Franchise Brands’ portfolio, which includes more than 600 locations in North America and the United Kingdom. The purchase of KKP Canada effectively triples the Canadian presence of Alliance Franchise Brands. The company’s brands include Allegra, Speedy Printing, image360, Insty-Prints, Signs by Tomorrow, Signs Now, Zippy Print (also Canadian), and KKP franchises in the United States. KKP Canada CEO and Vice-Chair Gigi Harding is to remain active in KKP Canada through the transition as an advisor.

Jim Mihaly, Publisher, Brandon Sun.

The Globe and Mai l and Brandon Sun, received top honours for online media initiatives in the 21st edition of the EPPY Awards, hosted by Editor & Publisher magazine. The Globe won three awards in the categories of Best Daily Newspaper Website with 1 million unique monthly visitors and over; Best Community Service (Fentanyl awareness) on a Media-Affiliated Website with 1 million unique monthly visitors and over; and Best Business Blog (Gen Y Money) with 1 million unique monthly visitors and over. The Brandon Sun won for its The Knights of D-Day project in the category of Best News or Event Feature Video with under 1 million unique monthly visitors.

Print World, a biannual tradeshow held in Toronto, was cancelled less than two weeks before opening day on November 19. Show organizers related the cancellation to unfortunate circumstances, the late pull out of a major manufacturer, and outright aggressive acts against the show as primary reasons for the cancelation.

Correction: In the November issue of PrintAction, Tri-Win Direct was incorrectly noted as being based in Malvern, PA. The company is based in Dallas, TX.

Michael Mugavero , one of North America’s most influential technology leaders for more than three decades, passed away on October 19 at age 63 after a battle with cancer. Since 2012, he was serving as Chief Executive Officer of Manroland Sheetfed USA and Canada. Mugavero’s printing career spanned 47 years after he began working part-time for a commercial printer during college. Fifteen years later, he was named President of the company, where he stayed for two and a half years, before taking an ownership position with a trade shop. Three years later, in 1992, after the trade shop was purchased, Mugavero joined Manroland as a sales representative. By 1999, he was named the first regional General Manager of Manroland Inc., responsible for the Northeast United States and Canada. He eventually worked for KBA for three years, before rejoining Manroland in 2007. Prior to becoming CEO in 2012, Mugavero had been serving as Manroland’s Vice President of Sales, Canada and Eastern United States.

Warren Wilkins, who led the prominent growth of Webcom Limited into one of North America’s leading book manufacturers, passed away on November 3, 2016, at the age of 88. Wilkins was one of the most instrumental leaders of Canadian printing from the 1980s to the 2000s, active in both domestic and international industry associations. Wilkins graduated from the University of Toronto in 1951 and 10 years later formed Web Offset Publications Limited with Bob Chittick, 14 years before the founding of Webcom. Wilkins served on the Board of the Ontario Printing Industries Association and, in 1989, was elected Chairman of the Government Affairs Committee of the Canadian Printing Industries Association (CPIA). In 1991, he became Chairman of the CPIA and in 1992 joined the Board of PIA representing the CPIA. In 2000, he assumed the Chairmanship of PIA. Wilkins was also the founding President of the Canadian Book Manufacturing Association in the late 1970s. He was the first recipient of the CPIA Honorary Lifetime Membership Award introduced in 2004.

Sparsh Bhargava, President and CEO of Presstek LLC, based in Hudson, New Hampshire, unexpectedly died on October 28. Bhargava, a partner at private

equity firm American Industrial Partners (AIP), had led Presstek for the past four years, becoming its CEO within the last year. In 2012, Bhargava was appointed as a partner at AIP and held numerous roles at other AIP companies prior to his role at Presstek.

Rainer Hundsdörfer becomes Chief Executive Officer of Heidelberger Druckmaschinen AG, succeeding the departing Gerold Linzbach.

Management board member Harald Weimer, responsible for Heidelberg Services, is stepping down and will be replaced by Ulrich Hermann. Stephan Plenz’s management board contract has been extended for a further three years. Hundsdörfer has managed a number of leading industrial technology companies, most recently as chairman of the board of management of ebm-papst. Prior to this, he was Chairman of the Industry Division and member of the executive board at Schaeffler.

Core-Mark International’s Calgary location added a new Bizhub Pro C1060L press, pictured with Core-Mark’s Glen Leguyder and Chandra Peel, Senior Account Executive at Konica Minolta Business Solutions Canada. The facility also runs a Bizhub C258.

John Robinson , former owner of Artcraft Label Inc., of Burlington, Ont., passed away at the age of 83. Robinson and his wife, Edna, purchased Artcraft (founded in 1977) in 1986 and together developed the company into an award-winning prime-label producer. In 2010, Artcraft acquired its first digital printing technology and continue to shift the company from its early sticker roots with an experienced team producing high-quality pressure-sensitive labels. In 2012, John and Edna Robinson retired as Alain Paquette, together with a silent partner, purchased Artcraft.

Dr. Kumar Menon, Director of Technical Specialty R&D with Sun Chemical, received the Technical Achievement Award presented annually by the National Association of Printing Ink Manufacturers (NAPIM). Menon is noted at the first person to formulate a dedicated UV screen ink for compact discs and DVDS.

Maranda Digital’s Vancouver location added three Ricoh presses to its production floor, including a Pro C9100 (pictured with Maranda operator Steve Hymers), Pro C7100X and Pro 8120SE. The company also integrated new Ricoh Total Flow software.

Ryerson University’s School of Graphic Communications Management received a new CDI Spark 2530 flexo plate imager, pictured with students Jewel Bolasco and Alisha Campitellilres. The system, donated by Esko, will help Ryerson students learn about flexo platemaking processes.

With its decision to purchase a 48-page Compacta 618, the Italian company Azienda Commerciale Meridionale from Torre Del Greco, on the outskirts of Naples, has again invested in a commercial web press from Koenig & Bauer (KBA).The press is scheduled to enter production at the end of 2016. Azienda Commerciale Meridionale (ACM) already operates a 16-page Compacta 215. ACM is a third-generation family business and is well known in the region for its innovative print products tailored specifically to individual customer needs. The company has recorded continuous growth ever since its founding more than 50 years ago.The 48-page Compacta 618 is engineered for a cylinder circumference of 1,240 mm (48.81 inches) and a maximum web width of 1,450 mm (57.1 inches). It features a Patras M reel-loading system, Pastomat RC reelstand, infeed unit, four printing units, chill-roller stand, a unique superstructure and a P5 pin folder. The management system KBA LogoTronic handles the loading of job and presetting data, as well as production monitoring and evaluation.

The 48-page KBA Compacta 618 for Italian printers Azienda Commerciale Meridionale from Acerra on the outskirts of Naples.

Dr. Ciro Gentile, Managing Director of ACM (left to right); Thomas Potzkai, Head of Service and Project Management, KBA-Digital & Web; Mariarosaria Barile Gentile, Managing Director, ACM; Vincenzo Gentile, General Manager, ACM; KBA Service Manager Martin Schoeps; and Dr. Guiseppe Gentile, General Manager of ACM.

Pageworks, a Grand Rapids, Michigan-based print provider with 60 years of experience, installed the first HP Indigo 12000 press in the U.S. in July 2016. Pageworks has operated HP Indigo printing technology for more than 10 years alongside its offset technology, serving the insurance, medical and education markets.

UK-based repro and platemaking house Flexoshop, located in Colchester, had been using Flat Top Dot platemaking systems for its printing clients. The company’s Managing Director, Simon Drane, explains he set out to find a new dot solution after hearing one of his printers was turning to a digital printing firm for its highest quality.

“I had my eye on Asahi’s water-washable plate systems,” said Drane, “but I thought they were unaffordable for my business. But when this customer explained his challenges to me, it spurred me to reconsider.”

