For over 60 years, Williamson Printing Materials has been the trusted industry leader, providing a single source for best-in-class products, services and support to the Canadian Packaging industry.

As the industry’s only 100% Canadian owned, managed and staffed company dedicated to Flexo, we have Canada’s largest and most recognized national team of technical Flexo experts in Sales, Service & Support. We are close, available and dedicated to help improve your efficiency, performance and competitiveness.

labels of Innovation

Forty companies driving one of printing’s most-dynamic sectors share their booth highlights for Chicago’s upcoming Labelexpo Americas exhibition 12

Technology Report

Heidelberg unveils VLF speed boost, Drytac, IP and NewPage launch new substrates, and next-generation presses from Canon, Kodak and Konica Minolta 17

5

Remembering industry analyst Charlie Corr, Heidelberg holds 100 percent of shares in Gallus, and H.I.G. Capital purchases Cascades Fine Papers

6

Kodak Canada hosts Sonora XP Road Show in Toronto, Canon breaks new ground in Brampton, and Howard Iron Works finds an 1886 Potter newspaper press

8

CAlENdAR

Graphics Canada prepares for 2015 springtime, Sustainable Forestry Initiative arrives in Montreal, and Xplor educates in Western Canada

ZAC BolAN life Without Photoshop

Amidst a wave of open-source image editors, a couple of matured Photoshop challengers become significant contenders in the pixel-pushing arena

22

August 1999

Who Wants To Be a Millionaire premieres, Boris Yeltsin fires his cabinet for the fourth time, and Gutenberg’s printing of the Bible is named Top Event of Millennium

• Pearlescent

• Textured Uncoated

• Fine Art Cover

• Colour Cover

• Starlight Photo Lustre Cover

CareerCast, an online employment Website, recently ranked the Top 10 Endangered Jobs of 2014 (listed below), based on statistics produced by the United States Bureau of Labor. Three of these jobs directly relate to the printing industry, including: 1. Mail Carrier, 4. Newspaper Reporter, and 9. Printing Worker.

This forecast – projecting job growth to 2022 – will not come as a shock to most in the printing industry, as CareerCast points out in a common refrain heard over the past decade: “The job landscape is bustling with new opportunities in the information technology sector, but the proliferation of these distinctly 21st century jobs comes at the expense of other industries.”

• Polyester Specialty Fine Papers

• Silver Mirri® Board

Pressure Sensitive Films

• Flex Vinyl

• Permanent Block-out

• Window Cling Vinyl

• ClingZ® Vinyl Magnetic Substrates

• Synthetic

• Ultra Green Film®

• Styrene

• Rigid Vinyl

• Teslin®

Pre-Converted Substrates

• Ultra Digital®

• FlexBind® Layflat Pages

• Mazina® Specialty

• Book Finishing Papers

• Specialty Application Substrates Non-Adhesive Films

• DigiMag® XTRA Flex Magnetic Material by Magnum Magnetics

It is hard for industry outsiders – and particularly with antiquated Bureau of Labor job definitions – to comprehend the amount of information technology being applied within the printing industry. The true job boundaries of a newspaper reporter today are certainly not drawn by a printing press. It is equally hard for those in the printing industry to understand what it means to simply be a printing worker.

Given that CareerCast’s report is based on U.S. Bureau of Labor statistics, it is also understandable why mail carrier, with an expected decline of 28 percent by 2022, finished number 200 out of 200 careers examined. Mail delivery certainly faces a range of challenges, but the USPS in particular, one of the world’s largest employers, is collapsing under its own weight. Its annual net losses over the past five years have been $3.8 billion (2009), $8.5 billion (2010), $5.0 billion (2011), $15.9 billion (2012) and $5.0 billion (2013). USPS career employee totals have decreased from 704,485 in 2004 to today’s count of 489,727.

Too often manufacturing is an afterthought when projecting the future, which plunged the U.S. into its long-lasting trade deficit. In filing a report about CareerCast’s Top 10 Endangered Jobs, Fast Company projected 8 New Jobs People Will Have in 2025, including: Digital death manager, un-schooling counsellor, armchair explorer, 3D printing handyman, microbial balancer, corporate disorganizer, digital detox specialist, and the urban shepherd. It is hard to envision how the new generation of IT-savvy printers will not play as significant of a role as any of these future workers.

Jon Robinson, Editor

Canada’s Graphic Communications

Editor Jon Robinson • 905.713.4302 • jrobinson@annexweb.com

Contributing Writers Zac Bolan, Peter Ebner, Chris Fraser, Victoria Gaitskell, Dr. Martin Habekost, Nick Howard, Thad McIlroy, Nicole Rycroft, Dr. Abhay Sharma, Trish Witkowski

Publisher Sara Young • 905.726.5444 • syoung@annexweb.com

Associate Publisher Stephen Longmire • 905.713.4300 • slongmire@annexweb.com

Group Publisher Paul Grossinger • 905.713.4387 • pgrossinger@annexweb.com

Advertising Sales Sara Young • 905.726.5444 • syoung@annexweb.com Stephen Longmire • 905.713.4300 • slongmire@annexweb.com

Art Director Clive Chan • 905.713.4301 • cchan@annexweb.com

Circulation Nicole Cuerrier • 866.790.6070 • ncuerrier@annexweb.com

Heidelberger druckmascHinen, led by CEO Gerold Linzbach, now holds 100 percent of shares in Gallus Holding AG, a Swiss manufacturer of equipment in the packaging industry for labels and folding carton. The full acquisition was made possible when Ferdinand Rüesch AG, also of Switzerland, used its existing 70 percent stake in Gallus as a contribution-in-kind investment into Heidelberg. Ferdinand Rüesch acquired around nine percent of Heidelberg’s shares, with the requirement of holding these shares until July 31, 2015. This Fall, Heidelberg and Gallus plan to unveil a new printing system using Fujifilm technology for the label market. In 2013, Gallus generated approximately $225 million with 500 employees.

landa corporation, led by Chairman and CEO Benny Landa, received a € 100 million investment from ALTANA Group of Wesel, Germany. ALTANA – with divisions BYK Additives & Instruments, ECKART Effect Pigments, and ACTEGA Coatings & Sealants – employs more than 5,700 people and 46 production facilities, which generated sales of € 1.8 billion in 2013. Landa of Rehovot, Israel, is in the process of developing what it terms as Nanographic Printing Presses.

H.i.g. capital of Miami purchased Cascades Fine Papers Group, owned by Cascades Inc. The resulting company, which includes investment from the current Cascades management team, is to be re-named Rolland Enterprises, resembling a prior identity for the historic paper maker headquartered at its mill in Saint-Jérôme, Quebec. Philip Rundle joins Cascades as CEO, bringing pulpand-paper experience as former CEO of North American Operations for Mercury Paper/Oasis Brands and a past VP with Kimberly Clark. Key executives staying on with Rolland include Pierre Guay, Richard Laramée, Marc Charbonneau, Normand Champagne and Guy Beaudin. Founded in 1993, H.I.G. is a private equity investment firm with more than 80 companies in its portfolio and $15 billion of equity capital under management.

cascades inc on October 3 is to cease its Kraft paper manufacturing activities in East Angus, Quebec. The company points to unfavorable market conditions, including new competitors that can convert newsprint paper machines to produce Kraft paper, and the failure of discussions concerning the plant’s transfer and turnaround. Close to 175 employees will be affected by the closure, which is another step in the company’s complete withdrawal from the Kraft paper sector. This news does not concern Cascades’ coated boxboard manufacturing plant also located in East Angus.

cHarlie corr, a highly respected printing industry analyst, passed away last month after a long illness. At the time of his death, Corr was the Group Director for InfoTrends Enterprise Document Strategy Services, a role he had taken on in May 2013 after nearly six years at Mimeo.com, where he served as Vice President of Corporate Strategy. His association with InfoTrends began in April of 1998 when Corr joined then CAP Ventures as a Senior Consultant. He came to InfoTrends/CAP Ventures from Harvard University where he was the Associate Director of Operations for Harvard’s Printing & Publication Services. During his time at Harvard, Corr also taught print, paper, and related courses at Northeastern University.

Jay mandarino, President and CEO of the C.J. Group of Companies of Toronto, lead the acquisition of Artwords Inc., which specializes in services for the retail sector. Artwords was established in 1984 as a typesetting and assembly studio. Today, the company provides graphic production, proofreading, short-run printing, large-format printing, installation, kitting and packaging, as well as logistics and distribution services. Dino Narsai is to remain as President of Artwords, which provides C.J. Graphics with a central Toronto location.

multicam, a CNC cutting equipment manufacturer, was acquired by Rosewood Private Investments, a familycontrolled equity firm. With more than 60 technology centres worldwide, MultiCam develops products like routing, knife, plasma, water-jet and laser CNC cutting systems. Rosewood of Dallas, Texas, is responsible for investing the capital of a single high-networth family. MultiCam is led by President and CEO, Kris Hanchette.

Jim colter, Chairman of Colter & Peterson, retired from the U.S.-based distribution company after a career that began in 1955. Upon completing high school, Colter began working for his father’s company, Roy Colter Cutting Services. While active in the business, Colter primarily focused on the parts and service end of Colter & Peterson (C&P), which was formed in a 1991 through a merger with distributor Bruce Peterson. With the later addition of Jeff Marr, Eric Peterson and Donald Shields, they built C&P into one of North America’s largest independent distributors of paper finishing equipment. Manufacturer of the Microcut line of retrofit back-gauge controllers, C&P today has around 50 employees.

brian ellis becomes Executive Director of the Canadian Printing Industries Association (CPIA), a national organization focused on the advancement of the prepress, press and bindery sectors. Since mid-2010, Ellis has served as President of his own communications business called Lucidity Marketing Inc. in Toronto, Ontario, which included a contract marketing position with Fujifilm Canada. Ellis previously spent 15 years with Heidelberg Canada Graphic Equipment Limited, which included close to seven years as a Product Manager for the press maker’s Printmaster product line, followed by marketing roles until mid-2010.

canadian printing equipment (CPE), headquartered in Winnipeg, becomes a distributor for Israel-based Highcon’s Euclid cutting and creasing equipment – with reverse-scoring capability. CPE was one of five recently named Euclid distributors, including A to Z Graphic Solutions in Israel, Castiel Group in Mexico, Matset in Turkey, MGraf in Italy and Monotech in India. Highcon reports clients have pushed the parameters of the Euclid system with N-flute and 10-point substrates, as well as metallic coated board. The company also points to Euclid’s growth with self-adhesive labels and stickers applications.

grimco inc of St. Louis, Missouri, acquires the Canadian operations of Proveer Sign and Graphics, a distributor of supplies and equipment with five locations across the country. Grimco previously purchased the United States-based operations of Proveer Sign and Graphics in May 2012. Grimco currently has 40 locations in the United States. In Canada, Grimco adds locations in Toronto, ON, Montreal, QC, Dartmouth, NS, Calgary, AB, and Vancouver, BC. Michael Bolinger from Grimco is to lead the merger process as the Vice-President of Canadian Operations.