Drane invested in an Asahi Photoproducts AWP 2530 plate system using AWP water washable plates. He explains the move not only brought his customer back in the fold, but he is now using the Asahi solution as the centerpiece of a new business acquisition strategy. Largely due to its adoption of Asahi AWP water washable plates, Flexoshop explains it has recently seen increasing interest from a range of printers.

Navi, Mumbai-based Rukson Packaging recently underwent a major transformation from its commercial offset printing roots to become a packaging solutions provider. The company has equipped its prepress division with Esko’s Kongsberg XE10 sample maker and Esko’s prepress workflow. Rukson specializes in met-pet folding box cartons and its product mix includes a large share of cartons for the pharmaceutical segment. Rukson Packaging is now using Esko’s DeskPack prepress editor software, which has functions like interactive trapping, remapping of ink channels, quality control and white under print, which is useful in met-pet printing.

“Over a period, our client base has expanded in the pharma and FMCG segments,” said Kishin Punjabi, Director at Rukson Packaging. “The adoption of Esko hardware and software solutions is an attempt to enhance our efficiency in prepress in order to drive our growth in line with the evolving demands of the consumer product companies.”

Going forward in its expansion, Rukson plans to extend its customer base in other segments, including FMCG. “To reach out to a wider client base, we develop and supply samples to brand owners, in order to acquire larger volumes of printing and converting,” said Punjabi. The Kongsberg XE10 sample maker is used as a digital tool for cutting blankets that are also used for spot varnishing.

On November 10, more than 200 people from across Canada gathered to celebrate some of the best printing in the country at the 11th annual Canadian Printing Awards gala, held at the Palais Royale on Toronto’s waterfront. A total of 87 awards were presented during the evening to both printers and technology companies, including 53 Gold, Silver and Bronze Awards among 28 printing categories that covered a range of applications from books to labels, as well as the primary printing processes of inkjet, offset, toner and flexography.

Among more than 220 entries into these printing categories, one project is determined as the Best of Show by the panel of judges. This year’s judging panel consisted of 11 industry leaders, who spent a full day analyzing and ranking all of the entries through a blind scoring system. The judges consider issues like printing process, run length and repeatability across the submitted samples, with a possible best score of 35 based on the weighting of four criterion.

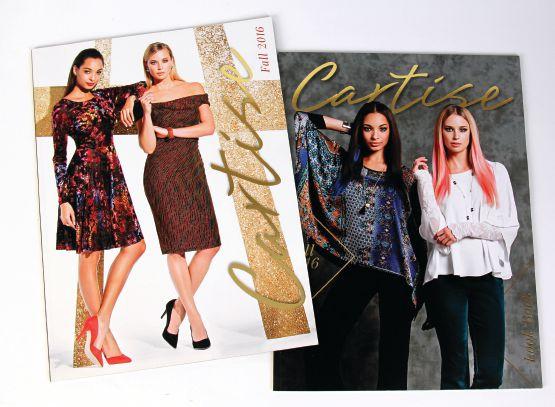

At the end of the day, the judges each collect their favourite projects and together debate which single entry, across all categories, should be awarded Best of Show. Finalists in the year’s Best of Show discussion included work from Friesens, MET Fine Printers and PDI Group (two submissions), with the award going to Montreal’s PDI Group for its production of the Cartise Autumn 2016 catalogue. A full report on the 2016 Canadian Printing Awards will be featured in PrintAction’s January 2016 issue.

The Cartise Autumn 2016 catalogue was printed in a 2,700-piece run on a 56-inch, 6-colour manroland Roland 900 press with aqueous coating. PDI explains its client Cartise, for their 40th anniversary, wanted to produce a special catalogue. “This beautiful edition was produced in tumble style,” explains PDI, “in order to highlight both the Fall 2016 line of clothing, as well as fashion tendencies in the market.”

PDI explains, that apart from careful colour balancing for the skin tones and background, the client added a gold foil stamp for additional effect on the cover. The challenge in the foil stamping was that it also ran across the narrow spine, leaving no margin for error. This particular production step required cooperation within its printing plant, the foil stamp provider, and PDI perfect-binding partner in order to produce the desired effect.

Cartise Autumn 2016 PDI Group, Montreal, QC

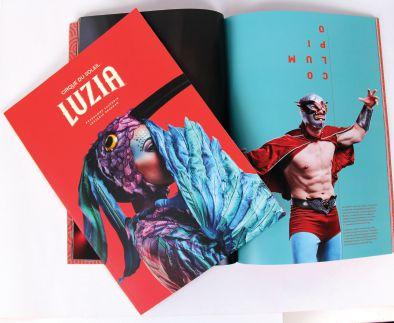

Cirque du Soleil, Luzia Souvenir Programme PDI Group, Montreal, QC

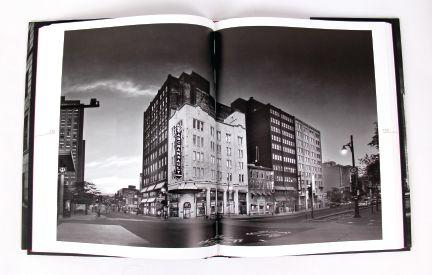

Montreal 375 Friesens, Altona, MB

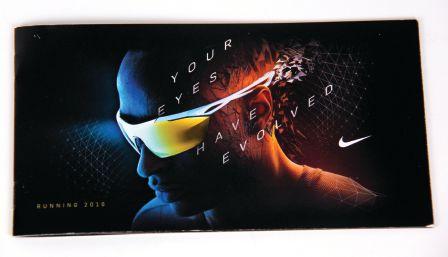

Nike Vision Running MET Fine Printers, Vancouver, BC

January 17-20, 2017

EFI Connect 2017

Wynn, Las Vegas, NV

January 30-February 1, 2017

PSDA CEO Summit Biltmore. Coral Gables, Florida

February 16, 2017

Ryerson GCM Colloquium GCM Building, Toronto, ON

February 16-18, 2017

Graphics of the Americas Great Fort Lauderdale Convention Centre, FL

February 20-23, 2017

Hunkeler Innovationdays Lucerne, Switzerland

March 1-4, 2017

Dscoop Phoenix, AZ

March 19-22, 2017

TAGA Annual Technical Conference Houston, TX

March 19-24, 2017

IPEX London, UK

March 23, 2017

Ryerson GCM Job Fair Mattamy Centre, Toronto, ON

April 6-8, 2017

Graphics Canada International Centre, Mississauga, ON

April 19-22, 2017

ISA International Sign Expo Mandalay Bay Convention Center, Las Vegas, NV

May 9-13, 2017

China Print 2017

New China International Exhibition Center, Beijing

May 11, 2017

Gutenberg Gala Centre des Sciences, Montreal, QC

May 12-13, 2017

Grafik’ Art Place Bonaventure, Montreal, QC

June 21-23, 2017

EskoWorld

Omni Orlando Resort, FL

September 10-14, 2017

Print 17

McCormick Center, Chicago, IL

October 10-12, 2017

SGIA Expo 2017

New Orleans, LA

40 years ago 15 years ago

Southam-Murray prepares for unprecedented changes: A clear indication that Jack Crawford, VP and GM of Southam-Murray Printing, intends for his company to be among the survivors of unprecedented changes in the industry is the recent installation of a more efficient computer in a completely remodeled and relocated Computer Services Department. The department now occupies 2,200 square feet compared with the previous 1,280 square feet. A Univac 90/30 computer replaces the former Univac 1810. With six times the capacity of its predecessor, the new computer incorporates a paper tape reader that can scan 2,000 characters per second, a card reader that can check 500 cards per minute, a printer that can produce 800 lines per minute, and four tape drives that can pass 44 inches of magnetic tape in one second.