Jeffrey beck becomes President and Chief Executive Officer of Presstek, succeeding David Savage who recently left to lead WaterJet Holdings Inc., which is another company held by Presstek’s owner, American Industrial Partners (AIP). Prior to joining Presstek, Beck served as COO for iRobot Corporation and earlier as President, Home Robots Division. He also served at AMETEK Corporation as VP and GM of the Aerospace and Defense Division, and earlier with the Power Systems and Instruments Division. AIP purchased Presstek in 2012. Beck also serves on the boards of Sun Edison Semiconductor and Fiber Optic Components, as well as on the advisory board of The New Jersey Institute of Technology’s Engineering College. r r donnelley, in partnership with Vancouver’s not-for-profit Canopy organization, has published new sustainable purchasing principles for its paper supply. “This latest development from R.R. Donnelley signals a course change for the entire North American printing sector and augers well for the future of our threatened forests,” stated Nicole Rycroft, Canopy’s Executive Director. RR Donnelley is one of the world’s largest printing operations with sales revenue of US$10.4 billion in 2013 and more than 300 global facilities.

Tel:905.238.1307

Fax:905.238.0589

E-mail:files@tradeimpressions.com quotes@tradeimpressions.com www.tradeimpressions.com

Kodak Graphic Communications Canada in mid-June spent an afternoon at the Rogers Centre in Toronto to highlight its Sonora XP technology, described as a true process-free plate with stability approaching conventional plate technology.

“It is our second-generation process-free plate, our first being Thermal Direct. We did have success with Thermal Direct, but it had limitations and we have eliminated almost all of those barriers,” says Greg Running, National Sales Manager, Kodak Graphic Communications Canada. “[Sonora XP] is now what I would call a conventional process-free offset plate, meaning it is not just for narrow applications.”

Released in Canada a little more than a year ago, Running explains Sonora XP is engineered to run in a range of press environments, from web to sheetfed offset, UV to regular inks, long and short runs. There is also a Sonora NEWS version for use on newspaper presses, only differentiated by plate size and packaging. More than 50 printing operations in Canada are now using Sonora XP plates.

“Sonora XP is the most stable plate on the market today,” says Todd Bigger, Kodak’s Worldwide Product Management Director for Graphics, during the Toronto road show, which reached five cities in four weeks, also including Boston, Chicago, Los Angeles and Miami.

Running notes Kodak’s long history in material sciences – applying coatings to substrates – as a key reason for Sonora XP’s wide range of use, as well as its environmentally progressive technology.

“It is the science behind the emulsion on the plate that allows you to go direct from CTP to on press, and there is zero contamination on press – that is important,” he explains. “A lot of people think, ‘Well it must contaminate the press.’ The regular gum on a traditional plate [contaminates] a press exponentially more than anything that Sonora XP would do, so it is a very unique plate that way.”

The non-ablative, thermal, negative-working Sonora XP plate, Kodak explains, can be imaged without processing chemistry and equipment. With a quality rating of 1-99% @ 200 lpi, the plate –when combined with the proper hardware and software – allows printers to produce FM 20 stochastic work.

Sonora XP is rated to run up to 200,000 impressions with heatset/commercial coldset web presses, 100,000 impressions with sheetfed presses, 50,000 impressions for offset packaging (non UV), and up to 10,000 impressions for UV-ink applications. “Everyone thinks there is nothing exciting happening in plates, but Sonora XP has changed that,” says Running. “We have seen a tremendous response from the industry worldwide.”

More than 70 people attended the Toronto stop of Kodak’s Sonora XP Plate road show on June 10. Peter Cober, President of Cober Evolving Solutions in Kitchener, Ontario, spoke about his company’s shift to Sonora XP plates. Following the program, customers joined Kodak and Spicers Canada for the Blue Jays game – a 4-0 loss to the Minnesota Twins.

PrintAction magazine signs on to produce the Show Guide for the upcoming Graphics Canada trade show running from April 16 to 18, 2015, at the International Centre in Mississauga, Ontario.

“Major suppliers and the industry have reacted with much support and enthusiasm to Graphics Canada’s new dates,” says Dan Mustata, Show Manager of Graphics Canada, which traditionally took place in late-fall every two years.

“PrintAction’s team is looking forward to publishing a top-quality Graphics Canada Show Guide,” says Sara Young, Publisher of PrintAction. “The new dates give exhibitors the opportunity to sell equipment and services in the 2015 calendar year.”

Planned pavilions and sections currently include the Sign & Wide Format Showcase, PacPrint Canada, Design Zone, Cross Media Canada Conference, Printing Sales Training Days, and the Paper & Ink Pavilion.

The team of Steve Thompson, Kevin Rice, Glen Kimber and Mike Bell from Heidelberg Canada posted the lowest overall score to take first place at the annual IAPHC Toronto Craftsmen golf tournament. Proceeds from the event, held this year at Wooden Sticks in Uxbridge on June 25, are used to support the organization’s annual scholarship awards.

Last year, 12 students developing a career in graphic communications at secondary and post-secondary schools received funding via the Toronto Craftsmen. This included eight students with the highest grade point averages in their respective programs, who received the Chai Tse Award named after a Ryerson student who passed away nearly 10 years ago. The IAPHC Toronto organization is celebrating its 40th annual awards program this coming year.

Japan’s Ambassador to Canada, the Consul-General of Japan and Brampton’s Mayor joined Canon Canada executives in a groundbreaking ceremony for a new five-story Canon headquarters to be built by December 2015.

“Our vision for Canon Canada’s headquarters goes beyond being an infrastructure investment or a building where our employees work,” stated Ted Egawa, President and CEO, Canon Canada Inc. “We want our new headquarters to become a community for our employees and for our customers, which aligns with our Kyosei philosophy, which means harmoniously living and working together for the common good.”

To be built on more than 18 acres at the corner of Mississauga Road and Steeles Avenue West in Brampton, Ontario, the new 180,000-square-foot headquarters will replace the company’s current office in Mississauga, which has been its home since 1984. Design of the Brampton facility is being led by the architectural firm of Moriyama & Teshima, which created the Ontario Science Centre in Toronto and The Canadian War Museum in Ottawa.

Canon aims to achieve Gold certifi-

cation under the Leadership in Energy and Environmental Design (LEED) rating system. Sustainable design elements planned include: The incorporation of lots of natural light, energy-efficient equipment and collecting rainwater for reuse.

The Province of Ontario has designated Brampton as an urban growth area; by 2031 the city’s population is expected to grow to 725,000. Canon joins a list of high-profile organizations to build corporate infrastructure in Brampton, such as Loblaw Companies, HBC, Chrysler Canada, Rogers Communications, Maple Lodge Farms and Canadian Tire.

Parent company Canon Inc. of Tokyo generates close to $46 billion in global revenue and has ranked among the top four in U.S. patents registered since 1994.

Taking part in breaking ground for Canon Canada’s new headquarters are (left to right): John Hutton, Brampton City Councillor; Ted Egawa, Canon Canada President and CEO; His Excellency Norihiro Okuda, Japanese Ambassador to Canada; Susan Fennell, Brampton Mayor; and Eiji Yamamoto, Consul-General of Japan.

Access Imaging Inc. held an open house at its Toronto location in June to update customers on new wide-format-imaging products reaching the market, particularly the recently introduced HP Latex 300 Series. Producing indoor-quality output at speeds of up to 17 m2/hr (183 ft2/hr), the printer line includes the HP Latex 360, 330, 310 and 280, the latter of which actually hits 18.4 m2/hr (198 ft2/hr).

Access Imaging also highlighted unique medias like certified canvas for applications like fine-art reproduction and portrait, landscape photography, retail installations and wall decorations. The company, with additional offices in Montreal, QC, and Richmond, BC, distributes and services plotters, scanners, RIPs, laminators and trimmers from manufacturers like Hewlett-Packard, Apple, Howtek, Rimage, Epson, GBCProtech, Heidelberg, Intergraph and Onyx.

John Visentin (left), President of Access Imaging, with Account Executive David Plommer.

Six printing companies from Canada earned eight Best of Category awards, represented by the Benjamin Franklin statue, in Printing Industries of America’s 2014 Premier Print Awards program. The Benny award-winning printers (listed below) are joined by Ryerson University’s School of Graphic Communications Management, which received a Benny in the Post-Secondary Students category. C.J. Graphics and PDI received two Best of Category awards each.