20 years ago

System measures colour on-line: Quad/Tech has introduced the Colour Measurement System (CMS), an online system designed to reduce the subjectivity of colour comparison. It displays colour density in numerical values, which reflect current ink key settings. Online measurements convey real-time density information for press operators to help make accurate quality and productivity decisions, while recording statistical process control run data. The CMS is video based, with the ability to automatically locate and track micro-colour bars, regardless of bleed. It operates at press speeds of up to 3,500 feet per minute, without coating marks.

$50k

For sale (2001 classified): Docucolor 40 with Scitex Front End. Comes complete with edit pad and high capacity feeder. Asking $50,000.

Ryerson’s Dedicated Building Underway: A throng of reporters waited for Ontario’s Finance Minister, Jim Flaherty, as he entered into a pit of dirt on Ryerson’s downtown Toronto campus, the eventual site for the school’s dedicated Graphic Communications Management building. The possibility of Flaherty replacing Mike Harris as Premier of Ontario overshadowed the efforts of the minister’s SuperBuild program, which provided $4.61 million needed to complete the $10.61 million Ryerson project.

The first $6 million of funding was provided by more than 30 industry contributors to support Canada’s only degree-level printing program. Quebecor World’s Chris Rudge, who along with Tony Gagliano of St. Joseph Corp. co-chaired the fund-raising committee, was on hand for the groundbreaking ceremony. Upon completion, scheduled for next summer, the three-story, 30,000-square-foot facility will house approximately 360 students.

$10,500

For Sale (1996 classified): ScanMate plus fixed drum scanner. 2600, 3.06OD. Scan area 210 x 295 mm. Mac/PC. SCSI. Demo, excellent condition. Certified cheque.

10 years ago

Luc Desjardins, CEO of Transcontinental, signed a 15-year deal with Hearst Corporation to print the San Francisco Chronicle. The deal is worth US$1 billion and will begin in the spring of 2009. Transcontinental also prints The New York Times and The Globe and Mail for upstate New York and Southern Ontario. The Chronicle will be printed in a new facility to be built in the San Francisco Bay area. The newspaper has the fourteenth largest circulation in the United States.

When dealing with print buyers it is critical to assume they do not know print jargon, making simplicity key

By Dave Fellman

What kind of printing do you sell? I asked that question during a recent seminar, and a young salesperson in the second row called out: “Any kind of printing you need!”

“Bad answer,” I said, and pointed at the person sitting next to him.

“Well,” she said, “we do both offset and digital, and really more short run than long run.”

“Another bad answer,” I said, and pointed at a veteran-looking salesperson in the first row.

“I don’t sell printing,” he said. “I sell business-building solutions.”

“Really bad answer,” I said, and pointed at another veteran-looking person toward the back of the room.

“I’m not playing your silly game,” she said. “Obviously this is some sort of trick question. Tell us what the trick is!”

“It’s no trick,” I said. “In fact, it’s one of the most basic issues you can imagine. Let’s say that we got a bunch of printing buyers together and asked them what kind of printing they buy. How many do you think would answer digital or offset… or short run or long run? I think it’s a lot more likely that they’d say brochures or business cards or mailers or manuals. It’s one thing to define yourself in terms of production capabilities in a room full of printing salespeople, but you want to speak a whole different language when you’re in front of printing buyers – you want to speak their language.”

“I still don’t see what was wrong with my answer,” said the young salesperson from the second row. “It covers everything you just said and more.”

“Does it?” I asked. “Let me ask you this, are you equipped to sell banners?”

“Yes, we have an HP inkjet that’s really good at banners.”

“OK then,” I said, “are banners printing?”

“Of course they are.”

“You know that,” I said, “and I know that too, but the question is, do they know that? I think it’s possible – and maybe even likely – that they don’t, so you could tell them that

you can handle any sort of printing they might need, but they would still buy their banners from someone else because they didn’t conclude ‘I can buy banners from this guy’ in what you said.”

“Bottom line,” I continued, “it is your responsibility to communicate with them. It is not their responsibility to interpret what you say. If you ask them to do that, if you expect them to do that, you’re going to miss out on a lot of opportunities.”

“I Sell Solutions!”

“I still don’t see what was wrong with my answer,” said the veteran-looking salesperson from the first row. “Printing has become a commodity, and you have to find ways of differentiating yourself in the marketplace. I focus on direct mail, and my whole thing is helping customers to increase their own sales.”

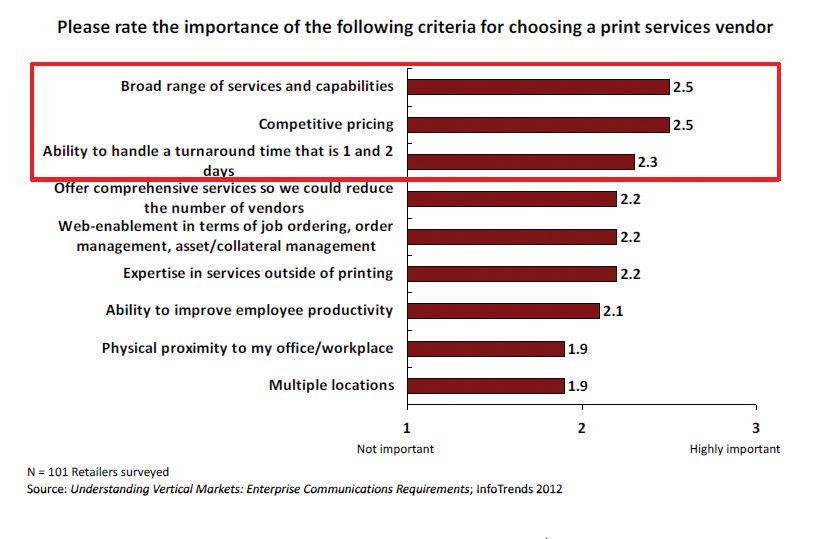

Identifying the right contacts in retail organizations – those with decision and budget authority – is a critical step in winning work, followed closely by then communicating your services to them properly.

(CHARTS PRODUCED BY INFOTRENDS).

“Okay,” I said, “Then say that! When you said business-building solutions, my first thought was that you were in construction. Again, if you ask them to interpret what you’re saying, you’re just asking for a communications failure.”

49%

On the SMB side of the retail market, InfoTrends’ research finds that 49% of retailers use commercial printers for marketing services and more than a third use online printing services or office superstores.

46%

The top three criteria when choosing a print service provider, in rank order, include quality of service (46%), lowest price (40%), and quality of print work (39%), according to InfoTrends.

The term solutions is a pet peeve of mine. I prefer the idea of printing salespeople differentiating themselves in the marketplace by conducting effective needs analyses and suggesting real solutions to real problems. I hate the idea of salespeople differentiating themselves with jargon, people are tired of it. Communication is the key to effective selling – starting with describing exactly what you sell.

DAVE FELLMAN is the President of David Fellman & Associates, a graphic arts industry consulting firm based in Cary, North Carolina. He is a popular speaker who has delivered keynotes and seminars at industry events across the United States, Canada, England, Ireland and Australia. He is the author of Sell More Printing (2009) and Listen To The Dinosaur (2010). Visit his website at davefellman.com.

North America’s largest corporations are starting to record sales increases based on environmental purchasing positions and expect buy-in

By Neva Murtha

hen Printing Impressions published its list of the top 50 print customers in North America, Canopy recognized some familiar brands, including many of the 800 companies that have developed paper procurement policies with our team.

WIn fact, 96 percent of these top 50 print customers in North America, according to Canopy, have language or purchasing policies on their Websites that support sustainable paper use. In almost every case, this language goes far beyond simply using paper from certified sources.

Out of the 50 largest print buyers in North America, 48 have set goals or commitments around combinations of the following: reducing and recycling packaging and/or paper, using recycled paper, protecting high conservation value (HCV) forests, protecting high carbon stock (HCS) forests or peat lands, protecting biodiversity and avoiding habitat destruction, reducing their green house gas emissions, and zero deforestation.