C.J. Graphics, Toronto, ON

Category: Stochastic Printing

Project: Mercedes-Benz, The All-New 2014 S-Class and Box Set

Category: Single Promotional Self-Mailer

Project: Until The Last Child Limited Edition Box Set

PDI Inc., Kirkland, QC

Category: Programs (four or more colours)

Project: LOVE Souvenir Program

Category: Campaign

Project: 13 + 1 Essential Ingredients Campaign

Colour Innovations, Toronto, ON

Category: Miscellaneous Specialties

Project: Empress of Ireland 100th Anniversary Collection

Flash Reproductions, Toronto, ON

Category: Promotional Campaigns, Business-to-Business

Project: Wayward Arts

McCallum Print Group, Edmonton, AB

Category: Other Special Finishing Techniques

Project: McCallum Print Group Arcades Package

Metropolitan Fine Printers, Vancouver, BC

Category: Booklets (four or more colours, 21-50 employees)

Project: Trump Book & Envelope

Ryerson University, Toronto, ON

Category: Post-Secondary Students

Project: 2014 GCM Grad Book

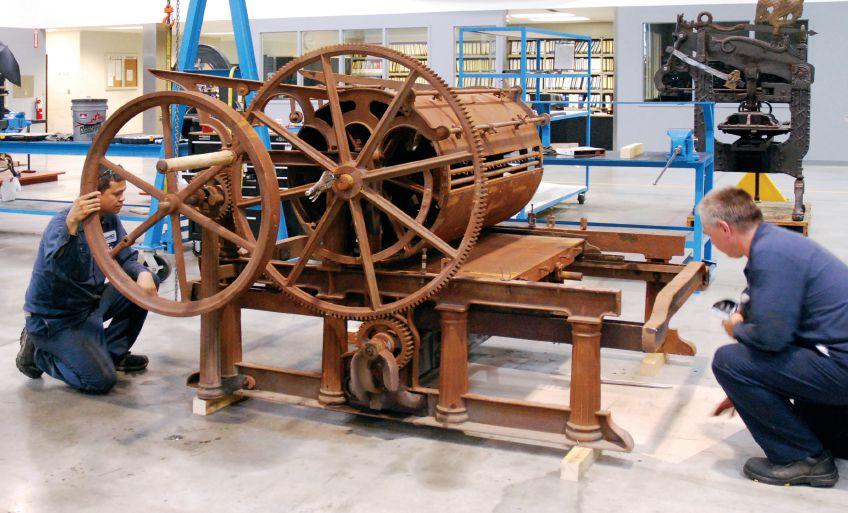

Howard Iron Works of Mississauga is now restoring its newly acquired C Potter Jr. newspaper press, first manufactured in 1866 – one year before the formation of Canada. Meanwhile, Howard Graphic Equipment experienced a spike in worldwide refurbished press sales.

Rare vintage presses are a lifelong passion for Nick and Liana Howard, who founded Howard Iron Works (HIW) in December 2013, but they remain intently focused on the sale of used modern printing presses through Howard Graphic Equipment (HGE) Ltd., founded in 1967.

The Howards explain HGE experienced one of its busiest months this June, receiving four U.S.-based orders for offset printing presses, including: A 6-colour Komori S640 plus coater and inter-deck UV drying; 10-colour S1040P plus coater; a pre-owned Komori G540 plus coater; and a 5-colour S540 plus coater. HGE explains the G540 is the world’s first pre-owned “G” series sold on the secondary market.

bished printing equipment to a customer base spread across 72 countries.

It was a barn in Southern Illinois, however, where Nick and Liana Howard found the newest gem for Howard Iron Works, which restores decades and sometimes centuries-old printing equipment. To help support this passion, HIW provides leasing and sales from within its large collection of rare printing machines, which includes a range of iron presses, cylinders, platens and bindery equipment

The single revolution C Potter Jr. press had been sitting in the Illinois barn for the past 30 years. This very rare Potter press, operated by hand, is rusty and missing parts, but Nick Howard expects its fluted columns “to look stunning” once fully restored, a process undertaken by the company’s highly skilled technicians.

August 18–20

Proveer/Avery Dennison

Car Wrap Workshop

Proveer facility, Toronto, Ontario, $999*

September 9–11

Labelexpo Americas

Donald E. Stephens Convention Center Chicago, Illinois

September 16–18

Sustainable Forestry Initiative

Annual Conference

Le Centre Sheraton, Montreal, Quebec

September 18

Entry Deadline: Canadian Printing Awards www.printaction.com/CPA

September 19–20

Consac Imagemakers 2014 International Centre Mississauga, Ontario

September 28–October 1

Graph Expo 2014

McCormick Place Chicago, Illinois

September 30–October 2

PAC Symposium, Retail Trends and Supply Chain Sustainability

Steam Whistle Brewery & Real Sports, Toronto

October 22–24

SGIA Expo 2014

HGE’s recent busy period also includes overseas sales of a Heidelberg CD 102-6+LX2, both a 5-colour and a 6-colour Komori NL28 plus coater, as well as a 5-colour S540 plus coater, two Lithrone 640 presses, and a 6-colour Mitsubishi 640. HGE has now provided refur-

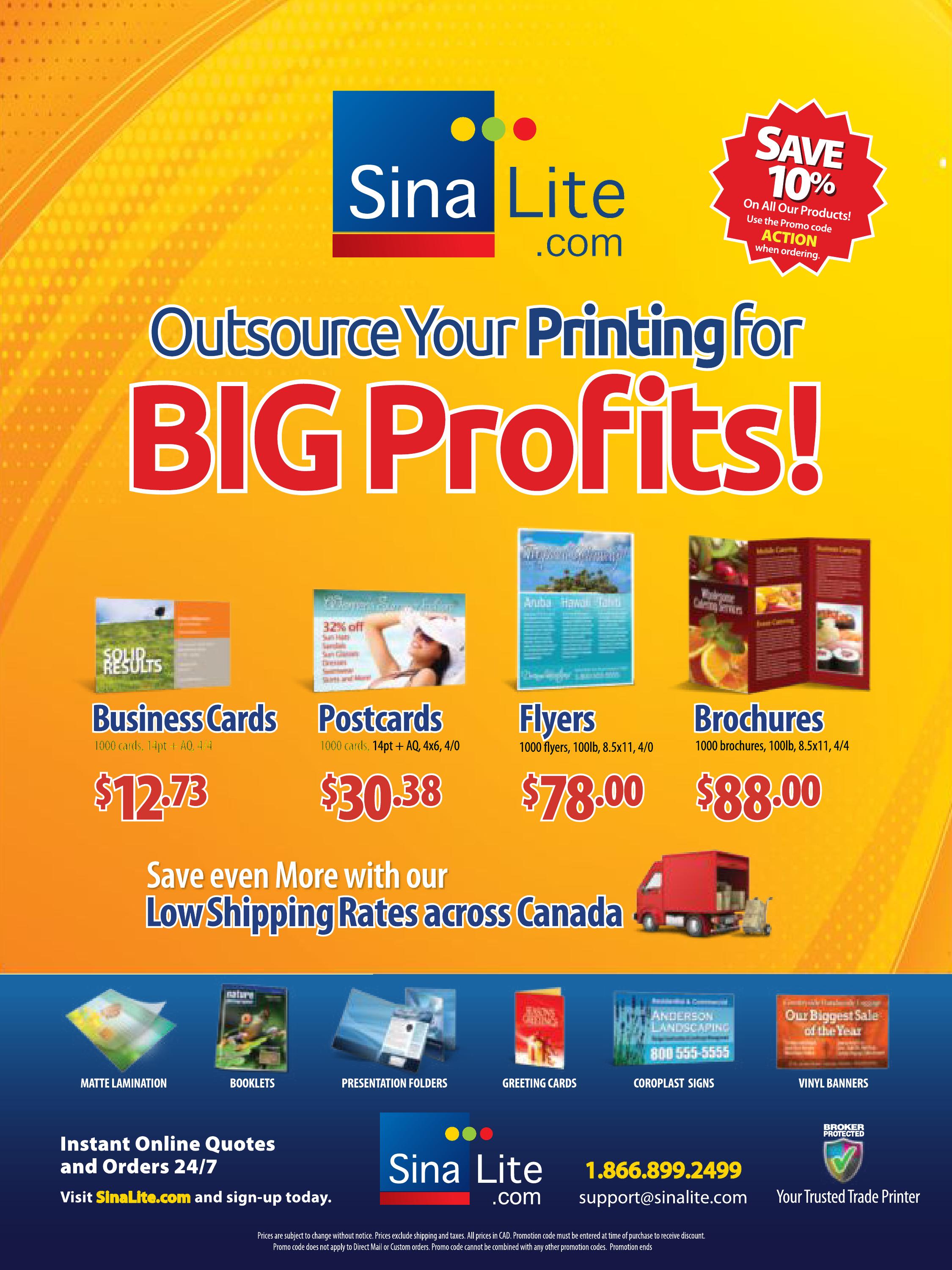

Sina Printing of Markham, Ontario, which operates SinaLite, installed a Brausse 1050 SE a few months ago and is now in full production with the industrial die-cutting system. The 1050 SE handles a sheet size of up to 41 1/8 x 29 1/2 inches at a top speed of 7,500 sheets per hour. Sina primarily plans to use the system for presentation folders, door hangers, and a range of packaging products.

The device complements a recently installed B&R Moll Marathon folder and gluer, also focused on presentation folders and packaging. The Markham trade printer explains the 1050 SE installation is in line with a vision to enter deeper into packaging work.

Headquartered in Richmond, BC, Brausse Group was recently recognized as a 2013 Canadian Excellence Award recipient by the U.S. Trade & Commerce Institute, based on an annual survey relating to benchmarks across a range of industries.

It will be a challenging restoration, however, because Howard traditionally aims to restore equipment just as it would have been when leaving the original factories. Despite his warehouse of technical books and reference materials, Howard can only find a single illustration of the C Potter Jr. press. Potter, he explains, also made the first rotary offset press, which was technology eventually acquired by Harris.

Las Vegas Convention Center Las Vegas, Nevada

October 30–November 1

Proveer/Avery Dennison

Car Wrap Training

Riley’s Reproductions, Calgary, Alberta, $999*

November 6

Canadian Printing Awards Gala, hosted by PrintAction

Toscana Conference Centre, Hilton Garden Inn, Toronto

April 16–18, 2015

Graphics Canada 2015

International Centre Mississauga

June 2–15, 2016

drupa 2016

Messe Dusseldorf

Dusseldorf, Germany

dept.

dept.

• 4 Epson 9900 Color Proofers, CGS O.R.I.S. RIP, 44” Certified GRACoL 7 with Built-in SpectroPhotometers

• Two 44” Fuji Fully Automated CTP Machines: 300 Line Screen Standard

• Canon IPF8000s 2 Sided Digital Color Dylux Proofer

• GRACoL 7 Certified 300 Co-Res + 10 Micron Taffeta Stochastic

• Xerox IGEN 4 EXP with 26” Kit

• Xerox IGEN 4 w/Bourg BDFX

• Xerox 700

• Konica C6501

• 2 Konica Bizhub Pro with Perfect Binding and Saddle Stitching

• Xerox Nuvera 120

• Digital UV Coater

• Inca S40i Onset Larger Format Super High Speed Digital Printer with Pro-Brite.

• Inca S20 Onset Large Format High Speed Digital Printer with White

• Fuji 96” Acuity Advance HS HD2545 x2 Color High Speed Flat Bed and Roll Feed, with White Ink

• 98” Scitex 6 Color Flatbed and Roll-Fed UV Printer

• Epson 64” Stylus Pro GS6000, 8 Color Ultra Chrome GS High Speed Roll Feed

• Durst 50” Lambda Photographic Imaging

• Two 62” Laminator / Mounters

• Zund I-cut Digital Flatbed Cutter

• Kongsberg Digital Flatbed Cutter with Auto-Load

• Heidelberg CD 102 40” UV 6 Color with Interdeck Curing and UV Anilox coater/Aqueous

• Heidelberg 40” 8 Color Perfector with Aqueous Coater

• Heidelberg 40” 6 Color with Aqueous Coater

• Mitsubishi UV 40” 6 Color with Inline UV Curing and Aqueous / UV Coater

• Color King 40” 4C (2/2) Web, Folds 32 pg. Signatures at 20,000 sph

• Heidelberg 20” 5 Color GTO

• Heidelberg 18” 2 Color Speedmasters

• Royal Zenith 5 Color Web Press

dept.

• 9 Pocket, 8 Pocket, and 6 Pocket Saddle Stitchers

• Mûller Martini 21 Pocket Perfect Binder

• 7 STAHL, 3 MBO Folders

• 85”, 60”, 44” and 30” Guillotines

• 40” Brausse Diecutter

• Digital Diecutting

• Horizon 9 Bin Collator / Stitcher

Ingersoll Paper Box (IPB), a folding-carton manufacturer headquartered in Ingersoll, Ontario, held on open house in June to highlight its new KBA Rapida 106 sheetfed press, among other recent investments. The 41-inch, seven-colour KBA sheetfed press is engineered for full UV production and is equipped with in-line colour control. IPB is a fourth-generation family-owned business established in 1922 by Robert Skinner.

The new KBA press is primarily focused on IPB’s pharmaceutical customers, which account for approximately 75 percent the company’s manufacturing. IPB’s remaining customer base comes from the food, consumer goods, and the health and medical industries. Located in an 80,000-square-foot plant, IPB also used its open house to feature a recently installed Masterwork MK420Q automatic sheet inspection system, purchased in the fall of 2013, as well as a new Agfa Avalon N8-22 and a Bobst ExpertFold system.

Ideal Labels of Toronto, which focuses on the production of pressure-sensitive labels, installed an Esko CDI 2350 flexo plate imager, which eliminates the use of film by directly imaging onto photopolymer plate material, and Esko DeskPack software, purchasing through Williamson Printing Materials.

“With films and chemistry, dots may vary in size and become smaller or larger, even if you are imaging the same job. The CDI eliminates a majority of the variables associated with film,” said Amar Kailas, Vice President of Ideal Labels, who runs the company with his brother and father. Ideal Labels first opened its doors in 1994.

Kailas, who oversees prepress, also points to the CDI Spark’s capability to image different

line screens simultaneously. “I can image jobs of different line screens all at once on one large sheet of plate material,” he said. “We used to have to produce them one at a time. For instance, we had to image 100-lpi screen jobs separately from 133-lpi or 150-lpi screen jobs. Being able to gang-up images with different line screens on the same sheet of plate material saves us time.”

The CDI Spark 2350 images plates up to 25 x 30 inches (635 x 762 mm) and features an EasyClamp II drum for faster plate loading. Ideal also uses Esko’s DeskPack, including modules for automatic trapping and pre-flighting. The software allows Ideal to set multiple presets simultaneously, with rules and exceptions to trap the file according to each job’s specifications.

Imagine if you dare a world without Photoshop – a barren image editing wasteland offering little to comfort those longing to adjust a photo’s hue, or straighten and crop a wayward picture. How would you apply effects to your pictures, convert to black and white or resize low-resolution images without Adobe? Sounds like a pretty bleak existence, doesn’t it? Thankfully it doesn’t have to be.

Photoshop remains at the heart of most serious image-editing workflows, but there are options on the market. These days, savvy software consumers can save a few dollars and still fulfill a surprising percentage of their image editing needs. While there are a number of open source and share-ware image-editing alternatives on the market, a couple of the early Photoshop challengers have matured into significant contenders in the pixel-pushing arena.

Pixelmator 3.2 (Mac OS X)

pixelmator.com

Apple App Store: $29.95

I first discovered this powerful yet unassuming app shortly after returning from drupa years ago and wrote about version 1 in PrintAction magazine (July 2008). At the time, I was impressed with the versatility of the inexpensive image editor and it soon became my go-to tool for quick image adjustments when away from my Photoshop workstation.

Over the years, Pixelmator matured with each successive release, bringing it ever closer to Photoshop functionality while remaining a fraction of the price. Within an intuitive and stylish interface, Pixelmator delivers most of the features you would expect in an image editor. The Tools palette will feel immediately familiar to anyone with a working knowledge of Photoshop. Pixelmator is replete with a full range of tools covering everything from selection; cropping; cloning; erasing; drawing; painting; shapes; and blurring to typography and effects.

And like that other image editor, Pixelmator supports layers – in fact, you can even open your layered .PSD files, edit them and export the file back to .PSD, or any one of several common image formats. I use the term ‘export’ because Pixelmator can only save images in its own proprietary format. This might not be such a bad thing because, on cursory inspection, Pixelmator appears to produce a smaller file size than .PSD for the same image. Pixelmator also features a number of tools geared toward those combining or creating new images, such as Alignment Guides and Relative Spacing Guides, which are much like the smart guides found in Creative Suite apps.

The latest release, Pixelmator 3.2, brings some new advanced editing features to the table including a completely re-engineered Repair Tool. The Repair Tool can be used for anything from simple dust and scratch removal to difficult repairs such as large image removal from a complex background. Pixelmator ‘patches’ the areas removed with colour-corrected pieces from the image surrounding it. Even if the object to be removed was not selected precisely, the Repair Tool builds a smooth transition area and matches the structure of the background. The results are often quite impressive. Other new Pixelmator features include support for 16-bit colour, lockable layers and a cool little feature

that apparently converts any selection into a shape for editing. I say ‘apparently’ because I cannot actually figure out how to do it, which highlights one of the few flaws of the application – the lack of a manual! There is, however, a fairly comprehensive help file and quite a few online tutorials to get new users up to speed. Also, because Pixelmator restricts users to living in an RGB world, it will not unseat Photoshop for heavy-duty prepress use anytime soon. Having said that, Pixelmator is a robust, fun and surprisingly fully featured image editor for a very, very good price!

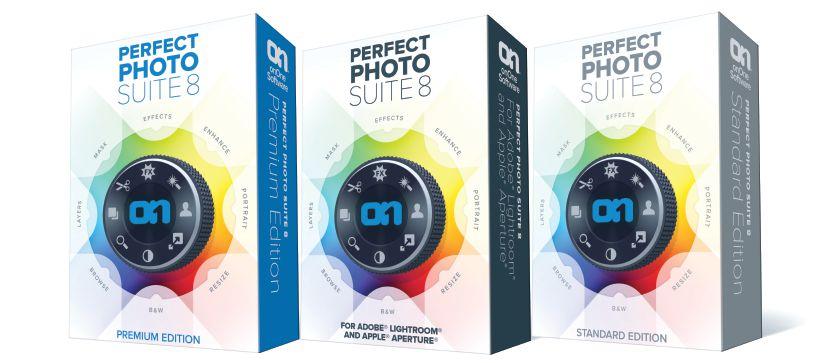

Perfect Photo Suite 8.5

(Mac OS X, Windows 7 & 8) onOnesoftware.com

Starting at $79.95

Another blast from my image-editing past, Perfect Photo Suite began its life as a collection of high-priced plugins for Photoshop. When I last reviewed the product (version 5 in PrintAction, August 2010), Perfect Photo Suite cashed out at a hefty $499 for the full assemblage of plug-ins. At the time, each of the plug-ins was also available as an independent product, so users could buy just the tools or effects they wanted.

onOne Software has since taken the collection in the opposite direction and combined Perfect Photo Suite into a fully featured standalone application containing all of the functionality of the individual plug-ins. As a

result, Perfect Photo Suite 8.5 has evolved into a surprisingly comprehensive image-editing workflow well suited for the artistic image manipulator and premedia pro alike.

When launching any Perfect Photo Suite plug-in from Photoshop, Lightroom or Aperture, the net result is the same: The full suite opens outside of the host application with the image and the selected functions active. From there, users can access any of the other Suite tools encompassing a wide range of image-editing chores.

The Enhance tool provides everything an image geek needs to improve brightness, contrast or hue, as well as play with focus or remove offending spots and elements in the style of Photoshop’s Content Aware Fill. Enhance provides loads of presets for the novice and a complete set of finicky adjustments for the pro. Once you make your perfect enhancement, save it as a preset for other images, or even batch processing.

As its name implies, Effects is the Suite tool for stylizing images. As with Enhance, this function comes with both a full catalogue of photographic effects and plenty of adjustable filter options to create entirely unique looks. Additionally, Effects filters can be stacked to create masterpieces or abhorrent messes, depending on the skill of the user.