This means that companies representing more than $3 trillion in forecasted revenues and $34 billion in printing contracts each year all support sustainability, forest conservation and paper recycling.

It begs the question: Are printers and their suppliers strongly positioned to support these major print buyers in achieving the most responsible paper use?

It is clear when analyzing and compiling these print customers’ growing commitments to sustainable procurement, that a printer simply saying they use certified and legal sources is no longer enough. Customers are increasingly aware and concerned that:

• Legal logging is taking place in certified forests that are by definition ancient and endangered. Many of these same endangered forests do not yet have scientifically driven conservation plans in place;

• Legal and certified logging is taking place in endangered species habitat and

high conservation value forests that also have high carbon values;

• Only some of the forest certification systems address HVCs; and

• Certified or legally sourced paper does not mean it is recycled, which is the most beneficial option for those looking to meet climate KPIs.

North America’s largest print customers are getting more serious about sustainability implementation and transparent reporting – 80 percent have published sustainability reports on their Websites. It is essential for printers to able to address in detail to how they can support these customers to meet their CSR goals. The Blueline Report ranking is the tool that these brands are now using to know which printers support their sustainability objectives.

Companies ranking at the top of the Blueline Report list are taking actions such as avoiding sourcing from contentious forest regions in favour of FSC-certified fibre, and offering chlorine-free recycled papers. The report also profiles a select number of printers that have developed into true supply chain and forest champions. Be it print-giant TC Transcontinental or the progressive EarthColor, an increasing number of printers are engaging their suppliers and government to encourage the completion of precedent-setting conservation plans such as the Great Bear Rainforest Agreements in British Columbia, or undertaking cutting-edge trial runs of newspapers made with agricultural residues.

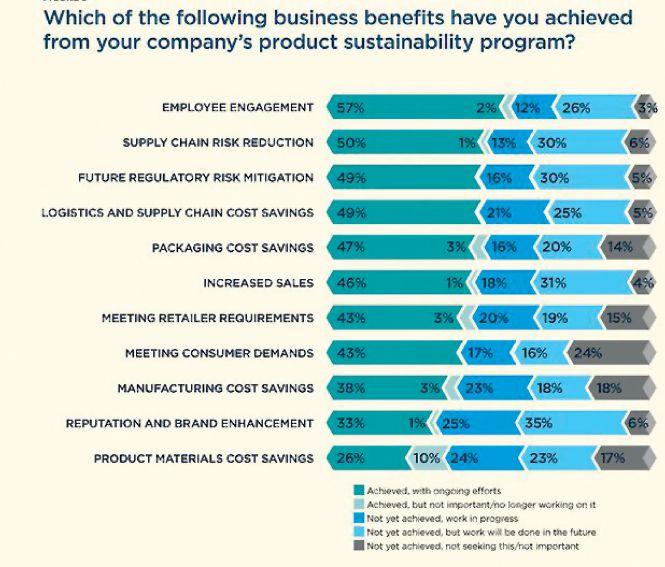

A 2015 report by Pure Strategies, which surveyed sustainability officers at 152 large companies, found that of the companies that had already implemented projects to create more sustainable products, such as by using recycled or non-toxic materials, 27 percent saw $1 million or more in increased sales and 33 percent generated $5 million or more in benefits from taking good care of their employees.

96%

Approximate number of sheetfed offset presses leaving the factory of major press makers that are set up to eventually integrate UV printing technology

There’s no question the industry has come a long way: 25 percent of the top 30 North American printers now have endangered forest commitments in place and are implementing them to stimulate the development of new eco-papers and help drive conservation in the world’s forest hotspots. With this surge in environmental leadership by printers, Canopy also notes a widening gap between top performers and printers that are slow to move. A surprising number of printers still do not have rigorous sourcing policies in place.

Businesses who are making the link between sales and sustainability practice are leaping forward. In February 2016, a 2015 report by consultant firm Pure Strategies, which surveyed sustainability officers at 152 large companies, found that “of companies that had already implemented projects to create more sustainable products, such as by using recycled or non-toxic materials, 27 percent saw $5 million or more in increased sales….”

Your dream customers – North America’s largest print buyers – have publicly posted their commitments to operational sustainability and are raising the bar on these efforts. Are you and your paper suppliers ready and able to meet their needs?

NEVA MURTHA works with Canada’s magazine publishers and printers to develop visionary procurement policies. neva@canopyplanet.org

More than 200 industry leaders, students and family members in November attend an annual awards night to recognize the achievements of dozens of students in Ryerson University’s School of Graphic Communications Management program

By Jon Robinson

The ceremony, which highlighted the program’s close ties to the Canadian printing industry, was held in the Sears Atrium of the George Vari Engineering Building. In addition to several awards donated by a range of companies, GCM students were acknowledged for their achievements through the Canada Printing Industry Scholarship Trust Fund, which provided $59,000 to students across Canada this year – a majority of which are studying at Ryerson.

Business and technological developments, both domestic and international, impact the direction of Canada’s printing industry

By Jon Robinson

The Reserve Bank of New Zealand wins the International Bank Note Society’s 2015 Banknote of the Year Award, based on the country’s new $5 polymer note designed and printed by Ottawa’s Canadian Bank Note Company.

In September, Agfa Graphics wins three Product of the Year Awards at SGIA Expo for the second year straight, including two high-end Jeti systems built in the company’s Mississauga manufacturing facility.

Gaetano Gagliano passes away

In April 2016, Gaetano Gagliano, one of Canadian printing icons as founder of St. Joseph Communications, passes away at age 98. In 2016, the Canadian industry also lost: Rob Ford, former Toronto mayor and Deco Labels VP; Lucien Rolland, Rolland Enterprises’ President from 1952 to 1992; Warren Wilkins, leader of Webcom Limited; Michael Mugavero, CEO of Manroland Sheetfed North America; Al George, McLaren Morris and Todd; Paul Theoret, Battlefield Press in Burlington; John Robinson, former owner of Artcraft Label; and Ross McConnell, founder of Gateway Visual.

systems.

More than 300 people came to the Centre des sciences de Montréal in May to celebrate Quebec’s printing-industry achievements at the 34th annual Gala Gutenberg. Divided into two distinct sections for Innovation and Technical Printing, 19 trophies were awarded, including the inaugural Gutenberg Coup de Coeur presented to Supremex for its project Osez l’effet lifting for Yves Rocher – as voted on by attendees at the gala.

More than 200 people in November attend the 11th annual Canadian Printing Awards gala, continuing networking amongst some of Canada’s leading printers from coast to coast.

HP Inc. in July acquires Samsung Electronics’ printer business in a deal valued at US$1.05 billion, the largest purchase in HP’s history. HP states the acquisition positions it to disrupt and reinvent the US$55 billion copier industry. The deal inlcudes more than 6,500 patents.

Forecasters predict the Canadian dollar would sink below 60 cents US in 2016, which would have eclipsed the all-time low for the loonie (61.79 cents US in January 2002). It fell to 74 cents US in March, opening up export for Canadian printers, who were less inclined to do so relative to past currency corrections.

Rainer Hundsdörfer becomes the CEO of Heidelberger Druckmaschinen AG on November 14, succeeding the departing Gerold Linzbach. Harald Weimer steps down to be replaced by Ulrich Hermann, former CEO of Wolters Kluwer Germany. Stephan Plenz’s management contract is extended for a further three years.

In October, Curwin Friesen steps down as President and CEO of Friesens Corp. in Altona, Manitoba, succeeded by Chad Friesen, who also retains his role as GM of the company’s vital Yearbook Division.

On February 1, The Lowe-Martin Group acquires RP Graphics Group and its 60,000square-foot Mississauga facility (adding 120 employees to Lowe-Martin’s 480).