Portrait provides both presets and manual tools to make short work of tedious portrait re-touching tasks like removing blemishes, shine and wrinkles. Portrait

Heidelberg XL106

18,000 SHEETS PER HOUR

8 COLOR PERFECTOR

PRinECT inPRESS COnTROL

Technology and Productivity

That

18,000 sheets per hour in straight printing and in perfecting mode are unrivaled peak values. A 20 percent higher production means new opportunities

Prinect Inpress Control automatically measures and controls colour and register on the fly and at any speed. Integrated directly into the press, the measuring unit measures process colours, spot colours and register in the print control strip. Any corrections required are forwarded directly to the Prinect Press Center for adjustment. As the press does not need to be stopped for either make-ready or monitoring of the production run, Prinect Inpress Control achieves maximum productivity. Only P ress O f

The perfect interplay using preset functionality, a sheet travel optimized for maximum production speed and a machine that is consequently designed for top print quality as well as straightforward operation make the Speedmaster XL 106 the Peak Performance machine

The Spectrophotometric

At pointone there are no sacrifices for quality. We offer trade competitive prices without going over your budget, while still keeping the environment in mind. We have leading edge technology to keep your cost in-line and to maximize quality. Come in and work with us to make your print job a work of art.

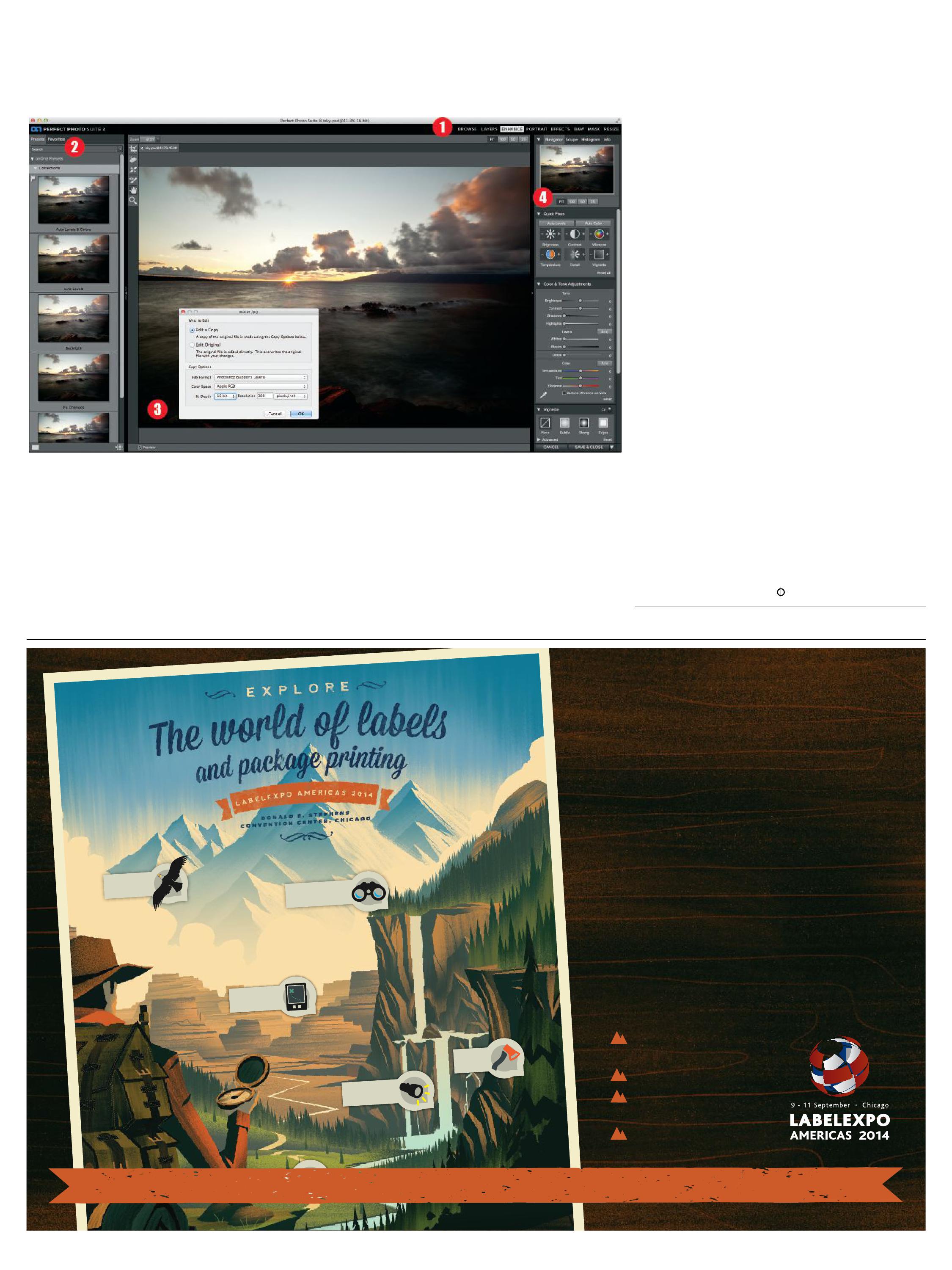

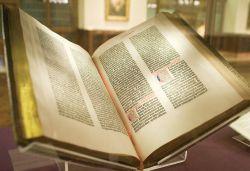

onOne Software’s Perfect Photo Suite 8.5 workspace: q Once the image has opened, users can tab between PPS modules with ease; w PPS comes with a large collection of presets for common image enhancements; e PPS prompts users to either work on the original image or a copy; r PPS provides access to a full range of advanced image editing tools should users wish to tweak presets, or create their own.

also has specific adjustments for eyes and mouths, including red-eye removal and teeth whitening – cheaper than a trip to the ophthalmologist or the dentist!

But for me the big draw to Perfect Photo Suite has always been its excellent Resize and Mask functions. Resize started life as a very pricey Photoshop plug-in

called Genuine Fractals and over its nearly 20-year life has matured into the very best software to scale a lower resolution image to a large print size. Able to make sharp enlargements up to 1,000 percent, Resize is well equipped with presets optimized to a wide range of large-format-inkjet printers and media in addition to

a full range of user-adjustable parameters to get your enlargement just right. Personally, I often use Resize to bring low-quality customer-supplied images up to prepress standards for print. And Mask has only improved with age – with a little practice, most users can easily mask around soft-edged image elements such as clouds or hair.

Perfect Photo Suite, however, is not the perfect way to kick the Photoshop habit. Like Pixelmator, the Suite only works with RGB images. Also, I found the application stuttered a bit with very large images on my 11-inch Macbook Air – the Suite seemed to want more RAM than I could muster. Working with the same images in Photoshop was no problem, suggesting there is room for improvement in the Perfect Photo Suite memory management department. But, considering Genuine Fractals alone used to sell for more than $200, the entire Perfect Photo Suite is a steal starting at $79.

If you wrangle images for a living, the short answer is no. There is a good reason Photoshop has been the tool of choice for pixel wranglers for decades, and likely for the foreseeable future. However, given Adobe’s subscription model not everyone will want to shell out for the Creative Cloud just to straighten a few images, downsize some photos for a blog or play with bokeh at home. Also, each of these innovative applications has unique strengths that can enhance any pro image editing workflow for a relatively small investment. Having alternatives is a great thing for users, and hopefully having some competition will keep the engineers at Adobe on its toes.

Zac Bolan’s blog: blog.softcircus.com

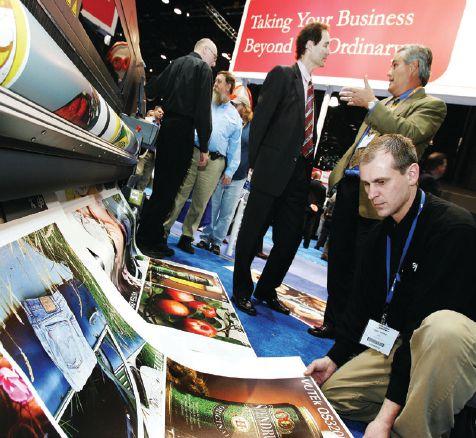

On SEPTEMBER 9-11 label and package printing explorers from across the Americas and the rest of the world will descend upon LABELEXPO AMERICAS 2014 – the industry’s largest event this year.

Join other converters, brand owners and designers to discover new opportunities in this growing market, see the latest technology in action and learn how to stay ahead of your competitors.

But come prepared – there are over 400 exhibitors and only three days to see it all!

If packaging stands as one of the most-stable printing sectors, in terms of annual growth relative to Gross Domestic Product, labels are both one of the industry’s most stable and innovative production areas. The newest technologies available for label printing will occupy close to 200,000 square feet of floor space at this year’s Labelexpo Americas in Rosemont, Illinois.

A preview of more than 65 technologies ready to drive printing’s dynamic sectors

A preview of more than 65 technologies ready to drive one of printing’s most dynamic sectors

A mid-level label press (released March 2014) running at 18 metres per minute (mpm) in roll-to-roll configuration or at nine mpm in a roll-to-laser and die-cutting configuration.

AV

A semi-automatic mounting machine for narrow web printing, featuring robotic positioning, patented camera beam calibration and 170x magnification.

A narrow web, modular press with full LED curing, enhanced varnish/lamination module, and a laser cutter available in single-head (500W) or dual-head (1000W) configuration.

Radius v15.1

MIS/ERP software designed specifically for packaging that includes a new mobile CRM module; improved scheduling with PrintFlow; Web-based SmartLinc shipping; and Radius Portal for Web-toprint function.

cJET-24

A flatbed conveyor inkjet system (released July 2014) for printing both flat and curved items, such as personalizing souvenirs, customizing gifts, and special promotional items, in short or long runs. It supports uni- and bi-directional CMYK+WW printing. The cJET-24 features a platen height adjustment system, for automatically detecting the distance between the print heads and substrate.

SurePress L-6034VW

Epson’s first single-pass industrial press (introduced September 2013) is also its first such system to use PrecisionCore line-head technology, and the first to use Epson’s new LED-cured UV ink with inline varnish. Available in two models: CMYK with varnish and white ink (SurePress L-6034VW) and without white ink (SurePress L-6034V).

The three-day event, from September 9 to 11, features over 400 exhibitors, including more than 60 companies exhibiting for the first time. HP is Labelexpo Americas’ largest show exhibitor in 2014, housed on a 8,500-square-foot booth. Forty companies provided PrintAction with the primary technologies they plan to highlight on their booth at this year’s event.

New product (since April 2014) Product preview Product update

Designed for prime label converters and commercial printers, updates on these presses – with White ink capability –include a sensor for printing on a clear substrate with a clear liner, as well as improved VDP processing.

esko

Suite 14

Designed for packaging preproduction and management (released July 2014), Suite 14 includes new features like WebCenter 14, now a 64-bit application; WebCenter server interaction; Automation Engine colour tasks (using Equinox profiles); Connect kit for third-party integration; and an updated ArtiosCAD editor.

Full

A prepress imaging process (released September 2013), based on software and platemaking systems (CDI devices), for creating screens – and what Esko describes as gravure-like ink laydowns –with deeper solids, smoother highlights and an expanded colour gamut.

A servo-driven, compact 25-foot machine (released September 2013) with a 13-inch (330 mm) web width for users to convert their own rolls of pressure-sensitive materials or labels.

A patent-pending system (released September 2013) designed to die cut thin release liners. Adaptable to Cohesio equipment or as a standalone unit, Pellicut can die cut a label on an 18-micron polyester film up to a speed of 750 feet per minute (fpm) or 225 mpm.

FTA’s Flexographic Image Reproduction Specifications & Tolerances certification program is designed for prepress and press operators, as well as implementation specialists. The association will highlight new publications Flexography: Principles & Practices 6.0 and FIRST 4.1 on its booth.

The organization will highlight its upcoming conference running from October 20 to 22 at the DoubleTree by Hilton in Minneapolis, Minnesota.

EkoCure

Described as the first commercially available UV LED coating (released September 2013), and developed in partnership with Mark Andy, EkoCure is mercury- and ozone-free ink technology. The line includes gloss coating, matte coating, product-resistant coating, shrink coating, cast-and-cure coating, rotary screen tactile coating, coating for non-top coated films, primer coating for various shrink films, non-yellowing coating and coatings with or without optical brighteners.

These flexo and screen inks (released in 2012) are described by Flint as the first-ever narrow web printing inks developed for use in combination printing, including UV rotary screen whites.

Covinax

A high-shear, removable pressure-sensitive adhesive (released in July 2014) that remains optically clear, even when exposed to UV and moisture, and can be repositioned multiple times without losing adhesion. It is well suited for applications like decals, window graphics, food packaging and specialty tapes. Covinax 234-01 is also designed for adhesion to substrates like polypropylene and polyethylene films and vinyl polystyrene, as well as low-surface-energy materials.

A modular UV inkjet press (released September 2013) with a 16-inch print width targeted at converters and printers producing labels, packaging and specialty print applications. Graphium reaches single-pass print speeds of up to 164 fpm, jetting Fujifilm’s Uvijet inks at drop sizes ranging from six to 42 picoliters, including white ink.

Requiring only a mild detergent for washout, this water-washable flexo plate (released September 2013) is designed to eliminate the use of solvents and wicking clothes. Rated by Fujifilm for a processing time of 30 minutes, Clarity is available in digital and analogue versions for UV-, water- and solventbased inks with imaging quality reaching 175 lpi and a 1% process dot.

Designed to produce colour profiles, with less information, the software (released December 2013) can be used to predict spot colours when produced with multi-colour printing. The upgraded version includes extended import of measurement data and further adjustment capabilities to the GMG OpenColor profiles.

An online project collaboration, soft-proofing and approval solution (released July 2013), CoZone Collaborate integrates cloud technology and project collaboration with GMG’s colour management toolsets.

The Vpak 500 (first installed in 2013) and wider-format Vpak 3000 (first installed July 2014) web offset presses are available in web widths from 520 mm to 1,905 mm (20.5 to 75 inches) and print at speeds of up to 457 mpm (1,500 fpm). Key features include quickchange sleeve adapter technology for what Goss describes as cost-effective size changes, and advanced offset inking, tension and control systems.

gtI grAPhIC teChnology

Simultaneous Color Viewer

Designed to help detect metamerism

and test colour harmony by allowing a visual side-by-side comparison of colours under four different light sources.

The EVS D50 colour viewing stations combine electronic ballasts with Graphiclite T8 fluorescent lamps to produce light evenness, rear-wall illumination, and enhanced energy efficiency. A built-in print bar and LiteGuard II, which displays lamp warm up, lamp hours, and remaining lamp life, are also included.

PDV Professional Desktop Viewers

Graphiclite PDV Professional Desktop Viewers are engineered for D50 controlled viewing of colour work, with areas ranging from 11.7 x 16.3 inches (30 x 41 cm) to 23.5 x 25.3 inches (60 x 64 cm).

hewlett-PACkArd

Indigo 20000

The Indigo 20000 (to be released this Fall) is a continuous-feed press capable of what HP describes as gravure-quality printing on films as thin as 10 microns, with a printing frame of 29 x 43 inches and an inline priming unit for substrate flexibility. It runs at 82 linear fpm in five-colour mode (process colours, plus white) and at 135 linear feet per minute when running in Enhanced Productivity Mode.

Indigo WS6800

The roll-fed press (released June 2014) includes a new inline spectrophotometer, an expanded frame width (increased from 317 mm to 320 mm) and new ink capabilities with Indigo ElectroInk White and Indigo ElectroInk Silver. It runs at 131 linear fpm using HP’s Enhanced Productivity Mode and supports the HP SmartStream Labels and Packaging Workflow Suite 4.1, powered by Esko.

IndustrIAl Inkjet

MK2 Controller

This fully automated ink system (released July 2014) that has gone through a pilot program at customer sites. It features individual purge by colour to reduce ink wastage. It uses Teflon and stainless steel materials to ensure the ink system is compatible with a range of UV-, solvent- and water-based inks, as well as some food-grade inks.

The Komori NW210 inkjet UV digital narrow web press includes 15 Xaar 1002 print heads capable of printing 7-picoliter drop sizes and inline laser cutting, which is integrated with INX’ JetINX print-head drive and ink recirculation system. The NW210 uses UV LED curing for single-pass output of up to 80 fpm on a range of label stocks.

The HMJ-200 small batch ink dispenser, developed by HMJtech Dispensing Solutions, is designed for the tag and label printing market. It provides single point dispensing into jugs with small openings. It is available for water-based ink or UV-curable ink and is configurable with up to 14 base ingredients.

The JFlex inkjet conversion system, first introduced on the JFlex870 and now the JFlex1700, will be demonstrated, for the first time, on a 25-year-old flexographic press, which effectively turns the press into a hybrid platform with speeds of up to 225 fpm, while printing at 1,600 to 1,375-dpi resolution. JFlex series of label conversion systems are engineered by RDP Marathon of Montreal.

EDGE 850

A roll-to-roll inkjet label system for printing colour BS5609-compliant chemical drum labels on demand. It received GHS certification in July 2014. Developed for the short-run label market, EDGE 850 also prints on a variety of substrates with die-cut, kiss-cut or continuous rolls.

An inkjet label press for short- to midrun production, working with media print widths ranging from three to 12.9-inches. iSys states users can print, slit and rewind 28,000 productionworthy labels in less than 37 minutes.

Bicor, Metallyte, Label-Lyte Films

First introduced at the recent InterPack show in May 2014, Jindal’s new films include Bicor, the first OPP-based sealant film for stand-up pouch applications; Metallyte, a metallized, surface printable monoweb technology; and Label-Lyte, a new white lightweight oriented PO film.

Described by the company as the first activation film capable of variable covert imaging, this peel-to-activate film (released July 2014) enables users to securely transport and conceal confidential codes within a single layer of optically thin film. It is well suited for anti-counterfeit product authentication applications, such as gift-card activation, software authentication, pharmaceutical authentication and PIN number transportation. The optical thin film has colour shifting metallic properties.

lAbel VIsIon systems

Integra 9580

The Integra 9580 is a handheld solution for off-line bar code verification to ISO/IEC standards. Featuring a high resolution 5.0 megapixel camera, the Integra 9580 reads and analyzes 1D and 2D codes up to three inches (76.19 mm) wide and up to 2.25 inches (57.15 mm) tall. The Integra 9580 verifies multiple bar code types, including any combination of linear, matrix (data matrix, QR code, and Aztec code), and stacked linear (PDF 417, micro PDF and composite codes).

The PDF Compare Module is integrated within the LVS 7000 and LVS 7500 in-line process control systems. The PDF Compare Module, powered by tech partner Global Vision, is designed to ensure an approved customer PDF file matches the actual print job. Any differences are automatically detected and flagged to the operator. A detailed inspection report can be generated for quality control records and approvals.

This module for the LVS 7000 is an inline process control system designed to improve the quality-inspection process. The AutoScan Web Viewer Module allows an operator to simultaneously monitor up to 16 areas of interest per job on the web without having to manually move between each area of interest.

Label Traxx version 7.1

MIS software specifically for the narrow web label industry, Label Traxx version 7.1 has a new external document system that can store multiple document types, including PDF, .MOV, .DOC and .XLS, among others, for maintaining paper trails, proofs, ISO and other information. Also new to Version 7.1 is onscreen backup verification, where users can view the last successful backup from their primary screen.

A new, hybrid press platform combining an inkjet printing module with the flexibility and inline finishing capabilities of flexo. The first beta sites took place in December 2013. The range of presses in this series can reach speeds over 200 fpm (76 mpm) with web widths beginning at 13 inches (330 mm). The company plans to demonstrate a Performance Series P7 press on its booth.

Mark Andy Print Products (MAPP) was established in July 2013 to focus on selling pressroom consumables and supplies, and this year (January 2014) agreed to distribute DuPont plates and Cyrel flexographic systems. The company will have a Mark Andy VPM400 plate mounter on its booth.