In April, Veritiv celebrates the ongoing construction of its new 450,000-squarefoot Canadian headquarters in Mississauga – Canada’s sixth largest city with a population of close to 800,000 and home to some 8,300 businesses.The new facility will house around 350 people. In Canada, Veritiv has around 950 employees, 115 tractor-trailer units and 17 warehouses.

Canadian Heritage Minister Mélanie Joly in April begins a digital cultural policy review for future governing of Canada’s $48 billion broadcasting, media and cultural industries. The review will impact national and local newspapers, media funding and subsidies.

In May, Xerox and Ricoh join forces to combat a claimed patent for converting print documents into digital files. Harvey Levenson leads a 2016 campaign to fight patent trolls, which he describes as “a new nemesis impacting print’s growth and employment.”

EFI sets out on a bold plan to become a $1 billion company by the end of the current fiscal year. For the nine months ended September 30, 2016, EFI reports revenue of US$725.4 million, up 16 percent year-overyear compared to US$626.0 million for the same period in 2015.

A massive environmental protection scheme for Canada, completed in February with the aide of Canopy, after 16 years of negotiations, makes 85 percent of the 6.4-million-hectare Great Bear Rainforest off-limits to logging. Home to some 400 Spirit Bears, the territory of the rainforest includes the traditional territory of 28 First Nations and 1,000-year-old Western Red Cedars.

In January, Xerox reveals plans separate into two publicly traded entities, including a new business process outsourcing company, called Conduent, and a Document Technology company, called Xerox Corp. Conduent is said to have the second-largest BPO market share –with services that touch two-thirds of all insured patients in the United States.

A positive drupa 2016 runs for 11 days into early June, featuring 1,837 exhibitors from 54 countries in 19 exhibition halls. The quadrennial had 260,000 visitors from 188 countries – 78 percent foreign.

HP in May signals digital print is making major strides into offset’s century of domination. In 2008, HP had a mid-sized relative to most offset press makers. In 2012, the company occupied half of a hall. In 2016, HP was the largest exhibitor at drupa with its own hall measuring 6,200 square metres.

Ryerson GCM continues as one of the world’s most-successful post-secondary programs relating to printing, experiencing a 20% growth in student applications over the past three years. Some 630 students are enrolled with more than 180 new first year students in the 2016/2017 school year.

As the world’s largest digital press makers build R&D-heavy inkjet systems, slowly migrating to critical lower-cost engines for adoption, RISO leverages a unique position providing the ComColor X1 Series of cutsheet inkjet systems for well under $100,000.

In September, Jones Packaging of London integrates Thin Film OpenSense tags – with a read-rate stated to be 20 times faster than conventional NFC products – into a production line that can apply and read up to 15,000 tags per hour.

Organizers of Print World in November inform exhibitors the tradeshow is cancelled five business days before it was scheduled to begin in Toronto.

Torstar closes print plant In January, Torstar confirmed plans to shutter its printing plant in Vaughan and that Transcontinental Inc. of Montreal will print its Toronto Star daily newspaper for the next five years.

Transcontinental begins

In July, WestRock Co. spends around US$105 million to acquire Cenveo Packaging, including six facilities that generated more than US$190 million.

In August, Supremex of LaSalle purchases Premier Envelope, which generated $12 million last year. This is the second major purchase by Canada’s largest envelope manufacturer.

In January, Navdeep Bains visits the Xerox Research Centre of Canada, where National Research Council of Canada is investing $25 million on a new Advanced Materials Manufacturing Centre.

C.J. Graphics print enhancement

C.J. Graphics’s new 80,000-square-foot facility in Toronto adds North America’s first Scodix Ultra Pro with foiling and a

Canadian-first Highcon Euclid II+ system for short-run finishing. The C.J. Group of Companies now owns three facilities totalling more than 150,000 square feet.

Kruger Packaging in January begins to implement its $250 million investment plan to convert – by 2017 – the No. 10 Newsprint Machine at its Trois-Rivières mill to manufacture 100% recycled lightweight linerboard. Providing $190 million in support, the Government of Québec has 25% ownership in a new company –holding $600 million and assets, as well more than 800 jobs (620 in Québec).

DATA Group, headquartered in Brampton, invests $6.7 million for multiple new Xerox presses, which continue to be installed into January across the company’s nine facilities in Canada and Chicago. The DATA Group has approximately 1,400 employees and generates around $313 million in annual revenue. Later in the year, OTC Group of London purchases three new Xerox iGen 5 presses.

German sheetfed offset press giant Heidelberg in June 2016 introduces the new B1-format Primefire 106 inkjet press, built in co-operation with Fujifilm print heads. The press, holding an industrial Heidelberg paper path, signals a major move in the industry toward the possibilities of inkjet printing in the packaging market.

In mid-2016, HP introduces four new models in its line of T-series PageWide inkjet web presses, noting that these disruptive production systems had surpassed the printing of 180 billion pages since 2009. HP explains customers are now running more than five billion pages per month, up from four billion pages per month in 2015.

At drupa 2012, Benny Landa introduced the printing world to his new concept inkjet presses under the brand Nanography, which jets pigment particles in a water-based inkjet ink. The difference to current inkjet systems is that the water is removed from the ink before the image is transferred to the substrate. At drupa 2016, Landa highlights upcoming beta installations, including Quad/Graphics.

In October, RR Donnelley, which regenerated $11.7 billion (all figures US) in revenue last year, splits into three public companies. BPO player RR Donnelley is the largest entity with $7 billion in sales and 42,000 employees. LSC Communications is a $3.7 billion, 22,000-employee company serving magazine, catalogue and book publishers, and online retailers. Donnelley Financial has 3,500 workers and $1.05 billion in sales.

In May, Rayacom Group of Edmonton purchases assets of Vancouver’s Generation Printing with the intention of launching a 30,000-square-foot trade shop.

St. Joseph Communications acquires Bassett Direct, founded in 1994. Bassett’s prime direct marketing client base can leverage St. Joseph’s annual output of more than 200 million catalogues and magazines, as well as one billion flyers.

Seiko Epson in October begins construction of a PrecisionCore print head factory in Shiojiri, Japan, to open in the first half of the 2018. Launched in late 2010, more than 15 million PrecisionCore units had been sold worldwide as of June 2016.

Ricoh first Copywell of Woodbridge installs two Ricoh presses, including a Pro C9110 and Canada’s first continuous-inkjet Pro VC60000 – able to hit 394 feet per minute.

Adobe reports record quarterly revenue of US$1.38 billion, a year-over-year growth of 25 percent. Leveraging cloud-subscriptions, its Digital Media segment revenue grew by 33% and Creative revenue grew 44%, year-over-year.

Advocate Printing of Nova Scotia acquires most of Transcontinental’s commercial printing assets in Dartmouth.

In November, for the second straight year, The Ellis Group wins the Folding Carton of the Year Award (M&M’s stocking stuffer pack) in the 73rd Paperboard Packaging Council competition. The award helps Ellis stand out amid a surge of newly integrated mill/printing giants.

After moving to acquire toner press maker Xeikon late in Q4 2015, Flint Group begins 2016 with a new Digital Printing Solutions division ready to leverage the new liquid toner Trillium press.

For around US$52.8 million, EFI acquires Optitex, a developer of design software for textile production, targeting fast fashion. Some 100 members of Optitex – with offices in the U.S., Italy, India, Hong Kong and Israel – join EFI.

In January, Holland & Crosby of Mississauga acquires assets of 40-year-old Colormark, a screen-printing operation with its own eco-progressive UV inks. By May, Holland & Crosby moves into a new 71,000-square-foot plant in Mississauga highlighted by two new Inca inkjet flatbed presses purchased through Fujifilm. In addition to installing some of the world’s first Onset X3 and X1 engines, the company adds two massive Esko Kongsbergs for cutting throughput, and its first box-making system to ship display work.