Rotoflex

An updated version of the Rotoflex URC 2.0 controller, the system now features the Report Management System to

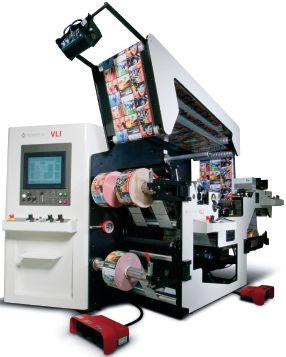

gather productivity data from Rotoflex equipment and wirelessly route it for analyzing. On its booth, the company will highlight RMS integrated into both the Rotoflex VSI with URC 2.0 and Rotoflex VLI with URC 2.0.

The company’s automatic roll change technology, which is based on a long-serving process, is to include demonstrations of the system’s MBS splicer and LRD rewinder. The demo is designed to show how non-stop splicing and rewinding can be applied to reduce waste.

nAstAr

SWDTX

This linerless direct thermal product (released July 2014) is a T2 repositionable adhesive and a printable food grade non-silicone release. The printable release allows the labels to be colour coded or printed flexo on both the face and adhesive side.

SWDTZ

This linerless direct thermal product (released July 2014) is a T1055 temporary adhesive with a traditional silicone release. NAStar explains when coated with a discontinuous cross web “DOT” adhesive pattern, the material layout allows for printers to cut without coming in contact with the adhesive.

MagneTernative

This auto-applied MagneTernative construction (released November 2012) is a temporary adhesive promotional product line designed to stick anywhere a regular magnet will, but also everywhere a magnet will not. The consumer removes the liner exposing NAStar’s temporary adhesive and affixes the promotional message.

neurAlAbel

NeuraLabel 300x

The colour printing system (released July 2014) is primarily designed for inhouse or on-demand label production. Built around HP’s page-wide-array technology, running pigmented inks, it features a variable width media handling of between three and 8.5 inches.

NeuraLabel 500e

This system is designed for medium-run label production. It features high-capacity cartridges to decrease downtime and is compatible with a range of media types.

ScrapTracker

A system for waste reduction through automatic marking and tracking of defects. ScrapTracker creates a data file or roll map associated with each roll of material manufactured, processed or printed. The data file contains all the information about the locations and types of any defects within the roll. ScrapTracker uses the AF2 WebFlagger to apply flags with unique ID numbers. The flags are preprinted with this unique number and a corresponding bar code. A flag can be triggered by an operator push-button or a signal from the machine.

This entry-level inspection system, according to the company, contains everything needed out of the box to provide 100 percent inspection for missing labels, un-removed matrix, and other larger defects. The defects can be displayed in real time or reviewed through the Defect Queue, which allows the operator to accept or reject flagged labels without stopping a press. Job setup can be saved for later recall on repeat runs.

Graphic-Vision GV530/Spectro System

This press web viewer, part of the new GV500 Series, provides LED lighting, high-resolution colour cameras, and a LCD monitor. As the most-advanced system in the line, GV530/Spectro now also offers colour measurement and real-time reporting.

PreCIsIon AIrConVey

EnviroPulse 14

This new oil mist system is designed for automated PSA matrix removal, which the company states can drastically reduces oil usage and cost. It is a critical component of PAC’s matrix waste removal systems, which convey waste matrix pneumatically from the press. The matrix is cut into small, confetti-like pieces that are whisked away to a wastebin or baler. EnviroPulse 14 applies a micro-thin film of food-grade mineral oil to the internal surfaces of the path via a fine mist.

Scheduled for release before the end of 2014, this colour label printer features large ink tanks for lower cost per label production, as well as pigment inks for better water and UV resistance. Other highlights include built-in wired/Ethernet or wireless connection options, pizza-wheel cutter, and a front colour LCD control panel and viewing window for label stock levels.

Guardian

An entry-level system to provide cross direction web profile for smaller tag, tape and label converters. Guardian System is designed to provide a large central display console with remote workstations and options for multiple scanners and multiple measurements down the line.

This updated plate mounter (July 2014) is aided by a split screen with a 100x magnified video alignment tool, while a single adjustment knob is now used to more accurately align the plate to the cylinder.

This slitter/rewinder series is described as holding heavy-duty construction relative to the equipment’s small footprint and simplicity of operation. The R Series has the ability to customize work.

SmartMotion is a new control unit that combines a stepper motor and drive technologies into a single device, which saves floor space. Its motor – employing a high heat dissipation range – is controlled to 1/128 step for accuracy and less noise.

This new remote control can manage multiple hardware devices with a unique keypad, which includes control of SmartMotion webguide systems. It is equipped with a 3.5-inch touchscreen to regulate all parameters of each webguide system.

rolAnd dgA

VersaCAMM VSi Series

A new generation of wide-format printer/cutters (first released September 2013) with a newly designed eightchannel Piezo inkjet print head, running Eco-Sol MAX 2 inks in five configurations, including white, metallic and light black. The series includes the 30-inch VS-300i, 54-inch VS-540i and 64-inch VS-640i. It features a new ink recirculation system to reduce waste of white and metallic inks.

VersaUV LEC-330

This UV-LED printer/cutter, according to Roland, is capable of printing directly on virtually any substrate. The system incorporates unique varnish and embossing effects.

VersaStudio BN-20

This 20-inch desktop printer/cutter is well suited for label applications and comes bundled with Roland’s VersaWorks RIP and R-Works design software.

rollem

Delta Series

A new flexo-magnetic rotary die cutter for labels, the machine will kiss cut labels, decals, retail shelf talkers and stickers. Available in 20 x 15 or 30 x 24-inch sizes, the Delta Series is designed for finishing short-run personalized labels.

sChober

A high-speed programmable robotic stacking and counting system that reaches speeds of up to 50 mpm (164 fpm), which allows for stacking of various types of products within the same print image. Aimed at digitally printed in-mold labels, this technology allows nested product configurations with a combination of large/long and small products. Spider is available with web widths of up to 850 mm (33 inches) and die-cutting repeat of 1.220 mm (48 inches).

Released April 2014, 1106 is described by the company as a breakthrough in its line of over-laminates. The 1106 matte product – measuring 0.95 mils – is designed to create labels with a softer look and feel. It holds a non-reflective surface.

First introduced at the recent Interpack, SunLase laser marking solutions, a coating that enables brand owners to add information to both secondary and primary packaging information after the filling and closure of the pack, whether for practical supply chain purposes or as a late-stage packaging differentiator.

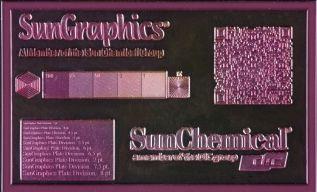

Sun’s HD Plates for narrow web, tag and label and corrugated printing recently achieved certification (June 2014) for Esko’s HD software and CDI imaging systems. Sun explains printers using its plates will see 30 to 60 percent less impression sensitivity compared to standard digital plates.

Building off of its preexisting commercial ink program, Sun states users of its water-based flexo ink program can decrease their overall bottom-line operating expenses in ink volume and ink costs by up to 25 percent.

This prepress workflow is specifically designed for flexographic and packaging applications. It combines the Global Graphics Harlequin RIP and Navigator workflow with an Adobe Illustrator plug-in to create film- or plate-ready artwork. The technology provides automated step-and-repeat with bleed control, nesting, .dxf import, and custom bearer bars, as well as raster-based trapping. Optional vector-based tools are also available.

1. ONE-STOP SHOP

Die Cutting, Bindery, Data & Lettershop –all under one roof.

2. ONGOING INVESTMENT IN SUPERIOR TECHNOLOGY

Die crease without a die, then fold and even glue all on the same machine, up to 30 pt.

3. INTEGRATED MODULAR UNITS

Combined in-line finishing: crease, fold, glue, tipping, envelope inserting, ink jetting (Duplex), clip seal (3 sides), mail prep.

4.

As a Certified Canada Post Direct Marketing Specialist, we get contract pricing reductions.

5.

Customized “Return Mailers” created in-line with “U” or “BOX-shape” remoistenable glue, time perfed applications and envelope formation.

6. MINI-BOOKLETS

We can saddle-stitch and trim 2-up booklets in-line to the size of a business card. No need to trim off-line, or do 2 passes.

7. HIGH SPEED EQUIPMENT

High speed Tipping, Folding, Saddle-stitching and soft folding ensuring on time delivery.

Detailing some of the newest printing hardware and software unveiled over the past couple of months, including important next-generation presses from Canon, Kodak and Konica Minolta, unique new substrates from Drytac and International Paper, and faster large-format Heidelberg presses.

Technologies Featured

• Agfa Avalon N16

• Canon Océ ImageStream 3500

• Color-Logic BEST Offset Silver Ink

• Drytac ViziPrint Impress

• Duplo UD-300

• Enfocus Switch 12.2

• Flint Varn Ecolo-Wash 401

• IP Alaska Plus

• Kodak Prosper 6000

• Konica Minolta bizhub PRESS C110O/1085

• Heidelberg XL 145/162 PSP

• MGI iFOIL

• Mimaki TS500-1800

• NewPage Blazer Digital

• Ultimate TechnoGraphics Absolutely Imposing 2.6

• Xaar 501 GS8

Kodak Prosper 6000

Eastman Kodak, in June, introduced what its calls two next-generation presses within its unique Prosper inkjet platform, including the Prosper 6000C and Prosper 6000P. The Prosper 6000C (with “C” standing for colour) press is aimed at commercial printing applications requiring high ink laydowns. The Prosper 6000P is designed for publishing applications likes books and newspapers that require the use of lightweight paper and low-to-medium ink laydowns. Both presses are scheduled to be made available later this year.

The Prosper 6000 presses, handling rolls widths of between eight to 25.5 inches, are driven by what Kodak calls the Intelligent Print System (IPS), which continuously monitors, evaluates and adjusts operations toward high-quality output. Both of the new Prosper presses print at speeds of up to 1,000 feet per minute (300 meters per minute) on matte and uncoated papers with a duty cycle of 90 million A4 pages per month. This equates to a speed that is up to 2.5 times faster than the existing Prosper 5000XLi press. An enhanced drying capability allows heavyweight glossy and silk stock to be printed on the Prosper 6000C at 650 (200 meters) feet per minute. The writing system of the new Prosper presses run Kodak’s newly formulated nanotechnology inks, which, coupled with its new transport and drying systems, allows the Prosper 6000 presses to lay down more ink than previous models in the line.