The Xerox Research Centre of Canada (XRCC) hosts one of several roundtables to develop the Canadian Manufacturers & Exporters action plan, called Industrie 2030, to double value-added manufacturing by 2030. The plan will help form Federal policy through the Innovation Agenda under the Minister of Innovation Science and Economic Development.

PaperWorks Industries announces plans to consolidate its Canadian folding carton production into its recently acquired Boehmer Box facility in Kitchener by May 2016. This includes closing its Hamilton plant by July 2016. A year earlier, PaperWorks acquires CanAmPac and Canada’s largest recycled board producer Strathcona Paper, creating an entity that can manufacture 400,000 tons of 100 percent recycled paperboard, annually.

Beginning in January, Komcan Inc. of Georgetown begins a late-2015 partner-

ship to represent Komori America in Eastern Canada, adding to its Ontario and Western provinces distribution.

Newspaper Association of America, to better reflect “the news media industry’s evolution to multi-platform, digitally-savvy businesses,” changes its name to News Media Alliance. The association explains mirroring its membership, approximately 2,000 news organizations, move into digital and mobile formats. For the first time, the association allows digital-first and digital-only news outlets to become members.

Unveiled at drupa, German press maker KBA is working with Xerox to develop a new B1 sheetfed press, called the KBA VariJET 106, aimed at folding-carton. The press combines offset printing and finishing technologies with inkjet systems in a highly modular system that can be tailored for customer requirements.

The Canadian Printing Industries Scholarship Trust Fund provides $59,000 in scholarships to 37 students in print-related programs across Canada.

Fastsigns International of Texas at the start of 2016 had surpassed a 600-franchise-location milestone. Over the preceding 12 months, it signed more than 50 franchise agreements, opened more than 40 units and reached global revenues of US$400 million.

In June, Hume Media of Toronto becomes the first company in the world to buy the new Xerox Brenva HD, one of the first major cutsheet inkjet press lines to sit around the $1 million mark.

Transcontinental divests 13 newspapers properties in markets like Moose Jaw, Prince Albert and Swift Current. The assets are bought by Star News Publishing, including some commercial printing equipment and related book of business in Saskatchewan.

In August, Konica Minolta Business Solutions Canada reaches an agreement

Brad King becomes VP of Xerox Canada’s newly redesigned national graphic communications organization. Prior to his new role, King was Xerox Canada’s VP of Central Operations, responsible for sales and marketing in Greater Toronto and southwestern Ontario.

In February, Mary Ann Yule assumes the role of Managing Director of HP Canada Co., responsible for all aspects of HP operations in Canada, succeeding the distinguished career of Lloyd Bryant.

Canada.

The Printing House hits its stride in 2016 with a prominent campaign to produce 3D figurines across its storefront network. In the west end of Toronto, Objex Unlimited develops innovative scanning booths that help its new storefront shop sell about 300 3D figurines per month in the summer of 2016.

Steve Cory, President of Objex Unlimited.

to distribute the print and finishing product lines of MGI Digital. The companies have several existing global partnerships, working together for nearly two decades.

MGI’s 3D print system at drupa.

Highcon and Scodix, Israeli-based startups, set up North American offices in 2016. Highcon holds the potential to disrupt finishing with its short-run polymer application and Scodix brings industry-unique print enhancement systems.

Veritiv continues to unite printers and designers across Canada with its uVU awards program. Vancouver’s MET Fine Printers wins 2016 Best of Show, Print, and the Award of Excellence for both design and print goes to a project produced by Laval’s Imprimerie l’Empreinte.

In early 2016, Pantone, a subsidiary of X-Rite, unveils its 2016 Color of the Year, which, for the first time, includes the blending of two shades, Serenity and Rose Quartz.

In June, Jeff Ekstein is elected as Chair of the Canadian Printing Industries Scholarship Trust Fund (CPISTF), which was initiated in 1971 and has since provided over a million dollars in funding to printing-industry students.

Jeff Ekstein, President of WIllow Printing.

Rose Quartz (PANTONE 13-1520) is a gentle tone conveying compassion.

After announcing it was in talks to sell Prosper, Kodak in May unveils a new Ultrastream platform (8-inch configuration for labels), built on the same continuous inkjet Stream technology. Ultrastream is scheduled for a 2017 launch.

Paragraph Inc., specializing in print and digital communications, acquires commercial printer Kayjon located in the same region of Saint-Laurent, bringing together 175 employees and sales targets of $26 million.

EFI unveils Nozomi

At drupa, putting an exclamation mark

on the push for inkjet-based packaging presses, EFI introduces the LED-based Nozomi C18000 that will target speeds of up to 75 linear metres (246 linear feet) per minute,

British Columbia Institute of Technology continues to grow its Graphic Communications program with a range of new initiatives, including a $3 million large-format centre for the full 2016/2017 year.

Despite an earlier decision made in 2015 to hold the world’s largest exhibition for the printing and imaging industry once every three years, drupa organizers Messe Düsseldorf in June 2016 return to a fouryear cycle – targeting 2020.

In September, Mimaki opens its first Canadian branch in Toronto, led Lucas Crossley. With a 11,000-square-foot demo centre, it is Mimaki’s seventh such North American facility for training and wide-format-imaging demonstrations.

Postmedia Network in March announces plans to close its London Free Press printing plant, after signing a deal with Metroland Media Group, owned Torstar, to print the London newspaper in Hamilton.

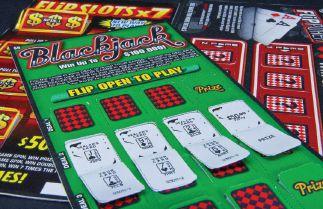

Pollard Banknote of Winnipeg in late March signs a three-year extension for printing instant tickets with Danske Lotteri Spil A/S, Denmark’s national lottery. The deal highlights Pollard’s position as a lottery partner to more than 50 lotteries worldwide, now leveraging its proprietary Scratch FX products.

In January, Ricoh of Tokyo buys U.S.based AnaJet, which develops direct to garment printing systems. Founded in 2006, AnaJet was one of the first companies in the world to mass-produce digital garment printers.

Toronto Club of Printing House Craftsmen provides funds for secondary and post-secondary students in a 41-year-old program, now called the Tai Chi Awards.

Toronto’s Prinova, which develops Customer Communications Management software, ranks No. 347 on the l PROFIT 500, buoyed by its fiveyear revenue growth of 148 percent.

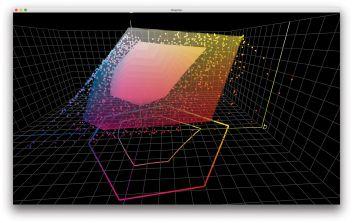

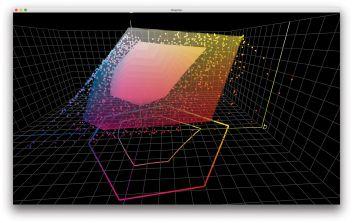

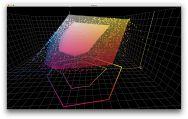

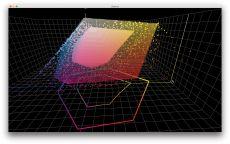

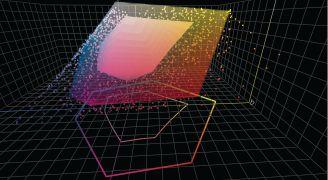

Extended gamut printing in mid-2016 is integrated into the print-software of many technology developers for packaging and commercial printing. In lieu of spot colours, extended gamut uses CMYK plus OGV to cover up to 95 percent of Pantone’s colour library.

Extended gamut does not rely on specials.

The 21st edition of the EPPY Awards, hosted by Editor & Publisher, celebrates the innovative of news Websites across 31 categories. From more than 300 international entries, The Globe and Mail (3) and Brandon Sun (1) receive top honours.

In July, The Burke Group of Edmonton becomes the first Canadian operation to sign a letter of intent for an Impremia NS40 press – built on a Komori platform with Landa Nanography inkjet imaging.