MGI Digital Graphic Technology, in July, installed the new iFOIL hot-foil-stamping system into its Florida headquarters for demonstration. iFOIL operates inline with MGI’s JETvarnish 3D UV spot coater to produce on-demand – and personalized – embossing, debossing and hot foil work. MGI points to applications like magazine covers, books, brochures, labels, invitations and packaging.

In addition to foil on foil work, iFOIL can apply up to three foils in one pass. It runs up to 1,700 B2-size sheets per hour, which equates to 25 metres per minute. Using market standard foil rolls, the inline configuration handles sizes ranging from A4 format (21 x 30 cm) to 52 x 105 cm and on paper substrates weighing from 150 to 700 microns. Users can also produce hot stamping with iFOIL with output from both offset and toner presses, including MGI’s Meteor series.

Heidelberger Druckmaschinen, in June, unveiled the Speedmaster XL 145 with a new top speed of 18,000 sheets per hour, as well as the Speedmaster XL 162 reaching 16,500 sheets per hour, primarily aimed at folding-carton work. The speed boost of both the XL 145 and XL 162 comes from what Heidelberg calls the Packaging Speed Performance (PSP) configuration, which uses a new high-speed suction head, optimized sheet travel, and a new chain guide in the delivery, coupled with new gripper bars and components such as the high-performance dryers. Heidelberg reports that over 100 of its large-format presses (in formats 6 and 7) have been sold worldwide since the start of series production in 2009. Approximately 70 percent of these installations are being used for packaging printing.

Konica Minolta, in July, released the bizhub PRESS C1100 and bizhub PRESS C1085 systems, which run at 100 pages per minute (ppm) and 85 ppm, respectively. Both machines maintain these duplex printing speeds with paperweights ranging from 55 gsm to 350 gsm (cardstock). Up to three paper-feeding modules can also be connected to operate nine trays and a capacity of 13,890 sheets. The bizhub PRESS C1100 and bizhub PRESS C1085 feature what Konica describes as enhanced Simitri HDE toner, as well as S.E.A.D. IV screen processing to maintain image stability over long press runs, air suction (vacuum) paper feeding and hybrid de-curling (zigzag plus moisture) for flat output consistency.

Ultimate TechnoGraphics of Montreal, in July, released Absolutely Imposing v.2.6 (an Adobe Acrobat plug-in) with compatibility for Windows 8.1 and Mac OS Mavericks, Electronic Software Licensing enhancement, A3-format display, and Automatic PDF Bleed Control. With the latter new feature, users can calculate bleed using the difference between TrimBox and CropBox when no BleedBox exists in the PDF or by using MediaBox if CropBox does not exist. Absolutely Imposing is designed for work like creating booklets, organizing step-and-repeat jobs, cutting and stacking, creating perfect-bound books, and setting different offset margins for printing. Version 2.6 of the software, which automatically finds the best template for a job, allows users to complete all their projects from Acrobat. Ultimate provides a fully functional 5-day trial of Absolutely Imposing v.2.6 online.

Canon in late-May introduced the new Océ ImageStream 3500 as the first full-colour press from its Océ inkjet product range that can print on offset coated paper stocks. The new press will be available from the beginning of 2015. The company explains the imaging system of the Océ ImageStream 3500, using pigment inks, allows for the elimination of treated paper or special add-ons such as bonding agents or primers to produce high-quality inkjet printing. The new pigment inks are engineered to create finer-edge sharpness, less fray and dot gain and increased optical density for a stronger contrast. Canon continues to explain that the perceived colour gamut on low-cost standard papers is higher on pigment inks than on dye inks. Océ ImageStream 3500 reaches speeds of up to 160 metres per minute (525 feet per minute) at 1,200 x 600 dpi, using flexible droplet modulation for higher apparent image resolution. The press also carries a compact footprint for its class, which Canon describes as a design that is 10 to 50 percent smaller than other similar production systems. The press is driven by Océ PRISMA workflow software with the scalable Océ SRA MP controller and the embedded Adobe APPEengine for support of native PDF formats.

Agfa Graphics, in July, launched its 16-up Avalon N16-80 XT thermal platesetter, which the company describes as its new range of top-line models suitable for large commercial and packaging operations. The Avalon N16’s 16-up external-drum engine is equipped with Grating Light Valve (GLV) imaging heads, with 512 or 1,024 channels (beams). The Avalon N16 range includes four models that produce between 16 and 42 plates (1,448 x 1,143 mm) per hour. The entry-level Avalon N16-50 E (16 pph) can be upgraded to the higher speed Avalon N16-50 S (24 pph) and Avalon N16-50 XT (30 pph) models in the field. The flagship Avalon N16-80 XT produces 42 pph.

Agfa Avalon N Automation for the N16 includes internal plate punching, dual, triple and quad cassette loading and online processing. A drum auto-balance system allows switching between different-sized plates. The Avalon N16 internal punching system performs punching for both the drum and the on-press registration, immediately before mounting the plate on the drum. By adding optional press punch blocks, imaged plates can be loaded straight onto presses with different punching.

Flint Group, in June, launched its new Varn Ecolo-Wash 401, described by the company as an ultra-low VOC press wash (blankets and rollers) for heatset and coldset web pressrooms. Ecolo-Wash 401, with less than 100 grams per liter VOCs, is designed without aromatic or halogen-based solvents. It can be used with manual and automatic blanket-wash systems.

Enfocus, in June, released Switch version 12.2 with new colour coding of folders and connections, as well as new Save Flow buttons (in the top menu bar), and Tool Tip Pop-Ups (descriptions of elements and flows when users hover on either). With Switch 12.2, users can apply their own colour coding to the folders and connections used in their workflow. As well, a third “conditional” colour has been added to show if the connection is set on hold. Users can now add a description to each element, connection, and tool in Switch, while “Read-only” use of Remote Designer is now indicated in the application title bar. When working in Split PDF mode, users can now apply variables and script expressions to define the number of pages per file.

With the introduction of the Remote Designer in Switch 12, Enfocus explains its users needed a better way to tell if their flow changes are saved when different Remote Designers connect to Switch Server. As soon as a user starts changing a flow, Enfocus explains the flow name will be displayed in italics and followed by an asterisk. This indicates that the flow has not yet been saved. Users can then save the flow using the new Save Flow button. As well, with the Revert Flow button, if the changes made to a flow are not correct, users can now go back to the last version.

Color-Logic launched its new BEST Offset Silver Ink for use with its existing Process Metallic Color System, which – relying on software – has the ability to trap process inks printed over it. Designed for sheetfed-offset pressrooms, BEST Offset Silver Ink, according to Color-Logic, prints with an ink-film thickness that is at least 50 percent less than conventional metallic silver inks. The company explains BEST Offset Silver Ink has a typical target ink density of 0.35 to 0.40 Status-T (0.60 to 0.70 polarized). The ink’s formulation, according to Color-Logic, allows the silver to retain its luster after aqueous or ultraviolet coating, varnishing or lamination. It can be used for blister-pack applications and foil stamping.

5-Colour

International Paper, in June, launched a lightweight board called Alaska Plus based on a recent project to modernize its Kwidzyn mill in Poland. Alaska Plus is designed for pharmaceutical, healthcare and beauty-care packaging, as well as for chocolate and all kinds of dry-food applications. At this moment, three basis weights are available to customers currently in Europe. The full range of products, comprising seven basis weights, starting from 200 g/m², will be available in the coming weeks. The standard Alaska GC2 board will continue to be available with unchanged technical specifications for a certain period of time in order to facilitate the transition to Alaska Plus.

Xaar, in July, launched its new 501 GS8 print head based on PrecisionPlus, which the company describes as a brand new architecture for both indoor and outdoor signage production. PrecisionPlus can be combined with the option of Xaar’s TF Technology – introduced on the recent Xaar 1002 print head launch – for more reliability in harsh environments. TF Technology reduces sedimentation when using heavily pigmented inks like white.

TF Technology combined with PrecisionPlus is available in Pulsed and High Flow modes. The new Pulsed mode recirculates ink during non-printing periods only. The High Flow mode is designed for continuous ink flow at a high rate directly past the back of the print head nozzles during drop ejection. This carries away air bubbles or unwanted particles in the fluid. The 501 GS8 print head can print in binary mode at up to 1,440 dpi with an 8-pL drop size or with four grey levels at 360 dpi – with an apparent resolution of over 600 dpi. It is compatible with a range of solvent and UV inks.

NewPage, in February, released two new sheet sizes for its Blazer Digital line of papers, engineered for HP Indigo 10000 presses. NewPage through the Rochester Institute of Technology (RIT) certifies all of its papers for the HP Indigo, including Sterling Premium Digital. The company has added 29.5 x 20.75 text and 20.75 x 29.5 cover sizes to Blazer Digital, available in gloss and satin, text and cover weights.

Mimaki launched the MJF5001800 industrial media handling system as an option for its new Mimaki TS500-1800 sublimation printers. The industrial design of the new MJF500 can handle paper rolls up to 600 pounds with an external diameter of 20 inches. The mediahandling unit is custom-built for Mimaki by Selco Inc. of South Carolina.

Drytac, in July, launched its ViziPrint Impress media, described as an optically clear, printable polyester window film. ViziPrint Impress is specifically designed for dry installation of graphics on glass surfaces. Its proprietary suction technology, according to Drytac, leaves no residue behind, helps to eliminate bubbling and is unaffected by moisture. The scratch-resistant, ultra-clear PET film is available in three versions: 4-mil clear UV for UV curable inks; 5-mil clear SEL for solvent, eco solvent, latex and UV curable inks; and 5-mil white SEL for solvent, eco solvent, latex and UV curable inks.