In June, PDI Group of Kirkland, Quebec, merges its subsidiary Trans-Optique with both Imagerie DB Inc. and LVP.ca Inc. to create one of the region’s most significant large-format inkjet operations, powered by years of offset and toner printing.

Ottawa’s Canadian Bank Note in 2015 acquired Unicom Graphics of Calgary, integrating the commercial printer into its McAra Printing facility, also of Calgary. This November, McAra Unicom rebrands as CBN Commercial Solutions.

In July, Allegra Network LLC commits to Avanti Slingshot as the new core of WorkStream, an online-storefront-to-MIS workflow used by its North American base of 270 franchises. The deal helps solidify Toronto’s Avanti as an MIS power.

Canada Post and the Canadian Union of Postal Workers on August 30 reach tentative short-term agreements via a Federally appointed mediator. The two-year agreements, as opposed to typical fouryear contracts, avert a work disruption heading into the holiday shipping season.

In July, Cober, one of North America’s most-innovative printing and media services companies, celebrates its 100-year anniversary at its facility in Kitchener.

RyeTAGA, a Ryerson GCM student chapter, wins the Helmut Kipphan Cup for the third consecutive year in March. The Kipphan Cup is TAGA’s top prize for the best student-produced journal –based on its printing, design and research content.

Heidelberg in May 2016 unveils its new Push to Stop printing philosophy to develop manufacturing automation – beyond CIM developments of the 2000s. Rather than having a press operator push a button to active jobs, instead they would only push a button to stop the press after running jobs queued up by Prinect.

In September, Delphax Technologies reaches an agreement with Weihai Printing Machinery to provide the Delphax elan 500 inkjet press in the Chinese printing market. The seven-year agreement aims to yield more than 35 systems, sold under Weifeng EL500 branding.

Asia Pulp & Paper, celebrates the threeyear anniversary of its Forest Conservation Policy, as part of a massive environmental overhaul. In February, the company launches the Belantara Foundation to further fund conservation projects in Indonesia.

North American industry associations

Idealliance and Epicomm merge to create an entity that addresses both management and technology issues. Idealliance has more than 3,000 members.

Advertek Printing buys Smart Laser Graphics to expand its capabilities primarily around wide format and digital, as well as direct mail and letter shop. In 2010, Advertek opened a new 30,000-square-foot plant in Vaughan.

A new four-point plan might save the USPS US$32 billion through fiscal 2020.

A draft bill is introduced in 2016 to move the USPS forward, as it faces US$125 billion in unfunded payment obligations.

Cansel buys PMP Media to expand its presence in Quebec. Founded in 2014, Cansel has quickly become one of Canada’s largest providers of wide format imaging technologies.

bution

KBR Graphics, which is celebrating its 40th year in business in 2016, expands its distribution of RMGT sheetfed offset presses to include all of Canada. In midJuly 2016, KBR moved its primary operation

to a new facility in Laval to support larger sales and tech service teams. KBR has distributed RMGT technologies in Canada’s Central and Eastern regions since 2012.

In November, Alliance Franchise Brands of Michigan buys the KKP Canada. The deal adds 50 franchises to Alliance’s portfolio, which holds more than 600 locations in North America and the UK.

Sun Chemical of New Jersey buys certain assets and liabilities of Toronto’s Colmar Inks (founded in 1984), a manufacturer of inks for corrugated and paper packaging.

The Globe and Mail in late-2016 prepares to move into its new downtown Toronto headquarters with a 15-year lease. The Globe will be housed on the top five floors of the 17-storey office tower called The Globe and Mail Centre.

In July, Swiss Pack of Burlington installs Canada’s first HP Indigo 20000 press, targeting short-run flexible packaging and labels. Swiss Pack specializes in customized and three-sided pouches.

In early 2016, HP, in co-development KBA, unveiled the HP PageWide Web Press T1100S with a 2.8-metre (110-inch) width and Multi-lane Print Architecture. Aimed at printing corrugated board, MLPA allows different box sizes and run lengths to be printed in individual lanes.

With a $500,000 state grant, Rochester Institute of Technology opens its 3,200-square-foot Additive Manufacturing and Multifunctional Printing Center.

Harmony Printing of Toronto enters receivership and longtime printing industry leader Don Gain, owner of Harmony, retires. Gain also completes his 11-year role as Chair of the Canadian Printing Industries Scholarship Trust Fund.

In March, digital textile printing hit the mainstream in North American fashion circles as Sophie Grégoire Trudeau visits Washington, D.C., with a dress made with digitally printed fabric produced by Mississauga’s Emerson Group.

gain attention in Washington.

The High Deposition (HD) source in the Bobst K5 Expert has an improved design for higher speed of operation for those metallization jobs that require a high deposition rate of up to 4.0 OD.

1x Mitsubishi 40” 10 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Tandem with AQ

1x Mitsubishi 40” 8 Colour Perfector with AQ

3x Mitsubishi 40” 6 Colour with AQ

2x Heidelberg Printmasters

3x Saddle Stitchers / 1 Perfect Binder / 10+ MBO Folders

Over 75,000 sq ft plant housing state-of-the-art nishing and bindery

Personalized account management and complete control over production

24/7 Production with fully automated and barcode controlled plant

FSC / PEFC / SFI certi ed

Introduced in November, the Bobst K5 EXPERT, successor to its K5000 metallizer, can run at speeds up to 1,200 metres per minutes and is available in widths from 2,450 to 3,650 mm. It can house increased roll diameters of up to 1,270 mm to meet new industry trends. The vacuum metallization system, aimed at the packaging industry, houses what Bobst describes as the largest coating drum in the industry at 700 mm, which improves collection efficiency by 16 percent. The K5 EXPERT features a redesigned evaporation source to increase the coating window, which Bobst states to be up to 50 percent wider than some competitors’ systems.This larger window translates in better coating uniformity and collection efficiency, minimizing aluminum wire waste.

In November, Heidelberger Druckmaschinen AG began offering an optional neon yellow spot colour for its Versafire CV printing system. The toner glows under UV light and the effect can also be used as a security feature, because the toner is near impossible to copy. Heidelberg explains this makes it especially interesting for printing admission tickets or wristbands, for example, and other applications in the event industry that only light up under UV light.

In total, three additional toners

can now be used with the Versafire CV in addition to CMYK: white, varnish, and neon yellow. To apply the toner, operators need an additional developer unit, while leveraging the Prinect Digital Frontend developed by Heidelberg and colour tools from its PDF toolbox.The new toner application can be retrofitted to all Versafire CV and Linoprint CV systems already in the market.

In October, Canon Canada launched the imagePRESS C850 and C750 production presses with a range of new features aimed at commercial printers, in-plant operations, franchise printers and other print service providers. The imagePRESS C850 Series is the successor to the imagePRESS C800 Series. The imagePRESS C850 Series is designed to provide offset-like image quality through Canon’s Gloss Optimization technology, enabling users to match the gloss of the toner image to that of the media used. The system also includes a 32-beam R-VCSEL red laser to help produce crisp and clear images efficiently at 2,400 x 2,400 dpi.With a number of screen patterns to choose from, the press now offers a new 190 lpi (lines per inch) dot screen for increased output flexibility. The system includes Canon’s CV Toner and an Advanced Image Transfer Belt to run a variety of media, including textured stocks.

The new toner application can be retrofitted to all Versafire CV and Linoprint CV systems

The imagePRESS C850 and C750 devices operate at print speeds of up to 85 and 75 letter-sized pages per minute, respectively, in colour and black-and-white. The presses deploy paper feeding with air separation and double sheet detection intended to reduce paper jams. Canon explains consistent colour and precise registration are achieved by the Compact Registration Module. A new option is the Booklet Trimmer-F1, which can help save time with a larger trim waste bin and continuous run capability with onthe-fly trim waste removal.

In November, Sydney Stone, which specializes in distributing and servicing short-run finishing systems, introduced two new Morgana products to the Canadian marketplace. As Morgana’s distribution partner for the country, Sydney Stone is launching Morgana’s next generation DigiFold Pro 385 and AutoCreaser Pro 385 systems.

One of the key changes from previous DigiFold models, explains Sydney Stone, is the introduction of a high-capacity vacuum top-feeder that can take a sheet pile of over 17.7 inches. The company continues to explain after the size and thickness of stock are entered, all other feeder functions including air and vacuum settings, side guide positions, and fold roller gaps are automatically adjusted for easy setup of jobs. Stock of up to 0.4mm can be creased and folded with virtually no cracking of the sheets or the toner on them. Another new feature is the dual creasing blades, the Morgana DynaCrease, for creasing and folding applications at over 6,000 sheets per hour, and one for “creasing only mode,” allowing for a range of applications to be produced on one machine. The AutoCreaser is still

Morgana’s best-selling machine and he expects further adoption with the new Pro 385 aimed at higher volume applications as a heavier duty machine.

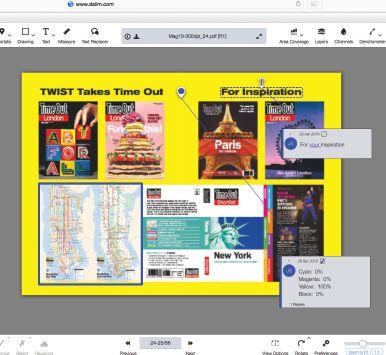

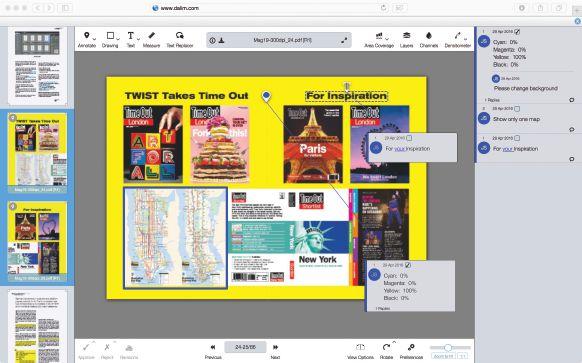

In October, DALIM SOFTWARE released DALIM ES 5, which is digital asset and production tracking software for project management and collaboration. The company explains the software serves all participants of the production cycle, including brand owners, content creators, agencies, publishers, premedia, printers and multichannel service providers.The fifth edition of DALIM ES (enterprise solution) is aimed at a range of final output, including print, packaging, large format, web, e-book, and video, among others.

For the new DALIM ES 5, the company worked with Silicon Publishing to offer its plug-in for integration of DALIM ES 5 with Adobe Creative Cloud, offering digital rights management and check incheck out file sharing capability. This feature allows Adobe Creative Cloud users direct access to content within DALIM ES, along with metadata capture. As a result, users can work from within any of the Adobe Creative Suite applications to access content from DALIM ES and then move forward within DALIM ES to prepare the content for print, Web, or other media forms.

The DALIM ES DAM features can also automatically catalogue, enrich and share 3D augmented reality models. A new link to CHILI Publisher Link lets the operator edit a document directly inside ES. When a document is selected, CHILI Publisher is automatically launched and the document can be remotely edited. DALIM ES also has open connections to extensive

2. SUPERIOR TECHNOLOGY — Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS — Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4. SAVE ON POSTAGE COSTS

—As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5. RETURN MAIL PRODUCTS — Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS — Saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT — High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

content libraries such as IDSPictureDesk and Getty Images, sharing metadata. Images can be selected and published to DALIM ES for use in work in process.

Kodak CTP Z-speed

Kodak, during October’s WANIFRA World Publishing Expo in Vienna, introduced enhancements to its thermal CTP portfolio for newspaper. Kodak highlighted a 16 percent laser power improvement for both its Generation News and the Trendsetter News platesetters, allowing newspaper printers to image more plates in a shorter time. Based on the additional laser power, the throughput of the Generation News Platesetter Z-speed version has increased from 258 to 277 Sonora News Process Free Plates per hour. The Trendsetter News Platesetter V-speed version is up from 116 to 129 plates. Kodak intends to make this enhancement commercially available as a standard feature in the first quarter of 2017.

The new speed imaging technology branded by Kodak as “W speed” is another optional addition to the Trendsetter News Platesetter. When used together with the Sonora News Process Free Plate and the Autoloader option, it boosts the throughput of the Trendsetter News Platesetter from 150 to 240 plates per hour, or in the configuration with the Single-Cassette Unit (SCU) from 116 to 150 plates. Kodak also provides integration into existing plate lines with optional single or dual plate rotation. The new W-speed option will be released in Q2 2017.

In October, Roland DGA launched the METAZA MPX-95 photo impact printer, as well as an optional Gift Kit, for personalizing metallic and plastic items with photos, logos, names, messages and other decorations. With its diamond stylus and powerful impact force, the MPX-95 can imprint on metals such as stainless steel, iron, titanium, platinum, gold, silver, copper, nickel and aluminum, as well as plastics, quickly and with pinpoint accuracy. Possibilities include personalized pens, smart devices, jewelry and pendants, trophies and awards, watches and belt buckles.

The Roland MPX-95 photo impact printer base unit has an MSRP of $4,995, while the optional Gift Kit is priced at $1,395 (MSRP).

blers. It comes standard with METAZA Studio software and a built-in laser pointer that assists in identifying the area to be marked, making it easy for users to imprint items without any special training. The Gift Kit includes a fully-adjustable center vise with clamp pins that holds irregular-shaped items for repeat personalization, plus a standard center vise that enables imprinting onto different items in quick succession.

In November, Xaar plc launched the Xaar 502 product family of greyscale piezoelectric drop-on-demand print heads designed for a wide variety of applications. The first release from this print head family is the Xaar 502 GS15 O optimized for Coding and Marking applications.

The MPX-95 and Gift Kit were developed primarily for kiosks, gift shops, jewelry store and other outlets selling products on-demand. Incorporating a removable base table and plate, the MPX-95 is capable of working with larger items like golf club heads, vases and tum-

The Xaar 502 GS15 O print head meets the needs of manufacturers developing machines to print high quality late-stage product identification such as text, product data, bar codes and graphics onto secondary packaging or directly onto shaped products and primary packaging. This print head launch, which demonstrates Xaar’s commitment to coding and marking, delivers a step change in product identification technology by combining binary and greyscale capabilities in one wide-swathe (70.5mm) print head to give users the ultimate in flexibility. With the ability to print drop sizes from 15-75 pL the print head can print up to 6 grey levels for high-resolution, intense blacks on low contrast surfaces such as cardboard outer boxes. The Xaar 502 GS15 0 delivers sharp, dense black text as well as fine text, quality graphics and smooth images on porous or semi-porous outer packaging and cardboard.

In November, Propago, a cloudbased Marketing Asset Management software firm headquartered in Austin,Texas, released native cXML PunchOut support for eProcurement connection capabilities. The cXML PunchOut protocol, explains the company, is the most commonly used method of connecting a procurement application to a supplier’s Web-based shopping cart.

The Propago platform’s support for cXML enables trusted supply chain partners (commercial printers, promotional, and apparel companies) to leverage Propago’s marketing asset management platform through a company’s eProcurement system, such as Ariba, Verian, Coupa, SAP, and Oracle. End users can utilize Propago’s personalization engine, browse the full marketing catalogue and order while remaining in compliance with enterprise procurement processes.

Propago was started within a large commercial printing conglomerate as an internal application to serve clients and support backend operations for those clients. In 2015, the team responsible for building and maintaining the Propago platform was given the opportunity to spin the technology away from the parent company and form a completely stand-alone organization.